EVCO S.p.A.

c-pro 3 micro CHIL

Programmable controllers for single-and

two-circuits chillers-heat pumps

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

Application manual | ENGLISH

Codice 144CP3CHE104

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

IMPORTANT NOTICE

This Instruction Manual should be read carefully before installation and before use, and all warnings relating

to installation and electrical connections should be observed; the Manual should then be kept for future

reference.

All devices must be disposed of in accordance with local regulations governing the disposal of

electrical and electronic devices.

page 2 of 120

EVCO S.p.A.

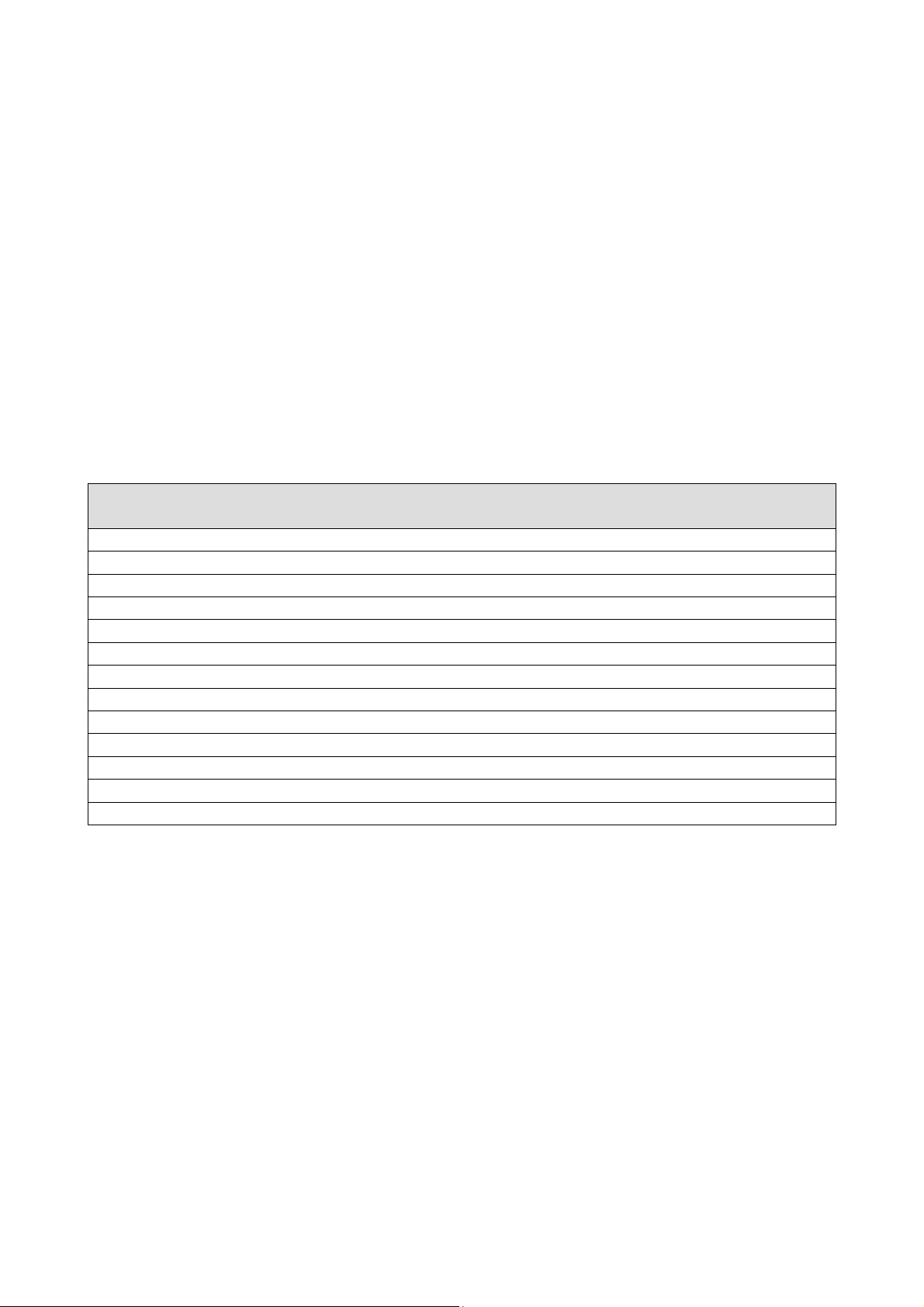

SOMMARIO

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

1 INTRODUCTION ................................................................................................... 6

1.1 Introduction ..................................................................................................... 6

2 APPLICATIONS .................................................................................................... 7

2.1 Basic application scheme of an Air-To-Water twin circuit chiller ...................... 8

3 HARDWARE SOLUTIONS ...................................................................................... 9

4 DIMENSIONS ..................................................................................................... 10

4.1 Dimensions of controller and user interface ....................................................... 10

4.1.1 Dimensionscontrol modulec-pro 3microCHILand c-pro 3 EXP micro+ ............................................................. 10

5 USER INTERFACE ............................................................................................... 12

5.1 Displays and Keyboards.................................................................................. 12

6 LIST OF PAGES ................................................................................................... 13

6.1 Password ........................................................................................................ 14

6.2 Unit OFF main page ........................................................................................ 14

6.3 Unit ON main page ......................................................................................... 15

6.4 Menu StAt (Only for display LED) ................................................................... 16

6.4.1

Meaning of LED (only for display LED) .................................................................................................. 17

6.5 General Menu ................................................................................................. 18

6.6 User Menu ...................................................................................................... 18

6.7 Maintenance Menu .......................................................................................... 18

6.8 Installer Menu ................................................................................................ 19

6.9 Constructor Menu ........................................................................................... 20

6.10 RTC Menu .................................................................................................... 20

6.11 Alarms Menu ............................................................................................... 20

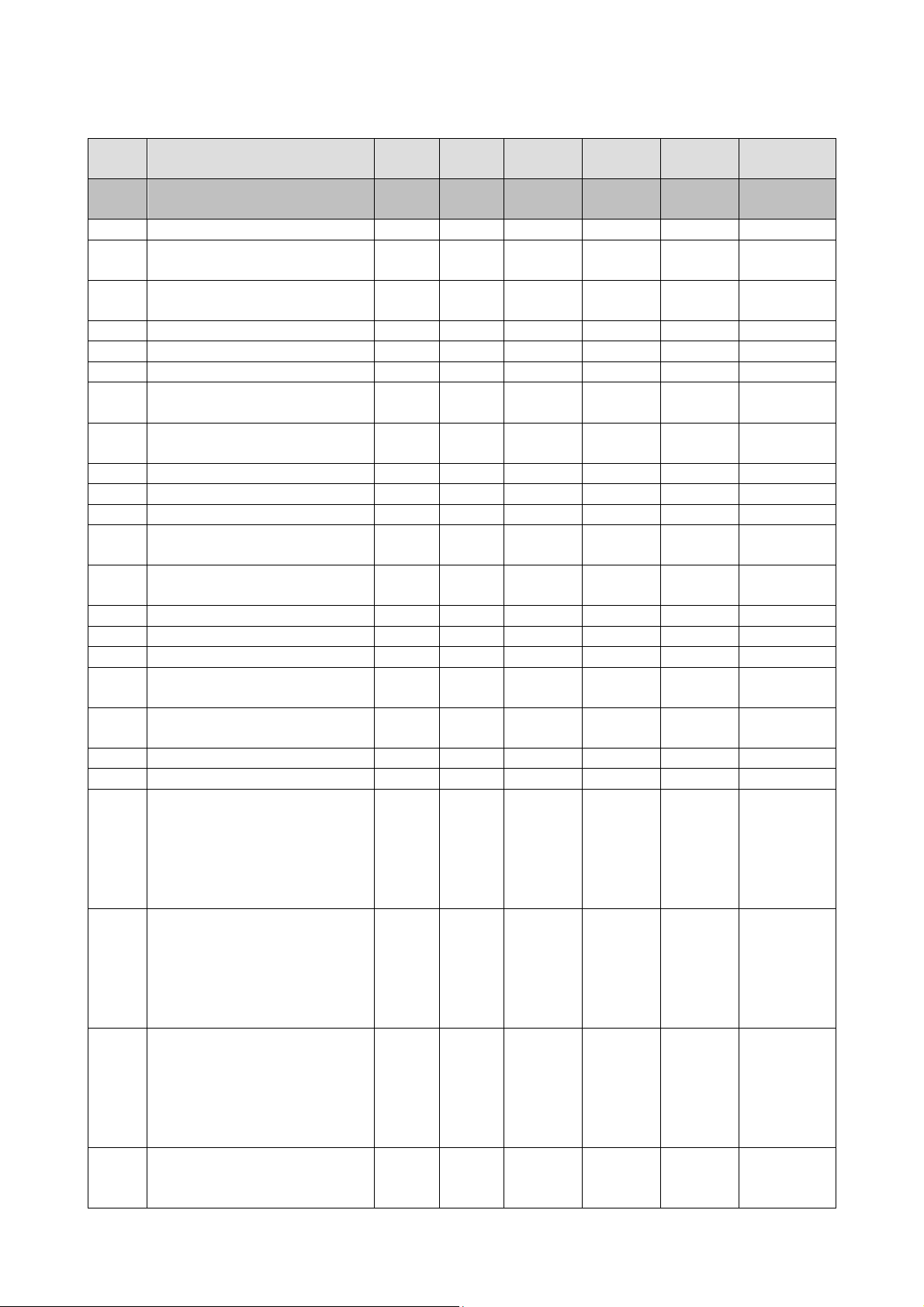

7 PARAMETERS LIST ............................................................................................. 21

7.1 List of Configuration Parameters .................................................................... 22

7.2 AI Configuration (HA01-HA18 parameters) .................................................... 41

7.3 DI Configuration(HB01-HB18 parameters) ..................................................... 42

7.4 AO Configuration (HC01-HC18 parameters) ................................................... 42

7.5 DO Configuration (HD01-HD18 parameters)................................................... 43

8 REGULATIONS.................................................................................................... 44

8.1 Machine Status ............................................................................................... 44

8.2 Unit Type ........................................................................................................ 45

8.2.1

Water-To-Water Chiller with EVDRIVE03 .............................................................................................. 45

8.2.2

Water-To-Water Chiller ......................................................................................................................... 46

8.2.3

Water-To-Water Chiller+Heat Pump with EVDRIVE03 ........................................................................... 47

8.2.4

Water-To-Water Chiller+Heat Pump ..................................................................................................... 48

8.2.5

Air-To-Water Chiller with EVDRIVE03 ................................................................................................... 49

8.2.6

Air-To-Water Chiller .............................................................................................................................. 50

8.2.7

Air-To-Water Chiller+Heat Pump with EVDRIVE03 ................................................................................ 51

8.2.8

Air-To-Water Chiller+Heat Pump .......................................................................................................... 52

page 3 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

8.3 Configuration of Circuits ................................................................................. 53

8.4 Operating Mode Control .................................................................................. 54

8.5 Setting the RTC .............................................................................................. 55

8.6 Compressor Control ........................................................................................ 56

8.6.1

Lateral-band (LB) control ...................................................................................................................... 56

8.6.2

Zero energy band (ZEB) control ............................................................................................................ 57

8.6.3

Auto adaptive control ........................................................................................................................... 58

8.7 Compressor Management ............................................................................... 58

8.7.1

Compressor status ................................................................................................................................ 58

8.7.2

Rotation of compressors ....................................................................................................................... 58

8.7.3

Pump-down switch-OFF procedure ....................................................................................................... 59

8.7.4

Relative-threshold pump-down ............................................................................................................. 59

8.7.5

Protection timings ................................................................................................................................. 60

8.7.6

Thermal protection inputs ..................................................................................................................... 61

8.8 Condenser control .......................................................................................... 61

8.8.1

Modulating fan control .......................................................................................................................... 61

8.8.2

Single stage fan control ........................................................................................................................ 64

8.8.3

Condenser valve control ........................................................................................................................ 64

8.8.4

Single condenser ................................................................................................................................... 64

8.9 Fan Management ............................................................................................ 65

8.9.1

Fan status ............................................................................................................................................. 65

8.9.2

Fan timings ........................................................................................................................................... 65

8.9.3

Thermal Protection Inputs .................................................................................................................... 65

8.10 Circulating Pump Management .................................................................... 66

8.10.1

Pump Status .......................................................................................................................................... 67

8.10.2

Flow Meter Management ....................................................................................................................... 67

8.11 Circulating Source Pump Management ........................................................ 68

8.12 Defrosting Management .............................................................................. 68

8.12.1

Defrosting cycle compensation ............................................................................................................. 69

8.13 Anti-freeze management / Chilling-support heating coils ........................... 69

8.14 Single evaporation ...................................................................................... 69

8.15 Free-Cooling Management........................................................................... 70

8.15.1

Enabling of Free-Cooling ....................................................................................................................... 70

8.15.2

Regulation of Free-Cooling .................................................................................................................... 70

8.15.3

Free-Cooling control valve .................................................................................................................... 72

8.16 Temperature Alarm Control ......................................................................... 73

8.16.1

Low and high temperature alarm management ..................................................................................... 73

8.16.2

Management of primary exchanger efficiency alarm ............................................................................. 73

8.17 Pressure Alarm Control ............................................................................... 73

8.17.1

Management of high-pressure pressure-switch alarm .......................................................................... 73

8.17.2

Management of high-pressure transducer alarm ................................................................................... 73

8.17.3

Management of low-pressure pressure-switch alarm (chiller mode) .................................................... 73

8.17.4

Management of low-pressure transducer alarm (heat pump mode) ...................................................... 74

8.17.5

Low start-up pressure alarm ................................................................................................................. 74

8.18 Time schedule ............................................................................................. 75

8.19 Miscellaneous Management ......................................................................... 76

8.19.1

Set point variation by schedule timer .................................................................................................... 76

8.19.2

Dynamic set point ................................................................................................................................. 76

page 4 of 120

EVCO S.p.A.

8.19.3

8.19.4

8.19.5

8.19.6

8.19.7

8.19.8

Forced shutdown ................................................................................................................................... 77

High-pressure reduction at high temperatures (chiller) ........................................................................ 77

Low-pressure partialization at low temperatures (heat pump) ............................................................. 78

Operating limit management (heat pump) ............................................................................................ 79

Function of Cooling/Heatingupon request ............................................................................................. 79

Set-point change from digital input ....................................................................................................... 79

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

8.20 Management of EVDRIVE03 integrated into the system .............................. 80

8.20.1

Enabling of EEV operation ..................................................................................................................... 80

8.20.2

PID parameters set ............................................................................................................................... 80

8.20.3

Modulation of the SH set ....................................................................................................................... 80

8.20.4

CAN Configuration ................................................................................................................................. 80

8.21 Manual operation ........................................................................................ 81

8.21.1

Compressors ......................................................................................................................................... 81

8.21.2

Fans ...................................................................................................................................................... 81

8.21.3

Pumps ................................................................................................................................................... 81

8.22 Resetting of default parameters .................................................................. 82

8.23 Parametering key ........................................................................................ 82

9 WIRING DIAGRAM ............................................................................................. 83

9.1 Connection layout c-pro 3 micro CHIL ................................................................ 83

9.2 Connection layout c-pro 3 EXP micro+ ............................................................... 85

9.3 Connection layout EVDRIVE03 ............................................................................ 87

9.4 Connection layout Vgraph ................................................................................... 89

9.5 c-pro 3 micro CHIL ............................................................................................ 90

10 9.5.1 Table of connection c-pro 3 micro CHIL .................................................... 91

11 DIAGNOSTICS .................................................................................................... 92

11.1 Manual and Automatic Alarms ..................................................................... 92

11.2 Manual-reset alarms ................................................................................... 92

11.3 Automatic-reset alarms ............................................................................... 92

11.4 Alarm Table ................................................................................................. 93

11.5 Alarms History ............................................................................................ 96

12 LIST OF Modbus® VARIABLES ........................................................................... 97

page 5 of 120

EVCO S.p.A.

1 INTRODUCTION

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

1.1 Introduction

The programmable controllers of the c-pro 3 micro CHILseries are devices studied for the management of singleandtwo-circuits

chillers-heat pumps up to three scrollcompressors for each circuit.

They make use of the programmable controllers, of the I/Oexpansions and of the remote user interfaces belonging tothe c-pro 3 series

and are programmed with an applicationsoftware implemented with the development environmentUNI-PRO 3.

They are available in built-in and in blind version; the blindversions must be used with a remote user interface.

The controllers can manage air to water and water to waterchillers-heat pumps; through the CAN communication portthe controllers

can also communicate with an externaldriver (EVDRIVE03) for bipolar stepper electronic expansionvalves.

They can be powered in alternating current (12 VAC). Through the programming port it is possible to make the upload and the

download of the configuration parameters (using a common USB peripheral); through the RS-485 one, with MODBUS communication

protocol, it is possible to connect the devices to the set-up software system Parameters Manager or to the plants monitoring and

supervision one via Internet CloudEvolution instead. Through the CAN communication port it is finally possible to connect the devices to

the I/O expansion, to the remote user interface and to the external electronic expansion valves driver.

The application program is capable of managing air-to-water and water-to-water units, mono or twin circuit.

The following are only some of the numerous control functions available:

Manage up to 3 scroll compressors for each circuit

Manage compressors with cooling – heating mode

Manage fans with phase-cut module

Manage electronic valve EVDRIVE03 for each circuit

Free-Cooling management

Defrost and anti-frost

Double set-point that can be enabled from external contact

Dynamic set point compensation

Pump-down management

Build in schedule with 2 daily programs

Control of condensing pressure / linear or stepped evaporation

One, two or no circulating pumps

One, two or no source circulating pumps

Available functions

page 6 of 120

EVCO S.p.A.

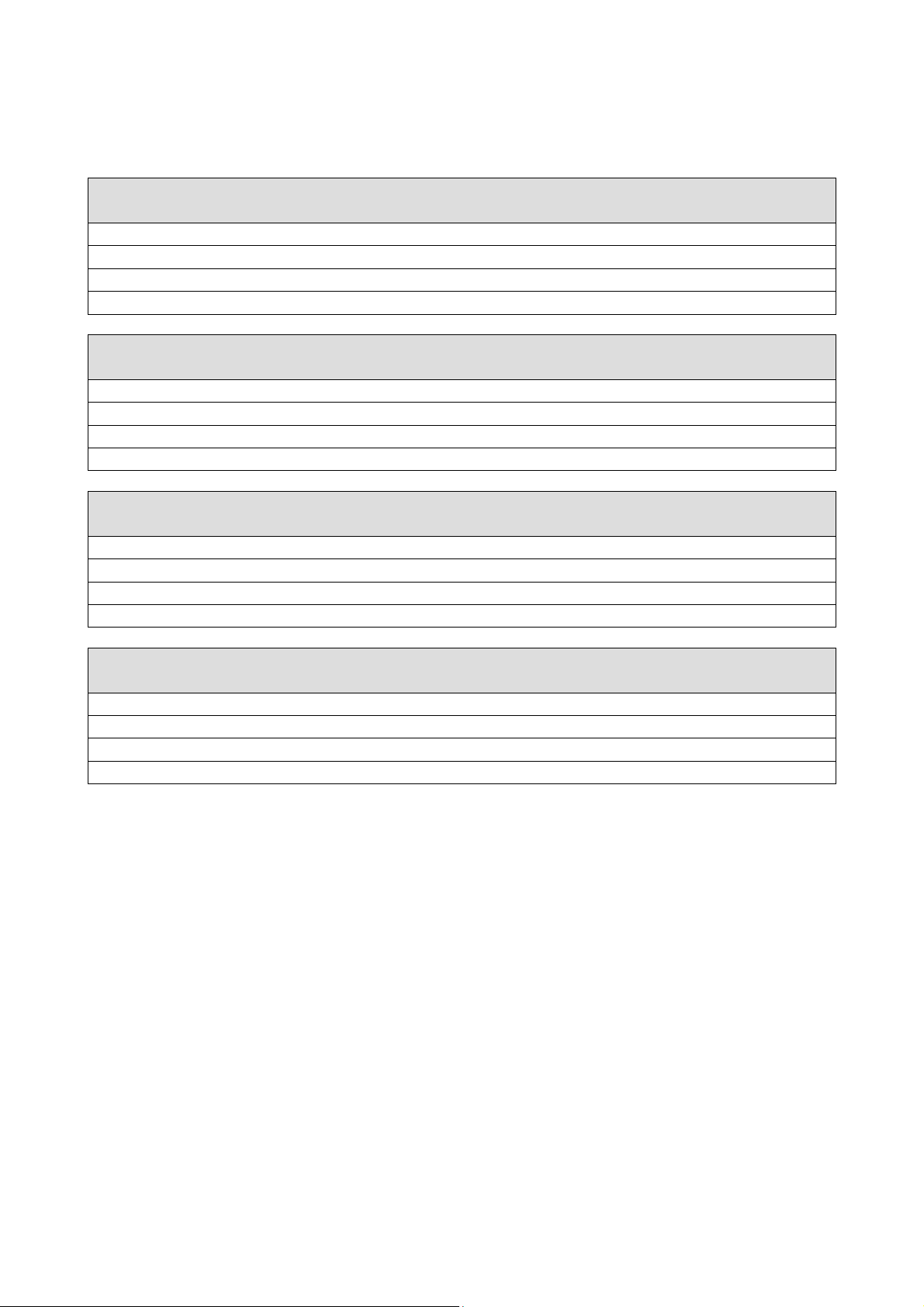

2 APPLICATIONS

The controllers are able to manage the following unit types :

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

Air-To-Water single circuit

Air-To-Water single circuit Chiller

Air-To-Water single circuit Chiller with EEV driver

Air-To-Water single circuit Chiller + HeatPump

Air-To-Water single circuit Chiller + HeatPump with EEV driver

Water-To-Water single circuit

Water-To-Water single circuit Chiller

Water-To-Water single circuit Chiller with EEV driver

Water-To-Water single circuit Chiller + HeatPump

Water-To-Water single circuit Chiller + HeatPump with EEV driver

Air-To-Water twin circuit

Air-To-Water twin circuit Chiller

Air-To-Water twin circuit Chiller with EEV driver

Air-To-Water twin circuit Chiller + HeatPump

Air-To-Water twin circuit Chiller + HeatPump with EEV driver

Water-To-Water twin circuit

Water-To-Water twin circuit Chiller

Water-To-Water twin circuit Chiller with EEV driver

Water-To-Water twin circuit Chiller + HeatPump

Water-To-Water twin circuit Chiller + HeatPump with EEV driver

page 7 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

2.1 Basic application scheme of an Air-To-Water twin circuit chiller

page 8 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

3 HARDWARE SOLUTIONS

Hardware Article Code

Controller (built-in version) c-pro 3micro CHIL EPU2LXP1CH

Controiller (blind version) c-pro 3micro CHIL EPU2BXP1CH

I/O expansion c-pro 3 EXP micro+ EPU2EXP

EEV driver (built-in version) EVDRIVE03 EPD4DF3

EEV driver (blind version) EVDRIVE03 EPD4BC3

To manage the second circuit it is necessary to use an I/O expansion c-proEXP micro+ and to manage the electronic expansion valve it

is necessary to use a driver EVDRIVE03.

For management of the blind versions it is also necessary to use a remote user interface LCDVgraph, an interfaceequipped with

6keys/edit pages, statesand enablingthe same.

A descriptionof the keysused by the application.

page 9 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

4 DIMENSIONS

4.1 Dimensions of controller and user interface

Below we will show the dimensions, assembly and electric connections of the c-pro 3 micro CHIL.

4.1.1 Dimensionscontrol modulec-pro 3microCHILand c-pro 3 EXP micro+

4 DIN modules, installation DIN rail mounting; the dimensions arein mm(in).

4.1.2 Dimensions remote user interface Vgraph.

Installation by panel; the dimensions are in mm (in).

page 10 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

4.1.3 Dimensions module EVDRIVE03

4 DIN modules, installation DIN rail mounting; the dimensions arein mm(in).

page 11 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

5 USER INTERFACE

For the application, two types of interface are provided:

• Built-in LED-display interface

• Remote LCD-display interface Vgraph.

Both interfaces feature 6 keys for navigation/page editing, and differ in their display mode of certain associated statuses, i.e. via icons.

For both versions, a description is provided of the keys used by the application; indeed, according to the interface in use, it is possible

to manage a different number of keys.

5.1 Displays and Keyboards

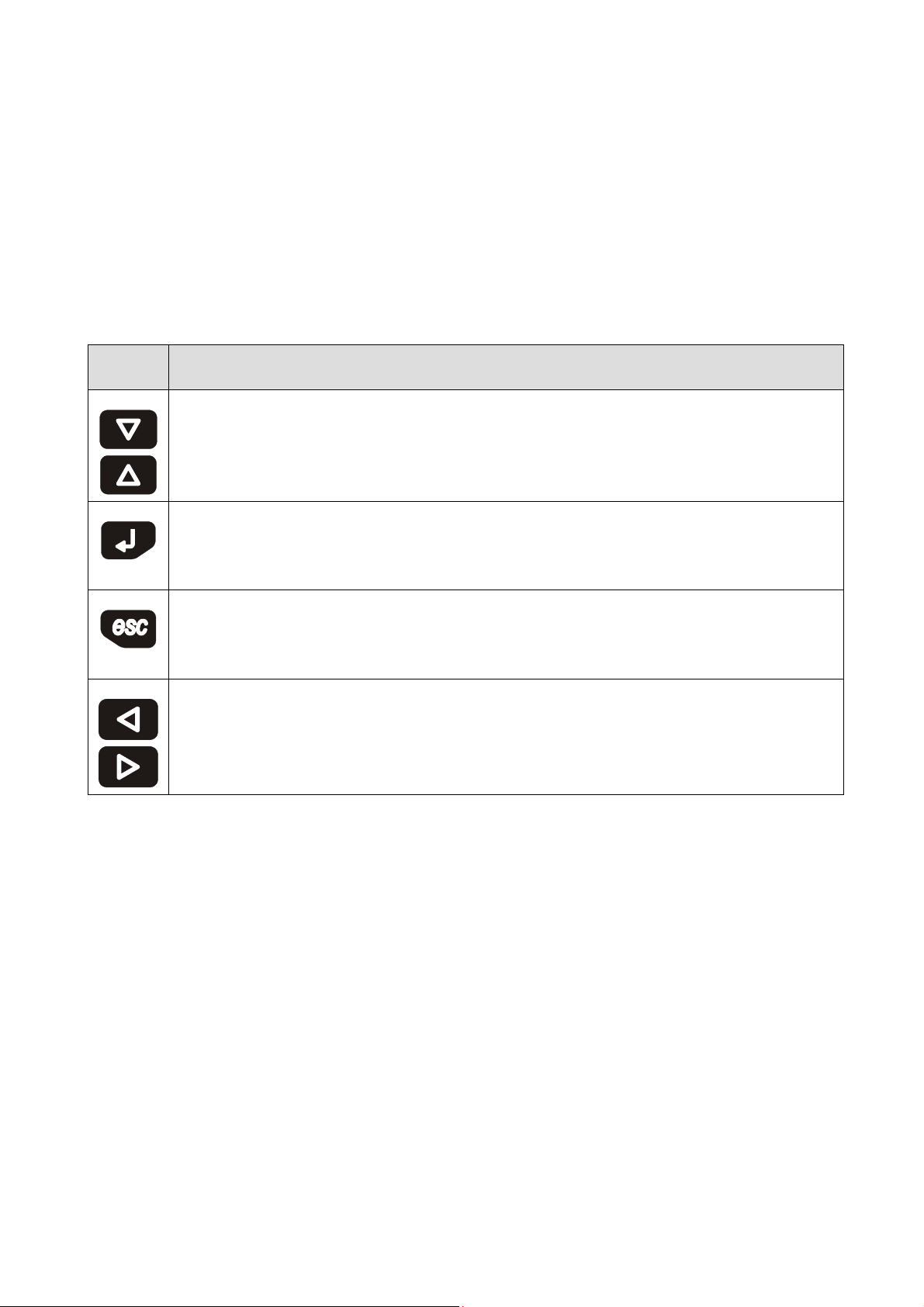

The keyboard features 6 page navigation and value editing keys, which have the following functions:

Symbol

Functions

In editing, it modifies parameters; otherwise, it moves the cursor.

During editing, it confirms the value; otherwise, it sends any commands associated to the text where the

cursor is positioned.If pressed down and held for about 2 seconds, the ENTER key enables access to the main menu.

If held down during display of an alarm page, this key enables resetting of the alarm.If alarm pages are being

displayed, every key press scrolls all active alarms.

During editing, it cancels the value; otherwise, it requests any default page that might e associated with the current

page.If pressed down and held for about 2 seconds, the ESC key enables ON/OFF switching of the machine.

If pressed in the main page, this key will display the list of all active alarms.

It displays the pages of the same level in succession.

page 12 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

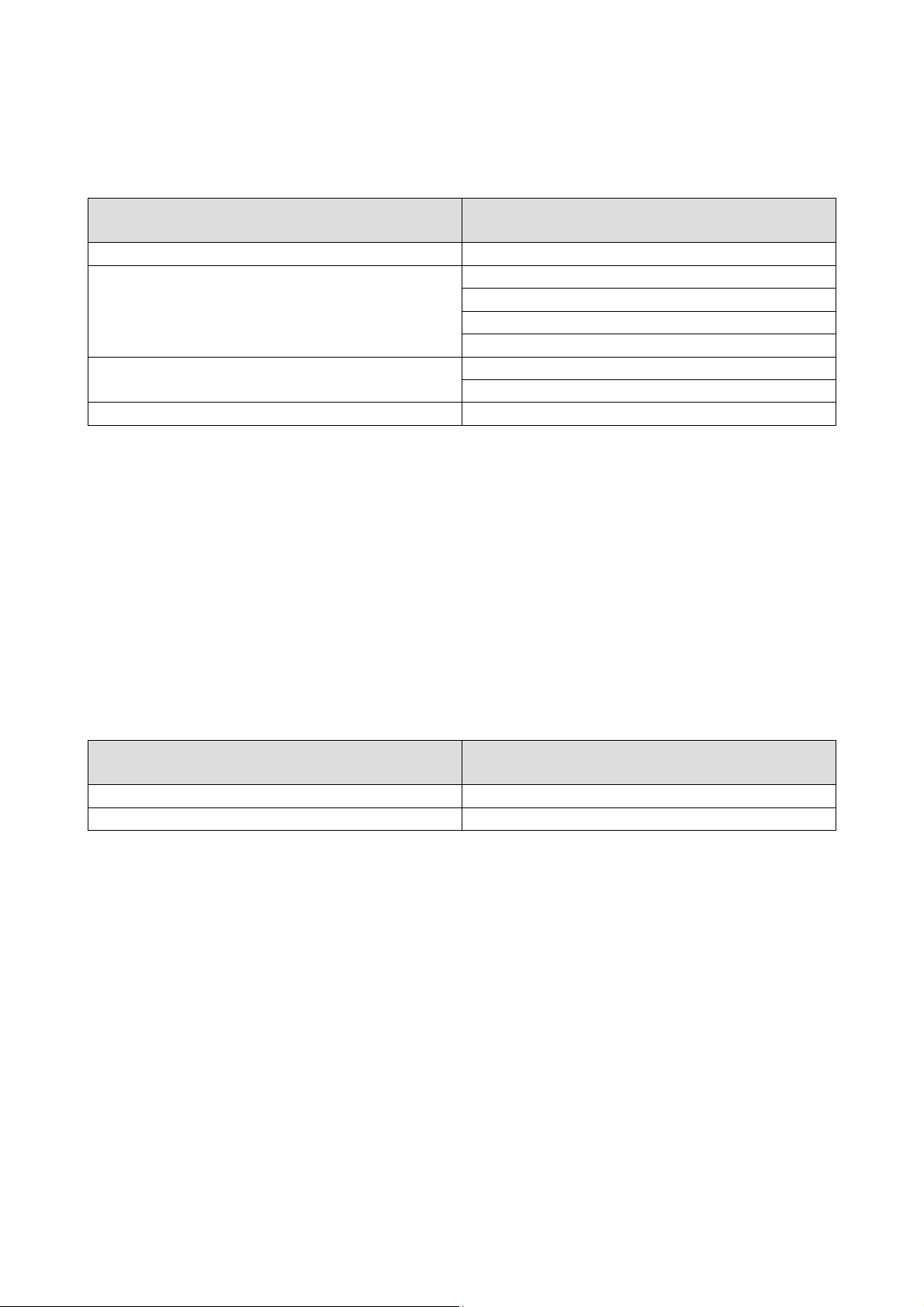

6 LIST OF PAGES

This chapter describes the main pages and menus featured in the application. As already described earlier, the general menu is

subdivided into four submenu levels: user, maintenance operator, installation operator, and configuration.

The menu structure is the following:

Menu

General Menu

Maintenance Menu

(Level 2)

Installer Menu

(Level 3)

Constructor Menu

(Level 4)

RTC Menu

Alarm Menu

User Menu (Level 1)

Operation

Manual

Calibration

Input/output

Compressors

Regulation

Fans

Defrost

Pumps

Anti-Freeze

Free-Cooling

Device safeties

Modbus

Various parameters

Configuration

Hardware configuration

EVDRIVE03 (Circuit 1, Circuit 2)

Function of the menu

page 13 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

6.1 Password

Each menu is assigned a level, which affects the accessibility of the various menus.

Each level is assigned a password, which enables access to the various functions featured in that menu; once the correct password has

been entered, protected functions become accessible. Entering of the correct password has two consequences:

• Unlocking of the related level;

• Unlocking of its sublevels.

All level passwords can be modified from the same level or from higher levels. For example, from the constructor level it will be possible

to modify all passwords of underlying levels, by using the appropriate page.

The range of values that can be set for a password is -999 / 9999.

After 4 minutes have elapsed without any key being pressed, the password expires and it is necessary to reset it.

6.2 Unit OFF main page

The main display page varies according to the machine status, i.e. on or off:If the machine is switched OFF, Unit OFF is displayed, with

indication of the cause for the shutdown (keyboard, DI, Supervisor, Scheduler, Alarm, Change-Over).

Pressing the ESC key from this page brings the user to the Alarm page.

page 14 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

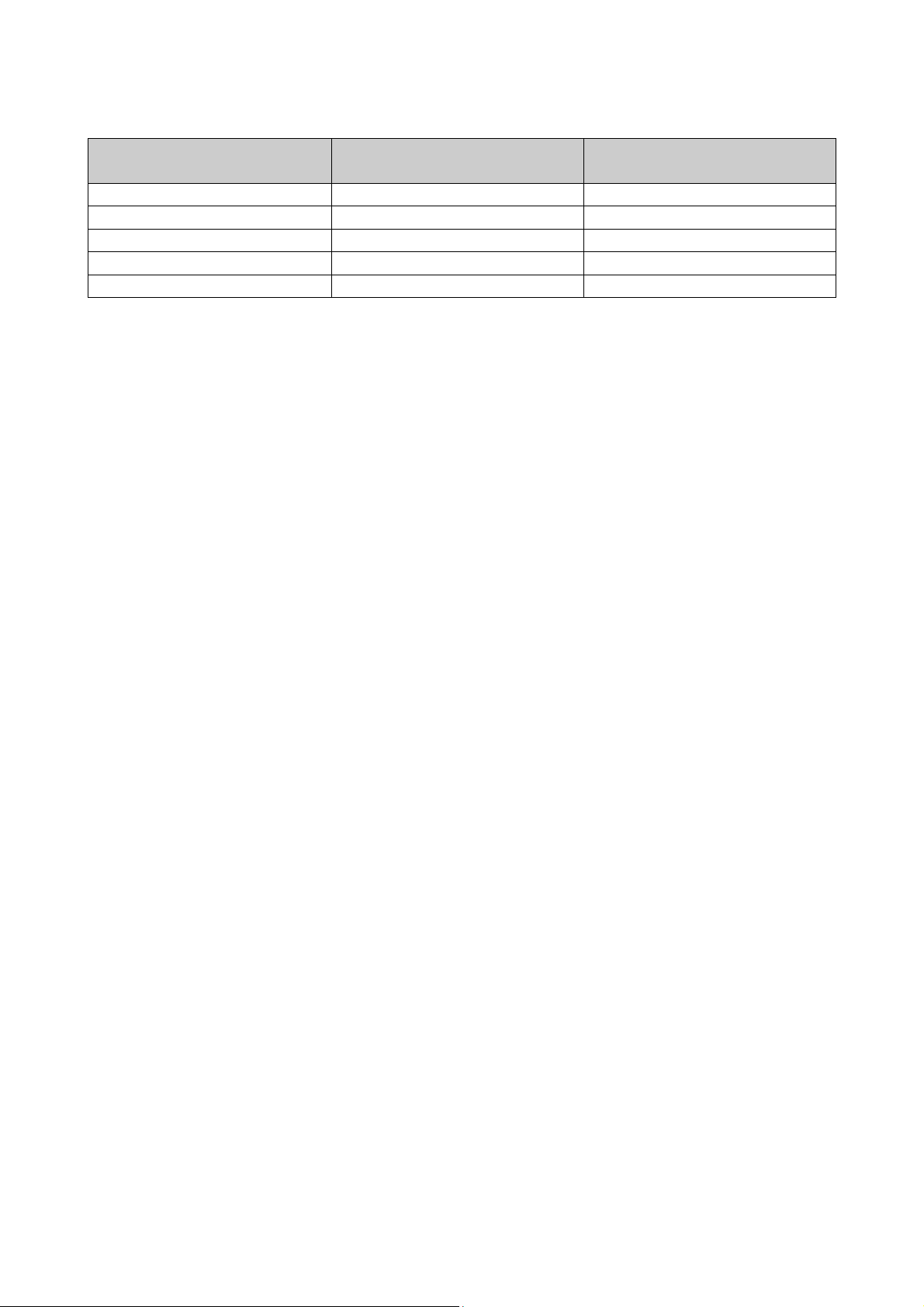

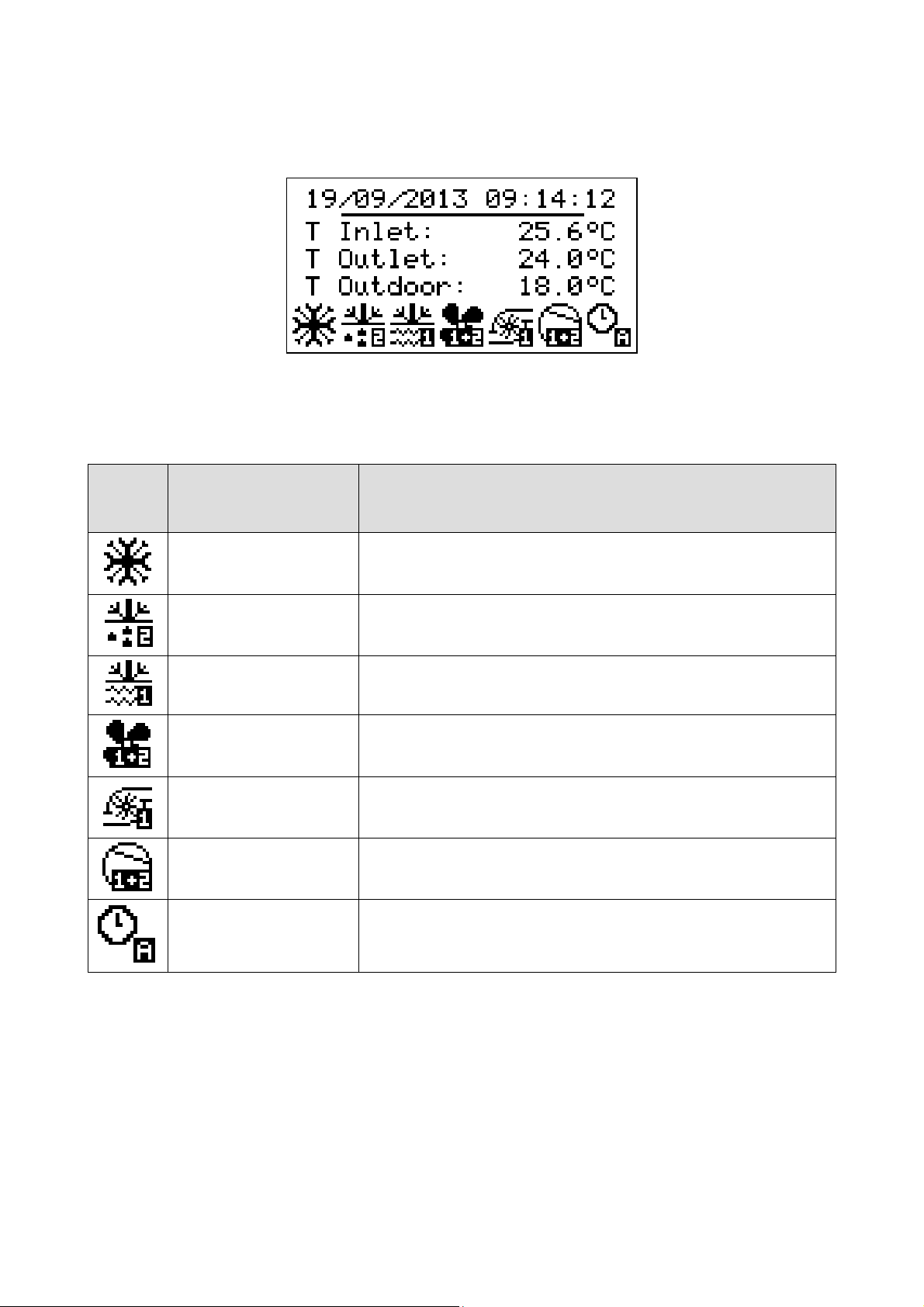

6.3 Unit ON main page

When the unit is turned on, the following main screen will be displayed:

At the bottom of the page, icons will be displayed that indicate various statuses of circuit operation.

The table below contains graphic representations of the individual icons, the relative operational status and what is being verified.

From left to right:

Icon

Operational status

Eventdisplayed

Summer/Winter/Alarm Icon

Defrost Icon

Antifreeze Icon

Fan Icon Indicates that the circuit fans (1,2, 1+2) are active

Pump Icon Indicates which circulation pump (1,2) is active

Compressor Icon Indicates that at least one circuit compressor (1,2, 1+2) is active

Time Slot Icon Indicates which time slot is active (A,B)

From this page, by pressing the RIGHT or LEFT keys, it is possible to display other information regarding pumps, fans, compressors,

defrost, circuit status, RTC and all configured sensors. In case of fault status of the sensors, the value field of the corresponding sensor

displays “----“, or else “----“ if the sensor is disabled.

Pressing the ESC key from this page brings the user to the Alarm page.

In case there is an active alarm, the alarm icon will be displayed alternatively with

the icon of the operational mode (summer/winter)

Indicates that circuit defrost is in progress (1,2).

If flashing, it is in dripping phase

Indicates that the antifreeze resistance mechanism is active (heat sink or source)

in the circuit indicated (1,2 1+2)

page 15 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

6.4 Menu StAt (Only for display LED)

If the StAt voice is chosen from the general menu, several main statuses of the system are displayed (can be navigatedwith the

Left/Right buttons) on the reference page:

Exampletable of system statuses displayed on Page 1

Reference page Status displayed System status

Page 1 Unit Indicates the status in which the machine operates (OFF, ChIL, pdC, dEFr, dRIp, F-C)

Page 1 ModE Indicates the operational mode of the machine (ChIL, pdC)

Page 1 tdF1 Accumulation of wait time for defrost circuit 1

Page 1 dFr1 Duration of circuit defrost 1

Page 1 tdF2 Accumulation of wait time for defrost circuit 2

Page 1 dFr2 Duration of defrostcircuit 2

Page 1 SEtC Summer mode current set point

Page 1 SEtH Winter mode current set point

Page 1 rEGP Main regulation probe

Page 1 PREq Power required [%]

Page 1 PSup Power supplied[%]

Example table of system statuses displayed on Page 2

Reference page Status displayed System status

Page 2 CMP1, CMP2 .. CMP6 Status of compressors (dIS, OFF, tOn, On, tOFF, ALAr, MAnU)

Page 2

Page 2

Page 2

Page 2

Page 2

Page 2

Page 2

Page 2

Page 2

Sample table of system statuses displayed on Page 3

Reference page Status displayed System status

Page 3 tExt External temperature probe

Page 3

Page 3

Page 3

Page 3

Page 3

Page 3

Page 3

Page 3

Page 3

Page 3

Page 3

FAn1, FAn 2 Status of fans (dIS, OFF, tOn, On, tOFF, ALAr, MAnU)

InF1,InF2 Speed of condenser fans [%]

PMP1, PMP2 Status of pumps (dIS, OFF, On, ALAr, MAnU)

PMS1, PMS2 Status of heat source pumps (dIS, OFF, On, ALAr, MAnU)

F-C Status of free-cooling activation

vF-C Free-cooling valve

FF-C Free-cooling regulation

vpC1 Status of C1splitter valve for free-cooling

vpC2 Status of C2 splitter valve for free-cooling

tAux Remote temperature probe

tiFc Machine input temperature probe (Free-Cooling)

tin Heat sink exchanger input temperature probe

toC1/2 Heat sink exchanger output temperature probe (circuit 1,2)

toS1/2 Heat source exchanger input temperature probe (circuit 1,2)

tCo1/2 Coil temperature probe (circuit 1,2)

GAS1/2 Exhaust gas compressor temperature probe (circuit 1,2)

tSu1/2 Intake compressor temperature probe (circuit 1,2)

PCO1/2 Condensing pressure probe (circuit 1,2)

PEV1/2 Evaporation pressure probe (circuit 1,2)

Pun1/2 Single pressure probe (circuit 1,2)

page 16 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

Pressing ENTER on the label causes the value of the relative status to be displayed;pressing ESC brings you back to the general menu

screen. This menu is not protected by a password.

6.4.1 Meaning of LED (only for display LED)

The LED display offers several icons that display particular statuses of the unit:

• OnOff. If on, it means that the unit has no power; if off, it means that the unit is on; if on with slow flashing light, it means

that the unit is not being powered by the Scheduler; if on with fast flashing light, it means that the unit is not being powered

by the Supervisor or Digital Input.

• Snow. If on, summer/winter function (seeparameter PH53); if on and flashing, the free-cooling function is active.

• Sun. If on, summer/winter function (see parameter PH53).

• Alarm. If on, the function indicates the presence of alarms; if on and flashing, it indicates the presence of new alarms not

displayed yet; if off, there are no alarms.

• Defrost. If on, it means that defrosting is active in one of the 2 circuits; if on and flashing, it means that draining is active in

one of the2 circuits

• Maintain. If on, it means that at least one device is functioning manually; if on and flashing, it means that a “device

operating hours” alarm is active.

• Compressor 1. If on, it means that at least one compressor of circuit 1 is active; if off, it means that no circuit compressors

are active; if on and flashing slowly, it means that a circuit compressor is in the alarm state; if on and flashing quickly, it

means that a circuit compressor is in manual mode.

• Compressor 2. If on, it means that at least one compressor of circuit 2 is active; if off, it means that no circuit compressors

are active; if on and flashing slowly, it means that a circuit compressor is in the alarm state; if on and flashing quickly, it

means that a circuit compressor is in manual mode.

• Pump. If on, it means that a heat sink pump is active; if off, it means that no pumps are active; if on and flashing slowly, it

means that a pump is in the alarm state; if on and flashing quickly, it means that a pump is in manual mode.

• Fan. If on, it means that one fan is active; if off, it means that no fans are active; if on and flashing slowly, it means that a

fan is in the alarm state; if on and flashing quickly, it means that a fan is in manual mode.

• Heaters: If on, it means that the strength of the antifreeze mechanism (heat sink or source) is active; if off, it means that no

antifreeze mechanisms are active; if on and flashing slowly, it means that an antifreeze mechanism is in the alarm state.

• EVCO. Icon linked to the functioning of parameter PH52.

page 17 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

6.5 General Menu

The general menu has no level and represents the access point for all the other system menus.

Display LCD Display LED

USER USEr

MAINTENANCE MAin

INSTALLER InSt

CONSTRUCTOR CoSt

RTC rTC

ALARMS ALrm

HISTORY HiSt

Not present StAt

It is possible to view this menu from any point within the user interface by pressing ENTER for approximately 2 seconds. From this

menu you can choose the menu you wish to view by pressing the UP and DOWN keys followed by pressing the ENTER key for

confirmation.

In the upper right hand corner of the image appears a “v” which represents the focus.

This indication specifies to the user that additional information is contained therein and can be viewed by pressing the DOWN key (or

UP key depending on the direction of the focus) scrolling to view the content that is not viewable in the current page.

6.6 User Menu

The User menu is a Level 1 menu, i.e. it requires entering of the User level (or higher) password, in order to be able to display/modify

the parameters contained in this branch.

6.7 Maintenance Menu

The Maintenance menu is a Level 2 menu, i.e. it requires entering of the Maintenance operator level (or higher) password, in order to

be able to display/modify the parameters contained in this branch.

Display LCD Display LED

OPERATION OPEr

MANUAL MAnU

CALIBRATION CAL

IN/OUT I-O

PASSWORD PSd2

In this menu, it is possible to view the status of the various devices, inputs and outputs utilized by the application.

In the OPERATION menu, it is possible to view/enable the features relating to the operation of compressors, fans and pumps. Some

examples of these are the hours of operation, the threshold of maximum allowable hours.

In the MANUAL menu, it is possible to set to manual/automatic operation compressors, pumps and fans, whose outputs can be forced,

in order to test their functionality.

In the CALIBRATION menu, it is possible to set the corrections to be applied to analogue inputs, to compensate the offsets due to

cabling and sensor positioning.

In the I/O STATUS menu, it is possible to view directly the card’s physical inputs and outputs

page 18 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

6.8 Installer Menu

The installation menu is a Level 3 menu, i.e. it requires entering of the installation level (or higher) password, in order to be able to

display/modify the parameters contained in this branch.

Display LCD Display LED

COMPRESSORS CoMP

REGULATION rEG

FANS FANS

DEFROST dEFr

PUMPS PuMP

ANTI-FREEZE A-F

FREE-COOLING F-C

SAFETIES SAFE

MODBUS MdbS

VARIOUS Par

SAVE/RESTORE MAp

PASSWORD PSd3

The installation operator menu contains all the parameters connected with the configuration of all functionalities (alarms, settings,

logic, rotation type, etc.) of the machine.

In the REGULATION menu, it is possible to set the parameters connected with lateral-band and zero energy band temperature control

of compressors.

In the COMPRESSORS menu, it is possible to set the parameters connected with the management of devices:

• rotation

• timings

• maximum number of start-ups.

In the FANS menu, it is possible to set the parameters connected with the control of condensation pressure, via the fans.

In the DEFROST menu, it is possible to set the parameters connected with the activation and duration of heat pump defrosting.

In the PUMP menu, it is possible to set the parameters connected with operation and protection of pumps.

In the ANTI-FREEZE menu, it is possible to set the parameters connected with the thermal control of resistors and control of the anti-

frost alarm.

In the FREE-COOLING menu, it is possible to set the parameters connected with free-cooling function and damper.

The SAFETIES DEVICES menu contains all parameters connected with alarms and management of safety devices which protect the

refrigerating circuit:

• activations

• reporting delays

• type of resetting.

In the MODBUS menu it is possible to set the parameters connected with modbus.

The VARIOUS PARAMETERS menu contains other general parameters connected with the management of Modbus communications,

transducer full-scale values and other configurable activations.

From the SAVE/RESTORE menu it is possible to restore the default values of all parameters of the application and save or download

from the programming key or internal controller memory.

page 19 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

6.9 Constructor Menu

The Configuration menu is a Level 4 menu, i.e. it requires entering of the Configuration level password, in order to be able to

display/modify the parameters contained in this branch. Furthermore, this level is only accessible with the machine in OFF mode.

Display LCD Display LED

CONFIGURATION COnF

H-AI

HARDWARE

EVCM C1-C2

PASSWORD PSd

This menu contains all the machine’s configuration parameters, which determine its operation mode and which functionalities are to be

enabled or disabled.

The CONFIGURATION menu contains the parameters machine configuration.

The HARDWARE menu allows to configure the I/O of the unit.

The EVCM menu allows to configure the main parameters of EVDRIVE03 for each Circuit.

H-dI

H-AO

H-dO

vCM1

vCM2

6.10 RTC Menu

This menu contains the functionality of the systems Real Time Clock, as setting the real time clock and setting daily scheduler (PTxx

parameters).

6.11 Alarms Menu

This menu allows viewing and acknowledging of alarms.

Display LCD Display LED

Show Alarms ALrm

Show History HiSt

The SHOW ALARMS menu shows the active alarms. Each time the DOWN key is pressed, the next active alarm is shown. If no alarms

are present, the message “NO ALARMS” is displayed.

The alarm can be acknowledged by pressing the ENTER key for 2 seconds, when the alarm condition is not active anymore.

The ALARM HISTORY page will show the latest alarm. To view the preceding alarm press ENTER key. This can be repeated until the first

alarm is displayed. The history is viewed in a circular manner.

By pressing the ESC key or after 60 seconds of no key activity, the main page will be displayed.

page 20 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

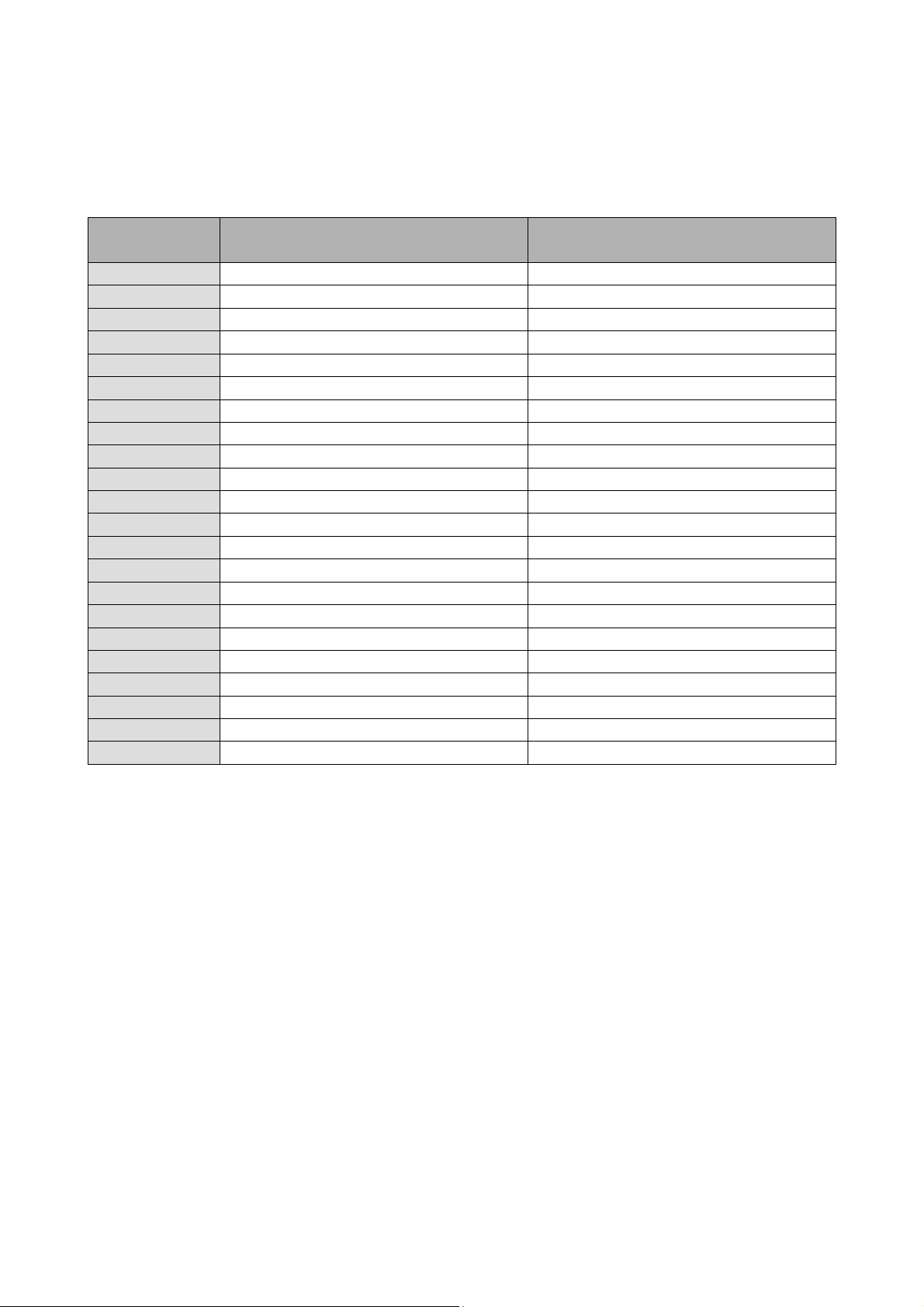

7 PARAMETERS LIST

The parameters managed by the application are listed below. Each parameter is accompanied by a brief description, the range of its

admissible values, units of measure, the assigned default value and the menu containing the parameter. Menus are structured on the

basis of the following logic:

Menu code Reference menu Status

OR RTC menu

UT User menu

MA Maintenance menu

MA-F Maintenance menu Operation

MA-M Maintenance menu Manual

MA-C Maintenance menu Calibration

MA-IO Maintenance menu Input/Output

IS Installation menu

IS-C Installation menu Compressors

IS-R Installation menu Regulation

IS-F Installation menu Fans

IS-D Installation menu Defrost

IS-P Installation menu Pumps

IS-AF Installation menu Anti-freeze

IS-FC Installation menu Free-Cooling

IS-S Installation menu Safeties

IS-M Installation menu Modbus

IS-V Installation menu Various

CO Configuration menu

CO-W Configuration menu Configuration

CO-HW Configuration menu Hardware

CO-V Configuration menu EVDRIVE03 circuit 1 and EVDRIVE03 circuit 2

page 21 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

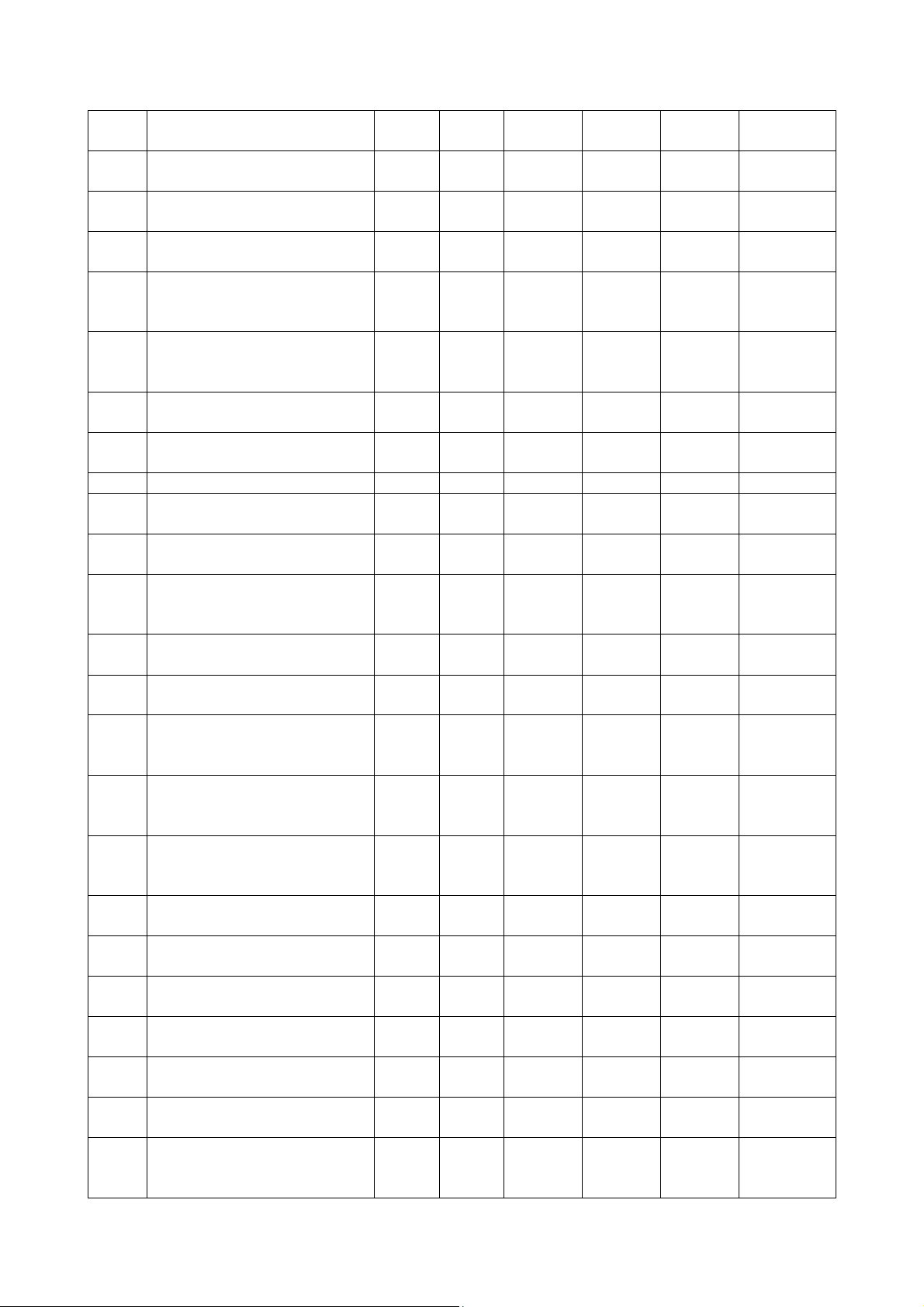

7.1 List of Configuration Parameters

Code

PT01 Working day 1 enable zone 1 0 0 1 OR

PT02 Working day 1 zone 1 start time 0

PT03 Working day 1 zone 1 stop time 0

PT04 Working day 1 zone 1 cooling offset 0 -20.0 20.0 °C OR

PT05 Working day 1 zone 1 heating offset 0 -20.0 20.0 °C OR

PT06 Working day 1 enable zone 2 0 0 1 OR

PT07 Working day 1 zone 2 start time 0

PT08 Working day 1 zone 2 stop time 0

PT09 Working day 1 zone 2 cooling offset 0 -20.0 20.0 °C OR

PT10 Working day 1 zone 2 heating offset 0 -20.0 20.0 °C OR

PT11 Working day 2 enable zone 1 0 0 1 OR

PT12 Working day 2 zone 1 start time 0

PT13 Working day 2 zone 1 stop time 0

PT14 Working day 2 zone 1 cooling offset 0 -20.0 20.0 °C OR

PT15 Working day 2 zone 1 heating offset 0 -20.0 20.0 °C OR

PT16 Working day 2 enable zone 2 0 0 1 OR

PT17 Working day 2 zone 2 start time 0

PT18 Working day 2 zone 2 stop time 0

PT19 Working day 2 zone 2 cooling offset 0 -20.0 20.0 °C OR

PT20 Working day 2 zone 2 heating offset 0 -20.0 20.0 °C OR

PT21 Monday schedule 1 0 2 OR

PT22 Tuesday schedule 1 0 2 OR

PT23 Wednesday schedule 1 0 2 OR

PT24 Thursday schedule 1 0 2 OR

Parameter Description Default Min. Max. M.U. Menu Notes

RTC MEN - This menu

is accessible ifPG03=1

00:00:0

0

00:00:0

0

00:00:0

0

00:00:0

0

00:00:0

0

00:00:0

0

00:00:0

0

00:00:0

0

page 22 of 120

23:59:59 OR

23:59:59 OR

23:59:59 OR

23:59:59 OR

23:59:59 OR

23:59:59 OR

23:59:59 OR

23:59:59 OR

0= none

working day

1= working

day1

2= working

day2

0= none

working day

1= working

day1

2= working

day2

0= none

working day

1= working

day1

2= working

day2

0= none

working day

1= working

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

PT25 Friday schedule 1 0 2 OR

PT26 Saturday schedule 0 0 2 OR

PT27 Sunday schedule 0 0 2 OR

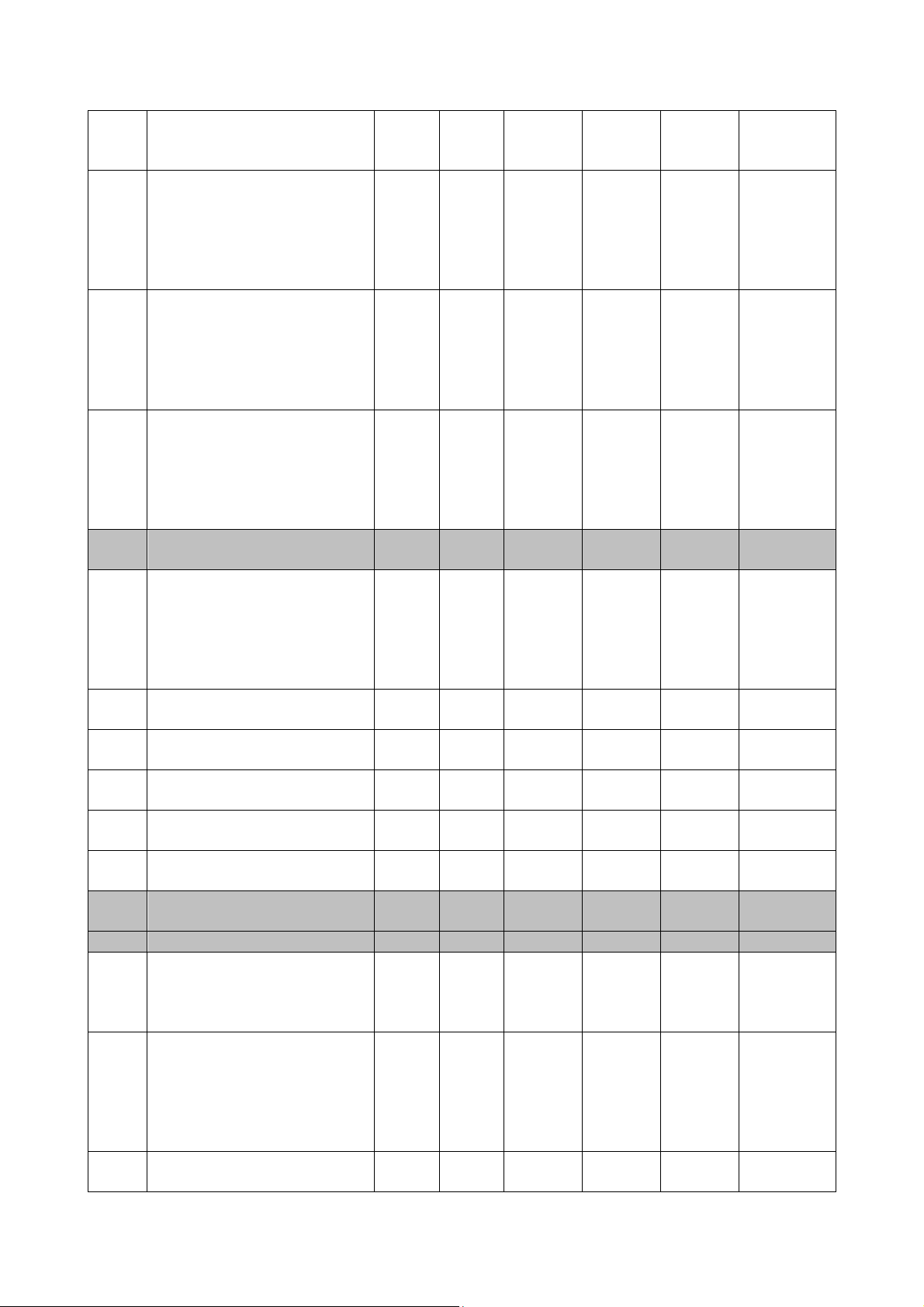

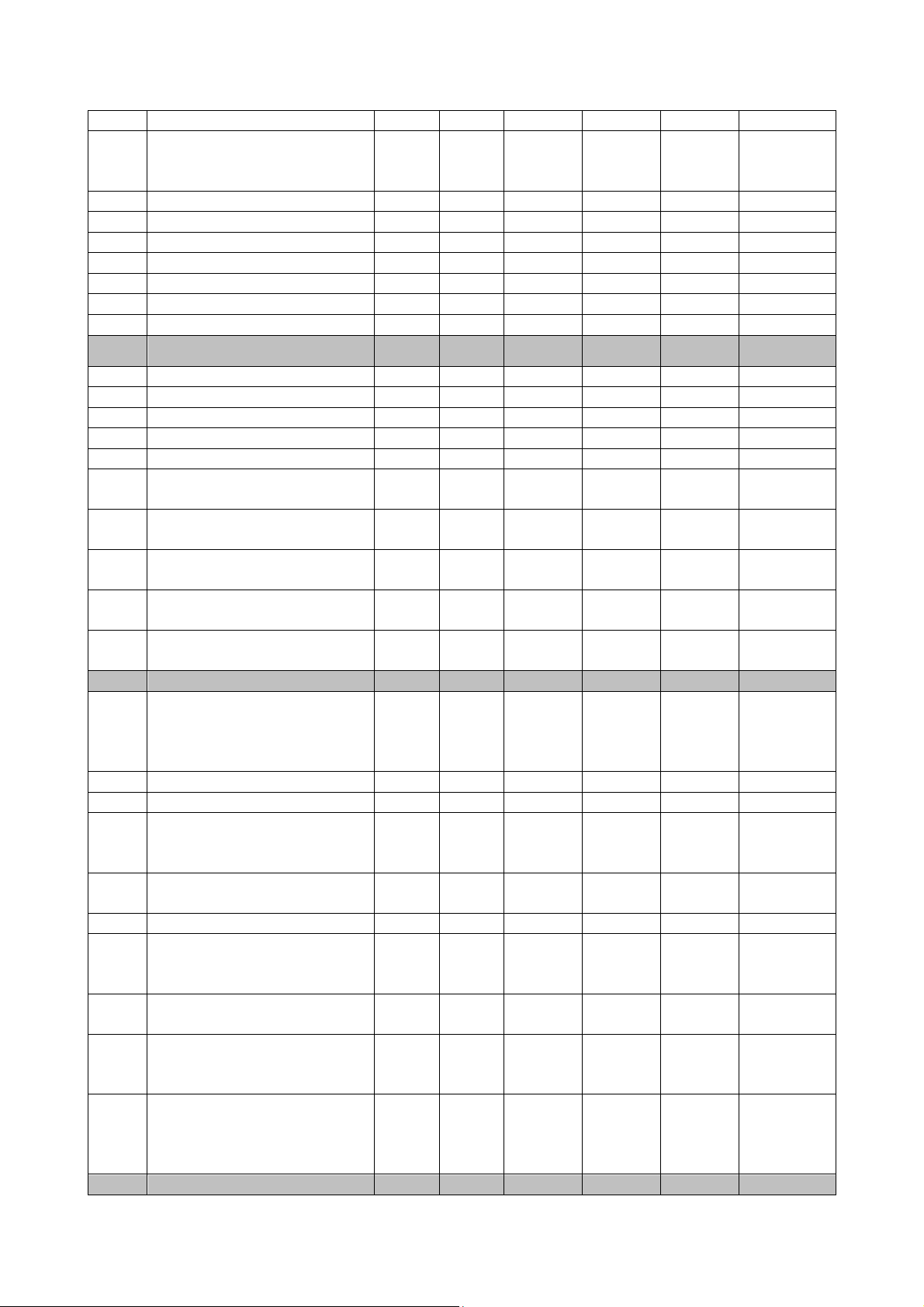

Level

1

It sets the operating mode:

ModE

0: Cool, (Chiller/summer)

1: Heat (Heat pump/winter)

SPC1

SPH1

PUC1

PUH1

PSd1

It sets the value of the summer set

point (chiller)

It sets the value of the winter set

point (heat pump).

Offset for the summer set point by

digital input

Offset for the winter set point by

digital input

It modifies the password at User

level.

Level

2

OPERATION

It sets the maximum number of

PM00

operating hours of compressors.

When this limit is exceeded, the

connected alarm is triggered.

PM01

PM02

PM03

PM04

PM05

It shows the number of operating

hours of compressors. One parameter

for each compressor.

PM06

PM30

It sets the maximum number of

operating hours of pumps. When this

USER MENU

0 0 1 UT

8.5 PC21 PC22 °C UT

44.0 PC23 PC24 °C UT

2.0 -20.0 20.0 °C UT

-2.0 -20.0 20.0 °C UT

0 -999 9999 UT

MAINTENANCE MENU

2000 0 9999 Hrs. x10 MA-F

0 0 9999

Hrs.

x10

2000 0 9999 Hrs. x10 MA-F

day1

2= working

day2

0= none

working day

1= working

day1

2= working

day2

0= none

working day

1= working

day1

2= working

day2

0= none

working day

1= working

day1

2= working

day2

Modifiable

only if the

units is a

chiller + heat

pump:

(PG00=2,4)

MA-F

page 23 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

limit is exceeded, the connected

alarm is triggered.

PM31

PM32

PM33

PM34

PM40

PM41

PM42

PM43

PM90 Last maintenance date - MA-F

PM11

PM12

PM13

PM14

PM15

PM16

PM21

PM22

PM23

PM24

PM25

PM26

PM35

PM36

PM37

PM38

PM45

PM46 It enables the manual/automatic 0 0 1 MA-M Only for

It shows the number of operating

hours of the first pump.

It shows the number of operating

hours of the second pump.

It shows the number of operating

hours of the first source pump.

It shows the number of operating

hours of the second source pump.

It sets the maximum number of

operating hours of fans. When this

limit is exceeded, the connected

0 0 9999 Hrs. x10 MA-F

0 0 9999

0 0 9999

0 0 9999

Hrs. x10

Hrs. x10

Hrs. x10

MA-F

MA-F

MA-F

Hrs. x10

2000 0 9999

MA-F

alarm is triggered.

It shows the number of operating

hours of the first fan or of the inverter

0 0 9999

Hrs. x10

MA-F

in Circuit # 1.

It shows the number of operating

hours of the second fan or of the

0 0 9999

Hrs. x10

MA-F

inverter in Circuit # 2.

It shows the number of operating

hours of the free-coolind dedicated

0 0 9999

Hrs. x10

MA-F

fan

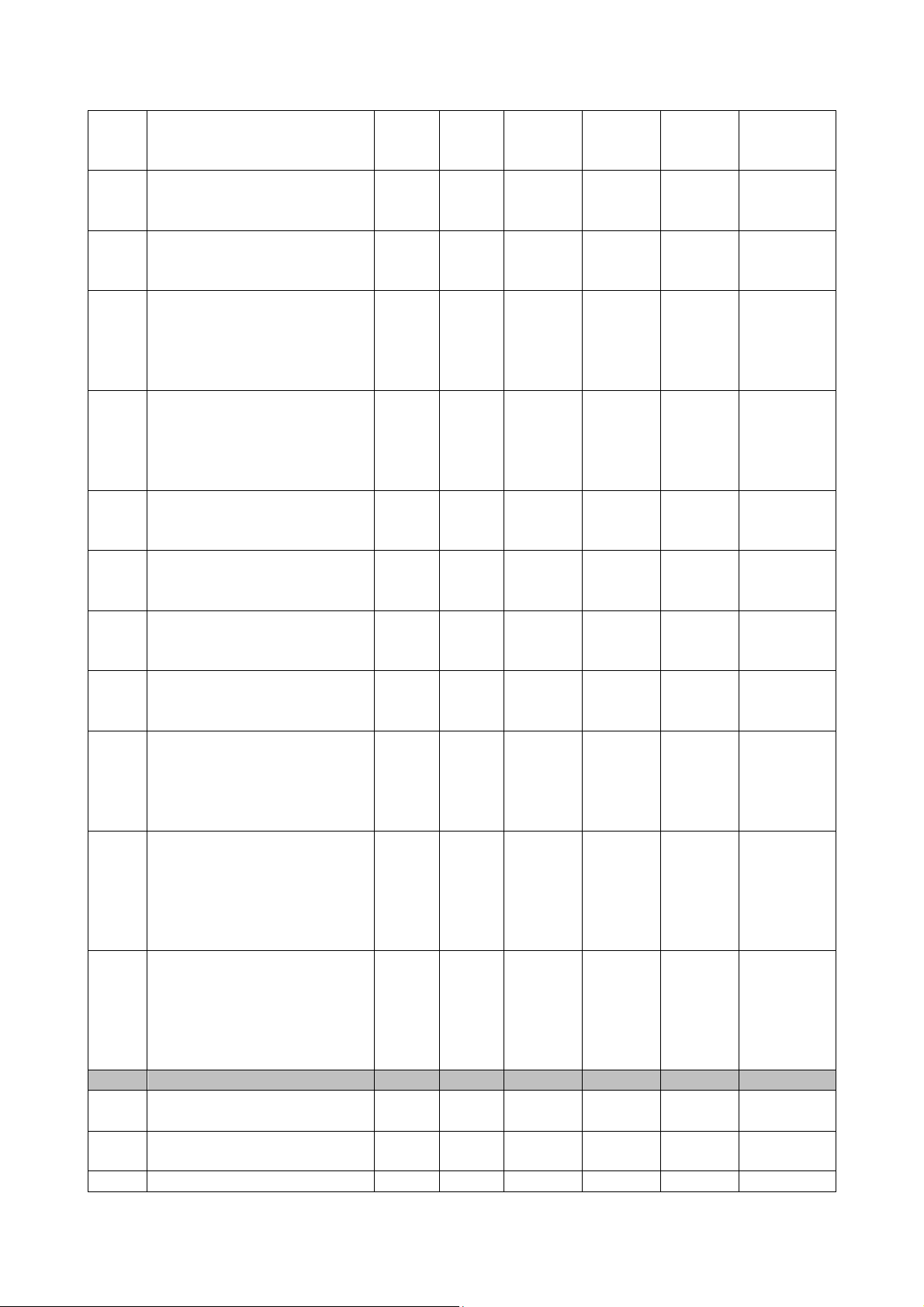

MANUAL

It enables the manual/automatic

operation of the compressor.

0: Auto – normal operation

0 0 1 MA-M

1: Manu – manual operation

One for each compressor.

During manual operation, it forces the

start-up/shutdown of the compressor.

0: switches the compressor OFF

0 0 1 MA-M

1: switches the compressor ON

One for each compressor.

It enables the manual/automatic

operation of the pump # 1.

0: Auto – normal operation

0 0 1 MA-M

1: Manu – manual operation

It enables the manual/automatic

operation of the pump # 2.

0: Auto – normal operation

0 0 1 MA-M

1: Manu – manual operation

During manual operation, it forces the

start-up/shutdown of pump #1

During manual operation, it forces the

start-up/shutdown of pump #2

0 0 1 MA-M

0 0 1 MA-M

It enables the manual/automatic

operation of the source pump # 1.

0: Auto – normal operation

0 0 1 MA-M

1: Manu – manual operation

Only for

Water-Water

unit

page 24 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

operation of the source pump # 2.

0: Auto – normal operation

1: Manu – manual operation

PM47

PM48

During manual operation, it forces the

start-up/shutdown of source pump #1

During manual operation, it forces the

start-up/shutdown of source pump #2

0 0 1 MA-M

0 0 1 MA-M

It enables the manual/automatic

operation of the condensing fan in

PM51

Circuit # 1.

0 0 1 MA-M

0: Auto – normal operation

1: Manu – manual operation

It enables the manual/automatic

operation of the condensing fan in

PM52

Circuit # 2.

0 0 1 MA-M

0: Auto – normal operation

1: Manu – manual operation

During manual operation, it forces the

PM61

value of the condensing fan in Circuit

0 0 100 % MA-M

#1.

During manual operation, it forces the

PM62

value of the condensing fan in Circuit

0 0 100 % MA-M

#2.

During manual operation, it forces the

PM63

value of the condensing fan in Circuit

0 0 1 MA-M

#1.

During manual operation, it forces the

PM64

value of the condensing fan in Circuit

0 0 1 MA-M

#2.

It enables the manual/automatic

operation of the dedicated free-

PM65

ccoling fan:

0 0 1 MA-M

0: Auto – normal operation

1: Manu – manual operation

During manual operation, it forces the

PM66

value of the dedicated free-cooling

0 0 100 % MA-M

fan

During manual operation, it forces the

PM67

value of the dedicated free-cooling

0 0 1 MA-M

fan

CALIBRATION

PM71

PM72

Calibration of external temperature

sensor

Calibration of free-cooling input

temperature sensor

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

PM73 Calibration of entering temperature 0.0 -10.0 10.0 °C MA-C

Water-Water

unit

Only for

Water-Water

unit

Only for

Water-Water

unit

With PF01=1

(Modulating

Control)

With PF01=1

(Modulating

Control)

With PF01=0

(Single stage

Control)

With PF01=0

(Single stage

Control)

Only for

Chillers

Air-Water unit

When PG13>0

Only for

Chillers

Air-Water unit

When PG13=1

Only for

Chillers

Air-Water unit

When PG13=2

page 25 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

sensor

PM74

PM75

PM76

PM77

PM78

PM79

PM80

PM81

PM82

PM83

PM84

PM85

PM86

PM87

PM88

PSd2

Level

PC01

PC02

PC04

PC05

PC06

Calibration of leaving temperature

sensor circuit 1

Calibration of leaving temperature

sensor circuit 2

Calibration of source leaving

temperature sensor circuit 1

Calibration of source leaving

temperature sensor circuit 2

Calibration of coil temperature sensor

circuit 1

Calibration of coil temperature sensor

circuit 2

Calibration of discharge compressors

temperature sensor circuit 1

Calibration of discharge compressors

temperature sensor circuit 2

Calibration of remote

aux.temperature sensor

Calibration of condensing pressure

sensor circuit 1

Calibration of condensing pressure

sensor circuit 2

Calibration of evaporatorating

pressure sensor circuit 1

Calibration of evaporatorating

pressure sensor circuit 2

Calibration of unique pressure sensor

circuit 1

Calibration of unique pressure sensor

circuit 2

It modifies the password at

Maintenance Operator level.

3

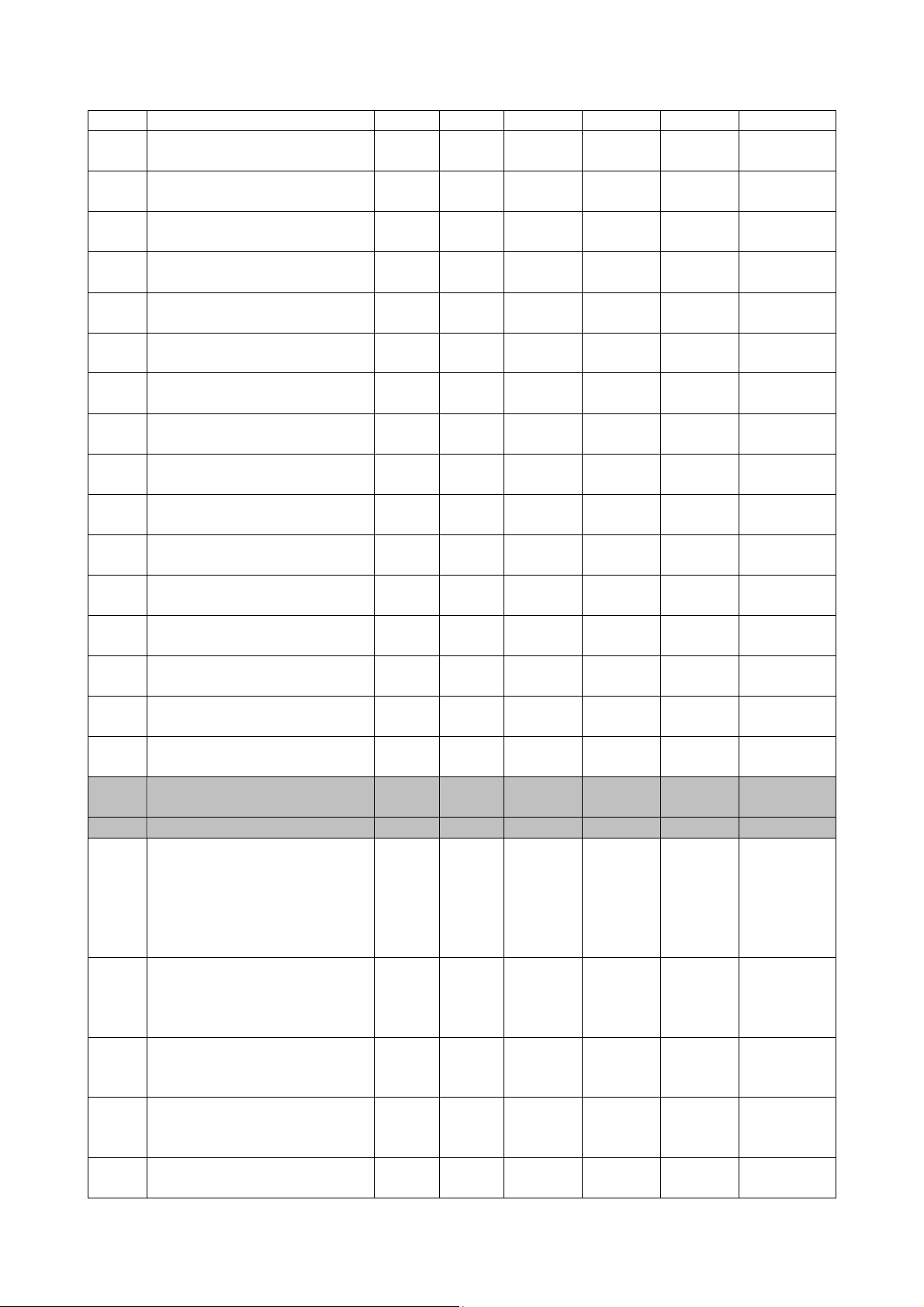

INSTALLATION MENU

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -10.0 10.0 °C MA-C

0.0 -20.0 20.0 Bar MA-C

0.0 -20.0 20.0 Bar MA-C

0.0 -20.0 20.0 Bar MA-C

0.0 -20.0 20.0 Bar MA-C

0.0 -20.0 20.0 Bar MA-C

0.0 -20.0 20.0 Bar MA-C

0 -999 9999 MA-F

COMPRESSORS

Rotation type used for compressor

management:

0: FIFO

1: LIFO

0 0 3 IS-C

2: FIFO + hours

3: LIFO + hours

Enabling mode of compressors in the

two circuits:

0: Circuit balancing

0 0 1 IS-C

1: Circuit saturation

Min. time for which the compressor

must remain ON, even if a shutdown

20 0 999 Sec. IS-C

has been requested.

Min. time for which the compressor

must remain OFF, even if a start-up

120 0 999 Sec. IS-C

has been requested.

Min. time which must elapse between

two start-ups of the same

360 0 999 Sec. IS-C

Only on twin

circuits

page 26 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

compressor.

Min. time which must elapse between

PC07

PC08

PC09

PC10

REGULATION

PC11

PC12

PC14

PC15

PC16

PC17

PC18

PC21

PC22

PC23

PC24

PC31 Power limiting for summer 50 0 100 % IS-R

PC32 Power limiting for winter 50 0 100 % IS-R

PC35

PC36 Summer forced shutdown set point 3.5 -30.0 23.0 °C IS-R

PC37 Winter forced shutdown set point 52.0 26.0 75.0 °C IS-R

PC41

PC42

PC43

PC45

start-ups of two different

compressors.

Min. time which must elapse between

shutdowns of two different

compressors.

Max. number of start-ups for every

hour (only for adaptive control).

Number of compressors per circuit

which will be forced in case of a

regulating-sensor alarm.

It sets the control type for

compressor management:

0: Lateral band

1: Zero energy band

Proportional band for lateral-band

control of compressors

Zone value for neutral-zone control of

compressors

Min. value of compressor zero energy

band

Max. value of compressor zero energy

band

Enabling/release time for subsequent

compressor step outside the zero

energy band

Enabling for auto-adaptive control of

the compressors’ zero energy band

Min. value of summer set point

(chiller)

Max. value of summer set point

(chiller)

Min. value of winter set point

(heat pump)

Max. value of winter set point

(heat pump)

Enabling of forced shutdown of

compressors

Enabling of pump-down

0 : No

1 : Yes, with timing

2 : Yes, with relative threshold

Compressor shutdown time in pump-

down

Relative threshold for pump-down

disabling

Enabling of high-temperature

pressure-switch control (chiller)

360 0 999 Sec. IS-C

180 0 999 Sec. IS-C

8 4 12 IS-C

1 0 PG03 IS-C

1 0 1 IS-R

2.5 1.0 20.0 °C IS-R

3.0 PC15 PC16 °C IS-R

1.0 0.1 10.0 °C IS-R

5.0 0.1 10.0 °C IS-R

20 0 999 Sec. IS-R

No (0) No (0) Yes (1) IS-R

5.0 -15.0 SPC1 °C IS-R

20.0 SPC1 23.0 °C IS-R

30.0 23.0 SPH1 °C IS-R

44.0 SPH1 70.0 °C IS-R

No (0) No (0) Yes (1) IS-R

1 0 2 IS-R

5 0 240 Sec. IS-R

1.5 0.0 5.0 Bar IS-R

No (0) No (0) Yes (1) IS-R

page 27 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

PC46

PC47

PC48

PC49

PC50

PC51

PC52

PC53

PC54

PC55

Pressure set point for high-

temperature pressure-switch control

Pressure differential for high-

temperature pressure-switch control

External high temperature threshold

for pressure-switch control

Min. time for maintaining pressure-

switch partialization

Enabling of low-temperature

pressure-switch control (heat pump)

Pressure setpoint for low-temperature

pressure-switch control

Pressure differential for low-

temperature pressure-switch control

External low temperature threshold

for pressure-switch control

Outlet water high-temperature

threshold for pressure-switch control

Delay for partialization from low

pressure alarm

27.0 0.0 45.0 Bar IS-R

2.0 0.0 5.0 Bar IS-R

12.0 -30.0 23.0 °C IS-R

10 0 99 Min. IS-R

No (0) No (0) Yes (1) IS-R

3.2 0.0 10.0 Bar IS-R

2.0 0.0 10.0 Bar IS-R

-5.0 -10.0 5.0 °C IS-R

48.0 30.0 70.0 °C IS-R

900 0 999 Sec. IS-R

PC61 Summer commutation set point 20.0 PC62 70.0 °C IS-R

PC62 Winter commutation set point 10.0 0.0 PC61 °C IS-R

PC64

PC65

PC66

PC67

PC68

PC69

Max. dynamic offset compared to

summer set point (chiller)

Compensation start temperature for

dynamic summer set point

Compensation stop temperature for

dynamic summer set point

Max. dynamic offset compared to

winter set point (heat pump)

Compensation start temperature for

dynamic winter set point

Compensation stop temperature for

dynamic winter set point

-10.0 -20.0 20.0 °C IS-R

30.0 -15.0 PC66 °C IS-R

60.0 PC65 70.0 °C IS-R

10.0 -20.0 20.0 °C IS-R

0.0 -15.0 PC69 °C IS-R

30.0 PC68 70.0 °C IS-R

Function limit management:

PC70

0 = Heat pump only

1 = Auxiliary output

0 0 2 IS-R

2 = Auxiliary output and heat pump

PC71 Function limit set point -7.0 -30.0 30.0 °C IS-R

PC72 Function limit differential 4.0 0.1 10.0 °C IS-R

PC80 Enabling of control upon request No (0) No (0) Sì (1) IS-R

PC81 Summer setpoint controlupon request 15.0 -15.0 70.0 °C IS-R

PC82 Winter setpoint control upon request 45.0 -15.0 70.0 °C IS-R

PC83

Summer differential control upon

request

4.0 0.1 10.0 °C IS-R

PC84 Winter differential control upon request 4.0 0.1 10.0 °C IS-R

PC85 Delayed control upon request 5 0 999 Sec IS-R

FANS

PF01 Condenser control type 0 0 1 IS-F

PF02 It gives the choice to enable fan Yes (1) No (0) Yes (1) IS-F

0=Modulating

control

1=Single

stage control

page 28 of 120

EVCO S.p.A.

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

control only if at least one compressor

is ON.

PF03

PF07

PF08

PF09

PF10

PF11

PF12

PF13 Enabling of forcing to maximum Yes (1) No (0) Yes (1) IS-F

PF14

PF15

PF16

PF21

PF22

PF24

PF25

PF26

PF27

PF28

PF31

PF32

PF33

PF34

PF36

It sets whether or not fans must

switch OFF during defrosting cycles.

Min. time which must elapse between

the start-ups of two different fans.

Min. time which must elapse between

the shutdowns of two different fans.

Forcing of fans in case of condensing

sensor alarm

Forcing of fans in case of condensing

sensor alarm

Condensing control set point for

summer operation (chiller)

Linear control band for condensation

in summer operation (chiller)

Max. forcing enabling set point in

summer operation (chiller)

Disabling differential for max. forcing

in summer operation (chiller)

Integral time for control of valves

(cooling)

Condensing control set point in winter

operation (heat pump)

Linear control band for condensation

in winter operation (heat pump)

Max. forcing activation set point in

winter operation (heat pump,

inverter)

Max. forcing de-activation differential

in winter operation (heat pump,

inverter)

Integral time for control of valves

(heat pump)

Min. value for condenser forcing

(inverter)

Speed-up time at fan start-up

(inverter)

Lower limit for condensing linear

control (inverter)

Upper limit for condensing linear

control (inverter)

Enabling of control under the

minimum condensing limit (inverter)

Switch-off differential under the

minimum condensing limit (inverter)

Enabling of preventilation

0: No

1: Winter only

No (0) No (0) Yes (1) IS-F

10 0 999 Sec. IS-F

20 0 999 Sec. IS-F

No (0) No (0) Yes (1) IS-F

0.0 0.0 100.0 % IS-F

20.0 5.0 45.0 Bar IS-F

12.0 0.1 15.0 Bar IS-F

26.0 15.0 45.0 Bar IS-F

2.0 0.1 5.0 Bar IS-F

0 0 999 Sec IS-F

9.0 0.5 15.0 Bar IS-F

2.0 0.1 15.0 Bar IS-F

3.2 0.5 20.0 Bar IS-F

0.5 0.1 5.0 Bar IS-F

0 0 999 Sec IS-F

0.0 0.0 100.0 % IS-F

4 0 999 Sec. IS-F

30.0 0 PF32 % IS-F

100.0 PF31 100.0 % IS-F

Yes (1) No (0) Yes (1) IS-F

2.0 0.0 5.0 Bar IS-F

0 0 2 IS-F

With PF01=0

(Single stage

Control)

With PF01=1

(Modulating

Control)

If PF16=0

Integral action

not present

If PF26=0

Integral action

not present

page 29 of 120

EVCO S.p.A.

Only for Air

-

c-pro 3 micro CHIL | Application manual ver. 1.0 | Codice 144CP3CHE104

2: Always

PF38 Preventilation speed 50.0 0.0 100.0 % IS-F

PF39 Preventilation time 10 0 999 Sec IS-F

PF41 Value x1 of fan linearization table 25.0 0.0 PF42 % IS-F

PF42 Value x2 of fan linearization table 50.0 PF41 PF43 % IS-F

PF43 Value x3 of fan linearization table 75.0 PF42 100.0 % IS-F

PF45 Value y1 of fan linearization table 25.0 0.0 PF46 % IS-F

PF46 Value y2 of fan linearization table 50.0 PF45 PF47 % IS-F

PF47 Value y3 of fan linearization table 75.0 PF46 100.0 % IS-F

DEFROST

Pd01 Pressure set point at defrosting start 6.0 0.0 Pd02 Bar IS-D

Pd02 Pressure set point at defrosting stop 12.0 Pd01 45.0 Bar IS-D

Pd03 Waiting interval at defrosting start 1200 60 Pd23 Sec. IS-D

Pd05 Max. duration of defrosting 300 10 600 Sec. IS-D

Pd06 Duration of dripping 120 0 600 Sec. IS-D

Pd07

Pd20

Pd21

Pd22

Pd23

PUMPS

PP01

PP02 ON time in cyclical operation 120 1 999 Sec. IS-P

PP03 OFF time in cyclical operation 120 1 999 Sec. IS-P

PP04

PP05

PP07 Shutdown of pump during defrosting No (1) No (0) Yes (1) IS-P

PP08

PP09

PP10

PP21

ANTI-FREEZE

Min. defrost waiting interval after

compressor re-start

Enabling of defrosting cycle

compensation

Outdoor air temperature set point for

defrosting compensation start

Outdoor air temperature set point for

defrosting compensation stop

Max. waiting interval at defrosting

stop

Pump operation:

0 = Continuous operation

1 = Operation at thermostat’s request

2 = Cyclical operation

Min. interval which must elapse

between pump start-up and first

compressor

Min. interval which must elapse

between circuit shutdown and pump

Difference in operating hours between

the two pumps, requiring their being

swapped.

Pump operating time at low water

flow (flow alarm)

Pump operating time at low

temperature of outflow water (anti-

frost alarm)

Source Pump operation:

0= Continuous operation

1=Operation at thermostat’s request

2 = Cyclical operation

60 0 600 Sec. IS-D

No (0) No (0) Yes (1) IS-D

5.0 Pd22 70.0 IS-D

0.0 -30.0 Pd21 IS-D

3600 Pd03 9600 IS-D

0 0 2 IS-P

60 1 999 Sec. IS-P

60 1 999 Sec. IS-P

4 1 240 Hours IS-P

15 0 999 Sec. IS-P

15 0 999 Sec. IS-P

0 0 2 IS-P

With PF01=1

(Modulating

Control)

Water unit

Only for

Water-Water

unit

page 30 of 120

Loading...

Loading...