Eurodent Absolute Service manual

1

10/08

COD. 653950021

2

|

|

Installation instructions |

INDEX |

|

|

SERVICE REQUIREMENT ....................................................................................................................................... |

4 |

|

DECLARATION OF RESPONSIBILITY .................................................................................................................... |

4 |

|

ARRANGEMENT ...................................................................................................................................................... |

5 |

|

A PACKAGE OF THE ISORAMA, ISO AND ABSOLUTE CHAIRS ..................................................................... |

6 |

|

|

TRANSPORT AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . 7 |

B INSTALLING THE ISORAMA CHAIR ............................................................................................................... |

8 |

|

|

PREPARATION .................................................................................................................................................. |

8 |

|

RELEASING THE BACKREST........................................................................................................................... |

8 |

|

FASTENING THE BACKREST .......................................................................................................................... |

8 |

|

OPERATING TEST ............................................................................................................................................ |

9 |

|

BACKREST PAD ............................................................................................................................................... |

9 |

|

SEAT PAD ......................................................................................................................................................... |

10 |

C INSTALLING THE ISO AND ABSOLUTE CHAIRS .......................................................................................... |

11 |

|

|

BACKREST......................................................................................................................................................... |

11 |

|

BACKREST UPHOLSTERY .............................................................................................................................. |

11 |

|

SEAT UPHOLSTERY.......................................................................................................................................... |

12 |

|

ARMRESTS ASSEMBLY (only ISO chair) ......................................................................................................... |

12 |

D |

HEADREST........................................................................................................................................................ |

12 |

|

PROSTHETIC HEADREST............................................................................................................................... |

13 |

E |

INSTALLING THE DENTAL UNIT...................................................................................................................... |

14 |

F ELECTRICAL AND ELECTROPNEUMATICAL CONNECTIONS..................................................................... |

20 |

|

G CONNECTING THE SUCTION PUMP .............................................................................................................. |

22 |

|

H |

ABSOLUTE ARRANGEMENT........................................................................................................................... |

22 |

I |

ABSOLUTE WAYFINDER ARRANGEMENT.................................................................................................... |

24 |

J SETTING OF HANDLE SENSIVITY................................................................................................................... |

28 |

|

K ADJUSTMENT OF WATER FLOW TO THE BOWL ........................................................................................ |

28 |

|

L ARRANGEMENT OF BLUE FOOT CONTROL ................................................................................................ |

29 |

|

M MAINTENANCE OF VISION LED MODE LAMP .............................................................................................. |

31 |

|

N WAYFINDER CONNECTION TO COMPUTER ................................................................................................ |

32 |

|

3

Installation instructions

SERVICE REQUIREMENT

The unit to be installed is CLASS I, with attached parts of TYPE B  ,

,

with electronic bistoury or electrobistoury with attached part of TYPE BF

.

.

0051 The apparatus complies with the fundamental requirements of EC Directive 93/42.

Classification headings (EN60 601-1):

5.3Common equipments (equipments with no waterproof casing);

5.5Equipments which cannot be used in presence of an anaesthetic mixture inflammable by air or by oxygen or by nitrous oxide;

5.6Equipments for continuous working with intermittent load.

VISION LED MODE lamp classification (IEC60825-1; IEC60825-1/A1; IEC60825-1/A2): Unit with white led light of class 1M.

Do not observe directly with optical instruments (e.g. magnifying glasses, etc...) Optical power: 350 μW max to 470 nm without protective screen

162.5 μW max to 470 nm with protective screen

Snowhow whitening system classification (IEC60825-1; IEC60825-1/A1; IEC60825-1/A2): Unit with blue led light of class 2. Optical power: 82 μW a 455 nm

|

|

|

|

|

Protection earth |

Operating instructions |

|

|

|

|

|

||

................................................................Power: |

230 V / 50 Hz / 1350 VA (550 VA only unit) |

|||||

Operating system: ............................................. |

continuous, with intermitting load |

|||||

Max. lifting capacity: ......................................... |

135 Kg (dental unit and lamp excluded) |

|||||

Total unit weight: .............................................. |

221 Kg |

|||||

Max. weight applicable to instrument tray: .... |

5 Kg |

|||||

•The floor must be in accordance with DIN 1055 B1.3 and DIN 18560 T1 regulations.

•It is necessary to install an outer bipolar main switch to wall, in compliance with the law and with the following electric characteristics: 250 V / 10 A for disconnecting the unit from the main feed in case of intervention or inspection in it.

•The electrical system must be in accordance with IEC regulations 64.8, and made up of difference protective conductors Idn O 30mA at 16A/250V. WARNING: To avoid the risk of electric shock, this equipment must only be connected to a supply mains with protective earth.

•Water pressure at the unit inlet must range from 1,8 to 3,0 bar. The pipes must be capable to supply at least 5 l/minute

of water flow rate.

Water characteristics must conform to DIN 1988 rules, with a hardness gradient ≤ 8° dH (corresponding to 1,432 mmol/lit). We recommend installing a pressure reducing tap at the water hose outlet (preferably of 15 mm Ø).

•The air pressure provided by the compressor must range from 5,0 to 7,0 bar. Use a dry compressor, with air output of 60 lit/min. at 5 bar. We recommend installing a tap at the hose outlet (preferably of 15 mm Ø).

•The diameter of the emptying hose must be 40 mm, and 32 mm at its inlet; moreover the descent gradient must be at least 1 cm/mt, and the bend angle should not be less than 135°.

•The diameter of the suction pipe must be approx. 32/40 mm. We recommend following the instructions provided by the suction pump’s manufacturer.

•All arrangements must be carried out according to the indications provided on the following page and consulting the full scale installation plan (code 633580010) attached to each dental unit.

•Please refer to Spare Parts catalogue (code 664803001) and apply to EURODENT for further information about what is not included in it. Eurodent will provide to supply a copy of wiring diagrams, if requested, to authorized technicians.

•EURODENT accepts responsibility for the equipment safety and reliability if and only if:

-installation, assembly, extension, adjustment and repair operations have been carried out by authorized people;

-the general and electric installation of the room complies with the above written requirements;

-the equipment has been installed in compliance with the “INSTALLATION INSTRUCTIONS”;

-the equipment is used in compliance with the “OPERATOR’S HANDBOOK”;

-the equipment has not been modified under Eurodent authorization.

4

Installation instructions

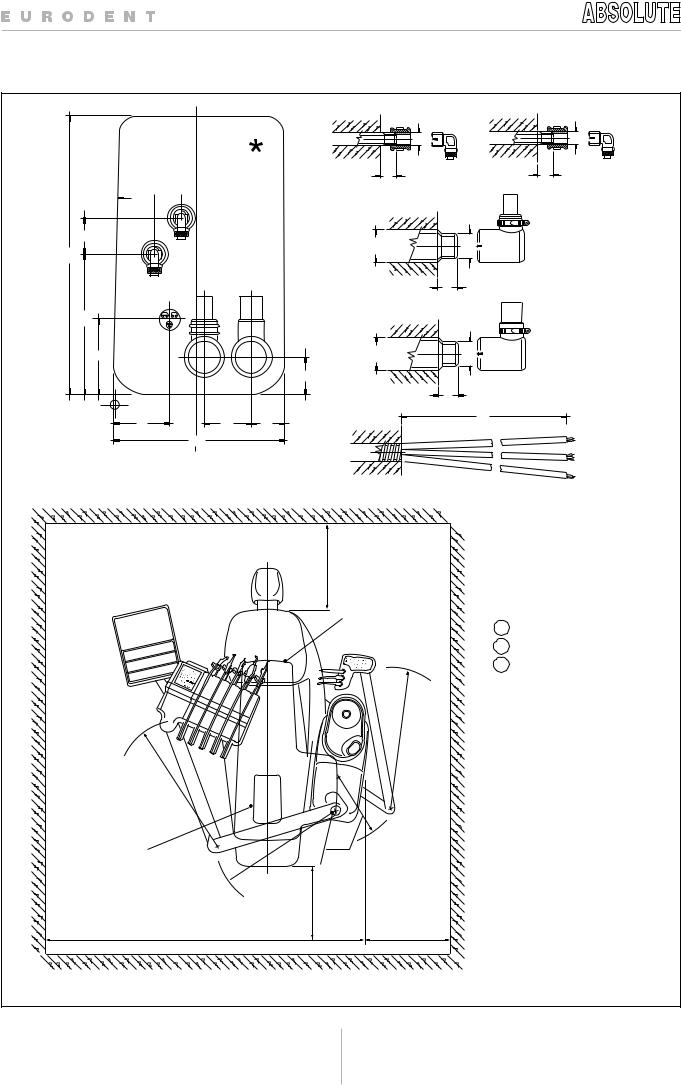

ARRANGEMENT

40

295

150

80

A |

3/8"G |

B |

3/8"G |

|

20 |

|

20 |

40  30

30

B |

|

ø 40 |

C |

ø 32 |

A |

|

|

|

|

|

|

|

|

25 |

E |

|

|

|

|

C |

D |

ø 40 |

D |

ø 32 |

|

|

40 |

|

|

|

|

|

|

25 |

|

|

|

|

500 |

60 |

50 |

35 |

|

|

175

E

R650

Hole for fastening to floor

R650

R650

1750 mm

900 mm

Hole for fastening to floor

R610

|

R425 |

|

ISOLUX |

mm |

VISION |

LED |

|

500 |

MODE |

|

700 mm

A.Water 3/8”G (green hose)

B.Air 3/8”G (white hose)

C.Outlet Ø 32

D.Suction Ø 32

.. Pump starting 2 x 1 sqmm

E. .. Bell 2 x 0,5 sqmm

... Net 3 x 2,5 sqmm

MAX. CHAIR OVERALL DIMENSIONS:

ISO: |

2 x 0,6 m |

ISORAMA: 2 x 0,7 m

ABSOLUTE: 2 x 0,6 m

5

Installation instructions

APACKAGE OF THE ISORAMA, ISO AND ABSOLUTE CHAIRS

The special packing system of these chairs has been thought in order to reduce its overall dimension.

For such a reason, the body of the chair is placed into the packing case 1 with the backrest bent over the seat (see figure A0), whereas upholstery, seat, backrest and headrest are contained into the packing case 2 .

When removing the chair from the packing case, cut the box 1 along the dotted line.

A0 |

|

ISORAMA |

|

ISORAMA |

ISO |

Net weight .... 131 |

Net weight .... 126 |

Gross weight .. 146 |

Gross weight .. 139 |

M3 .................. 0,6 |

M3 .................. 0,6 |

cm. 125 x 69 x 70 |

cm. 125 x 69 x 70 |

ABSOLUTE |

|

Net weight .... 122 |

|

Gross weight 135 |

|

M3 .................. 0,6 |

|

cm. 125 x 69 x 70 |

|

ISO/ABSOLUTE |

|

ISORAMA |

ISO/ABSOLUTE |

Net weight ...... 13 |

Net weight ...... 8 |

Gross weight .. 18 |

Gross weight .. 14 |

M3 .................. 0,2 |

M3 .............. 0,12 |

cm. 115 x 65 x 25 |

cm. 93 x 51 x 25 |

6 |

|

Installation instructions

TRANSPORT AND INSTALLATION

Remove the chair from its packing and, before moving it, take the covering guard of the connecting box off, so as to make the seizing of the chair and transport easier. Do not lift the chair by seizing the pantograph head or the legrest. Position the chair so as to place all couplings inside the connecting box (placed at the bottom of the chair parallelogram). Make sure that you do not inadvertently squash or tear the electrical cables of the chair when slipping it on the floor. Pay special care to the cable of the foot-control.

Check the level evenness of the floor with respect to the bearing surface of the base. Fasten the chair by fitting the expansion stoppers type Fischer (supplied with the accessories) into the two housings (see figure A1).

M6 expansion bolts and proper spanner are supplied with the chair. The hole in the floor must be at least 115-mm deep.

As regards installation, we advise connecting temporarily the chair to the main supply in order to have it lifted simply by operating the foot-control.

BE CAREFUL! Connect the backrest to the motor and to the Trendelenburg device before making it perform any movement.

When the chair reaches the height right for operating comfortably, cut out voltage.

A1

Bolt M6 x 140

Long spacer

Expansion nut

Expansion nut

A

A

Bolt M6 x 110

Short spacer

Expansion nut

B

B

A

B

IMPORTANT: if assembly does NOT allow connection A2 inside the chair base box, you can use the front base frame as outlet window, by removing the baffle plugs with

a cutter.

7

Installation instructions

B INSTALLING THE ISORAMA CHAIR

B1 |

PREPARATION |

|

|

|

Position properly the chair and remove the armrest by |

|

unscrewing the two M6 nuts with a 10-mm spanner. |

|

Cut the 2 plastic clamps which hold the worm screw of |

|

the backrest motor and the tie rod for the Trendelenburg |

|

movement. |

B2 |

RELEASING THE BACKREST |

|

By means of a 6-mm Allen wrench unloose the M4 dowel and remove the backrest pin from its housing using a 6-mm Allen wrench.

Note: Pay attention to the shim washer.

B3 |

FASTENING THE BACKREST

Lift the backrest so as to make the hitch point match with the motor rod eye and insert the backrest pin into its housing.

Tighten the pin firmly by means of an Allen wrench, then unloose the pin about 30° (less than one fourth turn of the wrench) in order to make it run freely and with minimum play. Finally, fasten it by tightening the M4 dowel.

Remove the polystyrene cube which protects the headrest.

8

B4 |

B5 |

B6 |

Installation instructions

OPERATING TEST

Now, proceed to fit the tie rod operating the Trendelenburg movement.

By using a 13-mm spanner remove the nut, then insert the tie rod eye and lock the rod again by the proper nut. Supply voltage to the chair and perform some trial movements in order to ascertain that the stop microswitches work properly.

Finally, mount upholstery.

BACKREST PAD

Position upholstery higher than backrest. Then, slide it downwards, in order to secure it properly and firmly to the three fastening screws, as shown in figure.

Fasten upholstery by the T-clamp, and press it against the two upholstery tags, as shown in figure.

Relocate the armrest.

9

B7 |

B8 |

Installation instructions

SEAT PAD

If not previously fitted, locate the dowels in their seats (the long one goes in the external rear hole), and fasten them by means of the proper lock nut.

Fit the two front dowels as well.

Then, as shown in the figure, position upholstery taking care of inserting the dowels into the proper holes.

Now, secure the pad by tightening the long cylindrical nuts of the dowels.

To carry out this operation, use the long spanner supplied.

In order to fix the front side, use M4 x 40 screws.

B9

10

Installation instructions

CINSTALLING THE ISO AND ABSOLUTE CHAIRS

C1 |

C2 |

BACKREST

Remove the chair from the packing by cutting along the dash-line, and lift the backrest until the hitch point matches the push rod.

Carefully insert the shim in its housing, and after fitting the screw in its housing, tighten it with the suitable wrench.

Now the chair can operate and some test movements should be performed to ensure that stop microswitches operate properly.

Then proceed by mounting upholstery.

C3 |

BACKREST UPHOLSTERY |

|

|

|

Position upholstery slightly over the backrest and make |

|

it slip down so that it fits in the two fastening screws. |

|

When upholstery is properly positioned, fit the screw into |

|

the suitable hole on the back side and tighten the M4 |

|

dowel by using the 2 mm Allen wrench. |

|

If the pad does not match properly with the backrest, |

|

adjust the two flathead screws as described for the |

|

headrest pad. |

11

Loading...

Loading...