Page 1

ATH2 Owner’s Manual

SAFETY! SAFETY!

1) Read and understand instructions and heed warnings before beginning installation.

2) Mount rail securely. The lens is heavy, and requires a secure and stable surface. Fasteners in

sheetrock alone are not safe. Reciprocal lens motion can and will work them loose. Use a

board, plate, or projector mount fixed to ceiling joists or studs.

3) Ladder caution: Exercise extreme caution when working on a ladder. Do not work directly

above another person, particularly a child. Plan all work carefully. Accidentally dropping a

drill, hammer, or the lens assembly can cause serious bodily injury.

4) Unexpected lens mo vement: Anticipate all lens motion. A malfunctio n can cause the lens to

move unexpectedly. While on a ladder, do not stand in direct path of lens in case of

unexpected or accidental movement. Disconnect power when installing, working on, or

repositioning the lens.

5) Indoor use only: Do not install lens in a wet or moist environment, or where the mechanism

will be exposed to extreme or external weather conditions.

6) Object and liquid entry: Never pour any liquid or push any object into the enclosure.

7) Power Sources: The power adaptor is intended for 100- 220 volt, 50-60 cycle AC power only.

8) Power Cord: Do not subject power cord to conditions which will wear through or cut the

insulation. Avoid excessive tension or chafing of the cord.

9) Service: Do not service the motor drive or electronics. There are no user serviceable parts.

Contact your dealer. Send only to a factory approved facility.

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation

©Panamorph Inc January 2009 – All rights reserved Page 1

Page 2

ATH2 Owner’s Manual

January 2009 Edition –

Printed January 2009

©Panamorph Inc.

All rights reserved

©Panamorph Inc January 2009 – All rights reserved Page 2

Page 3

ATH2 Owner’s Manual

.

1 Introduction

Congratulations, and thank you for purchasing a quality Panamorph product. Your ATH2 lens motor/sled is

outfitted with a custom mechanism designed exclusively for use in the home theater environment. No oil or

liquid based lubricants are used to assure the maximum cleanliness for optical components. Both lens and

drive will provide years of maintenance free service. The Panamorph system is built and tested in the USA

to the strictest quality standards and certifications.

Features and benefits:

Easy, straight forward installation and operation

Machined, high grade, anodized aluminum components

Repeatable precision positioning system

Flexible mounting options allowing table or ceiling mount

Speed selector for high or low speed operation

Configurable “lens in” position

Extra external IR sensor for remote mounting (if needed)

Input 12V jack for automatic lens trigger

Output 12V jack for screen masking trigger

Non mechanical long life optical stop sensors

Dry operating precision linear bearings

Custom built, high precision, low current NEMA 23 stepper motor

Custom built, low noise stepper drive circuitry and firmware

Endurance tested to over 2,000,000 traversals

8 button long range remote control (up to 50 feet) with discrete functions

Backlit logo with on/off lighting control

Reversible logo plates

Completely maintenance free

USA built and tested

FCC, CE, and UL certified

©Panamorph Inc January 2009 – All rights reserved Page 3

Page 4

ATH2 Owner’s Manual

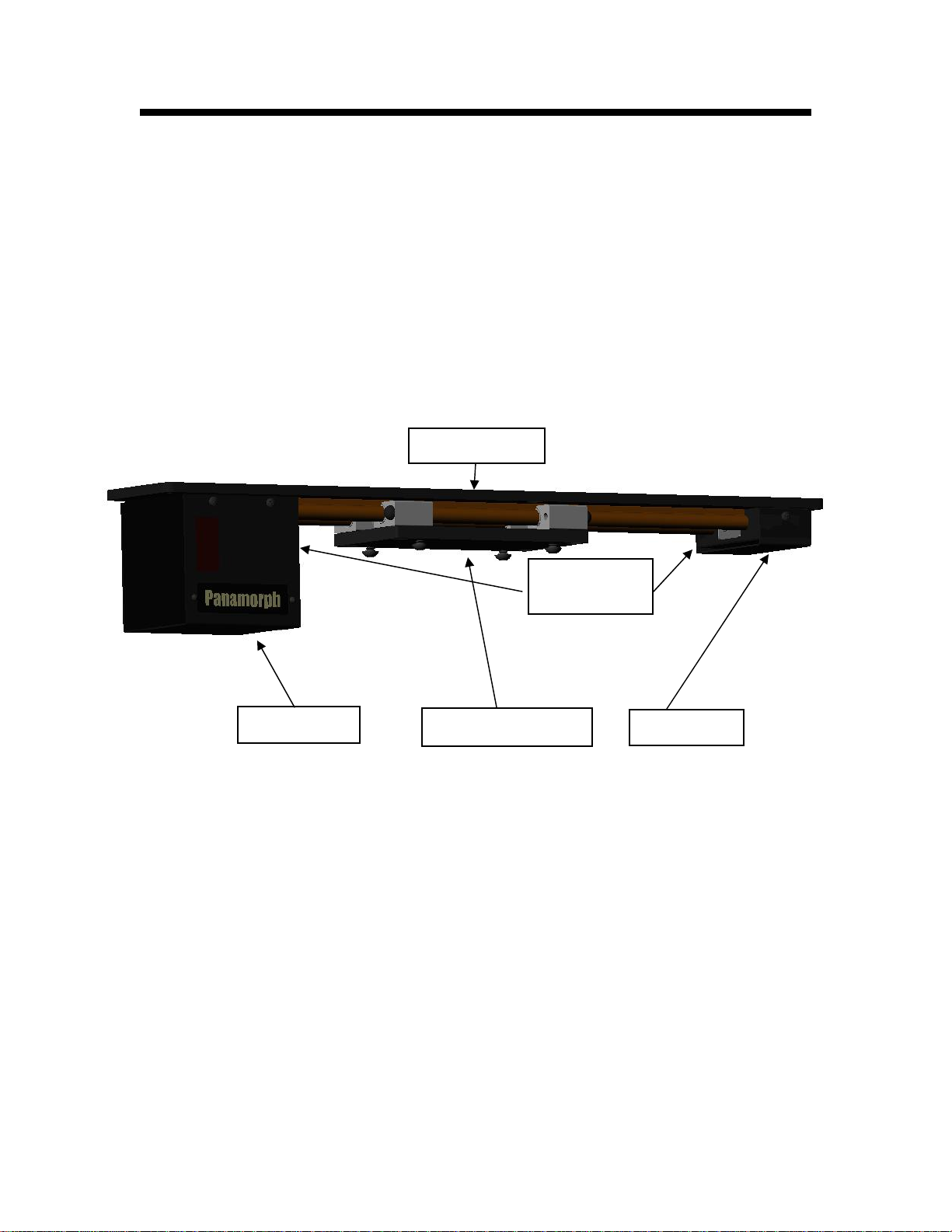

2 Motorized Lens Sled Parts

During installation, this manual will refer to the motor side, or the pulley side of the mechanism. Refer to

the picture below for a description. As shipped from the factory the “lens-in” side of the unit is at the motor

end. Depending on the projector, “Lens in” will either be on the motor or the pulley side of the sled. See

Chapter 6 – Setup, to configure the “lens in” orientation of the sled to the pulley side.

Mounting bar

Motor side

Optical

sensors

Lens adaptor plate

Pulley side

©Panamorph Inc January 2009 – All rights reserved Page 4

Page 5

ATH2 Owner’s Manual

3 Plan your installation

The lens assembly may be mounted in one of two ways:

1) To the ceiling or projector mount above the projector

2) To a shelf or table below the projector

When attaching motor assembly to the ceiling, use a board, plate, or lens enabled projector mount

attached to the ceiling joists or studs. Sheetrock embedded fasteners will work loose with repeated lens

movement causing the mechanism to fall, resulting in possible severe injury. The Panamorph AKX or

AKCPro mounting kit is highly recommended.

Changing Orientation of Logo Plate (optional)

As shipped, the lens sled is configured for ceiling mounted operation. As such, the logo reads right side up

with the mounting bar on top. If you are using the sled in a table or shelf mounted configuration, you may

optionally turn the logo around so that it is right side up with the mounting bar below the projector.

To reverse the logo, remove the 4 screws securing the motor housing cover. Lightly spread the sheet metal

cover and lift it off. Once removed, you can easily access the logo plate. Remove the two small plastic

screws securing the logo plate, turn the plate around, and re-install the screws. Lightly tighten the screws,

as the threads are plastic. Re-install the motor cover housing using the original screws. Make sure the fiber

optic light pipe connector is completely inside the housing before reinstalling motor hou sing screws.

An alternative to reversing the logo plate is to turn off the back light, thereby rendering the logo

inconspicuous. Simply press the PANEL OFF button to accomplish this.

4) Reinstall 4

cover screws

3) Turn plate

around replace 2

logo plate screws

©Panamorph Inc January 2009 – All rights reserved Page 5

1) Remove 4

cover screws

and remove

cover

2) Remove 2

logo plate screws

Page 6

ATH2 Owner’s Manual

4 Mount Sled to Projector Plate

When using the Panamorph AKX or AKXPro system follow directions supplied with the mounting

plate and skip to Chapter 5 – Attach Lens Bracket. Otherwise, follow the directions below for a

custom fabricated mount.

When building a custom mount, mark screw locations using only the sled as shipped, without the lens

and/or the lens bracket in place. Do not rely on fasteners embedded in sheetrock alone. Reciprocal lens

movement will work them loose, and cause the mechanism to fall. Mount the ATH2 to a plate, board, or

lens enabled projector mount ultimately affixed to ceiling joists for safety.

Recommended procedure:

1) Align mounting to center line of lens

Before beginning, the projector must be correctly focused with the zoom and iris set in their viewing

positions for 16:9 or 4:3 viewing depending on the native mode of the projector. This will determine

correct positioning of the front of the projector lens. Hold the motor/sled up to the projector and decide if

the LENS IN position will be at the motor housing or pulley housing side.

Measure 2 1/8 inches from the front of the focused projector lens, and lightly draw a line parallel to the

front of the lens. Mark the center line of the projector lens along this parallel line. Now, line up the back of

the mounting bar to the parallel line just marked. Align the center of the projector lens to the following

locations as appropriate:

“Lens In” position at motor housing side – center of lens is 7.25” from end of mounting bar

“Lens-In” position at pulley housing side – center of lens is 5.375” from end of mounting bar

Refer to dimensioned drawing at back of this manual for clarification (page 15).

Mark the six hole locations using the mounting bar itself as a template. Drill the holes for secure (never use

sheetrock inserts) fasteners.

2) Secure mounting bar

As the mechanism and lens are heavy, make sure the fasteners, and surface are extremely secure.

Remember that the sled motor will be starting and stopping a heavy weight thousands of times through

normal use. Ceiling mounted lenses require a secure and flat surface. Sheetrock anchors alone are

insufficient and will work loose over time causing potential injury. Secure the mounting bar to a plate,

painted board, or lens enabled projector mount securely affixed to the studs or ceiling joists. Periodically

re-check the security of the mounting. Use of a commercial mounting system designed for anamorphic

lenses is highly recommended. Use all six screw holes, and tighten fasteners securely. Vibration from the

motor and reciprocal lens movement will loosen any fasteners that are not absolutely tight and secure from

vibration.

©Panamorph Inc January 2009 – All rights reserved Page 6

Page 7

ATH2 Owner’s Manual

5 Attach Lens Bracket

1)Attach lens bracket to adapter plate

Remove the bracket mounting screws and hex key from the parts package and use them to attach the

Panamorph lens bracket supplied with the ATH2. Snug up the bolts with the supplied hex key. Maintain

even pressure on each bolt. The angled portion of the bracket fork faces the rear of the mechanism. Do not

attach the lens or power up the sled just yet! Adjustment and alignment are easier without the lens for

now.

Front of unit

Bracket mounting

screws

©Panamorph Inc January 2009 – All rights reserved Page 7

Page 8

ATH2 Owner’s Manual

6 Setup

1) Power up the sled and set LENS IN position

Bright lights, particularly direct sunlight shining into the optical sensors at either end of the sled will

prevent the sled from operating normally. Test the sled under normal or low lighting conditions. Now

slide the lens into the middle of the sled before powering up. Plug the power adaptor into an AC outlet,

then into the back of the unit. Put two AAA batteries in the battery compartment of the hand held remote

control. Back away from the lens or descend the ladder. Hit ON, wait for the LED to flash 3 times, and

then hit the LENS IN button on the remote. The lens sled will now position itself into the factory default

LENS IN position. The edge of the adaptor plate will land approximately ½ inch from the motor housing

side of the sled.

If the bracket is not in front of the projector lens, you will need to change the “lens in”position so that

“lens in” is at the pulley side of the mechanism. Simply press the LENS OUT button on the remote, and

wait for the bracket to move in front of the projector lens. Press and hold the LENS OUT button again,

until the lens begins to move, and release. The sled will confirm the new setting by moving the bracket

away from the projector lens, to the new LENS OUT location (now the motor side). You have now reprogrammed the sled to reverse the “lens in” side.

2) Verify centering

Press LENS IN and observe where the lens stops. If needed, you may make small adjustments (+ or – ¼

inch) to the lens bracket after disconnecting the power, by loosening the screws and sliding the bracket to

the left or right as needed to achieve centering. Reconnect the power and check your work. The optical

sensors will stop the edge of the lens adaptor plate approximately ½ inch from the housings on either side

of the sled. It will always stop at exactly the same spot. You may use this gap on the motor or the pulley

side for fine adjustments.

Gap

©Panamorph Inc January 2009 – All rights reserved Page 8

Page 9

ATH2 Owner’s Manual

3) Attach anamorphic lens to bracket

Attach the UH480 lens to the bracket using the lens knobs supplied with the lens. Adjust the anamorphic

lens vertically for correct alignment. See the instructions accompanying the UH480 attachment kit for fine

tuning the lens position and screen image. Instructions are downloadable from http://www.panamorph .com.

When the image is correct, tighten the knobs against the bracket. Test run LENS IN and LENS OUT using

the remote. It is important to note that the lens is vertically oriented to the projected beam coming out of

the bottom half of the projector lens (assuming ceiling mount). Usually, the top of the anamorphic lens

will lie somewhere near the center of the projector lens as shown below.

Note

alignment of

top of lens

Lens knob

4) Configure Operating Speed (optional)

The lens sled has two operating speed modes – FAST and SLOW. FAST is the default from the factory,

and is ideal under most circumstances. The slow mode reduces the forces exerted by the lens on the

mounting system by accelerating and decelerating very slowly, and by limiting the top speed of the lens as

it traverses the sled. Some users set the speed to SLOW when used in conjunction with screen masking

systems to synchronize mask traversal time to sled traversal time.

CONGRATULATIONS!!!! YOU ARE NOW READY TO

ENJOY FULL WIDESCREEN CINEMA IN YOUR HOME

THEATER

.

©Panamorph Inc January 2009 – All rights reserved Page 9

Page 10

ATH2 Owner’s Manual

7 Lens Sled Operation

The status LED indicator behind the plastic window on the ATH2 will flash three times when the unit is

powered ON, and flash when any remote button is pressed. When in standby the LED is off. Once turned

ON, the unit remains in the ON state, even if the power fails and is reinstated.

Buttons:

OFF – Puts the ATH2 in standby mode.

ON –Turns the ATH2 ON.

LENS OUT – Moves to the LENS OUT position.

LENS IN –Moves to the LENS IN position.

PANEL OFF – Switches the logo back light and status LED

off.

PANEL ON – Switches the logo back light and status LED

on.

SLOW – Sets the acceleration/deceleration and maximum

speed for slow (low inertia) traversal.

FAST – Sets the acceleration/deceleration and maximum

speed for rapid traversal.

Note: If LENS IN does not position the lens to the correct

side of the mechanism, see Chapter5 (middle of page 8) to

reverse orientation.

Users of Pronto compatible devices may download an IR

code hex file from the following URL:

http://www.remotecentral.com

The Panamorph ATH2 will appear in the FILES section of

the website as Panamorph M380.

©Panamorph Inc January 2009 – All rights reserved Page 10

Page 11

ATH2 Owner’s Manual

00

8 Rear Panel –Triggers

To use the automatic lens trigger, with a projector or scaler equipped with an external 12V lens trigger, use

a standard double-ended 3.5 mm (1/8 inch) male mono or stereo jack cable. Simply plug the cable into the

projector or scaler lens trigger jack, and then into the ATH2 +12V Trigger In jack. Follow projector or

scaler instructions to configure the lens trigger to send the lens in when the vertical strectch aspect ratio is

selected on the projector. Any voltage change (12V to 0V, 0V to 12V) will automatically turn the sled on

causing it to move to the designated position. When using the trigger, the remote control is not required

after configuration.

NOTE: Plugging a live trigger in will automatically turn the sled on and cause it to move. Stand clear of

the lens path when inserting the trigger cable.

The

Trigger In (tip positive) operates as follows:

+12V LENS IN

0V LENSOUT

NOTE: The input trigger jack may be temporarily overridden by the remote control. When the next

change of voltage at the trigger occurs (up or down), the projector or scaler will take control of the sled.

Optionally, you may use the +12V Trigger Out jack on the rear of the device to control motorized screen

masking. The output jack is toggled to +12V whenever the sled is in the LENS OUT position. The output

trigger voltage is toggled when the lens begins traversal so that masking and lens movement may be

overlapped. Maximum output current is 100mA which is sufficient for most masking screen control

modules. The sled is configured to trigger the masking in when the lens it out, so the signal is opposite the

input trigger.

Trigger Out jack (tip positive) is intended to for use with external masking screens, It operates as

The

follows:

+ 0V Lens is moving to, or is in the LENS IN position. Note this is the inverse of the input signal.

+12V Lens is moving to, or is in the LENSOUT position. Note this is the inverse of the input signal.

The equipment control port is used by OEM projector manufacturers for custom control options. It can be

ignored by installers.

+9v to +12v In

+12v Trigger Out

+12v Trigger In

Auxiliary In

To screen

masking

controller, max

mA

1

From

projector or

OEM equipment

scaler trigger,

min 3.5uA

control port

©Panamorph Inc January 2009 – All rights reserved Page 11

Page 12

ATH2 Owner’s Manual

9 Cleaning & maintenance

The Panamorph system is completely maintenance free. It will deliver many years of trouble free service as

delivered from the factory.

Clean the outside of the lens prisms occasionally with glass cleaner and an appropriate lens cloth. We

recommend cleaning the lens while in the path of the projected beam to clearly observe the surface.

Clean the metal components with a damp cloth, taking care not to drip any water into the enclosure.

The ATH2 internal drive is permanently lubricated. Keep the rail linear bearing clean, dry, and contaminant

free. In case of accidental soiling (i.e. spilled soda), clean all contaminants with water, and finally wipe

down with denatured alcohol. The drive mechanism relies upon a clean rail to operate smoothly. The linear

bearing, and all enclosed bearings are constructed of specialized material to self lubricate. Lubricants will

gum up the mechanism, and possibly produce a film across the projector and lenses.

Never use lubricants of any nature on any part of the mechanism.

©Panamorph Inc January 2009 – All rights reserved Page 12

Page 13

ATH2 Owner’s Manual

10 specifications

Electrical Characteristics

Model ATH2 motorized sled

Power supply 100-240VAC, 50-60 cycles

Power Supply Output 12V DC, .8-1.5A (depending on supply in use)

Operating Voltage 9 -18V DC, .5-1.5A

Operating current draw Avg : 650mA

Standby current draw 60mA

Trigger jacks 3.5 mm mono or stereo jack, 12V tip positive,

100mA max output, 3.5mA minimum trigger input

Auxiliary jack 2.5 mm stereo jack for special OEM control

Remote 3oz, IR emitter

IR Range 50ft from IR sensor

IR Carrier Frequency 38 kHz

Batteries 2 AAA

Certification FCC, CE (ATH2 motor drive unit)

UL Class II (power supply only)

Design Life Greater than 2,000,000 rail traversals

Physical characteristics

Weight 7 lbs.

Dimensions See accompanying drawings

©Panamorph Inc January 2009 – All rights reserved Page 13

Page 14

ATH2 Owner’s Manual

Dimensions

Center of lens

motor side

Center of lens

pulley side

©Panamorph Inc January 2009 – All rights reserved Page 14

Page 15

ATH2 Owner’s Manual

©Panamorph Inc January 2009 – All rights reserved Page 15

Page 16

ATH2 Owner’s Manual

Warranty

Panamorph Inc, warrants this product to be free of defects in original

workmanship and material for a period of twenty four months from the date of

manufacture. During this period, a defective unit may be repaired or replaced,

at the discretion of Panamorph, Inc., by returning it in its original packaging

with a copy of your receipt. This warranty does not cover damage resulting from

tampering, lack of prudent care, accident or misuse (including contravention of

cautions stated in the instructions), or any cosmetic damage not reported within

15 days of purchase. All liability for damage is limited to the cost of the product

and does not include incidental injury or peripheral damage to other equipment,

persons, or property. Panamorph Inc. is not responsible for personal injury

resulting from faulty installation. A service charge may be applied to any

returned product requiring cosmetic attention, or to the repair of any damage

not covered under this warranty

©Panamorph Inc January 2009 – All rights reserved Page 16

Loading...

Loading...