Page 1

Chapter 4

Adjustment

4.1 OVERVIEW............................................................................................................4-1

4.1.1 Required Adjustments ........................................................................................................... 4-1

4.1.2 Tools Required for Adjustment.............................................................................................4-1

4.2 Adjustments..........................................................................................................4-2

4.2.1 Paper Gap Adjustment........................................................................................................... 4-2

4.2.2 Adjustment using Adjustment Program............................................................................... 4-4

4.2.2.1 Overview of Adjustment Program .............................................................................4-4

4.2.2.2 Preparation for Adjustment........................................................................................ 4-5

4.2.2.3 Ink Charge Operation................................................................................................ 4-6

4.2.2.4 VH Setting ................................................................................................................. 4-6

4.2.2.5 Head Angular Adjustment ......................................................................................... 4-8

4.2.2.6 Bi-D Alignment Adjustment .....................................................................................4-10

Page 2

Chapter 4 Adjustment

4.1 OVERVIEW

This section describes the procedure for adjustments required when the printer is disassembled and

assembled for repair.

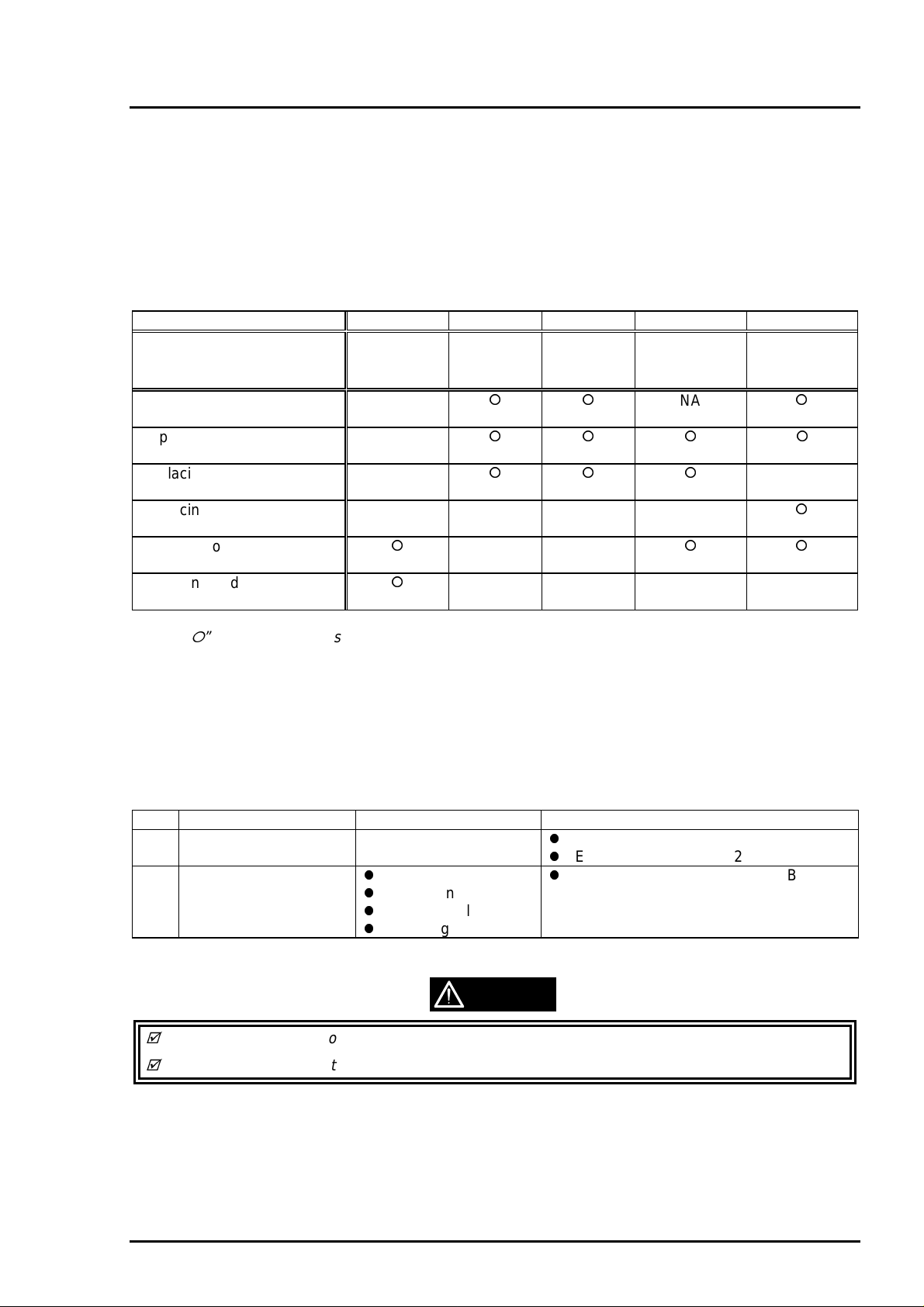

4.1.1 Required Adjustments

Table 4-1 lists all the adjustments required with this printer. If any service listed in this table is carried out,

all adjustments corresponding to that service should be performed to ensure proper operation of the

printer.

Table 4-1. Required Adjustments

Performance Order 1 2 3 4 5

Service Performed Paper-Gap

Adjustment

Replacing

the printer mechanism

Replacing

the C209 MAIN board

Replacing

the printhead unit

Replacing

the CR Motor

Replacing or disassembling

the carriage assembly

Replacing or disassembling

the PF Roller assembly

NA

NA

NA

NA NA NA NA

Ink

Charge

NA NA

NA NA NA NA

VH

Setting

Head

Angular

Adjustment

NA

Bi-D

Adjustment

NA

Note) “”: Required adjustment

“NA”: Not applicable

4.1.2 Tools Required for Adjustment

Table 4-2 lists all the tools required to make the specified adjustments.

Table 4-2. Required Tools

No. Name Adjustment Notes

1 Thickness Gauge Paper-Gap Adjustment

2 Adjustment Program

Ink Charge

VH Setting

Head Angular

Bi-D Alignment

CAUTION

Do not use rusty or deformed thickness gauge for adjustment.

Wipe off any dirt or dust from the thickness gauge before using.

Thickness: 1.04mm

EPSON Code: B776702201

Program Name: K00A10VE.BAS

Rev. A

4-1

Page 3

EPSON Stylus Photo

2

4.2 Adjustments

This section describes the detail procedure of each adjustment.

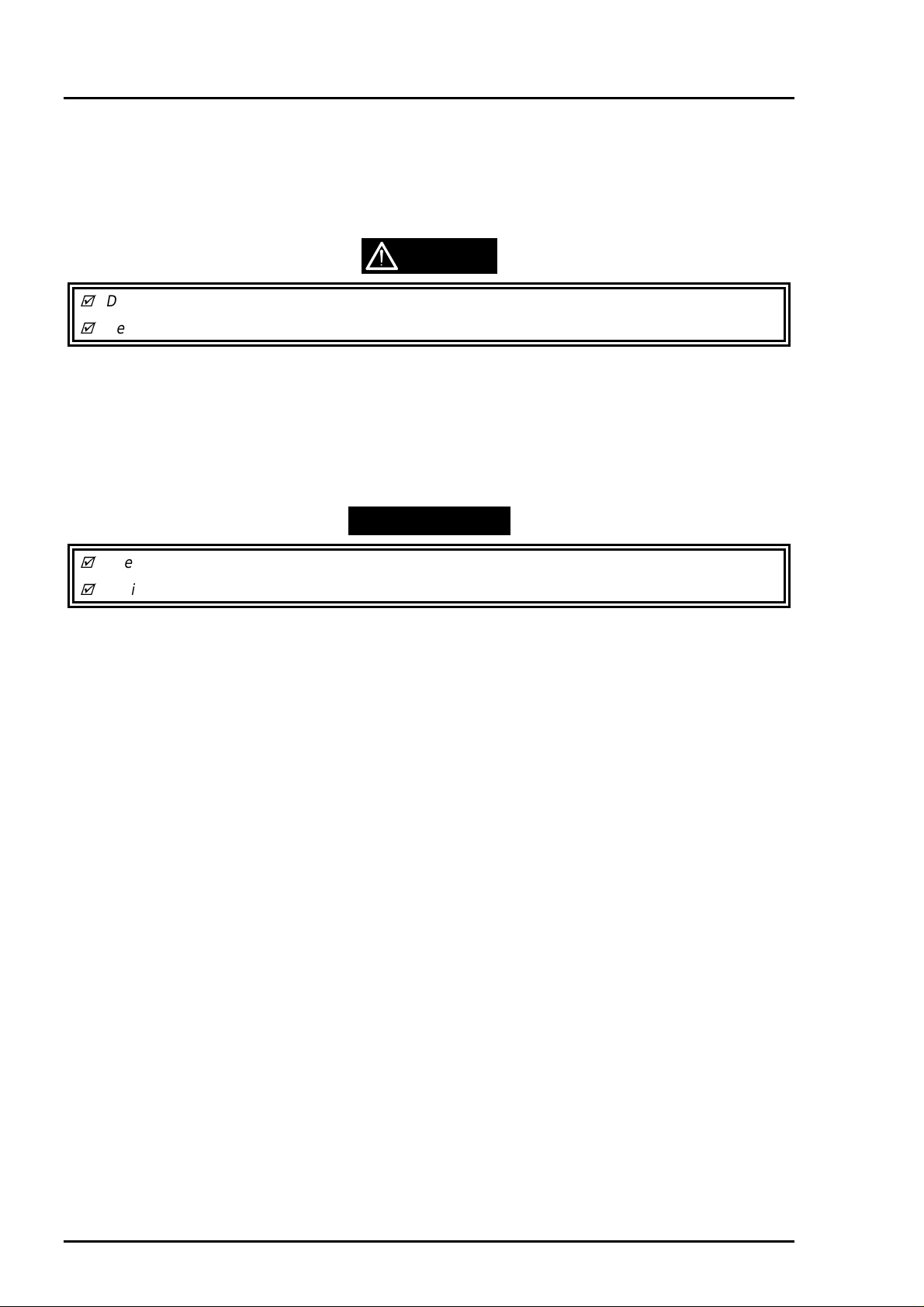

4.2.1 Paper Gap Adjustment

The paper gap is a distance between nozzle surface of the printhead unit and a paper surface and is

adjusted to specified gap at the assembly. Therefore, if the carriage assembly is removed from the printer

mechanism for any reason, this adjustment should be made to fix the gap.

CAUTION

Do not scratch the surface of “PAPER GUIDE, FRONT;B” and “ROLLER, ASSEMBLY, PF”.

Be careful not to damage or make dirty the nozzle surface of the printhead unit.

[Paper gap - Right-hand side Adjustment]

1. Attach both “BUSH, PARALLEL ADJUST” (L/R) to the side frame and align the position mark on top

edge of it to a notch on the edge of the side frame.

2. Set “LEVER, PG” to front side (Position “0”).

3. Move the carriage assembly to the middle, and put the thickness gauge at the position specified in the

figure.

4. Move the carriage assembly over the thickness gauge.

WORK POINT

The thickness gauge must be placed on a flat surface of the ribs of “PAPER GUIDE, FRONT;B”.

During adjustment, always pull the timing belt to move the carriage assembly.

5. Shift the position of “BUSH, PARALLEL ADJUST, RIGHT” to backward (Gap: Narrower) until when the

thickness gauge starts sliding together with the carriage assembly when you move it to right and left for

about 20mm.

6. At the point of above step, shift the position of “BUSH, PARALLEL ADJUST, RIGHT” for one notch to

forward (Gap: Wider).

7. Then, confirm that the thickness gauge do not slide when you move the carriage assembly, with either

“LEVER, PG” is at position “0” or “+”.

[Paper gap - Left-hand side Adjustment]

8. Repeat the above step 2 to 7 with “BUSH, PARALLEL ADJUST, LEFT”.

[Gap Confirmation]

9. Repeat the step 3 to 4 again.

10. Confirm that the thickness gauge do not slide when you move the carriage assembly to right and left

for above 20mm.

11. Shift the position of “BUSH, PARALLEL ADJUST, RIGHT” for one notch to backward (Gap: Narrower)

and confirm that the thickness gauge is sliding by moving the carriage assembly. If not, return to step 1

and repeat adjustment again.

12. If the gap is correct, shift “BUSH, PARALLEL ADJUST, RIGHT” for one notch to forward (Gap: Wider).

[Fixing “BUSH, PARALLEL ADJUST”]

13. Fix both bushes with 2 screws (1 each : No.1).

When the paper gap adj ustment complete, confirm that the overlap of printhead nose and “CLEANER,

HEAD”.

1. Move the carriage assembly next to “CLEANER, HEAD”.

2. Confirm that the overlap of printhead nose and top edge of “CLEANER, HEAD” is more than 0.5mm.

4-

Rev. A

Page 4

Chapter 4 Adjustment

3

Left

Rib: Avoid 2ribs from left

"ROLLER, ASSEMBLY, PF"

Figure 4-1. Paper Gap Adjustment - Thickness Gauge Setting

"PAPER GUIDE, FRONT;B"

Carriage

Assembly

"PAPER GUIDE, FRONT;B"

Right

(HP side)

[Thickness Gauge] Rib: Avoid 1 rib at right end

*Put the gauge on a flat face

*Align the center of gauge and

the ribs

"LEVER, PG"

Figure 4-2. Paper Gap Adjustment - Adjustment Procedure

Forward

(Gap: Wider)

Position Mark

Backward

(Gap: Narrower)

Side Frame

"BUSH, PARALLEL ADJUST, RIGHT"

Overlap = 0.5mm or more

Printhead

(Nose face)

"CLEANER, HEAD"

Figure 4-3. “CLEANER, HEAD” Overlap

Rev. A

4-

Page 5

EPSON Stylus Photo

4

4.2.2 Adjustment using Adjustment Program

Since the characteristic of printer mechanism and its components are varying, every printer mechanism

are checked and it’s own characteristic information is stored in EEPROM of the main control board as a

compensation parameter for the mechanism control. Therefore, if the combination of printer mechanism

and the main control board is changed, the printer should be adjusted using the adjustment program in

order to maintain optimum performance of the printer.

4.2.2.1 Overview of Adjustment Program

This adjustment program(K00A10VE.BAS) is developed specifically for this printer and the basic operation

with this adjustment program is illustrated in figure below.

Main Menu

(Item Selection)

Initial Ink Charge

Performance of Initial

ink charge process

Head VH voltage

ID writing.

Input of appointed

VH voltge ID

Head Angle

Adjustment

*Pattern printing

*Confirmation/

Mechanism

Adjustment

Figure 4-4. Adjustment Program Flow

Bi-D Adjustment

*Pattern printing

*Confirmation/

Input of correct

values

4-

Rev. A

Page 6

Chapter 4 Adjustment

5

4.2.2.2 Preparation for Adjustment

Before you start adjustment, have the following items ready for adjustment.

PC (MS-DOS Machine)

I/F cable (Parallel)

Brand new ink cartridges (Black and Color)

Photo quality ink jet paper (#S041061/2)

Printer that is necessary to adjust (At least, the printer mechanism, electrical

circuits, boards and panel should be connected.)

CAUTION

Make sure to use the new ink cartridge, which is not used and also not opened before.

Use the special ink-jet paper in order to check the adjustment result accurately.

1. Connect the PC to the printer and turn the PC and the printer on. Then, unpack a brand-new ink

cartridges and install them on to the printer.

2. Load “GWBASIC.EXE” and execute the adjustment program “K00A10VE”.

3. At the menu [SCREEN-1], input “2” to select “Cartridge” and press ENTER key.

4. Then, at the menu [SCREEN-2], input the number corresponding to your market and press ENTER

key.

[SCREEN-1] ***** TOOL ***** PM-700C/STYLUS COLOR PHOTO K00A10V e

1. Jig

2. Cartridge

Input ITEM No. : ?_

[SCREEN-2] ***** CUSTOMER ***** PM-700C/ STYLUS COLOR PHOTO K00A10Ve

1. 000: (WORLD)

2. 100: (JAPAN)

3. 000: (KOREA)

4. 000: (RUSSIA)

Input ITEM No. :?__

[SCREEN-3] <MAIN MENU for Production> STYLUS COLOR PHOTO K00A10Ve

1: VH Setting

2: Ink Charge

3: Angular Adjust Printing XX-XX-XXXX XX:XX:XX

K: Angular Adjust Setting

4: Bi-d Adjust CUSTOMER:WORLD

P: Print Inspection (GOS) Jig No. :CT

L: Print Inspection (S/F) M/C No. :

M: Print Inspection (Post-card)

HEAD VH :

CL. Cleaning:

9. INK Discharge

E. END / Go to SETTING MENU

Input ITEM No. :?_

Rev. A

4-

Page 7

EPSON Stylus Photo

6

4.2.2.3 Ink Charge Operation

If either of the following service is made, internal ink paths of the printhead unit is completely empty.

Therefore, a brand-new ink cartridge must be installed and all ink paths must be charged with fresh ink by

performing the following operation to ensure proper printing operation.

Replacing the printer mechanism

Replacing the printhead unit

CAUTION

Since this operation consumes large amount of ink, do not perform it unnecessarily:

*Black: Approx. 8.8% of the ink charged in the cartridge

*Color: Approx. 16.2% of the ink charged in the cartridge (CMYcm total)

The ink charge operation takes long time to complete. Do not turn off the printer until it stops

completely.(The POWER indicator blinks during the operation.)

1. Start “Preparation for Adjustment” and complete 1 to 4 procedures. (Refer to section 4.2.2.2)

2. At the main menu [SCREEN-3], input “2” to select “Ink Charge” and press ENTER key. Then, the

printer starts the ink charge operation.

4.2.2.4 VH Setting

The piezo-electric element used in each printhead unit has unique electrical characteristic and the

electrical characteristic of each printhead is measured at the production and each printhead unit is given

with the ID code. Therefore, this ID code is need to be stored in EEPROM on the main board when the

following service is made and the printer read this information to compensate the difference of

characteristic for printing control and an amount of injected ink is maintained at the specified level.

Replacing the printhead unit

Replacing the printer mechanism (the after-service unit comes with the printhead unit installed)

*Refer to the next page for [SCREEN -1] to [SCREEN-3].

1. When replacing the part mentioned above, take a note of the ID code indicated on the unit as below.

Printhead Unit: Stamped at the side of the unit

Printer mechanism: Indicated on a label attached to the packing box for the after-service unit.

2. Re-assemble the printer.

3. Start “Preparation for Adjustment” and complete 1 to 4 procedures.(Refer to section 4.2.2.2)

4. At the main menu [SCREEN-1], Input “1” to select “VH Setting” and press ENTER key.

5. At the next menu screen[SCREEN-2], input “0” as “M/C No.” and press ENTER key.

6. Then next menu [SCREEN-3] appears on the screen, and input the ID code which you noted at the

beginning of this procedure.

VH ID Code format: *1

*3

7. After inputting the ID code, the program returns to the m ain menu and you can continue to another

adjustments.

st/2nd

digits (from left) =Normal dot VH ID

rd

digit =Drive frequency ID

th/5th

digits =Micro dot VH ID

*4

WORK POINT

Timing to write the specified value to EEPROM: Upon pressing ENTER key after ID code input.

4-

Rev. A

Page 8

7

*[SCREEN-1] to [SCREEN-3] for VH Setting.

Chapter 4 Adjustment

[SCREEN-1]

[SCREEN-2]

[SCREEN-3]

MAIN MENU for Production >STYLUS COLOR PHOTO K00A10Ve

<

1. VH Setting

2. Ink Charge

3. Angular Adjust-Printing XX-XX-XXXX XX:XX:XX

K. Angular Adjust-Setting

4. Bi-d Adjust CUSTOMER:WORLD

P. Printing Inspection (GOS) JIG No. :CT

L. Printing Inspection (S/F) M/C No. :

M. Printing Inspection (Post-card)

HEAD VH :

CL. Cleaning

9. INK Discharge

E. Go to SETTING MENU

Input ITEM No.: ?_

M/C No. ?_

<<<< HEAD VH WRITE >>>>

Head VH ( 5 digit ID (ex.18109 or 18A0 ):

-------------------

M/C No. :0

HEAD VH :

M/C No. ? 0

VD VALUE

-------------------

Head VH ID

Viewed from front

Figure 4-5.Head VH ID Indication

Rev. A

4-

Page 9

EPSON Stylus Photo

8

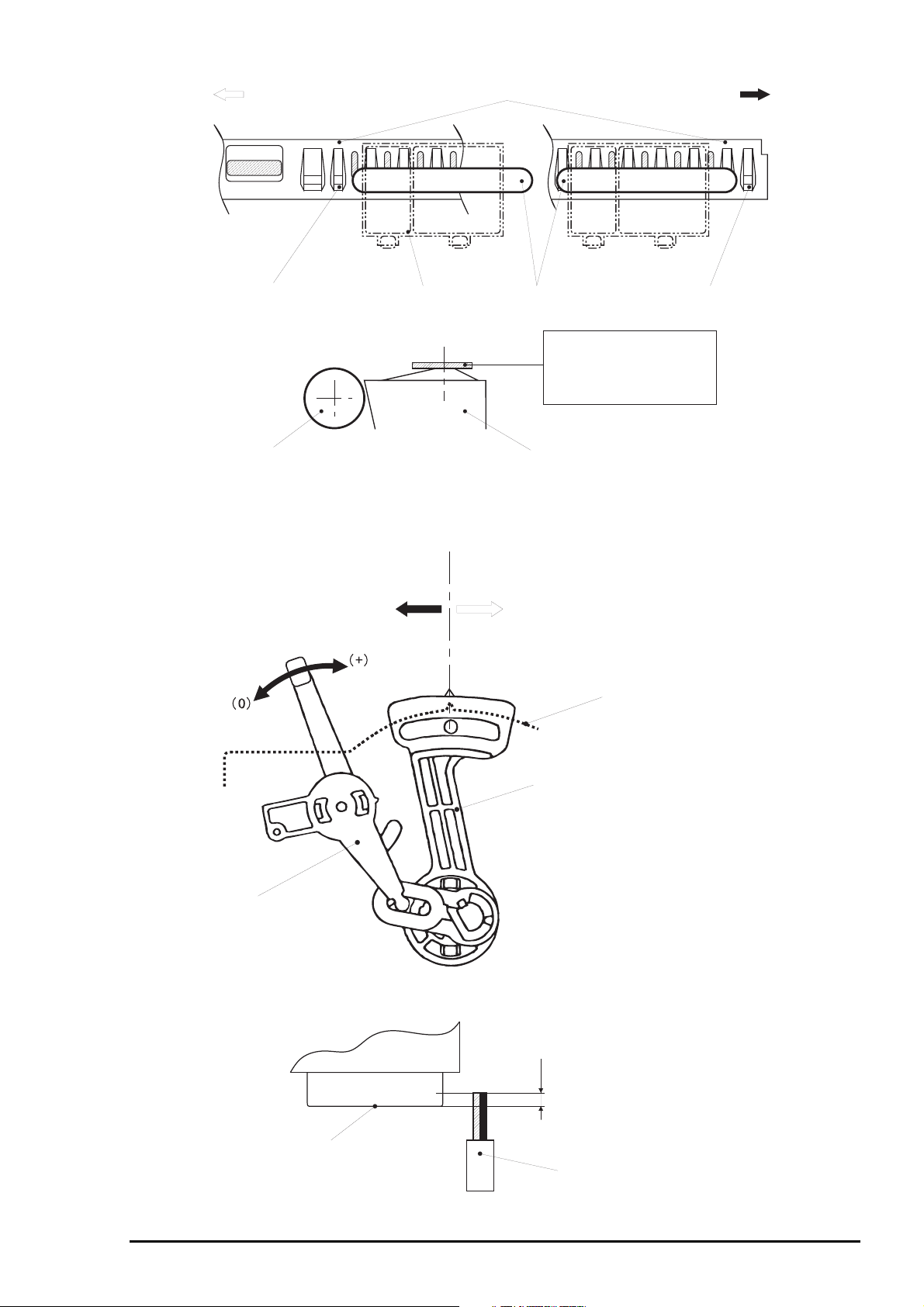

4.2.2.5 Head Angular Adjustment

The head angular means the angle at which the printhead unit installed on the carriage assembly against

the carriage movement direction and the printhead must be parallel with the carriage movement direction

so that the lines printed with each nozzle are evenly positioned. Therefore, this adjustment should be

made when the following service is made:

Replacing or removing the printhead unit

The head angular actually set by the adjust lever installed on the carriage assembly and the program print

the check pattern to see the level of head angular.

*Refer to next page for [SCREEN-1] to [SCREEN-2].

1. Before performing this adjustment, be sure to perform “VH Setting” (Refer to section 4.2.2.4)

2. At the main menu [SCREEN-1], input “3” to select “Angular Adjust Printing” and press ENTER key.

3. Check to see if the lines printed in MAGENTA color is positioned in the middle of two BLACK lines with

the check pattern printed by the program. If the position of MAGENTA lines are incorrect, input “K” to

select “Angular Adjust Setting” at the main menu and the carriage assembly moves to the middle of the

printer. Then, loosen a screw (No.3) fixing “FASTNER, HEAD” a little bit and shift the position of

angular adjust level located at the right bottom of the carriage assembly to either forward (move

MAGENTA line to down) or backward (move MAGENTA line to up).

4. After adjusting the position of angular adjust lever, input “Y” and press ENTER key and the carriage

assembly returns to the home position.

5. Input “3” to print the check pattern again. If the level is still not correct, repeat the step 3 and 4.

6. If the level is correct, input “K” again and tighten a screw to fix “FASTNER, HEAD”. Then, at the menu

[SCREEN-2], input “Y” and press ENTER key to complete the adjustment.

BLACK line

Printed pattern

Printed pattern

MAGENTA line

Shift the lever to:

Backward

Shift the lever to:

Forward

Angular Adjust Lever

(Right bottom of the Carriage Assembly)

Figure 4-6. Head Angular Adjustment

4-

Rev. A

Page 10

9

[SCREEN-1] to [SCREEN-2] for Head Angular Adjustment.

*

Chapter 4 Adjustment

[SCREEN-1]

CL.Cleaning

Input ITEM No. : ?__

[SCREEN-2]

MAIN MENU for Production >STYLUS COLOR PHOTO K00A10Ve

<

1. VH Setting

2. Ink Charge

3. Angular Adjust Printing XX-XX-XXXX XX:XX:XX

K. Angular Adjust Setting

4. Bi-d Adjust CUSTOMER:WORLD

P. Printing Inspection (GOS) JIG No. :CT

L. Printing Inspection (S/F) M/C No. :

M. Printing Inspection (Post-card)

9. INK Discharge

E. Go to SETTING MENU

Input ITEM No.: ? k

Angular Adjustment Finish (Yes):?_

HEAD VH :

Rev. A

4-

Page 11

EPSON Stylus Photo

0

4.2.2.6 Bi-D Alignment Adjustment

This adjustment defines the carriage drive control parameters to compensate the variation in mechanism

components characteristic so that the print position become even in bi-directional printing. This

adjustment is required when one of the following service is made:

Replacing the printer mechanism

Replacing the main board (C209 MAIN)

Replacing the CR Motor assembly

Replacing the carriage assembly

The values defined with this adjustment are stored in EEPROM on the main board.

*Refer to next page for [SCREEN-1] to [SCREEN-3].

1. If the printer mechanism is replaced, the ink charge operation and the VH Setting operation should

be performed prior to this adjustment. (Refer to section 4.2.2.3 and 4.2.2.4)

2. Go to the main menu [SCREEN-1].

3. Input “4” to select “Bi-d Adjust” and press ENTER key.

4. The program prints the check pattern (one with the compensation value=“0” and another two patterns

each printed with the value “-2” and “+2”). Select the number of the pattern with which the printed lines

are most properly aligned, and input the number and press ENTER key at the menu [SCREEN-2].

Then, the program print the sample pattern with the compensation value you have selected.

5. If all patterns printed by the program are completely mis-aligned, confirm the inclination of

misalignment with the pattern printed with the value “0” by checking the relative position of the EVEN

line to the ODD line:

If EVEN line is shifted to RIGHT = Requires (−) value

If EVEN line is shifted to LEFT = Requires (+) value

Then, once input “Y” and press ENTER key to return to the main menu, and input “E” to select “Go to

SETTING MENU” and press ENTER key. At the setting menu screen [SCREEN-3], input “6” to select

“BI-D Center” and input the approximation number that corresponding to the inclination of

misalignment you have confirmed previously. After changing the reference value for the Bi-D alignment

check printing, input “1” to select “(Production)” and back to the main menu and continue for the Bi-D

alignment adjustment from step 4.

WORK POINT

Timing to write the specified value to EEPROM: Upon pressing ENTER key after input “Y”.

[Printed pattern]

Input (-) value

Input (+) value

Figure 4-7.Bi-D Alignment

4-1

Rev. A

Page 12

*[SCREEN-1] to [SCREEN-3] for Bi-D Alignment Adjustment.

Chapter 4 Adjustment

[SCREEN-1]

CL. Cleaning

[SCREEN-2]

MAIN MENU for Production >STYLUS COLOR PHOTO K00A10Ve

<

1. VH Setting

2. Ink Charge

3. Angular Adjust Printing XX-XX-XXXX XX:XX:XX

K. Angular Adjust Setting

4. Bi-d Adjust CUSTOMER:WORLD

P. Printing Inspection (GOS) JIG No. :CT

L. Printing Inspection (S/F) M/C No. :

M. Printing Inspection (Envelope)

9. INK Discharge

E. Go to SETTING MENU

Input ITEM No. : ?_

<< Definable Range (-30=< x <=30). >>

HEAD VH :

Input Adjust Value (If OK, input Y) :? _

[SCREEN-3] ***** SETTING MENU ***** K00A10Ve

1: (Production)/Adjustment

2:

3: DATE/TIME [XX-XX-XXXX] [XX:XX:XX]

4: TOOL [CT] JI=JIG CT=Cartridge WAIT=80s

5: CUSTOMER [WORLD]

6: BI-D Center [ 0 ]

7: Print Position [60]

Q: QUIT

Input ITEM No.: ?

Rev. A

4-1 1

Loading...

Loading...