Page 1

Chapter 5

Troubleshooting

5.1 Troubleshooting....................................................................................................5-1

5.2 Unit Level Troubleshooting .................................................................................5-3

5.2.1 Printer does not operate at power on................................................................................... 5-4

5.2.2 Error is detected.....................................................................................................................5-5

5.2.3 Failure occurs during printing .............................................................................................. 5-6

5.2.4 Printer does not feed the paper correctly............................................................................5-7

5.2.5 Control panel operation is abnormal.................................................................................... 5-8

5.3 Unit Repair C206 PSB/PSE Board.......................................................................5-9

5.3.1 Unit Repair - C209 MAIN Board........................................................................................... 5-11

5.4 Repair of the Printer Mechanism.......................................................................5-13

Page 2

EPSON Stylus Photo

5.1 Troubleshooting

The printer may exhibit different symptoms for the same problem, which makes troubleshooting more

difficult. This section, however, provides simple and effective ways to facilitate troubleshooting.

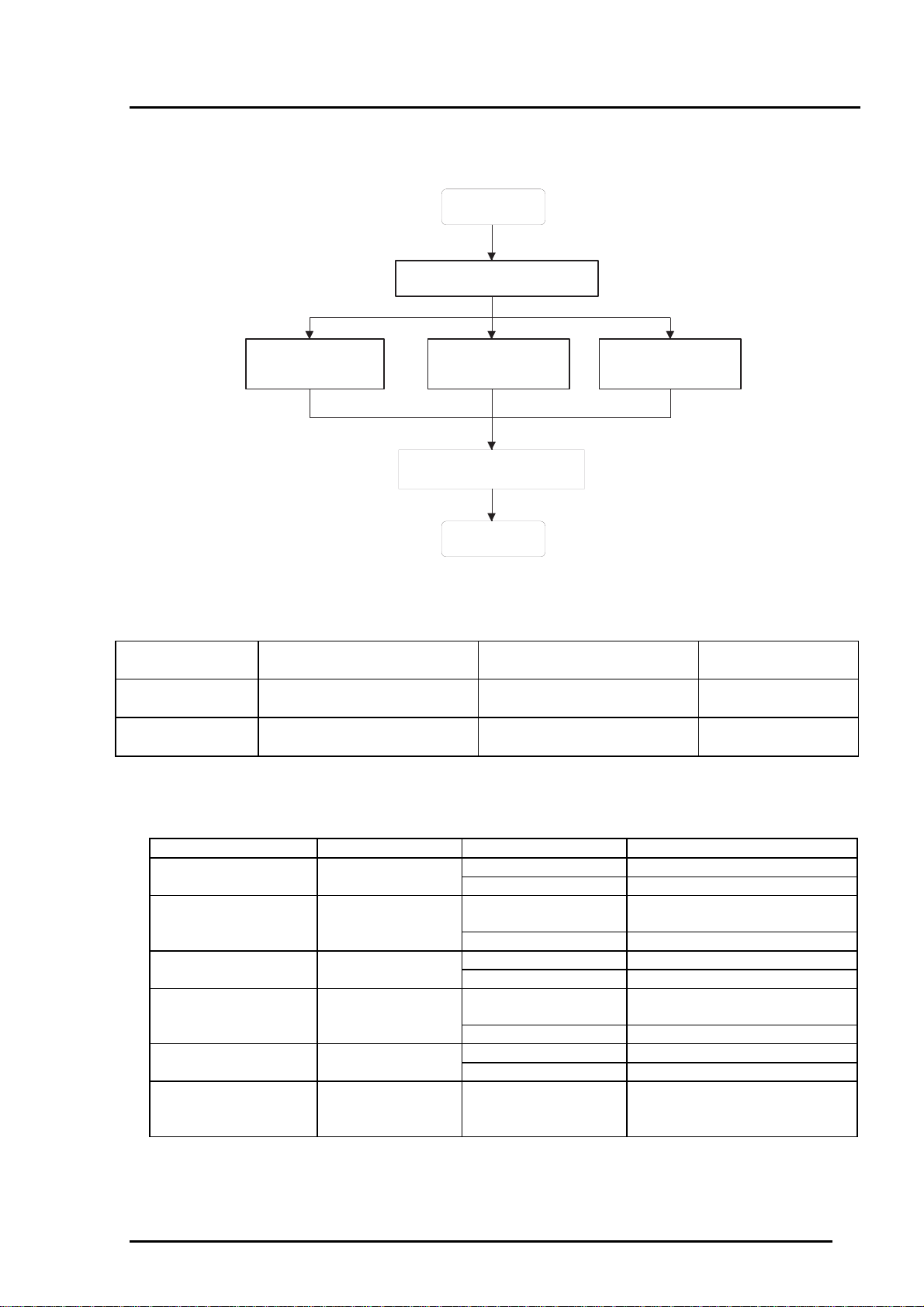

The following flowchart illustrates the main steps of the troubleshooting process.

START

Unit Level Troubleshooting

Unit Repair

(C206 PSB/PSE)

Unit Repair

(C209 Main)

Disassembly and Adjustment

END

Unit Repair

Printer Mechanism

Figure 5-1. Troubleshooting Process Flowchart

Table 5-1. Motor Resistance and Measurement Procedure

Motor Name Location Check Point No.* Meter Reading

CR Motor

Assembly

PF(Pump) Motor

Assembly

Note*)

Set the Multi-meter for measuring resistance range.

CN6(C209 MAIN) 1 & 3pin or,

2 & 4pin

CN7(C209 MAIN) 1 & 3pin or,

2 & 4pin

7.8 Ohms ±10%

(25 °C)

7.8 Ohms ±10%

(25 °C)

Make sure the power is off and remove the motor connectors from the main board.

Table 5-2. Sensor Check

Sensor Name Check Point Signal Level Sensor Status

Paper end sensor CN4 / 1-pin, H (5V) No paper

L (GND) Paper in

Carriage home

CN5 / 1-pin, H (5V) Home position

position sensor

(HP sensor) L (GND) Out of home position

ASF phase Sensor CN11 / 1-pin, H (5V) Friction(paper feeding) position

L (GND) Release(waiting) position

Black cartridge

CN8 / 1-pin, H (5V) Black ink cartridge out

sensor

L (GND) Black ink cartridge exists

Color cartridge sensor CN8 / 2-pin, H (5V) Color ink cartridge out

L (GND) Color ink cartridge exists

Thermistor CN8 / 3-pin, Resistance value It changes according to the

peripheral temperature.

(10KOhms ±1% at 25°C)

Rev. A

5-1

Page 3

Chapter 5 Troubleshooting

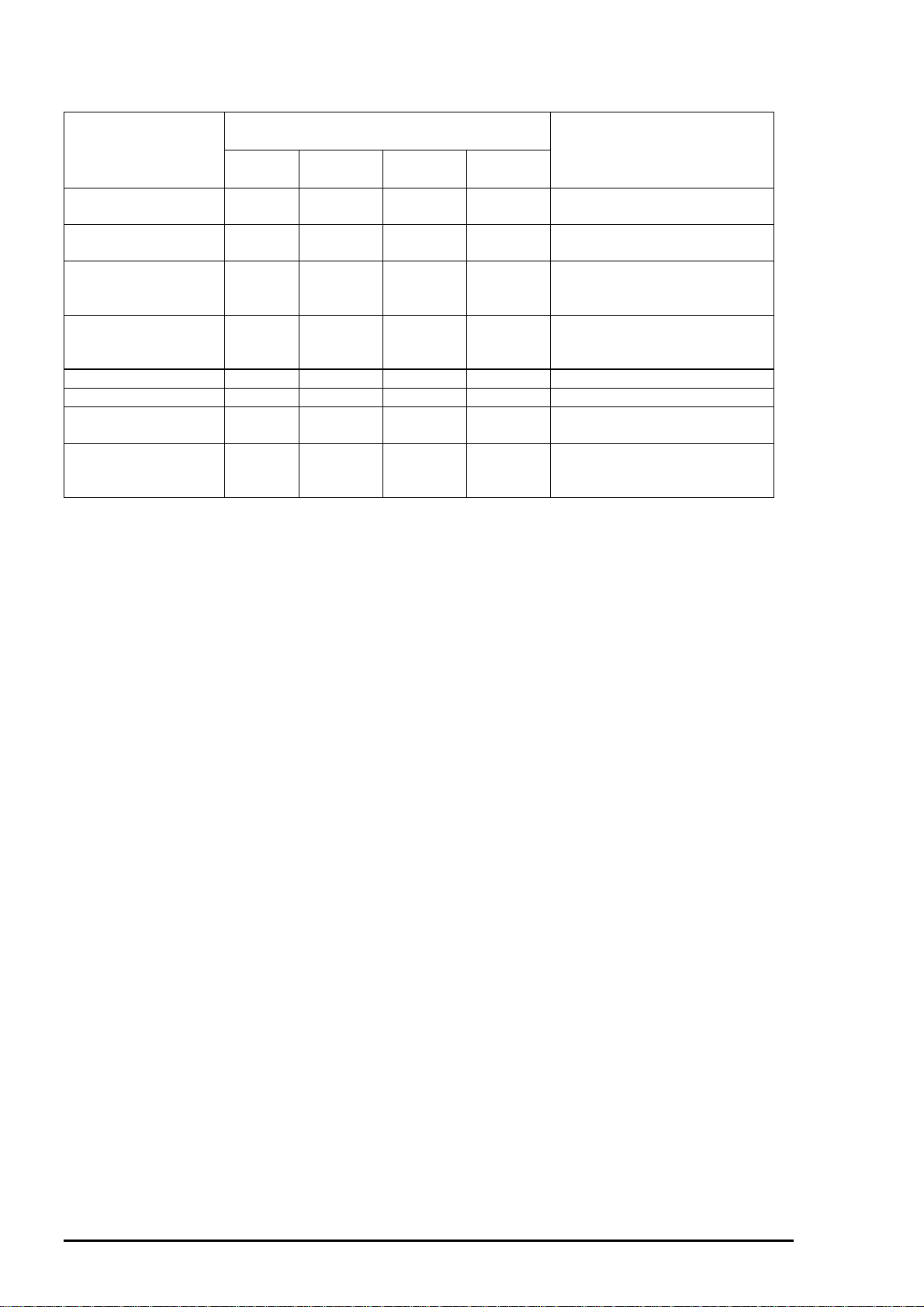

Table 5-3. Printer Condition and Panel Status

Indicators

Error status

Power Ink Out

(Black)

Paper Out --- --- --- On Load paper then press

Paper jam condition --- Off Off Blink Eliminate a paper then press

No Ink cartridge or Ink

end(black)

No Ink cartridge or Ink

end(color)

Ink low (Black) --- Blink --- --- ---

Ink low (Color) --- --- Blink --- --Maintenance error Blink Blink Blink Blink Change the waste ink absorber

Fatal error Blink On On Blink Turn off the printer and turn it

--- On --- --- Install a new black ink cartridge

--- --- On --- Install a new color ink cartridge

Ink Out

(Color)

Paper Out

load/eject button.

load/eject button.

according to ink cartridge

exchange operation.

according to ink cartridge

exchange operation.

and reset the protect counter.

on again. If the printer can not

recover, repair the suitable part.

Recovery

5-2

Rev.A

Page 4

EPSON Stylus Photo

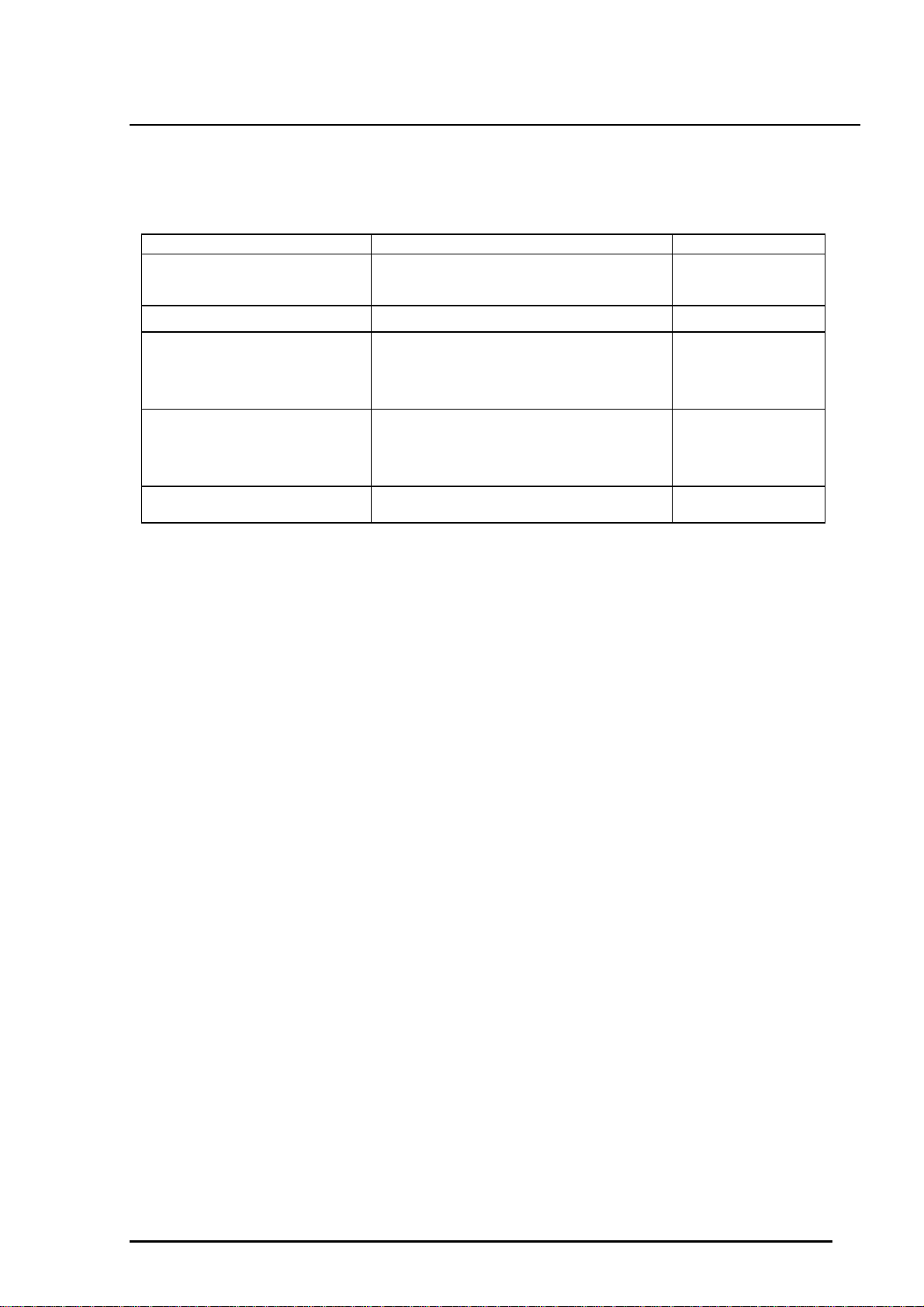

5.2 Unit Level Troubleshooting

When a problem occurs, you can identify the defective unit according to the symptoms exhibited.

The table below lists the symptoms of certain problems. Once the problem is identified, refer to the

flowchart that corresponds to the problem.

Table 5-4. Symptom and Problem

Symptom Problem Flowchart No.

Printer does not operate at

power on

Error is detected

Failure occurs during printing

Printer does not feed the paper

correctly

Control panel operation is

abnormal

•

LEDs do not light up.

•

Printer mechanism does not operate.

•

Error is indicated by LED indication.

•

Printing is not performed.

•

Abnormal printing(missing dot, etc.)

•

Print quality is poor

•

No paper is fed.

•

Paper feed is irregular.

•

Paper jam occurs.

•

No response to button access.

1

2

3

4

5

Rev. A

5-3

Page 5

Chapter 5 Troubleshooting

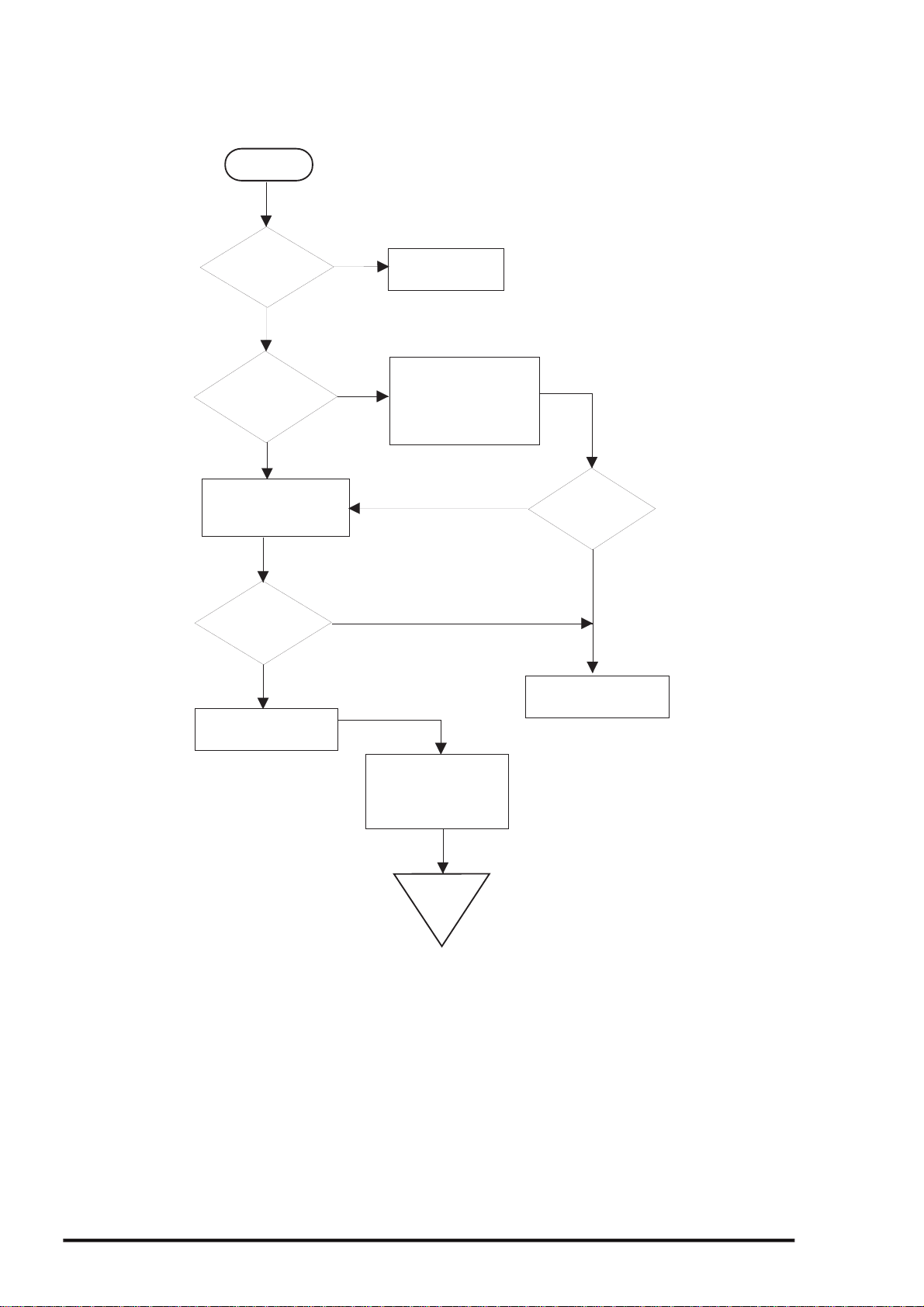

5.2.1 Printer does not operate at power on

START

Is AC

power voltage

normal?

YES

Is the

fuse(F1) of

power supply

board

opened?

NO

Check output voltage

of CN2 in the power

supply board.

Is the

output voltage

of power supply

normal?

YES

Exchange the main

board.

NO

NO

YES

Input normal

power supply.

Exchange the fuse.

Disconnect CN10 in

the main board and

turn the power on

again.

NO

Is the

fuse opend

again?

YES

Exchange the power

supply board

Check the motor and

head. Refer to the

repair item of the

printer mechanism.

END

Figure 5-2. Flow Chart 1

5-4

Rev.A

Page 6

EPSON Stylus Photo

5.2.2 Error is detected

START

Check the error

message.(Refer to

Table5-3)

Is it carriage

error?

NO

No ink cartridge

error?

NO

Maintenance Error

Exchange the waste

ink absorber and reset

the counter.

(Refer to 1.4.2)

Check ink cartridge

sensor and exchange

the head if it's ubnormal.

Yes

Yes

Turn off the printer,

and move the carriage

by hand.

Exchange the inkcartridge with new

one.

Yes

Does error

appear again?

NO

Does the carriage

move smoothly?

Yes

Check CR motor.

Exchange the main

board if there is no

problem.

Yes

Is the problem

solved?

NO

Refer to 5.4

Repair of the printer

mechanism.

NO

Rev. A

END

Figure 5-3. Flow Chart 2

END

5-5

Page 7

Chapter 5 Troubleshooting

5.2.3 Failure occurs during printing

START

Perform selftest printing

Is printing

carried out

O.K?

YES

Is printing

quality

normal?

NO

Perform cleaning

NO

Perform printing

adjustment.

YES

(Refer to Chapter4)

Is all

cables connected

to the main

board?

NO

Connect cables

YES

problem

solved?

YES

Is the

END

Exchange the ink

cartridge with new

one and perform

NO

self-test.

Is the

problem

YES

YES

solved?

NO

Refer to 5.4 Repair of

the printer-mechanism.

Is the

problem

solved?

NO

END

Is the

problem

solved?

YES

Replace the Main

board

Refer to 5.4 Repair of

the printer-mechanism.

NO

Is the

problem

NO

solved?

END

YES

5-6

Figure 5-4.Flow Chart 3

Rev.A

Page 8

EPSON Stylus Photo

5.2.4 Printer does not feed the paper correctly

START

Are

papers set

in the ASF

correctly?

YES

NO

Set the paper correctly

Does

the PF roller

and platen

rotate?

YES

Remove any obstruction

in the paper path if

there is any.

Perform cleaning for

the roller of paper path.

Is the

problem

solved?

YES

NO

NO

Is the

PF motor

running?

YES

Refer to 5.4.Repair

of the printer

mechanism.

NO

Check the PF motor.

If there is no problem,

replace the main board.

Rev. A

END

END

Figure 5-5. Flow Chart 4

5-7

Page 9

Chapter 5 Troubleshooting

5.2.5 Control panel operation i s abnor mal

START

Is the

control panel

connected

correctly?

NO

YES

Replace the control

panel.

Is the

problem

solved?

YES

Connect the

control panel

correctly.

Is the

problem

solved?

YES

NO

NO

Replace the

main board.

5-8

END

Figure 5-6. Flow Chart 5

END

Rev.A

Page 10

EPSON Stylus Photo

5.3 Unit Repair C206 PSB/PSE Board

This section describes the problems related to the power supply board(C206 PSB/PSE). The table below

provides various symptoms, likely causes, and checkpoints. The checkpoints refer to waveforms,

resistance, and other values to be checked to evaluate the operation of each component.

Table 5-5. C206PS B Power Supply Borad

Symptom Condition Cause Checkpoint Solution

The printer

does not

operate at all.

+42V line is

dead.

F1 is open. Check F1 by using a

tester.

Replace F1.

Transformer coils

are open.

Switching FET (Q1)

is dead.

Feed back

transistor(Q2, Q3)

are dead.

+42 V line is

abnormal.

Check the waveform at

the drain of Q1.

Check drain side. Replace Q1.

Check corrector side.

Check following parts.

• ZD87,ZD83

• ZD51,ZD81•`ZD86

• PC1

Replace T1.

Replace Q2

or Q3.

Replace

suitable

parts.

Rev. A

5-9

Page 11

Chapter 5 Troubleshooting

Table 5-6. C206PSB Power Supply Board (Continued)

Symptom Condition Cause Checkpoint Solution

+5V line is

dead.

IC51 (L4962E) is

dead.

Check the oscillation(5

-pin) and switching (7pin) waveform of IC51.

(5-pin)

(7-pin)

Replace

IC51.

5-10

Rev.A

Page 12

EPSON Stylus Photo

5.3.1 Unit Repair C209 MAIN Board

This section describes the problems related to the main controller board(C209 MAIN). The table below

provides various symptoms, likely causes, and checkpoints. The check points refer to waveforms,

resistance, and other values to be checked to evaluate the operation of each component.

Table 5-7. Repair of the C209 MAIN Board

Symptom Condition Cause Checkpoint Solution

The printer

does not

operate at all.

CPU does

not operate.

The reset

circuit is

defective.

Check the waveform of

the +5V and /Reset signal

(IC8=5,1-pin)

Replace IC8

The carriage

does not

operate

normally.

Carriage

motor does

not operate

at all.

Control ROM is

not selected

correctly or it’s

dead.

RAM is

defective.

CPU is

defective.

IC2 is defective. Check the signal

Check if the signal

waveform at 11 pin of the

IC3 can be reversed High

or Low.

Check the clock waveform

at 27 or 28-pin of IC1.

waveform at 1, 2, 23 and

24 pin of IC14.

Replace IC3.

Replace RAM.

Replace IC1 if

the oscillation

waveform is

normal, if it is

abnormal,

replace the

oscillator CR1.

Replace IC2.

Rev. A

IC14 is

defective.

Check the signal

waveform at 3, 6,or 18, 21

pin of IC14.

Replace IC14.

5-11

Page 13

Chapter 5 Troubleshooting

Table 5-8.Repair of the C209 MAIN Board (Continued)

Symptom Condition Cause Checkpoint Solution

Printing is

abnormal

Printing is not

executed or,

black specks or

dots appears on

the printing.

IC2 is defective. Check the output

waveform at 7, 9 and 11

pin of CN8.

Replace IC2.

Paper feed

operation is

abnormal.

Paper feed

motor does not

work.

IC2 is defective. Check the output

waveform of at 1, 2pin

and 23, 24 pin of IC15.

IC15 is defective. Check the output

waveform of at 3, 6 pin

or 18, 21 pin of IC15.

Replace IC2

Replace IC15

5-12

Rev.A

Page 14

EPSON Stylus Photo

5.4 Repair of the Printer Mechanism

This section provides instruction for repairing the printer mechanism. It describes various problems,

symptom, likely causes, checkpoints, and solutions. Select appropriate symptom from the table and

check each parts and its function as described in the checkpoint.

Table 5-9. Repair of the Printer Mechanism

Symptom Condition Cause Checkpoint Solution

Abnormal pump

mechanism

operation

Ink is not

absorbed

or is poorly

absorbed.

Abnormal carriage

operation.

Printing is not

performed.

Abnormal PF

motor operation

when the

power is turned

on.

Used ink does not

go through the

waste ink tube.

Abnormal carriage

operation at power

on.

Abnormal carriage

operation during

printing.

The carriage

moves, but no

printing is

performed.

Foreign substances

are loaded in the PF

gears.

The PF motor is

defective.

(Refer to Table5-1)

The pump tube is

crashed.

Capping rubber is

damaged or

deformed.

The tube is out of

the cap.

Pump bulb is not

closed at

absorption.

Foreign substance

in the CR drive

gear.

CR motor is

defective.

Carriage movement

is not smooth.

Head FFC is out of

connection.

The FFC is

disconnected

inside.

I/C is defective. Install a new I/C and

Head unit is

defective.

Manually drive the

PF drive gear

and check if it

rotates normally .

Check the inner coil

resistance and see

if there is any

disconnection of the coil.

Check the tube

visually.

Check the capping

rubber visually.

Check if the tube is out of

the cap visually.

Check the bulb

operation visually.

Check visually if

there is any

substances or not.

Check the inner coil

resistance and see

if there is any

disconnection of the coil.

Check whether the

carriage moves

smoothly when

moved manually.

Check tension of the

timing belt.

Check if there is any

foreign substances

in the carriage path.

Check if the head

FFC on the board or

carriage is connected

surely.

Check the FFC by using

a tester.

perform the self-test.

If the condition does

not improve even

after 2or 3 times

cleaning operation,

replace the head

unit and perform the

self-test.

Remove any foreign

objects.

Exchange the PF

motor.

Fix the crashed part

by the airgun.

Replace the cap

mechanism.

Connect the tube

properly.

Replace the cap

mechanism.

Remove any foreign

substances.

Replace the CR

motor.

Clean and lubricate

the carriage guide

axis.

Adjust tension

mechanism or

exchange it.

Remove any foreign

substances.

Connect the FFC

properly.

Replace the FFC.

Replace I/C.

Replace the head

unit.

Rev. A

5-13

Page 15

Chapter 5 Troubleshooting

Table 5-10. Repair of the Printer Mechanism (Continued.)

Symptom Condition Cause Check-point Solution

Abnormal printing Only a particular dot

causes abnormal

printing.

A dot is not printed

occasionally.

Black specks or

dots.

A vertical line is not

aligned.

White line appears

in the image data.

Print head surface is

not clean.

(dot missing)

The head unit is

defective.

Absorber in the cap

is touching the head

surface.

Print head surface

is not clean.

(dot-missing)

The head FFC is

disconnected inside.

The head FFC is out

of connection.

The head unit is

detective.

I/C is defective. Install the new I/C

The head FFC is out

of connection.

The head unit is

detective.

Bi-directional

alignment is not

adjusted.

Head angle is not

correct.

Paper feed assembly

adjustment is not

correct.

Perform the cleaning

operation several

times and check

printing.

Perform the cleaning

operation several

times and check

printing.

Check the absorber

in the cap visually.

Perform the cleaning

operation several

times and check

printing.

Check the FFC by

using a tester.

Check if the head

FFC on the board or

carriage is

connected surely.

Perform the cleaning

operation several

times and check

printing.

and perform selftest.

Check if the head

FFC on the board or

carriage is

connected surely.

Check connection

with the head FFC.

Perform Bi-D

adjustment.

Perform head angle

adjustment.

Perform paper feed

assembly

adjustment

Perform the

cleaning.

If condition does not

improve even after

the cleaning, replace

the head.

Replace the

absorber in the cap if

it is deformed.

Perform the

cleaning.

Replace the head

FFC.

Connect the FFC

properly.

If condition does not

improve even after

the cleaning, replace

the head.

Replace I/C.

Connect the FFC

properly.

Replace the head if

there is no

connection problem

with the FFC.

Refer to Chapter4.

Refer to Chapter4.

Refer to Chapter4.

5-14

Dot shooting

direction is tilted

because head

surface is not clean

I/C is defective. Install a new I/C and

Head unit is

defective.

Perform the cleaning

operation several

times and check

printing.

perform the self-test.

Perform the cleaning

operation several

times and check

printing.

Perform the

cleaning operation.

Replace I/C.

Replace the head

unit.

Rev.A

Page 16

EPSON Stylus Photo

Table 5-11. Repair of the Printer Mechanism (Continued)

Symptom Condition Causes Checkpoint Solution

Abnormal paper

feeding.

Printer stops during

initialization.

Paper is not fed. Friction of the PF

roller.

Abnormal operation

of the hopper.

Malfunction of ASF

drive change-over.

Printing start point is

not right.

Fatal error appears. ASF sensor is

Friction of the PF

roller.

defective.

PE sensor is

defective.

HP sensor is

defective.

Head FFC is

disconnected.

Check if the PF

roller rotates when

paper is not fed.

Check movement of

the ASF hopper

visually.

Check if the ASF

gear rotates visually.

Check if the PF

roller slips during

paper feeding.

Check the signal

level of the ASF

sensor.(Refer to

Table 5-2)

Check the signal

level of the PE

sensor.(Refer to

Table 5-2)

Check the signal

level of the HP

sensor .(Refer to

Table 5-2.)

Check if the head

FFC is connected.

Clean the PF roller

by the cleaning

sheet. Replace the

PF roller if it does

not recover.

Replace ASF.

Replace gears of

the ASF drive

change-over.

Clean the PF roller

by the cleaning

sheet. Replace the

PF roller if it does

not recover.

Replace ASF

sensor.

Replace PE sensor.

Connect the head

FFC.

CR motor is

defective.

PF motor is

defective.

Check the CR motor

cable is connected.

Check if the PF

motor cable is

connected.

Replace the CR

motor if there is no

problem in the cable

connection.

Replace the PF

motor if there is no

problem in the cable

connection.

Rev. A

5-15

Loading...

Loading...