Page 1

CMOS 16-BIT SINGLE CHIP MICROCOMPUTER

(Software Evaluation Tool for S1C17801)

S5U1C17801T1100

Hardware Manual

Page 2

NOTICE

No part of this material may be reproduced or duplicated in any form or by any means without the written permission

of Seiko Epson. Seiko Epson reserves the right to make changes to this material without notice. Seiko Epson does

not assume any liability of any kind arising out of any inaccuracies contained in this material or due to its application

or use in any product or circuit and, further, there is no representation that this material is applicable to products requiring high level reliability, such as medical products. Moreover, no license to any intellectual property rights is granted by implication or otherwise, and there is no representation or warranty that anything made in accordance with this

material will be free from any patent or copyright infringement of a third party. This material or portions thereof may

contain technology or the subject relating to strategic products under the control of the Foreign Exchange and Foreign

Trade Law of Japan and may require an export license from the Ministry of Economy, Trade and Industry or other approval from another government agency.

Windows 2000 and Windows XP are registered trademarks of Microsoft Corporation, U.S.A.

PC/AT and IBM are registered trademarks of International Business Machines Corporation, U.S.A.

All other product names mentioned herein are trademarks and/or registered trademarks of their respective owners.

© SEIKO EPSON CORPORATION 2008, All rights reserved.

Page 3

Devices

S1 C 17xxx F 00E1

Packing specifications

00 : Besides tape & reel

0A : TCP BL 2 directions

0B : Tape & reel BACK

0C : TCP BR 2 directions

0D : TCP BT 2 directions

0E : TCP BD 2 directions

0F : Tape & reel FRONT

0G : TCP BT 4 directions

0H : TCP BD 4 directions

0J : TCP SL 2 directions

0K : TCP SR 2 directions

0L : Tape & reel LEFT

0M : TCP ST 2 directions

0N : TCP SD 2 directions

0P : TCP ST 4 directions

0Q : TCP SD 4 directions

0R : Tape & reel RIGHT

99 : Specs not fixed

Specification

Package

D: die form; F: QFP, B: BGA

Model number

Model name

C: microcomputer, digital products

Product classification

S1: semiconductor

Development tools

S5U1 C 17000 H2 1

Packing specifications

00: standard packing

Version

1: Version 1

Tool type

Hx : ICE

Dx : Evaluation board

Ex : ROM emulation board

Mx : Emulation memory for external ROM

Tx : A socket for mounting

Cx : Compiler package

Sx : Middleware package

Corresponding model number

17xxx: for S1C17xxx

Tool classification

C: microcomputer use

Product classification

S5U1: development tool for semiconductor products

00

00

Configuration of product number

Page 4

Page 5

TABLE OF CONTENTS

- Table of Contents -

1 Features .......................................................................................................................... 1

2 Contents of Package .....................................................................................................

3

Name and Functions of Each Part ............................................................................... 3

Name of Each Part ................................................................................................................... 3

CPU Board Dimensions ................................................................................................ 7

ICD Board Dimensions .................................................................................................8

LCD Board Dimensions ................................................................................................9

LCD Panel Board Dimensions ..................................................................................... 10

Main Parts ............................................................................................................................... 11

Functions of Each Part ............................................................................................................ 12

ICD Board .................................................................................................................... 12

CPU Board ................................................................................................................... 12

2

4 Block Diagram .............................................................................................................. 14

5

Operating Environments and Starting Procedures ................................................... 15

Software Simple Development Environments ......................................................................... 15

Standalone Operation of SVT17801 ....................................................................................... 18

ICD Board Firmware Update Procedures ............................................................................... 18

6 Difference between ICD Board and ICD Mini ............................................................. 19

7 I/O Port ...........................................................................................................................

8 Jumper Switch Settings ...............................................................................................

Setting for JP1 ......................................................................................................................... 22

Setting for JP2 ......................................................................................................................... 23

Setting for JP3 ......................................................................................................................... 24

20

22

9

Connection Circuit to External Memory ..................................................................... 25

SRAM Connection Circuit ....................................................................................................... 25

NOR Flash Connection Circuit ................................................................................................ 26

NAND Flash Connection Circuit .............................................................................................. 27

EEPROM Connection Circuit .................................................................................................. 28

10 Power Control Circuit for Battery Backup Function ............................................... 29

Battery Backup Function ......................................................................................................... 29

Power Control Circuit for Battery Backup Function ................................................................. 29

11 LCD Panel Connection Circuit ................................................................................... 32

Touch Panel Controller Connection Circuit ............................................................................. 33

12 Key Input Circuit on CPU Board ............................................................................... 34

13 Rotary Encoder Connection Circuit ..........................................................................

14 Tri-color LED Connection Circuit ..............................................................................

15 LED/LCD Backlight Control Circuit with MFT0 ........................................................

16 Infrared Emitting Diode/Receiving Module Connection Circuit .............................

Emitting and Receiving from/by Infrared Area ......................................................................... 39

35

36

37

38

17 MMC (Multi-Media Card) Connection Circuit ..............................................................40

18 USB Connection Circuit .............................................................................................

41

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

i

Page 6

TABLE OF CONTENTS

19 Audio Connection Circuit .......................................................................................... 42

Switching Audio Master Clock ................................................................................................. 42

20 Exclusive Control of Ports ......................................................................................... 43

21 Serial ............................................................................................................................

22

Specifications For Cpu Board Connectors .............................................................. 45

44

J6 Connector (to Connect with ICD) ....................................................................................... 45

J7 Connector ........................................................................................................................... 46

J8 Connector ........................................................................................................................... 47

J12 Connector ......................................................................................................................... 48

J13 Connector ......................................................................................................................... 49

J18 Connector ......................................................................................................................... 50

Appendix A How to Measure Current Consumption .................................................... 51

A.1 Measuring VDD Current Consumption .............................................................................. 51

A.2 Measuring AVDD Current Consumption ............................................................................ 52

A.3 Measuring RTCVDD Current Consumption ...................................................................... 52

ii

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 7

1 FEATURES

1 Features

S5U1C17801T1100 (Software eValuation Tool for S1C17801. Hereafter referred to as SVT17801)is an evaluation

board for MCU S1C17801 manufactured by SEIKO EPSON.

The SVT17801, consisting of the three boards, i.e., CPU, ICD and LCD, can debug software by connecting to

the ICD and CPU boards without using ICD or other debug tool. By connecting to the CPU and LCD boards, the

SVT17801 can also be used for simple evaluation of LCD panel display.

In addition, serial port, AD input port, and other expansion interfaces built in the SVT17801 allow customerʼs original

expansion boards to connect with the SVT17801.

〈CPU Board〉

CPU S1C17801

Input power voltage +5.0V (DC)

Regulator output voltage +3.3V

CPU Input Clock OSC1:32.768kHz

OSC3:48MHz

Built-in Functions/Devices - Reset switch

- Expansion interface connectors (LCD, GPIO, UART, I

- ICD board connector

• SRAM (16Mbit)

• NOR Flash (64Mbit)

• NAND Flash (2Gbit)

• EEPROM (256Kbit)

- Battery backup control circuit/Power switch

- Key input circuit (6 keys)

- Rotary encoder with switch

- Status display LED (tri-color LED/mono-color LED x 2)

- Infrared LED/Receiver module

- AudioCodec

- USB miniB type connector

- MMC card socket

2

C, AD)

〈ICD Board〉

Interface with PC USB 1.1

Supply voltage USB bus power (On-board regulator output voltage of 3.3V)

Built-in Functions/Devices - Status display LED (tri-color)

- Reset switch

- CPU board connector

〈LCD board〉

LCD panel module 3.5 inch STN QVGA 320 x 240 dots B&W panel

Membrane type touch panel

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

1

Page 8

2 CONTENTS OF PACKAGE

2 Contents of Package

The following lists the contents of S5U1C17801T1100 package:

(1) SVT17801 CPU Board (Main body) ..........................

(2) SVT17801 ICD Board .................................................

(3) SVT17801 LCD Board ................................................

(4) USB Cable ....................................................................

(5) Coin Battery (CR2032/3V) .........................................

(6) AC Adapter ..................................................................

(7) Warranty Registration Card ....................................... 1 each for English/Japanese

(8) Warranty Card ............................................................. 1 each for English/Japanese

(9) Precautions in Use ....................................................... 1 each for English/Japanese

(10) Manual Download Guide ............................................1 each for English/Japanese

1

1

1

1

1

1

2

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 9

3 NAME AND FUNCTIONS OF EACH PART

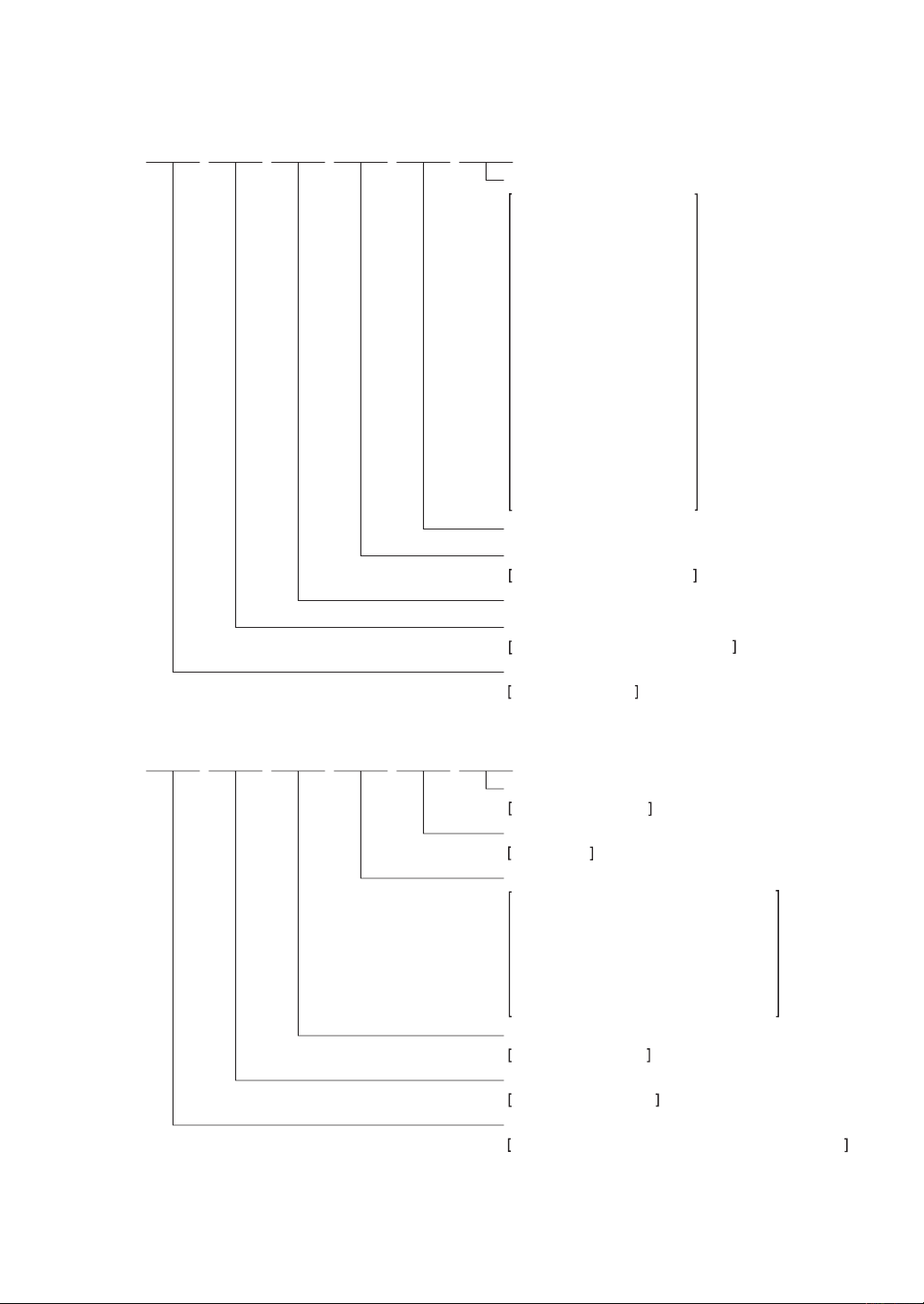

3 Name and Functions of Each Part

Name of Each Part

The following describes name and functions of each part:

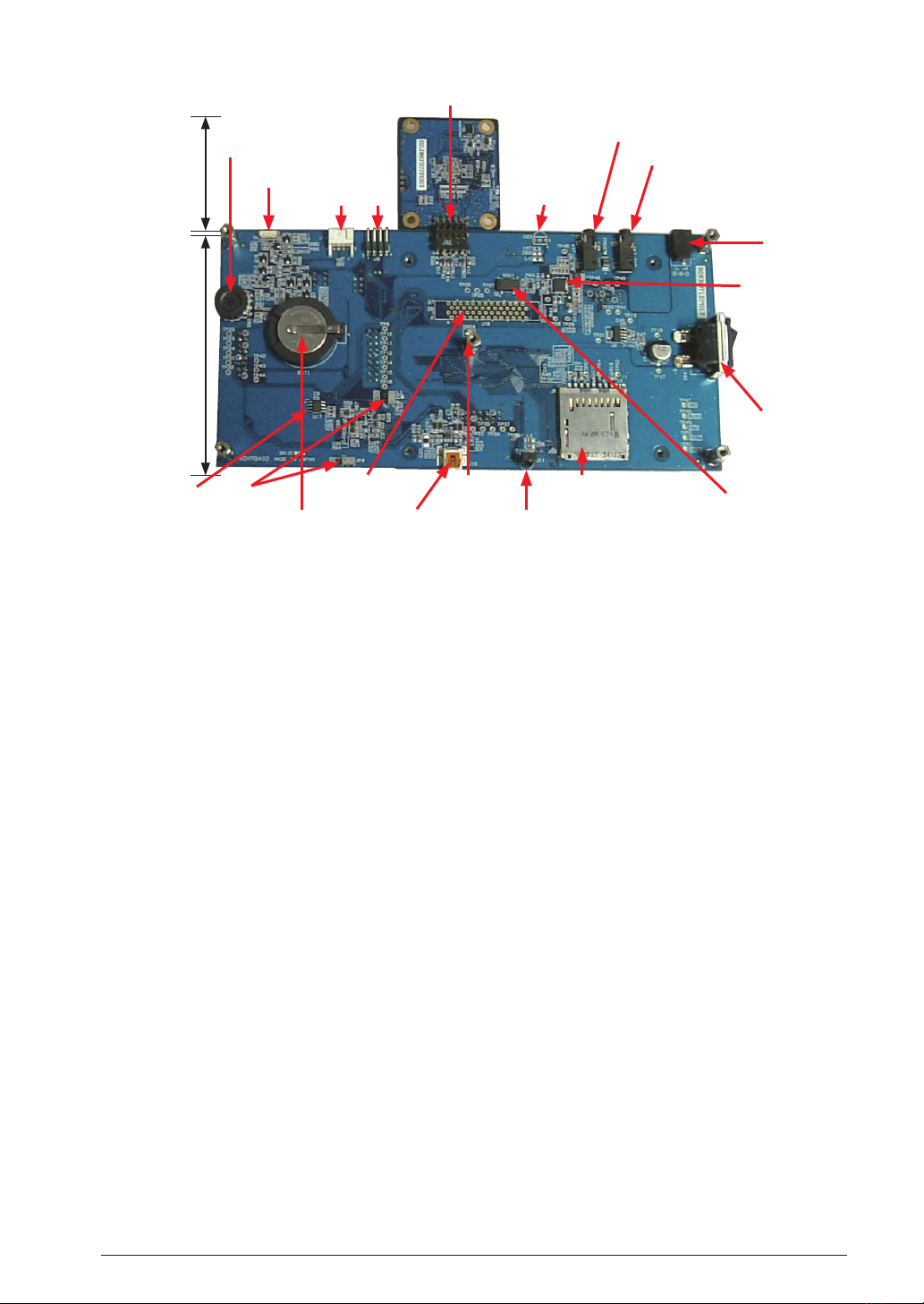

(4)

(2)

(1)

3.5inch

STN QVGA B&W

CPU board ICD board

Fig. 3.1.1 Name of Each Surface Mounted Part (with LCD Panel)

(1)

Power LED (Blue) (7) LED (13) Key switch

(2)

Speaker (Left) (8) POWER SW (14) Crystal oscillator (48MHz/32KHz)

(3) RESET SW (9)

(4)

USBminiB connector (10) Speaker (Right) (16) LCD board

(5)

LED (RGB) (11) JP pin

(6)

MIC (12) Expansion connector

Membrane touch panel

(3)

GND pin (15) S1C17801

(5)

(6) (7)

(8)

(9)

(10)

(5)

(11)

(12)

(13)(15)

(14) (9)(16)(9)

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

3

Page 10

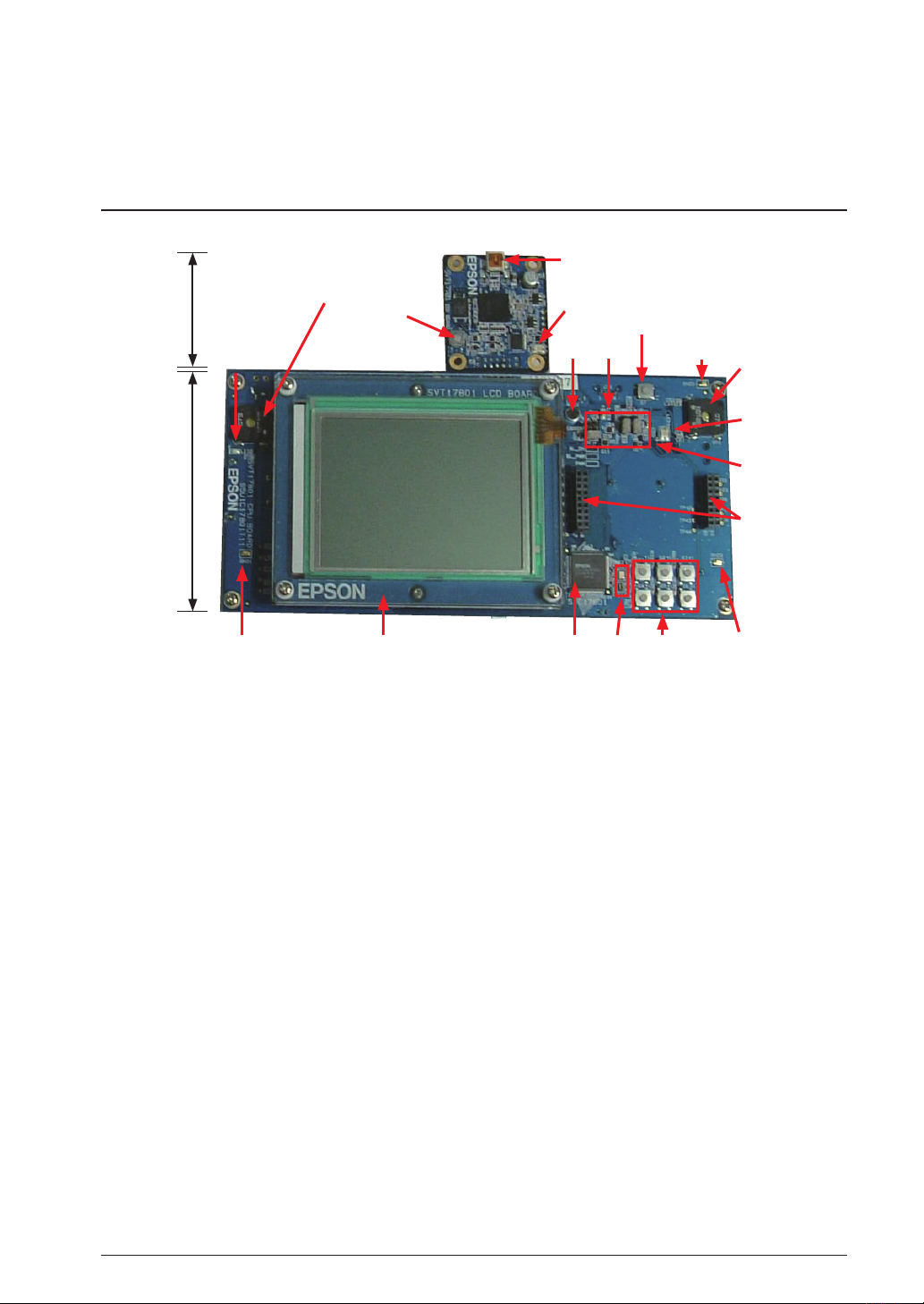

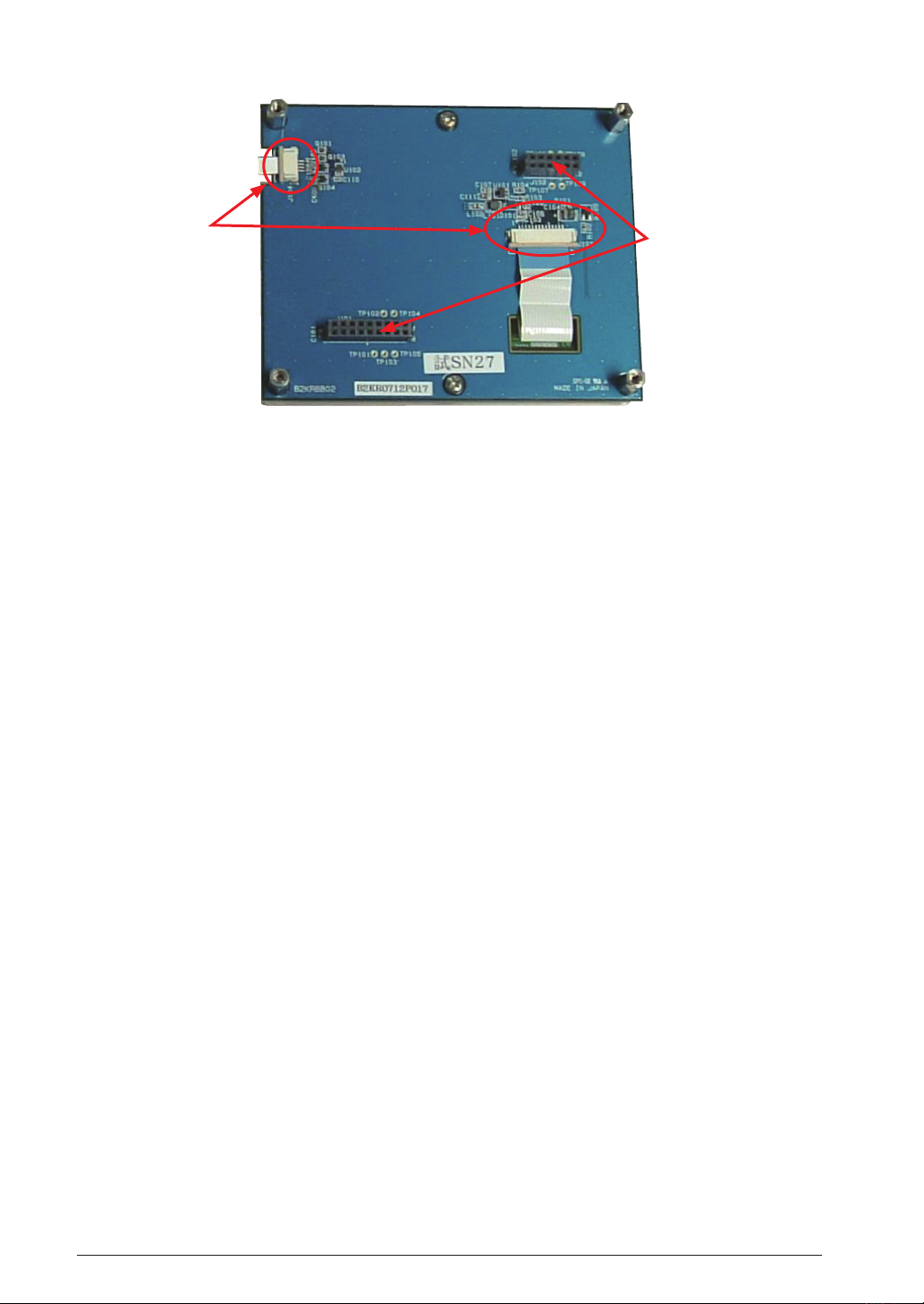

3 NAME AND FUNCTIONS OF EACH PART

(1)

(2)

CPU board ICD board

(3)

(4)

(5)

Fig. 3.1.2 Name of Each Surface Mounted Part (without LCD Panel)

(1)

Infrared emitting module LED (3) SRAM (5) Expansion connector (LCD board)

(2)

FLASH (NOR) (4) FLASH (NAND)

4

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 11

(4)

3 NAME AND FUNCTIONS OF EACH PART

(1)

(7)

(2)

(6)

(3)

(3)

(5)

CPU board ICD board

(19)

(18)

(17)

(16)

(15)

(14)

(12)

(11)

(13)

Fig. 3.1.3 Name of Each Rear Face Mounted Part

(1)

Rotary encoder with Switch (7) Audio connector (IN) (14) GND pin

(2) RESET SW (8) Power supply connector (5V) (15)

(3)

ICDminiI/F (9) AudioCodec (16)Bus connector (Not available)

(4)

ICD board connector (10) Power Switch (17) Coin Battery

(5)

Placement of infrared receiver

module (substitute)

(11) AudioCodec Oscillator (18) Measuring JP for IC consumed

(12)

MMC Card Socket

USBminiB connector

current

(6) Audio connector (OUT) (13) Infrared receiver module (19) EEPROM

(8)

(9)

(10)

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

5

Page 12

3 NAME AND FUNCTIONS OF EACH PART

(1)

Fig. 3.1.4 Name of Each Part Mounted on Rear Face of LCD Board

(1)

Connector (to connect LCD panel)

(2)

Connector (to connect CPU board)

(2)

6

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 13

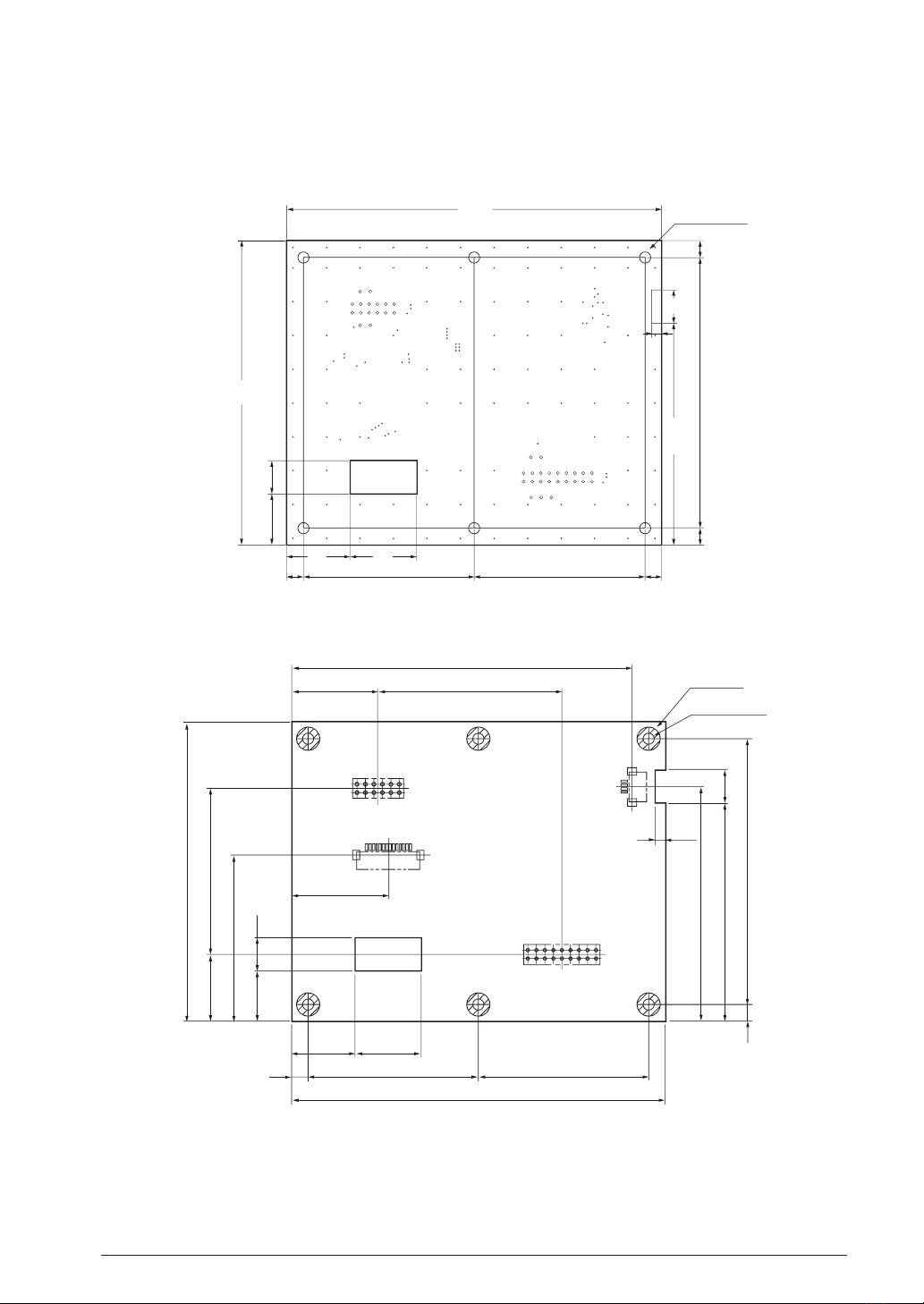

Board Dimensions

SP1

SP2

11 1

J13

12 2

D1

17 1

J12

1 2

S7

63

53

7.5

1

1 2

1516

2

17 18

J7 J8

50

40

10.58

26.5

46.5

9 9

S1S4S2S5S3

S6

4 197

205

170

142

85

102.5

11220

46

137

10225

167

2

55

Parts installed within this dash line must be max. 8 mm in height

100

895.5

807

90

5022

10

9-φ3.3 hole

9-φ7

10

9 1

D1 Installation instruction diagram

J11 J9

J6

U23

1 3

J15J14

6

4

4

4

50

52.5

140

155

185

110

72.5

37.515

2

67.5

55

10.5

8.2

9-φ7

SW1

3

32

9123 45678

J5

80

110

155

(CARD CENTR)

4

J10

1 5

1

BAT1

3

1

2

J4

1

2

3

1

4

2

3

U21

13

1.5

210

19

1 4

14

2.7

S8

2 1

SW2

10

B

C

S

A

15

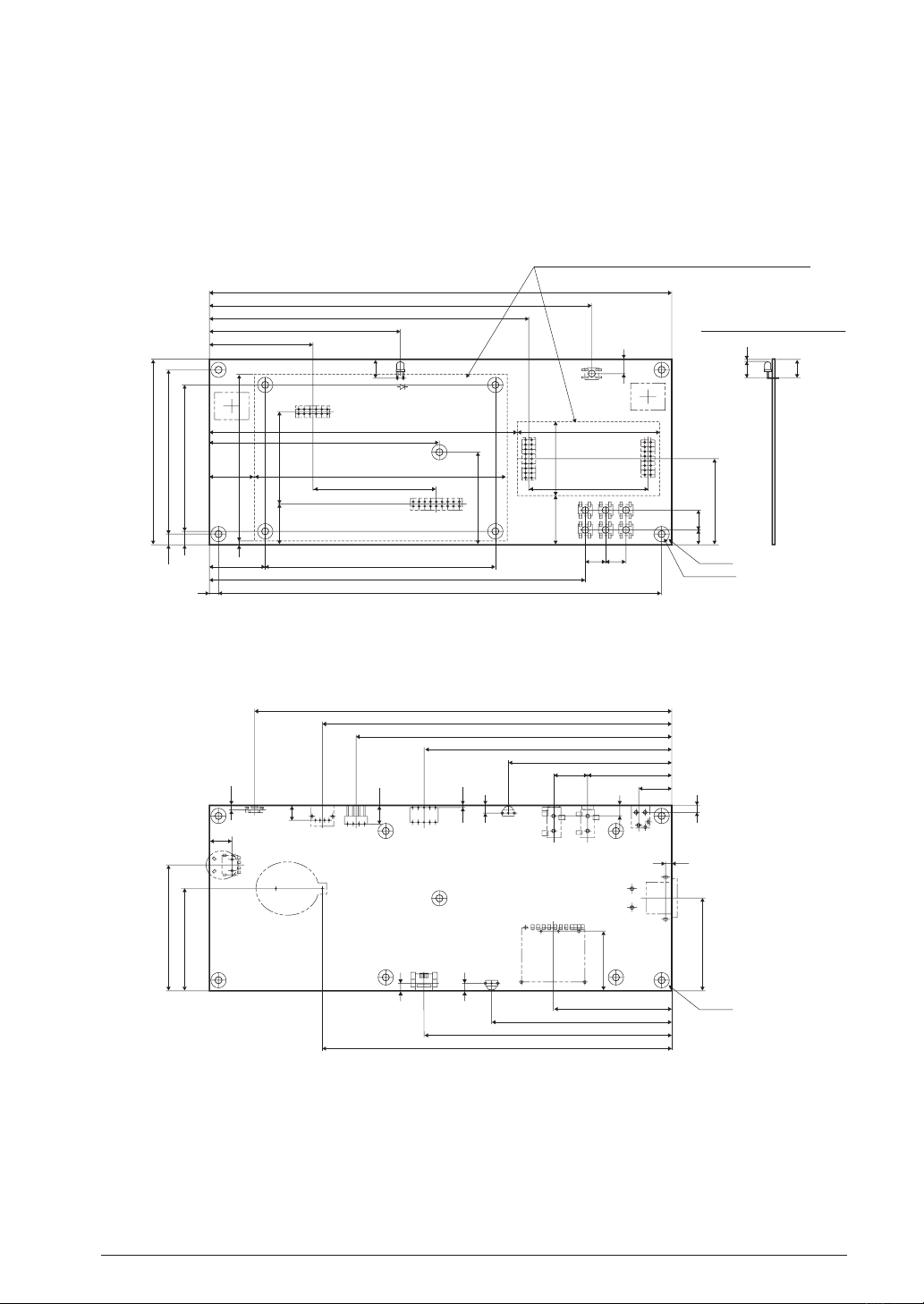

CPU Board Dimensions

The following drawing shows dimensions of the CPU board.

<Surface>

3 NAME AND FUNCTIONS OF EACH PART

<Rear Face>

∗ Precautions

• Unit for the above dimensions is millimeter (mm).

• Board thickness: 1.6 mm, U23 is not mounted.

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

Fig. 3.2.1.1 CPU Board Dimensions

7

Page 14

3 NAME AND FUNCTIONS OF EACH PART

4

21.5

37.5

43

50

4-φ3.5 through hole

4-R2

4

4-φ7 land

5.5

9

JUSB

15

4.95

JICD

1

2

9

10

ICD Board Dimensions

The following drawing shows dimensions of the ICD board.

<Parts Side View>

<Soldering Side View>

Fig. 3.2.2.1 ICD Board Dimensions

∗ Precautions

• Unit for the above dimensions is millimeter (mm).

• Material: FR4, Board thickness: 1.6 mm

8

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 15

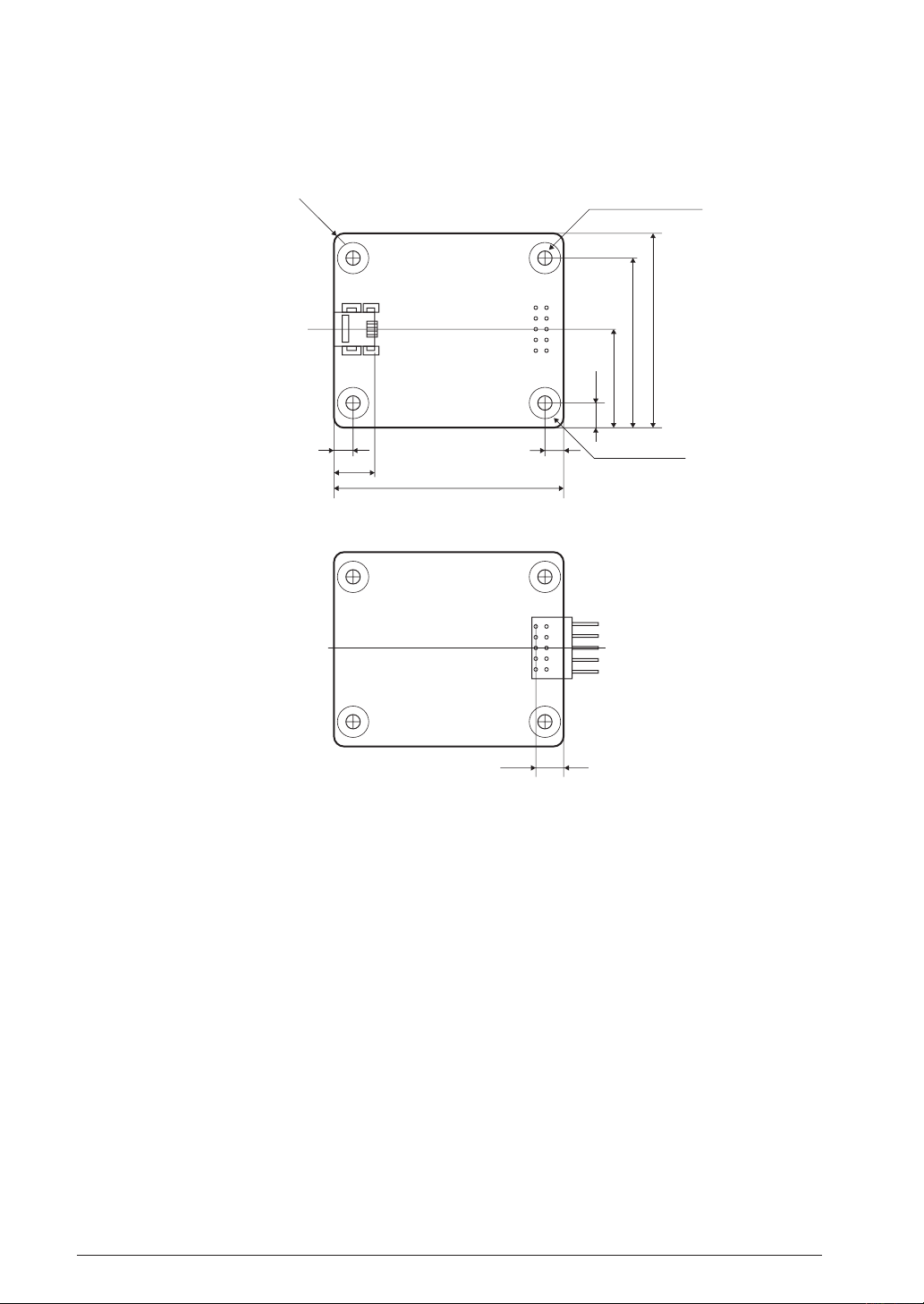

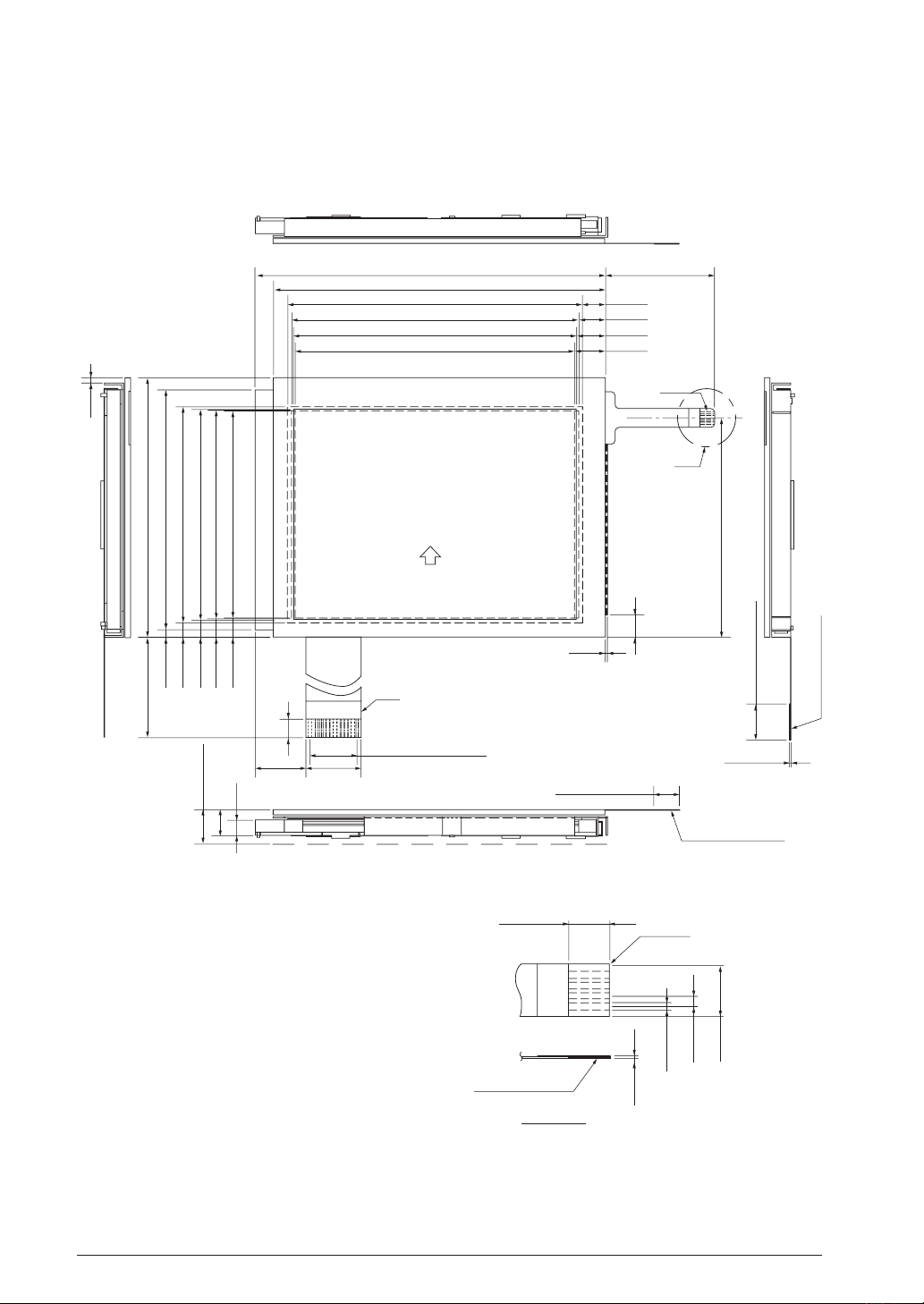

LCD Board Dimensions

112

6-φ3.3(NTH)

19

5

15 10

5

3

5 580

10

51 51

20

90

65.5

6-φ7

6-φ3.3 hole

102

26

29

(Hole)

19 20

5 51 5

1

11

2

J101

J103

J102

J104

17

11

14 1

12

1

1

4

2

18

1

2

3

70.5

65.5

805

10

55

90

50

50

20

1015

The following drawing shows dimensions of the LCD board.

<Surface>

3 NAME AND FUNCTIONS OF EACH PART

<Rear Face (View from Surface)>

∗ Precautions

• Unit for the above dimensions is millimeter (mm).

• Board thickness: 1.6 mm

• Figure 3.2.3.1 is a rear face drawing seen from the board surface.

Fig. 3.2.3.1 LCD Board Dimensions

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

9

Page 16

3 NAME AND FUNCTIONS OF EACH PART

96.2

TO

P

IF1

14±1

15

1

5

4.3

27.8±5

2.2

72

1.4

66.6

60(viewing area of touch panel)

58.59±0.3(viewing area of bazel)

58(active area of touch panel)

57.59±0.01(display area)

4

4.7

(5.0)

5.205

9.3 Max.

7.1

13(P1.0*13),W=0.7

VIEWING DIRECTION

BOTTOM

0.6

6.2

PIN1

IF2

60.9

RIGHT

LEFT

10±2(STIFFER)

7±1(STIFFER)

CONTACT SIDE

”A”

6.3

30.0

7.3

7.9

8.405

0.3±0.05

CONTACT SIDE

2-R0.3

4.0±0.3

UNIT : mm

SCALE : NTS

NOT SPECIFIED TOLERANCE IS ±0.5

CONDUCTOR

A

DETAIL

5±0.1

1±0.1

0.3

0.65±0.1

91.3(touch panel)

81(viewing area of touch panel)

79(active area of touch panel)

77.79±0.3(viewing area of bezel)

79.79±0.01(display area)

LCD Panel Board Dimensions

The following drawing shows dimensions of the LCD panel (EW32F92FLWP manufactured by IMAGING DIS-

PLAY).

(Abstracted from specifications for the IMAGING DISPLAY EW32F92 series products)

Fig. 3.2.4.1 LCD Panel Dimensions

10

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 17

3 NAME AND FUNCTIONS OF EACH PART

Main Parts

<CPU Board>

CPU (U13) S1C17801 SEIKO EPSON CORP.

Crystal oscillator (32.768kHz) (X1) FC-135 EPSON TOYOCOM CORP.

Crystal oscillator (48MHz) (X2) FA-238 EPSON TOYOCOM CORP.

Reset switch (RESET SW) (S8) SKQTLCE010 ALPS

Expansion connector (J7) SSW-109-01-S-D SAMTEC

Expansion connector (J8) SSW-108-01-S-D SAMTEC

Expansion connector (J12) TSW-109-07-S-D SAMTEC

Expansion connector (J13) TSW-106-07-S-D SAMTEC

ICD board connector (J6) PS-10SD-D4T1-1 JAE

SRAM (U18) CY62167DV30LL-55ZXI CYPRESS

Flash(NOR) (U3) S29JL064H55TFI000 Spansion

Flash(NAND) (U7) MT29F2G08AACWP MICRON

EEPROM (U17) 24AA256-I/SN ST-Micro

POWER SW (S7) SKRAAKE010 ALPS

Key switches (S1 - S6) SKRAAKE010 ALPS

Rotary encoder with switch (SW2) SIQ-02FVS3 MITSUMI

LED(RGB) (LED1) 598-9920-307F Dialight

Power LED (Blue) (LED2) 598-8191-107F Dialight

LED (LED3) LTW-170TK Lite-On

Infrared emitting module (D1) AN333 STANLEY

Infrared receiver module (U21) GP1UX311QS SHARP

Infrared receiver module (for U21) PNA4702M Panasonic

AudioCodec (U22) PCM3793ARHB TI

AudioCodec Oscillator (OSC1) SG-8002JC-12.288M-PCCB EPSON TOYOCOM CORP.

Audio connector (J14) SJ-43514-SMT CUI Inc

Audio connector (J15) SJ-3523-SMT CUI Inc

Speakers (SP1, SP2) NDT-03B STAR MICRONICS

MIC (MIC1) EM6022P-42BC10&33-G Horn Industrial

USB miniB connector (J10) 54819-0578 molex

MMC card socket (J5) DM1B-DSF-PEJ(22) HIROSE

Battery holder (BAT1) 106 KEYSTONE

Coin Battery CR2032 (3V) maxell

Power supply connector (5V) (J4) HEC3600-010510 Hosiden

Power Switch (SW1) SDDJE12300 ALPS

ICDmini i/f (J9) A2-4PA-2.54DS (71) HIROSE

ICDmini i/f (J11) S04B-PASK-2 (LF) (SN) JST

<ICD Board>

USB miniB type connector 54819-0572 molex

LED (RGB) 598-9920-307F Dialight

Reset switch (RESET SW) (SW1) SKRAAKE010 ALPS

<LCD board>

LCD panel module EW32F92FLWP IMAGING DISPLAY

Connector (to connect CPU board) (J101)

Connector (to connect CPU board) (J102)

Connector (to connect LCD panel) (J103)

Connector (to connect LCD panel) (J104)

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

DF9-13P-1V(32) HIROSE

DF9-9P-1V(32) HIROSE

52207-1485 Molex

52207-0485 Molex

EPSON

11

Page 18

3 NAME AND FUNCTIONS OF EACH PART

Functions of Each Part

ICD Board

The ICD board is a hardware tool (emulator) to facilitate the efficiency of software development for the S1C17801.

It controls communication between your PC and the target IC (S1C17801) on the CPU board, providing simple

software development environments for S1C17801. For information about its functional difference from the ICD

Mini (S5U1C17001H), a development tool supporting all S1C17 core product models, see Chapter 6.

ICD Board Reset Switch

Pressing the reset switch (SW1) on the ICD board reboots firmware on the ICD board and outputs the target

reset signal (#RESET_OUT) to the CPU board. This establishes the communication connection between the

CPU board and the ICD board if they are physically connected. If the CPU board and the ICD board are not

connected physically, the communication connection becomes in the stand-by status.

ICD Board LED

The LED indicates ICD board and target statuses in different colors.

● (Blue) Power on (before the initial connection with the target is established.)

● (Green) The target is currently in debug mode.

● (Red) The target is not connected, or not properly connected.

The target is currently executing a user program.

CPU Board

The CPU board is a simple target evaluation board equipped with the target CPU (S1C17801). It is also equipped

with SRAM, NOR Flash, NAND Flash, EEPROM and other external memories,as well as peripheral functions and

circuits such as a LCD panel, RTC control circuit, MMC card, USB Audio IC, speaker, microphone, and remote

control emitting/receiving module, enabling the CPU board to be used for the development and evaluation of control software and other purpose.

CPU Board Reset Switch

Pressing the reset switch on the CPU board (S8 mounted on the rear face) resets the CPU board.

Coin Battery

A coin cell battery (of CR2032 standard) socket is mounted on the rear face of the CPU board. The socket is

used for power supply to RTCV

DD.

12

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 19

3 NAME AND FUNCTIONS OF EACH PART

∗ Installing and Removing Coin Battery

The following describes installation and removal procedures of a coin cell to/from the socket on the rear

face of the CPU board.

Install Step 1: Insert coin cell under the long metal contact on the socket with the plus (+) side up, and press it

in the direction of the arrow.

Fig. 3.4.2.1 Installing/Removing Coin Battery - 1/4

Install Step 2: Figure 3.4.2.2 shows the installation has been completed.

Fig. 3.4.2.2 Installing/Removing Coin Battery - 2/4

Remove Step 1: Insert a slotted screw driver into space between the coin cell and socket, lift the driver up as

a lever and move it in the direction of arrow to secure a small space on the right side of the

socket as shown in the figure 3.4.2.3.

Fig. 3.4.2.3 Installing/Removing Coin Battery - 3/4

Remove Step 2: Insert the slotted driver into the space on the right side as shown in the figure 3.4.2.4. Then

pressing it to the right removes the coin cell. (The cell can also be removed by lifting the driver

up as a lever.)

Fig. 3.4.2.4 Installing/Removing Coin Battery - 4/4

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

13

Page 20

4 BLOCK DIAGRAM

CPU board

ICD board

Debug i/f

OSC1

32kHz

Debug i/f

OSC3

48MHz

Reset

(SW)

B&W QVGA LCD Panel

Module

LCD board

LCDC

Key(6)

REMC

REMC communi cation

RESET

3-color LED x 1

I2S

Audio

AD/D

A

Audio output

SPI

SD Card I/f

SD Card

USB

USBminiB

USB 2.0(FS)

I2C

SW

5V DC

100V AC

Regul ator

5V

→3.3V

SRAM

FLASH

ADx

ADx

EPPROM

Card i /f

GPIO

RTC

+RAM

UART

NAND FLA SH

Audio input

MFT0

SW

LED

ADx

ADx

ADx

ICD

connector

ADx

GPIO

Speaker

I/O connector

ICD mini connector

ICDmini

Exte rnal Device

Coin

Cell

ADx

GPIO

Audio jack

Microphone

Bus

Audio jack

Infrared LED

Rotary switch

Receiving module

Touch panel control

Bus connector

(Not available)

LCD panel connector

GPIO

ADx

Host PC

USB 1.

1

Regulator

5V->3.3V

Regulator

5V->1.8V

S1C33E07

5V

500mA

Max.

USB1.1

CPU Board

Flash ROM

3-color

LED x1

OSC3

48MHz

4 Block Diagram

Each block diagram for the the SVT17801 CPU board and ICD board is shown below.

<CPU Board>

Fig. 4.1 Block Diagram for CPU Board

<ICD Board>

Fig. 4.2 Block Diagram for ICD Board

14

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

S5U1C17801T1100 HARDWARE MANUAL

Page 21

5 OPERATING ENVIRONMENTS AND STARTING PROCEDURES

USB cable

AC power adapter

ICD

board

S5U1C17001C

(Debugger)

C17801

B/W QVGA

LCD panel module

CPU board

5 Operating Environments and Starting

Procedures

By connecting with your PC via the ICD board, the SVT17801 can be operated in accordance with commands ex-

ecuted by a debugger on the PC. The SVT17801 CPU board can be operated as stand-alone without using the ICD

board and PC. The following explains the connection and starting procedures required for each operation.

Software Simple Development Environments

The SVT17801 can provide simple development environments of software using the CPU board as a target. This

can be achieved by connecting the SVT17801 to your PC via the ICD board and using the S1C17 development tool

on the PC (such as GNU17 IDE, compiler and debugger included in the S5U1C17001C package).

Fig. 5.1.1 Software Simple Development Environments

Operation under Software Simple Development Environments

Under these operating environments,the target CPU (the S1C17801 on the CPU board) operates according to

commands executed by a debugger on your PC connected with the ICD board. A command executed by the

debugger is sent to the ICD board via USB to be analyzed and converted into a debug signal, and then sent

to the CPU board. The debugger on your PC can be used to download programs or data to the CPU board, or

debug programs by controlling their execution and stop.

Operating Mode of CPU

The "brk" command or debugging interrupts (such as forcible breaking operation by the debugger) from the

ICD board causes the target CPU (the S1C17801 on the CPU board) to stop executing the target program and

enter into debug mode (or break status). In this status, commands can be executed from the debugger on your

PC. LED on the ICD board lights in green during debug mode. On the other hand, the status where the target

CPU executes the target program is called normal mode. LED on the ICD board lights in red during normal

mode.

Connection and Start

The following describes connection and startup procedures to allow for the software simple development

environments.

(1) Connect the ICD board with the CPU board. Connect JICD 10 pin connector on the ICD board with the

counterpart on the CPU board. Then turn on the CPU board.

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

15

Page 22

5 OPERATING ENVIRONMENTS AND STARTING PROCEDURES

(2) Turn on the PC (if it is turned off).

(3) Connect the evaluation board to your PC via a USB cable.

(4) When a screen appears on your PC prompting you to install USB driver, install an appropriate driver. This

operation is required only for the first connection. It is not required for the second connection and afterward. For the installation procedure, see the later section “Installing USB driver”.

(5) Make sure that LED on the ICD board lights in blue

→ green (the target is in debug mode).

(6) Start the debugger on your PC to execute the program. Make sure that LED on the ICD board lights in red (the

target is in normal mode).

For details on the operation of the debugger and debugging commands, see the “S5U1C17001C Manual (S1C17

Family C Compiler Package).”

Note: Be sure never to disconnect a USB cable between PC and ICD board while the debugger is run-

ning.

Installing the USB driver

(1) When the SVT17801 is connected with the host computer via USB cable, the following screen appears.

(2) Follow the wizard to install USB driver.

For brows directory of the USB driver, specify “C:\EPSON\GNU17\utility\drv_usb.”

∗ This indicates a directory path where IDE is installed.

16

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 23

5 OPERATING ENVIRONMENTS AND STARTING PROCEDURES

When the USB driver has been installed successfully,it appears on the device manager as shown below.

Notes: If the driver does not appears on the device manager as shown above, install the USB driver again.

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

17

Page 24

5 OPERATING ENVIRONMENTS AND STARTING PROCEDURES

Standalone Operation of SVT17801

The SVT17801 CPU board can be operated as stand-alone without using the ICD board and PC.

Standalone Operation

In this operation environment, the S1C17801 on the CPU board operates in normal mode to execute a program

written in the built-in flash memory. Therefore, a user program must be downloaded previously to the flash

memory built in the S1C17801. (A demo-program is written in the flash memory of the SVT17801 as factory

default.)

For information about how to download a user program to the memory, see the "S5U1C17001C Manual (S1C17

Family C Compiler Package)."

Connection and Start

The following describes a method to operate the SVT17801 as standalone.

(1) Turn on the PC (if it is turned off).

(2) While the ICD board is connected with the CPU board, connect your PC to the ICD board via USB cable,

and turn on the CPU board.

(3) Start the debugger on your PC and download a user program to the flash memory built in the S1C17801.

For information about downloading a program, see the “S5U1C17001C Manual (S1C17 Family C Compiler

Package).”

(4) After exiting the debugger, remove the USB cable to disconnect the ICD board from your PC.

(5) Disconnect the ICD board from the CPU board, and install a coin cell battery.

(6) Press the reset switch on the CPU board. Then the S1C17801 on the CPU board starts executing a user pro-

gram downloaded to the flash memory.

ICD Board Firmware Update Procedures

The SVT17801 can update the firmware of the ICD board using the debugger on your PC. The ICD board firmware

will be provided by EPSON if necessary. An update file has an “.sa” extension.)

The following describes firmware update procedures.

Note: USB driver must be installed before starting firmware update.

(1) Connect the evaluation board to your PC via a USB cable.

(2) Press the reset switch on the CPU board.

(3) Start the debugger from the command prompt.

>cd c:\EPSON\gnu17 (Specify the directory path where the gnu17 is installed.)

>gdb

(4) When the debugger starts, enter the following commands.

(gdb) target icd usb

(gdb) c17 firmupdate

(where “

(5) Finally, when the LED on the ICD board gets green(

(6) Press the reset switch on the ICD board to reboot the firmware.

path\filename.sa

path\filename.sa” is the update file name.)

●), the firmware has been updated.

18

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 25

6 DIFFERENCE BETWEEN ICD BOARD AND ICD MINI

6 Difference between ICD Board and

ICD Mini

The table 6.1 shows specifications comparison between the SVT17801 ICD board and the S5U1C17001H (ICD

Mini), a development tool for the S1C17 Family. While the SVT17801 is equipped with the ICD mini interface, the

ICD board and the ICD mini cannot be connected at the same time. For information about how to use the ICD mini,

refer to the S5U1C17001H User Manual.

Table 6.1 Comparison of Functions between ICD Board and ICD mini

Product name

Corresponding core

Host interface

Maximum speed of data download

Communications frequency with target

(DCLK frequency)

Standalone flash writer function

Firmware update function

Power supply for writing to flash ROM

Reset signal output to target

Target system I/O support voltage

Connector to connect target

Power supply connector for writing to

flash ROM ∗3

∗1 Supported frequency when I/O interface voltage = 3.3V Depending on ambient noise, temperature conditions, and

types and variations of products,

the maximum frequency may become lower than the specification value.

∗2 Only for connection with the CPU board.

∗3 Separate power supply is not required for the S1C17801 to write to flash ROM.

∗4 Operating frequency is 48MHz (DCLK=24MHz) for SVT17801.

3.3V, 1.8V, and voltage input from

S5U1C17000H

ICD mini

S1C17 core

USB 1.1

Approx. 65KB/s DCLK = at 40MHz (Max.) ∗1

Approx. 50KB/s DCLK = at 20MHz ∗1∗4

4KHz - 40MHz

Available None

Available

Available None

Available

target (1.0 - 5.0V)

4 pins 10 pins

4 pins –

SVT17701 (S5U1C17001T)

(including reset signal) ∗2

ICD board

3.3V

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

19

Page 26

7 I/O PORT

7 I/O Port

Table 7.1 lists ports on the S1C17801 and the destination of the connection for the SVT17801.

For information about expansion interface and connectors, see Chapter 22.

Table 7.1 I/O Port Function List

Port Direction Multiplex Signal Name Connected to

P00 I AIN0 P00/AIN0 Expansion I/F (Connector No.: J8)

P01

P02

P03

P04

P05

P06

P07

P10

P11

P12

P13

P14

P15

P16

P20

P21

P22

P23

P24

P25

P26

P27

P30

P31

P32

P33

P34

P35

P36

P37

P40

P41 I/O UART/Memory P41/SOUT0/#SMWR

P42 I/O UART/EXCL P42/#SCLK0/EXCL0

P43 I/O REMC

P44

P45

P50

P51 I/O I2C P51/I2C_SCL

P52 I/O REMC/TM0 P52/REMC_IN/#TM0 Remote control light receiving module

P53

P55

P56

P57

P60

P61 I/O Memory P61/A1

I AIN1 P01/AIN1

I AIN2 P02/AIN2

I AIN3 P03/AIN3

I AIN4 P04/AIN4

I AIN5 P05/AIN5 Expansion I/F (Connector No.: J13)

I AIN6 P06/AIN6

I AIN7 P07/AIN7 Key input

I/O SPI0 P10/SPI_SDI0 MMC I/F & TP52

I/O SPI0 P11/SPI_SDO0 MMC I/F & TP53

I/O SPI0 P12/SPI_SCK0 MMC I/F & TP54

I/O SPI0/SPI1 P13/SPI_SSI0/SPI_SSI1 MMC I/F & TP55

I/O SPI1 P14/SPI_SDI1 Tri-color LED

I/O SPI1 P15/SPI_SDO1

I/O SPI1 P16/SPI_SCK1

I/O I2S0 P20/I2S_SDO0 AudioCodecIC & TP49

I/O I2S0 P21/I2S_WS0 AudioCodecIC & TP48

I/O I2S0 P22/I2S_SCK0 AudioCodecIC & TP47

I/O I2S0 P23/I2S_MCLK0 AudioCodecIC

I/O I2S1 P24/I2S_SDI1 AudioCodecIC & TP50

I/O I2S1 P25/I2S_WS1 AudioCodecIC & TP48

I/O I2S1 P26/I2S_SCK1 AudioCodecIC & TP47

I/O I2S1 P27/I2S_MCLK1 AudioCodecIC & TP51

I/O TM0 P30/TM0 Switch IC → Uni-color LED

I/O TM0/ADTRG P31/#TM0/#ADTRG Rotary encoder & key input

I/O WDT/CMU P32/WDT_CLK/

#WDT_NMI/CMU_CLK

I/O Memory/TM0 P33/#SMRD/#TM0 Switch IC → NAND Flash or

I/O Memory P34/#SMWR

I/O ICD i/f P35/DCLK ICD I/F (Connector No.: J6)

I/O ICD i/f P36/DSIO

I/O ICD i/f P37/DST2

I/O UART/Memory P40/SIN0/#SMRD

P43/REMC_IN/PWMPRT0

I/O REMC P44/REMC_OUT NAND Flash & NOR Flash

I/O WAIT P45/#WAIT Switch IC

I/O I2C/EXCL0 P50/I2C_SDA/EXCL0

I/O REMC P53/REMC_OUT Remote control light emitting module

I/O LCD P55/FPLINE Expansion I/F (Connector No.: J12)

I/O LCD P56/FPSHIFT/#TM0

I/O LCD P57/FPDRDY

I/O Memory P60/A0/#BSL

Switch IC

expansion I/F (Connector No.: J13)

Expansion I/F (Connector NO.: J8) & TP42

Expansion I/F (Connector NO.: J8) & TP43

Expansion I/F (Connector NO.: J8) & TP44

STBY(S1C17801)

Expansion I/F (Connector No.: J8) & EEPROM

Expansion I/F (Connector No.: J8) & EEPROM

Expansion I/F (Connector No.: J18) & SRAM

Expansion I/F (Connector No.: J18) & SRAM

20

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 27

Port Direction Multiplex Signal Name Connected to

P62 I/O Memory P62/A2 Expansion I/F (Connector No.: J18) &

P63

P64

P65

P66

P67

P70

P71

P72

P73

P74

P75

P76

P77

P80

P81

P82

P83

P84

P85

P86

P90

P91

P92

P93

P94

P95

P96

P97

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC0

PC1

PC2

PC3

I/O Memory P63/A3

I/O Memory P64/A4

I/O Memory P65/A5

I/O Memory P66/A6

I/O Memory P67/A7

I/O Memory P70/A8

I/O Memory P71/A9

I/O Memory P72/A10

I/O Memory P73/A11

I/O Memory P74/A12

I/O Memory P75/A13

I/O Memory P76/A14

I/O Memory P77/A15

I/O Memory P80/A16

I/O Memory P81/A17

I/O Memory P82/A18

I/O Memory P83/A19

I/O Memory P84/A20

I/O Memory P85/A21 Expansion I/F (Connector No.: J18) &

I/O Memory P86/A22/CMU_CLK

I/O Memory P90/D0 Expansion I/F (Connector No.: J18) &

I/O Memory P91/D1

I/O Memory P92/D2

I/O Memory P93/D3

I/O Memory P94/D4

I/O Memory P95/D5

I/O Memory P96/D6

I/O Memory P97/D7

I/O Memory PA0/#CE0 NOR Flash

I/O Memory PA1/#CE1 SRAM

I/O Memory PA2/#CE2 NAND Flash

I/O Memory PA3/#CE3 NAND Flash

I/O Memory PA4/#RD NOR Flash & SRAM

I/O Memory PA5/#WRL NOR Flash & SRAM

I/O Memory PA6/#WRH/#BSH SRAM

I/O Memory PB0/D8 Expansion I/F (Connector No.: J18) &

I/O Memory PB1/D9

I/O Memory PB2/D10

I/O Memory PB3/D11

I/O Memory PB4/D12

I/O Memory PB5/D13

I/O Memory PB6/D14

I/O Memory PB7/D15

I/O LCD PC0/FPDAT0/CMU_CLK Rotary encoder

I/O LCD PC1/FPDAT1/#WDT_NMI

I/O LCD PC2/FPDAT2/#ADTRG Switch IC → NAND Flash or reset

I/O LCD PC3/FPDAT3/PWMPRT0 Switch IC → NAND Flash or

SRAM & NOR Flash

NOR Flash

SRAM & NOR Flash & NAND Flash

SRAM & NOR Flash

expansion I/F (Connector No.: J8)

PC4

PC5

PC6

PC7

I/O LCD PC4/FPDAT4 Expansion I/F (Connector No.: J12)

I/O LCD PC5/FPDAT5

I/O LCD PC6/FPDAT6

I/O LCD PC7/FPDAT7

7 I/O PORT

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

21

Page 28

8 JUMPER SWITCH SETTINGS

To 3.3V regulator

JP1

JP1

JP1

ENABLE WAKEUP

DISABLE WAKEUP

To POWER SW

To

WAKEUP pin

1

2

2

3

DIC-149-3P

R59

10K

Q11

UNR5213

1

U24

SN74LVC1G98DCKR

3

C49 0.1µF

5

6

4

+5V

G

G V

8 Jumper Switch Settings

Three jumper switches are installed on the surface of the SVT17801. Each function is as follows:

Setting for JP1

JP1 can be used to select Wakeup Enable or Disable as shown in the following. 1-2 on JP1 must be shorted to select

Wakeup Enable. Wakeup Enable can be controlled by the Wakeup pin on the S1C17801 or on-board power switch.

For details, see the description of RTC control circuit in Chapter 10. Shorting 2-3 on JP1 disables the Wakeup func-

tion.

Factory default setting for JP1 is Wakeup Enable.

22

(SOFTWARE EVALUATION TOOL FOR S1C17801)

Fig. 8.1.1 JP1 Related Circuit

EPSON

S5U1C17801T1100 HARDWARE MANUAL

Page 29

8 JUMPER SWITCH SETTINGS

JP2

JP2

C55

0.1µF

C47

10µF

JP2

DIC-149-3P

1

2

12

3

To

RTCVDD

V

DD

D10

CRS06

BAT1

106

VDD

Battery

+

–

Setting for JP2

JP2 can be used to select the power supply source for RTCVDD as shown in the following. Short 2-3 on JP2 to se-

lect V

DD for the power supply to RTCVDD, whereas 1-3 to select battery. For details, see the description of RTC

control circuit in Chapter 10. Note that, when 1-2 is shorted, a coin cell battery is required to activate RTCV

Factory default setting for JP2 is 1-2 shorted.

DD.

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

Fig. 8.2.1 JP2 Related Circuit

EPSON

23

Page 30

8 JUMPER SWITCH SETTINGS

DIC-152-6P

1

1

5

3

5

3

2

6

4

2

4

G V

VDD

VLSS (LCD module)

VDD

JP3

JP3

MFT0

U20

TS5A3166

R90

470

LED3

LT

W-170TK

C65

0.1µF

LCD_BL_ON

LCD_BL_PWM

D201_PWM

Setting for JP3

JP3 wiring, allowing for three functions, is shown in the following.

∗ 1-2 Shorted

Power is supplied to LCD backlight. Shorting 3-4 is not allowed while 1-2 is shorted.

∗ 3-4 Shorted

Power with phase generated by.MFT0 on the S1C17801 is supplied to LCD backlight. It can be used to adjust the

brightness of LCD backlight. Shorting 1-2 is not allowed while 2-3 is shorted. For details, see Chapter 15 “LED/

LCD BACKLIGHT CONTROL CIRCUIT WITH MFT0.”

∗ 5-6 Shorted

Power with phase generated by MFT0 is supplied to LED3. It can be used to adjust the brightness of LED3. Ei-

ther 1-2 or 2-3 can be shorted while 5-6 is shorted. For details, see Chapter 15 “LED/LCD BACKLIGHT CON-

TROL CIRCUIT WITH MFT0.”

Factory default setting for JP3 is 1-2 and 5-6 shorted.

24

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

Fig. 8.3.1 JP3 Related Circuit

S5U1C17801T1100 HARDWARE MANUAL

Page 31

9 CONNECTION CIRCUIT TO EXTERNAL MEMORY

VDD

VDD

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15/A-20

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

CY62167DV30

S1C17801

NC

DNU

VCC

29

31

33

35

38

40

42

44

30

32

34

36

39

41

43

45

VSS

VSS

CE1

RD

WRL

WRH/RSH

A0/BSL

25

24

23

22

21

20

19

18

8

7

6

5

4

3

2

1

48

17

16

9

A1 to A20

D0 to D15

CE2

CE1

OE

WE

BHE

BLE

BYTE

10

13

12

26

28

11

14

15

37

47

R11

10K

C11

0.1µF

46

27

R20 10K

R19 10K

R15 10K

R73 10K

9

Connection Circuit to External Memory

SRAM, NOR Flash, NAND Flash, and EEPROM are connected to the SVT17801 as external memory modules.

SRAM Connection Circuit

CYPRESS 16M bits SRAM (CY62167DV30) is installed on the SVT17801. The following diagram shows how the

EEPROM is connected to the SVT17801.

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

Fig. 9.1.1 SRAM Connection Circuit

EPSON

25

Page 32

9 CONNECTION CIRCUIT TO EXTERNAL MEMORY

V

DD

VDD

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15/A-1

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

S29JL064H

S1C17801

VCC

29

31

33

35

38

40

42

44

30

32

34

36

39

41

43

45

VSS

VSS

CE0

RD

WRL

P44

RESET

25

24

23

22

21

20

19

18

8

7

6

5

4

3

2

1

48

17

16

9

10

13

A1 to A22

D0 to D15

CE

OE

WE

RY/BY

WP/ACC

RESET

BYTE

26

28

11

15

14

12

37

47

R7

10K

C10

0.1µF

46

27

R8 10K

R9 10K

R10 10K

NOR Flash Connection Circuit

SPANION 64M bits NOR Flash (S29JL064H) is installed on the SVT17801. The following diagram shows how the

EEPROM is connected to the SVT17801.

Fig. 9.2.1 NOR Flash Connection Circuit

26

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 33

9 CONNECTION CIRCUIT TO EXTERNAL MEMORY

VDD

VDD

D0

D1

D2

D3

D4

D5

D6

D7

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

D0

D1

D2

D3

D4

D5

D6

D7

MT29F2G08AACWP

S1C17801

29

30

31

32

41

42

43

44

25

26

27

28

33

34

35

38

39

40

45

46

47

48

VCC

VCC

VSS

VSS

CE2

SMRD

SMWR

1

2

3

4

5

6

10

11

14

15

20

21

22

23

24

D0 to D7

R/B

WP

CE

RE

WE

CLE

ALE

37

12

36

13

10K

10K

R87

R82

R74

10K

10K

R89

R88

10K

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

16

17

9

8

18

7

19

PC2

PC3

P44

SMWP

NAND Flash Connection Circuit

MICRON 2G bits NAND Flash (MT29F2G08AACWP) is installed on the SVT17801. The following diagram

shows how the EEPROM is connected to the SVT17801.

Fig. 9.3.1 NAND Flash Connection Circuit

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

27

Page 34

9 CONNECTION CIRCUIT TO EXTERNAL MEMORY

1

5

6

SCL WC

VCC

VSS

SDA

E0

E1

E2

3

8

7

4

2

VDD

S1C17801

U17

24AA256-I/SN

I2C_SDA

R5 2.2K

R6 2.2K

I2C_SCL

C9

0.1µF

EEPROM Connection Circuit

MICROCHIP 256K bits EEPROM (24AA256) is installed on the SVT17801. The following diagram shows how

the EEPROM is connected to the SVT17801.

Fig. 9.4.1 EEPROM connection circuit

28

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 35

10 POWER CONTROL CIRCUIT FOR BATTERY BACKUP FUNCTION

VDD, AVDD

POWER SW

RESET SW

#RESET

WAKEUP GPIO(P43)

GPIO(PC2) #STBY

S1C17801

RT

C

RTCVDD

IVRAM

5V

3.3VEN

(WAKEUP: Active HIGH signal)

Power switch

Active HIGH

Regulator

10 Power Control Circuit for Battery

Backup Function

SVT17801 has a battery backup function, and is equipped with a power control circuit allowing for this function.

Battery Backup Function

Three power supply lines are available on the S1C17801, i.e., VDD, AVDD and RTCVDD. VDD covers CPU core, log-

ic circuits, and I/O interface circuits, AV

The battery backup function supplies power only to RTCV

means that the function stops all operations except operating RTC and retaining contents inside IVRAM with low

power consumption. Because the power is supplied only to the minimum indispensable functions, leak current can

also be reduced drastically compared with sleep mode.

DD covers analog circuits (ADC), and RTCVDD covers RTC and IVRAM.

DD while stopping the power to AVDD and VDD. This

AVDD

VDD

S1C17801

RTCVDD

The SVT17801 is designed to connect the coin battery (CR2032) with RTCVDD, enabling RTC to keep functioning

and IRAM to retain its contents even if power supply from AC/DC adapter should be stopped.

In normal status, the power is supplied from AC/DC adapter without using the battery.

Power Control Circuit for Battery Backup Function

Figure 10.2.1 shows the power control circuit for SVT17801 battery backup function.

Fig. 10.2.1 Power Control Circuit for Battery Backup Function

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

29

Page 36

10 POWER CONTROL CIRCUIT FOR BATTERY BACKUP FUNCTION

#STBY Pin

This pin is used to disconnect the RTCVDD line from the VDD line (AVDD line) electrically.

If a LOW signal is input to the pin, area covered by the RTCV

area. Stopping power supply to the V

DD line (AVDD line) while a high signal is input causes inconstant signals

to be entered into RTC or IVRAM, or current to be leaked from the RTCV

sure to input a LOW signal to #STBY pin before stopping power supply to the V

DD line becomes electrically independent of other

DD line to the VDD line. Therefore, be

DD line (AVDD line).

∗ Notes: The RTCVDD area cannot be accessed while the #STBY pin is in LOW status. A HIGH signal must be

output from P43 to make the #STBY pin HIGH status before gaining access to the RTCV

DD area.

WAKEUP Pin

This signal pin is used to restore the SVT17801 from battery backup status to normal status.

The V

DD and AVDD lines can be turned on using the WAKEUP pin. For the SVT17801, this pin is connected to

the ENABLE pin on regulator,and so the power supply can be resumed by outputting a HIGH signal to the ENABLE pin.

The WAKEUP pin can be controlled by using RTC.

JP2 and JP3 Settings

In order to enable backup battery function on the circuit installed on SVT17801 as shown in the figure 10.2.1,

JP2 and JP3 must be set to WAKEUP ENABLE and Battery respectively (both factory default).

JP2 is located just before the WAKEUP pinʼs entering into an OR circuit, and if JP2 is set to WAKEUP DIS-

ABLE, 5V instead of WAKEUP pin is input to the OR circuit, turning regulator always ON.

JP3 selects supply source of RTCV

from the coin cell battery (CR2032) and if V

tings, see Chapter 8.

DD shown in the figure 10.2.1. If Battery is selected, RTCVDD is supplied

DD is selected, RTCVDD is supplied from VDD. For detail of JP set-

RSTO (Power Switch) and WAKEUP Pin

The following list shows GPIO (PC2) status and VDD voltage according to power switch and WAKEUP pin

statuses when JP1 and JP2 are set to EnableWakeup and Battery respectively in the circuit shown in the figure

10.2.1.

Table 10.2.1 PC2 and VDD Status According to Power Switch and WAKEUP Pin

Power Switch WAKEUP (HIGH Active) GPIO(PC2) VDD (V)

CLOSE (being pressed) HIGH HIGH 3.3

OPEN HIGH LOW 3.3

CLOSE (being pressed) LOW HIGH 3.3

OPEN LOW LOW 0

GPIO(PC2) is a signal representing OPEN/CLOSE status of power switch, and used when controlling power

supply.

Shifting to Standby Mode

The following is an example to show how to set up standby mode in the circuit shown in the figure 10.2.1.

➀ Set JP1 to EnableWakeup and turn the system power (VDD) on.

➁ CPU starts working.

➂ After setting P43 to HIGH output and the STBY pin to HIGH, set WAKEUP to HIGH active and

WAKEUP output signal to HIGH. (to enable WAKEUP status)

• • •

➃ Press power switch. (Pressing the power switch turns PC2 HIGH.)

➄ If PC2ʼs HIGH status is detected, set P43 to HIGH output and the STBY pin to HIGH (to enable write

to IVRAM inside RTC).

➅ Write RTC setting data to IVRAM.

30

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 37

10 POWER CONTROL CIRCUIT FOR BATTERY BACKUP FUNCTION

➆ Set the WAKEUP signal to LOW. → ∗ The power switch is being pressed during above steps.

➇ Setting for standby mode has been completed. (RTCVDD is running in ON status.)

After

➇, the VDD line (AVDD line) can be turned off.

Releasing Standby Mode

The following is an example to show how to release standby mode in the circuit shown in the figure 10.2.1.

(Example 1)

➀ In Step ➄ of above set-up example 1, the standby mode is released (WAKEUP pin is turned HIGH) af-

ter predefined time has passed, and the output of regulator shown in figure 10.2.1 becomes always 3.3V.

(Example 2)

➀ Press power switch.

➁ While the power switch is being pressed, the output of regulator shown in figure 10.2.1 becomes 3.3V,

S1C17801 starts operating and, immediately after that, the standby mode is released by turning the

WAKEUP signal HIGH.

➂ By turning the WAKEUP signal HIGH at Step ➁, the output of regulator shown in figure 10.2.1 be-

comes always 3.3V.

∗ This power control circuit should be used only for reference. The circuit is designed for reducing the current con-

sumption of whole system by turning the V

DD line (AVDD line) has a longer power-off time, or a board has many peripheral parts with relatively HIGH

the V

current consumption. Other technique (such as Sleep or Halt) may still be advantageous depending on your approach to control the overall system. We recommend you review all necessary factors to choose the optimal way

when you design a total system.

DD line (AVDD line) off. This technique is effective for the case where

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

31

Page 38

11 LCD PANEL CONNECTION CIRCUIT

LCD panel module

(EW32F92FLWP)

VDD

VDD

R101 0

R102 1K

SW

VDD

V

SS

VLCD

FLM

NC

CL1

CL2

D0

D1

D2

D3

DISPOFF

VLED

VLSS

FPFRAME

FPLINE

FPSHIFT

FPDAT4

FPDAT5

FPDAT6

FPDAT7

FPDRDY

MFT0

C103

0.1µF

C104

47µF

C106

1µF

C107

4.7µF

C111

10µF

S1C17801

R103

2.2M

1%

R104

130K

1%

U101

TPS61040

L101

LQH32CN4R7M23L

L102

MPZ2012S601A

VDD

D101

B0530W-7-F

1

SW

FB

GND

VIN

EN

3

2 4

5

C105

22PF

Q105

MMBTA42-TP

11 LCD Panel Connection Circuit

The S1C17801 has a built-in LCD controller (LCDC) that supports the monochrome STN LCD panel and paral-

lel interface. The SVT17801 is equipped with the QVGA panel module (EW32F92FLWP including driver) with a

built-in monochrome STN panel.

This panel module is equipped with a 4-bit STN LCD panel, to which data bus is connected as shown above. The

following lists function of each signal on the module side.

For information about controlling the LCD panel, see the Application Note.

32

(SOFTWARE EVALUATION TOOL FOR S1C17801)

Fig. 11.1 LCD Panel Module Connection Circuit

Table 11.1 Name and Function of Signal on LCD Panel Module

Signal Name Functionalities

VDD Logic power supply inside module

VSS GND of logic power supply inside module

VLCD LCD driver power supply

FLM Frame clock

CL1

CL2

D0

D1

D2

D3

DISPOFF LCD ON/OFF Control (L:OFF, H:ON)

VLED Backlight power supply

VLSS Backlight power supply

EPSON

Display data line clock

Display data shift clock

Display data bus

Display data bus

Display data bus

Display data bus

S5U1C17801T1100 HARDWARE MANUAL

Page 39

11 LCD PANEL CONNECTION CIRCUIT

V

DD

S1C17801

P33

P34

AIN5

AIN6

6

5

4

1

2

3

U102

74LVC2G14

C110

0.1µF

1Y

VCC

2Y

1A

GND

2A

C109

470P

C108

470P

Q104

UNR5213

Q102

UNR5213

Q101

UNR31A300L

Q103

UNR31A300L

LEFT

TOP

RIGHT

BOTTOM

LCD panel module

(EW32F92FLWP)

VDD

AIN5 (Voltage HIGH)

AIN5 (Voltage LOW)

Y-

axis

X-axis

AIN6 (Voltage HIGH) AIN6 (Voltage LOW)

SVT17801 LCD BOARD

EPSON

Touch Panel Controller Connection Circuit

The touch panel function is installed in the LCD panel module on the SVT17801. The following shows how the

touch panel is connected to the S1C17801.

Fig. 11.1.1 Touch Panel Connection Circuit

In the above connection diagram (figure 11.1.1), panelʼs touch position information entered from AIN5/AIN6 is ob-

tained as an AD value while the circuit shown above is controlled by P33/P34 of the S1C17801. The following lists

each signal status of the panel module and the S1C17801.

Table 11.1.1 Function of Touch Panel Control Signal

Pin No. X-axis Y-axis

S1C17801 P33 LOW HIGH

P34

AIN5

AIN6 0 to V

LCD panel module LEFT HIGH Hi-Z

TOP

RIGHT LOW 0 to VDD(V)

BOTTOM 0 to V

In order to obtain panelʼs touch position information on X-axis of the figure 11.1.2, an AD value obtained from

AIN6 is used to determine the position of X-axis when P33 is turned LOW while P34 HIGH as shown in X-axis

fields shown in the table 11.1.1. (The AIN6 value becomes gradually larger for the left side of the figure 11.1.2.)

On the other hand, to obtain panelʼs touch position information on the Y-axis of the figure 11.1.2, an AD value ob-

tained from AIN5 is used to determine the position of Y-axis when P33 is turned HIGH while P34 LOW as shown

in Y-axis fields of table 11.1.1. (The AIN6 value becomes gradually larger for the upper side of the figure 11.1.2.)

This principle to obtain X-axis and Y-axis data helps acquire two-dimensional touch position information by obtaining X-axis and Y-axis AD values while alternately switching between P33 and P34 statuses with a short duration.

HIGH LOW

LOW 0 to VDD(V)

DD(V) LOW

Hi-Z HIGH

DD(V) LOW

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

Fig. 11.1.2 Image of X-axis and Y-axis Analog Values of Touch Panel

EPSON

33

Page 40

12 KEY INPUT CIRCUIT ON CPU BOARD

AV

DD

AIN7

S1C17801

P31

S1 S2 S3 S4 S5 S6

5.1K

5.1K

3

4

3

4

3

4

3

4

3

4

3

4

1

2

1

2

1

2

1

2

1

2

1

2

5.1K

5.1K

5.1K

5.1K

5.1K

AVDD

R1

R2

V

12 Key Input Circuit on CPU Board

Switches connected to the SVT17801 (S1 - S6) are connected with the AD input port (AIN7) and input port (P31)

on the S1C17801 as shown in the figure 12.1.

Fig. 12.1 Key Input Connection Circuit on CPU Board

In this circuit, the press of a switch is detected by the port (P31) status and the pressed switch is determined by

detecting an input value of AD (AIN7).

The mechanism of detecting the switch status by the port (P31) status is as follows: If all switches are open, the

port (P31) is in HIGH state as it is pulled up by the 35.7KΩ resistor (5.1KΩ x 7) as shown in the figure 12.1. If

any of the switches is pressed, on the other hand, the pull-down resistor value becomes smaller than the pull-up

resistor value, and this turns the port (P31) LOW. The mechanism of this circuit enables the press of any switch to

be detected by using interrupt or other method.

Figure 12.1 also indicates that the pressed switch can be determined by the variance of ratio between the pullup resistance value and the pull-down resistance value, because the ratio changes depending on the switch being

pressed. The change can be detected by an AD (AIN7) input value. Figure 12.2 shows the equivalent circuit of the

figure 12.1.

The following equation is satisfied in this equivalent circuit:

V = R2/(R1+R2)×AV

DD

"V" value for each switch is obtained by resistance values of R1 and

R2 that are obtained when the switch is pressed. Thus the pressed

switch can be determined by comparing the "V" value with the value

actually entered into AD (AIN7).

Fig. 12.2 Equivalent Circuit of Single Key Input

34

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 41

13 ROTARY ENCODER CONNECTION CIRCUIT

0.01µF 0.01µF

A

COM

B

S

10K

S1C17801

PC0 PC1

P31

S1C17801

10K

10K 10K

V

DD

13 Rotary Encoder Connection Circuit

The rotary encoder connected to the SVT17801 is connected with three port inputs (P31, PC0 and PC1) on the

S1C17801 as shown in the figure 13.1.

Fig. 13.1 Rotary Encoder Connection Circuit

Rotating the rotary encoder closes the A and B switches shown above, and the time difference of switching occurs

depending on the rotative direction. When the encoder does not rotate, both of two ports connected to the S1C17801

are pulled up to HIGH. When the encoder rotates, on the contrary, they are turned LOW, and phase difference arises

between the HIGH and LOW timings of those ports. The phase difference can be detected by software to govern

the rotative direction. As a switch is directly connected to a port, pressing the switch turns the port LOW. The LOW

zone can be detected by software.

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

35

Page 42

14 TRI-COLOR LED CONNECTION CIRCUIT

+5V

LED1

598-9920-307F

R92

R31

MMBTA42-TP

S1C17801

P14

P16

P15

MMBTA42-TP

MMBTA42-TP

Q4

Q2

Q3

1K

R29 1K

R30 1K

R28

R26

R27

5.1K

1.8K

1.8K

1

2

3

0

4

14 Tri-color LED Connection Circuit

The SVT17801 is equipped with a tri-color LED being connected to the S1C17801 as shown in the following dia-

gram.

Fig. 14.1 Tri-color LED Connection Circuit

As the figure 14.1 shows, P14/P15/P16 ports are connected to the tri-color LED, H/L combination of which can

represent total seven colors. The following table lists the LED colors formed by H/L combination of each port.

Table 14.1 Color on Tri-color LED Corresponding to Port Status

S1C17801 Color on Tri-color LED

P16 P15 P14

L L L ●(light off)

L L H ●(green)

L H L ●(blue)

L H H ●(aqua)

H L L ●(red)

H L H ●(orange)

H H L ●(purple)

H H H ○(white)

36

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 43

15 LED/LCD BACKLIGHT CONTROL CIRCUIT WITH MFT0

DIC-152-6P

1

1

5

3

5

3

2

6

4

2

4

G V

V

DD

J12 11pin

(LCD backlight)

V

DD

JP3

JP3

MFT0

U20

TS5A3166

R90

470

LED3

LT

W-170TK

C65

0.1µF

LCD_BL_ON

LCD_BL_PWM

D201_PWM

S1C17801

15 LED/LCD Backlight Control Circuit

with MFT0

The SVT17801 is equipped with a LED that can be controlled by MFT0. The following diagram shows how the

EEPROM is connected to the SVT17801.

Fig. 15.1 Connection Circuit between MFT0 and LED/LCD Backlight

Pre-stage switching IC (TS5A3166) is switched by changing phase in MFT0 H/L areas, and brightness of the LED

can be changed visually by turning ON and OFF the backlight of LED and LCD panel repeatedly in accordance

with the MFT0 phase.

∗ MFT0 is an I/O port with 12 mA of drive current. A circuit shown in the figure 15.1.has a pre-stage switch IC,

which however can be replaced simply by a 470

proximately 7 mA.)

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

Ω resistor for direct drive. (The drive current in this case is ap-

37

Page 44

16 INFRARED EMITTING DIODE/RECEIVING MODULE CONNECTION CIRCUIT

VDD

VDD

C15

4.7µF

C66

10µF

C14

4.7µF

R12

100

D1

AN333

➀

S1C17801

REMO

VOUT

GND

VCC

REMI

➂

U21

1

2

3

GP1UX311QS

Q1

MMBTA42-TP

R14 1K

R24 47

➁

Infrared Emitting Diode

Infrared Receiver Module

16 Infrared Emitting Diode/Receiving

Module Connection Circuit

Following diagram shows the connection of infrared emitting diode (AN333)/infrared receiving modules

(GP1UX31QS/GP1UX51QS/PNA4702M) installed on the SVT17801.

Fig. 16.1 Infrared Emitting Diode/Receiving Module Connection Circuit

S5U1C17801T1100 HARDWARE MANUAL

38

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

Page 45

16 INFRARED EMITTING DIODE/RECEIVING MODULE CONNECTION CIRCUIT

Emitting and Receiving from/by Infrared Area

When two SVT17801 units are used for sender and receiver as shown in the figure 16.1.1, that is one for emitting

and the other for receiving, waveform from each part

<Send> <Receive>

Fig. 16.1.1 Infrared Emission/Reception Evaluation Environment Using SVT17801

∗ The following describes the transmit waveform ➀ from REMO on the S1C17801, and corresponding waveforms

➁ and ➂. For the monitoring points of ➀ to ➂, see Table 16.1.

➀ to ➂ of the infrared area are described in this section.

<Waveform for ➀>

<Waveform for ➁>

<Waveform for ➂>

Fig. 16.1.2 Waveform for Each Point Shown in Figure 16.1

∗ Infrared communication in this case covers approximately 3 m by our measurement when emitting and receiving

modules are placed face to face without any obstacle between them. Please use this value only for reference.

∗ A solid red circle on the receiver side in the figure 16.1.1. shows the location where the infrared receiving mod-

ule is installed. A spare module can be installed in the area marked by a dotted red circle. (Module is not installed

in the area marked by a dotted red circle.)

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

39

Page 46

17 MMC (MULTI-MEDIA CARD) CONNECTION CIRCUIT

VDD

J5

DM1B-DSF-PEJ(22)

R17

10K

R18

10K

R16

10K

C16

0.1µF

1

2

3

4

5

6

7

8

9

SPI_SSI0

SPI_SDO0

SPI_SCK0

SPI_SDI0

MMC_CARD

17 MMC (Multi-Media Card)

Connection Circuit

The SVT17801 is equipped with a MMC card socket being connected to the S1C17801 with SPI mode as shown in

the following diagram.

Fig. 17.1 MMC Card Connection Circuit

For information about controlling the MMC card using SPI mode, see the Application Note.

40

EPSON

(SOFTWARE EVALUATION TOOL FOR S1C17801)

S5U1C17801T1100 HARDWARE MANUAL

Page 47

18 USB Connection Circuit

VDD

S1C17801D4

1N5819D61N5819

C21

1µF

L5

BLM21PG600SN1D

R25

R52

R22

R23

1.5K

5.1K

22

22

U19

SN65220DBVT

A

GND

B

NC

GND

NC

J10

54819-0578

1

2

3

4

5

FG6

FG7

FG8

FG9

VBUS

D–

D+

ID

GND

6

5

4

1

2

3

USB

C24

22P

C51

22P

PUENB

USBVBUS

USBDM

USBDP

R53

10KD31N5819D51N5819

18 USB Connection Circuit

The SVT17801 is equipped with a USB miniB connector being connected to the S1C17801 as shown in the

following diagram.

Fig. 18.1 USB Connection Circuit

For information about controlling USB, see the Application Note.

S5U1C17801T1100 HARDWARE MANUAL

(SOFTWARE EVALUATION TOOL FOR S1C17801)

EPSON

41

Page 48

19 AUDIO CONNECTION CIRCUIT

VDD

VDD

OSC1

SG-8002JC-12.288M

U32

TS5A3159A

G V

VDD

R55 33

R83

47K

2

OE

GND

VDD

OUT

3

4

41

63

2

5

L6

L7

BLM18PG300SN1D

BLM18PG300SN1D

C41

10µF

AV

DD

R54 10K

R46 10K

S1C17801

S1C17801

I2C SCL

I2C_SDA

I2S MCLK1

I2S SDI1

I2S_SDO0

I2S_WS0/1

I2S_SCK0/1

I2S_MCLK0

P32

C43

C44

C45

C53

0.1µF

4.7µF

4.7µF

4.7µF

C29

L8

L9

L10

L11

BLM18PG121SN1D

BLM18PG121SN1D

BLM18PG121SN1D

BLM18PG121SN1D

1µF

C35

C36

C34

C33

C37

C38

C32

+

+

+

–

+

–

C31

1µF

1µF

1µF

1µF

1µF

1µF

R51

R50

R49

R48

R93

R94

2.2K

2.2K

2.2K

2.2K

2.2K

2.2K

47µF

C59

1000pF

C61

1000pF

C62

1000pF

C60

1000pF

47µF

R43

1

MIC1

EM6022P-42BC10&33-G

MIC GND

J15

SJ-3523-SMT

J14

SJ-43514-SMT

SP1

SP2

NDT-03B

NDT-03B

2

2

1

3

3

2

1

4

4.7

R42 4.7

C30

4.7µF

C64 0.1µF

R44

10K

R45

33K

U22

PCM3793ARHB

31

30

29

28

7

3

2

32

1

MC/SCL

MD/SDA

MS/ADR

MODE

SCKI

DOUT

DIN

LRCK

BCK

VIO

VDD

VCC

VPA

DGND

AGND

PGND

MICB

AIN1L

AIN1R

AIN2L

AIN2R

AIN3L

AIN3R

HDTI

HPOL/LOL

HPOR/LOR

HPCOM/MONO

SPOLP

SPOLN

SPORP

SPORN

VCOM

4

5

20

12

6

19

13

21

27

26

25

24

23

22

8

17

16

9

15

14

11

10

18

19 Audio Connection Circuit