EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Code 114CP3E324

c-pro 3

PROGRAMMABLE CONTROLLERS

ENGLISH

HARDWARE MANUAL ver. 3.2

CODE 114CP3E324

page 1 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

Important

Important

Read this document carefully before the installation and before the use and follow all the additional information for the installation and

for the electrical connection; keep this document close to the devices for future consultations.

The following symbols support the reading of the document:

it indicates a suggestion

it indicates an additional information to be followed.

The devices must be disposed according to the local legislation about the collection for electrical and electronic equipment.

page 2 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

Index

1.

INTRODUCTION ...................................................................................................................................................................... 5

1.1. Introduction ............................................................................................................................................................................... 5

2.

DESCRIPTION ......................................................................................................................................................................... 8

2.1. Description c-pro 3 hecto and c-pro 3 hecto+ ............................................................................................................................ 8

2.2. Description c-pro 3 mega .......................................................................................................................................................... 9

2.3. Description c-pro 3 mega+ ...................................................................................................................................................... 10

2.4. Description c-pro 3 NODE mega ............................................................................................................................................. 12

2.5. Description c-pro 3 EXP hecto and c-pro 3 EXP hecto+.......................................................................................................... 13

3.

SIZE AND INSTALLATION ..................................................................................................................................................... 14

3.1. Size c-pro 3 hecto, c-pro 3 hecto+, c-pro 3 EXP hecto and c-pro 3 EXP hecto+ .................................................................... 14

3.2. Size c-pro 3 mega and c-pro 3 mega+ .................................................................................................................................... 14

3.3. Size c-pro 3 NODE mega ....................................................................................................................................................... 15

3.4. Installation .............................................................................................................................................................................. 16

3.5. Additional information for installation....................................................................................................................................... 16

4.

ELECTRICAL CONNECTION ................................................................................................................................................. 17

4.1. Electrical connection c-pro 3 hecto and c-pro 3 hecto+ ........................................................................................................... 17

4.1.1.

Meaning of the connectors of c-pro 3 hecto and of c-pro 3 hecto+ ............................................................................... 17

4.1.2.

Example of electrical connection of c-pro 3 hecto ......................................................................................................... 24

4.2. Electrical connection c-pro 3 mega and c-pro 3 NODE mega ................................................................................................. 25

4.2.1.

Meaning of the connectors of c-pro 3 mega and of c-pro 3 NODE mega ...................................................................... 25

4.2.2.

Example of electrical connection of c-pro 3 mega ........................................................................................................ 33

4.3. Electrical connection c-pro 3 mega+ ....................................................................................................................................... 34

4.3.1.

Meaning of the connectors of c-pro 3 mega+ ............................................................................................................... 34

4.3.2.

Example of electrical connection of c-pro 3 mega+ ...................................................................................................... 44

4.4. Electrical connection c-pro 3 EXP hecto and c-pro 3 EXP hecto+ ........................................................................................... 46

4.4.1.

Meaning of the connectors of c-pro 3 EXP hecto and of c-pro 3 EXP hecto+ ............................................................... 46

4.4.2.

Example of electrical connection of c-pro 3 EXP hecto ................................................................................................. 51

4.5. Additional information for electrical connection ....................................................................................................................... 52

5.

USER INTERFACE ................................................................................................................................................................ 53

5.1. Keyboard ................................................................................................................................................................................ 53

5.2. Signalling LEDs ...................................................................................................................................................................... 53

5.2.1.

LEDs at the front of the device ..................................................................................................................................... 53

5.2.2.

LEDs on the RS-485 ports ........................................................................................................................................... 54

6.

CONFIGURATION ................................................................................................................................................................. 55

6.1. Configuring a programmable controller ................................................................................................................................... 55

6.1.1.

Configuring a built-in programmable controller ............................................................................................................. 55

6.1.2.

Configuring a blind programmable controller ................................................................................................................ 57

6.2. Configuring an I / O expansion ............................................................................................................................................... 58

6.3. Configuring a device through an user interface (Vgraph, Vtouch or Vroom) ........................................................................... 59

6.4. List of configuration parameters .............................................................................................................................................. 60

6.4.1.

List of configuration parameters of c-pro 3 hecto and of c-pro 3 hecto+ ........................................................................ 60

6.4.2.

List of configuration parameters of c-pro 3 mega and of c-pro 3 NODE mega .............................................................. 67

6.4.3.

List of configuration parameters of c-pro 3 mega+ ........................................................................................................ 77

6.4.4.

List of configuration parameters of c-pro 3 EXP hecto and of c-pro 3 EXP hecto+ ....................................................... 92

7.

USER INTERFACES .............................................................................................................................................................. 96

7.1. Preliminary information ........................................................................................................................................................... 96

7.2. Vgraph .................................................................................................................................................................................... 96

7.2.1.

Introduction .................................................................................................................................................................. 96

7.2.2.

Summarizing table of the main features and available models ..................................................................................... 96

7.2.3.

Size.............................................................................................................................................................................. 97

page 3 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

7.3. Vtouch .................................................................................................................................................................................... 98

7.3.1.

Introduction .................................................................................................................................................................. 98

7.3.2.

Summarizing table of the main features and available models ..................................................................................... 98

7.3.3.

Size.............................................................................................................................................................................. 99

7.4. Vroom ................................................................................................................................................................................... 100

7.4.1.

Introduction ................................................................................................................................................................ 100

7.4.2.

Summarizing table of the main features and available models ................................................................................... 100

7.4.3.

Size............................................................................................................................................................................ 101

8.

ACCESSORIES.................................................................................................................................................................... 102

8.1. Programming kit EVIF20TUXI ............................................................................................................................................... 102

8.1.1.

Introduction ................................................................................................................................................................ 102

8.1.2.

Description ................................................................................................................................................................. 102

8.1.3.

Size............................................................................................................................................................................ 103

8.1.4.

Connection to the Personal Computer ........................................................................................................................ 103

8.2. Programming key EVKEY10 ................................................................................................................................................. 103

8.2.1.

Introduction ................................................................................................................................................................ 103

8.2.2.

Description ................................................................................................................................................................. 103

8.2.3.

Size............................................................................................................................................................................ 104

8.2.4.

Connection to the controller ....................................................................................................................................... 104

9.

TECHNICAL DATA ............................................................................................................................................................... 105

9.1. Technical data ...................................................................................................................................................................... 105

page 4 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

1. INTRODUCTION

1.1. Introduction

c-pro 3 is a family of programmable controllers.

The family consists of:

- programmable controllers (c-pro 3 hecto, c-pro 3 hecto+, c-pro 3 mega, c-pro 3 mega+ and c-pro 3 NODE mega)

- I / O expansions (c-pro 3 EXP hecto and c-pro 3 EXP hecto+).

c-pro 3 hecto is available in blind version and can be used for example with an user interface such as Vgraph, Vtouch or Vroom.

The controllers have got:

- real time clock

- 3 analog inputs configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers

- 5 non optoisolated free of voltage digital inputs

- 3 analog outputs of which 1 non optoisolated PWM output and 2 non optoisolated outputs configurable via configuration

parameter for 0-20 mA / 4-20 mA / 0-10 V signal

- 6 digital outputs (electromechanical relays) of which five 5 res. A @ 250 VAC SPST outputs and one 8 res. A @ 250 VAC

SPDT output

- 3 non optoisolated communication ports of which 1 CAN port with CANbus communication protocol, 1 RS-485 port with

Modbus master / slave communication protocol (configurable via application software) and 1 programming and debugging

port.

Through the I / O expansion c-pro 3 EXP hecto or c-pro 3 EXP hecto+ it is possible to increase the number of inputs and outputs.

c-pro 3 hecto+ is available in the following versions:

- with 128 x 64 pixel single colour LCD graphic display (black with rearlighting through white LEDs) and with a 6 buttons (with

preset functions) keyboard made of silicone rubber integrated in the controller, hereinafter also called “built-in versions”

- blind (can be used for example with an user interface such as Vgraph, Vtouch or Vroom), hereinafter also called “blind

versions”.

The controllers have got:

- real time clock

- alarm buzzer (not available in the blind versions)

- 4 analog inputs of which 3 configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA /

0-5 V ratiometric / 0-10 V transducers and 1 for NTC probes

- 5 optoisolated digital inputs at 24 VAC / DC

- 3 analog outputs of which 1 non optoisolated PWM output and 2 non optoisolated outputs configurable via configuration

parameter for 0-20 mA / 4-20 mA / 0-10 V signal

- 6 digital outputs (electromechanical relays) of which five 3 res. A @ 250 VAC SPST outputs and one 5 res. A @ 250 VAC

SPDT output

- 3 non optoisolated communication ports of which 1 CAN port with CANbus communication protocol, 1 RS-485 port with

Modbus master / slave communication protocol (configurable via application software) and 1 programming and debugging

port.

Through the I / O expansion c-pro 3 EXP hecto or c-pro 3 EXP hecto+ it is possible to increase the number of inputs and outputs.

c-pro 3 mega and c-pro 3 NODE mega are available in the following versions:

- with 122 x 32 pixel single colour LCD graphic display (black with rearlighting through white LEDs) and with a 6 buttons (with

preset functions) keyboard made of silicone rubber integrated in the controller, hereinafter also called “built-in versions”

- blind (can be used for example with an user interface such as Vgraph, Vtouch or Vroom), hereinafter also called “blind

versions”.

The controllers have got:

- real time clock

- alarm buzzer (not available in the blind versions)

page 5 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

- 5 analog inputs configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers

- 7 optoisolated digital inputs at 24 VAC / DC

- 3 analog outputs of which 1 non optoisolated PWM output and 2 non optoisolated outputs configurable via configuration

parameter for 0-20 mA / 4-20 mA / 0-10 V signal

- 8 digital outputs (electromechanical relays) of which three 5 res. A @ 250 VAC SPST outputs, four 8 res. A @ 250 VAC SPST

outputs and one 8 res. A @ 250 VAC SPDT output

- 4 non optoisolated communication ports of which 1 CAN port with CANbus communication protocol, 1 RS-485 port with

Modbus slave communication protocol, 1 RS-485 port with Modbus master / slave communication protocol (configurable via

application software) and 1 programming and debugging port

- 1 non optoisolated communication port for gateway c-pro 3 plug-in (available in c-pro 3 NODE mega only).

Through the I / O expansion c-pro 3 EXP hecto or c-pro 3 EXP hecto+ it is possible to increase the number of inputs and outputs.

c-pro 3 mega+ is available in the following versions:

- with 122 x 32 pixel single colour LCD graphic display (black with rearlighting through white LEDs) and with a 6 buttons (with

preset functions) keyboard made of silicone rubber integrated in the controller, hereinafter also called “built-in versions”

- blind (can be used for example with an user interface such as Vgraph, Vtouch or Vroom), hereinafter also called “blind

versions”.

The controllers have got:

- real time clock

- alarm buzzer (not available in the blind versions)

- 8 analog inputs of which 3 configurable via configuration parameter for NTC / 0-20 mA / 4-20 mA transducers and 5

configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V ratiometric / 0-10 V

transducers

- 12 optoisolated digital inputs at 24 VAC / DC

- 5 analog outputs of which 1 non optoisolated PWM output, 2 non optoisolated outputs configurable via configuration

parameter for PWM / 0-10 V signal and 2 non optoisolated outputs configurable via configuration parameter for 0-20 mA /

4-20 mA / 0-10 V signal

- 10 digital outputs (electromechanical relays) of which five 5 res. A @ 250 VAC SPST outputs, four 8 res. A @ 250 VAC SPST

outputs and one 8 res. A @ 250 VAC SPDT output

- 5 non optoisolated communication ports of which 1 CAN port with CANbus communication protocol, 1 CAN port or MP-Bus

port (according to the model), 1 RS-485 port with Modbus slave communication protocol, 1 RS-485 port with Modbus master /

slave communication protocol (configurable via application software) and 1 programming and debugging port.

Through the I / O expansion c-pro 3 EXP hecto or c-pro 3 EXP hecto+ it is possible to increase the number of inputs and outputs.

c-pro 3 EXP hecto is available in blind version and can be used for example with a programmable controller such as c-pro 3 hecto,

c-pro 3 hecto+, c-pro 3 mega or c-pro 3 NODE mega.

The expansion has got:

- 3 analog inputs configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V

ratiometric / 0-10 V transducers

- 5 non optoisolated free of voltage digital inputs

- 3 analog outputs of which 1 non optoisolated PWM output and 2 non optoisolated outputs configurable via configuration

parameter for 0-20 mA / 4-20 mA / 0-10 V signal

- 6 digital outputs (electromechanical relays) of which five 5 res. A @ 250 VAC SPST outputs and one 8 res. A @ 250 VAC

SPDT output

- 2 non optoisolated communication ports of which 1 CAN port with CANbus communication protocol and 1 port to update the

firmware of the instrument.

page 6 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

c-pro 3 EXP hecto+ is available in blind version and can be used for example with a programmable controller such as c-pro 3 hecto,

c-pro 3 hecto+, c-pro 3 mega or c-pro 3 NODE mega.

The expansion has got:

- 4 analog inputs of which 3 configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA /

0-5 V ratiometric / 0-10 V transducers and 1 for NTC probes

- 5 optoisolated digital inputs at 24 VAC / DC

- 3 analog outputs of which 1 non optoisolated PWM output and 2 non optoisolated outputs configurable via configuration

parameter for 0-20 mA / 4-20 mA / 0-10 V signal

- 6 digital outputs (electromechanical relays) of which five 3 res. A @ 250 VAC SPST outputs and one 5 res. A @ 250 VAC

SPDT output

- 2 non optoisolated communication ports of which 1 CAN port with CANbus communication protocol and 1 port to update the

firmware of the instrument.

Through the development environment UNI-PRO 3 (to order separately) it is possible to realize the application software and through the

programming kit EVIF20TUXI (to order separately) it is possible to program the controllers.

The devices look in case 4 DIN modules (c-pro 3 hecto, c-pro 3 hecto+, c-pro 3 EXP hecto and c-pro 3 EXP hecto+), 10 DIN modules

(c-pro 3 mega and c-pro 3 mega+) or 14 DIN modules (c-pro 3 NODE mega).

Installation is in electrical panel, on DIN rail.

Through the programming key EVKEY 10 (to order separately) it is also possible to make the upload and the download of the

configuration parameters.

page 7 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

2. DESCRIPTION

2.1. Description c-pro 3 hecto and c-pro 3 hecto+

The following drawing shows the aspect of c-pro 3 hecto and of c-pro 3 hecto+.

The following table shows the meaning of the parts of the controller.

Part Meaning

1 RS-485 port with Modbus master / slave communication protocol

micro-switch to:

2

3 CAN port

4 digital outputs

5 display and keyboard (available in c-pro 3 hecto+ only, not available in the blind versions)

6 analog outputs in c-pro 3 hecto, analog inputs and analog outputs in c-pro 3 hecto+

7 analog inputs

8 programming and debugging port

- plug in the termination of the RS-485 port

- polarize the network of the RS-485 port

- plug in the termination of the CAN port

9 power supply

10 digital inputs

11 signalling LEDs

page 8 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

2.2. Description c-pro 3 mega

The following drawing shows the aspect of c-pro 3 mega.

The following table shows the meaning of the parts of the controller.

Part Meaning

1 RS-485 port with Modbus slave communication protocol (hereinafter also called first RS-485 port)

2 RS-485 port with Modbus master / slave communication protocol (hereinafter also called second RS-485 port)

micro-switch to:

3

4 CAN port

5 digital outputs

6 display and keyboard (not available in the blind versions)

7 analog outputs

8 digital inputs

- plug in the terminations of the RS-485 ports

- polarize the network of the second RS-485 port

- plug in the termination of the CAN port

9 analog inputs

10 programming and debugging port

11 power supply

12 signalling LEDs

page 9 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

2.3. Description c-pro 3 mega+

The following drawing shows the aspect of c-pro 3 mega+.

The following table shows the meaning of the parts of the controller.

Part Meaning

1 RS-485 port with Modbus slave communication protocol (hereinafter also called first RS-485 port)

2 RS-485 port with Modbus master / slave communication protocol (hereinafter also called second RS-485 port)

micro-switch to:

3

4 first CAN port

5 digital outputs 1... 8

6 second CAN port or MP-Bus port (according to the model)

7 micro-switch to plug in the termination of the second CAN port

8 display and keyboard (not available in the blind versions)

- plug in the terminations of the RS-485 ports

- polarize the network of the second RS-485 port

- plug in the termination of the first CAN port

9 digital inputs 8... 12

10 analog outputs 1... 3

11 digital inputs 1... 7

12 analog inputs 1... 5

page 10 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

13 programming and debugging port

14 power supply

15 analog inputs 6... 8

16 signalling LEDs

17 analog outputs 4 and 5

18 digital outputs 9 and 10

page 11 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

2.4. Description c-pro 3 NODE mega

The following drawing shows the aspect of c-pro 3 NODE mega.

The following table shows the meaning of the parts of the controller.

Part Meaning

1 RS-485 port with Modbus slave communication protocol (hereinafter also called first RS-485 port)

2 RS-485 port with Modbus master / slave communication protocol (hereinafter also called second RS-485 port)

micro-switch to:

3

4 CAN port

5 digital outputs

6 display and keyboard (not available in the blind versions)

7 slot for gateway c-pro 3 plug-in

8 analog outputs

9 digital inputs

- plug in the terminations of the RS-485 ports

- polarize the network of the second RS-485 port

- plug in the termination of the CAN port

10 analog inputs

11 programming and debugging port

12 power supply

13 signalling LEDs

page 12 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

2.5. Description c-pro 3 EXP hecto and c-pro 3 EXP hecto+

The following drawing shows the aspect of c-pro 3 EXP hecto and of c-pro 3 EXP hecto+.

The following table shows the meaning of the parts of the expansion.

Part Meaning

1 micro-switch to plug in the termination of the CAN port

2 CAN port

3 digital outputs

4 analog outputs in c-pro 3 EXP hecto, analog inputs and analog outputs in c-pro 3 EXP hecto+

5 analog inputs

6 port to update the firmware of the expansion

7 power supply

8 digital inputs

9 signalling LEDs

page 13 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

3. SIZE AND INSTALLATION

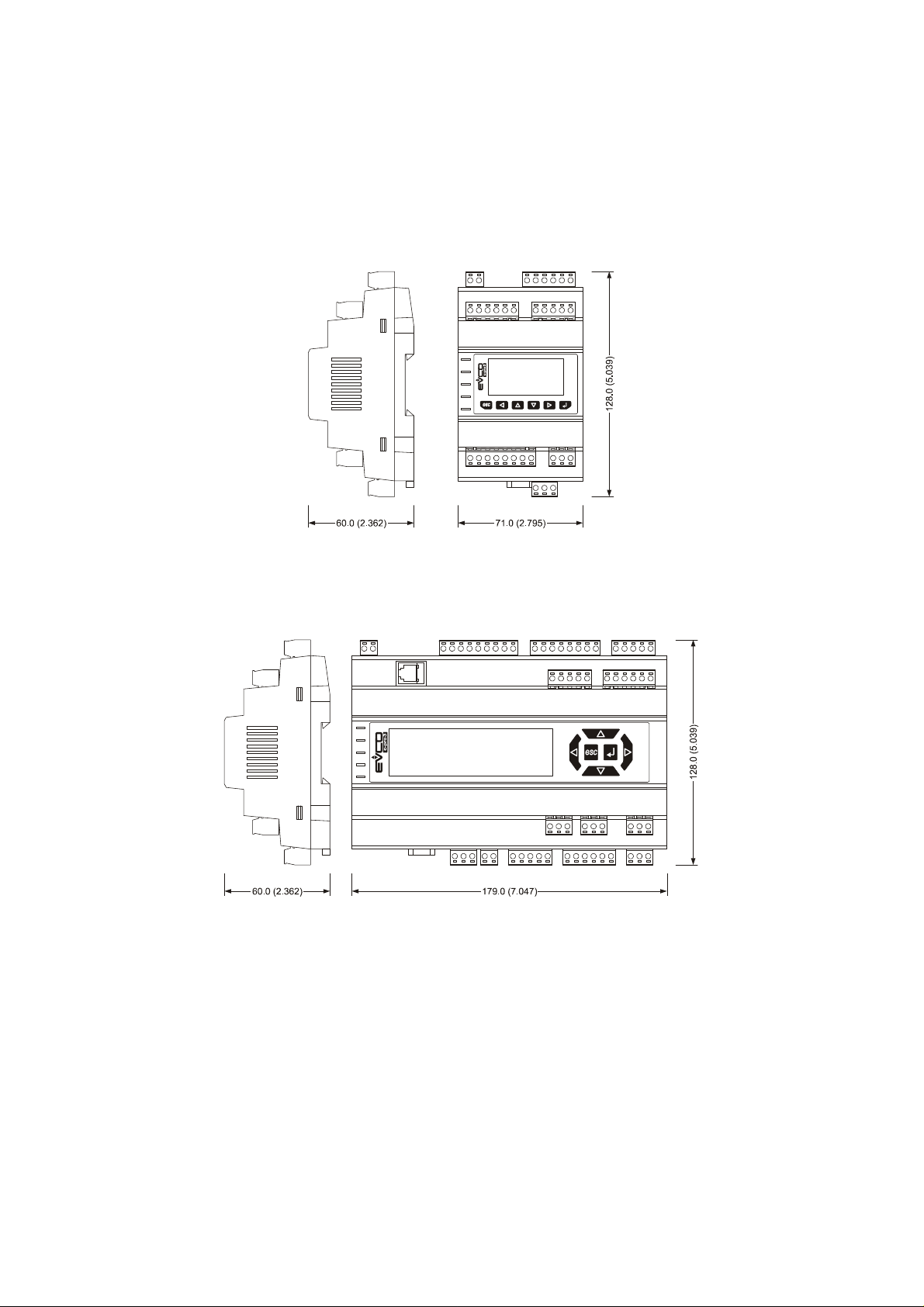

3.1. Size c-pro 3 hecto, c-pro 3 hecto+, c-pro 3 EXP hecto and

c-pro 3 EXP hecto+

4 DIN modules; size in mm (in).

3.2. Size c-pro 3 mega and c-pro 3 mega+

10 DIN modules; size in mm (in).

page 14 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

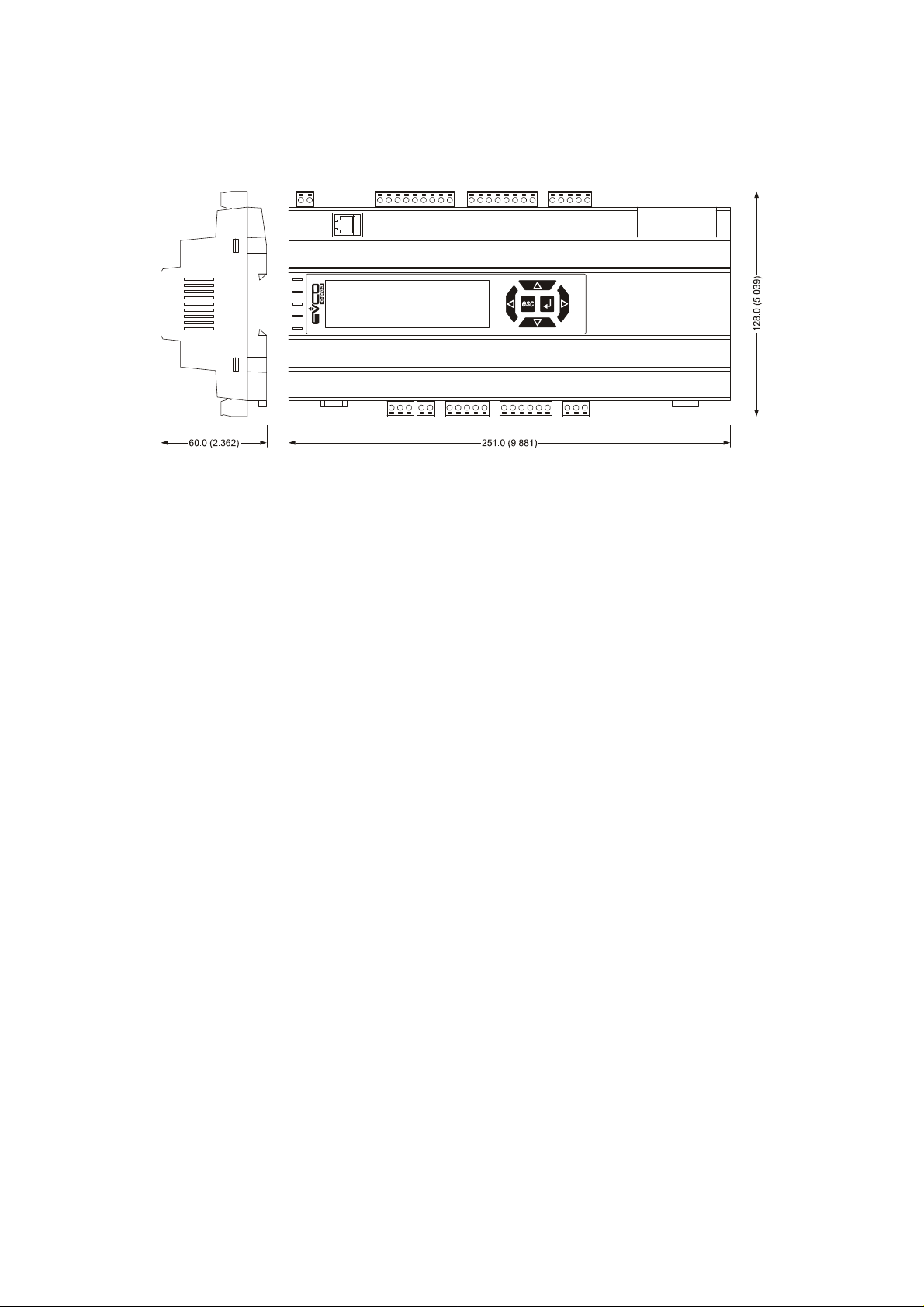

3.3. Size c-pro 3 NODE mega

14 DIN modules; size in mm (in).

page 15 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

3.4. Installation

On DIN rail 35.0 x 7.5 mm (1.377 x 0.295 in) or 35.0 x 15.0 mm (1.377 x 0.590 in).

To install the devices operate as shown in the following drawing.

1 2

To remove the devices remove possible extractable screw terminal blocks plugged at the bottom first, then operate on the DIN rail clips

with a screwdriver as shown in the following drawing.

3 4

To install the devices again press the DIN rail clips to the end first.

3.5. Additional information for installation

- working conditions (working temperature, humidity, etc.) must be between the limits indicated in the technical data

- do not install the devices close to heating sources (heaters, hot air ducts, etc.), equipments provided with big magnetos (big

speakers, etc.), locations subject to direct sunlight, rain, humidity, dust, mechanical vibrations or bumps

- according to the safety legislation, the protection against electrical parts must be ensured by a correct installation of the

devices; the parts that ensure the protection must be installed so that you can not remove them if not by using a tool.

page 16 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

4. ELECTRICAL CONNECTION

4.1. Electrical connection c-pro 3 hecto and c-pro 3 hecto+

4.1.1. Meaning of the connectors of c-pro 3 hecto and of c-pro 3 hecto+

The following drawing shows the connectors of c-pro 3 hecto and of c-pro 3 hecto.

The following tables show the meaning of the connectors.

MODBUS

RS-485 port with Modbus master / slave communication protocol (configurable via application software).

The following drawing shows the aspect of the RS-485 port.

The following table shows the meaning of the pins of the RS-485 port.

Pin Meaning

1 common

2 not connected

3 not connected

4 D0 = B = - (terminal 0 of the transceiver)

5 D1 = A = + (terminal 1 of the transceiver)

6 not connected

7 not connected

page 17 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

8 not connected

The maximum length of the connecting cables of the RS-485 port is 1,000 m (3,280 ft); also look at the Modbus specifications

and implementation guides manual (the document is available on the internet site www.modbus.org).

Connect the RS-485 port using a twisted pair.

The following table shows the function codes supported by the controller.

Function

code

FC 01 read coils

FC 02 read discrete inputs

FC 03 read multiple registers

FC 04 read input registers

FC 05 write single coil

FC 06 write single register

FC 08 diagnostic

FC 15 write multiple coils

FC 16 write multiple registers

Meaning

FC 23 read write multiple registers

For the settings about the RS-485 port look at chapter 6 “CONFIGURATION”.

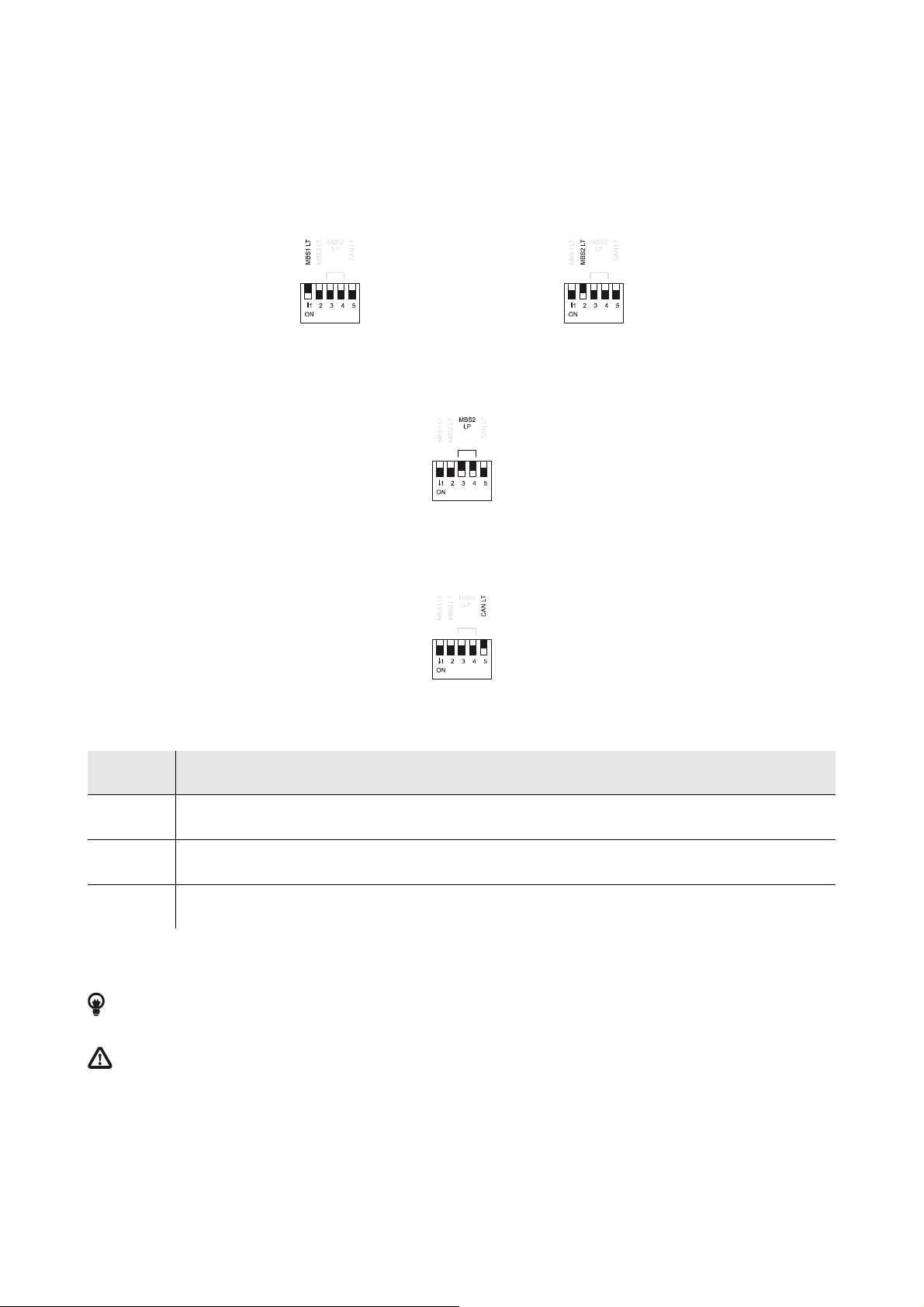

MICRO-SWITCH

Micro-switch to:

- plug in the termination of the RS-485 port (120 Ω, 0.25 W); position micro-switch 1 on position ON to plug in the termination of

the RS-485 port (plug in the termination of the first and of the last element of the network)

page 18 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

- polarize the network of the RS-485 port (560 Ω, 0.25 W); position micro-switches 2 and 3 on position ON to polarize the

network of the RS-485 port (the network must be polarized by an element of the network same).

- plug in the termination of the CAN port (120 Ω, 0.5 W); position micro-switch 4 on position ON to plug in the termination of the

CAN port (plug in the termination of the first and of the last element of the network).

CAN BUS

CAN port.

Terminal Meaning

CAN + signal +

CAN - signal -

GND ground

The maximum number of devices that can make a CAN network (32) depends on the bus load; the bus load depends on the baud rate

of the CANbus communication and on the kind of device in the network.

For example: a CAN network can be made of a programmable controller, of four I / O expansions and of four user interfaces

with baud rate 500,000 baud.

The maximum length of the connecting cables of the CAN port depends on the baud rate of the CANbus communication, as

follows:

- 1,000 m (3,280 ft) with baud rate 20,000 baud

- 500 m (1,640 ft) with baud rate 50,000 baud

- 250 m (820 ft) with baud rate 125,000 baud

- 50 m (164 ft) with baud rate 500,000 baud.

Connect the CAN port using a twisted pair.

For the settings about the CAN port look at chapter 6 “CONFIGURATION”.

DIGITAL OUTPUTS

In c-pro 3 hecto.

Digital outputs 1, 2, 3, 4 and 5 (electromechanical relays).

Terminal Meaning

CO1/2 common digital outputs 1 and 2

NO1 normally open contact digital output 1

page 19 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

NO2 normally open contact digital output 2

CO3 common digital output 3

NO3 normally open contact digital output 3

CO4/5 common digital outputs 4 and 5

NO4 normally open contact digital output 4

NO5 normally open contact digital output 5

Digital output 6 (electromechanical relay).

Terminal Meaning

CO6 common digital output 6

NO6 normally open contact digital output 6

NC6 normally closed contact digital output 6

The maximum length of the connecting cables of the digitalhecto:cuts is 100 m (328 ft).

The maximum current allowed on the loads is 10 A.

DIGITAL OUTPUTS

In c-pro 3 hecto+.

Digital outputs 1, 2, 3, 4 and 5 (electromechanical relays).

Terminal Meaning

CO1/2 common digital outputs 1 and 2

NO1 normally open contact digital output 1

NO2 normally open contact digital output 2

NO3 normally open contact digital output 3

CO3/4/5 common digital outputs 3, 4 and 5

CO3/4/5 common digital outputs 3, 4 and 5

NO4 normally open contact digital output 4

NO5 normally open contact digital output 5

page 20 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

Digital output 6 (electromechanical relay).

Terminal Meaning

CO6 common digital output 6

NO6 normally open contact digital output 6

NC6 normally closed contact digital output 6

The maximum length of the connecting cables of the digital(6) non

hecto only)

Analog outputs.

Terminal Meaning

VDC power supply driving analog output 1 (24 VDC, 50 mA max.)

AO1 analog output 1 (PWM signal)

GND ground

AO2 analog output 2 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

AO3 analog output 3 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

The maximum length of the connecting cables of the PWM analog output is 1 m (3

280 ft); the one of the connecting cables of the 0-20 mA / 4-20 mA / 0-10 V analog outputs is instead of 30 m (98 ft).

For the settings about the analog outputs look at chapter 6 “CONFIGURATION”.

The analog output 1 is usable on condition that the controller is powered in alternate current and the phase powering the controller is the

same powering the user driven by the output.

ANALOG INPUTS/OUTPUTS (in c-pro 3 hecto+ only)

Analog inputs and analog outputs.

Terminal Meaning

AI4 analog input 4 (NTC probes)

AO1 analog output 1 (PWM signal)

GND ground

AO2 analog output 2 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

AO3 analog output 3 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

The maximum length of the connecting cables of the PWM analog output is 1 m (3.280 ft); the one of the connecting cables of

the 0-20 mA / 4-20 mA / 0-10 V analog outputs is instead of 30 m (98 ft).

page 21 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

For the settings about the analog outputs look at chapter 6 “CONFIGURATION”.

The analog output 1 is usable on condition that the controller is powered in alternate current and the phase powering the controller is the

same powering the user driven by the output.

The analog output 1 and the analog output 2 are not independent each other but they work in the same way.

DIGITAL INPUTS

Free of voltage digital inputs.

Terminal Meaning

COM common digital inputs

DI1 digital input 1

DI2 digital input 2

DI3 digital input 3

DI4 digital input 4

DI5 digital input 5

The maximum length of the connecting cables of the digital inputs is 100 m (328 ft).

ANALOG INPUTS

Analog inputs.

Each analog input is configurable via configuration parameter for PTC / NTC / Pt 1000 probes / 0-20 mA / 4-20 mA / 0-5 V ratiometric /

0-10 V transducers.

Terminal Meaning

AI1 analog input 1

AI2 analog input 2

AI3 analog input 3

GND ground

+5V power supply 0-5 V ratiometric transducers (5 VDC, 40 mA max.)

+24V power supply 0-20 mA / 4-20 mA / 0-10 V transducers (24 VDC, 120 mA max.)

The maximum length of the connecting cables of the analog inputs and the one of the power supply of the transducers is

100 m (328 ft).

The controller incorporates a restorable thermal protection of the power supplies against the short circuit and the overload.

For the settings about the analog inputs look at chapter 6 “CONFIGURATION”.

PROG

Programming and debugging port.

page 22 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

POWER SUPPLY

Power supply.

Terminal Meaning

V≅

V≅

The maximum length of the connecting cables of the power supply of the controller is 30 m (98 ft).

Protect the power supply with a fuse rated 0.8A-T 250 V.

If the controller is powered in direct current, one will not have to respect the polarity of the power supply voltage.

power supply controller (24 VAC / 20... 40 VDC)

power supply controller (24 VAC / 20... 40 VDC)

page 23 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

4.1.2. Example of electrical connection of c-pro 3 hecto

The following shows an example of electrical connection of c-pro 3 hecto.

To reduce the reflections on the signal transmitted through the cables connecting the devices each other, plug in the

termination of the CAN port of the first and of the last element of the network.

page 24 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

4.2. Electrical connection c-pro 3 mega and c-pro 3 NODE mega

4.2.1. Meaning of the connectors of c-pro 3 mega and of c-pro 3 NODE mega

The following drawing shows the connectors of c-pro 3 mega and of c-pro 3 NODE mega.

The following tables show the meaning of the connectors.

MODBUS1

RS-485 port with Modbus slave communication protocol.

The following drawing shows the aspect of the RS-485 port.

The following table shows the meaning of the pins of the RS-485 port.

Pin Meaning

1 common

2 not connected

3 not connected

4 D0 = B = - (terminal 0 of the transceiver)

5 D1 = A = + (terminale 1 of the transceiver)

6 not connected

7 not connected

page 25 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

8 not connected

The maximum length of the connecting cables of the RS-485 port is 1,000 m (3,280 ft); also look at the Modbus specifications

and implementation guides manual (the document is available on the internet site www.modbus.org).

Connect the RS-485 port using a twisted pair.

The following table shows the function codes supported by the controller.

Function

code

FC 01 read coils

FC 02 read discrete inputs

FC 03 read multiple registers

FC 04 read input registers

FC 05 write single coil

FC 06 write single register

FC 08 diagnostic

FC 15 write multiple coils

FC 16 write multiple registers

Meaning

FC 23 read write multiple registers

For the settings about the RS-485 port look at chapter 6 “CONFIGURATION”.

MODBUS2

RS-485 port with Modbus master / slave communication protocol (configurable via application software).

The following drawing shows the aspect of the RS-485 port.

The following table shows the meaning of the pins of the RS-485 port.

Pin Meaning

1 common

2 not connected

page 26 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

3 not connected

4 D0 = B = - (terminal 0 of the transceiver)

5 D1 = A = + (terminale 1 of the transceiver)

6 not connected

7 not connected

8 not connected

The maximum length of the connecting cables of the RS-485 port is 1,000 m (3,280 ft); also look at the Modbus specifications

and implementation guides manual (the document is available on the internet site www.modbus.org).

Connect the RS-485 port using a twisted pair.

The following table shows the function codes supported by the controller.

Function

code

FC 01 read coils

FC 02 read discrete inputs

FC 03 read multiple registers

FC 04 read input registers

FC 05 write single coil

FC 06 write single register

FC 08 diagnostic

FC 15 write multiple coils

FC 16 write multiple registers

Meaning

FC 23 read write multiple registers

For the settings about the RS-485 port look at chapter 6 “CONFIGURATION”.

page 27 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

MICRO-SWITCH

Micro-switch to:

- plug in the terminations of the RS-485 ports (120 Ω, 0.25 W); position micro-switch 1 on position ON to plug in the termination

of the first RS-485 port and micro-switch 2 on position ON to plug in the termination of the second RS-485 port (plug in the

termination of the first and of the last element of the network)

- polarize the network of the second RS-485 port (560 Ω, 0.25 W); position micro-switches 3 and 4 on position ON to polarize

the network of the second RS-485 port (the network must be polarized by an element of the network same).

- plug in the termination of the CAN port (120 Ω, 0.5 W); position micro-switch 4 on position ON to plug in the termination of the

CAN port (plug in the termination of the first and of the last element of the network).

CAN BUS

CAN port.

Terminal Meaning

CAN + signal +

CAN - signal -

GND ground

The maximum number of devices that can make a CAN network (32) depends on the bus load; the bus load depends on the baud rate

of the CANbus communication and on the kind of device in the network.

For example: a CAN network can be made of a programmable controller, of four I / O expansions and of four user interfaces

with baud rate 500,000 baud.

The maximum length of the connecting cables of the CAN port depends on the baud rate of the CANbus communication, as

follows:

- 1,000 m (3,280 ft) with baud rate 20,000 baud

- 500 m (1,640 ft) with baud rate 50,000 baud

- 250 m (820 ft) with baud rate 125,000 baud

- 50 m (164 ft) with baud rate 500,000 baud.

Connect the CAN port using a twisted pair.

page 28 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

For the settings about the CAN port look at chapter 6 “CONFIGURATION”.

Power supply user interface.

Terminal Meaning

GND ground

VDC power supply user interface (24 VDC, 120 mA max.)

The maximum length of the connecting cables of the power supply of the user interface is 30 m (98 ft).

The controller incorporates a restorable thermal protection of the power supplies against the short circuit and the overload.

DIGITAL OUTPUTS

Digital outputs 1, 2 and 3 (electromechanical relays).

Terminal Meaning

CO1/2 common digital outputs 1 and 2

NO1 normally open contact digital output 1

NO2 normally open contact digital output 2

CO3 common digital output 3

NO3 normally open contact digital output 3

Digital outputs 4, 5, 6 e 7 (electromechanical relays).

Terminal Meaning

CO4/5 common digital outputs 4 and 5

NO4 normally open contact digital output 4

NO5 normally open contact digital output 5

CO6/7 common digital outputs 6 and 7

NO6 normally open contact digital output 6

NO7 normally open contact digital output 7

Digital output 8 (electromechanical relay).

Terminal Meaning

CO8 common digital output 8

page 29 of 116

EVCO S.p.A. c-pro 3 | Hardware manual ver. 3.2 | Codice 114CP3E324

NO8 normally open contact digital output 8

NC8 normally closed contact digital output 8

The maximum length of the connecting cables of the digital outputs is 100 m (328 ft).

The maximum current allowed on the loads is 10 A.

BMS CONNECTIVITY SLOT (in c-pro 3 NODE mega only)

Slot for gateway c-pro 3 plug-in; also look at the User guide of c-pro 3 plug-in.

ANALOG OUTPUTS

Analog outputs.

Terminal Meaning

VDC power supply driving analog output 1 (24 VDC, 50 mA max.)

AO1 analog output 1 (PWM signal)

GND ground

AO2 analog output 2 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

AO3 analog output 3 (configurable via configuration parameter for 0-20 mA / 4-20 mA / 0-10 V signal)

The maximum length of the connecting cables of the PWM analog output is 1 m (3.280 ft); the one of the connecting cables of

the 0-20 mA / 4-20 mA / 0-10 V analog outputs is instead of 30 m (98 ft).

For the settings about the analog outputs look at chapter 6 “CONFIGURATION”.

The analog output 1 is usable on condition that the controller is powered in alternate current and the phase powering the controller is the

same powering the user driven by the output.

DIGITAL INPUTS

Digital inputs.

Terminal Meaning

DI1 digital input 1

DI2 digital input 2

DI3 digital input 3

DI4 digital input 4

DI5 digital input 5

DI6 digital input 6

page 30 of 116

Loading...

Loading...