Page 1

ENGLISHENGLISH

5. START-UP

5.1. CONNECTION TO ELECTRONIC CONTROL UNIT

Warning: Always turn off the electricity supply before

carrying out any work on the electronic control unit

(connections, programming, maintenance).

Observe points 10, 11, 12, 13 and 14 in the GENERAL SAFETY

INSTRUCTIONS.

Since the system requires two different power supplies (230

and 400 Vac), install two differential magneto-thermal

circuit breakers with adequate trip threshold up-line of the

system.

Connect the earth cable to the connection on the base of

the operator. See fig. 15.

The gearmotor is provided with a safety device (Fig.1 Ref.

7) operated by the relase system.

While activated the safety device keeps the gearmotor

from making any movement.

As shown in Fig. 3, prepare the conduits and make the

electrical connections from the 844MPST electronic control

unit to the chosen accessories.

Always route the power supply cables separately from the

control and safety cables (keyswitch, receiver, photocells,

etc.). Use separate conduits to avoid any interference.

Table 2 Technical specifications 844MPST

Power supply 230 V (+6% - 10%) 50 Hz

Absorbed power 10W

Max. motor load 800W

Max. electric lock load 0.5A

Temperature range -20 °C +55 °C

Fuses 3 (see fig. 5.1.1)

Operation logics Automatic / Semiautomatic /

Safety / Semiautomatic B /

Deadman C

Pause time Adjustable by dip-switches

Terminal block inputs Open / Partial opening-Close

Stop / Closing safeties /

Power supply

Terminal block outputs Flashing light - motors -

24 Vdc accessories power supply -

24 Vdc warning lamp power supply -

Quick connector Decoder cards / RP-SL-DS

Programmable functions Operating logics / Pause times /

Warning lamp operation

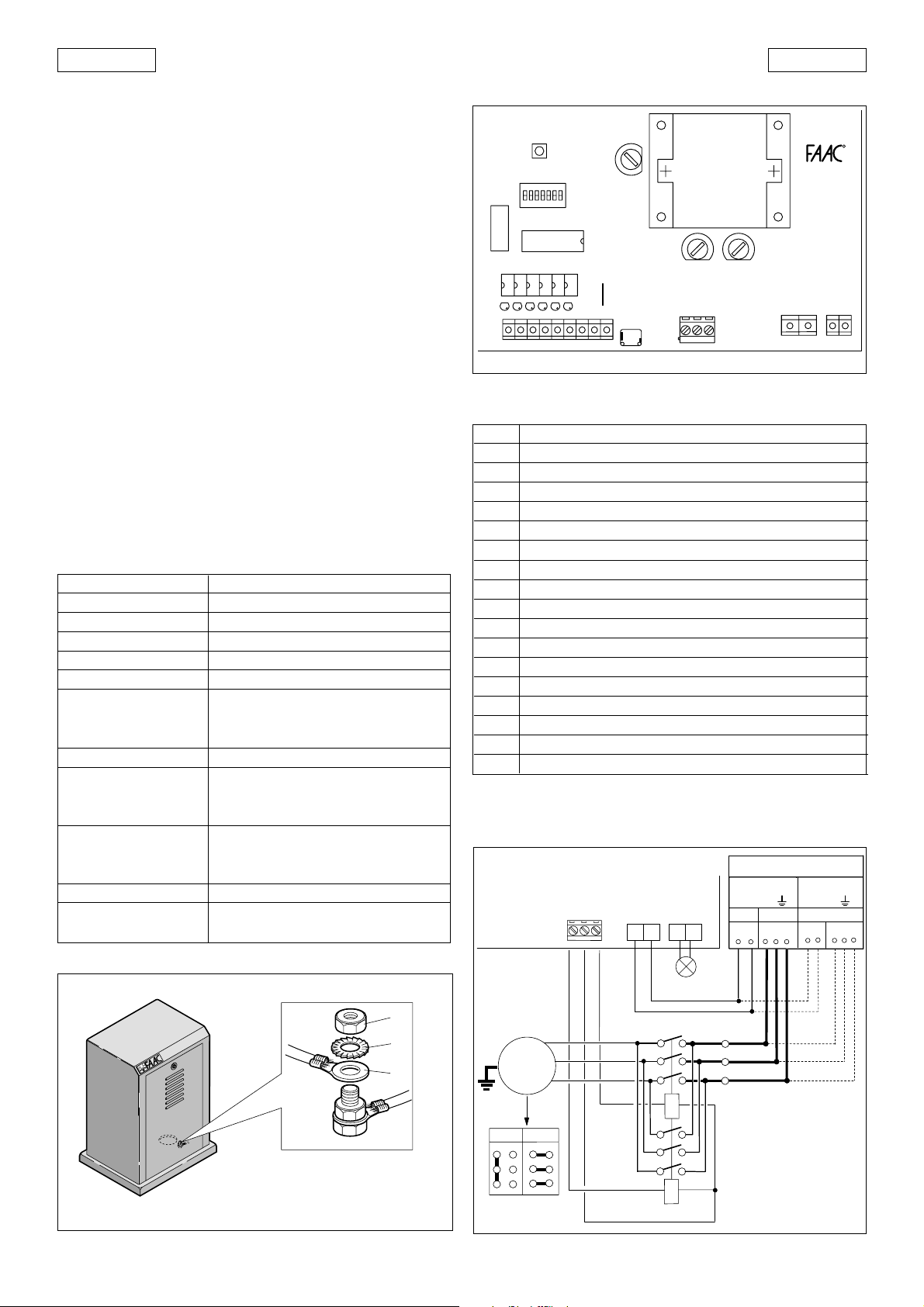

5.1.1. LAYOUT AND ELECTRICAL CONNECTIONS

F2

LK1

ACCESS.

J3

TRASF.

F3

J5

F1

J8

LN

P1

RESET

DS1

J1

DECODER

DECODER-SL

DL6

DL1 DL2 DL3 DL4 DL5

CLOSE OPEN STOP FSW FCC FCA

J2

123456789

Table 3 Control unit components 844MPST

LD1 OPEN LED

LD2 STOP LED

LD3 SAFETY LED

LD4 CLOSURE LIMIT SWITCH LED

LD5 OPENING LIMIT SWITCH LED

LD6 LED OPEN PARTIAL / CLOSE

P1 RESET BUTTON

J1 DECODER CONNECTOR

J2 LOW VOLTAGE TERMINAL BLOCK

J3 LIMIT SWITCH CONNECTOR

J5 CONTACTOR CONNECTION TERMINAL BLOCK

J7 FAAC LAMP CONNECTION TERMINAL BLOCK

J8 POWER SUPPLY

F1 CONTACTOR FUSE (F5 A)

F2 ACCESSORIES FUSE (T 1.6 A)

F3 TRANSFORMER FUSE (T250 mA)

LK1 WARNING LAMP FREE CONTACT

DS1 PROGRAMMING DIPSWITCH

5.1. 2 HIGH VOLTAGE ELECTRICAL CONNECTIONS

POWER SUPPLY

844 MPST

J5

AP COM CH

J8

J7

400V

3Ph+N+

230V

NR

380V

R

T

S

844MPS

J7

Fig. 16

230V

3Ph+

230V

R

SRS

T

1

2

3

Fig. 15

15

M 3Ph

400 230

T1

T2

T3

FLASHING LIGHT

A1

C1

A1

C2

(max 60W)

A2

A2

L1

L2

L3

Fig. 17

Page 2

ENGLISH

ENGLISH

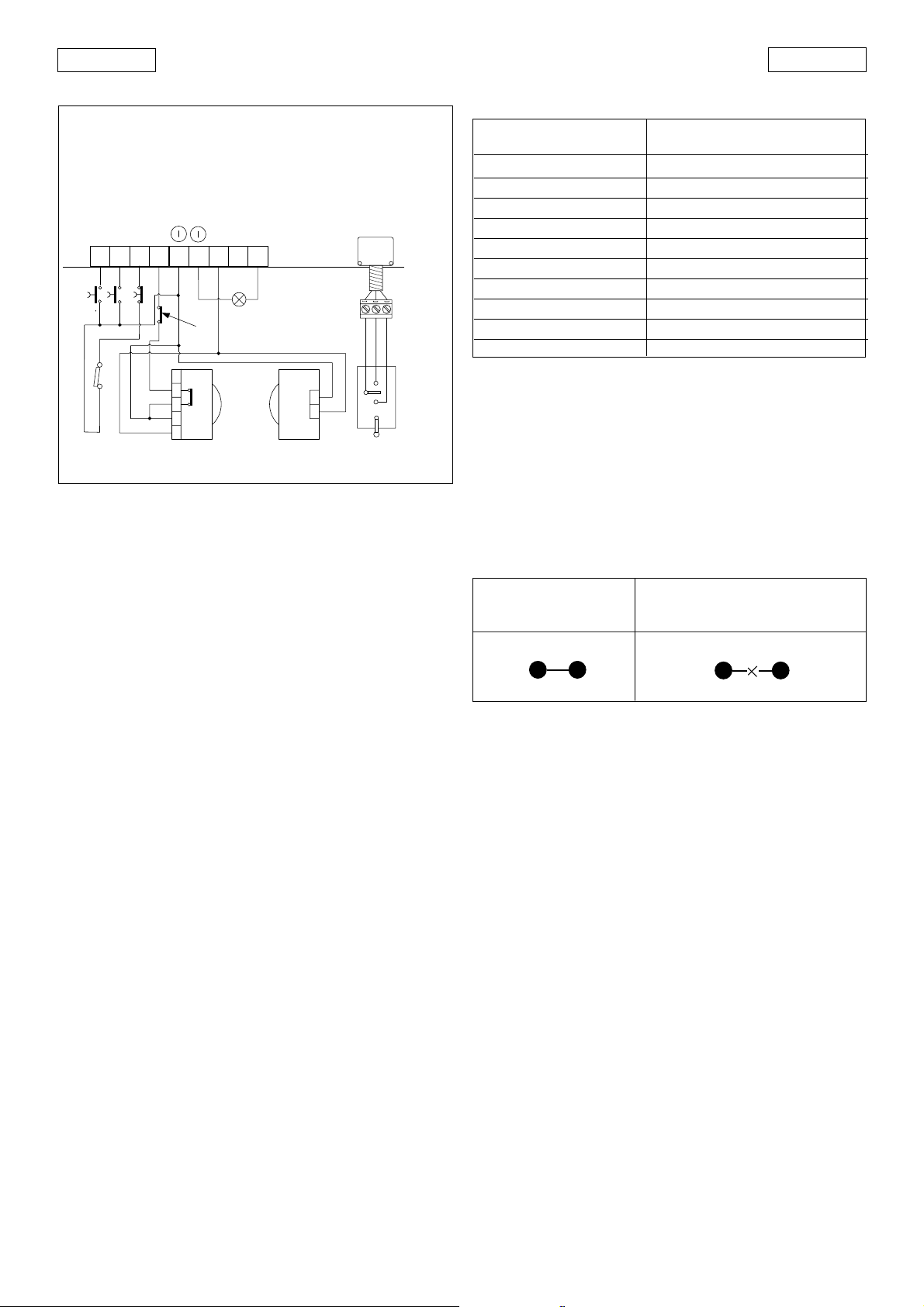

Tab. 4Accessories current draw

TYPE OF ACCESSORY NOMINAL CURRENT DRAW

/ COM

844MPST

WHITE

J3

BROWN

GREEN

MS3

Fig. 18

A/C

OPEN

STOP

FSW

J2

1 23456789

MS1

1

2

3

4

5

+24 Vdc

Warning

light

5W max

Other

Safeties

CLOSING

PHOTOCELLS

W. LIGHT

+24 Vac

1

2

a Low voltage terminal block J2 (Fig. 16) is used to

connect all accessories (see Table 4).

1. A/C Partial opening

This means any control device with a N.O. contact

which causes partial opening of the gate when

activated in E1, E2, A1, A2, S1 or S2 logics. In B and C

logics it causes the gate to close. To install more than

one partial opening control device, connect the N.O.

contacts in parallel.

2. OPEN

This means any control device with a N.O. contact

which causes the gate to open when activated. In

automatic and semiautomatic logics it is active for

both opening and closure. To install more than one

opening control device, connect the N.O. contacts in

parallel.

3. STOP

This means a control device with a N.C. contact which

causes the gate status (opening-pause-closure) to be

interrupted until the next impulse is sent. To install more

than one stop device, connect the N.C. contacts in

series to MS1 and MS2.

4. FSW SAFETIES

This means all devices (photocells, safety edges,

magnetic loops) with a N.C. contact which stop the

movement of the gate when an obstacle is present in

the area protected by the safety devices. To install

more than one safety device, connect the N.C.

contacts in series.

N.B.: if safety devices are not connected, jumper

terminals 4 and 5 on the electronic control unit.

5.

Controls common and accessories power supply

negative

6. 24 Vac output for warning lamp power supply

7. +24 Vdc accessories power supply positive

Warning: the maximum load of the accessories is 500mA.

To calculate power consumption refer to the corresponding

table.

PLUS 40SL 30mA

PLUS E 20mA

MINIDEC SL / DS 6mA

DECODER SL/DS 20mA / 55mA

RP ESL / EDS 12mA / 6mA

DIGICARD 15mA

METALDIGIKEY 15mA

FOTOSWITCH 90mA

DETECTOR F4 / PS6 50mA

PHOTOBEAM 50mA

W.LIGHT (terminals 6 - 8 - 9)

These are the 24 Vdc terminals to which the warning lamp

must be connected. With jumper LK1 intact it is possible to

power a 24V / 5W max. warning lamp between terminals

6 and 9. In case a potential free contact is needed

between the terminal strips 8 and 9, the link LK1must be

cut. (see Table 5).

WARNING: If the jumper LK1 is broken, the 24 Vac

accessories power supply (terminals 6 and 8) is no longer

available.

Table 5: Warning lamp connection

LK1 INTACT LK1 BROKEN

(FREE CONTACT)

b Connector J3 limit switch unit connection

c Terminal block J5 contactor connection

The motor control contactors must be connected to

these terminals.

d Terminal block J6 (fig. 16)

L: 230V power supply (live)

N: 230V power supply (neutral)

e Terminal block J7 (fig. 16)

Flashing light output (230V)

6. BEHAVIOUR OF SAFETY DEVICES

The safety devices operate during closure only. In "A1", "E1"

and "S1" logics, interrupting the safety device contacts

causes the gate to stop closing and start opening

immediately. In "A2", "E2" and "S2" logics, interrupting the

safety device contacts causes the gate to stop closing,

then to start opening again when the safety devices are

released.

In "B" and "C" logics, interrupting the safety device contacts

causes the gate to stop closing.

7. DIPSWITCH SETTINGS

To program automation operation, set the dipswitches as

shown in the diagram below.

16

Page 3

Logic SW1 SW2 SW3

E1 ON ON ON

B OFF ON ON

S2 ON OFF ON

E2 OFF OFF ON

A1 ON ON OFF

C OFF ON OFF

S1 ON OFF OFF

A2 OFF OFF OFF

1234567

Warning lamp operation

Closed Opening/Open Closing

SW6

ON

OFF

(1) Pause times include pre-flashing.

(2) Pre-flashing commences 5 seconds before the start of each

movement.

Off

Gate status

Steady light

Pause time (sec) (1)

Logic

A1 A2 S2 S1 SW4 SW5

515ONON

10 30 OFF ON

30 60 O N OFF

120 180 OFF OFF

Pre-flashing (2) SW7

Yes ON

No OFF

Steady light

Flashing

N.B.: PRESS THE RESET BUTTON AFTER ALL PROGRAMMING

OPERATIONS.

8. OPERATION IN VARIOUS LOGICS

The following 8 logics are available:

E1/E2/B: "Semiautomatic" A1/A2: "Automatic"

S1/S2: "Safety" C: "Deadman"

Operation of the various logics is shown in tables 6-7-8-9-10-1112-13.

TABLE 6 LOGIC E1 (SEMIAUTOMATIC)

LOGIC E1

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN - A/C (1) -

opens (2)

recloses (2

inverts motion

stops

recloses (reopens when safety

devices are engaged) (2)

IMPULSES

STOP

no effect

no effect

stops

stops

no effect

SAFETY

no effect

no effect

inverts motion

no effect

no effect

TABLE 7 LOGIC E2 (SEMIAUTOMATIC)

TABLE 8 LOGIC A1 (AUTOMATIC)

LOGIC A1

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN - A/C (1) -

opens and recloses after

pause time (2)

recloses after 5 s (3)

inverts motion

no effect

recloses (2)

TABLE 9 LOGIC A2 (AUTOMATIC)

LOGIC A2

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN - A/C (1) -

opens and recloses after

pause time (2)

recloses after 5 s

(3)

inverts motion

no effect

recloses (2)

TABLE 10 LOGIC S1 (SAFETY)

LOGIC S1

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN - A/C (1) -

opens and recloses after

pause time (2)

recloses immediately

(2 and 3)

inverts motion

inverts motion

recloses (2)

TABLE 11 LOGIC S2 (SAFETY)

LOGIC S2

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN - A/C (1) -

opens and recloses after

pause time (2)

recloses immediately

(2 and 3)

inverts motion

inverts motion

recloses (2)

TABLE 12 LOGIC B (SEMIAUTOMATIC)

LOGIC B IMPULSES

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN

opens (2)

no effect

no effect

no effect

completes

opening (2)

A/C (5)

no effect

closes (2)

no effect

no effect

completes

closing (2)

TABLE 13 LOGIC C (DEADMAN)

LOGIC C IMPULSES

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

OPEN (4)

opens

no effect

no effect

completes opening

A/C (4 and 5)

no effect

closes

no effect

completes closing

IMPULSES

STOP

no effect

stops counting

stops

stops

no effect

IMPULSES

STOP

no effect

stops counting

stops

stops

no effect

IMPULSES

STOP

no effect

stops counting

stops

stops

no effect

IMPULSES

STOP

no effect

stops counting

stops

stops

no effect

SAFETY (until

disengagement)

no effect

inhibits closing

stops

no effect

inhibits closing

SAFETY (until

disengagement)

no effect

inhibits closing

stops

no effect

inhibits closing

ENGLISHENGLISH

SAFETY

no effect

freezes pause until

disengagement

no effect

no effect

no effect

SAFETY

no effect

recloses after 5 s when

disengaged

inverts motion

no effect

no effect

SAFETY

no effect

recloses after 5 s when

disengaged

inverts motion

no effect

no effect

SAFETY

no effect

freezes pause until

disengagement

stops and inverts motion

when disengaged (2)

no effect

no effect

STOP

no effect

no effect

stops movement

stops movement

no effect

STOP

no effect

no effect

stops

stops

stops

no effect

LOGIC E2

GATE STATUS

CLOSED

OPEN

CLOSING

OPENING

STOPPED

IMPULSES

OPEN -A/C(1)-

opens (2)

recloses (2)

inverts motion

stops

recloses (reopens when safety

devices are engaged) (2)

STOP

no effect

stops counting

stops

stops

no effect

SAFETY

no effect

no effect

freezes pause until

disengagement

no effect

no effect

17

(1) The A/C input enables partial opening.

(2) With pre-flashing selected movement starts after 5

seconds.

(3) If the impulse is sent after pre-flashing the timer recounts.

(4) For operation in C logic keep the pushbutton depressed.

Movement stops upon release.

(5) The A/C input controls closure.

Loading...

Loading...