Faw J6p User Manual

TCE I / II

Central Electronic in

Trailers

815 000 375 3

2nd Edition

This publication is not subject to any update service.

New versions are available in INFORM at

www.wabco-auto.com

815 000 329 3

8150003293

© 2007 WABCO

Vehicle Control Systems

The right of amendment is reserved

Version 002/11.03(en)

8150100303 815 010 030 3

Table of contents

1 Objective

1.1 Concept and Implementation 4

2 General

2.1 External Communication Possibilities 5

2.2 Standards 6

3 Line connection Description

3.1 Functional overview 7

3.2 Electronics 446 122 00. 0 8

3.2.1 TCE top view with connector coding 9

3.3 System connections 10

4 Cable Overview 22

4.1 TCE connection system with connecting cable and PIN connection 15

4.1.1 Overview of plug-in connectors and corresponding cables 15

5 System Functions (acc. to terminals)

5.1 Brake lining wear indicator 37

5.2 Electrical Supply 39

5.2.1 Standardised motor vehicle plug-in connections 39

5.2.2 Supply 40

5.3 Diagnosis mode and warning light function 41

5.3.1 Gateway ISO 7638 / ISO 12098 Trailer data bus 41

5.3.2 warning light function 42

5.4 Freely programmable I/O (special modules) 42

5.4.1 Monitoring functions 42

5.5 Trailer EBS and RGE connection 42

5.5.1 Trailer EBS 42

5.5.2 RGE connection 43

5.6 Rear underdrive protection terminal 44

5.7 Ramp approach help 44

5.8 Paver brake 46

5.9 Electronically controlled air suspension (ECAS) in TCE 46

5.9.1 Components 47

5.9.2 Distance sensor(s) and trailer battery 51

5.10 Pneumatic components and installation instructions 57

6 Commissioning and Diagnosis 82

6.1 Commissioning and Diagnosis 59

6.1.1 The Calibration Process 59

7 PC - Diagnosis 23

7.1 Start- and diagnostic menu 62

7.2 Vehicle definition 63

7.2.1 Chassis & lighting 64

7.2.2 Special parameters 65

7.2.3 ECAS parameters 66

7.3 Special parameters 67

7.4 Axle load calibration 72

7.5 Switch positions / Outputs 72

7.6 Service management 73

7.7 System plate 73

7.8 End Of Line - Protocol 74

8. Annex 77

8.1 Abbreviations 78

8.2 Overview of Outline Drawings 79

2

Objective

TCE

1

In modern motor vehicles the onboard information for

drivers becomes more and more extensive. In future

drivers will be able to read information about truck and

trailer via a display on their dashboard They will get this

information via data buses, i.e. via communication

connections between different electronics having a CAN

interface. As a result the connected electronic systems

will be able to exchange, evaluate and further process

information. In future lighting on vehicles will also be

controlled via data buses and errors will be displayed in

trucks.

Trailers will be included in this exchange of information

via a 7-pin ABS/EBS plug connection acc. to ISO 7638

and in parallel via a 15-pin plug connection acc. to

ISO 12098. In both cases the data connection

corresponds to ISO 11992 part 1.

By a consequent use of the available data connections

between motor vehicle and trailer WABCO creates the

precondition for new innovative vehicle functions while

at the same time the number of the required electrical

connections is limited.

In summary the objectives are as follows:

System data bus in trailers

Integration of trailers into the motor vehicle

system

• Limitation of number of electrical connections

• Extension of the motor vehicle system functions

to trailers

Integration of trailer system functions

• Level control and lifting axle control

• Ramp approach help

• Lighting control

• Telematic connection

• Additional functions

TCE II

Modifications due to the introduction of TCE II are

marked in the following text in expanded type.

• New trailer system functions via data exchange

• More simple realisation of current system

functions

Telematics

Power 7 Pin ISO 7638

Power 15 Pin ISO 12098

IVTM - Integrated

Vehicle Tire

Monitoring system

TCE

ECAS

wear

Customer

functions

approach help

Lighting

Ramp

CAN

Trailer

Data

Diagnosis

EBS modulator

BUS

Brake lining

3

1

TCE

Objective

1.1 Concept and Realisation

As trailer central electronic TCE enables the

communication between motor vehicle and trailer res.

motor vehicle and trailer systems. Moreover TCE

supports the connection of intelligent individual systems

in trailers to a powerful system like in the towing vehicle.

TCE itself assumes the following electronic and

electrical functions:

Electrical supply of trailer systems including battery

supply and battery charging equipment. With a trailer battery diagnostic and ramp operations are possible without a motor vehicle.

Motor vehicle - trailer communication for brake and

”running gear“ systems (ISO 7638), as well as for

general vehicle systems (ISO 12098). ”Running

gear“ means components concerning the driving

safety, e.g. chassis, tires, steering and suspension.

Trailer data bus for EBS, running gear, tire systems

and vehicle systems with separate CAN connections. As a result an exchange of electrical consumers and transmission of information via data

connection is possible.

Future central diagnostic connection for TCE and

all systems connected via CAN. Future diagnosis

from the motor vehicle is provided (e.g. via an onboard display).

Brake lining wear sensing system with up to six

sensors.

In future reading and processing of analogue and

digital information will be possible.

e.g.

Programmable inputs and outputs for recording of

switch positions and analogue values, as well as for

controlling modulators and additional lighting. Individual customer modules will be created by

WABCO. These are adjustable via diagnosis.

Integrated electronic level control (ECAS) for semi-

trailers and trailers with one or two level sensors.

Integrated electronic lift axle control with automatic

functions as traction help, load dependent lowering

/ lifting and manoeuvring aid.

Ramp approaching help with automatic braking

when backing and approaching the ramp.

Electronically secured lighting control and monitor-

ing with status reports to the motor vehicle.

tire pressure recording and tire pressure monitoring

with connected IVTM system.

Service support (operating hours counter, mileage

counter, electronic notebook, battery hours counter).

ISO 7638 (5/7-pin.)

Green warning light

ISO 12098 (15/7-pin.)

Side marking and limiting lights

Diagnostic plug EBS

ABS wheel sensors

EBS

LA-Ventil

LF-Vent i l

DSENS

EBS

ABS wheel sensors

Brake lining wear sensors

DSENS2

WSENS2

WSENS1

DSENS1

Trailer battery

Brake lining wear sensors

Ultra sonic sensors

TCE

IVTM

BAT

Ultra sonic

sensor

Diagnostic

plug TCE

Remote remote control unit

4

General

)

TCE

2

The following data can be transmitted to the motor

vehicle provided the respective system is installed:

• Axle loads:

• Tire pressure values

• Status of vehicle lighting

• Distance to ramp

• Brake lining wear

• Status of ramp approach help RAH

• Lift axle status

Under same conditions as in the motor vehicle the

following data can be transmitted to a telematic system:

• Error in lighting

• Error in RAH function

• Vehicle stopped before ramp

• Service date achieved

• Vehicle overloaded

• Red /yellow/green warning light

• Axle load

• Tire pressure values

• Error in RAH function

• Vehicle hitched/unhitched

• Battery status

• Vehicle door open/closed

• Operating hours

• Mileage

• Brake lining wear

2.1 External Communication

Possibilities

When a telematic system is connected to the TCE

location of the vehicle resp. recall of vehicle specific data

is possible.

The following transmission systems can be used:

The Global Positioning System, shortly called

GPS, enables identification of the vehicle position.

The Global System for Mobile Communication

(GSM) enables wireless data transmission. Thus

remote diagnosis will also be possible in future.

The 'Short Range Communication' is only possible

in the yard near a correspond. transmitting / receiving station.

Satellite

Satellite

GPS

Global Positioning System

Short wave

Communication

(Blue Tooth, DECT, ..)

Local Server

Carrier owner

Fleet owners

Satellite

Satellite

GSM

Global System for

Mobile Communication

(D1, D2, ...)

z

h

M

0

0

9

z

h

M

0

0

8

1

z

h

M

z

3

h

3

4

M

8

6

8

Telecommunications

Company

ISDN

Internet

(TCP/IP)

Fleet Management

Carrier Park Management

Services Provider

WWW Server

Satellite Antenna

Data

5

2

TCE

General

The different systems may be used from trucks with

trailer connection or separately on trucks and on trailers

(e.g. for cooler and service information).

Thus the carrier resp. the controller can check for

instance position of the vehicle, temperature of the

cooling system and state of the vehicle. On short term

he may have the vehicle turned around and pick up

another load. In case of vehicle problems the controller

can inform a nearby repair shop in advance about the

vehicle state and can care for spare parts if required.

Telematic problems can only be corrected by the

respective telematic manufacturer in his service

repair shops.

2.2 Standards

TCE observes the following standards:

TCE II

Telematic systems in trucks and trailers can retrieve

more special information from the TCE II.

– event and profile data

– Service schedule

– Vehicle master data

Telematic systems in trailers will automatically be

informed on additional events

– Vehicle door open/closed

– Vehicle hitched/unhitched

– Tire pressure changes

– Service intervals etc.

– ISO 11992 defines data interfaces

between motor vehicles and trailers

• Part 1: Exchange of digital data between truck

and trailer

• Part 2: Application for brake and ”running gear“

of part 1

• Part 3: Application for all further systems of part

1 which were not considered in part 2

• Part 4: Diagnosis (in preparation)

– ISO 7638, 7-pin electrical truck-trailer

connection for braking and running gear

systems

• Chassis, tires and brake

• Use for lighting, superstructure control or similar

is expressly excluded.

– ISO 12098, 15-pin electrical truck-trailer

connection for lighting and superstructure

• Lighting, conventional lifting and steering axle

control

• Electrical supply and data connection for non

braking and ”running gear systems“

– Brake directive ECE-R13

• Supply of braking and running gear equipment

• Cut-off of running gear systems / Functions at

electrical overload

6

Line connection Description

3.1 Functional overview

Note:

TCE I/II is already fully operational, when except

connection to the motor vehicle only the EBS system is

connected, i.e. Ramp approaching help, ECAS, lighting,

tire pressure control and GPS/GSM do not need to be

installed resp. connected.

Bremse / Fahrwerk

Brake/running gear

Ramp approaching help

Rampenanfahrhilfe

TCE

3

Anhänger-

Trailer

+

batterie

battery

EBS

Brake lining wear sensors

Bremsbelagverschleißsensoren

ISO 7638 (7-pol.)

ISO 7638 (7-pin)

ISO 12098 (15-pol.), alternativ 24N/S

ISO 12098 (15-pin) alternative 24N/S

Diagnose

Diagnosis

IVTM

System zur Reifendrucküberwachung

TCE

TCE-

warning light

Warnlampe

(Integrated Vehicle Tire Monitor)

RGE input and output

RGE Ein- und Ausgangs-

expansion (control box)

erweiterung

RGE CAN Expansion

RGE CAN-Erweiterung

(Telematic connection)

(Telematikanschluss)

(Bedienbox)

TCE

X11

X12

X13

X14 X34X24

X31X21

X22 X42

X32

X23 X33

X41 X61

X43 X63X53

X44 X64X54

X51

X52

Pressure sensors

U

P

U

Operating

Bedienei nheit(en)

interfaces

Wegsensor(en)

Path sensors

X62

Not

occupied

Solenoid

Magnetventile

valves

Drucksensor(en)

P

Magnetventil für

Solenoid valve

Liftachssteuerung

for Lifting axle

control

Nicht

belegt

Verteiler

Lighting/superstructure systems

Beleuchtung / Aufbausysteme

Superstructure system -CAN Expansion

Aufbausystem - CAN-Erweiterung

Superstructure -additional lighting, Additional

Aufbau - Zusatzbeleuchtung, zusätzl. elektr.

Versorgung und Ein- und Ausgänge

electrical supply and Inputs and outputs

7

3

TCE

Line connection Description

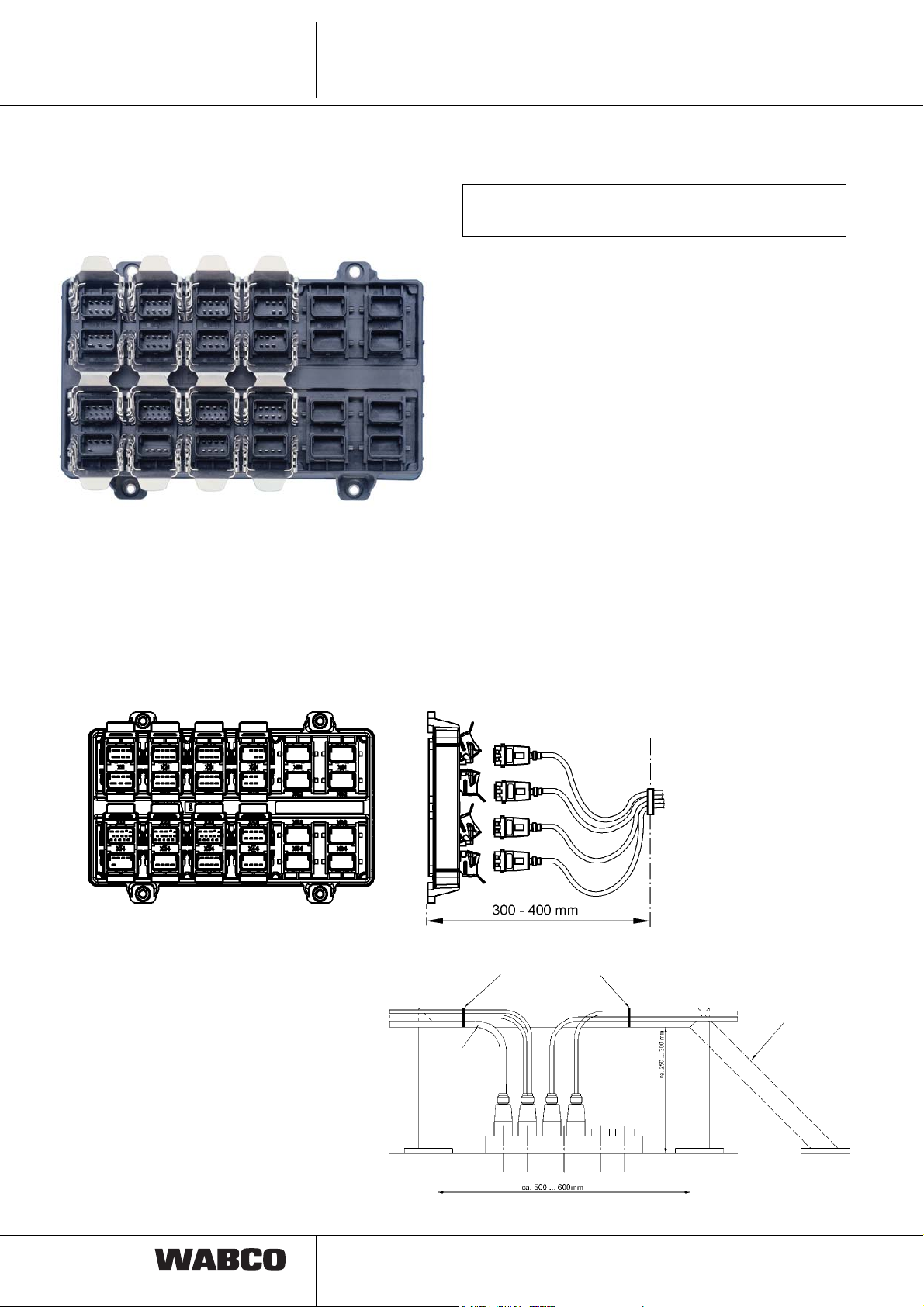

3.2 Electronic 446 122 000 0 /

446 122 001 0

Do not open the electronic remote control unit!

All terminals have to be closed.

All plug in connections are marked with an X and a

number and fitted with special locking clips. To connect

a cable, it is necessary to fold up the locking clip, push

in the plug and then close the locking clip.

Since the terminals are located very close, cables

should be plugged into the electronic in the order from

X11 to X41, X12 to X42, etc.

The front of the electronic consists of coded plug-in

terminals and thus is protected against interchange of

plugs. Unused terminals have to be closed by means of

cap 894 110 139 2.

Installation position:

Fixation to clip by means of cable binder or similar

In order to reverse the

cable back to the vehicle

frame the 45° solution

could be the better one.

Free cable

length to the

point of

fixation

approx.

300 mm

8

Line connection Description

3.2.1 TCE Top View with connector coding

TCE

3

control unit

X41-Remote remote

help

X31-Ramp approaching

X21-RGE and I/O

6 5

3 2 1

Battery

X42-Height sensor

4 3 2 1

8 7 6 5

4 3 2 1

8 7 6 5

X32-IVTM and super-

structure CAN

X22-EBS and RGE CAN

4 3 2

8 7 6

4 3 2 1

8 7 6 5

4 3 2 1

8 7 6 5

X43-Solenoid valve

lighting

X33-Superstructure

X23-Lighting

4 3 2 1

8 7 6 5

1

2

12 11

13

9 7 6

4 3

1415

10 8

5

1

2

12 11

13

9 7 6

4 3

1415

10 8

5

X44-Pressure sensor

lighting

X34-Tank vehicle

X24-Side marking

8 7 6 5

4 3 2 1

8 7 6 5

8 7 6 5

X11-Brake lining wear

1

2

12 11

13

9 7 6

4 3

7 6 5

4 3 2 1

8 7 6 5

X12-ISO 7638 (7-pin)

4 3 2 1

X13-ISO 12098 (15-pin)

1415

10 8

5

2

X14-Diagnosis and

Warning lamp

3 2 14

8

9

3

TCE

Line connection Description

3.3 System connections

TCE terminals in numeric order

1. Row

Connection X11 (optional)

Brake lining wear sensors

Connection for up to six brake lining wear sensors or up

to six wear indicators (side wire). Brake lining wear

sensors measure the thickness of the brake lining only

when braking. If wear indicators are installed, thickness

of the brake lining is actualised in braked or unbraked

condition. For example, if for all indicators 0 Volt will be

measured, connector break will be identified.

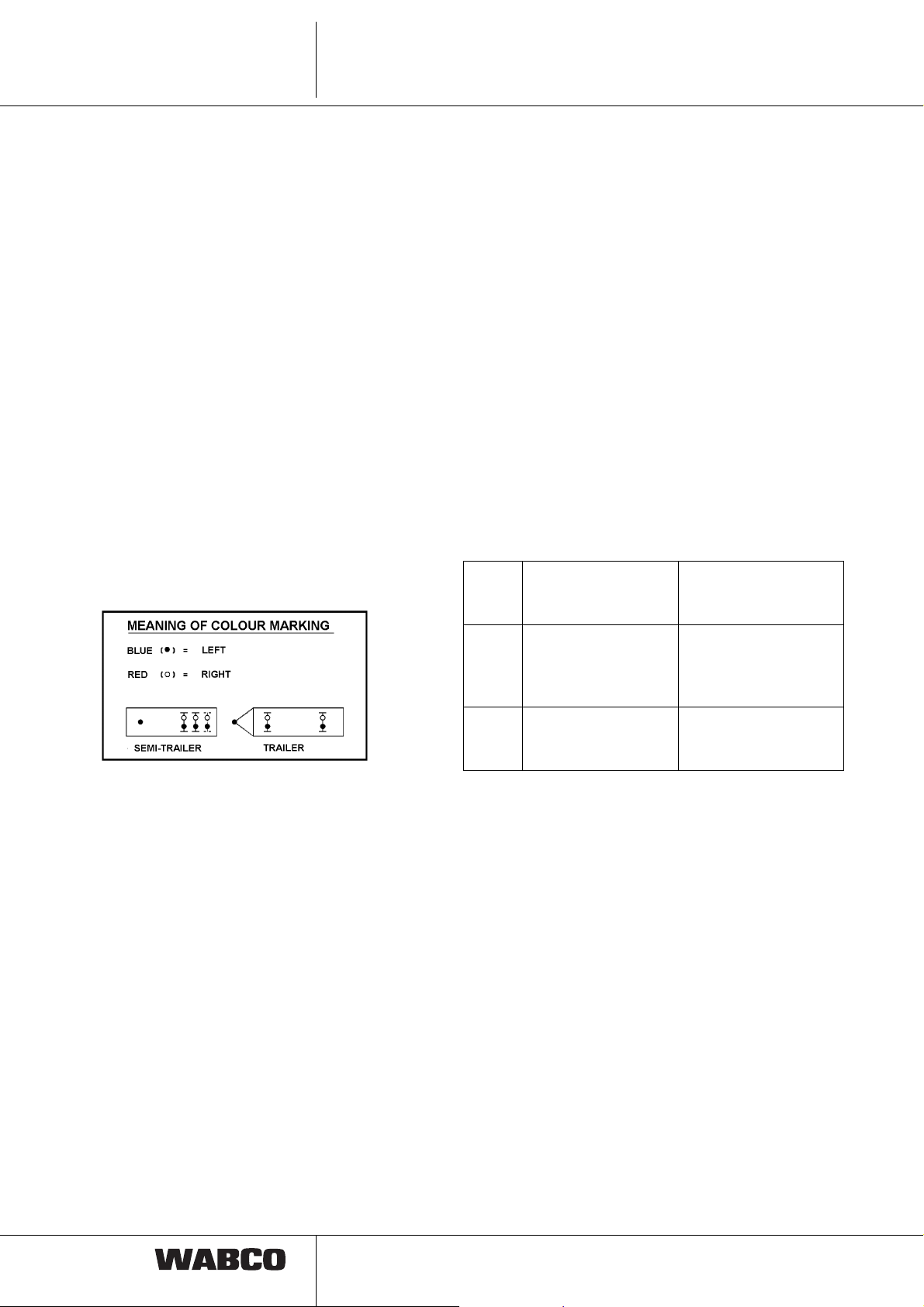

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side. Furthermore the axle assignment can be found

behind the plug (L1 = 1 axle on the left).

• corresponding TCE error (e.g. failure of EBS

modulator)

• Switch on of ignition (Pin)

• Interruption of ground connection

(Pin 3 and 4).

Connection X13

Motor vehicle connection acc. to ISO 12098

(15-pin)

Connection of power supply and lighting lines with data

connection acc. to ISO 12098 (15-pin). The data bus

contains information on lighting and superstructure

systems.

Plug-in pins 10, 11 and 12 are not controlled via PC

diagnosis. These can be parameterize per PC diagnosis

by means of special modules:

Pin 10

Pin 11

Pin 12

Pin 10

Pin 11

Pin 12

Pin 10,

11, 12

Brake lining sensor

not used

Axle lift

not used / steering

axle lock

Traction help

Axle lift

not controlled

according to

ISO 12098 / 1990

according to

ISO 12098 / 2000

New standard

Standard, if no trailer

or lift axle control from

the truck desired

Connection X12

Motor vehicle connection acc. to ISO 7638

Connection motor vehicle connection 7-pins (or 5-pins,

if there is no CAN-connection) acc. to ISO 7638 with

truck-trailer data connection acc. to ISO/ 11992 part 1

and 2.

Communication truck-trailer acc. to ISO 11992.

Support of the ABS module in trucks.

Monitoring of ground connections for break

Recognition of supply under or over voltage

Recognition of overload (current and voltage

measurement) and cut-off of running gear

Systems

Active control of trailer warning light (Pin 5) at:

10

Communication truck-trailer acc. to ISO 11992.

Support of trailer recognition via flashing and/or

brake light line

Maximum input impedance ≤ 2 kOhm.

Sensing/monitoring of lighting lines

Under / over voltage recognition of electrical supply

Truck-trailer data connection acc. to ISO 11992

part 1 and 3 (only with plug connection acc. to

ISO 12098)

Freely programmable inputs and outputs (special

modules; only with plug connection acc. to

ISO 12098)

Emergency supply of EBS via brake light, if

ISO 7638 interface has failed.

Line connection Description

TCE

3

Connection X14

Diagnostic connection:

Central connection for a diagnostic tool and optional

connection for a trailer warning light (green warning

light).

Diagnostic tool connection

The electrical power is supplied from ISO 7638

Pin 30 (Pin 1). Without a towing vehicle diagnosis

is enabled with a trailer battery. Raising/lowering

per remote remote control unit is also possible in

the diagnosis mode.

Connection of a warning light

An optional green warning light can be mounted to

the vehicle.

The electrical power is supplied from ISO 7638

Pin 30 (Pin 1).

Following display info is available:

Warning light status

– flashing: Display of general TCE errors

– on: trailer vehicle not within the

normal level

– off: vehicle within normal level

and without faults or ignition

switched off.

CAN communication via trailer data bus acc. to

ISO 11898 with 250 kBaud.

In case of interferences the external CAN data con-

nections can be cut off separately.

Information to connection X23/X24/X33/X34

Trailer lighting

Vehicle lighting left/right is protected separately in the

TCE.

Note:

Errors only appear when the lighting is actuated.

Connect all lights directly to the corresponding cable.

Cables must not be shortened or lengthened!

In order to avoid malfunctions during operation, the

maximum number of consumers must be observed.

Thus installation of an additional flashing light to the

underdrive protection is not allowed! At any rate the

manufacturer specifications must be observed.

Activation, control signal and electrical supply of trailer

lighting and extension for superstructure functions are

made via plug connection acc. to ISO 12098 (15-pin).

Electronic control / protection acc. to control sig-

nals via ISO 12098.

Error detection for short circuit and interruption,

when activated.

Connection X23

2. Row

Connection X21(optional)

Extension running gear / brake

Connection of 24 V-users and/or 24 V-Sensor analysis.

Power is supplied by means of motor vehicle plug

connection acc. to ISO 7638. Functional assignment is

programmable via special modules.

Note: Since the supply is made via ISO 7638, only such

systems/components may be connected, which either

belong to the vehicle brake or belong to ”running gear“

system!

The same concerns systems/components referring to

driving security, e.g. chassis, tires, steering, suspension

Connection X22

Trailer EBS & Running Gear-Systems

Connection of Trailer EBS and of an external Running

Gear Systems.

The electrical power is supplied from ISO 7638 Pin

(pin 1) with electronic overload protection.

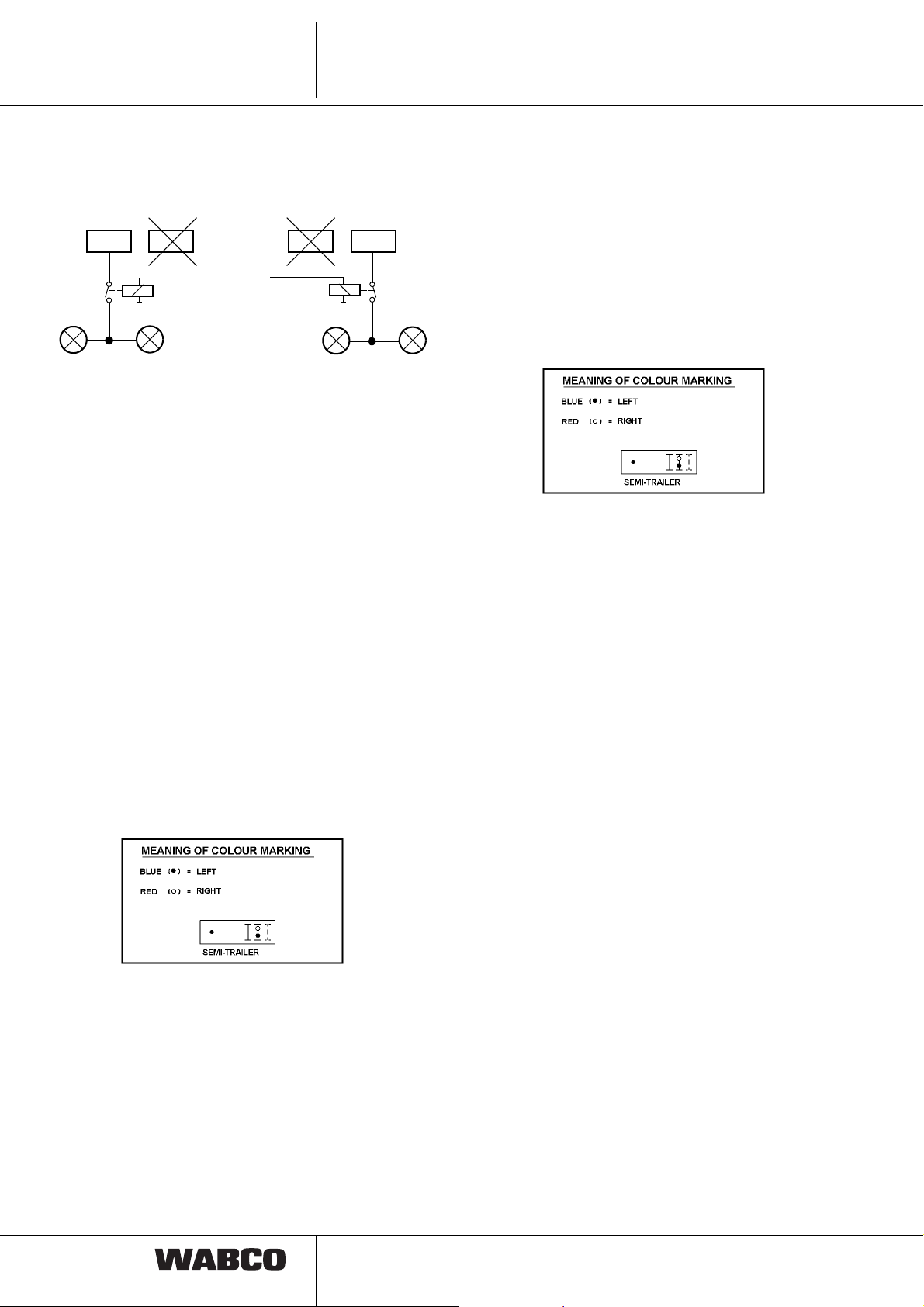

Standard lighting rear underdrive protection

(Performance per vehicle side)

TCE I TCE II

Brake light 21 WA 2 x 21 W

Flashing light 21 WA 2 x 21 W

Rear light 30 W 30 W

(2 x10 W Rear light +

2 x 5 W Identification

light)

Reverse

light 21 W 2 x 21 W + 2 x 70 W each

Side with freely

adjustable parameters

Rear fog

light 21W 2 x 21 W per side

with parameters

adjustable

Position

lamps 2 x 10 W 2 x 10 W or LED’s

TCE I:

2 x 70 W reverse lights can be connected either to the

24 V outputs of X23 pin3 or to X33 pin 3. However, the

11

3

TCE

Line connection Description

load must only be connected to one of the plugs. A relay

is required between reverse light and the respective pin.

X23 X33 X23 X33

70 W

70 W

or

Reverse light

70 W

70 W

TCE II

Now also the connection of LED lamps to TCE II is

possible! Moreover the light failure recognition was

improved.

Via PC diagnosis the sensibility of the parameters for

cable break recognition can be set.

Standard setting: In the case of a failure of one of two

connected lights (e.g. brake light), this will not be

detected as an error.

Extended parameters: At this setting the failure of the

light with same or higher electrical power is detected.

No break recognition with light emitting diodes.

Electrical supply via separate 8 V power genera-

tion in the TCE, supplied via motor vehicle connection acc. to ISO 7638

Sending / receiving signal lines separately for each

sensor

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side.

Connection X32 (optional)

Tire pressure monitoring IVTM & general vehicle

systems

Connection tire pressure monitoring and general vehicle

systems (no braking and running gear systems) with

CAN data connection.

Connection X24

Side marker lamp

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side.

side marking lamps (25 W)

3. Row

Connection X31 (optional)

Ramp approaching help (RAH)

Connection of two ultrasonic sensors for measuring the

reverse distance between vehicle and ramp at backing.

General vehicle systems

Electrical supply for IVTM via ISO 7638; electrical

supply of general vehicle systems via ISO 12098

In the case of an error in the CAN communication,

it will be cut off separately (CAN connection)

Remark: Due to the electrical supply separated from

ISO 7638, the connected systems are not subject to the

overload cut-off for non braking systems.

Connection X33 (optional)

Additional lighting for superstructure like position

lamps and extensions for the superstructure

Connection of 24 V-users and/or 24 V-Sensor

analysis.

Functional assignment for freely programmable in-

puts and outputs is done via special modules of the

PC diagnosis.

12

Line connection Description

TCE

3

TCE II

Following functions may be activated via special

modules.

(Line)

normal level switch I / II PIN 7 white - green

Spring brake actuator

(ISO 11992) Pin 8 grey

Door open / closed Pin 9 white - blue

Hitched / unhitched Pin 10 white - black

normal level III / Unloading- Pin 13 red

level switch

Outputs are short circuit resp. overload protected

electrically, or by self reversion. Short circuit against

earth/power or a break is detected as error. 2 x 70 W

reverse lights can be connected either to X23 Pin 3 or

X33 Pin 3. However, the load must only be connected to

one of the plugs.

(See pict. connection X23, page 12).

Back lights (21 W)

Connection X34 (optional)

Additional lighting for tank vehicles

For high level lighting carriers with

X42: 1 or 2 level sensors (without temperature

compensation) and trailer battery

X43: Valves for 1 or 2 point control as well as lift

axle control

X44: 1 or 2 pressure sensors for axle load calcula-

tion

Connection X41

Control elements

As maximum two control elements can be connected.

By pushing button IRCU the TCE is activated (Pin 30 or

battery mode!).

For connecting two control elements a Y cable has to be

used. The Y cable is colour marked. Below the

connector there is a red resp. blue stripe. The red

marked plug leads to the second control element,

the blue marked plug to the first control element.

By means of a further plug connection between trailer

and tractor installation of a control element in the motor

vehicle is possible.

TCE I : A cable length of 25 m must not be exceeded.

TCE II : Cable lengths up to 60 m are permissible.

Brake lights (21 W)

Flashing lights (21 W)

Back lights (21 W)

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side.

4. Row

Electronic level control

Electronic level control with following equipment :

X41: 1 or 2 remote control units (IRCU; Intelligent

Remote remote control unit)

Connection X42

Height sensor(s), trailer battery

A maximum of 2 height sensors can be connected to the

TCE. Here different configurations of the height sensor

arrangement are possible. This configuration is set by

means of parameters.

If only one height sensor is connected to the TCE, height

sensor 2 is active via the prefabricated cable In case of

two height sensors the plug marked with a blue

stripe is to be connected to the rear axle resp. to the

left height sensor (1

red stripe is to be connected to the front axle resp.

st

HS). The plug marked with a

13

3

TCE

Line connection Description

to the right height sensor (2nd HS). Otherwise

incorrect error display !!!

If a battery with battery box 446 156 090 0 (without

batteries), 446 156 094 0 (incl. batteries) is installed onto

the trailer, connect the prefabricated cable only.

Only lead gel accumulators may be used in the battery

box. WABCO recommend use of Panasonic LC R127R2PG lead gel accumulators, 12 V, 7,2 A.

If another box is used for the batteries, the plug of the

prefabricated cable has to be cut-off. The blue lead must

be connected to a 10 A fuse and the brown lead with the

earth pole of the battery.

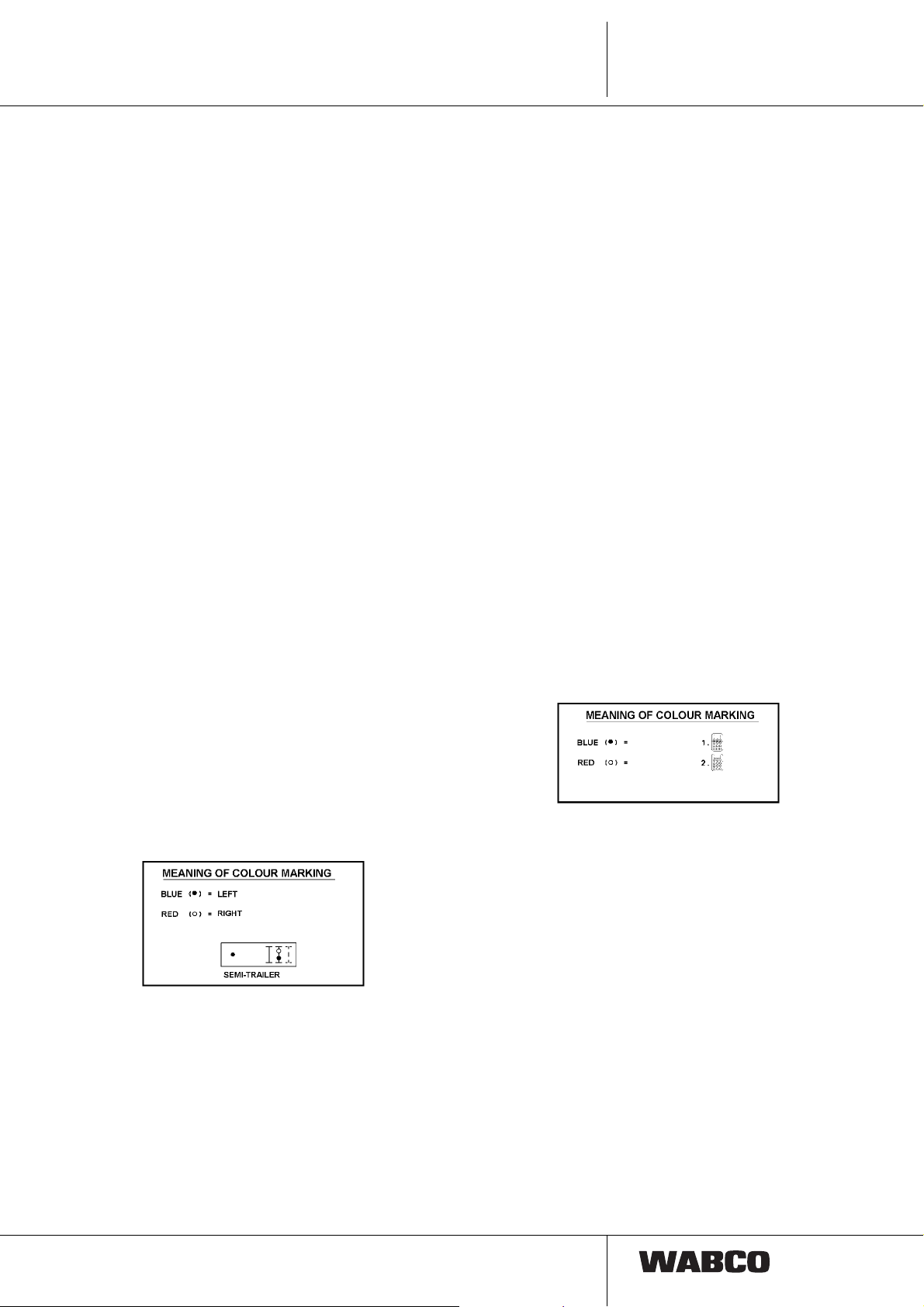

Connection X43

Connection X44

Pressure sensor

TCE I:

A maximum of two pressure sensors can be connected

to the TCE. The 1

has to be connected. Among others is is used for axle

load calculation for the trailer EBS system.

st

pressure sensor (1st PS) always

TCE II

For the TCE II system it is not compulsory under certain

circumstances (dependent on the connected EBS

modulator) to connect one or two pressure sensors.

The required pressure sensor signal is directly sent from

the EBS modulator (D version) to the TCE II. If the ECAS

is to actuate a lateral or a drawbar trailer control, a

pressure sensor can be connected to the TCE.

If two pressure sensors are to be installed, the red

marked cable end is to be connected to the pressure

sensor (2

The blue marked cable end is to be connected to the

pressure sensor (1

axle.

nd

PS) to the right resp. to the front axle.

st

PS) to the left resp. to the rear

Valves 1-/2-point-control, lift axle valve

Levelling valves for semitrailers with 1- or 2- point

control (right/left), for drawbar trailers 2 point control

(front/rear). Lift axle valve(s) for one or two separately

controlled lift axle(s).

The plug marked blue leads to the lift/lower valve. The

plug marked red to the 1st lift axle valve.

14

Cable overview

4.1 The TCE plug in system with

connection cable and the

Pin assignment

Cables are supplied in different lengths. In the

following the different cable types and lengths are listed

and in column ”remark“ among others the components

to be connected. (Outline drawing see appendix).

4.1.1 Overview on terminals and the

respective cables:

Terminal X11:

Brake lining wear indicator

TCE-Electronic

TCE-Elektronik

X 11

X12 X 22 X 32 X 42 X 52 X 62

X 21 X 31 X 41 X 51 X 61

TCE

4

X 13 X 23 X 33 X 43 X 53 X 63

X 14 X 24 X 34 X 44 X 54 X 64

449 874 ...0

Used

Cable

449 874 010 0

L = 1 m

Plug

R1-2 / L1-2

R-1 „A“ +5 V 1 Brake lining

R-1 „C“ Ground 2 + 5 V

L-1 „A“ + 5 V 3 Ground

L-1 „C“ Ground 4 Brake Lining

see:

Drawing

449 874 000 0 Limit value indicator,

Assignment Plug

Remark

one axle 2x1

for PAN 17: 12480038

for PAN 19-1:

12480036 **)

Assign-

A

ment

wear R

wear L

Distributor not measurable, since with W network

**) Knorr brake to BPW axle 32480057

15

4

449 884 ... 0

TCE

Cable overview

Used

Cable

449 884 023 0

L

= 1 m

1

L

= 0.4 m

2

see:

Drawing

449 884 000 0 Limit value indicator,

Remark

two axles 2x2

for PAN 17: 12480038

for PAN 19-1:

12480036 **)

449 894 ... 0

Plug

R1-2 / L1-2

R-2 „A“ + 5 V 1 Brake lin. w. R1

R-2 „C“ Ground 5 Brake lin. w. R2

R-1 „A“ + 5 V 2 + 5 V

R-1 „C“ Ground 3 Ground

L-1 „C“ Ground 3 Ground

L-1 „A“ + 5 V 2 + 5 V

L-2 „C“ Ground 4 Brake lin. w. L1

L-2 „A“ + 5 V 8 Brake lin. w. L2

Distributor not measurable, since with W network

Used

Cable

449 894 023 0

L

= 1 m

1

L

= 0.4 m

2

449 894 043 0

L

= 1 m

1

L

= 1 m

2

Assignment PlugAAssignment

see:

Drawing

449 894 000 0 Limit value indicator,

Remark

three axles 2x3

for PAN 17: 12480038

for PAN 19-1:

12480036 **)

16

Plug

R1-3 / L1-3

R-3 „A“ + 5 V 1 Brake lin. w. R1

R-3 „C“ Ground 5 Brake lin. w. R2

R-2 „A“ + 5 V 6 Brake lin. w. R3

R-2 „C“ Ground 2 + 5 V

R-1 „A“ + 5 V 3 Ground

R-1 „C“ Ground

L-1 „A“ + 5 V

L-1 „C“ Ground 3 Ground

L-2 „A“ + 5 V 2 + 5 V

L-2 „C“ Ground 4 Brake lin. w. L1

L-3 „A“ + 5 V 8 Brake lin. w. L2

L-3 „C“ Ground 7 Brake lin. w. L3

Distributor not measurable, since with W network

Assignment PlugAAssignment

Terminal X12: Supply cable

TCE-Electronic

TCE-Elektronik

X 11

X12 X 22 X 32 X 42 X 52 X 62

X 13 X 23 X 33 X 43 X 53 X 63

X 14 X 24 X 34 X 44 X 54 X 64

X 21 X 31 X 41 X 51 X 61

449 172 ... 0

Cable overview

Used

Cable

449 172 090 0

L = 9 m

449 172 100 0

L = 10 m

449 172 120 0

L = 12 m

449 172 130 0

L = 13 m

449 172 150 0

L = 15 m

TCE

see:

Drawing

449 172 000 0 ABS/EBS

Remark

Power supply

cable

ISO 7638 (7-pin)

from

semi trailer

to motor vehicle

4

Plug A Plug B

449 272 ... 0

449 133 ... 0

Plug

A

17 red Pin 30

26black Pin 15

34yellow Ground 15

45brown Ground 30

53white Warning light

62white/green CAN H

71white/brown CAN L

Used

Cable

449 272 090 0

L = 9 m

Plug

B

see:

Drawing

449 272 000 0 ABS/EBS

Colour Assignment

Remark

Supply cable to

ISO 7638

(7-pin) from

drawbar trailer

to motor vehicle

Plug A Plug B

Used

Cable

449 133 120 0

L = 12 m

see:

Drawing

449 133 000 0 ABS/EBS

Remark

Power supply

cable with

bayonet connection

17

4

449 135 ... 0

TCE

Cable overview

Plug A Plug B

449 333 ... 0

Plug A Plug B

Used

Cable

449 135 005 0

L = 0,5 m

Plug

A

17 red Pin 30

26black Pin 15

34yellow Ground 15

45brown Ground 30

53white Warning light

62white/green CAN H

71white/brown CAN L

Used

Cable

449 333 003 0

L = 0,3 m

see:

Drawing

449 135 000 0 Power supply cable

Plug

B

see:

Drawing

449 333 000 0 Power supply cable

Remark

for semitrailer with

bayonet terminal

Colour Assignment

Remark

for semitrailer /

drawbar trailer

with bayonet

counterpart to

449 133 ... 0

449 335 ... 0

Plug A Plug B

Plug

A

11white/brown CAN L

22white/green CAN H

33white Warning light

44yellow Ground 15

55brown Ground 30

66black Pin 15

77 red Pin 30

Used

Cable

449 335 110 0

L = 11 m

449 335 140 0

L = 14 m

Plug

B

see:

Drawing

449 335 000 0 Power supply cable

Colour Assignment

Remark

for semitrailer

with bayonet

counterpart to

449 135 ... 0

18

Terminal X13: Supply

TCE-Electronic

TCE-Elektronik

X 11 X 21 X 31 X 41 X 51 X 61

X12 X 22 X 32 X 42 X 52 X 62

X 13 X 23 X 33 X 43 X 53 X 63

X 14

X 24 X 34 X 44 X 54 X 64

449 113 ... 0

Cable overview

Used

Cable

449 113 100 0

L = 10 m

449 113 120 0

L = 12 m

449 113 140 0

L = 14 m

TCE

see:

Drawing

449 113 000 0 Power supply cable

Remark

Adapter from 15 pin

to 2 x 7 pin (24 N/S)

may be used

4

Plug B Plug A

Plug

A

1 8 pink Backing light

2 3 blue Rear fog light

3 9 orange Supply Ub

4 4 white/red Ground (GND 3)

5 white Ground (GND 2)

6 15 white/brown CAN_Low

7 14 white/green CAN_High

8 10 grey Brake lining wear

9 12 white/blue Lifting Axle

10 11 white/black Pressure sensor

11 5 black Back light left

12 6 brown Back light right

13 7 red Brake light

14 2 green Turn signal right

15 1 yellow Turn signal left

Plug

B

Colour Assignment

(pin 30-2)

449 121 ... 0

Used

Cable

449 121 120 0

L = 12 m

see:

Drawing

449 121 000 0 Power supply

Remark

cable

for Aspöck

2 x 7 pin to 15 pin

Terminal

19

4

449 123 ... 0

TCE

Cable overview

449 311 ... 0

Plug B

Plug A

Used

Cable

449 123 120 0

L = 12 m

Used

Cable

449 311 120 0

L = 12 m

Plug assignment see page 19

see:

Drawing

449 123 000 0 Power supply

see:

Drawing

449 311 000 0 Power supply

Remark

cable

for

drawbar trailer

Remark

cable

for Hella

Plug adapter

20

2

Terminal X14: Diagnosis

TCE-Electronic

TCE-Elektronik

X 11 X 21 X 31 X 41 X 51 X 61

X12

X 22 X 32 X 42 X 52 X 62

Cable overview

TCE

4

X 13 X 23 X 33 X 43 X 53 X 63

X 14

449 672 ... 0

Plug B

449 644 ... 0

X 24 X 34 X 44 X 54 X 64

Plug A

Plug A

Used

Cable

449 672 030 0

see:

Drawing

449 672 000 0 Diagnostic cable

L = 3 m

449 672 040 0

L = 4 m

449 672 060 0

L = 6 m

449 672 080 0

L = 8 m

449 672 090 0

L = 9 m

Plug

A

Plug

B

14 K wire

21 Supply

37 Ground

Used

Cable

449 644 196 0

L

= 10 m

1

L

= 4 m

2

see:

Drawing

449 644 000 0 Y diagnostic cable

Remark

with terminal

for connection cable

446 300 329 2

( 6 m long ) to

Diagnostic Interface

Set 446 301 021 0

Assignment

Remark

with terminal

for connection cable

446 300 329 2

( 6 m long ) to

Diagnostic Interface

Set 446 301 021 0

and warning light

cable with green

warning light:

446 105 521 2 (cable

with plug

441 032 312 2)

Plug B

Plug

A

Plug

B

Assignment

4 Ground

8 warning light

14 K wire

21 Supply

37 Ground

2

21

4

TCE

Cable overview

Terminal X21: I/O Typ, Erweiterung

TCE-Elektronik

TCE-Electronic

X 11

X12

X 21

X 22

X 31 X 41 X 51 X 61

X 32 X 42 X 52 X 62

X 13

X 14

449 902 ... 0

X 23

X 24

X 33 X 43 X 53 X 63

X 34 X 44 X 54 X 64

Plug A

Used

Cable

449 902 050 0

L = 5 m

see:

Remark

Drawing

449 902 000 0 RGE

special functions

449 902 070 0

L = 7 m

Plug

Colour Assignment

A

1 white/green Supply 2

2 purple Digital inlet 2

3 yellow Digital inlet 1

4 green Supply 1

5 brown Ground

6 black Digital inlet 4

7 white Digital inlet 3

8 white/brown Ground

449 903 ... 0

Plug B Plug A

Used

Cable

449 903 050 0

see:

Drawing

449 903 000 0 for ECAS control box

L = 5 m

449 903 090 0

L = 9 m

Plug

A

Plug

B

24 Inlet 2

33 Inlet 1

41 Supply

52 Ground

75 Inlet 3

Remark

446 156 000 0

Assignment

22

Terminal X22: Cable to Trailer EBS

TCE-Elektronik

TCE-Electronic

X 11

X12

X 31 X 41 X 51 X 61

X 21

X 32 X 42 X 52 X 62

X 22

Cable overview

TCE

4

X 13

X 14

449 399 ... 0

Plug B Plug A

449 394 ... 0

Plug B

X 33 X 43 X 53 X 63

X 23

X 34 X 44 X 54 X 64

X 24

Plug A

Used

Cable

449 399 020 0

see:

Drawing

449 399 000 0 to EBS trailer

L = 2 m

Plug

A

Plug

B

15 Ground

27 Supply

51 CAN L

82 CAN H

Used

Cable

449 394 346 0

L

= 2 m

1

L

= 15 m

2

see:

Drawing

449 394 000 0 to EBS trailer

449 394 366 0

L

= 2 m

1

L

= 18 m

2

449 394 386 0

L

= 2 m

1

L

= 20 m

2

Remark

modulator

480 102 002 0

Assignment

Remark

modulator

480 102 002 0

and RGE with CAN

(telematic)

Plug

A

Plug

B

Colour Assignment

15 Ground

27 Supply

51 CAN L

62 CAN H

3

4 red Supply

7 blue CAN L

open

brown Ground

8 yellow CAN H

23

Loading...

Loading...