EURODENT Absolute User manual

Manuale d’uso

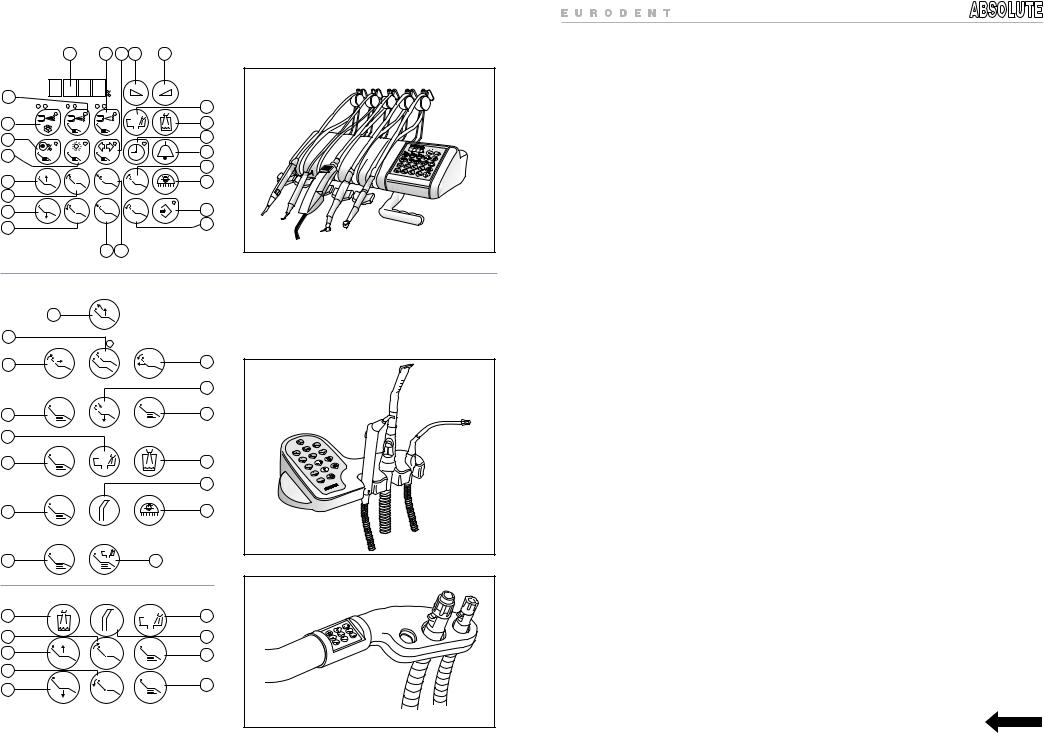

IPer garantire la migliore igiene del Vostro impianto, EURODENT Vi raccomanda di sostituire le parti raffigurate sotto con la frequenza riportata a fianco.

GB

F

E

To maintain thorough hygiene in your equipment, EURODENT recommends you to replace the parts in drawing hereunder at the timings shown aside.

Pour optimiser l’hygiène de votre équipement, EURODENT vous recommande de remplacer les parties représentées ci-dessous selon la fréquence relative.

Para la mejor higiene en Su equipo, EURODENT Le aconseja que Ud. sustituya las piezas representadas por debajo según la frecuencia correspondiente.

DUm die bestmögliche Hygienisierung Ihres Arbeitsplatzes zu erreichen, empfehlen wir Ihnen die unten bebilderten Teile in regelmässigen Zeitabständen, wie angegeben auszutauschen.

MESI |

MESI |

MONTHS |

MONTHS |

MOIS |

MOIS |

MESES |

MESES |

MONATE |

MONATE |

|

24 |

1 6 |

|

10/08

COD. 653950011

23 |

3 |

6 |

21 |

22 |

2 |

|

|

|

|

|

|

|

|

18 |

1 |

1 |

2 |

|

17 |

|

|

19 |

||

4 |

|

|

|

|

|

|

|

|

|

5 |

|

|

|

15 |

4 |

LP |

|

|

|

3 |

|

13 |

||

|

|

|

|

|

7 |

|

|

|

16 |

9 |

|

|

|

|

8 |

|

|

|

20 |

10 |

|

|

|

14 |

|

|

|

|

|

|

12 |

11 |

|

|

27 |

|

31 |

|

29 |

30 |

|

28 |

1 |

LP |

33 |

36 |

24 |

|

2 |

26 |

34 |

|

|

38 |

3 |

25 |

35 |

|

4 |

|

32 |

37 |

41 |

|

39 |

44 |

|

40 |

42 |

P |

46 |

|

||

|

|

|

45 |

|

|

43 |

O |

47 |

|

||

|

|

TASTIERA OPERATORE

OPERATOR KEYBOARD CLAVIER DE L’OPERATEUR TECLADO OPERADOR KONSOLE BEHANDLER

TASTIERA ASSISTENTE

ASSISTANT KEYBOARD CLAVIER DE L’ASSISTANTE TECLADO ASISTENTE KONSOLE HELFERIN

P

O

Operator’s handbook

MODES

1 - Water / air for spray presetting • Water selector - physiological solution for instrument 2 - Water / air for automatic C.B. presetting • Chair program 1

3 - Water / air for C.B. presetting • Chair program 2 4 - Power adjustment • Chair program 3

5 - Cold light adjustment • Chair program 4

6 - Operating mode • Chair last position memory

7 - Chair up

8 - Chair down

9 - Backrest forwards

10 - Backrest backwards

11 - Headrest up (for ISORAMA chair only)

12 - Headrest down (for ISORAMA chair only)

13 - Headrest forwards (for ISORAMA chair only)

14 - Headrest backwards (for ISORAMA chair only)

15 - Service push-button / nurse bell

16 - Operating lamp starting

17 - Tumbler filler

18 - Bowl rinsing

19 - Alarm mode / timer

20 - Memory ENTER (data storage confirmation) 21 - Displayed data decrease • Air / water selection 22 - Displayed data increase • Air / water selection 23 - Display

24 - Bowl rinsing

25 - Operating lamp starting

26 - Tumbler filler

27 - Chair up / Headrest up (for ISORAMA chair only)

28 - Chair down / Headrest down (for ISORAMA chair only)

29 - Backrest forwards / Headrest up (for ISORAMA chair only)

30 - Backrest backwards / Headrest backwards (for ISORAMA chair only) 31 - Selection between chair or headrest movements

32 - Chair program 4

33 - Chair program 1

34 - Chair program 2

35 - Chair program 3

36 - Chair last position memory

37 - Rinsing position

38 - Suction rinsing

39 - Bowl rinsing

40 - Suction rinsing

41 - Tumbler filler

42 - Chair up

43 - Chair down

44 - Backrest forwards

45 - Backrest backwards

46 - Programm 1

47 - Chair last position memory

ABSOLUTE Way nder |

|

|

TASTIERA OPERATORE |

|||

|

|

|

|

|

|

OPERATOR KEYBOARD |

|

|

|

|

|

|

CLAVIER DE L’OPERATEUR |

1 |

2 |

21 |

3 |

4 |

5 |

TECLADO OPERADOR |

KONSOLE BEHANDLER |

||||||

20 |

1 |

2 |

3 |

4 |

SP |

17 |

|

|

|

|

|

||

|

|

P |

|

|

|

18 |

|

|

|

|

|

|

|

6

LP

LP

|

|

|

23 |

19 |

|

|

16 |

|

|

|

|

24 |

|

|

25 |

|

|

|

|

7 |

|

|

13 |

|

|

|

|

9 |

|

|

11 |

|

|

|

|

8 |

|

|

14 |

|

|

|

|

10 |

15 |

22 |

12 |

28 |

TASTIERA ASSISTENTE |

|

ASSISTANT KEYBOARD |

||

|

||

32 |

CLAVIER DE L’ASSISTANTE |

|

TECLADO ASISTENTE |

||

|

||

30 |

KONSOLE HELFERIN |

|

|

||

|

31 |

|

|

29 |

|

1 |

LP |

|

33 |

37 |

|

40 |

|

|

2 |

|

|

34 |

27 |

|

|

39 |

|

3 |

|

|

35 |

26 |

|

|

||

4 |

SP |

|

36 |

38 |

42 |

49 |

45 |

41 |

|

|

1 |

43 |

47 |

|

|

46 |

|

|

LP |

44 |

48 |

|

Operator’s handbook

FUNZIONI

1 - Water / air for spray presetting • Chair program 1

2 - Water / air for automatic c.b. presetting • Chair program 2 3 - Water / air for c.b. presetting • Chair program 3

4 - Power adjustment • Chair program 4

5 - Cold light adjustment • Rinsing position

6 - Operating mode • Chair last position memory

7 - Chair up

8 - Chair down

9 - Backrest forwards

10 - Backrest backwards

11 - Headrest up (only with electric headrest)

12 - Headrest down (only with electric headrest)

13 - Headrest forwards (only with electric headrest)

14 - Headrest backwards (only with electric headrest)

15 - Service push-button / nurse bell

16 - Operating lamp starting

17 - Tumbler filler

18 - Bowl rinsing

19 - Alarm mode / timer

20 - Water / desinfected water presetting

21 - Browser menu key / data increase

22 - Browser menu key / data decrease

23 - Browser menu key / right arrow key

24 - Browser menu key / left arrow key

25 - ENTER (data storage confirmation)

26 - Operating lamp starting

27 - Tumbler filler

28 - Chair up / Headrest up (only with electric headrest)

29 - Chair down / Headrest down (only with electric headrest)

30 - Backrest forwards / Headrest up (only with electric headrest)

31 - Backrest backwards / Headrest backwards (only with electric headrest) 32 - Selection between chair or headrest movements

33 - Chair program 1

34 - Chair program 2

35 - Chair program 3

36 - Chair program 4

37 - Chair last position memory

38 - Rinsing position

39 - Suction rinsing

40 - Bowl rinsing

41 - Suction rinsing

42 - Tumbler filler

43 - Chair up

44 - Chair down

45 - Backrest forwards

46 - Backrest backwards

47 - Programm 1

48 - Chair last position memory

49 - Bowl rinsing

|

|

|

Operator’s handbook |

INDEX |

|

||

1 |

FOREWORD ........................................................................................................................................................ |

3 |

|

2 |

TECHNICAL FEATURES ...................................................................................................................................... |

4 |

|

3 |

SWITCHING ON .................................................................................................................................................... |

5 |

|

4 POSITIONING THE MODULE ARM .................................................................................................................... |

5 |

||

5 |

ABSOLUTE.......................................................................................................................................................... |

6 |

|

|

5.1 |

CLOCK ADJUSTMENT .............................................................................................................................. |

6 |

|

5.2 |

PATIENT POSITIONING ............................................................................................................................ |

6 |

|

5.3 |

ALARM MODE / TIMER .............................................................................................................................. |

9 |

|

5.4 |

TUMBLER FILLER ...................................................................................................................................... |

10 |

|

5.5 |

BOWL RINSING .......................................................................................................................................... |

10 |

|

5.6 |

LAMP OPERATION ..................................................................................................................................... |

10 |

|

5.7 |

SERVICE PUSH BUTTON ......................................................................................................................... |

11 |

|

5.8 |

FOOT-CONTROL SWITCHES ........................................................................................... |

........................ 12 |

|

|

Isotron Foot-Control ....................................................................................................................................... |

12 |

|

|

Blue Foot Control ....................................................................................................................................... |

13 |

|

5.9 PROGRAMMABLE MODES FOR THE INSTRUMENTS ........................................................................... |

15 |

|

|

5.10 MODULES .................................................................................................................................................. |

17 |

|

|

|

Syringe module and fibre optic syringe module ......................................................................................... |

18 |

|

|

Turbine module and variable speed turbine module with fibre optic .......................................................... |

18 |

|

|

Fibre optic micromotor module ................................................................................................................... |

19 |

|

|

High torque micromotor module with fibre optic / with physiodispenser ..................................................... |

19 |

|

|

Induction micromotor module...................................................................................................................... |

20 |

|

|

Induction micromotor module with physiodispenser ................................................................................... |

22 |

|

|

Scaler module ............................................................................................................................................. |

23 |

|

|

Isojet powder cleaner module .................................................................................................................... |

23 |

|

|

Camera module .................................................................................................................................... |

24 |

|

|

Bistoury module .......................................................................................................................................... |

24 |

|

|

Mini Led light cure module ......................................................................................................................... |

25 |

|

|

Snowhow whitening module ....................................................................................................................... |

26 |

|

5.11 ASEPSIS MODE ......................................................................................................................................... |

27 |

|

|

5.12 MESSAGES EXPLANATION ..................................................................................................................... |

27 |

|

|

5.13 PARAMETERS PRESETTING ................................................................................................................... |

29 |

|

6 |

ABSOLUTE WAYFINDER.................................................................................................................................... |

30 |

|

|

6.1 |

GENERAL DESCRIPTION OF THE DISPLAY .......................................................................................... |

30 |

|

6.2 |

PATIENT POSITIONING ............................................................................................................................ |

31 |

|

6.3 |

ALARM ....................................................................................................................................................... |

35 |

|

6.4 |

TUMBLER FILLER ...................................................................................................................................... |

36 |

|

6.5 |

BOWL RINSING ......................................................................................................................................... |

36 |

|

6.6 |

LAMP OPERATION .................................................................................................................................... |

36 |

|

6.7 |

SERVICE PUSH-BUTTON .......................................................................................................................... |

37 |

|

6.8 |

FOOT-CONTROL SWITCHES ................................................................................................................... |

38 |

|

|

Isotron Foot-Control ...................................................................................................................................... |

38 |

|

|

Blue Foot Control ....................................................................................................................................... |

39 |

|

6.9 |

STRUCTURE OF THE MAIN MENU ......................................................................................................... |

42 |

1

|

|

Operator’s handbook |

6.10 PROGRAMMABLE INSTRUMENT FEATURES ........................................................................................ |

47 |

|

6.11 MODULES ................................................................................................................................................. |

|

52 |

Syringe module and fibre optic syringe module ......................................................................................... |

53 |

|

Turbine module and variable speed turbine module with fibre optic .......................................................... |

54 |

|

Fibre optic micromotor module .................................................................................................................. |

|

55 |

High torque micromotor module with fibre optic / with physiodispenser .................................................... |

56 |

|

Induction micromotor module..................................................................................................................... |

|

57 |

Induction micromotor module with physiodispenser .................................................................................. |

60 |

|

Scaler module ............................................................................................................................................ |

|

61 |

Isojet powder cleaner module .................................................................................................................... |

|

62 |

Camera module ....................................... |

............................................................................................ 63 |

|

Bistoury module ......................................................................................................................................... |

|

63 |

Mini Led light cure module ......................................................................................................................... |

|

64 |

Snowhow whitening module ....................................................................................................................... |

|

65 |

6.12 ASEPSIS MODE ........................................................................................................................................ |

|

66 |

6.13 MESSAGES EXPLANATION .................................................................................................................... |

|

66 |

7 STERILIZATION METHODS AND WORKING TIMES ...................................................................................... |

69 |

|

8 MAINTENANCE .................................................................................................................................................. |

|

70 |

MODULE-HOLDER ARM BALANCING .................................................................................................... |

|

70 |

WATER DRAIN FROM AIR FILTER.......................................................................................................... |

|

71 |

CLEANING OF SUCTION FILTER .................................................................................................................. |

|

71 |

FILLING OF DETERGENT TANK .............................................................................................................. |

|

71 |

FILLING OF MEDICAMENT TANK ............................................................................................................ |

|

72 |

FILLING OF PHYSIOLOGICAL SOLUTION .............................................................................................. |

|

72 |

DISINFECTANT SOLUTION ..................................................................................................................... |

|

73 |

PARAMETERS SETTING ......................................................................................................................... |

|

73 |

REPLACEMENT OF STERILE SOLUTION BOTTLE ................................................................................... |

73 |

|

BLUE FOOT CONTROL BATTERY RECHARGE ..................................................................................... |

74 |

|

SURFACE CLEANING .............................................................................................................................. |

|

74 |

9 METASYS MST1 AMALGAM SEPARATOR ..................................................................................................... |

|

75 |

REMOVING AND CLEANING THE FILTER .............................................................................................. |

|

76 |

REMOVING THE AMALGAM SEPARATOR VESSEL .............................................................................. |

76 |

|

ECOLOGIC SYSTEM OF RECOVERY ...................................................................................................... |

|

77 |

2

Operator’s handbook

1FOREWORD

Dear Doctor,

the EURODENT GROUP is pleased with your choice of the ABSOLUTE equipment and proud of the favour you grant us.

The Absolute unit has been designed according to three main principles:

ASEPSIS CONTROL, OPERATIONAL FLEXIBILITY AND COMFORT.

Surface smoothness, combined with roundish contours and lack of slits and corners, allows an easy external cleaning and prevents from dusts and sprays deposit. Controls are made so that contact with fingers is avoided whenever possible.

All handpieces are fitted with anti-retraction valving, to prevent risks of cross-contamination.

Lightness of movement and breadth of operational displacement of the modules arm, easyness of access to the patient for both Doctor and Assistant and, last but not least, the flexible microprocessor control of the main activities of the apparatus, all make of ABSOLUTE a ductile system ready to match and support the Operators’ work attitudes.

The soft profile of the unit and handpieces asset, the anatomic shaping of the chair, the reassuring design of control decks, everything cooperates to frame the comfortable sensation induced into the patient, who will more confidently relax himself so making easier the Operators’ activity.

Wa are certain that your choice will prove widely fulfilling both because of the equipment functionality and reliability and thanks to the benefits in terms of prestige as to your Patients and Collegues.

This booklet will help you to obtain the best from your ISOTRON. While reminding you that we are at your disposal for any information that you might require, we remain

Sincerely yours,

3

|

Operator’s handbook |

2 TECHNICAL FEATURES |

|

Trade-Mark: ............................................................................................................................................... |

EURODENT |

Model: ........................................................................................................................................................ |

ABSOLUTE |

Voltage: ........................................................................................................................................ |

230 V (~ alternating) |

Frequency: .......................................................................................................................................................... |

50 Hz |

Power: ................................................................................................................................ |

1350 VA (550 VA only unit) |

UV lamp power (option) .......................................................................................................................................... |

4 W |

Classification: ................................................................................................. |

Class I with attached parts of type B |

Classification headings (EN60 601-1): |

|

5.3 Common equipments (equipments with no waterproof casing); |

|

5.5Equipments which cannot be used in presence of an anaesthetic mixture inflammable by air or by oxygen or by nitrous oxide;

5.6Equipments for continuous working with intermittent load.

VISION LED MODE lamp classification (IEC60825-1; IEC60825-1/A1; IEC60825-1/A2): Unit with white led light of class 1M.

Do not observe directly with optical instruments (e.g. magnifying glasses, etc...) Optical power: 350 μW max to 470 nm without protective screen

162.5 μW max to 470 nm with protective screen

Snowhow whitening system classification (IEC60825-1; IEC60825-1/A1; IEC60825-1/A2): Unit with blue led light of class 2. Optical power: 82 μW a 455 nm

Electronic bistoury or electrobistoury: ........................................................................... |

Attached part of type BF |

0051 The equipment complies with the fundamental requirements of EC Directive 93/42.

•Please refer to the Spare Parts catalogue, and apply to EURODENT for further information about what is not included in it.

•EURODENT accepts responsibility for the equipment safety and reliability if and only if:

-installation, assembly, extension, adjustment and repair operations have been carried out by authorized people.

-the general and electric installation of the room complies with the equipment pertinent requirements.

-the equipment has been installed in compliance with the “installation instructions” of the equipment.

-the equipment is used in compliance with the “OPERATOR’S HANDBOOK”.

•EURODENT hereby declares that the equipment is a dental complex intended as an operative tool for therapeutic use on people by personnel highly skilled in dental practices.

•The unit can withstand the following weather conditions when packed for shipping and storage:

-Ambient temperature from -20 °C to +40 °C.

-Relative humidity from 10% to 90%; it does not stand condensation.

It should be used in the following weather conditions:

-Ambient temperature from +10 °C to +40 °C.

-Relative humidity from 10% to 90%; it does not stand condensation.

•If the equipment is transported, stored or used in weather conditions different from the above-mentioned ones, malfunctions could occur.

•The unit does not generate electromagneticor other forms of interference into other equipments nearby, nor is it affected by electromagnetic interference.

Equipments working at high frequency (e.g. electronic bistoury) could interfere with the equipment working.

4

Operator’s handbook

Comply with all applicable local laws when disposing of the unit and its parts. Suction circuit components in particular must be considered as medical waste products and therefore they should be treated accordingly.

The symbol indicates that this appliance shall be handed over to the applicable collection point for the recycling of electrical and electronic equipment or to the dealer where you purchased a new product. By ensuring this product is disposed of correctly, you will help prevent potential negative consequences for the environment and human health, which could otherwise be caused by inappropriate waste of this product. Disposal must be carried out in accordance with local environmental regulations for waste disposal.

Burrs, the points of the instruments and the suction tips not provided by EURODENT, must be made of bio-compatible materials (for example, compliant with ISO 10993 standards).

The use of equipments different from the recommended ones (e.g. micromotors of other brands) could cause malfunctions.

Caution

Protection earthing

Operating instructions

Refer to instruction manual/booklet

3SWITCHING ON

The unit sets for operation whenever the green switch is pressed in order to become lit up.

The clock on the operator’s keyboard starts functioning.

WAYFINDER

LCD screen will show main menu.

4POSITIONING THE MODULES ARM

The air clutch gets released by wrapping the handle with one’s palm and fingers. As long as the hand grips the handle, the height of the modules array can be adjusted. When the hand releases the handle, the modules arm stays at the relevan t height.

3 |

4 |

LP |

5

Operator’s handbook

5ABSOLUTE

5.1CLOCK ADJUSTMENT

The time is set during factory tests.

Keeping pushed both keys

ENTER  and CLOCK

and CLOCK

press key

or

until the display shows the proper time.

Hours appear in the two left hand cells and minutes appear in the two right hand ones:

5.2 PATIENT POSITIONING

OPERATOR’S KEYBOARD

DRIVEN MOVEMENTS: keep the pertinent purple or blue keys on the operator’s keyboard pressed (blue keys usable only with ISORAMA chair). Chair up and down movements and backrest forwards and backwards movements may be controlled also by chair foot-control (if present):

CHAIR UP |

BACKREST FORWARDS |

CHAIR DOWN |

BACKREST BACKWARDS |

HEADREST UP |

HEADREST FORWARDS |

HEADREST DOWN |

HEADREST BACKWARDS |

The operation of the unit foot-control prevents the driven movements from starting.

6

Operator’s handbook

PROGRAMMABLE AND NON-PROGRAMMABLE AUTOMATIC MOVEMENTS: press and release once the relevant orange key.

1

1

3

3

LP

LP

POSITION MEMORY 1

POSITION MEMORY 3

LAST POSITION MEMORY (non-programmable)

2

2

4

4

POSITION MEMORY 2

POSITION MEMORY 4

2 1

Memories 1 and 2 are available also by the chair foot-control:

Programming procedure: set the chair by foot-control or pushbuttons at the desired position, then keep pressing the memory pushbutton where the new position should be stored; the confirmation of the occurred recording is got with a

blinking of the led placed on ENTER  key.

key.

The position previously in memory for such pushbutton is cancelled and replaced by the new one.

If the VISION LED MODE lamp is present, the position 1 can be set as end-operation position (see installation handbook chapter 1 “Prearrangement of lamp”). In this case, by pressing the program 1 key, the chair will reach the end-operation position and the lamp will switch off automatically.

See chapter “Foot-control switches” for BLUE FOOT control switches.

Lifting up any instrument but the syringe and the light cure prevents the automatic movements from starting.

A safety device stops the chair downwards movement, when it meets an obstacle.

The ISORAMA chair is also equipped with a similar safety device in order to stop the backrest backwards tilting in such case.

7

Operator’s handbook

ASSISTANT’S KEYBOARD

DRIVEN MOVEMENTS: keep the pertinent purple keys on the assistant’s keyboard pressed:

Press the key  in order to select the chair or the electric headrest (if present) movements.

in order to select the chair or the electric headrest (if present) movements.

If the pilot light on the key is off, the 4 keys are selected for CHAIR movements.

CHAIR UP |

CHAIR DOWN |

BACKREST FORWARDS |

BACKREST BACKWARDS |

Press the key  in order to light the pilot light up and select the ELECTRIC HEADREST movements:

in order to light the pilot light up and select the ELECTRIC HEADREST movements:

HEADREST UP |

HEADREST DOWN |

HEADREST FORWARDS |

HEADREST BACKWARDS |

The operation of the unit foot-control prevents the driven movements from starting.

PROGRAMMABLE AND NON-PROGRAMMABLE AUTOMATIC MOVEMENTS: press and release once the relevant orange key:

1

3

LP

LP

|

2 |

POSITION MEMORY 1 |

POSITION MEMORY 2 |

|

4 |

POSITION MEMORY 3 |

POSITION MEMORY 4 |

LAST POSITION MEMORY |

RINSING POSITION |

(non-programmable) |

(non-programmable) |

If the VISION LED MODE lamp is present, the position 1 can be set as end-operation position (see installation handbook chapter 1 “Prearrangement of lamp”). In this case, by pressing the program 1 key, the chair will reach the end-operation position and the lamp will switch off automatically.

When key  is pressed only the backrest moves, in order to reach the vertical position.

is pressed only the backrest moves, in order to reach the vertical position.

If the backrest is already in vertical position, pressing the key |

|

|

the backrest returns in to the last position. |

|

|

|

|

|

|

|

|

8

Operator’s handbook

With a VISION LED MODE lamp, the light intensity will reach a lower intensity level. When the last-position memory key or one of the programmed position key are pressed, the lamp will reach the previous light intensity level.

Lifting up any instrument but the syringe and the light cure prevents the automatic movements from starting.

OPERATOR’S KEYBOARD WITH 9 KEYS

DRIVEN CONTROLS: keep the pertinent purple keys on the operator’s keyboard pressed:

CHAIR UP |

CHAIR DOWN |

BACKREST FORWARDS |

BACKREST BACKWARDS |

The operation of the unit foot-control prevents the driven movements from starting.

AUTOMATIC PROGRAMMABLE CONTROLS: are started pressing the orange keys.

1POSITION MEMORY 1

LP LAST OPERATION POSITION MEMORY USED

LP LAST OPERATION POSITION MEMORY USED

See details about position memory 1 in the previous paragraph.

Lifting up any instrument but the syringe and the light cure prevents the automatic movements from starting.

5.3 ALARM MODE/TIMER

Push key: |

CLOCK |

that shall start blinking. |

By pressing key: |

obtain on the display the time desired. |

Minutes are on the first 2 digits on the left of the display, the seconds are on the 2 digits on the right . To start counting,

the key  should be pressed again; when the count-down is started, all other functions of the unit can work normally.

should be pressed again; when the count-down is started, all other functions of the unit can work normally.

At the end of the count-down a sound warns that time has elapsed.

If, after having set the alarm, you do not desire to start it and want to go back to normal operation mode,

just push key |

|

ENTER |

is used for setting the waiting time in the “Autoforward” mode. |

|

|

||||

If the induction Micromotor Module is up, the key |

|

|||

|

||||

|

||||

9

Operator’s handbook

5.4 TUMBLER FILLER

It can be operated either by using the control on the suction tubings support arm or pressing the white key:

TUMBLER

or, if the handpieces lie in resting array, with the foot-control (see Chap. “Foot-control switches”) by pushing downward the small pedal in the foot-control.

TIME ADJUSTMENT:

Push both keys TUMBLER and

ENTER

The display shall show a count-up in tenths of second;

when reaching the quantity of water desired in the tumbler, release the keys.

From now until next adjustment, and whenever the key TUMBLER is activated, the tumbler filler shall supply water for the programmed time.

5.5 BOWL RINSING

The bowl flush starts automatically following the tumbler filler stop, and stops automatically when the programmed time has elapsed. To change the programmed time, see the section:

“PARAMETERS PRESETTING”.

To start the bowl flush independently from the tumbler filling, press the white key:

BOWL

or use the control on the suction tubings support arm.

5.6 LAMP OPERATION

ISOLUX LAMP

The lamp can be switched on by photocell or by switch. The unit should be properly programmed just as the lamp installation.

The white key:

LAMP

switches the lamp on. The lamp can also be switched on and off from the foot-control lever, by pushing it from the proper lever leftward when the instruments are in resting array.

Do not point the beam at the patient’s eyes.

10

Operator’s handbook

VISION LED MODE LAMP

The lamp has two intensity levels, each of them can be set.

Pressing the key shortly:

The lamp will be switched on at the lower level of light intensity. To increase the intensity, press again the same key. On the back side of the lamp there are two leds, a green one that indicates when it is on, that the lamp is correctly supplied and a blue one that shows when it is on, that the lamp is at the lowest intensity level, while if the led is off, this means that the intensity is at the highest level.

The light intensity of each level can be changed by pressing simultaneously the keys: |

and |

||

to decrease the intensity, and the keys: |

and |

to increase it. |

|

|

|

|

|

When the maximum or minimum intensity level is reached, a blue led will start blinking.

When the lamp is switched off the new settings will be stored. The lamp is switched off by pressing the key for more

than 1 s:

All these functions can be activated by the no-touch sensors placed on the lamp’s head. Placing the hand in the area

where the symbol is positioned (without touching the guard) : |

the lamp is switched on, |

the change in intensity and the switching off are obtained with the same modalities seen previously.

By placing the hand near the symbol: |

the light intensity will increase and reach the selected level and |

|

in the same way, by placing the hand near the symbol: |

the intensity will decrease. |

|

The above-mentioned functions of switching on, switching off and change in intensity can be activated by the footcontrol, too (Chap. “Foot-control switches”). By shifting once the lever rightward for less than 1 s, the lamp will be switched on at the lowest intensity, another stroke increases the level of intensity, the switching off is obtained by shifting the lever rightward for more than 1 s.

Do not point the beam at the patient’s eyes..

5.7 SERVICE PUSH-BUTTON

The white key:

SERVICE

closes any external circuit (max 24 V - 1 A) for the assistant call, door opening, and so on.

11

5.8 FOOT-CONTROL SWITCHES

ISOTRON FOOT-CONTROL

By pushing rightward the lever any handpiece except the syringe, the bistoury, and the light cure can be started. In case of adjustable power handpieces, i.e. micromotors, the supplied power stands proportional to the lever stroke.

If mounted, the telecamera gets the still image.

By pushing the lever leftwards, the “reverse” mode of the micromotor gets preset. Another shift leftwards restores the rightwise mode.

If the bistoury is up, touching leftwards the lever presets one of the functioning modes (cut, coagulation, coagulated cut).The selected mode gets automatically stored.

When instruments are not picked up, touching the lever leftwards turns ON or OFF the ISOLUX and VISION LED MODE lamps.

By pushing the small pedal downwards, the spray can be enabled or disabled.

If all the instruments are lying in resting array (or only the syringe is up), such switch operates the tumbler filler.

This control starts the bistoury working.

By pushing the small pedal rightwards, the c.b. of the lifted handpiece starts operating.

If a handpiece without spray is up, the control starts the cold light if equipped with the instrument.

If a handpiece without c.b. or the syringe or all the handpieces lie in resting array, the switch has no effect.

Operator’s handbook

12

BLUE FOOT CONTROL

FOOT-CONTROL SWITCHES WITH NO INSTRUMENTS PICKED UP (EXCEPT SYRINGE AND LIGHT CURE)

The joystick is used to move the chair or the electric headrest:

•pushed forward: chair up or headrest up;

•pulled backward: chair down or headrest down;

•pushed rightward: backrest forwards or headrest forwards;

•pushed leftwards: backrest backwards or headrest backwards.

By pressing the central push-button,is selected the movement of the headrest for 20 s and then it is ready again for the chair movements. The time is calculated from the moment the central push-button is started and it starts again every time the joystick is pushed for moving the headrest. The display will show the message HEAD all time this mode is on. The movements of the chair will start again if the push-button is pressed again within 20 s.

Side push-button: pushing it once, the chair reaches the rinse position, pushing it when the chair is in rinse position, the chair goes back to the last position memory.

Operator’s handbook

Foot-control lever pressed downwards: when the pedal is pressed for less than a second position No. 1 is selected, if it’s pressed for longer than 1 s position No. 2 is obtained.

While the lamp is switched off, by shifting the lever rightward for less than a second, the lamp reaches a lower light intensity; another shift of the lever rightward for less than 1 s brings the light to a different intensity level. If, on the other hand, the lever is shifted rightward for more than a second at any light intensity, the lamp is switched off.

13 |

FOOT-CONTROL SWITCHES WITH INSTRUMENT LIFTED (EXCEPT SYRINGE AND LIGHT CURE)

By shifting rightward the lever any handpiece can be started. In case of adjustable power handpieces, the supplied power stands proportional to the lever stroke. If mounted, the telecamera gets the still image.

By pushing the lever downwards, the c.b. of the handpiece selected starts. If a handpiece without c.b. is lifted, the switch has no effect.

If a handpiece without spray is up, the control starts the cold light if equipped with the instrument.

By pushing the side push-button, the spray is enabled to the selected instrument. Pushing it again, it is disabled. The push-button stops or reactivates the peristaltic pump of the induction micromotor with physiodispender.

The microprocessor stores the control automatically. This control starts the electrosurgery working, too.

By pushing the central push-button, the tumbler filler is activated.

The joystick is used as follow:

•pushed forward, for assistant call (or door-opening);

•pushed rightwards, for optical fibre switching off and on if the handpiece is provided with it; if the fibre optic has been already set to 0, the switch has no effect. If the handpiece is put into resting position, the initial position is restored;

•pushed leftwards, the reverse mode of the micromotor working gets preset, if it is up. Another pressure leftwards eliminates it. The control is automatically stored;

•if the “induction Micromotor Module” is up, if pulled it is used for selecting the different functioning modes;

•if the electrosurgery is selected, the different functioning modes (cut, coagulation, coagulated cut) are selected pressing the joystick leftwards. In this case the microprocessor stores commands automatically.

Operator’s handbook

14

Operator’s handbook

5.9 PROGRAMMABLE MODES FOR THE INSTRUMENTS

The key: |

SPRAY |

(with instrment is resting position) allows to select the type of SPRAY or TUMBLER solution (this option is possible only if the CALBENIUM mixing tank is installed; if the surgical kit is present only the SPRAY solutionis selected): with yellow light turned on, WATER or CALBENIUM will be selected; with yelow light turned off, only WATER will be supplied. When the instrument is lifted up, the key allows WATER and AIR selection of the spray of the lifted handpiece.

The YELLOW light lits up when WATER is preset, the GREEN light lits up when AIR is preset. If both lights are off, then the handpiece will work in dry conditions; if you desire to program another condition, first press the key so that the red light starts blinking: the blinking means that the microprocessor is waiting for the new instructions.

By pressing once the key:

the yellow light will turn on; by pressing it again the green light will turn on; a further touch shall switch on both yellow and green. Pushing again the button, the yellow light will lit up and the green one will blink. In this condition pushing the pedal lever rightwards as far as about end-of-stroke, only the instrument will work only in dry conditions, while at lever end-of-stroke the spray function will start (water + air) in the instrument. Coming back in the pedal stroke, only the instrument dry function will be possible.

Now the handpiece can work in the chosen conditions, but if it is placed back in the resting array the microprocessor restores the previous conditions in memory. If on the contrary the new conditions must be preserved, the key:

ENTER

must be pressed: one blink shall confirm that the new instruction has been stored and the previous one cancelled.

Similarly, by pressing the key:

first WATER, then AIR, and eventually both shall DISAPPEAR. Therefore: yellow light on means that only water is preset; green light on means that only spray air is preset; green and yellow lights both on at the same time means that complete spray is preset; no light on means that dry operation is preset.

The key:

1

permits selection of WATER and AIR in the automatic purge at foot-control release.

This function consists of a water or air or spray jet emitted for an adjustable time after the handpiece stop, to the purpose of cleaning both the operating zone and the final parts of the pipes. If you do not want to use such device, just program the key with yellow and green lights off.

NOTE: the variables of this key (water and air) depend on the ones of the key - 1 - spray (see table A). When eleasing the foot-control lever, the preset automatic purge persists during a certain time; such time can be adjusted according to the procedure explained in the section “PARAMETERS PRESETTING”.

The key:

2

permits selection of WATER and AIR in the operated c.b.. It is therefore possible to preset a normal c.b. of sole air, or a sole water c.b., or eventually a spray c.b. In other words, this key turns the handpiece in a syringe.

Introduction and change of modes is obtained in the same way as seen for the SPRAY.

15

Operator’s handbook

The orange key:

3

permits to adjust the maximum power provided to the instrument lifted (such max. power will be obtained when the footcontrol lever is at end stroke). The power can be controlled and displayed in N% from 01% to 100%; to adjust its max., press the key once so that the red light starts blinking; then push:

until the desired N% gets displayed, and then start working.

If you want to store in memory the new max. power, just press once the key:

that shall confirm storage by one blink; the instrument replaced, when picking it up again the new max. value shall appear on the two rightside cells of the display.

In case of induction Micromotor Module, the key is used to set the maximum torque too. See the pertaining paragraph.

The key:

4

permits to adjust the light intensity of the fibre optic handpiece that has been picked up, from a minimum “0” to a maximum of “9”.

When releasing the foot-control, the light persists during a certain time; such time can be adjusted according to the procedure explained in the section “PARAMETERS PRESETTING”, and is the same time for each of the fibre optic handpieces.

The light intensity must be adjusted according to the same procedure explained for the key POWER; the intensity lever shall appear on the first cell of the display.

The key:

LP

LP

permits to choose the rotation mode (clockwise/reverse) of the micromotor. Once the key has been pressed and the red light is blinking, by pushing:

the reverse mode gets preset and the mark “r” appears on the third cell of the display; to go back to the clockwise mode,

the key |

must be pressed. |

The key: |

must also be used to select the operation mode of the surgery. |

|

LP |

See the paragraph “Induction Micromotor Module” for using this key.

TABLE “A”

SPRAY KEY |

AUTO C.B. KEY |

choice restricted to: |

||

|

|

|

|

|

Yellow light = water |

Yellow light = water |

or |

ø = nothing |

|

|

|

|

|

|

Green light = air |

Green light = air |

or |

ø = nothing |

|

|

|

|

|

|

Lights off ø = nothing |

ø = nothing |

|

|

|

|

|

|

|

|

Yellow and green lights = both water and air |

Yellow light = water |

or |

Green light = air or |

|

ø = nothing |

or |

Yellow and green lights = both water and air |

||

|

||||

|

|

|

|

|

16

Operator’s handbook

5.10 MODULES

The unit can be equipped with 8 instrument modules, besides the syringe, which can be installed on the left or the right side of the control keyboard. The instruments available can be chosen among a large gamma and it can be used two or more modules of the same type (i.e. two or more turbines).

TO REMOVE ANY MODULE FOLLOW THE PROCEDURE BELOW:

1Switch off the unit and press the syringe levers up to the complete depressurization.

2Press the disconnection pin of the module (pin located under the module), holding the module or the group of modules following the one whose pin is pressed.

3Once all air has flown out, shift the module or group of modules aside.

4Press the disconnection pin of the module preceeding the one to be taken out, and once all air is out slide the latter aside.

5Place back the module or group of modules previously taken off, or a new module in between, by sliding in the supporting brackets. Taking care of proper matching between modules edges and tightness protection, switch the unit on again.

6If now the handpiece of the module placed in the position previously occupied by another is picked up, a beep is heard and the display shows “AV04”. In fact the microprocessor, whose memory matches that particular position with the data of the previous module, is asking for the data relevant to the new one. To store them in, first push the key:

ENTER

to delete “AV04” and push again to store the data shown on keyboard and display.

Such data can be varied according to the procedures above explained for the various functions.

If the position of other modules has been changed, this sequence of operations for re-programming must be repeated for all of them. All modules are fitted with flow rate adjustments for spray/c.b. water, spray/c.b. air and drive/cooling air, provided they include such operative functions. The adjustment devices are located underneath the module, beside the disconnection valve pin (see HANDPIECES PRESSURE ADJUSTMENT).

HANDPIECES PRESSURE ADJUSTMENT

1Drive air (Turbines, Airmotor, Powder cleaner) or

cooling air (Micromotor, Light cure). |

3 2 1 |

5 |

4 |

6 |

|

|

|

|

2 C.B. or spray air.

3 Spray water/C.B. water.

4 Whip balance adjustment.

5 Disconnection valve pin.

6 Syringe air adjustment.

17

Operator’s handbook

SYRINGE MODULE AND FIBRE OPTIC SYRINGE MODULE

This module has no programmable functions and is independent from the foot-control.

1.Control push-button for WATER

2.Control push-button for AIR

3.Selector for hot air and water

4.Fibre optics (if present)

When pressing simultaneously the push buttons 1 and 2, spray jets out.

•The outer envelope can be slipped off from the syringe body for sterilization (chap. “Sterilization methods and working times”).

3

2

1

4 |

|

Release |

push-button |

SYRINGE CHASSIS DISASSEMBLY |

|

TURBINE MODULE AND VARIABLE SPEED TURBINE MODULE WITH FIBRE OPTIC

When picking up the handpiece, the function keys of the turbine modules without fibre optic light up their pilot leds, as well as the key for the fibre optic: (if present) on the first cell of the display a number from 0 to 9 appears.

When the variable speed turbine module has been preset, also the power adjustment key switches on, while on the two right side cells of the display a number appears: it corresponds to the power intensity (in percent between 01% and 100%) memorized.

If the turbine is lubricated with oil, an oil storage filter should be fitted. It should be regularly emptied and before the oil reaches the lower part of the filter otherwise the carter could be damaged.

•As for the sterilization of the instrument, compare chap “Sterilization methods and working times”.

18

FIBRE OPTIC MICROMOTOR MODULE

When picking up the handpiece, the function keys of the micromotor module light up their pilot leds, as well as the key for the fibre optic: on the first cell of the display a number from 0 to 9 appears, indicating the memorized intensity level of the fibre optic.

On the two right side cells of the display a number in percent (between 01% and 100%) appears, corresponding to the memorized power intensity.

If reversed rotation has been preset, the symbol “r” appears on the second cell.

•Regarding the sterilization procedures see chap. “Sterilization methods and working times” .

HIGH TORQUE MICROMOTOR MODULE WITH FIBRE OPTIC

If the max. programmable power is set between 11% and 100%, the module operates just as the MICROMOTOR MODULE WITH FIBRE OPTIC.

If the max. programmable power is set between 01% and 10%, the high torque/slow speed operation mode gets automatically selected.

Operator’s handbook

MICROMOTOR MODULE

WITH PHYSIODISPENSER

It operates as the Micromotor, if the maximum power is set between 11% and 100%. If the maximum power is set between 01% and 10% the slow-speed operation with high torque is automatically selected.

Spray can be obtained in two ways:

I a |

function (position I ): the external spray source |

|

supplies only liquid. Make use of the potentiometer |

|

under the module to adjust the spray flow rate. |

II a |

function (position 0 ): spray comes from the unit |

|

circuit |

1 |

Spray setting switch |

2 |

External spray adjustment (position I) |

3Internal spray adjustment (position 0)

1 |

2 |

3 |

To obtain best results when operating at slow speed, it is advisable to make use of reducing handpieces.

•Regarding the sterilization procedures see chap. “Sterilization methods and working times”. .

19

Operator’s handbook

INDUCTION MICROMOTOR MODULE

When picking up the instrument spray, automatic c.b., c.b. light up their pilot leds on the display.

In the first left cell of the display a letter appears indicating the functioning mode, in the second left cell the symbol “r” appears if the reverse mode has been programmed.

The functioning modes are:

•Drive mode: is indicated with letter “d” on the display. In this case the micromotor can work from 100 to 40000 rpm. A maximum functioning speed can be set corresponding to the foot-control end of stroke. It is possible to reverse the direction of rotation with the proper key or foot-control.

•Autoreverse mode: is indicated with the letter “A” on the display and the micromotor can work from 100 to 6000 rpm. A maximum functioning speed can be set corresponding to the end of stroke of the foot-control lower than 6000 rpm. A torque value (between 3 and 30 mNm) can be set, when it is reached the micromotor starts to rotate in reverse direction. The reverse mode is marked by the optical fibre light blinking. Releasing the foot-control and starting the micromotor again, it starts to rotate clockwise until the torque value is reached again then reverse the direction of rotation. With this mode it is not possible to reverse the direction of rotation with the proper key or foot-control.

•Autoforward mode: is indicated with the letter “F” on the display. It works as the autoreverse mode but a waiting time between 0.5 and 3.5 s can be set, too. Reaching the set torque value, the micromotor starts rotating in reverse mode until a null torque value is reached; it waits for the set time and then reverses the way of rotation again starting the clockwise rotation again. Also in this mode, the reverse mode is marked by the optical fibre light blinking and it is not possible to reverse the direction of rotation with the proper key or foot-control.

Functioning mode setting: pressing the key |

|

|

|

the different settings are set and the internal light will start to |

|||

blink. If the drive mode is set, the key |

|

|

|

|

|

LP |

|

|

starts the reverse mode, the key |

stops it. |

|||||

For changing the functioning mode, the key |

|

|

|

|

should be pressed again cyclically. The new setting is automatically |

||

|

|

|

LP |

|

|||

stored when the foot-control lever is started.

Maximum speed setting: with the key |

|

|

the change of speed is set and the internal light will start to blink. The |

|

value is set with the keys |

|

|

|

3 |

and |

|

|

: the display shows the real set value /10 (40000 rpm, 4000 is visualized). |

|

If there is a handpiece with reducer or multiplier this value is not real and the operator should multiply or divide by the reduction or multiplication ratio.

The storage is carried out with the key  .

.

If the work is carried out without storing the parameter, the setting will be lost laying the instrument.

20

Loading...

Loading...