Page 1

Chapter 1

Product Descriptions

1.1 Features.................................................................................................................1-1

1.2 Specifications.......................................................................................................1-2

1.2.1 Printing Specification............................................................................................................. 1-2

1.2.2 Paper Specification ................................................................................................................ 1-4

1.2.2.1 Cut Sheet...................................................................................................................1-4

1.2.2.2 Transparency, Glossy Paper.....................................................................................1-4

1.2.2.3 Envelope....................................................................................................................1-4

1.2.2.4 Index Card................................................................................................................. 1-4

1.2.3 Adjust Lever Settings (PG adjust lever)............................................................................... 1-5

1.2.4 Printing Area...........................................................................................................................1-6

1.2.4.1 Cut Sheet...................................................................................................................1-6

1.2.4.2 Envelope....................................................................................................................1-7

1.2.5 Environmental Condition....................................................................................................... 1-8

1.2.6 Ink Cartridge Specifications.................................................................................................. 1-9

1.2.6.1 Black Ink Cartridge....................................................................................................1-9

1.2.6.2 Color Ink Cartridge .................................................................................................. 1-10

1.2.7 Physical Specification.......................................................................................................... 1-11

1.2.8 Input Data Buffer .................................................................................................................. 1-11

1.2.9 Electric Specification ........................................................................................................... 1-12

1.2.10 Reliability............................................................................................................................. 1-12

1.2.11 Safety Approvals................................................................................................................. 1-12

1.2.12 Acoustic Noise.................................................................................................................... 1-12

1.2.13

CE Marking.......................................................................................................................... 1-12

1.2.14 Printer Language and Emulation...................................................................................... 1-13

1.3 Interface...............................................................................................................1-14

1.3.1 Parallel Interface (Forward Channel).................................................................................. 1-14

1.3.2 Parallel Interface (Reverse Channel) .................................................................................. 1-15

1.3.3 Serial Interface...................................................................................................................... 1-18

1.3.4 Prevention Hosts from Data Transfer Time-out.................................................................1-19

1.3.5 Interface Selection................................................................................................................ 1-19

1.4 Control Panel ......................................................................................................1-20

1.4.1 Indicators............................................................................................................................... 1-20

1.4.2 Panel Functions.................................................................................................................... 1-21

1.4.3 Printer Condition and Panel Status.................................................................................... 1-22

1.5 Error Status.........................................................................................................1-23

1.5.1 Ink Out ................................................................................................................................... 1-23

1.5.2 Paper Out............................................................................................................................... 1-23

1.5.3 Paper Jam.............................................................................................................................. 1-23

1.5.4 No Ink-Cartridge ...................................................................................................................1-24

1.5.5 Maintenance Request........................................................................................................... 1-24

1.5.6 Fatal Errors............................................................................................................................ 1-24

1.6 Printer Initialization ............................................................................................1-25

1.7 Initialization Settings..........................................................................................1-25

Page 2

1.8 Main Components..............................................................................................1-26

1.8.1 C209 Main Control Board.....................................................................................................1-26

1.8.2 C206 PSB/PSE(Power Supply) Board .................................................................................1-27

1.8.3 C209PNL Panel Unit..............................................................................................................1-27

1.8.4 Printer Mechanism................................................................................................................1-27

1.8.5 Housing..................................................................................................................................1-28

Page 3

EPSON Stylus Photo

1.1 Features

EPSON Stylus Photo is a high quality color ink jet printer designed for printing photo images and color

graphics. The major printer features are;

High color print quality

720(H) x 720(V) dpi printing

6 color printing CMYK and output of photo quality by light-C/M

Traditional and New Microwave

32 nozzles x 6 (Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta)

During 360 dpi printing, 1 dot is fired by 2 shots, and 1 dot is fired by

1 shot during 720 dpi printing.

Built-in auto sheet feeder

Holds 100 cut-sheets (55g/‡u)

Holds 10 envelopes

Holds 50 transparency films

Holds 65 special papers

Built-in 2 I/F

Mac serial I/F(up to approx.900 kbps)

Bi-directional parallel I/F(Nibble mode. IEEE-1284 level 1 device)

High-speed print

200cps

By driving the print head at frequency; 14.4KHz, printing speed is twice faster than Stylus Color.

Windows/Macintosh exclusive

Compact size

Non-operating : 429mm(W) x 234mm(D) x 162mm(H)

Operating : 429mm(W) x 695mm(D) x 309mm(H)

Weight : 5.2Kg(without cartridge)

Acoustic noise

Approximately 45 dB

One unit combined with black and color heads

The following table shows consumable and option.

Table 1-1. Consumables and options

Item Code Remark

Black Ink Cartridge S020093 Color: Black

Color Ink Cartridge S020110 Color: Cyan/Magenta/Yellow/Light

Light Cyan/Light Magenta

EPSON 360 dpi Ink Jet Paper S041025 Size: A4(200 sheets)

EPSON 360 dpi Ink Jet Paper S041059 Size: A4(100 sheets)

EPSON 360 dpi Ink Jet Paper S041060 Size: Letter(100 sheets)

Photo Quality Ink Jet Paper S041026 Size: A4(200 sheets)

Photo Quality Ink Jet Paper S041061 Size: A4(100 sheets)

Photo Quality Ink Jet Paper S041062 Size: Letter

Photo Quality Ink Jet Paper S041067 Size: Legal

Photo Quality Glossy Paper(New Release) S041126 Size: A4

Photo Quality Glossy Paper(New Release) S041124 Size: Letter

Photo Quality Glossy Film S041071 Size: A4

Photo Quality Glossy Film S041072 Size: Letter

Photo Quality Glossy Film S041107 Size: A6

Ink Jet Transparencies S041063 Size: A4

Ink Jet Transparencies S041064 Size: Letter

Photo Quality Ink Jet Card S041054 Size: A6

Photo Quality Ink Jet Card S041121 Size: 5.8 inches

Photo Quality Ink Jet Card S041122 Size: 10.8 inches

Photo Quality Self Adhesive Sheet S041106 Size: A4

Rev.A

1-1

Page 4

Chapter 1 Product Description

2

1.2 Specifications

This section describes each specification for EPSON Stylus Photo; 1) Printing specification, 2) Paper

specification, 3) Adjust lever settings, 4) Printing area, 5) Environmental condition, 6) Ink Cartridge

specification, 7) Physical specification, 8) Electric specification, 9) Reliability.

1.2.1 Printing Specification

Print method

On demand ink jet (E-CHIPS type. One unit combined with black and color head)

Nozzle configuration

Black head: 32 nozzles (Space between nozzle: 90DPI)

Color head: 32 nozzles/ each color x 5 colors (Space between nozzle: 90DPI)

Note)

During 360 dpi printing mode, one line is completed by 2-pass for black and by 4-pass for CMYcm.

Print direction

Bi-direction with logic seeking

Print speed

Raster Graphics Mode. Refer to Table 1-2.

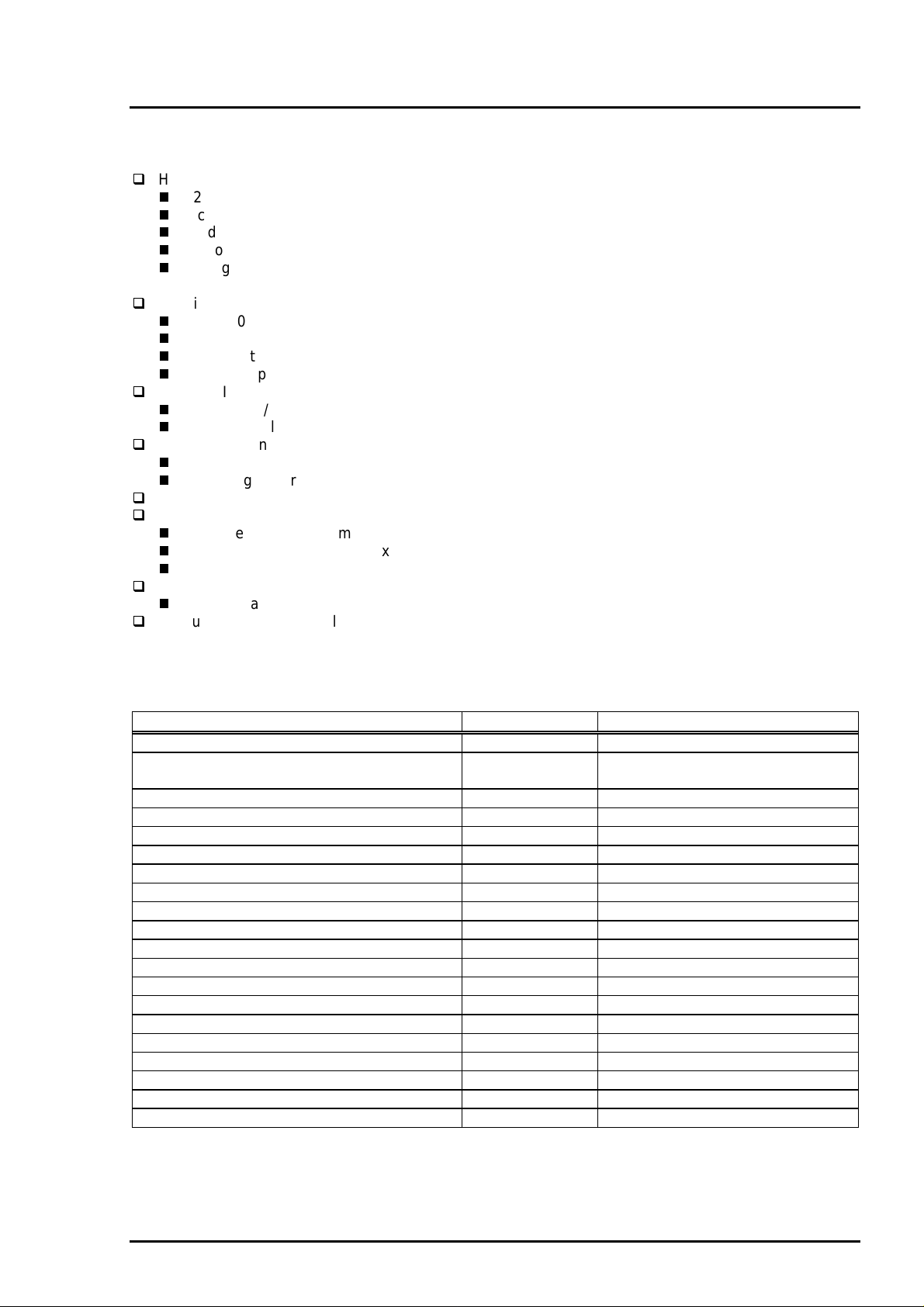

Table 1-2. Raster Graphics Mode

Horizontal Resolution Printable Area Available Dot CR Speed(IPS)

180 dpi 8.26 inch 1488 20 IPS

360 dpi 8.26 inch 2976 20 IPS

720 dpi 8.26 inch 5952 20 IPS

Character Mode*. Refer to Table 1-3.

Table 1-3. Character Mode

Character Pitch Printable Colums LQ Speed

10CPI 80 200CPS **

Note)

* Reference only.

**This value is the speed of one print-pass in which the 1/4of character matrix is printed.

Nozzle arrangement

Refer to figure1-1.

22.5777 mm

(320/360")

10.16 mm

(144/360")

2.2578 mm

(32/360")

#32

(4/360")

0.2822 mm

#1

Black

Cyan

Light Cyan

Magenta

Light Magenta

Yellow

Figure 1-1. Head Nozzle Arrangement

1-

Rev.A

Page 5

EPSON Stylus Photo

3

Feeding method

Friction feed with ASF

Line spacing

1/6 inch or programmable at 1/360 inch

Paper path

Cut-sheet ASF(Top entry)

Feeding speed

66.6ms (1/6 inch)

3.0 inch/sec (Continuous)

Ink supply

Exclusive ink cartridge(Black and CMYcm)

Built in ASF

Size : Index card•`Legal

Thickness : Less than 8mm

Paper capacity : Holds 100 Cut sheets

: Holds 10 Envelopes

: Holds 10 transparency sheet

: Holds 65 ink jet papers (A4)

: Holds 30 index card (A6)

: Holds 30 glossy papers

Note1)

Those numbers above should be considered as reference. The actual paper accumulation should

be considered first.

Note2)

Note3)

transparency sheet.

The printer can hold 10 transparency sheets only when the top margin is 30mm. Otherwise, only

one sheet can be hold.

Change the paper support position for the transparency printing position when you print on the

Character tables*

PC437(US, Standard Europe)

PC850(Multilingual)

Typeface*

Bit map LQ font : EPSON Courier 10CPI

Control code

ESC/P Raster

EPSON Remote command

Note)

* Reference only.

Rev.A

1-

Page 6

Chapter 1 Product Description

4

1.2.2 Paper Specification

This section describes the printable area and types of paper that can be used in this printer.

Note)

1.2.2.1 Cut Sheet

Do not perform reverse feed more than 9.5mm(0.38”).

[Size]

[Thickness]

[Weight]

[Quality]

: A4 [Width 210mm(8.3”) x Length 297mm(11.7”)]

: Letter [Width 216mm(8.5”) x Length 279mm(11.0”)]

: B5 [Width 182mm(7.2”) x Length 257mm(10.1”)]

: Legal [Width 216mm(8.5”) x Length 356mm(14.0”)]

: Statement [Width 139.7mm(5.5”) x Length 215.9mm(8.5”)]

: Exclusive [Width 190.5mm(7.5”) x Length 254mm(10”)]

: 0.08mm(0.003”) - 0.11mm(0.004”)

2

: 64g/m

: Exclusive paper, Bond paper, PPC

(17Ib.) - 90g/m2 (24Ib.)

1.2.2.2 Transparency, Glossy Paper

[Size]

[Thickness]

Note)

Transparency printing is only available at normal temperature.

: A4 [Width 210mm(8.3”) x Length 297mm(11.7”)]

: Letter [Width 216mm(8.5”) x Length 279mm(11.0”)]

: 0.075mm(0.003”) - 0.085mm(0.0033”)

1.2.2.3 Envelope

[Size]

[Thickness]

[Weight]

[Quality]

Note 1)

Note 2)

Envelope printing is only available at normal temperature.

Keep the longer side of the envelope horizontally at setting.

: No.10 [Width 241mm(9 1/2”) x Length 104.8mm(4 1/8”)]

: DL [Width 220mm(8.7”) x Length 110mm(4.3”)]

: C6 [Width 162mm(6.4”) x Length 114mm(4.5”)]

: 0.16mm(0.006”) - 0.52mm(0.02”)

: 45g/m

: Bond paper, Plain paper, Air mail

1.2.2.4 Index Card

[Size]

[Thickness]

Note 1)

Note 2)

Note 3)

Note 4)

No curled, wrinkled, scuffing or torn paper be used.

Set the lever to the proper position according to the paper type you print. (Refer to section

1.2.3 for details)

Printing should be performed at room temperature in spite of the paper types.

Perform printing under the room temperature.

: A6 Index card: [Width 105mm(4.1”) x Length 148mm(5.8”)]

: A5 Index card: [Width 148mm(5.8”) x Length 210mm(8.3”)]

: 5x8” Index card: [Width 127mm(5.0” x Length 203mm(8.0”)]

: 10x8” Index card: [Width 127mm(5.0”) x Length 203mm(8.0”)]

: Less than 0.23mm(0.0091”)

2

(12Ib.) - 75g/m2 (20Ib.)

1-

Rev.A

Page 7

EPSON Stylus Photo

5

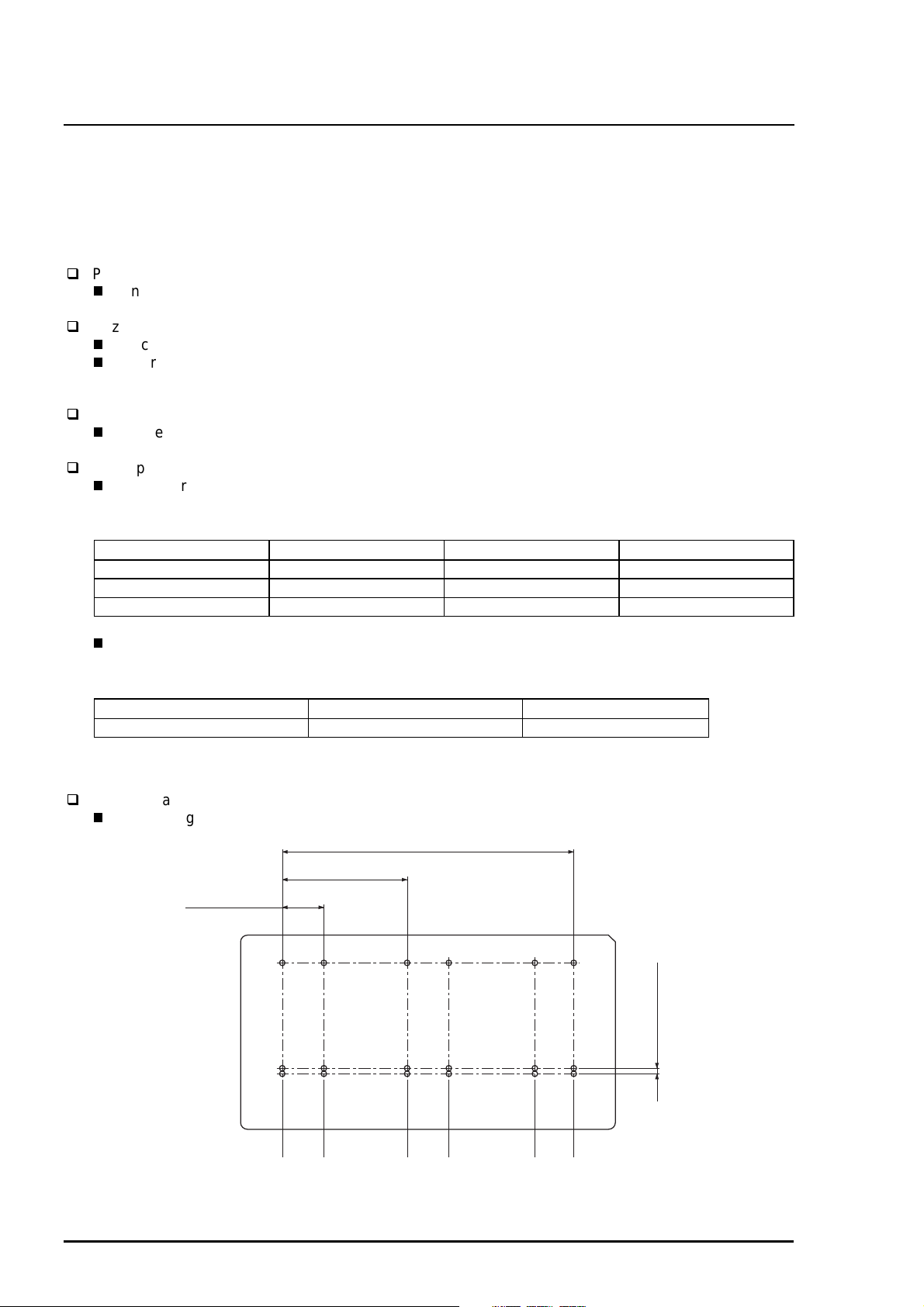

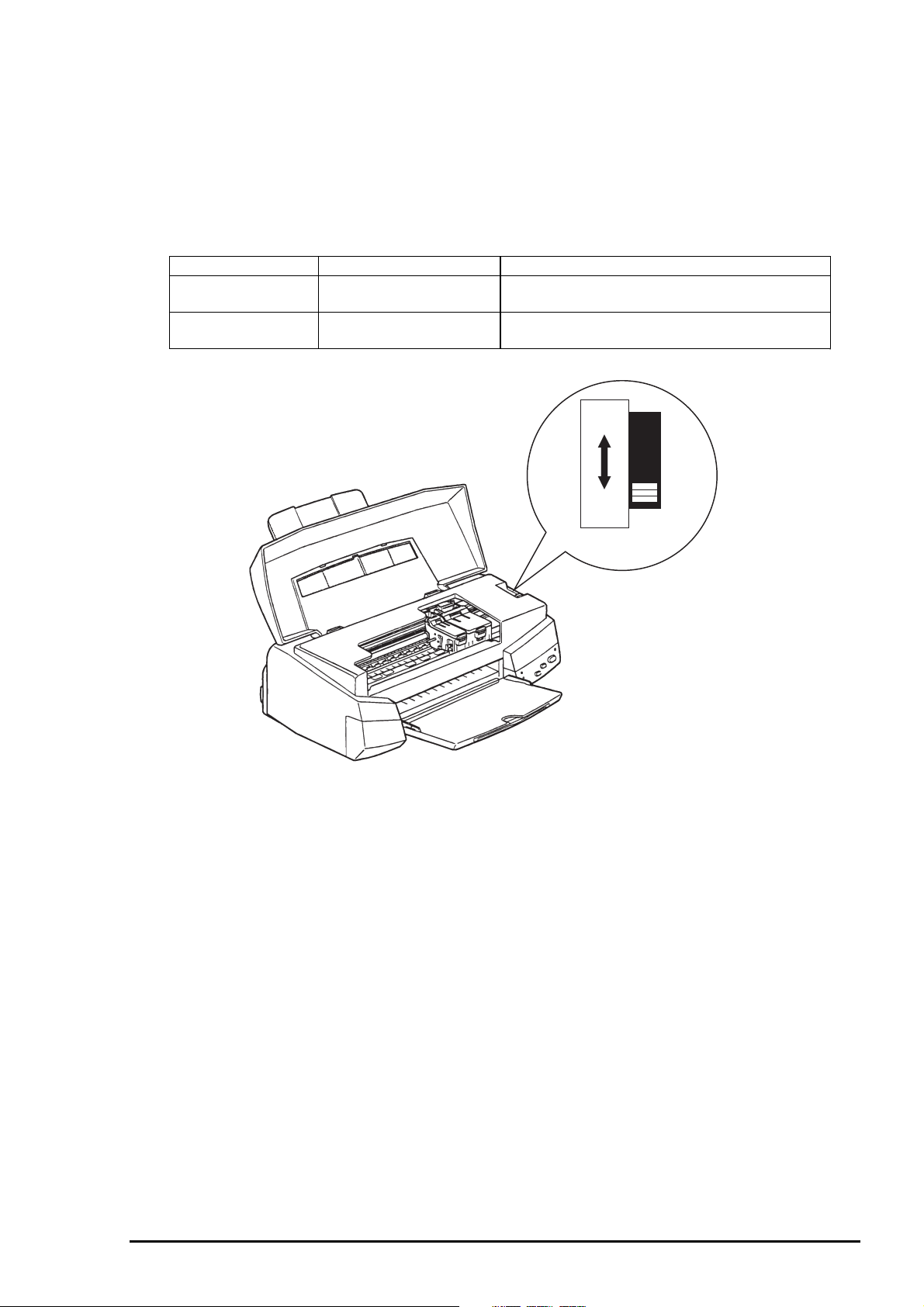

1.2.3 Adjust Lever Settings (PG adjust lever)

The adjust lever located on the right side(blue) that is under the printer cover needs to be set to the proper

position according to the paper you print. (Refer to the table below). Also, if there is any dirt caused by

friction on the wavy or wrinkled paper, this can be prevented by changing the lever position to rear

position (marked with “+”) in spite of paper types.

Table 1-4. Adjust Lever Settings

Paper Lever position PG adjustment value

Normal paper,

Coated paper

Envelopes Rear(+) 0.9 mm (1.94mm between head and paper

Front (0) 0 mm (1.04mm between head and paper feed

assembly)

feed assembly)

+

Figure 1-2. Adjust Lever

0

Paper Adjust Lever

Rev.A

1-

Page 8

Chapter 1 Product Description

6

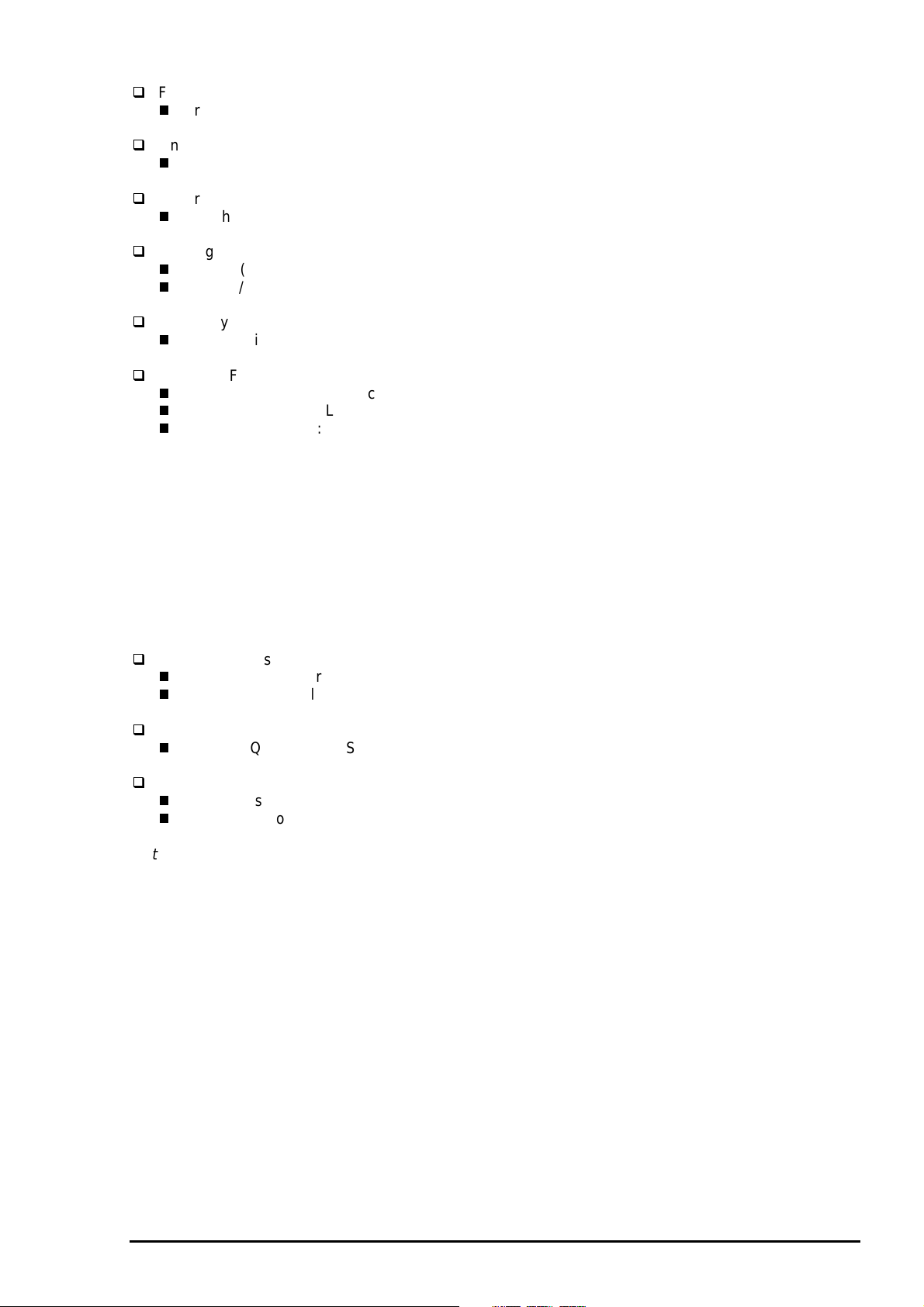

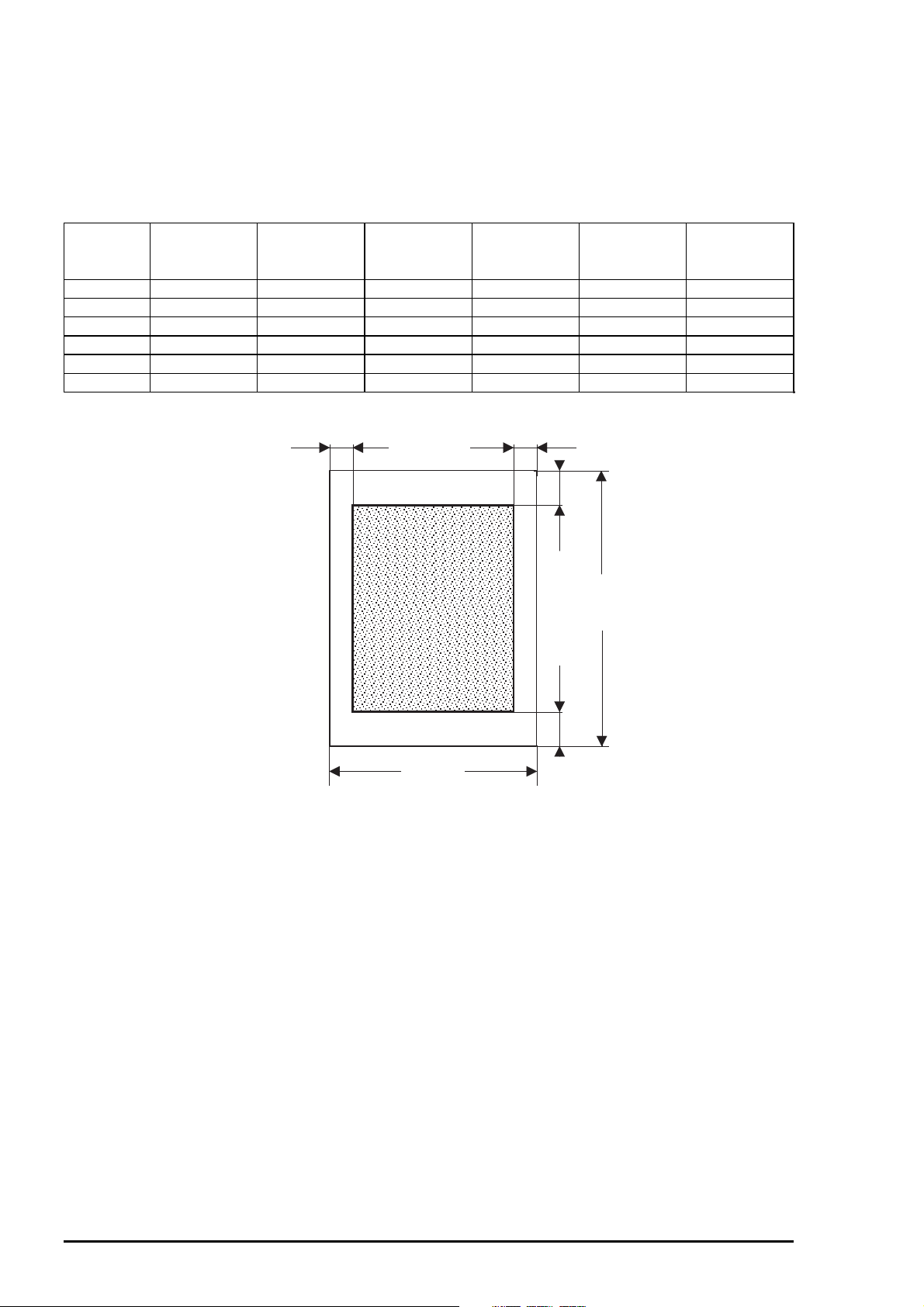

1.2.4 Printing Area

1.2.4.1 Cut Sheet

The following table shows printable area.

Table 1-5.Printable Area for Cut Sheet

Paper size PW(Paper

width)

(typ)

PL(Paper

Length)

(typ.)

LM(Left

margin)

(min.)

RM(Right

margin)

(min.)

TM(Top

margin)

(min.)

BM(Bottom

margin)

(min.)

A4 210mm(8.3”) 297mm(11.7”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Letter 216mm(8.5”) 279mm(11.0”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

B5 182mm(7.2”) 257mm(10.1”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Legal 216mm(8.5”) 356mm(14.0”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Statement 139.7mm(5.5”) 215.9mm(8.5”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

Executive 190.5mm(7.5”) 254mm(10”) 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.54”)

LM

Printable area

RM

TM

PL

BM

PW

Figure 1-3. Printing Area for Cut Sheet

1-

Rev.A

Page 9

EPSON Stylus Photo

7

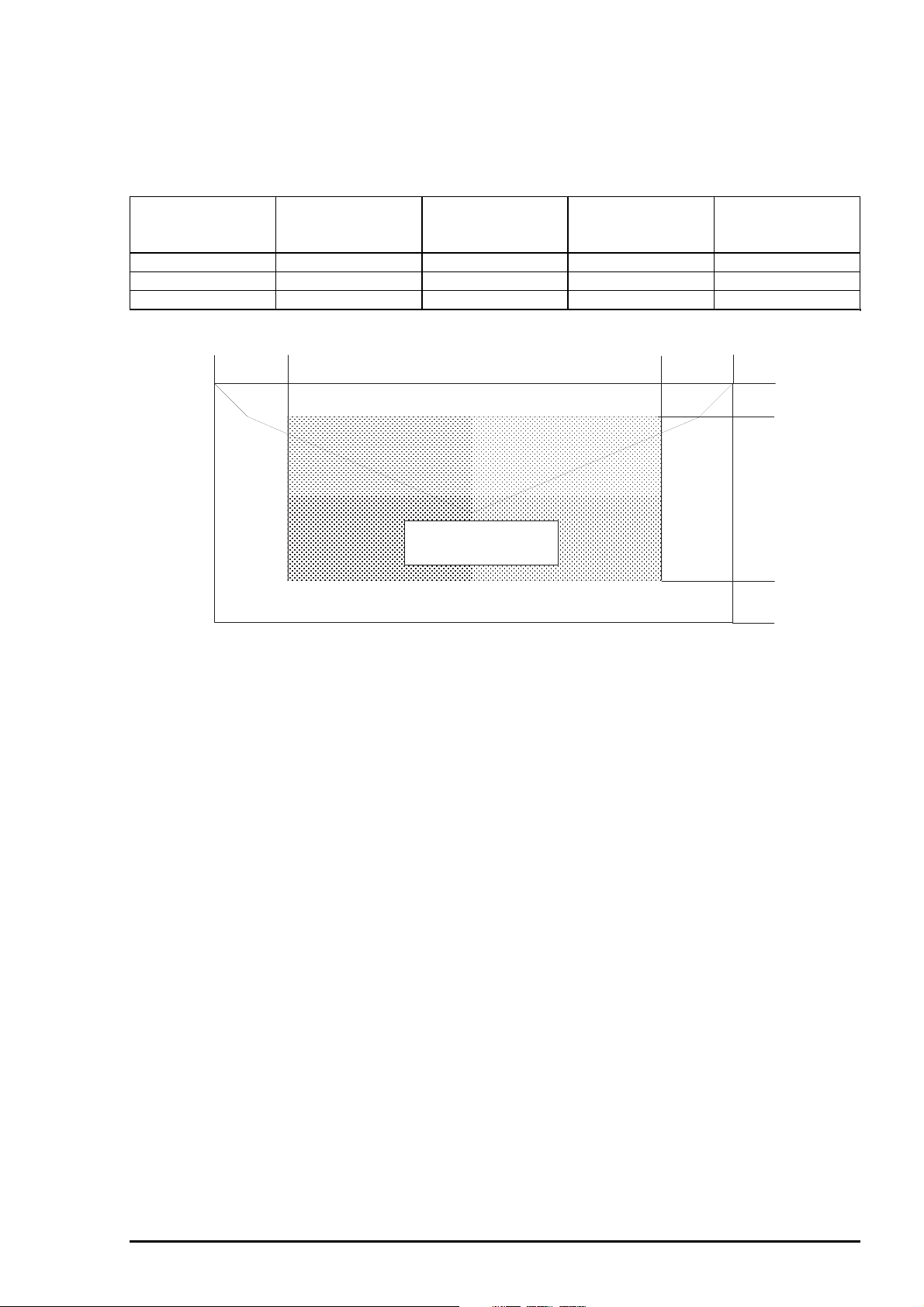

1.2.4.2 Envelope

The table and figure below show the printable area for envelopes.

Table 1-6. Printable Area for Envelope

Paper size LM(Left margin)

(min.)

RM(Right margin)

(min.)

TM(Top margin)

(min.)

BM(Bottom

margin)

(min.)

#10 28mm(1.10”) 3mm(0.12”) 3mm(0.12”) 14mm(0.55”)

DL 7mm(0.28”) 3mm(0.12”) 3mm(0.12”) 14mm(0.55”)

C6 3mm(0.12”) 3mm(0.12”) 3mm(0.12”) 14mm(0.55”)

LM

RM

TM

Printable Area

BM

Figure 1-4. Printing Area for Envelope

Rev.A

1-

Page 10

Chapter 1 Product Description

8

1.2.5 Environmental Condition

Temperature

Operating :10 to 35°C (Refer to the figure below for condition)

Non-operating : -20 to 60°C (with shipment container)

Note)

1 month at 40°C and 120 hours at 60°C

Humidity

Operating : 20 - 80% RH (without condensation. Refer to the figure below for

condition)

Non-operating : 5 - 85% RH (without condensation and with shipment container)

Humidity

(%RH)

Guranteed Range

Resistance to shock

Operating : 1G, within 1 ms X,Y,Z directions

Non-operating : 2G, within 2 ms X,Y,Z directions (with shipment container)

Resistance to vibration

Operating : 0.15G, 10 - 55Hz X,Y,Z directions

Non-operating : 0.50G, 10 - 55Hz X,Y,Z directions (with shipment container)

Note 1)

Note 2)

During non-operating, make sure that the head is capped.

During the transport, make sure that the head is capped and ink cartridge is

installed to the printer.

Note 3)

If the head is not capped at the power-off state, turn the power on with installed ink

cartridge and turn off the power after confirming that Power on operation is completed and

the head is capped.

Note 4)

Ink will be frozen under -4°C environment, however it will be useable after placing it

more than 3 hours at 25°C.

(50 F)

(80 F)

(95 F)

Temperature

( F)

Figure 1-5. Temperature/Humidity of

Range

1-

Rev.A

Page 11

EPSON Stylus Photo

9

1.2.6 Ink Cartridge Specifications

1.2.6.1 Black Ink Cartridge

Table 1-7. Black Ink Cartridge Specifications

Item Specifications

Type Exclusive cartridge

Color Black

Print capacity 540 pages / A4 (ISO/IE10561 Letter Pattern at 360 dpi)

Validity 2 years from production date(sealed in package) / 6months(out of package)

Environmental

conditions

Temperature

Storage : -20 - 40°C (within a month at 40°C)

Packing storage : -30 - 40°C (within a month at 40°C)

Transit : -30 - 60°C (within 120 hours at 60°C and within a month

at 40°C)

Humidity

5 - 85%(without condensation)

Resistance to vibration

Sealed in package : 5 - 55Hz

Acceleration : 29.4m/s less than 3G

Direction : X, Y, Z direction

Time : 1 hour

Drop

Sealed in package :

Dropping height : Less than 0.8m

Direction : Drop it facing the 6 areas, bottom, sides and one

edge down.

Dimension 19.8mm(W) x 52.7mm(D) x 38.5mm(H)

Weight

Note 1)

Note 2)

Note 3)

Ink cartridge can not re-fill, only ink cartridge is prepared for article of consumption.

Do not use the ink cartridge which is passed away the ink life.

Ink will be frozen under -4°C environment, however it will be usable after placing it more than

3 hours at room temperature.

Total ink cartridge : 54g

Total ink :16.4±0.5g (Quantity in the ink cartridge)

Consumable ink :More than 12.1g(Usable ink quantity until ink ends)

Figure 1-6. Black Ink Cartridge

Rev.A

1-

Page 12

Chapter 1 Product Description

0

1.2.6.2 Color Ink Cartridge

Table 1-8. Color Ink Cartridge Specification

Item Specifications

Type Exclusive cartridge

Color 5 Colors(Magenta, Cyan, Yellow, Light Magenta, Light Cyan)

Print capacity 190 pages / A4 (360 dpi, 5% duty each color)

Validity 2 years from production date (sealed in package) / 6months(out of package)

Environmental

conditions

Temperature

Storage : -20 - 40°C (within a month at 40°C)

Packing storage : -30 - 40°C (within a month at 40°C)

Transit : -30 - 60°C (within 120 hours at 60°C and within a month

at 40°C)

Humidity

5 - 85%(without condensation)

Resistance to vibration

Sealed in package : 5 - 55Hz

Acceleration : 29.4m/s less than 3G

Direction : X, Y, Z direction

Time : 1 hour

Drop

Sealed in package :

Dropping height : Less than 0.8m

Direction : Drop it facing the 6 areas, bottom, sides and one edge

down.

Dimension 51.4mm(W) x 52.7mm(D) x 38.5mm(H)

Weight

Note 1)

Note 2)

Note 3)

Ink cartridge can not re-fill, only ink cartridge is prepared for article of consumption.

Do not use the ink cartridge which is passed away the ink life.

Ink will be frozen under -4°C environment, however it will be usable after placing it more than

3 hours at room temperature.

Total ink cartridge : 81g

Total ink : 8.6±0.5g (Each color quantity in the ink cartridge)

Only Yellow 11.7±0.5g

Consumable ink : More than 8.7g for Yellow and 6.1g for other colors.

(Usable ink quantity until ink ends)

Yellow

(Y)

Cyan

(C)

Light Magenta

Magenta(M)

(LM)

Light Cyan(LC)

Figure 1-7. Color Ink Cartridge

1-1

Rev.A

Page 13

EPSON Stylus Photo

1.2.7 Physical Specification

[Dimension]

[Weight]

309mm

: 429mm(W) x 234mm(D) x 162mm(H)

: 429mm(W) x 695mm(D) x 309mm(H) with extended stacker and paper support.

: 5.2Kg

695mm

162mm

429mm

Figure 1-8. Dimension of EPSON Stylus Photo

1.2.8 Input Data Buffer

64 Kbytes

Rev.A

1-11

Page 14

Chapter 1 Product Description

2

1.2.9 Electric Specification

120V version

[Rated voltage] : AC120V

[Input voltage range] : AC103.5 ∼132V

[Rated frequency range] : 50 ∼ 60Hz

[Input frequency range] : 49.5 ∼ 60.5Hz

[Rated current] : 0.4A(Max. 0.5A)

[Power consumption] : Approx.15W(ISO/IEC 10561 Letter pattern)

: Energy Star compliant

[Insulation Resistance] : 10M ohms min.(between AC line and chassis, DC500V)

[Dielectric strength] : AC1000 V rms. 1 minute or AC1200 V rms. 1 second (between

AC line and chassis)

220 ∼ 240V version

[Rated voltage] : AC220V ∼ 240V

[Input voltage range] : AC198 ∼ 264V

[Rated frequency range] : 50 ∼ 60Hz

[Input frequency range] : 49.5 ∼ 60.5Hz

[Rated current] : 0.2 A(Max. 0.3A)

[Power consumption] : Approx.15W(ISO/IEC 10561 Letter pattern)

: Energy Star compliant

[Insulation Resistance] : 10M ohms min.(between AC line and chassis, DC500V)

[Dielectric strength] : AC1500 V rms. 1 minute (between AC line and chassis)

1.2.10 Reliability

Total print volume : 10,000 pages(A4, letter)

Print head life : 2000 million dots/nozzle

1.2.11 Safety Approvals

[120V version]

Safety standard : UL1950 with D3

: CSA22.2 No.950 with D3

EMI : FCC part 15 subpart B class B

: CSA C108.8 class B

[220 - 240V]

Safety standard : EN 60950(VDE,NEMKO)

EMI : EN55022(CISPR Pub.22) class B

: AS/NZS 3548 class B

1.2.12 Acoustic Noise

Noise Level : Approx.45 dB(A) (According to ISO 7779)

1.2.13

[220 - 240V version]

CE Marking

Low voltage Directive 73/23/EEC :EN60950

EMC Directive 89/336/EEC :EN55022 Class B

:EN61000-3-2

:EN61000-3-3

:EN50082-1

:IEC801-2

:IEC801-3

:IEC801-4

1-1

Rev.A

Page 15

EPSON Stylus Photo

3

1.2.14 Printer Language and Emulation

Printer Language : ESC/P Raster

: EPSON Remote

[ESC/P control codes]

< Character mode >

General Operation

Initialize Printer : ESC@

Paper feeding

Form Feed : FF

Line Feed : LF

Carriage Return : CR

< Graphic mode >

General operation

Initialize Printer : ESC@

Unidirectional Printing : ESC U

Print a Image : ESC ACK*

CSF Mode Control : ESC EM

Paper feeding:

Form Feed : FF

Line Feed : LF

Line Spacing : ESC+

Carriage Return : CR

Page format

Page Length : ESC(C

Top/Bottom Margin : ESC(c

Print position motion

Horizontal Print Position : ESC$, ESC\

Vertical Print Position : ESC (V,ESC (v

Spacing

Define Unit : ESC(U

Graphics

Graphics Mode : ESC(G

Raster Graphics : ESC.

Microweave control : ESC(i

Dot size control : ESC(e

Color

Printing color : ESC r, ESC(r

EEPROM control

EEPROM control : ESC•b

Rev.A

1-1

Page 16

Chapter 1 Product Description

4

1.3 Interface

This printer provides parallel interface and serial interface as standard.

1.3.1 Parallel Interface (Forward Channel)

[Transmission mode]

[Synchronization]

[Handshaking]

[Signal level]

[Adaptable connector]

BUSY signal is set high before setting either/ERROR low or PE high and held high until all these

signals return to their inactive state.

BUSY signal is at high level in the following cases.

During data entry (see Data transmission timing)

When input data buffer is full

During -INIT signal is at low level or during hardware initialization

During printer error (See /ERROR signal)

When the parallel interface is not selected

: 8 bit parallel, IEEE-1284 compatibility mode

: By STOPBE pulse

: BY BUSY and ACKLG signal

: TTL compatible level

: 57-30360 (amphenol) or equivalent

ERROR signal is at low level when the printer is in one of the following states.

Printer hardware error (fatal error)

Paper-out error

Paper-jam error

Ink-out error

PE signal is at high level during paper-out error.

Table 1-9 shows the signal and connector pin assignments for parallel interface(forward channel*1).

In case of these signals, twist pair line is used and returning side is connected to signal GND.

(*1): Forward channel is the mode when the ordinary data such as an order to print is sent

from the PC to the printer.

Table 1-9. Signal and Connector Pin Assignment for Parallel Interface

Pin No. Signal Name Return GND pin In/Out Functional Description

1 /STROBE 19 In The strobe pulse. Read-in of data is performed

at the falling edge of this pulse.

2-9 DATA0-7 20-27 In The DATA0 through DATA7 signals represent

data bits 0 to 7, respectively. Each signal is at

high level when data is logical 1 and low level

when data is logical 0.

10 /ACKNLG 28 Out This signal is a negative pulse indicating that

the printer can again accept data.

11 BUSY 29 Out A high signal indicates that the printer cannot

receive data.

12 PE 28 Out A high signal indicates paper-out error.

13 SLCT 28 Out Always at high level when the printer is

powered on.

14 /AFXT 30 In Not used.

31 /INIT 30 In The falling edge of a negative pulse or a low

signal on this line causes the printer to

initialize. Minimum 50 us pulse is necessary.

32 /ERROR 29 Out A low signal indicates printer error condition.

36 /SLIN 30 In Not used.

18 Logic H - Out Pulled up to +5V via 3.9K ohm resistor.

35 +5V - Out Pulled up to +5V via 3.3K ohm resistor.

17 Chassis GND - - Chassis GND.

16,33,19-30 GND - - Signal GND.

15,34 NC - - Not connected.

Note)

In/Out refers to the direction of signal flow from the printer’s point of view.

1-1

Rev.A

Page 17

EPSON Stylus Photo

5

1.3.2 Parallel Interface (Reverse Channel)

[Transmission mode]

[Synchronization]

[Handshaking]

[Data trans. timing]

[Signal level]

[Adaptable connector]

[Extensibility request]

Note)

The printer sends following device ID string when it is requested.

<00H> *1

Note*1)

Note*2)

The table below shows pin assignment for reverse channel(*3). In these case of signals, twist pair line

is used and returning side is connected to Signal GND.

(*3): Reverse channel is the mode that any data is transferred from the printer to the PC.

[00H] denotes a hexadecimal value of zero.

MDL value depends on the EEPROM setting. Model name can be changed by changing a

certain address in the EEPROM.

: IEEE-1284 nibble mode

: Refer to the IEEE-1284 specification

: Refer to the IEEE-1284 specification

: Refer to the IEEE-1284 specification

: IEEE-1284 level 1 device

: TTL compatible level

: 57-30360 (amphenol) or equivalent

: The printer responds affirmatively when the extensibility

request values are 00H or 04H, that mean,

00H :Request Nibble Mode Reverse Channel Transfer.

04H :Request device ID; Return Data using Nibble Mode Rev

Channel Transfer.

Table 1-10. Device ID Description

H> Contents

<38

MFG EPSON Production Maker

CMD ESCPL2,BDC Command system

MDL Stylus[SP]PHOTO Model name *2

CLS PRINTER Class

Table 1-11. Pin Assignment for Reverse Channel

Pin No. Signal Name Return

GND pin

1 HostClk 19 In Host clock signal.

2-9 Data0-7 20-27 In The DATA0 through DATA7 signals

10 PrtClk 28 Out Printer clock signal.

11 PtrBusy, Data Bit-3,7 29 Out Printer busy signal and reverse channel

12 AckDataReq, DataBit-2,6 28 Out Acknowledge data request signal and

13 Xflag, DataBit-1,5 28 Out X-flag signal and reverse channel

14 HostBusy 30 In Host busy signal.

31 /INIT 30 In Not used.

32 /DataAvail, DataBit-0,4 29 Out Data available signal and reverse

36 1284-Active 30 In 1284 active signal.

18 Logic-H - Out Pulled up to +5V via 3.9K ohm resister.

35 +5V - Out Pulled up to +5V via 3.3K ohm resister.

17 Chassis GND - - Chassis GND.

16,33,19-30 GND - - Signal GND.

15,34 NC - - Not connected.

In/Out Functional description

represent data bits 0 to7, respectively.

Each signal is at high level when data is

logical 1 and low level when data is

logical 0. These signals are used to

transfer the 1284 extensibility request

values to the printer.

transfer data bit 3 or 7.

reverse channel transfer data bit 2 or 6.

transfer data bit 1 or 5.

channel transfer data bit 0 or 4.

Note)

In/Out refers to the direction of signal flow from the printer’s point of view.

Rev.A

1-1

Page 18

Chapter 1 Product Description

6

Following lists “Notes” when using Parallel Interface.

Note1) “

Return GND pin” in the table means twist pair return and is used for all control signals

except for Logic H,+5V, Chassis, GND and NC. In this twist pair return, returning side

is connected to GND (16, 33, 19-30 pin) for twist pair return. Also, these cables are shielded

wires and it is effective to connect to each chassis GND in the PC and printer for electrostatic

noise.

Note2)

Conditions for Interface are based on TTL level. Rise and fall time should be within 0.2µs.

Note3)

Note4)

Refer to the figure 1-9 for transmission timing of each signals.

Do not perform data transmission ignoring /ACK or BUSY signal. (Perform the data transmission

after confirming that /ACK and BUSY signals are Low.)

Note5)

It is possible to perform the printing test including interface circuit without using equipment

from outside when 8-bit data signal(20-27 pin) is set to appropriate word code and connect

them forcefully to /ACK and /STRB.

[Data Transmission Timing for Forward Channel]

DATA

/STRB

BUSY

/ACK

data byte n

t

hold

Min. 500 ns

t

setup

Min. 500 ns

t

readytbusy

Min. 0

tt-out Max. 120 ns : Rise and fall time of every output signals

tt-in Max. 200 ns : Rise and fall time of everu input signals

Typical value of tack takes followig values according to Parallel I/F speed(by the settin of

EEPROM 24H).

High speed (default) 1 us.

Ordinary 3us

t

stb

Min. 500 ns

Max. 500 ns

t

reply

Min. 0 Min. 0

t

acktnbusy

Min. 500 ns

Max. 10 us

data byte n+1

t

next

Min. 0

Figure 1-9. Parallel Interface Timing Chart (Forward Channel)

Table 1-12. Maximum and Minimum Timing for Data Transmission

Parameter Minimum Maximum

tsetup 500ns ---

thold 500ns ---

tstb 500ns ---

tready 0 ---

tbusy --- 500ns

tt-out* --- 120ns

tt-in** --- 200ns

treply 0 ---

tack 500ns 10us

tnbusy 0 ---

tnext 0 -- * Rise and fall time of every output signals.

** Rise and fall time of every input signals.

Typical time of tack is shown below.

Parallel I/F mode Typical time of tack

High speed 1us

Normal speed 3us

Table 1-13. Typical Time of Tack

1-1

Rev.A

Page 19

EPSON Stylus Photo

7

[Signal level: TTL compatible (IEEE-1284 level 1 device)]

Table 1-14. Signal Level

Parameter Minimum Maximum Condition

VOH* --- 5.5V

VOL* -0.5V ---

IOH* --- 0.32mA VOH = 2.4V

IOL* --- 12mA VOL = 0.4V

CO --- 50pF

VIH --- 2.0V

VIL 0.8V ---

IIH --- 0.32mA VIH = 2.0V

IIL --- 12mA VIL = 0.8V

CI --- 50pF

*A low logic level on the Logic H signal is 2.0V or less when the printer is powered off and this

signal is equal or exceeding 3.0V when the printer is powered on. The receiver shall provide an

impedance equivalent to 7.5K ohm to ground.

Rev.A

1-1

Page 20

Chapter 1 Product Description

8

1.3.3 Serial Interface

[Standard]

[Synchronization]

[Bit rate]

[Word format]

[Handshaking]

[Adaptable Connector]

[Recommended interface cable]

Following table shows connector pin assignment and signals:

Table 1-15. Connector Pin Assignment and Signals

Pin No. Signal Name In/On Function Description

1 SCLK Out Synchronous clock

2 CTS In Clear to send

3 TxD- Out Transmit data4 S.G. In Signal ground

5 RxD- In Receive data6 TxD+ Out Balanced Transmit+

7 DTR Out Data terminal ready

8 RxD+ In Balanced Receive+

: based on RS-423

: Synchronous

: Approx. 900Kbps

: Start bit 1 bit

: Data bit 8 bit

: Parity bit none

: Stop bit 1 bit

: X-ON/X-OFF, DTR protocol

: 8-pin mini circular connector

: Apple System Peripheral-8 cable

Note)

In/out refer to the direction of signal flow as viewed from the printer.

Following figure shows port arrangement of serial I/F connector.

678

12

Figure 1-10. Serial I/F Connector Port

Following table shows timing relation of DTR, X-on/X-off handshaking.

345

Table 1-16. DTR, X-ON/X-OFF Protocol

State Buffer Space X-ON/X-OFF DTR

Busy Less than 3072 bytes Send X-OFF code Off

Ready More than 5120 bytes Send X-ON code On

1-1

Rev.A

Page 21

EPSON Stylus Photo

9

1.3.4 Prevention Hosts from Data Transfer Time-out

Generally, hosts abandon data transfer to peripher als when a peripheral is in the busy state f or dozens of

seconds continuously. To prevent hosts from this kind of time-out, the printer receives data very slowly,

several bytes per minute, even if the printer is in busy state. This slow down is started when the rest of the

input buffer becomes several hundr eds of bytes. Finally, the printer is in the busy state continuously when

the input buffer is full.

1.3.5 Interface Selection

The printer has 2 built-in interfaces; the parallel interface and serial interface. These interfaces are

selected automatically.

Automatic selection

In this automatic interface selection mode, the printer is initialized to the idle state scanning which

interface receives data when it is powered on. Then the interface is that receives data first is

selected. When the host stops data transfer and the printer is in the stand-by state for the

seconds, the printer is returned to the idle state. As long as the host sends data or the printer

interface is busy state, the selected interface is let as it is.

Interface state and interface selection

When the parallel interface is not selected, the interface got into the busy state. When the serial

interface is not selected, the interface sets the DTR signal MARK. When the printer is initialized or

returned to the idle state, the parallel interface got into the ready state, the serial interface sets the

DTR signal SPACE. Caution that the interrupt signal such as the /INIT signal on the parallel

interface is not effective while that interface is not selected.

Rev.A

1-1

Page 22

Chapter 1 Product Description

0

1.4 Control Panel

EPSON Stylus Photo does not require many buttons since the printer driver can s tart various settings and

motions. Therefore, there are only 2 non-lock type push buttons, 1 lock type push button and 4 LEDs.

Following figure shows control panel of EPSON Stylus Photo.

Power LED :Green

Paper out LED:Red

Ink Out (Black)LED :Red

Power SW

Ink Out (Color) LED: Red

Cleaning button

Load/Eject button

Figure 1-1 1. Control Panel

1.4.1 Indicators

(1) Power

Lights when the operate button is “ON”, and AC power is supplied.

(2) Paper out

Lights during the paper-out condition, and blinks during the paper-jam condition.

(3) Ink Out (Black)

Lights during no Black ink condition, and blinks during the Black ink low condition.

(4) Ink Out (Color)

Lights during no Color ink condition, and blinks during the Color ink low condition.

1-2

Rev.A

Page 23

EPSON Stylus Photo

1.4.2 Panel Functions

[Panel Functions]

Table 1-17. Panel Function

Button Function

Load/Eject

(Pushing within 2 seconds)

Load/Eject

(Pushing for 2 seconds)

Cleaning

(Pushing for 2 seconds)

Cleaning

(Pushing within 2 seconds)

*This function is not available in printing status.

[Panel Functions with Power ON]

•

Loads or Ejects the paper.

•

When carriage is on the Ink Cartridge change position, return carriage

from Ink Cartridge change position.

•

Starts the Ink Cartridge change sequence.*

Moves the carriage to cartridge change position.

•

Starts the Cleaning of head.

•

In the condition of “Ink Low” or “Ink Out” or “No Ink Cartridge” starts the

Ink Cartridge change sequence.*

•

When carriage is on the Ink Cartridge change position, return carriage

from Ink Cartridge change position.

Table 1-18. Panel Function with Power On

Button Function

Load/Eject

Cleaning

Load/Eject

+

Cleaning

** status printings prints firmware version, ink counter, selected code page and nozzle check patterns.

[Particular setting mode]

Button Function

Load/Eject

(Pushing for 10 seconds)

*** Refer to EEPROM map.(Refer to EEPROM map in the Appendix)

•

Starts status printings.**

•

Changes a Code Page.

•

Enters the particular settings mode.(Factory use only.)

•

To enter the particular settings m ode, it is necessary to push following

button while Paper Out LED is blinking.(It blinks about 5 seconds)

Table 1-19. Particular Setting Mode

•

Initialize EEPROM*** and reset timer IC.

Rev.A

1-21

Page 24

Chapter 1 Product Description

2

[Maintenance Error Reset Procedure]

You can reset the maintenance error by pressing the cleaning button after you enter the particular setting

mode(Refer to table 1-18, 19). There are no function which can be reset the all address in EEPROM on

the EPSON Stylus Photo. Following are detail procedure of maintenance error reset operation

[Step 1] By pushing Load/Eject and Cleaning buttons at the same time, turn on the power switch.

(By operating this performance, the LED for paper out starts blinking.(5 seconds only) )

[Step 2] Push the Load/Eject button for 10 seconds while the LED for Paper Out is blinking.

Note)

If the printer accepts this function correctly, it returns to the standby mode after the

Maintenance LEDs (both black and CMYcm) blink for 1 second.

Following shows the lists that will be cleared by this performance.

1. Clear the value of Ink Counter

2. Clear Time IC

3. Initialization of I/F selection (returns to AUTO)

WARNING

Since EPSON Stylus Photo does not have “All Clear function” for EEPROM like other printers, do

not perform this operation except for the purpose of the maintenance error reset.

Be sure to replace a waste ink pad in the printer enclosure with a new one after you perform

[Maintenance error reset procedure].

If the waste ink pad is replaced regardless of maintenance error, perform this operation.

1.4.3 Printer Conditi on and Panel Status

The table below shows printer condition and panel status. Since this table shows var ious error status and

also presents printer status, you can judge appropriate repair ways from this table.

Table 1-20. Printer Condition and Panel Status

Indicators

Printer status Power Ink Out

(Black)

Power on condition On --- --- --- 9

Ink sequence Blink --- --- --- 6

Ink Cartridge change

mode

Data processing Blink --- --- --- 8

Paper Out 1* --- --- --- On 4

Paper jam condition1* --- Off Off Blink 3

No Ink cartridge or Ink

end(black)1*

Ink level low(black) --- Blink --- --- 7

No Ink cartridge or Ink

end(color)1*

Ink level low(color) --- --- Blink --- 7

Enter EEPROM and

Timer IC reset 2*

Maintenance request1* Blink Blink Blink Blink 2

Fatal error1* Blink On On Blink 1

Note1*)

Note2*)

Note3*)

: Refer to section 1.5 for error status.

: It does not mean that all address would be cleared.

: --- means no changes.

Blink --- --- --- 5

--- On --- --- 7

--- --- On --- 7

--- On

(1 second only)On(1 second only)On(1 second only)

Ink Out

(Color)

Paper Out Priority

---

1-2

Rev.A

Page 25

EPSON Stylus Photo

3

1.5 Error Status

When following status occur, the printer goes to the error status and stops taking data, setting the

/ERROR signal in the interface as “Low”, and Busy signal as “High”. At this time, the printer goes to non

printable status. Refer to section 1.4.3 f or more details of LED Panel indicators during the various error

status.

1.5.1 Ink Out

When the printer runs out m os t part of the ink of any one color, it warns ink-low and keeps printing. When

the printer runs out the whole ink of any one color, it stops printing and indicates ink -out error. User is

requested to install a new ink-cartridge in this s tate. A ink-car tridge once taken out s hould never be used

again. Re-installation of the cartridge not filled f ully upsets the ink level detec tion and may cause a serious

problem in the print head as a result.

WARNING

Never use the ink cartridge once taken out.

Following explains above warning sign.

[Step 1]

[Step 2]

[Step 3]

After the cartridge is once taken out, bubbles come in from the ink supply hole located at

the top of cartridge and are absorbed into the head during printing performance.

Therefore, the head will be unable to discharge the ink properly. Also, inevitable

entering of bubbles when installing a new ink cartridge can be absorbed to ink itself since

the ink itself in the cartridge is deaerated during the production process.

However, this absorbing ability can last only about one hour after the cartridge is installed.

Even after the bubble absorbing ability described above stops, there is no worry about

entering bubbles as long as the ink cartridge is being installed to the printer.

However, if the ink cartridge which does not have absorbing ability any more is once

removed from the printer, new coming bubbles into the cartridge will never disappear

naturally. These bubbles may cause not only printing malfunction but also thickening ink.

This thickened ink goes into the head and clogs ink path in the head or nozzle and may

cause serious head damage.

As standard specification for EPSON Stylus Photo, ink consumption counter is reset when

the ink cartridge is removed. If an ink cartridge is removed and re-installed unnecessarily

the value on the ink consumption monitor which the user can check will be wrong and

printer may keep printing even though the ink cartridge is installed empty.

This may cause head damage.

1.5.2 Paper Out

When printer fails to load a sheet after power on operation including timer-cleaning is done and Load/Eject

button on the FF command or operation panel is pressed, it goes paper out error.

1.5.3 Paper Jam

When the printer fails to ejec t a sheet even after f eeding m otion is com pleted or Load/Eject button on the

FF command or operation panel is pressed, it goes paper jam error.

Rev.A

1-2

Page 26

Chapter 1 Product Description

4

1.5.4 No Ink-Cartridge

Following reasons can be the causes when printer goes to this error mode.

1) When the printer is turned on for the first time.

(This is a normal error state and it returns to the normal state after installing an ink cartridge according

to the ink cartridge exchange operation.)

2) Ink cartridge exchange operation is not done correctly.

After the position of carriage is moved by exchange operation, if the cleaning button is pushed without

installing ink cartridge or if the carriage returns to the home-position automatically without doing any

operation, it is considered as handling mistake. However, it returns to normal state by performing

ink exchange operation again and installing cartridge correctly.

3) If “No ink-cartridge error” appears even after the ink cartridge is installed, the printer must be

something wrong and around the sensor area in the carriage need to be repaired.

4) If sometimes printer can print normally but also sometimes “No ink-cartridge error” appears, the

printer must be something wrong. (Same reason as 3) above)

1.5.5 Maintenance Request

When the total quantity of ink wasted through the cleanings and flushing reaches to the limit, printer

indicates this error and stops. T he absorber in the printer enclosure is needed to be replac ed with new

one by a service person. The ink quantity that is absorbed by the absorber (waste ink pad) is monitored by

the software counter as “total ink counter”. This counter is added by point system and also absorber ’s

maximum ability is set at the following reference value.

37000 X 0.0113 ml = Approximately 418 ml

1-point = 0.0113ml (the value which is multiplied evaporating rate and 1-dot ink weight 0.02ml)

37000 = Maximum point number (Maintenance error threshold)

However, considering dispers ion of ink abs or bing quantity and the number of us ing nozzles, ink total value

is calculated by the following formula.

418 X 1.1/ 67% = 526 ml (but up to 687ml can be retained)

WARNING

When you perform self test after completing repairs, it is possible to check the present value of total

ink counter conditions of all nozzles by performing status printing in the built-in function. Therefore,

make sure that the printer has enough value of total ink counter (if the number is close to 29500 or

not). If there is not enough value, the service man is required to judge if it is necessary to clear

EEPROM after replacing the absorber (waste ink pad) or not. Refer to section 1.4.2 if you need to

perform EEPROM Clear.

1.5.6 Fatal Errors

When printer detects fatal errors such as carriage control error or CG access error, it goes to this

error mode. Refer to followings for each error.

1) Carriage control Error : Parallel adjustment malfunction, HP detection malfunction,

shortage of lubricant on the carriage guide shaft, etc.

2) CG Access Error : Short circuit, etc.

1-2

Rev.A

Page 27

EPSON Stylus Photo

5

1.6 Printer Initialization

EPSON Stylus Photo has three kinds of initialization methods. Following explains each initialization.

[1.Power-on initialization]

This printer is initialized when turning the printer power on, or printer recognized the cold-res et com mand

(remote RS command). When printer is initialized, following action is performed.

(a) Initializes printer mechanism.

(b) Clears input data buffer.

(c) Clears print buffer.

(d) Sets default values.

[2.Operator(Panel) initialization]

This printer is initialized when turning the printer power on again within 10 seconds from las t power off, or

printer recognized the /INIT signal (negative pulse) of parallel interface. When printer is initialized,

following action is performed.

(a) Cap the printer head.

(b) Eject a paper.

(c) Clears input data buffer.

(d) Clears print buffer.

(e) Sets default values.

[3. Software initialization]

The ESC@ command also initializes the printer. When printer is initialized, following action is performed.

(a) Clears print buffer.

(b) Sets default values.

1.7 Initialization Settings

EPSON Stylus Photo initializes following settings when the initialization is performed. Also, if the user

changes the settings in the Panel setting, Default setting or Remote command setting, values or settings

which are possible to be stored are initialized as initialization settings.

Page position : Page heading location as present paper location

Line spacing : 1/6 inch

Right margin position : 80 lines

Left margin position : first line

Character pitch : 10CPI

Printing mode : Text mode (Not Raster graphics mode)

Rev.A

1-2

Page 28

Chapter 1 Product Description

6

1.8 Main Components

EPSON Stylus Photo has following major units. Also, it is one of the major characteristics that the bottom

of the Printer mechanism plays the role as Lower case at the same time. Each units from 2) to 4) are

simply explained as following.

1) C209 Main control board

2) C206 PSB/PSE(Power Supply Board)

3) C209 PNL(Panel Board)

4) Printer Mechanism

5) Upper Case

1.8.1 C209 Main Control Boar d

In the C209 main control board, TMP95C061BF(Toshiba, TLCS900/H series) is mounted and it is

operated by 25.0 MHz drive frequency. By this CPU, circuit in 16 bit bus width is consisted and various

memories are added. These memories are controlled by MMU of the gate array(E05B43YA).

IC15PF Motor Driver

IC7 Head Driver

IC14 CR Motor Driver

IC11Timer

IC11 EEPROM

Figure 1-12. C209 Main Control Board

CN1 Parallel I/F

CN2 Serial I/F

IC3 P-ROM (4M)

IC5 D-RAM (4M)

IC1 CPU (TMP95C061BF)

IC2 Gate Array (E05B43YA)

1-2

Rev.A

Page 29

EPSON Stylus Photo

7

1.8.2 C206 PSB/PSE(Pow e r Suppl y) Board

The C206 PSB/PSE board is a switching regulator type power supply unit and constantly supplies stable

logic and power voltages to the printer mechanism and the main control board. Also, since this C206

PSB/PSE board has the power switch in the secondly side of the circuit, it is possible to keep supplying

electricity to the C209 MAIN control board for 30 seconds even after the power switch is tur ned off. Using

this time difference, even when mis-operation is done by the user such as turning off the power during the

middle of printing work, it prevents unexpected trouble with the printhead from occurring, by transferr ing

the printhead to the cap position before complete shut down. The C206 PSB Board is for AC100 - 120V

input voltage and the C206 PSE Board is for AC220-240V input voltage.

F1 Fuse

CN1 AC Input

Q1 Main FET

T1 Maintrans

CN1 Power Output

PC1 Photo Coupler for Power

L1 Filter

C11 Smoothing Electrolytic

Capacitor

Supply Control

Figure 1-13. C206 PSB Board

1.8.3 C209PNL Panel Unit

Panel unit (C209 PNL board) consists of 3 switches, 4 LEDs and 1 connector as they are illustrated in the

figure below.

Load/Eject SW

Cleaning SW

Paper Out LED

Ink Out(Black) LED

Ink Out(Color) LED

Figure 1-14. C209 PNL Panel Unit

Power SW

Power LED

1.8.4 Printer Mechanism

This printer mechanism consists of ASF(auto sheet feeder) mechanism, paper load mechanism,

carriage mechanism, print head, pump mechanism and waste ink absorber.

Rev.A

1-2

Page 30

Chapter 1 Product Description

8

1.8.5 Housing

This printer’s housing consists of upper case, print cover, paper support and paper eject tray.

In this printer, there is no lower case since the printer mechanism plays its role.

Paper Support

Printer Cover

Upper Case

Figure 1-15. Housing

1-2

Rev.A

Loading...

Loading...