Page 1

VIGILO

2250 - 2263 - 2280

GB Instructions manual pages 1 - 16

VIGILO

2250 - 2263 - 2280

FULLY RETRACTABLE OIL-HYDRAULIC BOLLARDS.

POST DIAMETER 100 mm

EN 13241

EN 12453

EN 12445

the gate opener

Page 2

VIGILO

VIGILO

GENERAL WARNINGS FOR PEOPLE SAFETY

INTRODUCTION

This operator is designed for a specic scope of applications as

indicated in this manual, including safety, control and signaling

accessories as minimum required with FADINI equipment. □

Any applications not explicitly included in this manual may

cause operation problems or damages to properties and

people. □ Meccanica Fadini snc is not liable for damages

caused by the incorrect use of the equipment, or for

English

applications not included in this manual or for malfunctioning

resulting from the use of materials or accessories not

recommended by the manufacturer. □ The manufacturer

reserves the right to make changes to its products without

prior notice. □ All that is not explicitly indicated in this manual

is to be considered not allowed.

fully retractable oil-hydraulic bollard

□ The installer must inform and instruct the end user about the

proper use of the system by releasing him a technical dossier,

including: layout and components of the installation, risk

analysis, verication of safety accessories, verication of

impact forces and reporting of residual risks.

INFORMATION FOR END-USERS

The end-user is required to read carefully and to receive

information concerning only the operation of the installation

so that he becomes himself responsible for the correct use of it.

□ The end-user shall establish a written maintenance contract

with the installer/maintenance technician (on -call). □ Any

maintenance operation must be done by qualied technicians.

□ Keep these instructions carefully.

BEFORE INSTALLATION

Before commencing operator installation assess the suitability

of the access, its general condition and the structure. □

To check that the ground is stable, to avoid subsequent settling

or deformation in the trac control post installation area. □

Make sure that there is no risk of impact, crushing, shearing,

conveying, cutting, entangling and lifting situations, which

may prejudice people safety. □ Do not install near any source of

heat and avoid contacts with ammable substances. □ Keep all

the accessories able to turn on the operator (transmitters,

proximity readers, key-switches, etc) out of the reach of the

children. □ Transit through the access only with stationary

operator. □ Do not allow children and/or people to stand in the

proximity of a working operator. □ To ensure safety in the

whole movement area of a bollard it is advisable to install

photocells, sensitive edges, magnetic loops and detectors. □

Use yellow-black strips or proper signals to identify dangerous

spots. □ Before cleaning and maintenance operations,

disconnect the appliance from the mains by switching o the

master switch. □ If removing the actuator, do not cut the

electric wires, but disconnect them from the terminal box by

loosening the screws inside the junction box.

INSTALLATION

All installation operations must be performed by a qualied

technician, in observance of the Machinery Directive

2006/42/CE and safety regulations EN 12453 - EN 12445. □

Verify the presence of a thermal-magnetic circuit breaker

0,03 A - 230 V - 50 Hz upstream the installation. □ Use

appropriate objects to test the correct functionality of the

safety accessories, such as photocells, sensitive edges, etc. □

Carry out a risk analysis by means of appropriate instruments

measuring the crushing and impact force of the main opening

and closing edge in compliance with EN 12445. □ Identify the

appropriate solution necessary to eliminate and reduce such

risks. □ In case where the gate to automate is equipped with a

pedestrian entrance, it is appropriate to prepare the system in

such a way to prohibit the operation of the engine when the

pedestrian entrance is used. □ Apply safety nameplates with CE

marking on the gate warning about the presence of an

automated installation.

WARNINGS FOR THE CORRECT OPERATION OF THE

INSTALLATION

For optimum performance of system over time according to

safety regulations, it is necessary to perform proper

maintenance and monitoring of the entire installation: the

automation, the electronic equipment and the cables

connected to these. □ The entire installation must be carried

out by qualied technical personnel, lling in the Maintenance

Manual indicated in the Safety Regulation Book (to be

requested or downloaded from the site

www.fadini.net/supporto/downloads).

□ Operator: maintenance inspection at least every 6 months,

while for the electronic equipment and safety systems an

inspection at least once every month is required. □ The

manufacturer, Meccanica Fadini snc, is not responsible for

non-observance of good installation practice and incorrect

maintenance of the installation.

DISPOSAL OF MATERIALS

Dispose properly of the packaging materials such as

cardboard, nylon, polystyrene etc. through specializing

companies (after verication of the regulations in force at the

place of installation in the eld of waste disposal). Disposal of

electrical and electronic materials: to remove and dispose

through specializing companies, as per Directive 2012/19/UE.

Disposal of substances hazardous for the environment is

prohibited.

CE DECLARATION OF CONFORMITY of the manufacturer:

Meccanica Fadini snc (Via Mantova, 177/A - 37053 Cerea - VR - Italy) declares under own responsibility that: Vigilo complies

with the 2006/42/CE Machinery Directive, and also that it is sold to be installed in an “automatic system”, along with original

accessories and components as indicated by the manufacturing company. An automatic gate operator is, by law, a

“machinery” and therefore the installer must t the equipment with all of the applicable safety norms. The installer is also

required to issue the installer’s Declaration of Conformity. The manufacturer is not liable for possible incorrect use of the

product. The product complies with the following specic norms: analysis of the risks and subsequent action to cure them

as per EN 12445 and EN 12453, Low Voltage Directive 2014/35/UE, Electromagnetic Compatibility 2014/30/UE. In order to

certify the product, the manufacturer declares under own responsibility the compliance with the EN 13241-1 PRODUCT

NORMS.

Meccanica Fadini s.n.c.

Director in charge

2

Page 3

VIGILO

VIGILO

INSTRUCTIONS TO BE FOLLOWED BEFORE INSTALLING THE OPERATOR

FOR OPTIMAL APPLICATION AND USE OF THE OPERATOR PLEASE READ THE INSTRUCTIONS AND CONSULT EXPLANATORY DIAGRAMS.

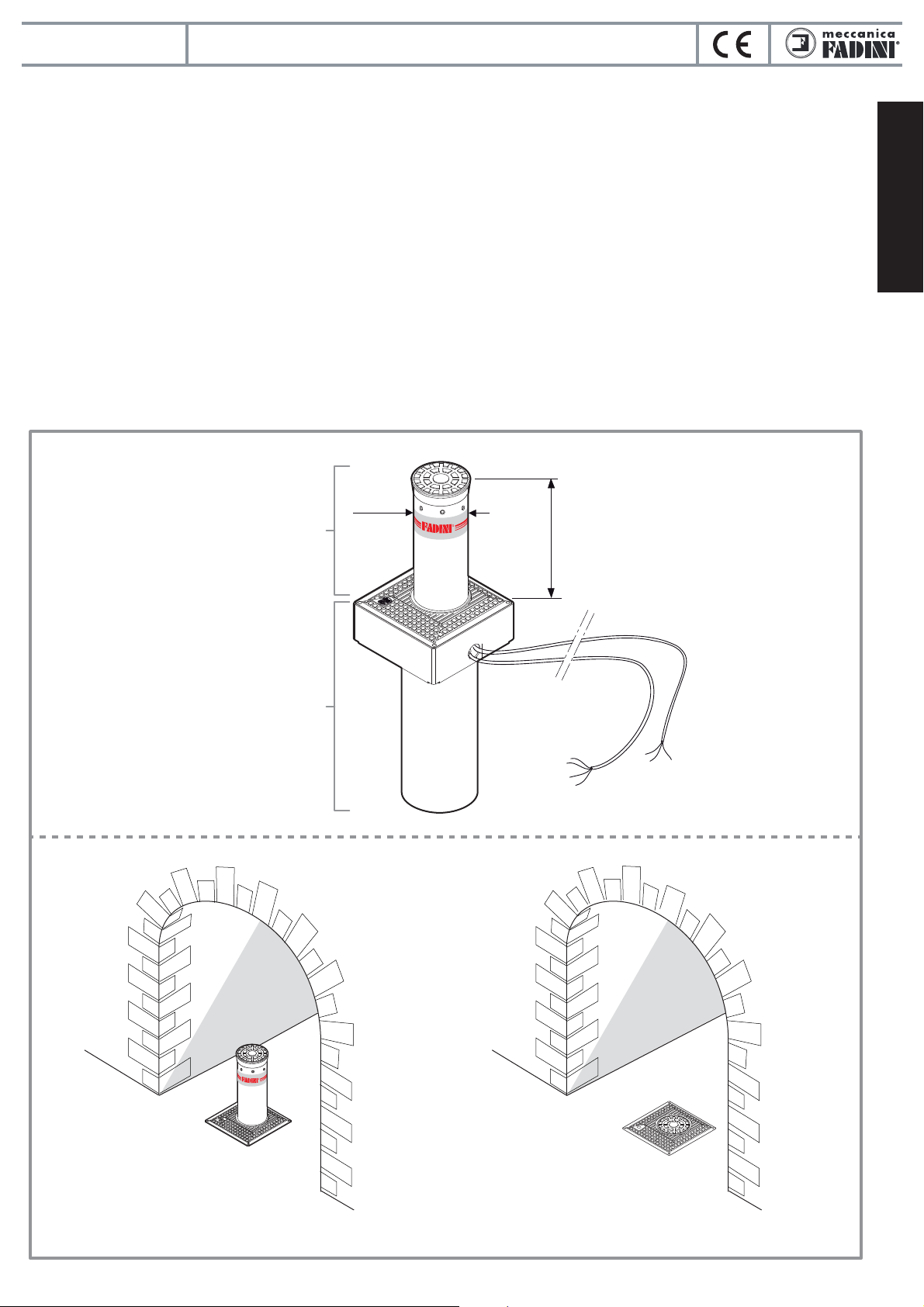

OVERVIEW

This product belongs to our range of retractable trac control posts. It is quick and easy to install, as it does not need to be

adjusted or calibrated and has been designed to regulate and prohibit vehicular access.

The oil-hydraulic bollards VIGILO 2250 (500 mm height, with or without LEDs), VIGILO 2263 (600 mm height, with or without

LEDs), VIGILO 2280 (800 mm height, with or without LEDs) are tted with posts made of rust-treated steel, 200 mm diameter;

bollards are also available in stainless steel AISI 304 version.

The product’s hallmark is its ease of installation: once the housing has been secured, the operator can be introduced ready for

operation, as soon as the wiring has been completed.

As soon as the retractable post receives a command (from a key switch or radio transmitter), it rises from its interred position.

The post is clearly visible at nighttime thanks to a reective strip and the possibility of connecting a ashing light or trac light.

Versions with led lights are also available to signal when the post is in the fully up position and when moving up or down.

Using the electronic microprocessor programmer, the operator can also be customised with presence indicator accessories

(magnetic coils, photocells).

fully retractable oil-hydraulic bollard

English

Retractable post

Container unit inside the housing

to be sunk in a dedicated trench

in the ground

Ø 200

stroke 500 mm (Vigilo 2250)

stroke 600 mm (Vigilo 2263)

stroke 800 mm (Vigilo 2280)

Length of cables 10 metres

Raised post, access prohibited Lowered post, access free

3

Pic. 1

Page 4

VIGILO

VIGILO

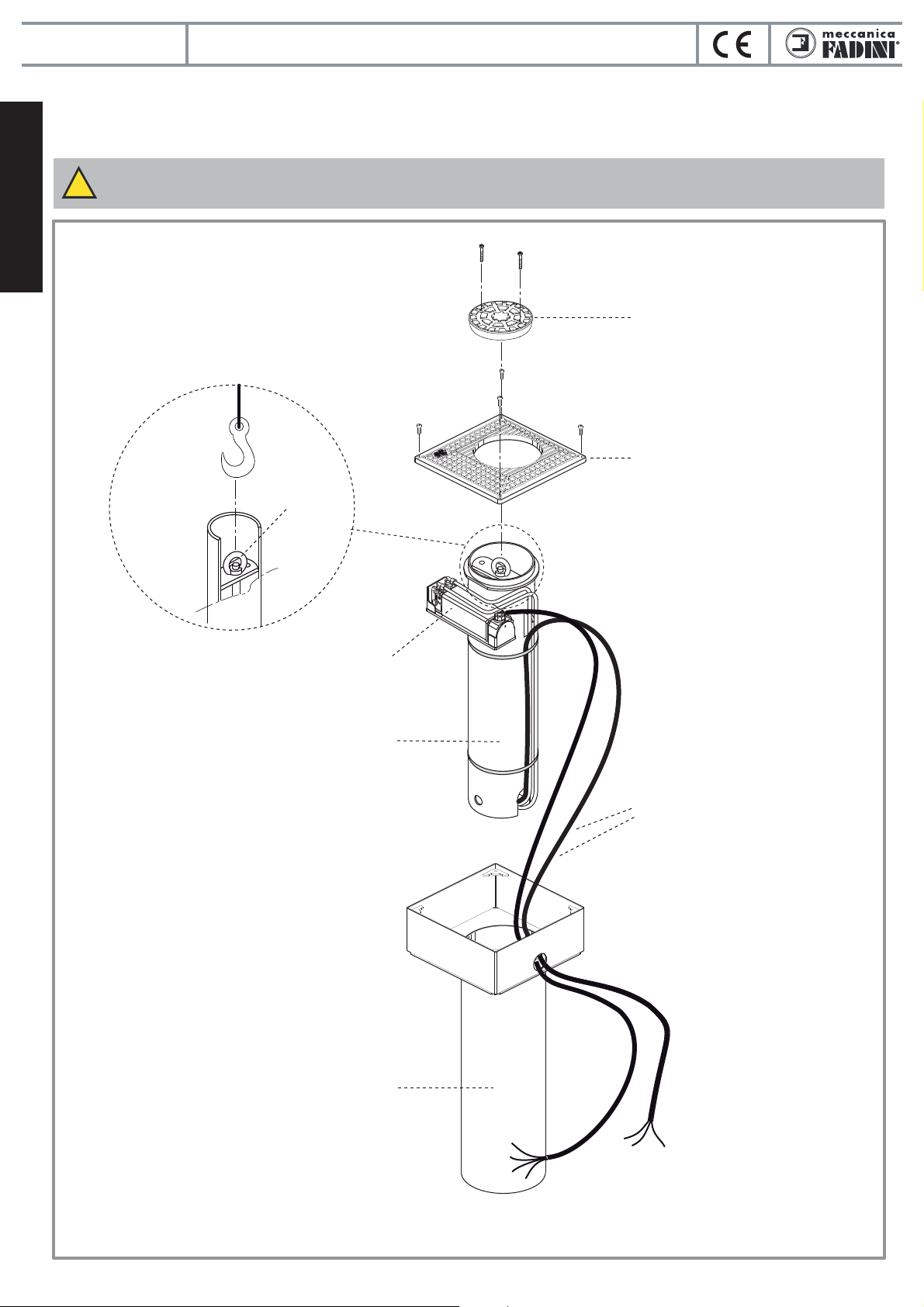

PRELIMINARY OPENING OF ALL FUNCTIONAL COMPONENTS

Start by removing the cover plate to reveal the operator and separate the individual components, with the aid of a hoist (Pic. 2):

this makes it easy to extract the internal piston and hydraulic main unit container unit.

IMPORTANT: TAKE CARE NOT TO TEAR OR CUT WIRES.

!

fully retractable oil-hydraulic bollard

English

Post cover with

rubber buer

Cover plate

Detail of retractable post

with hoisting connection

Cylindrical container

for oil-hydraulic piston

Eyebolt

Hydraulic main unit

Motor and limit switch cables.

LED and solenoid valve versions

also come with pre-tted

cables in lengths of 10 m each

Housing

Pic. 2

4

Page 5

VIGILO

VIGILO

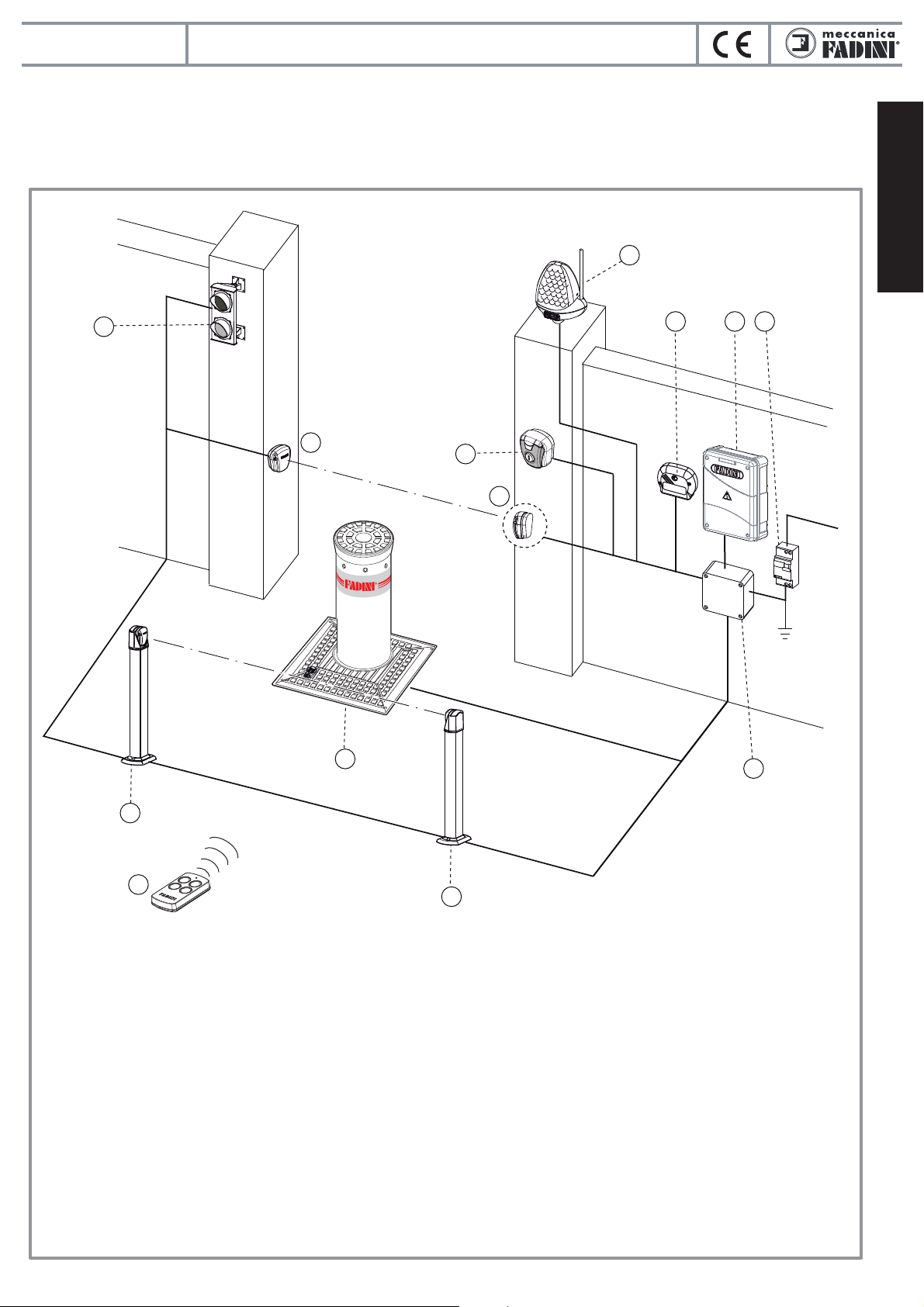

ELECTRICAL LAYOUT OF THE INSTALLATION

To check that the mains supply and voltage to the electric motor is 230 V at 50 Hz.

The power supply to the operator’s built-in motor must be made using electricity cables with a 1,5 mm² section for a maximum

distance of 50 metres. For distances of over 50 metres, use electric cables with sections suited to the installation.

fully retractable oil-hydraulic bollard

1

English

10

2x1 mm²

4x1 mm²

234

2x1 mm²

cable RG58

6

7

11

4x1 mm²

3x1 mm²

8

2x1 mm²

F

ADINI

230 V - 50 Hz

4x1 mm²

4x1 mm²

5

8

4x1 mm²

9

1 - MIRI 4-Led ashing light with built-in aerial

2 - Stand alone VIX 53/1 R radio receiver

3 - ELPRO S40 electronic programmer

4 - Dierential circuit breaker switch (sensitivity 30 mA, protection 6-10 A)

5 - Junction box, electric wires

6 - FIT 55 photocell receiver

7 - VIGILO post

8 - FIT 55 photocell projector

9 - VIX 53/4 TR transmitter

10 - Trac light with two lights

11 - CHIS 37 key-switch

6

Pic. 3

5

Page 6

VIGILO

VIGILO

ARRANGING THE HOUSING

fully retractable oil-hydraulic bollard

English

850 - stroke 500 mm

170

960 - stroke 600 mm

1.140 - stroke 800 mm

410

FRONT SIDE

Ø 275

410 mm

Ø 60

Possible

submersed

pump

Check soil natural permeability: 50 liters of water must be

able to soak away in not longer than 30/40 minutes.

!

Otherwise provide a pipe to allow rain water to ow either

into the sewage system or a sump well equipped with a

submersed pump.

Soakaway pebbles

IMPORTANT: once the housing has been positioned and installation completed, it is important for the top edge

!

to be level with the ground.

Concrete

Cover with

about 30 cm

30 cm

of concrete

1,0 m - stroke 500

1,2 m - stroke 600

1,3 m - stroke 800

23 cm

87 cm

87 cm

43,5 cm

FRONT SIDE

43,5 cm

23 cm

Piping Ø 5 cm

for passage

of electric wires

12 cm

depth piping

centre

Housing

Spirit level

Pic. 4

cast

15 cm

loose pebble

drainage layer

6

15 cm

Pic. 5

Page 7

VIGILO

VIGILO

PLACING THE TRAFFIC CONTROL POST INSIDE THE HOUSING

Before performing this operation, wait for the housing to be secured rmly in place. Do not commence until the concrete has set

and the electric wire pipe has been secured and covered with soil.

• Use a hoisting hook to lift the piston unit with the post and main unit (using the eyebolt) and place on top of the housing.

• The subsequent phase of this operation consists in threading the motor, limit switch, solenoid valve and LED power supply

electric wires through the piping and simultaneously starting to delicately place the operator inside the housing.

IMPORTANT: PASS THE MOTOR, LIMIT SWITCH, SOLENOID VALVE AND LED POWER SUPPLY ELECTRIC WIRES

!

THROUGH THE PIPING WITHOUT TEARING OR CUTTING THE CABLES.

Hoisting

hook

fully retractable oil-hydraulic bollard

English

Oil-hydraulic

piston

container unit

Housing

FRONT SIDE

Electric motor, limit switch,

solenoid valve and LED

power supply cables,

10 metres

Buried piping

Ø 50 mm

For distances greater than 10 metres, make extensions using sealed

!

junction boxes inside an accessible dividing box.

ELPRO S40

Junction

boxes

IF THE OPERATOR IS REMOVED

!

• Disconnect the main switch before opening the lid of the electric cable junction box.

• Do not cut the electric wires, rather remove them from the terminal board loosening the clamping screws inside the

dividing box.

Seal the junction boxes

using bands

7

Pic. 6

Page 8

VIGILO

VIGILO

MAGNETIC LOOP PREPARATIONS

IMPORTANT:

!

make sure that no other electro-magnetic sources are located on or under the ground near the installation to

prevent interference or any aecting action with the magnetic loops of the vehicle detecting device if installed or

with any other electronic equipment included in the system for commanding and controlling operations.

The magnetic loop detector is a safety device operating all the time to detect any transiting vehicle: the bollard is prevented from

English

rising should a vehicle cross the loop.

A hole is to be dug in the ground as indicated (see relative instructions sheet). For proper and correct functioning of the loop

detector it is recommended to strictly keep to the installation geometry as indicated in the instructions.

fully retractable oil-hydraulic bollard

Loop in

exit gateway

Loop in

exit gateway

Loop in

entry gateway

• Pre-assembled loop 6 meters across

(optional in the catalogue)

• Pre-assembled loop 12 meters across

(optional in the catalogue)

min 80 cm

ARRANGEMENT OF THE PHOTOCELLS

Visual 344

Ø 275

VIGILO bollard

Loop in

entry gateway

Power supply cable

10 meters max,

pre-tted to the loops

Fit 55

Pic. 7

Metal detector.

See instructions included

with the equipment

(optional in the catalogue)

Pic. 8

Chis 37

Elpro S40

Fit 55

1.890 mm

Electric cables laid in the ground in a corrugated sheath

min 1,0 m

min 1,0 m

Fit 55

8

Fit 55

Pic. 9

Page 9

VIGILO

VIGILO

fully retractable oil-hydraulic bollard

ELECTRICAL CONNECTIONS TO THE CONTROL BOARD

Vigilo with LED lights

ELPRO S40

closing limit switch M1

(post up)

opening limit switch M1

(post down)

VIGILO bollard

Standard Vigilo

20 μF

A

common

B

Solenoid valve

power supply

LED power supply

blinking light

11 12 13 16 17 18 22 23 52 53 52 53

brown

motor live

motor live

STABILIZER

Vigilo with

solenoid valve

Led

LED

CICALINO

Vigilo with

LED lights

blue common

Beeper

black

LED

CICALINO

Vigilo with

LED lights

FINECORSA

BLU COMUNE

Limit switch

Blue common

Standard Vigilo

blue common

blue common

LED power supply

brown

blue common

Led

Beeper

English

steady light

black

Pic. 10

FIRST OPERATION MANOEUVRES

NOTE WELL: supply the system with electric power only after all of the electrical connections have been made as

!

required for proper operations.

Having terminated installation of the trac control post and all the safety and control accessories (all of the NC contacts on the

Elpro S40 board are to be bridged), and the respective connections with the Elpro S40 programmer, and having completed

thorough risk analysis, the rst operation manoeuvres can be performed. If you have a radio transmitter, encode the radio receiver

according to the relative instructions before giving the command to raise the retractable post, or give the manoeuvre command

using a key switch. Once power is supplied, connect the motor/pump cable and, satised that the limit switch LEDs are properly

alight, the post should move up on the rst commanding pulse; should it fail, disconnect power supply and swap the connections

to the live terminals.

NC

230 V

All NC contacts are to be closed

Should the motor fail

to drive the post up by

A

rst pulsing, swap the

B

connections to the electric

20 μF

motor live terminals only

16 1817 16 1817

common

common

st

pulse

1

In case of multiple installations go

through the same procedure with each post

9

Pic. 11

Page 10

VIGILO

VIGILO

fully retractable oil-hydraulic bollard

VERSION OF CORAL WITH SOLENOID VALVE

In the version of VIGILO with solenoid valve no manual overriding action is needed, and in case of power failure the post descends

automatically ush with pavement level. To enable the solenoid valve to operate properly, the electric wires labelled

“ELETTROVALVOLA - Solenoid valve” from the post assembly are to be connected, through the voltage stabilizer, to terminals 22

and 23 in the Elpro S40 control box.

VIGILO with solenoid valve

English

22 23

STABILIZER

SOLENOID VALVE

230 V

GROUND-LEVEL CLOSURE - COVER PLATE

• Use the four screws to close the cover plate.

• Lift the retractable post for facilitate closure of the post cover

with the buer, give the command (by encoding a transmitter

with the radio receiver or a key switch) to lift the retractable

post.

==

VIGILO with solenoid valve VIGILO with solenoid valve

230 V

Pic. 12

Post cover

Rubber buer

Cover plate

Retractable

post

NO

IMPORTANT:

WE RECOMMEND

GREASE

GREASING ALL CLAMPING

SCREWS

MANUAL RELEASE OPERATIONS

In the case of a blackout, the post can be lowered manually following the instructions show in pic. 14.

1

4

2 3

Insert the release key

in the release key recess

Release the hydraulic circuit

by turning the release key

one turn anti-clockwise

5

12

1

11

2

10

9

3

8

4

Block the hydraulic circuit

567

by turning the release key

clockwise (tighten until

securely locked)

Pic. 13

12

11

10

9

8

1

2

3

4

567

Press to lower the post manually

Pic. 14

10

Page 11

VIGILO

VIGILO

fully retractable oil-hydraulic bollard

MAINTENANCE RECORD

hand over to the end user of the installation

the gate opener

Installation address:

Installation type:

Sliding gate

Swinging gate

Over-head door

Lateral folding

door

NOTE WELL: this document must record any ordinary and extraordinary services including installation, maintenance,

repairs and replacements to be made only by using Fadini original spare parts.

This document, for the data included in it, must be made available to authorized inspectors/ocers, and a copy of it must

be handed over the end user/s.

The installer/maintainer are liable for the functionalities and safety features of the installation only if maintenance is

carried on by qualied technical people appointed by themselves and agreed upon with the end user/s.

Service date

N°

Folding door

Road barrier

Bollard

.............................

Maintainer: Date:

Operator model:

Dimensions per gate leaf:

X

Weight per gate leaf: Installation date:

Technical maintainer End user/sService description

Quantity of models

installed:

English

1

2

3

4

give to the end-user of the installation

5

6

Stamp and signature

installation technician/maintainer

Signed for acceptance

end user

buyer

11

Page 12

VIGILO

VIGILO

English

fully retractable oil-hydraulic bollard

12

Page 13

VIGILO

VIGILO

OPERATIONS FOR ORDINARY ROUTINE MAINTENANCE OF FADINI AUTOMATIC BOLLARDS (EVERY SIX MONTHS)

The standard maintenance routine sequence is as follows:

• Clean the ground cylinder and suck all material settlements.

• Clean water drains located at the bottom of the ground cylinder and/or excavation pit.

• Check any possible oil leaking from the hydraulic piston and, in case, x it.

• Overhaul the screws fastening the bollard to the ground cylinder, making sure they are properly tightened and lubricated.

• Check the oil-hydraulic motor-pump and oil pressure by assessing the rising times of the bollard. If required, top up oil in the

reservoir and/or parallel add an extra capacitor to the existing one (instructions manual is to be referred to).

• Check the correct functioning of the signal LED lights (if incorporated) in the bollard head.

• Sight check the electronic board controlling the bollard/s (e.g.: “ooded” relay contacts, oxidized terminal clamps, etc.).

• Check the correct functioning and positioning of the limit switches.

• Check the release system for bollard manual operations.

• Clean and recondition the rising cylinder if required, e.g.: paint patching up, replacing the back reecting sticker and /or the

cover tted with rubber edge.

IF OPTIONAL ACCESSORIES ARE INCLUDED, FURTHER MAINTENANCE IS REQUIRED AS FOLLOWS:

• Check the correct functioning of the safety accessories such as the inductive loop/s and the photocells.

• Check the correct functioning of the radio receiver and all of the remote controls.

• Check the correct functioning of the pressure switch.

• Check the correct functioning of the beeper.

• Check the correct functioning of the trac lights and the respective control card.

• Check the correct functioning of the solenoid valve in emergency cases such as power failure or disconnection, assess

therefore the status of the 24 Vdc voltage stabilizer.

• Check the correct functioning of EAR 35 acoustic analyzer to lower the bollard in emergency.

fully retractable oil-hydraulic bollard

English

13

Page 14

VIGILO

VIGILO

fully retractable oil-hydraulic bollard

!

1) Installation operations, testing, analysis of the risks and future maintenance are to be executed by qualied and authorized

technicians in compliance with the existing regulations (www.fadini.net/supporto/download).

2) This automatic system is intended to be exclusively used for the applications described in this manual, including all of the

English

safety and command accessories, at least as required.

3) Any application not indicated in this manual may cause malfunctioning or damages to people and properties.

4) Make sure the soil is adequate to take the bollard to avoid that settling at a later stage causes problems to the system.

5) Make sure the site is free from utilities that may interfere with it.

6) Make sure that electromagnetic sources are at a suitable distance from the accessories, especially from the loop detectors.

The magnetic elds of other sources might aect the detections of the safety loops as well as those of the other command

and safety devices of the system.

7) Make sure the power supply to the electric motor is 230 V (50 Hz).

8) It is recommended either of the following power supply cables:

- 10 meters electric cable 4x1 mm² for motor pump power supply;

- 10 meters electric cable 3x0,5 mm² for limit switches.

The section of the ground cable is to be chosen in compliance with the requirements of the installation site.

9) In case any components or accessories need replacing, use only original parts as provided by the manufacturer.

10) The installer shall provide the nal user with information related to all of the operating commands and functions of the

system, including that concerning lowering of the post in case of an emergency (manual release operation).

11) The installer shall inform the nal user of the dangers coming from the presence of persons, especially children, in the

proximity of the bollard.

12) The manufacturer reserves the right to change this manual without previous notice.

As far as conguration and execution of the system are concerned, these are to comply with the laws in the country of

installation.

INFORMATION ABOUT SAFETY AND PROPER FUNCTIONING OF THE SYSTEM

!

Meccanica Fadini is not liable for any possible damages derived from incorrect use or from any use not

indicated in this manual, furthermore it is not answerable for malfunctioning caused by the use of materials

!

or accessories not approved by the company itself.

It is to be noted that the product respects the impact and breakout resistance values as indicated provided

that the installation of the same is carried out in observance of the specications included in this manual of

instructions. Various factors are to be carefully taken into consideration such as compaction index, soil

permeability coecient, concrete type, which may aect the indicated values even signicantly.

PRODUCT SPECIFICATIONS

Heavy duty, fully retractable, automatic bollard made up of an incorporated oil-hydraulic motor pump unit and an

oil-hydraulic actuator inside the moving cylinder. Suitable for applications in private and commercial areas, and for industrial

installations. IP67. The height of the rising cylinder (from ground level) can be 500/600/800 mm. The rising cylinder is made

of S235JRH steel, thickness 4 mm and Ø 200 mm, cataphoresis treated and powder coated. Rising cylinder also available in

AISI 304 brushed stainless steel. Rubber ring on rising cylinder head. Cataphoresis treated aluminium cover with slip proof

nish on treadable top. Rising cylinder tted with high intensity, microprismatic, retroreecting approved sticker (h 80 mm),

available with signal LEDs (N.8) with ashing light tted all around the top. Hot dip galvanized steel casing for ground

foundation, tted with a cover allowing access to the hydraulic release for manual lowering of the bollard by a special

spanner in an emergency. Impact resistance 30.000 J, breakout resistance 160.000 J, static load max 1.600 kg in standing

position, max 20.000 kg in lowered position. Working temperature -40°C +80°C. Supply voltage 230 Vac ± 10%, 50 Hz.

Absorbed power 330 W. Rising time ~ 5,1 s [rising cylinder H 500 mm], ~ 5,9 s [rising cylinder H 600 mm] ~ 7,7 s [rising cylinder

H 800 mm]. Frequency of use 2.000 cycles/day. Hydraulic device to lock the bollard in the standing position, on request a

solenoid valve can be tted for the spontaneous descent of the bollard in case of a power failure.

14

Page 15

VIGILO

VIGILO

TECHNICAL DATA

ELECTRIC MOTOR

Power output 0,25 kW (0,33 HP)

Supply voltage 230 Vac

Frequency 50 Hz

Absorbed power 330 W

Absorbed current 1,8 A

Motor revolutions 2.800 rpm

Capacitor 20 μF

Service mode S3

HYDRAULIC ACTUATOR

Shaft diameter 16 mm

Piston diameter 30 mm

Pre-set pushing power 15 daN

Protection standard complete IP 55

fully retractable oil-hydraulic bollard

OIL-HYDRAULIC MOTOR-PUMP UNIT VICO 2240

Hydraulic pump P10

Pump ow rate 4,45 l/min

Working pressure 20 atm

Max pressure 40 atm

Working temperature -20 °C +80 °C

Oil type Oil Fadini - Item 708L

Static weight of pump assembly 10 kg

Pump protection standards IP 67

[A] -40 °C with specic optional accessories (Ref. General Catalogue).

[A]

English

FEATURES

Impact resistance

Crash resistance

Max static load

Bollard weight

Post diameter

Post height

Post nishing

Post material

Post material Stainless Steel/inox version

Bollard thickness

Ground sleeve treatment

[B] With Vigilo models tted with a solenoid valve,the weights are 20 kg higher than those indicated in the table.

PERFORMANCE - VIGILO 2250

Frequency of use intensive

Service cycle rise ~5,1 s

dwell 30 s

lower ~4,3 s

dwell 30 s

Complete cycle time ~69 s

Complete cycles

rise-dwell-lower-dwell No. 52/hour

Annual cycles

(with 8 hours of use per day) No. 151.840

[B]

VIGILO 2250

30.000 J

160.000 J

20.000 kg

102 kg

ø 200 mm

powder coating polyester

anthracite grey RAL 7016

PERFORMANCE - VIGILO 2263

Frequency of use intensive

Service cycle rise ~5,9 s

dwell 30 s

lower ~5,2 s

dwell 30 s

Complete cycle time ~71 s

Complete cycles

rise-dwell-lower-dwell No. 51/hour

Annual cycles

(with 8 hours of use per day) No. 148.920

500 mm

powder coating polyester

anthracite grey RAL 7016

S235J steel

AISI 304

4 mm

hot dip galvanization

VIGILO 2263

30.000 J

160.000 J

20.000 kg

110 kg

ø 200 mm

600 mm

S235J steel

AISI 304

4 mm

hot dip galvanization

PERFORMANCE - VIGILO 2280

Frequency of use intensive

Service cycle rise ~7,7 s

dwell 30 s

lower ~7,0 s

dwell 30 s

Complete cycle time ~74 s

Complete cycles

rise-dwell-lower-dwell No. 48/hour

Annual cycles

(with 8 hours of use per day) No. 140.160

VIGILO 2280

30.000 J

160.000 J

20.000 kg

131 kg

ø 200 mm

800 mm

powder coating polyester

anthracite grey RAL 7016

S235J steel

AISI 304

4 mm

hot dip galvanization

15

Page 16

VIGILO

VIGILO

OVERALL DIMENSIONS AND DIAGRAM

fully retractable oil-hydraulic bollard

100

65

55

English

45

28

24

19

Vehicle SPEED (km/h)

Vehicle

MASS (kg)

Various factors, such as the compaction index, soil permeability

coecient and kind of concrete may reduce the values indicated in

the diagram even signicantly.

Overall dimensions

Vigilo 2250

Vigilo 2263

Vigilo 2280

1.000

1.400

2.100

A

500

600

410Cø 200D410E170Fø 275

800

30.000 J

160.000 J

3.000

B

850

960

1.140

N.W. - Measurements are in millimeters (mm).

- Each Vigilo bollard is supplied equipped with electric cables of 10 meters in length

(for electric motor, limit switch, solenoid valve, leds).

C=200

AA

BD

E

F

Cable

length

10 meters

G

H

1.350

410

1.560

1.940

410

H

G

Pic. 15

Via Mantova, 177/A - 37053 Cerea (VR) Italy

Ph. +39 0442 330422 Fax +39 0442 331054

info@fadini.net - www.fadini.net

2012/19/UE Directive

GB

Re. disposal of electric

and electronic waste

DISPOSE PROPERLY OF MATERIALS

ARMFUL TO THE ENVIRONMENT

2018/11

Loading...

Loading...