Page 1

EC DECLARATION OF CONFORMITY

Manufacturer : FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: 844 T control board,

• conforms to the essential safety requirements of the following directives:

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

Additional note:

This product underwent tests in a typical uniform configuration

(all products manuf actured by FAA C S.p.A.).

Bologna, 01 January 2005

The Managing Director

A. Bassi

W ARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read

all the following instructions. Incorrect installation or incorrect use of

the product could cause serious harm to people.

2) Carefully read the instructions before beginning to install the product.

3) Do not leave packing materials (plastic, polystyrene, etc.) within reach

of children as such materials are potential sources of danger.

4) Store these instructions for future reference.

5) This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be a

source of danger.

6) FAAC declines all liability caused by improper use or use other than that for

which the automated system was intended.

7) Do not install the equipment in an explosive atmosphere: the presence of

inflammable gas or fumes is a serious danger to safety.

8) The mechanical parts must conform to the provisions of Standards EN 12604

and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the Standards

mentioned above must be observed, in addition to national legal

regulations.

9) FAAC is not responsible for failure to observe Good Technique in the

construction of the closing elements to be motorised, or for any deformation

that may occur during use.

10) The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the Standards

mentioned above must be observed, in addition to national legal

regulations.

11) Before attempting any job on the system, cut out electrical power .

12) The mains power supply of the automated system must be fitted with an allpole switch with contact opening distance of 3mm or greater. Use of a 6A

thermal breaker with all-pole circuit break is recommended.

13) Make sure that a differential switch with threshold of 0.03 A is fitted upstream

of the system.

14) Make sure that the earthing system is perfectly constructed, and connect

metal parts of the means of the closure to it.

15) The safety devices (EN 12978 standard) protect any danger areas

against mechanical movement Risks, such as crushing, dragging, and

shearing.

16) Use of at least one indicator-light (e.g. FAACLIGHT ) is recommended for

every system, as well as a warning sign adequately secured to the frame

structure, in addition to the devices mentioned at point “15”.

17) FAAC declines all liability as concerns safety and efficient operation of

the automated system, if system components not produced by FAAC

are used.

18) For maintenance, strictly use original parts by FAAC.

19) Do not in any way modify the components of the automated system.

20) The installer shall supply all information concerning manual operation of

the system in case of an emergency, and shall hand over to the user the

warnings handbook supplied with the product.

21) Do not allow children or adults to stay near the product while it is

operating.

22) Keep remote controls or other pulse generators away from children, to

prevent the automated system from being activated involuntarily.

23) Transit through the leaves is allowed only when the gate is fully open.

24 ) The user must not attempt any kind of repair or direct action whatever

and contact qualified personnel only.

25) Maintenance: check at least every 6 months the efficiency of the system,

particularly the efficiency of the safety devices (including, where

foreseen, the operator thrust force) and of the release devices.

26 ) Anything not expressly specified in these instructions is not permitted.

7

Page 2

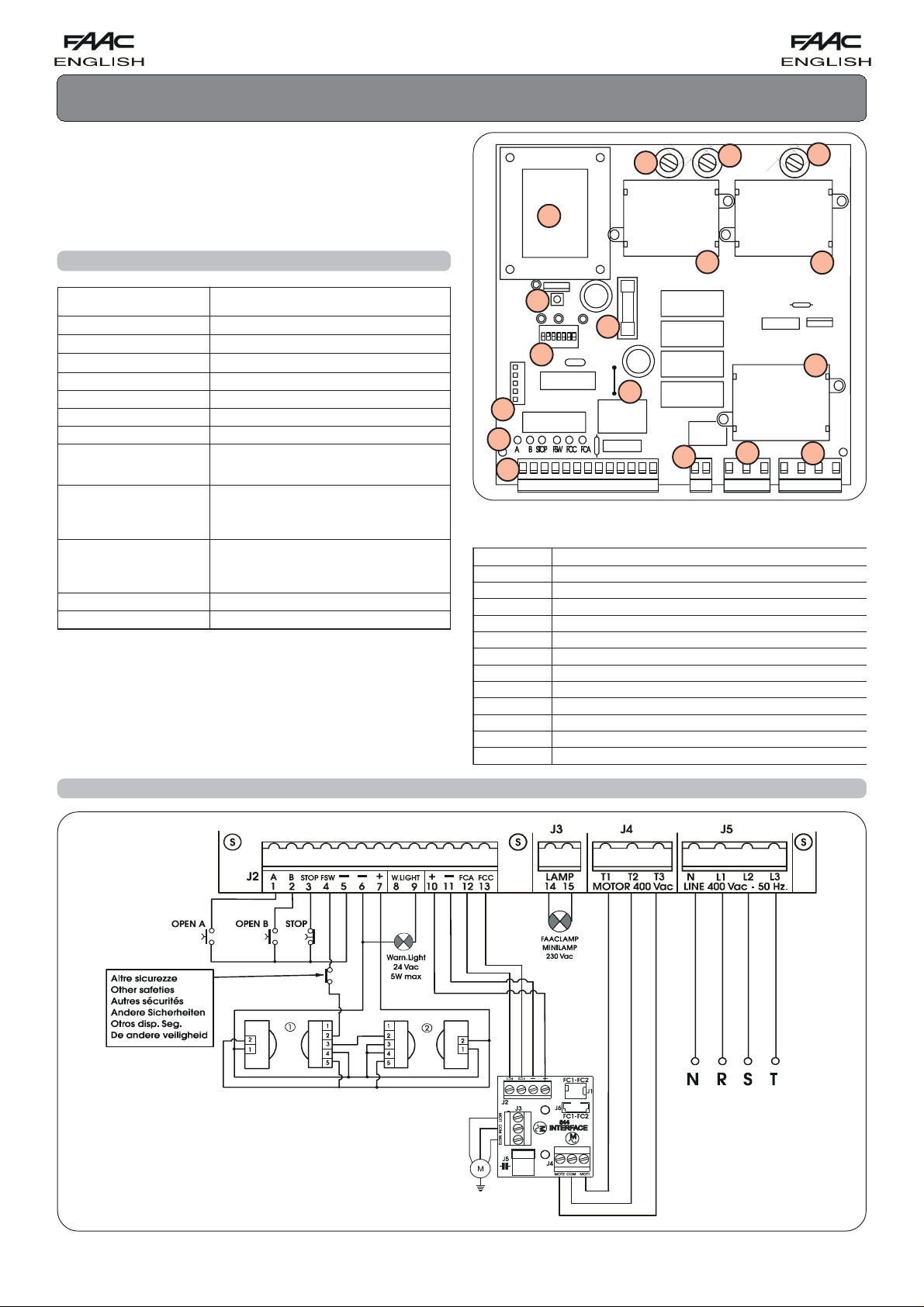

CONTROL BOARD 844 T

These instructions apply to the following model:

844T Electronic control unit

This appliance can be installed in containers mod. E, L and

LM. Before securing the card in the container, fit the supplied

support feet (long for mod. E, short for models L and LM) in the

3 S-holes (Fig.1).

1. TECHNICAL SPECIFICATIONS

ylppusrewoP

daolxamrotoM

ylppusrewopseirosseccA

daolxamseirosseccA

ylppusrewopthgilgininraW

egnarerutarepmeT

sesuF

sgulptif-kciuQ

stupnI

stuptuO

gnimmargorP

gnikarbrotoM

gnimitytefaS

.wK3,1

.cdV42

.Am005

C°55+C°02-

SROSNES-TIMIL

thgilginraw

thgilhsalf

rotom

gnihsalf-erp

dexif

.ces552

).zH05%01-%6+(hp3.caV032

).zH05%01-%6+(N+hp3.caV004

).ttaW5xam(.caV42

)1.baT(7F,6F,5F,2F

sreviecerPRrosdracgnidoced

/NEPOLAITRAP/NEPO

/ECIVEDYTEFASERUSOLC/POTS

seirossecca.cdV42otylppusrewop

06-03-51-01-5(emitesuap

).ces081-021

C/B/2E/1E/2S/1S/2A/1Ascigol

F7

F6

TF1

RL7

SW1

F2

DS1

LK1

J1

LED

J3

J2

Tab. 1 - 844 T CONTROL UNIT COMPONENTS

7F-6F-5F

2F

1WS

1SD

DEL

1J

2J

3J

4J

5J

1KL

7LR-6LR

8LR

nottub-hsupTESER

sehctiwsorcimgnimmargorP

draoblanimrettuptuorotoM

tcatnoceerfthgilgninrawrofegdirB

yalerrotoM

yalergnikarB

J4

F5

RL6

RL8

J5

)sesufylppusrewop(diparV052/A523x3,61FesuF

)seirossecca(diparV052/A6,102x52FesuF

ACF,CCF,WSF,POTS,B,AsDELgnillangissutatstupnI

sreviecerPR/sdracgnidocedrofgulptif-kciuQ

seirossecca/stupnirofdraoblanimretegatlovwoL

)W06xam~V032(draoblanimrettuptuothgilhsalF

draoblanimrettupniylppusrewopeniL

2. ELECTRICAL CONNECTIONS WITH 400V 3ph (N.B.: for connection to 230 V 3ph, see Chapter 8)

Fig. 1

8

Page 3

3. DESCRIPTION

3.1. J1 PLUG

The J1 plug is used for rapid connection of cards MINIDEC,

DECODER, RP RECEIVERS (Fig. 3, 4, 5)

Install by fitting the accessory cards so that their components

side faces the inside of the 844 T electronic appliance.

Insert and remove the cards after cutting power.

Fig. 3 Fig. 4 Fig. 5

PLUS

9 = Warning light output (24 Vac)

The maximum load of the warning light is 5 W.

For instructions on operation of the warning light, consult

microswitch programming.

!!

! If you cut out jumper LK1, you obtain a voltage free

!!

contact between terminals 8 and 9 (see Fig. 6).

10 = 24 Vdc (+) power supply for inductive limit switch

11 = Limit switch common contact

12 = Opening limit switch (N.C.)

13 = Closing limit switch (N.C.)

3.3. TERMINAL BOARD J3 (high voltage)

Terminal board for connecting flashlight (max 60W).

844MPS

844 T

MINIDEC

SL/DS

844MPS

844 T

DECODER

SL/SLP/DS

844MPS

844 T

3.2. TERMINAL BOARD J2 (low voltage)

1 = OPEN A (N.O.) – T otal opening

This is any pulse generator with N.O. contact which, when

activated, produces a gate opening movement. In A, E

and S logics, it commands both opening and closing.

To install several Open A devices, connect N.O. contacts

in parallel.

2 = OPEN B (N.O.) – Opening for pedestrians / Closing

This is any pulse generator with N.O. contact which, when

activated in logics A, E and S, produces a gate opening

movement for pedestrians. In B and C logics, it commands

a closing movement.

To install several Open B devices, connect N.O. contacts

in parallel.

3 = STOP command (N.C.)

This is any device (e.g. a push-button) which, by opening

a contact, stops gate movement.

To install several stop devices, connect the N.C. contacts

in series.

!If Stop devices are not connected, link the input to the

common contact (terminal 5) via a jumper.

4 = FSW closing safety devices contact (N.C.)

Safety devices are all devices (photocells, sensitive edges,

magnetic coils) with N.C. contact, which, if there is an

obstacle in the area they protect, operate to interrupt

gate movement. The purpose of the closing safety devices

is to protect the gate movement area during closing.

If the safety devices are tripped during closure, gate

movement is reversed, whereas they have no effect during

opening. If used when the gate is open or pausing, closing

safety devices prevent its closing.

To install several safety devices, connect the N.C. contacts

in series.

!!

! If closing safety devices are not connected, link this

!!

input to the common contact (terminal 5) via a jumper.

5 = Common contact for commands

6 = Negative of accessories power supply

7 = 24 Vdc (+) power supply for accessories

Max load of accessories is 500 mA.

To calculate absorption values, refer to the instructions

for individual accessories.

3.4. TERMINAL BOARD J4 (high voltage)

Terminal board for connection of motor.

3.5. TERMINAL BOARD J5 (high voltage)

Terminal board for supplying power of 400V 3ph + Neutral - 50 Hz

(see Fig. 1) or 230V 3ph - 50 Hz (see Fig. 8).

Connect the yellow-green earth cable as shown in Fig. 7.

!!

INTERRUPTED LK1

!

COMPLETE LK1

7

6

8

24V~ 5W max

9

Fig. 6

!!

(Free contact)

8

2A max

9

Fig. 7

9

Page 4

3.6. SIGNALLING LEDs

6 LEDs are fitted on the card, indicating status of terminal board

inputs:

LED

LIGHTED

LED

= contact closed

OFF

= contact open

Tab. 2 - STATUS OF LEDS

DELDETHGILFFO

ANEPO

BNEPO

POTS

WSF

CCF

ACF

evitcadnammoC

evitcadnammoC

evitcanidnammoC

gnitarepotonsecivedytefaS

eerfrosnestimilgnisolC

eerfrosnestimilgninepO

evitcanidnammoC

evitcanidnammoC

evitcadnammoC

gnitareposecivedytefaS

degagnerosnestimilgnisolC

degagnerosnestimilgninepO

NB.: The status of the LEDs while the gate is closed at rest are

shown in bold.

4.1. FUNCTION LOGICS

The following are available:

A1/A2 = “Automatic” S1/S2 = “Safety”

E1/E2/B = “Semi-automatic” C = “Dead man”

Operation of automation in the different logics is indicated in

Tables 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10.

4.2. PAUSE TIME

Pause time is waiting time in open position before re-closing

when an automatic logic was selected.

Pause times include pre-flashing if any

4. PROGRAMMING

To program operation of automation, use the microswitches as

shown below.

Logic SW1 SW2 SW3

E1 ON ON ON

B OFF ON ON

S2 ON OFF ON

E2 OFF OFF ON

A1 ON ON OFF

C OFF ON OFF

S1 ON OFF OFF

A2 OFF OFF OFF

ON

1 2 3 4 5 6 7

OFF

Operation of warning light

Closed Opening/Open Closing

SW6

ON

Light

Off

OFF

(1) Pause times include pre-flashing if any

(2) Pre-flashing begins 5” before every movement.

Gate status

Steady light

Light

Flashing

! You must press the RESET push-button after every program-

ming job.

Pause time (sec) (1)

Logic

A1-A2-S2 S1 SW4 SW5

515ONON

10 30 OFF ON

30 60 ON OFF

120 180 OFF OFF

Pre-flashing (2)

Yes ON

No OFF

SW7

4.3. OPERATION OF WARNING LIGHT

Used to change the appearance of the warning light at closing

by making it flash.

4.4. PRE-FLASHING

Flashlight pre-flashing time of 5 sec before any movement can

be selected. This warns anyone near the gate that it is about to

move.

5. FAULT CONDITIONS

The following conditions cause certain effects to normal operation of automation:

햲 microprocessor error

햳 safety electronic timing tripped (operation is interrupted if

continuous work time exceeds 255 sec. ).

햴 limit sensors disconnected (or both engaged)

• Conditions 햲 and 햳 cause automation to stop and nothing

more.

• Condition 햴 causes an alarm situation disabling any activity:

• Normal operation can be restored only after eliminating the

alarm cause and pressing the RESET push-button (or turning

off power supply momentarily).

• To have this condition signalled, the warning light must be

connected: the alarm is signalled by very rapidly flashing light

(0.25 sec).

10

Page 5

6. LIMIT SENSORS CONNECTION CHECK

1) Manually take the gate toward opening position, and

check if, with the leaf open, the FCC LED is lighted and the

FCA LED is off.

2) Manually take the gate toward closing position, and check

if, with the leaf closed, the FCA LED is lighted and the FCC

LED is off.

2) If the LEDs are inverted, changeover the cables conected to

trminals 12 and 13.

7. ROTATION DIRECTION CHECK

1) Release the operator, take it manually to mid-travel and relock it.

2) Power up the system and then press the RESET push-button.

3) Give an Open command to the operator, check if the gate

moves in opening direction and then press the RESET pushbutton to stop the leaf moving.

4) If rotation direction is incorrect, change over wiring of cables

T1 and T3 of the electric motor.

8. ELECTRICAL CONNECTIONS WITH 230V 3ph

To connect the 844 T appliance to a 3-phase 230 V mains, observe the diagram in Fig. 8.

N.B.: The electric motor of the gearmotor must be 230V 3-phase.

Fig. 8

11

Page 6

Tab. 3 - LOGIC A1 (AUTOMATIC)

"1A"cigoLSESLUP

SUTATSSETAG)1(BNEPO-ANEPOPOTSSECIVEDYTEFAS

DESOLC

ESUAPNONEPO

GNISOLC

GNINEPO

DEPPOTS

retfasesolcdnasnepO

)2(emitesuap

)3("5retfasesolc-eRtnuocehtspotStnemegagnesidlitnuesuapsezeerF

noitomsesreveRspotSnoitomsesreveR

tceffeoNspotStceffeoN

)2(sesolc-eRtceffeoNtceffeoN

tceffeoNtceffeoN

Tab. 7 - LOGIC E1 (SEMI-AUTOMATIC)

"1E"cigoLSESLUP

SUTATSSETAG)1(BNEPO-ANEPOPOTSSECIVEDYTEFAS

DESOLC

NEPO

GNISOLC

GNINEPO

DEPPOTS

)2(snepOtceffeoNtceffeoN

)2(sesolc-eRtceffeoNtceffeoN

noitomsesreveRspotSnoitomsesreveR

spotSspotStceffeoN

secivedytefasnehw(sesolc-er

)2()snepo-erti,degagne

tceffeoNtceffeoN

Tab. 4 - LOGIC A2 (AUTOMATIC PLUS)

"2A"cigoLSESLUP

SUTATSSETAG)1(BNEPO-ANEPOPOTSSECIVEDYTEFAS

DESOLC

ESUAPNONEPO

GNISOLC

GNINEPO

DEPPOTS

retfasesolcdnasnepO

)2(emitesuap

)3("5retfasesolc-eRtnuocehtspotS

noitomsesreveRspotS

tceffeoNspotStceffeoN

)2(sesolc-eRtceffeoNtceffeoN

Tab. 5 - LOGIC S1 (SAFETY)

"1S"cigoLSESLUP

SUTATSSETAG)1(BNEPO-ANEPOPOTSSECIVEDYTEFAS

DESOLC

ESUAPNONEPO

GNISOLC

GNINEPO

DEPPOTS

retfasesolcdnasnepO

)2(emitesuap

)3-2(yletaidemmisesolCtnuocehtspotS

noitomsesreveRspotSnoitomsesreveR

noitomsesreveRspotStceffeoN

)2(sesolc-eRtceffeoNtceffeoN

tceffeoNtceffeoN

tceffeoNtceffeoN

Tab. 8 - LOGIC E2 (SEMI-AUTOMATIC PLUS)

"2E"cigoLSESLUP

SUTATSSETAG)1(BNEPO-ANEPOPOTSSECIVEDYTEFAS

DESOLC

,degagnesidnehW

"5retfasesolc-er

sesreverdnaspotS

)2(tnemegagnesidta

NEPO

GNISOLC

GNINEPO

DEPPOTS

)2(snepOtceffeoNtceffeoN

)2(sesolc-eRtceffeoNtceffeoN

noitomsesreveRspotS

spotSspotStceffeoN

ytefasnehw(sesolc-eR

)2(

)snepo-erti,degagnesecived

tceffeoNtceffeoN

sesreverdnaspotS

)2(tnemegagnesidta

Tab. 9 - LOGIC B (SEMI-AUTOMATIC)

"B"cigoLSESLUP

SUTATSSETAGANEPO)4(BNEPOPOTSSECIVEDYTEFAS

DESOLC

,degagnesidnehw

”5retfasesolc-er

NEPO

GNISOLC

GNINEPO

DEPPOTS

)2(snepOtceffeoNtceffeoNtceffeoN

tceffeoN)2(sesolCtceffeoNgnisolcstneverp

tceffeoNtceffeoNtnemevomspotStnemevomspotS

tceffeoNtceffeoNtnemevomspotStceffeoN

)2(gnineposetelpmoC)2(gnisolcsetelpmoCtceffeoNgnisolcstneverp

Tab. 6 - LOGIC S2 (SAFETY PLUS)

"2S"cigoLSESLUP

SUTATSSETAG)1(BNEPO-ANEPOPOTSSECIVEDYTEFAS

DESOLC

ESUAPNONEPO

GNISOLC

GNINEPO

DEPPOTS

retfasesolcdnasnepO

)2(emitesuap

)3-2(yletaidemmisesolCtnuocehtspotStnemegagnesidlitnuesuapsezeerF

noitomsesreveRspotS

noitomsesreveRspotStceffeoN

)2(sesolc-eRtceffeoNtceffeoN

tceffeoNtceffeoN

tasesreverdnaspotS

)2(tnemegagnesid

Tab. 10 - LOGIC C (DEAD MAN)

"C"cigoL

SUTATSSETAG)5(ANEPO)5dna4(BNEPOPOTSSECIVEDYTEFAS

DESOLC

NEPO

GNISOLC

GNINEPO

DEPPOTS

snepOtceffeoNtceffeoNtceffeoN

tceffeoNsesolCtceffeoNgnisolcstneverp

tceffeoNtnemevomspotStnemevomspotS

gnineposetelpmoC

(1) OPEN B input commands partial opening.

(2) With pre-flashing selected, movement begins after 5 sec.

(3) If the pulse is sent during pre-flashing, counting is restarted.

(4) OPEN B input commands closing.

(5) Push-button must be kept pressed to activate gate movement. When the push-button is released, the gate stops.

12

NWODDLEHSLORTNOC

YLSUOUNITNOC

tceffeoNtnemevomspotStceffeoN

setelpmoC

gnisolc

SESLUP

tceffeoNgnisolcstneverp

Loading...

Loading...