Page 1

EPSON COLOR INKJET PRINTER

Stylus Pro XL+

SERVICE MANUAL

EPSON

4006101

Page 2

PREFACE

This document provides supplementary information to describe the Stylus Pro XL+, which is a follow-on version

of the Stylus Pro XL. Therefore, you must refer to this information in conjunction with the Stylus Pro XL Service

Manual for details on any subjects common to both printers.

Page 3

REVISION SHEET

Revision Issue Date Revision Page

A March 15, 1996 - 1st issue

-ii-

Page 4

Stylus Pro XL+ Product Description

1.1 FEATURES

The Stylus Pro XL+ is a high-quality, high-performance color ink jet printer. This printer is provided with a

standard bidirectional parallel interface suitable for the Microsoft

interface for the Macintosh. The main components and case of this printer are similar to the Stylus Pro XL.

The main features are:

❒ High-quality color printing 720 dpi printing using EPSON Micro Dot mode

720 dpi printing on:

plain paper

EPSON premium paper

transparencies

❒ High print speed 720 dpi printing of raster graphics at 200 cps

❒ Built-in-3 I/F Bidirectional parallel interface (IEEE-1284 nibble mode)

Mac serial interface

Type-B interface (optional)

❒ Ink out / low indicators Black and color ink out / ink low indicator LEDs

®

Windows™ 95 environment and a serial

Rev.A 1-1

Page 5

Product Description Stylus Pro XL+

1.2 SPECIFICATIONS

This section provides statistical facts and other detailed information for the printer.

1.2.1 Printing Specifications

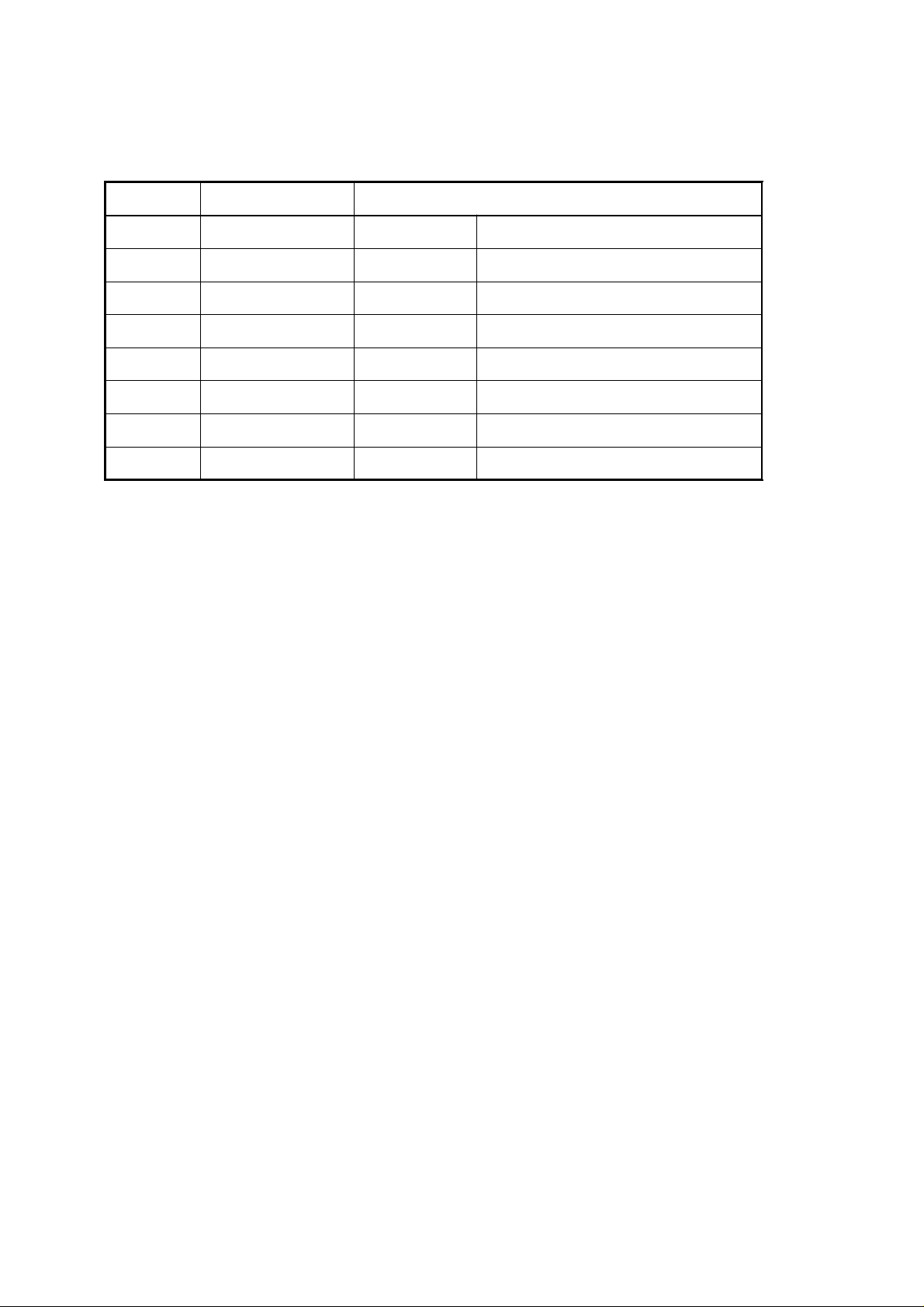

The table below shows print speeds and printable columns.

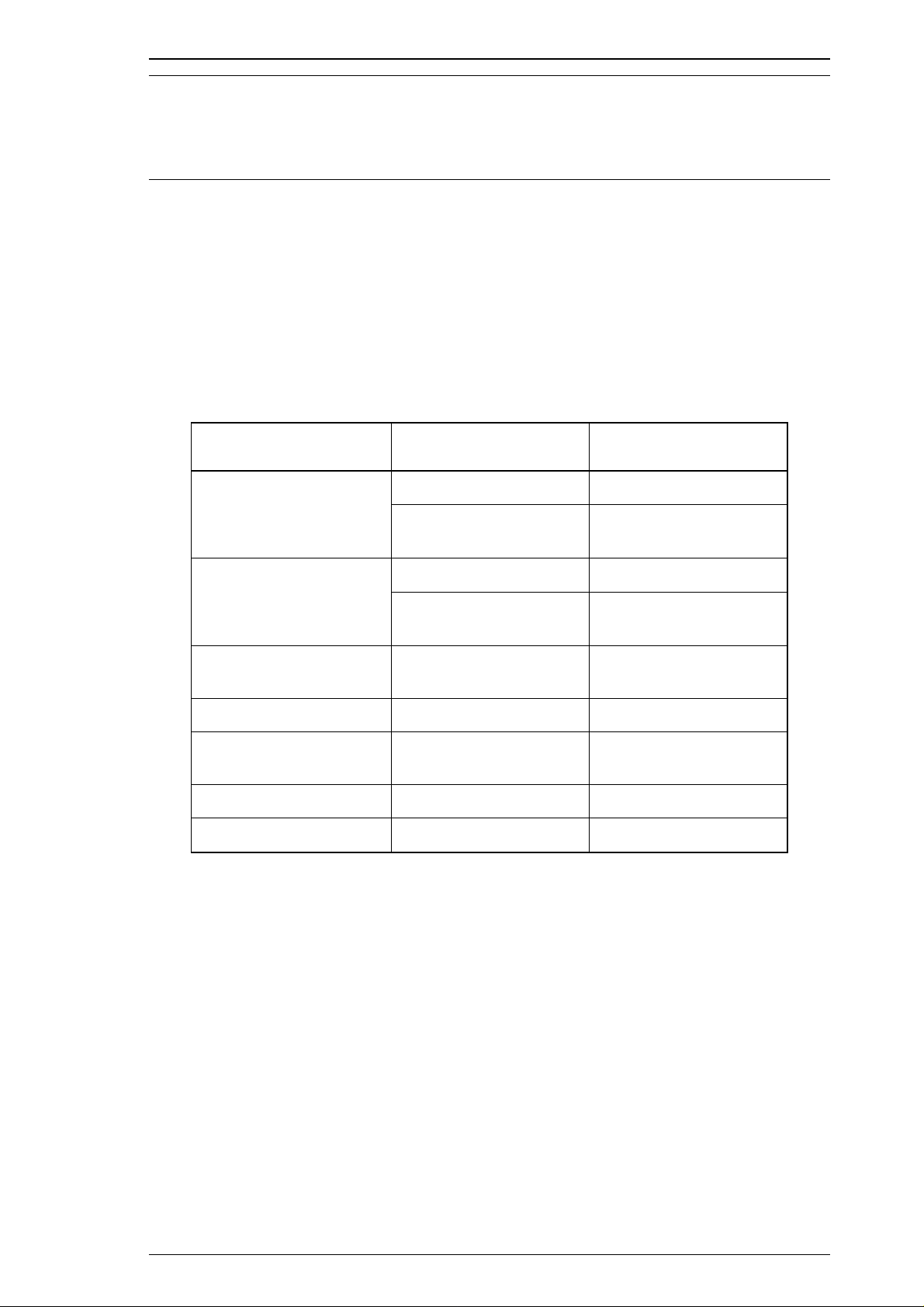

Table 1-1. Print Speed and Printable Columns

Character Pitch Printable Columns Print Speeds (LQ)

10 cpi (pica) 127 200 cps

12 cpi (elite) 152 240 cps

15 cpi 190 300 cps

17 cpi (pica condensed) 218 343 cps

20 cpi (elite condensed) 254 400 cps

Graphics Density Printable Dots Print Speed (10 cpi)

180 dpi × 180 dpi

360 dpi × 360 dpi

H — 720 dpi × V — 360 dpi

720 dpi × 720 dpi

Control codes: ESC/P 2 and expanded raster graphics codes

Input data buffer: 128K bytes

2289

4578

9156

9156

200 cps

1-2 Rev.A

Page 6

Stylus Pro XL+ Product Description

1.2.2 Ink Cartridge Specifications

Black

Type: Exclusive cartridge

Color: Black

Print capacity: 1170 pages (ECMA132 letter)

Life: The effective life from the indicated production date is 2 years.

Storage temperature:

Dimensions (W × D × H): 26.9 × 67.4 × 41.8 mm (1.06 ×2.65 × 1.65 in.)

–30 ∼ 40° C(−22 ∼ 104° F) Storage under a month at 40° C (104° F)

−30 ∼ 60° C (−22 ∼ 140° F) Transit under a month at 40° C (104° F)

−30 ∼ 60° C (−22 ∼ 140° F) Transit under 120 hours at 60° C (140° F)

Color

Type: Exclusive cartridge

Colors: Cyan, magenta, yellow

Print capacity: 620 pages (5% duty for each color, A4, 360 dpi)

Life: The effective life from the indicated production date is 2 years.

Storage Temperature:

Dimensions (W × D × H): 54.0 × 67.4 × 41.8 mm (2.13 × 2.65 × 1.65 in.)

Notes:

❒

The ink cartridge cannot be refilled; it is the only consumable item in the printer.

❒

Do not use an ink cartridge that has exceeded the ink life.

❒

Ink freezes below−3°C; however, it can be used after it returns to room temperature.

–30 ∼ 40° C(−22 ∼ 104° F) Storage under a month at 40° C (104° F)

−30 ∼ 60° C (−22 ∼ 140° F) Transit under a month at 40° C (104° F)

−30 ∼ 60° C (−22 ∼ 140° F) Transit under 120 hours at 60° C (140° F)

Rev.A 1-3

Page 7

Product Description Stylus Pro XL+

1.3 INTERFACE SPECIFICATIONS

The Stylus Pro XL+ comes standard-equipped with two interfaces: an 8-bit bidirectional parallel and an

RS-422 mini-DIN serial interface for the Macintosh. This printer is also equipped with a slot for an optional

Type B interface.

1.3.1 Parallel Interface Specifications

1.3.1.1 Forward Channel

Transmission mode: 8-bit parallel, IEEE-1284 compatibility mode

Synchronization: By

Handshaking: By BUSY and

Signal level: TTL compatible level

Adaptable connector: 36-pin 57-30360 (Amphenol or equivalent)

Data transmission timing: See Figure 1-7 of the Stylus Pro XL Service Manual.

Note:

Transition time (rise time and fall time) of every input signal must be less than 0.2

Transition time (rise time and fall time) of every output signal must be less than 0.12

The printer sets the BUSY signal HIGH before setting either the ERROR signal LOW or the PE signal HIGH.

BUSY is held HIGH until all these signals return to their inactive state. The BUSY signal is active (HIGH)

under the following conditions:

❒ During data reception (See Figure 1-7 of the Stylus Pro XL Service Manual..)

❒ When the input buffer is full

❒ When the

❒ During initialization

❒ When the

❒ During self-test

❒ During default setting

❒ When the parallel interface is not selected

ERROR signal is active (LOW) under the following conditions:

The

INIT input signal is active

ERROR is active

STROBE pulse synchronization

ACKNLG signals

µ

s.

µ

s.

❒ When a paper-out error occurs

❒ When a release lever operation error occurs

❒ When a hardware error (a fatal error) occurs

The PE signal is active (HIGH) under the following conditions:

❒ When a paper-out error occurs

1-4 Rev.A

Page 8

Stylus Pro XL+ Product Description

Table 1-2 shows connector pin assignments and signal functions of the 8-bit parallel interface forward

channel.

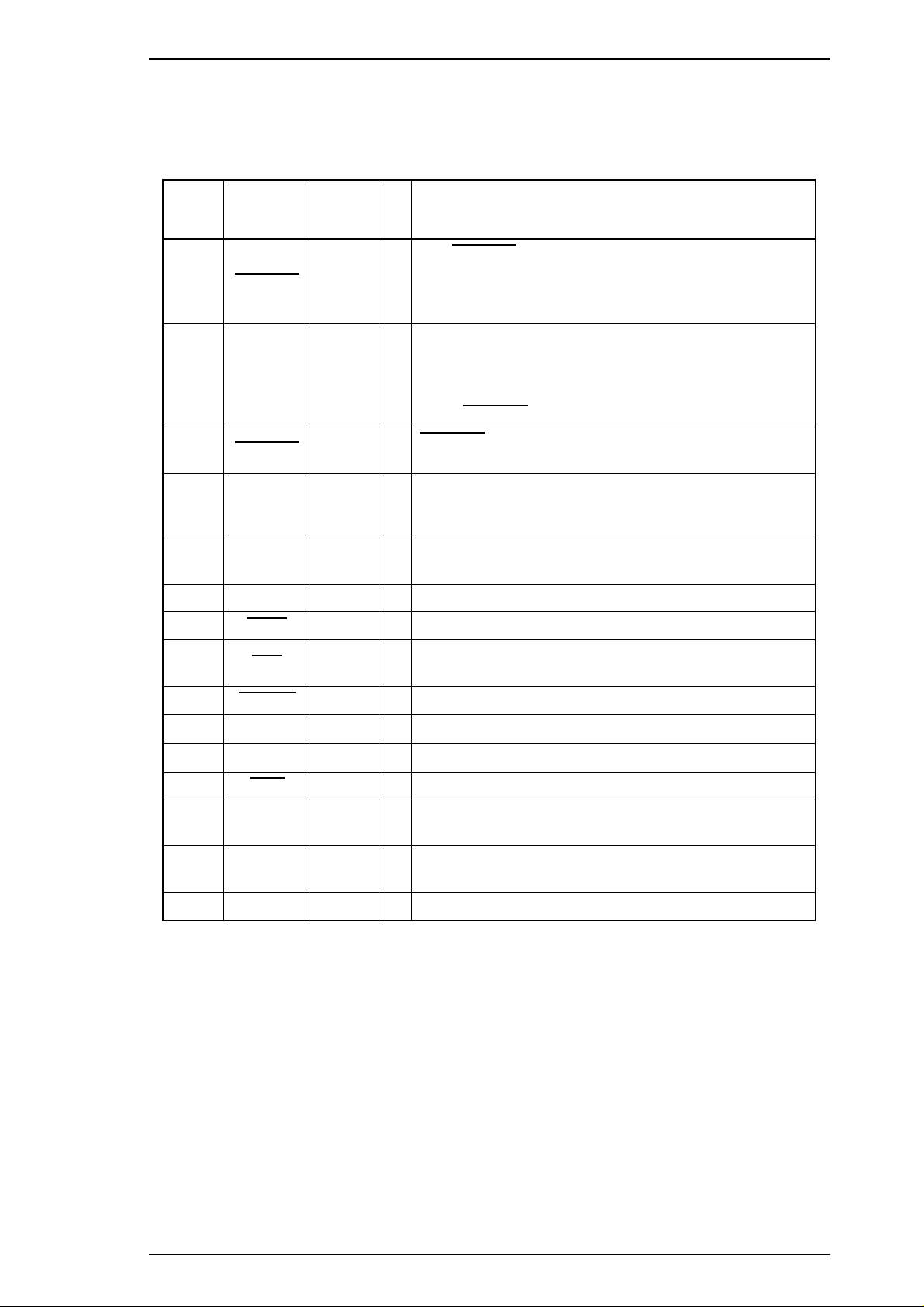

Table 1-2. Signal and Connector Pin Assignments for the Parallel Interface

(Forward Channel)

Pin No.

1

2-9 DATA 0-7 20 - 27 I

10

11 BUSY 29 O

12 PE 28 O

13 SLCT 28 O This signal is always at HIGH while printer power is on.

14 AFXT 30 I Not used.

Signal

Name

STROBE 19 I

ACKNLG 28 O

Return

GND Pin

I/O* Description

The

STROBE pulse is used to read data from the host

computer. Pulse width must be 0.5 µs or more. Normally,

it is HIGH, and data is latched with the rising edge of this

signal.

DATA 0-7 are parallel data bits. When one of these

signals is HIGH, the data bit is 1; when LOW, the data bit

is 0. The most significant bit (MSB) is DATA 8. The

signal state must be maintained for 0.5 µs on either side

of the

STROBE signal’s active edge.

ACKNLG is a negative pulse indicating that the printer

can accept data again.

The BUSY signal informs the host computer of the

printer’s status. When this signal is HIGH, the printer

cannot accept any more data.

This signal indicates whether paper is available in the

printer or not. A HIGH level indicates no paper.

31

32

18 Logic H — O

35 +5 V — —

36

17

16, 33,

19-30

15, 34 NC — — Not connected

INIT 30 I

ERROR 29 O This signal goes LOW if the printer has detected an error.

SLIN 30 I Not used.

Chassis

GND

GND — — Signal ground.

— — Chassis ground.

If this signal goes LOW, the printer is initialized. The

pulse width of this signal must be 50 µs or more.

Pulled up to +5 V through 3.9K Ω resistor in the printer.

Pulled up to +5 V through 3.3K Ω resistor in the printer.

* The I/O column indicates the direction of the signal as viewed from the printer.

Rev.A 1-5

Page 9

Product Description Stylus Pro XL+

1.3.1.2 Reverse Channel

Transmission mode: 8-bit parallel, IEEE-1284 nibble mode.

Synchronization: Refer to the IEEE-1284 specification.

Handshaking: Refer to the IEEE-1284 specification.

Signal level: IEEE-1284 level 1 device (See the forward channel.)

Adaptable connector: The same as for the forward channel.

Data transmission timing: Refer to the IEEE-1284 specification.

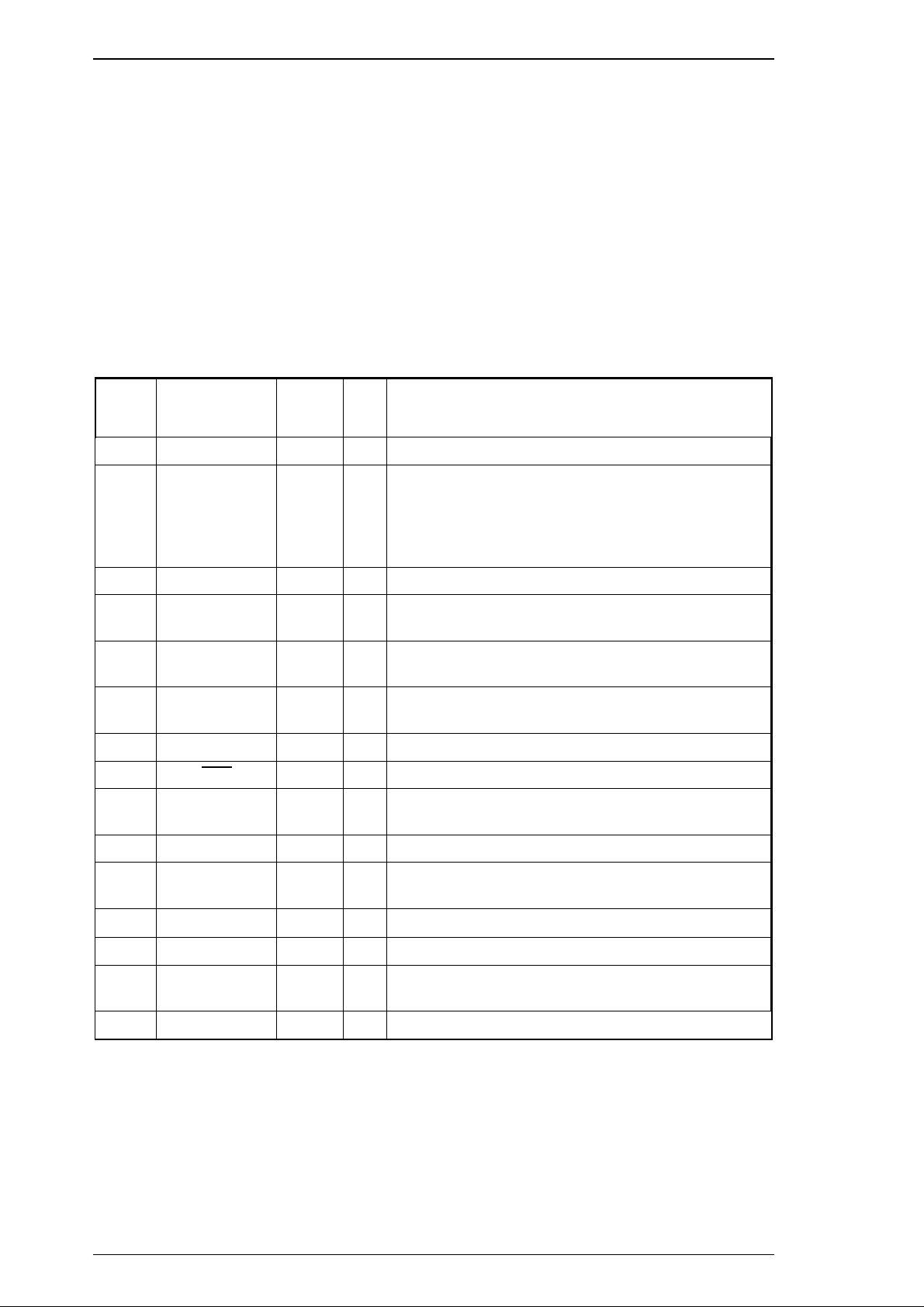

Table 1-3 shows connector pin assignments and signal functions of the 8-bit parallel interface for reverse

channel.

Table 1-3. Signal and Connector Pin Assignments for the Parallel Interface

(Reverse Channel)

Pin No. Signal Name

1 Host Clk 19 I Host clock signal.

2 - 9 DATA 0 - 7 20 - 27 I

10 Ptr Clk 28 O Printer clock signal.

11

12

13

14 Host Busy 30 I Host busy signal.

31

32

36 1284-Active 30 I 1284 active signal.

Ptr Busy / Data

Bit 3, 7

Ack Data Req /

Data Bit 2, 6

Xflag / Data Bit

1, 5

INIT 30 I Not used.

Data Avail / Data

Bit 0, 4

Return

GND Pin

29 O

28 O

28 O

29 O

I/O* Description

DATA 0-7 signals represent data bits 0 - 7,

respectively. Each signal is at a HIGH level when data

is logical 1 and LOW level when data is logical 0.

These signals are used to transfer the 1284

extensibility request values to the printer.

Printer busy signal and reverse channel transfer data

bits 3, 7.

Acknowledge data request signal and reverse channel

transfer data bits 2, 6.

X-flag signal and reverse channel transfer data bits

1, 5.

Data available signal and reverse channel transfer

data bits 0, 4.

18 Logic-H — O

35 +5V — O

17 Chassis GND — — Chassis GND.

16, 33,

19 - 30

15, 34 NC — — Not connected.

GND — — Signal GND.

A HIGH signal indicates that all other signals sourced

by the peripheral are in valid status.

Pulled up to +5 V via 3.3K Ω resistor.

* : The I/O column indicates the direction of the signal as viewed from the printer.

1-6 Rev.A

Page 10

Stylus Pro XL+ Product Description

Extensibility Request: The printer responds affirmatively when the extensibility request values

are 00H or 04H, values that mean —

00H: Request Nibble Mode Reverse Channel Transfer

04H: Request Device ID

Return data using nibble mode reverse channel transfer.

Device ID: The printer sends following device ID string when it is requested.

[00H][39H]

MFG:EPSON;

CMD:ESCPL2-00;

MDL:Stylus Pro XL+;

CLS : PRINTER;

Note: [00H] denotes a hexadecimal value of zero.

1.3.2 Optional Interface Specifications

Type-B interface Level-2 (300 mA type) is supported.

Note : With the simplified serial interface card C82305*, “Disregard a parity bit” setup is not

supported.

Reply message ESC/P 2 is selected

Main-Type: MTP48p,PW127cl10cpi,PRG(VCxxxx)rev,AP300ma

Product-Name: Stylus Pro XL+

Emulation-Type: ESCP-00

Entity-Type: EPSONLQ2

Rev.A 1-7

Page 11

Product Description Stylus Pro XL+

1.4 OPERATIONS

This section describes the basic operations of the printer.

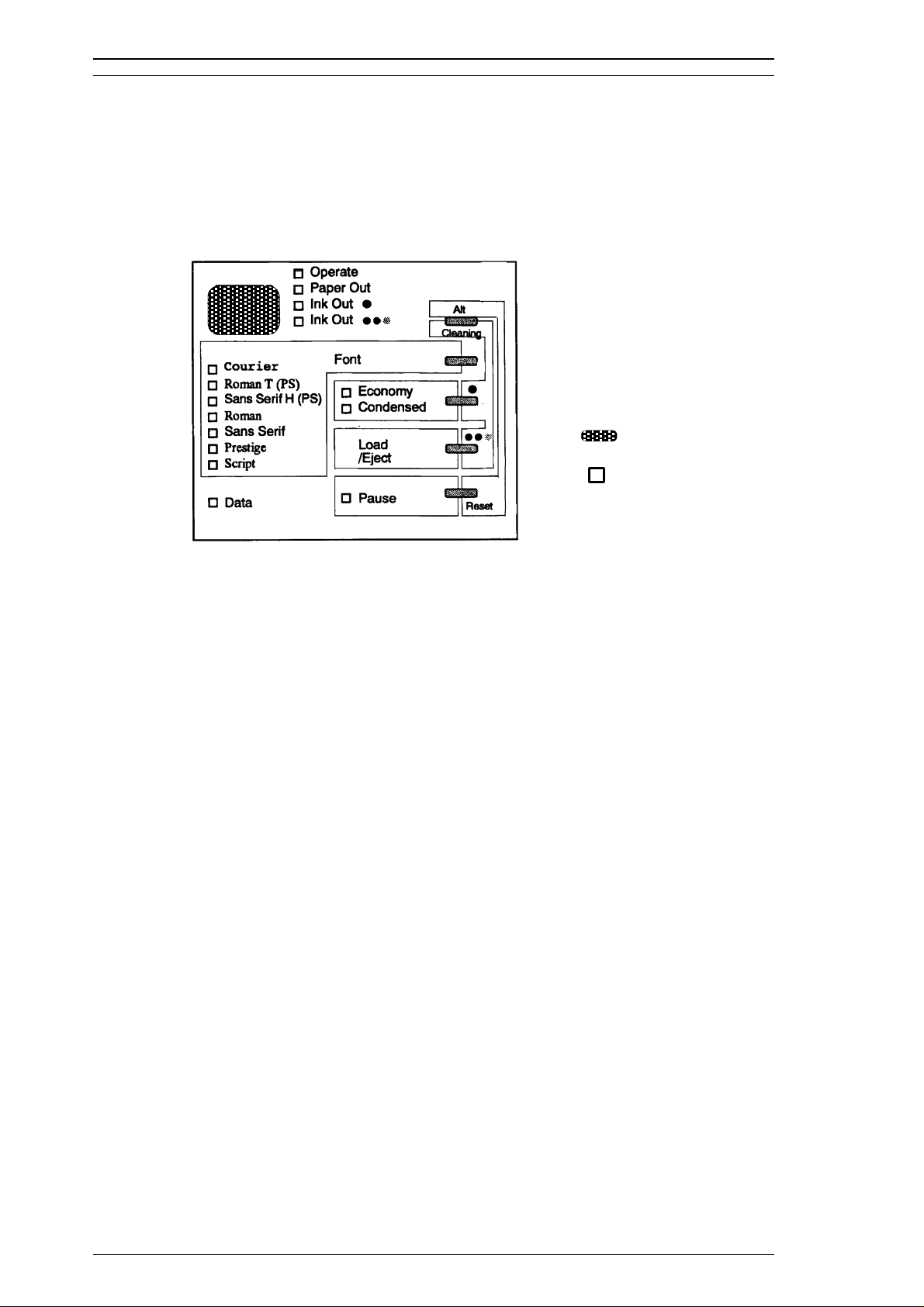

1.4.1 Control Panel

The control panel for this printer has 1 lock-type and 5 non-lock-type pushbuttons, and 15 LED indicators for

easy operation of the various printer functions.

: Button

: LED

Figure 1-1. Control Panel Appearance

Buttons

Operate Turns the printer on or off. This button is in the secondary circuit of the

power supply. This lets the printer execute the head-capping function after

it receives the signal to turn off and before actual printer power down.

Alt Modifies the functions of other buttons. Holding down this button for 3

seconds causes the printer to move the carriage to the ink cartridge

installation position. Pressing Alt again causes the carriage to return to the

home position.

Font Cycles through the font choices. Pressing the Font button while holding

down the Alt button causes the carriage to move to the gap-adjustment

position. Pressing the Alt button again causes the carriage to return to the

home position.

Economy/Condensed Selects either economy or condensed printing mode. Pressing the

Economy/Condensed button while holding down the Alt button starts the

black printhead cleaning cycle.

Load/Eject Either loads a new sheet into the printer or ejects paper currently in the

paper path. Pressing the Load/Eject button while holding down the Alt

button starts the color printhead cleaning cycle.

Pause Stops printing temporarily or resumes printing if it has been stopped

temporarily. Pressing Pause while holding down the Alt button resets the

printer.

1-8 Rev.A

Page 12

Stylus Pro XL+ Product Description

Indicators

Operate On when the printer is on. Blinks while the printer is powered on or off.

Paper Out On when the printer is out of paper. Blinks when a paper jam occurs.

Ink Out (Black) On when the black ink cartridge is out of ink or not installed. Blinks when

black ink is low.

Ink Out (Color) On when the color ink cartridge is out of ink or not installed. Blinks when

color ink is low.

Economy On when economy printing mode is selected.

Condensed On when condensed printing mode is selected.

Font These LEDs indicate the selected font.

Pause On when printing is paused.

Data On when print data is in the input buffer. Data and Pause lights blink if an

error occurs.

1.4.2 Panel Operation at Power On

The list below contains printer modes and the procedures you can use to activate them:

Self-test mode Turn on the printer while holding down the Load/Eject button.

Hex dump mode Turn on the printer while holding down the Font and Load/Eject buttons.

Once this mode is selected, the printer prints all received data in

hexadecimal format.

Default setting mode Turn on the printer while holding down the Economy/Condensed button.

The printer enters the default setting mode.

Initialize EEPROM Turn on the printer while holding down the Alt, Font, Load/Eject, and

Pause buttons.

Note: You can exit self-test, hex dump, or default setting by turning off the printer.

Rev.A 1-9

Page 13

Product Description Stylus Pro XL+

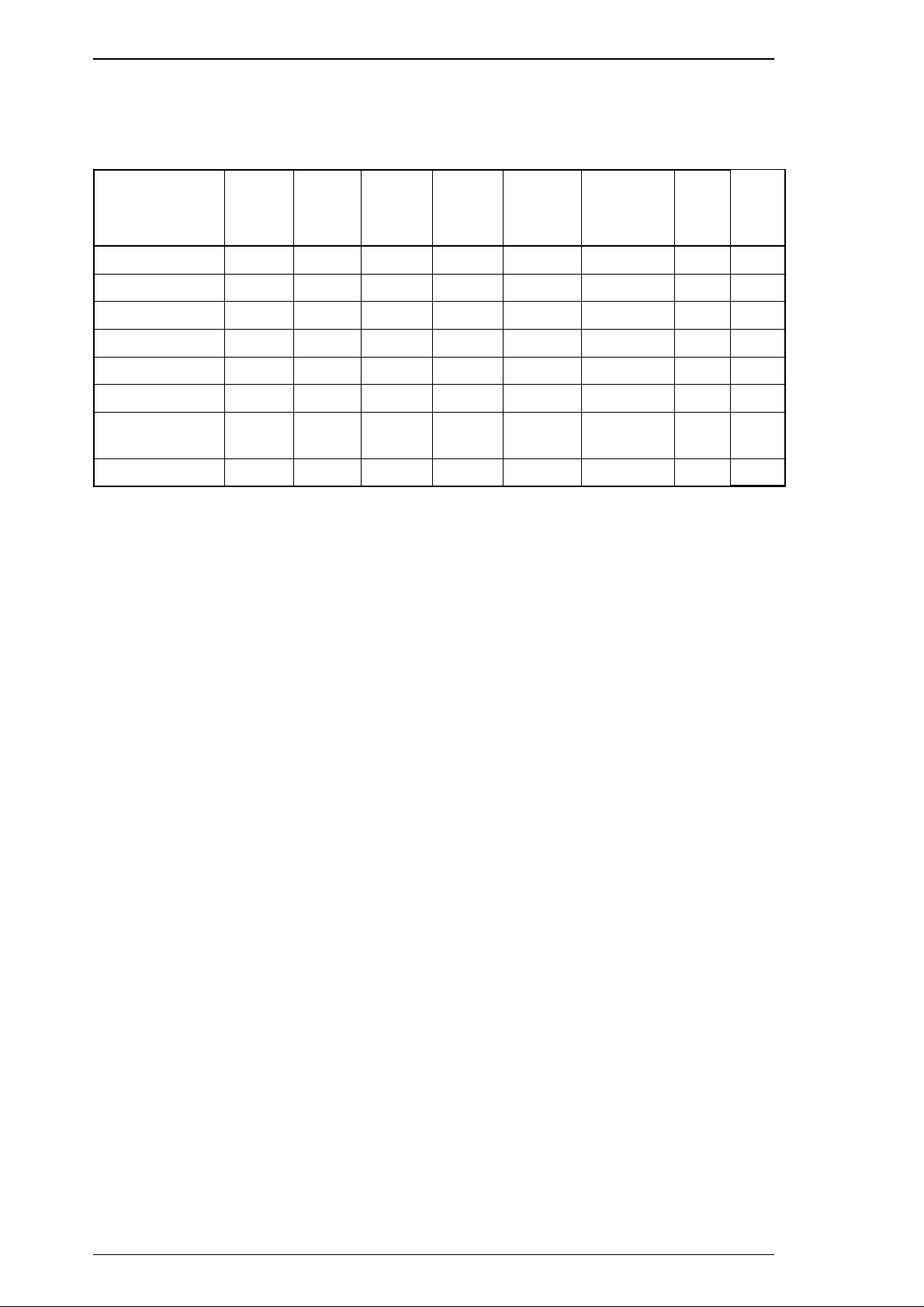

1.4.3 Error Conditions

The printer can detect the various errors and indicate them with LEDs.

Table 1-4. Error Indications

Error Operate

Paper out — On — — — — — —

Black ink end — — On — — — — —

Black ink low — — Blink — — — — —

Color ink end — — — On — — — —

Color ink is low — — — Blink — — — —

Paper jam — Blinks — — — — — —

Maintenance

request

Carriage error — — — — — — Blinks Blinks

— Blinks Blinks Blinks Blinks Blinks Blinks Blinks

Paper

Out

Ink

Out

(Black)

Ink

Out

(Color)

Economy Condensed Pause Data

— Not used to indicate the specified error.

1-10 Rev.A

Page 14

Stylus Pro XL+ Service Manual Operating Principles

2.1OPERATING PRINCPLES - OVERVIEW

Thissectiondescribestheoperatingprinciplesoftheprintermechanismandtheelectricalcircuitsofthe

Stylus Pro.

2.2OPERATINGPRINCIPLES OFTHEPRINTERMECHANISM

2.2.1Principlesof thePrintingOperation

TheprintingmechanismfortheStylusProXL+hasadrop-on-demandinkjetsystem,similartothesystemin

allotherEPSONinkjetprinters.TheStylusProXL+printerusestheMicroDotprintingfunctionbothwith

blackinkandsuper720dpicolorprinting.ThetypeofMicroDotprintingtheStylusProXL+performsisthe

sameasisavailableintheStylusCOLORIIandStylusCOLORIIs/820.However,withthoseprinters,

MicroDotprintingisavailableforprintingwithblackinkonly.TheMicroDotprintingmodecanbeselected

automaticallywith720dpiprintingqualityusing theprinter driversettingsdescribed inthefollowingtable.

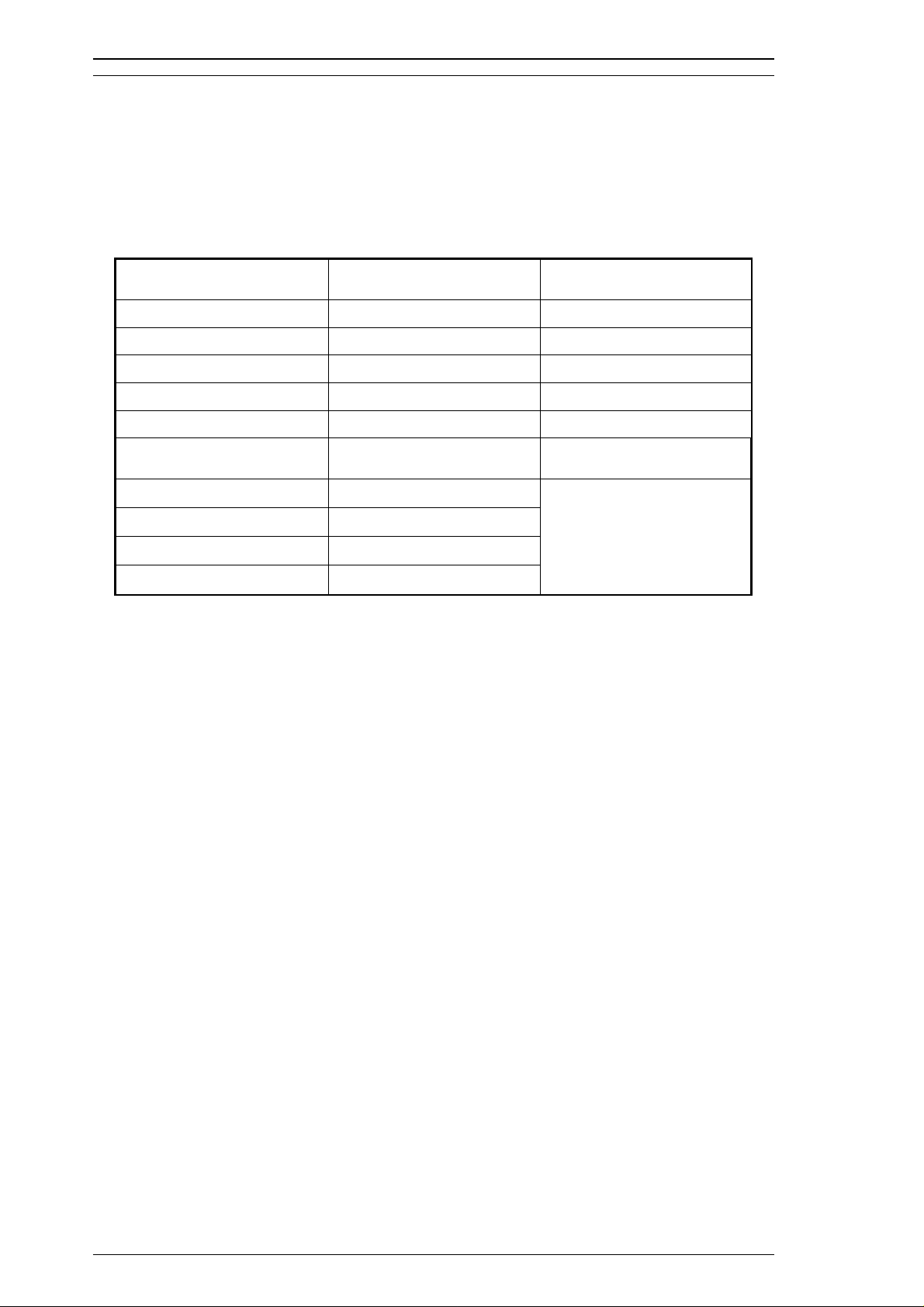

Table 2-1.Special Printing Mode

Paper Type Print Density (DPI) Print Mode

360 NormalDotPrinting

NormalPaper

H —720×

V— 360

EPSON Micro Dot Printing

360 NormalDotPrinting

EPSON Premium Paper

for 360dpi

EPSON Premium Paper

for 720dpi

Labelsfor720dpi 720 EPSON Micro Dot Printing

High Quality Glossy

Card Stock

HighQualityGlossy Paper 720 EPSON Micro Dot Printing

Transparencyfilm 360 NormalDotPrinting

MicroDotprintingmodecanimproveoutputquality,becauseiteliminatesbandingthatcansometimesoccur

innormalmode.ThedotsizeinEPSONMicroDotPrintingmodeissmallerthanthedotsizeinnormal

printing.Normalprintmodeis mainly usedin resolutionsof360 dpior less.

H— 720×

V— 360

720 EPSON Micro Dot Printing

720 EPSON Micro Dot Printing

EPSON Micro Dot Printing

Rev.A 2-1

Page 15

Operating Principles Stylus Pro XL+ Service Manual

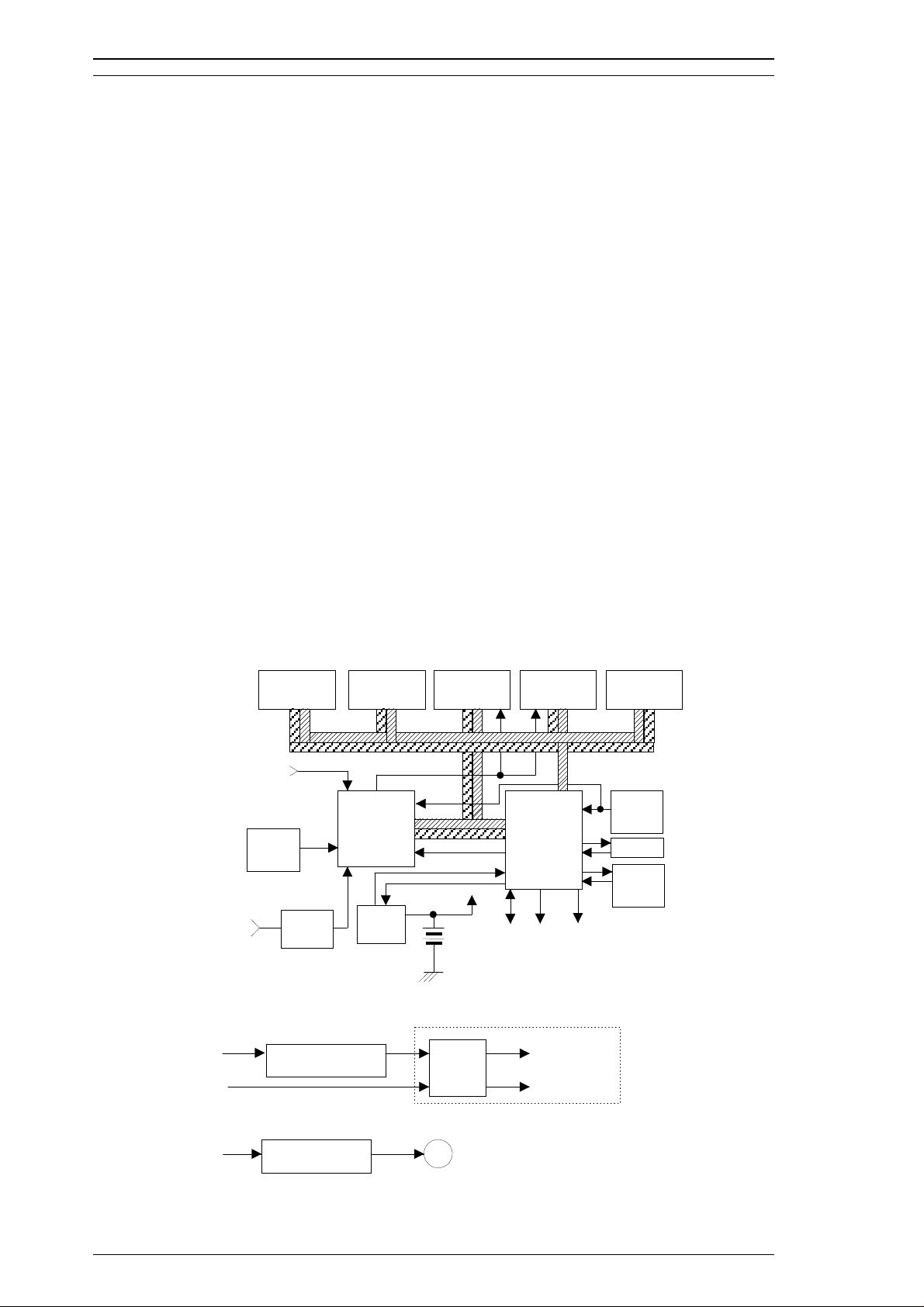

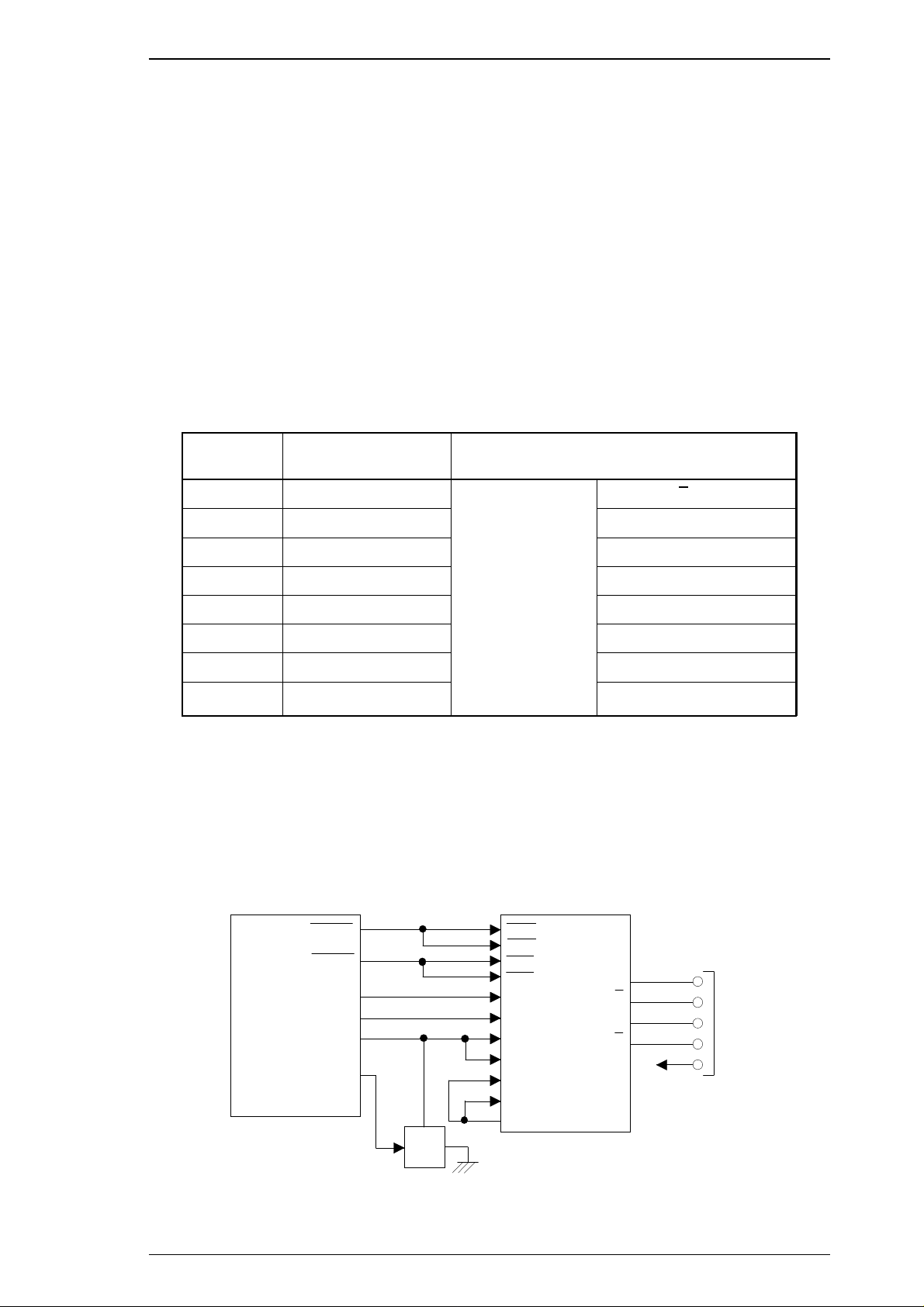

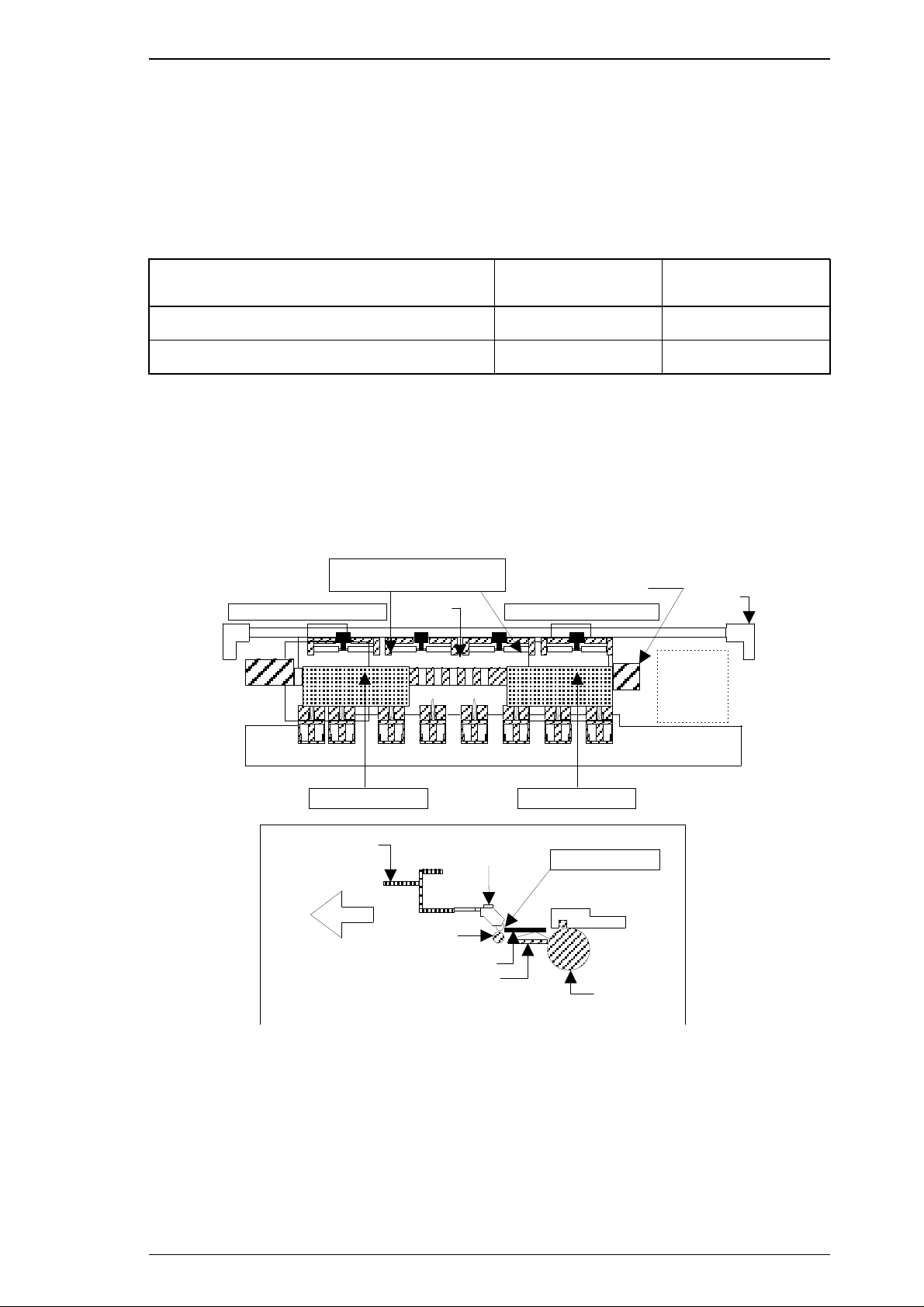

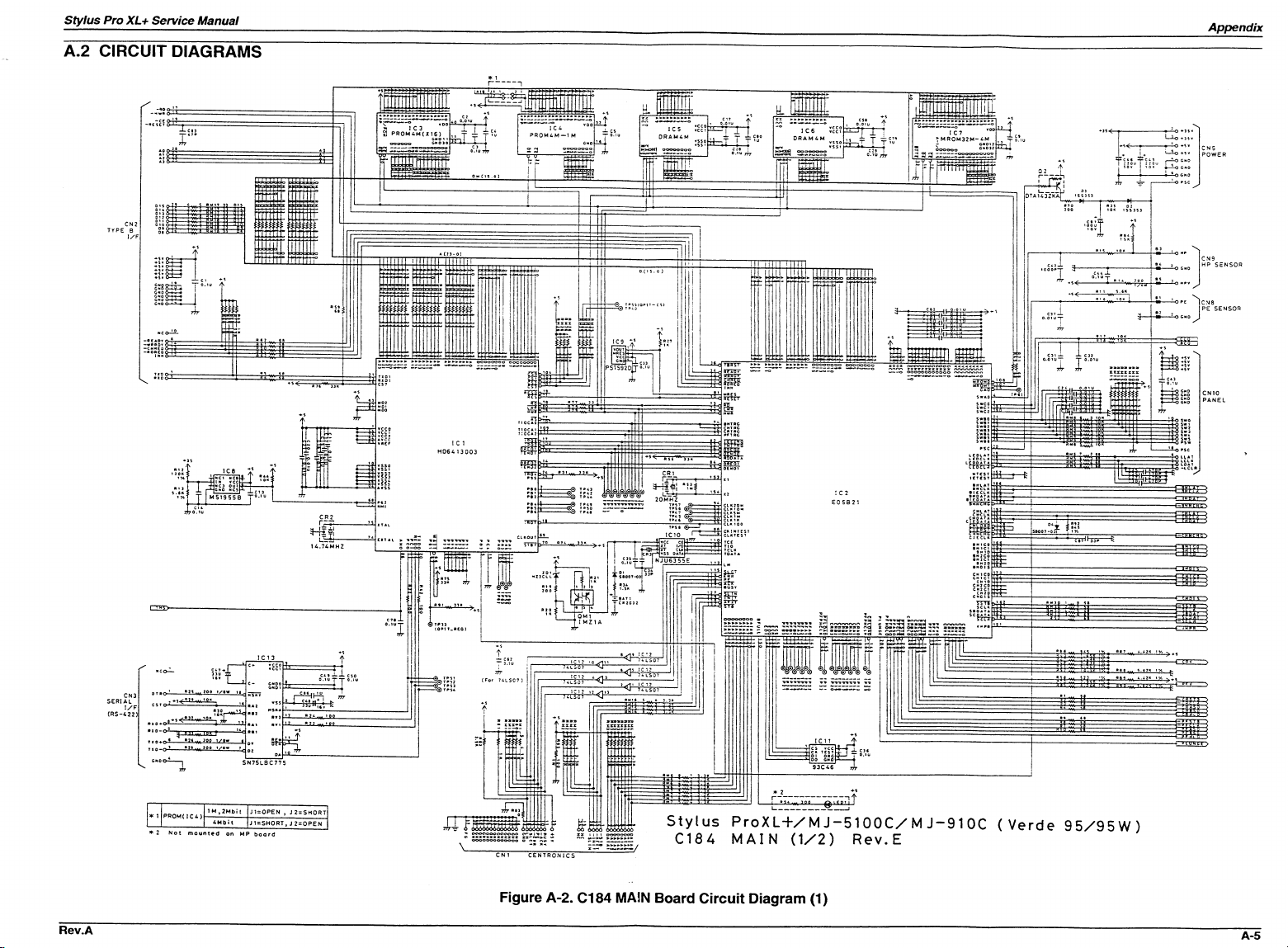

2.3 OPERATING PRINCIPLES OF THE ELECTRICAL CIRCUITS

The Stylus Color Pro XL+ contains the following circuit board units:

❒ C184 MAIN board (main control circuit board).

❒ C137 PSB/PSE board (power supply circuit board). This board is the same as Stylus Color’s

❒ C137 PNL (control panel board). This board is similar to Stylus Color’s.

In addition to the circuit boards above, part of the printhead drive circuit is built on a separate circuit board

installed in the carriage unit; the printhead is attached directly to this board. The figure below shows a block

diagram of the electrical circuits.

2.3.1 Operating Principles of the Main Control Circuit

The main control circuit for this printer is the C184 MAIN board. This circuit is controlled by a 16-bit

H8/3003 CPU (IC1), running at 14.7456 MHz. The CPU has a unique architecture, capable of handling data

on the data bus at either an 8-bit or 16-bit bus width. Because of this, both a 16-bit and an 8-bit data bus

width-type ROM can be used on the board, increasing the internal processing speed. Also, the CPU’s unique

architecture is capable of refresh control. In addition, the CPU controls the serial interface (RS-422 for Mac)

and optional interface (Type B interface).

Gate array E05B21 (IC2) manages the printhead driver, the external Centronics

extension CG board, and the control panel. The gate array also oversees the controls that create the 4-bit

signals for the carriage or the paper feed motor. (The carriage and paper feed motor are controlled by current

duty data.) This board also is equipped with a 93C46 EEPROM (IC11) to store certain parameters, such as the

black/color head data, printer mechanism control parameters, default setting parameters, as well as a special

counter value used for printhead (ink management) protection.

®

parallel interface, the

Timer IC NJU6355E (IC10) counts each time the printer goes through its cleaning cycle and keeps track of

how much time has elapsed since the printer has been used, thereby allowing the printer to be cleaned only

when necessary. The timer value is backed up by the lithium battery.

D-RAM (4M)

(IC5)

DMAREQ

I/

SD

C

SED6110DOA

(U1, U2)

D-RAM (4M)

( IC 6)

E05B21

(IC2)

O

L

K

B

Vx

o

T

Par a llel I/F

Carriage / Paper Feed

Motor Driver Signal

Black 64 Nozzles

Color 48 Nozzles

Data Bu s

Address Bus

A

o

T

Black / Color Head

Comm on and Nozzle

MROM (4-32M)

(IC7 )

Reset (Log ic )

(IC9)

PST592D

Panel

EEPROM

(IC11)

93C46

Selector Drive Signal

From A

RS-422

Seria l I/ F

P-ROM (4M)

(IC3)

Type-B I/F

Reset (Power)

(IC8)

M51955B

SN75LBC775

(IC13)

C184 MAIN Boar d

H8D2778A (IC16, 17)

Black/Color Head

Common Driver Circuit

P-ROM (1-4M)

(IC4)

Refresh

CPU

H8/3003

(I C1 )

(IC10)

NJU6355E

(Timer Cou nter)

SLA7043M (IC14, 15)

From B

Carriage / Paper Fe ed

Motor Driver

M

Figure 2-1. Main Control Circuit Block Diagram

2-2 Rev.A

Page 16

+35 V

+5 V

NMI

P62

CPU (IC1)

+5 V

PST592D

(IC X)

E05B21 (IC2)

RES

RESET

80

71

1

672

68

M51955 B

(I C 8 )

TBRST

RST

Type B

55

Stylus Pro XL+ Service Manual Operating Principles

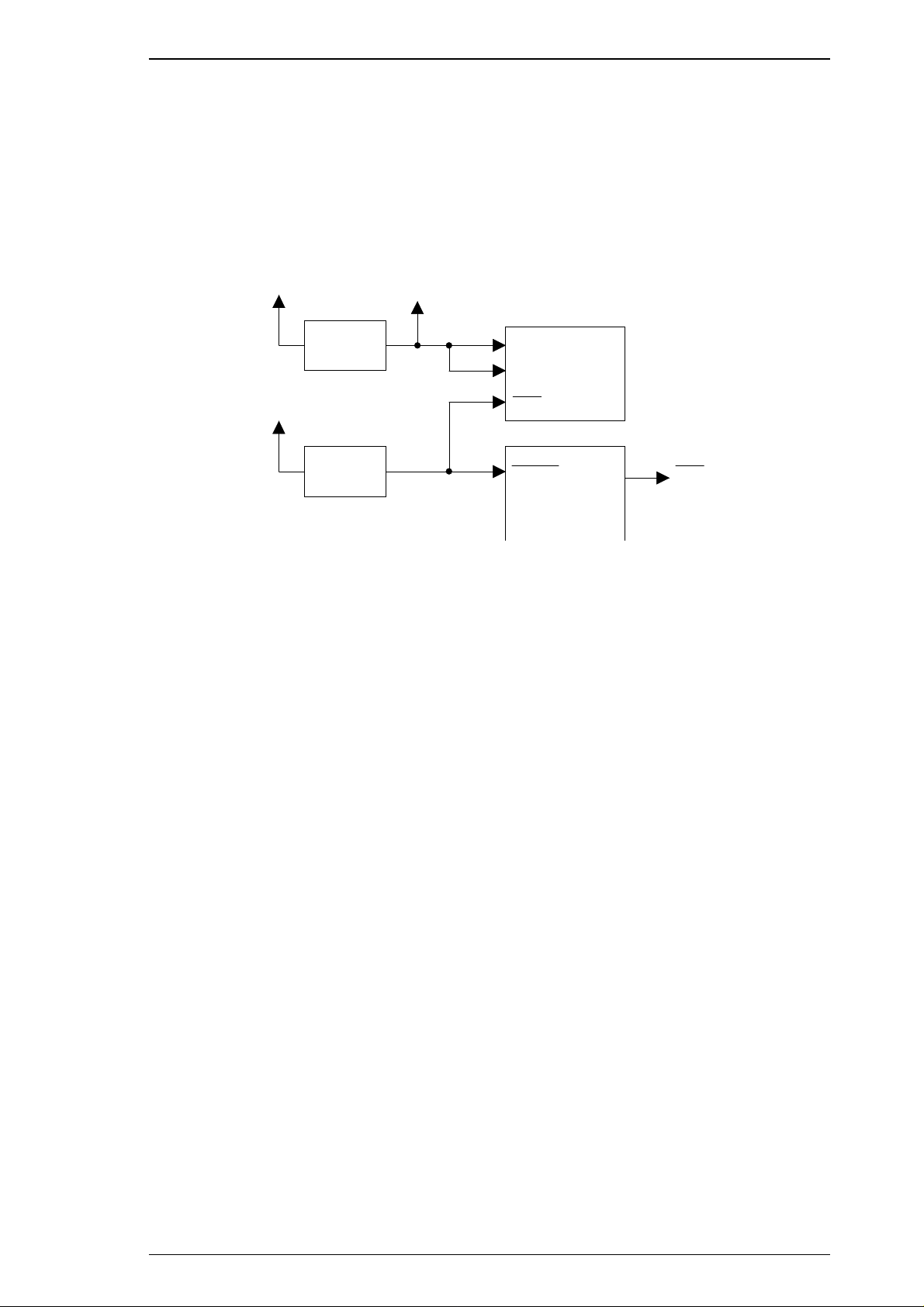

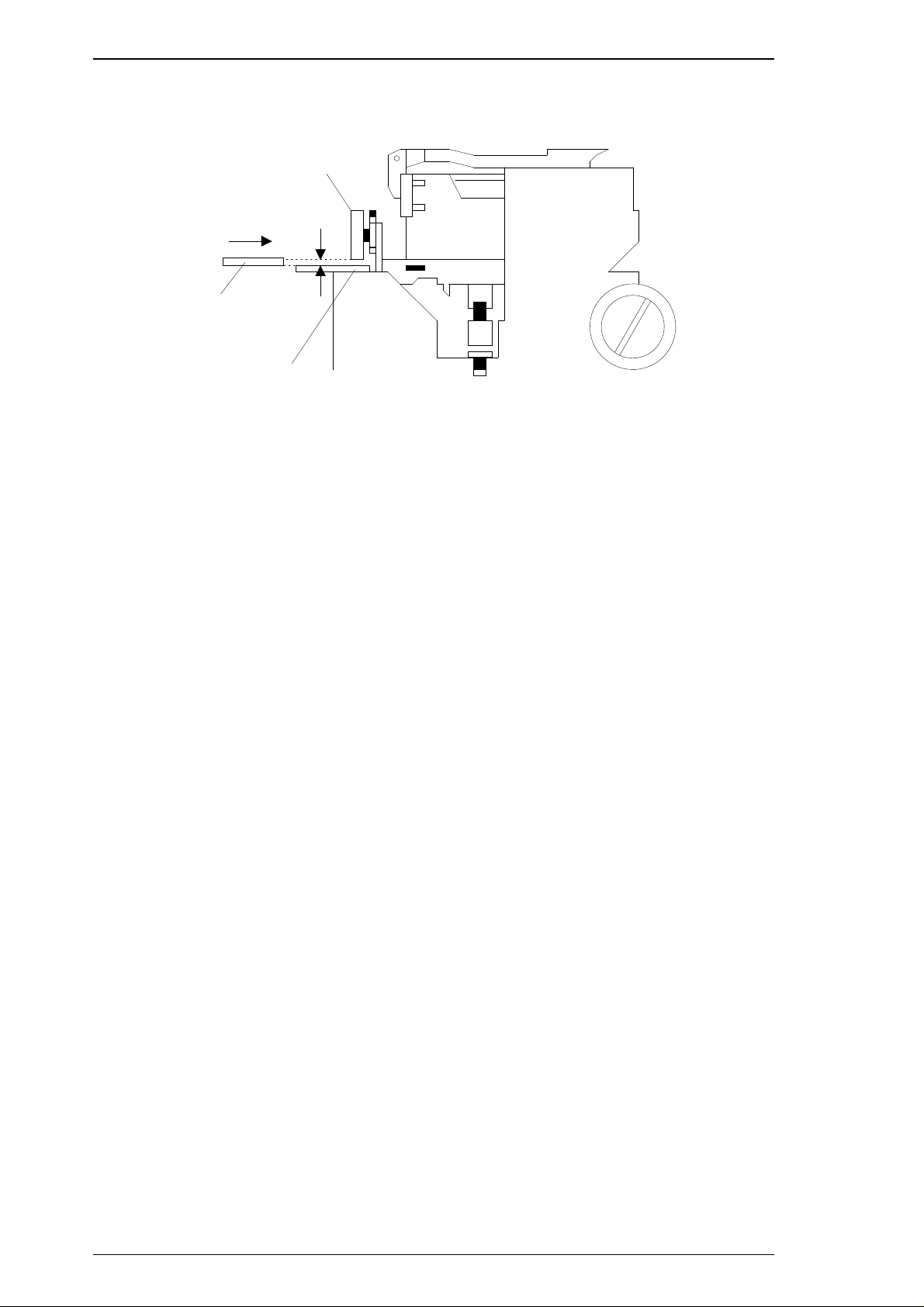

2.3.2.1 Reset Circuits

The C184 MAIN board contains 2 reset circuits: the +5 V monitor reset circuit and the +35 V monitor reset

circuit. The +5 V monitor reset circuit monitors the voltage level of the +5 V line (logic line), using reset IC

PST592D (IC9), and outputs a reset signal to the CPU (IC1) and the E05E21 gate array (IC2) when the

voltage level drops below +4.2 V. The +35 V monitor reset circuit monitors the voltage level of the +35 V

line, using reset IC M51955B (IC8), and outputs a reset signal to the CPU. The reset signal is generated when

the voltage level drops below +28 V, and this causes a non-maskable interrupt (NMI).

Figure 2-2. Reset Circuit Block Diagram

Rev.A 2-3

Page 17

TH

(CN12)

CCO

181

CPU (IC1)

SWA0

HP

PE

(CN8)

(CN9)

180

BCO

(CN11)

GA (IC 2)

AN0

86

SWC1

SWC2

(CN12)

4

3

SWC0

5

PB3

Operating Principles Stylus Pro XL+ Service Manual

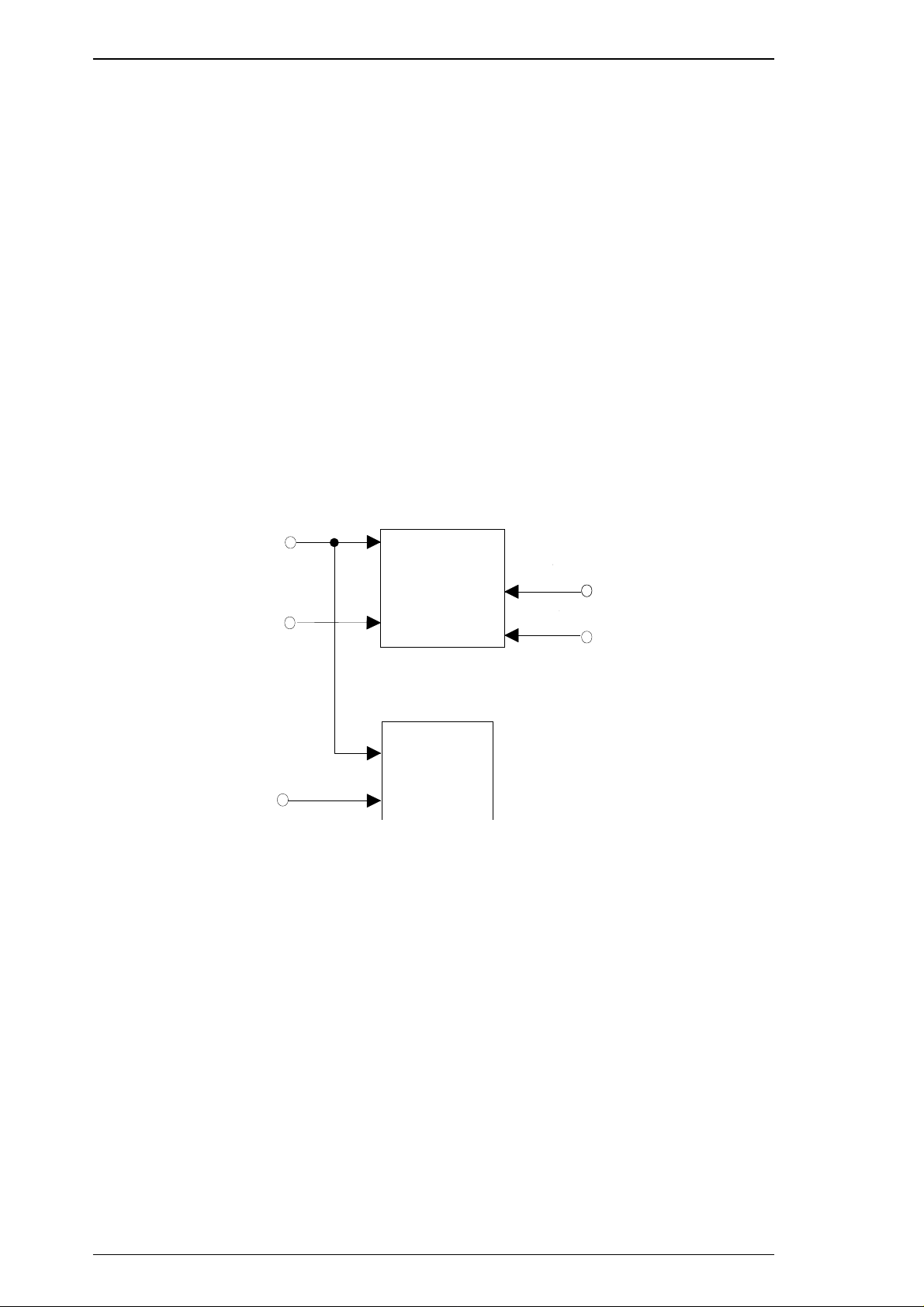

2.3.2.2 Sensor Circuits

The following sensor circuits enable the C184 MAIN board to monitor printer mechanism status:

HP sensor A photocoupler-type HP (home position) sensor is attached to the surface of the printer

mechanism to detect the carriage home position. A HIGH level from the signal indicates

that the carriage is in home position.

PE sensor A mechanical switch PE (paper end) sensor is built into the printer mechanism to determine

whether there is paper in the printer or not. A LOW level from the signal indicates that no

paper is loaded.

BCO sensor,

CCO sensor

Thermistor A thermistor is attached to the color printhead driver board to monitor its temperature using

Micro switches (BCO sensor for the black ink cartridge, CCO sensor for the color ink

cartridge) are attached to the bottom of ink cartridge holder in the carriage unit. When the

ink cartridge is installed, these switches are pressed and a LOW level from the signal

indicates that the ink cartridge is installed into the ink cartridge holder. These sensing

timing is only in the cartridge installation mode and one minute after the carriage holed to

prevent from miss censoring owing from switch actuators shock in printing condition.

the thermistor’s resistance value (at 25° C (77° F), the normal value is approximately

10K Ω). The CPU changes the printhead drive signal’s pulse width (charge pulse width)

based on the temperature level.

Figure 2-3. Sensor Circuit Block Diagram

2-4 Rev.A

Page 18

Stylus Pro XL+ Service Manual Operating Principles

2.3.2.3 Carriage Motor Driver Circuit

Carriage motor driver IC SLA7043 (IC15) outputs a constant current to drive the carriage motor in the printer

mechanism. Gate array E05B21 (IC2) decides the motor phase and speed, and then it sends a signal to the

carriage motor driver IC (SLA7043), using the 4-bit serial transmission line. The first bit indicates the

direction of motor rotation. The other three bits (a, b, c) are current duty data for the motor speed for each

printing sequence. (Refer to Table 2-2, below.)

SLA7043 can select the reference voltage itself based on these three bits of current duty data. Also, the driver

IC receives these signals via two serial transmission lines for the two motor phases (phase A and phase B). As

a result, the carriage motor can be driven in micro step sequence (

1

⁄

inches, minimum). The SLA7043

720

motor driver reads four-bit serial data using four clock counts from the E05B21 (IC2) clock.

Each bit is read at the falling edge of the clock pulses. Then, received serial data is written into the shift

register and then shifted the latch register. When the strobe pulse becomes active from the E05B21 (IC2),

serial data is moved into the reference voltage selection circuit and the voltage is changed. Therefore, when

the printer is in the constant speed mode, this strobe pulse becomes inactive. The following table indicates the

current duty of each carriage motor speed mode.

Table 2-2. Serial Data Contents

Mode c b a* Vref (Typical)

0 000

1 001

2 010

3 011

4 100

5 101

6 110

7 111

Vref × 1/3

(Vref = +5 V)

× 0%

×20%

×40 %

×55.5%

×71.4%

×83%

×91%

×100%

* “a” indicates the 2nd bit, “b” indicates the 3rd bit, and “c” indicates the 4th bit.

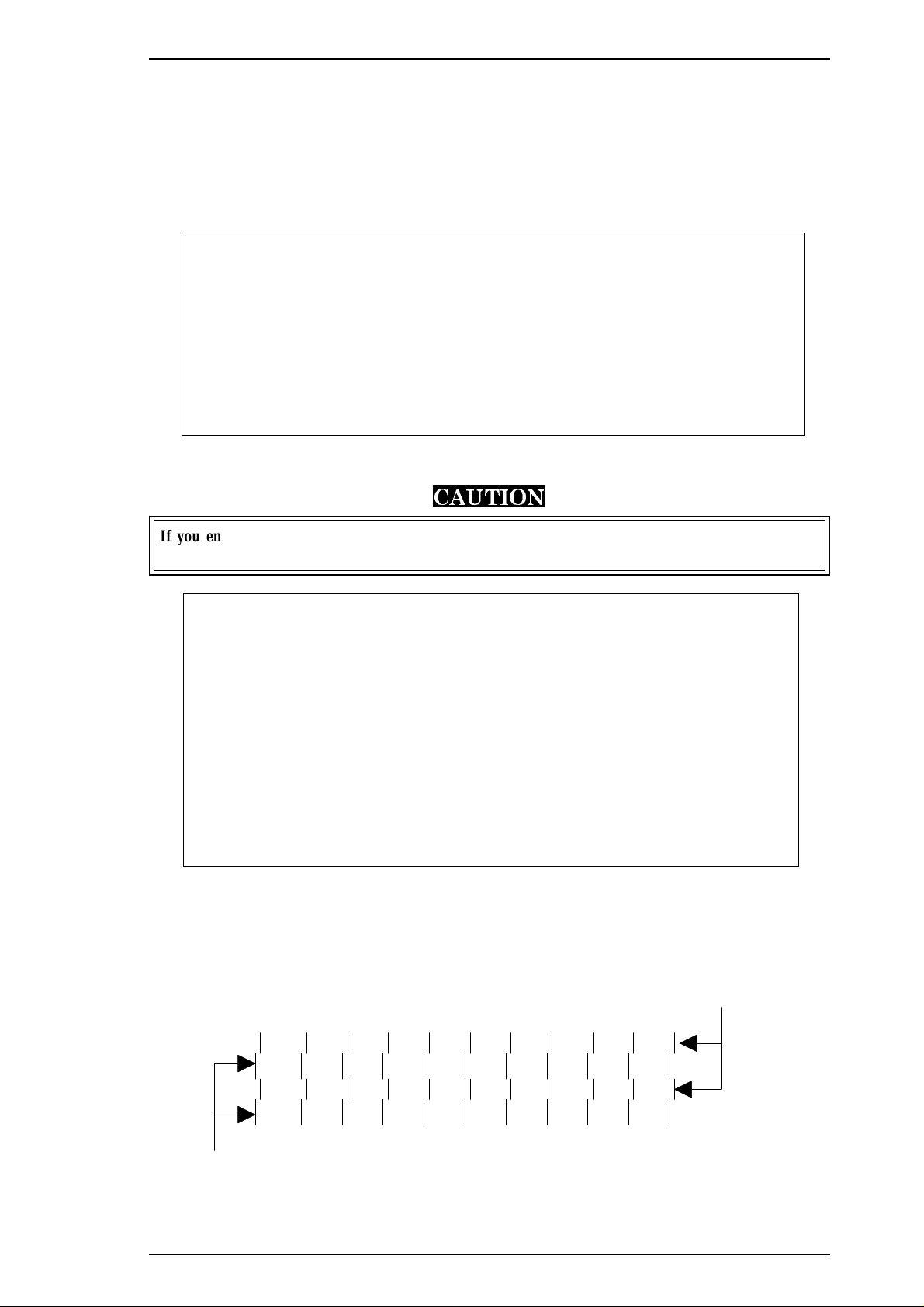

The following figure shows 4-bit serial data and how this data is transferred by the SLA7043 driver. The step

time for the reference voltage is determined by the interval time of the strobe pulse.

5

16

2

13

6

17

3

14

9

10

SLA7043

(IC15)

CLKA

CLKB

STBA

STBB

DATA A

DATA B

REF A

REF B

RSA

RSB

GND

1

11

18

1

8

2

3

(CN6)

4

5

V

5

3

+

A

A

B

B

E05B21

(IC2)

CRCLK

CRSTB

CRASO

CRBSO

CRV0-5

CRHOLD

197

198

199

196

5-10

205

C

B

E

Q5

Figure 2-4. Carriage Motor Circuit Block Diagram

Rev.A 2-5

Page 19

Operating Principles Stylus Pro XL+ Service Manual

2.3.2.4 Paper Feed Motor Driver Circuit

The paper feed motor for this printer drives the following mechanisms:

❒ Paper feed mechanism

❒ Paper pickup mechanism

❒ Pump mechanism

Driver IC SLA7043 (IC14) drives the paper feed motor by a constant current. The principle of operation is

same as for the carriage motor driver circuit. However, the paper feed motor drives not only the paper feed

mechanism but also the pump unit. (Refer to Section 2.3.2.4.)

Table 2-3. Paper Feed Motor Drive Modes

Mode Phase Excitation Drive Frequency

Paper feed 2-2 phase or 2W1-2 phase 391 or 1600 pps

Pump drive 2-2 phase 300 or 1800 pps

E05B21

(IC2)

PFCLK

PFSTB

PFASO

PFBSO

PFV0-2

PFHOLD

202

198

204

201

11-13

205

B

Q4

5

16

2

13

6

17

3

14

9

10

E

SLA7043

(IC14)

CLKA

CLKB

STBA

STBB

DATA A

DATA B

REF A

REF B

RSA

RSB

GND

1

A

A

B

B

1

8

2

11

3

(CN7)

4

18

5

V

5

3

+

Figure 2-5. Paper Feed Motor Driver Circuit Block Diagram

2-6 Rev.A

Page 20

Stylus Pro XL+ Service Manual Operating Principles

2.3.2.5 Printhead Driver Circuit

The printhead driver circuit for this printer is composed of the following two parts:

❒ Common driver circuit (common drive pulse generation)

❒ Head driver circuit (nozzle control built on the printhead)

The common driver circuit is hybrid IC H8D2778A on the C184 MAIN board. The head driver circuit is IC

SED61110D0A on the printhead unit itself. The printhead drive signals are output from gate array E05B21.

They consist of the common driver control signals (SBDT/SCDAT, SCLK,

BH1C1/CH1C1, BH1D/CH1D, BHDIS/CHDIS) and the nozzle select signals (BHDAT/CHDAT,

BHCLK/CHCLK, BHLAT/CHLAT,

BHNCHG/CHNCHG).

The common driver control signals from gate array E05B21 are translated to common drive voltage pulses by

IC H8D2778A and input to each printhead nozzle PZT. The nozzle select signals are also output from gate

array E05B21 to SED6110D0A on the head unit to select the print nozzles. Then the ink dots are ejected from

the selected nozzles.

SSTB, SCLR, BH1C0/CH1C0,

On Carriage (Head Driver Board)

SED6110DOA

COM

CN11

1

N

C

COM

CN12

1

N

C

(U1)

CLK

LAT

SI

SED6110DOA

(U2)

CLK

LAT

SI

E05B21 (IC2)

BH1C0/1

BHNCHG

CH1C0/1

CHNCHG

SBDAT

SCLK

SSTB

SCLR

BH1D

BHDIS

BHCLK

BHLAT

BHDAT

SCDAT

CH1D

CHDIS

CHCLK

CHLAT

CHDAT

C184 MAIN

Common Driver

H8D2778A

Common Driver

H8D2778A

Figure 2-6. Printhead Driver Circuit Block Diagram

Black Head Nozzles

Color Head Nozzles

Rev.A 2-7

Page 21

Operating Principles Stylus Pro XL+ Service Manual

Common Driver Signals

The common driver control signals consist of the common voltage control signals (SBDAT/SCDAT, SSTB,

SCLR, SCLK) and the common drive pulse generation signals (BH1C0/CH1C0, BH1C1/CH1C1,

BH1D/CH1D, BHDIS/CHDIS). The common voltages (VH), ranging between the maximum voltage and 0

(V), are split into 256 levels, which are then translated into 8-bit serial data for the common voltage control

signal (BHDAT/CHDAT), which is output from gate array E05B21 to the common driver H8D2778A to fit

with each printhead specifically. The signals are received by

SSTB, SCLR and SCLK to the common driver.

SCLT

SDAT

SCLR

SSTB

H

L

H

L

H

L

H

L

Figure 2-7. Common Driver Signal Timing Chart

After the common voltage (VH) is stabilized, common drive pulse generation signals are translated to

generate the common drive pulses from gate array E05B21 to the H8D2778A common driver.

COM

VH

BH1C 0/CH1C0

BH1C 1/CH1C1

BH1D/CH1D

Figure 2-8. Common Drive Pulses

2-8 Rev.A

Page 22

VH

COM

BH1C0/CH1C0

BH1C1/CH1C1

BH1D/CH1D

BHNCHG/CHNCHG

BHLAT/CHLAT

BHCLK/CHCLK

BHDAT/CHDAT

# 1

# 64

Stylus Pro XL+ Service Manual Operating Principles

Nozzle Select Signals

The nozzle select signals are output from gate array E05B21 to SED6110D0A on the head unit to select the

printhead nozzles. Nozzle select data (BHDAT/CHDAT) is HIGH for selected nozzles and LOW for

unselected nozzles. Nozzle select data translation timing is controlled by 64 clock signals (BHCLK/CHCLK),

one for each nozzle. After the print nozzles are selected, the common drive pulses are input to each PZT on

the selected nozzles via SED6110D0A. Then the ink dots are ejected from each selected nozzle’s PZT.

Figure 2-9. Common Drive / Nozzle Select Signal Timing

(Normal Dot Printing)

Rev.A 2-9

Page 23

VH

COM

BH1C0/CH1C0

BH1C1/CH1C1

BH1D/CH1D

Operating Principles Stylus Pro XL+ Service Manual

Normal Dot Versus EPSON Micro Dot Printing Mode

The Stylus Color Pro XL+ can eject ink in two different modes (normal print mode and EPSON Micro Dot

Mode). These modes are the same as the modes used in the Stylus Color II/Stylus Color IIs. (Refer to Section

2.2.1.) However, EPSON Micro Dot Printing in the Stylus Color II and Stylus Color IIs can be used only for

printing with black ink. EPSON Micro Dot Printing in the Stylus Pro XL+ can be used with both black and

color printing.

In normal dot printing, a pair of common drive pulses are translated to the printhead to produce one dot. On

the other hand, one print dot consists of single dot in the EPSON Micro Dot Printing. A single common drive

pulse is translated to the printhead, as shown in the following figure.

Figure 2-10. Common Drive Pulse for EPSON Micro Dot

2-10 Rev.A

Page 24

Stylus Pro XL+ Service Manual Operating Principles

2.4 INK SYSTEM MANAGEMENT

This section explains how the ink system is managed to protect the printhead and the ink supply system and to

ensure high-quality output. Ink system operations are controlled by the following counters:

❒ Protect counter

❒ Ink consumption counter

2.4.1 Counters

EEPROM 93C46 (IC11) on the main board stores the counter values used for controlling ink system

operation.

2.4.2.1 Protect Counters

The values of protect counters A and B, C are stored in the EEPROM on the main board, and while the printer

is on, this data is also stored in the RAM on the main board.

❒ Protect counter A This counter manages the total amount of drained ink. If the counter value

is equal to or exceeds 51,000, the printer indicates an error on the control

panel indicating that maintenance is required.

Notes for Service

Protect counter A is reset:

1. Upon shipment from the factory.

2. After maintenance is performed (whenever you replace the ink drain tank).

❒ Protect counter B, C These counters set limits to prevent the user from frequent initial ink

charging. The counters values are stored in the EEPROM as flags and are

reset by the EEPROM reset function.

2.4.2.2 Ink Consumption Counter

This counter manages black and color ink consumption. The counter is counted up during printing,

automatically. It also counts compulsory head cleaning and the interval times between usage of the ink

cartridge. This counter is only reset by the installation of a new ink cartridge.

Rev.A 2-11

Page 25

Stylus Pro XL+ Service Manual Disassembly and Assembly

3.1DISASSEMBLY AND ASSEMBLEY - OVERVIEW

Thissectiondescribesproceduresfordisassemblingthemaincomponentsoftheprinter.Unlessotherwise

specified,disassembledunitsorcomponentscanbereassembledbyreversingthedisassemblyprocedure.

Thereforenoassemblyproceduresareincluded.Precautionsforanydisassemblyorassemblyprocedureare

describedundertheheading“Disassembly/AssemblyPoints.”Adjustmentsrequiredafterassemblingtheunit

aredescribed undertheheading “RequiredAdjustments.”

3.1.1Precautions for DisassemblingthePrinter

Seetheprecautionsbelowwhendisassemblingtheprinter.

WARNING

❒Disconnectthepowercablebeforedisassemblingorassemblingtheprinter.

❒Wearprotectivegogglestoprotectyoureyesfromink.Ifinkgetsinyoureye,flushitwith

freshwaterandseeadoctorimmediately.Ifinkcomesintocontactwithyourskin,washit

offwithsoapandwater.Ifirritationoccurs,contactaphysician.

❒AlithiumbatteryisinstalledontheC184MAINBoardofthisprinter.Besuretoobserve

thefollowinginstructionswhenservicingthebattery:

1.Keepthebatteryawayfromanymetalorotherbatteriessothatelectrodesofopposite

polaritydonotcomeincontactwitheachother.

2.Donotheatthebatteryorputitnearfire.

3.Donotsolderonanypartofthebattery.(Doingsomayresultinleakageofelectrolyte

fromthebattery,burning,orexplosion.Theleakagemayaffectotherdevicesclosetothe

battery.)

4.Donotchargethebattery.(Anexplosivegasmaybegeneratedinsidethebattery,and

causeburningorexplosion.)

5.Donotdismantlethebattery.(Thegasinsidethebatterymayhurtyourthroat.Leakage,

burning,orexplosionmayalsoresult.)

6.Donotinstallthebatteryinthewrongdirection.(Thismaycauseburningorexplosion.)

CAUTION

Thereisdangerofexplosionifthebatteryisincorrectlyreplaced.Replaceonlywiththesameor

equivalenttyperecommendedbythemanufacturer.Disposeofusedbatteriesaccordingto

government’slawsandregulations.

ATTENTION

Risqued’explosionsilapileestremplacéeincorrectement.Neremplacerqueparunepiledu

mêmetypeoud’untypeéquivalentrecommandéparlefabricant.Elminerlespilesdéchargées

selonlesloisetlesrèglesdesécuritéenvigueur.

CAUTION

❒Neverremovetheinkcartridgefromthecarriageunlessspecifiedtodoso.

❒Whentransportingtheprinteraftertheinkcartridgehasbeeninstalled,besurenottoremove

theinkcartridgewhenyoupacktheprinterforshipping.

❒Useonlyrecommendedtoolsfordisassembling,assembling,oradjustingtheprinter.

❒Applylubricantsandadhesivesasspecified.(SeeStylusProXLServiceManualChapter6.)

❒Makespecifiedadjustmentswhenyoudisassembletheprinter.(SeeChapter4.)

Rev.A 3-1

Page 26

Stylus Pro XL+ Service Manual Disassembly and Assembly

3.2 DISASSEMBLY AND ASSEMBLY

CAUTION

❒ When you remove the ink cartridge, always install a new cartridge immediately after taking

out the old one.

❒ When you replace the ink cartridge, the printer performs the ink cartridge replacement

operation automatically.

The exclusive service cartridges have the following part numbers:

Monochrome: 1020626

YMC: 1027990

❒ Never keep ink cartridges longer than 6 months.

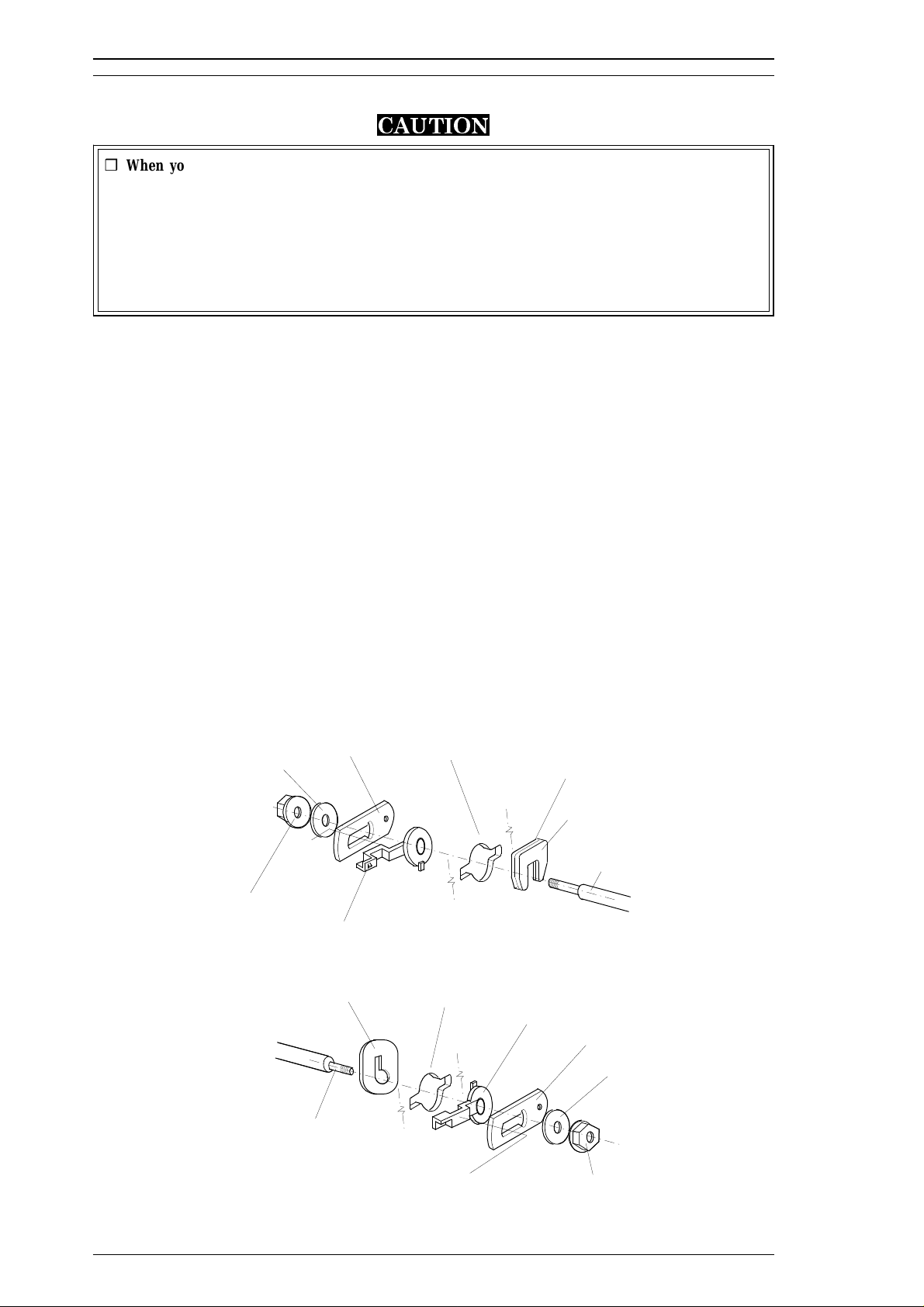

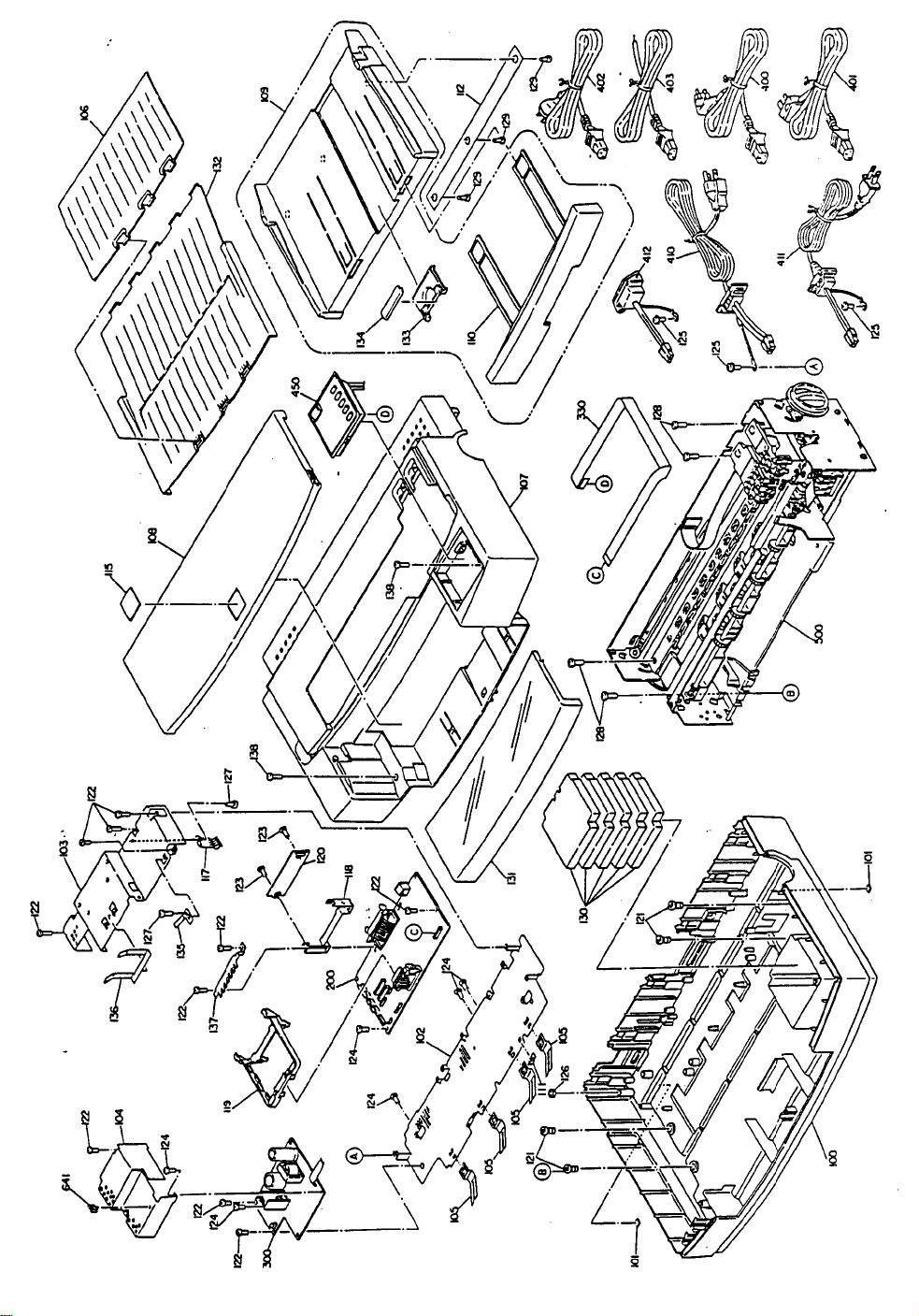

3.2.1 Printer Mechanism Disassembly

The procedures described in this section explain how to remove components in the printer mechanism.

3.2.1.1 Carriage Unit Removal

1. Remove the printer mechanism. (See Stylus Pro XL Service Manual, Section 3.2.4.)

2. Move the carriage to the left side of the printer while pressing the hook that fixes the carriage to the

home position.

3.

Remove the 2 CBS (O) (M3× 6) screws securing the front frame to both side frames.

4. Remove the cartridge holder with from the carriage unit. (See the Stylus Pro XL Service Manual,

Section 3.2.5.1.)

5. Release the carriage timing belt from the belt pulley while pressing the pulley lever.

6. Remove the both sides flange nuts and plain washers.

7. Remove 2 parallelism adjustment bushings and carriage shaft spacers from both side frames.

8. Take off carriage shaft spacer L and carriage shaft spacers B, C, or D (if they have been installed).

Carriage Shaft Spacer

Plain Washer

Flange Nut (M4)

Parllelism Adjust Bushing

Carriage Shaft Spacer R

Carriage Guide Shaft

Left Side Frame

Carriage Shaft Spacer L;B

Carriage Shaft Spacer L;C

Carriage Shaft Spacer L;D

Carriage Shaft Spacer L

Carriage Guide Shaft

Right Side Frame

Parllelism Adjust Bushing

Carriage Shaft Spacer

Plain Washer

Flange Nut (M4)

Figure 3-1. Fixing the Carriage Guide Shaft

3-2 Rev.A

Page 27

Stylus Pro XL+ Service Manual Disassembly and Assembly

9. Lift the carriage unit with the carriage guide shaft out of the printer mechanism.

CAUTION

❒ Take appropriate measures to protect the printhead unit from static electricity, because the

driver IC is directly attached to the printhead unit.

❒ Never touch the metallic nozzle surface of the printhead cover. Handle it only by holding the

edges of the printhead.

❒ After you have replaced the printhead or the printer mechanism, you must perform the

head data writing operation before any other adjustments. (See Section 4.1.1.)

❒ Put the carriage shaft spacers L, B, C and D between the left frame and the carriage guide

shaft to minimize the gap between them. The adjustable range is from 0.8 mm to 1.8 mm.

The thickness of carriage shaft spacers are as follows:

Carriage Shaft Spacer L 0.6 mm

Carriage Shaft Spacer L and B 0.8 mm

Carriage Shaft Spacer L and C 1.0 mm

Carriage Shaft Spacer L and D 1.2 mm

ADJUSTMENT REQUIRED

❒ Platen gap adjustment (See Chapter 4.)

Rev.A 3-3

Page 28

Stylus Pro XL+ Service Manual Adjustment

4.1ADJUSTMENT - OVERVIEW

Thissectiondescribesadjustmentsrequiredwhentheprinterisdisassembledandassembledafterrepair.

Sincethisprinterhasbothablackandcolorhead,itneedsnewadjustmentsnotrequiredforpreviousprinters.

Refertothefollowing table toperformtheappropriateadjustments.

CAUTION

❏Alwaysperformadjustmentsintheorderindicated.

❏Afterperformingsteps1-5,dothecleaningoperationfortheblackandcolorprintheads.

Thecleaningoperationisnecessary,becauseprintingsamplepatternsfortheheadangle,

Bi-Dalignment,andtheheadgapincreasestheviscosityoftheink,andtheprinterwill

notprintthecorrectvalue.Forinstanceifyoureplacetheblackhead,youmustdothe

followingadjustmentsintheordershown:

(1)Blackheadangle,(2)black-colorheadvertical,(3)headgap,(4)Bi-Dalignment.

❏Afterremovinganinkcartridge,alwaysinstallanewcartridgeimmediately.During

adjustmentsandtesting,usecartridgesdesignedexclusivelyforservice

(Monochrome:1020626,CMY:1027990)

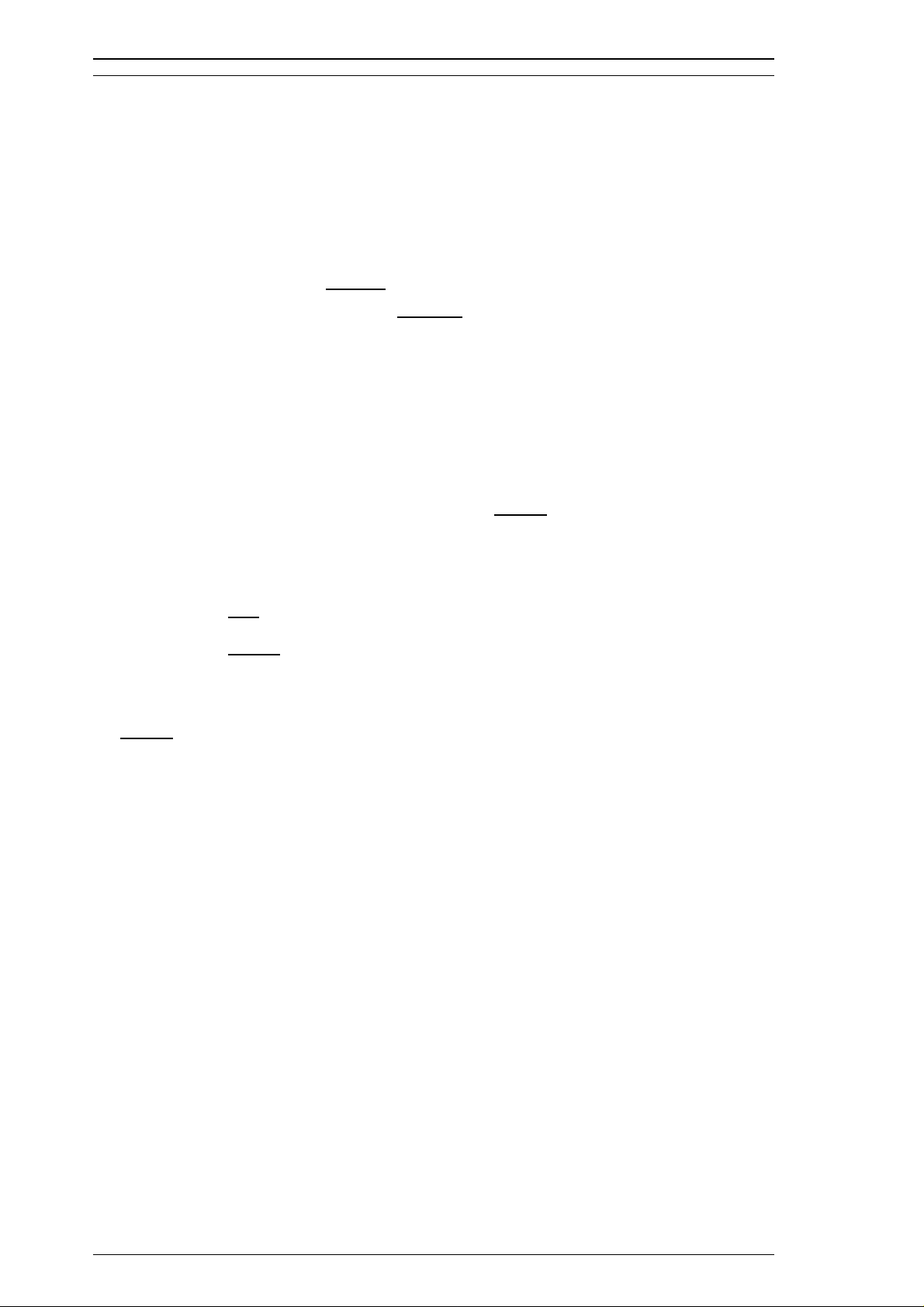

Table 4-1. Required Adjustments

ServicePerformed AdjustmentNeeded

When replacing the

printermechanism

When replacing or

disassembling the main

boardor printermechanism

When replacing or

disassembling the

black head(board)

When replacing or

disassembling

the colorhead(board)

When replacing or

disassembling both the

colorand black head

1. Writingheaddata(see Section 4.1.1)

2. Bi-Dalignment adjustment (seeSection4.1.2).

3. Head gapadjustment(see Section 4.1.3).

1. Writingheaddata(see Section 4.1.1)

2. Bi-Dalignment adjustment (seeSection4.1.2).

3. Head gapadjustment(see Section 4.1.3).

1. Writingheaddata(see Section 4.1.1)

2. Blackheadangleadjustment(see Section 4.1.4).

3. Black- color headverticaladjustment (seeSection4.1.5).

4. Head gapadjustment(see Section 4.1.3).

5. Bi-Dalignment adjustment (seeSection4.1.2).

1. Writingheaddata(see Section 4.1.1)

2. Color headangle adjustment (seeSection4.1.6).

3. Black- color headverticaladjustment (seeSection4.1.5).

4. Head gapadjustment(see Section 4.1.3).

5. Bi-Dalignment adjustment (seeSection4.1.2).

1. Writingheaddata(see Section 4.1.1)

2. Color headangle adjustment (seeSection4.1.6).

3. Blackheadangleadjustment(see Section 4.1.4).

4. Black- color headverticaladjustment (seeSection4.1.5).

5. Head gapadjustment(see Section 4.1.3).

6. Bi-Dalignment adjustment (seeSection4.1.2).

When replacing or

disassembling

the carriageunit

1. Platen gap adjustment(see Section 4.1.7).

2. Writingheaddata(see Section 4.1.1)

3. Bi-Dalignment adjustment (seeSection4.1.2).

4. Head gapadjustment(see Section 4.1.3).

NOTE: The destination data writing operation (see Section 4.1.2) is performed automatically

when you quit the program from the adjustment main menu and turn off the printer.

When you need to replace the printer mechanism, you will find the head data information

written on the outside of carton containing the printer mechanism.

Rev.A 4-1

Page 29

Adjustment Stylus Pro XL+ Service Manual

4.1.1 Head Data Writing Operation

Data unique to the specific black and color printhead used in the printer is stored in the EEPROM on the

C184 MAIN board. These values must be written to the EEPROM first when the printhead unit, the printer

mechanism, main board, or EEPROM chip is replaced. However, it is not necessary to write them to

EEPROM again, even if the EEPROM is reset from the control panel.

CAUTION

Before running this program, be sure the interface setting is set to parallel or auto select.

1. Connect the PC to the target printer using a parallel interface cable, and turn the printer on.

2. Load BASIC on the PC, and run the adjustments program. You see the following destination select

menu:

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown in the menu that follows.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. Select “1, Head VH input” typing 1 and pressing Enter to perform the head data writing operation.

Then the menu for setting the black head data appears, as shown below:

input head VH

BK VH = ? ■

4-2 Rev.A

Page 30

Nozzle Select Circuit Board

Head VH Valu e

Stylus Pro XL+ Service Manual Adjustment

5. Input the black head VH values. Then the menu for setting color head VH values appears.

6. Input the color head VH values. Then the program returns to the main menu.

CAUTION

❏ The head VH data is written on the each head unit as shown in the following figure.

❏ The setting values are not stored permanently in the EEPROM until you turn the printer off.

Turn off the printer immediately after the adjustments.

Figure 4-1. Printhead VH Value

7. When the main menu appears, choose “10. Change customer & data / END” by typing 10 and Enter.

8. Choose “END” by typing 7 to exit the adjustment program.

CAUTION

Specific destination parameters, including the destination, interface mode, TOF value, and

economy/condensed, are not written to the EEPROM yet. Turn off the printer immediately after

the adjustments.

9. Turn off the printer.

4.1.1.1 Head VH Indication

This function prints out the VH values for the installed black and color heads stored in the EEPROM. The

values are in HEX, so convert them into the head VH values using a conversion table and input in the printer.

1. Select “7, Head VH indication” by typing 7 and pressing Enter to print out the head VH settings. The

printer prints the head values in four columns, as shown below:

Head VH : X1 X2 X3 X4

CAUTION

X1 and X2 show the VH for the black head; X3 and X4 show the VH for the color head.

Rev.A 4-3

Page 31

Adjustment Stylus Pro XL+ Service Manual

4.1.2 Destination Data Writing Operation

The setup value that specifies the printer destination is stored in EEPROM on the C184 MAIN board.

Therefore, this setup value must be written to the EEPROM when the main board or EEPROM chip is

replaced. This function is always selected to finish the program using END operation.

CAUTION

Before writing the destination data writing, set the interface to parallel or auto select.

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown shown below.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. When the main menu appears, choose “10, Change customer & data / END” by typing 10 and pressing

Enter.

5. The main menu immediately disappears briefly and then the destination select menu appears.

6. Choose “END” by typing 7 to exit the adjustment program.

CAUTION

Settings have not yet been written to the EEPROM. Turn off the printer immediately after the

adjustments.

7. Turn off the printer.

4-4 Rev.A

Page 32

Black Head

(Angle Adjustment)

Head Base

Head Carriage

Angular Spacer

Linear Spacer

Stylus Pro XL+ Service Manual Adjustment

4.1.3 Black Head Angle Adjustment

The black head angle adjustment is required when the black head is replaced or disassembled. If this

adjustment is not correct, a white banding problem may occur, or color head timing may not match black

head timing. The following figure illustrates the black head angle adjustment. The black head angle is

adjusted with linear and angular spacers. A linear spacer is attached to both sides of the head base, and an

angular spacer is attached only to the right side of the head base. Spacers for the black head come in different

shapes for the thickness needed. The following figure shows the relationship between the shape and thickness.

Figure 4-2. Black Head Angle Adjustment

Angular Spacers (for Black Head)

Spacer Nam e Th ickne ss Shap e

angular s pacer BK

angular spac er BK- C

angular spac er BK- D

angular spacer BK-E

0.05

0.10angular spacer BK-B

0.15

0.20

0.25

Linear Spacers (Only for Black Head)

Spacer Name Thickness Shape

linear spacer K

linear spacer J

li nea r sp ac er I

linear spacer

linear spacer B

linear spacer C

linear spacer D

linear spacer E

0.05

0.12

0.19

0.26

0.33

0.40

0.47

0.54

Rev.A 4-5

Figure 4-3. Types of Spacers and Relationship between

linear spacer F

linear spacer G

linear spacer H

Shape and Thickness

0.61

0.68

0.75

Page 33

Adjustment Stylus Pro XL+ Service Manual

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown below.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. Choose “3, Head angular & linear adjustment” by typing 3 and pressing ENTER. (The printer prints the

check pattern, along with the sample name. )

CAUTION

❏ When you replace both the black and color heads, always adjust the color head angle first.

The black head angle is based on the color head angle.

❏ After you replace the black head and print the black head angle pattern, you only have

to insert an angular spacer if the pattern is incorrect.

4-6 Rev.A

Page 34

Position A Position A

Replac e the ri ght

angula r spacer with

a thin ner one

Look at position A

Replac e the ri ght

angula r spacer with

a thi cker o ne

Stylus Pro XL+ Service Manual Adjustment

5.

3-2. BLACK HEAD ANGLE ADJUSTMENT

B

A

Figure 4-4. Black Head Angle Adjustment Sample

The printer prints a pattern like one in the following sample. Only the nozzles in rows A and D are fired

(making it is easy to see the angle of the black head).

6. In the figure above, pay attention to position A. (Do not look at position B.)

7. Using the following flowchart, replace the angular spacer for the black head, which is under the right

8. Turn the printer power off now.

9. Manually move the carriage to the center while pressing the carriage lock lever, and remove the two ink

10. Remove the rubber cap covering the head screw at the side of color ink cartridge. Then loosen (but do

Rev.A 4-7

Figure 4-5. Spacer Selection Flowchart

linear spacer. The procedure for this replacement is explained beginning with step 7.

cartridges.

not remove) 3 screws. (Refer to Figure 4-6.)

CAUTION

After replacing the spacer, always install new ink cartridges before returning the printer to the

user. During this adjustment, use ink cartridges exclusively for service:

(Monochrome: 1020626, CMY: 1027990 ).

Page 35

1. Push

Head Ba se

Linear Spacers

Platen Gap Adjust Lever

Angular Spacer

Carriage Unit

Black Head

2. Replace

Adjustment Stylus Pro XL+ Service Manual

Rubber Cap

Color Ink Cartridg e Holder

CBB(M3x11)

CBB(M3x1 1)

CBB(M3x11)

Figure 4-6. Removing the Rubber Cap

11. Replace the angular spacer for the black head with a new one. (Refer to Figure 4-7.)

(To replace the angular spacer, use tweezers to push the head base toward the rear.)

12. After replacing the angular spacer, reassemble the ink cartridge holder and reinstall the ink cartridges.

Use the BASIC program to verify the angle of the black head. Confirm the angle by performing the

steps 1 to 6 again, and if the angle is wrong, perform the adjustment again until the head angle is correct.

CAUTION

❏ The angular spacers come in five thicknesses. Continue performing this adjustment by

changing the black head spacers until the angle is correct.

❏ When inserting an angular spacer, always place the angular spacer on the linear spacer.

Figure 4-7. Angular Spacer Replacement Method

4-8 Rev.A

Page 36

Color Head

Color Head

(Reverse Side)

Head Base

(Angle Adjustment Concept)

(Spacer Setting Location)

Carriag e

Angular Spa cer

Stylus Pro XL+ Service Manual Adjustment

4.1.4 Color Head Angle Adjustment

The color head angle adjustment is required when the color head is replaced or disassembled. If this

adjustment is not correct, a white banding problem may occur, or the black head timing may not match the

color head timing. The following figure illustrates the color head angle adjustment. The color head angle is

adjusted with the angular spacer. The angular spacer is attached only to the left side of the head base.

Figure 4-8. Color Head Angle and Angular Spacer Position

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown below.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

10. Change customer & data / END

0. Cleaning

Rev.A 4-9

Select Menu ? ■

Page 37

3-1 YMC HEAD ANGULAR

Magenta

Mage nta Cyan

Cyan

A

B

Adjustment Stylus Pro XL+ Service Manual

4.

Figure 4-9. Color Head Angle Confirmation Sample

When the main menu appears, choose “3, Head Angle Confirmation Pattern Printing” by typing 3 and

pressing ENTER. (The printer prints a check pattern with the sample name.)

CAUTION

When replacing both the black and color heads, always adjust the color head angle first. The

black head angle and the black - color head vertical position adjustments are based on the color

head angle adjustment.

Figure 4-10. Relationship between the Shape and Thickness

Angular spacers for the color head come in five thicknesses, each having its own shape. The following figure

shows the relationship between the shape and thickness. Since the color head is not equipped with a linear

spacer, the angle adjustment is decided only by the angular spacer (specifically designed for the color head),

which is placed under the left side of the head base.

5. In Figure 4-9, pay attention to the position of A and B while you reset the left angular spacer. The

replacement procedure is explained beginning in step 6.

6. Turn off the printer now.

Angular Spacers (Fo r Color Head)

Spacer Name Thick ness Shape

angular spacer YMC

angular spacer YMC-C

angular spacer YMC-D

angular spacer YMC-E

0.30

0.35angular spacer YMC-B

0.40

0.45

0.50

4-10 Rev.A

Page 38

Stylus Pro XL+ Service Manual Adjustment

7. Move the carriage to the center manually, and loosen (but do not remove) the screw securing the color

head to the carriage.

Look at

positions A, B

Position A, B Position A, B

(A) (B) (A) (B)

Replace the right

angular sp acer

with a thicker one

Replace the right

angular s pacer

with a thinner one

Figure 4-11. Spacer Selection

8. Remove the rubber cap covering the head screw at one side of color ink cartridge. Then loosen (but do

not remove) 3 screws. (Refer to the Figure 4-9.)

9. Replace the angular spacer on the left side with a new one, referring to the figure below. (Replace the

angular spacer using tweezers to push the head base toward the rear.)

10. Rerun the BASIC program and choose “3, Head Angle Confirmation Pattern Printing” again by typing 3

and pressing ENTER. Then verify that the confirmation sample is correct.

Carriage Unit

1

Push

Color Head

Base Head

Paper Gap Adjust Lever

Spacer Angular

(one side only)

Replace

2

Figure 4-12. YMC Angular Spacer Replacement

11. If the sample is incorrect, repeat steps 6-10 until the upper lines in the sample are aligned with one

another and the lower lines in the sample are exactly equidistant to one another (as shown at B in Figure

4-11).

12. When you complete this adjustment, turn off the printer.

Rev.A 4-11

Page 39

Adjustment Stylus Pro XL+ Service Manual

4.1.5 Black - Color Head Vertical Adjustment

This adjustment calibrates the vertical position between the black head and the color head. Align the top

nozzles (both nozzle # 1 on the black head and nozzle # 1 on the color head). You can make this adjustment

by using only the linear spacers for the black head. This adjustment is required when the black head or the

color head is replaced or disassembled. The following figure illustrates this adjustment.

Adjust

Carriage Unit

#1

#2

#16

Color Head

Magenta

Cyan

Ye llo w

#3

#7

#63

Black Head

#4

#6

#8

#64

#62

#5

#9

#61

#1#2

Vertical Position

Vertical Position

Figure 4-13. Black - Color Head Vertical Adjustment

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown below.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

4-12 Rev.A

Page 40

Stylus Pro XL+ Service Manual Adjustment

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. When the main menu appears, choose “3, Head angular & linear adjustment” by typing 3 and pressing

ENTER. (The printer prints the check pattern, along with the sample name.)

CAUTION

When replacing the black head, always adjust the black head angle first, because the black - color

head vertical adjustment is based upon the black head angle.

3-3. BLACK HEAD SPACE R SELECTION

Magenta

Black

-5 -4

+1 +2 +3 +4

-3 -2 -1

OK(0)

+5

Figure 4-14. Linear Spacer Selection Sample

5. In Figure 4-14, the vertical position is correct when both the magenta line and the black line are aligned

(as shown in position OK (0)). If the vertical position is correct, turn off the printer. If the black and

magenta lines are not aligned, perform the vertical adjustment as described in steps 6-10.

CAUTION

❏ The number shown in the sample indicates the thickness level compared to the current

linear spacer. (See * .) There are 11 linear spacers with 11 different thicknesses.

❏ The linear spacer is attached by two pieces, one on each side of the head base. Therefore,

when you need to replace one linear spacer, always replace both linear spacers at the

same time.

❏ When replacing the linear spacer, place it under the angular spacer.

* If necessary, replace the linear spacer. For instance, if your pattern is similar to the pattern

shown under –2, replace the linear spacer with a thinner linear spacer. If your pattern is similar

to the pattern shown under 2, replace the linear spacer with a thicker spacer.

6. Turn the printer off.

7. Move the carriage to the center while pressing the carriage lock lever, and remove the two ink cartridges.

8. Remove the rubber cap that covers a head screw at the side of color ink cartridge, and then loosen (but

do not remove) 3 screws. (Refer to the figure on the next page.)

CAUTION

After replacing the spacer, always install new ink cartridges before returning the printer to the

user. During adjustment, use the ink cartridges exclusively for service (Monochrome: 1020626,

CMY: 1027990 ).

Rev.A 4-13

Page 41

Adjustment Stylus Pro XL+ Service Manual

9. Change the linear spacers (2 spacers for the monochrome head only) with new ones, referring to the

figure below. (Replace linear spacers by using tweezers to push the head base toward the rear.)

Carriage Unit

1

Push

Head Base

Angular Spacer

Platen Gap Adjust Lever

Linear Spacers x 2

(Linear Spacer Replacement Position)

2

Replace

Figure 4-15. Linear Spacer Replacement Method

10. Rerun the BASIC program, and choose the “Head Vertical Position Confirmation” by typing 3 and

pressing ENTER; then confirm that the sample print is correct. If the sample is incorrect, change the

thickness of the linear spacer and perform this adjustment again until the two black and magenta lines

are aligned at the position “OK (0)."”

11. When you complete this adjustment, exit the BASIC program and turn off the printer.

4-14 Rev.A

Page 42

HEAD GAP ADJUST N O. X

Black Line

Color (Magenta) Line

Stylus Pro XL+ Service Manual Adjustment

4.1.6 Head Gap Adjustment (Black and Color Head)

The head gap adjustment is required when the printer mechanism, main board, or printhead (board) is

replaced or disassembled. This adjustment calibrates the head drive timing between the black and color head.

If this adjustment is not made, the vertical alignment will not be completed.

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown below.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. When the main menu appears, choose “5, BK. YMC head gap adjustment” by typing 5 and pressing

ENTER. (The printer prints a check pattern sample with a sample compensation value. The printer prints

a sample like the one shown in the following figure.)

Figure 4-16. Head Gap Adjustment Sample

Rev.A 4-15

Page 43

Adjustment Stylus Pro XL+ Service Manual

The adjustment value input menu appears as shown:

INPUT ADJUST No. (IF OK INPUT Y)? ■

adjust range (from –32 to 32)

5. If the sample print is not vertically aligned for both odd-numbered lines (black lines) and

even-numbered lines (magenta lines), enter a compensation value in the range from −32 to +32.

❏ Positive compensation value: Shifts the 2nd line to the left

❏ Negative compensation value: Shifts the 2nd line to the right

When both the black and magenta lines are vertically aligned, input Y or y, and press ENTER. This

returns you to the main menu.

6. When the main menu appears, choose “10, Change customer & data / END” by typing 10 and Enter.

(This returns you the destination setting menu.)

7. Choose “7, END” by typing 7 and pressing ENTER to quit the adjustment program.

CAUTION

Settings have not yet been written to the EEPROM. Turn off the printer immediately after the

adjustments.

8. Turn off the printer.

4-16 Rev.A

Page 44

Stylus Pro XL+ Service Manual Adjustment

4.1.7 Bi-D (Bidirectional Printing) Alignment Adjustment

The bidirectional alignment is required when the printer mechanism, main board, or printhead (board) is

replaced. Performing this adjustment determines a compensation value to rectify any deviation in the print

position. This deviation could be caused by different print speeds, which are due to tolerances in the

mechanical components, or to differences in print timing between odd-numbered lines and even-numbered

lines in bidirectional printing. The printer stores the compensation data in the EEPROM on the C184 MAIN

board and refers to this data when performing bidirectional printing.

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown below.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. When the main menu appears, choose “6, Bi-D Adjustment” by typing 6 and pressing ENTER. (The

printer prints a check pattern with a sample compensation value. The next menu appears on the display.)

INPUT ADJUST No. (If OK INPUT Y)? ■

720 DPI adjust range ( from –30 to 30)

Rev.A 4-17

Page 45

Adjustment Stylus Pro XL+ Service Manual

5. If the sample print is not vertically aligned for both the odd-numbered and even-numbered lines, enter a

compensation value in the range from –30 to +30.

❏ Positive compensation value: Shifts the 2nd line to the left

❏ Negative compensation value: Shifts the 2nd line to the right

When the sample print becomes vertically aligned for both lines, press Y and ENTER; then the printer

prints out the current Bi- D setting pattern, and this returns you to the 360 DPI Bi-d adjustment mode.

6. Adjust the 360 DPI Bi-d setting mode in the same way as 720 dpi Bi-D adjustment.

7. If you have finished the 360 dpi Bi-d adjustment, choose “10, END” by typing 10 and pressing

ENTER. (The destination setting menu appears on the display again.)

8. Choose “7, END” by typing 7 and pressing ENTER to quit the adjustment program.

CAUTION

Settings have not been written to the EEPROM yet. Turn off the printer immediately after the

adjustments.

9. Turn off the printer.

4-18 Rev.A

Page 46

Bushing

Right Adjustment Position

Left Adjustment Positio n

Paper Guide Plate

Pump Unit

Front Frame

Thickness GaugeThickness Gauge

Platen

Attach the thickness gauge

under the PF p inch roller u nit.

FRONT

Platen

PF Pinch Roller

Unit

Front Frame

Paper Guid e

Tension Roller

Thickness Gauge

Attachment Point

Stylus Pro XL+ Service Manual Adjustment

4.1.8 Platen Gap Adjustment

This adjustment is required when the carriage unit is replaced or removed from the printer mechanism. Adjust

the distance between the printhead nose and the paper surface to 1.1 mm.

1. Attach a thickness gauge (commercially available) to the left side adjustment position on the paper guide

plate, as shown in the figure below, so that one side hooks the paper feed pinch roller unit.

2. Move the carriage unit manually onto the thickness gauge.

Table 4-2. Gap and Adjustment Direction

Gap between Head Nose and Gauge Surface Left Bushing Right Bushing

Narrow CW CCW

Spread CCW CW

3. Rotate the parallelism adjustment bushing, attached to the left and right ends of the carriage guide shaft,

when the black and color printheads contact the thickness gauge.

4. After attaching the printheads to the gauge surface, verify that the gap between the carriage roller and the

front frame is less than 0.04 mm. (See Figure 4-18.)

5. Attach the 1.1 mm thickness gauge to the right side adjustment position on the paper guide plate, as

shown below, so that one side hooks the paper feed pinch roller unit.

Rev.A 4-19

Figure 4-17. Adjusting the Paper Gap

Page 47

Adjustment Stylus Pro XL+ Service Manual

Note: When checking the gap between the carriage roller and the front frame, use the thickness

gauge or the paper guide plate. If the gap is correct the gauge cannot be installed into the

gap. If the gap is incorrect, the gauge can be inserted in the gap.

Carriage Roller

GAP

0.04 m m

Thick ness

Gauge

Eject Fra me

Figure 4-18. Confirming the Gap

6. Move the carriage manually to the right adjustment position and repeat steps 3, 4 and 5 referring to

Figures 4-17 and 4-18.

4-20 Rev.A

Page 48

Stylus Pro XL+ Service Manual Adjustment

4.1.9 Ink Consumption Counter Reset Operation

This operation is required when the ink cartridge is replaced. Usually, this operation is performed by the panel

operation. But if you perform this operation, you can reset the ink consumption counter value at any time.

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown below.

CAUTION

If you enter an incorrect number as the destination selection, printer functions are not

guaranteed.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. When the main menu appears, choose “2, Ink consumption counter reset” by typing 2 and pressing

ENTER. This resets the internal timer. The following message then appears.

Ink Counter Reset

Black Ink Counter Reset only——- 1

Color Ink Counter Reset only ——- 2

Both Ink Counters Reset ——- 3

Quit Ink Counter Reset ——- 4

Select No.

5. Choose and type the selection number. This returns you to the main menu.

Rev.A 4-21

Page 49

Adjustment Stylus Pro XL+ Service Manual

4.1.10 Head Cleaning Function

This function performs the compulsory ink charging to the printer head in order to check using the service

tool for ink charging.

1. Connect the PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. You see the following destination select menu.

***** Customer *****

1. EAI, EAI (Latin America), EAL, ESP

2. EDG, EUL, EFS, EIS, EIB, EUL (Northern Europe), EUL (Middle East), EHK

3.

4. JAPAN

5.

6.

7. END

Select Menu ?

3. Input the number for the destination. Then the main menu appears, as shown below.

STYLUS Pro XL+ Program : Rev. X

customer :

1. Head VH input

2. Ink consumption counter reset

3. Head angular & linear adjustment

4. Head position check

5. BK. YMC head gap adjustment (head gap center )

6. Bi-D adjustment (Bi-d center )

7. Head VH indication

10. Change customer & data / END

0. Cleaning

Select Menu ? ■

4. When the main menu appears, choose “0, Cleaning” by typing 0 and pressing ENTER. This resets the

internal timer. The following message then appears.

Ink Counter Reset

Black Ink counter Reset only ——- 1

Color Ink Counter Reset only ——- 2

Both Ink Counter Reset ——- 3

Quit Ink Counter Reset ——- 4

Select No.

5. Choose and type the selection number. This returns you to main menu.

CAUTION

If you perform this function on the same ink cartridge repeatedly, the ink life of this cartridge

becomes shorter than normal.

4-22 Rev.A

Page 50

CN1

CN2

CN1

CN5

C

N

1

1

C

N

9

C

N

8

CN7CN6

CN10

CN

CN

C

N

CN2

Type B I/F

(Option)

CN3

RS-4 22

Serial I/F

C

N

1

2

C

N

Parallel I/F

C

N

1

3

C137 PNL

AC Inlet

ASF Plung er

Printhead Unit

HP Sensor

CR Sensor

C184 MAIN

C137 PSB/PSE

RF Motor

CR Motor

Printer Mechanism

STYLUS PRO XL+ Service Manual Appendix

A.1 CONNECTOR SUMMARY

The figure below shows the interconnection of major components of the Stylus Color Pro XL+.

Figure A-1. Interconnection of major components

Rev.A A-1

Page 51

Appendix STYLUS PRO XL+ Service Manual

Table A-1. Connector Summary

Board Location Pins Description

C164 MAIN CN1 36 Centronics parallel I/F

CN2 36 Type B parallel I/F

CN3 8 RS-422 serial I/F

CN5 6 Power supply from PS board

CN6 5 Carriage motor phase output

CN7 5 PF/PM motor phase output

CN8 2 Paper end sensor