Page 1

CNC

8065

Probing (·T· model)

(Ref: 1309)

Page 2

MACHINE SAFETY

It is up to the machine manufacturer to make sure that the safety of the machine

is enabled in order to prevent personal injury and damage to the CNC or to the

products connected to it. On start-up and while validating CNC parameters, it

checks the status of the following safety elements. If any of them is disabled, the

CNC shows a warning message.

• Feedback alarm for analog axes.

• Software limits for analog and sercos linear axes.

• Following error monitoring for analog and sercos axes (except the spindle)

both at the CNC and at the drives.

• Tendency test on analog axes.

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC resulting from any of the safety

elements being disabled.

HARDWARE EXPANSIONS

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC resulting from any hardware

manipulation by personnel unauthorized by Fagor Automation.

If the CNC hardware is modified by personnel unauthorized by Fagor Automation,

it will no longer be under warranty.

COMPUTER VIRUSES

FAGOR AUTOMATION guarantees that the software installed contains no

computer viruses. It is up to the user to keep the unit virus free in order to

guarantee its proper operation.

Computer viruses at the CNC may cause it to malfunction. An antivirus software

is highly recommended if the CNC is connected directly to another PC, it is part

of a computer network or floppy disks or other computer media is used to transmit

data.

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC due a computer virus in the

system.

If a computer virus is found in the system, the unit will no longer be under warranty.

All rights reserved. No part of this documentation may be transmitted,

transcribed, stored in a backup device or translated into another language

without Fagor Automation’s consent. Unauthorized copying or distributing of this

software is prohibited.

The information described in this manual may be changed due to technical

modifications. Fagor Automation reserves the right to make any changes to the

contents of this manual without prior notice.

All the trade marks appearing in the manual belong to the corresponding owners.

The use of these marks by third parties for their own purpose could violate the

rights of the owners.

It is possible that CNC can execute more functions than those described in its

associated documentation; however, Fagor Automation does not guarantee the

validity of those applications. Therefore, except under the express permission

from Fagor Automation, any CNC application that is not described in the

documentation must be considered as "impossible". In any case, Fagor

Automation shall not be held responsible for any personal injuries or physical

damage caused or suffered by the CNC if it is used in any way other than as

explained in the related documentation.

The content of this manual and its validity for the product described here has been

verified. Even so, involuntary errors are possible, thus no absolute match is

guaranteed. Anyway, the contents of the manual is periodically checked making

and including the necessary corrections in a future edition. We appreciate your

suggestions for improvement.

The examples described in this manual are for learning purposes. Before using

them in industrial applications, they must be properly adapted making sure that

the safety regulations are fully met.

Page 3

Probing (·T· model)

INDEX

About the product ......................................................................................................................... 5

Version history .............................................................................................................................. 9

Safety conditions ........................................................................................................................ 11

Warranty terms ........................................................................................................................... 15

Material returning terms.............................................................................................................. 17

CNC maintenance ...................................................................................................................... 19

CHAPTER 1 PREVIOUS NOTIONS ABOUT THE PROBE.

1.1 Activate the probe. ......................................................................................................... 22

1.2 Geometric configuration of axes and work planes. ........................................................ 24

1.3 Behavior of the feedrate in probing movements. ........................................................... 25

CHAPTER 2 PROBING.

2.1 G100/G103. Probing. ..................................................................................................... 27

2.2 G101/G102. Include/exclude the measuring error in the theoretical coordinate. ........... 30

2.3 G104. Probe movement up to the programmed position. .............................................. 33

2.4 Properties of measurement related variables. ............................................................... 34

CHAPTER 3 CANNED CYCLES. ISO CODED PROGRAMMING.

3.1 #PROBE 1. Tool calibration. .......................................................................................... 37

3.1.1 Programming the cycle. ............................................................................................. 39

3.1.2 Basic operation. ......................................................................................................... 40

3.2 #PROBE 2. Tabletop probe calibration.......................................................................... 42

3.2.1 Programming the cycle. ............................................................................................. 44

3.2.2 Basic operation. ......................................................................................................... 45

3.3 #PROBE 3. Part measuring along the ordinate axis...................................................... 47

3.3.1 Programming the cycle. ............................................................................................. 48

3.3.2 Basic operation. ......................................................................................................... 49

3.4 #PROBE 4. Part measuring along the abscissa axis..................................................... 50

3.4.1 Programming the cycle. ............................................................................................. 51

3.4.2 Basic operation. ......................................................................................................... 52

3.5 Check the data of the canned cycles (variables). .......................................................... 53

CHAPTER 4 CANNED CYCLES. CYCLE EDITOR.

4.1 How to define the data of the editor. .............................................................................. 56

4.2 Tool calibration............................................................................................................... 57

4.2.1 Programming the cycle. ............................................................................................. 59

4.2.2 Basic operation. ......................................................................................................... 61

4.3 Tabletop probe calibration ............................................................................................. 63

4.3.1 Programming the cycle. ............................................................................................. 65

4.3.2 Basic operation. ......................................................................................................... 67

4.4 Part measuring along the ordinate axis. ........................................................................ 69

4.4.1 Programming the cycle. ............................................................................................. 70

4.4.2 Basic operation. ......................................................................................................... 72

4.5 Part measuring along the abscissa axis. ....................................................................... 73

4.5.1 Programming the cycle. ............................................................................................. 74

4.5.2 Basic operation. ......................................................................................................... 75

4.6 Simulating a cycle from the editor.................................................................................. 76

CNC 8065

(REF: 1309)

·3·

Page 4

Page 5

Probing (·T· model)

ABOUT THE PRODUCT

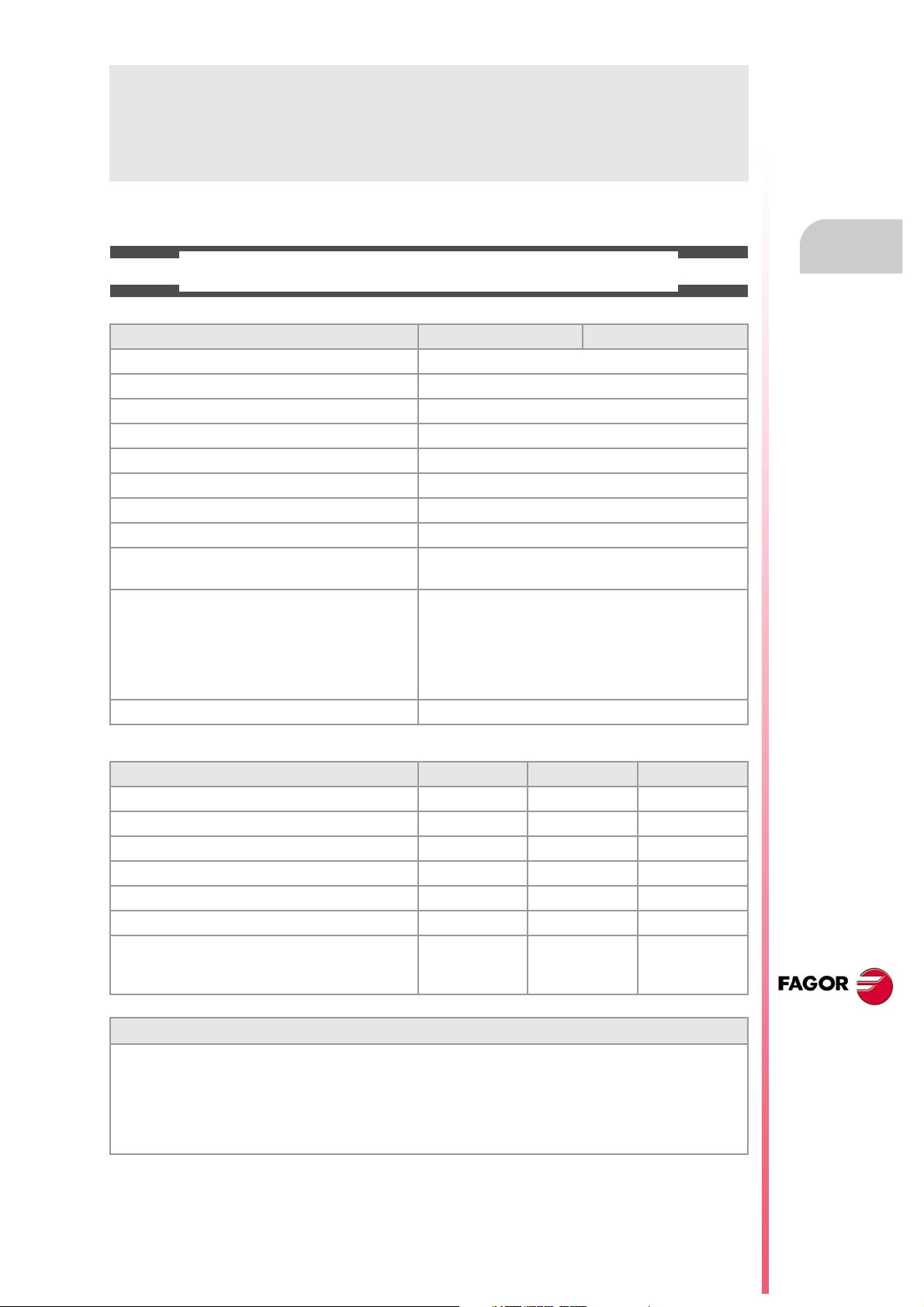

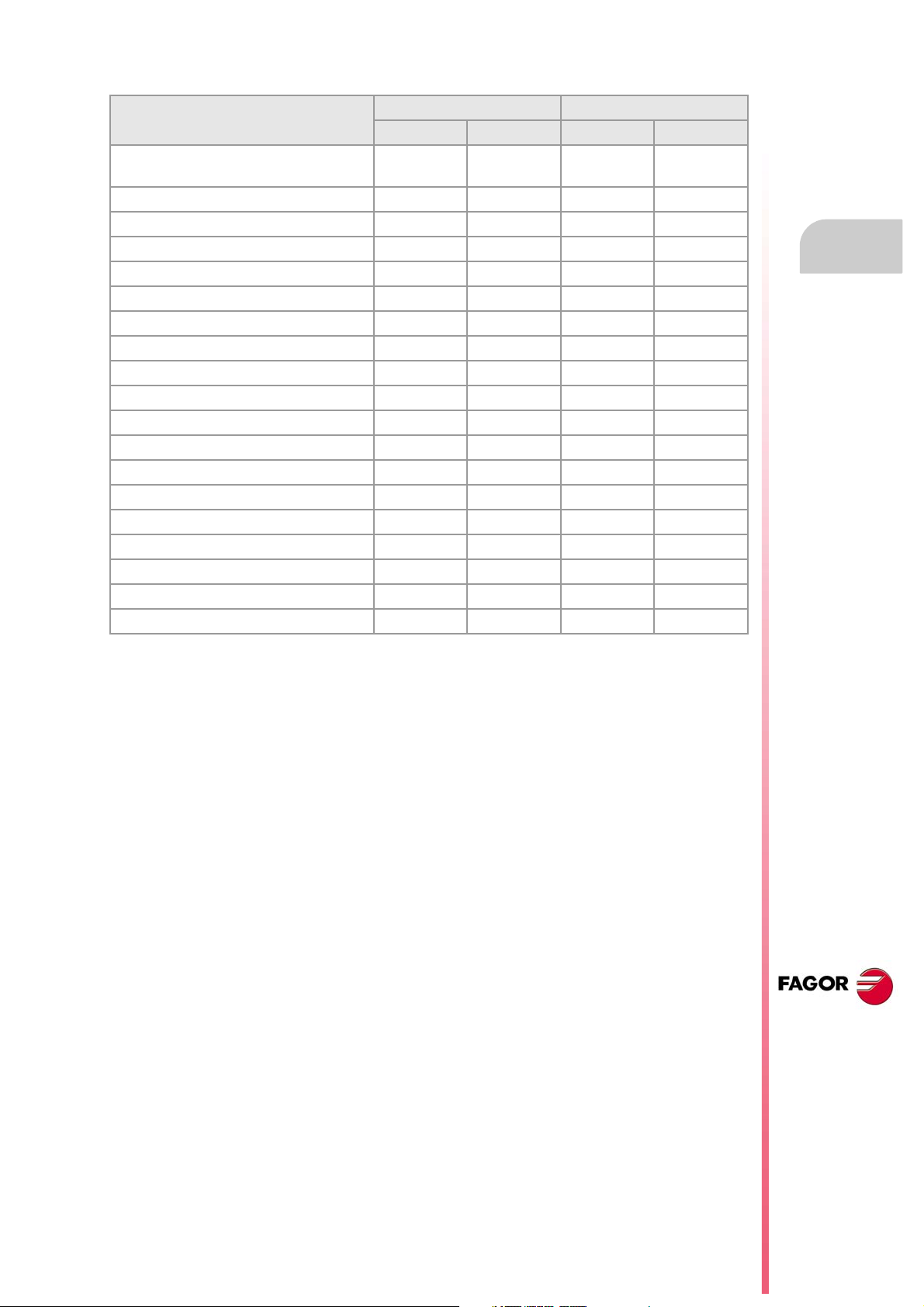

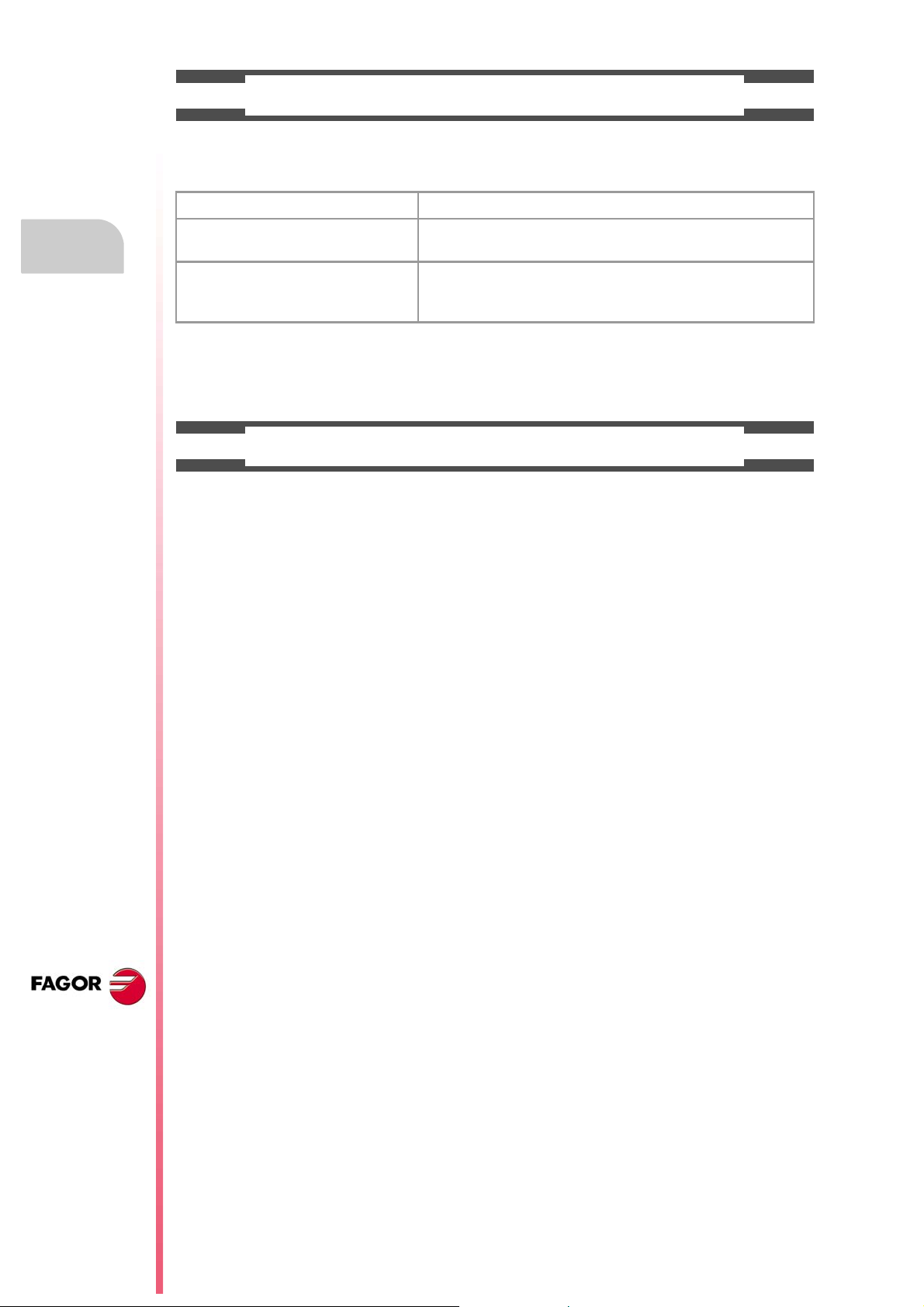

BASIC CHARACTERISTICS.

Basic characteristics. ·M· ·T·

PC-based system. Open system

Operating system. Windows XP

Number of axes. 3 to 28

Number of spindles. 1 to 4

Number of tool magazines. 1 to 4

Number of execution channels. 1 to 4

Number of handwheels. 1 to 12

Type of servo system. Analog / Digital Sercos / Digital Mechatrolink

Communications. RS485 / RS422 / RS232

Ethernet

Integrated PLC.

PLC execution time.

Digital inputs / Digital outputs.

Marks / Registers.

Timers / Counters.

Symbols.

Block processing time. < 1 ms

< 1ms/K

1024 / 1024

8192 / 1024

512 / 256

Unlimited

Remote modules. RIOW RIO5 RIO70

Communication with the remote modules. CANopen CANopen CANfagor

Digital inputs per module. 8 16 or 32 16

Digital outputs per module. 8 24 or 48 16

Analog inputs per module. 4 4 8

Analog outputs per module. 4 4 4

Inputs for PT100 temperature sensors. 2 2 - - -

Feedback inputs. - - - - - - 4

Differential TTL

Sinusoidal 1 Vpp

Customizing.

PC-based open system, fully customizable.

INI configuration files.

FGUIM visual configuration tool.

Visual Basic®, Visual C++®, etc.

Internal databases in Microsoft® Access.

OPC compatible interface

CNC 8065

(REF: 1309)

·5·

Page 6

Probing (·T· model)

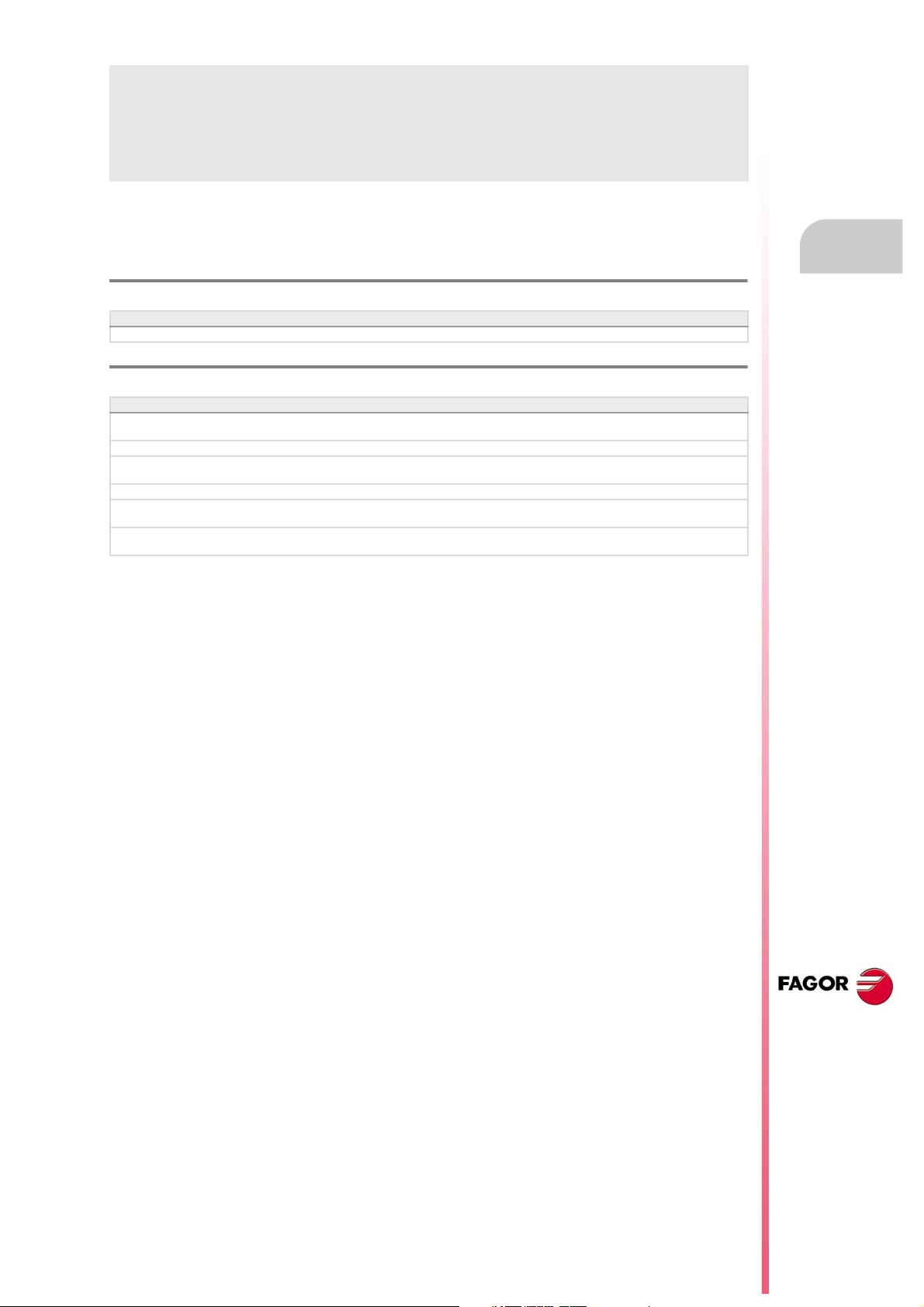

SOFTWARE OPTIONS.

Bear in mind that some of the features described in this manual depend on the software options that are

installed. The information of the following table is informative only; when purchasing the software options,

only the information provided in the ordering handbook is valid.

Software options (·M· model).

8065 M 8065 M Power

Basic Pack 1 Basic Pack 1

Open system.

Access to the administrator mode.

Number of execution channels 1 1 1 1 to 4

Number of axes 3 to 6 5 to 8 5 to 12 8 to 28

Number of spindles 1 1 1 to 4 1 to 4

Number of tool magazines 1 1 1 1 to 4

Limited to 4 interpolated axes Option Option Option Option

IEC 61131 language - - - - - - Option Option

HD graphics Option Option Standard Standard

Conversational IIP Option Option Option Option

Dual-purpose machines (M-T) - - - - - - Option Standard

"C" axis Standard Standard Standard Standard

Dynamic RTCP - - - Option Option Standard

HSSA machining system. Standard Standard Standard Standard

Probing canned cycles Option Standard Standard Standard

Tandem axes - - - Option Standard Standard

Synchronism and cams - - - - - - Option Standard

Tangential control - - - Standard Standard Standard

Volumetric compensation (up to 10 m³). - - - - - - Option Option

Volumetric compensation (more than 10 m³). - - - - - - Option Option

- - - - - - Option Option

CNC 8065

(REF: 1309)

·6·

Page 7

Probing (·T· model)

Software options (·T· model).

8065 T 8065 T Power

Basic Pack 1 Basic Pack 1

Open system.

Access to the administrator mode.

Number of execution channels 1 1 to 2 1 to 2 1 to 4

Number of axes 3 to 5 5 to 7 5 to 12 8 to 28

Number of spindles 2 2 3 to 4 3 to 4

Number of tool magazines 1 1 to 2 1 to 2 1 to 4

Limited to 4 interpolated axes Option Option Option Option

IEC 61131 language - - - - - - Option Option

HD graphics Option Option Standard Standard

Conversational IIP Option Option Option Option

Dual-purpose machines (T-M) - - - - - - Option Standard

"C" axis Option Standard Standard Standard

Dynamic RTCP - - - - - - Option Standard

HSSA machining system. Option Standard Standard Standard

Probing canned cycles Option Standard Standard Standard

Tandem axes - - - Option Standard Standard

Synchronism and cams - - - Option Option Standard

Tangential control - - - - - - Option Standard

Volumetric compensation (up to 10 m³). - - - - - - Option Option

Volumetric compensation (more than 10 m³). - - - - - - Option Option

- - - - - - Option Option

CNC 8065

(REF: 1309)

·7·

Page 8

Page 9

Probing (·T· model)

VERSION HISTORY

Here is a list of the features added to each manual reference.

Ref. 1103

First version.

Ref. 1309

Software V04.27

Executing G100/G103/G104 updates variables (V.)A.MEAS.Xn,

(V.)A.MEASOF.Xn and (V.)A.MEASOK.Xn of all the axes of the channel.

The variable keeps its value after a reset. • Variable: (V.)A.MEASOK.Xn

The CNC lets make a measurement (G100/G103/G104) on any axis of the

channel even when function G101 is active.

Measuring an axis does not change the G101 of the rest of the axes. • Function: G101.

The CNC lets program any axis of the channel in a G101 block even if it has

not been involved in the previous measurement (G100/G103/G104).

The CNC lets program any axis of the channel in a G102 block even if it does

not have a measuring offset included (G101).

• Variables: (V.)A.MEAS.Xn

(V.)A.MEASOF.Xn (V.)A.MEASOK.Xn

• Function: G101.

• Function: G101.

• Function: G102.

CNC 8065

(REF: 1309)

·9·

Page 10

Page 11

Probing (·T· model)

SAFETY CONDITIONS

Read the following safety measures in order to prevent harming people or damage to this product and those

products connected to it. Fagor Automation shall not be held responsible of any physical damage or

defective unit resulting from not complying with these basic safety regulations.

Before start-up, verify that the machine that integrates this CNC meets the 89/392/CEE Directive.

PRECAUTIONS BEFORE CLEANING THE UNIT

If the CNC does not turn on when actuating the start-up switch, verify the connections.

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate the

Do not handle the connectors with the unit

connected to AC power.

inside of this unit.

Before manipulating the connectors (inputs/outputs, feedback, etc.)

make sure that the unit is not connected to AC power.

PRECAUTIONS DURING REPAIR

In case of a malfunction or failure, disconnect it and call the technical service.

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate the

inside of this unit.

Do not handle the connectors with the unit

connected to AC power.

Before manipulating the connectors (inputs/outputs, feedback, etc.)

make sure that the unit is not connected to AC power.

PRECAUTIONS AGAINST PERSONAL DAMAGE

Interconnection of modules. Use the connection cables provided with the unit.

Use proper cables. To prevent risks, use the proper cables for mains, Sercos and Bus

CAN recommended for this unit.

In order to avoid electrical shock at the central unit, use the proper

power (mains) cable. Use 3-wire power cables (one for ground

connection).

Avoid electrical overloads. In order to avoid electrical discharges and fire hazards, do not apply

electrical voltage outside the range selected on the rear panel of the

central unit.

Ground connection. In order to avoid electrical discharges, connect the ground terminals

of all the modules to the main ground terminal. Before connecting the

inputs and outputs of this unit, make sure that all the grounding

connections are properly made.

In order to avoid electrical shock, before turning the unit on verify that

the ground connection is properly made.

Do not work in humid environments. In order to avoid electrical discharges, always work under 90% of

relative humidity (non-condensing) and 45 ºC (113 ºF).

Do not work in explosive environments. In order to avoid risks or damages, do no work in explosive

environments.

CNC 8065

(REF: 1309)

·11·

Page 12

Probing (·T· model)

PRECAUTIONS AGAINST PRODUCT DAMAGE

Working environment. This unit is ready to be used in industrial environments complying with

the directives and regulations effective in the European Community.

Fagor Automation shall not be held responsible for any damage

suffered or caused by the CNC when installed in other environments

(residential or homes).

Install the unit in the right place. It is recommended, whenever possible, to install the CNC away from

coolants, chemical product, blows, etc. that could damage it.

This unit complies with the European directives on electromagnetic

compatibility. Nevertheless, it is recommended to keep it away from

sources of electromagnetic disturbance such as:

Powerful loads connected to the same AC power line as this

equipment.

Nearby portable transmitters (Radio-telephones, Ham radio

transmitters).

Nearby radio/TV transmitters.

Nearby arc welding machines.

Nearby High Voltage power lines.

Enclosures. The manufacturer is responsible of assuring that the enclosure

involving the equipment meets all the currently effective directives of

the European Community.

Avoid disturbances coming from the

machine.

Use the proper power supply. Use an external regulated 24 Vdc power supply for the keyboard and

Grounding of the power supply. The zero volt point of the external power supply must be connected

Analog inputs and outputs connection. Use shielded cables connecting all their meshes to the corresponding

Ambient conditions. The storage temperature must be between +5 ºC and +45 ºC (41 ºF

Central unit enclosure. Make sure that the needed gap is kept between the central unit and

Main AC power switch. This switch must be easy to access a nd at a distance between 0.7 and

The machine must have all the interference generating elements

(relay coils, contactors, motors, etc.) uncoupled.

the remote modules.

to the main ground point of the machine.

pin.

and 113 ºF).

The storage temperature must be between -25 ºC and 70 ºC (-13 ºF

and 158 ºF).

each wall of the enclosure.

Use a DC fan to improve enclosure ventilation.

1.7 m (2.3 and 5.6 ft) off the floor.

CNC 8065

(REF: 1309)

·12·

PROTECTIONS OF THE UNIT ITSELF

Remote modules. All the digital inputs and outputs have galvanic isolation via

optocouplers between the CNC circuitry and the outside.

Page 13

Probing (·T· model)

i

SAFETY SYMBOLS

Symbols that may appear on the manual.

Danger or prohibition symbol.

It indicates actions or operations that may hurt people or damage products.

Warning symbol.

It indicates situations that certain operations could cause and the suggested actions to prevent them.

Obligation symbol.

It indicates actions and operations that must be carried out.

Information symbol.

It indicates notes, warnings and advises.

Symbols that the product may carry.

Ground protection symbol.

It indicates that that point must be under voltage.

CNC 8065

(REF: 1309)

·13·

Page 14

Page 15

Probing (·T· model)

WARRANTY TERMS

INITIAL WARRANTY

All products manufactured or marketed by FAGOR carry a 12-month warranty for the end user which could

be controlled by the our service network by means of the warranty control system established by FAGOR

for this purpose.

In order to prevent the possibility of having the time period from the time a product leaves our warehouse

until the end user actually receives it run against this 12-month warranty, FAGOR has set up a warranty

control system based on having the manufacturer or agent inform FAGOR of the destination, identification

and on-machine installation date, by filling out the document accompanying each FAGOR product in the

warranty envelope. This system, besides assuring a full year of warranty to the end user, enables our service

network to know about FAGOR equipment coming from other countries into their area of responsibility.

The warranty starting date will be the one appearing as the installation date on the above mentioned

document. FAGOR offers the manufacturer or agent 12 months to sell and install the product. This means

that the warranty starting date may be up to one year after the product has left our warehouse so long as

the warranty control sheet has been sent back to us. This translates into the extension of warranty period

to two years since the product left our warehouse. If this sheet has not been sent to us, the warranty period

ends 15 months from when the product left our warehouse.

This warranty covers all costs of material and labour involved in repairs at FAGOR carried out to correct

malfunctions in the equipment. FAGOR under takes to repair or replace their products within the period from

the moment manufacture begins until 8 years after the date on which it disappears from the catalogue.

It is entirely up to FAGOR to determine whether the repair is or not under warranty.

EXCLUDING CLAUSES

Repairs will be carried out on our premises. Therefore, all expenses incurred as a result of trips made by

technical personnel to carry out equipment repairs, despite these being within the above-mentioned period

of warranty, are not covered by the warranty.

Said warranty will be applied whenever the equipment has been installed in accordance with instructions,

has not be mistreated, has not been damaged by accident or by negligence and has not been tampered

with by personnel not authorised by FAGOR. If, once servicing or repairs have been made, the cause of

the malfunction cannot be attributed to said elements, the customer is obliged to cover the expenses

incurred, in accordance with the tariffs in force.

Other warranties, implicit or explicit, are not covered and FAGOR AUTOMATION cannot be held responsible

for other damages which may occur.

CNC 8065

(REF: 1309)

·15·

Page 16

Probing (·T· model)

WARRANTY ON REPAIRS

In a similar way to the initial warranty, FAGOR offers a warranty on standard repairs according to the

following conditions:

PERIOD 12 months.

CONCEPT Covers parts and labor for repairs (or replacements) at the

network's own facilities.

EXCLUDING CLAUSES The same as those applied regarding the chapter on initial

warranty. If the repair is carried out within the warranty period, the

warranty extension has no effect.

When the customer does not choose the standard repair and just the faulty material has been replaced,

the warranty will cover just the replaced parts or components within 12 months.

For sold parts the warranty is 12 moths length.

SERVICE CONTRACTS

The SERVICE CONTRACT is available for the distributor or manufacturer who buys and installs our CNC

systems.

CNC 8065

(REF: 1309)

·16·

Page 17

Probing (·T· model)

MATERIAL RETURNING TERMS

When sending the central nit or the remote modules, pack them in its original package and packaging

material. If the original packaging material is not available, pack it as follows:

1 Get a cardboard box whose three inside dimensions are at least 15 cm (6 inches) larger than those

of the unit. The cardboard being used to make the box must have a resistance of 170 Kg (375 lb.).

2 Attach a label indicating the owner of the unit, person to contact, type of unit and serial number. In case

of malfunction also indicate symptom and a brief description of the problem.

3 Wrap the unit in a polyethylene roll or similar material to protect it. When sending a central unit with

monitor, protect especially the screen.

4 Pad the unit inside the cardboard box with poly-utherane foam on all sides.

5 Seal the cardboard box with packing tape or industrial staples.

CNC 8065

(REF: 1309)

·17·

Page 18

Page 19

Probing (·T· model)

CNC MAINTENANCE

CLEANING

The accumulated dirt inside the unit may act as a screen preventing the proper dissipation of the heat

generated by the internal circuitry which could result in a harmful overheating of the unit and, consequently,

possible malfunctions. Accumulated dirt can sometimes act as an electrical conductor and short-circuit the

internal circuitry, especially under high humidity conditions.

To clean the operator panel and the monitor, a smooth cloth should be used which has been dipped into

de-ionized water and /or non abrasive dish-washer soap (liquid, never powder) or 75º alcohol. Do not use

highly compressed air to clean the unit because it could generate electrostatic discharges.

The plastics used on the front panel are resistant to grease and mineral oils, bases and bleach, dissolved

detergents and alcohol. Avoid the action of solvents such as chlorine hydrocarbons, venzole, esters and

ether which can damage the plastics used to make the unit’s front panel.

PRECAUTIONS BEFORE CLEANING THE UNIT

Fagor Automation shall not be held responsible for any material or physical damage derived from the

violation of these basic safety requirements.

• Do not handle the connectors with the unit connected to AC power. Before handling these connectors

(I/O, feedback, etc.), make sure that the unit is not connected to main AC power.

• Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate

the inside of this unit.

• If the CNC does not turn on when actuating the start-up switch, verify the connections.

CNC 8065

(REF: 1309)

·19·

Page 20

Page 21

PREVIOUS NOTIONS ABOUT THE PROBE.

Number of probes in the system and active probe.

The CNC may have configured two probes, it will usually be a tabletop probe to calibrate tools

and a touch probe to measure the part.

Before any probing moves, select the probe to be used. See "1.1 Activate the probe." on

page 22.

Probe operation.

Both probes operate by levels, not by flanks.

Probing.

1

With function G100, it is possible to program movements that will end when the CNC receives

the probe signal (when the probe makes contact). When done probing, the CNC updates

the real coordinates.

With function G103, it is possible to program movements that will end when the CNC stops

receiving the probe signal (when the probe no longer makes contact). When done probing,

the CNC updates the real coordinates.

The G104 function prevents a G100 or G103 probe movement from finishing with the probe

signal The CNC updates the coordinates with the probe signal, but without interrupting the

movement which continues until the probe reaches the programmed position.

Programming the canned cycles.

The probing canned cycles may be edited in ISO code or with using the cycle editor. These

cycles may be defined anywhere in the program, that is, in the main program as well as in

a subroutine. ISO coded cycles can also be executed in MDI.

Probe parameter setting.

The machine manufacturer must have properly set the following machine parameters.

• General machine parameters.

PROBE PROBEDATA PROBETYPE1 PROBETYPE2

PRBDI1 PRBDI2 PRBPULSE1 PRBPULSE2

• General machine parameters per channel.

PROBEDATA PRB1MAX PRB1MIN PRB2MAX

PRB2MIN PRB3MAX PRB3MIN

• Axis machine parameters.

PROBEAXIS PROBERANGE PROBEFEED PROBEDELAY

PROBEDELAY2

CNC 8065

(REF: 1309)

·21·

Page 22

1.1 Activate the probe.

The CNC can have configured two probes. Before any probing move, the CNC must know

which is the active probe, or, which is the same, which of the two probes it must attend to.

It is selected via part-program or MDI using the instruction #SELECT PROBE.

If a probing move is executed without activating the probe, it will not send any signal to the CNC when

it makes contact. This can cause the probe to break because the probing move will not be stopped.

Probing (·T· model)

1.

Activate the probe.

PREVIOUS NOTIONS ABOUT THE PROBE.

Programming.

When programming this instruction, you must define which probe is active and whether it's

active high or low.

Programming format.

The programming format is the following; the list of arguments appears between curly

brackets and the optional ones between angle brackets.

#SELECT PROBE [<{probe}><, {pulse}>]

{probe} Optional. Number of probe to activate.

If not programmed, the CNC uses the active probe.

{pulse} Optional. Logic level to activate probe. The CNC uses the high level with

"POS" and the low level with "NEG".

If not programmed, the CNC uses the default probe activation level.

Although both parameters are optional, at least one of them must be programmed.

#SELECT PROBE [1]

#SELECT PROBE [NEG]

#SELECT PROBE [2, POS]

#SELECT PROBE [1, NEG]

Probe number. Which is probe 1 and which probe 2?

CNC 8065

(REF: 1309)

The names of the probes are set in the order they have been defined in the machine

parameters. The CNC assumes as first probe the one connected to the input indicated in

machine parameter PRBDI1 and as second probe the one connected to the input indicated

in machine parameter PRBDI2.

Logic level to activate probe; high (5 V / 24 V) or low (0 V).

Changing the default activation level reverses the operation of functions G100 and G103.

When changing the probe logic activation level, G100 makes a movement until the probe

stops making contact and G103 makes a movement until the probe makes contact. Since

probing canned cycles use functions G100 and G103, changing the logic activation level also

changes the operation of the canned cycles accordingly.

The logic activation level indicates whether the probe operations are active high (24V or 5

V) or active low (0V) of the signal provided by the probe. Programming the logic activation

level is optional because each probe has been assigned one by default.

The logic activation level of each probe by default is set in the machine parameters

(parameters PRBPULSE1 for probe ·1· and PRBPULSE2 for probe ·2·) and it depends on

the connection between the probe and the CNC.

Properties of the instruction and influence of reset, turning the

CNC off and of the M30 function.

The instruction #SELECT PROBE is modal. The probe and the selected logic activation level

stays active after an M02 or M30 and after an error or a reset. On power-up and after

validating the machine parameters, the CNC activates probe ·1· and initializes the logic

activation level of both probes with the values set in the machine parameters.

·22·

Page 23

Probing (·T· model)

Knowing which is the active probe.

The CNC offers the following variable to know which is the active probe. The variable can

only be read via part-program, MDI, PLC and interface.

Variab le. Meaning.

(V.)[ch].G.ACTIVPROBE This variable indicates which one is the active probe in channel n.

1.

Activate the probe.

PREVIOUS NOTIONS ABOUT THE PROBE.

CNC 8065

(REF: 1309)

·23·

Page 24

1.

X+

Z+

Y+

X+

Z+

Probing (·T· model)

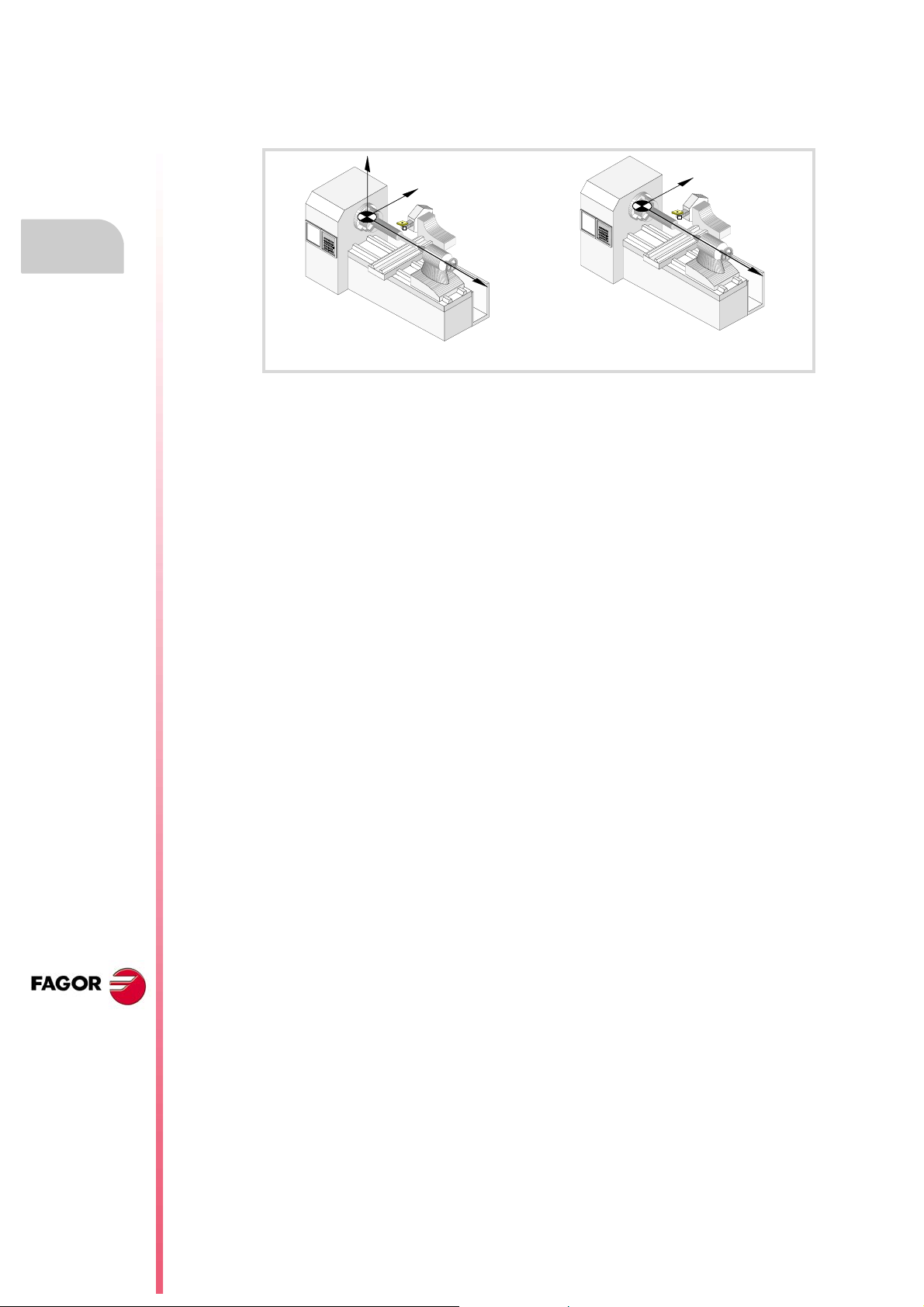

1.2 Geometric configuration of axes and work planes.

The CNC admits two types of geometric configurations; "Trihedron" type and "Plane" type

axis configuration.

Trihedron Plane

Configuration of "Trihedron" type axes.

In this configuration, there are three axes forming a Cartesian XYZ type trihedron like on a

milling machine. There may be more axes besides those forming the trihedron.

PREVIOUS NOTIONS ABOUT THE PROBE.

Geometric configuration of axes and work planes.

With this configuration, the planes behave in the same way as on a milling machine except

that the usual work plane will be G18 (if it has been configured like that).

All the movements of these cycles are executed on the X Y Z axes; the work plane must be

formed by 2 of these axes (XY, XZ, YZ, YX, ZX, ZY). The other axis, that must be

perpendicular to that plane must be selected as axis perpendicular to the work plane.

Configuration of "plane" type axes.

In this configuration, there are two axes forming the usual work plane. There may be more

axes, but they cannot be part of the trihedron; there must be auxiliary, rotary, etc.

With this configuration, the work plane is always G18 and will be formed by the first two axes

defined in the channel. If the X (first) and Z (second) axes have been defined, the work plane

will be the ZX (Z as abscissa and X as ordinate).

The probing movements can only be executed in the work plane. The CNC ignores the

programmed variables that are related to the axis perpendicular to the work plane.

Configuration of "plane" type axes. Plane selection.

The work plane is always G18; machine parameter IPLANE is not applied and it is not

possible to change planes via part-program. The following functions have these effects:

G17 It does not change planes and shows a warning about it.

G18 It has no effect.

G19 It does not change planes and shows a warning about it.

G20 It is permitted if it does not change the main plane; i.e. it can only be used to

change the longitudinal axis.

CNC 8065

(REF: 1309)

·24·

The ·G· functions associated with the work planes are not displayed because it is always the

same plane.

Page 25

Probing (·T· model)

1.3 Behavior of the feedrate in probing movements.

The probing moves are carried out at the active feedrate, the one defined for machining. If

the probing feedrate is changed, the new feedrate will be the active one for the machining

moves.

The feedrate may be selected by programmed using the "F" code which remains active until

another value is programmed. In the canned cycles, the feedrate may be programmed inside

the parameters of the cycle.

The units depend on the active work mode; G93, G94 or G95.

G93 Machining time in seconds.

G94 Feedrate in millimeters/minute (inches/minute).

G95 Feedrate in millimeters/revolution (inches/revolution).

The active feedrate may be varied between 0% and 200% using the selector switch on the

CNC's operator panel or it may be selected by program or by PLC.

Maximum probing feedrate.

The maximum probing feedrate in each axis will be limited by machine parameter

PROBEFEED and this value will not be exceeded even when programming a higher value.

1.

PREVIOUS NOTIONS ABOUT THE PROBE.

Behavior of the feedrate in probing movements.

CNC 8065

(REF: 1309)

·25·

Page 26

1.

Probing (·T· model)

PREVIOUS NOTIONS ABOUT THE PROBE.

Behavior of the feedrate in probing movements.

CNC 8065

(REF: 1309)

·26·

Page 27

PROBING.

2.1 G100/G103. Probing.

With function G100, it is possible to program movements that will end when the CNC receives

the probe signal (when the probe makes contact) or when the probe reaches the

programmed position. When done probing, the CNC assumes as the theoretical position the

current position of the axes involved in the movement, their real (actual) position at that

instant.

With function G103, it is possible to program movements that will end when the CNC stops

receiving the probe signal (when the probe stops making contact) or when the probe reaches

the programmed position. When done probing, the CNC assumes as the theoretical position

the current position of the axes involved in the movement, their real (actual) position at that

instant.

Functions G100 and G103 do not execute the tool change to select the probe, the probe must

be selected in a previous block of the program. Likewise, when using more than one probe,

the probe to be used must be selected before probing.

2

Probing programming.

The probing movement is defined using function G100 or G103 followed by the coordinates

of the probe's target point. Programming the feedrate is optional; if not programmed, these

movements are carried out at the active feedrate.

Programming format.

The programming format is: Optional parameters are indicated between angle brackets.

G100 X..C <F>

G103 X..C <F>

X..C Coordinates of the probing point.

F Optional. Feedrate.

If not programmed, the CNC uses the active feedrate.

G100 X45.23 Z23.45

G100 Z50 F100

G103 X2.6 Z3 F20

G103 Z1 F20

Probing feedrate.

The CNC uses the same feedrate for probing and for machining. The feedrate "F" set for the

probe will be the feedrate active at the CNC when done probing.

CNC 8065

The maximum probing feedrate in each axis will be limited by machine parameter

PROBEFEED and this value will not be exceeded even when programming a higher value

or exceeded with the switch on the operator panel.

The active feedrate may be varied between 0% and 200% using the selector switch on the

CNC's operator panel or it may be selected by program or by PLC.

(REF: 1309)

·27·

Page 28

2.

PROBING.

G100/G103. Probing.

Probing (·T· model)

Properties of the function and Influence of the reset, turning the

CNC off and of the M30 function.

Functions G100 and G103 are not modal. After executing one of these functions, the CNC

restores the function G0, G1, G2 ó G3, G33 or G63 that was active.

CNC 8065

(REF: 1309)

Updating variables after probing.

When done probing, the CNC updates the following variables. After a probing, the CNC

updates all the variables of all the axes of the channel even if they were not involved in the

probing movements. For the axes not involved in the probing movements, the variables that

save the measured value take the value of the real position of the axis and the variables that

indicate the measured error are reset to zero.

Mnemoni. Variabl e.

V.G.MEASOK The probe has made contact (G100) or stopped making contact (G103).

• The variable takes the value of ·1· if the probe has made contact (G100)

or has stopped making contact (G103).

• The variables takes the value of ·0· if the probe reaches the programmed

coordinate.

V.A.MEASOK.xn Probing done on any axis of the channel.

• The variables of the axes involved in the probing operation take the value

of ·1· when the probing movement ends.

• The variables of the rest of the axes take the value of ·0·.

The variable keeps its value after a reset.

V.G.PLMEASOK1

V.G.PLMEASOK2

V.G.PLMEASOK3

V.A.MEAS.xn Measured value. Machine coordinates of the tool base.

V.A.ATIPMEAS.xn Measured value. Part coordinates of the tool tip.

V.G.PLMEAS1

V.G.PLMEAS2

V.G.PLMEAS3

Probing on the plane axes completed.

• The variables of the axes involved in the probing operation take the value

of ·1· when the probing operation ends.

• The variables of the rest of the axes take the value of ·0·.

• The variables of the axes involved in the probing operation take the

measured value.

• The variables of the rest of the axes take the real position value of the

axis.

• The variables of the axes involved in the probing operation take the

measured value.

• The variables of the rest of the axes take the real position value of the

axis.

Value measured on the axes of the plane. Part coordinates of the tool tip.

• The variables of the axes involved in the probing operation take the

measured value.

• The variables of the rest of the axes take the real position value of the

axis.

·28·

Page 29

Probing (·T· model)

Mnemoni. Varia ble .

V.A.MEASOF.xn Measuring error.

• The variables of the axes involved in the probing operation take the

measuring error (difference between the programmed coordinate and

the one measured).

• The variables of the rest of the axes take the value of ·0·.

2.

PROBING.

G100/G103. Probing.

CNC 8065

(REF: 1309)

·29·

Page 30

2.

PROBING.

Probing (·T· model)

2.2 G101/G102. Include/exclude the measuring error in the theoretical coordinate.

The measuring error is the difference between the programmed coordinate and the

coordinate reached by the probe. The measuring error is given in the active units, radius or

diameter.

coordinate.

After probing, the CNC assumes the current axis position as the theoretical position.

Functions G101 and G102 determine whether to consider or ignore the measuring error

when updating the theoretical coordinate.

G101 Include the measuring error in the theoretical coordinate.

G102 Exclude the measuring error in the theoretical coordinate.

CNC 8065

Influence of the reset, turning the CNC off and of the M30.

Functions G101 and G102 are modal and incompatible with each other. On power-up, after

G101/G102. Include/exclude the measuring error in the theoretical

an M02 or M30 and after an EMERGENCY or a RESET, the CNC maintains the values

programmed with G101.

G101 Include the measuring error in the theoretical

coordinate.

When executing this function, the CNC includes the error resulting from the measurement

to set the theoretical axis positions; in other words, the CNC will assume as theoretical axis

position the programmed coordinate (position reached by the probe + the measuring error).

Function G101 must be executed after taking a measurement. The CNC lets program any

axis of the channel in a G101 block even if it has not been involved in the previous

measurement (G100/G103/G104).

The CNC lets make a measurement (G100/G103/G104) on any axis of the channel even

when function G101 is active. The measurement on an axis does not change the G101 of

other axes and, therefore, it does not change its variable (V.)A.MEASIN.xn.

Programming format.

To include the measuring error, program function G101 and then the axes in which to include

the measuring error. For each axis, you must define how many times the measuring error

is added to the coordinate. Usually, the measuring error needs to be included only once.

G101 X..C

X..C Axes whose theoretical coordinate includes the measuring error .

(REF: 1309)

·30·

G101 X1 Z1

G101 X2

Page 31

Probing (·T· model)

Updating the variables after executing function G101.

Variab le Valu e

(V.)[n].A.MEASOF.Xn It is initialized to 0 (zero).

(V.)[n].A.MEASIN.Xn Measuring error added to the Xn axis.

2.

PROBING.

coordinate.

G101/G102. Include/exclude the measuring error in the theoretical

CNC 8065

(REF: 1309)

·31·

Page 32

2.

PROBING.

coordinate.

Probing (·T· model)

G102 Exclude the measuring error in the theoretical

coordinate.

After executing this function, the CNC will ignore the error resulting from the measurement

to set the theoretical position of the axes; i.e. the CNC considers the coordinate reached as

theoretical coordinate.

The CNC lets program any axis of the channel in a G102 block even if it does not have a

measuring offset included (G101).

Programming format.

To ignore the measuring error, program function G102 and then the axes in which to ignore

it. If no axis is programmed, the CNC ignores the measuring error in all the axes.

The programming format is: Optional parameters are indicated between angle brackets.

G102 <X..C>

X..C Optional. Axes whose theoretical coordinate does not include the measuring error

.

G102 X Z

G102

Once function G102 is executed, function G101 cannot be executed again until a new

measurement is taken.

Updating the variables after executing function G102.

Variable Valu e

(V.)[n].A.MEASIN.Xn It is initialized to 0 (zero).

G101/G102. Include/exclude the measuring error in the theoretical

CNC 8065

(REF: 1309)

·32·

Page 33

Probing (·T· model)

2.3 G104. Probe movement up to the programmed position.

When programming function G104 together with G100 or G103, the CNC makes the selected

probing movement, updates the coordinates when it receives the probe signal, but keeps

moving the axes until they reach their programmed position.

Function G101 may be used to make the CNC assume the measuring error resulting from

a G104 movement,

Probing programming.

The G104 must be programmed together with a G100 or G103 probe movement; otherwise,

it will be ignored.

Programming format.

The programming format is: Optional parameters are indicated between angle brackets.

G100 G104 X..C <F>

G103 G104 X..C <F>

X..C Coordinates of the probing point.

F Optional. Feedrate.

If not programmed, the CNC uses the active feedrate.

G100 G104 Z23.45

G103 G104 Z1 F20

Properties of the function and Influence of the reset, turning the

CNC off and of the M30 function.

Function G104 is not modal; it only acts in the block where it is programmed.

2.

PROBING.

G104. Probe movement up to the programmed position.

CNC 8065

(REF: 1309)

·33·

Page 34

2.

PROBING.

Properties of measurement related variables.

Probing (·T· model)

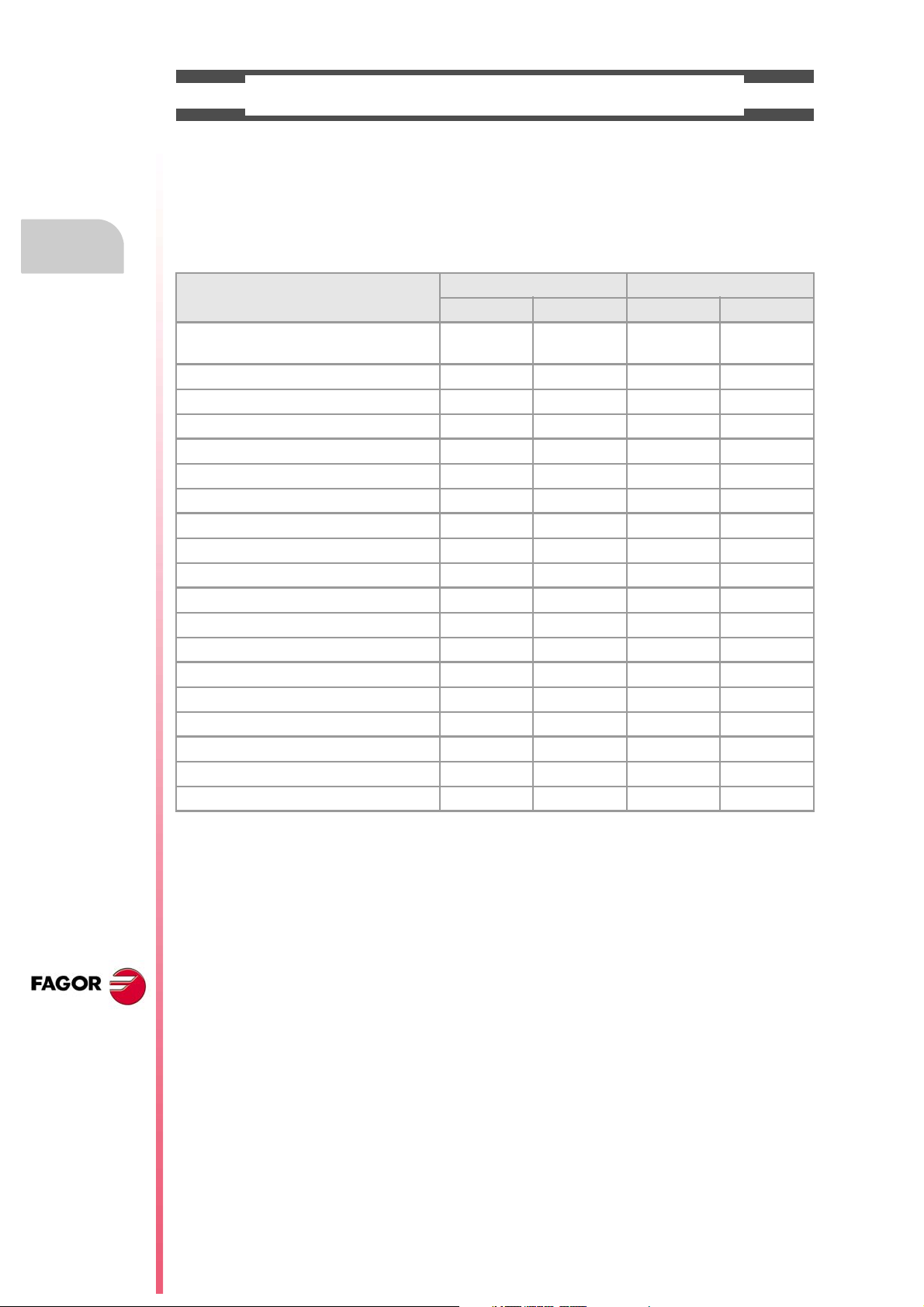

2.4 Properties of measurement related variables.

For further information about the access and the use of variables, refer to the programming manual.

The following variables are read-only (R) synchronous and are evaluated while in execution.

The mnemonics of the variables have generic names.

• Replace the "Xn" character by the name, logic number or index in the channel of the axis.

• Replace the "n" character with the channel number, maintaining the brackets. The first

channel is identified with the number 1, "0" is not a valid number.

Mnemonic PRG PLC INT

(V.)[n].A.MEASOK.Xn R R R Probing done on the Xn axis.

"0" = No "1"= Yes

(V.)[n].G.PLMEASOK1 R — — Probing done on the first axis of the plane.

"0" = No "1"= Yes

(V.)[n].G.PLMEASOK2 R — — Probing done on the second axis of the plane.

"0" = No "1"= Yes

(V.)[n].G.PLMEASOK3 R — — Probing done on the axis perpendicular to the

plane.

"0" = No "1"= Yes

(V.)[n].A.MEAS.Xn R R R Value measured on the Xn axis.

Machine coordinates of the tool base.

(V.)[n].A.ATIPMEAS.Xn R — — Value measured on the Xn axis.

Part coordinates of the tool tip.

(V.)[n].G.PLMEAS1 R — — Value measure d on the f irst axi s of the pla ne

(abscissa).

Part coordinates of the tool tip.

(V.)[n].G.PLMEAS2 R — — Value measured on the second axis of the plane

(ordinate).

Part coordinates of the tool tip.

(V.)[n].G.PLMEAS3 R — — Value measured on the axis perpendicular to the

plane.

Part coordinates of the tool tip.

(V.)[n].A.MEASOF.Xn R R R Me a su r i ng e r ror. D i f fe ren c e be t w ee n t h e

programmed coordinate and the value measured

on the Xn axis.

(V.)[n].A.MEASIN.Xn R R R Measuring error added to the Xn axis.

CNC 8065

(REF: 1309)

·34·

Page 35

CANNED CYCLES. ISO CODED PROGRAMMING.

Canned cycles may be edited in ISO code (described in this chapter) or with using the cycle

editor. See chapter "4 Canned cycles. Cycle editor.".

The cycles may be defined anywhere in the program, that is, in the main program as well

as in a subroutine. ISO coded cycles can also be executed via MDI mode.

Programming ISO coded cycles.

ISO coded cycles are defined with the #PROBE instruction followed by the number of the

cycle to be executed and the call parameters.

#PROBE 1

#PROBE 2

#PROBE 3

#PROBE 4

Tool calibration.

Tabletop probe calibration

Part measuring along the ordinate axis.

Part measuring along the abscissa axis.

3

Probing canned cycles are not modal; therefore, they must be programmed every time any

of them is to be executed. The execution of these cycles does not change the program history.

Cycle data programming.

The cycle number and the rest of parameters may be defined with a number, an arithmetic

parameter or expression whose result is a number.

#PROBE 4 X10 Z20 B5 F10

P1=4 P2=10

#PROBE P1 XP2 Z[P2*2] B5 FP2

When using global parameters, bear in mind that some cycles modify the value of these

parameters at the end of the execution. Refer to each cycle to see which parameters it

modifies.

Limitations for executing the cycles.

These cycles cannot be executed if tool radius compensation is active.

Canned cycles and the work planes.

A canned cycle may be defined anywhere in the program, that is, in the main program as

well as in a subroutine. When working in a plane other than the ZX, the CNC interprets the

canned cycle parameters as follows:

CNC 8065

Parameter Z-X plane W-X plane A-B plane

Parameter Z and all related to it, with the abscissa

axis

Parameter X and all related to it, with the ordinate

axis

Z axis W axis A axis

X axis X axis B axis

(REF: 1309)

·35·

Page 36

3.

Probing (·T· model)

Combined (dual-purpose) machines Milling and turning canned

cycles available at the same CNC.

On dual-purpose machines, those where milling and turning operations may be carried out,

the CNC offers the possibility to run canned cycles of both machines. Since both types of

canned cycles share the same #PROBE instructions, the user can select which cycles to

execute. By default, it executes the cycles of the software installed.

On a mill model CNC (milling software installed).

By default, it will execute the milling canned cycles. To execute the turning canned cycles,

use the following instructions:

#LATHECY ON - To activate the turning canned cycles.

#LATHECY OFF - To deactivate the turning canned cycles.

On a lathe model CNC (lathe software installed).

By default, it will execute the turning canned cycles. To execute the milling canned cycles,

use the following instructions:

#MILLCY ON - To activate the milling canned cycles.

#MILLCY OFF - To deactivate the milling canned cycles.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·36·

Page 37

Probing (·T· model)

3.1 #PROBE 1. Tool calibration.

This cycle may be used to calibrate the dimensions of a tool or a touch probe. Once the cycle

has concluded, it updates the dimensions in the tool table and initializes the tool wears to

0 (zero).

The calibration is done using a tabletop probe.

The cycle calibrates the active tool. The tool must be selected at the CNC before executing

the cycle.

Requirements prior to the calibration.

If it is the first time the tool or the probe is being calibrated, enter in the tool table an

approximate dimensions, location code and the radius value. If it is a probe, the "R" value

will correspond to the radius of the probe ball and the location code will depend on how it

has been calibrated.

3.

#PROBE 1. Tool calibration.

Tabletop probe.

Executing this cycle requires a table-top probe, installed in a fixed position of the machine

and with its sides parallel to the axes of the plane. The probe position must be given in

absolute coordinates referred to machine reference zero using the machine parameters

PRB1MIN, PRB1MAX, PRB2MIN, PRB2MAX, PRB3MIN, PRB3MAX.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·37·

Page 38

3.

Probing (·T· model)

Data returned by the cycle after the measurement.

Once the cycle is over, the CNC will return the detected error in the following arithmetic

parameters. A detected error is the difference between the real tool length and the value

assigned in the table.

P298 Error detected along the abscissa axis.

This value is given in radius.

P299 Error detected along the ordinate axis.

P297 Error detected on the axis perpendicular to the plane.

This value is given in radius.

Once the cycle has concluded, it updates the dimensions in the tool table and initializes the

tool wears to 0 (zero).

#PROBE 1. Tool calibration.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·38·

Page 39

Probing (·T· model)

3.1.1 Programming the cycle.

The programming format for this cycle is. Optional parameters are indicated between angle

brackets.

#PROBE 1 B F <K> <X U Z W Y V>

B

F

K

X··W

·B· Safety distance.

This parameter only admits positive values greater than 0 (zero). Value defined in radius.

Distance with respect to the point to touch, to which the tool approaches in G00 before

making the probing movement. When calling the cycle, the tool must be located, with respect

to the point to be measured, at a greater distance than this value

·F· Probing feedrate.

This parameter sets the probing feedrate. The rest of the movements will be carried out in

G00.

·K· Sides of the probe to be used.

Safety distance.

Probing feedrate.

Optional. Sides of the probe to be used.

Optional. Tabletop probe position.

3.

#PROBE 1. Tool calibration.

Optional parameter, by default 0.

This parameter indicates how many sides of the probe will be used for calibration. In a "Plane"

type of axis configuration, two sides of the probe will always be used. In a "Trihedron" type

of axis configuration, it is possible to choose to use either two or three sides of the probe.

K=0 Calibration on the X, Z sides.

K=1 Calibration on the X, Z, Y+ sides.

K=2 Calibration on the X, Z, Y- sides.

·X U Y V Z W· Tabletop probe position.

They are optional parameters that usually need not be defined. In certain machines, due to

lack of repeatability in the mechanical positioning of the probe, the probe must be calibrated

again before each calibration. Instead of re-defining the machine parameters every time the

probe is calibrated, those coordinates may be indicated in these parameters.

Parameters X Z Y refer to the minimum coordinates of the probe on the first axis, second

axis and on the axis perpendicular to the plane respectively. Parameters U W V refer to the

maximum coordinates of the probe on the first axis, second axis and on the axis

perpendicular to the plane respectively.

This data does not modify the machine parameters. The CNC takes this data into account

only during this calibration. If any of this data is left out, the CNC takes the value assigned

to the corresponding machine parameter.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·39·

Page 40

3.

Probing (·T· model)

3.1.2 Basic operation.

#PROBE 1. Tool calibration.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·40·

Page 41

Probing (·T· model)

1 Approach movement.

Rapid probe movement (G00) from the cycle calling point to the approach corner. This

point is located in front of the associated probe corner, at a ·B· distance from it.

This approach movement is made in two stages. It first moves along the Z axis and then

along the X axis.

2 Probing movement.

The sides of the probe used in this probing move as well as the path traveled by the tool

depend on the location code assigned to the selected tool. When having a "Trihedron"

type geometrical configuration and the ·K· parameter has been defined with a value other

than zero, it will execute an additional probing move on the Y axis.

Each probing move will consist of an approach move, a probing move per se and a

withdrawal move.

Approach movement. Rapid probe move (G00) to the approach point located in front of

the side to be probed at a ·B· distance from it.

Probing movement. Probing movement at the indicated feedrate (F) until the probe signal

is received. The maximum probing distance is ·2B·. If the CNC does not receive the probe

signal before reaching moving this probing distance, it stops the axes and displays the

relevant error message.

Withdrawal movement. Rapid probe movement (G00) from the probing point to the

approach corner.

3 Withdrawal movement.

Rapid probe movement (G00) from the approach corner to the cycle calling point.

This withdrawal movement is made in two stages. It first moves along the X axis and then

along the Z axis.

3.

#PROBE 1. Tool calibration.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·41·

Page 42

3.

Probing (·T· model)

3.2 #PROBE 2. Tabletop probe calibration

This cycle may be used calibrate the sides of the tabletop probe. Once the cycle has ended,

the user must enter the data returned by the cycle into the machine parameters that define

the position of the probe.

The calibration is carried out with a tool of known dimensions.

Requirements prior to the calibration.

To execute the cycle, use a master tool whose dimensions have already been defined in the

tool table. Since the probe needs to be calibrated along the X and Z axes, the location code

of the master tool must be F1, F3, F5 or F7.

#PROBE 2. Tabletop probe calibration

CANNED CYCLES. ISO CODED PROGRAMMING.

Data returned by the cycle after the measurement.

Once the cycle has ended, the CNC returns the real values obtained in the measurement

in the following arithmetic parameters: All the values will be given in absolute coordinates

referred to machine reference zero.

P298 Real coordinate of the measured side along the abscissa axis.

P299 Real coordinate of the measured side along the ordinate axis.

This value is given in radius.

P297 Real coordinate of the measured side along the axis perpendicular to the plane

(if it has been measured).

This value is given in radius.

Define the probe position.

CNC 8065

(REF: 1309)

·42·

Once the values of these parameters and the probe dimensions are known, the user must

calculate the coordinates of the other sides and update the following general machine

parameters.

PRB1MIN Minimum probe coordinate along the first axis of the channel.

PRB1MAX Maximum probe coordinate along the first axis of the channel.

PRB2MIN Minimum probe coordinate along the second axis of the channel.

PRB2MAX Maximum probe coordinate along the second axis of the channel.

PRB3MIN Minimum probe coordinate along the third axis of the channel.

PRB3MAX Maximum probe coordinate along the third axis of the channel.

Page 43

Probing (·T· model)

The probe position must be given in absolute coordinates referred to machine reference zero.

Example:

If the tool used has a location code F3 and the probe is square with 40 mm sides, the machine

parameters will assume the following values.

PRB1MIN = P298 - 40

PRB1MAX = P298

PRB2MIN = P299 - 40

PRB2MAX = P299

3.

#PROBE 2. Tabletop probe calibration

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·43·

Page 44

3.

3.2.1 Programming the cycle.

The programming format for this cycle is. Optional parameters are indicated between angle

brackets.

#PROBE 2 B F <K> <X U Z W Y V>

B

F

K

X··W

·B· Safety distance.

This parameter only admits positive values greater than 0 (zero). Value defined in radius.

Distance with respect to the point to touch, to which the tool approaches in G00 before

making the probing movement. When calling the cycle, the tool must be located, with respect

to the point to be measured, at a greater distance than this value

·F· Probing feedrate.

This parameter sets the probing feedrate. The rest of the movements will be carried out in

G00.

·K· Sides of the probe to be used.

Safety distance.

Probing feedrate.

Optional. Sides of the probe to be used.

Optional. Tabletop probe position.

Probing (·T· model)

#PROBE 2. Tabletop probe calibration

CANNED CYCLES. ISO CODED PROGRAMMING.

Optional parameter, by default 0.

This parameter indicates how many sides of the probe will be used for calibration. In a "Plane"

type of axis configuration, two sides of the probe will always be used. In a "Trihedron" type

of axis configuration, it is possible to choose to use either two or three sides of the probe.

K=0 Calibration on the X, Z sides.

K=1 Calibration on the X, Z, Y+ sides.

K=2 Calibration on the X, Z, Y- sides.

·X U Y V Z W· Tabletop probe position.

They are optional parameters that usually need not be defined. In certain machines, due to

lack of repeatability in the mechanical positioning of the probe, the probe must be calibrated

again before each calibration. Instead of re-defining the machine parameters every time the

probe is calibrated, those coordinates may be indicated in these parameters.

Parameters X Z Y refer to the minimum coordinates of the probe on the first axis, second

axis and on the axis perpendicular to the plane respectively. Parameters U W V refer to the

maximum coordinates of the probe on the first axis, second axis and on the axis

perpendicular to the plane respectively.

This data does not modify the machine parameters. The CNC takes this data into account

only during this calibration. If any of this data is left out, the CNC takes the value assigned

to the corresponding machine parameter.

CNC 8065

(REF: 1309)

·44·

Page 45

Probing (·T· model)

3.2.2 Basic operation.

3.

1 Approach movement.

Rapid probe movement (G00) from the cycle calling point to the approach corner. This

point is located in front of the associated probe corner, at a ·B· distance from it.

This approach movement is made in two stages. It first moves along the Z axis and then

along the X axis.

#PROBE 2. Tabletop probe calibration

CANNED CYCLES. ISO CODED PROGRAMMING.

2 Probing movement.

The sides of the probe used in this probing move as well as the path traveled by the tool

depend on the location code assigned to the selected tool. When having a "Trihedron"

type geometrical configuration and the ·K· parameter has been defined with a value other

than zero, it will execute an additional probing move on the Y axis.

CNC 8065

(REF: 1309)

·45·

Page 46

3.

Probing (·T· model)

Each probing move will consist of an approach move, a probing move per se and a

withdrawal move.

Approach movement. Rapid probe move (G00) to the approach point located in front of

the side to be probed at a ·B· distance from it.

Probing movement. Probing movement at the indicated feedrate (F) until the probe signal

is received. The maximum probing distance is ·2B·. If the CNC does not receive the probe

signal before reaching moving this probing distance, it stops the axes and displays the

relevant error message.

Withdrawal movement. Rapid probe movement (G00) from the probing point to the

approach corner.

3 Withdrawal movement.

Rapid probe movement (G00) from the approach corner to the cycle calling point.

This withdrawal movement is made in two stages. It first moves along the X axis and then

along the Z axis.

#PROBE 2. Tabletop probe calibration

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·46·

Page 47

Probing (·T· model)

3.3 #PROBE 3. Part measuring along the ordinate axis.

This cycle measures the part along the ordinate axis. With this cycle, it is also possible to

correct the value of the wear of the tool used to machine the surface. The wear correction

only takes place when the measuring error exceeds a programmed value.

For this cycle, a probe mounted in the tool holding spindle must be used, it must be previously

calibrated with the tool calibration canned cycle.

Tool wear compensation.

To enable wear compensation, the calling instruction must define all the parameters ·T· (tool)

and ·D· (offset). The wear correction only takes place when the measuring error exceeds

the tolerance programmed in parameter ·L·.

Data returned by the cycle after the measurement.

Once the cycle has ended, the CNC returns the real values obtained in the measurement

in the following arithmetic parameters:

P298 Actual (real) surface coordinate.

This value is given in the active units, radius or diameter.

P299 Detected error. Difference between the actual surface coordinate and the

programmed theoretical coordinate.

This value is given in radius.

If wear correction is enabled in the calling instruction, the CNC updates those values in the

programmed tool. This correction is applied only if the measuring error is equal to or greater

than the programmed tolerance.

3.

#PROBE 3. Part measuring along the ordinate axis.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·47·

Page 48

3.

3.3.1 Programming the cycle.

The programming format for this cycle is. Optional parameters are indicated between angle

brackets.

#PROBE 3 X Z B F <L> <T D>

X Z

B

F

L

T

D

·X· Theoretical coordinate of the probing point along the ordinate axis.

Theoretical ordinate coordinate of the point being measured. This value is given in the active

units, radius or diameter.

·Z· Theoretical coordinate of the probing point along the abscissa axis.

Theoretical abscissa coordinate of the point being measured.

·B· Safety distance.

Theoretical coordinates of the measuring point.

Safety distance.

Probing feedrate.

Optional. Tolerance for the measuring error.

Optional. Tool to be corrected.

Optional. Tool offset to be corrected.

Probing (·T· model)

#PROBE 3. Part measuring along the ordinate axis.

CANNED CYCLES. ISO CODED PROGRAMMING.

This parameter only admits positive values greater than 0 (zero). Value defined in radius.

Distance with respect to the point to measure and along the ordinate axis, to which the probe

approaches in G00 before making the probing movement. When calling the cycle, the probe

must be located, with respect to the point to be measured, at a greater distance than this value

·F· Probing feedrate.

This parameter sets the probing feedrate. The rest of the movements will be carried out in

G00.

·L· Tolerance for the measuring error.

Optional parameter, by default 0. This parameter only admits positive values.

If the measuring error (difference between the theoretical and the real values) is within this

tolerance, the CNC does not change the tool data. If the measuring error is equal to or greater

than this tolerance, the CNC corrects the data of the tool defined in parameters ·T· and ·D·.

·T· Tool to be corrected.

Optional parameter, by default 0. If T=0 (or not programmed), tool wear is not corrected. To

correct tool wear, program parameters ·T· and ·D· with a value other than zero.

Tool whose wear is to be corrected, which will be the tool used to machine the surface.

·D· Tool offset to be corrected.

Optional parameter, by default 0. If D=0 (or not programmed), tool wear is not corrected. To

correct tool wear, program parameters ·T· and ·D· with a value other than zero.

CNC 8065

(REF: 1309)

·48·

Tool offset whose wear is to be corrected, which will be the tool offset used to machine the

surface.

Page 49

Probing (·T· model)

3.3.2 Basic operation.

In the following description, the Z axis is the abscissa axis and the X axis is the ordinate axis.

1 Approach movement.

Rapid probe movement (G00) from the cycle calling point to the approach point. This

point is located in front of the point being measured, at a ·B· distance from it.

This approach movement is made in two stages. It first moves along the Z axis and then

along the X axis.

2 Probing movement.

Probing movement along the X axis at the indicated feedrate (F) until the probe signal

is received. Once probing is over, the CNC will assume the actual position of the axes

when the probe signal is received as their theoretical position.

The maximum probing distance is ·2B·. If once this distance has been reached, the CNC

has not yet received the probe signal, it will issue the relevant error code and stop the

movement of the axes.

3 Withdrawal movement.

Rapid probe movement (G00) from the probing point to the cycle calling point.

This withdrawal movement is made in two stages. It first moves along the X axis and then

along the Z axis.

3.

#PROBE 3. Part measuring along the ordinate axis.

CANNED CYCLES. ISO CODED PROGRAMMING.

CNC 8065

(REF: 1309)

·49·

Page 50

Probing (·T· model)

3.4 #PROBE 4. Part measuring along the abscissa axis.

This cycle measures the part along the abscissa axis. With this cycle, it is also possible to

correct the value of the wear of the tool used to machine the surface. The wear correction

only takes place when the measuring error exceeds a programmed value.

For this cycle, a probe mounted in the tool holding spindle must be used, it must be previously

calibrated with the tool calibration canned cycle.

Tool wear compensation.

3.

#PROBE 4. Part measuring along the abscissa axis.

CANNED CYCLES. ISO CODED PROGRAMMING.

To enable wear compensation, the calling instruction must define all the parameters ·T· (tool)

and ·D· (offset). The wear correction only takes place when the measuring error exceeds

the tolerance programmed in parameter ·L·.

Data returned by the cycle after the measurement.

Once the cycle has ended, the CNC returns the real values obtained in the measurement

in the following arithmetic parameters:

P298 Actual (real) surface coordinate.

P299 Detected error. Difference between the actual surface coordinate and the

programmed theoretical coordinate.

If wear correction is enabled in the calling instruction, the CNC updates those values in the

programmed tool. This correction is applied only if the measuring error is equal to or greater

than the programmed tolerance.

CNC 8065

(REF: 1309)

·50·

Page 51

Probing (·T· model)

3.4.1 Programming the cycle.

The programming format for this cycle is. Optional parameters are indicated between angle

brackets.

#PROBE 4 X Z B F <L> <T D>

X Z

B

F

L

T

D

·X· Theoretical coordinate of the probing point along the ordinate axis.

Theoretical ordinate coordinate of the point being measured. This value is given in the active

units, radius or diameter.

·Z· Theoretical coordinate of the probing point along the abscissa axis.

Theoretical abscissa coordinate of the point being measured.

·B· Safety distance.

Theoretical coordinates of the measuring point.

Safety distance.

Probing feedrate.

Optional. Tolerance for the measuring error.

Optional. Tool to be corrected.

Optional. Tool offset to be corrected.

3.

This parameter only admits positive values greater than 0 (zero).

Distance with respect to the point to measure and along the abscissa axis, to which the probe

approaches in G00 before making the probing movement. When calling the cycle, the probe

must be located, with respect to the point to be measured, at a greater distance than this value

·F· Probing feedrate.

This parameter sets the probing feedrate. The rest of the movements will be carried out in

G00.

·L· Tolerance for the measuring error.

Optional parameter, by default 0. This parameter only admits positive values.

If the measuring error (difference between the theoretical and the real values) is within this

tolerance, the CNC does not change the tool data. If the measur ing error is equal to or greater

than this tolerance, the CNC corrects the data of the tool defined in parameters ·T· and ·D·.

·T· Tool to be corrected.

Optional parameter, by default 0. If T=0 (or not programmed), tool wear is not corrected. To

correct tool wear, program parameters ·T· and ·D· with a value other than zero.

Tool whose wear is to be corrected, which will be the tool used to machine the surface.

·D· Tool offset to be corrected.

Optional parameter, by default 0. If D=0 (or not programmed), tool wear is not corrected. To

correct tool wear, program parameters ·T· and ·D· with a value other than zero.

#PROBE 4. Part measuring along the abscissa axis.

CANNED CYCLES. ISO CODED PROGRAMMING.

Tool offset whose wear is to be corrected, which will be the tool offset used to machine the

surface.

CNC 8065

(REF: 1309)

·51·

Page 52

3.

#PROBE 4. Part measuring along the abscissa axis.

CANNED CYCLES. ISO CODED PROGRAMMING.

Probing (·T· model)

3.4.2 Basic operation.

In the following description, the Z axis is the abscissa axis and the X axis is the ordinate axis.

1 Approach movement.

Rapid probe movement (G00) from the cycle calling point to the approach point. This

point is located in front of the point being measured, at a ·B· distance from it.

This approach movement is made in two stages. It first moves along the X axis and then

along the Z axis.

2 Probing movement.

Probing movement along the Z axis at the indicated feedrate (F) until the probe signal

is received. Once probing is over, the CNC will assume the actual position of the axes

when the probe signal is received as their theoretical position.

The maximum probing distance is ·2B·. If once this distance has been reached, the CNC

has not yet received the probe signal, it will issue the relevant error code and stop the

movement of the axes.

3 Withdrawal movement.

Rapid probe movement (G00) from the probing point to the cycle calling point.

This withdrawal movement is made in two stages. It first moves along the Z axis and then

along the X axis.

CNC 8065

(REF: 1309)

·52·

Page 53

Probing (·T· model)

3.5 Check the data of the canned cycles (variables).

Check the value of the programmed parameters.

(V.)C.a-z

Variable that can be read and written from the part-program or MDI. The variable is

evaluated during block preparation.