Page 1

CEM3

®

User Manual

Version 1.5.1

Copyright © 2014 Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

7140M1200-1.5.1

Released: 2014-06

Rev A

Page 2

ETC® and Sensor® are either registered trademarks or trademarks of Electronic Theatre Controls, Inc. in the

United States and other countries.

All other trademarks, both marked and not marked, are the property of their respective owners.

ETC intends this document, whether printed or electronic, to be provided in its entirety.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Text Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Help from ETC Technical Services . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chapter 1

Chapter 2

Getting Started . . . . . . . . . . . . . . . . . . . . . . .5

The User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

CEM3 face panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Performing a Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Other Setup Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

System Reference . . . . . . . . . . . . . . . . . . . . 9

Important Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Advanced Features (AF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Balanced (rack numbering) . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Dimmer Doubling (UL/ 120V 60 Hz systems only) . . . . . . . . . .11

Latch-Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Lug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Panic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Preset Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Redundant Tracking (ESR and FDX racks only) . . . . . . . . . . . .15

Straight (rack numbering) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Dimmer Property Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Rack Property Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Dimmer Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Linear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Modified Linear (Mod-Linear). . . . . . . . . . . . . . . . . . . . . . . . . . .25

Square Law (Square). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Modified Square Law (Mod-Square) . . . . . . . . . . . . . . . . . . . . .26

Sensor 2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Fluor 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Fluor 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Andi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Table of Contents i

Page 4

VIP 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Dimmer Output Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Chapter 3

Common Tasks. . . . . . . . . . . . . . . . . . . . . .31

Recording and Playing Back Presets . . . . . . . . . . . . . . . . . . . . . . . .32

Preset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Saving or Uploading Files and Firmware . . . . . . . . . . . . . . . . . . . . .33

Saving Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Loading Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Loading CEM3 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Setting Up Panic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Setting Up Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Automatic Patch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Manual Patch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Set Data Loss Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Setting Up CEM3 on the Network . . . . . . . . . . . . . . . . . . . . . . . . . .39

Network Setup for Redundant Tracking Racks . . . . . . . . . . . . .39

Working with an FTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Setting Rack DIP Switches and Termination . . . . . . . . . . . . . . . . . .40

DIPswitch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Termination Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Rack Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Cleaning Rack Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Vacuuming Dimmer Modules. . . . . . . . . . . . . . . . . . . . . . . . . . .43

Appendix A

Appendix B

Appendix C

Replacing AF Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Restore Rack Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Error Messages. . . . . . . . . . . . . . . . . . . . . . 47

Using the CEM3 Web Interface . . . . . . . . . 49

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Dimmers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Set Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Redundant Tracking Systems. . . . . . . . . . .51

Redundant Tracking Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Automatic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Display Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Configuration Management in Redundant Tracking Systems . .53

Firmware Upgrades in Redundant Tracking Systems . . . . . . . .53

ii CEM3 User Manual

Page 5

Appendix D

FDX 3000 Dimmer Racks . . . . . . . . . . . . . . 55

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Module Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Advanced Features in FDX . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

FDX2000 vs. FDX3000 Dimmer Curve Comparison . . . . . . . . .59

iii

Page 6

iv CEM3 User Manual

Page 7

Introduction

Welcome to your new CEM3 Power Control system!

This manual is designed to introduce you to the CEM3 user interface and the primary

features and functions available to you in the setup and use of your CEM3 power control

system.

For additional information you may also access our online CEM3 wiki page at http://

www.etcconnect.com/Sensor3help.This wiki is updated regularly to reflect the most current

information and may provide information on less commonly used features of your CEM3.

The introduction contains the following sections:

• Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

• Text Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

• Help from ETC Technical Services. . . . . . . . . . . . . . . . . . . . . .3

Introduction 1

Page 8

Using this Manual

The following graphics and conventions are used throughout this manual to convey

important information.

Note:

CAUTION:

WARNING:

WARNING:

Notes are helpful hints and information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss or an equipment

problem.

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an

action.

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of electric shock.

Text Conventions

Many of the procedures in this manual use a combination of text conventions to identify

various types of inputs that are used to program your CEM3. Below is a list of commonly

used conventions in this manual.

Bold is used to indicate a necessary action (such as a button press or menu path)

in a procedure.

[Brackets] are used to indicate the press of a tactile button on the face of the CEM3

(such as [Setup], [Test], and [Enter]).

Italics are used to indicate a menu item listed in the display window.

Right angle bracket (>) is used to indicate a flow of button presses and menu

selection options.

When used together, this instruction: [Setup]>Panic>Record Panic Look>[Enter]

indicates you should, “Press [Setup], select Panic from the menu, select Record Panic Look

from the menu, Press [Enter].”

Advantages of Electronic Version

ETC's technical documentation is designed for printed or electronic use. However, there

are many bonuses to using the electronic (.PDF) versions of our documents. Aside from

having all of the benefits of a PDF (such as word find, bookmarks, and commenting tools)

ETC documents include the ability to click headings in the Table of Contents or Index and

jump to the desired page. Also, our cross-references (indicated in blue italics like this:

Introduction, page 1) are links that may be clicked to jump to the specific part of the manual.

And all of ETC's documents are available for free download from our website:

www.etcconnect.com

You can download a .PDF copy of this manual directly from the USB port on the CEM3. See

About CEM3, page 17.

Please email comments about this manual to: TechComm@etcconnect.com

2 CEM3 User Manual

.

Page 9

Help from ETC Technical Services

If you are having difficulties, your most convenient resources are the references given in

this user manual. To search more widely, try the ETC Web site at www.etcconnect.com

the Sensor3 Online Community Wiki at http://www.etcconnect.com/Sensor3help.

If none of these resources is sufficient, contact ETC Technical Services directly at one of

the offices identified below. Emergency service is available from all ETC offices outside of

normal business hours.

When calling for help, please have the following information handy:

• Product model and serial number (located on the bottom of the CEM3)

• Dimmer manufacturer and installation type

• Other components in your system (Unison

Americas United Kingdom

Electronic Theatre Controls Inc. Electronic Theatre Controls Ltd.

Technical Services Department Technical Services Department

3031 Pleasant View Road 26-28 Victoria Industrial Estate

Middleton, WI 53562 Victoria Road,

800-775-4382 (USA, toll-free) London W3 6UU England

+1-608 831-4116 +44 (0)20 8896 1000

service@etcconnect.com service@etceurope.com

®

, other consoles, etc.)

or

Asia Germany

Electronic Theatre Controls Asia, Ltd. Electronic Theatre Controls GmbH

Technical Services Department Technical Services Department

Room 1801, 18/F Ohmstrasse 3

Tower 1, Phase 1 Enterprise Square 83607 Holzkirchen, Germany

9 Sheung Yuet Road +49 (80 24) 47 00-0

Kowloon Bay, Kowloon, Hong Kong techserv-hoki@etcconnect.com

+852 2799 1220

service@etcasia.com

Introduction 3

Page 10

4 CEM3 User Manual

Page 11

Chapter 1

Getting Started

This chapter contains the following sections:

• The User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

• Navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

• Performing a Quick Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1 Getting Started 5

Page 12

The User Interface

Eject - Pull

both levers

forward from

the top edge.

Grasp and pull

to remove

control module

(power down

the rack before

removing).

Eject

LEDs identify current states of:

Power DMX Ports Network Panic

Reset

Net3

Ethernet

USB

Load Software and

configurations

Display window Navigation

Buttons

Scroll wheel

Keypad

This section will clarify the physical features of the hardware interface and the general

functionality with the software.

CEM3 face panel

These are the various components in the hardware interface. Familiarize yourself with

these terms as they are used throughout this manual.

Navigation

Scroll Wheel

Use the scroll wheel and up/down arrows to move the selection cursor on any menu screen

until the desired item is highlighted. You can also tap the top or bottom of the scroll wheel

to move the display cursor up or down.

The scroll wheel also lets you scroll through number fields (such as circuit number) or

through the available options for a selected item (such as Module Type).

The center button of the scroll wheel functions as [Enter]. Press [Enter] to select the

highlighted item on the display window or to commit entered data.

Keypad

Use keypad to enter values for any value fields in the display window. When setting levels

you can select individual dimmers or ranges of dimmers using the [and] and [thru] buttons.

Both the center button of the scroll wheel and the bottom right keypad button function as

[Enter]. Press [Enter] to select the highlighted item on the display window or to commit

entered data.

The menu buttons ([Test], [About], [Setup]) and the [Back] button are integral in navigating

the menu structure.

Display Menus

The navigation buttons are used to navigate the menu structure.

6 CEM3 User Manual

Press the menu buttons ([Test], [About], [Setup]) to access features within that menu type

(see Menu Structure, page 17).

Use the scroll wheel to navigate through menu items in the display window, using [Enter]

to select desired items, entry fields, or access submenus.

Press [Back] to return to the previous screen on any menu.

Page 13

Performing a Quick Setup

Quick Setup is used to set up your rack using a minimum amount of data to achieve a basic

configuration.

Note:

CAUTION:

You can begin a quick setup by navigating to [Setup]>Quick Setup>[Enter].

From this interface you can use the CEM3 interface to enter data in up to four fields to

quickly establish your rack configuration: Rack Number, First Circuit, Numbering, and

Dimmer Double (see below for field descriptions).

Once you have entered data in the desired fields, select [Go] and press [Enter] to save the

setup changes.

Rack Number

Enter a reference number between 1-999 to identify the rack. Default is 1.

First Circuit

Enter the desired number for the first circuit in the rack. If this is your first or only rack, this

number is typically 1. If this rack is one of many in your system, this number typically

continues the numbering sequence from the previous rack. Default is 1.

Prior to performing a Quick Setup, make sure that your rack DIP switch settings

are set appropriately for your rack type. See Setting Rack DIP Switches and

Termination, page 40 for more information.

Quick rack setup will overwrite some of the data in your rack. Only perform a quick

setup when you wish to reconfigure your system or are instructed to do so by ETC

Technical Services.

Numbering

Choose between “Straight” or “Balanced”. “Straight” results in circuit numbering that will

proceed sequentially straight through the entire rack. See Straight (rack numbering), page

16 for more information.

“Balanced” results in circuit numbering that will distribute the circuits evenly across the

different power phases so that neighboring circuits do not place an uneven load on any

phase. See Balanced (rack numbering), page 10 for more information.

Default for Sensor3 installed racks (SR3)is “Balanced”. Default for Sensor3 portable racks

(SP3) is “Straight.”

Dimmer Double

Choose between “Yes” and “No” to activate or deactivate dimmer doubling for the rack.

Default is “No” (see Dimmer Doubling (UL/ 120V 60 Hz systems only), page 11).

1 Getting Started 7

Page 14

Other Setup Functions

Once you have completed the quick setup, you may wish to proceed to these other

common setup tasks:

Setting the module type in Circuit Assignment, page 18.

Setting Up Patch, page 37,

Setting Up Panic, page 35,

or Setting Up CEM3 on the Network, page 39.

8 CEM3 User Manual

Page 15

Chapter 2

System Reference

Refer to this chapter for information about the general concepts behind the features of your

CEM3, the general menu structure of the software, definitions of all dimmer properties, and

illustrations of the various dimmer curves available in your system.

This chapter contains the following sections:

• Important Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

• Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

• Dimmer Property Definitions . . . . . . . . . . . . . . . . . . . . . . . . .19

• Rack Property Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . .22

• Dimmer Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

• Dimmer Output Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2 System Reference 9

Page 16

Important Concepts

This section introduces you to some of the primary concepts and their functionality, which you

may encounter through your use of the CEM3 power control system. Topics are listed

alphabetically.

Advanced Features (AF)

Advanced Features (AF) allow you to receive feedback from your dimmer modules about

their current state, including the amount of current being drawn on each circuit, whether the

module is installed or not, and whether the circuit breaker on the module has tripped. This

feedback information is available both at the front panel of the rack and at remote devices

including ETC's Eos and Congo control systems, and other ACN capable devices.

Having Advanced Features also allows you to monitor circuit loads by recording and

running a rig check (see Rig Check, page 13).

In order to use AF you need AF capable modules (denoted by having AF in the module

name, for example D20AF or ED15AF), and also AF cards installed in the rack.

Balanced (rack numbering)

Balanced rack numbering alternates dimmer numbering across phases in groups of two

dimmers.

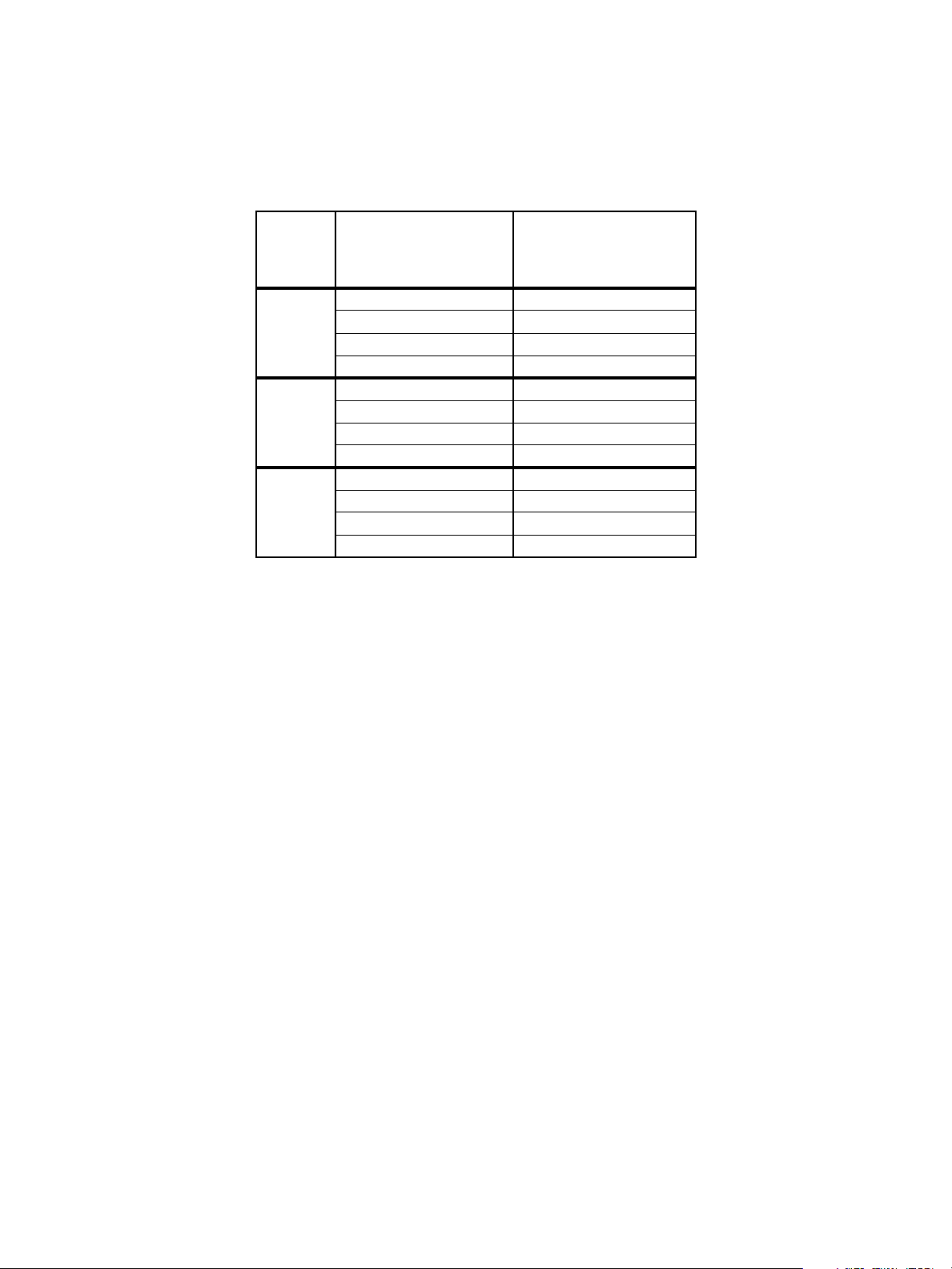

This table compares the circuit numbering of an SR3-6 filled with D20 modules when set to

straight or balanced numbering:

SR3-6

Rack

Phase

A

B

C

Racks can be set as balanced by Performing a Quick Setup, page 7.

Straight Circuit

Numbering

11

22

37

48

53

64

79

810

95

10 6

11 11

12 12

SR3-6

Balanced Circuit

Numbering

10 CEM3 User Manual

Page 17

Circuit

A circuit is a user assignable number, between 1 and 99999. the circuit is the reference

number for that dimmer in the rack. Circuit numbers must be unique per space; it is possible

to have multiple circuits of the same number, but they must be in different spaces.

Configuration

The rack configuration is a collection of all of the data stored about the rack and all of its

circuits. The configuration is stored automatically in the CEM3 whenever you make a

change (for example, changing a circuit from switched to dimmed).

The configuration of any rack is automatically stored on both the CEM3 module and the

CEM3 backplane. Therefore, you can remove a CEM3, replace it with a new, unconfigured

CEM3, and the configuration from the backplane will be loaded to the new CEM3.

You can save and load rack configurations by connecting a USB removable media device

to the USB port on the front of the module. Saving and loading are performed from the File

Operations menu (see File Operations, page 18).

Dimmer Doubling (UL/ 120V 60 Hz systems only)

ETC’s Dimmer Doubler™ technology allows you to double the number of controllable

circuits in your system without adding dimmer modules or running additional cable. The key

to this feature is the Dimmer Doubler two-fer.

The Dimmer Doubler two-fer is installed between a Sensor dimmer module and two ETC

Source Four 77 volt fixtures. It splits the output of a single dimmer into two, separately

controlled outputs.

2 System Reference 11

Page 18

Latch-Lock

Level

Time

LatchLock On Range

LatchLock On Time

LatchLock Off Range

LatchLock Off Time

In this range the control source can go

to any level, as long as it does not stay

in the off time range for more than the

latchlock off time value

Control Level

Relay Closes

Relay Opens

Diagram of How Latch-Lock is Applied to a Circuit

Latch Lock is a control mode available to any dimmer circuit (see Control:, page 20). Similar

to switched mode, Latch-Lock features an additional safeguard so that circuits can not be

turned on or off as easily. The circuit only turns on when a defined control level range is

held for a specified amount of time, and only turns off when a different control level range

is held for another amount of time. Latch-lock is useful for avoiding accidental dowsing of

arc lamps during shows (often caused by running the Grandmaster down). By requiring a

level range and time, most master fades will not hover in a given range for long enough to

trigger on or off.

The level ranges and times can be edited on a per dimmer basis (see Dimmer Property

Definitions, page 19). On and Off level ranges may not overlap.

Lug

“Lug” refers to a physical position in the rack. Lugs are always numbered counting

downwards from the top of the rack, starting at “1.” Some modules may take up multiple lug

positions in the rack.

Panic

CEM3 offers a Panic capability that complies with UL 924 Panic functionality.

When a properly connected and enabled CEM3 has a panic “look” stored, when it receives

a signal over the panic circuit it will automatically play the recorded look.

Panic can be enabled when a maintained (normally open or normally closed) contact

closure is properly wired to the backplane (for more information, see the data termination

guide or installation guide that was supplied with the rack).

For information on how to configure Panic on your CEM3, see Setting Up Panic, page 35.

12 CEM3 User Manual

Page 19

Patch

Patching governs the relationship between control input sources (DMX A, DMX B, and

sACN) and the control of circuits in the rack. This relationship can be edited to match the

needs of your control sources and rack constraints. For information on patching, see

Setting Up Patch, page 37.

Preset Functions

CEM3 supports a built-in preset control system allowing the recording and playback of

preset looks. Preset looks can be played back either from the CEM3 face panel or using

connected Echo preset stations. For more information on recording and playing back

presets see Recording and Playing Back Presets, page 32.

CEM3 allows the circuits within the rack to be divided up into spaces (performed in Circuit

Assignment, page 18) with 64 presets available per space. Each space can only have one

active preset at a time.

CEM3 includes default presets that include all circuits in the space. The default presets for

any space start with 100% and then cycle through 75%, 50%, 25%, 100% and so on.

Sensor3’s built-in EchoConnect power supply is limited to powering six racks or panels and

six stations. An additional wall mounted or rack mounted power supply can be added to a

system to support up to sixteen hosts and sixteen stations

CAUTION:

Preset activation propagates across the Net3 network. So if a given preset is activated for

Space 1, all CEM3s on the network will activate that preset for space 1.

Rig Check

In Sensor3 racks with Advanced Features (see Advanced Features (AF), page 10) you can

record a special preset called “Rig Check” which includes both circuit levels and the amount

of load (current) expected on each circuit.

Once recorded, the rig check can be played back, either from the CEM3 face panel or

remotely, and the CEM3 will post load high, load low, or no load messages based on how

the load of the circuit has changed since you recorded the rig check preset. These

messages will be available on the CEM3 display or on a connected console that monitors

AF feedback.

Recording, running, and clearing a rig check can be performed from the Test menu (See

“Test” on page 17.)

Do not activate “Station power” on more than one CEM3 on the same

EchoConnect bus. Doing so may cause undesirable station function.

2 System Reference 13

Page 20

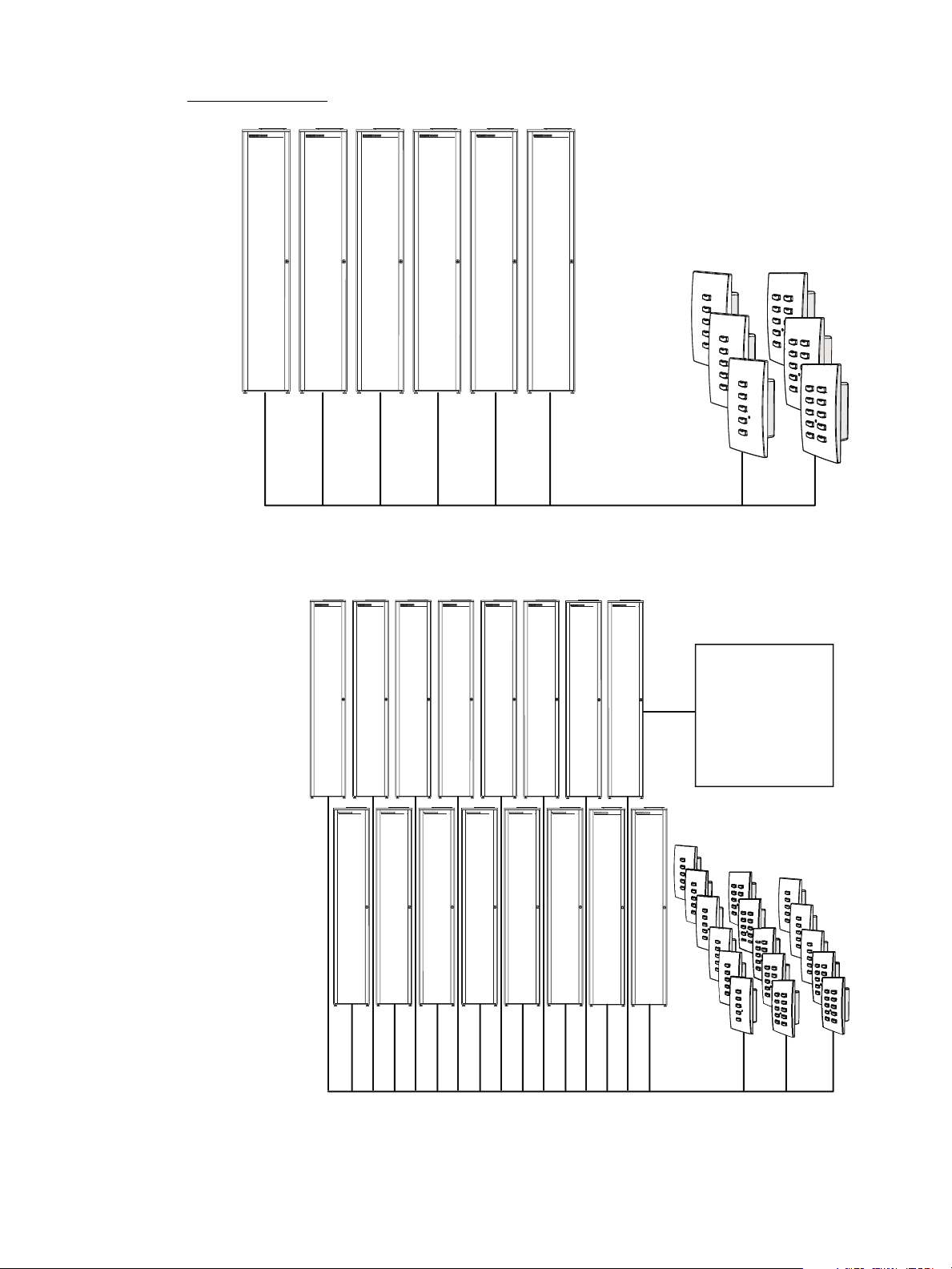

System Topology

EchoConnect - Belden 8471 + (1) 14 AWG ESD Ground Wire

External Power

Supply

Facilitates up to

16 racks and 16

stations

EchoConnect - Belden 8471 + (1) 14 AWG ESD Ground Wire

14 CEM3 User Manual

Page 21

Spaces

Spaces are logical divisions within a system (such as different rooms) that isolate station

control (preset and sequence control) to the defined group of controllable outputs in that

division. CEM3 supports separation of its controllable circuits into spaces.

Station Functions

Presets can be played back from preset stations in the system.

• Press a preset station button to activate a preset.

• Press it again to deactivate the preset.

• Stations can be configured with an “Off” button. This option is performed at the

station and should only be done by a qualified technician.

• The group of presets controlled by any station can be altered at the station. This

should only be done by a qualified technician.

For more information see the Echo Preset Station Installation Guide available from the ETC

web site.

Zones

A space can be broken down further into zones. You can assign zone control to a preset

station for direct control using that station’s buttons and fader knob. Multiple zones can exist

within a space and a single zone can control multiple outputs across multiple racks.

A circuit’s control zone is a dimmer property and is assigned by accessing the dimmer setup

menu (see “Arch Zone:” in Dimmer Property Definitions, page 19).

Each space can have up to 16 zones assigned (numbered 1-16).You can omit a circuit from

zone control by setting the Arch Zone value to zero.

Redundant Tracking (ESR and FDX racks only)

Redundant tracking provides extra security in the event of system failure, allowing a

secondary CEM3 control module to immediately take control of the rack.

Redundant tracking is available in ESR and FDX racks only.

For more information, see Redundant Tracking Systems, page 51.

2 System Reference 15

Page 22

Straight (rack numbering)

Straight rack numbering assigns consecutive dimmer numbering vertically, from top of the

rack to the bottom, regardless of phasing.

This table compares the circuit numbering of an SR3-6 filled with D20 modules when set to

straight or balanced numbering:

SR3-6

Rack

Phase

A

B

C

Racks can be set to straight through Performing a Quick Setup, page 7.

Straight Circuit

Numbering

11

22

37

48

53

64

79

810

95

10 6

11 11

12 12

SR3-6

Balanced Circuit

Numbering

16 CEM3 User Manual

Page 23

Menu Structure

This section lays out the entire menu structure for the software. Press the desired button to

access the menu items below. Use the standard navigation method to select and enter

options in the menus (see Navigation, page 6).

Test

Set Levels

Set levels for all circuits in a space.

Dimmer Check

Quickly run through all circuits in a space to test their output at a given percentage.

Release Set Levels

Release any active levels for a given space at once.

Presets

Record or play back presets. See Recording and Playing Back Presets, page 32.

Record Rig Check

Records a rig check preset to facilitate AF reporting. See Rig Check, page 13 and

Advanced Features (AF), page 10 for more information.

Run Rig Check

Runs a rig check preset. You will be notified of any load inconsistencies found during the

rig check.

Clear Rig Check

Clears the recorded rig check from the CEM3.

About

Dimmers

View all properties for any circuit in a space. See Dimmer Property Definitions, page 19.

Rack

View all properties for the host Sensor rack. See Rack Property Definitions, page 22.

Errors

View any current errors or other status messages. See Error Messages, page 47.

Source Info

View the current control source (Highest-Takes-Precedence or “HTP”) and related output

level being received by all circuits in a space.

About CEM3

Download a PDF of the CEM3 User Manual to a connected USB drive.

2 System Reference 17

Page 24

Setup

Commonly used features found here include:

• changing dimmer, rack, and network settings

• enabling control ports

• changing operating mode

• upgrading software or backing up the rack configuration

• changing curve and firing mode

Dimmers

View and alter the settings for any circuit in a space. See Dimmer Property Definitions, page

19.

Rack

View and alter the settings for the host Sensor3 rack. See Rack Property Definitions, page

22.

Circuit Assignment

Assign the space, circuit number, and module type for any circuit slot in the rack. You can

auto assign or manually edit the options for any circuit.

Note:

Patching

Allows editing of the patch and functionality for any port (DMX or sACN). See Setting Up

Patch, page 37.

Network

Allows setup and editing of network properties for the CEM3. See Setting Up CEM3 on the

Network, page 39.

File Operations

Save configurations, load configurations, or upgrade CEM3 software using a USB memory

device, or you can do this from a computer on the network or FTP server. See Saving or

Uploading Files and Firmware, page 33.

Panic

Record a Panic look and set the specific details (such as fade and delay times) for when a

Panic look is executed. See Setting Up Panic, page 35.

Time/Date

Allows you to set or alter the rack’s time and date or switch between automatic or manual

time setting.

Single and half density modules such as the D20F need to be changed in the “Edit

Circuit Layout” screen of Circuit Assignment to adjust circuit numbering prior to

performing final patch updates.

Quick Setup

Allows for fast configuration of the rack. For more information see Performing a Quick

Setup, page 7.

18 CEM3 User Manual

Page 25

UI Preferences

Allows you to alter various settings regarding the user interface.

Backlight Mode

This setting affects the backlight behind the display window. Choices are “On,” “Off,”

and “Auto”. Auto will illuminate the window after a button press or boot up for the time

specified in Backlight Time. Default is “Auto.”

Backlight Time

Appears only when Backlight Mode is set to “Auto”. Specify the time in minutes and

seconds (between 0:10 and 9:59) for the backlight to stay lit after a reboot or button press.

Default is 3:00.

Contrast

Adjusts the contrast of the display window. This can also be done from the home screen by

holding the back arrow and using the scroll wheel.

Language

Alters the display language for the display window. Default is English.

Temp Locale

Alters the units used for the temperature display, Celsius (C) or Fahrenheit (F). Default is

“F”.

sACN

Determines the method of displaying sACN addresses: Universe/Channel (Uni/Ch) or

absolute address (Abs). Default is Uni/Ch.

Dimmer Property Definitions

Each dimmer has specific properties that dictate how the dimmer functions and how CEM3 will

control it. These properties are accessible and editable for any dimmer by navigating to

[Setup]>Dimmers.

Below is a list of the various dimmer properties in the order they appear on the display:

Dimmer Property Definition

Circuit Number. A user-assigned number for a unique circuit

Cct:

Lug:

Lvl:

Module:

within a “space.” Typically the circuit number matches the labelling

at the corresponding power outlet.

Describes the physical location of a circuit in a rack. This field

cannot be altered. Some module types may take up multiple lug

positions in the rack. In this case, not all module “slots” will have a

circuit number

The current level (0-100%) of the HTP source in control of the

dimmer.

The type of module controlling the circuit. Defines module density,

ratings, and features to ensure proper function of the connected

equipment and power devices in the module.

2 System Reference 19

Page 26

Dimmer Property Definition

The firing mode of the dimmer module. Options are: Normal,

Firing:

Control:

Curve:

Threshold%:

On-Level%:

Off-Level%:

On Time (sec):

Off Time (sec):

DMX A: The DMXA channel the circuit is patched to.

Dimmer Double, or Fluorescent. Specific module types will also

offer respectively: Reverse Phase, and Thru-Power.

Determines the control mode of the dimmer. Possible settings are

Dimmable, Smoothing, Off, Always-On, Switched, Latch Lock,

TPAuto, and TPDMX (see individual definitions below).

Dimmable - Circuit dims according to curve within the minimum and

maximum scaled voltages.

Smoothing - The dimmer adds a deliberately slow reaction time to

changes in control level to “smooth out” dimming performance with

loads that react quickly such as LEDs or low wattage lamps.

Off - Circuit ignores incoming levels and will not turn on even with

local overrides.

Always-On - Circuit ignores incoming levels and will not turn off even

with local overrides.

Switched - Circuit operates as a relay with output unregulated AC

voltage when the control level is above the control threshold level.

Latch-Lock - similar to switched mode, Latch-Lock functions as a

relay but features an additional safeguard so that circuits can not be

turned on or off so easily. See Latch-Lock, page 12.

TPAuto - For ThruPower modules. The control input to the circuit

dims the circuit if it is between 0 and 99%. When the output is set to

100%, the relay of the ThruPower module closes.

TPDMX - For ThruPower modules. Two addresses (or three

addresses when combined with 16-bit mode) control the dimmer and

the relay of the ThruPower module. When the second address is

below 50%, the first address acts as a relay control, turning the relay

on at the threshold value. When the second address is above 50%,

the first address acts as a dimmer in the normal manner, dimming the

output.

The current operating curve for the dimmer. Options are: Mod-

Square, Square, Linear, Mod-Linear, Sensor 2.0, and Custom 1-5.

For more information curves see Dimmer Curves, page 23.

In switched mode the threshold value defines the control

percentage at which the output turns on. In dimmed mode, the

threshold defines the level at which preheat is applied. See

Dimmer Output Diagram, page 30 for an illustration of how

threshold works with other dimmer properties.

Latch-Lock only - The control level range (as percentage) that

causes the “On Time” to start counting down. Ranges available in

10% increments. Default is 41-50%.

See Latch-Lock, page 12.

Latch-Lock only - The control level range (as percentage) that

causes the “Off Time” to start counting down. Ranges available in

10% increments. Default is 81-90%.

See Latch-Lock, page 12.

Latch-Lock only - The time that a level must be maintained before

a circuit is switched on.

seconds. See Latch-Lock, page 12.

Available range is 1-360 seconds. Default is 5

Latch-Lock only - The time that a level must be maintained before

a circuit is switched off.

seconds.See Latch-Lock, page 12.

Available range is 1-360 seconds. Default is 5

20 CEM3 User Manual

Page 27

Dimmer Property Definition

DMX A 16-Bit:

DMX B The DMXB channel the circuit is patched to.

DMX B 16-Bit:

sACN:

sACN 16-Bit:

Arch Zone:

Scale Load:

AF Enabled

Recorded Load: AF-Enabled only - Displays the recorded load for this circuit.

Actual Load: AF-Enabled only - Displays the current load for this circuit.

Min Scale (VAC):

Max Scale (VAC):

Regulation:

Preheat: Displays whether the Preheat setting is on (Yes = On).

Time (sec):

DC Out Prevent:

Inrush Protect:

Allow in Panic: Determines if this circuit should be included in the panic look.

Allow in Preset:

Determines if the circuit receives 16-Bit data from DMX A. Yes/No

(Default = No)

Determines if the circuit receives 16-Bit data from DMX B. Yes/No

(Default = No)

The sACN channel the circuit is patched to. Displayed as either

universe/channel or absolute, based on UI Preference settings

(see UI Preferences, page 19).

Determines if the circuit receives 16-Bit data from DMX A. Yes/No

(Default = No)

Set the desired zone that the circuit will control. Range is from 0-

16. Default is 1. Zero will exclude the circuit from zone control.

The scale load setting allows hyper-accurate regulation of the

voltage of the dimmer output. The scale load allows the CEM3

dimming engine to compensate for power losses occurring in the

choke of the dimmer. The scale load is calculated as the load on

the channel divided by the channel’s capacity (in Amperes) and is

expressed as a percentage. For example, a 5A load on a 20A

channel would have a scale load of 25% (5A / 20A x 100% =

25%).

Enables/disables advanced features for this circuit. Yes = AF

enabled. This field is not available for circuits set to Dimmer

Double.

Displays the minimum scale voltage of the circuit. See Dimmer

Output Diagram, page 30 for an illustration relating to this

property.

Displays the maximum scale voltage of the circuit. See Dimmer

Output Diagram, page 30 for an illustration relating to this

property.

Displays whether voltage regulation is enabled for the circuit (Yes/

No). Default is “Yes”.

Preheat Time value allows the preheat level to be sneaked back in

after a blackout to allow rapid snap blackouts. This property

specifies the length of time for the ramp back to preheat level.

Default = 2 seconds.

If enabled, ensures that both positive and negative half cycles of

the dimmer output are always equal. This setting is typically used

for loads sensitive to DC for example transformers and electronic

loads. Default is “No” (No = Off, Yes = On).

Provides a soft start feature when lamps are turned on from “0” by

ramping up the level over three mains cycles. Default is “No” (No

= Off, Yes = On).

Determines if this circuit should be included in any presets that

may be recorded in the future.

2 System Reference 21

Page 28

Dimmer Property Definition

AF-Enabled only - Defines the load reporting mode for this circuit.

Reporting Mode:

Sensitivity:

AF Reaction:

Options are: Off, No-Load, and Load Change. Default for AF

modules is Load Change.

AF-Enabled only - Defines the threshold a load can be within

before triggering a load error. Available in 0.5Amp increments. 2A

is default.

AF-Enabled only - Determines the length of time for an AF

reaction to occur. Default = 5 seconds.

Rack Property Definitions

Each rack has specific properties that dictate how the rack is identified and functions. When

selected in the Rack Setup display ([Setup]>Rack), the rack’s properties are shown on the

display window. Below is a list of the various rack properties in the order they appear on the

display:

Rack Property Definition

Rack Number:

System Number:

DMX A:

Priority (DMX A):

DMX B:

Priority (DMX B):

sACN:

Preset Priority

Fan:

AF Enabled:

Displays the current rack number, which you can change to be

between 1-999.

Displays the current system number, which you can change to be

between 1-999. Default is 1.

Toggles the output of the DMX A port between “Enabled” and

“Disabled.” When disabled the respective “Priority” field is not

visible and “Off” is displayed on the home screen. Default for DMX

A is “Enabled”.

Visible only when DMX A output is enabled. This field allows you

to configure the priority of the DMX A output signal from the rack.

Range is between 1-200 (200 = highest priority). Default is 100.

Toggles the output of the DMX B port between “Enabled” and

“Disabled.” When disabled the respective “Priority” field is not

visible and “Off” is displayed on the home screen. Default for DMX

B is “Disabled”.

Visible only when DMX B output is enabled. This field allows you

to configure the priority of the DMX B output signal from the rack.

Range is between 1-200 (200 = highest priority). Default is 100.

Toggles the output of the sACN port between “Enabled” and

“Disabled.” When disabled, “Off” displays on the home screen.

Default for sACN is “Enabled”.

Set the priority for all outgoing preset levels. Range is between

1(lowest) - 200 (Highest). Default is 100.

This is the length of time (in minutes) the rack fan will stay on after

the last load in the rack has reached 0%. Range is between 30180 minutes or can be set to “Always-on”. Default is 30.

Displays whether the rack has Advanced Features (AF) enabled

or not (Yes/No). Default is based on the backplane DIP switch

setting.

22 CEM3 User Manual

Page 29

Rack Property Definition

Presets on Boot:

Setup at Home:

Voltage High Warn:

Tem p H i g h Warn:

Station Power:

Remote Record

Data Loss Behavior:

Dimmer Curves

If enabled, and rack is rebooted when a preset (or presets) are

active, then those same presets will be reactivated when the rack

reboots.

Allows the “Quick Setup” shortcut menu option to be displayed on

the home screen. Default is “Yes” for portable racks and “No” for

install racks.

This setting defines the threshold to report an “over voltage”

condition

250VAC for 230-240VAC systems.

This setting defines the threshold to report an “over temperature”

condition

(65°C)

This setting determines whether the preset station power supply

for this CEM3 is turned on. Default is “Off” (see Preset Functions,

page 13 for more information)

This setting determines whether presets can be remotely

recorded from preset stations. Default is “No”.

Opens the “Data Loss behavior” submenu (see Set Data Loss

Behavior, page 38).

. Default is 140VAC for 100-120VAC systems and

. The range is between 32-158°F (0-70°C). Default is 149°F

Dimmer curves determine how dimmers set voltage output in response to control signal

input. To accommodate designer preferences and load response variations, Sensor3 offers

several dimmer curves which can be applied to individual dimmers (see Curve:, page 20).

The available curves in CEM3 are as follows.

Linear

The linear curve matches the control input percentage to Root Mean Squared (RMS)

voltage output. Each percent increase in control level increases dimmer voltage output by

2 System Reference 23

Page 30

the same amount.

0 20406080100

0

20

40

60

80

100

Control Input (%)

Dimmer Output (%)

24 CEM3 User Manual

Page 31

Modified Linear (Mod-Linear)

0 20406080100

0

20

40

60

80

100

Control Input (%)

Dimmer Output (%)

Control Input (%)

Dimmer Output (%)

A modified linear curve reduces the voltage change at low control levels for better

performance in low-wattage fixtures.

Square Law (Square)

At low control levels, much of a traditional incandescent fixture’s light output is in the

invisible infrared spectrum. This results in poor visible response to low control levels. A

square law curve applies a multiple derived from the square root of the control level (with

full output equal to 1.00) to increase voltage response at low control levels to compensate

for the infrared loss.

100

80

60

40

20

0

0 20406080100

2 System Reference 25

Page 32

Modified Square Law (Mod-Square)

Control Input (%)

Dimmer Output (%)

Control Input (%)

Dimmer Output (%)

A standard square law curve may overcompensate for infrared loss, resulting in “steppy”

response to incremental control changes at low levels. ETC’s modified square law curve

applies a second multiple to the standard square law curve for more uniform response to

control levels changes across the entire range of dimmer output.

100

80

60

40

20

0

0 20406080100

Sensor 2.0

The Sensor 2.0 curve is the previous version of ETC’s modified square law curve. It

provides backwards compatibility for shows created using earlier versions of ETC

equipment and familiar response for designers who prefer the earlier version.

100

80

60

40

20

0

0 20406080100

26 CEM3 User Manual

Page 33

Stage 1

Control Input (%)

Dimmer Output (%)

Control Input (%)

Dimmer Output (%)

This curve matches the stage curve of the Transtechnik PM90 dimming system.

100

80

60

40

20

0

Stage 2

This is a traditional German stage lighting curve.

0 20406080100

100

80

60

40

20

0

0 20406080100

2 System Reference 27

Page 34

Fluor 1

Control Input (%)

Dimmer Output (%)

Control Input (%)

Dimmer Output (%)

This curve is specifically for Nesys fluorescent devices.

100

80

60

40

20

0

Fluor 2

This curve is tuned to work with common 3-wire fluorescent ballasts.

0 20406080100

100

80

60

40

20

0

0 20406080100

28 CEM3 User Manual

Page 35

Andi

Control Input (%)

Dimmer Output (%)

Control Input (%)

Dimmer Output (%)

This curve is tuned to match the curve of Strand ANDI dimmer systems.

100

80

60

40

20

0

VIP 90

VIP90 is a curve specifically tuned to produce good dimming performance with the VIP-90

fluorescent ballast from SE Light management AG, commonly used in European theatrical

fluorescent luminaires.

0 20406080100

100

80

60

40

20

0

0 20406080100

2 System Reference 29

Page 36

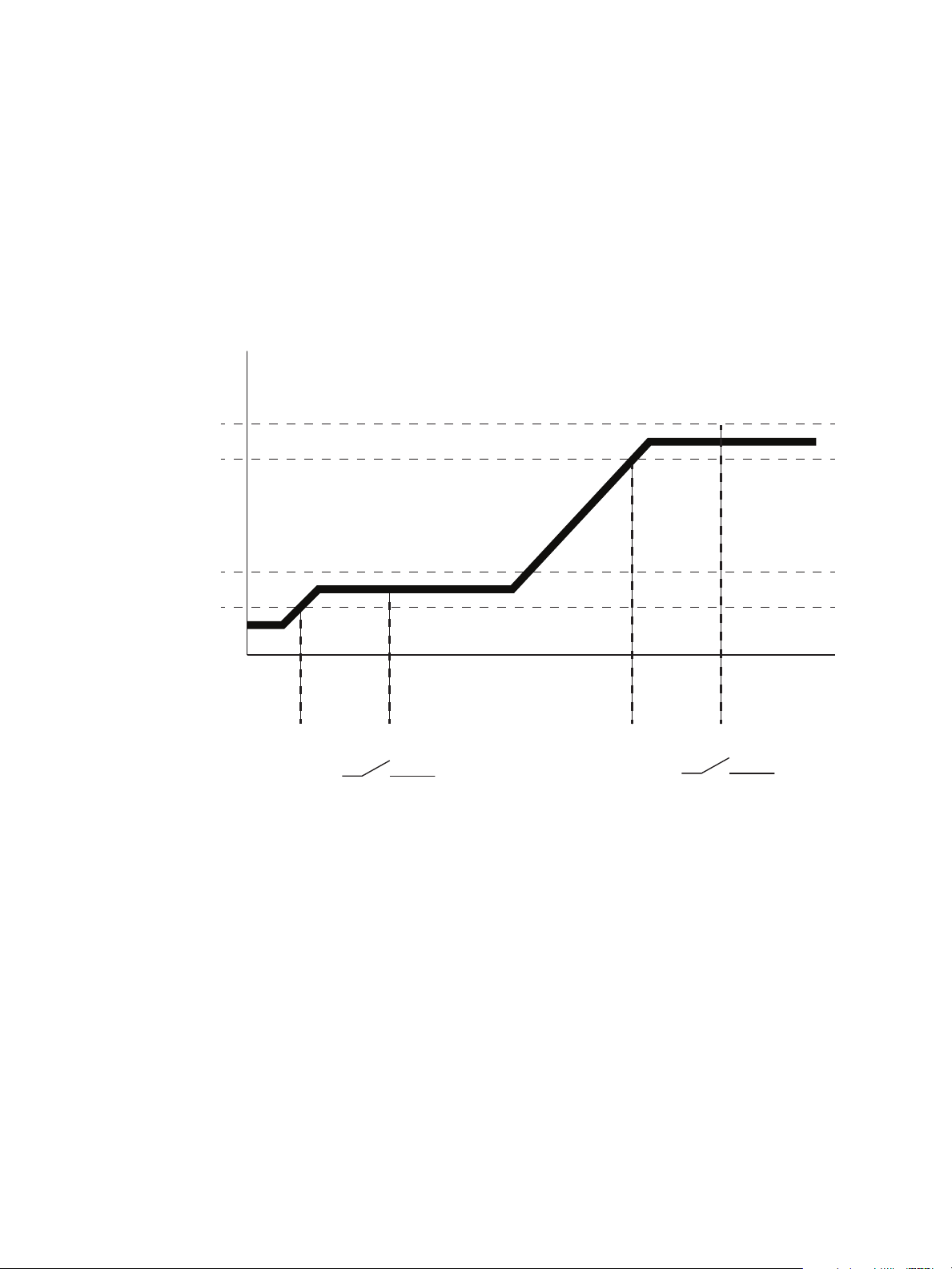

Dimmer Output Diagram

This diagram illustrates the relationship between min scale, max scale, curve, threshold,

and preheat for the dimmer output from a CEM3 channel.

Threshold(%)

Output Voltage

100%

Max Scale Voltage

Min Scale Voltage

Control Level

With Preheat Disabled

Output goes to zero

With Preheat Enabled

Output is at min scale

below threshold

30 CEM3 User Manual

Page 37

Chapter 3

Common Tasks

This chapter contains the following sections:

• Recording and Playing Back Presets . . . . . . . . . . . . . . . . . .32

• Saving or Uploading Files and Firmware . . . . . . . . . . . . . . .33

• Setting Up Panic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

• Setting Up Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

• Set Data Loss Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

• Setting Up CEM3 on the Network. . . . . . . . . . . . . . . . . . . . . .39

• Setting Rack DIP Switches and Termination. . . . . . . . . . . . .40

• Rack Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . .42

• Replacing AF Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3 Common Tasks 31

Page 38

Recording and Playing Back Presets

CEM3 has the ability to record and play back snapshot looks called “Presets.”

Presets can be recalled from the CEM3 or from any compatible Echo preset stations. For

information on wiring preset stations, see the Sensor3 CEM3 Data Terminations Guide and

the Echo Preset Station Installation Guide.

Up to 64 presets can be recorded for each space, numbered from 1-64. Only one preset

can be active at a time in the same space.

Preset Menu

Presets are recorded by taking a snapshot of the current levels for all circuits assigned to

the space that are set to be included in presets (see Allow in Preset:, page 21). If a circuit

is not set to be included in presets, any level it is currently using will be withheld from the

record action.

To record or play back a preset:

Step 1: Set the desired output levels for any dimmers in your rack using any method

(methods include: “Set Levels” feature on CEM3, DMX device, or sACN device).

Step 2: Using the CEM3 face panel, navigate to [Test]>Presets. The “Select Space”

screen will appear (if multiple spaces exist).

Step 3: Select the space you wish to record the preset for (if applicable) and then select

OK. The Preset screen will open.

Step 4: Select the preset (1-64) that you wish to record for the space. This will then give

you access to the preset menu. From this menu you can now perform the

following actions:

• [Activate/Deactivate] - [Enter] toggles the preset between on and off.

• [Snapshot/Record] - [Enter] records the current levels for the space to the

selected preset.

• Fade Time: set the desired time (in seconds) for the preset to fade in and out

when activated/deactivated. Range is from 0-360 seconds. Default is 2

seconds.

Step 5: Release the output levels ([Test]>Release Set Levels) or turn off the control

source data.

32 CEM3 User Manual

Page 39

Saving or Uploading Files and Firmware

CEM3 allows you to save configurations to USB removable media, a computer connected

to the network (using the CEM3 web interface), or an FTP server on the network.

You can also upload a configuration or update the CEM3 software using the same methods.

Saving Configurations

To USB media

Step 1: Navigate to [Setup]>File Operations>Save to USB. The “Save As” screen will

appear.

Step 2: If desired, edit the name of the configuration using the scroll wheel and keypad.

a: Select the file name using the scroll wheel and press [Enter]. The first

character of the rack name will be highlighted.

b: Use the keypad to alter the selected character. Keypad numbers have

standard keypad text input letters. Multiple presses of any key will cycle

through the number, lower case letters, and then upper case letters for that

key.

c: When the desired character is displayed, use the scroll wheel to move to the

next character in the rack name. If you want the name to be longer, press

[Next] to add another character.

d: Repeat steps b-c until the desired rack name is displayed.

e: When the rack name is correct, press [Enter].

Step 3: Select “OK” and press [Enter]. The configuration will be saved to the device.

To a computer

To save a configuration to a computer on the system network, see the appendix Using the

CEM3 Web Interface, page 49.

To an FTP server

To save a configuration to an FTP server on the system network, see Working with an FTP

Server, page 39.

Loading Configurations

From USB media

Step 1: Navigate to [Setup]>File Operations>Load from USB. The “Load cfg file”

screen will appear.

Step 2: Use the scroll wheel to navigate the file structure to the desired configuration file

(the file name will end in “.etc”) and press [Enter]. The configuration will load.

From a computer

To load a configuration from a computer on the system network, see the appendix Using

the CEM3 Web Interface, page 49.

To an FTP server

To load a configuration from an FTP server on the system network, see Working with an

FTP Server, page 39.

3 Common Tasks 33

Page 40

Loading CEM3 Software

You can upgrade your CEM3 software using the same methods as loading configurations

(see above). CEM3 software can be obtained by contacting ETC Technical Services (see

page 3).

From USB media

Step 1: Back up the rack configuration using the steps outlined in Saving Configurations,

page 33.

Step 2: Navigate to [Setup]>File Operations>Upgrade from USB. The “software

upgrade” screen will appear.

Step 3: Use the scroll wheel to navigate the file structure to the desired configuration file

(CEM3 software file names will end in “.bld”) and press [Enter]. A confirmation

screen will appear.

Step 4: Select “Yes” to continue. Select “No” abort the upgrade. The software upgrade

process will take several minutes.

From a computer

To load a configuration from a computer on the system network, see the appendix Using

the CEM3 Web Interface, page 49.

You can also use ETC’s Updaterator software to upgrade your CEM3. Updaterator can be

downloaded from ETC’s website www.etcconnect.com

To an FTP server

.

To load software from an FTP server on the system network, see Working with an FTP

Server, page 39.

34 CEM3 User Manual

Page 41

Setting Up Panic

To fully enable Panic functionality for your CEM3, the following criteria must be met:

• a maintained contact closure has been wired to the panic circuit on the CEM3

backplane (for more information, see the Sensor3 CEM3 Data Terminations Guide

that ships with the Sensor3 rack),

• the “Emergency Contact” switch on the CEM3 backplane is the correct position for

the contact closure type (normally open “NO” or normally closed “NC”),

• a snapshot of the desired Panic look has been recorded in the CEM3 software.

Note:

To set the Emergency Contact switch on the CEM3 backplane:

WARNING:

Step 1: Remove the CEM3 control module.

Step 2: Move the switch labeled “EMERGENCY CONTACT” to the appropriate setting:

To record a Panic look:

A Panic look can be recorded, regardless of if you have a wired Panic circuit.

Power must be turned OFF when you perform this procedure. Before

removing dimmer or control modules for service, de-energize main feed to

dimmer rack and follow appropriate Lockout/Tagout procedures as

described in NFPA Standard 70E. It is important to note that electrical

equipment such as dimmer racks can present an arc flash safety hazard if

improperly serviced. This is due to available large short circuit currents on

the feeders of the equipment. Any work on energized equipment must

comply with OSHA Electrical Safe Working Practices.

• “NC” - Use this setting if the emergency contact closure is a “Normally

Closed” contact closure.

• “Disabled” - This setting disables the Panic function for this CEM3 control

module.

• “NO” - Use this setting if the emergency contact closure is a “Normally Open”

contact closure.

Step 1: Set the desired output levels for any dimmers in your rack using any method

(methods include: Set Levels, DMX device, or sACN device).

Step 2: Using the CEM3 face panel, navigate to [Setup]>Panic>Record Panic

Look>[Enter]. If a panic look was already recorded, a confirmation screen will

appear asking you if you wish to overwrite the Panic look.

• Select “Yes/Save” to overwrite the old Panic Look. The look will be saved.

• Select “No/Cancel” to abort the record. The look will be aborted.

Once a Panic look is recorded, when the emergency contact closure is triggered the Panic

look will be activated. When the contact closure is returned to its normal state, the Panic

look will be deactivated.

Other Panic Settings

From the Panic Setup menu ([Setup]>Panic) you have access to the following settings that

will affect the manner of a Panic look activation:

• In Delay (sec) - This setting determines the length of time (in seconds) for the Panic

look to delay before activating (default is 0).

3 Common Tasks 35

Page 42

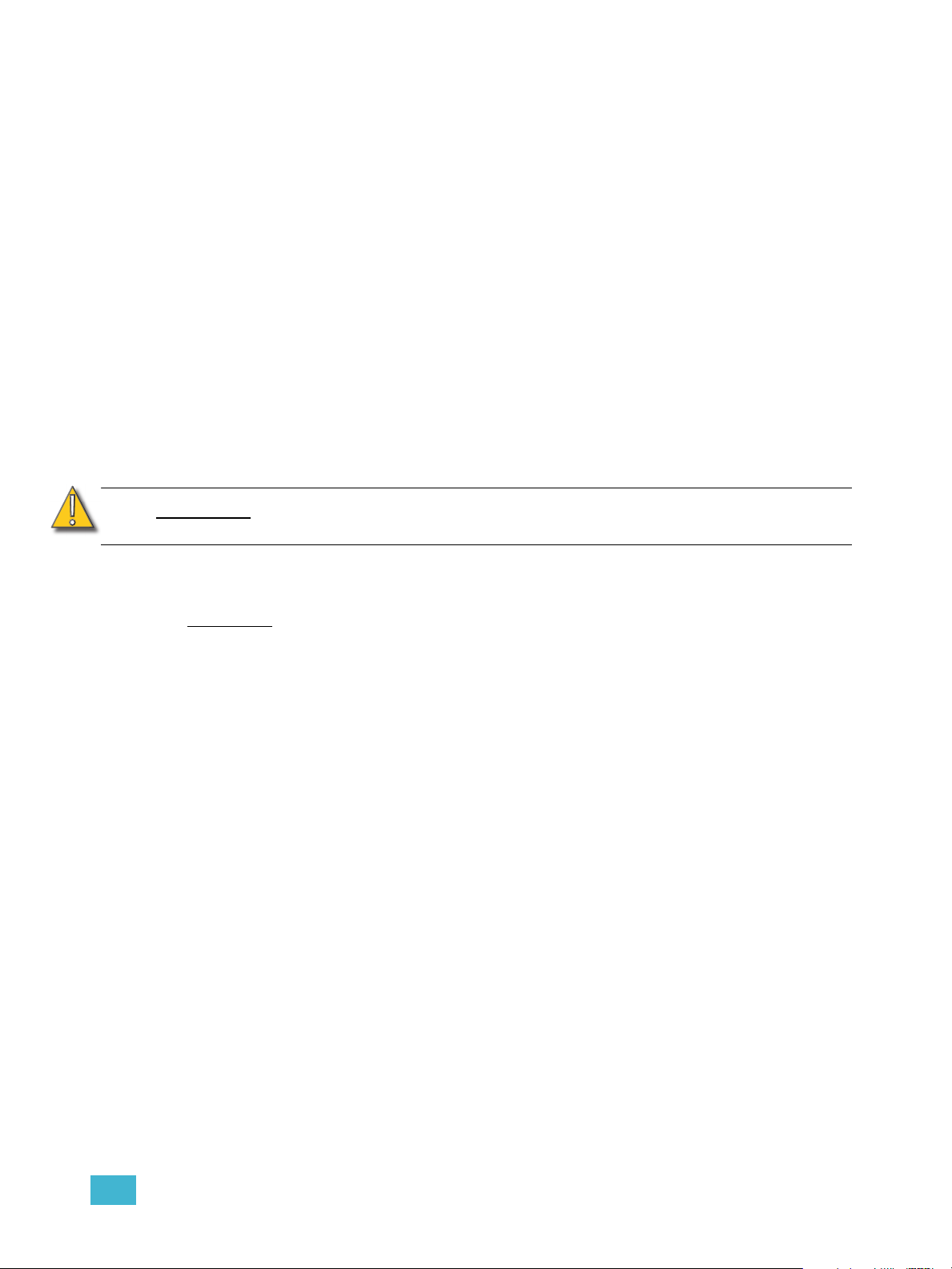

• Out Delay (sec) - This setting determines the length of time (in seconds) for the Panic

Level

Time

Panic

Activated

Panic

DeActivated

In Delay

0-360s

Fade In

0-360s

Out Delay

0-360s

Fade Out

0-360s

Steady State

until contact changes

Indicator turns on

Indicator turns off

Panic Levels

Off

Panic Fade Diagram

look to delay before deactivating (default is 0).

• Fade In (sec) - This setting determines the length of time (in seconds) for the Panic look

to fade in when activated (default is 2).

• Fade Out (sec) - This setting determines the length of time (in seconds) for the Panic

look to fade out when deactivated (default is 2).

• Shed Other Loads - This Yes/No setting determines if active levels at the moment of

the Panic trigger should remain active or be forced off. Default is “N” (No).

The following graphic illustrates how these settings affect panic function:

36 CEM3 User Manual

Page 43

Setting Up Patch

Patch governs the relationship between control sources (DMX A, DMX B, and sACN) and

the rack’s circuits and is editable from the CEM3 face panel. Typically, repatching is used

in portable rack situations where the dimmer rack must adapt to different control sources

and lighting systems. For permanent rack installs, altering your patch is rarely needed.

Racks with only one assigned space can have their patch edited through one of two

methods: Manual or Automatic. Racks with multiple assigned spaces can only be edited

manually. For racks edited using an automatic method, circuits will be numbered

sequentially from the specified starting address following the designated “Straight” or

“Balanced” setting in Quick Setup.

Any circuit set to a patch of “0” will render that circuit uncontrollable from the data source

specified.

Automatic Patch

Note:

When you chose an automatic patching method the entire rack will be patched sequentially

based on the criteria of the chosen option in Quick Setup. Only racks with one assigned

space can use these methods.

If dimmer doubling is enabled, you will see additional fields for addressing dimmer doubled

circuits.

There are three options offered for automatic patching: Simple, Split, and Independent.

Simple

This patching method specifies the same starting circuit for all three data ports (DMX A,

DMX B, and sACN) at once. Enter the starting number for the patch. Universe size is 512

dimmers (256 if dimmer doubling is enabled). If the patch count exceeds 512, the patch will

“wrap” and start numbering again at 1 (257 for dimmer doubling).

Split

This patching method should be used when a DMX universe will end part way through the

rack’s patch. Enter the starting number for the patch. If the patch sequence exceeds 512

(256 if dimmer doubling is enabled) DMX A will patch the rest of the circuits to “0” and DMX

B will restart the patch numbers at 1 for those remaining circuits.

Independent

This method allows you to specify different starting numbers for each data port in the patch

(DMX A, DMX B, and sACN). Select a data port and assign the desired starting address for

the rack. If the rack count then exceeds 512 (for DMX ports) the remainder of circuits in the

rack will be patched to zero for that DMX port.

Module density can affect patching. Prior to patching, make sure you set up the

module type in [Setup]>Circuit Assignment.

To set an automatic patching method:

Step 1: Navigate to [Setup]>Patching>Automatic: <choose method>.

Step 2: Enter or scroll to the desired starting channel number using the keypad. For

Independent Mode, repeat for the other data ports.

Step 3: Press [Enter] and confirm to save the changes.

3 Common Tasks 37

Page 44

Manual Patch

Manual patching allows you to alter the patch on a circuit-by-circuit basis. There are two

independent options for manual patch editing: DMX and sACN. Both can be set individually

for your needs.

To edit the patch manually:

Step 1: Navigate to [Setup]>[Patching]>[Edit DMX / sACN Patch]

Step 2: Press [Enter]. The Select Space screen will appear (if multiple spaces exist).

Step 3: Select the desired space (if applicable) and then select OK. The Patch Table will

open.

Step 4: Use the scroll wheel or keypad to select the DMX port (A or B) or sACN universe

and channel for the desired circuit.

Step 5: Press [Enter]. The field will become editable.

Step 6: Scroll to or enter the desired channel from the keypad.

Step 7: Press [Enter].

Step 8: Repeat steps 4-7 for all desired circuits in the space.

Step 9: Press [Back] when done. A confirmation dialog will open.

Step 10: Select [Yes/Save] to save the changes. Press [No/Cancel] to abort. Press

[Continue Editing] to edit further circuits.

Step 11: Repeat steps 2-10 for any additional spaces.

Set Data Loss Behavior

You can designate the rack’s reaction to a loss of data from any of the three data ports

(DMX A, DMX B, or sACN). For each of the ports you can select one of the following

behaviors:

• Crossfade - On loss of data, the look will transition to a specified internal preset.

• Wait & Fade - On loss of data, the rack will wait for a specified amount of time and

then fade to black over another specified time.

• Hold Last Look - On loss of data, no transition occurs. The levels will stay at the

last known look until data is restored to the port. Resetting the processor will

release the levels.

To set the data loss behavior for any port:

Step 1: Navigate to [Setup]>Rack>Data Loss Behavior. The Data Loss Behavior

screen will be displayed.

Step 2: Use the scroll wheel to highlight the desired port behavior (DMX A, DMX B, or

sACN) and press [Enter]. The behavior will be highlighted.

Step 3: Use the scroll wheel to select the desired behavior (see above) and press

[Enter].

a: Select “Fade Time” (if applicable) and set the desired time (range is 0-360

seconds).

b: Select “Wait Time” (if applicable) and set the desired time (range is 0-360

seconds).

c: Select “Preset Space” (Crossfade only) and select the space that contains

38 CEM3 User Manual

Page 45

the desired crossfade preset.

d: Select “Preset Number” (Crossfade only) and select the desired preset (1-

64) for the crossfade.

Step 4: Repeat for the remaining data ports if desired.

Setting Up CEM3 on the Network

Network setup allows editing of the CEM3 network properties to establish the rack’s IP,

address. Three options for setting network characteristics are available: Link Local, DHCP,

and custom. The default is DHCP.

You can access this menu by navigating to [Setup]>Network>[Enter]. After the desired

method is set, a confirmation window will open asking you to confirm or abort the changes.

Link Local

Choose Link Local if you work in a touring system where equipment changes frequently.

Link Local automatically assigns an IP address, in a special rang, with the IP being

randomly generated.

DHCP

Choose DHCP if your system includes a DHCP server (for example, an Eos console).

This setting will attempt to acquire an IP address from a DHCP server. If the request fails,

CEM3 will acquire its address through Link-Local (see above) for this boot cycle only. If

rebooted, the rack will attempt a DHCP request again.

Custom

With this method you can directly set the IP address, Subnet, and Gateway manually using

the keypad. ETC’s convention for IP address is to use 10.101.xxx.yy (“x” varies by ETC

product line, “y” increments for products of the same type).

Network Setup for Redundant Tracking Racks

The Redundant Tracking option is only available for ESR and FDX systems.

In a redundant tracking system, each processor has a separate network connection to

which a separate IP address may be assigned. When working in a redundant tracking

system CEM3 will prompt to select which processor (A or B) you wish to alter the IP settings

for.

Working with an FTP Server

CEM3 supports automatic or manual backup of the dimmer rack configuration to a server

on an Ethernet network using the FTP (File Transfer Protocol) standard.

Before you can save to an FTP server you must first set one up from the CEM3 face panel.

To set up an FTP server from CEM3:

Step 1: Navigate to [Setup]>File Operations>Set Up Server.

Step 2: Press enter to change enable to “yes”.

Step 3: Specify the IP address of the server.

Step 4: Specify the file name in “File”.

Step 5: Set AutoSave. When set to “Yes,” every time a change is applied to the

3 Common Tasks 39

Page 46

configuration it will be saved to the server. “No” means you will have to manually

save.

To manually save a configuration to an FTP server, navigate to [Setup]>File

Operations>Save to Server.You can edit the file name prior to saving using the scroll

wheel and the keypad to enter letters.

To load a configuration from an FTP server, navigate to [Setup]>File Operations>Load

from Server and choose the desired file from the list that appears (CEM3 configuration file

names end in “.etc”).

To upgrade CEM3 software from an FTP server, navigate to [Setup]>File

Operations>Load from Server and choose the desired file from the list that appears

(CEM3 software file names end in “.bld”).

Setting Rack DIP Switches and Termination

WARNING:

On the CEM3 backplane, located in the rack behind the CEM3 control module, there is a

small bank of 8 DIP switches. The setting of these switches should be set to match the

specific size, features, and desired behavior of your dimmer rack.

Generally, you should not need to alter these settings as they should have been set when

your system was commissioned by an ETC technician. However in the event that you must

replace your CEM3 control module or backplane, you will need to ensure these settings

match the previous controller.

Use this section to determine the required settings for your dimmer rack. There is also a

label on the underside of the CEM3 that explains the function of each switch.

When setting the DIP switches, you may also need to check the DMX A and DMX B

termination settings for the rack. Reference the backplane label to determine the

appropriate position of the termination switch.

To avoid the possibility of electric shock, power must be turned OFF when

you perform this procedure. Before removing dimmer or control modules,

de-energize main feed to dimmer rack and follow appropriate Lockout/

Tagout procedures as described in NFPA Standard 70E. It is important to

note that electrical equipment such as dimmer racks can present an arc

flash safety hazard if improperly serviced. This is due to available large

short circuit currents on the feeders of the equipment. Any work on

energized equipment must comply with OSHA Electrical Safe Working

Practices.

DIPswitch settings

The eight DIP switches relate to behavior, features, or the module size of the rack. In the

descriptions below, switches set in the up position are “On” and switches set in the down

position are “Off”.

DIP 1 - “DBM”

This switch disables the backplane memory so that the configuration is not stored on the

rack itself. Default is “OFF”. If set to “ON”, a Rack Memory Error will be displayed on the

CEM3.

40 CEM3 User Manual

Page 47

DIP 2 - “AF”

This switch should be set to “On” if your rack has Advanced Features (AF - see Advanced

Features (AF), page 10).

DIP 3 - “HSR 240V”

This switch should be set to “On” if your rack is an HSR rack intended for use with 240VAC

power feeds.

DIP 4 - “ESR 230V”

This switch should be set to “On” if your rack is an ESR rack intended for use with 230VAC

power feeds.

Note:

For JSR dimmer racks, intended for use with 100VAC power feeds, both DIP 3

and DIP 4 should be set to “On”.

DIP 5 - “ND”

This switch should be set to “On” if your rack includes a neutral disconnect.

DIPs 6-8

These DIP switches are used together to determine the number of module slots in your

rack. Refer to the table below to find the desired settings for your rack size.

Rack size 6 7 8

6 module slots Off On On

12 module slots Off On Off

24 module slots Off Off On

36 module slots On Off Off

48 module slots Off Off Off

Termination Switches

DMX signal requires a a signal termination at the end of a data run. If your rack is the last

device on the data run for either DMX A or DMX B, set the termination switch for the

appropriate run to “ON”. The switches are labeled “B” or “A” on the backplane label.

If the rack is not the last device on either data run, leave these set to “Off”.

DIP Number

3 Common Tasks 41

Page 48

Rack Maintenance and Cleaning

Proper air flow is necessary for your Sensor3 rack to function properly and consistently.

Perform the following procedures regularly to keep dust and foreign debris from impeding

the proper function of your rack.

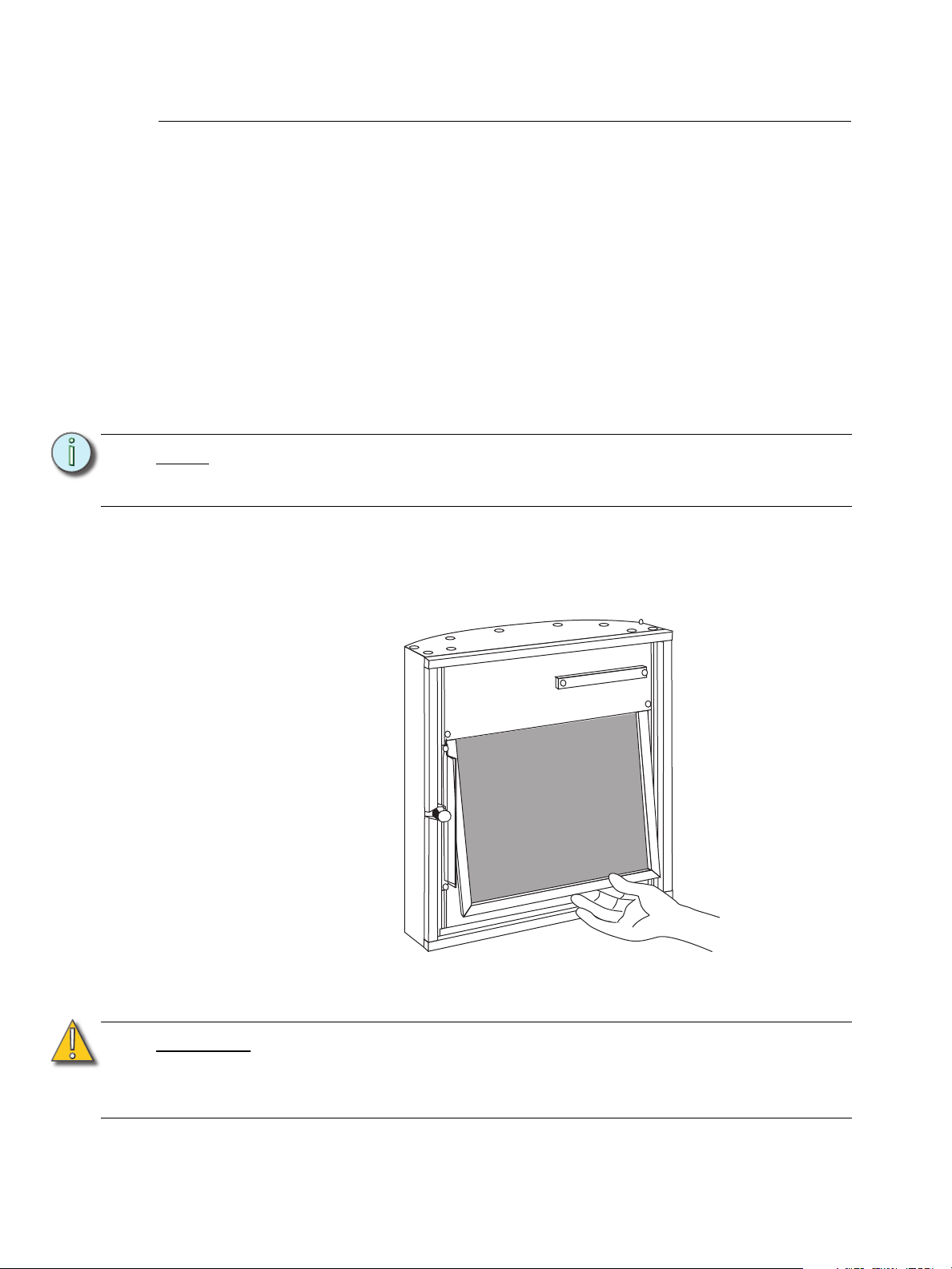

Cleaning Rack Air Filters

Clean the air filter in the Sensor3 rack door a minimum of every six months, more often if

your system operates in a dusty environment. This will also provide an opportunity to

inspect the dimmer module air vents and clean them if necessary (see Vacuuming Dimmer

Modules, page 43).

To clean your rack air filter:

Step 1: Open the dimmer rack door. The air filter is mounted on the inside of the door,

held in by a metal lip at the bottom of the door frame.

Note:

Sensor3 48-module racks have two filters, one stacked on top of the other with a

retention bar in the middle of the rack. Remove the top filter screen before

removing the bottom one.

Step 2: Slide the filter upwards approximately 1/2 inch (1.25cm) until the base of the filter

clears the top of the metal lip.

Step 3: Pull the bottom of the air filter out and away from the door far enough to clear the

retaining lip and slide the filter downwards and out of the door frame.

Step 4: In an area away from your dimmer rack and other dust-sensitive equipment,

remove all dust or debris from the filter using either compressed air or a vacuum.

CAUTION:

42 CEM3 User Manual

You may rinse the filter under cold tap water, but it must be completely dry before

you reinstall it.

Do not use soap or other chemical cleaners to clean the filter. They may damage

the filter screen.

Page 49

Step 5: Slide the top of the filter up into the slot at the top of the door until the base clears

O

FF

OFFO

F

FOF

F

12

11

6

5

Dimmer choke vent SCR air inlet

the metal retaining lip at the bottom.

Step 6: Ease the filter back into the door frame and carefully let it drop back into place.

Note:

For Sensor3 48-module racks, install the bottom filter first. The top filter rests on

the top edge of the bottom filter.

Vacuuming Dimmer Modules

As with cleaning the air filters, you should inspect the dimmer module air vents and SCR

power cube inlets every six months and clean if necessary, more often if your system

operates in a dusty environment.

WARNING:

To vacuum the dimmer module air inlets:

Step 1: Open the rack door and inspect the air vents on the CEM3 and the air vents and

Step 2: If necessary, use a vacuum cleaner and nozzle to remove any visible dust or

To avoid the possibility of electric shock, power must be turned OFF when

you perform this procedure. Before vacuuming dimmer or control modules

de-energize main feed to dimmer rack.and follow appropriate Lockout/

Tagout procedures as described in NFPA Standard 70E. It is important to

note that electrical equipment such as dimmer racks can present an arc

flash safety hazard if improperly serviced. This is due to available large

short circuit currents on the feeders of the equipment. Any work on

energized equipment must comply with OSHA Electrical Safe Working

Practices.

Do not remove dimmer modules when vacuuming. Phase voltages inside