EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.1 | Code 114CP3UKE114

c-pro 3 micro and c-pro 3 kilo

PROGRAMMABLE CONTROLLERS

ENGLISH

HARDWARE MANUAL ver. 1.1

CODE 114CP3UKE114

page 1 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Important

Important

Read this document carefully before the installation and before the use and follow all the additional information for the installation and

for the electrical connection; keep this document close to the devices for future consultations.

The following symbols support the reading of the document:

it indicates a suggestion

it indicates an additional information to be followed.

The devices must be disposed according to the local legislation about the collection for electrical and electronic equipment.

page 2 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Index

1. INTRODUCTION ....................................................................................................................................................................... 5

1.1. Introduction ............................................................................................................................................................................... 5

2. DESCRIPTION .......................................................................................................................................................................... 6

2.1. Description programmable controllers ....................................................................................................................................... 6

2.2. Description I/O expansions ........................................................................................................................................................ 8

3. SIZE AND INSTALLATION........................................................................................................................................................ 9

3.1. Size programmable controllers .................................................................................................................................................. 9

3.2. Size I/O expansions .................................................................................................................................................................. 9

3.3. Installation ............................................................................................................................................................................... 10

3.4. Additional information for installation ....................................................................................................................................... 10

4. ELECTRICAL CONNECTION ................................................................................................................................................. 11

4.1. Connectors programmable controllers ..................................................................................................................................... 11

4.2. Connectors I/O expansions ..................................................................................................................................................... 13

4.3. Meaning of connectors ............................................................................................................................................................ 15

4.3.1. Example of electrical connection .................................................................................................................................... 23

4.4. Additional information for electrical connection ........................................................................................................................ 24

5. USER INTERFACE ................................................................................................................................................................. 25

5.1. Keyboard ................................................................................................................................................................................. 25

5.2. Signalling LEDs ....................................................................................................................................................................... 25

5.2.1. LEDs at the front of the device ....................................................................................................................................... 25

6. CONFIGURATION .................................................................................................................................................................. 27

6.1. Configuring a programmable controller .................................................................................................................................... 27

6.1.1. Configuring a built-in programmable controller ............................................................................................................... 27

6.1.2. Configuring a blind programmable controller .................................................................................................................. 29

6.2. Configuring an I / O expansion ................................................................................................ ................................................ 30

6.3. Configuring a device through an user interface (Vgraph, Vtouch, Vroom or Vcolor) ................................................................ 31

6.4. List of configuration parameters .............................................................................................................................................. 32

7. USER INTERFACES ............................................................................................................................................................... 46

7.1. Preliminary information ............................................................................................................................................................ 46

7.2. Vgraph .................................................................................................................................................................................... 46

7.2.1. Introduction .................................................................................................................................................................... 46

7.2.2. Summarizing table of the main features and available models ....................................................................................... 46

7.2.3. Size ............................................................................................................................................................................... 47

7.3. Vtouch ..................................................................................................................................................................................... 48

7.3.1. Introduction .................................................................................................................................................................... 48

7.3.2. Summarizing table of the main features and available models ....................................................................................... 48

7.3.3. Size ............................................................................................................................................................................... 49

7.4. Vroom ..................................................................................................................................................................................... 50

7.4.1. Introduction .................................................................................................................................................................... 50

7.4.2. Summarizing table of the main features and available models ....................................................................................... 50

7.4.3. Size ............................................................................................................................................................................... 51

7.5. Vcolor ...................................................................................................................................................................................... 52

7.5.1. Introduction .................................................................................................................................................................... 52

7.5.2. Summarizing table of the main features and available models ....................................................................................... 52

7.5.3. Size ............................................................................................................................................................................... 53

8. TECHNICAL DATA ................................................................................................................................................................. 54

8.1. Technical data ......................................................................................................................................................................... 54

page 3 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

page 4 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

1. INTRODUCTION

1.1. Introduction

c-pro 3 micro and c-pro 3 kilo are two families of programmable controllers.

The family consists of:

- programmable controllers (c-pro 3 micro, c-pro 3 micro+, c-pro 3 kilo and c-pro 3 kilo+)

- I / O expansions (c-pro 3 EXP micro, c-pro 3 EXP micro+, c-pro 3 EXP kilo and c-pro 3 EXP kilo+).

c-pro 3 micro and c-pro 3 micro+ are available in the following versions:

- with 4 + 4 digits custom LED display (with function icons) and with a 6 buttons (with preset functions) keyboard made of

silicone rubber integrated in the controller, hereinafter also called “built-in LED versions”

- blind (they can be used for example with an user interface such as Vgraph, Vtouch, Vroom or Vcolor), hereinafter also

called “blind versions”.

c-pro 3 kilo and c-pro 3 kilo+ are available in the following versions:

- with 128 x 64 pixel single colour LCD graphic display (black with rearlighting through white LEDs) and with a 6 buttons (with

preset functions) keyboard made of silicone rubber integrated in the controller, hereinafter also called “built-in LCD versions”

- with 4 + 4 digits custom LED display (with function icons) and with a 6 buttons (with preset functions) keyboard made of

silicone rubber integrated in the controller, hereinafter also called “built-in LED versions”

- blind (they can be used for example with an user interface such as Vgraph, Vtouch, Vroom or Vcolor), hereinafter also

called “blind versions”.

Some integrate an unipolar stepper electronic expansion valves driver.

The I/O expansions are available in blind version.

Through the development environment UNI-PRO 3 (to order separately) it is possible to realize the application software and through a

commun USB cable it is possible to program the controllers.

The devices look in case 4 DIN modules; installation is in electrical panel, on DIN rail.

Through a common USB peripheral it is possible to make the upload and the download of the configuration parameters.

page 5 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

2. DESCRIPTION

2.1. Description programmable controllers

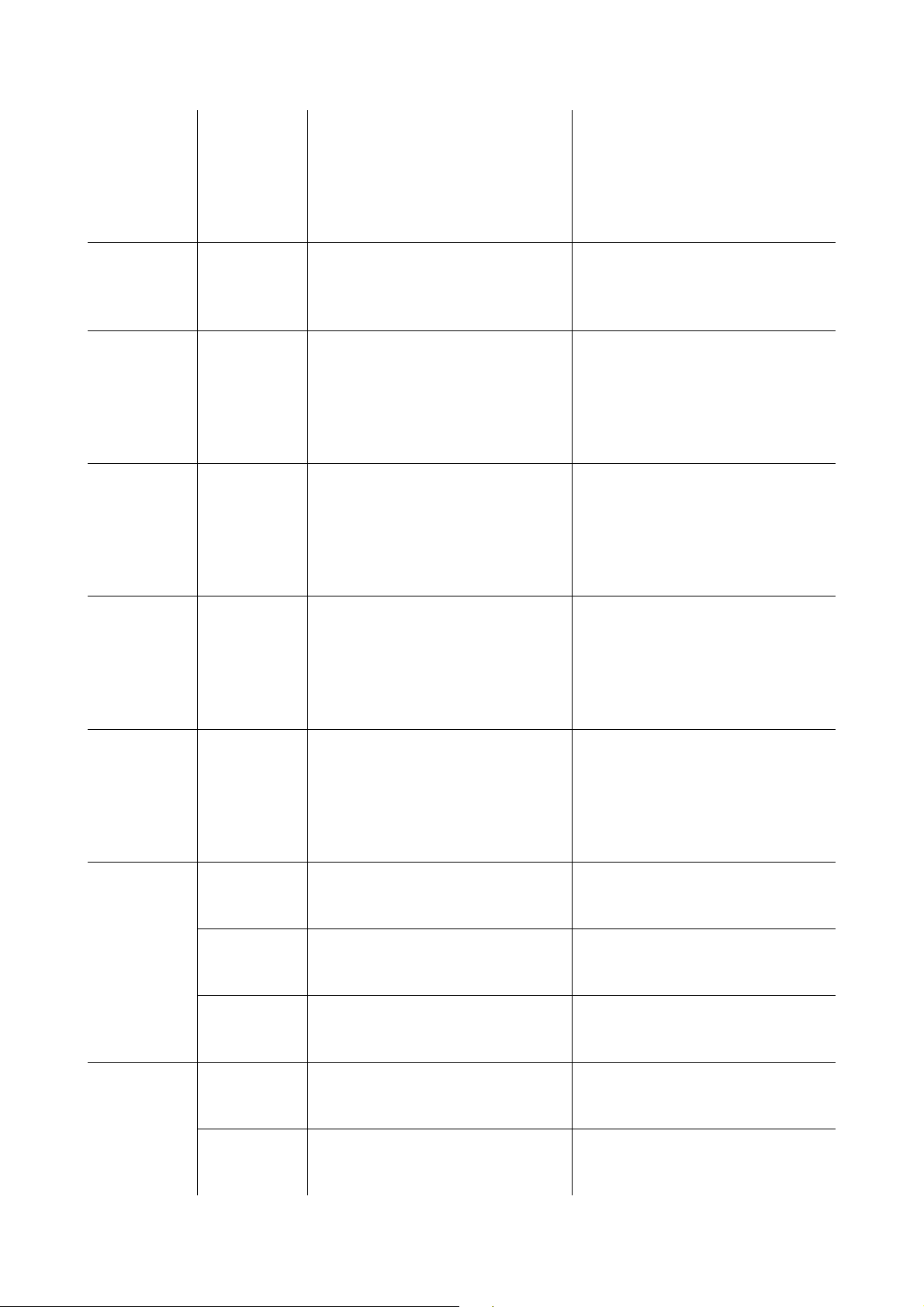

The following drawing shows the aspect of the programmable controllers.

The following table shows the meaning of the parts of the controller.

Part Meaning

1 digital outputs 6 and 7

2 digital outputs 1 and 5

according to the model:

3

4 display and keyboard (not available in the blind versions)

5

6 analog inputs 1... 6, digital inputs 1... 5 and analog outputs 1... 3

- digital outputs 9 (available in models c-pro 3 micro+ and c-pro 3 kilo+ only)

- unipolar stepper electronic expansion valves driver (available in models c-pro 3 micro+ and c-pro 3 kilo+

only)

analog inputs 7... 9, digital inputs 6... 9 and analog outputs 4... 6 (available in models c-pro 3 micro+ and c-pro 3

kilo+ only)

7 OTG USB port

micro-switch to:

8

9 power supply, RS-485 port with Modbus master communication protocol and CAN port

page 6 of 62

- plug in the termination of the RS-485 port with Modbus slave communication protocol

- plug in the termination of the CAN port

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

10

11

RS-485 port with Modbus master communication protocol (available in models c-pro 3 micro+ and c-pro 3 kilo+

only)

micro-switch to plug in the termination of the RS-485 port with Modbus master communication protocol (available in

models c-pro 3 micro+ and c-pro 3 kilo+ only)

12 signalling LEDs

according to the model:

13

- digital outputs 8 (available in models c-pro 3 micro+ and c-pro 3 kilo+ only)

- unipolar stepper electronic expansion valves driver (available in models c-pro 3 micro+ and c-pro 3 kilo+

only)

page 7 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

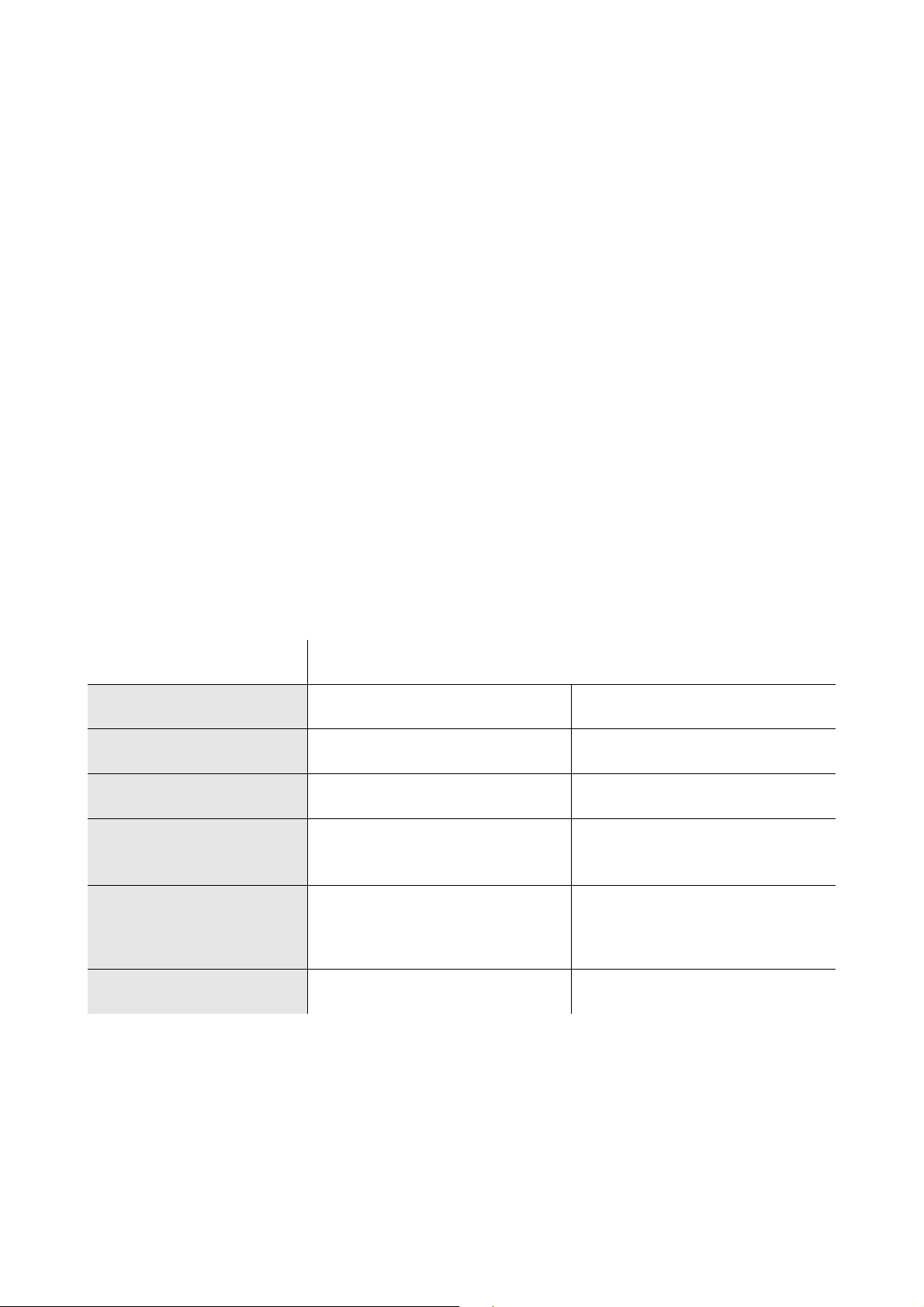

2.2. Description I/O expansions

The following drawing shows the aspect of the I/O expansions.

The following table shows the meaning of the parts of the expansion.

Part Meaning

1 digital outputs 6 and 7

2 digital outputs 1 and 5

3 digital outputs 9 (available in models c-pro 3 EXP micro+ and c-pro 3 EXP kilo+ only)

4

5 analog inputs 1... 6, digital inputs 1... 5 and analog outputs 1... 3

6 OTG USB port

7 micro-switch to plug in the termination of the CAN port

8 power supply and CAN port

analog inputs 7... 9, digital inputs 6... 9 and analog outputs 4... 6 (available in models c-pro 3 EXP micro+ and

c-pro 3 EXP kilo+ only)

9 signalling LEDs

10 digital outputs 8 (available in models c-pro 3 EXP micro+ and c-pro 3 EXP kilo+ only)

page 8 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

3. SIZE AND INSTALLATION

3.1. Size programmable controllers

4 DIN modules; size in mm (in).

3.2. Size I/O expansions

4 DIN modules; size in mm (in).

page 9 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

3.3. Installation

On DIN rail 35.0 x 7.5 mm (1.377 x 0.295 in) or 35.0 x 15.0 mm (1.377 x 0.590 in).

To install the devices operate as shown in the following drawing.

1 2

To remove the devices remove possible extractable screw terminal blocks plugged at the bottom first, then operate on the DIN rail clips

with a screwdriver as shown in the following drawing.

3 4

To install the devices again press the DIN rail clips to the end first.

3.4. Additional information for installation

- working conditions (working temperature, humidity, etc.) must be between the limits indicated in the technical data

- do not install the devices close to heating sources (heaters, hot air ducts, etc.), equipments provided with big magnetos (big

speakers, etc.), locations subject to direct sunlight, rain, humidity, dust, mechanical vibrations or bumps

- according to the safety legislation, the protection against electrical parts must be ensured by a correct installation of the

devices; the parts that ensure the protection must be installed so that you can not remove them if not by using a tool.

page 10 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

4. ELECTRICAL CONNECTION

4.1. Connectors programmable controllers

The following drawing shows the connectors of c-pro 3 micro and of c-pro 3 kilo.

The following drawing shows the connectors of c-pro 3 micro+ and of c-pro 3 kilo+.

Models with 9 electromechanical relays

page 11 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Models with 7 electromechanical relays and 2 solid state relays

Models with integrated unipolar stepper electronic expansion valves driver

page 12 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

4.2. Connectors I/O expansions

The following drawing shows the connectors of c-pro 3 EXP micro and of c-pro 3 EXP kilo.

The following drawing shows the connectors of c-pro 3 EXP micro+ and of c-pro 3 EXP kilo+.

Models with 9 electromechanical relays

page 13 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Models with 7 electromechanical relays and 2 solid state relays

page 14 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

4.3. Meaning of connectors

The following tables show the meaning of the connectors.

Digital outputs 1… 7

Electromechanical relays.

Terminal Meaning

NO6 normally open contact digital output 6 (3 res. A @ 250 VAC)

NO7 normally closed contact digital output 7 (3 res. A @ 250 VAC)

CO6/7 common digital outputs 6 and 7

Terminal Meaning

NO1 normally open contact digital output 1 (3 res. A @ 250 VAC)

NO2 normally open contact digital output 2 (3 res. A @ 250 VAC)

CO1/2 common digital outputs 1 and 2

NO3 normally open contact digital output 3 (3 res. A @ 250 VAC)

NO4 normally open contact digital output 4 (3 res. A @ 250 VAC)

NO5 normally open contact digital output 5 (3 res. A @ 250 VAC)

CO3/4/5 common digital outputs 3, 4 and 5

The maximum length of the connecting cables of the digital outputs is 100 m (328 ft).

Digital outputs 8 and 9

According to the model, electromechanical or solid state relays.

Terminal Meaning

CO8 common digital output 8

NO8

NC8 normally closed contact digital output 8

Terminal Meaning

CO9 common digital output 9

page 15 of 62

normally open contact digital output 8 (3 res. A @ 250 VAC in case of electromechanical relay; 24 VAC/DC, 0,6 A

max in case of solid state relay)

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

NO9

normally open contact digital output 9 (3 res. A @ 250 VAC in case of electromechanical relay; 24 VAC/DC, 0,6 A

max in case of solid state relay)

NC9 normally closed contact digital output 9

The maximum length of the connecting cables is:

- 100 m (328 ft) in case of electromechanical relay

- 100 m (328 ft) in case of solid state relay.

Unipolar stepper electronic expansion valves driver

The following drawing shows the connectors of the unipolar stepper electronic expansion valves driver.

The following table shows the meaning of the connectors.

Terminal Meaning

SOA unipolar stepper motor coli 1

SOB unipolar stepper motor coli 2

SOC unipolar stepper motor coli 3

SOD unipolar stepper motor coli 4

COM12V motor power supply (12 VDC, 260 mA max.)

The maximum length of the connecting cables is 3 m (9,842 ft).

page 16 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

RS-485 port

RS-485 port with Modbus master communication protocol (with network already polarized internally).

Terminal Meaning

GND ground

A / + terminal 1 of the transceiver

B / - terminal 0 of the transceiver

The maximum length of the connecting cables of the RS-485 port is 1,000 m (3,280 ft); also look at the Modbus specifications

and implementation guides manual (the document is available on the internet site www.modbus.org).

Connect the RS-485 port using a twisted pair.

The following table shows the function codes supported by the controller.

Function

code

Meaning

FC 01 read coils

FC 02 read discrete inputs

FC 03 read multiple registers

FC 04 read input registers

FC 05 write single coil

FC 06 write single register

FC 08 diagnostic

FC 15 write multiple coils

FC 16 write multiple registers

FC 23 read write multiple registers

For the settings about the RS-485 port look at chapter 6 “CONFIGURATION”.

Termination RS-485 port

Micro-switch to plug in the termination of the RS-485 port with Modbus master communication protocol (120 Ω, 0.25 W); position micro-

switch 1 on position ON to plug in the termination of the RS-485 port (plug in the termination of the first and of the last element of the

network).

page 17 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Analog inputs 7... 9, digital inputs 6... 9 and analog outputs 4... 6

Terminal Meaning

GND common analog inputs and analog outputs

AI7

AI8

AI9

analog input 7 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers)

analog input 8 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers)

analog input 9 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers)

AO4 analog output 4 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

AO5 analog output 5 (for 0-10 V signal)

AO6 analog output 6 (for 0-10 V signal)

DI6 digital input 6 (optoisolated, 24 VAC / DC and 50 / 60 Hz)

DI7 digital input 7 (optoisolated, 24 VAC / DC and 50 / 60 Hz)

DI8 digital input 8 (optoisolated, 24 VAC / DC and 50 / 60 Hz)

DI9 digital input 9 (optoisolated, 24 VAC / DC and 50 / 60 Hz)

COM common digital inputs

The maximum length of the connecting cables is:

- 100 m (328 ft) for the analog inputs

- 100 m (328 ft) for the digital inputs

- 100 m (328 ft) for the analog outputs.

For the settings about the analog inputs look at chapter 6 “CONFIGURATION”.

page 18 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Power supply, RS-485 port with Modbus slave communication protocol and CAN port

Terminal Meaning

V≅ +

V≅ -

power supply controller (12 VAC in c-pro 3 micro and in c-pro 3 micro+, 24 VAC / 20... 30 VDC in c-pro 3 kilo and in

c-pro 3 kilo+); if the controller is powered in alternating current, connect the phase

power supply controller (12 VAC in c-pro 3 micro and in c-pro 3 micro+, 24 VAC / 20... 30 VDC in c-pro 3 kilo and in

c-pro 3 kilo+); if the controller is powered in alternating current, connect the neutral

A / + terminal 1 of the transceiver RS-485 port

B / - terminal 0 of the transceiver RS-485 port

CAN + signal + CAN port

CAN - signal - CAN port

The maximum length of the connecting cables is:

- 100 m (328 ft) for the power supply

- 1,000 m (3,280 ft) for the RS-485 port; also look at the Modbus specifications and implementation guides manual

(the document is available on the internet site www.modbus.org).

The maximum length of the connecting cables of the CAN port depends on the baud rate of the CANbus communication, as

follows:

- 1,000 m (3,280 ft) with baud rate 20,000 baud

- 500 m (1,640 ft) with baud rate 50,000 baud

- 250 m (820 ft) with baud rate 125,000 baud

- 50 m (164 ft) with baud rate 500,000 baud.

Protect the power supply with a fuse rated 2 A-T 250 V.

If the controller is powered in direct current, it will be necessary to respect the polarity of the power supply voltage.

In case of connection in a network:

- for the devices powered at 12 VAC, the power supply of the devices in the network must be galvanically isolated one another

- for the devices powered at 24 VAC, it is necessary the phase powering the device is the same powering the remaining

devices in the network

- for the devices powered at 20... 30 VDC, it is necessary to recpect the polarity ot the power supply voltage of all the devices in

the network.

Connect the RS-485 port using a twisted pair.

page 19 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

The following table shows the function codes supported by the controller.

Function

code

Meaning

FC 01 read coils

FC 02 read discrete inputs

FC 03 read multiple registers

FC 04 read input registers

FC 05 write single coil

FC 06 write single register

FC 08 diagnostic

FC 15 write multiple coils

FC 16 write multiple registers

FC 23 read write multiple registers

For the settings about the RS-485 port look at chapter 6 “CONFIGURATION”.

The maximum number of devices that can make a CAN network (32) depends on the bus load; the bus load depends on the baud rate

of the CANbus communication and on the kind of device in the network.

For example: a CAN network can be made of a programmable controller, of four I / O expansions and of four user interfaces

with baud rate 500,000 baud.

Connect the CAN port using a twisted pair.

For the settings about the CAN port look at chapter 6 “CONFIGURATION”.

Termination RS-485 port and termination CAN port

Micro-switch to:

- plug in the termination of the CAN port (120 Ω, 0,5 W); position micro-switch 2 on position ON to plug in the termination of the

CAN port (plug in the termination of the first and of the last element of the network).

- to plug in the termination of the RS-485 port with Modbus slave communication protocol (120 Ω, 0.25 W); position micro-

switch 1 on position ON to plug in the termination of the RS-485 port (plug in the termination of the first and of the last element

of the network).

page 20 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

USB port

OTG USB port.

Analog inputs 1... 6, digital inputs 1... 5 and analog outputs 1... 3

Terminal Meaning

AI1

AI2

AI3

analog input 1 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers)

analog input 2 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers)

analog input 3 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers)

AI4 analog input 4 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes)

AI5 analog input 5 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes)

AI6 analog input 6 (configurable via configuration parameter for PTC / NTC / Pt 1000 probes)

DI4 digital input 4 (optoisolated, 24 VAC / DC and up to 2 KHz)

DI5 digital input 5 (optoisolated, 24 VAC / DC and up to 2 KHz)

COM common digital inputs

+12V power supply 0-20 mA / 4-20 mA / 0-10 V transducers (12 VDC, 120 mA max.)

5VS power supply 0-5 V ratiometric transducers (5 VDC, 60 mA max.)

GND common analog inputs and analog outputs

AO1 analog output 1 (configurable via configuration parameter for PWM / 0-10 V signal)

AO2 analog output 2 (configurable via configuration parameter for PWM / 0-10 V signal)

AO3 analog output 3 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

DI1 digital input 1 (optoisolated, 24 VAC / DC and 50 / 60 Hz)

DI2 digital input 2 (optoisolated, 24 VAC / DC and 50 / 60 Hz)

DI3 digital input 3 (optoisolated, 24 VAC / DC and 50 / 60 Hz)

page 21 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

The maximum length of the connecting cables is:

- 100 m (328 ft) for the analog inputs

- 100 m (328 ft) for the power supply of the transducers

- 100 m (328 ft) for the digital inputs

- 1 m (3.280 ft) for the PWM analog outputs

- 100 m (328 ft) for the 0-20 mA / 4-20 ma / 0-10 V analog outputs.

For the settings about the analog inputs look at chapter 6 “CONFIGURATION”.

page 22 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

4.3.1. Example of electrical connection

The following drawing shows an example of electrical connection of c-pro 3 kilo+ with c-pro 3 EXP kilo+ and with Vgraph.

For the devices powered at 12 VAC, the power supply of the devices in the network must be galvanically isolated one another.

page 23 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

For the devices powered at 24 VAC, it is necessary the phase powering the device is the same powering the remaining devices

in the network.

For the devices powered at 20... 30 VDC, it is necessary to recpect the polarity ot the power supply voltage of all the devices in

the network.

To reduce the reflections on the signal transmitted through the cables connecting the devices each other, plug in the

termination of the CAN port of the first and of the last element of the network.

4.4. Additional information for electrical connection

- do not operate on the terminal blocks with electrical or pneumatic screwers

- if the device has been moved from a cold location to a warm one, the humidity could condense on the inside; wait about an

hour before powering it

- test the working power supply voltage, working electrical frequency and working electrical power of the controller; they must

correspond with the local power supply

- connect the device to the other devices using a twisted pair

- disconnect the local power supply before servicing the device

- do not use the device as safety device

- for repairs and information on the device please contact the EVCO’s sales network.

page 24 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

5. USER INTERFACE

5.1. Keyboard

The following table shows the meaning of the keyboard.

Button Preset function

cancel, hereinafter also called “button ESC”

move to left, hereinafter also called “button LEFT”

increase, hereinafter also called “button UP”

decrease, hereinafter also called “button DOWN”

move to right, hereinafter also called “button RIGHT”

confIrmation, hereinafter also called “button ENTER”

The keyboard is not available in the blind versions.

5.2. Signalling LEDs

5.2.1. LEDs at the front of the device

The following table shows the meaning of the LEDs at the front of the device.

LED Meaning

LED power supply

ON

RUN

if it is lit, the device will be powered

if it is out, the device will not be powered

LED run

if it is lit, the application software will be compiled and running in release modality

if it flashes slowly, the application software will be compiled and running in debug modality (condition not allowed in

c-pro 3 EXP micro / micro+ and in in c-pro 3 EXP kilo / kilo+)

if it flashes quickly, the application software will be compiled, running in debug modality and stopped in a breakpoint

(condition not allowed in c-pro 3 EXP micro / micro+ and in in c-pro 3 EXP kilo / kilo+)

if it is out (condition not allowed in c-pro 3 EXP micro / micro+ and in in c-pro 3 EXP kilo / kilo+):

- the controller will not be compatible with the application software

- the controller will not be enabled to work with the Special ABL (Application Block Libraries)

LED system alarm

if it flashes slowly, a system alarm with automatic reset will be running

if it is lit, an alarm system not restorable via software will be running

if it flashes very slowly, an access to the external flash memory will be running

if it flashes quickly, a system alarm with manual reset will be running

if it is out, no alarm system will be running

page 25 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

LED CANbus comm unication

if it is lit, the device will be configured to communicate via CANbus with another device but the CAN communication

CAN

will not have been set up

if it flashes slowly, the CANbus communication will have been set up but it will not be completely correct

if it flashes quickly, the CANbus communication will have been set up and will be correct

if it is out, no CANbus communication will be running

L1

LED auxiliary (not used in c-pro 3 EXP micro / micro+ and in in c-pro 3 EXP kilo / kilo+)

The operation of this LED can be programmed through the development environment UNI-PRO 3

page 26 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

6. CONFIGURATION

6.1. Configuring a programmable controller

6.1.1. Configuring a built-in programmable controller

To gain access to the procedure operate as follows:

1. Make sure the power supply is switched on.

2. Keep pressed 2 s buttons UP and DOWN: the display will show the following menu (hereinafter called Main menu).

<CPro 3 Kilo LCD>

Info

English

Parameters

...

Backup / Restore

Diagnostic

Debug

It is also possible to configure the controller using an user interface; look at paragraph 6.3 “Configuring a device through en

user interface”.

To gain access to a submenu operate as follows:

3. Press and release button UP or button DOWN to select the submenu.

4. Press and release button ENTER.

The access to the Parameters submenu, to the Networks submenu, to the Password submenu and to the Backup / Restore

submenu is protected by password.

To gain access to the Parameters submenu, to the Networks submenu, to the Password submenu and to the Backup / Restore

submenu operate as follows:

5. From step 2, press and release button UP or button DOWN to select the submenu.

6. Press and release button ENTER.

7. Press and release button ENTER again to set the password value.

8. Press and release button DOWN over and over again to set “-19”.

9. Press and release button ENTER again.

To modify a parameter operate as follows:

10. From step 9, press and release button UP or button DOWN to select the parameter (some parameters belong to a possible

submenu; press and release button ENTER to gain access to them).

11. Press and release button ENTER.

12. Press and release button UP or button DOWN to modify the value.

13. Press and release button ENTER to confirm the value.

14. Press and release button ESC over and over again to go back to the Main menu.

To modify the language of the application software pages operate as follows:

15. From step 2, press and release button UP or button DOWN to select the voice Language (according to the factory setting it

has value “English”).

16. Press and release button ENTER.

17. Press and release button UP or button DOWN to modify the language.

18. Press and release button ENTER to confirm the value.

page 27 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

To modify the real date and time operate as follows:

19. From step 2, press and release button UP or button DOWN to select the voice Data e ora reale.

20. Press and release button ENTER.

21. Press and release button UP or button DOWN to modify the value.

22. Press and release button ENTER or button RIGHT to confirm the value and modify the following field (press and release

button LEFT or button RIGHT to move among the fields).

23. Repeat steps 21 and 22.

To copy the parameters from the controller to an USB peripheral operate as follows:

24. Make sure the power supply is switched on.

25. Connect the peripheral to the controller.

26. Gain access to the submenu Backup / Restore, then choose Parameter key (choose Backup memory for the backup

memory).

27. Press and release button UP or button DOWN to select “Application par” to copy the application software parameters or

“Hardware config” to copy the configuration parameters.

28. Press and release button UP or button DOWN to select “Save on the key”.

29. Press and release button ENTER: the parameters will be copied from the controller to the peripheral (this operation usually

takes a few seconds; if an error had to arise the LED system alarm (look at paragraph 5.2.1 “LEDs at the fron of the device”)

will light up and parameter Key Par (it belongs to the Diagnostic submenu) will assume value Err.

30. Disconnect the programming key.

To copy the parameters from an USB peripheral to the controller operate as follows:

31. Make sure the power supply is switched on.

32. Connect the peripheral to the controller.

33. Gain access to the submenu Backup / Restore, then choose Parameter key (choose Backup memory for the backup

memory).

34. Press and release button UP or button DOWN to select “Restore from the key”.

35. Press and release button ENTER: the parameters will be copied from the peripheral to the controller (this operation usually

takes a few seconds; if an error had to arise the LED system alarm (look at paragraph 5.2.1 “LEDs at the fron of the device”)

will light up and parameter Key Par (it belongs to the Diagnostic submenu) will assume value Err.

36. Disconnect the peripheral.

The copy of the parameters from the programming key EVKEY10 to the controller is allowed on condition that the

firmware of the controllers coincides.

To quit the procedure operate as follows:

37. Press and release button ESC over and over again: possible modifications will not be saved.

Switch off the power supply after the modification of the configuration.

page 28 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

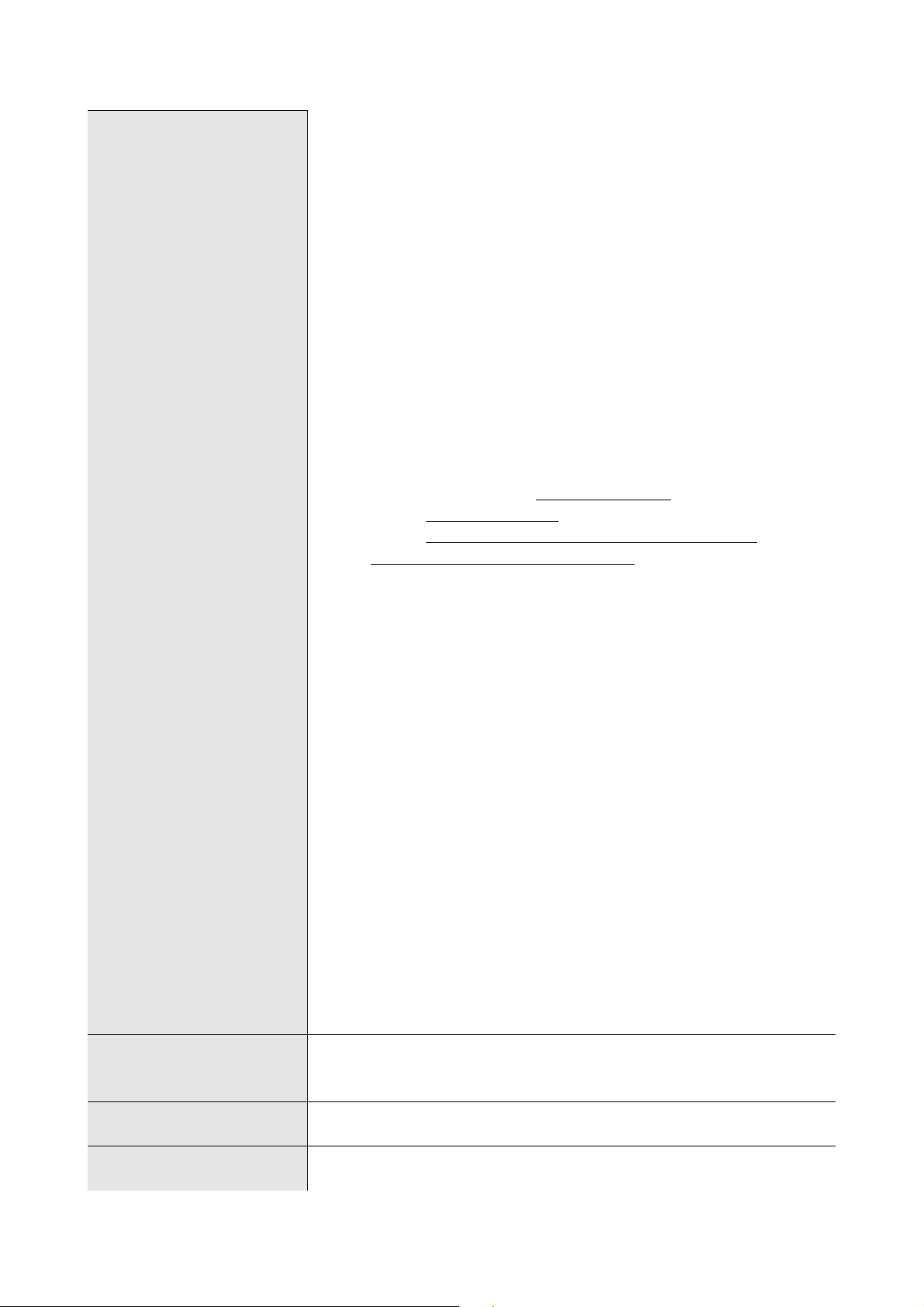

6.1.2. Configuring a blind programmable controller

The following procedures show an example of configuration of a blind programmable controller through a built-in programmable

controller (in the example it is c-pro 3 kilo) and through its user interface.

It is also possible to configure the controller using an user interface; look at paragraph 6.3 “Configuring a device through an

user interface”.

Operate as follows:

1. Switch off the power supply of the controllers.

2. Connect the blind controller to the built-in controller through the CAN port; look at chapter 4 “ELECTRICAL CONNECTION”.

3. Switch on the power supply of the controllers.

4. Keep pressed 2 s buttons UP and DOWN: the display will show the following menu.

5. Press and release button UP or button DOWN to select “Networks”.

6. Press and release button ENTER.

7. Press and release button ENTER again to set the password value.

8. Press and release button DOWN over and over again to set “-19”.

9. Press and release button ENTER again.

10. Press and release button UP or button DOWN to select “CAN Bus”.

11. Press and release button ENTER again.

12. Set parameter NetworkNode using button UP or button DOWN to select the parameter and using button ENTER to modify

and to confirm the value.

<CPro 3 Kilo LCD>

Info

English

Parameters

...

Backup / Restore

Diagnostic

Debug

According to the factory setting the address of the CAN node of a programmable controller has value 1 (therefore operate on

the controller to set parameter NetworkNode to [ 1 ] 1).

13. Press and release button UP or button DOWN to select “>”.

14. Press and release button ENTER again: the display will show the Main menu of the blind controller.

15. Operate as shown in paragraph 6.1.1 “Configuring a built-in programmable controller”.

page 29 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

6.2. Configuring an I / O expansion

The following procedures show an example of configuration of an I / O expansion through a built-in programmable controller (in the

example it is c-pro 3 kilo) and through its user interface.

It is also possible to configure the expansion using an user interface; look at paragraph 6.3 “Configuring a device through an

user interface”.

Operate as follows:

1. Switch off the power supply of the controller and of the expansion.

2. Connect the controller to the expansion through the CAN port; look at chapter 4 “ELECTRICAL CONNECTION”.

3. Switch on the power supply of the controller and of the expansion.

4. Keep pressed 2 s buttons UP and DOWN: the display will show the following menu.

5. Press and release button UP or button DOWN to select “Networks”.

6. Press and release button ENTER.

7. Press and release button ENTER again to set the password value.

8. Press and release button DOWN over and over again to set “-19”.

9. Press and release button ENTER again.

10. Press and release button UP or button DOWN to select “CAN Bus”.

11. Press and release button ENTER again.

12. Set parameter NetworkNode using button UP or button DOWN to select the parameter and using button ENTER to modify

and to confirm the value.

<CPro 3 Kilo LCD>

Info

English

Parameters

...

Backup / Restore

Diagnostic

Debug

According to the factory setting the address of the CAN node of an I / O expansion has value 2 (therefore operate on the

controller to set parameter NetworkNode to [ 2 ] 2).

13. Press and release button UP or button DOWN to select “>”.

14. Press and release button ENTER again: the display will show the Main menu of the expansion.

15. Operate as shown in paragraph 6.1.1 “Configuring a built-in programmable controller”.

page 30 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

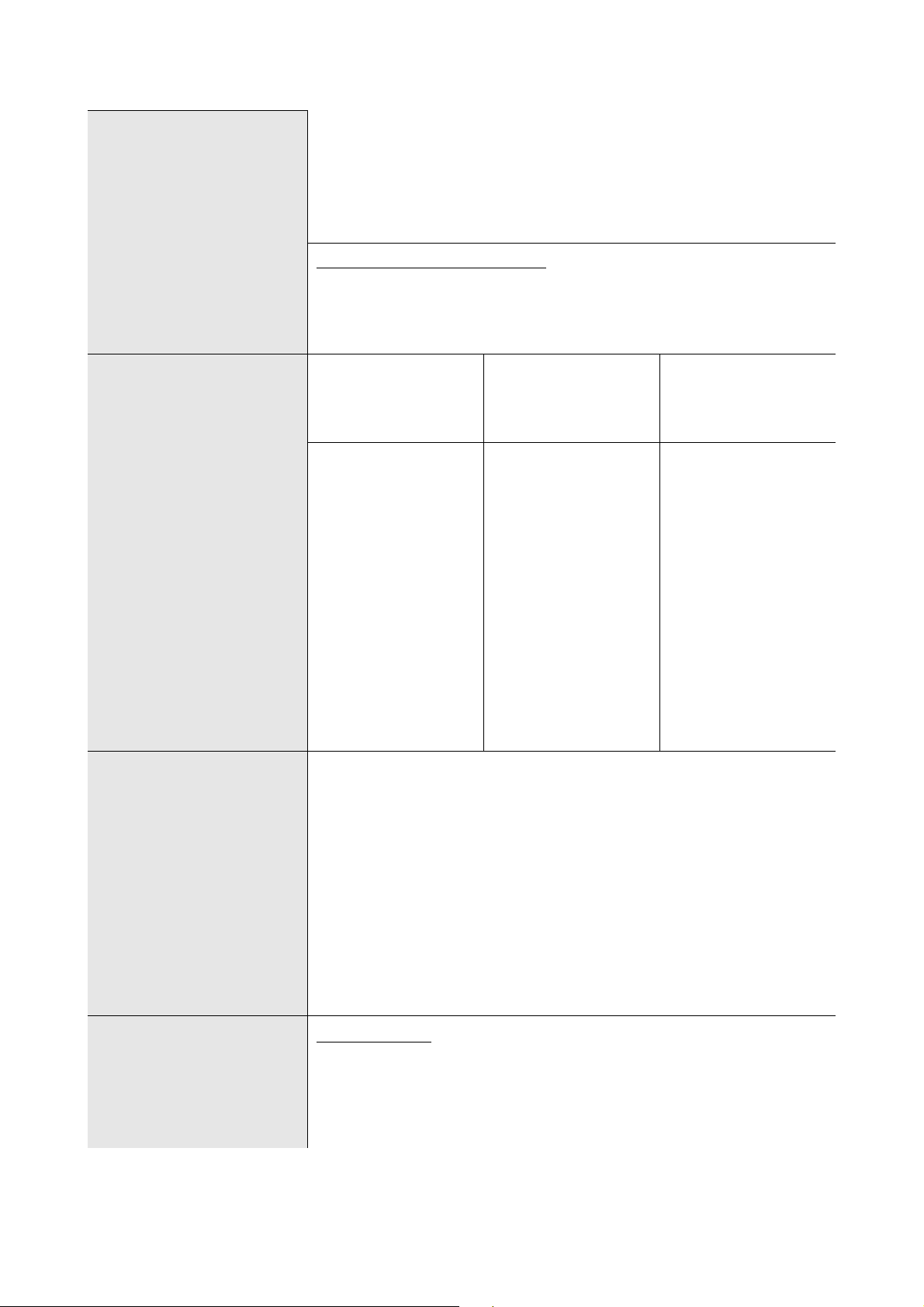

V

K

K

6.3. Configuring a device through an user interface (Vgraph, Vtouch,

Vroom or Vcolor)

The following procedures show an example of configuration of a device through an user interface (in the example Vgraph) and through

its user interface.

For further information please consult the hardware manual of the user interface.

Operate as follows:

1. Switch off the power supply of the device and of the interface.

2. Connect the device to the interface through the CAN port; look at chapter 4 “ELECTRICAL CONNECTION”.

3. Keep pressed 2 s buttons ESC and RIGHT.

4. Switch on the power supply of the device and of the interface.

5. When the display of the interface will show the following menu release buttons ESC and RIGHT.

6. Press and release button UP or button DOWN to select “CAN Network”.

7. Press and release button ENTER.

8. Press and release button ENTER again to set the password value.

9. Press and release button DOWN over and over again to set “-19”.

10. Press and release button ENTER again.

11. Set parameter NW Node using button UP or button DOWN to select the parameter and using button ENTER to modify and to

confirm the value.

graph

Parameters

Contrast

CAN Network

Modbus

Info

Real date and time

According to the factory setting the address of the CAN node of a programmable controller has value 1 (therefore operate on

the interface to set parameter NW Node to [ 1 ] 1) and the address of the CAN node of an I / O expansion has value 2

(therefore operate on the interface to set parameter NW Node to [ 2 ] 2).

12. Switch off the power supply of the interface.

13. Switch on the power supply of the interface.

14. Keep pressed 2 s buttons LEFT and ENTER: the display will show the following menu.

Network Status

Loc 99 O

1 1 OK > >

2 2 O

3 0 - > >

4 0 - > >

5 0 - > >

15. Press and release button UP or button DOWN to select the device.

16. Press and release button ENTER: the display will show the Main menu of the device.

17. Operate as shown in paragraph 6.1.1 “Configuring a built-in programmable controller”.

> >

> >

page 31 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

6.4. List of configuration parameters

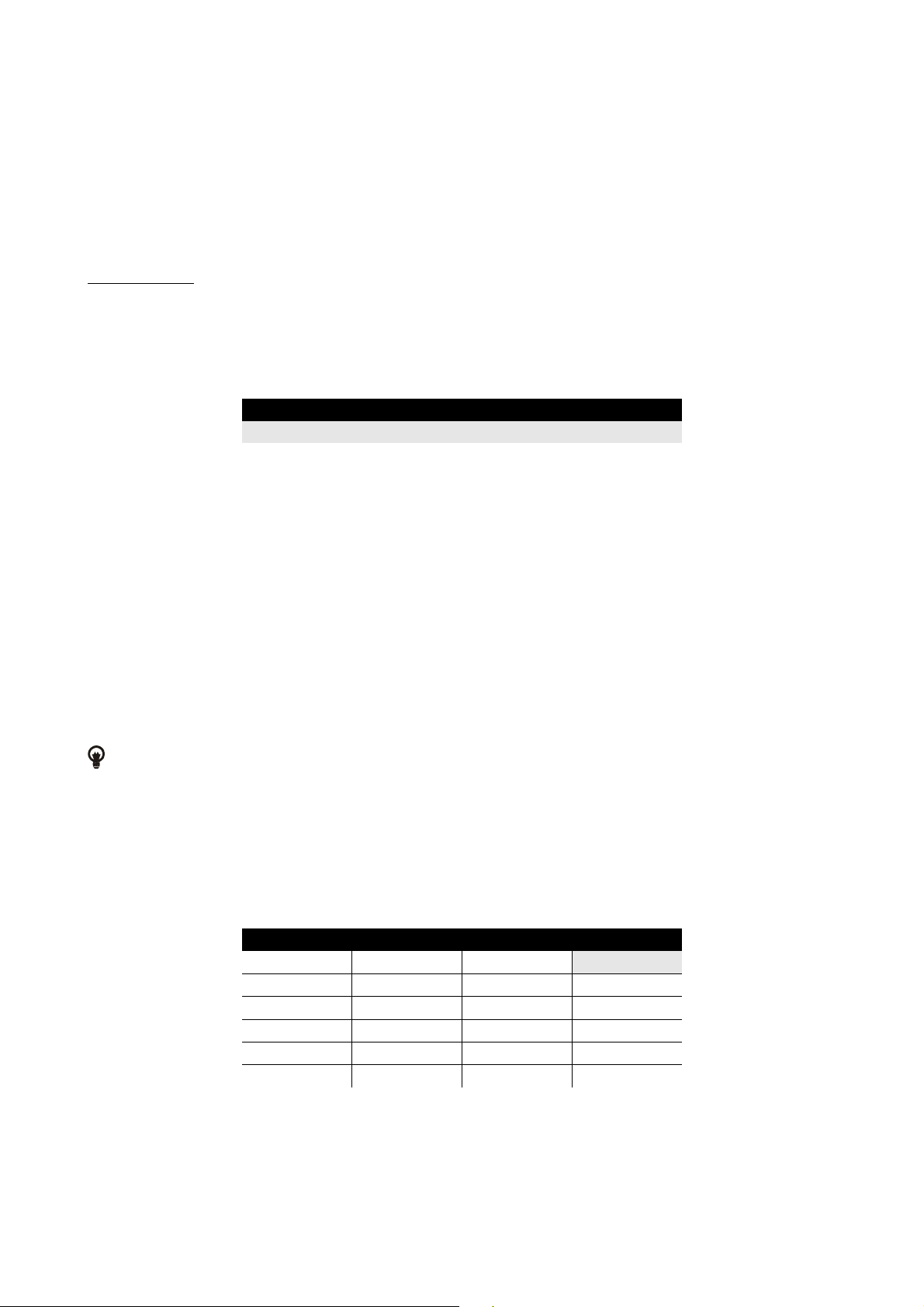

Submenu Parameter Min. Max. Unit Preset Description

Info PROJ parameter available in read only modality

Info FW parameter available in read only modality

Info HW parameter available in read only modality

Info SW parameter available in read only modality

Info SN parameter available in read only modality

Info MASK parameter available in read only modality

Info date and time parameter available in read only modality

information about the application project

(project, version and revision)

information about the firmware (project,

version, revision and subrevision)

information about the hardware (version,

revision, generic (G) or special (S))

information about UNI-PRO 3 (version and

revision)

information about the serial number and the

result of the productive test

information about the mask (it depends on

the builder’s coding system)

date and time of the last compilation of the

application project

Parameters (1) AI1 - - - - - - - - - NTC

kind of probe analog input 1

PTC = PTC probe

NTC = NTC probe

0-20mA = 0-20 mA transducer

4-20mA = 4-20 mA transducer

0-5V = 0-5 V ratiometric transducer

0-10V = 0-10 V ratiometric transducer

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

page 32 of 62

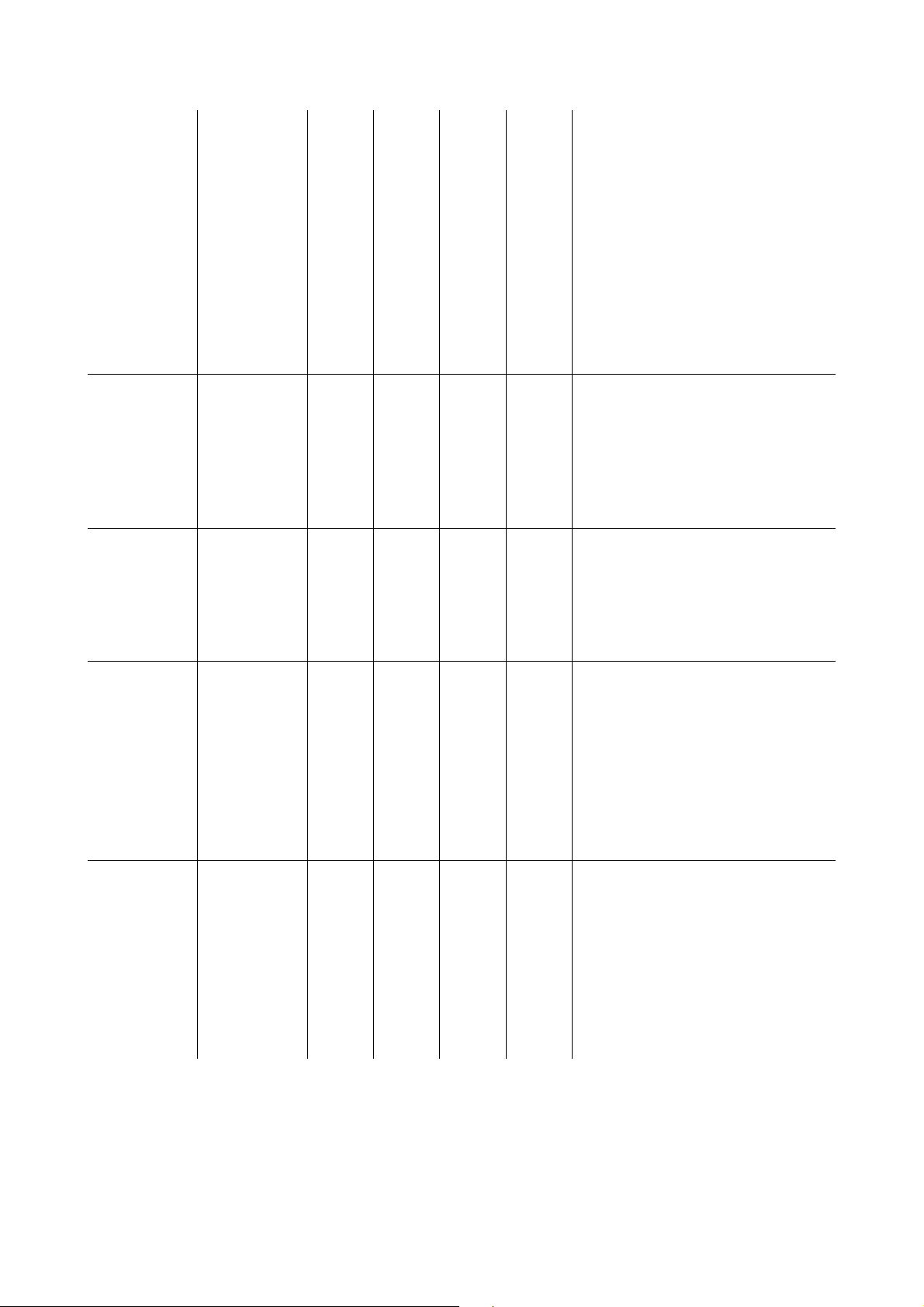

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

kind of probe analog input 2

PTC = PTC probe

NTC = NTC probe

0-20mA = 0-20 mA transducer

4-20mA = 4-20 mA transducer

Parameters (1) AI2 - - - - - - - - - NTC

0-5V = 0-5 V ratiometric transducer

0-10V = 0-10 V ratiometric transducer

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

kind of probe analog input 3

PTC = PTC probe

NTC = NTC probe

0-20mA = 0-20 mA transducer

4-20mA = 4-20 mA transducer

Parameters (1) AI3 - - - - - - - - - NTC

0-5V = 0-5 V ratiometric transducer

0-10V = 0-10 V ratiometric transducer

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

Parameters (1) AI4 - - - - - - - - - NTC

Parameters (1) AI5 - - - - - - - - - NTC

kind of probe analog input 4

PTC = PTC probe

NTC = NTC probe

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

kind of probe analog input 5

PTC = PTC probe

NTC = NTC probe

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

page 33 of 62

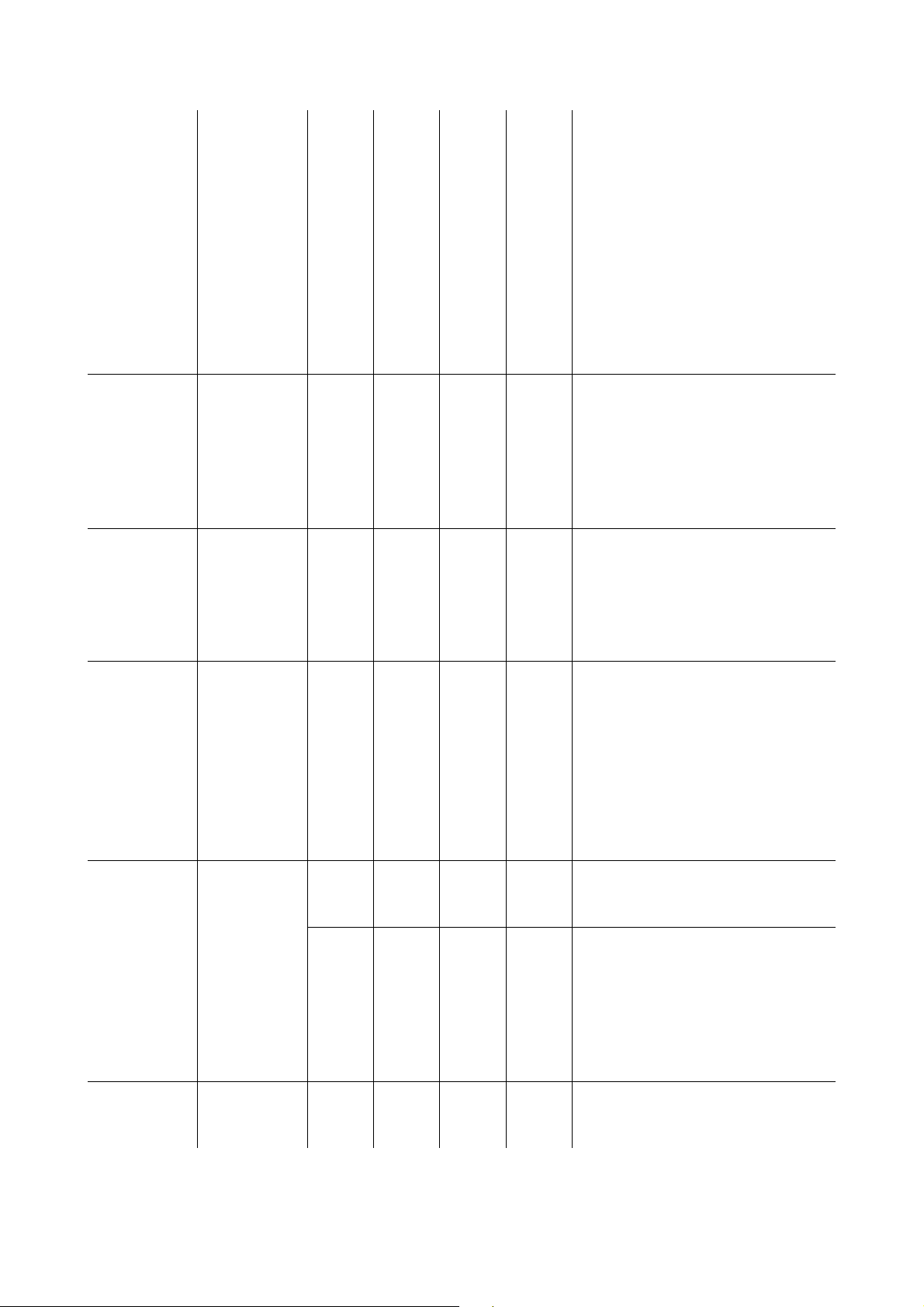

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

kind of probe analog input 6

PTC = PTC probe

NTC = NTC probe

Parameters (1) AI6 - - - - - - - - - NTC

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

kind of probe analog input 7

PTC = PTC probe

NTC = NTC probe

0-20mA = 0-20 mA transducer

4-20mA = 4-20 mA transducer

Parameters (1) AI7 - - - - - - - - - NTC

0-5V = 0-5 V ratiometric transducer

0-10V = 0-10 V ratiometric transducer

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

Parameters (1) AI8 - - - - - - - - - NTC

Parameters (1) AI9 - - - - - - - - - NTC

kind of probe analog input 8

PTC = PTC probe

NTC = NTC probe

0-20mA = 0-20 mA transducer

4-20mA = 4-20 mA transducer

0-5V = 0-5 V ratiometric transducer

0-10V = 0-10 V ratiometric transducer

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

kind of probe analog input 9

PTC = PTC probe

NTC = NTC probe

0-20mA = 0-20 mA transducer

4-20mA = 4-20 mA transducer

0-5V = 0-5 V ratiometric transducer

0-10V = 0-10 V ratiometric transducer

PT1000 = Pt 1000 probe

NTCK2 = NTC probe type 2

NTCK3 = NTC probe type 3

RESIST = reading of the electric

resistance

page 34 of 62

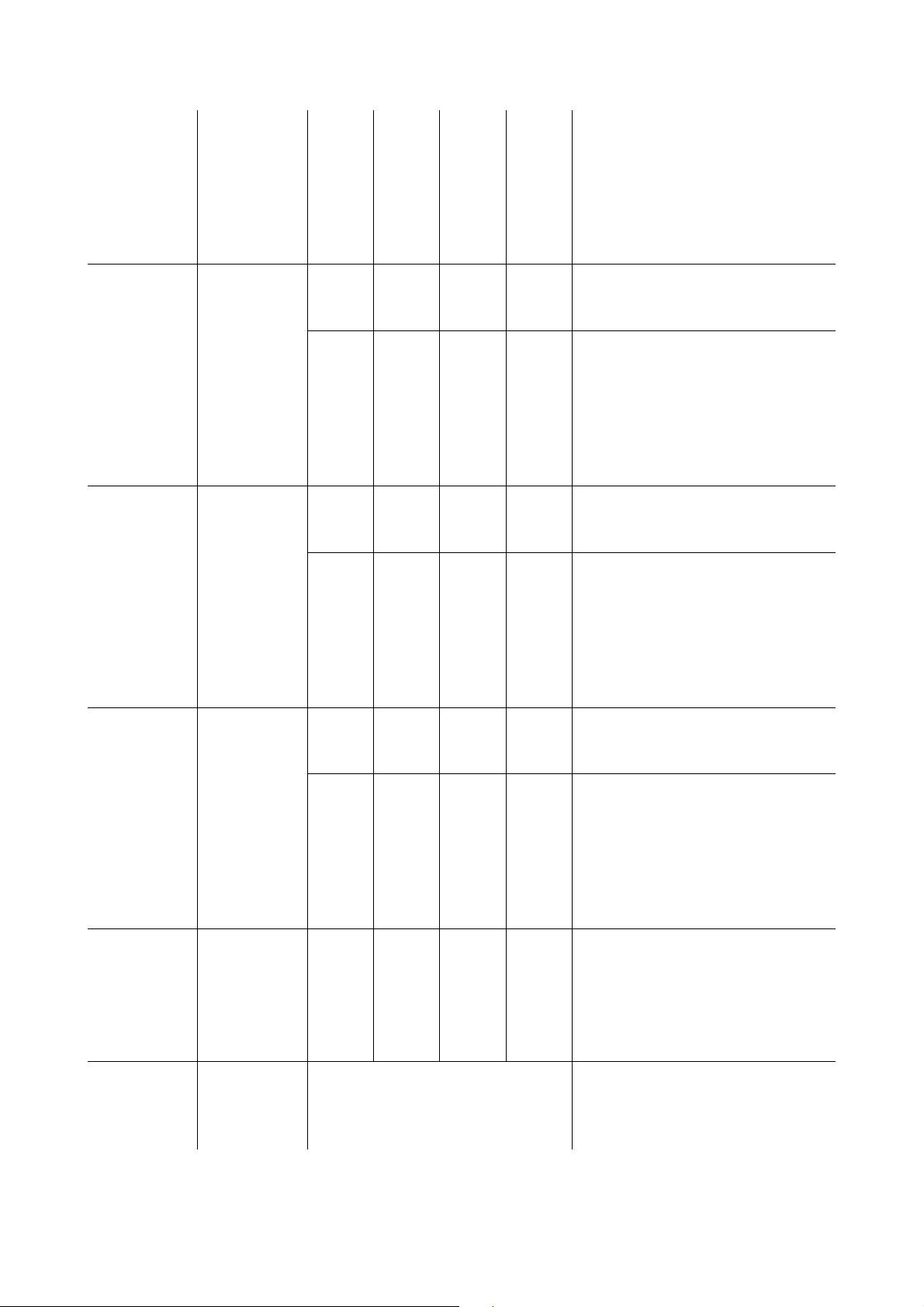

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

analog inputs time-out (after this time without

Parameters (1) AI Err Time 0 240 s 2

communication with an analog input, the

controller signals the analog input error)

Parameters (1) AO impulse 1 50 ms/10 20 cut phase pulse duration

kind of signal analog input 1

Parameters (1) AO1 - - - - - - - - - 0-10V

FAN = FAN (for cut phase module)

0-10V = 0-10 V

PWM = PWM (Pulse With Modulation)

Parameters (1) freq 10 2000 Hz 1000

Parameters (1) Delay ph. 0 50 ms/10 0

frequency of the PWM signal of the analog

output 1

displacement of the cut phase pulse of the

analog output 1

kind of signal analog input 2

Parameters (1) AO2 - - - - - - - - - 0-10V

FAN = FAN (for cut phase module)

0-10V = 0-10 V

PWM = PWM (Pulse With Modulation)

Parameters (1) freq 10 2000 Hz 1000

Parameters (1) Delay ph. 0 50 ms/10 0

frequency of the PWM signal of the analog

output 2

displacement of the cut phase pulse of the

analog output 2

kind of signal analog input 3

Parameters (1) AO3 - - - - - - - - - 0-10V

0-20mA = 0-20 mA

4-20mA = 4-20 mA

0-10V = 0-10 V

kind of signal analog input 4

Parameters (1) AO4 - - - - - - - - - 0-10V

0-20mA = 0-20 mA

4-20mA = 4-20 mA

0-10V = 0-10 V

Parameters (1) AO5 - - - - - - - - - 0-10V

Parameters (1) AO6 - - - - - - - - - 0-10V

kind of signal analog input 5

0-10V = 0-10 V

kind of signal analog input 6

0-10V = 0-10 V

Parameters (1) EEV_StepRate 25 1000 step/s 100 movement speed of the valve

page 35 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

driving mode of the stepper motor

Parameters (1) EEV_DrvMode 0 2 - - - 1

0 = full step 2 phases on

1 = full step 1 phase on

2 = half step

Parameters (1) EEV_DutyForce 50 100 % 1

Parameters (1) EEV_OvrSteps 0 4900 step 2000

Parameters (2)

[ press button

RIGHT to

I/O Timeout 1 240 s 60

show it ]

Parameters (2)

[ press button

RIGHT to

En. Prg Level - - - - - - - - - NO

show it ]

duty cicle to avoid the overheating

100% = always forced movement

number of steps required to totally close the

valve

time-out of the CANbus communication for

the test of the remote values of the I / O

(after this time without CANbus

communication, the I / O of the controller is

disabled)

enabling the access to the first level page

pressing a combination of buttons

YES = yes, operating as follows:

- keep pressed 3 s button

ENTER to gain access

to the first page of

level 1

- keep pressed 3 s

buttons ENTER and

ESC to gain access to

the first page of level 2

- keep pressed 3 s

buttons LEFT and

RIGHT to gain access to

the first page of level 3

Parameters (2)

[ press button

RIGHT to

Password Indi - - - - - - - - - NO

show it ]

Parameters (2)

[ press button

RIGHT to

Ena BkMem

RTC

- - - - - - - - - YES

show it ]

page 36 of 62

connection among the passwords to gain

access to the levels

NO = one has not to set any

password to gain access to

levels lower than the one one

has already gained access

YES = one has to set a password to

gain access to each level

enabling the real time clock and the backup

memory

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Parameters (2)

[ press button

RIGHT to

show it; not

available in the

built-in LED

versions and in

the blind

Backlight - - - - - - - - - TIME

kind of backlight

OFF = the backlight is never lit

ON = the backlight is always lit

TIME = the backlight is lit the time one

has set with parameter

B. Time since the last

operation with the buttons

versions ]

Parameters (2)

[press button

RIGHT to

show it; not

available in the

built-in LED

B. Time 0 60 s 240

backlight duration (only if parameter

Backlight has value TIME)

versions and in

the blind

versions ]

Parameters (2)

[press button

RIGHT to

show it; not

available in the

built-in LED

versions and in

the blind

versions ]

Parameters (2)

[press button

RIGHT to

show it; not

available in the

built-in LED

versions and in

the blind

versions ]

Parameters (2)

[press button

RIGHT to

show it; not

available in the

built-in LED

versions and in

the blind

versions ]

Contrast 0 100 - - - 50 display contrast

Date Char Sep - - - - - - - - - / date separator (ASCII character)

year format

Year format - - - - - - - - - YY

YY = two numbers (for example 10)

YYYY = four numbers (for example

2010)

page 37 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Parameters (2)

[press button

RIGHT to

show it; not

available in the

built-in LED

versions and in

Date format - - - - - - - - - D-M-Y

date format

D-M-Y = day, month and year

M-D-Y = month, day and year

Y-M-D = year, month and day

the blind

versions ]

Parameters (2)

[press button

RIGHT to

show it; not

available in the

Time Char Sep - - - - - - - - - : time separator (ASCII character)

built-in LED

versions and in

the blind

versions ]

Parameters (2)

[press button

RIGHT to

show it; not

available in the

built-in LED

versions and in

the blind

versions ]

Parameters (2)

[press button

RIGHT to

show it; not

available in the

built-in LED

versions and in

the blind

versions ]

Networks / CAN

Bus

Time With Sec - - - - - - - - - YES

showing the seconds in the real time

YES = yes

time format

Time AM/PM - - - - - - - - - NO

NO = 24 h (for example 15:20)

YES = 12 h (for example 3:20 PM)

MyNode 1 127 - - - 1 local (or of the controller) CAN node address

Networks / CAN

Bus

Master - - - - - - - - - YES

page 38 of 62

enabling the operation as master in a CAN

network

YES = yes

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

CANbus communication baud rate

Networks / CAN

Bus

Baud - - - - - - - - - 20K

20K = 20,000 baud

50K = 50,000 baud

125K = 125,000 baud

500K = 500,000 baud

remote (or with a device in the network)

Networks / CAN

Bus

Timeout 1 60 s 5

CANbus communication time-out (after this

time without CANbus communication with a

device, it is excluded by the network)

address of a remote (or of a device in the

Networks / CAN

Bus

NetworkNode [ 1 ] 0

[ 32 ]

127

- - - [ 1 ] 99

network) CAN node; example for [ 1 ] 2:

[ 1 ] = node

2 = node’s address

Networks / CAN

Bus

[ press button

TSEG1 0 15 - - - 10 reserved

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

TSEG2 1 7 - - - 2 reserved

SJW 0 3 - - - 0 reserved

BTR(1) 1 255 - - - 100 reserved

CAN machine status

INIT = initialization

Status parameter available in read only modality

STOPPED = CAN stop

OPERAT = operative

PRE-OP = in pre-operative

page 39 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

CAN bus status

OK = status OK

Bus Status parameter available in read only modality

WARNING = warning

PASSIVE = bus working in rx only

BUS OFF = bus stopped

Cnt Rx parameter available in read only modality number of packages received

Cnt Tx parameter available in read only modality number of packages transmitted

Cnt Ovf parameter available in read only modality number of packages in overflow

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks / CAN

Bus

[ press button

RIGHT to

show it ]

Networks /

UART1 (1)

Cnt Passive parameter available in read only modality number of transactions in passive status

Cnt Bus Off parameter available in read only modality number of transactions in Bus off status

local (or of the controller) Modbus node

Address 1 247 - - - 1

address in a RS-485 network wired on the

RS-485 port with Modbus slave

communication protocol

page 40 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Modbus communication baud rate in a

RS-485 network wired on the RS-485 port

with Modbus slave communication protocol

1200 = 1,200 baud

Networks /

UART1 (1)

Baud Rate - - - - - - - - - 9600

2400 = 2,400 baud

4800 = 4,800 baud

9600 = 9,600 baud

19200 = 19,200 baud

28800 = 28,000 baud

38400 = 38,400 baud

57600 = 57,600 baud

Modbus communication parity in a RS-485

network wired on the RS-485 port with

Networks /

UART1 (1)

Parity - - - - - - - - - EVEN

Modbus slave communication protocol

NONE = no parity

ODD = odd

EVEN = even

Networks /

UART1 (1)

Networks /

UART1 (1)

Networks /

UART1 (1)

Modbus communication stop bit number in a

RS-485 network wired on the RS-485 port

Stop - - - - - - - - - 1 BIT

with Modbus slave communication protocol

1 BIT = 1 bit

2 BIT = 2 bit

Modbus communication time-out in a

RS-485 network wired on the RS-485 port

with Modbus slave communication protocol

Timeout 2 240 s 10

for the test of the remote values of the I / O

(after this time without Modbus

communication, the request is considered

not sent and the controller moves to the

following request) (1)

local (or of the controller) Modbus node

Address 1 247 - - - 1

address in a RS-485 network wired on the

RS-485 port with Modbus slave

communication protocol

page 41 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Modbus communication baud rate in a

RS-485 network wired on the RS-485 port

with Modbus master communication protocol

1200 = 1,200 baud

Networks /

UART2 (2)

Baud Rate - - - - - - - - - 9600

2400 = 2,400 baud

4800 = 4,800 baud

9600 = 9,600 baud

19200 = 19,200 baud

28800 = 28,000 baud

38400 = 38,400 baud

57600 = 57,600 baud

Modbus communication parity in a RS-485

network wired on the RS-485 port with

Networks /

UART2 (2)

Parity - - - - - - - - - EVEN

Modbus master communication protocol

NONE = no parity

ODD = odd

EVEN = even

Networks /

UART2 (2)

Networks /

UART2 (2)

Stop - - - - - - - - - 1 BIT

Timeout 2 240 s 10

Password Level 1:

-32768 32767 - - - 0

- - - - - - - - - ON

Modbus communication stop bit number in a

RS-485 network wired on the RS-485 port

with Modbus master communication protocol

1 BIT = 1 bit

2 BIT = 2 bit

Modbus communication time-out in a

RS-485 network wired on the RS-485 port

with Modbus master communication protocol

for the test of the remote values of the I / O

(after this time without Modbus

communication, the request is considered

not sent and the controller moves to the

following request) (3)

value of the password to gain access to

level 1

enabling the password to gain access to

level 1

OFF = to gain access to level 1 one

has not to set any password

ON = to gain access to level 1 one

has to set a password

Password Level 2: -32768 32767 - - - 0

page 42 of 62

value of the password to gain access to

level 2

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

enabling the password to gain access to

level 2

- - - - - - - - - ON

OFF = to gain access to level 2 one

has not to set any password

ON = to gain access to level 2 one

has to set a password

-32768 32767 - - - 0

Password Level 3:

-32768 32767 - - - 0

Password Level 4:

-32768 32767 - - - 0

- - - - - - - - - ON

- - - - - - - - - ON

value of the password to gain access to

level 3

enabling the password to gain access to

level 3

OFF = to gain access to level 3 one

has not to set any password

ON = to gain access to level 3 one

has to set a password

value of the password to gain access to

level 4

enabling the password to gain access to

level 4

OFF = to gain access to level 4 one

has not to set any password

ON = to gain access to level 4 one

has to set a password

value of the password to gain access to

level 5

Password Level 5:

- - - - - - - - - ON

Password Timeout 0 240 s 240

Diagnostic Memory parameter available in read only modality

page 43 of 62

enabling the password to gain access to

level 5

OFF = to gain access to level 5 one

has not to set any password

ON = to gain access to level 5 one

has to set a password

time-out of the passwords to gain access to

the levels (after this time since the last

operation with the buttons, to gain access to

the level one has to set a password again, if

foreseen)

non volatile memory status

ok = not in error

err = in error

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

clock status

ok = not in error

Diagnostic RTC parameter available in read only modality

err = in error

low = loss of data

disab = disabled

stack status

Diagnostic STACK parameter available in read only modality

ok = not in error

err = in error (because of overflow)

status of the power supply voltage of the

ratiometric transducers

Diagnostic 5V Ratio parameter available in read only modality

ok = not in error

err = in error (because of out of

range voltage)

status of the power supply voltage of the

0-20 mA / 4-20 mA / 0-10 V transducers

Diagnostic 12V Sensor parameter available in read only modality

ok = not in error

err = in error (because of out of

range voltage)

Diagnostic Math parameter available in read only modality

Diagnostic Key Par parameter available in read only modality

Main time parameter available in read only modality

Debug

[ Algo ]

Max. time parameter available in read only modality

Free stack parameter available in read only modality

Math status

ok = not in error

err = in error (because of overflow,

underflow, division by zero or

NaN)

result of the copy of the parameters from the

controller to the USB peripheral

ok = operation successful

completed

err = operazione failed

main cycle time of the application software

(in milliseconds)

maximum main cycle time of the application

software (in milliseconds)

time of execution of the application software

temporized at 100 ms

100 ms time parameter available in read only modality

Debug

[ CAN bus ]

Max. time parameter available in read only modality

page 44 of 62

maximum time of execution of the

application software temporized at 100 ms

free stack of the interrupt cycle at 100 ms of

the application software (in byte)

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

Free stack parameter available in read only modality number of packages in reception

Debug 5V probe parameter available in read only modality

Debug 12V probe parameter available in read only modality

Debug 12V exp parameter available in read only modality

reading the power supply voltage of the

ratiometric transducers

reading the power supply voltage of the

0-20 mA / 4-20 mA / 0-10 V transducers

reading the power supply voltage coming

from the upper board

Notes:

(1) the submenu is visible on condition that the application software expects the RS-485 port with Modbus slave communication

protocol is configured to support the Modbus communication protocol

(2) the submenu is visible on condition that the application software expects the RS-485 port with Modbus master communication

protocol is configured to support the Modbus communication protocol

(3) the parameter is meaningful on condition that the RS-485 port is configured to support the Modbus master communication

protocol.

page 45 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

7. USER INTERFACES

7.1. Preliminary information

The controllers in blind version can be used for example with an user interface such as Vgraph, Vtouch, Vroom or Vcolor.

7.2. Vgraph

7.2.1. Introduction

Vgraph is a new and innovative user interface for the programmable controllers of the family c-pro 3.

The main features of the interface are the possibility to communicate to the user a great deal of information and the remarkable ease of

control; these features are due to the use of a 128 x 64 pixel single colour LCD graphic display (black with rearlighting through white

LEDs), to the 6 buttons (with preset functions) membrane keyboard and to the CAN bus (for the connection to the controllers).

This last also allows the use of the interface in multimaster networks.

Thanks to its constructive features, Vgraph offers several mounting typologies; this is possible:

- by panel, at the front of units, of machines for refrigeration or for air conditioning, of electrical panels and as well as in all those

applications where a frontal protection degree IP65 is required

- built-in by wall, in traditional box (like "506" by BTicino)

- by wall, on the support CPVW00 by EVCO (to order separately).

Also the necessity to customize the interface, in order to integrate it aesthetically in residential and commercial environments, is

satisfied by Vgraph since at the front of the interface one can apply both the plates CPVP* by EVCO (to order separately, made in

plastic material and available in two different colorations, white and black) and the numerous plates series "Living" and "Light" by

BTicino.

Vgraph also has got:

- real time clock

- alarm buzzer.

For further information consult the Hardware manual of Vgraph.

7.2.2. Summarizing table of the main features and available models

Vgraph

Power supply

Real time clock

Alarm buzzer

Display

Communication ports

a) CAN port with CANbus

communicatio n protocol

b) programming port

Code

For further models please contact the EVCO’s sales network at the address sales@evco.it.

24 VAC / 20... 40 VDC not isolated 12... 24 VAC / 15... 40 VDC isolated

incorporated incorporated

incorporated incorporated

128 x 64 pixel

LCD graphic display

2

a + b

EPV4GBR EPV3GBR

128 x 64 pixel

LCD graphic display

2

a + b

page 46 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

7.2.3. Size

Size in mm (in).

Size Minimum Typical Maximum

A 104.0 (4.094) 104.0 (4.094) 104.8 (4.125)

B 70.0 (2.755) 70.0 (2.755) 70.8 (2.787)

C 22.0 (0.866) 23.0 (0.905) 24.0 (0.944)

D 40.8 (1.606) 41.8 (1.645) 42.8 (1.685)

page 47 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

7.3. Vtouch

7.3.1. Introduction

Vtouch is a new and innovative user interface for the programmable controllers of the family c-pro 3.

The main features of the interface are the possibility to communicate to the user a great deal of information and the remarkable ease of

control; these features are due to the use of a 240 x 140 pixel single colour touch-screen LCD graphic display (black with rearlighting

through white LEDs), to the 6 buttons (with preset functions) membrane keyboard and to the CAN bus (for the connection to the

controllers).

This last also allows the use of the interface in multimaster networks.

Thanks to its constructive features, Vtouch offers several mounting typologies; this is possible:

- by panel, at the front of units, of machines for refrigeration or for air conditioning, of electrical panels and as well as in all those

applications where a frontal protection degree IP65 is required

- built-in by wall, in traditional box (like "506" by BTicino)

- by wall, on the support CPVW00 by EVCO (to order separately).

Also the necessity to customize the interface, in order to integrate it aesthetically in residential and commercial environments, is

satisfied by Vtouch since at the front of the interface one can apply both the plates CPVP* by EVCO (to order separately, made in

plastic material and available in two different colorations, white and black) and the numerous plates series "Living" and "Light" by

BTicino.

Vtouch also has got:

- real time clock

- alarm buzzer.

For further information consult the Hardware manual of Vtouch.

7.3.2. Summarizing table of the main features and available models

Vtouch

Power supply

Real time clock

Alarm buzzer

Display

Communication ports

a) CAN port with CANbus

communicatio n protocol

b) programming port

Code

For further models please contact the EVCO’s sales network at the address sales@evco.it.

24 VAC / 20... 40 VDC not isolated 12... 24 VAC / 15... 40 VDC isolated

incorporated incorporated

incorporated incorporated

240 x 140 pixel

touch-screen LCD graphic display

2

a + b

EPV4TBR EPV3TBR

touch-screen LCD graphic display

240 x 140 pixel

2

a + b

page 48 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

7.3.3. Size

Size is in mm (in).

Size Minimum Typical Maximum

A 104.0 (4.094) 104.0 (4.094) 104.8 (4.125)

B 70.0 (2.755) 70.0 (2.755) 70.8 (2.787)

C 22.0 (0.866) 23.0 (0.905) 24.0 (0.944)

D 40.8 (1.606) 41.8 (1.645) 42.8 (1.685)

page 49 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

7.4. Vroom

7.4.1. Introduction

Vroom is a new and innovative user interface for the programmable controllers of the family c-pro 3.

The main features of the interface are the possibility to communicate to the user a great deal of information and the remarkable ease of

control; these features are due to the use of a 128 x 64 pixel single colour LCD graphic display (black with rearlighting through white

LEDs), to the 6 buttons (with preset functions) membrane keyboard and to the CAN bus (for the connection to the controllers).

This last also allows the use of the interface in multimaster networks.

The user interface incorporates a temperature sensor or a temperature and humidity one; the values read by these sensors are

transmitted via CAN bus, making easier the wiring.

Thanks to its constructive features, Vroom offers several mounting typologies; this is possible:

- by panel, at the front of units, of machines for refrigeration or for air conditioning, of electrical panels and as well as in all those

applications where a frontal protection degree IP65 is required

- built-in by wall, in traditional box (like "506" by BTicino)

- by wall, on the support CPVW00 by EVCO (to order separately).

Also the necessity to customize the interface, in order to integrate it aesthetically in residential and commercial environments, is

satisfied by Vroom since at the front of the interface one can apply both the plates CPVP* by EVCO (to order separately, made in

plastic material and available in two different colorations, white and black) and the numerous plates series "Living" and "Light" by

BTicino.

Vroom also has got:

- real time clock

- alarm buzzer.

For further information consult the Hardware manual of Vroom.

7.4.2. Summarizing table of the main features and available models

Vroom

Power supply

Real time clock

Alarm buzzer

Alarm buzzer

Display

Communication ports

a) CAN port with CANbus

communicatio n protocol

b) programming port

24 VAC / 20... 40

VDC not isolated

incorporated incorporated incorporated incorporated

incorporated incorporated incorporated incorporated

temperature

128 x 64 pixel

LCD graphic display

2

a + b

24 VAC / 20... 40

VDC not isolated

temperature and

humidity

128 x 64 pixel

LCD graphic display

2

a + b

12... 24 VAC / 15...

40 VDC isolated

temperature

128 x 64 pixel

LCD graphic display

2

a + b

12... 24 VAC / 15...

40 VDC isolated

temperature and

humidity

128 x 64 pixel

LCD graphic display

2

a + b

Code

EPV4QBR EPV4RBR EPV3QBR EPV3RBR

For further models please contact the EVCO’s sales network at the address sales@evco.it.

page 50 of 62

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

7.4.3. Size

Size in mm (in).

Size Minimum Typical Maximum

A 104.0 (4.094) 104.0 (4.094) 104.8 (4.125)

B 70.0 (2.755) 70.0 (2.755) 70.8 (2.787)

C 22.0 (0.866) 23.0 (0.905) 24.0 (0.944)

D 40.8 (1.606) 41.8 (1.645) 42.8 (1.685)

page 51 of 62