Page 1

Confidential

Technical manual

Thermal printer unit

EU-T532/T542

English

4012872

Issued Date 199 , ,

Issued by

Page 2

Rev. A i

M-T532/T542 Technical Manual

Confidential

CONFIDENTIALITY AGREEMENT

BY USING THIS DOCUMENT, YOU AGREE TO ABIDE BY THE TERMS OF THIS AGREEMENT.

PLEASE RETURN THIS

DOCUMENT IMMEDIATELY IF YOU DO NOT AGREE TO THESE TERMS.

❏ This document contains confidential, proprietary information of Seiko Epson Corporation or its affiliates. You

must keep such information con fident ial. If the us er is a busin ess en tity or org aniz ation, you mus t limit disclos ure

to those of your employees, agents and contractors who have a need to know and who are also bound by

obligations of confidentiality.

❏ On the earlier of (a) termination of your relationship with Seiko Epson, or (b) Seiko Epson’s request, you must

stop using the confidential information. You must then return or destroy the information, as directed by Seiko

Epson.

❏ If a court, arbitrator, government agen cy or t he like or ders you to disclos e a ny confid ent ial in forma ti on, you must

immediately notify Seiko Epson. You agree to give Seiko Epson reasonable cooperation and assistance in the

negotiation.

❏ You may use confidential information only for the purpose of operating or servicing the products to which the

document relates, unless you obtain the prior written consent of Seiko Epson for some other use.

❏ Seiko Epson warrants that it has the right to disclose the confidential information. SEIKO EPSON MAKES NO

OTHER WARRANTIES CONCERNING THE CONFIDENTIAL INFORMATION OR ANY OTHER

INFORMATION ON THE DOCUMENT, INCLUDING (WITHOUT LIMITATION) ANY WARRANTY OF TITLE

OR NON-INFRINGEMENT. Seiko Epson has no liability for loss or damage arising from or relating to your use of

or reliance on the information on the document.

❏ You may not reproduce, store or transmit the confidential information in any form or by any means (electronic,

mechanical, photocopying, recording, or otherwise) without the prior written permission of Seiko Epson.

❏ Your obligations under this Agreement are in addi tion to a ny other lega l obl iga ti ons. Seiko Epson does not wa iv e

any right under this Agreement by failing to exercise it. The laws of Japan apply to this Agreement.

Cautions

❏ Should any discrepancy exist between the contents of this document and the provisions of the "Master Contract"

or "Specifications," the latter shall take precedence over the former.

❏ We shall not be responsible for any troubles that might occur from the application of this document by customer

either to a machine other than this product, or to a drive circuit or other device that is the industrial property of a

third party.

❏ No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation.

❏ The contents of this document are subject to change without notice. Please contact us for the latest information.

❏ While every precaution has been taken in the prepa ra ti on of t his d ocument, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties

for damages, loss es, c osts, or expe nses i ncu rred by the purcha se s or thi rd par ties as a resu lt of: acci dent, m isus e, or

abuse of this product or unauthoriz ed modifi cation s, repairs , or a lterations to th is product , or (excludin g the U. S.)

failure to strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options

or any consumable products other than those designated as Original EPSON Products or EPSON Approved

Products by Seiko Epson Corporation.

Page 3

ii Rev. A

Confidential

Trademarks

EPSON® is a registered trademark of Seiko Epson Corporation.

General Notice: Other product and company names used herein are for identification purposes only and may be

trademarks of their respective companies.

Points That Must Be Observed

To Assure Product Safety

To assure the safe operation of this product, carefully observe the specifications as well as the notes provided below.

Seiko Epson Corporation will not bear any responsibility for any damage or injuries arising from use of this product

that is not in accordance with the specifications and the notes provided below.

Notes on Head Control

❏ The conditions setting forth the maximum time power can be applied (and the maximum voltage that can be

applied) to electronic components such as the head, motor, and magnets must be observed.

If the maximum time power can be applied (or the maximum voltage that can be applied) is exceeded, the components

mentioned above could overheat and start a fire or beg i n to smoke.

❏ Always include protective circuitry governing the length of time power is applied and the amount of current that

is applied when designing the drive and control circuits for the head, motor, magnets, etc.

If protective circuitry is not included, misoperation of the printer control circuits could cause the comp onents mentioned

above to overheat and begin to smoke or burn.

Notes on Handling

❏ The case must be designed so that movable parts such as gears, etc., are not exposed.

Touching moving parts could cause a laceration or other injury.

Page 4

Rev. A iii

M-T532/T542 Technical Manual

Confidential

About This Manual

This manual is consisted of the following chapters.

Symbols

Notes in this manual are identified by their level of importance, as defined below.

CAUTION:

Observe cautions to avoid minor injury to yourself, damage to your equipment, or loss of

data.

Note:

Notes have important information and useful tips on the operation of your equipment.

Chapter 1

Features and Specifications

This chapter contains features, general specifications for the

EU-T532/T542.

Chapter 2

Operation Principle

This chapter contains the outline and principles of

mechanisms.

Chapter 3

Handling

This chapter contains precautions on handling, paper

loading/unloading pap er an d rem ovi ng jamm ed pap e r.

Chapter 4

Maintenance

This chapter contains cleaning, inspection, lubrication and

tools.

Chapter 5

Repair

This chapter contains repair levels, repair procedure and

troubleshooting.

Chapter 6

Assembly and Disassembly

This chapter contains assembly and disassembly for the unit s

and the modules of the EU-T532/T542.

Appendix

Appendix contains the exploded, and the lubrication

diagrams of the EU-T532/T542.

Page 5

iv Rev. A

Confidential

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Chapter 1

Features and Specifications

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Configuration and Module Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Module Combinations and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2

Operation Principles

Outline of Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Paper Roll Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Paper Holding Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Paper Load-absorbing Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Paper NE Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Printer Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Drive Force Transmission Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Printing Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Paper Guide Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Detector Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Autocutter Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Cut Sheet Presenter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Paper Carrying Operation (With Loop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Paper Carrying Operation (Without Loop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Retract Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Detector Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Control Circuit Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Memory Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Chapter 3

Handling

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Transport Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Carrying Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storage Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Opening/Closing Units and Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Paper Roll Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Printer Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Cut Sheet Presenter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Loading/Removing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Removing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Removing Jammed Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Removing Jammed Paper in the Cut Sheet Presenter Module . . . . . . . . . . . . 3-8

Removing Jammed Paper in the Printer Module . . . . . . . . . . . . . . . . . . . . . . . 3-8

Paper NE Detector Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Page 6

Rev. A v

M-T532/T542 Technical Manual

Confidential

Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Performing the Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Self Test End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

POWER LED (Power Supply Error): Green . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

PAPER OUT LED (Paper-End Error): Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

ERROR LED (Error): Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Chapter 4

Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Thermal Head Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing Stains (Except for the Thermal Head) . . . . . . . . . . . . . . . . . . . . . . . 4-2

Removing Dirt and Dust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Removing Foreign Matter When the Cutter Locks . . . . . . . . . . . . . . . . . . . . . . 4-2

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Daily Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Periodic Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Lubrication Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Lubrication Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Lubricant List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Chapter 5

Repair

Repair Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Repair Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Chapter 6

Assembly, Disassembly

Small Parts Abbreviation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Component Configurations Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Unit Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Module Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Unit Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Cover, circuit board A/B and Control circuit board module . . . . . . . . . . . . . 6-30

Paper Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Cut sheet presenter module, Holding plate, printer, Plate, lower paper guide,

Plate, paper guide holder, and Holder, paper roll . . . . . . . . . . . . . . . . . . . . . . 6-34

Module Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Paper roll supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Cut sheet presenter module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Appendix

EU-T532/T542 Exploded Diagram (Type 1 and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

EU-T532/T542 Exploded Diagram (Type 3 and 4) . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Paper Roll Supply Module Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Printer Module Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Cut Sheet Presenter Module Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Paper Roll Supply Module Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Printer Module Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Cut Sheet Presenter Module Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Page 7

vi Rev. A

Confidential

Page 8

Rev. A Features and Specifications 1-1

EU-T532/T542 Technical Manual

秘秘秘秘 /Confidential

Chapter 1

Features and Specifications

Features

The EU-T532/T542 (EU-T532 for 79.5 mm {3.13"} paper width/ EU-T542 for 82.5 mm {3.25"}

paper width) is designed to be used for issuing tickets and receipts at banks, kiosks and other

similar locations. The features of the EU-T532/T542 are as follows:

❏ High speed receipt issuing: 150 mm/s {5.9"/s} maximum

❏ High reliability: 600,000 receipt issue

❏ Length of receipt: 228.4 mm {9"} maximum

❏ Available for large paper roll core dimensions: 254 mm {10"} diameter maximum

❏ Supports ESC/POS

equivalent commands

❏ Able to print bar codes (fence and ladder) and graphics

❏ Options available for all models:

• Japanese Kanji model: Supports JIS Level 1 and 2

• Simple Chinese model: Supports GB50007-85

• Traditional Chinese model: Supports BIG5 Level 1 and 2

❏ Optional cut sheet retracting mechanism can be used for the EU-T532/T542 Type 2 and 4

❏ Able to perform the remote monitoring using a status monitor

Page 9

1-2 Features and Specifications Rev. A

秘秘秘秘 /Confidential

System Configuration and Module Names

The whole systems is called the “EU-T532/T542,” and each unit is called a “module” which can

be separated from the others. The EU-T532/T542 has four types, type 1 to 4, depending on the

combination of the modules. (See “Module Combinations and Specifications” on page 1-4.) The

configurations of the modules are as follows:

Figure 1-1 EU-T532/T542 appearance (Type 1 and 2)

Figure 1-2 EU-T532/T542 appearance (Type 3 and 4)

paper roll supply modu le

control circuit board module (inside)

printer module

cut sheet presenter module

holding plate, printer

printer module

cut sheet presenter

module

control circuit board module

*The mounting place for the contro l circui t

module will differ depending on users.

Page 10

Rev. A Features and Specifications 1-3

EU-T532/T542 Technical Manual

秘秘秘秘 /Confidential

Specifications

The specifications of the EU-T532/T5 42 are shown belo w. Refer to specificat ions for th e EU-T532

and the EU-T542 issued by Seiko Epson Corporation for details.

Table 1.1 Specifications

Item

Specification

Paper roll Outside diameter

254 mm {10"}

Paper width

EU-T532: 79.5 ± 0.5 mm {3.13 ± 0.02"}

EU-T542: 82.5 ± 0.5 mm {3.25 ± 0.02"}

Paper carrying speed

150 mm/s {5.9"/s} maximum

Paper length to be

presented and retracted

Issuing the cut sheet

(Receipt printing)

76.2 to 228.6 mm {3" to 9"}

(When the cut sheet is looped)

76.2 to 3000 mm {3" to 118.1"}

(When the cu t sh e et is not looped )

Retracting the cut sheet 76.2 to 228.6 mm {3" to 9"}

(When the cut sheet is ejected downward of the cut

sheet presenter module: Type 2 and 4)

Print speed

150 mm/s {5.9"/s} maximum

Print width

72 mm {2.84"} maximum (recommended)

Reliability Receipt printing

600,000 times

Cut sheet retracting

60,000 times

Printer

Mechanism: 15,000,000 lines

Thermal head: 100 km {62.14 miles}

Paper roll Specified thermal paper

Original paper No.: P350 KSP

Original paper No.: TF50KS-E NIPPON PAPER

INDUSTRIES CO.,LTD

Original paper No.: KF50 KANZAN

Original paper No.: PD160R

OJI PAPER MFG.CO., LTD

Original paper No.: TF11KS-ET NIPPON PAPER

INDUSTRIES CO.,LTD

Original paper No.: TF51KS-X1 NIPPON PAPER

INDUSTRIES CO.,LTD

Original paper No.: PD200N

OJI PAPER MFG.CO., LTD

Original paper No.: AFP234 MITSUBISHI PAPER MILLS

CO., LTD

A different paper type may give a different print

quality.

Paper thickness 60 to 150 µm

Page 11

1-4 Features and Specifications Rev. A

秘秘秘秘 /Confidential

Module Combinations and Specifications

The EU-T532/T542 can be used as four different types by the mod ule c ombinations. The mod ule

combinations, functions and specifications are as follows:

(*): The printer pulls a cut sheet that has been forgotten in the print er an d ejects it to the low er part of the cut

sheet presenter module.

Environmental condition Operating temperat ure 0 to 50°C

Operating humidity 10 to 80% RH

Item

Type 1

Type 2

Type 3 Type 4

Functions Paper roll is held by

a fixed shaft.

Yes Yes

Cut paper is

advanced by a cut

sheet presenter.

Yes Yes Yes Yes

Cut sheet is

retracted if the user

forgets to remove

the paper.

Yes (*)

Yes (*)

Module

combination

Paper roll supply

module

Yes Yes

Printer module

Yes Yes Yes Yes

Control circuit

board module

Yes Yes Yes Yes

Cut sheet presenter

module

Yes Yes

(with a retracting

function)

Yes Yes

(with a retracting

function)

Mass

Approximately

5.5 kg

{12.13 lb}

Approximately

5.5 kg

{12.13 lb]

Approximately

2 kg

{4.41 lb}

Approximately

2 kg

{4.41 lb}

External dimensions

(W × D × H): mm {inch}

176

×

520.7

×

231.4

{6.93 × 20.5

×

9.11"}

176 × 520.7

×

231.4

{6.93 × 20.5 × 9.11"}

139.3 × 174.6

×

165

{5.48 × 6.85 × 6.5"}

139.3 × 174.6

×

165

{5.75 × 6.85 × 6.5"}

Table 1.1 Specifications

Item

Specification

80

50

10

0

0 5 10 20 30 40 5550

+

50°C 35%

40°C 58%

34°C 80%

Print quality is

guaranteed.

Operation is

guaranteed

.

Page 12

Rev. A Operation Principles 2-1

EU-T532/T542 Technical Manual

Confidential

Chapter 2

Operation Principles

Outline of Mechanism

The EU-T532/T542 consists of four modules: the paper roll supply module, the printer module,

the cut sheet presenter module, and the control circuit board module.

Paper Roll Supply Module

The paper roll supply module holds a large diameter paper roll and gu ides the paper to the

printer mod ule. This modu le consists of the paper holding part, the paper load-absorbing

mechanism, and the paper nearend detector. The appearance of this module is shown below.

Figure 2-1 Paper roll supply module appearance

frame, main

paper nearend detector

screw, paper nearend detector

holder, paper roll

(Inside: shaft, paper roll)

holding plate, pape r roll

paper roll hold unit

plate, fixed

frame, paper roll tension

(Inside: spring, pape r roll tension)

shaft, paper roll tension roller

roller, paper roll tension

Page 13

2-2 Operation Principles Rev. A

Confidential

Paper Holding Section

The paper roll holding mechanism is a shaft support type. The paper roll holding section

consists of the

shaft, paper roll

fixed to the

frame, main a sse m b l y

, the

holder, paper roll A

(for the inner diameter of the paper core: 25. 4 mm {1 inch}) that fits the size of t he paper roll core

used, and

paper roll hold unit

that holds the sides of the paper roll.

The

paper roll hold unit

is supported by the

holding plate, paper roll

so that it can open/

close. The

plate, fixed

slides into the groove of the

shaft, paper roll

and is automatically

locked when the

paper roll hold unit

pushes against the

shaft, paper roll

. To open the

paper

roll hold unit

, see the illustration (a sticker) on the

plate, fixed

: slightly lif t the bottom of the

plate, fixed

in the direction of the arrow (upwards) to release the lock, and then pull it toward

the near side to open the unit. (For the illustrati on of the sticker, see page 3-6.)

Note:

If the paper inner core dimension differs from the

holder, paper roll A

due to the paper thickness, you

can replace it with the

holder, paper roll B

(for the inner diameter of the paper core: 50.8 mm {2 inch})

or the

holder, paper roll C

(for the inner diameter of the paper core: 76.2 mm {3 inch}) packed in the

box. (See page 6-37, “Assembly and Disassembly.” for replacement.)

Paper Load-absorbing Mechanism

The paper load-absorbing mechanism consists of four parts: the

rolle r, pape r ro l l t ensi o n

, the

shaft, paper roll tension roller

, the

frame, paper roll tension

, and the

spring, paper roll

tension

. The

roller, paper roll tension

receives the paper tension. The

shaft, paper roll

tension roller

supports the

roller, paper roll tension

so that the

roller, paper roll tension

can

rotate. The

frame, paper roll tension

fixes the previous two parts and is mounted on the

shaft,

paper roll

. The

spring, paper roll tension

is hooked on one end to the

frame, main

assembly

, and on the other end to the

frame, paper roll tension

.

Using the paper tensile force generated when feeding the paper, this mechanism oscillates the

roller, paper roll tension

around the

shaft, paper roll

, and reduces the paper feeding load due

to inertia of the paper ro ll.

Note:

In order to use the function of this mechanism properly, paper must be fed along the paper rout e indicated

in the illustration on the

paper roll hold unit

. Feeding paper along the paper route other than the route

in the illustration may cause improper operation or printing disorders.

Paper NE Detector

The

paper NE detector

has two kind of detections, the primary NE detection and the

secondary NE detection. The primary NE detection can detect the amount remaining on the

paper roll using a reflecting photo sensor. After the primary NE detection, the secondary

detection can be used to return the status when the paper is fed to the length specified by the

memory switch setting. (See SW No. 2, 3 in Table 2-8 [page 2-22])

The

paper NE detector

is mounted on the

frame, paper roll tension

, and is secured with the

screw, NE detector

. The position of th e

paper NE detector

can be altered to adjust the sett ing

for the amount remaining on the paper roll. (See “Paper NE detector setting method”on page

3-9.)

Page 14

Rev. A Operation Principles 2-3

EU-T532/T542 Technical Manual

Confidential

Printer Module

The printer module has a printing mechanism with the paper feeding and a cutting mechanism

to cut the paper.

The printer consists of the following six mechanisms: the drive force transmission mechanism,

the paper feed mechanism, the printing mechanism, the paper guide mechanism, the detector

mechanism, and the autocutter mechanism.

Figure 2-2 Printer module appearance

Drive Force Transmission Mechanism

This mechanism consists of the

motor, paper feed, receipt, B

(fixed to pinion), the

gear,

reduction

, the

gear, idle r

, and the

gear, platen

. The printer uses a stepping motor, the

rotation force of which is reduced in sequence by the

gear, reduction

and the

gear, idl er

before being transmitted to the

gear, platen

. (The arrows in the figure below indicate the

direction of the gear rotation.) The

gear, platen

is mounted to the frame platen unit and

separates from the

gear, idle r

when the

platen

is open.

Figure 2-3 Drive force transmission mechanism

printer module

holding plate, printer

gear, platen

gear, idler

gear, reduction

motor, paper feed, receipt, B

Page 15

2-4 Operation Principles Rev. A

Confidential

This printer uses a 4-phase bi-polar stepping motor driven by 24 V voltage controlled 2-2 phase

excitation. The maximum drive frequency of 2-2 phase excitation is 1200 pps. [pps: pulses per

second]

Paper Feed Mechanism

This mechanism consists of the paper feed mechanism and the platen-open mechanism.

Paper feed mechanis m

The paper feed mechanism consists of the

platen

(paper feed roller) and the

thermal head

.

When the

motor, paper feed, receipt, B

rotates counterclockwise as viewed from the shaft,

the gear train transmits the motion to the

platen

which rotates in direction A.

Figure 2-4 Paper feed mechanism

Paper feed operation during prin ting

The

platen

presses the thermal paper against the

thermal head

with a constant force. When

the

platen

rotates in direction A, the thermal paper advances in direction B.

Figure 2-5 Paper feed operation during printing

thermal head

platen

motor, paper feed, receipt, B

A

B

platen

thermal paper

A

Page 16

Rev. A Operation Principles 2-5

EU-T532/T542 Technical Manual

Confidential

Platen-open mechanism

The platen-open mechanism is used for the following purposes:

• Paper loading when using the printer with the curved path type. (Excluding when

using semi-autoloading mode.)

• Removing a paper jam when the paper jam has occurred

• The

thermal head

and the

platen

cleaning

The mechanism consists of the

frame, platen

, the

lever, platen

, the

shaft, platen

, the

spring,

lever

, the

lock lever

, the

spring, lock lever

, and the

pushplate , p l aten, B

.

In the

frame, platen

, the

platen

is mounted. The

lever, platen

is operated by hand to open

the frame platen unit. The

shaft, platen

connects the

lever, platen

and the

frame, platen

to

the

frame, base

in a manner which allows them to rotate. The

spring, lever

pulls the

lever,

platen

in the opposite direction of arrow A when the

platen

is open. The

lock lever

is located

on the gear train side of the

frame, platen

and locks the frame platen unit to the

frame, base

.

The

spring, lock lever

(inside the

lock lever

) pushes the

lock lever

back. The

pushplate,

platen, B

is secured on top of the

frame, platen

and covers the

fixed blade

.

When the frame platen unit is closed, the

platen

is in the print- ready position where the

gear,

platen

and the

gear, idler

are engaged and the power can be transmitted readily. Also, the

lock lever

is locked at a part of the

frame, base

to prevent the gears from disengaging.

To open the

platen

, turn the

lever, platen

in the direction of arrow A as shown in Figure 2-6.

Simultaneously, the

lock lever

is released and the frame platen unit is opened. To close the

platen

, turn the

lever, platen

in the opposite direction of arrow A until the lever stops.

Figure 2-6 Platen-open mechanism

frame, platen

shaft, platen

frame, base

spring, lock leve r

spring, lever

lever, platen

lock lever

gear, idler

gear, platen

A

< platen-open >

< platen-close >

push plate, platen, B

*The cover, gear is removed in these figures.

Page 17

2-6 Operation Principles Rev. A

Confidential

Printing Mechanism

This mechanism consists of the

thermal head

which has the head heating elements a rrange d in

a series and has a driver IC for controlling voltage to the head heating elements, the

platen

which is also used for the paper feed mechanism as well as this mechanism (the

thermal head

is also used for both mechanisms), and the

spring, press head

. The

platen

presses the thermal

paper wrapped around the

platen

against the head heating elements pressed by the

spring,

press head

. When the elements are activated, the paper will be heated at the designated points,

resulting in the printing actio n.

Printing operation principles

The cross-sections of the

thermal head

and the thermal paper are shown below. Printing is

performed in the following steps:

Figure 2-7 Cross -section of thermal head and thermal paper

1. Drive pulses are sent to the designated dot electrodes in accordance with the print signal.

2. Since the resistor layers are formed at the top of each electrode inside of the

thermal head

,

the resistor layers are heated up when the drive pulses are sent to the electrodes.

3. The thermal energy of the heated resistors is transferred via the protective layer of the

thermal head

to the surface of the thermal paper, and the heat-sensitive layer of the paper

changes color, thus forming the printed character.

<cross-section of thermal paper>

<cross-section of thermal head>

<top view of thermal head>

base

heat- sensitive layer

resistor layer

protective layer

electrode layer

ceramic base plate

glaze layer

electrode laye r

electrode laye r

resistor layer

Page 18

Rev. A Operation Principles 2-7

EU-T532/T542 Technical Manual

Confidential

Data input and printing

The

thermal head

consists of the head heating elements, the head driver, which controls or

drives the head heating elements, and the

thermistor,

which detects the temperature of the

thermal head

. The serial print data input from Data In (DI1) is synchronized to the CLOCK

(CLK) input, and temporarily placed in the SHIFT REGISTER. Using the LATCH (/LAT) signal

timing, these data are then stored in the LATCH REGISTER. Activated by the STROBE signals

(/STR1, /STR2), the stored print data is used to control the gate ON condition for the head

heating element drive pulse.

This printer is equipped with two strobes, and can print using a maximum of four divisions.

The drive pulse width is controlled by the control circuit board module.

Figure 2-8 Thermal head block diagram

Table 2-3 Strobe and Dot Number

STROBE No. Dot No. Dots/STROBE

1 1 to 320 320

2 321 to 640 320

*The STB terminals are pulled down in the con trol IC.

64 output each

Page 19

2-8 Operation Principles Rev. A

Confidential

Paper Guide Mechanism

This mechanism consists of the paper guide mechanism. The paper path consists of the

paper

guide, straight, front

and the

paper guide, straight, back

. The paper path is shown below.

Figure 2-9 Paper path

Detector Mechanism

This mechanism consists of the paper-end mechanism, the platen-open detector mechanism, the

head temperature detector mechanism, and the black mark detector mechanism.

Paper-end detector mechanism

The paper-end detector mechanism is located inside the paper guide mechanism to detect the

end of the thermal paper and the paper insertion state in the semi-autoloading mode. This

mechanism consists of the

transparent photo sensor

, the

lever, paper detector

which

presses against the thermal paper and the

spring, paper detector

which pulls the

lever,

paper detector

.

Figure 2-10 Paper -end detector circuit

paper guide, straight, back

paper guide, straight, front

platen

paper

<printer side>

paper-end detector signal

Photo interrupter

Pin No.

220

Ω

75 K

Ω

13 V

13

V

DD

11

7, 8, 10

GND

Page 20

Rev. A Operation Principles 2-9

EU-T532/T542 Technical Manual

Confidential

The

transparent photo

sensor is in a high state (HI) when the paper is present, and in a low

state (LOW) when the paper is not present because the

lever, paper detector

blocks light to

the sensor. When the end of the thermal paper passes through the paper guide, the

lever,

paper detector

operates as shown in Figure 2-11. At this time, the output level from the

transparent photo sensor

varies as shown in Figure 2-12, then the absence of paper is

detected. When the semi-autoloading function is used, the insertion of paper changes the status

from “no paper” to “paper.” Since the outpu t l evel cha nges fro m LOW to H I, the st atus c hanges

to “paper”; then the semi-autoloading function is initiated.

Figure 2-11 Paper-end detector mechanism

Figure 2-12 Paper-end detector operation

platen

thermal head

transparent photo

sensor

lever, paper detector

paper guide, straight, front

frame, base

paper

<paper-present condit ion >

<paper-absent cond it io n>

paper guide, straight, back

paper-end signal

conductive confirma tion

paper-end detection

Page 21

2-10 Operation Principles Rev. A

Confidential

Platen-open detector mechanism

The platen-open detector mechanism has a

microswitch

which detects whether the

platen

is

open (printing impossible because the

thermal head

is away from the

platen

) or closed

(printing possible). The

microswitch

can be OFF only when the

frame, platen

is perfectly

closed, and at all other times is ON.

Figure 2-13 Platen-open detector circuit

Head temperature detector mechanism

The

thermal head

has a

thermistor

to detect the temperature of the

thermal head

.

Black mark detector mechanism

The black mark mechanism is a device whi ch can be at tached insi de the paper g uide mechanism

to determine the printing position when using pre-p ri nted ther mal pap er. Th is mec hani sm uses

the reflective photo sensor.

Figure 2-14 Black mark detector circuit

<printer side> Pin No.

platen open

platen open

The pin No.s 14 and 15 can be reversed.

14

15

SW2

SW1

Pin No.

black mark de tector

output

<printer side>

220

Ω

0 to 100 K

Ω

10 K

Ω

13

V

DD

12

7, 8, 10

GND

Page 22

Rev. A Operation Principles 2-11

EU-T532/T542 Technical Manual

Confidential

Black marks are detected through changes in output level from the reflective photo sensor. The

changes in reflectivity between the pre-printed black marks and blank areas of the thermal

paper cause the amount of light returning to the sensor to vary; then the sensor output level is

also varied as shown in Fig ure 2-15 . These v ariat ions ar e used t o detec t the black mark. Si nce the

relationship between the black mark an d the pri nt positi on can be specified in the pr inter set up,

detecting the black mark permits the correct positioning of the paper.

Figure 2-15 Black mark detecting operation

Autocutter Mechanism

This mechanism consists of the fixed blade mechanism, the movable cutter blade mechanism

and the emergency cutter mechanism.

The basic principl e of t he aut ocutt er mecha nism is an appl icati on of the sci ssors princi ple, where

the paper is cut by two crossi ng blades. A config urati on which al lows the two blades to separate

has been adopted so that the

fixed blade, H

separates from the

movable cutter blade, full, H

when the

platen

is open.

Fixed blade mechanism

This mechanism is mounted on the frame platen unit. This configuration consists of the

fixed

blade, H

which cuts the paper directly, the

spring, fixed b l ade

which stabilizes the vertical

positioning of the

fixed blade, H

, and the

cover, fixed blade

which covers the

fixed blade,

H

and is a paper guide as well as makes the operation to open the

platen

safe.

Figure 2-16 Fixed blade mechanism

black mark de tector signal

conductive confirmation

black mark detection

spring, fixed blade

fixed blade, H

cover, fixed blade

frame, platen unit

Page 23

2-12 Operation Principles Rev. A

Confidential

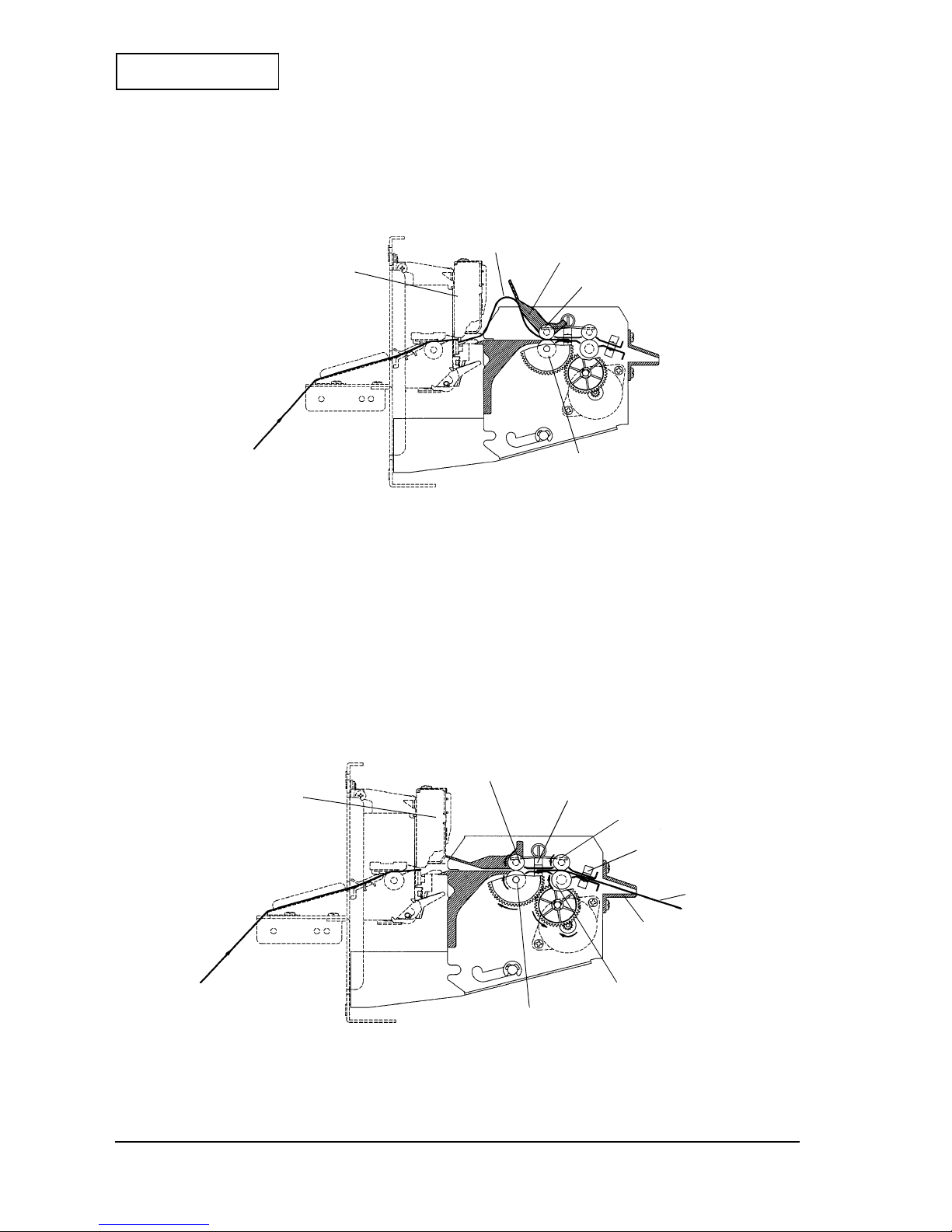

Movable cutter blade m ec h an ism

This mechanism is mounted on t he

frame, base

. The drive force transmission mechanism is on

the

cover, cutter, H

side. The

motor, cutter, H

, which is a DC brush motor attached the

gear,

cutter motor

. It supplies the power and is attached on the

cover, cutter, H

with screws. The

gear, cutter worm, H

is supported by the

shaft, reduction A/C

, and the

gear, cutter drive,

H

is attached with push nuts to the

shaft, cutter drive gear

fixed on the

cover, cutter, H

.

After being transmitted through the

gear, cutter worm, H

, the power is transmitted to the

gear, cutter drive, H

.

The rotational movement of the

gear, cutter drive, H

is translated to the back and forth

movement of the

movable cutter blade, full, H

by being engaged the

shaft, movabl e cu tte r

blade drive

with the oval hole of the

movable cutter blade, full, H

on the

frame, cutter

.

Also, the

microswitch

attached to the

cover, cutter, H

is connected to the

gear, cutter drive,

H

, enabling it to detect the position of the

movable cutter blade, full, H

. The lead wires of the

motor, cutter, H

and the

microswitch

are bound together and connect to the

circuit board

.

The

shaft, movable cutter blade

is on the

frame, cutter

side. The

receiver, movable

cutter blade

, the

spacer, movable cutter blade

, the

spring, movable cutter blade

and

the

washer, movable cutter blade spring

are mounted on the

shaft, movable cutter blade

in a group with a push nut.

When putting the

cover, cutter, H

and the

frame, cutter

together, engage the

shaft, movable

cutter blade drive

with the oval hole of the

movable cutter blade, full, H

, and secure the

cover, cutter, H

and the

frame, cutter

with screws.

Figure 2-17 Movable cutter blade mechanism

gear, cutter drive, H

shaft, cutter drive gear

cover, cutter, H

shaft, movable cutter

blade drive

gear, cutter worm, H

shaft, reduction A/C

(inside the gear, cutter

worm: dot lined part)

frame, cut ter

movable cut ter blade , full, H

receiver, movable

cutter blade

spring, movable

cutter blade

washer, mo vab l e

cutter blade spring

shaft, movable cutter blade

spacer, movable cutter blade

motor, cutter, H

microswitch

gear, cutter motor

Page 24

Rev. A Operation Principles 2-13

EU-T532/T542 Technical Manual

Confidential

Auto cutting operation

The

autocutter

will operate when the frame platen unit is closed and a paper is loaded. (The

frame platen unit can be closed when the

movable cutter blade, full, H

is in the standby

position. The auto cutting operation is perform ed in the followi ng steps:

1. Drive the

motor, cutter, H

in the forward rotation.

2. The

microswitch

is switched from OFF (open) to ON (closed), while the

motor, cutter, H

continues to rotate in the forward rotation. The

movable cutter blade, full, H

intersects

with the

fixed cutter blade, H

and cuts the paper from the right to the left, to the direction

of the first column.

3. After cutting the paper, the

movable cutter blade, full, H

starts to return to the home

position.

4. As the

movable cutter blade, full, H

approaches the home position, the

microswitch

is

switched from ON (close) to OFF (open); then the

motor, cutter, H

stops rotating and the

brake is applied.

Figure 2-18 Auto cutting operation

Figure 2-19 Auto cutting control example

fixed blade, H

spring, fix e d blade

movable cut ter blade , full, H

cutter motor forward driving

cutter motor brake

switch signal rectifying

waveform

Page 25

2-14 Operation Principles Rev. A

Confidential

Note:

If the

movable cutter blade, full, H

can not be returned to the home position because of a foreign

matter locking the blade when powered by the

motor

, rotate the knob on the

gear, cutter w o r m, H

with a tool such as a ball-point pen or tweezers to move the

movable cutter blade, full , H

to the home

position. The window on the

cover, cutter, H

can be used to check if the

movable cutter blade,

full, H

has returned to the home position.

Figure 2-20 Home position check

window

<Movable cutter blade in the home position>

knob

Page 26

Rev. A Operation Principles 2-15

EU-T532/T542 Technical Manual

Confidential

Cut Sheet Presenter Module

The cut sheet presenter module has a mechanism to carry the paper printed and cut by the

printer module to the paper exit. Also, it has an optiona l cut sheet retr acting func tion to r etract a

cut sheet when the cut sheet is not removed.

Figure 2-21 Appearance of cut sheet presenter module

Paper Carrying Operation (With Loop)

A paper carrying operation is performed at the same time with the start of the paper feeding of

the printer module. The

motor, paper fe ed rec eip t, B

rotates in the clockwise direction as

seen from the shaft direction, and the

roller, cut sheet presenter

rotates in the clockwise

direction via the gears. The

roller, cut sheet hold

is pressed to the

roller, cut sheet presenter

by a spring. The first

roller, cut sheet presenter

and the

roller, cut sheet hold

, and the

second

roller, cut sheet presenter

and the

roller, cut sheet hold

are connected with the

belt,

cut paper presenter transmission

(not shown) and rotate in the same direction.

The paper sent from the printer module is fed along the paper guiding part, and carried between

the first

roller, cut sheet presenter

and the

roller, cut sheet hold

. When the tip of the paper

reaches the detection position, the

motor, paper feed receipt, B

stops temporarily.

Figure 2-22 Start of the cut sheet carrying

carried paper sensor

roller, cut sheet hold (first)

cut sheet

roller, cut sheet presenter (second)

motor, paper feed,

receipt, B

roller, cut sheet hold (second)

roller, cut sheet presenter (first)

Page 27

2-16 Operation Principles Rev. A

Confidential

The tip of the paper sent from the pri nter mod ule is in the stand by state be tween the first

roller,

cut sheet presenter

and the

roller, cut sheet hold

, and the paper is contin uously fed fr om the

printer module. The paper pushes up the

paper guide, upper

and temporarily forms a loop.

Figure 2-23 Cut Sheet with Loop

When the paper feed from the printer module is finished, the

motor, paper feed receipt, B

resumes rotating. At this time, the cutter on the printer module cuts the paper. The cut sheet is

passed from the first

roller, cut sheet presenter

to the second

roller, cut sheet presenter

,

and is carried to the

paper exit

.

When the

carried paper sensor

detects the end of the cut sheet, the

motor, paper feed

receipt, B

will stop. With the cut sheet between the second

roller, cut sheet presenter

and the

second

roller, cut sheet hold

, a series of operations is completed and the cut sheet is ejected

from the

paper exit

.

A

cut sheet presence sensor

is provided near the

paper exit

to detect whether or not the cut

paper is remo ved by a recipient.

Figure 2-24 End of the Cut Sheet Carrying Operation

roller, cut sheet presenter (first)

roller, cut sheet hold (first)

paper guide, upper

cut sheet

autocutter

autocutter

carried paper sensor

roller, cut sheet hold (second)

cut sheet p resence sensor

paper exit

roller, cut sheet presenter (second)

cut sheet

roller, cut sheet hold (first)

roller, cut sheet presenter (first)

Page 28

Rev. A Operation Principles 2-17

EU-T532/T542 Technical Manual

Confidential

Paper Carrying Operation (Without Loop)

The cut sheet can be carried without forming a loop.

Figure 2-25 Cut Sheet Operation without Loop

Note:

During paper carrying operations without a loop, do not pull out the paper.

Retract Function

The retract function retracts the cut sheet inside the unit if the recipient does not take the cut

sheet. The retract mechanism consists of the

frame, paper route change

, the

plate, route

change guide

, the

roller, retract

, the

solenoid

, and the

paper path change sens or

.

The retracting operation is started by a command signal for the retraction. At first, the

paper

route change

performs the paper path change operation to retract the cut sheet. When the

solenoid

linked with the

frame, paper route c h a nge

is energized, the

frame, paper route

change

and the

plate, route change guide

move in direction A. After the

paper route

change sensor

detects the end of the paper route change operation, the

motor, paper feed

receipt, B

begins to rotate in the counterclockwise direction; then through the gears, the

roller,

cut sheet presenter

and the

roller, retract

inside the retracting paper route rotate and the cut

sheet is retracted into the unit through the retracting paper route. The retracted cut sheet will fall

to the bottom of the cut sheet presenter module.

roller, cut sheet hold

cut sheet

roller, cut sheet presenter

Page 29

2-18 Operation Principles Rev. A

Confidential

Figure 2-26 Retract Function

Detector Mechanism

The detector mechanism consists of the

cover, open sensor

, the

carried paper sensor

, the

cut sheet presence sensor

, the

paper path change sensor

, and the

retracted paper

sensor 1

.

Cover open sensor

This sensor detects whether the

upper frame, cut sheet pres e nte r unit

is open or not.

Carried paper sensor

This sensor detects the paper presence in the paper carrying route.

Cut sheet presence sensor

This sensor detects whether or not a recipient has taken the cut sheet.

Paper path chan ge sensor

This sensor detects the retracted paper route change when the cut sheet is not taken.

Retracted paper sensor 1

This sensor detects the paper presence in the retracted paper route.

cut sheet

retracted paper sensor 1

plate, paper route

change guide

paper path change sensor

roller, retract

frame, paper route change

Page 30

Rev. A Operation Principles 2-19

EU-T532/T542 Technical Manual

Confidential

Control Circuit Board Module

The control circuit board module controls all functions of each module and has the interface

connectors and the power supply terminals. Each function can be set by using the DIP switches

and the memory switches.

Figure 2-27 Appearance of the control circuit board module

DIP Switches

The circuit board has two DIP switches (DSW 1/2). Each setting is as follows:

DIP Switch 1

*: Effective only when the serial interface is selected .

Table 2-1 DSW 1

SW No. Function

ON OFF

Default Setting

1 Black mark sensor Enabled Disabled

OFF

2

Interface selection

Refer to Table 2-2

3

4 Serial interface

handshaking

XON/XOFF DTR/DSR or

CTS/RTS

OFF*

5 Serial interface

parity check

Yes No

6 Serial interface

parity selection

Even Odd

7

Serial interface

baud rate selection

Refer to Table 2-3

8

DIP switch 1

DIP switch 2

Page 31

2-20 Operation Principles Rev. A

Confidential

bps: bits per second

DIP Switch 2

(*1): Fixed to OFF

(*2): Effective only w he n th e s eria l in terface is selected.

Table 2-2 Interface Selection

Interface

Switch No. 2 Switch No.3

Parallel interface (IEEE1284) OFF OFF

Serial interface (RS232) OFF ON

Optional interface ON ON or OFF

Table 2-3 Baud Rate Selection

Transmission speed (bps) Switch No.7 Switch No.8

4800 ON ON

9600 OFF ON

19200 ON OFF

38400 OFF OFF

Table 2-4 DSW 2

SW No. Function

ON OFF

Default setting

1

Model type selection Refer to Table 2-5

ON

2

OFF

3

Print density selec tio n

Refer to Table 2-6

4

5 Operation mode

selection

Refer to Table 2-7

6Factory use OFF (*1)

7 I/F pin 6 reset signal-1

Enabled

Disabled

OFF (*2)

8 I/F pin 6 reset signal-2

Enabled

Disabled

Table 2-5 Model Type Selection

Model Switch No.1 Switch No.2

EU-T532 (79.5 mm {3.15"} paper-width model: 576 dots) ON OFF

EU-T542 (82.5 mm {3.25"} paper-width model: 640 dots) OFF OFF

Page 32

Rev. A Operation Principles 2-21

EU-T532/T542 Technical Manual

Confidential

Notes:

・Changes in DIP switch settings (excluding switches 2-7 and 2-8 interfac e reset signal s) are reco gn ized on ly

when the printer power is turned on or when the printer is reset by using the interface.

・If you turn on DIP SWs 2-7 and 2-8 while the printer power is turned on, the printer may be reset, depending on

the signal state. DIP switches should not be changed while the printer power is on.

Memory Switches

Other settings except DIP switches 1 and 2 are set by the memory switches. (The settings are

changed with a

GS (E

command, and also can be changed by using the MEMSW.exe included

with an EPSON Advanced Windows Driver.) The settings of the memory switches are as

follows:

(*1): Effective only in th e s eria l in terface model.

(*2): Effective only in the parallel interface mode l.

Table 2-6 Print Density Selection

Level Print Density Switch No.3 Switch No.4

1

Slightly light

ON ON

2

Normal

OFF OFF

3

Slightly dark

ON OFF

4

Dark

OFF ON

Table 2-7 Operation Mode Selection

Operation mode Switch No.5

Hexadecimal dump ON

Normal

OFF

Table 2-8 Memory Switch 1

SW No. Function

ON (1) OFF (0)

Default setting

1

Reserved

Fixed to OFF OFF(0)

2

3 BUSY condition Receive buffer full Receive buffer full

or offline

ON(1)

4 Receive error Ignored Prints “?” OFF(0) (*1)

5 Auto line feed Always enabled Always disabled OFF(0) (*2)

6 to 8 Rese r ved

Fixed to OFF OFF(0)

Table 2-9Memory Switches 2 to 6

SW No. Function

ON (1) OFF (0)

Default setting

1 to 8

Reserved

Fixed to OFF OFF(0)

Page 33

2-22 Operation Principles Rev. A

Confidential

(*1): •Effective only f or the model type with the paper roll supp ly module

•This setting lets the printer tell the paper neare nd by sending the seco ndary pa per ne arend status when the

specified length of paper is fe d aft er the primary paper neare nd se ns o r in th e paper roll supply modu le

detects the paper nearend.

(*2): Effective only when using with the cut sheet presenter module .

Definition of the primary paper nearend and the secondary paper nearend :

•

The primary paper nearend is defined as when the paper nearend sensor in the paper roll supply module detects

the paper roll nearend.

•

The secondary paper nearend is defined as when the paper is fed for the specific length after the primary paper

nearend is detected.

When the primary and the secondary paper nearends are detected, the status from the printer changes. However,

printer controls, such as the printing stop are not affected.

Table 2-10 Memory Switch 7

SW No. Function

ON (1) OFF (0)

Default setting

1

Reserved

Fixed to OFF OFF(0)

2 Setting for the

secondary paper

near-end position

Refer to Table 2-11

OFF(0) (*1)

3

4 Operation after

cutting

Complete ejection Clamp

OFF(0) (*2)

5 Paper initializing

operation when the

power is turned on

Paper edge is

always cut.

Paper edge is

detected.

6 to 8 Rese r ved

Fixed to OFF OFF(0)

Table 2-11 Setting for Paper Nearend Detecting Position

Paper length

(for the time between detecting the

primary paper nearend with the

nearend sensor and sending the status

of the secondary paper near-end)

Memory SW No.7-2 Memory SW No.7-3

Approximately 5 m {196.85"}

OFF OFF

Approximately 10 m {393.70"}

ON OFF

Approximately 20 m {787.40"}

OFF ON

Approximately 30 m {1181.10"}

ON ON

Page 34

Rev. A Operation Principles 2-23

EU-T532/T542 Technical Manual

Confidential

(*1): Do not set SW 3 to ON in the following condition:

•

The partial cutter is used when the cut sheet pre sent er mo d ule is not used .

When backward paper feeding is enab led , the follo win g pro cess is execut ed .

•

After cutting the paper with a

GS V

command, backward paper feeding is executed. (When the Black

mark sensor is disabled.)

•

The print star ti ng position adju s tment with a

GS (F

command can be set to the backward direction

relative to the cutting position. In this case, the maximum backward correction value is 14 mm {0.55"}

(112 step × 0.125 mm {0.005"} per step).

(*2): Specific offline means the following states.

• Error state except an automatic recovery error state

• Platen open

• Cut sheet presenter module or cover open

• Paper empty

If this switch is turned on, the printer clears the receive buffer when the offline status shown above occurs. Then

the printer executes any real-time command (

DLE ENQ, DLE EOT

) if it is there, and discard s all ot h er da ta.

When the receive buffer is cleared, if this switch is turned on, three bytes of data, 37H, 24H, and 00H, are

transmitted.

Table 2-12 Memory Switch 8

SW No. Function

ON (1) OFF (0)

Default setting

1 to 2

Print control mode

Refer to 2-13 OFF(0)

3 Backward paper

feeding

Enabled Disabled OFF(0) (*1)

4 Autocutter

installation

Not installed Installed OFF(0)

5 Specific offline

operation

Discards receive

data

Keeps receive data OFF(0) (*2)

6 Backward paper

feeding amount

88 steps 108 steps

OFF(0)

7 Test print when the

paper is loaded

Enabled

Disabled

8 Black mark position Initializes the BM

position

Not initialize the BM

position

Table 2-13 Print Control Mode Selection

Default for the print

control mode SW 1 SW 2

Non-divided energi zin g

mode

OFF OFF

Two-part energizing

mode

ON OFF

Four-pa rt energizing

mode

Either ON or OFF ON

Page 35

2-24 Operation Principles Rev. A

Confidential

Page 36

Rev. A Handling 3-1

EU-T532/T542 Technical Manual

Confidential

Chapter 3

Handling

Precautions

Transport Precautions

❏ When shipping the printer, use anti-static packing materials.

❏ Remove a paper roll when transporting the EU-T532/T542.

❏ Make sure to close the

paper roll hold unit

of the paper roll supply module, the

platen unit

of the printer module, and the main unit and the

upper frame, cut sheet presenter unit

of

the cut sheet presenter module when transporting.

Carrying Precautions

❏ Hold the

frame, mai n

and the holding the

plate, printer

of the paper roll supply module

when carrying.

Note:

Do not hold parts other than above such as the

holder, paper roll

(or

shaft, paper roll

) or the

roller, paper roll tension

; otherwise the functions may be affected because of damage or

deformation of parts.

❏ When you put this unit on a place such as a desk, be sure to put it on a flat place; otherwise,

the unit may fall down or a malfunction may occur because of deformation of parts.

Figure 3-1 Correct way of holding the EU-T532/T542

holding plate, printe r

frame, main

hole for ground wire

holder, paper roll

(Inside: shaft, paper roll)

roller, paper roll tension

Page 37

3-2 Handling Rev. A

Confidential

Installation Precautions

❏ When installing the unit, secure firmly four mounting parts at the bottom of the paper roll

supply module to the system side with screws.

❏ Make sure to ground the unit by using the hole for a ground wire. (See Figure 3-1 for the

position.)

Note:

If the system side where the unit is installed is not flat, that could cause deformation of parts and

malfunction. (It is recommended the difference in level is 0.3 mm {0.012"} or less.)

Handling Precautions

Paper roll supply module

❏ Do not apply excessive pressure to the

paper roll hold unit

when opening or closing it;

otherwise, the unit may not open/close properly because of deformation of parts.

❏ Do not touch the light emission or receivi ng surfaces of t he

paper NE detector

, as dirt may

stick to them, or cause damage by static electricity.

Printer module

CAUTION:

Since the thermal head area and the motor surface can become hot right after or

during printing, never touch them with your bare hands; allow about 15 minutes for

them to cool.

❏ Since the EU-T532/T542 contain permanent magnets (in the motor) as well as

electromagnets, they should not be used in an environment with excessive dirt, dust or

metallic dust.

❏ Never print without p ap er inst all ed or wi t h t he head away from the

platen

, because the life

of the

thermal head

may be shortened.

❏ Never pull out the paper (forward or backward) with the head down (against the

platen

).

❏ Do not turn off the power during operations, especially during a cutting operation;

otherwise the cutter blade could be exposed, leaving the

platen un i t

difficult to open.

❏ Since the head heating elements and the driver IC are very delicate, avoid touching them

with any metal objects such as tweezers or screwdrivers.

❏ Open the

platen unit

only when required.

❏ Never touch the surface of the head heating elements and the driver IC, as dirt may stick to

them, affecting the head heating elements or causing damage from static electricity.

Page 38

Rev. A Handling 3-3

EU-T532/T542 Technical Manual

Confidential

❏ Before handling the

thermal head

, use proper body grounding procedures to avoid

damage from static electricity.

❏ Make sure no dust collects on the thermal paper.

❏ Since the printer uses a line thermal print head, condensation must be avoided. If

condensation occurs, do not turn on the printer until it has disappeared.

❏ Do not apply excessive pressure to the

thermal head

connectors.

❏ An FFC can be replaced only ten times; then you must use a new one.

❏ Do not apply excessive pressure to the

lever, platen

when opening or closing the

platen

unit

with the lever.

Cut sheet presenter module

CAUTION:

Since the paper feed motor and the solenoid surface can become hot af ter print ing for

a long period of time, never touch them with your bare hands; allow about 15 minutes

for them to cool.

❏ Since the EU-T532/T542 contain permanent magnets as well as electromagnet s in the motor

and the solenoid part, they should not be used in an environment with excessive dirt, dust

and metallic dust.

❏ Operate the cut sheet presenter module or the

upper frame, cut shee t presenter unit

only

when required.

❏ Do not turn off the power during operations, since that could cause a paper jam.

Control circuit module

Serial interf ace i s secu re d with inch- ty pe hexa gonal lo ck scr ews for the de fault set ting. I f you u se

millimeter-type screws, replace the inch-type screws with the millimeter-type screws attached to

the

frame, main

for type 1 and 2. (For type 3 and 4, millimeter-type screws are enclosed in the

box.)

Paper roll

❏ Use only the recommended thermal paper because thermal paper contains a high ion

content such as Na, K and Cl may damage the head heating elements.

❏ Avoid heat, humidity, sunlight and solvents, regardless of whether or not the paper has

been used. (Thermal paper gradually darkens at about 70°C {158°F}.)

❏ Remove the installed paper roll when the unit is not used for a long time in a high

temperature, or high humidity condition; otherwise the thermal sensitive materials

contained in the thermal paper may stick to the thermal head area, affecting the printing

quality.

❏ Label sheets are not available for the EU-T532/T542.

Page 39

3-4 Handling Rev. A

Confidential

Storage Precautions

❏ Do not store the printer in environments with excessive dust, high temperature, high

humidity, or in direct sunlight.

❏ Before storing the EU-T532/T542 for an extended time, remove the paper and wipe off dirt

and dust; then clean parts such as the

platen

and the

thermal head

of the printer module,

rollers of the cut sheet presenter module with alcohol. After the alcohol evaporates, close

each module and store the unit.

Note:

If you leave the printer with the paper installed, discoloration of the paper and stickiness between the

paper and the

platen

may occur. In this case, replace the paper.

❏ Storing the printer for an extended period with the

platen

closed could cause the platen

rubber to deform and result in defective printing. If the platen rubber is deformed, it can be

restored to its proper shape by feeding paper through the printer. Just feed paper through

the printer until the

platen

works properly; then resume printing.

Opening/Closing Units and Modules

Note:

❏

Do not apply excessive pressure to any operation part; otherwise its function may be damaged because

of deformation or damage of the part.

❏ Apply pressure to each operation part only in the specified direction; otherwise its function may be

damaged because of deformation or damage of the part.

Paper Roll Supply Module

Opening/closing the paper roll hold unit (See Figure 3-2. )

1. Lift the

plate, fixed

upward (in t he direction of arrow B) to release th e lock with the

shaft,

paper roll

.

2. Pull the

plate, fixed

in the direction of arrow A to open the unit.

3. To close the unit, push it to the

shaft, paper roll

until it stops. A t this time, make sure that

the

plate, fixed

is securely engaged with the groove on the

shaft, paper roll

. (Make sure

the unit is not open when it is pulled in the direction of arrow A.)

Printer Module

Opening/closing the platen unit (See Figure 3-2.)

1. Turn the

lever, platen

(green lever) of the printer module in the direction of arrow C to

open the unit.

2. To close the unit, turn the

lever, platen

in the direction of arrow D.

Page 40

Rev. A Handling 3-5

EU-T532/T542 Technical Manual

Confidential

Cut Sheet Presenter Module

Opening/closing the cut sheet presenter module (See Figure 3-2.)

1. Remove the white screw on the opposite side of the mounting dowels.

2. Put your fingers on/around the

seal, paper exit guides

(green stickers) on the

upper

frame, cut sheet presenter unit

and on the

paper exit

; then pull the cut sheet presenter

module in the direction of arrow E to slide it in direction E.

Note:

Be careful with your hand, as the module is pulled in the direction of arrow F with spring.

3. Pull the module further until the mounting dowels on the module are disengaged; then the

module is turned dow n ward and opened.

4. To put the module back to the pr evious posi tion, li ft up the bott om of the

paper exit

. At this

time, make sure that the mounting dowels (both on the right and le ft sides) are securely

engaged with the mounting parts on the module.

Opening/closing th e upper frame, cut sh eet presenter unit ( Se e Figure 3-2.)

1. Turn the

lever, clamp

in the direction of arrow G to open the unit. You can operate either

lever on the right or the left.

2. To close the unit, turn the

lever, clamp

in the direction of arrow H. At this time, make sure

that the

lever, clamp

is properly engaged with the

shaft, clamp lever

.

Note:

Do not lift the

upper paper gui de

when the

upper frame, cut sheet presenter unit

is

closed.

Figure 3-2 Opening/closing units and module

holder, paper roll

(Inside: shaft, paper roll)

plate, fixed

paper roll hold unit

lever, platen

cut sheet presenter module

mounting dowels

upper frame, cut sheet

presenter unit

upper paper guide

lever, clamp

A

B

C

D

F

E

G

H

paper exit

seal, paper exit guide

white screw side

Page 41

3-6 Handling Rev. A

Confidential

Loading/Removing Paper

Loading Paper

See the sticker on the

paper roll hold unit

for the paper loading.

Figure 3-3 Paper loading display on sticker

Note:

Use only the paper specified in the EU-T532 and the EU-T542 specifications issued by Seiko Epson

Corporation.

Loading paper for the paper roll supply module

Follow the steps below to load the paper for the paper roll supply module.

1. Lift the

plate, fixed

upward to release the lock with the

shaft, paper roll

.

2. Open the

paper roll hold unit

.

3. Attach a

holder, paper roll

which meets the inside diameter of the paper core to the

shaft,

paper roll

; then secure it with a C-ring.

Note:

At the default setting, the

holder, paper roll A

(for the inner diameter of the paper core is 25.4 mm

{1"}) is attached to the paper roll supply module. Since two holders, the

holder, paper roll B

(if the

inner diameter of the paper core is 50.8 mm {2"}), and the

holder, paper roll C

(if the inner

diameter of the paper core is 76.2 mm {3"}), are also packed in the box, use the appropriate

holder,

paper roll

that meets your paper core size.

4. Load the paper roll to th e

holder, paper roll

with the printing surface of the paper facing

upwards.

5. Close the

paper roll hold unit

to secure the paper roll. At this time, make sure that the

plate, fixed

is securely engaged with the

shaft, paper roll

.

plate, fixed

paper roll hold unit

Page 42

Rev. A Handling 3-7

EU-T532/T542 Technical Manual

Confidential

Loading paper for printer module

Follow the steps below to load the paper for the printer module from the paper roll supply

module.

1. Cut the edge of the paper as shown in Figure 3-4.

Figure 3-4 Shape of paper edge

2. Pull out the paper and pass it under the

roller, paper roll tension

.

3. After inserting the paper edge straight into the paper slot of the printer module so that the