Page 1

CNC

8065 TC

Operating manual

(Ref: 1201)

Page 2

MACHINE SAFETY

It is up to the machine manufacturer to make su re that the safety of the machine

is enabled in order to prevent personal injury and damage to the CNC or to the

products connected to it. On start-up and while validating CNC parameters, it

checks the status of t he following safety elements. If any of them is disabled, the

CNC shows a warning message.

• Feedback alarm for analog axes.

• Software limits for analog and sercos linear axes.

• Following error monitoring for analog and sercos axes (except the spindle)

both at the CNC and at the drives.

• Tendency test on analog axes.

FAGOR AUTOMATION shall no t be held responsible for any personal injuries or

physical damage cause d or suffered by the CNC resulting from any of the safety

elements being disabled.

HARDWARE EXPANSIONS

FAGOR AUTOMATION shall no t be held responsible for any personal injuries or

physical damage caused or suffered by the CNC resulting from any hardware

manipulation by personnel unauthorized by Fagor Automation.

If the CNC hardware is modified by personnel unauthor ized by Fagor Automation,

it will no longer be under warranty.

COMPUTER VIRUSES

FAGOR AUTOMATION guarantees that the software installed contains no

computer viruses. It is up to the user to keep the unit virus free in order to

guarantee its proper operation.

Computer viruses at the CNC may cause it to malfunction. An antivirus software

is highly recommended if the CNC is connected directly to another PC, it is part

of a computer network or floppy disks or other compute r media is used to transmit

data.

FAGOR AUTOMATION shall no t be held responsible for any personal injuries or

physical damage caused or suffered by the CNC due a computer virus in the

system.

If a computer vir us is found in the syste m, the unit will no longe r be under warranty.

All rights reserved. No part of this documentation may be transmitted,

transcribed, stored in a backup device or translated into another language

without Fagor Automation’s consent. Unauthorized copying or distributing of this

software is prohibited.

The information described in this manual may be changed due to technical

modifications. Fagor Automation reserves the right to make any changes to the

contents of this manual without prior notice.

All the trade marks a ppearing in the manual belong to the c orresponding owners.

The use of these marks by third parties for their own purpose could violate the

rights of the owners.

It is possible that CNC can execute more functions than those described in its

associated documentation; however, Fagor Automation does not guarantee the

validity of those applications. Therefore, except under the express permission

from Fagor Automation, any CNC application that is not described in the

documentation must be considered as "impossible". In any case, Fagor

Automation shall not be held responsible for any personal injuries or physical

damage caused or suffered by the CNC if it is used in any way other than as

explained in the related documentation.

The content of this manual and its validi ty for the product descr ibed here has been

verified. Even so, involuntary errors are possible, thus no absolute match is

guaranteed. Anyway, the contents of the manual is periodically checked making

and including the necessary corrections in a future edition. We appreciate your

suggestions for improvement.

The examples described in this manual are for learning purposes. Before using

them in industrial applications, they must be properly adapted making sure that

the safety regulations are fully met.

Page 3

Operating manual

INDEX

About the product ......................................................................................................................... 7

Declaration of conformity ............................................................................................................ 11

Version history ............................................................................................................................ 13

Safety conditions ........................................................................................................................ 15

Warranty terms ........................................................................................................................... 19

Material returning terms.............................................................................................................. 21

CNC maintenance ...................................................................................................................... 23

CHAPTER 1 GENERAL CONCEPTS

1.1 Accessing the conversational mode .............................................................................. 25

1.2 Keyboard........................................................................................................................ 26

CHAPTER 2 OPERATING IN JOG MODE

2.1 Introduction .................................................................................................................... 30

2.1.1 Standard screen of the conversational mode............................................................. 30

2.1.2 Auxiliary screen of the conversational mode.............................................................. 31

2.1.3 Cycle editing............................................................................................................... 33

2.1.4 Cycle simulation ......................................................................................................... 34

2.1.5 Cycle execution .......................................................................................................... 35

2.2 Operations with the axes. .............................................................................................. 36

2.2.1 Home search.............................................................................................................. 36

2.2.2 Jog ............................................................................................................................. 37

2.2.3 Jogging the axes with handwheels ............................................................................ 39

2.2.4 Moving an axis to a particular position (coordinate)................................................... 41

2.2.5 Coordinate preset....................................................................................................... 41

2.3 Spindle control ............................................................................................................... 42

2.4 Tool selection and tool change ...................................................................................... 43

2.5 Setting the feedrate and spindle speed. ........................................................................ 43

2.6 Setting and activating the zero offsets and the fixture offsets........................................ 44

2.7 Tool calibration............................................................................................................... 45

2.7.1 Manual calibration. Calibration without a probe ......................................................... 47

2.7.2 Semi-automatic calibration. Calibration with a probe ................................................. 50

2.7.3 Automatic calibration with a probe and a canned cycle (“plane” geometric configuration)

2.7.4 Automatic calibration with a probe and a canned cycle (“trihedron” geometric configu-

53

ration)55

CHAPTER 3 WORKING WITH OPERATIONS OR CYCLES

3.1 Canned cycles available in the editor. ........................................................................... 59

3.1.1 Configuring the cycle editor. ...................................................................................... 60

3.1.2 Teach-in mode. ......................................................................................................... 61

3.1.3 Selecting data, profiles and icons .............................................................................. 62

3.1.4 Definition of spindle conditions................................................................................... 63

3.1.5 Definition of machining conditions.............................................................................. 64

3.2 Positioning cycle. ...........................................................................................................65

3.3 Positioning cycle with M functions. ................................................................................ 66

3.4 Simple turning cycle....................................................................................................... 67

3.4.1 Basic operation .......................................................................................................... 69

3.5 Turning cycle with vertex rounding. ............................................................................... 71

3.5.1 Basic operation .......................................................................................................... 73

3.6 Simple facing cycle. ....................................................................................................... 75

3.6.1 Basic operation .......................................................................................................... 77

3.7 Facing cycle with vertex rounding. ................................................................................. 79

3.7.1 Basic operation .......................................................................................................... 81

3.8 Vertex chamfering cycle................................................................................................. 83

3.8.1 Basic operation .......................................................................................................... 86

3.9 "Chamfering between points" cycle. .............................................................................. 88

3.9.1 Basic operation .......................................................................................................... 91

3.10 Vertex chamfering cycle 2.............................................................................................. 93

3.10.1 Basic operation .......................................................................................................... 96

3.11 Vertex rounding cycle. ................................................................................................... 98

3.11.1 Basic operation ........................................................................................................ 101

CNC

8065 TC

(REF: 1201)

·3·

Page 4

Operating m anual

3.12 "Rounding between points" cycle................................................................................. 103

3.12.1 Basic operation ........................................................................................................ 106

3.13 Longitudinal threading cycle. ....................................................................................... 108

3.13.1 Basic operation ........................................................................................................ 111

3.14 Taper threading cycle. ................................................................................................. 112

3.14.1 Basic operation ........................................................................................................ 115

3.15 Face threading cycle.................................................................................................... 116

3.15.1 Basic operation ........................................................................................................ 119

3.16 Thread repair cycle. ..................................................................................................... 120

3.16.1 Basic operation ........................................................................................................ 123

3.17 Multi-entry threading cycle. .......................................................................................... 124

3.17.1 Basic operation ........................................................................................................ 127

3.18 Simple longitudinal grooving cycle. .............................................................................. 128

3.18.1 Basic operation ........................................................................................................ 131

3.18.2 Calibration of the grooving tool ................................................................................ 133

3.19 Simple face grooving cycle. ......................................................................................... 135

3.19.1 Basic operation ........................................................................................................ 138

3.19.2 Calibration of the grooving tool ................................................................................ 140

3.20 Inclined longitudinal grooving cycle. ............................................................................ 141

3.20.1 Basic operation ........................................................................................................ 144

3.21 Inclined face grooving cycle......................................................................................... 146

3.21.1 Basic operation ........................................................................................................ 149

3.22 Cut-off cycle. ................................................................................................................ 151

3.22.1 Basic operation ........................................................................................................ 153

3.23 Drilling cycle................................................................................................................. 154

3.23.1 Basic operation ........................................................................................................ 156

3.24 Tapping cycle...............................................................................................................157

3.24.1 Basic operation ........................................................................................................ 159

3.25 Multiple drilling cycle. ................................................................................................... 160

3.25.1 Basic operation ........................................................................................................ 163

3.26 Multiple tapping cycle. ................................................................................................. 164

3.26.1 Basic operation. ....................................................................................................... 166

3.27 Multiple slot milling cycle. ............................................................................................ 167

3.27.1 Basic operation ........................................................................................................ 170

3.28 Point-to-point turning cycle. ......................................................................................... 171

3.28.1 Basic operation ........................................................................................................ 175

3.28.2 Programming example............................................................................................. 176

3.29 Profile turning cycle. .................................................................................................... 177

3.29.1 Basic operation ........................................................................................................ 181

3.29.2 Programming examples ........................................................................................... 182

3.30 ZC plane profiling cycle. .............................................................................................. 188

3.30.1 Basic operation. ZC profile....................................................................................... 190

3.31 ZC/YZ rectangular pocket cycle................................................................................... 191

3.32 ZC/YZ circular pocket cycle. ........................................................................................ 193

3.33 2D ZC/YZ profile pocket cycle. .................................................................................... 195

3.34 XC plane profiling cycle. .............................................................................................. 197

3.34.1 Basic operation. XC profiles..................................................................................... 199

3.35 XC/XY rectangular pocket cycle. ................................................................................. 200

3.36 XC/XY circular pocket cycle......................................................................................... 202

3.37 2D XC/XY profile pocket cycle. .................................................................................... 204

CNC

8065 TC

(REF: 1201)

·4·

CHAPTER 4 STANDARD THREADS

4.1 Regular pitch metric thread — M (S.I.) ........................................................................ 208

4.2 Fine pitch metric thread — M (S.I.F.) ........................................................................... 209

4.3 Regular pitch Whitworth thread — BSW (W.) .............................................................. 210

4.4 Fin pitch Whitworth thread — BSF .............................................................................. 211

4.5 Regular pitch Unified American thread — UNC (NC, USS) ......................................... 212

4.6 Fine pitch Unified American thread — UNF (NF, SAE) ............................................... 213

4.7 Whitworth gas thread — BSP ...................................................................................... 214

CHAPTER 5 SAVING PROGRAMS

5.1 List of saved programs ................................................................................................ 216

5.2 Edit a new part-program .............................................................................................. 217

5.3 Delete a new part program .......................................................................................... 217

5.4 Save a cycle ................................................................................................................ 217

CHAPTER 6 EXECUTION AND SIMULATION

6.1 Execute a part-program ............................................................................................... 220

6.1.1 Execute a portion of a part-program ........................................................................ 220

6.1.2 Graphics screen in execution................................................................................... 221

Page 5

Operating manual

6.2 Simulating a part-program ........................................................................................... 222

6.2.1 Simulate a portion of a part-program ....................................................................... 222

6.2.2 Graphics screen in simulation. ................................................................................. 223

6.3 Simulating or executing an operation that has been saved ......................................... 224

6.3.1 Simulating a cycle .................................................................................................... 224

6.3.2 Cycle execution ........................................................................................................ 225

CNC

8065 TC

(REF: 1201)

·5·

Page 6

Page 7

Operating manual

ABOUT THE PRODUCT

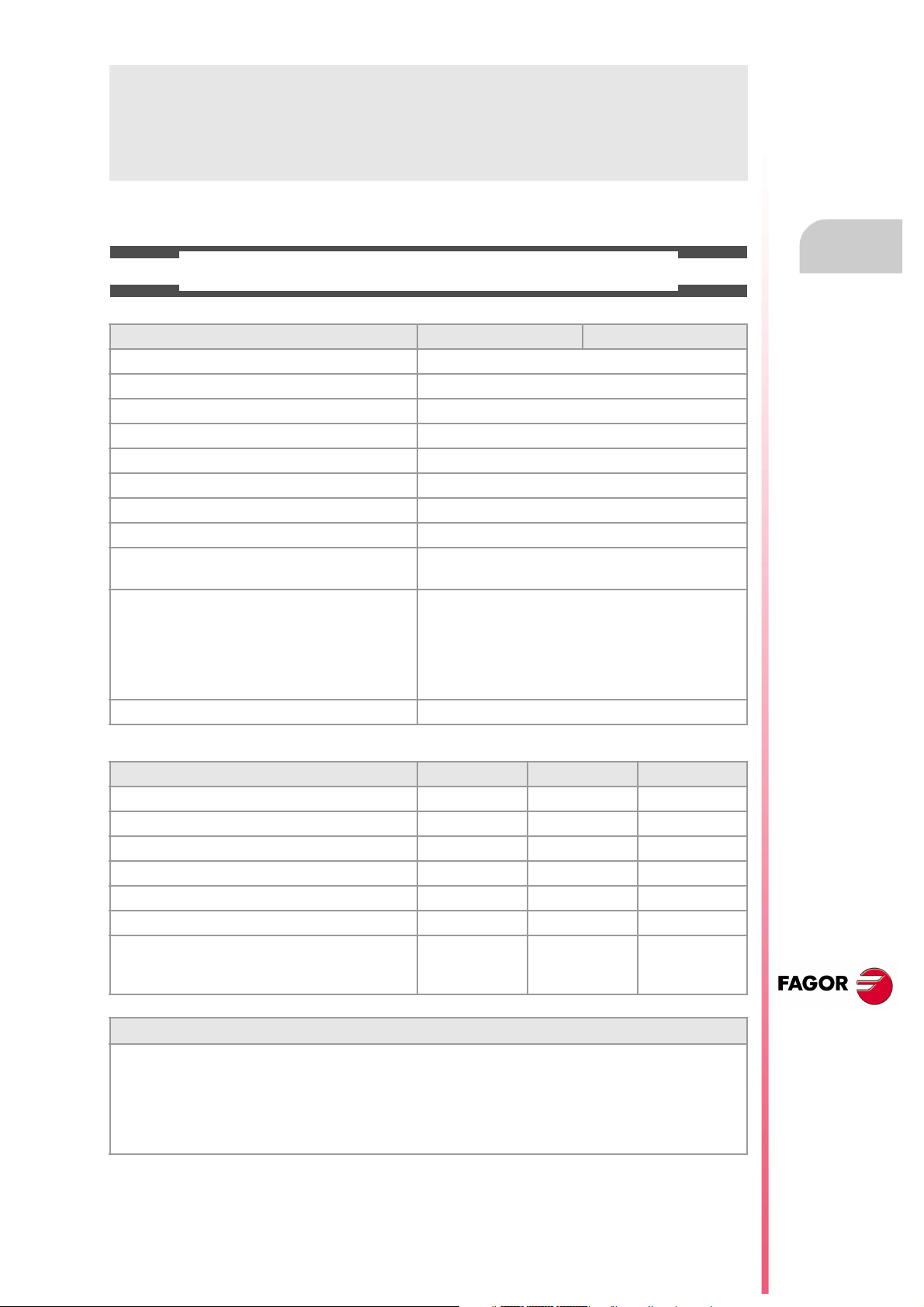

BASIC CHARACTERISTICS.

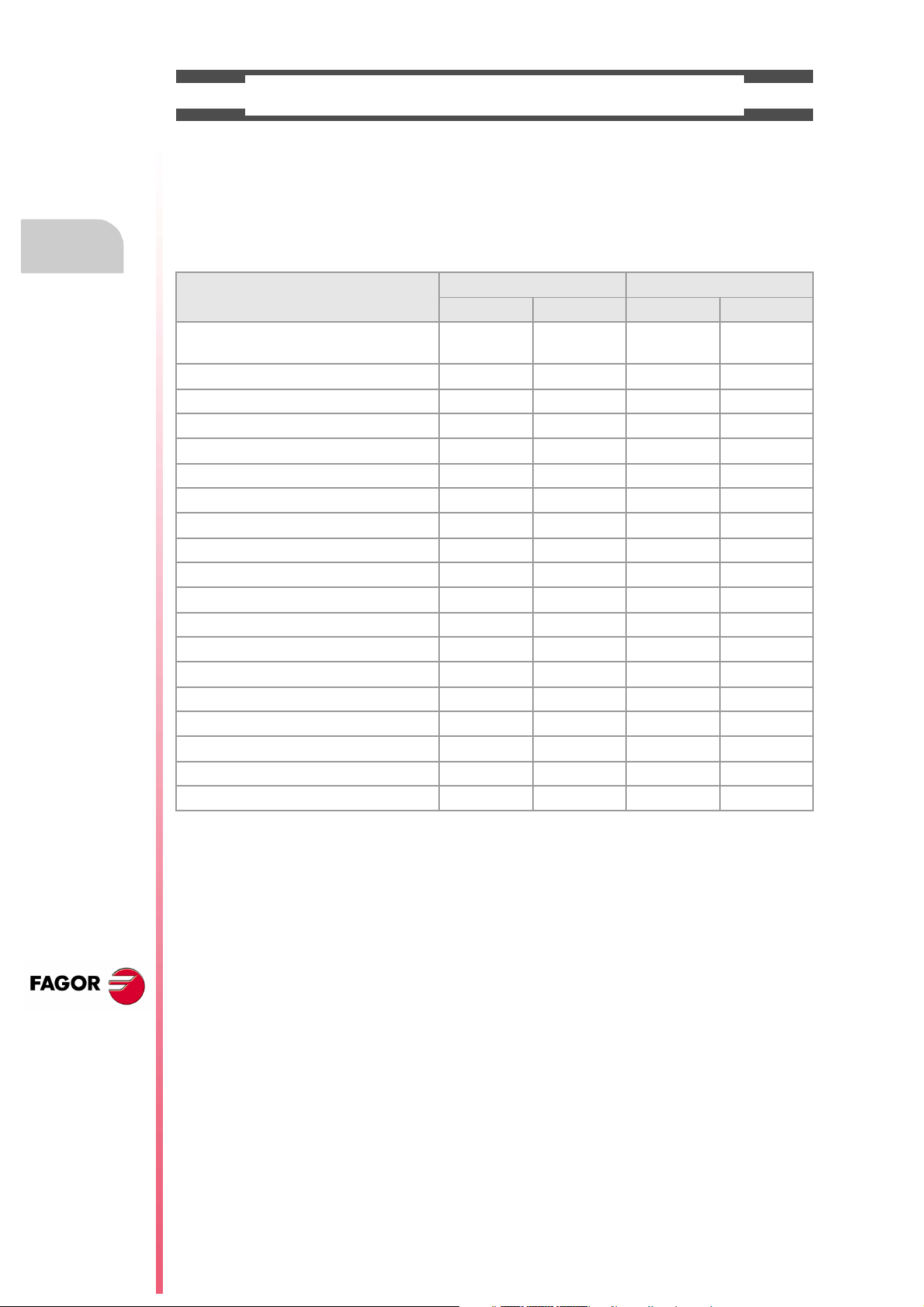

Basic characteristics. ·M· ·T·

PC-based system. Open system

Operating system. Windows XP

Number of axes. 3 to 28

Number of spindles. 1 to 4

Number of tool magazines. 1 to 4

Number of execution channels. 1 to 4

Number of handwheels. 1 to 12

Type of servo system. Analog / Digital Sercos / Digital Mechatrolink

Communications. RS485 / RS422 / RS232

Ethernet

Integrated PLC.

PLC execution time.

Digital inputs / Digital outputs.

Marks / Registers.

Timers / Counters.

Symbols.

Block processing time. < 1 ms

< 1ms/K

1024 / 1024

8192 / 1024

512 / 256

Unlimited

Remote modules. RIOW RIO5 RIO70

Communication with the remote modules. CANopen CANopen CANfagor

Digital inputs per module. 8 16 or 32 16

Digital outputs per module. 8 24 or 48 16

Analog inputs per module. 4 4 8

Analog outputs per module. 4 4 4

Inputs for PT100 temperature sensors. 2 2 - - -

Feedback inputs. - - - - - - 4

Differential TTL

Sinusoidal 1 Vpp

Customizing.

PC-based open system, fully customizable.

INI configuration files.

FGUIM visual configuration tool.

Visual Basic®, Visual C++®, etc.

Internal databases in Microsoft® Access.

OPC compatible interface

CNC

8065 TC

(REF: 1201)

·7·

Page 8

Operating m anual

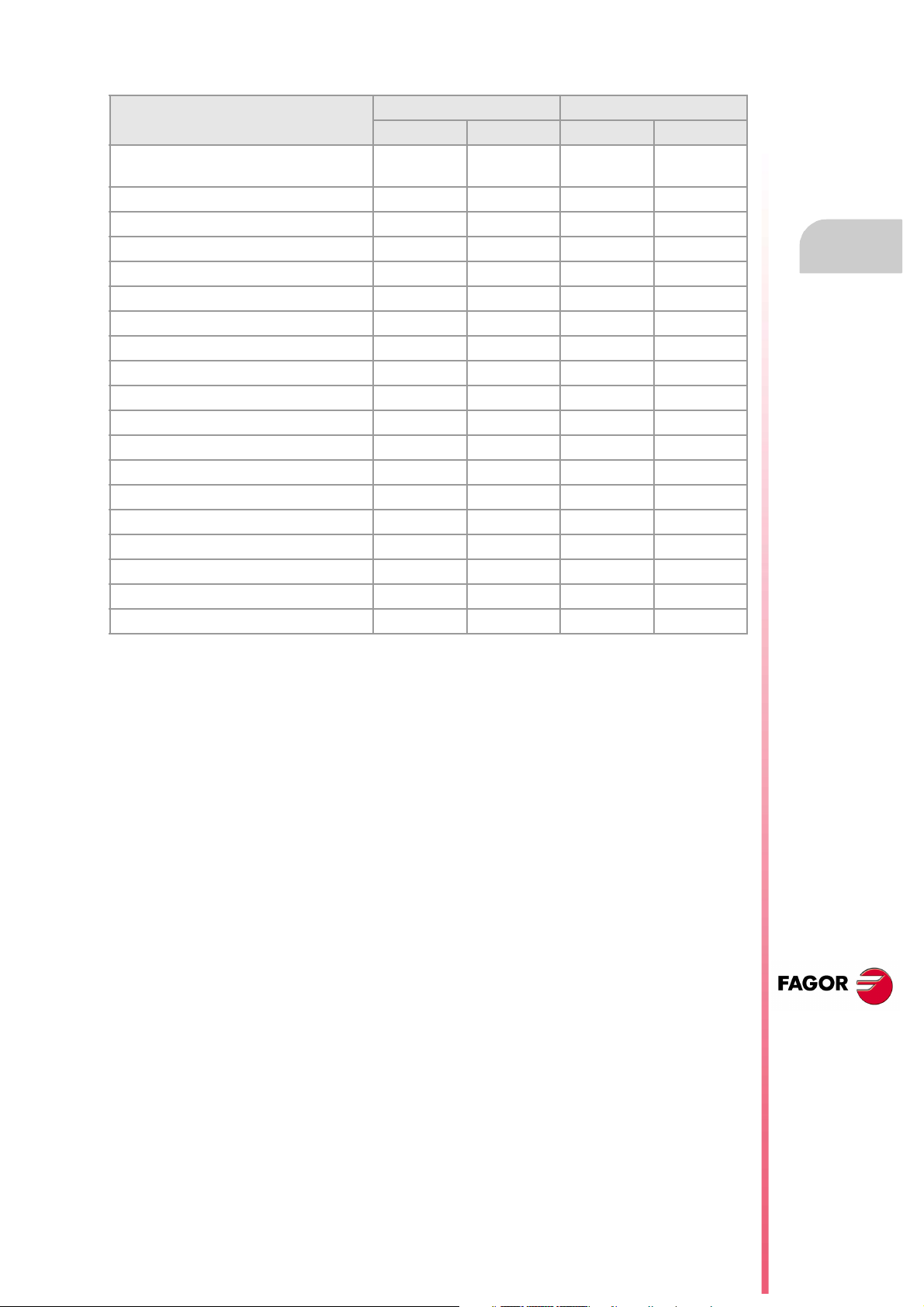

SOFTWARE OPTIONS.

Bear in mind that some of the features described in this manual depend on the software options that are

installed. The information of the following table is informative only; when purchasing the software options,

only the information provided in the ordering handbook is valid.

Software options (·M· model).

8065 M 8065 M Power

Basic Pack 1 Basic Pack 1

Open system.

Access to the administrator mode.

Number of execution channels 1 1 1 1 to 4

Number of axes 3 to 6 5 to 8 5 to 12 8 to 28

Number of spindles 1 1 to 2 1 to 4 1 to 4

Number of tool magazines 1 1 1 to 2 1 to 4

Limited to 4 interpolated axes Option Option Option Option

IEC 61131 language - - - Option Option Option

HD graphics Option Option Standard Standard

Conversational IIP Option Option Option Option

Dual-purpose machines (M-T) - - - - - - Option Standard

"C" axis Standard Standard Standard Standard

Dynamic RTCP - - - Option Option Standard

HSSA machining system. Standard Standard Standard Standard

Probing canned cycles Option Standard Standard Standard

Tandem axes - - - Option Standard Standard

Synchronism and cams - - - - - - Option Standard

Tangential control - - - Standard Standard Standard

Volumetric compensation (up to 10 m³). - - - - - - Option Option

Volumetric compensation (more than 10 m³). - - - - - - Option Option

- - - - - - Option Option

CNC

8065 TC

(REF: 1201)

·8·

Page 9

Operating manual

Software options (·T· model).

8065 T 8065 T Power

Basic Pack 1 Basic Pack 1

Open system.

Access to the administrator mode.

Number of execution channels 1 1 to 2 1 to 2 1 to 4

Number of axes 3 to 5 5 to 7 5 to 12 8 to 28

Number of spindles 2 2 3 to 4 3 to 4

Number of tool magazines 1 1 to 2 1 to 2 1 to 4

Limited to 4 interpolated axes Option Option Option Option

IEC 61131 language - - - Option Option Option

HD graphics Option Option Standard Standard

Conversational IIP Option Option Option Option

Dual-purpose machines (T-M) - - - - - - Option Standard

"C" axis Option Standard Standard Standard

Dynamic RTCP - - - - - - Option Standard

HSSA machining system. Option Standard Standard Standard

Probing canned cycles Option Standard Standard Standard

Tandem axes - - - Option Standard Standard

Synchronism and cams - - - Option Option Standard

Tangential control - - - - - - Option Standard

Volumetric compensation (up to 10 m³). - - - - - - Option Option

Volumetric compensation (more than 10 m³). - - - - - - Option Option

- - - - - - Option Option

CNC

8065 TC

(REF: 1201)

·9·

Page 10

Page 11

Operating manual

DECLARATION OF CONFORMITY

The manufacturer:

Fagor Automation S. Coop.

Barrio de San Andrés Nº 19, C.P.20500, Mondragón -Guipúzcoa- (Spain).

Declares:

The manufacturer declares under their exclusive responsibility the conformity of the product:

8065 CNC

Consisting of the following modules and accessories:

8065-M-ICU

8065-T-ICU

MONITOR-LCD-10, MONITOR-LCD-15

HORIZONTAL-KEYB, VERTICAL-KEYB, OP-PANEL

BATTERY

Remote Modules RIOW, RIO5, RIO70

Note.Some additional characters may follow the model references indicated above. They all comply with the

directives listed here. However, compliance may be verified on the label of the unit itself.

Referred to by this declaration with following directives:

Low-voltage regulations.

EN 60204-1: 2006 Electrical equipment on machines — Part1. General requirements.

Regulation on electromagnetic compatibility.

EN 61131-2: 2007 PLC — Part 2. Equipment requirements and tests.

According to the European Community Directives 2006/95/EC on Low Voltage and 2004/108/EC

on Electromagnetic Compatibility and their updates.

In Mondragón, October 1st 2011.

CNC

8065 TC

(REF: 1201)

·11·

Page 12

Page 13

Operating manual

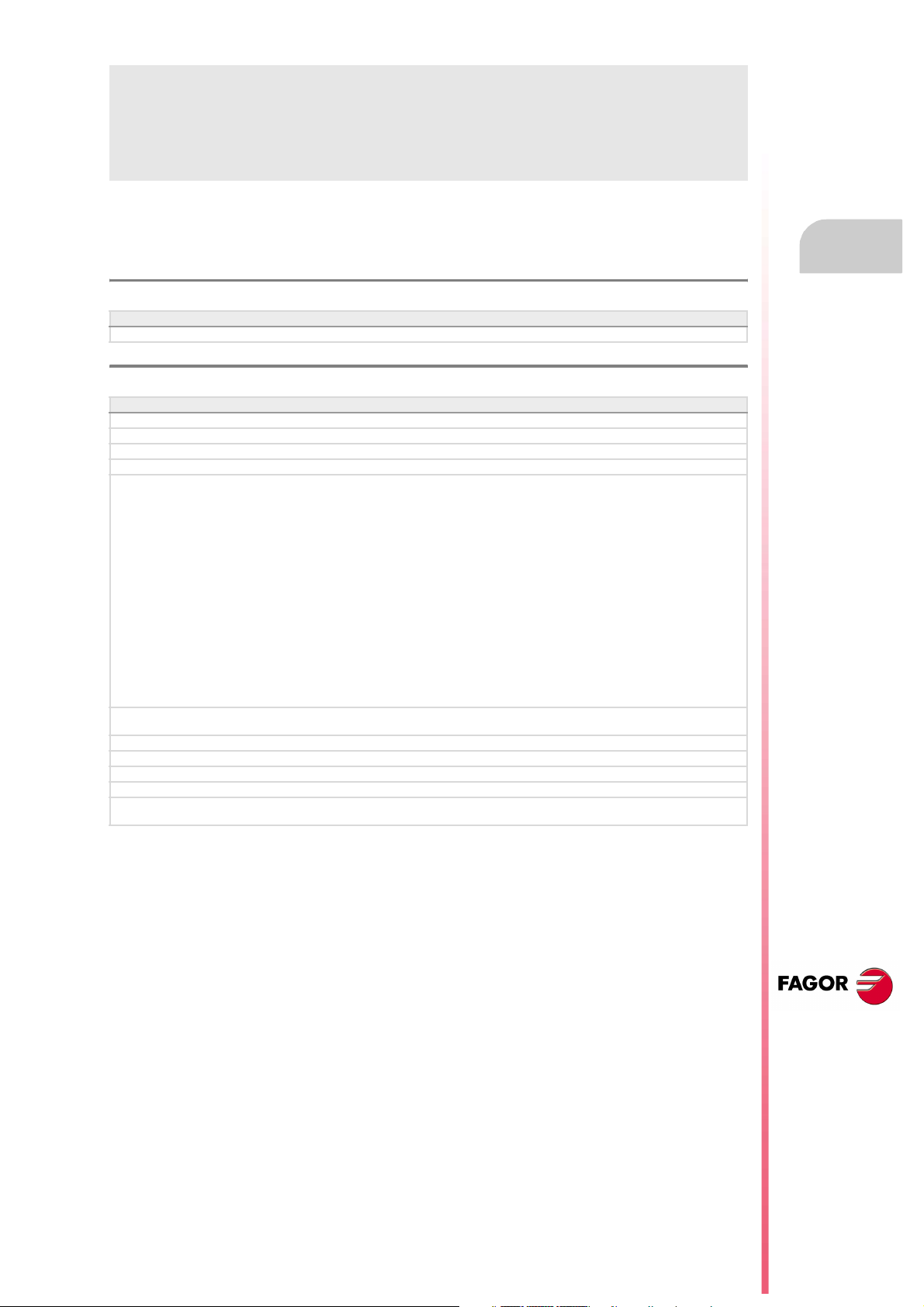

VERSION HISTORY

Here is a list of the features added to each manual reference.

Ref. 1103

Software V04.20

First version.

Ref. 1201

Software V04.22

Canned cycles. Point-to-point turning cycle. The table to define the points of the profile admits 25 points.

Canned cycles. Point-to-point turning cycle. New icon to delete all the points of the table.

Canned cycles. Multiple tapping cycle. The cycle allows programming the dwell at the bottom.

Canned cycles. Multiple slot milling cycle. The cycle allows defining several penetration passes.

Canned cycles. By default, the cycles assume for Xf the value set for Xi.

• Simple turning cycle.

• Turning cycle with vertex rounding.

• Simple facing cycle.

• Facing cycle with vertex rounding.

• "Chamfering between points" cycle.

• "Rounding between points" cycle.

• Taper threading cycle.

• Face threading cycle.

• Thread repair cycle.

• Multi-entry threading cycle.

• Simple longitudinal grooving cycle.

• Simple face grooving cycle.

• Inclined longitudinal grooving cycle.

• Inclined face grooving cycle.

Canned cycles. When selecting it in a constant surface speed cycle, it allows selecting the gear (range) even if the gear change is

automatic.

Canned cycles. The cycles make the approach to the starting point on both axes of the plane at the same time.

Canned cycles. The [DEL] key deletes a profile from the list.

Canned cycles. Pressing [RECALL] on a tool gives access to the tool table.

Keyboard shortcuts [CTRL][C] and [CTRL][V] may be used on the programs list to copy and paste a program.

Selecting a program for e diting no longer involves selecting it a lso for execution. Use the "Execute Program" softkey to select a pr ogram

for execution.

CNC

8065 TC

(REF: 1201)

·13·

Page 14

Page 15

Operating manual

SAFETY CONDITIONS

Read the following safety measures in order to prevent harming people or damage to this product and those

products connected to it. Fagor Automation shall not be held responsible of any physical damage or

defective unit resulting from not complying with these basic safety regulations.

Before start-up, verify that the machine that integrates this CNC meets the 89/392/CEE Directive.

PRECAUTIONS BEFORE CLEANING THE UNIT

If the CNC does not turn on when actuating the start-up switch, verify the connections.

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate the

Do not handle the connectors with the unit

connected to AC power.

inside of this unit.

Before manipulating the connectors (inputs/outputs, feedback, etc.)

make sure that the unit is not connected to AC power.

PRECAUTIONS DURING REPAIR

In case of a malfunction or failure, disconnect it and call the technical service.

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate the

inside of this unit.

Do not handle the connectors with the unit

connected to AC power.

Before manipulating the connectors (inputs/outputs, feedback, etc.)

make sure that the unit is not connected to AC power.

PRECAUTIONS AGAINST PERSONAL DAMAGE

Interconnection of modules. Use the connection cables provided with the unit.

Use proper cables. To prevent risks, use the proper cables for mains, Sercos and Bus

CAN recommended for this unit.

In order to avoid electrical shock at the central unit, use the proper

power (mains) cable. Use 3-wire power cables (one for ground

connection).

Avoid electrical overloads. In order to avoid electrical discharges and fire hazards, do not apply

Ground connection. In order to avoid electrical discharges, connect the ground terminals

Do not work in humid environments. In order to avoid electrical discharges, always work under 90% of

Do not work in explosive environments. In order to avoid risks or damages, do no work in explosive

electrical voltage outside the range selected on the rear panel of the

central unit.

of all the modules to the main ground terminal. Before connecting the

inputs and outputs of this unit, make sure that all the grounding

connections are properly made.

In order to avoid electrical shock, before turning the unit on verify that

the ground connection is properly made.

relative humidity (non-condensing) and 45 ºC (113 ºF).

environments.

CNC

8065 TC

(REF: 1201)

·15·

Page 16

Operating m anual

PRECAUTIONS AGAINST PRODUCT DAMAGE

Working environment. This unit is ready to be used in industrial environments complying with

the directives and regulations effective in the European Community.

Fagor Automation shall not be held responsible for any damage

suffered or caused by the CNC when installed in other environments

(residential or homes).

Install the unit in the right place. It is recommended, whenever possible, to install the CNC away from

Enclosures. The manufacturer is responsible of assuring that the enclosure

Avoid disturbances coming from the

machine.

Use the proper power supply. Use an external regulated 24 Vdc power supply for the keyboard and

Grounding of the power supply. The zero volt point of the external power supply must be connected

Analog inputs and outputs connection. Use shielded cables connecting all their meshes to the corresponding

Ambient conditions. The storage temperature must be between +5 ºC and +45 ºC (41 ºF

Central unit enclosure. Make sure that the needed gap is kept between the central unit and

Main AC power switch. This switch must be easy to access and at a distance between 0.7 and

coolants, chemical product, blows, etc. that could damage it.

This unit complies with the European directives on electromagnetic

compatibility. Nevertheless, it is recommended to keep it away from

sources of electromagnetic disturbance such as:

Powerful loads connected to the same AC power line as this

equipment.

Nearby portable transmitters (Radio-telephones, Ham radio

transmitters).

Nearby radio/TV transmitters.

Nearby arc welding machines.

Nearby High Voltage power lines.

involving the equipment meets all the currently effective directives of

the European Community.

The machine must have all the interference generating elements

(relay coils, contactors, motors, etc.) uncoupled.

the remote modules.

to the main ground point of the machine.

pin.

and 113 ºF).

The storage temperature must be between -25 ºC and 70 ºC (-13 ºF

and 158 ºF).

each wall of the enclosure.

Use a DC fan to improve enclosure ventilation.

1.7 m (2.3 and 5.6 ft) off the floor.

CNC

8065 TC

(REF: 1201)

·16·

PROTECTIONS OF THE UNIT ITSELF

Remote modules. All the digital inputs and outputs have galvanic isolation via

optocouplers between the CNC circuitry and the outside.

Page 17

Operating manual

SAFETY SYMBOLS

Symbols that may appear on the manual.

Danger or prohibition symbol.

It indicates actions or operations that may hurt people or damage products.

Warning symbol.

It indicates situations that certain operations could cause and the suggested actions to prevent them.

Obligation symbol.

It indicates actions and operations that must be carried out.

Information symbol.

i

Symbols that the product may carry.

It indicates notes, warnings and advises.

Ground protection symbol.

It indicates that that point must be under voltage.

CNC

8065 TC

(REF: 1201)

·17·

Page 18

Page 19

Operating manual

WARRANTY TERMS

INITIAL WARRANTY

All products manufactured or marketed by FAGOR carry a 12-month warranty for the end user which could

be controlled by the our service network by means of the warranty control system established by FAGOR

for this purpose.

In order to prevent the possibility of having the time period from the time a product leaves our warehouse

until the end user actually receives it run against this 12-month warranty, FAGOR has set up a warranty

control system based on having the manufacturer or agent inform FAGOR of the destination, identification

and on-machine installation date, by filling out the document accompanying each FAGOR product in the

warranty envelope. This system, besides assuring a full year of warranty to the end user, enables our service

network to know about FAGOR equipment coming from other countries into their area of responsibility.

The warranty starting date will be the one appearing as the installation date on the above mentioned

document. FAGOR offers the manufacturer or agent 12 months to sell and install the product. This means

that the warranty starting date may be up to one year after the product has left our warehouse so long as

the warranty control sheet has been sent back to us. This translates into the extension of warranty period

to two years since the product left our warehouse. If this sheet has not been sent to us, the warranty period

ends 15 months from when the product left our warehouse.

This warranty covers all costs of material and labour involved in repairs at FAGOR carried out to correct

malfunctions in the equipment. FAGOR undertakes to repair or replace their products within the period from

the moment manufacture begins until 8 years after the date on which it disappears from the catalogue.

It is entirely up to FAGOR to determine whether the repair is or not under warranty.

EXCLUDING CLAUSES

Repairs will be carried out on our premises. Therefore, all expenses incurred as a result of trips made by

technical personnel to carry out equipment repairs, despite these being within the above-mentioned period

of warranty, are not covered by the warranty.

Said warranty will be applied whenever the equipment has been installed in accordance with instructions,

has not be mistreated, has not been damaged by accident or by negligence and has not been tampered

with by personnel not authorised by FAGOR. If, once servicing or repairs have been made, the cause of

the malfunction cannot be attributed to said elements, the customer is obliged to cover the expenses

incurred, in accordance with the tariffs in force.

Other warranties, implicit or explicit, are not covered and FAGOR AUTOMATION cannot be held responsible

for other damages which may occur.

CNC

8065 TC

(REF: 1201)

·19·

Page 20

Operating m anual

WARRANTY ON REPAIRS

In a similar way to the initial warranty, FAGOR offers a warranty on standard repairs according to the

following conditions:

PERIOD 12 months.

CONCEPT Covers parts and labor for repairs (or replacements) at the

network's own facilities.

EXCLUDING CLAUSES The same as those applied regarding the chapter on initial

warranty. If the repair is carried out within the warranty period, the

warranty extension has no effect.

When the customer does not choose the standard repair and just the faulty material has been replaced,

the warranty will cover just the replaced parts or components within 12 months.

For sold parts the warranty is 12 moths length.

SERVICE CONTRACTS

The SERVICE CONTRACT is available for the distributor or manufacturer who buys and installs our CNC

systems.

CNC

8065 TC

(REF: 1201)

·20·

Page 21

Operating manual

MATERIAL RETURNING TERMS

When sending the central nit or the remote modules, pack them in its original package and packaging

material. If the original packaging material is not available, pack it as follows:

1 Get a cardboard box whose three inside dimensions are at least 15 cm (6 inches) larger than those

of the unit. The cardboard being used to make the box must have a resistance of 170 Kg (375 lb.).

2 Attach a label indicating the owner of the unit, person to contact, type of unit and serial number. In case

of malfunction also indicate symptom and a brief description of the problem.

3 Wrap the unit in a polyethylene roll or similar material to protect it. When sending a central unit with

monitor, protect especially the screen.

4 Pad the unit inside the cardboard box with poly-utherane foam on all sides.

5 Seal the cardboard box with packing tape or industrial staples.

CNC

8065 TC

(REF: 1201)

·21·

Page 22

Page 23

Operating manual

CNC MAINTENANCE

CLEANING

The accumulated dirt inside the unit may act as a screen preventing the proper dissipation of the heat

generated by the internal circuitry which could result in a harmful overheating of the unit and, consequently,

possible malfunctions. Accumulated dirt can sometimes act as an electrical conductor and short-circuit the

internal circuitry, especially under high humidity conditions.

To clean the operator panel and the monitor, a smooth cloth should be used which has been dipped into

de-ionized water and /or non abrasive dish-washer soap (liquid, never powder) or 75º alcohol. Do not use

highly compressed air to clean the unit because it could generate electrostatic discharges.

The plastics used on the front panel are resistant to grease and mineral oils, bases and bleach, dissolved

detergents and alcohol. Avoid the action of solvents such as chlorine hydrocarbons, venzole, esters and

ether which can damage the plastics used to make the unit’s front panel.

PRECAUTIONS BEFORE CLEANING THE UNIT

Fagor Automation shall not be held responsible for any material or physical damage derived from the

violation of these basic safety requirements.

• Do not handle the connectors with the unit connected to AC power. Before handling these connectors

(I/O, feedback, etc.), make sure that the unit is not connected to main AC power.

• Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate

the inside of this unit.

• If the CNC does not turn on when actuating the start-up switch, verify the connections.

CNC

8065 TC

(REF: 1201)

·23·

Page 24

Page 25

GENERAL CONCEPTS

1.1 Accessing the conversational mode

Once the CNC has been started up, press the key sequence [SHIFT] [ESC] to switch to

conversational mode. Press [SHIFT] + [ESC] again to return to T mode.

1

[SHIFT] [ESC]

[SHIFT] [ESC]

The CNC setup must be done in T mode. Likewise, some errors must be eliminated in T mode.

CNC

8065 TC

(REF: 1201)

·25·

Page 26

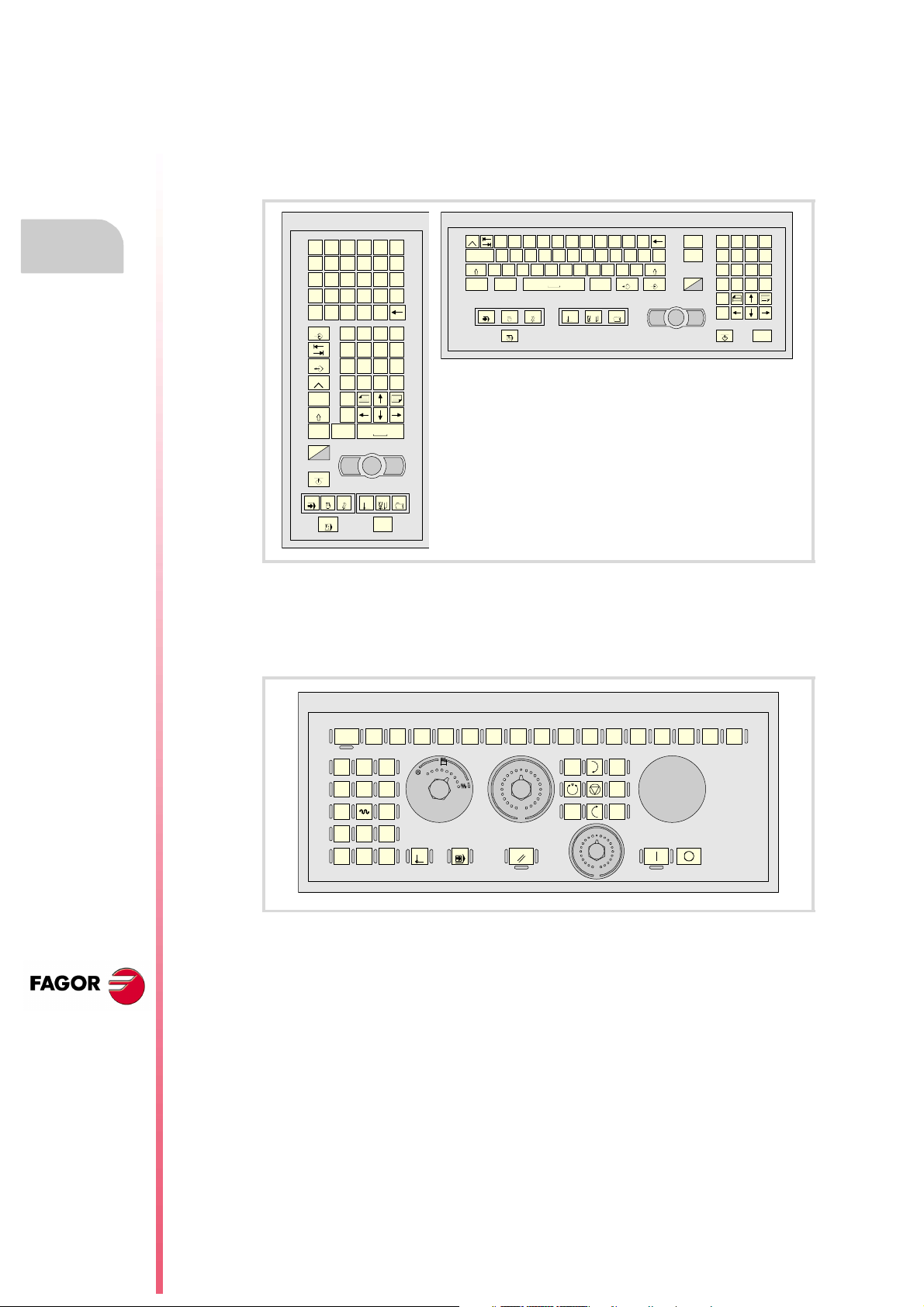

1.2 Keyboard

Vertical and horizontal keyboard

They may be used to select characters, move around various screens and select the various

work modes.

Operating m anual

1.

Keyboard

GENERAL CONCEPTS

A B C D E F

G H I J K L

M N Ñ O P Q

R S T U V W

INS DEL

X Y Z

ENTER

RECALL

ESC

CAPS

SHIFT

CTRL

CUSTOM

789

=

456

/

123

*

_

+

0

HOME

END

SPACE

ALT

EDITMANUALAUTO

TABLES TOOLS UTILITIES

MDI

MAIN

MENU

ESC

Q W E R T Y U I O P

CAPS INS

S D F G H J K L ÑA

ZXCVBNM

<

SPACE

ALTGRALTCTRL

MDI

,.-

RECALL ENTER

UTILITIESTOOLSTABLESEDITM ANUALAUTO

^

.

{}

SHIFTSHIFT

DEL

HOME

END

CUSTOM

=

/

*

+

789

456

123

_

.

0

MAIN

MENU

JOG keys

They may be used to move the axes of the machine, govern the spindle, modify the feedrate

of the axes and the spindle speed as well as start and stop the exection.

CNC

8065 TC

(REF: 1201)

CNC

OFF

X+X-Y+ Z+

Y- Z-

7+ 7-

4+ 5+ 6+

4- 5- 6-

jog

1

1

10

10

100

100

1000

10000

ZERO SING LE RESET

70

60

50

40

30

20

10

4

2

0

1009080

+

110

120

130

140

150

160

170

180

190

_

200

FEED

1009080

110

70

120

60

130

50

140

40

150

30

160

20

170

10

180

4

190

2

200

0

SPEED

·26·

Page 27

Operating manual

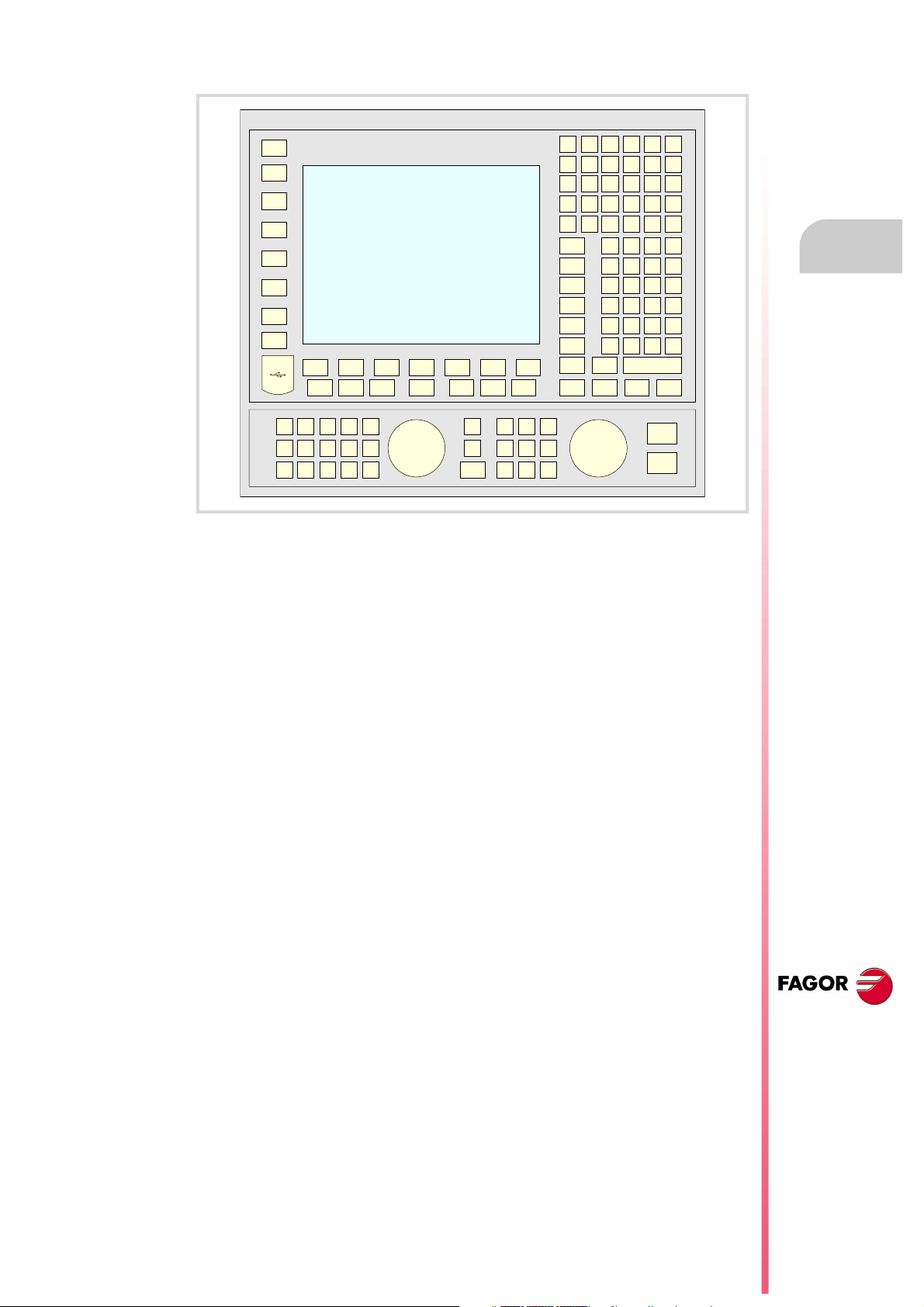

Keyboard set with jog keypad and monitor.

1.

Keyboard

GENERAL CONCEPTS

CNC

8065 TC

(REF: 1201)

·27·

Page 28

1.

Operating m anual

Keyboard

GENERAL CONCEPTS

CNC

8065 TC

(REF: 1201)

·28·

Page 29

OPERATING IN JOG MODE

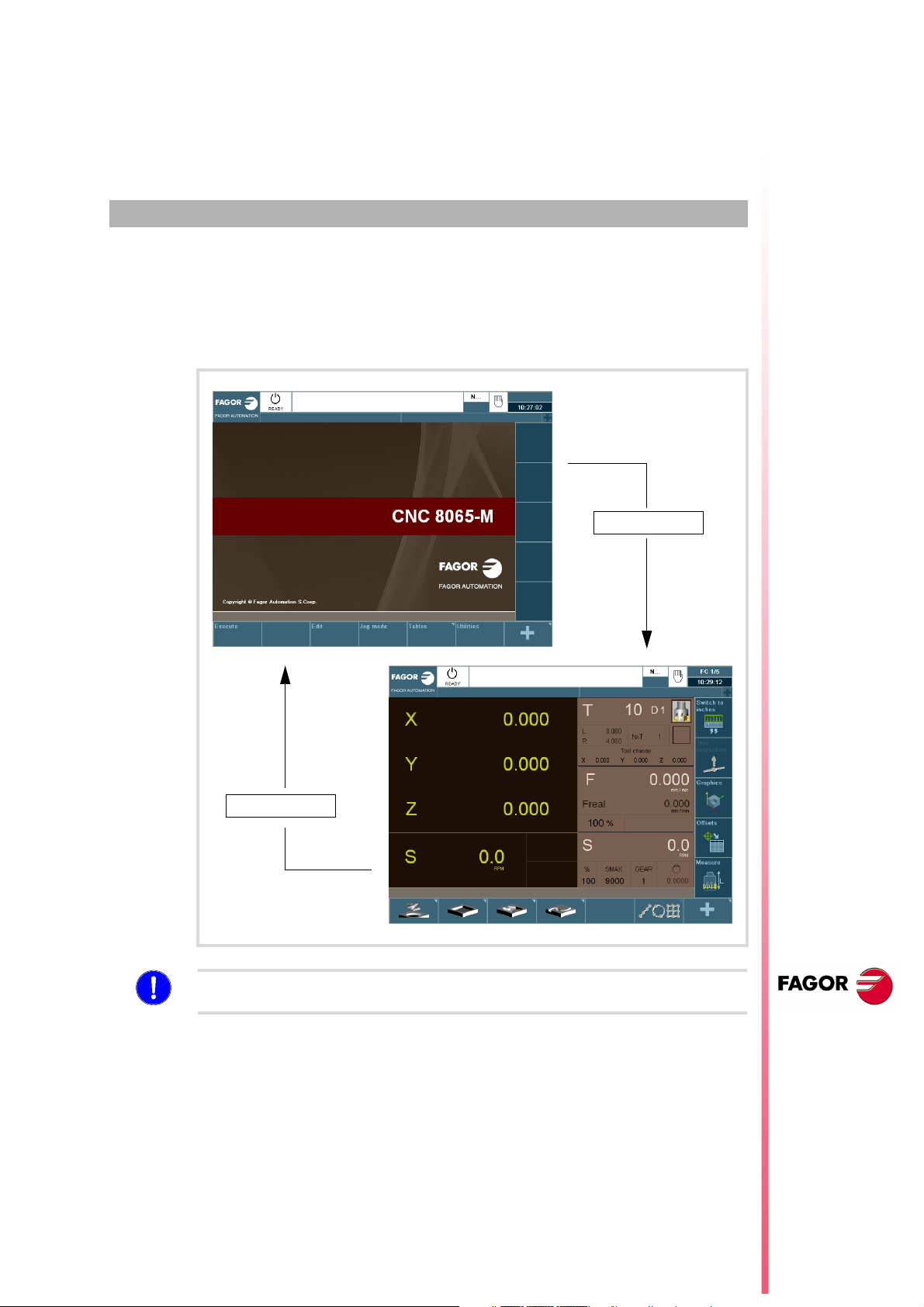

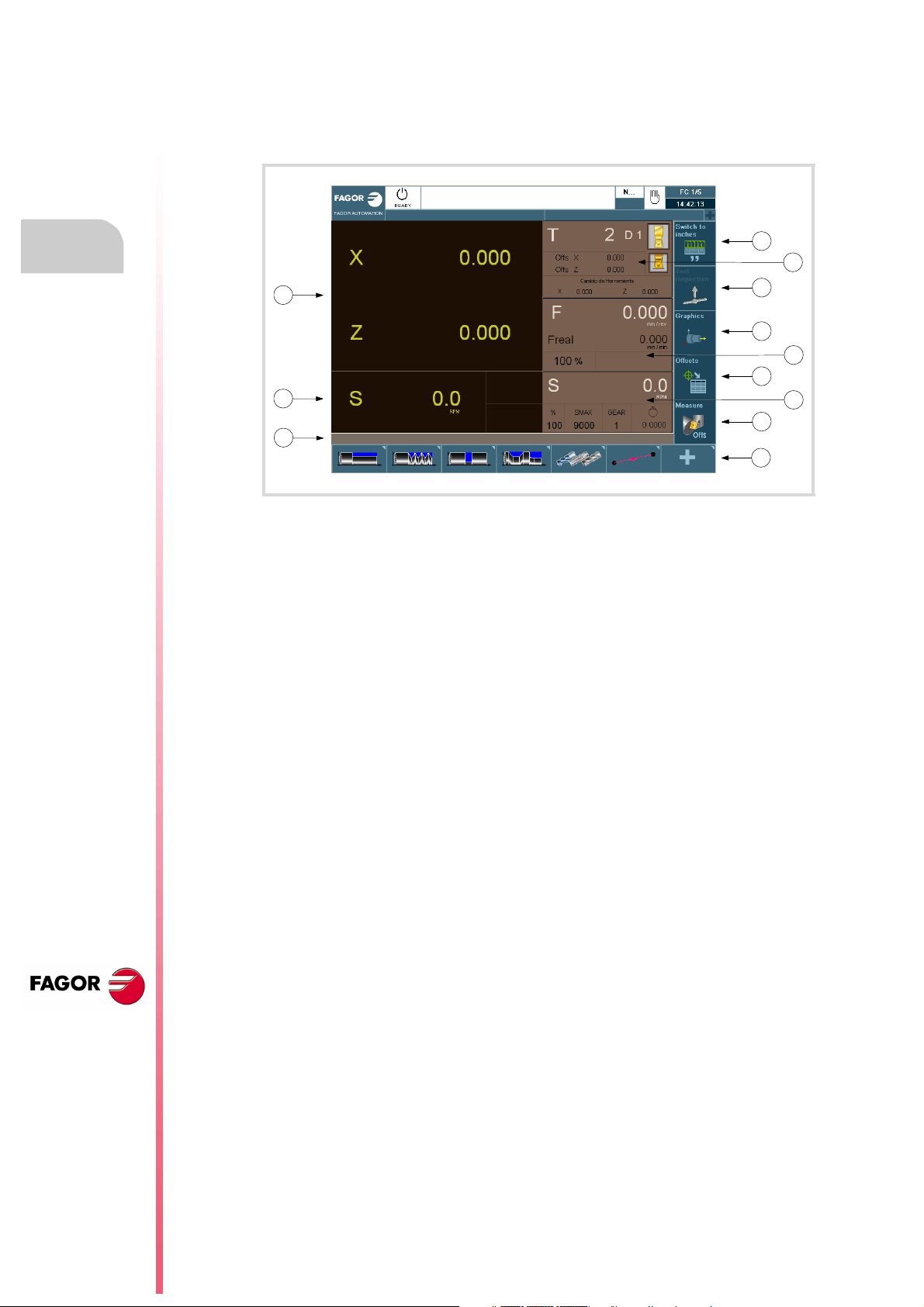

The standard screen of the TC work mode is:

2

When pressing the two-colored key, the CNC shows the auxiliary screen of the TC mode:

CNC

8065 TC

(REF: 1201)

·29·

Page 30

2.1 Introduction

2.1.1 Standard screen of the conversational mode

Operating m anual

2.

OPERATING IN JOG MODE

CNC

8065 TC

(REF: 1201)

Introduction

1

6

12

11

10

1 Softkey for selecting units mm/inches.

2 Softkey to go into tool inspection.

3 Softkey to access the graphics in execution mode.

4 Softkey for selecting OFFSETS.

5 Softkey for tool calibration.

6 Window that shows:

• The selected tool (T).

• Graphic representation of the location code (shape).

• The (D) offset number associated with the selected tool.

• The offset defined for the tool.

• The position values (coordinates) of the tool change point referred to machine

reference zero. If one of these coordinates is selected, it may be assigned the value

of the current position of that axis by pressing [RECALL].

7 Window showing the axis feedrate F currently selected, the % of F being applied and the

real F value. When selecting an incremental jog or a handwheel, this window will also

show the selected % with the corresponding icon and the selected %.

8 Window showing spindle related information:

• The selected theoretical turning speed. S value when working in rpm and CSS value

when working at constant surface speed.

• Spindle status. It is represented with an icon and may be turning clockwise,

counterclockwise or stopped.

• The % of spindle speed being applied.

• Maximum spindle rpm (Smax).

• Active spindle range (gear).

9 Softkeys for cycle editing.

10Message bar.

11Real spindle rpm.

12Position (coordinates) of the axes. The f symbol indicates that the axis is working in

diameter.

2

3

7

4

8

5

9

·30·

If there are more than one spindle in the active channel, S may be pressed repeatedly to

select the spindle whose data is being displayed. If the cell for programmed turning speed

is already selected, every time S is pressed, it will show the data of the next spindle.

Page 31

Operating manual

2.1.2 Auxiliary screen of the conversational mode

14

13

12

11

6

1

7

2

3

8

9

4

10

5

2.

Introduction

1 Softkey for selecting units mm/inches.

2 Softkey to go into tool inspection.

3 Softkey to access the graphics in execution mode.

4 Softkey for selecting OFFSETS.

5 Softkey for tool calibration.

6 Window that shows the status of the G, F, T, D, M functions.

7 Window that shows:

• The selected tool (T).

• Graphic representation of the location code (shape).

• The (D) offset number associated with the selected tool.

8 Window showing the axis feedrate F currently selected, the % of F being applied and the

real F value.

9 Window that shows the value of the variables:

• Partc: It indicates the number of consecutive parts executed with the same partprogram. Every time a new program is selected, this variable is reset to "0".

• CyTime: It indicates the time elapsed while executing the part. It is given in "hours

: minutes : seconds : hundredths of a second" format. Every time a part-program

execution starts, even when repetitive, this variable is reset to "0".

• Timer: It indicates the count of the timer enabled by PLC. It is given in "hours : minutes

: seconds" format.

10Window with spindle related information:

• The selected theoretical turning speed. S value when working in rpm and CSS value

when working at constant surface speed.

• The % of spindle speed being applied.

• Maximum spindle rpm (Smax).

• Active spindle range (gear).

11Message bar.

12Window with spindle related information:

• Theoretical speed.

• Speed in RPM.

• Speed in m/min.

OPERATING IN JOG MODE

CNC

8065 TC

(REF: 1201)

·31·

Page 32

2.

Operating m anual

13Window with axis related information:

• COMMAD: It indicates the programmed coordinate or position that the axis must

reach.

• ACTUAL: It indicates the actual (current) position of the axis.

• TO GO: It indicates the distance which is left to run to the programmed coordinate.

14Window that shows the lines of the program being executed.

Introduction

OPERATING IN JOG MODE

CNC

8065 TC

(REF: 1201)

·32·

Page 33

Operating manual

2.1.3 Cycle editing

To edit a cycle, press the softkey for the desired cycle.

2.

Introduction

OPERATING IN JOG MODE

To select another cycle of the same family as the one selected, press the softkey again to

drop the menu with the available cycles.

Once the cycle to be edited has been selected, enter the data in the windows corresponding

to each parameter of that cycle. To validate each parameter and go on to the next one,

[ENTER].

For further information on editing cycles, see the chapter

cycles"

.

After editing a cycle, it may be simulated, executed or saved using the vertical softkey menu.

For further information on saving cycles, see the chapter

"3 Working with operations or

"5 Saving programs"

.

CNC

8065 TC

(REF: 1201)

·33·

Page 34

2.

Operating m anual

2.1.4 Cycle simulation

To simulate the edited cycle, press the vertical softkey [Simulate cycle].

1

2

3

Introduction

4

OPERATING IN JOG MODE

5

1 Softkey to start cycle simulation.

2 Softkey to stop cycle simulation.

3 Softkey to reset the simulation.

4 Softkey to simulate the cycle block by block.

5 The horizontal softkeys may be used to configure how to display the simulated cycle.

• Type of view.

• Configuration.

• Actions.

• Delete.

• Dimensions.

• Measurement.

CNC

8065 TC

(REF: 1201)

·34·

Page 35

Operating manual

2.1.5 Cycle execution

To execute an edited cycle, press the vertical softkey [Execute cycle]. An icon will then appear

with the start symbol to warn the user that it is going to execute the cycle.

To execute the cycle, press [START]. Otherwise, press [ESC].

2.

Introduction

OPERATING IN JOG MODE

CNC

8065 TC

(REF: 1201)

·35·

Page 36

2.

Operations with the axes.

OPERATING IN JOG MODE

2.2 Operations with the axes.

2.2.1 Home search.

Home search is the operation used to synchronize the system. This operation must be

carried out when the CNC loses the position of the origin point (e.g. by turning the machine

off).

When "searching home", the axes move to the machine reference point and the CNC

assumes the coordinate values assigned to that point by the machine manufacturer, referred

to machine zero. When using distance-coded reference marks or absolute feedback, the

axes will only move the distance necessary to verify their position.

The axes may be homed manually (axis by axis from the operator panel) or automatically

(using a subroutine).

Manual home search (one axis at a time).

The axis-by-axis home search cancels the zero offset, the fixture offset and the measuring offset. The

i

CNC assumes the machine reference zero point (home) as the new part zero.

X Y Z

ZERO

1 Select the axis to be homed using the alphanumeric keyboard. The

CNC will highlight that axis to indicate that it is selected.

To select the numbered axes (e.g. "X1"), select any axis and then move

the selection until positioning on the desired one. The focus moves with

the [©][ª] keys.

2 Press the homing key [ZERO]. The CNC will display the "1" symbol in

the numeric area indicating that a home search will take place.

3 Press [START] to go ahead with the home search or [ESC] to cancel

ESC

the operation.

Operating m anual

CNC

8065 TC

Automatic home search (with subroutine).

This homing method is only available if the machine manufacturer has previously defined

a homing subroutine.

ZERO

1 Press the homing key [ZERO]. The CNC will display a dialog box

requesting confirmation to execute the home search.

2 Press [START] to go ahead with the home search or [ESC] to cancel

ESC

the operation.

(REF: 1201)

·36·

Page 37

Operating manual

2.2.2 Jog

The axes may be jog using the JOG keyboard on the operator panel. The type of jog is

selected with the jog selector switch on the operator panel.

jog

100

1

1

10

jog

10

100

1000

10000

Continuous jog Incremental jog Handwheels

The jog keyboard and the feedrate selector

JOG keypad.

There are two types of jog keyboards depending on the behavior of the keys.

X+X-Y+ Z+

Y- Z-

7+ 7-

X

Y Z

4 5 6

+

The keypad has two keys for each axis. One to jog the axis in the

positive direction and another one to move it in the negative direction.

To move a single axis, press the axis key and the one for its jogging

direction.

The keypad has a key for each axis and two keys for moving direction,

common to all the axes.

To jog an axis requires activating both the axis key and the moving

direction. There are two options, depending on how the jog keyboard

has been configured.

_

• The axis will move while both keys are pressed, the axis key and

the direction key.

• When pressing the axis key, the key remains active. The axis will

move while the direction key is kept pressed. To de-select the axis,

press [ESC] or [STOP].

2.

Operations with the axes.

OPERATING IN JOG MODE

User keys as jog keys

The CNC offers the OEM the possibility to enable the user keys as jog keys. The user keys

defined this way behave like the jog keys.

Feedrate selector.

1009080

70

60

50

40

30

20

10

4

2

200

0

FEED

The movement is carried out at the feedrate defined by the OEM. The

110

feedrate may be varied between 0% and 200% using the feedrate override

120

130

switch on the operator panel.

140

150

160

170

180

190

Movement in continuous jog.

In continuous jog, the axes keep moving while the jog keyboard is acted upon. Continuous

jog allows moving several axes at the same time.

1 Turn the jog selector switch of the operator panel to the continuous jog position on the dial.

2 Jog the desired axis using the JOG panel (keypad). If while moving, a second axis is

selected, the new one will move at the same time and under the same conditions.

If while the axes are moving, the rapid key is pressed, the axes will move at the rapid rate

set by the machine manufacturer. This feedrate will be applied while that key is kept pressed

and, when released, the axes will recover their previous feedrate. This rapid rate may be

varied between 0% and 200% with the feedrate override switch on the operator panel.

CNC

8065 TC

(REF: 1201)

·37·

Page 38

2.

Operating m anual

Movement in incremental jog.

In incremental jog, the axis moves a specific distance every time the key is pressed. In

incremental jog, the axes may be jogged simultaneously.

1 Turn the jog selector switch of the operator panel to one of the incremental jog positions.

Each position will move the axis a fixed distance; the typical values are the following.

Position. Movement for each key push.

1 0.001 mm or 0.0001 inch.

10 0.010 mm or 0.0010 inches.

100 0.100 mm or 0.0100 inches.

1000 1.000 mm or 0.1000 inches.

10000 10.000 mm or 1.0000 inches.

2 Jog the desired axis using the JOG panel (keypad). Every time the JOG panel is acted

upon, the axis will move the distance indicated on the dial of the jog selector switch. If

while moving, a second axis is selected, the new one will move at the same time and

under the same conditions.

Operations with the axes.

OPERATING IN JOG MODE

CNC

8065 TC

(REF: 1201)

·38·

Page 39

Operating manual

2.2.3 Jogging the axes with handwheels

Electronic handwheels may be used to move the axes. Depending on the type of handwheel,

The CNC may have general handwheels to move any axis or individual handwheels that will

only move their associated axes.

To move the axes with the handwheels, turn the jog selector switch of the operator panel to

one of the handwheel positions. Every position indicates the multiplying factor applied to the

handwheel pulses; the typical values are the following.

Position. Movement per revolution of the handwheel.

1 0.100 mm or 0.0100 inches.

10 1.000 mm or 0.1000 inches.

100 10.000 mm or 1.0000 inches.

Once the desired resolution has been selected and depending on the type of handwheel

being used, general or individual, proceed as follows.

2.

General handwheel

The CNC may have several general handwheels. The general handwheel is not associated

with any axis in particular, it may be used to move any axis of the machine even if it has an

individual handwheel associated with it.

• If there are several axes selected in handwheel mode, the general handwheel will move

all of them.

• If an axis has been selected which has an individual handwheel selected with it, this axis

may be moved with the general handwheel, with the individual one or with both at the

same time. When using both handwheels simultaneously, the CNC will add or subtract

the pulses provided by both handwheels depending on which direction they are turned.

• If the CNC has several general handwheels, any of them can move the axes selected

in handwheel mode. When using several handwheels simultaneously, each axis involved

will be applied the sum of the increments of all the handwheels.

These are the steps to follow for moving one or several axes with the general handwheel.

1 Select the axis or axes to be jogged. The CNC will highlight the selected axes. When

selecting an axis or quitting the handwheel mode using the movement selector, the

previous one is automatically deselected.

2 Once the axis has been selected, the CNC will move it as the handwheel is turned

depending on the setting of the selector switch and on the turning direction of the

handwheel.

The feedrate depends on how fast the handwheel is turned.

Selecting the axes to be jogged

Operations with the axes.

OPERATING IN JOG MODE

There are two ways to select the axes.

1 On the JOG keyboard, press one of the keys for the axis to be jogged. Selecting an axis

de-selects the previous one. To select several axes, press one of the keys of each key

at the same time.

An axis needs not belong to the active channel in order to be selected. An axis from one

channel may be set in handwheel mode from another channel, if the channel of the axis

is also in jog mode.

2 When using a handwheel with a push-button, the push-button may be used to select,

sequentially, the axes to be jogged. Pushing the button selects the first one of the axes

being displayed. If an axis has already been selected, it de-selects it and selects the next

one. If it was the last one, it selects the first one again.

Only the axes being displayed in the active channel may be selected, regardless of the

channel they belong to. The axes of another channel cannot be selected if they are not

being displayed.

An axis is de-selected when quitting the handwheel mode using the movement selector and

after a reset. If an axis has been set in handwheel mode from the PLC, it can only be

deactivated from the PLC; a reset does not deactivate it.

CNC

8065 TC

(REF: 1201)

·39·

Page 40

2.

Operations with the axes.

OPERATING IN JOG MODE

Operating m anual

Selecting an axis from the automatic mode

When having only one channel, if while in automatic mode, you set the switch in handwheel

mode and select an axis, when going to jog mode, it maintains the selected axis.

Individual handwheel

The CNC can have several individual handwheels, where each of them is associated with

a particular axis. The CNC moves each axis as its relevant handwheel is turned depending

on the setting of the selector switch and on the turning direction of the handwheel.

In handwheel mode, this symbol next to an axis indicates that the axis has an

individual handwheel associated with it.

When moving several axes simultaneously using handwheels, all the axes having their own

handwheel plus the ones that may be selected with the general handwheel may be involved.

When moving several axes at the same time, the feedrate of each axis depends on how fast

its associated handwheel is turned.

It may happen that depending on the turning speed and the selector position, the CNC be demanded

i

a faster feedrate than the maximum allowed. In that case, the CNC will move the axis the indicated

distance but at the maximum feedrate allowed.

Feed handwheel.

Usually, when machining a part for the first time, the feedrate is controlled by the switch on

the operator panel. The "feed handwheel" allows using one of the handwheels of the machine

to control that feedrate depending on how fast the handwheel is turned.

This feature must be managed from the PLC. Usually, this feature is turned on and off using an external

i

push button or key configured for that purpose.

CNC

8065 TC

(REF: 1201)

·40·

Page 41

Operating manual

2.2.4 Moving an axis to a particular position (coordinate)

X Y Z

ESC

Feedrate behavior

The moving feedrate depends on whether G00 or G01 is active. This feedrate may be varied

between 0% and 200% using the feedrate override switch on the operator panel. The

percentage will be applied on to all the movements carried out in G00 and in G01.

• If G00 is active, the movement is carried out at the rapid rate defined by the machine

manufacturer.

• If G01 is active, the movement is carried out at the active feedrate. If no feedrate is active,

the movement is executed at the feedrate defined by the machine manufacturer.

2.2.5 Coordinate preset

1 Select the axis to be moved using the alphanumeric keyboard. The

CNC will highlight that axis to indicate that it is selected.

To select the numbered axes (e.g. "X1"), select any axis and then move

the selection until positioning on the desired one. The focus moves with

the [©][ª] keys.

2 Enter the coordinate of the target point.

3 Press [START] to execute the movement or [ESC] to cancel the

operation.

2.

Operations with the axes.

OPERATING IN JOG MODE

The coordinates must be preset one axis at a time. The preset may be canceled by homing

the axes one by one or by means of function "G53".

X Y Z

1 Use the alphanumeric keyboard to select the axis whose position value

(coordinate) is to be preset. The CNC will highlight that axis to indicate

that it is selected.

To select the numbered axes (e.g. "X1"), select any axis and then move

the selection until positioning on the desired one. The focus moves with

the [©][ª] keys.

2 Key in the desired preset value.

3 Press [ENTER] to preset the entered value or [ESC] to cancel the

operation.

CNC

8065 TC

(REF: 1201)

·41·

Page 42

2.3 Spindle control

Displaying the data of several spindles.

The screen only shows the data on one spindle. If there are several spindles in the channel,

the data on the next spindle may be displayed by pressing the "S" key. The first push is to

program the turning speed, the second one shows the data on the second spindle and so on.

Operating m anual

2.

Spindle control

OPERATING IN JOG MODE

Spindle control

The spindle may be controlled manually using the following keys of the operator panel. The

keys always refer to the master spindle of the active channel.

The spindle speed should be set (in the MDI mode) before selecting the turning direction,

thus avoiding a sudden start of the spindle when setting an "S" because the turning direction

was active.

Key. Meaning.

Start the spindle clockwise (same as M03 function) at the active speed. The CNC

shows the M03 function in the program history.

Start the spindle counterclockwise (same as M04 function) at the active speed. The

CNC shows the M04 function in the program history.

Stop the spindle (same as M05 function). The CNC shows the M05 function in the

program history.

Orient the spindle (same as M19 function). The CNC shows the M19 function in the

program history.

Vary the speed override from the operator panel.

With the operator panel, it is possible to change the percentage of spindle speed using a

jog keyboard or a switch (depending on model).

Key. Meaning.

Increases or decreases the percentage of spindle speed. The maximum and

_

+

70

60

50

40

30

20

10

4

2

0

SPEED

minimum values as well as the incremental step are set by the OEM, the typical values

being a variation between 50% and 120% with a 5% step.

It sets the percentage of turning speed to be applied. The maximum and minimum

1009080

110

120

values are set by the OEM, the typical values being a variation between 50% and

130

140

120%.

150

160

170

180

190

200

CNC

8065 TC

(REF: 1201)

·42·

Page 43

Operating manual

2.4 Tool selection and tool change

The tool located in the spindle may be changed in manual mode. Proceed as follows.

1 Press [T] at the alphanumeric keyboard. The CNC will highlight the current tool indicating

that it is selected.

2 Key in the number of the tool to be placed in the spindle.

3 Press [START] to execute the tool change or [ESC] to cancel the operation.

2.5 Setting the feedrate and spindle speed.

Setting a new feedrate in the channel.

The feedrate set in jog mode is only applied in that work mode and for the active channel.

When setting a new feedrate in the MDI/MDA mode, it will become the new feedrate for the

jog and automatic modes.

Follow these steps to set a new feedrate.

1 Press [F] at the alphanumeric keyboard. The CNC will highlight the relevant data

indicating that it is selected.

2 Enter the new feedrate.

3 Press [START] to assume the entered value or [ESC] to cancel the operation.

2.

OPERATING IN JOG MODE

Tool selection and tool change

Setting a new spindle speed.

The spindle speed set in the jog mode is applied to the spindle displayed at the time. If there

are several spindles in the channel, the rest of the spindles may be displayed by pressing

the [S] key. The spindle speed set in jog mode is maintained when switching to automatic

mode and vice versa.

Follow these steps to set a new spindle speed.

1 Press [S] at the alphanumeric keyboard until selecting the desired spindle. When

pressing this key for the first time, the CNC will highlight the relevant data indicating that

it is selected.

2 Enter the new spindle speed.

3 Press [START] to assume the entered value or [ESC] to cancel the operation.

CNC

8065 TC

(REF: 1201)

·43·

Page 44

Operating m anual

2.6 Setting and activating the zero offsets and the fixture offsets.

In jog mode, it is possible to save the active offset in the zero offset table or in the fixture offset

table (zero offset, coordinate presetting, etc.) and to activate a zero offset already defined

in the tables.

This softkey shows the zero offsets and the fixture offsets of the system and their value in

each axis of the channel. This list is a brief information of the zero offset tables and fixture

offset tables and any change made in jog mode also affects those tables.

2.

Loading a new zero offset or fixture offset into the table.

With an active offset, use the cursor to select an offset from the list and press [ENTER] to

save the current offset in that zero offset. The position of all the axes of the channel are

updated at the selected zero offset.

Applying a zero offset or fixture offset stored in the table.

Use the cursor to select a zero offset or fixture offset from the list and press the [START] key

to activate. The new zero offset is applied to all the axes of the channel.

OPERATING IN JOG MODE

Setting and activating the zero offsets and the fixture offsets.

CNC

8065 TC

(REF: 1201)

·44·

Page 45

Operating manual

2.7 Tool calibration

Tool calibration is available in the jog mode. The softkey to access tool calibration will be

different depending on the software installed (lathe model or mill model). To quit the

calibration mode and return to jog mode, press the [ESC] key.

Tool calibration in a lathe model.

The CNC offers in both models the possibility to calibrate lathe tools and milling tools. The

CNC will show the necessary data and will update the help graphics according to the selected

tool.

Types of calibration

There are several ways to calibrate a tool. Some ways are only available when using a tabletop probe.

Only manual calibration is possible when not using a table-top probe.

All types of calibration are available when using a table-top probe. The

different calibration methods may be selected from the vertical softkey

menu.

The active kinematics are taken into account and do not prevent tool calibration in this mode.

Manual or semi-automatic calibration will not be possible if a coordinate ( #CS or #ACS)

transformation is active or when either the RTCP or TLC function is active.

Manual calibration. Calibration without a probe.

It is done without the table-top probe. A reference part is required to calibrate the tool. All

the movements are carried out manually.

Semi-automatic calibration. Calibration with a probe.

This calibration mode is available when using a table-top probe. The positioning movements

are carried out manually and the CNC executes the probing movements.

2.

Tool calibration

OPERATING IN JOG MODE

Automatic calibration. Calibration with a probe and a canned cycle.

This calibration mode is available when using a table-top probe. The CNC executes all the

movements using the calibration canned cycle #PROBE.

Probe selection

Two probes may be configured at the CNC. The probe active at the time is used for calibration.

The active probe may be changed via part-program or MDI using the instruction

#SELECT PROBE.

#SELECT PROBE [1]

Selects the first probe.

#SELECT PROBE [2]

Selects the second probe.

CNC

8065 TC

(REF: 1201)

·45·

Page 46

2.

Operating m anual

Geometrical configuration of the axes on a lathe: "plane" or

"trihedron".

At the lathe model, the geometrical configuration of the axes may be either of the "plane"

or "trihedron" type depending on the availability of a third main axis, usually the ·Y· axis. The

different calibration modes adapt to the current configuration showing the necessary data

for each one of them.

Geometrical configuration of "trihedron" type axes.

Y+

X+

Tool calibration

X+

It is the typical configuration of a milling machine or of a lathe

that has a third main axis (·Y· axis).

There are three axes forming a Cartesian XYZ type trihedron

like on a milling machine. There may be more axes besides

Z+

those forming the trihedron.

With this configuration, the planes behave in the same way as

on a milling machine except that the usual work plane will be

G18 (if it has been configured like that).

Geometrical configuration of "plane" type axes.

It is the typical configuration of a lathe.

OPERATING IN JOG MODE

There are two axes forming the usual work plane. There may

be more axes, but they cannot be part of the trihedron; there

Z+

must be auxiliary, rotary, etc.

With this configuration, the active plane will be formed by the

first two axes defined in the channel. If the X (first) and Z

(second) axes have been defined, the work plane will be the ZX

(Z as abscissa and X as ordinate).

The work plane is always G18; the plane cannot be changed

via part-program.

Configuration of "plane" type axes. The longitudinal axis.

In this configuration, the second axis of the channel is considered as longitudinal axis. If the

X (first) and Z (second) axes have been defined, the work plane will be the ZX and Z will be

the longitudinal axis. Tool length compensation is applied on this longitudinal axis when using

milling tools. With lathe tools, tool length compensation is applied on all the axes where a

tool offset has been defined.

When using milling tools on a lathe, the longitudinal compensation axis may be changed by

means of the #TOOL AX instruction or the G20 function.

CNC

8065 TC

(REF: 1201)

·46·

Page 47

Operating manual

2.7.1 Manual calibration. Calibration without a probe

In this mode, only the active tool can be calibrated and it may be a milling tool or a lathe tool.

The CNC will show the necessary data and will update the help graphics according to the

selected tool.

B

2.

C

A

A Machine data. Position of the axes, tool and active tool offset, real spindle speed and real

feedrate of the axes.

B Data of the part used for calibration and drawing showing that calibration is possible. If

the window does not show this drawing, some of the data is missing.

C Necessary data for calibration.

D Tool data.

D

Tool calibration

Since there is no probe, a reference part is required to calibrate the tool. The calibration

consists in moving the tool manually until it touches the part and then validating the calibration

on each axis. After validating them, the new values are saved in the tool table.

Selecting a tool

The tool and the active tool offset may be changed from the calibration mode. After defining

the new tool or tool offset in the cycle data, press [CYCLE START] and the CNC will execute

the tool change.

Tool calibration

OPERATING IN JOG MODE

Bear in mind that if the defined tool is the active tool, when pressing [START] the CNC

assumes the values that the offset has at the time.

Tool calibration in a lathe model (Configuration of plane type axes).

For lathe and mill tools, it calibrates the tool offsets on each axis. When validating the

calibration in one of the offsets, the wear of that offset is reset to zero.

Tool calibration in a lathe model (Configuration of trihedron type axes).

• For the lathe tools, it calibrates the tool offsets on each axis. When validating the

calibration in one of the offsets, the wear of that offset is reset to zero.

• There are two options for the milling tools and may be selected with the following icons.

Tool length calibration. This option may be used to update the length value

and resets the wear value to zero. It also updates the tool table data.

Tool offset calibration. This option may be used to update the value of the

offsets on each axis. The offset wears are set to zero.

CNC

8065 TC

(REF: 1201)

·47·

Page 48

2.

Operating m anual

Validating the calibration.

They are validated from the vertical softkey menu. Once the tool has been calibrated, when

pressing [START] the CNC assumes the new values of the offset.

Softkey. Description.

Validating the length calibration of a milling tool.

Validating the offsets of a milling tool.

Validating the offsets of a lathe tool.

Tool calibration

OPERATING IN JOG MODE

When on a lathe the axis have a "trihedron" type configuration, the calibration on the axis

perpendicular to the work plane is done using the horizontal softkey menu.

Definition of data

To define the data, place the focus on the relevant data, key in the desired value and press

[ENTER].

For a lathe tool.

The nomenclature of the axes depends on the geometrical configuration of the "plane" or

"trihedron" axes. For a "plane" configuration, the nam es of the axes assume the DIN standard

for lathes; the Z axis as the abscissa axis and the X axis as the ordinate axis.

Data Meaning

Zp Xp Dimensions of the reference part being used in the calibration. These coordinates

are referred to the main axes of the tool.

T Tool to be calibrated.