2012-11-14

EN_Englisch

Operation

Log Boiler

20-60 kW

2

www.eta.co.at

Contents

Conditions for warranty, guarantee, liability ........ 4

Emission measurement ...................................6

Chimney renovation .......................................7

Boiler functionality ........................................8

Start-up ..................................................... 10

Checking water pressure, suitable fuel ................ 10

Correct quantity of wood ................................ 11

Water pressure, heating lines, cleaning lever ........ 12

Charging status of buffer storage tank ................ 13

Adding wood .............................................. 14

Ignition, closing doors ................................... 15

Closing ignition and insulation doors ................. 16

Adding fuel ................................................. 17

Safety ........................................................ 18

Safety devices to prevent overheating ................18

Maintenance ............................................... 20

Overview of activities .................................... 20

Each time the boiler is filled ............................ 21

Every 1 - 2 weeks ........................................ 22

Annually .................................................... 24

Every 3 years ............................................... 28

Approval, antifreeze, pressure equalisation, venting

32

Softened water, safety valve .......................... 33

Return riser and safety devices ....................... 34

Minimum heat consumption, buffer storage tank 35

Split wood will dry out in just one summer .........36

Heating value of wood .................................. 37

User interface .............................................. 38

Adjusting the date and time ............................ 38

Changing the language .................................. 39

Changing function block names ........................40

Alarm, error, warning, message ........................41

Opening the text menu .................................. 42

Buffer [Buffer] ............................................. 46

Overview, buttons, functions ........................... 46

Buffer with solar .......................................... 47

Combination tank with solar ...........................48

"Buffer bottom max." for solar heating systems .... 49

Heating circuit [HC1] ..................................... 50

Meanings of symbols

Important NOTICES for operation.

CAUTION: Failure to observe these notices can

result in property damage.

STOP: Failure to observe these notices can result in

personal injury.

Overview, buttons and functions ...................... 50

Operating states ........................................... 52

Setting heating time slots ............................... 54

The heating curve ......................................... 56

"Day Heating threshold" and "Night Heating

threshold" .................................................. 57

Adjusting the heating curve ............................ 58

Setting the "enable temperature" .....................60

Adjusting the "Set-back" ................................ 61

Service and maintenance records ..................... 62

3

2012-11

Preface

SH Operation

Dear Customer,

We are delighted to count you among our

customers.

To ensure satisfactory operation of your new boiler,

you need to know how to operate, clean and

maintain it. This manual contains information and

advice on much more than just the boiler itself.

Warranty and guarantee

You should also read the "Conditions for warranty,

guarantee, liability" (page 4) carefully. As a

rule, these conditions will be satisfied by a professional heating technician. Nevertheless, inform the

technician of our warranty conditions. All of the

requirements we impose are intended to prevent

damage that neither you nor we wish to occur.

Information worth knowing in this regard can also

be found starting on page 32.

Optimum use of the control systems installed in

our boilers

There are two different access levels for the control

system:

At the CUSTOMER level, you can adjust the control

system to your wishes and needs without any risk

of altering the system configuration set by the

heating system expert.

Only your technician or a customer service

employee should change settings at the SERVICE

level. Before making any adjustments to these

settings yourself, it is essential that you consult an

expert.

Read this manual

carefully before starting up the system. This is the

only way to ensure that you can operate your new

boiler efficiently and with minimum environmental impact.

Take advantage of the knowledge and skills of an

expert.

Only allow an expert to assemble, install and

commission the equipment and make the basic

boiler settings. Insist on receiving an explanation

and training on how your new boiler functions and

how to operate and maintain it.

Extended warranty for commissioning performed

by an authorised partner company

If your newly installed boiler is commissioned

by an authorised partner company or one of our

customer service employees, we offer an extended

warranty. Refer to our warranty conditions in

effect at the time of purchase.

Service agreement

You can ensure the best care for your heating

system by taking out a service agreement with one

of our certified heating system contractors or our

own customer service.

4

www.eta.co.at

Conditions for warranty, guarantee, liability

We can only guarantee and accept liability for the

function of our boiler if it is properly installed and

operated.

Requirement for warranty, guarantee and liability

is that this boiler be used in accordance with its

intended purpose, only for heating and hot

water supply with no more than 2,000 fullload hours annually, and, in particular, that the

following general conditions be observed during

installation and operation:

For set-up, a dry room is required. In particular,

only condensation dryers may be used as clothes

dryers in the same room.

Local building and fire protection regulations must

be observed.

The log wood boiler is suitable for use with

air-dried split logs with no more than 20%

water content and wood briquettes. Use with

unsuitable fuels, especially refuse, coal and coke,

and also wet wood, is not permitted.

The combustion air must be free of aggressive

substances such as chlorine and fluorine

from solvents, cleaning agents, adhesives and

propellants, or ammonia from cleaning agents,

to prevent corrosion of the boiler and chimney.

Water is the intended heat-transfer medium. For

special anti-frost requirements, up to 30% glycol

may be added. Softened water is required for

the initial fill-up of the heating system and for

refilling after repairs. For the initial fill-up, the

value of 20,000 lt°dH for the system volume in

litres multiplied by the hardness (in degrees of

German hardness) may not be exceeded. The

pH value should be set between 8 and 9.

Addition of hard water should be minimised to

limit limescale build-up in the boiler. Set enough

shut-off valves to avoid bleeding large amounts of

water during repairs. Any leaks in the system must

be repaired at once.

Ensure a minimum return temperature of 60°C

to the boiler.

A safety valve (3 bar) as protection against excess

pressure and a thermal relief valve (95°C) to

protect against overheating must be installed by

the contractor.

To protect against air suction if the system cools

off, an expert must provide a sufficiently large

expansion tank or a pressure maintenance

system. Sufficient air venting must also be

ensured. Open expansion tanks or underfloor

heating with permeable piping also have a

high air intake, resulting in above-average boiler

corrosion. Corrosion damage to the boiler due to

improper air venting or high air intake is excluded

from warranty, guarantee and liability.

Operation at lower power than the lowest power

specified on the type plate is not permitted.

Only components provided by us may be used

for expansion of the control system, except for

commonly used units such as thermostats.

Cleaning and maintenance are required as

specified in the user manual.

Repairs are only permitted with spare parts

provided by us. The only exceptions are common

standardised parts such as electrical fuses or

fastening materials, as long as they possess

the required features and do not restrict the

functionality of the system.

5

2012-11

Conditions for warranty, guarantee, liability

SH Operation

Subject to technical alterations

We reserve the right to make technical

modifications without notice. Printing and

typesetting errors or changes of any kind made

in the interim are not cause for claims. Individual

configurations depicted or described here are only

optionally available. In the event of contradictions

between individual documents regarding delivery

scope, the information in our current price list

applies.

The installing contractor is liable for proper

installation according to the boiler's installation

instructions and the relevant rules and safety

regulations. If you as customer have installed

the heating system partly or entirely without

relevant training and in particular without

up-to-date practical experience, without having

the installation checked by a trained and

responsible expert, we exclude defects in our

delivery and consequential damages resulting

from this cause from our warranty, guarantee and

liability.

For repair of defects carried out by the

customer or by third parties, ETA only bears the

costs or remains obligated by warranty if this work

was approved in advance by the customer service

of ETA Heiztechnik GmbH.

6

www.eta.co.at

Emission measurement

Why measure emissions?

It is a requirement for the carbon monoxide (CO)

emissions of every boiler to be measured periodically. In Germany, this periodical measurement

must also include a dust measurement.

There are several aspects of this that could go

wrong, resulting in incorrect measurements even

though the boiler fully and consistently complies

with these limits when operating in accordance

with the relevant standards.

Boiler and flue tube must be cleaned thoroughly

3 days before measurement

The chimney sweep will contact the owner of

the boiler when the measurement is due to take

place. The boiler and the flue tube must be cleaned

thoroughly 3 days before the measurement takes

place. The remaining charcoal stays in the fuel

chamber.

Heat up the boiler after cleaning

After cleaning, the boiler must be heated up again.

This allows dust that was stirred up during cleaning

to settle.

Under no circumstances clean the boiler and flue

tube on the day of the measurement!

Cleaning on the day of measurement should be

avoided as the chimney sweep's measuring probe

would measure the unsettled dust, resulting in a

falsely high dust reading.

The buffer must be empty at the start of the

measurement

The boiler and the buffer should be shut down

before the measurement. This is best done the

night before to prevent the boiler from switching

to partial load during the emission measurement.

Use half-metre logs for the emission

measurement

For the emission measurement, split half-metre

logs are to be used, stacked as tightly as possible

in the boiler (no round logs). The fuel chamber

should be filled as full as possible and the burnthrough openings on the grate must remain free.

Heat up boiler 1-2 hours before measurement

Heat up the boiler 1-2 hours before the chimney

sweep's arrival.

Ensure sufficient heat consumption

Open all the radiator valves and turn the radiator

thermostats to maximum.

Close doors at 100°C exhaust gas temperature

At 100°C exhaust gas temperature, close the

ignition door and the insulation door. Do not

open any doors before and during the emission

measurement. Also, do not stoke the fire.

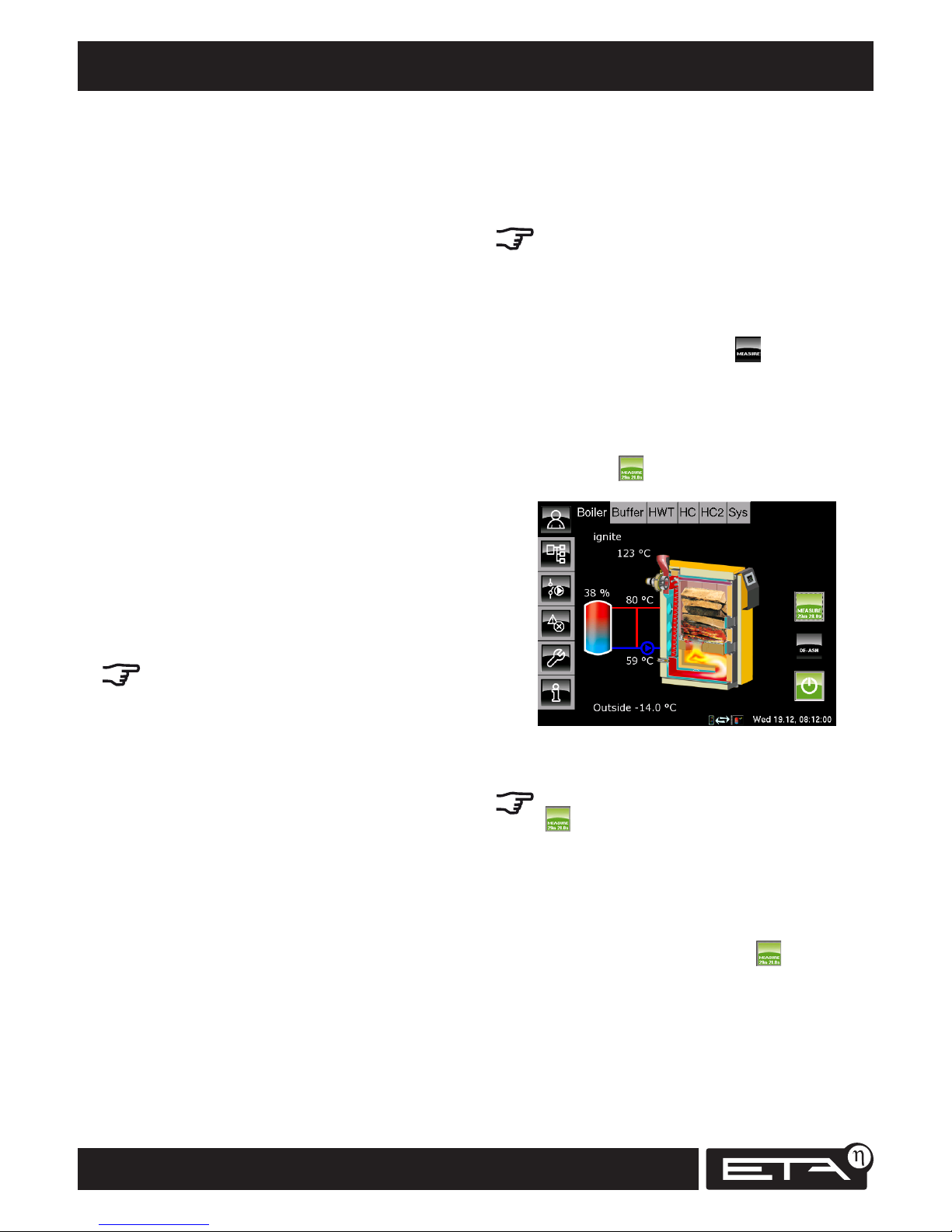

Switch boiler to emission measuring mode

In the boiler overview screen, tap . This

switches the boiler into emission measurement

mode and operates it for 30 minutes at full load.

The control system ensures that sufficient heat is

channelled to the buffer, the heating circuits and

the hot water tank. The button shines green and

a countdown for the emission measurement

mode is displayed.

Wait 10 minutes, then perform emission

measurement

Once emission measuring mode has been activated

( ), wait for 10 minutes until the boiler has

reached the required operating temperature and

stable combustion is ensured. Then carry out the

emission measurement.

After the measurement

After the measurement, emission measurement

mode can be deactivated by pressing again. If

this button is not pressed, the boiler will automatically switch back to normal mode after 30

minutes.

7

2012-11

Chimney renovation

SH Operation

Chimney renovation

With its controlled induced-draught fan and

adjustable minimum exhaust gas temperature,

your new boiler will largely adjust to existing flues

without the need for any special measures. Nevertheless, you should have the suitability of your flue

checked by a chimney sweep or chimney builder.

If the draught exceeds 30 Pa in very tall flues, a

draught-regulating damper is required.

Modern heating boilers are more efficient than

older ones and thus produce smaller amounts of

exhaust gas at considerably lower exhaust gas

temperatures.

Flues with "too large a cross-section" in particular

are no longer heated adequately. The moisture

contained in the exhaust gases condenses in the

flue and leads to very slow but inexorable destruction of old masonry chimneys.

Furthermore, if the diameter of the flue is too large,

the exit velocity and temperature are too low. The

exhaust gas does not have enough energy to rise

and, in extreme cases, the smoke can flow down

the roof.

If your flue does not have a water-resistant liner or

its diameter is too large, it will need to be renovated with the addition of a moisture-insensitive

inner lining. If the existing flue cross-section is

adequate, a ceramic liner that is also resistant to

chimney fires is preferable to a stainless steel liner

when burning wood.

In the case of short flues that are not resistant to

moisture, it may suffice to raise the lower limit

for the exhaust gas temperature to 180°C in the

boiler's control system. In addition an auxiliary

air damper will help to keep the flue dry. If these

measures are deemed satisfactory, the flue should

be inspected to check whether it actually remains

dry. This is best discussed with the chimney sweep.

Also keep in mind that chimneys have a limited

service life. Timely renovation before the chimney

wall has been destroyed can be performed quickly

and easily by inserting a tube. But if the flue gas

condensates have penetrated the mortar joints,

then the entire flue must be dismantled and

rebuilt.

8

www.eta.co.at

1

2

3

4

5

6

7

Boiler functionality

Wood gasification

Before wood can burn, it must first be converted

into gas by application of heat. From 100°C, the

moisture contained in the wood is driven off. From

200°C, the process of decomposition into 20%

charcoal and 80% wood gas, a mixture of carbon

dioxide, carbon monoxide, hydrogen, methane,

methanol, various phenols, acetone and acetic

acid begins. Gas is released from a temperature of

400°C. However, a temperature of at least 900°C

is required to fully break down phenols (wood tar)

into combustible carbon, carbon monoxide and

hydrogen; 1100°C is better. In addition to a high

temperature, breaking down complex compounds

into wood gas also requires time; this explains why

the gas flame of a wood fire lasts so long.

Large wood supply in the fuel chamber

At the base of the stack of wood in the fuel

chamber, a small gasification fire is maintained

through a controlled flow of air (primary air) (1).

The boiler's control system regulates the output

of the gasification fire via the flow of primary air

(2). The wood gas is drawn downwards into a hot

combustion chamber. This prevents the stack of

wood in the fuel chamber from undergoing uncontrolled gasification and starting to burn and makes

it possible to have a boiler with a large supply of

wood that burns slowly for a long time.

Mixing nozzle and complete turbulence

A mixing nozzle (3) is located between the fuel

chamber and the combustion chamber. Here

preheated combustion air (secondary air) is mixed

with the wood gas. The flame exiting the mixing

nozzle hits the hot bottom of the combustion

chamber with high velocity and experiences

further turbulence (4), ensuring that every bit

of combustible gas finds sufficient oxygen for

complete burnout.

Complete burnout in the glow zone

To achieve uncooled combustion at high temperatures, the patented glow-zone combustion

chamber is made from refractory brick and is also

thermally insulated (5). In this glow zone, the

flame has enough time at temperatures between

900°C and 1100°C to break down and burn the

very last of the resistant carbon rings (phenols)

from the lignin in the wood. This enables the log

boiler to go below the limit of 100 mg of carbon

monoxide in the exhaust gas per MJ of output.

9

2012-11

Boiler functionality

SH Operation

Induced-draught adjusts to the flue

Thanks to the induced draught concept, the entire

interior of the boiler is under a negative pressure.

This means that no smoke or low-temperature

carbonisation gases can escape from the boiler

regardless of the phase of operation. The induceddraught fan accommodates every flue, even those

with small cross-sections. Speed control and continuously adjustable dampers for combustion air

make draught limiters in the flue virtually unnecessary. Setting a minimum exhaust gas temperature prevents condensate formation in masonry

flues and allows the low-temperature capability of

modern flues to be fully utilised.

Turbulent heat exchanger with simple cleaning

The hot gas only enters the cold section of the

boiler following complete combustion. Once in the

cold section, it transfers its heat to the boiler water,

first while smoothly flowing through a long ash

collection duct (7) and then turbulently through

heat exchanger tubes equipped with turbulators.

The more turbulent the flow, the more the gas

comes into contact with the tube walls, thus

ensuring maximum transfer of heat to the boiler

water. This ensures low exhaust gas temperatures

and high efficiency. Pulling the cleaning lever

about 10 times prior to opening the boiler to refill

with fuel moves the turbulators up and down in

the heat exchanger tubes. The resulting fly ash

drops into the ash collecting duct, leaving the heat

exchanger clean.

Optimum fuel efficiency with lambda control

Gasification of the wood (output) can be controlled

via the flow of primary air. Through use of the

lambda-controlled secondary air (6), combustion

is kept clean and highly efficient. A lack of air

means there is not enough oxygen for complete

combustion. On the other hand, too much air

also results in incomplete combustion as it cools

the fire. Below 700°C, not all of the wood gas is

burned. Too much air also pulls unused heat out

of the boiler. The lambda probe ensures optimum

combustion and maximum fuel utilisation not only

with selected wood on the test stand, but also in

everyday operation.

10

www.eta.co.at

Checking water pressure, suitable fuel Star t-up

Suitable fuel

The firewood must be air-dry, i.e. it must have

dried for at least one year and have a water

content under 20%. We recommend using halfmetre split logs with an average diameter of 10

cm.

7 - 9 cm

13 - 16 cm

8 - 10 cm

12 - 15 cm

Boards may only be added between the logs and

in no case should they be included in the first layer

as they would block the burn-through opening in

the grate.

Small pieces of firewood may only be used for

heating if added as a minor component to the

primary fuel. The smaller the pieces of firewood,

the less of them should be added.

Wood briquettes measuring 6 cm to 10 cm in

diameter in compliance with ÖNORM M 7135;

Germany: 1.BimSchV 15 July 1988 Fuel Class 4.

Only one oversized log per boiler filling

Only 1 oversized split log or 1 stump can be placed

in the top layer, but no more. Complete burning

may require 2 combustion phases.

Unsuitable fuel

Wet fuel with a moisture content in excess of 20%

may not be burned as it results in condensation

which can lead to corrosion of the boiler's fuel

chamber walls. The following may not be burned:

rubbish, paper and cardboard (only for start-up),

wood dust from sanding, sawdust, wood chips

smaller than thumb-sized, coal and coke, and fuels

generally prohibited by local air quality regulations, such as railway sleepers, plastic-coated

plywood, impregnated wood etc.

Check water pressure

With a log boiler, it is no trouble to glance at the

pressure gauge daily or at least regularly. In houses

with up to three storeys, the water pressure in a

cold system should be between 1 and 2 bar, for a

warm system between 1.5 and 2.5 bar.

The most common defects in a heating system, i.e.

leaks and boiling over, result in a low water alert.

In the event of insufficient volume compensation,

water is released via the safety release valve. Either

the expansion tank is too small, the diaphragm

in the expansion tank is torn or a tap or valve

between the heating system and the expansion

tank was shut unintentionally. In this case, open

the valve or tap, remove the lever or hand wheel

and attach it to the valve with a wire.

Water will generally need to be added after the

radiators have been bled.

Minimum pressure

To establish the minimum pressure for a cold

heating system (especially when the buffer is also

cold from top to bottom), determine the height

of the space requiring heating above the heating

system's pressure gauge and add three metres. The

result is the minimum pressure in metres. Dividing

the metre value by ten gives you the minimum

pressure in bar, as shown on most pressure gauges.

Return temperature at least 60°C

The boiler return temperature should be at least

60°C to prevent corrosive condensation of flue

gases in the heat exchanger. The control system

monitors the return temperature. If the boiler

return temperature is too low, a warning appears

on the display.

11

2012-11

Star t-up Correct quantity of wood

SH Operation

Correct quantity of wood

When not much heating is needed only place a

small amount of wood in the boiler

Absorbing all the heat from a boiler fully loaded

with wood would require buffer storage tanks

larger than needed for winter operation and also

larger than those normally installed. When less

heat is required, i.e. for hot water in the summer,

or during the evening shortly before the night

set-back, only load the boiler with the amount of

wood actually needed.

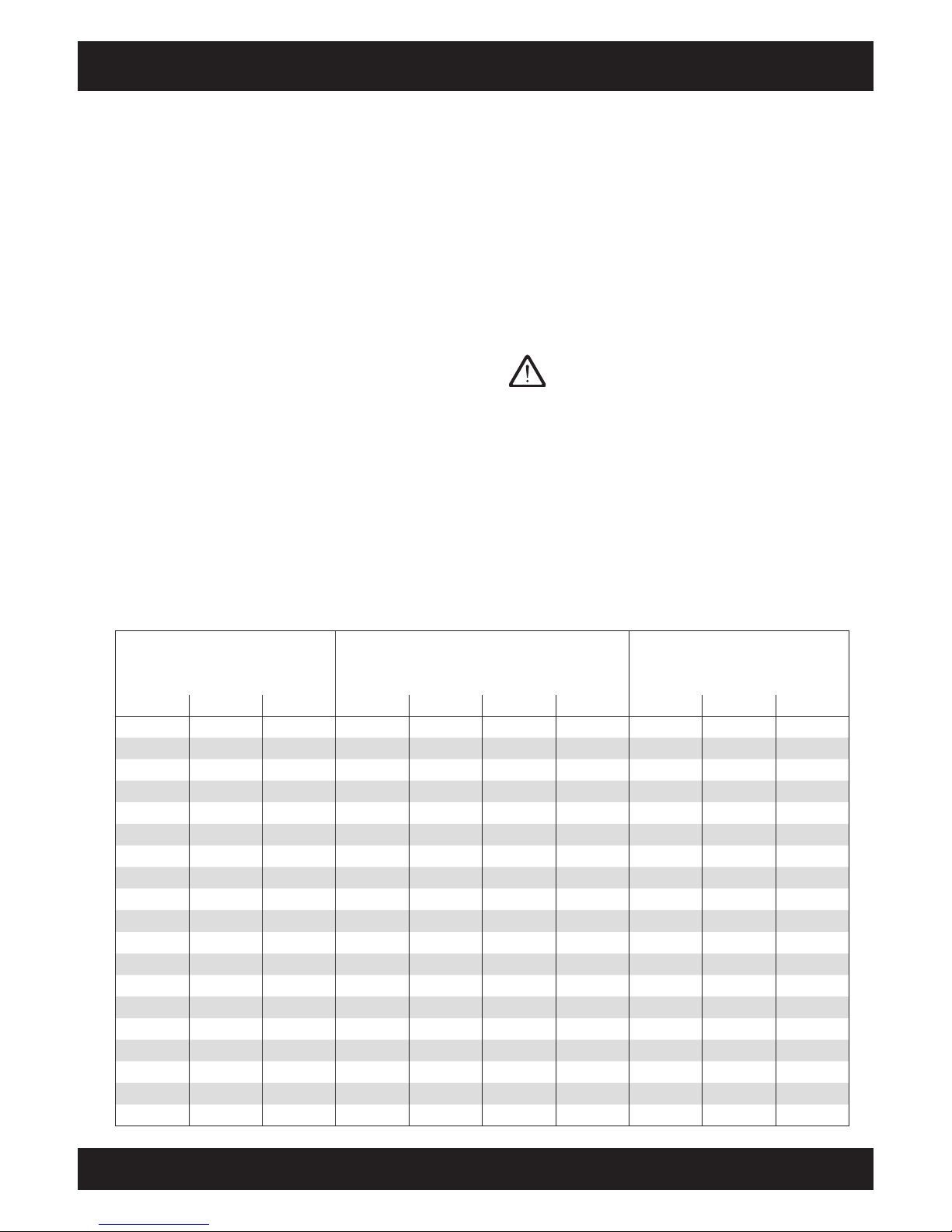

The table below displays the amount of wood

needed for summer operation for different boiler

sizes (= fuel chamber capacity), wood type, buffer

volume and buffer charging status. Bear in mind

that an "buffer top" temperature sensor that is

installed too low reduces the usable volume.

If the living space already needs some heating,

start with the amount of wood in indicated in

the table below. To establish the correct amount,

approach the fully charged buffer state slowly,

adding one or two more logs every heating

cycle. If too much wood is loaded, an emergency

shutdown of the boiler will occur. If the boiler

overheats, the flow of air is stopped. The fire

will go out, but the hot wood will continue to

smoulder for a while and the unburned wood gas

resulting from the lack of air will create tar deposits

in the boiler and flue. This happening once or

twice in an emergency is not a problem. However,

if this situation occurs every day, the boiler's heat

exchanger will become clogged with tar.

Note the energy density of the fuel

The energy content of 50 litres of wood briquettes

corresponds to 100 litres of beech wood or 150

litres of spruce.

Current buffer charging status is shown in

overview

The current buffer charging status in percent is

shown in the boiler [Boiler] and buffer [Buffer]

overviews. The buffer charging status is the

average of the three buffer temperatures (top,

middle, bottom) between 30°C (=0%) and 80°C

(=100%).

SH20, SH30 Buffer charging status SH40, SH50, SH60

Maximum fuel load Buffer size Maximum fuel load

Briquettes Beech Spruce 3,300 l 2,200 l 1,650 l 1,100 l Spruce Beech Briquettes

90% 85% 80% 70%

85% 78% 70% 55%

1/4 80% 70% 60% 40%

1/4 75% 63% 50% 25% 1/4

70% 55% 40% 10%

1/2 65% 48% 30% 0%

60% 40% 20% 1/4 1/8

55% 33% 10%

1/4 1/2 3/4 50% 25% 0% 1/2

45% 18%

40% 10%

Full 35% 0%

30%

3/4 25% 3/4 1/2 1/4

20%

15%

10%

5%

1/2 Full 0% Full

12

www.eta.co.at

Water pressure, heating lines, cleaning lever Start-up

Boiler start-up

Check water pressure

Before starting up, check the heating system's

water pressure (see also page 10). In houses

with up to three storeys, the water pressure in a

cold heating system should be between 1 and 2

bar, for a warm system between 1.5 and 2.5 bar.

Open heating lines

If the system is new or has been out of operation

for some time, verify whether the return riser

mixing valve is in "AUTO" position and all

shut-off valves in the heating lines are open.

Keep ball valves completely open to avoid ruining

the seals. Open valves by turning anti-clockwise,

and then turn back 1/4 turn from the fully open

position to relieve pressure on the valve stem.

Operate cleaning lever

With the insulation door still closed, clean the heat

exchanger by operating (10x) the cleaning lever

on the side.

10x

Afterwards, leave the lever pointing towards the

rear of the boiler. Then the turbulators remain in

position in the water-cooled heat exchanger.

Open insulation door, draught fan starts

automatically

When the insulating door is opened, the draught

fan starts automatically and the on/off button

in the boiler overview shines green. The operating

mode changes to "Insulation door open".

13

2012-11

Star t-up Buffer charging status

SH Operation

If the draught fan does not start, it has been

deactivated by the safety temperature limiter due

to boiler overheating and a corresponding warning

appears on the display. The safety temperature

limiter can be manually released as soon as the

boiler temperature has fallen below 70°C.

Open fuel chamber door

The draught fan must be running before the

fuel chamber door is opened so that any

combustion gas can be extracted from the fuel

chamber. If the boiler has not safely cooled, no

boiler doors may be opened without an operating

draught fan. A sudden inflow of air in the presence

of smouldering wood may result in an explosion.

Combustion chamber

door

Fuel chamber door

The fuel chamber door is always closed during

both start-up and heating operation. It is

opened only when ash is removed from the boiler.

Check fuel chamber

Use the poker to distribute ashes and charcoal

evenly throughout the fuel chamber. In the panels,

the two upper openings for primary air must

be free. Also, the 3 burn-through openings in

the grate must stay open so that the fire reaches

the combustion chamber during ignition.

Primary air openings

Burn-through openings

Check buffer charging status

Before starting the boiler, check the current buffer

charging status to avoid adding too much

wood. The table on page 11 shows how much

wood should be added. The buffer charging status

is shown in percent values in the boiler overview.

Pay particular attention to the different energy

densities of the fuels.

14

www.eta.co.at

Adding wood Start-up

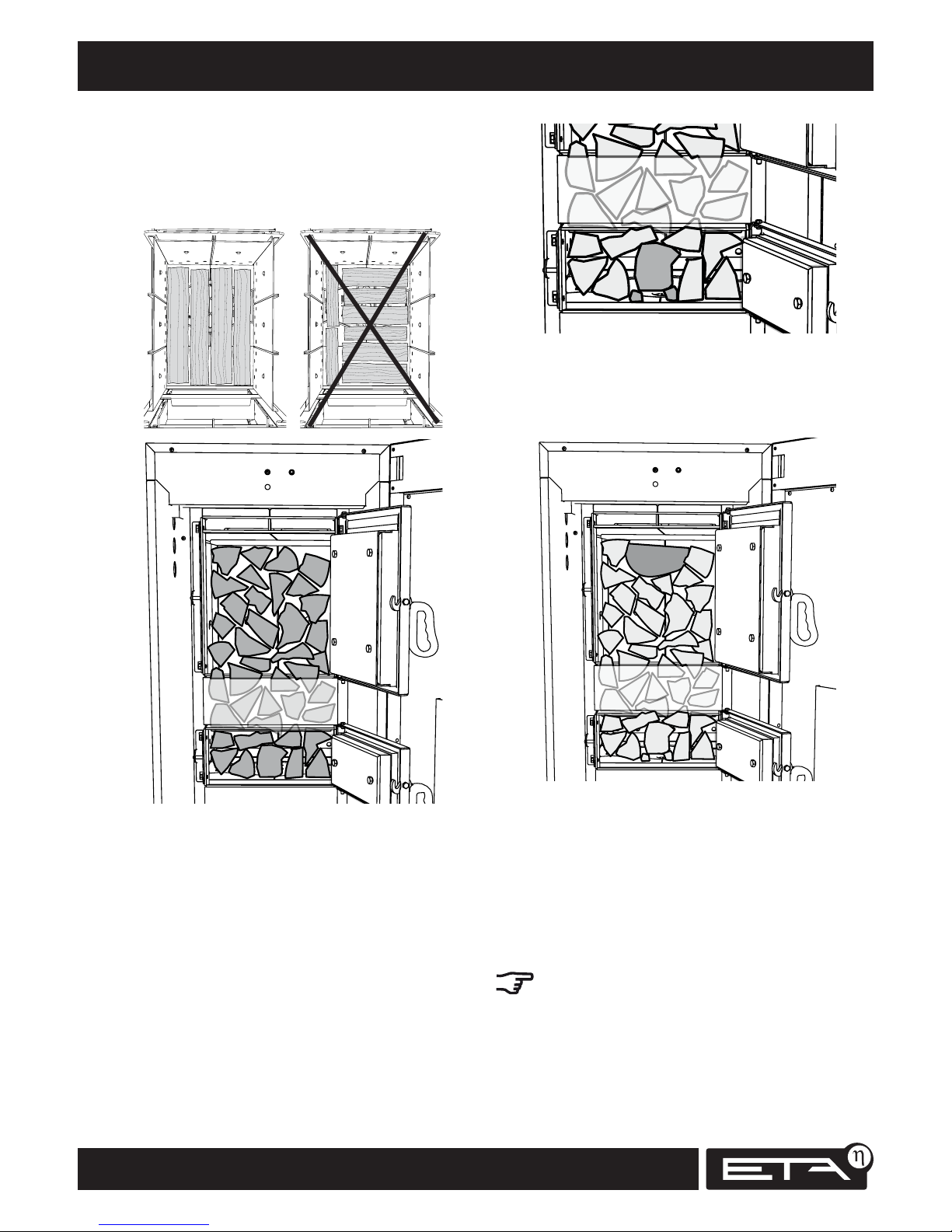

Place logs close together in fuel chamber

Add the required amount of closely spaced logs

to the fuel chamber. Stack the logs instead of

throwing them in at random. Always place the first

layer of logs lengthwise.

Adjust log over burn-through opening

Lift the bottom log above the burn-through

opening with the poker and place pieces of

charcoal (from the fuel chamber) or small pieces

of wood under it so that the burn-through

openings in the grate remain clear. To make

ignition easier, next to the log on the left and

right there should be a small gap separating it

from the neighbouring logs.

Place only 1 oversized log on top

Only 1 oversized split log or 1 stump can be placed

in the top layer, but no more. Two combustion

phases may be needed for complete burning.

Brushwood, coarse wood chips or carpentry

waste should be added only as a secondary fuel

among the split logs

First place half of the required amount of logs in

the fuel chamber (at least 3 layers). Then alternately add the secondary fuel (brushwood, coarse

wood chips or carpentry waste) and additional

logs.

The smaller the pieces of secondary fuel are,

the more logs must be added between them.

15

2012-11

Star t-up Ignition, closing doors

SH Operation

Under no circumstances should brushwood,

coarse wood chips or carpentry waste be used

for the bottom layer. Such fine material burns

too quickly, resulting in incomplete combustion in

the combustion chamber, which is still cold during

start-up. As a result, soot builds up in the heat

exchanger.

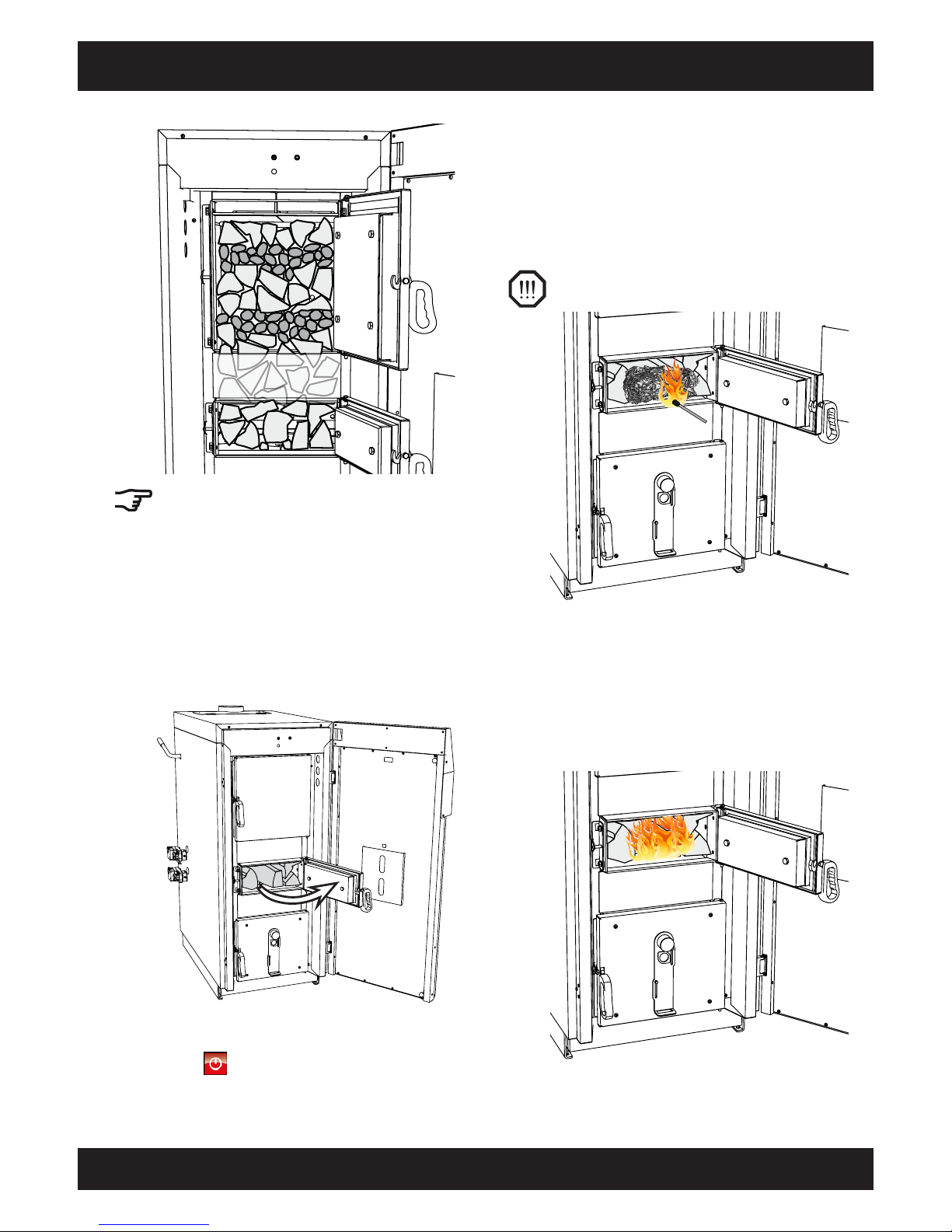

Close fuel chamber door, open ignition door

Close the fuel chamber door and then open the

ignition door.

If the boiler is not to be started up yet, close both

doors and in the boiler overview, press the on/off

button so that it shines red.

Ignite the fire with cardboard and newspaper

Place crumpled paper or a few pieces of cardboard

in front of the first layer of wood and ignite it.

The draught fan sucks the flame over the tightly

stacked logs, causing them to ignite more quickly.

For heavy, smooth hardwood, larger pieces of

kindling may be needed for ignition.

Never use petrol, turpentine or similar

materials as an "ignition aid": risk of explosion!

The ignition door should be kept open after

ignition to monitor the progress of the fire. It

should only be closed once the boiler's exhaust gas

temperature has reached 100°C. How long it takes

the fire to start depends on the type of wood used;

rough spruce may need only 2 minutes, smooth

beech may require 5 minutes until the required

exhaust gas temperature of 100°C is reached.

16

www.eta.co.at

Closing ignition and insulation doors Star t-up

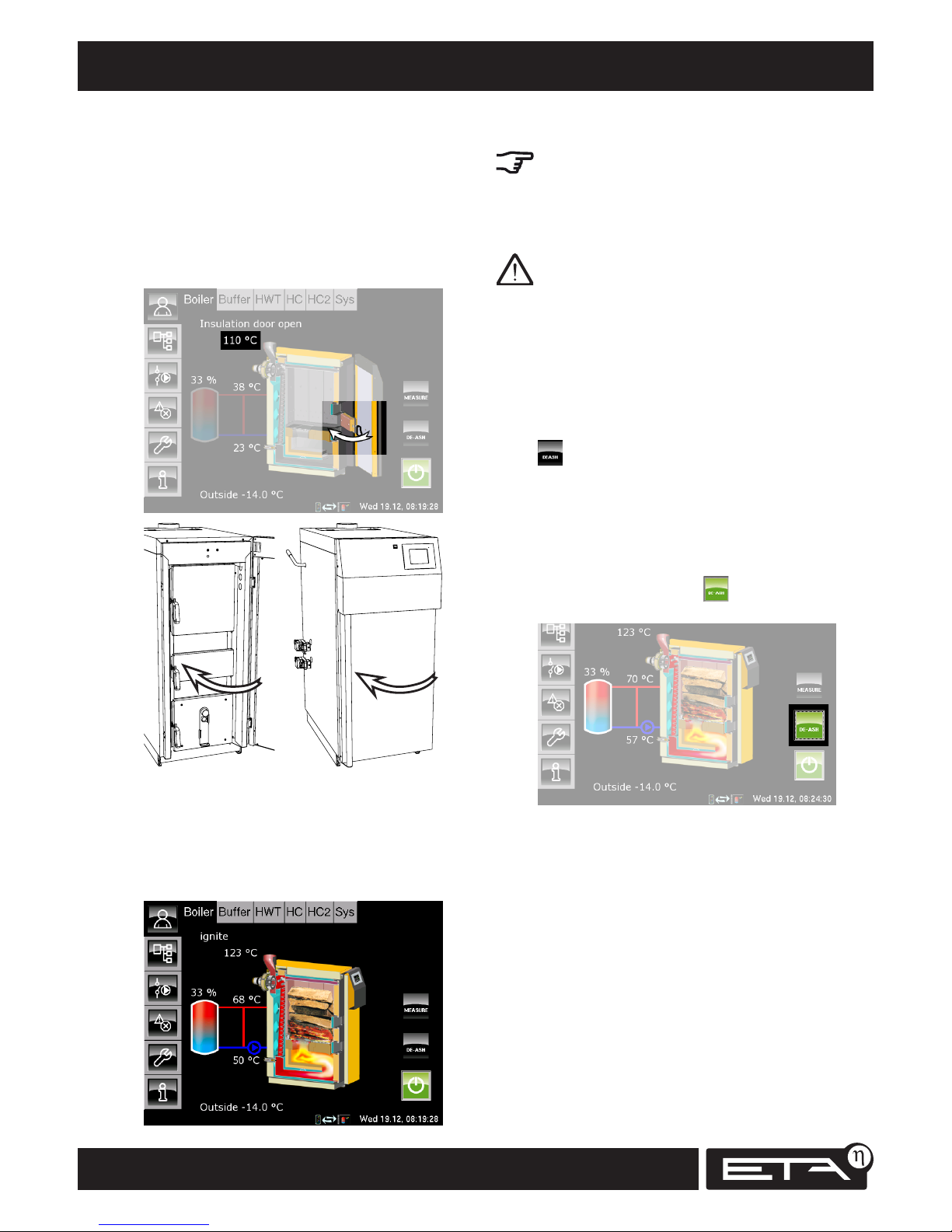

At 100°C exhaust gas temperature, close ignition

door and insulating door.

Once a few logs are burning well and the

exhaust gas temperature is over 100°C, close

the ignition door and the insulating door. The

exhaust gas temperature is displayed in the boiler

overview. At over 100°C, an arrow appears to

indicate that the ignition door should be closed.

When the insulating door is closed, the boiler

automatically switches to ignite mode and,

once the residual oxygen content is below 15%,

to heating mode. The boiler is now in heating

mode and regulates the combustion of the wood

independently.

Avoid opening boiler doors unnecessarily

Avoid opening the insulating door and the fuel

chamber door unnecessarily in heating mode.

That disrupts the boiler control and increases fuel

consumption. Also keep the ignition door and the

combustion chamber door closed.

Never open the insulating door and the fuel

chamber door when the boiler is in "Calibrating

lambda probe" or overtemperature mode.

Completion of heating mode with ember burnout

Once the wood in the boiler has been burned

(residual oxygen content below 15% for more than

5 minutes) or the exhaust gas temperature falls

below 80°C, the boiler automatically starts burnout

("Ember burnout" mode). If the de-ash button

was not pressed, the boiler frees the secondary air ducts of ash with fresh air. Charcoal and

embers remain in the boiler by design so that

newly added wood can be ignited more easily.

Complete ember burnout for cleaning

For cleaning after the last heating operation, in the

overview press the de-ash button (which

then shines green).

Ember retention is then deactivated and the boiler

performs a complete ember burnout (duration

~1 hour), burning most of the charcoal in the fuel

chamber to make subsequent cleaning of the boiler

easier.

17

2012-11

Star t-up Adding fuel

SH Operation

Adding fuel

You should only add fuel when the buffer

charging status is below 30% and the fuel

chamber has burned to empty.

If wood has been added and there are still embers

in the boiler, it automatically tries to ignite the

wood again. If the wood is hard to ignite and

there are only a few remaining embers, it may help

to push the charcoal together in the middle before

refilling. If the remaining embers do not ignite the

wood, light it with paper and cardboard through

the ignition door.

18

www.eta.co.at

Safety devices to prevent overheating Safety

Safety devices to prevent overheating

The following safety chain takes effect if the boiler

exceeds the operating temperature for any reason:

• over 87°C -> pump safety run

• over 90°C -> draught fan switched off

• over 95°C -> thermal emergency cooling valve

• over 105℃ -> safety temperature limiter

• over 3 bar water pressure -> safety valve

Pump safety run

If the boiler temperature exceeds 87°C (=factory

setting [Pump safety run]), the pump safety run

starts. All heating pumps and boiler pumps

that are connected to the boiler control are

switched on to dissipate heat from the boiler.

This action prevents the boiler temperature from

rising further and triggering further safety devices

such as the safety temperature limiter and thermal

emergency cooling valve. This emergency cooling is

indicated on the display by "heat dissipation".

The heat dissipation is limited with the

maximum flow temperature set in the

heating circuits and the hot water setpoint

temperature.

Boiler overheating

If 90°C boiler temperature (factory setting [Boiler

max.]) is reached, the control system switches

the draught fan off and a warning message

appears on the display. Reasons for a boiler temperature increase include:

• too much wood added (see page 11)

• heating circuits unexpectedly switched off

• heating pump failed

• heating line inadvertently shut off

Once the boiler temperature has fallen below 86°C,

heating resumes automatically.

During such emergency shutdowns the wood

continues to emit gas and the unburned wood

gas causes tar deposits in the boiler and

chimney.

Thermally actuated drain valve (to be supplied by

technician)

Independent of the other safety devices, the

thermal emergency cooling valve is non-electri-

cally triggered at boiler temperatures between

92°C and 97°C. The thermal emergency cooling

valve is opened by means of a sensor system

containing a liquid that expands when heated (no

electricity required). It causes the boiler's safety

heat exchanger to be flooded with drinking

water, dissipating the excess heat out of the boiler

into the sewer.

If the thermal emergency cooling valve activates

frequently, check whether it activates at a

temperature below 92°C and replace it if necessary.

Safety temperature limiter

For additional safety against boiler overheating, a

safety temperature limiter is built into the boiler.

When a boiler temperature of 105°C (tolerance

100°C to 106°C) is reached, the power supply to

the draught fan is switched off.

If the boiler temperature falls below 70°C, the

safety temperature limiter can be manually reset.

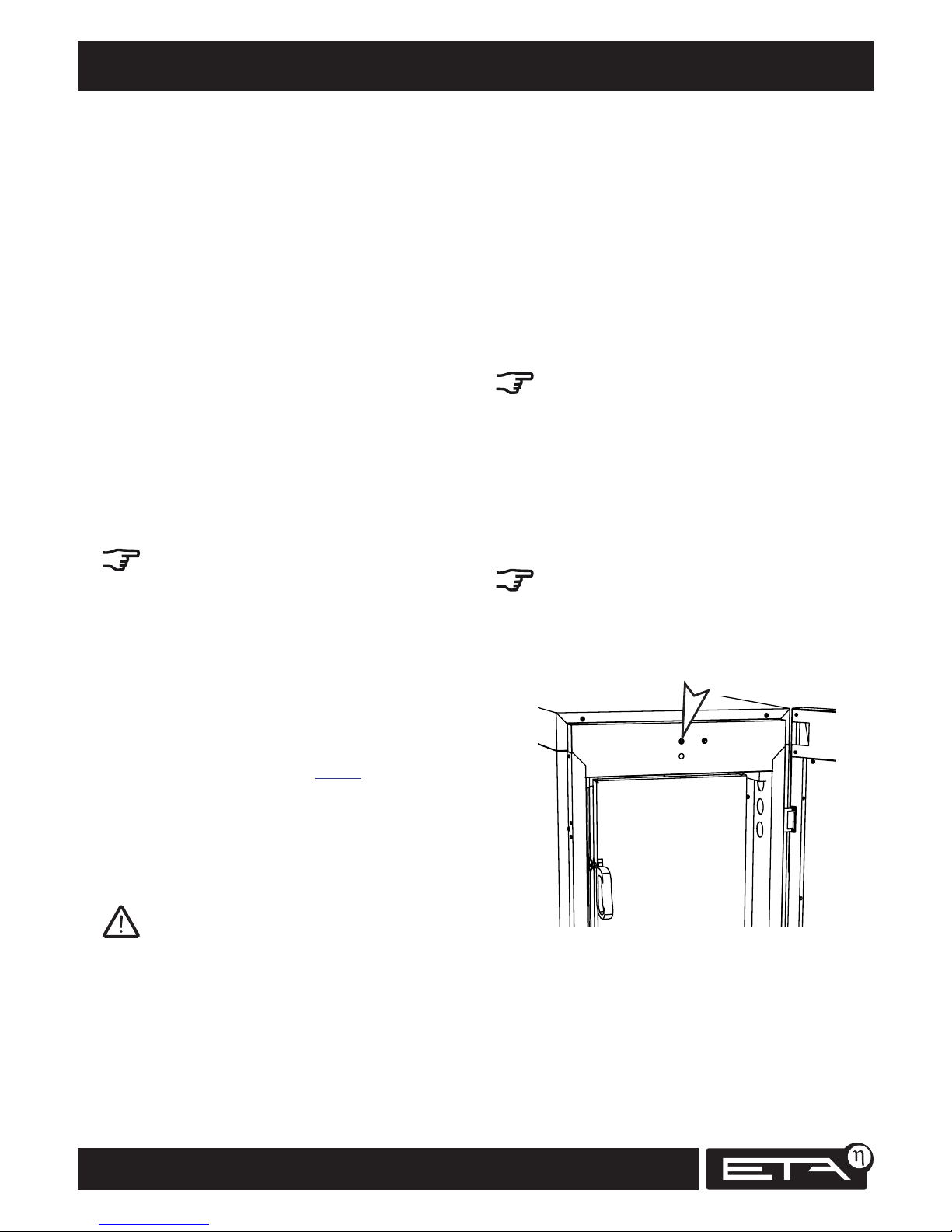

The reset button is recessed into the door frame

above the fuel chamber door. To reset, press it

deeply into the recess.

Safety temperature limiter

Safety valve against excess pressure (to be

supplied by technician)

The most common cause of safety valve activation

is either an undersized expansion tank or heating

lines that have been shut off. The safety valve also

serves as a backup safety device to prevent boiler

overheating in the event that all other devices in

the safety chain fail.

19

2012-11

Safety Safety devices to prevent overheating

SH Operation

The safety valve must be installed in the flow

line right where it leaves the boiler, as it cannot

dissipate any heat if installed in the return line.

In rare cases when neither the thermal emer-

gency cooling valve nor the safety temperature

limiter trips, the pressure and temperature will

increase until the safety valve opens. If this occurs,

it is crucial to check that the thermal emergency

cooling valve and the safety temperature limiter

are working properly. If cold water is drawn from

an on-premises well with its own pump, a power

failure may be the reason for failure of the thermal

emergency cooling valve. If this occurs frequently,

a larger air chamber in the building's water supply

or a separate air chamber for the thermal emergency cooling valve is required.

20

www.eta.co.at

Overview of activities Maintenance

Regular cleaning and servicing

To ensure that the boiler operates optimally and

reliably, it must be cleaned and serviced at regular

intervals.

Maintenance and cleaning of the boiler must be

performed within the specified periods (see table).

Cleaning and maintenance overview

The table provides an overview of the required

cleaning and maintenance.

The "To be done by" column indicates which

activities you as customer can deal with and which

must be performed by an expert.

Activity

Frequency

To be done by

Every 1 - 2

weeks

Annual

maintenance

Every

3 years

Operate cleaning lever X X X Customer

Check water pressure X X X Customer

De-ash boiler X X X Customer

Check walls of ash collection duct X X X Customer

Check safety valves and thermal emergency cooling valve X X X Customer

Clean casing and display X X X Customer

Remove ash behind panels X X Customer

Clean primary and secondary air duct X X Customer

Check and clean flue tube X X Customer

Clean heat exchanger box X X Customer

Check turbulators for tar deposits X X Customer

Clean draught fan X X Customer

Check safety valves X X Customer

Check door seals X X Customer

Check safety devices X Expert

Clean the lambda probe X Expert

Inspect seal on heat exchanger cover X Expert

Perform emission measurement X Expert

Calibrate lambda probe X Expert

Perform heating test X Expert

Reset maintenance counter X Expert

Loading...

Loading...