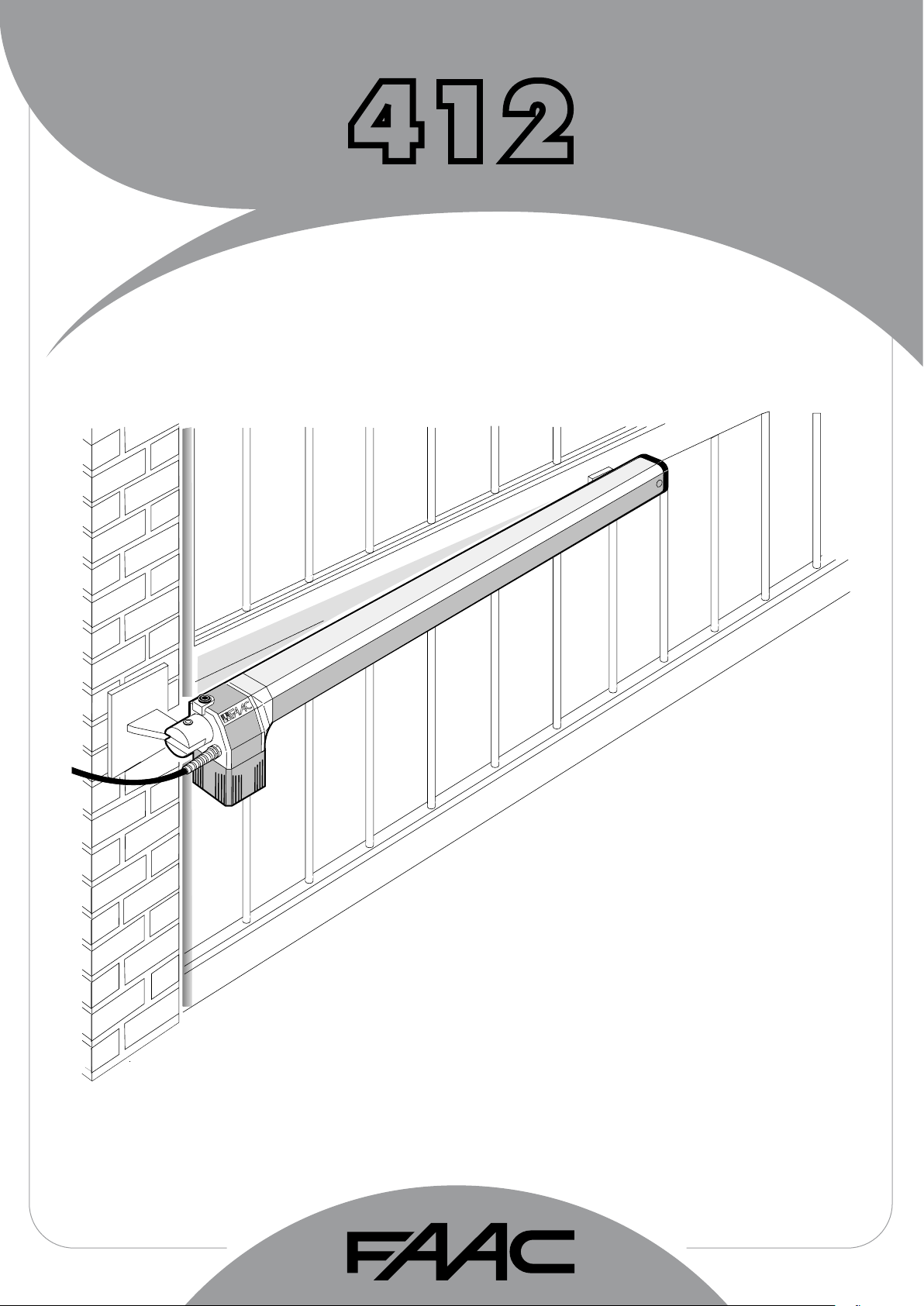

Page 1

412

Page 2

Page 3

ENGLISH

EC DECLARATION OF CONFORMITY FOR MACHINES

(DIRECTIVE 2006/42/EC)

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

ENGLISH

Declares that:

Operator mod. 412

is built to be integrated into a machine or to be assembled with other machinery to create a machine under

the provisions of Directive 98/37/EC;

conforms to the essential safety requirements of the following EEC directives:

2006/95/EC Low Voltage Directive

2004/108/EC Electromagnetic Compatibility Directive

and also declares that it is prohibited to put into service the machinery until the machine in which it will be

integrated or of which it will become a component has been identified and declared as conforming to the

conditions of Directive 2006/42/EEC and subsequent amendments.

Bologna, 01-01-2009

The Managing Director

A. Marcellan

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read

all the following instructions. Incorrect installation or incorrect use of

the product could cause serious harm to people.

2) Carefully read the instructions before beginning to install the product.

3) Do not leave packing materials (plastic, polystyrene, etc.) within reach

of children as such materials are potential sources of danger.

4) Store these instructions for future reference.

5) This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be

a source of danger.

6) FAAC declines all liability caused by improper use or use other than that

for which the automated system was intended.

7) Do not install the equipment in an explosive atmosphere: the presence

of inflammable gas or fumes is a serious danger to safety.

8) The mechanical parts must conform to the provisions of Standards EN

12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the Stand

ards mentioned above must be observed, in addition to national legal

regulations.

9) FAAC is not responsible for failure to observe Good Technique in the

construction of the closing elements to be motorised, or for any defor

mation that may occur during use.

10) The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the Stand

ards mentioned above must be observed, in addition to national legal

regulations.

11) Before attempting any job on the system, cut out electrical power.

12) The mains power supply of the automated system must be fitted with an

all-pole switch with contact opening distance of 3 mm or greater. Use

of a 6A thermal breaker with all-pole circuit break is recommended.

13) Make sure that a differential switch with threshold of 0.03 A is fitted

upstream of the system.

14) Make sure that the earthing system is perfectly constructed and con

nect metal parts of the closure to it.

15) The automated system is supplied with an intrinsic anti-crushing safety

device consisting of a torque control. Nevertheless, its tripping thresh

old must be checked as specified in the Standards indicated at point

10.

16) The safety devices (EN 12978 standard) protect any danger areas

against mechanical movement Risks, such as crushing, dragging, and

shearing.

17) Use of at least one indicator-light (e.g. FAACLIGHT ) is recommended

for every system, as well as a warning sign adequately secured to the

frame structure, in addition to the devices mentioned at point “16”.

18) FAAC declines all liability as concerns safety and efficient operation of

the automated system, if system components not produced by FAAC

are used.

19) For maintenance, strictly use original parts by FAAC.

20) Do not in any way modify the components of the automated sys

tem.

-

21) The installer shall supply all information concerning manual operation

of the system in case of an emergency and shall hand over to the user

the warnings handbook supplied with the product.

22) Do not allow children or adults to stay near the product while it is

operating.

23) Keep remote controls or other pulse generators away from children,

to prevent the automated system from being activated involuntarily.

-

24) Transit is permitted only when the automated system is idle.

25) The user must not attempt any kind of repair or direct action whatever

and contact qualified personnel only.

26) Check at least every 6 months the efficiency of the system, particularly

the efficiency of the safety devices (including, where foreseen, the

operator thrust force) and of the release devices.

27) Anything not expressly specified in these instructions is not permit

ted.

-

-

-

-

5

Page 4

ENGLISH ENGLISH

412 AUTOMATION SYSTEM

These instructions apply to the following models:

Operators 412 and 412-24V

The FAAC 412 AUTOMATION SYSTEM for swing gates comprises

two electromechanical operators which drive the gate leaves

by means of a worm screw.

The system locks mechanically; therefore no electric lock is

required.

ÜÜ

Ü To obtain anti-crushing protection, you have to use elec-

ÜÜ

tronic control units with a torque control electronic device.

The 412 automation was designed and manufactured to control access of vehicles.

Avoid any other use whatever.

1. DESCRIPTION AND TECHNICAL SPECIFICATIONS

4

3

7

5

Drawing A

a

INSTALLATION DIMENSIONS

b

d

z

892

80

Table A: Recommended dimensions

Opening a b c (*) d (**)

αα

angle "

α" (mm) (mm) (mm) (mm)

αα

90° 145 145 290 100

110° 125 125 290 80

(*) working excursion of piston rod (**)maximum dimensions

Fig. A

a

Motor Unit

b

Power cable

c

162

Worm screw

d

Front bracket

e

Rear bracket

f

Cable cover

g

Cover

Fig. 1

Table 1:

Power supply 230 V~ 50 Hz 24Vdc

Absorbed power (W) 280 70

Current drawn (A) 1,5 3

Electric motor 1400 rpm

Motor winding thermal cutout 140 °C /

Capacitor 8 µF/400V /

Max. thrust/traction force (daN) 350 250

Rod stroke (mm) 290

Rod speed (cm/s) 1,6

Temperature range (°C) -20 v +55 °C

Operator weight (Kg) 6,5

Housing protection IP 44

Duty cycle (cycles/hour ) 18 50

Maximum leaf length (m) 1,80

412 operator technical specifications

412 412-24V

CALCULATING INSTALLATION DIMENSIONS:

GENERAL RULES

If modifications to the dimensions specified in Table A

are necessary, proceed as follows:

- For 90° leaf opening: a + b = c

- For leaf opening over 90°: a + b < c

- The lower the dimensions of a and b the higher the gate

speed. Always respect current standards.

- Limit the difference between a and b to within 4 cm: larger

differences alter speed considerably during opening and

closing.

- For reasons of operator clearance, the minimum value for

Z is 45 mm (fig. A)

If the dimensions of the gate post or position of the hinge do

not allow for the specified distance of “a”, make a recess

in the gate post as shown in fig. B.

100 mm

300 mm

150 mm

Fig. B

6

Page 5

ENGLISHENGLISH

2. STANDARD INSTALLATION LAYOUT

a Operators 412

b Photocells

c Control unit

d Pushbutton

e Receiver

f Flashing light

•Use suitable rigid/flexible pipes for laying power cables.

•Always keep low voltage accessory cables separate from 230V~ power

cables. To avoid interference, use separate sheaths.

Fig. 2

3. INSTALLATION OF THE AUTOMATION SYSTEM

3.1. PRELIMINARY CHECKS

To ensure trouble-free operation, make sure that the gate

(whether existing or yet to be installed) has the following

specifications:

• max. length of each gate leaf: 1.8 metres

• strong and rigid leaf frame

• smooth gate movement, with no stiff points

• hinges in good condition

• mechanical travel limit stops

If any welding or brazing has to be done on the gate, do this

before installing the automation system. The good order of the

structure directly influences the reliability and safety of the

automation system.

3.2. INSTALLATION OF THE OPERATORS

1) Fix the rear bracket to the gate post according to the

instructions in Table A. Adjust the length of the bracket if

necessary.

Warning:

correct operator functioning.

In the case of iron gate posts, weld the bracket directly

onto the gate post.

In the case of brick/concrete gate posts, flush-mount a

wall plate (fig. 3), and weld the bracket to the plate.

2) Fix the operator to the rear bracket by means of the screws

supplied (fig. 3).

Observe the specified dimensions to ensure

Caution: the operators supplied in the kit are left and right

hand versions.

For correct installation the operator must be positioned as

shown in fig. 3.

3) Release the operator (see paragraph 5).

4) Extend the rod to the end of its stroke (fig. 4).

5) Lock the operator (see paragraph 6).

6) Rotate the operator rod two full turns clockwise (fig. 4).

7) Fit the front bracket onto the rod as shown in fig. 5.

8) Close the gate leaf and, keeping the operator perfectly

horizontal, locate the leaf attachment position of the front

bracket (fig. 6).

9) Fix the front bracket temporarily to the leaf by two welds.

N.B.: If the gate frame does not allow for secure fixing of

the bracket, add a support plate.

Fig. 4

Fig. 5

Fig. 3

Fig. 6

10) Release the operator and ensure that the gate opens

smoothly with no stiff points and that it stops on the

mechanical travel stops.

11) Completely weld the front bracket to the leaf. To weld,

detach the operator temporarily from the bracket to

prevent any waste material from damaging it.

7

Page 6

ENGLISH ENGLISH

SBLOCCA

DESBLOQUEAR

DEBLOQUE

UNLOCK

ENTRIEGELT

BLOCCA

BLOQUEAR

BLOQUE

LOCK

VERRIEGELT

SBLOCCA

DESBLOQUEAR

DEBLOQUE

UNLOCK

ENTRIEGELT

BLOCCA

BLOQUEAR

BLOQUE

LOCK

VERRIEGELT

N.B.: 1) Grease all pivots on brackets

2) If welding is not possible, the front and rear

bracket plates are also designed for fixing by

screws and screw anchors.

12) Fit the cover (fig. 7) on the operator as shown in fig. 8.

N.B.: Fix the guide support of the cover on the hole furthest

from the cap (fig.7).

13) Repeat the above operations to install the second operator.

14) Make the control unit connections.

15) Programme the control unit to set the specific installation

requirements.

Fig. 7

4. TESTING THE AUTOMATED UNIT

On completing installation, affix a danger warning adhesive

label in a clearly visible position on the side of the operator (fig.

9).

Careful check operation of the operator and all accessories

connected to it.

Give the customer the “User guide” and demonstrate how to

use the operator correctly. Point out the potential danger

zones of the automated unit.

5. MANUAL OPERATION

In the event of a power failure or malfunction, the gate can be

operated manually by removing the plug and inserting the

special release key as shown in fig. 10.

To release the operator, turn the key in the direction of leaf

closing (fig. 10).

Open or close the leaves manually.

6. RETURNING TO NORMAL OPERATION

Turn off the electricity supply to the system before re-locking

the operators to avoid all risk of starting them accidentally.

To re-lock the operator, turn the key in the leaf opening

direction (fig. 10).

Fig. 8

Fig. 9

Fig. 10

7. SPECIAL APPLICATIONS

There are no special applications.

8. MAINTENANCE

Carry out periodic checks of the gate structure and ensure in

particular that the hinges are in perfect working condition.

Check periodically that the electronic anti-crushing system is

adjusted correctly and that the release mechanism for manual

movement is fully operative (see relative paragraph).

Safety devices installed on the plant must be checked every

six months.

9. REPAIRS

For repairs, refer to authorised FAAC service centres.

8

Page 7

412

Page 8

END-USER GUIDE

412 Automation Systems

ENGLISHENGLISH

Read the end user guide carefully before using the product

and keep it in a safe place for future reference.

GENERAL SAFETY REGULATIONS

When correctly installed and used, the 412 automation

system ensures a high degree of safety.

A few simple rules should be followed to prevent accidental

problems.

- Do not pass between the leaves when they are still moving:

always wait until they have opened completely.

- Do not linger between the leaves.

- Do not linger near the automation system; do not allow

children or adults to linger near it; and do not leave

objects near it.

- Keep wireless control devices, or other devices that might

accidentally activate the automation system, out of the

reach of children.

- Do not allow children to play with the automation system.

- Do not impede the movement of the leaves.

- Do not allow branches or bushes to interfere with the

movement of the leaves.

- Ensure that the warning lamps are in always in working

order and visible.

- Do not attempt to actuate the leaves manually unless you

have first unlocked them.

- In case of a malfunction, unlock the leaves to allow

vehicles to pass, and call a qualified technician.

- If you have set the manual mode, before restoring normal

operation, disconnect the power supply.

- Do not modify the components of the automation system.

- Do not attempt to repair the automation system or to

perform any operation on it. Call qualified technicians

only.

- At least once every 6 months, have qualified personnel

check that the automation system, safety devices and

earth connection are in working order.

DESCRIPTION

The FAAC 412 automation consists of two

electromechanical operators which are ideal for controlling

swinging gates with each leaf up to 1.80 m long.

The two electromechanical operators transmit movement

to the leaves by a worm screw system.

The operators are controlled by an electronic control unit,

mounted in an enclosure which assures adequate

protection against atmospheric agents.

The leaves are normally closed. When the electronic control

unit receives an open command from the remote radio

control or any other control device, it activates the

electromechanical system and causes the leaves to rotate

by an angle of up to 110° to their open position, so as to

allow access.

If automatic operation has been selected, the leaves close

automatically after the selected pause time.

If semiautomatic operation has been selected, a second

impulse must be sent to close the leaves.

An open command given while the leaves are closing

causes the leaves to reverse direction of movement.

A stop command (if available) stops movement at any

time.

For detailed information on the operation of the automation

system in the various operating modes, contact the

installation technician.

The automation system is equipped with a photocell safety

device which prevents the leaves from closing when the

photocells are darkened by an obstacle.

The 412 automation system is also equipped with an anticrushing safety device (fitted as standard) that limits the

torque transmitted to the leaves.

The operators ensure that the system is mechanically locked

when the motor is not running, so there is no need to install

a lock.

The leaves can be opened manually only by operating the

unlocking device.

The lamp flashes while the leaves are moving.

MANUAL OPERATION

If the gate has to be operated manually due to a malfunction

or power supply failure, remove the safety cap and insert

the key provided into the release system as shown in fig. 1.

To release the operator, turn the key in the leaf closure

direction (fig. 1).

Open or close the leaf manually.

RETURNING TO NORMAL OPERATION

To prevent an accidental impulse from activating the

operators during this operation, disconnect the system

from the power supply before re-locking the operators.

To re-lock the operator, turn the key in the leaf opening

direction (fig. 1).

BLOCCA

LOCK

BLOQUE

VERRIEGELT

BLOQUEAR

SBLOCCA

UNLOCK

DEBLOQUE

ENTRIEGELT

DESBLOQUEAR

SBLOCCA

UNLOCK

DEBLOQUE

ENTRIEGELT

DESBLOQUEAR

BLOCCA

LOCK

BLOQUE

VERRIEGELT

BLOQUEAR

Fig. 1

9

Page 9

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La FAAC si riserva il diritto, lasciando inalterate le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque momento e senza impegnarsi

ad aggiornare la presente pubblicazione, le modifiche che essa ritiene convenienti per miglioramenti tecnici o per

qualsiasi altra esigenza di carattere costruttivo o commerciale.

The descriptions and illustrations contained in the present manual are not binding. FAAC reserves the right, whilst

leaving the main features of the equipments unaltered, to undertake any modifications it holds necessary for either

technical or commercial reasons, at any time and without revising the present publication.

Les descriptions et les illustrations du présent manuel sont fournies à titre indicatif. FAAC se réserve le droit d’apporter à

tout moment les modifications qu’elle jugera utiles sur ce produit tout en conservant les caractéristiques essentielles,

sans devoir pour autant mettre à jour cette publication.

Die Beschreibungen und Abbildungen in vorliegendem Handbuch sind unverbindlich. FAAC behält sich das Recht

vor, ohne die wesentlichen Eigenschaften dieses Gerätes zu verändern und ohne Verbindlichkeiten in Bezug auf die

Neufassung der vorliegenden Anleitungen, technisch bzw. konstruktiv/kommerziell bedingte Verbesserungen vorzunehmen.

Las descripciones y las ilustraciones de este manual no comportan compromiso alguno. FAAC se reserva el derecho,

dejando inmutadas las características esenciales de los aparatos, de aportar, en cualquier momento y sin comprometerse a poner al día la presente publicación, todas las modificaciones que considere oportunas para el perfeccionamiento técnico o para cualquier otro tipo de exigencia de carácter constructivo o comercial.

FAAC S.p.A.

Via Benini, 1

40069 Zola Predosa (BO) - ITALIA

Tel. 0039.051.61724 - Fax. 0039.051.758518

www.faac.it

www.faacgroup.com

732238 - Rev. C

Loading...

Loading...