Page 1

Confidential

Service manual

TM-U675/U675P

(with autocutter)

Issued Date , ,

Issued by

EPSON

English

401239100

Page 2

Confidential

TM-U675/U675P (with autocutter) Service Manual

CONFIDENTIALITY AGREEMENT

BY USING THIS DOCUMENT, YOU AGREE TO ABIDE BY THE TERMS OF THIS AGREEMENT. PLEASE RETURN

THIS DOCUMENT IMMEDIATELY IF YOU DO NOT AGREE TO THESE TERMS.

❏ This document contains confidential, proprietary information of Seiko Epson Corporation or its affiliates. You

must keep such information confidential. If the user is a business entity or organization, you must limit disclosure

to those of your employees, agents, and contractors who have a need to know and who are also bound by

obligations of confidentiality.

❏ On the earlier of (a) termination of your relationship with Seiko Epson, or (b) Seiko Epson’s request, you must

stop using the confidential information. You must then return or destroy the information, as directed by Seiko

Epson.

❏ If a court, arbitrator, government agency, or the like orders you to disclose any confidential information, you must

immediately notify Seiko Epson. You agree to give Seiko Epson reasonable cooperation and assistance in the

negotiation.

❏ You may use confidential information only for the purpose of operating or servicing the products to which the

document relates, unless you obtain the prior written consent of Seiko Epson for some other use.

❏ Seiko Epson warrants that it has the right to disclose the confidential information. SEIKO EPSON MAKES NO

OTHER WARRANTIES CONCERNING THE CONFIDENTIAL INFORMATION OR ANY OTHER

INFORMATION IN THE DOCUMENT, INCLUDING (WITHOUT LIMITATION) ANY WARRANTY OF TITLE

OR NON-INFRINGEMENT. Seiko Epson has no liability for loss or damage arising from or relating to your use of

or reliance on the information in the document.

❏ You may not reproduce, store, or transmit the confidential information in any form or by any means (electronic,

mechanical, photocopying, recording, or otherwise) without the prior written permission of Seiko Epson.

❏ Your obligations under this Agreement are in addition to any other legal obligations. Seiko Epson does not waive

any right under this Agreement by failing to exercise it. The laws of Japan apply to this Agreement.

Cautions

❏ No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation.

❏ The contents of this document are subject to change without notice. Please contact us for the latest information.

❏ While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties

for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or

abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.)

failure to strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options

or any consumable products other than those designated as Original EPSON Products or EPSON Approved

Products by Seiko Epson Corporation.

®

EPSON

and ESC/POS® are registered trademarks of Seiko Epson Corporation

Rev. A i

Page 3

Confidential

Contents

Confidentiality Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

For Safe Repair and Maintenance Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Key to Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety Precautions on Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety Precautions on Maintenance/Repair/Inspection . . . . . . . . . . . . . . . . . vii

Note on Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Modular Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Aim of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Manual Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1

Before Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Diagnosing Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Symptoms and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer Mechanism Power on Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Opening and Closing the Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Detecting the Head Carriage Home Position . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Feeding Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Starting and Stopping Self Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Printing Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

MICR Reader Test (Only with Printers that Have a MICR Unit) . . . . . . . . . . 1-7

Troubleshooting Using the ERROR LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Test Points on the Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Test Points on the Main Circuit Board Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Locations of the Main Elements on the Main Circuit Board Unit . . . . . . . . . . . . . . 1-14

Procedures for Replacing the Print Head Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Removing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Paper Jams in the Autocutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Paper Jams in the Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Paper Jams in the Slip Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Detector Functions and Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Chapter 2

Before Assembly and Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

About this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Assembling the Mechanism Assembly (M-U675) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Pre-assembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Assembly of the Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Assembling the TM-U675/U675P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-94

Pre-assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-94

Assembly of the TM-U675 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

Troubleshooting

Assembly and Disassembly

Chapter 3

Before Adjusting and Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Phase Adjusting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Adjusting the Platen Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Setting Threshold Values for Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Adjusting and Setting

ii Rev. A

Page 4

Confidential

TM-U675/U675P (with autocutter) Service Manual

Appendix A

Appendix B

Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

MICR Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Cleaning Sheet Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Procedures for Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Appendix C

Connecting to the Host PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Connecting the Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Connecting to a Direct Connection Display Module . . . . . . . . . . . . . . . . . . . . . . . . C-3

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Appendix D

Component Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Outline of Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Printing Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Detection Mechanism Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Roll Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-15

Slip Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-25

Validation Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-29

Ribbon Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-29

MICR Mechanism (Factory Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-31

Cutter Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-34

Autocutter Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-34

Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-35

Cutter Blade Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-36

Clutch Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-36

Autocutter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-36

Cutter Blade Knobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-37

Emergency Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-38

Outline of Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-39

Connection of Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-39

Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-40

Memory Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-41

Main Circuit Board Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-42

CPU and Peripheral Logic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-44

Slip Mechanism Drive Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-55

Input Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-66

Control Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-69

Malfunction Protective Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-70

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-71

Important Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-72

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-73

Serial Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-73

Parallel Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-75

Outline of Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-76

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-76

Printer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-77

Service Tools and Lubricants

Maintenance

Installation

Product Overview

Rev. A iii

Page 5

Confidential

MICR Reader (Factory Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-78

Autocutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-78

Overall Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-79

Interface Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-80

Appendix E

Alphanumeric List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Reference Number List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-10

Appendix F

TM-U675/U675P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Autocutter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Mechanism Assembly (without MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Mechanism Assembly (with MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Frame Assembly (without MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Frame Assembly (with MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Carriage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7

PF Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8

MICR Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

Appendix G

TM-U675/U675P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Autocutter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Mechanism Assembly (without MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

Mechanism Assembly (with MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-4

Frame Assembly (without MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Frame Assembly (with MICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-6

Carriage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

PF Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

MICR Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-9

Parts List

Exploded Diagrams

General Lubrication Point Diagrams

Appendix H

Main Circuit Board Assembly (Outline) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

Main Circuit Board Assembly (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-2

Main Circuit Board Assembly (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-3

Main Circuit Board Assembly (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-4

Main Circuit Board Assembly (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-5

Main Circuit Board Assembly (MICR I/F Block) . . . . . . . . . . . . . . . . . . . . . . . H-6

Main Circuit Board Assembly (Memory Block) . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-7

Appendix I

Using the Power Switch Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Opening the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-2

Opening and Closing the Roll Paper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-2

Opening the Roll Paper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-2

Closing the Roll Paper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

Installing or Replacing the Paper Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

Removing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-7

Installing the Ribbon Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-8

Inserting Slip Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-10

Inserting Validaton Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-10

Reading MICR Characters On Personal Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-11

Adjusting the Roll Paper Near End Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-12

Using the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-13

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-13

Circuit Board Unit Circuit Diagrams

Printer Handling

iv Rev. A

Page 6

Confidential

Control Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-13

TM-U675/U675P (with autocutter) Service Manual

Appendix J

Appendix K

Main Circuit Board Unit (Parts Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K-1

Main Circuit Board Unit (Solder Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K-2

Screw Types

Parts Layout

Rev. A v

Page 7

Confidential

For Safe Repair and Maintenance Work

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read

the following carefully before handling the product.

WARNING:

You must follow warnings carefully to avoid serious bodily injury.

CAUTION:

Observe cautions to avoid minor injury to your self, damage to your equipment, or loss

of data.

Note:

Notes have important information and useful tips on the operation of your equipment.

Safety Precautions on Handling

This section presents important information intended to ensure safe and effective use of this

product. Please read this section carefully and store it in an accessible location.

WARNING:

Shut down your equipment immediately if it produces smoke, a strange odor, or unusual

noise. Continued use may lead to fire or electric shock. Immediately unplug the

equipment.

Only disassemble this product as described in this manual. Do not make modifications to

the unit. Tampering with this product may result in injury, fire, or electric shock.

Be sure to use the specified power source. Connection to an improper power source

may cause fire or shock.

Never insert or disconnect the power plug with wet hands. Doing so may result in severe

shock.

Do not allow foreign matter to fall into the equipment. Penetration by foreign objects

may lead to fire or shock.

If water or other liquid spills into this equipment, unplug the power cord immediately.

Continued usage may lead to fire or shock.

Do not place multiple loads on the power outlet (wall outlet). Overloading the outlet

may lead to fire.

vi Rev. A

Page 8

Confidential

Always supply power directly from a standard domestic power outlet.

Handle the power cord with care. Improper handling may lead to fire or shock.

Do not modify or attempt to repair the cord.

Do not place any object on top of the cord.

Avoid excessive bending, twisting, and pulling.

Do not place cord near heating equipment.

Check that the plug is clean before plugging it in.

Be sure to push the prongs all the way in.

TM-U675/U675P (with autocutter) Service Manual

CAUTION:

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage and burning.

Be sure to set this equipment on a firm, stable, horizontal surface. Product may break or

cause injury if it falls.

Do not use in locations subject to high humidity or dust levels. Excessive humidity and

dust may cause equipment damage, fire, or shock.

Do not place heavy objects on top of this product. Never stand or lean on this product.

Equipment may fall or collapse, causing breakage and possible injury.

To ensure safety, please unplug this product prior to leaving it unused for an extended

period.

Do not touch the print head or the paper feed motor. Wait for the head and the motor

to cool. The head and the motor can be very hot after printing for a long time. Touching

them may cause burns.

Safety Precautions on Maintenance/Repair/Inspection

WARNING:

Be sure to use the designated type of fuse for the circuit board. Use of a different type

may result in fire.

Remove the power cord and all other cables from this product before disassembly or

reassembly to prevent electrical shock.

To prevent the possibility of electrical shock, do not perform maintenance, repair, or

inspection during a thunder storm.

Rev. A vii

Page 9

Confidential

CAUTION:

Wear a grounded wrist band when handling the internal circuit boards to prevent

damage from static electricity.

When removing an internal circuit board, place it on an anti-static rubber sheet or

similar surface to prevent damage from static electricity.

Parts on the circuit board may become hot during operation. Therefore, wait

approximately 10 minutes after turning the power off before touching them.

Be careful not to subject the circuit boards to shock or vibration, because this may

damage them.

Do not touch the circuit board or cable terminals with your hands to prevent

contamination that may result in a malfunction.

Do not use an alcohol, benzine, thinner, trichloroethylene, or ketone-based solvent to

clean the parts. This type of solvent may damage the plastic and rubber parts.

Wipe off any dirt with a dry or slightly moist cloth. Be sure to remove the power cord

from the outlet at this time.

Note on Disposal

Note:

Be sure to follow current laws or regulations when disposing of the product.

Modular Connector

The following label is visible near the two modular connectors on the back of this product.

Use the modular connectors specifically designed for the cash drawer and customer display for

this product. Do not connect these connectors to an ordinary telephone line.

viii Rev. A

Page 10

Confidential

TM-U675/U675P (with autocutter) Service Manual

About This Manual

Aim of the Manual

This manual was created to provide the information on printer maintenance and repair required

by technicians who handle this work.

Manual Content

The manual is made up of the following sections:

Chapter 1 Troubleshooting

Chapter 2 Assembly and Disassembly

Chapter 3 Adjusting and Setting

Appendix A Service Tools and

Lubricants

Appendix B Maintenance

Appendix C Installation

Appendix D Product Overview

Appendix E Parts List

Appendix F Exploded Diagrams

Appendix G General Lubrication

Point Diagrams

Describes troubleshooting procedures (specific

problems and remedies)

Describes product assembly and disassembly

Describes product adjustment and setting

procedures

Describes tools and lubricants required to

perform maintenance and repair

Describes required procedures to perform

maintenance and inspection

Describes installation procedures

Provides reference information for maintenance

and inspection

Contains a list of spare parts

Disassembly diagrams for the product

Lubrication point diagrams for this product

Appendix H Circuit Board Unit Circuit

Diagrams

Appendix I Printer Handling

Appendix J Screw types

Appendix K Parts layout

Rev. A ix

Circuit diagrams for the product

Describes required handling procedures when

performing maintenance and repair

Describes screw types

Describes parts layout

Page 11

Confidential

x Rev. A

Page 12

Confidential

TM-U675/U675P (with autocutter) Service Manual

Chapter 1

Troubleshooting

Before Servicing

The beginning of this manual (pages vi to viii) provides precautions you should observe to

perform work safely and the necessary information to service this product safely. Always read

that information before starting your work.

Diagnosing Failures

Use one of the following methods to diagnose the area where a failure occurred.

❏ See Table 1-1 for diagnosing the area where a failure occurred by the symptom of the

problem.

❏ See Table 1-2 on page 1-9 for diagnosing the area where a failure occurred from the ERROR

LED code.

❏ See Table 1-4 on page 1-12 when the failure is on the main circuit board unit.

Note:

The explanation of how to use the self test is on page 1-6.

The explanation of power on self checks is on page 1-4.

Symptoms and Solutions

This explains how to find the source of a problem using the symptom. The numbers in the

Solutions column indicate the order to use to check the problem. If you cannot determine the

cause of the problem after checking the first item, proceed to the next number.

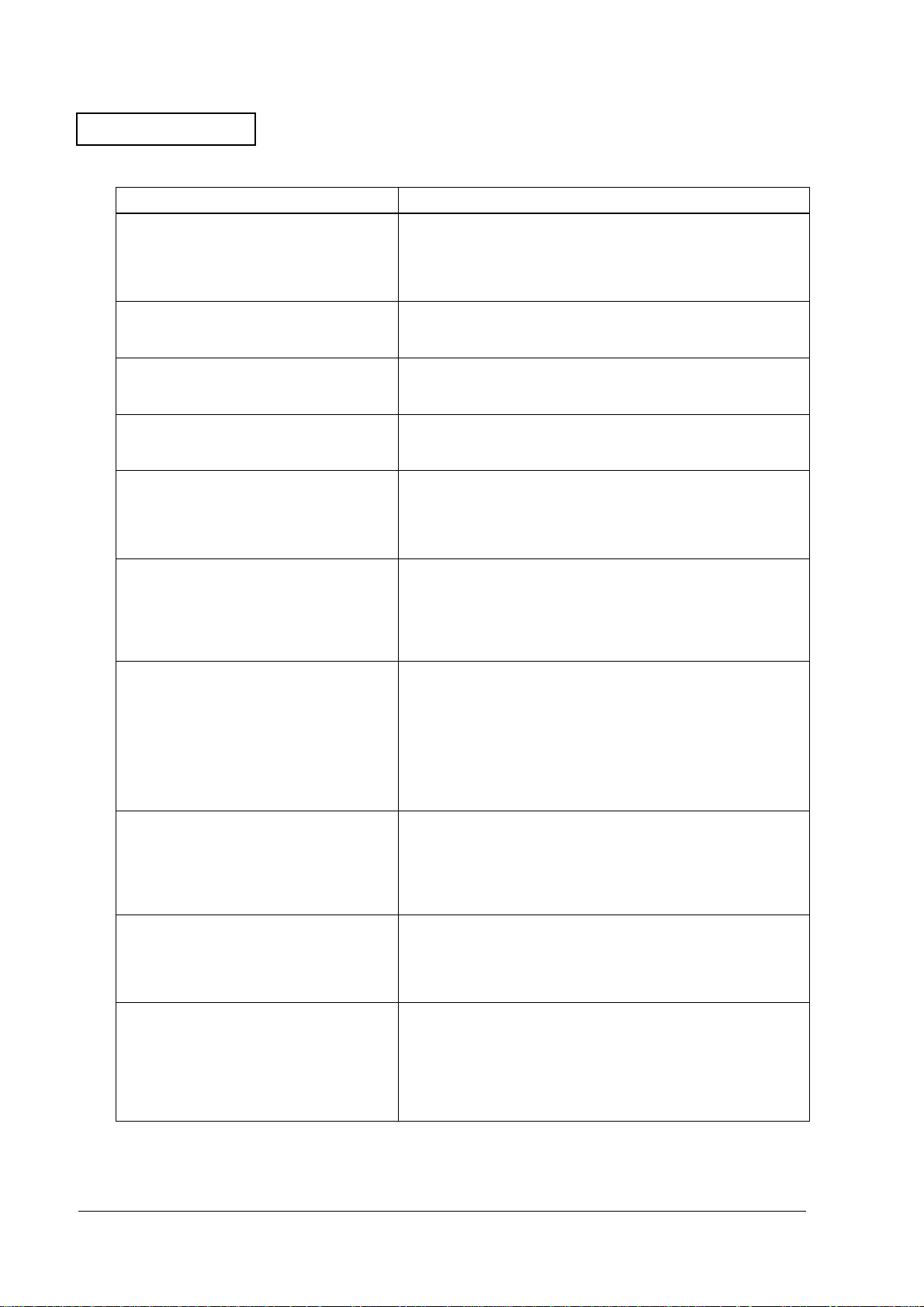

Table1-1 Symptoms and Checkpoint

Symptom Checkpoints (by Priority)

Power does not turn on.

Power on self check is not completed.

Or, POWER LED does not light.

There are missing dots in the print. 1. Replace the print head unit. (See page 1-15.)

1. Check the power supply unit. Check that 24V is coming out of

the power supply.

2. Check the main circuit board unit. (See page 1-12.)

3. Unplug the printer. Then unplug each motor or coil's connector

from the main board one by one; plug the printer back in, and

power it on. This will let you know if any motor or coil has burned

out and is pulling down the power. (See page 1-11.)

4. Replace the I/F circuit board. (See page 2-129.)

2. Replace the main circuit board unit. (See page 2-96.)

The print is thin. 1. Replace the ribbon cassette. (See page I-8.)

2. Proceed to “Ribbon won’t feed” below.

Rev. A Troubleshooting 1-1

Page 13

Confidential

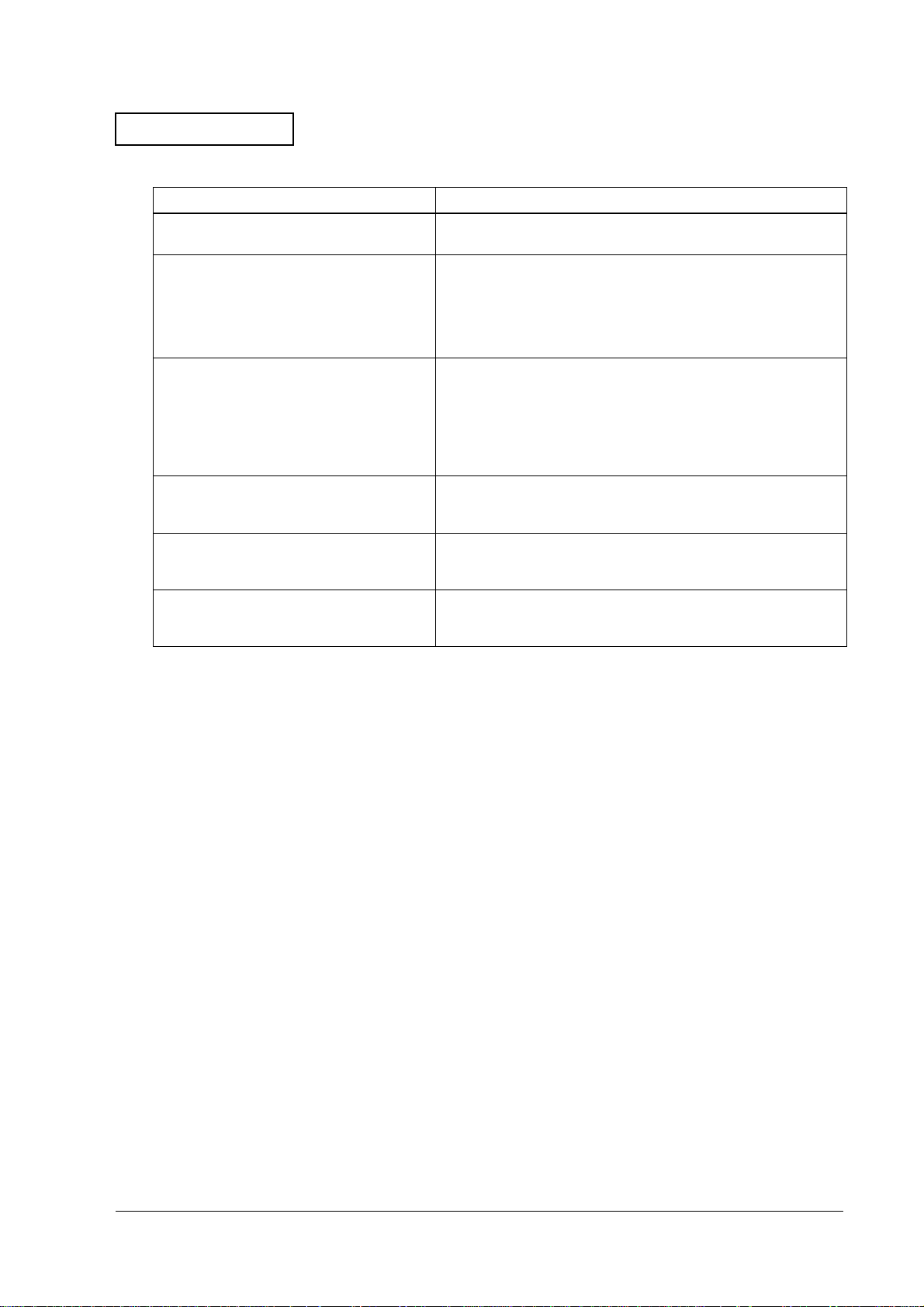

Table1-1 Symptoms and Checkpoint

Symptom Checkpoints (by Priority)

Ribbon won’t feed. 1. Replace the ribbon cassette. (See page I-8.)

2. Check sprocket and gears for paper particles.

3. Check the carriage motor and gears. (See page 1-11.)

4. Replace the main circuit board. (See page 2-96.)

Unevenness occurs in the concentration of

the print.

There is ink smudging on the print surface. 1. Check for paper residue around the print head unit.

Paper jams Remove the jammed paper by following the directions in

Roll paper feed failure 1. Check that the roll paper is inserted correctly. (See page I-3.)

Slip paper/validation paper feed failure 1. Check that the slip paper/validation paper is inserted correctly.

Roll paper take-up failure 1. Check that the roll paper is inserted correctly. (See page I-3.)

1. Replace the ribbon cassette. (See page I-8.)

2. Adjust the platen gap. (See page 3-8.)

2. Adjust the platen gap. (See page 3-8.)

“Removing Paper Jams” on page 1-19.

2. Check the paper feed motor. (See page 1-11.)

3. Check the J/S change solenoid. (See page 1-11.)

4. Replace the main circuit board unit. (See page 2-96.)

(See page I-10)

2. Check the paper feed motor. (See page 1-11.)

3. Check the J/S change solenoid. (See page 1-11.)

4. Replace the main circuit board unit. (See page 2-96.)

2. Check that the take-up assembly is installed correctly into the

printer. (See page I-6.)

3. Check that the take-up belt is attached correctly.

(See page 2-112.)

4. Check the paper feed motor. (See page 1-11.)

5. Check the J/S change solenoid. (See page 1-11.)

6. Replace the main circuit board. (See page 2-96.)

The printer won’t recognize when slip paper

is inserted.

The printer won’t recognize when validation

paper is inserted.

Roll paper semi-auto loading paper feed

failure

1. Clean away dirt around the slip B. O. F. detector assembly or the

slip T. O. F. detector assembly. (See page B-2.)

2. Replace the slip B. O. F. detector assembly. (See page 2-63.)

3. Replace the slip T. O. F. detector assembly. (See page 2-77.)

4. Replace the main circuit board unit. (See page 2-96.)

1. Clean away dirt around the validation detector assembly. (See

page B-2.)

2. Replace the validation detector assembly. (See page 2-63.)

3. Replace the main circuit board unit. (See page 2-96.)

1. Check that the roll paper is inserted correctly. (See page I-3.)

2. Remove paper residue and dirt from the inside the paper feed

frame assembly.

3. Check the paper feed motor. (See page 1-11.)

4. Check the J/S change solenoid. (See page 1-11.)

5. Replace the main circuit board unit. (See page 2-96.)

1-2 Troubleshooting Rev. A

Page 14

Confidential

TM-U675/U675P (with autocutter) Service Manual

Table1-1 Symptoms and Checkpoint

Symptom Checkpoints (by Priority)

Drawer kick operation failure 1. Replace the main circuit board unit. (See page 2-96.)

Display module display failure 1. Check that the unit is a serial model. (The display module will

MICR reading failure 1. Clean the MICR head. (See page B-3.)

Missing characters/misprinted characters/

font breakdown

ERROR LED is lit.

(When it is flashing, see page 1-9.)

Autocutter does not work 1. Check the cutter motor assembly. (See page 1-11.)

not work on parallel models.)

2. Check that DIP switch 2-2 is set to ON. (If it is OFF, the display

module will not work.)

3. Replace the main circuit board unit. (See page 2-96.)

2. Replace the MICR head. (See page 2-9.)

3. Replace the MICR fixing and MICR fixing sheet.

(See page 2-10)

4. Replace the MICR solenoid. (See page 2-12.)

5. Replace the main circuit board unit. (See page 2-96.)

1. Check the settings of the DIP switches. (See page D-73.)

2. Replace the interface cable. (See page C-1.)

1. Close the front cover or roll paper cover (rear cover).

2. Replace with new roll paper. (See page I-3.)

2. Replace the main circuit board unit. (See page 2-96.)

Rev. A Troubleshooting 1-3

Page 15

Confidential

Printer Mechanism Power on Checks

The printer mechanism runs through the following tests when you turn on the power supply to

the printer.

❏ Opens and closes the platen.

❏ Detects carriage home position.

❏ Feeds roll paper to the printer.

This section describes the items that you can check visually.

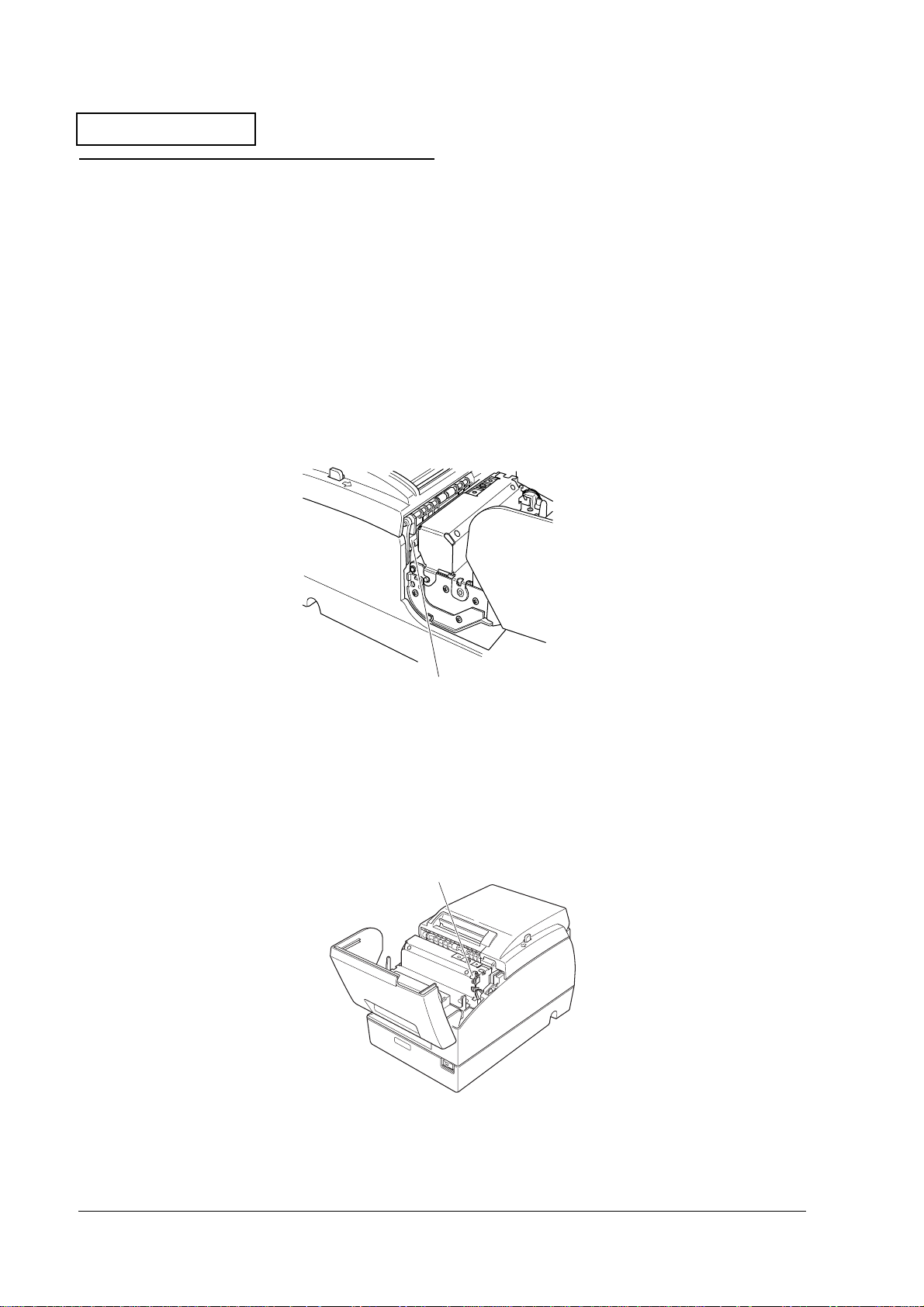

Opening and Closing the Platen

The printer opens and closes the platen once. Check this operation with the front cover opened.

check for the platen open and

close operation

Figure 1-1 Opening and closing the platen

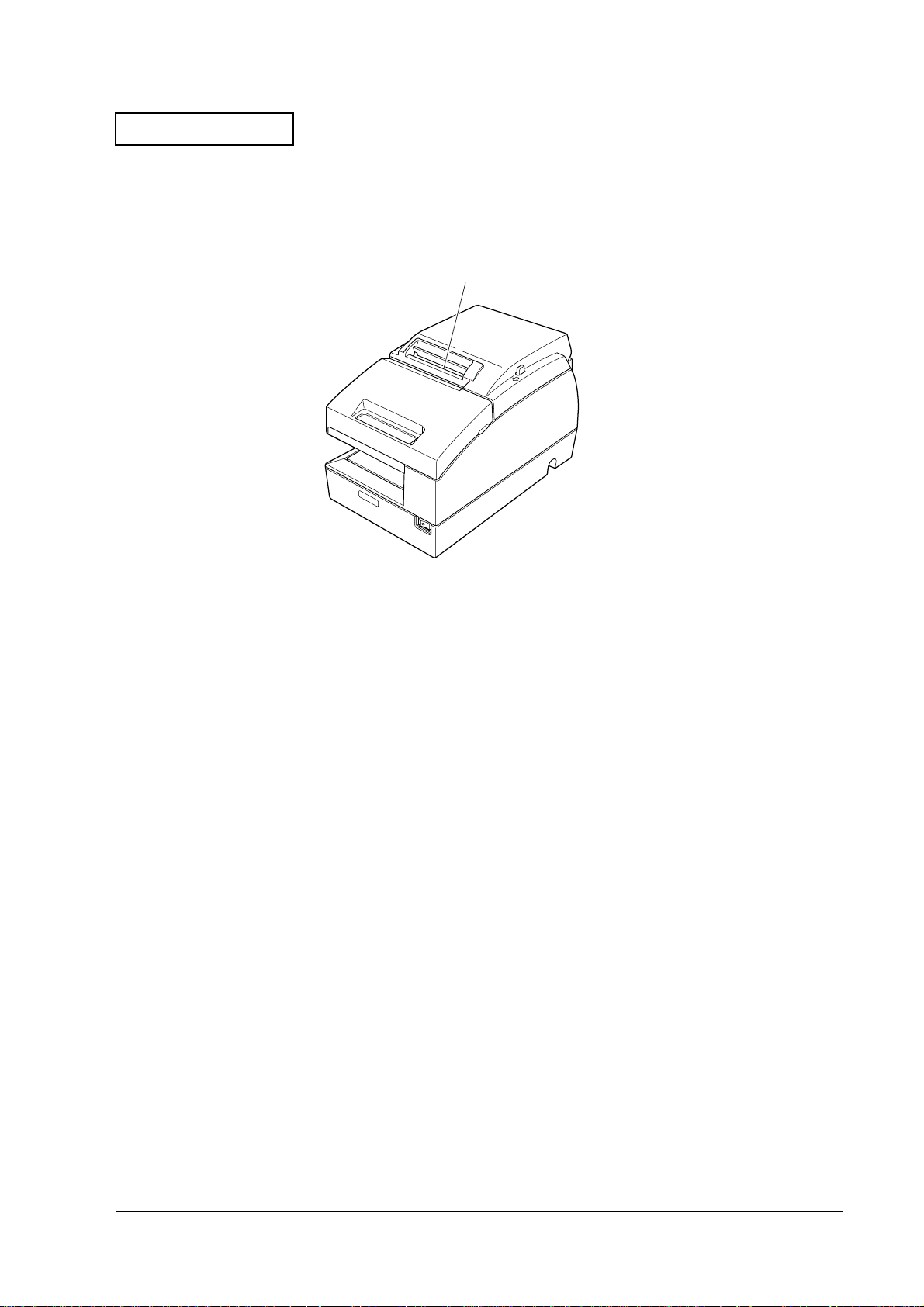

Detecting the Head Carriage Home Position

The head carriage on a dot impact printer moves to the left side (home position) once and then

to the right side before stopping. Check this operation with the front cover opened.

check for head carriage

movement

Figure 1-2 Detecting the head carriage home position

1-4 Troubleshooting Rev. A

Page 16

Confidential

TM-U675/U675P (with autocutter) Service Manual

Feeding Roll Paper

Roll paper is fed 1 to 2 mm. You cannot see this if the roll paper is not inserted.

check for paper feed

Figure 1-3 Feeding roll paper

Rev. A Troubleshooting 1-5

Page 17

Confidential

Starting and Stopping Self Tests

Printing Tests

Starting the Tests

❏ Roll paper self test:

The printer starts printing on the roll paper when you turn on the power while holding

down the receipt FEED button when all the covers are closed.

operate the autocutter to cut the receipt.

❏ Slip paper self test:

The SLIP LED flashes and the printer enters the slip paper wait mode when you turn on the

power while holding down the RELEASE button when all the covers are closed. Printing

starts on the slip paper when you insert a slip of paper in the printer.

❏ Validation paper self test:

Turn on the power supply while holding down the FEED and the RELEASE buttons while

the cover is closed. The SLIP LED flashes and the printer enters the validation paper wait

status. In this state, printing begins on the validation paper when you insert validation

paper.

After printing is completed,

Test Wait Mode

❏ Roll paper self test:

After the test print is completed, the printer enters the self test wait mode. The PAPER OUT

LED flashes after printing "SELF-TEST printing. Please press PAPER FEED button."

Test printing starts when you press the receipt paper FEED button.

❏ Slip paper self test:

When the printer status print is completed, the printer ejects the slip and waits for the next

slip of paper. Test printing starts when you insert a slip of paper in the printer.

❏ Validation paper self test:

When the printer has ejected the validation paper, you can insert the next validation sheet

and printing continues.

Ending the Test

The printer prints "***completed***" and the test ends when the determined number of lines

have been printed. The printer enters the normal mode after the power on tests are

completed.

After printing to the paper roll, operate the autocutter to cut the receipt

.

1-6 Troubleshooting Rev. A

Page 18

Confidential

TM-U675/U675P (with autocutter) Service Manual

MICR Reader Test (Only with Printers that Have a MICR Unit)

1. Load the roll paper in the printer.

2. Turn off the power supply to the printer.

3. Open the roll paper cover.

4. Press the RELEASE button while turning on the power supply.

5. Press the RELEASE button seven times.

6. Close the roll paper cover.

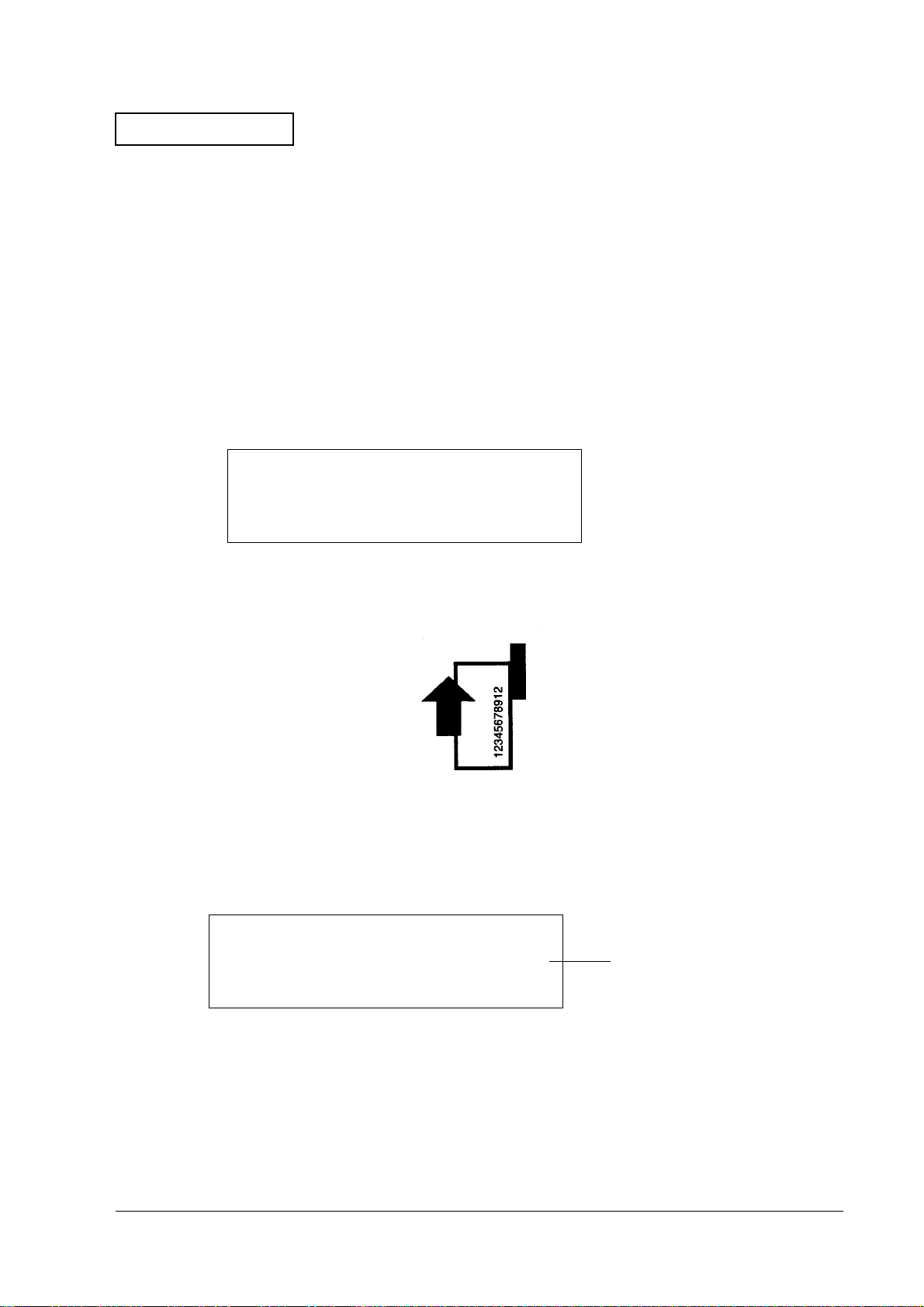

7. The following message is printed on the roll paper. The SLIP LED flashes.

**** RECOGNITION MODE ****

Please set check.

8. Insert check paper into the printer. Insert so that the MICR characters are facing upward on

one side of the paper insertion slot. The printer will run a test to read the check.

9. After reading is completed, remove the check. The printer prints the check data on the roll

paper.

<Example Printing> With E13B Font Check Paper

??????????? ?? ?? ?? ?? ????? ????

T012345678T 90 12 34 56 78900 1234

Data that was read

(lower line).

Rev. A Troubleshooting 1-7

Page 19

Confidential

<Example Printing> With CMC7 Font Check Paper

=0000066 =123456789012^ 210987654321/

???????? ?????????????? ?????????????

10. Verify that the check was read correctly. You can continue running the test by inserting

more checks.

11. When you have finished the test, turn off the power supply to the printer.

Data that was read

(lower line).

1-8 Troubleshooting Rev. A

Page 20

Confidential

TM-U675/U675P (with autocutter) Service Manual

Troubleshooting Using the ERROR LED

You can learn the cause of a failure by checking the ERROR LED code. The following table

shows problems and solutions to repair the printer. Numbers in the "Solutions" column indicate

the order to use to check the problem. If you cannot determine the cause of the problem after

checking all the solutions listed, go back to the flowchart given earlier in this chapter.

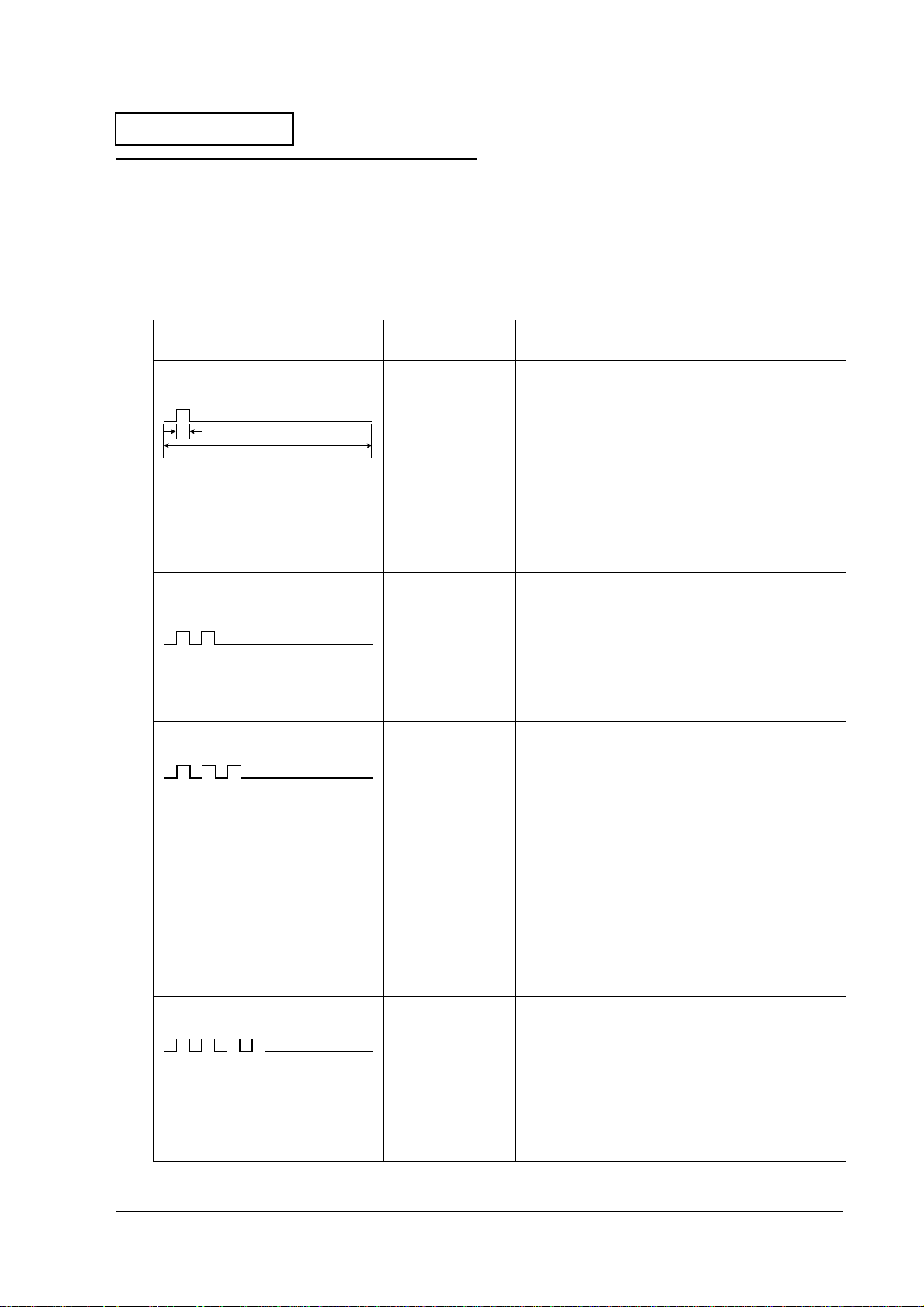

Table1-2 Error causes and solutions

Type of Error and ERROR LED Pattern Explanation

Autocutter Error An autocutter error

LED ON

320ms

5120ms

Carriage home position detection

error

was detected.

The head carriage

home position was

not correctly

detected.

Solutions

(Listed in the order you should use to check printer)

1. Check for paper jams around the autocutter. (See

page 1-19.)

2. Check the cutter motor assembly. (See page 1-11.)

If there has been a short in the cutter motor

assembly, replace the main circuit board unit at

the same time. (See page 2-96.)

3. Replace the main circuit board unit and see if the

problem is fixed. (See page 2-96.)

If the printer is repaired, refer to Test Points on the

Main Circuit Board Unit (See page 1-12.) to analyze

the defective areas on the board.

1. Check the carriage assembly for a paper jam.

(To remove the carriage cover, see page 1-16.)

2. Check for paper dust on the H.P. detector

assembly. (To remove the carriage cover, see

page 1-16.)

Carriage out-of-step error There is no carriage

detector output

even when the

carriage is

instructed to move.

Slip eject error The slip paper was

not ejected

normally.

3. Replace the H.P. detector assembly. (See page 2-

22.)

1. Check the carriage assembly for a paper jam.

(To remove the carriage cover, see page 1-16.)

2. Check the rotary encoder on the carriage motor

gear used to detect carriage position (The rotary

encoder is on the intermediate circuit board

assembly. You need to disassemble the

intermediate circuit board assembly to check the

encoder. To remove the intermediate circuit

board assembly, see page 2-22.)

3. Check the carriage motor. (See page 1-11.)

If the motor is shorted, replace it along with the

main board.

4. Replace the main circuit board unit and see if the

problem is fixed. (See page 2-96)

1. Look into the printer from the left side to check for

a paper jam in the slip paper transport path.

2. Check the paper feed motor. (See page 1-11)

If the motor is shorted, replace it along with the

main board.

3. Try installing a new main circuit board unit to see if

the printer is fixed. (See page 2-96)

Rev. A Troubleshooting 1-9

Page 21

Confidential

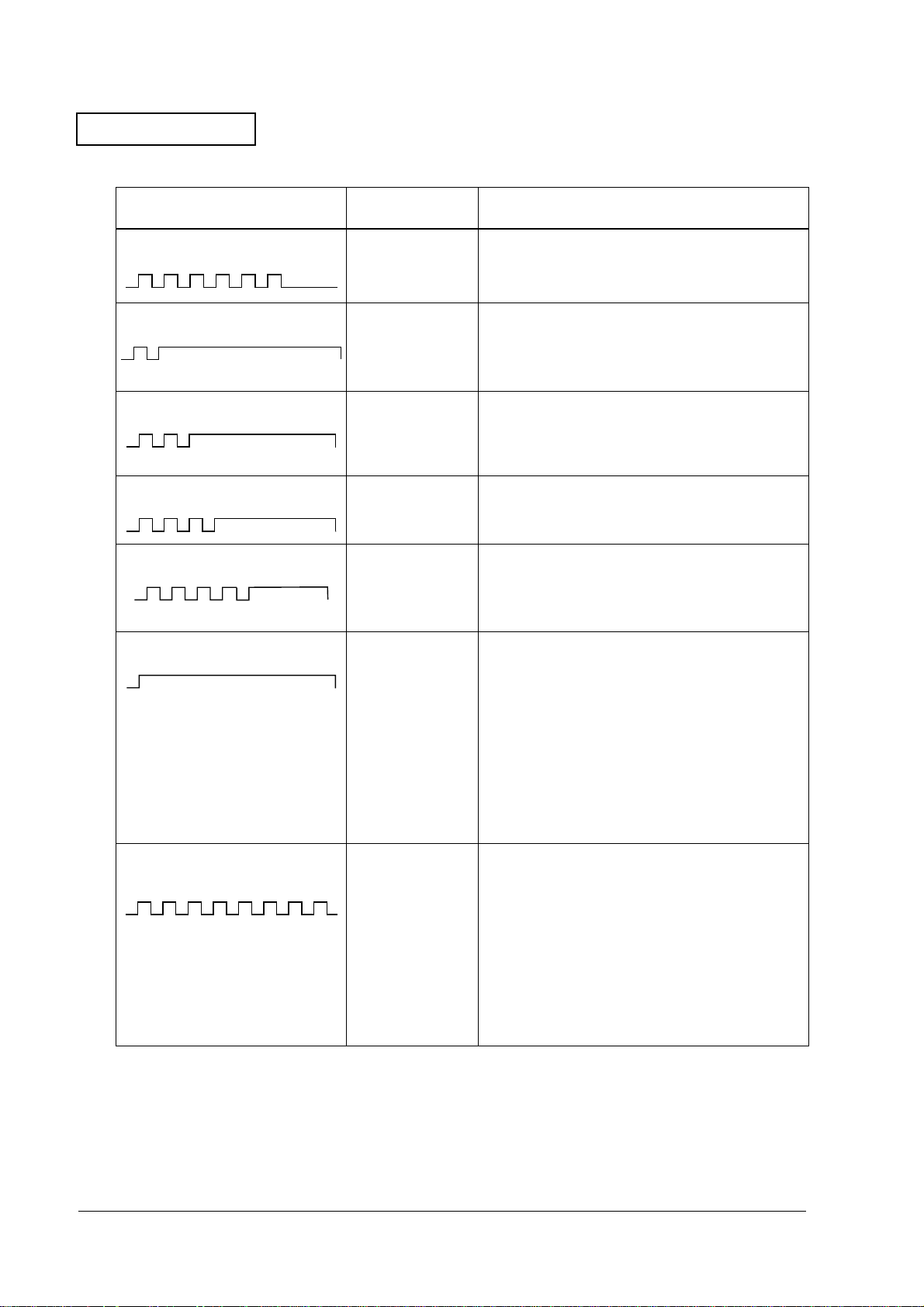

Table1-2 Error causes and solutions

Type of Error and ERROR LED Pattern Explanation

Roll paper cover open error The roll paper cover

(rear cover) was

detected as open

when printing.

Solutions

(Listed in the order you should use to check printer)

Close the roll paper cover (rear cover).

Memory or gate array R/W error The R/W check did

not operate

properly for the

memory or the

gate array.

High voltage error The power supply

voltage is high.

Low voltage error The power supply

voltage is low

CPU execution error An abnormal CPU

Drive circuit error One of the

operation was

detected, or the I/F

board is

disconnected.

following was

detected.

❏

Print head

thermistor

detection error

❏

Lever drive motor

assembly error

Replace the main circuit board unit to see if the

printer is repaired. (See page 2-96.)

Replace the power supply unit to see if the printer is

repaired. (See page C-4.)

Replace the power supply unit to see if the printer is

repaired. (See page C-4.)

1. Check whether the I/F board is connected.

2. Replace the main circuit board unit to see if the

printer is repaired. (See page 2-96.)

1. Check if the printer is repaired after replacing the

print head unit. (See page 1-15.)

2. Check the resistance of the lever drive motor

assembly. (See page 1-11.) Replace if shorted.

3. Check if the printer is repaired after replacing the

lever motor T. P. detector assembly. (See page 2-

78.)

4. Check if the printer is repaired after replacing the

main circuit board unit. (See page 2-96.)

Head high temperature error/roll

paper error

One of the

following problems

has occurred.

❏

The roll paper

has been

inserted into the

path wrong.

❏

The print head

temperature is

high.

1. If the error has occurred after loading the roll

paper, the roll paper has been inserted into the

path wrong. Reinstall the roll paper.

2. If the error occurred during printing, a high head

temperature has been detected. This error may

occur if you print continuously for too long. Leave

the printer as it is. The error will be automatically

cleared when the temperature has decreased. If

this error occurs frequently, check if the ambient

temperature is within specifications.

1-10 Troubleshooting Rev. A

Page 22

Confidential

TM-U675/U675P (with autocutter) Service Manual

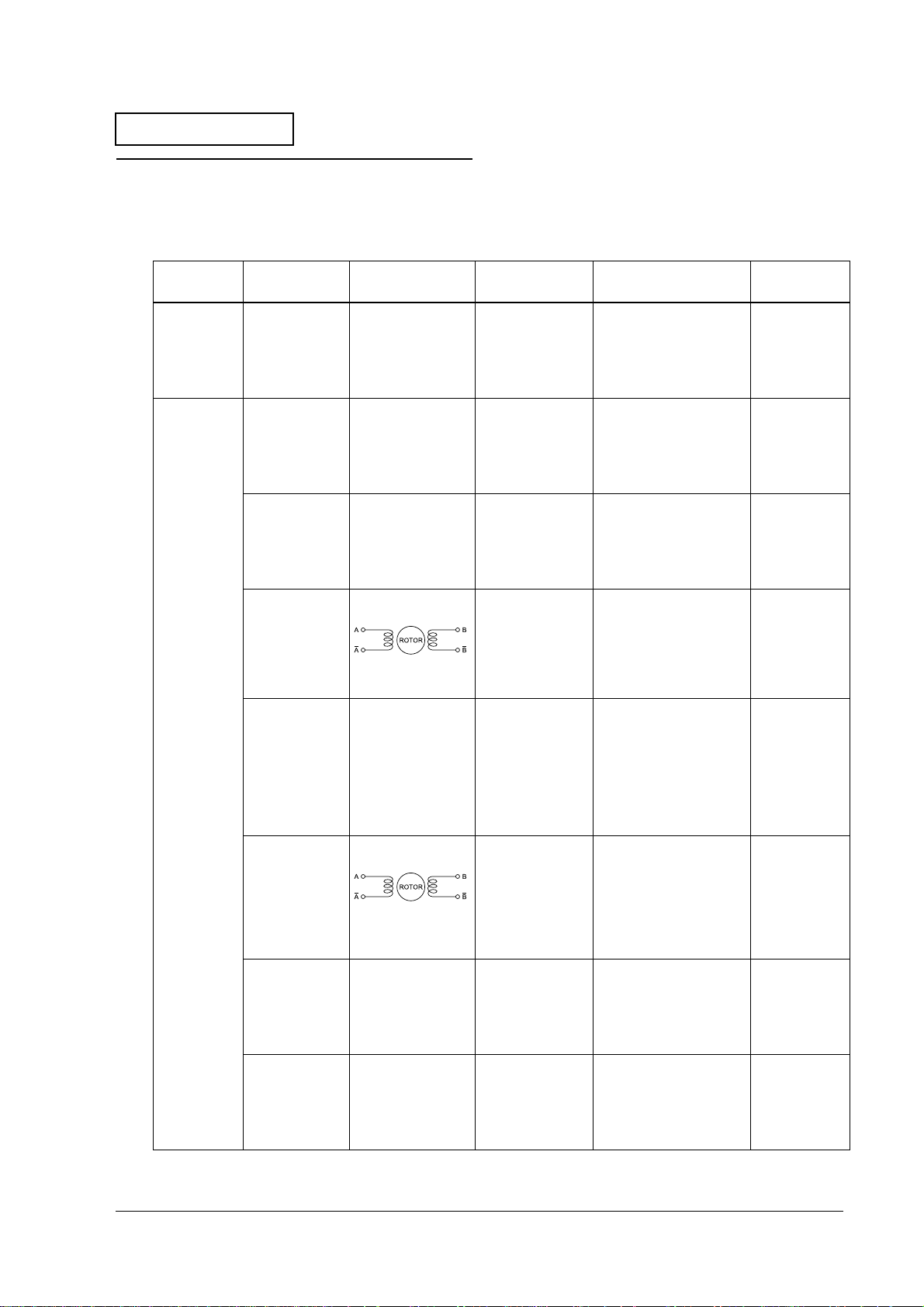

Test Points on the Printer Mechanism

This section shows how to test the motor and the coils.

Table1-3 Test points on the printer mechanism

Name of

Mechanism Part Name Internal Element Function Where to Check Normal Status

Autocutter

unit

Mechanism

assembly

(M-U675)

Cutter motor

assembly

Lever drive coil

A (left side

when facing

the front of the

printer)

Lever drive coil

B (right side

when facing

the front of the

printer)

Carriage motor 4 phase stepping

Lever drive

motor assembly

Paper feed

motor

J/S change

solenoid

MICR solenoid Coil MICR hold drive Remove the cable

DC brush motor Autocutter drive Remove the cable

Coil • Form stopper

Coil • Platen open

motor

DC brush motor • Form stopper

4 phase stepping

motor

Coil Change of

operation

• Slip paper roller

(sub) operation

and close.

• Cylindrical

printer platen

open and close

Head carriage

drive

operation

• Slip paper roller

(sub) operation

• Platen open

and close

• Endorsement

printer platen

open and close

Slip paper feed Remove the cable

journal paper

drive/slip paper

drive.

connector connected

to CN7 on the main

circuit board unit and

test between pin 1 and

pin 2.

Remove the cable

connector connected

to CN30 on the main

circuit board unit and

test between pin 26

and pin 27.

Remove the cable

connector connected

to CN30 on the main

circuit board unit and

test between pin 26

and pin 28.

Remove the cable

connector connected

to CN30 on the main

circuit board unit and

test between pin 1 and

pin 2 and between

pin 3 and pin 4.

Remove the cable

connector connected

to CN30 on the main

circuit board unit and

test between pin 29

and pin 30.

connector connected

to CN30 on the main

circuit board unit and

test between pin 17

and pin 18 and

between

pin 19 and pin 20.

Remove the cable

connector connected

to CN30 on the main

circuit board unit and

test between pin 21

and pin 22 .

connector connected

to CN27 on the main

circuit board unit and

test between pin 1 and

pin 2 .

The line must

be continuous.

Approx. 70 Ω

Approx. 70 Ω

Approx. 4.5 Ω

(per 1 phase)

The line must

be continuous.

Approx. 8 Ω

(per 1 phase)

Approx. 45 Ω

Approx. 28.8 Ω

Rev. A Troubleshooting 1-11

Page 23

Confidential

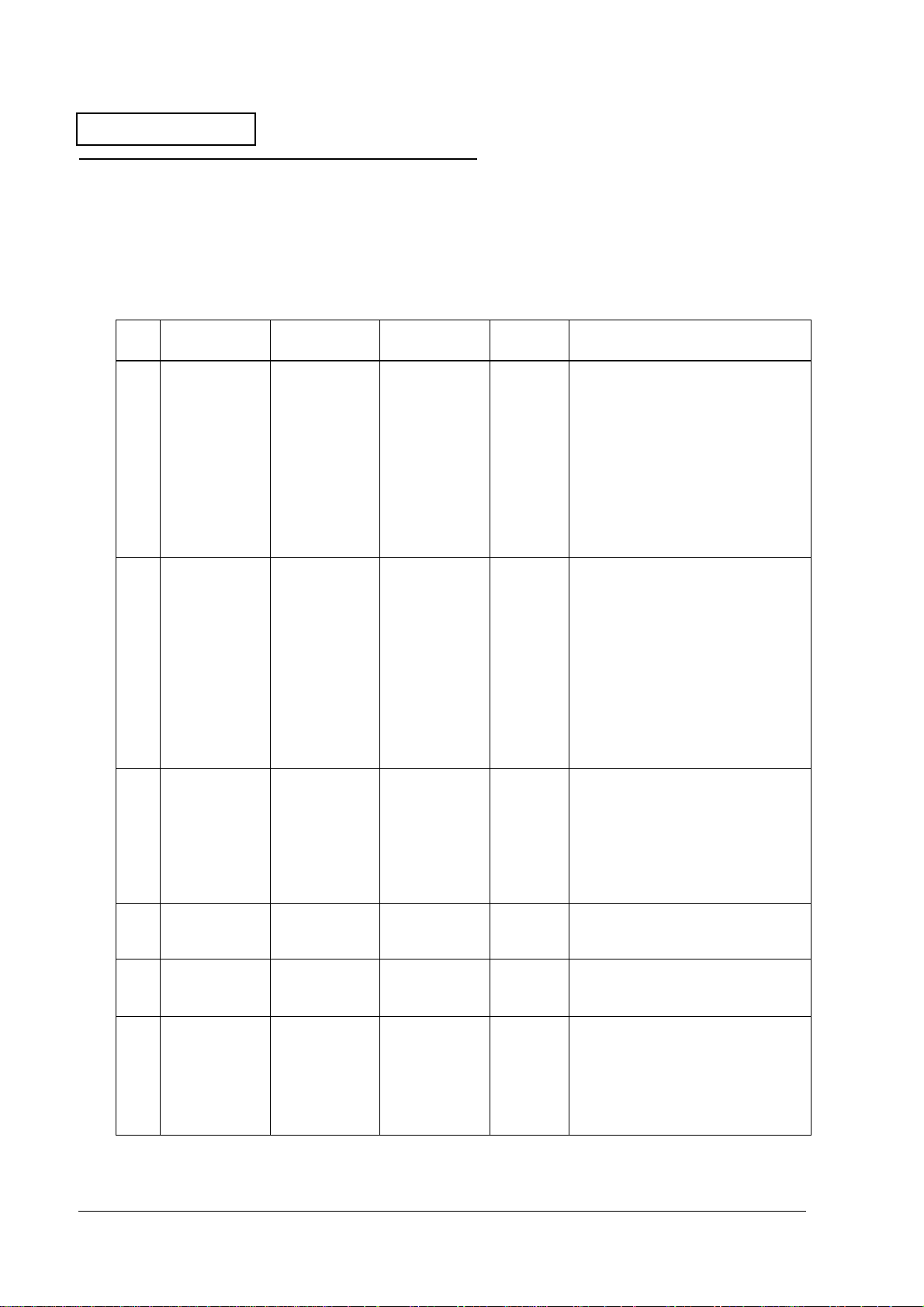

Test Points on the Main Circuit Board Unit

After a main circuit board unit failure, one basic method for diagnosing the cause of the problem

on the main circuit board unit is to check the power supply line. Use the following table to check

the power supply line. First, check step number 1, and proceed to the next step if that is not the

problem.

Table1-4 Checking the power supply line

Step

# Type of Voltage

1 Voltage input

from the power

supply

2 Voltage input

from the power

supply

Location of

Measurement

CN29, pin 1 Output when

U11, pin 1 Output when

Condition of

Measurement

the power

supply is ON.

the power

supply is ON.

Normal

Value Presumed Cause of the Error

24 V ± 10 % It is possible that the problem is pre-

arcing of the F1 fuse. The fuse may

have pre-arced because of an

unusual input circuit.

Always replace the fuse after

removing the cause of the pre-arcing.

If you do not remove the cause of the

pre-arcing, and replace this fuse, the

problem may expand to

misoperation. Also, always use the

specified type of fuse when replacing.

24 V ± 10 % It is possible that the problem is pre-

arcing of the R3 fuse. The fuse may

have pre-arced because of a

problem in the logic power supply

circuit or because of a VCC overvoltage.

3 Logic voltage

(VCC)

4 Logic voltage

(VCC-PWR)

5 Logic voltage

(VCC-PWR2)

6 Logic voltage

(VCC_SEN)

VCC pad

(near L2)

VCC-PWR pad

(near U14,

pin 40)

U19, pin 8

potential

CN30, pin 5

potential

Output when

the power

supply is ON.

Output when

Q51 (C) is "0."

(24V SW1="H")

Output when

Q60 (C) is "0."

(24V SW2="H")

Output only

when there is

output sensor

conductivity

when CPU

output port

(SEN_PWR) is "L."

If pre-arcing of the R3 fuse happens,

do not repair the main circuit board

unit. The quality of several parts on the

circuit board is weakened by prearcing of the R3 fuse and safe

operation cannot be guaranteed.

5 V ± 5 % It is possible that the logic power

supply circuit has malfunctioned.

If you find this line has a problem, do

not repair the main circuit board unit.

The quality of several parts on the

circuit board is weakened, and safe

operation cannot be guaranteed.

5 V ± 5 % The logic power supply circuit or Q44

could have malfunctioned.

5 V ± 5 % The logic power supply circuit or Q59

could have malfunctioned.

5 V ± 5 % The logic power supply circuit or Q44

could have malfunctioned.

1-12 Troubleshooting Rev. A

Page 24

Confidential

Table1-4 Checking the power supply line

Step

# Type of Voltage

7 Mechanism

voltage

(24 VA)

8 Mechanism

voltage

(24 VB)

9 Mechanism

voltage

(24C)

Location of

Measurement

Located near

Q17 drain

Located near

Q7 Source

Located near

Q29 base

TM-U675/U675P (with autocutter) Service Manual

Condition of

Measurement

Output when

Q24 (C) is "0."

(24V SW2 = "H")

Only output

continuously

when power

supply unit is

connected.

Output when

Q46 (C) is "0."

(24V SW1="H")

Normal

Value Presumed Cause of the Error

24 V ± 10 % Q17 could have malfunctioned.

24 V ± 10 % Q61 could have malfunctioned.

24 V ± 10 % It is possible that the problem is pre-

arcing of the F2 fuse. The fuse may

have pre-arced because of a defect

in the 24V line circuit elements.

If pre-arcing of the F2 fuse happens,

do not repair the main circuit board

unit. The quality of several parts on the

circuit board is weakened by prearcing of the F2 fuse, and safe

operation cannot be guaranteed.

Rev. A Troubleshooting 1-13

Page 25

Confidential

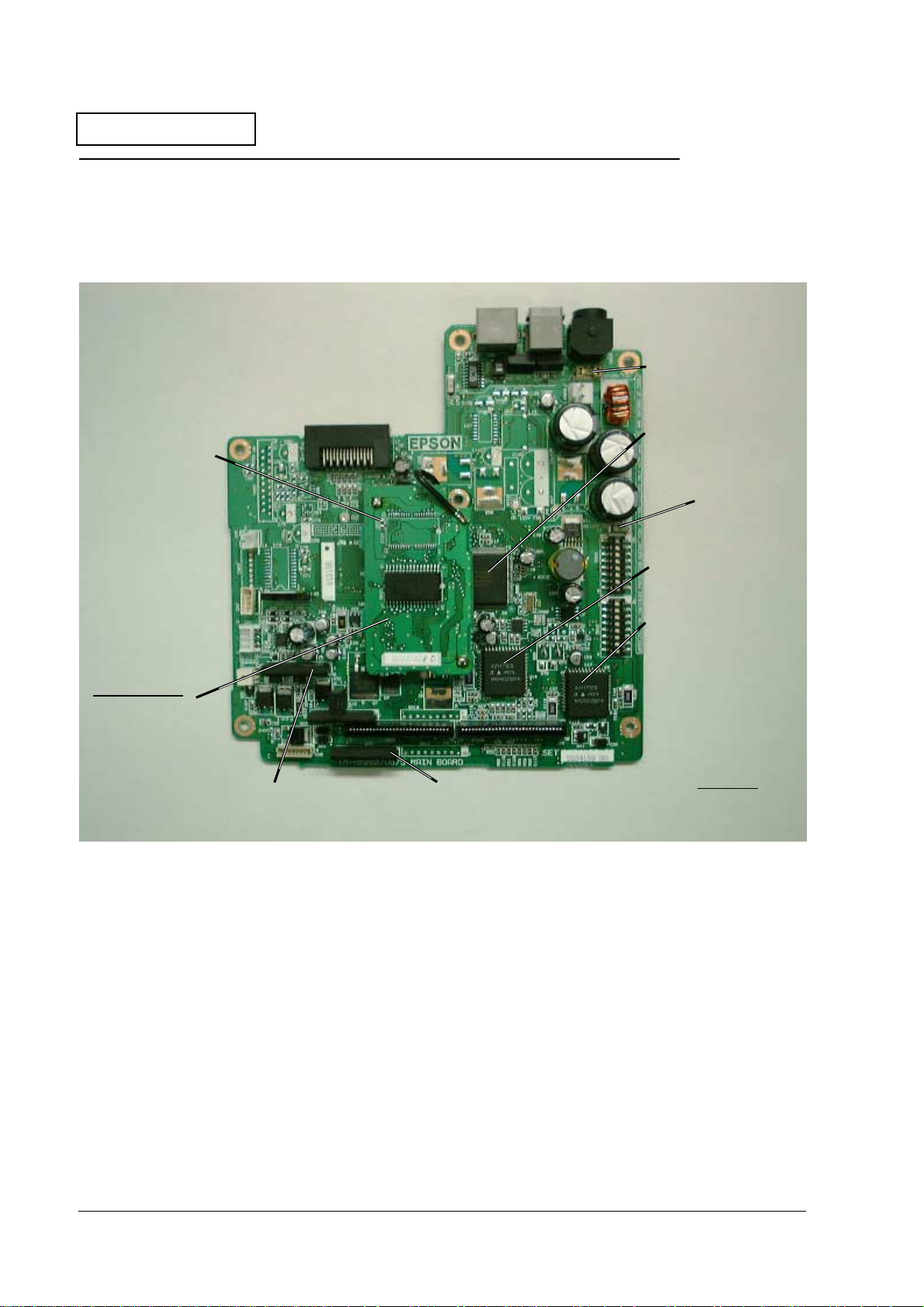

Locations of the Main Elements on the Main Circuit Board Unit

The following shows the locations of the main elements on the main circuit board unit.

Fuse (F1)

CPU (U3)

Gate array (U30)

*under the

memory board

Carriage motor

controller (U14)

Fuse (F2)

Memory board

Font ROM (U513)

Program ROM (U508)

SRAM (U509)

Figure 1-4 Locations of the main elements on the main circuit board unit

Impact dot head

drivers (QM8)

Impact dot head

drivers (QM6)

Slip paper feed motor

controller (U17)

*Rear side

Fuse (F4)

Fuse (R3)

1-14 Troubleshooting Rev. A

Page 26

Confidential

TM-U675/U675P (with autocutter) Service Manual

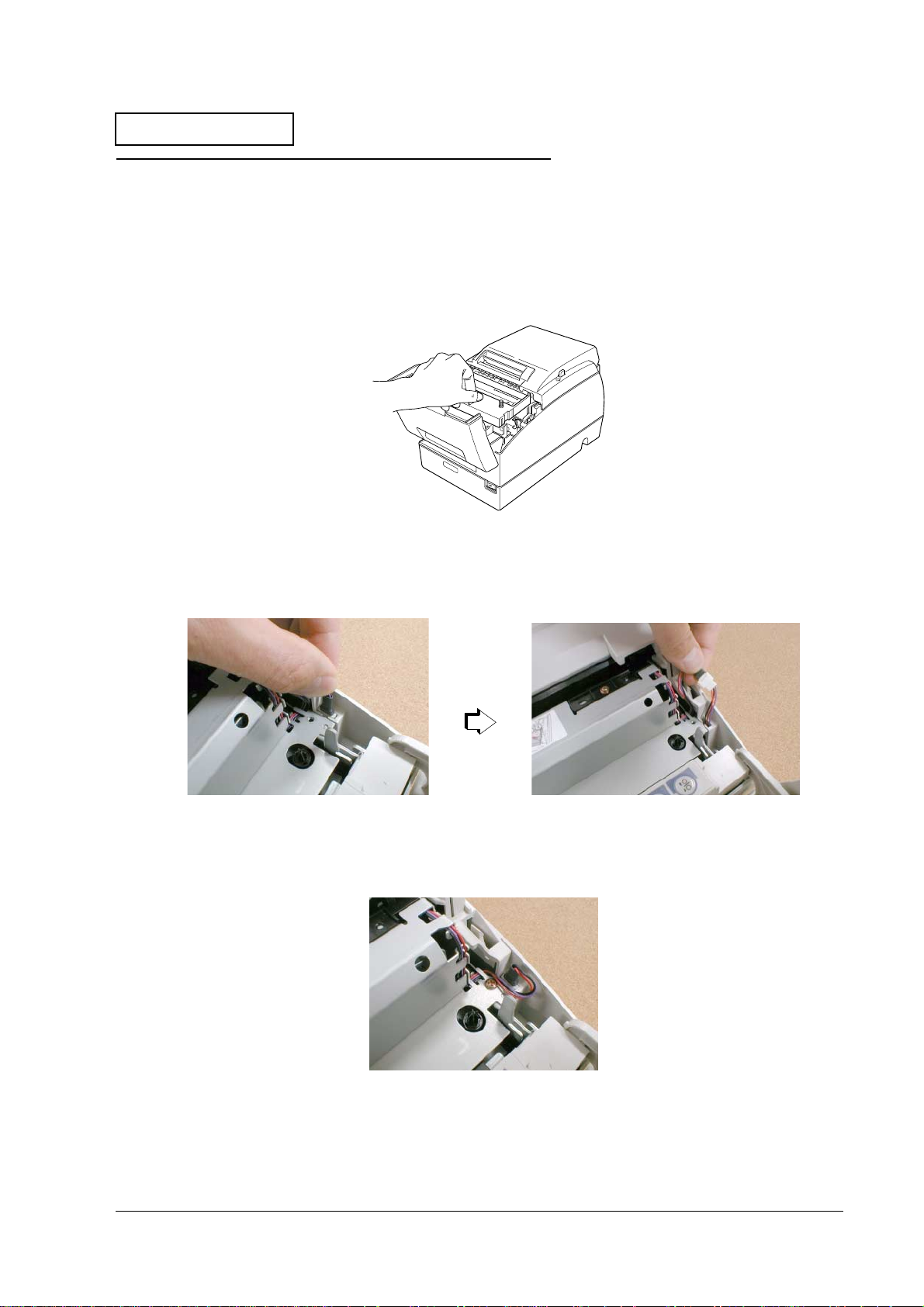

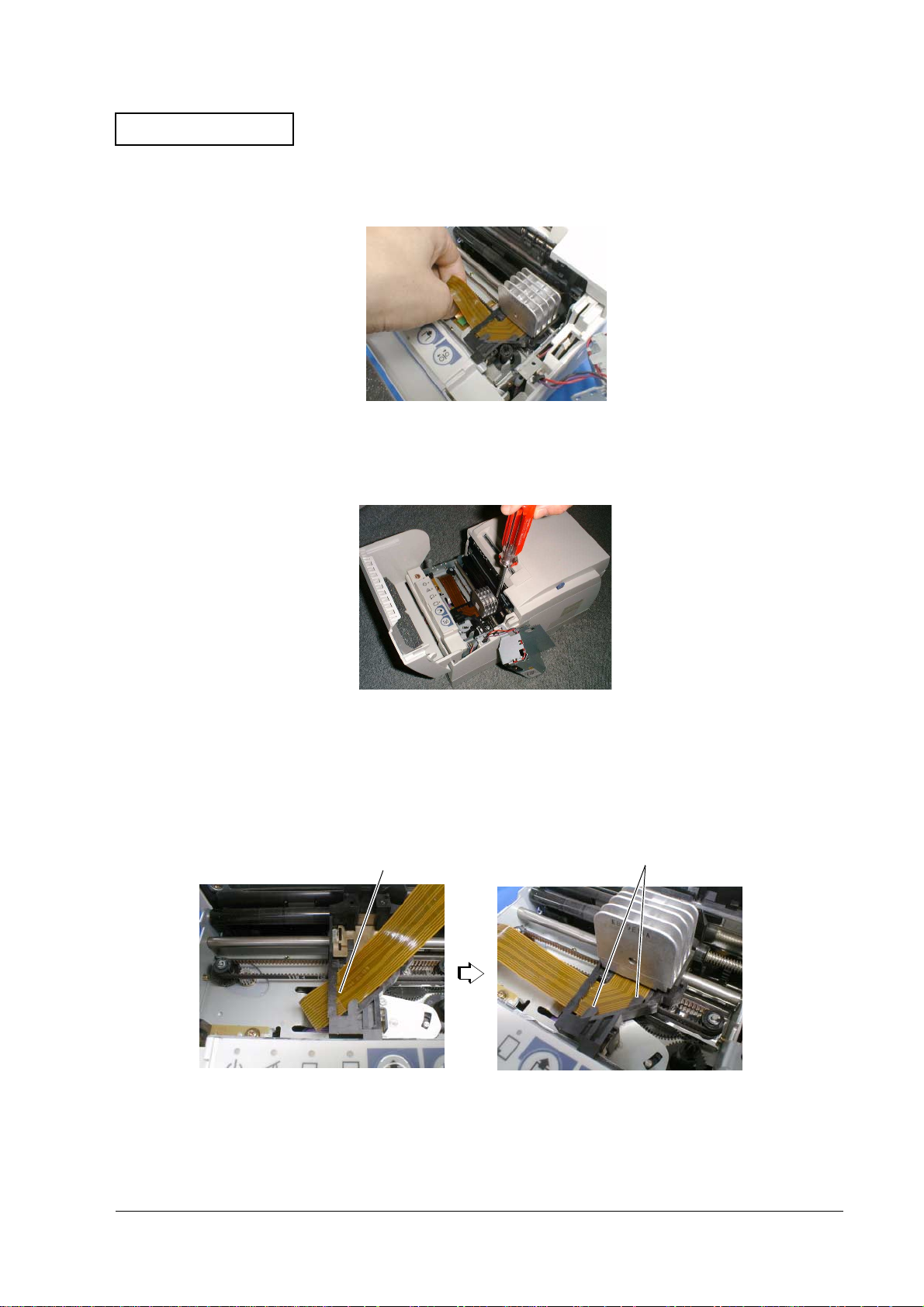

Procedures for Replacing the Print Head Unit

1. Turn off the power switch to the printer. Remove the power supply unit from the printer.

2. Open the printer front cover and remove the ribbon cartridge.

Figure 1-5 Removing the ribbon cartridge

3. Pull the cable connector out of the slit in the case.

Figure 1-6 Pulling the cable connector out

When you are reattaching the cable, arrange the cable wires as shown below.

Figure 1-7 Arranging the cable wires

Rev. A Troubleshooting 1-15

Page 27

Confidential

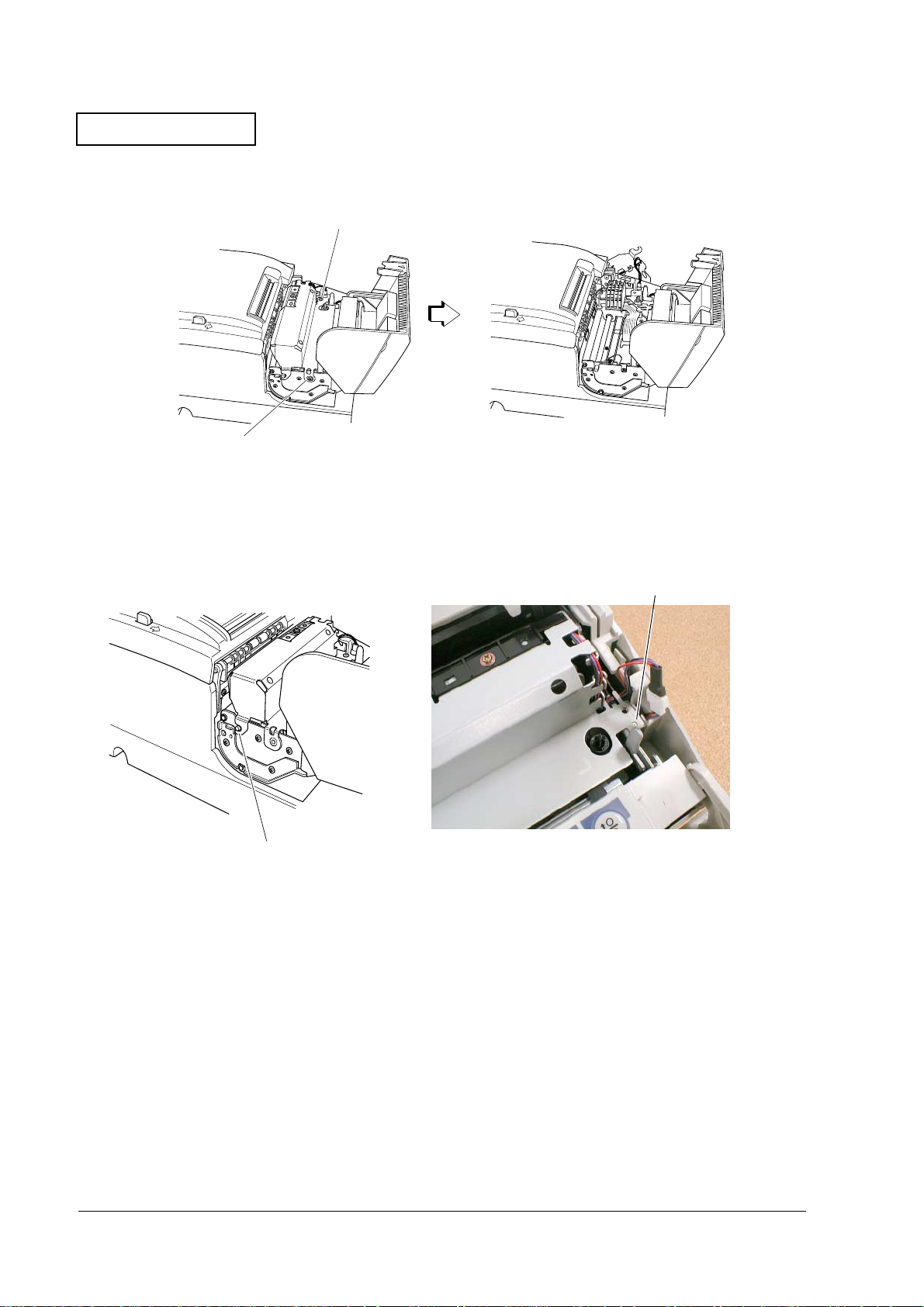

4. Remove the two screws and remove the carriage cover frame assembly.

screw

screw

Figure 1-8 Removing the carriage cover frame assembly

When you are reattaching the frame, insert the tooth on the left side into the shaft and align

the nib on the right side with the nib hole.

nib

tooth

Figure 1-9 Tooth and nib

1-16 Troubleshooting Rev. A

Page 28

Confidential

5. Move the head carriage to the right side and remove the print head unit flexible plastic cable

(FPC) from the connector.

Figure 1-10 Removing the print head unit FPC

6. Remove the screw and remove the print head unit.

TM-U675/U675P (with autocutter) Service Manual

Figure 1-11 Removing the print head unit

When attaching, pass the print head unit FPC through the slit in the head carriage and attach

below the two nibs.

two nibsslit

Figure 1-12 Slit and two nibs

Rev. A Troubleshooting 1-17

Page 29

Confidential

7. Remove the nose guide from the print head unit.

nose guide

Figure 1-13 Removing the nose guide

8. To reinstall the print head, reverse the procedures you used to remove it. When reinstalling,

affix the head seal to the print head unit.

print head unit

head seal

Figure 1-14

1-18 Troubleshooting Rev. A

Page 30

Confidential

TM-U675/U675P (with autocutter) Service Manual

Removing Paper Jams

Paper Jams in the Autocutter

Retract the autocutter movable blade using the following procedure.

1. Pull the latch levers on the right and left sides to the front and open the roll paper cover.

2. Rotate the knob on the autocutter in the direction of the arrow to align the axis with the

circular hole (marked with a triangular hole) in the center of the arc-shaped slit.

3. Remove the paper.

knob

marked arrow

Figure 1-15

Paper Jams in the Roll Paper

1. Pull the latch lever to the front and open the roll paper cover.

2. Remove the take-up assembly.

3. Open the clamshell mechanism while pushing on the levers on both ends.

levers

arc-shaped slit

axis

Figure 1-16

Rev. A Troubleshooting 1-19

Page 31

Confidential

4. Remove the paper.

5. Close the clamshell mechanism. Push on the clamshell mechanism until you hear a clicking

sound.

6. Close the roll paper cover.

Paper Jams in the Slip Paper

1. Check that the power to the printer is turned ON. If it is not ON, turn it ON.

2. If the slip paper does not release, press the RELEASE button to free the slip paper.

3. Remove paper from the paper insertion side.

If you cannot remove the paper from the paper insertion side, or paper is cut partially while you

are removing it, follow the directions in the previous section entitled “Paper Jams in the Roll

Paper” to open the clamshell mechanism and remove the paper.

1-20 Troubleshooting Rev. A

Page 32

Confidential

TM-U675/U675P (with autocutter) Service Manual

Detector Functions and Positions

The following shows the positions and the functions of the detectors.

Table1-5 Detectors and functions

Mechanism Function

Home position detection

mechanism

Carriage detection mechanism Detection of head carriage malfunction

B.O.F. detection mechanism Slip detection

T.O.F. detection mechanism Slip detection

Paper ejection detection

mechanism

Roll paper end detection

mechanism

*Roll paper near-end

detection mechanism

Validation detector mechanism Validation paper detection

Lever motor T.P. detection

mechanism

Front cover detection mechanism Front cover open/closed status detection

Rear cover detection mechanism Detects the open/close status of the rear cover

Autocutter detector function Detects the position of the autocutter movable

Initial setting of printer (carriage home position)

Slip detection

Roll paper detection

Roll paper detection

Lever drive motor timing signal detection

blade.

*The roll paper near-end detector mechanism is installed in the paper supply unit.

Autocutter detector assembly

Rear cover detector assembly

Roll paper N.E. detector (micro switch)

Roll paper end detector assembly

Lever motor T.P. detector

assembly

Home position detector

assembly

Figure 1-17

Paper ejection detector assembly

Front cover detector assembly

Validation detector assembly

T.O.F. detector

assembly

Carriage detector

assembly

B.O.F. detector

assembly

Rev. A Troubleshooting 1-21

Page 33

Confidential

1-22 Troubleshooting Rev. A

Page 34

Confidential

TM-U675/U675P (with autocutter) Service Manual

Chapter 2

Assembly and Disassembly

Before Assembly and Disassembly

Always observe the following precautions when disassembling and assembling the printer.

CAUTION:

Always remove the power supply unit from the printer before working. Power is flowing

in the internal circuit board even if you turn the printer off with the power supply switch.

You can damage the printer if you work with the power supply still attached.

Remove all peripheral equipment connected to the printer before starting your work.

Do not perform any work that is not described in this chapter. Doing so can result in

injuries or damage to the printer.

Do not touch the FPC or the FFC pins with your hands.

About this Chapter

Procedures

This chapter provides the procedures for assembling. Reverse them to disassemble the printer.

Assembly is organized into “Assembling the Mechanism Assembly (M-U675),” and

“Assembling the TM-U675.” Each section is further divided into “Pre-assembly” and

“Assembly.”

Do “Pre-assembly” steps first, and then do “Assembly” after you have assembled the parts into

units to some degree.

Rev. A Assembly and Disassembly 2-1

Page 35

Confidential

Assembling the Mechanism Assembly (M-U675)

Pre-assembly Procedures

Pre-assembly of the Validation Detector Assembly

1. Solder lead wires S, T, R to the validation circuit board.

697 Validation detector assembly

757 Lead wire (type R)

758 Lead wire (type S)

759 Lead wire (type T)

Figure 2-1

2-2 Assembly and Disassembly Rev. A

Page 36

Confidential

TM-U675/U675P (with autocutter) Service Manual

Pre-assembly of the Slip B.O.F. Detector Assembly

1. Solder lead wires C, D, E to the slip B. O. F. detector assembly.

2. Insert the slip B. O. F. detector assembly into the slip insertion detector holder.

606 Slip insertion detector holder

696 Slip B.O.F. detector assembly

742 Lead wire (type C)

743 Lead wire (type D)

744 Lead wire (type E)

Figure 2-2

Rev. A Assembly and Disassembly 2-3

Page 37

Confidential

Pre-assembly of the Lever Drive Coil Assembly

1. Attach lever drive coils (type A, B) to the lever coil mounting plate sub assembly. The rack

for lever drive coil (type A, B) should face upward. Do not confuse type A and B. Type A

uses brown lead wires. Type B uses gray lead wires.

2. Assemble the paper feed trigger attraction plates to the lever drive coils (type A, B).

3. Hook paper feed trigger claw springs onto the lever coil mounting plate sub assembly and

paper feed trigger attraction plate. One side of the hook on the paper feed trigger claw

spring is single and the other side is double. Attach the double side onto the paper feed

trigger attraction plate.

4. Lubricate the areas where the paper feed trigger attraction plate contacts other parts (eight

places).

G-36

732

Paper feed trigger attraction plate

621

Lever drive coil (type A)

731

Paper feed trigger claw spring

G-36

731

Paper feed trigger claw spring

Figure 2-3

732

Paper feed trigger attraction plate

G-36

622

Lever drive coil (type B)

695

Lever coil mounting plate sub assembly

2-4 Assembly and Disassembly Rev. A

Page 38

Confidential

TM-U675/U675P (with autocutter) Service Manual

Pre-assembly of the Paper Feed Motor

Note:

Perform the following three steps only if your printer has a MICR unit.

1. Insert the paper feed motor into the motor shield case. Insert the paper feed motor gear into

the hole in the motor shield case. Check that the motor printed circuit board (PCB) fits into

the notch.

2. Insert two motor shield spacers into the motor shield case.

3. Attach the motor shield cover onto the motor shield case (two places). Align the screw holes

and the nibs on the opposite side, and push in so that they snap fit.

781 Motor shield cover

Screw (C.C.S-tite, 2.5X5)

725

779

Motor shield spacer

739

Paper feed motor

780

Motor shield case

726

Screw (C.B.S-tite F, 3X6)

Figure 2-4

Rev. A Assembly and Disassembly 2-5

Page 39

Confidential

Pre-assembly of the J/S Change Solenoid Assembly

1. Attach the J/S change solenoid to the J/S solenoid mounting plate. When doing so, tighten

the screw while the J/S change solenoid is touching the nib on the right side of the J/S

solenoid mounting plate.

2. Attach the J/S change lever to the J/S solenoid mounting plate, and hook the J/S change

spring.

3. Lubricate the sliding part of the J/S change solenoid mounting plate and the J/S change

lever in four places.

651

J/S change spring

716

Screw (C.C., 2X3)

774

J/S solenoid mounting plate

G-36

G-36

650 J/S change lever

727

J/S change solenoid

Figure 2-5

2-6 Assembly and Disassembly Rev. A

Page 40

Confidential

Pre-assembly of the Slip T. O. F. Detector Assembly

1. Solder lead wires I, J, K to the slip T. O. F. detector assembly.

703 Slip T.O.F. detector assembly

Figure 2-6

TM-U675/U675P (with autocutter) Service Manual

748 Lead wire (type I)

749 Lead wire (type J)

750 Lead wire (type K)

Rev. A Assembly and Disassembly 2-7

Page 41

Confidential

Pre-assembly of the Lever Motor T. P. Detector Assembly

1. Solder lead wires F, G, H to the lever motor T. P. detector assembly.

704 Lever motor T.P. detector assembly

745 Lead wire (type F)

746 Lead wire (type G)

747 Lead wire (type H)

Figure 2-7

2-8 Assembly and Disassembly Rev. A

Page 42

Confidential

TM-U675/U675P (with autocutter) Service Manual

Pre-assembly of the MICR Unit

Note:

Perform the following 16 steps only if your printer has a MICR unit.

1. Solder the MICR connector assembly lead wires to the MICR head.

2. Align the MICR frame and MICR head with the nib and attach with one screw.

782 MICR assembly

MICR connector assembly

786

Screw (C.P.(S-P2), 2.5X5)

793

792 MICR frame assembly

Figure 2-8

Rev. A Assembly and Disassembly 2-9

Page 43

Confidential

3. Attach the MICR fixing sheet to the MICR fixing. Set the hole on the MICR fixing sheet over

the MICR fixing nib and attach so that the MICR fixing sheet does not protrude from the

MICR fixing.

4. Attach the MICR fixing to the MICR lever. The tabs on the MICR fixing should fit into the

MICR grooves.

5. Assemble by inserting the MICR roller shaft. (Attach the shaft with one E-ring.)

787 MICR lever

778 E-ring (1.2)

777 MICR roller shaft

Hole

791 MICR fixing sheet

Nibs

Tabs

Looking directly from the bottom

Figure 2-9

788 MICR fixing

2-10 Assembly and Disassembly Rev. A

Page 44

Confidential

TM-U675/U675P (with autocutter) Service Manual

6. Insert the two MICR lever guide shafts into the MICR frame, starting with the end with the

smaller diameter.

7. Lubricate the areas where the MICR lever and the MICR frame are in contact (six places).

8. Attach the MICR frame to the MICR lever as shown in the drawing.

787 MICR lever

792 MICR frame assembly

796 MICR lever guide shaft

G-47

G-47

Figure 2-10

G-47

Rev. A Assembly and Disassembly 2-11

Page 45

Confidential

9. Fit the MICR solenoid into the MICR case.

10. Align and fit the MICR solenoid nib into the MICR frame assembly.

11. Position and attach the MICR lever fixing plate to the MICR lever nib. (Use two screws to

attach.)

Note:

Tighten the screws while holding the MICR solenoid. Check that the MICR lever will fall under its

own weight.

784 MICR lever fixing plate

794

Screw (C.P.(S), 2.6X8)

783 MICR case

789 MICR solenoid

Figure 2-11

2-12 Assembly and Disassembly Rev. A

Page 46

Confidential

TM-U675/U675P (with autocutter) Service Manual

12. Insert to attach the MICR roller shaft from the opposite direction of the MICR lever fixing

plate. Attach with one E-ring.

13. Attach the MICR lever spring on the hooks.

14. Check that opening and closing the MICR head assembly has a clicking feel to it.

15. Insert the MICR shield cover into the three slits in the MICR frame.

16. Hook the MICR connector assembly lead wire to the hook on the MICR frame.

785 MICR shield cover (type A)

778 E-ring (1.2)

MICR lever spring

790

777 MICR roller shaft

Figure 2-12

Rev. A Assembly and Disassembly 2-13

Page 47

Confidential

Pre-assembly of the Carriage Frame Unit

1. Lubricate the carriage motor shaft.

2. Insert the carriage drive pulley into the carriage motor shaft.

3. Lubricate the inside of the carriage drive pulley.

4. Attach the belt drive cap to the carriage drive pulley and secure it with one E-ring. Place the

belt drive cap with flat surface face up to install it.

720

E-ring (2)

603

Belt drive cap

633

Carriage drive pulley

G-36

G-36

Carriage motor

733

Figure 2-13

2-14 Assembly and Disassembly Rev. A

Page 48

Confidential

TM-U675/U675P (with autocutter) Service Manual

Pre-assembly of the Carriage Assembly

1. Insert the oil rings into the carriage assembly and lubricate. When doing so, insert the flat

surface of the oil rings so that they are facing up and down.

2. Hook the carriage spring to the carriage assembly. Push in until you feel the carriage spring

click.

709

Carriage assembly

605

Oil ring

611 Carriage spring

Rounded side

O-10

O-10

Figure 2-14

Rev. A Assembly and Disassembly 2-15

Page 49

Confidential

3. Insert the carriage belt into the carriage assembly. Fit the belt along the grooves in the

bottom side of the carriage assembly. For the direction of the belt, see the illustration below.

629

Carriage belt

709

Carriage assembly

Figure 2-15

2-16 Assembly and Disassembly Rev. A

Page 50

Confidential

Pre-assembly of the H. P. Detector Assembly

1. Solder lead wires L, M, N in that order to the H. P. detector assembly.

707 H.P. detector assembly

Figure 2-16

TM-U675/U675P (with autocutter) Service Manual

751 Lead wire (type L)

752 Lead wire (type M)

753 Lead wire (type N)

Rev. A Assembly and Disassembly 2-17

Page 51

Confidential

Pre-assembly of the Carriage Frame

1. Lubricate five shafts on the carriage frame sub assembly.

2. Insert the ribbon feed spring into the shaft shown in the figure below. Set the ribbon feed

spring claw upward and insert all the way by rotating the ribbon feed spring clockwise.

3. Lubricate the surface of the ribbon feed spring.

4. Attach the ribbon take-up gear assembly to the top of the ribbon feed spring. Align the

ribbon feed spring claw and the ribbon take-up gear assembly and insert.

5. Attach the carriage transmission pulley to the shaft shown in the figure below.

6. Apply lubrication to the hole in the carriage transmission pulley.

7. Attach the belt drive cap. Place the belt drive cap with the flat surface face up to install it.

712 Ribbon take-up gear assembly

G-36

Ribbon feed

601

spring

603 Belt drive cap

G-36

Carriage frame

sub assembly

632

Carriage transmission pulley

G-36

G-36

Figure 2-17

2-18 Assembly and Disassembly Rev. A

Page 52

Confidential

TM-U675/U675P (with autocutter) Service Manual

8. Insert the carriage drive transmission gear into the shaft shown in the figure below.

9. Insert the ribbon reduction gear into the shaft shown in the figure below.

10. Insert the ribbon intermediate gear into the shaft shown in the figure below. The smaller

diameter ribbon intermediate gear should be on the lower side.

11. Attach the ribbon drive plate assembly above the ribbon reduction gear and the ribbon

intermediate gear. Set the gear side of the ribbon drive plate assembly downward.

12. Attach the gear train cover to the carriage drive transmission gear.

13. Fasten the belt drive cap, carriage drive transmission gear, and ribbon drive plate assembly

with three E-rings.

720

E-ring (2)

Ribbon drive plate assembly

Ribbon reduction gear

Carriage frame sub assembly

720

E-ring (2)

706

682

768

Gear train cover

634 Carriage drive transmission gear

683 Ribbon intermediate gear

720 E-ring (2)

Figure 2-18

Rev. A Assembly and Disassembly 2-19

Page 53

Confidential

14. Insert the hole in the carriage motor onto the carriage frame sub assembly nib. Temporarily

fasten the screw on the lead wire side.

15. Loosen the screw you temporarily tightened in the previous step (less than one turn).

16. Hook the belt tension spring on the carriage motor and carriage frame sub assembly.

Carriage frame sub assembly

Nib

Carriage motor

733

775

Screw

(C.P.S-tite(P4), 3x6)

630 Belt tension spring

Figure 2-19

2-20 Assembly and Disassembly Rev. A

Page 54

Confidential

TM-U675/U675P (with autocutter) Service Manual

17. Attach the carriage assembly to the carriage frame sub assembly. When doing so, set the

carriage spring under the bent part on the carriage frame sub assembly as shown in the

illustration. Insert the carriage guide shaft and secure it with one E-ring.

18. Lubricate the right and left sides of the carriage guide shaft.

19. Hook the carriage belt onto the carriage drive pulley (shown with “1” in the illustration) and

carriage transmission pulley (shown with “2” in the illustration) in that order.

20. Tighten the screw (the screw loosened in step 15) on the lead wire side of the carriage motor.

21. Secure another screw to firmly tighten the carriage motor.

688

Carriage

frame sub

assembly

1

688

Carriage frame sub assembly

611 Carriage spring

709

Carriage assembly

723 E-ring (5)

O-10

775

Screw (C.P.S-tite(P4), 3x6)

Figure 2-20

2

631

Carriage guide shaft

O-10

Rev. A Assembly and Disassembly 2-21

Page 55

Confidential

22. Align the intermediate circuit board assembly to the carriage frame sub assembly with two

dowels, and attach the intermediate circuit board cover.

23. Tighten the intermediate circuit board assembly and intermediate circuit board cover

together with two screws.

24. Attach the H. P. detector assembly to the carriage frame sub assembly with one screw. Pass

the H. P. detector assembly lead wires to the bottom through the hole in the carriage frame

sub assembly.

775 Screw (C.P.S-tite(P4), 3x6)

707 H.P. detector assembly

688

Carriage

frame sub

assembly

769

Intermediate circuit board cover

775

Screw (C.P.S-tite(P4), 3x6)

708

Intermediate

circuit board assembly

775 Screw (C.P.S-tite(P4), 3x6)

Figure 2-21

2-22 Assembly and Disassembly Rev. A

Page 56

Confidential

TM-U675/U675P (with autocutter) Service Manual

25. Pass the flexible plastic cable (FPC) for the print head unit (Eb) through the slit in the

carriage assembly. When you do this, the FPC should be below the two hooks on the

carriage assembly. Install the print head unit (Eb) onto the carriage assembly. Connect the

FPC to the intermediate circuit board assembly connector.

26. Attach the nose guide on the print head unit (Eb) while aligning the three nibs. Secure the

nose guide with one screw.

27. Attach the head seal to the print head unit (Eb).

28. Lubricate the carriage motor gear and the top of the E-ring fastening the ribbon drive plate

assembly.

Slit

Hooks

FPC

795

Head seal

G-36

623

Nose guide

Print head unit (Eb)

FPC

689

608

Screw (C.P.P-tite, 3X12)

G-36

Figure 2-22

Print head unit (Eb)

689

FPC

688

Carriage frame sub assembly

709 Carriage assembly

708

Intermediate circuit board assembly

Figure 2-23

Rev. A Assembly and Disassembly 2-23

Page 57

Confidential

29. Solder four carriage motor cables and three H. P. detector assembly cables to the

intermediate circuit board assembly.

30. Solder intermediate cables A, B, C to the intermediate circuit board assembly.

31. Cover intermediate cables A, B, C with the intermediate cable tube. Fold the intermediate

cables A, B, C to the right side.

Four cables

for motor

carriage

Three cables

for H.P. detector

assembly

Intermediate cable tube

771

734 Intermediate cable (type A)

735 Intermediate cable (type B)

736 Intermediate cable (type C)

708 Intermediate circuit board assembly

Figure 2-24

2-24 Assembly and Disassembly Rev. A

Page 58

Confidential

Pre-assembly of the Front Cover Detector Assembly

1. Solder lead wires V, U, W in that order to the front cover detector assembly.

691 Front cover detector assembly

760 Lead wire (type U)

761 Lead wire (type V)

762 Lead wire (type W)

Figure 2-25

TM-U675/U675P (with autocutter) Service Manual

Rev. A Assembly and Disassembly 2-25

Page 59

Confidential

Pre-assembly of the Rear Cover Detector Assembly

1. Solder lead wires X, Y, Z to the cover detector circuit board.

692 Rear cover detector assembly

763 Lead wire (type X)

764 Lead wire (type Y)

765 Lead wire (type Z)

Figure 2-26

2-26 Assembly and Disassembly Rev. A

Page 60

Confidential

Pre-assembly of the Paper End Detector Assembly

1. Solder lead wires O, P, Q to the paper end detector circuit board.

754 Lead wire (type O)

755 Lead wire (type P)

756 Lead wire (type Q)

Figure 2-27

TM-U675/U675P (with autocutter) Service Manual

710 Paper end detector assembly

Rev. A Assembly and Disassembly 2-27

Page 61

Confidential

Pre-assembly of the Assist Paper Guide Assembly

1. Attach the backup paper guide cap to the center of the assist paper guide.

2. Attach the paper hold roller and assist paper guide spring to the assist paper guide. When

doing so, attach the assist paper guide spring in the direction shown in the figure.

3. Pass the paper hold roller shaft through the assist paper guide and fasten C-rings in 2 places.