Page 1

Chapter 3

Disassembly and Assembly

3.1 OVERVIEW............................................................................................................3-1

3.1.1 Precautions for Disassembling the Printer.......................................................................... 3-1

3.1.2 Specification for Screws........................................................................................................ 3-2

3.1.3 Tools........................................................................................................................................3-2

3.1.4 Work Completion Check........................................................................................................3-3

3.2 DISASSEMBLY AND ASSEMBLY.........................................................................3-4

3.2.1 Housing Removal ................................................................................................................... 3-5

3.2.2 Circuit Boards Removal......................................................................................................... 3-6

3.2.3 Control Panel Removal .......................................................................................................... 3-8

3.2.4 Waste Ink Pad Assembly Removal ....................................................................................... 3-9

3.2.5 Disassembling the Printer Mechanism............................................................................... 3-10

3.2.5.1 Printhead Removal.................................................................................................. 3-10

3.2.5.2 Pump Assembly and Cap Assembly Removal........................................................3-12

3.2.5.3 CR Motor Assembly Removal .................................................................................3-14

3.2.5.4 PF Motor Assembly Removal.................................................................................. 3-16

3.2.5.5 ASF Assembly Removal.......................................................................................... 3-18

3.2.5.6 Carriage Assembly Removal................................................................................... 3-22

3.2.5.7 PF Roller Assembly Removal.................................................................................. 3-24

3.2.5.8 PE Sensor Assembly Removal ...............................................................................3-26

3.2.5.9 HP Sensor Assembly Removal ............................................................................... 3-27

3.2.5.5.1 ASF Disassembly.........................................................................................3-20

3.2.5.5.2 Pick-Up Roller Assembly Removal ..............................................................3-21

Page 2

Chapter 3 Disassembly and Assembly

3.1 OVERVIEW

This section describes procedures for disassembling the main components of EPSON Stylus Photo.

Unless otherwise specified, disassembly units or components can be reassembled by reversing the

disassembly procedure. Therefore, no assembly procedures are included in this section. Precautions for

any disassembly or assembly procedure are described under the heading “WORK POINT”. Any

adjustments required after disassembling the units are described under the heading “REQUIRED

ADJUSTMENT”.

3.1.1 Precautions for Disassembling the Printer

See the precautions below when disassembling or assembling EPSON Stylus Photo.

WARNING

Disconnect the power cable before disassembling or assembling the printer.

Wear protective goggles to protect y our eyes from ink. If ink gets in your eye, flush the eye with

fresh water and see a doctor immediately.

If ink comes into contact with your skin, wash it off with soap and water. If irritation occurs, contact

a physician.

A lithium battery is installed on the main board of this printer. Be sure to observe the following

instructions when servicing the battery:

Keep the battery away from any metal or other batteries so that electrodes of the opposite

polarity do not come in contact with each other.

Do not heat the battery or put it near fire.

Do not solder on any part of the battery. (Doing so may result in leakage of electrolyte from the

battery, burning or explosion. The leakage may affect other devices close to the battery.)

Do not charge the battery. (An explosive may be generated inside the battery, and cause burning

or explosion.)

Do not dismantle the battery. (The gas inside the battery may hurt your throat. Leakage, burning

or explosion may also be resulted.)

Do not install the battery in the wrong direction. (This may cause burning or explosion.)

CAUTION

Danger of explosion if the battery is incorrectly replaced. Replace only with the same or equivalent

type recommended by the manufacture. Dispose the used batteries according to government’s law

and regulations.

Risque d’explosion si la pile est remplacée incorrectment. Ne remplacer que par une pile du même

type ou d’un type équivalent recommandé par le fabricant. Eliminer les piles déchargées s elon les lois

et les règles de sécurité en vigueur.

CAUTION

Never remove the ink cartridge from the carriage unless manual specify to do so.

When transporting the printer after installing the ink cartridge, be sure to pack the printer for

transportation without removing the ink cartridge.

Use only recommended tools for disassembling, assembling or adjusting the printer.

Apply lubricants and adhesives as specified. (See Chapter 6 for details.)

Make the specified adjustments when you disassemble the printer. (See Chapter 4 for details.)

Rev. A

3-1

Page 3

EPSON Stylus Photo

2

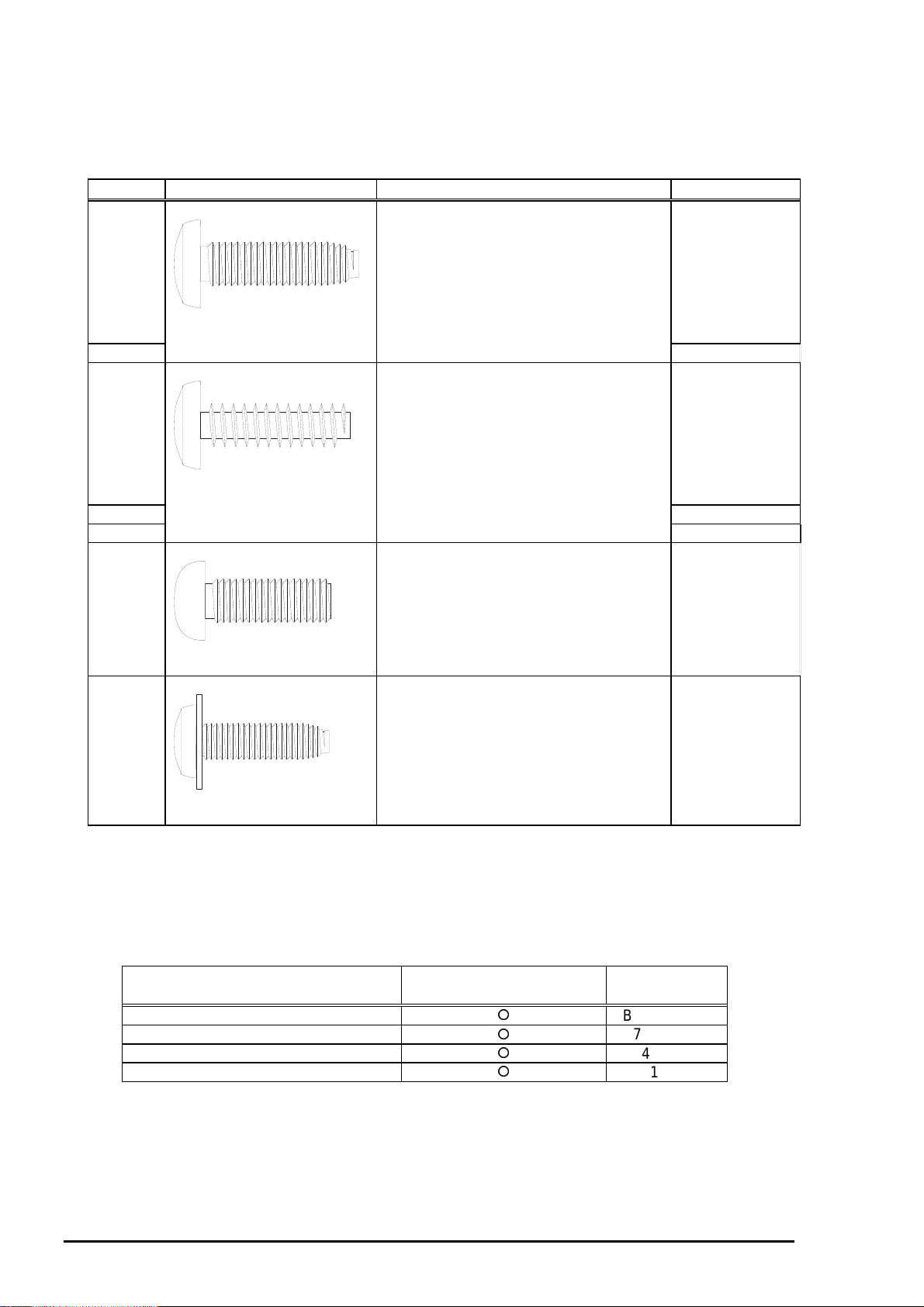

3.1.2 Specification for Screws

Table 3-1 lists the abbreviation of screws and its use. Refer to the screw number in the following table to

identify the type of screw shown in the disassembly procedures.

Table 3-1. Screw Identification Table

No. Shape Name Standard

1 CBS

(Cross/Bind/S-tight screw)

2 M3x10

3 CBP

(Cross/Bind/P-tight screw)

M3x6

M3x6

4 M3x10

5 M3x8

6 CP

(Cross/Pan-head screw)

7 CBS with Washer

(Cross/Bind/S-tight screw with washer)

M3x4

M3x6

3.1.3 Tools

Table 3-2 lists the tools required for disassem bling and ass embling the printer. Use only specified tools to

avoid damaging the printer.

Table 3-2. Required Tools

Name Availability EPSON

Parts Code

Philips Screw Driver (No.1)

Philips Screw Driver (No.2)

Tweezers

Hexagonal Box Driver (5.5mm)

3-

B743800200

B743800400

B741000100

B741700100

Rev. A

Page 4

Chapter 3 Disassembly and Assembly

3

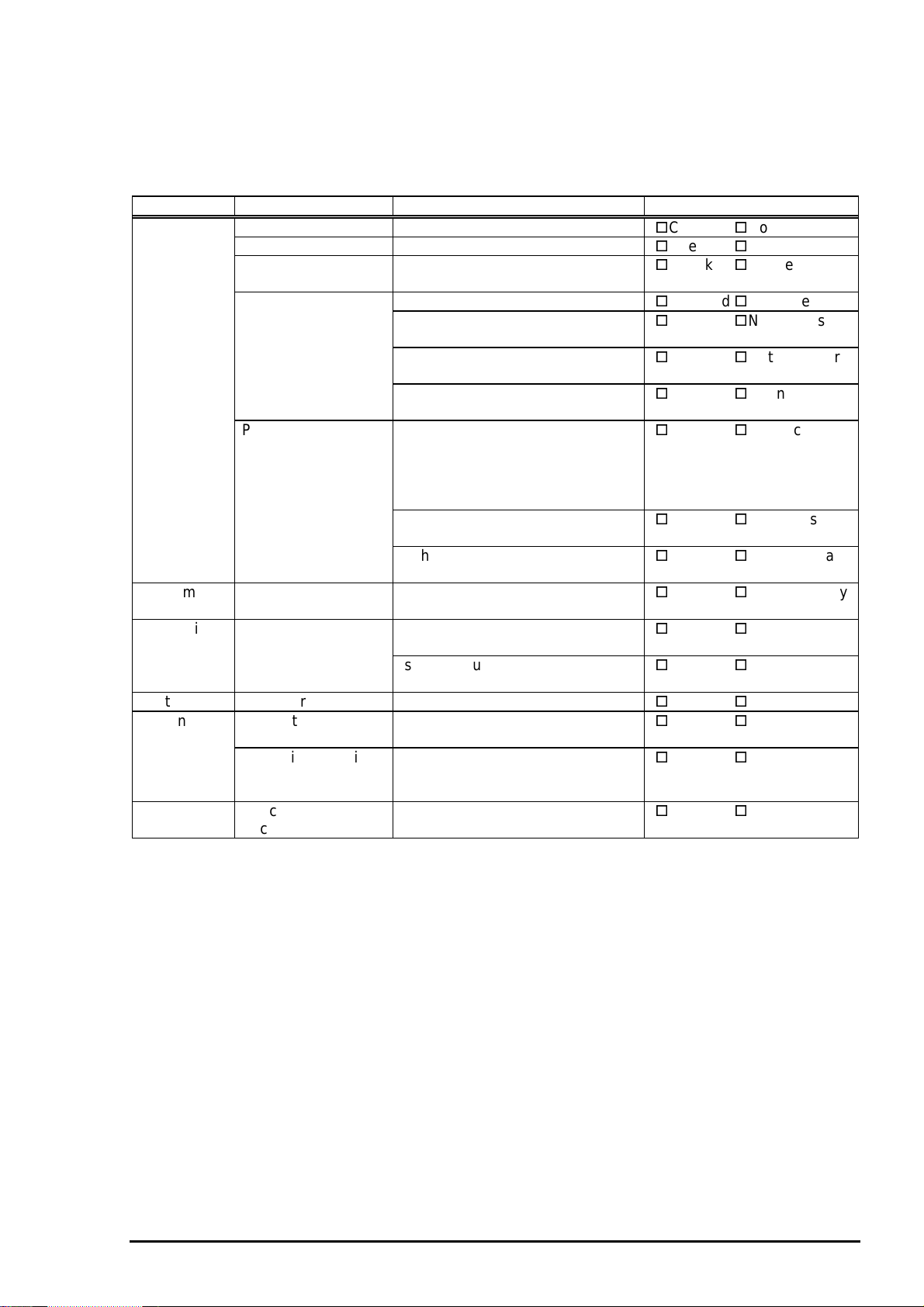

3.1.4 Work Completion Check

If any service is made to the printer, use the check list shown below, to confirm that all works are

completed properly and the printer is ready to return to the user.

Category Item Check Point Status

Main Unit Self-Print Test Is the printing successful?

Online Print Test Is the printing successful?

Printhead Is ink discharged norm ally fr om all

nozzle?

Carriage Mechanism Does it moves smoothly?

Is there any abnormal noise in its

motion?

Is there any dirt or scratch in the

CR guide shaft?

Is the CR Motor at the correct

temperature? (Not too hot)

Paper Feeding

Mechanism

Adjustment Specified

Adjustment

Lubrication Specified Point Does all the lubrication made at

System ROM Version Version (Latest):

Packing Ink Cartridge Are brand-new ink cartridges

Protective Materials Have all relevant protective

Other Attachment,

Accessories

Is paper advanced smoothly?

*No paper jamming

*No paper skew

*No multiple feeding

*No abnormal noise

Is the PF Motor at the correct

temperature? (Not too hot)

Is the paper path clear of all

obstructions?

Are all the adjustments done

correctly?

specified points?

Is the amount of lubrication

correct?

installed correctly?

materials been attached to the

printer?

Have all relevant items been

included in the package?

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Checked/Not necessary

Rev. A

3-

Page 5

EPSON Stylus Photo

4

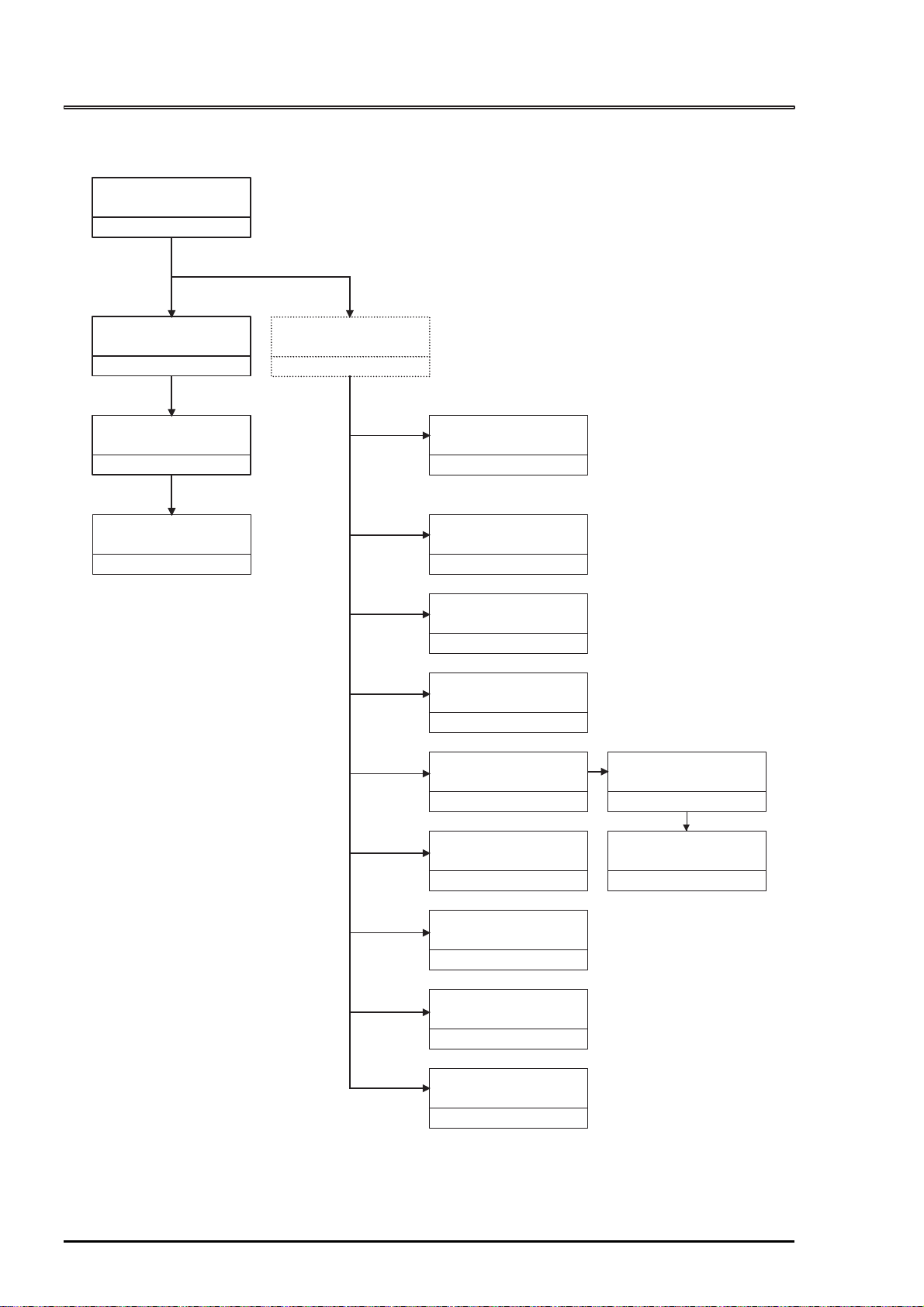

3.2 DISASSEMBLY AND ASSEMBLY

This section describes the step-by-step disassembly procedures shown in the diagram below.

Housing

Removal

Section 3.2.1

Circuit Boards

Removal

Section 3.2.2

Control Panel

Removal

Section 3.2.3

Waste Ink Pad Assembly

Removal

Section 3.2.4

Printer Mechanism

Disassembly

Seciton 3.2.5

Printhead

Removal

Section 3.2.5.1

Pump/Cap Assembly

Removal

Section 3.2.5.2

CR Motor Assembly

Removal

Section 3.2.5.3

PF Motor Assembly

Removal

Section 3.2.5.4

ASF Assembly

Removal

Section 3.2.5.5

ASF

Disassembly

Section 3.2.5.5.1

3-

Carriage Assembly

Removal

Section 3.2.5.6

PF Roller Assembly

Removal

Section 3.2.5.7

PE Sensor Assembly

Removal

Section 3.2.5.8

HP Sensor Assembly

Removal

Section 3.2.5.9

Figure 3-1. Flow Chart of Disassembly

Pick-Up Roller Assembly

Removal

Section 3.2.5.5.2

Rev. A

Page 6

Chapter 3 Disassembly and Assembly

5

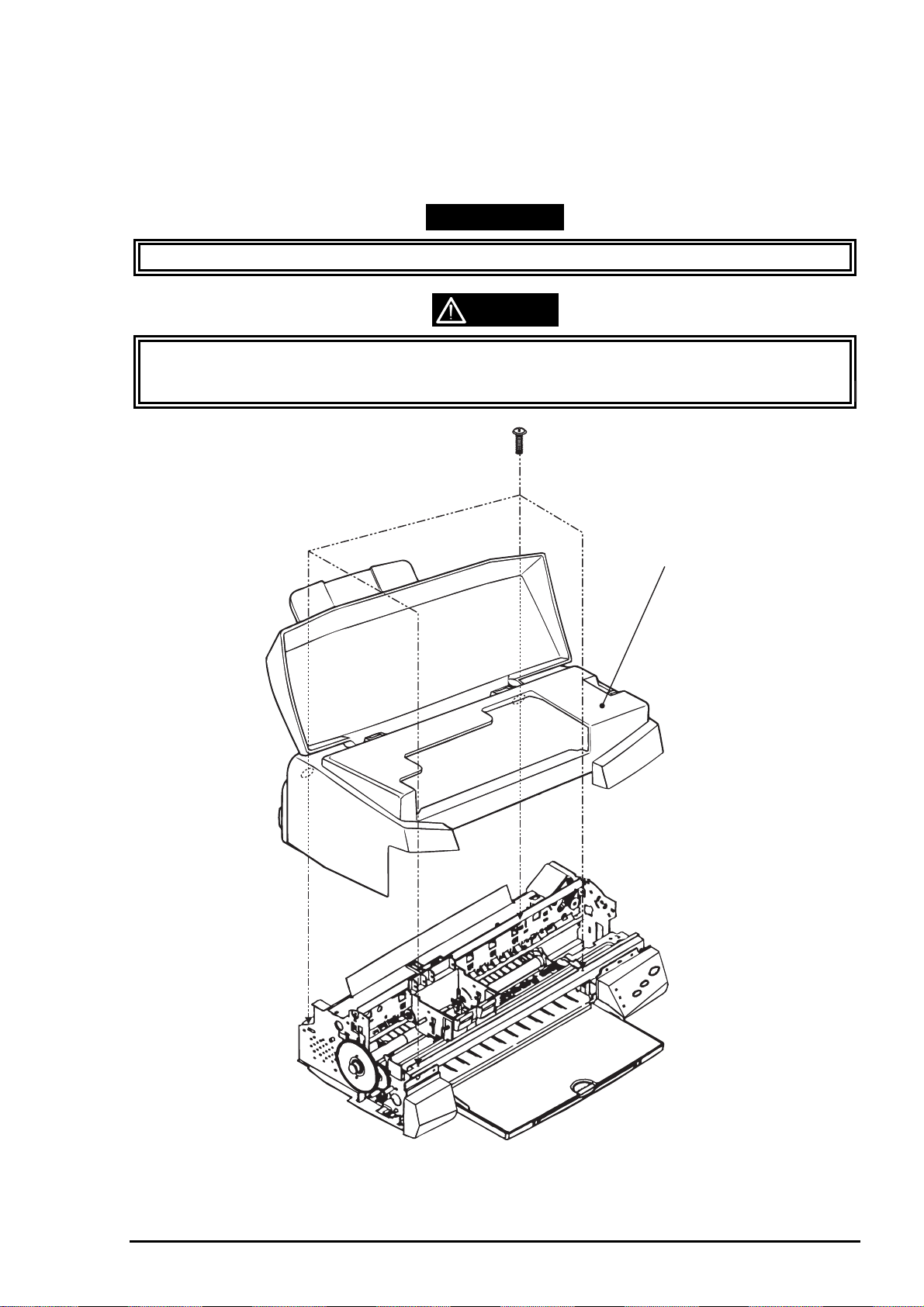

3.2.1 Housing Removal

Since the EPSON Stylus Photo has no lower housing as previous EPSON printers, the printer mechanism

can be taken out by only removing the upper housing.

1. Open the printer cover and set the PG adjust lever on the right-hand side to (+) position.

2. Remove 4 screws (No.2) and remove the upper housing.

WORK POINT

Pull the front end of the upper housing while lifting up the upper housing to remove it.

CAUTION

Be careful not to pinch the cables with the posts of the upper housing when reins talling it. (Espec ially

with the cables from the motors and doing so causes fatal damage to the mechanism and the electric

circuitry.)

Upper Housing

Figure 3-2. Housing Removal

Rev. A

3-

Page 7

EPSON Stylus Photo

6

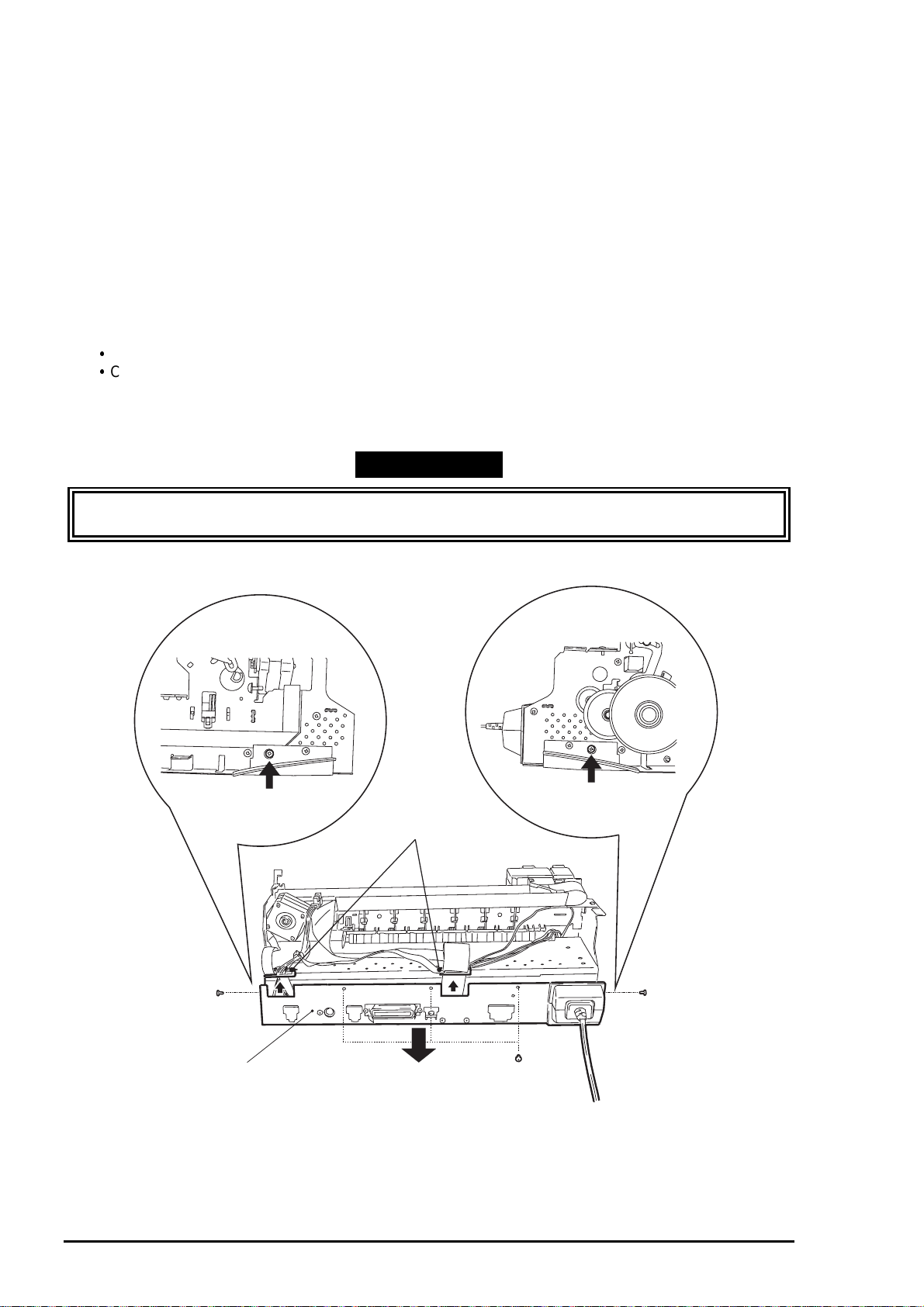

3.2.2 Circuit Boards Removal

The electric circuit boards of the printer (Main control circuit board: C209 MAIN / Power supply circuit

board: C206 PSB/PSE) are both installed on single metal chassis and attached to the printer mechanism.

Therefore, first detach the metal chassis from the printer mechanism to remove the electric circuit boards.

1. Remove the upper housing (Refer to section 3.2.1)

2. Remove 5 screws (No.1 / three at the back of the printer mechanism and one each at both sides

of the printer mechanism)

3. Slightly pull out “SHIELD PLATE, M/B” (metal chassis) from the printer mechanism and take out

the cable holders inserted to the edge of “SHIELD PLATE, M/B”.

4. Fully separate “SHIELD PLATE, M/B” from the printer mechanism and remove all cables

connected to the connectors on the main board; C209 MAIN.

5. If you need further to remove each electric circuit board from “SHIELD PLATE, M/B”, remove the

screws fixing each board and remove the board.

C209 MAIN BOARD: 10 screws (No.1 = 7 screws, No.6 = 3 screws)

C206 PSB/PSE BOARD: 4 screws (No.1)

Also disconnect the cable from the connector; CN10 (locking type) on the C209 MAIN, when you

remove the C206 PSB/PSE BOARD.

WORK POINT

Unlock the connector CN6/7 on the C209 MAIN by pulling its loc k before disconnect the cables, and

be sure to lock it when reconnecting the cables.

[Cable Holders]

SHIELD PLATE, M/B

Figure 3-3. SHIELD PLATE M/B Removal

3-

Rev. A

Page 8

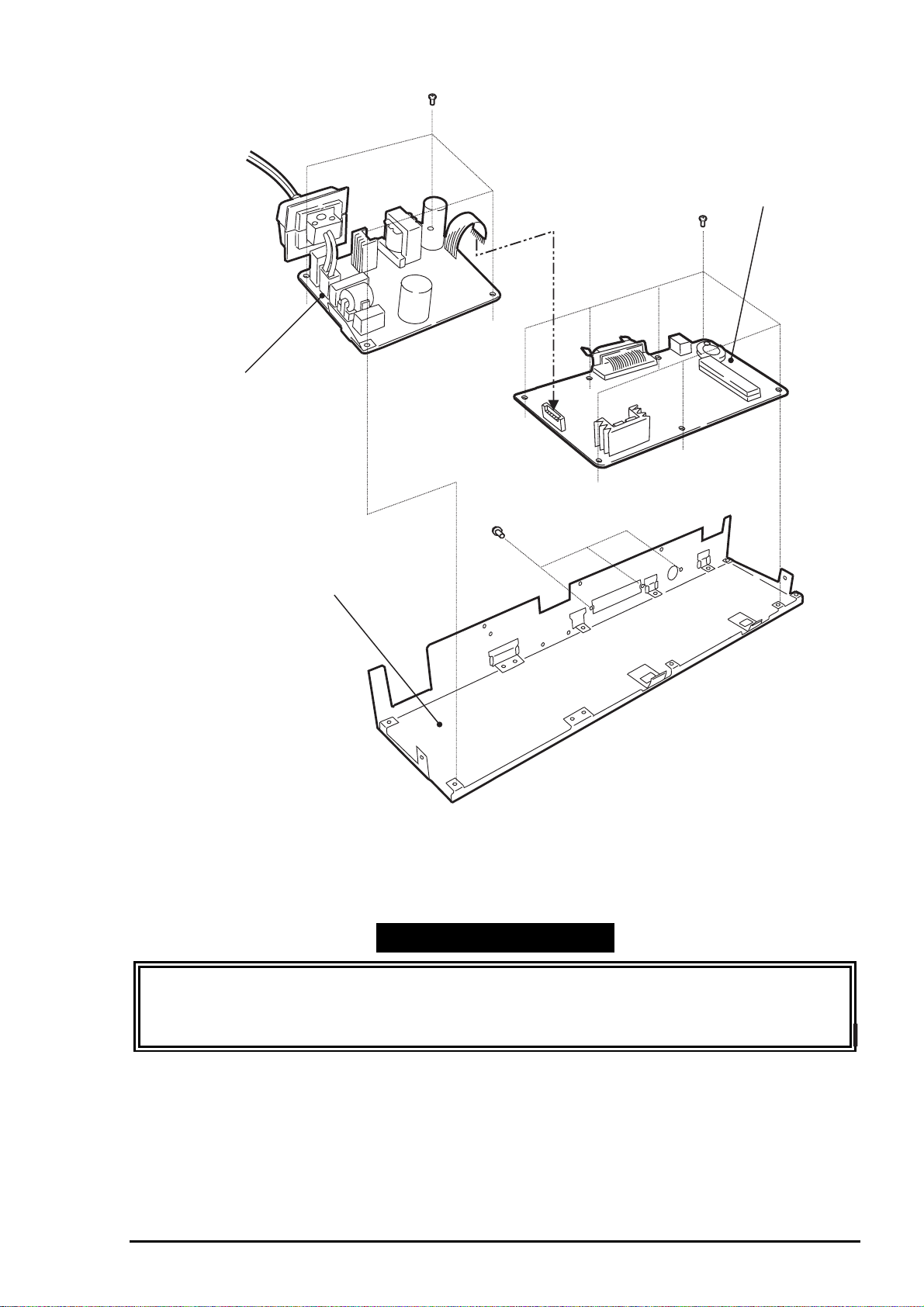

7

Power Supply Board

(C206 PSB/PSE)

Chapter 3 Disassembly and Assembly

MAIN Board

(C209 MAIN)

SHIELD PLATE, M/B

Figure 3-4. Circuit Boards Removal

REQUIRED ADJUSTMENT

Be sure to perform the following adjustments when the C209 MAIN board is replaced:

1) VH Setting (Refer to Chapter 4 / Section 4.2.2.4.)

2) Head Angular Adjustment (Refer to Chapter 4 / Section 4.2.2.5.)

3) Bi-D Alignment Adjustment (Refer to Chapter 4 / Section 4.2.2.6.)

Rev. A

3-

Page 9

EPSON Stylus Photo

8

3.2.3 Control Panel Removal

1. Remove the upper housing (Refer to Section 3.2.1)

2. Remove 2 screws (No.1) and remove the “PANEL, ASSEMBLY” and “HOUSING, PANEL, LEFT” from

the printer mechanism and disconnect the flat cable from the connector of the panel assembly.

WORK POINT

By removing the control panel assembly, the stacker assembly is also detached from the printer

mechanism since it is held by the control panel assembly.

SHIELD PLATE, PANEL

C209 PNL Board

HOUSING, PANEL, LEFT

PANEL, ASSEMBLY

STACKER, ASSEMBLY

Figure 3-5. Control Panel Removal

3-

Rev. A

Page 10

Chapter 3 Disassembly and Assembly

9

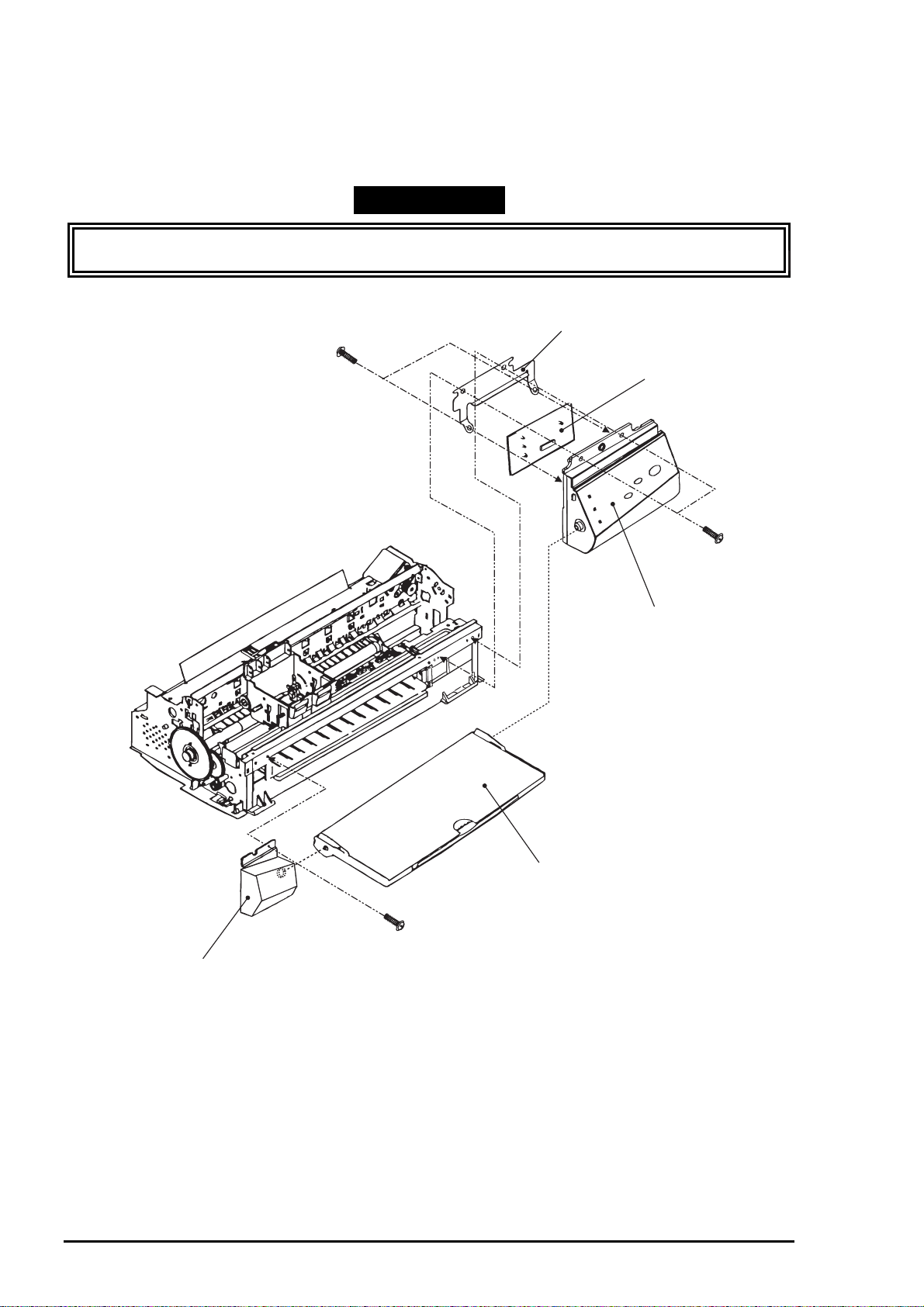

3.2.4 Waste Ink Pad Assembly Removal

1. Removing the upper housing (Refer to section 3.2.1)

2. Removing the control panel assembly (Refer to section 3.2.3)

3. Remove 1 screw (No.4) at the right-hand side of the printer mechanism, that fixing “Waste Ink Pad

Assembly”.

4. Remove “SPACER, TRAY” fixing “Waste Ink Pad Assembly” at the left-hand side of the printer

mechanism and remove “Waste Ink Pad Assembly” by pulling it dow nward.

CAUTION

When you replace “Was te Ink Pad Assembly” to new one, be sure to perform the ink counter reset

operation. (Refer to Chapter 1 / Section 1.4.2 for details)

WORK POINT

When re-installing “Waste Ink Pad Assembly ”, be sure that “Stopper, Stacker” that attached to the exit

roller shaft is correctly pushed in to back of the projections of “Waste Ink Pad Assembly”.

SPACER, TRAY

Section (A)

[Projections]

Paper Exit Roller Shaft

Front side

STOPPER, STACKER

Push it to the back of

projection

Figure 3-6. Waste Ink Pad Assembly Removal

Waste Ink Pad Assembly

Rev. A

3-

Page 11

EPSON Stylus Photo

0

3.2.5 Disassembling the Printer Mechanism

This section describes the procedures for removing the main components consisting the printer

mechanism.

3.2.5.1 Printhead Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. Rotate “Gear, 67.2” (largest gear at the left-hand side of the printer mechanism) toward the front to

disengage the carriage lock mechanism, and move the carriage assembly to the middle of the printer.

3. Remove both black and color ink cartridges.

4. Remove both carriage cover assemblies from the carriage.

5. Remove “Twist Spring, 49” at left-hand side of the carriage and remove 1 screw (No.3) fixing

“FASTNER, HEAD”. Then, remove “FASTNER, HEAD” from the carriage.

6. Unhook the flat cables from the carriage assembly and tae out the printhead unit from the carriage.

7. Disconnect the cables from the connector of the printhead unit.

WORK POINT

Notice that the grounding plate is installed in correct pos ition. (there are two fixing pins in the

carriage)

Be sure that fixing pin of the carriage is correctly located into the cut out of the printhead unit.

CAUTION

Once the ink cartridge is removed, it is not re-usable and always install brand-new ink cartridge

before returning the printer to the user.

When returning the printer to the user, be sure that the ink cartridge is installed and the carriage

is at the capping position. (Turn the printer off while the carriage is at the capping position and

pack it in that state)

This part should

be touching the

CR axis receiver.

Make sure that this

protrusion is in the

U ditch of the priht head

side.

Make sure that protrusion

of carriage is in the hole

of the earth board.

Carriage Assembly

Print Head

Figure 3-7.Printhead Installation

3-1

Rev. A

Page 12

Printhead Unit

TWIST SPRING, 49

Chapter 3 Disassembly and Assembly

Flat Cable

FASTNER, HEAD

Figure 3-8. Printhead Unit Removal

CAUTION

If you remove the Flat cable from the printer mechanism, make s ure that the Flat cable is fixed to

the frame firmly when assembling.

REQUIRED ADJUSTMENT

When you remove or replace the printhead unit, be sure to perform the following adjustments:

1) Ink Charge Operation (Refer to Chapter 4 / Section 4.2.2.3.)

2) VH Setting (Refer to Chapter 4 / Section 4.2.2.4.)

3) Head Angular Adjustment (Refer to Chapter 4 / Section 4.2.2.5.)

Rev. A

3-1 1

Page 13

EPSON Stylus Photo

2

3.2.5.2 Pump Assembly and Cap Assembly Removal

1. Removing the upper housing. (Refer to Section 3.2.1)

2. Removing the control panel assembly. (Refer to section 3.2.3)

3. Removing “Waste Ink Pad Assembly”. (Refer to section 3.2.4)

4. Loosen 2 screws (No.1) fixing the exit frame assembly and disengage the frame from the side frames.

Then, put the printer mechanism on its back as you can see the bottom of the mechanism.

5. At the right-hand of the mechanism, unhook the cap assembly by releasing one hook and take out the

cap assembly by lifting up the right end of it. (Note that the cap assembly is still connected to the pump

assembly by the ink tube.)

6. Remove 2 screws (No.5) fixing the pump assembly to the frame.

7. Unhook the pump assembly by releasing one hook and slide the pump assembly to the right direction

to remove it.

CAUTION

Be careful not to damage rubber part of the cap assembly. (Damaging the rubber part causes

incomplete capping and the nozzle condition become unstable.)

Be careful with the followings when you handle “CLEANER, HEAD”:

•Do not handle it with bare hands and avoid attaching any oil or dust.

•Make sure that the rubber side of “CLEANER, HEAD” is facing to the right.

WORK POINT

Be careful not to popping the components from the pump assembly when you remove it from the

mechanism, since there is a spring inside the pump assembly.

Be sure that the ink tube from the cap assembly is routed to the correct position and not pinched

by the cap assembly and the frame.

Verify that “CLEANER, HEAD” moves smoothly by rotating “GEAR, 67.2” after you re-assemble

the pump assembly. (Hold the cap assembly to the right direction while you rotating the gear for

check)

Ink Tube Routing

OK

(Ink tube goes behind of

the cap assembly)

Viewed from front

NG

(The ink tube is on the part of

the cap assembly)

Figure 3-9. Ink Tube Routing

3-1

Rev. A

Page 14

3

Loosen screw and

lift up the exit frame

PUMP ASSEMBLY

Chapter 3 Disassembly and Assembly

Unhock the cap assembly

CAP ASSEMBLY

CLEANER, HEAD

Remove 2 screws and unhook the hooks

to remove the pump assembly

Figure 3-10.Cap Assembly Removal

Pump Components

Assembly Order

Figure 3-11.Pump Assembly Removal

Rev. A

3-1

Page 15

EPSON Stylus Photo

4

3.2.5.3 CR Motor Assembly Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. Rotate “Gear, 67.2” (largest gear at the left-hand side of the printer mechanism) toward the front to

disengage the carriage lock mechanism, and move the carriage assembly to the middle of the printer.

3. Push “HOLDER, PULLEY, DRIVEN” inward to loosen the timing belt and detach the timing belt from

the drive pulley of CR Motor assembly.

4. Remove 2 screws (No.1) and remove “MOTOR, ASSEMBLY, CR” from the mechanism.

WORK POINT

Be sure that the projections of the motor bracket is inserted to the holes of the frame properly.

REQUIRED ADJUSTMENT

When you replace “MOTOR, ASSEMBLY, CR”, be sure to perform the following adjustment:

1) Bi-D Alignment Adjustment (Refer to Chapter 4 / Section 4.2.2.6.)

COMPRESSION SPRING, 19.6 PULLEY, ASSEMLBLY, DRIVEN

Outside side frame

TIMING BELT

Inside side frame

HOLDER, PULLEY, DRIVEN

Figure 3-12. Driven Pulley Removal

3-1

Rev. A

Page 16

Chapter 3 Disassembly and Assembly

5

The projections of motor assembly must

locate inside the holes

Figure 3-13. CR Motor Removal

Rev. A

3-1

Page 17

EPSON Stylus Photo

6

3.2.5.4 PF Motor Assembly Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. Removing “Waste Ink Pad Assembly”. (Refer to section 3.2.4)

3. By referring the figure below, remove the specified gears from the mechanism:

“GEAR, 67.2”

“COMBINATION GEAR, 8, 14.4”

“COMBINATION GEAR, 8.8, 21.6”

“GEAR, 36”

4. Remove 2 hexagonal lock nuts and remove “MOTOR, ASSEMBLY, PF”.

WORK POINT

When removing the PF Motor, first, slightly pulling out the PF Motor from the frame and slide the

motor shaft to a larger cut out of the frame and remove it.

Be careful with the routing direction of the cable from the PF motor.

COMPRESSION SPRING, 0.9

GEAR, 67.2

MOTOR, ASSEMBLY, PF

Hexagonal Nut

COMBINATION GEAR, 8, 14.4

COMBINATION GEAR, 8.8, 21.6

GEAR, 36

Lock Ring

Figure 3-14. PF Motor Removal

3-1

Rev. A

Page 18

7

MOTOR, ASSEMBLY, PF

(behind the frame)

Cable Direction

Chapter 3 Disassembly and Assembly

Put the motor shaft once in a larger hold

then slide it to a smaller hole

Figure 3-15. PF Motor and Frame

Rev. A

3-1

Page 19

EPSON Stylus Photo

8

3.2.5.5 ASF Assembly Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. Remove the locking pin from center of “GEAR, 34” and remove “GEAR, 34” from the shaft.

3. Unhook the cables from the cable hook of the ASF and the printer mechanism.

4. Remove 2 screws (Refer to the figures) fixing the ASF and remove the ASF from the mechanism by

detaching the projection of ASF (at left) from the hole of the mechanism.

WORK POINT

Make sure that the ASF is firmly attached to the mechanism.

Use proper type of screw at specified position (viewed from the back of the mechanism):

Right: “SHAFT, FIXING, CR”

Left: Screw - No.7 (CBS with washer)

CAUTION

When re-installing the ASF, be sure that no c ables (except the flat c able to the printhead) are pinched

between the ASF and the frame.

Especially, if the cables from CR/PF Motor is pinched, there is a danger of short-circuit with the frame

and possibly causes hazardous problem like over-heating, burning of components.

3-1

Rev. A

Page 20

9

[CBS with washer]

Chapter 3 Disassembly and Assembly

SHAFT, FIXING, CR

GEAR, 34

The projections of ASF must be

in these holes

Figure 3-16. ASF Assembly Removal

Rev. A

3-1

Page 21

EPSON Stylus Photo

0

3.2.5.5.1 ASF Disassembly

1. Removing the ASF. (Refer to section 3.2.5.5)

2. Remove “TWIST SPRING, 41.2” by unhooking one end from the ASF frame and remove “LEVER,

BRAKE”.

3. Remove “BUSH, FIXING, SHAFT” from the right end of “SHAFT, ROLLER, LD” and remove “LEVER,

HOPPER, RELEASE”.

4. Move the left paper pick-up assembly to the middle of the ASF and remove “BUSH” from the shaft.

5. Push out “SHAFT, ROLLER, LD” to the left and remove “BUSH, FIXING, SHAFT, LEFT” from the leftend of the shaft by unhook it.

6. Unhook the top of “HOPPER, ASSEMBLY” from the both sides of “FRAME, ASF”.

7. Push out “SHAFT, ROLLER, LD” to the right while pulling up “PICKUP, ROLLER ASSEMBLY, RIGHT”

slightly. Then, detach the left end of “SHAFT, ROLLER, LD” from “FRAME, ASF”.

8. Holds “HOPPER, ASSEMBLY” and remove the right cam part of “HOPPER, ASSEMBLY” through the

hole at the right side of “FRAME, ASF”.

To this point, the ASF assembly is disassembled and both left and right “ PICKUP, ROLLER ASSEMBLY”

and “HOPPER, ASSEMBLY” are separated.

WORK POINT

When removing “HOPPER, ASSEMBLY”, be careful that the grease that applied to the cam part

of it, not to attach to the other part of the ASF. If so, wipe it off completely.

Be careful of the direction when you install the “LEVER, HOPPER, RELEASE”.

Make sure that bushes at the both ends of the shaft are firmly attached.

HOPPER, ASSEMBLY

LEVER, BRAKE

TWIST SPRING, 41.2

BUSH, FIXING, SHAFT, LEFT

CAM part

FRAME, ASF

LEVER, HOPPER, RELEASE

BUSH

SHAFT, ROLLER, LD

BUSH, FIXING, SHAFT

Figure 3-17. ASF Disassembly

3-2

Rev. A

Page 22

Chapter 3 Disassembly and Assembly

3.2.5.5.2 Pick-Up Roller Assembly Removal

1. Disassemble the ASF and separate “PICKUP, ROLLER ASSEMBLY” and “HOPPER, ASSEMBLY”.

(Refer to section 3.2.5.5.1)

2. Remove “COMPRESSION SPRING, 1.66” from the back of “HOPPER, ASSEMBLY”.

3. Pull out the right cam part of “HOPPER, ASSEMBLY” though the hole of right frame of “PICKUP,

ROLLER ASSEMBLY, RIGHT”.

<To this point, “HOPPER, ASSEMBLY” and “PICKUP, ROLLER ASSEMBLY” is separated>

4. Unhook “ROLLER ASSEMBLY, LD” from the assembly frame and remove “COVER, ROLLER, LD” by

unhooking it from the assembly frame. Then, remove “ROLLER ASSEMBLY, LD”.

WORK POINT

When you re-assemble, be sure that “ROLLER ASSEMBLY, LD” is hooked to assembly frame

firmly.

Before re-assemble the unit, make sure that “COMPRESSION SPRING, 1.66” is set on the

assembly frame and hooked to the hooks as shown in the figure. This helps you easier

assembly. After assemble the unit, do not forget to unhook the springs by rotating the spring

from the holes located at the back of the ASF assembly.

COVER, ROLLER, LD (L/R)

+

HOLDER, SHEET, PF

ROLLER, ASSEMBLY, LD (L/R)

COMPRESSION SPRING, 1.66

ASSEMBLY FRAME

Rev. A

Set the spring and hook it

to the assembly frame as

illustrated, before re-assembly

Figure 3-18. Pick-Up Roller Removal

3-21

Page 23

EPSON Stylus Photo

2

3.2.5.6 Carriage Assembly Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. Push “HOLDER, PULLEY, DRIVEN” inward to loosen the timing belt and detach the timing belt from

the drive pulley of CR Motor assembly.

3. Take out “COMPRESSION SPRING, 19.6” from “HOLDER, PULLEY, DRIVEN”.

4. Remove “PULLEY, ASSEMBLY, DRIVEN” and the timing belt together from “HOLDER, PULLEY,

DRIVEN” and remove “HOLDER, PULLEY, DRIVEN” from the mechanism.

5. Unhook “LEVER, PG” and remove it.

6. Unhook “LEVER, PG, SUB” and remove “LEVER, PG, SUB” and a spring washer from the end of

“SHAFT, CR, GUIDE”.

7. Remove 1 screw (No.7) and rotating “BUSH, PARALLEL ADJUST, RIGHT” to match it with the cut out

of the frame. Then, take out “BUSH, PARALLEL, ADJUST, RIGHT”.

8. Remove “CARRIAGE, ASSEMBLY” together with “SHAFT, CR, GUIDE”.

WORK POINT

It is good idea to mark the current position of “BUSH, PARALLEL ADJUST, RIGHT” before

removal. This enables you to omit the paper gap adjustment after the assembly.

Be careful with the direction of spring washer at the assembly. (A convex side must face the

bush)

REQUIRED ADJUSTMENT

When you remove or replace the carriage assembly, be sure to perform the following adjustments:

1) Paper Gap Adjustment (Refer to Chapter 4 / Section 4.2.1.)

2) Head Angular Adjustment (Refer to Chapter 4 / Section 4.2.2.5.)

3) Bi-D Alignment Adjustment (Refer to Chapter 4 / Section 4.2.2.6.)

BUSH, PARALLEL ADJUST, RIGHT

BUSH, PARALLEL ADJUST, RIGHT

Side frame of

printer mechanism

Figure 3-19. BUSH PARALLEL ADJUS T Removal

3-2

Cut out of side frame

Rev. A

Page 24

3

BUSH, PARALLEL ADJUST, LEFT

Chapter 3 Disassembly and Assembly

Carriage Assembly

SHAFT, CR, GUIDE

Spring Washer

(Convex side must be facing the bush)

Figure 3-20. Carriage Assembly Removal

BUSH, PARALLEL ADJUST, RIGHT

LEVER, PG, SUB

Rev. A

3-2

Page 25

EPSON Stylus Photo

4

3.2.5.7 PF Roller Assembly Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. Removing the carriage assembly (Refer to section 3.2.5.6)

3. Remove 2 screws (No.1) at the top of mechanism and remove “GUIDE PLATE, CABLE”.

4. From the back of the mechanism, unhook the springs from the frame and remove “PAPER GUIDE,

ASSEMBLY, UPPER” (total 6 pieces).

5. Unhook “PAPER GUIDE, FRONT;B” and remove it.

6. Unhook the both shaft holders of “ROLLER, ASSEMBLY, PAPER EXIT” and remove it.

7. Unhook the left shaft holder of “ROLLER, ASSEMBLY, PF” and rotate it as to match with the cut out of

the frame.

8. Slide “ROLLER, ASSEMBLY, PF” to the left and pulling it out.

WORK POINT

When reinstalling “PAPER GUIDE, ASSEMBLY, UPPER” at right-most position (viewed from the

front), be careful with the detection lever of the PE sensor.

Be careful not to damage the hook of “PAPER GUIDE, FRONT;B” during disassembly and

assembly.

Be careful not to damage the black coated part of “ROLLER, ASSEMBLY, PF” during

disassembly and assembly.

Be careful not to damage the gears.

PAPER GUIDE, LEFT

GUIDE PLATE, CABLE

PAPER GUIDE, ASSEMBLY, UPPER

SHAFT, PAPER GUIDE, UPPER

TWIST SPRING, 117.6

(6 pieces)

Figure 3-21. PAPER GUIDE ASSEMBLY Removal

3-2

Rev. A

Page 26

5

PAPER GUIDE, LEFT

GUIDE PLATE, CABLE

Chapter 3 Disassembly and Assembly

PAPER GUIDE, ASSEMBLY, UPPER

SHAFT, PAPER GUIDE, UPPER

TWIST SPRING, 117.6

(6 pieces)

Figure 3-22. ROLLER, ASSEMBLY, PAPER EXIT Removal

ROLLER, ASSEMBLY, PAPER EXIT

PAPER GUIDE, FRONT;B

Figure 3-23. ROLLER, ASSEMBLY, PF Removal

Rev. A

3-2

Page 27

EPSON Stylus Photo

6

3.2.5.8 PE Sensor Assembly Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. From the front side of the mechanism, unhook two hooks fixing “SENSOR, ASSEMBLY, PE” to the

mechanism. Then, slide it to upward to remove it. After removal, disassemble the assembly if

necessary.

WORK POINT

When re-install the assembly, be sure that the sensor lever is corr ectly insert ed into a hole of “PAPER

GUIDE, ASSEMBLY”, UPPER”.

Release these hooks to

remove the PE Sensor Assembly

From the back side of

the mechanism

HOLDER, PE

To frame

BOARD ASSY., PE

LEVER, PE

Figure 3-24.PE Sensor Assembly Removal

CAUTION

Be careful not to damage the cable when inserting or pulling out it from the PE sensor board.

Make sure the sensor lever moves smoothly when installing it.

3-2

Rev. A

Page 28

Chapter 3 Disassembly and Assembly

7

3.2.5.9 HP Sensor Assembly Removal

1. Removing the upper housing. (Refer to section 3.2.1)

2. Detach the cable from the sensor and remove it by unhook it from the frame.

SENSOR, HP

CR MOTOR

Figure 3-25. HP Sensor Removal

CAUTION

Make sure that the sensor itself is attached firmly to the frame when installing the HP sensor

again.

Be careful not to damage the sensor board when installing or pulling out the cable from the HP

sensor.

Rev. A

3-2

Loading...

Loading...