Page 1

L

®

EPSON EPL-N4000/EPL-N4000+

OPTIONAL FINISHER STAP

Page 2

Notice

g

g

g

g

g

g

g

EPSON is a re

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademar ks of their

Copyright © 1998 SEIKO EPSON CORPORATION. Printed in Japan.

hts reserved. No part of t his manual may be r eprod uced, st ored in a r etri eval sy ste m, or t ransmit ted in any for m or by an y means el ectroni c,

All ri

mechanical, photocopyin

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The contents of this manual are subject to chan

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The above not withstandin

thereof.

istered trademark of SEIKO EPSON CORPORATION.

respective owners. EPSON disclaims any and all rights in those marks.

, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

e without notice.

SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

Page 3

PRECAUTIONS

g

g

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performin

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performin

Signals a precaution which, if ignored, could result in damage to equipment.

procedures preceded by DANGER Headings.

repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

EPSON WARRANTY.

Page 4

About This Manual

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

This manual describes basic functions, theory of electrical and mechanical operations, and repair procedures of EPL-N4000/N-400+ Optional

Finisher Stapler. The instruct ions and procedures included herein are intended for the experienced repair technicians, and attention should be

to the precautions on the precedin

page.

iven

Contents

This manual consists of three chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for

disassemblin

APPENDIX

Provides the followin

reference:

• Connector pin assi

• Electric circuit boards components layout

• Exploded dia

eneral overview and specifications of the

and assembling the product.

additional information for

nments

ram

Symbols Used in This Manual

Various symbols are used throughout this manual either to provide

additional information on a specific topic or to warn of possible dan

present durin

they are used, and always read WARNING, CAUTION or NOTE

messa

es.

a procedure or an action. Be aware of all symbols when

er

CAUTION

CHECK

POINT

Indicates an operatin

or condition that, if not strict ly obser ved, could r esult in injur y

or loss of life.

Indicates an operatin

or condition that, if not strictly observed, could result in

dama

May indicate an operatin

practice or condition that is necessary to accompli sh a task

efficiently. It may also provide additional information that is

related to a specific subject, or comment on the results

achieved throu

e to, or destruction of, equipment.

h a previous action.

or maintenance procedure, practice

or maintenance procedure, practice,

or maintenance procedure,

Page 5

Revision Status

Revision Issued Date Description

Rev. A September 16, 1999 First Release

Page 6

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

Contents

Product Description

Outline

........................................................................................................ 12

General Specification (TBD) ................................................................ 12

Stapler Specification (TBD) .................................................................. 12

Compiler Specification (TBD) .............................................................. 12

Stacker Specification (TBD) ................................................................. 12

Offset Specification (TBD) .................................................................... 13

Operating Principles

Power Supply

Control over the Finisher Stapler ........................................................ 15

Control Main Parts of the Finisher Stapler ......................................... 16

Transport ............................................................................................ 16

Compiler ............................................................................................. 16

Stapler ................................................................................................ 17

Eject and Offset .................................................................................. 18

Stacker Unit ........................................................................................ 18

Stacker Top Tray ................................................................................ 18

Stacker Middle Tray ........................................................................... 19

Stacker Bottom Tray ........................................................................... 19

Transmission of the Driving Force

Transport Motor ................................................................................... 20

Eject Motor ............................................................................................ 20

End Wall Motor ..................................................................................... 21

Tamper Motor ....................................................................................... 21

Set Clamp Motor .................................................................................. 22

Offset Motor .......................................................................................... 22

Stacker Elevator Motor ........................................................................ 23

Tray Motors ........................................................................................... 24

Paper Path

Paper Path on the Unstaple Mode ...................................................... 25

DOC ................................................................................................... 25

............................................................................................. 15

........................................................... 20

.................................................................................................. 25

Transport ............................................................................................ 26

Exit/Eject ............................................................................................ 26

Stacker Trays ..................................................................................... 27

Paper Path on the Staple Mode .......................................................... 27

DOC ................................................................................................... 27

Transport ............................................................................................ 27

Exit/Eject ............................................................................................ 28

Compiler/Tamper .................... .................... ................... .................... . 28

Stapler ........................ ....................................................................... . 29

Eject/Offset ....................... ............................................. ..................... 30

Stacker Trays ..................................................................................... 31

Disassembly and Assembly

Outline

Up and Down of Finisher Stapler

Installation and Removal of Finisher Stapler and Stapler Cartridge

Disassembly and Assembly

........................................................................................................ 33

Preparation ........................................................................................... 33

Attention for Handling ......................................................................... 33

Notation for Removal and Installation ............................................... 33

............................................................. 34

Finisher Stapler .................................................................................... 35

Installation .......................................................................................... 35

Removal ................................................................................................ 37

Installing and Replacing Stapler Cartridge ........................................ 38

Replacing the Stapler Cartridge .......................................................... 39

...................................................................... 40

Front Cover Assembly ......................................................................... 40

Removal ............................................................................................. 40

Installation .......................................................................................... 40

Front Cover Inner Assembly ................................................................ 41

Removal ............................................................................................. 41

Installation .......................................................................................... 41

Front Low Cover ................................................................................... 42

Removal ............................................................................................. 42

..... 35

6

Page 7

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

Installation .......................................................................................... 42

L/H Cover ............................................................................................... 43

Removal ............................................................................................. 43

Installation .......................................................................................... 43

L/H Cover Low ....................................................................................... 44

Removal ............................................................................................. 44

Installation .......................................................................................... 44

Eject Cover ............................................................................................ 45

Removal ............................................................................................. 45

Installation .......................................................................................... 45

Rear Cover ............................................................................................. 46

Removal ............................................................................................. 46

Installation .......................................................................................... 46

Harness Cover ....................................................................................... 46

Removal ............................................................................................. 46

Installation .......................................................................................... 46

Add Cover ............................................................................................. 47

Removal ............................................................................................. 47

Installation .......................................................................................... 47

Finisher Stapler PWB Cover and Connector Cover ........................... 48

Removal ............................................................................................. 48

Installation .......................................................................................... 48

Stacker Upper Limit Switch ................................................................. 50

Removal ............................................................................................. 50

Installation .......................................................................................... 50

Stacker Lower Limit Switch ................................................................. 51

Removal ............................................................................................. 51

Installation .......................................................................................... 51

Finisher Stapler Interlock Sensor and Actuator ................................. 52

Removal ............................................................................................. 52

Installation .......................................................................................... 52

Stacker Tray ID Sensor ......................................................................... 53

Removal ............................................................................................. 53

Installation .......................................................................................... 53

R/H Rack Cover Assembly .................................................................... 54

Removal ............................................................................................. 54

Installation .......................................................................................... 55

Stacker Elevator Motor ........................................................................ 56

Removal ............................................................................................. 56

Installation .......................................................................................... 56

Bottom (Lower) Tray Assembly .......................................................... 57

Removal ............................................................................................. 57

Installation .......................................................................................... 57

Bottom Tray Front Cover ..................................................................... 58

Removal ............................................................................................. 58

Installation .......................................................................................... 58

Bottom Tray Half and Full Sensors ..................................................... 59

Removal ............................................................................................. 59

Installation .......................................................................................... 59

Bottom Tray Lower and Upper Limit Sensor ..................................... 60

Removal ............................................................................................. 60

Installation .......................................................................................... 60

Bottom Tray .......................................................................................... 61

Removal ............................................................................................. 61

Installation .......................................................................................... 61

Bottom Tray Paper Sensor .................................................................. 62

Removal ............................................................................................. 62

Installation .......................................................................................... 62

Bottom Tray Safety Sensor ................................................................. 63

Removal ............................................................................................. 63

Installation .......................................................................................... 63

Bottom Tray Motor ............................................................................... 64

Removal ............................................................................................. 64

Installation .......................................................................................... 64

Bottom Tray Drive Belts ....................................................................... 65

Removal ............................................................................................. 65

Installation .......................................................................................... 66

Middle Tray Assembly ......................................................................... 67

Removal ............................................................................................. 67

Installation .......................................................................................... 67

Middle Tray Front Cover ...................................................................... 68

Removal ............................................................................................. 68

Installation .......................................................................................... 68

Middle Tray Half and Full Sensors ...................................................... 69

Removal ............................................................................................. 69

Installation .......................................................................................... 69

Middle Tray Lower and Upper Limit Sensor ...................................... 70

Removal ............................................................................................. 70

Installation .......................................................................................... 70

Middle Tray ........................................................................................... 71

7

Page 8

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

Removal ............................................................................................. 71

Installation .......................................................................................... 71

Middle Tray Paper Sensor ................................................................... 72

Removal ............................................................................................. 72

Installation .......................................................................................... 72

Middle Tray Motor ................................................................................ 73

Removal ............................................................................................. 73

Installation .......................................................................................... 73

Middle Tray Drive Belts ........................................................................ 74

Removal ............................................................................................. 74

Installation .......................................................................................... 75

Middle Tray Safety Switch ................................................................... 76

Removal ............................................................................................. 76

Installation .......................................................................................... 76

Top Tray Assembly .............................................................................. 77

Removal ............................................................................................. 77

Installation .......................................................................................... 77

Top Tray Front Cover ........................................................................... 78

Removal ............................................................................................. 78

Installation .......................................................................................... 78

Top Tray Half and Full Sensors ........................................................... 79

Removal ............................................................................................. 79

Installation .......................................................................................... 79

Top Tray Lower and Upper Limit Sensor ........................................... 80

Removal ............................................................................................. 80

Installation .......................................................................................... 80

Top Tray ................................................................................................ 81

Removal ............................................................................................. 81

Installation .......................................................................................... 81

Top Tray Paper Sensor ........................................................................ 82

Removal ............................................................................................. 82

Installation .......................................................................................... 82

Top Tray Motor ..................................................................................... 83

Removal ............................................................................................. 83

Installation .......................................................................................... 83

Top Tray Drive Belts ............................................................................. 84

Removal ............................................................................................. 84

Installation .......................................................................................... 85

Top Tray Safety Switch ........................................................................ 86

Removal ............................................................................................. 86

Installation .......................................................................................... 86

Tamper Motor ....................................................................................... 87

Removal ............................................................................................. 87

Installation .......................................................................................... 87

Tamper Home Sensor .......................................................................... 88

Removal ............................................................................................. 88

Installation .......................................................................................... 88

Compiler Paper Sensor ........................................................................ 89

Removal ............................................................................................. 89

Installation .......................................................................................... 89

End Wall Open Sensor ......................................................................... 90

Removal ............................................................................................. 90

Installation .......................................................................................... 90

Tamper Motor Drive Belt ..................................................................... 91

Removal ............................................................................................. 91

Installation .......................................................................................... 91

Compiler Tray Solenoid Assembly ..................................................... 92

Removal ............................................................................................. 92

Installation .......................................................................................... 92

Eject Shaft Assemblies ........................................................................ 93

Removal ............................................................................................. 93

Installation .......................................................................................... 93

Upper Exit Chute Assembly ................................................................ 95

Removal ............................................................................................. 95

Installation .......................................................................................... 95

Exit Shaft Assembly ............................................................................. 96

Removal ............................................................................................. 96

Installation .......................................................................................... 96

Paddle Shaft Assembly ........................................................................ 97

Removal ............................................................................................. 97

Installation .......................................................................................... 98

Eject Chute Assembly .......................................................................... 99

Removal ............................................................................................. 99

Installation .......................................................................................... 99

Eject Pinch Roll Shaft Assembly ....................................................... 100

Removal ........................................................................................... 100

Installation ........................................................................................ 100

Stack Height Sensor ........................................................................... 101

Removal ........................................................................................... 101

Installation ........................................................................................ 101

8

Page 9

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

Paddle Drive Belt ................................................................................ 102

Removal ........................................................................................... 102

Installation ........................................................................................ 102

Stapler Assembly ............................................................................... 103

Removal ........................................................................................... 103

Installation ........................................................................................ 103

Stapler Position Sensors .................................................................... 104

Removal ........................................................................................... 104

Installation ........................................................................................ 104

Top Cover Assembly .......................................................................... 105

Removal ........................................................................................... 105

Installation ........................................................................................ 105

Compiler Tray Exit Sensor ................................................................. 106

Removal ........................................................................................... 106

Installation ........................................................................................ 106

Upper Transport Chute Assembly .................................................... 107

Removal ........................................................................................... 107

Installation ........................................................................................ 107

Top and Front Cover Interlock Switches .......................................... 108

Removal ........................................................................................... 108

Installation ........................................................................................ 108

Compiler Cover and Safety Interlock Switches ................................ 109

Removal ........................................................................................... 109

Installation ........................................................................................ 110

Unload While Run Switch .................................................................. 111

Removal ........................................................................................... 111

Installation ........................................................................................ 111

End Wall Motor ................................................................................... 112

Removal ........................................................................................... 112

Installation ........................................................................................ 113

Transport Motor ................................................................................. 114

Removal ........................................................................................... 114

Installation ........................................................................................ 114

Set Clamp Motor ................................................................................ 115

Removal ........................................................................................... 115

Installation ........................................................................................ 115

Set Clamp Motor Drive Belt ............................................................... 116

Removal ........................................................................................... 116

Installation ........................................................................................ 116

Set Clamp Home Sensor .................................................................... 116

Removal ........................................................................................... 116

Installation ........................................................................................ 116

Eject Motor .......................................................................................... 117

Removal ........................................................................................... 117

Installation ........................................................................................ 117

Stapler Transport Motor .................................................................... 118

Removal ........................................................................................... 118

Installation ........................................................................................ 118

Stapler Transport Motor Drive Belt .................................................. 119

Removal ........................................................................................... 119

Installation ........................................................................................ 119

Transport Motor Drive Belt ................................................................ 120

Removal ........................................................................................... 120

Installation ........................................................................................ 120

Eject Bracket Assembly ...................................................................... 121

Removal ........................................................................................... 121

Installation ........................................................................................ 121

Eject Clamp Offset Motor .................................................................. 122

Removal ........................................................................................... 122

Installation ........................................................................................ 122

Eject Clamp Sensor ............................................................................ 123

Removal ........................................................................................... 123

Installation ........................................................................................ 123

Offset Home Sensor ........................................................................... 124

Removal ........................................................................................... 124

Installation ........................................................................................ 124

Finisher Stapler PWB Assembly ....................................................... 125

Removal ........................................................................................... 125

Installation ........................................................................................ 125

LVPS (OP11/OPR4H) ........................................................................... 126

Removal ........................................................................................... 126

Installation ........................................................................................ 126

DOC Cover Assembly ......................................................................... 127

Removal ........................................................................................... 127

Installation ........................................................................................ 127

IN Gate Support Assembly ................................................................ 128

Removal ........................................................................................... 128

Installation ........................................................................................ 128

IN Gate Support Actuator .................................................................. 129

Removal ........................................................................................... 129

9

Page 10

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

Installation ........................................................................................ 129

Transport Assembly ........................................................................... 130

Removal ........................................................................................... 130

Installation ........................................................................................ 130

Transport Assembly Drive Belt ......................................................... 131

Removal ........................................................................................... 131

Installation ........................................................................................ 132

IN Gate Interlock Switch .................................................................... 133

Removal ........................................................................................... 133

Installation ........................................................................................ 133

IN Gate Solenoid Assembly ............................................................... 134

Removal ........................................................................................... 134

Installation ........................................................................................ 134

Roller Unit ........................................................................................... 135

Removal ........................................................................................... 135

Installation ........................................................................................ 135

Transport Cover Assembly ................................................................ 136

Removal ........................................................................................... 136

Installation ........................................................................................ 136

Transport Interlock Sensor ................................................................ 137

Removal ........................................................................................... 137

Installation ........................................................................................ 137

Transport Roll ..................................................................................... 138

Removal ........................................................................................... 138

Installation ........................................................................................ 138

Transport Entrance Sensor ................................................................ 140

Removal ........................................................................................... 140

Installation ........................................................................................ 140

IOT Paper Full Sensor ........................................................................ 141

Removal ........................................................................................... 141

Installation ........................................................................................ 141

Transport Exit Sensor ........................................................................ 142

Removal ........................................................................................... 142

Installation ........................................................................................ 142

Exploded Diagram and Parts List

HCS Transport .................................................................................... 165

HCS Covers Front ............................................................................... 166

HCS Covers Rear ................................................................................ 167

Rack ..................................................................................................... 168

Rails and Trays ................................................................................... 169

Lower Tray .......................................................................................... 171

Lower Tray Frame .............................................................................. 173

Middle Tray ......................................................................................... 174

Middle Tray Frame ............................................................................. 176

Top Tray .............................................................................................. 178

Top Tray Frame .................................................................................. 180

Tray Eject ............................................................................................ 181

Exit ....................................................................................................... 183

Offset and Eject .................................................................................. 184

Stapler ................................................................................................. 185

Transport ............................................................................................. 186

Front Frame ........................................................................................ 187

Rear Frame 1 ....................................................................................... 188

Rear Frame 2 ....................................................................................... 189

Rear Frame 3 ....................................................................................... 190

Electrical Module ................................................................................ 191

Harness ............................................................................................... 192

HCS DOC ............................................................................................. 193

Frame Transport, Rear ....................................................................... 194

Frame Transport, Open ...................................................................... 195

........................................................... 165

Appendix

Wiring Diagram and Signal Data

Connector

P/J Connector Table and Location Map ............................................ 154

................................................................................................. 154

............................................................ 144

10

Page 11

PRODUCT DESCRIPTION

CHAPTER

1

Page 12

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

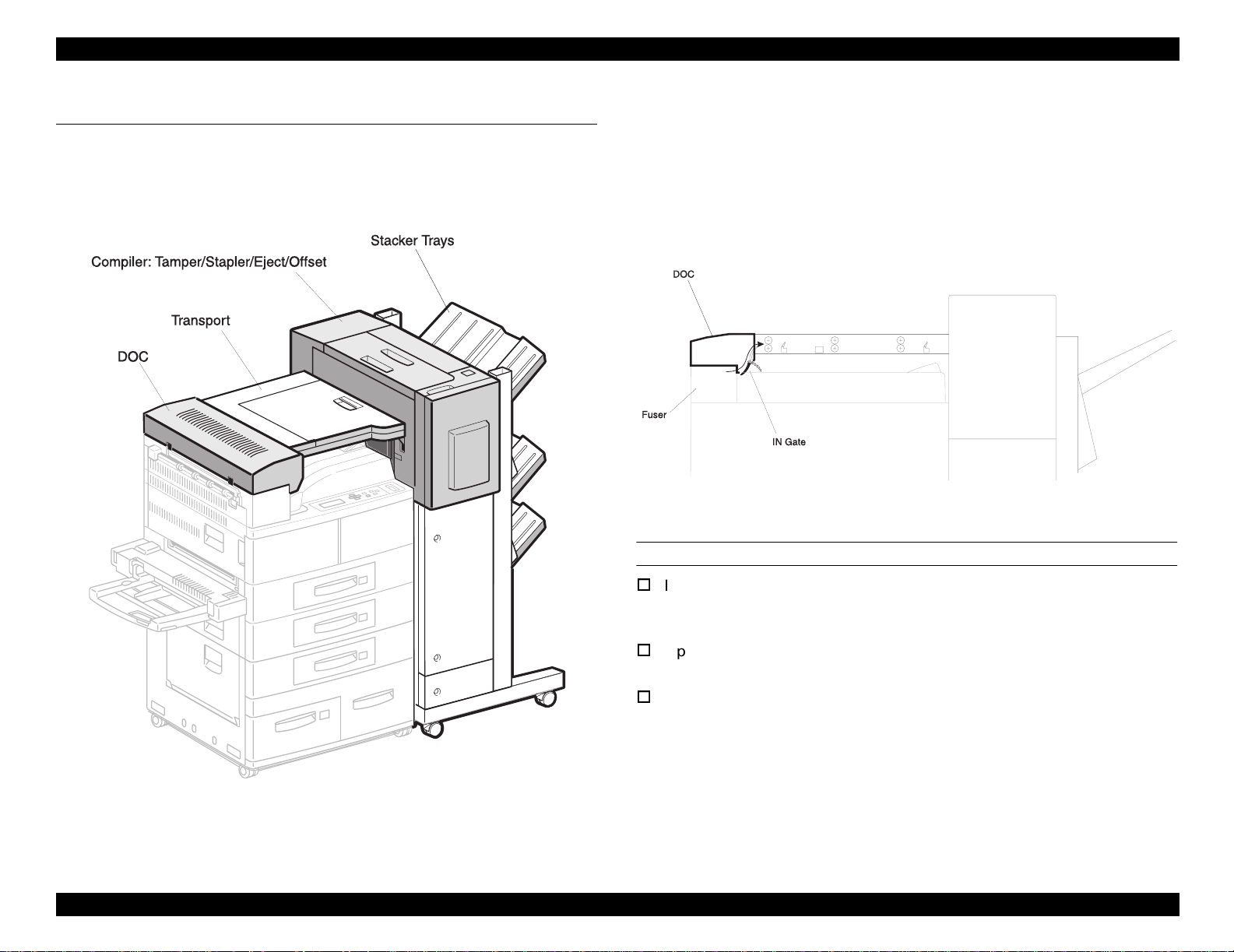

1.1 Outline

This chapter describes the specification of the Finisher Stapler.

1.1.1 General Specification (TBD)

STRUCTURE

Finisher Stapler is the option of the EPSON EPL-N4000/EPL-N4000+. It is

consists of hirizontal transport unit and stack tray unit. Hirizontal transport uit

is installed to the face down output tray of the printer, and stack tray is

installed to the right side of the printer.

NOTE: Finisher Stapler cannot be used with 10 pin multipin.

FUNCTION

Stapling at the specified position.

Three ejecting paper stack trays

PAPER

Refer to product specification for EPSON EPL-N4000/EPL-N4000+.

1.1.2 Stapler Specification (TBD)

STAPLE (TBD)

Maximum amount of paper:50 sheets (paper: Xerox DP 20lb)

Staple position:Front, Rear (Corner), Rear (Straight), Multiple staple

STAPLE CARTRIDGE (TBD)

5000 staples

1.1.3 Compiler Specification (TBD)

COMPILER

Ejected paper is stacked on the Complier Tray, jogged by the tamper to the

front, and sent to the Stacker.

MAXIMUM SETTABLE AMOUNT OF PAPER

50 sheets

MINIMUM PAPER WIDTH

ELECTRIC POWER CONSUMPTION (TBD)

55W (110VAC)

210mm

1.1.4 Stacker Specification (TBD)

NOISE (TBD)

Continuous noise on the job: max. 72.8dB

SIZE AND WEIGHT

Dimensions:1,133 x 633 x 658 mm (HxWxD)

Weight:58kg

Product Description Outline 12

STACKER

Tray: 3

Page 13

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

PAPAER CAPACITY

Without Staple:500 sheets/tray

With staple:Max. 30 sets or 600 sheets/tray

Real Staple Mode:15 sheets (B5 LEF, B5, B4 SEF)

Multiple Staple Mode:15 sheets (B5, SEF)

NOTE: LEF= Long Edge First, SEF= Short Edge First

1.1.5 Offset Specification (TBD)

OFFSET (TBD)

By shifting the ejecting roller, the Finisher Stapler can eject paper 15mm

offset.

Product Description Outline 13

Page 14

OPERATING PRINCIPLES

CHAPTER

2

Page 15

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.1 Power Supply

The Power Supply of the Finisher Stapler is supplied by the 100V AC via the

printer and generated by the LVP PWB in the Finisher Stapler.

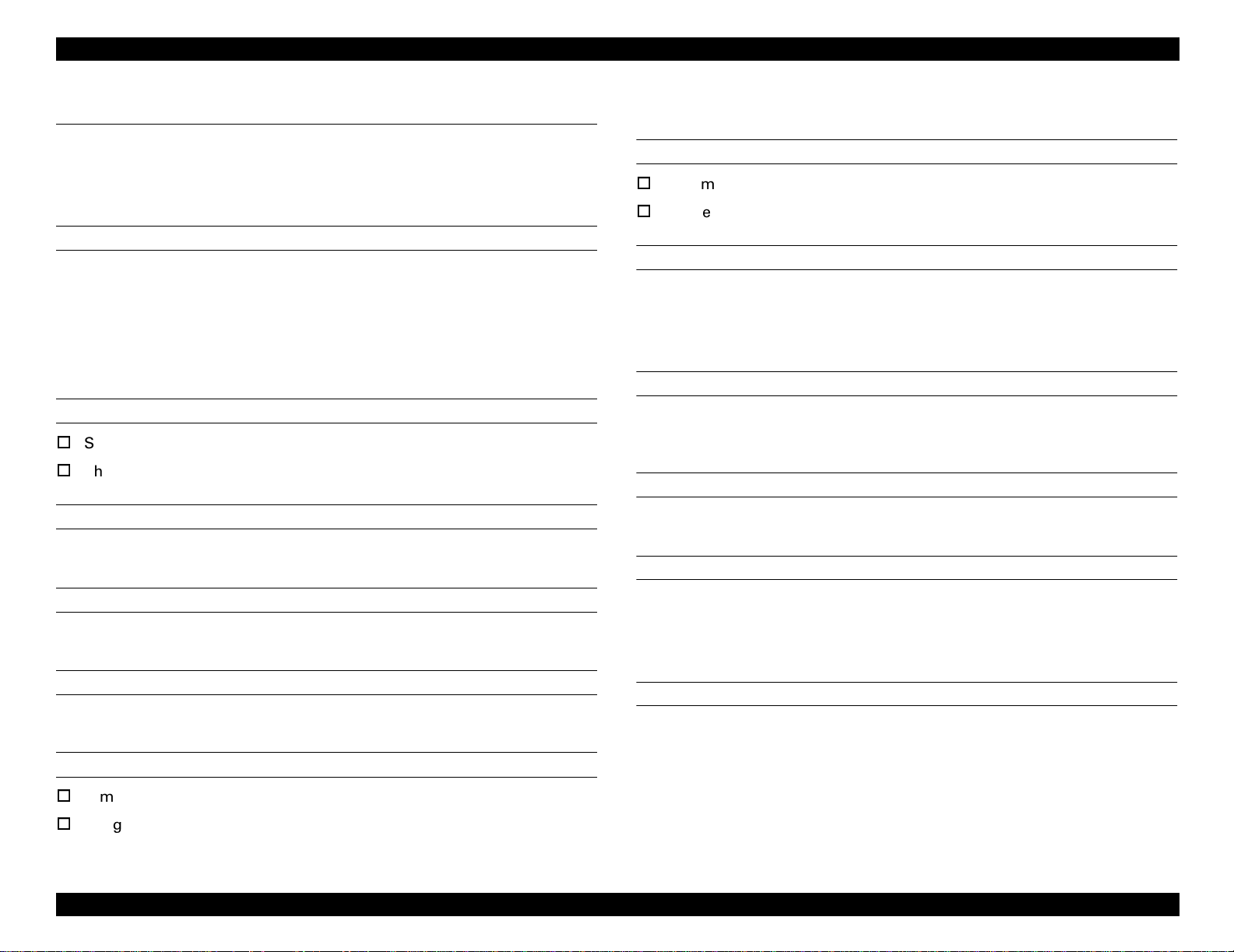

2.1.1 Control over the Finisher Stapler

LVPS sends the sensor data in the Finisher Stapler to the MCU of the printer.

Commands from the MCU of the printer is transferred to the Finisher PWB

and controls over respective components of the Finisher Stapler.

Figure 2-1. Components

Operating Principles Power Supply 15

Page 16

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.1.2 Control Main Parts of the Finisher Stapler

Finisher PWB

LVPS PWB sends sensor data in the Finisher Stapler to MCU of the

printer. Commands from the MCU of the base engine is transferred to

the Finisher PWB and controls over respective components of the

Finisher Stapler.

HCS Low Voltage Power Supply

Generates +5VDC and +24VDC from 100VAC.

Unload While Run Switch and LED

This switch is for user to interrupt Finisher Stapler when it is

proceeding its job.

LED flashes when interruption is made.

Finisher Interlock Sensor

Supervises that the door of the Finisher Stapler is not open.

Front Cover Interlock Switch

When Front Cover is open, shut off 24VDC.

Compiler Cover Safety Switch

When Compiler Cover is open, shut off 24VDC.

IOT Full Paper Sensor

Supervises the amount of paper on the eject tray of the printer.

Transport Exit Sensor

Supervises paper passing from Transport Assembly.

Transport Interlock Sensor

Supervises the condition of the Transport Cover.

Transport Motor

Drives Transport Rolls.

2.1.2.2 Compiler

Compiler arranges paper as set.

Tamper Motor

Drives Tamper which pushes paper to the end.

Tamper Home Sensor

Supervises the position of the Tamper.

Top Tray Safety Switch

Detects if there are any obstructions under the Top Tray and shut off

+24VDC and stop the Elevator Motor.

Middle Tray Safety Switch

Detects if there are any obstructions under the Middle Tray and shut

off +24VDC and stop the Elevator Motor. Top Tray Safety Switch and

Middle Tray Safety Switch are connected in series.

2.1.2.1 Transport

Shift paper from DDC to Compiler.

IN Gate Solenoid

Alternate the direction of IN Gate.

IN Gate Interlock Sensor

Supervises the position of IN Gate. (Up/Down)

Transport Entrance Sensor

Supervises paper passing to Transport Assembly.

Compiler Tray Up/Down Solenoid

Slant Compiler Tray when the amount of paper has reached twenty

five.

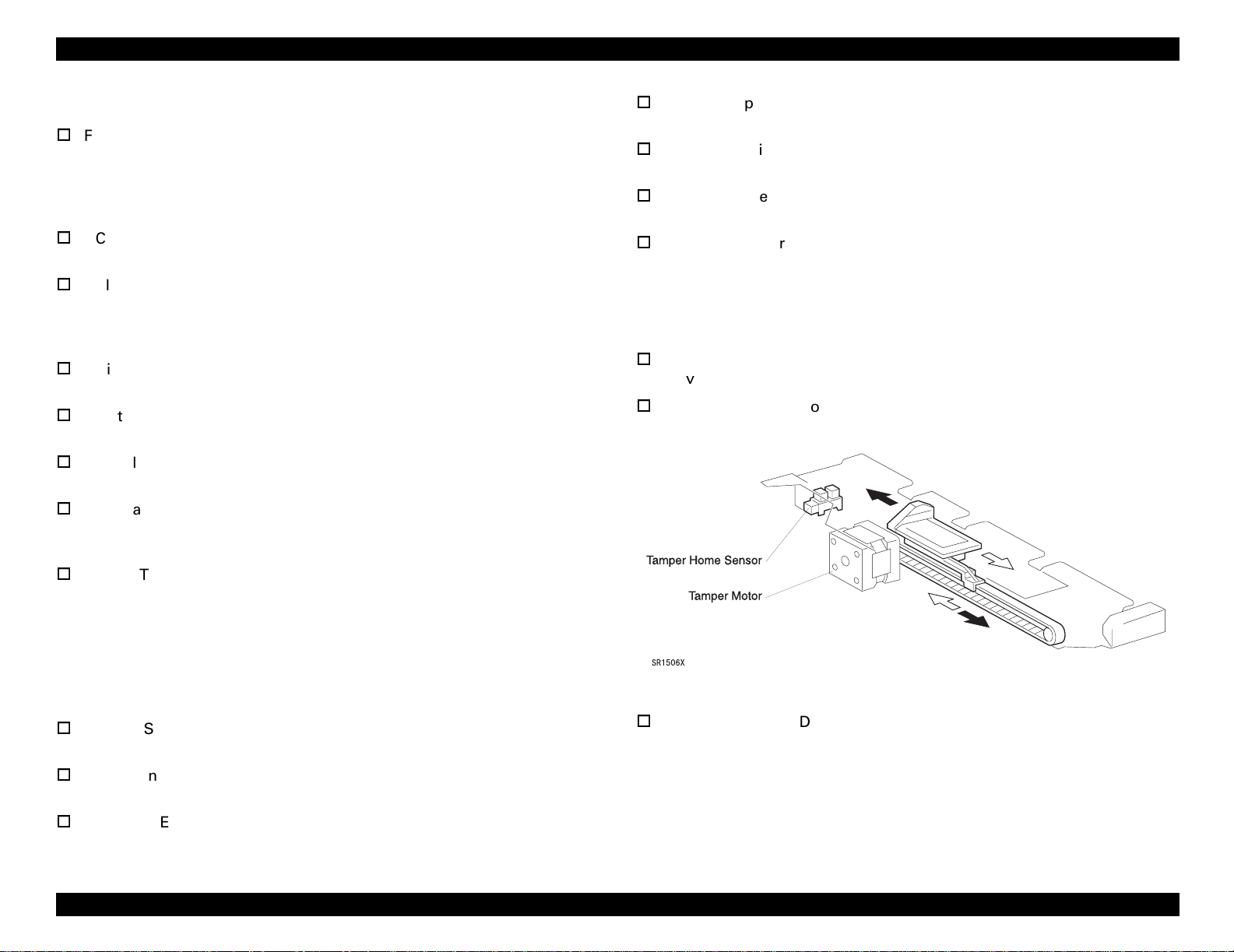

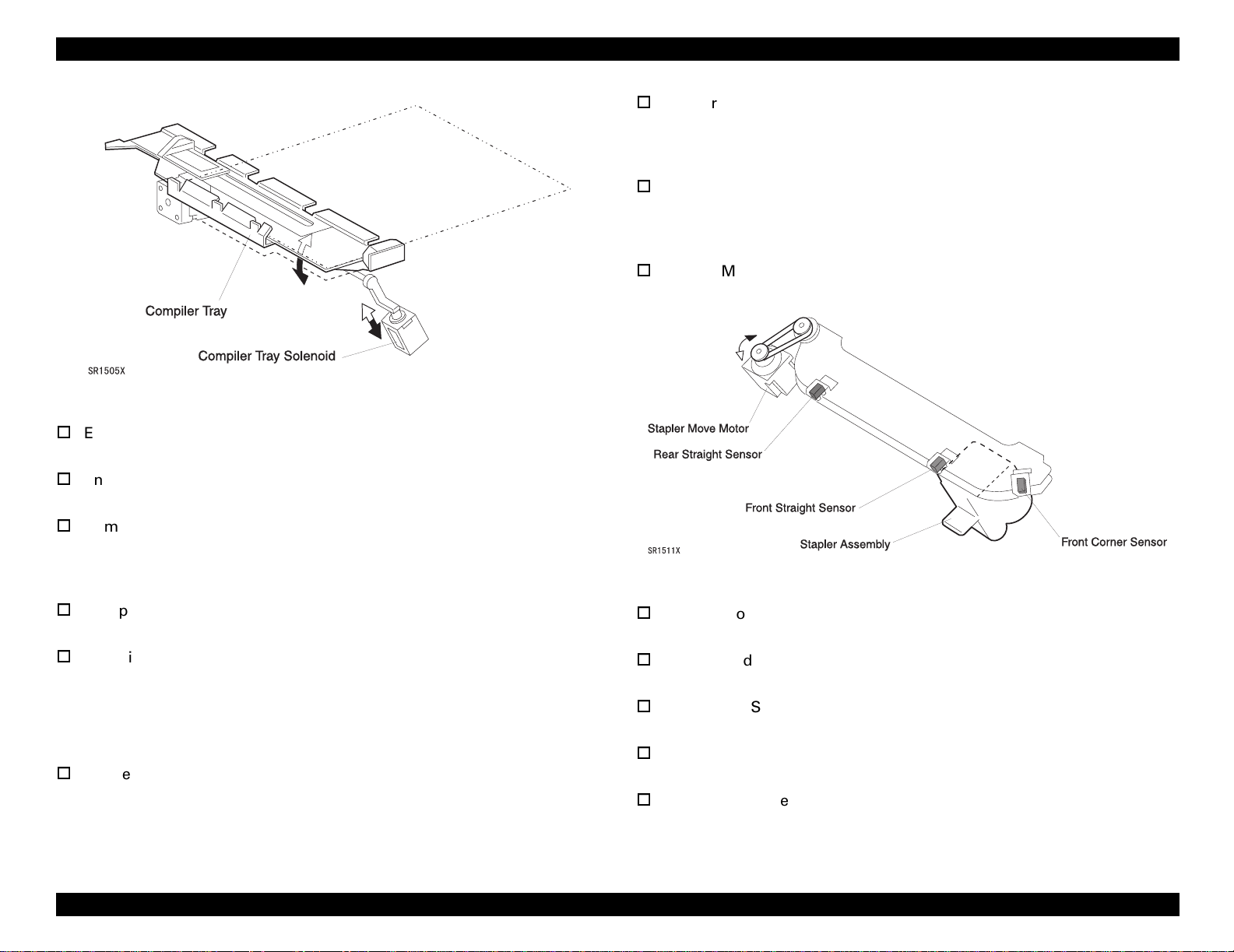

Figure 2-2. Tamper/Tamper Home Sensor

Operating Principles Power Supply 16

Page 17

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

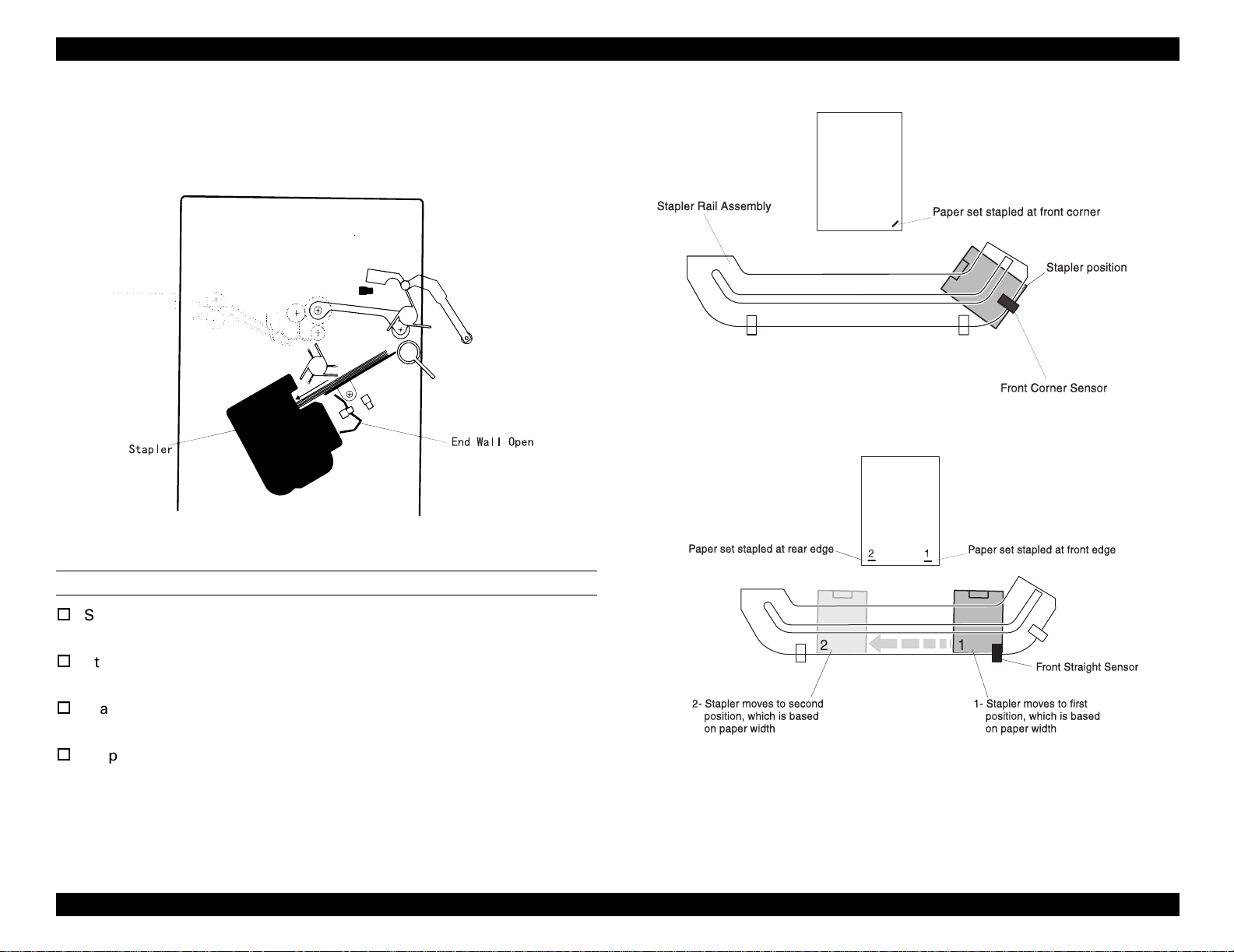

Stapler Front Straight Sensor

Commands the position of the Stapler Unit as the Move Motor can

drive Stapler until the Stapler Unit comes to the staple position at the

front and rear edge of paper.

Stapler Rear Straight Sensor

Commands the position of the Stapler Unit as the Move Motor can

drive Stapler until the Stapler Unit comes to the staple position at the

rear corner of paper.

Stapler Move Motor

Shift the Stapler Head to the Staple position.

Figure 2-3. Compiler Tray Up / Down Solenoid

End Wall Open/Close Motor

Controls opening and closing of the End Wall.

End Wall Open Sensor

Supervises the position of the End Wall.

Compiler Tray Exit Sensor

Supervises paper ejecting through the entrance of the Compiler. HCS

uses the signal from the sensor to determine start and stop of the

Transport Motor and Eject Motor.

Compiler Paper Sensor

Supervises paper on the Compiler Tray.

Compiler Cover Interlock Switch

Supervises the position of the Compiler Cover.

2.1.2.3 Stapler

Stapler bundles paper with staple.

Stapler Front Corner Sensor

Commands the position where Stapler Unit staples at the front corner

of paper.

Stapler Motor

Drives Stapler Head during stapler stapling paper.

Staple Ready Sensor

Supervises the existence of the staple in Staple Head.

Low Staple Sensor

Supervises the remaining of the staple in Stapler.

Stapler Head Home Sensor

Supervises if the Stapler Head is at the home position.

Set Clamp Home Sensor

Supervises if the Set Clamp is at the home position.

Figure 2-4. Stapler / Sensors

Operating Principles Power Supply 17

Page 18

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

Set Clamp Motor

Drives Set Clamp paddle to clamp paper on the Compiler Tray before

stapling.

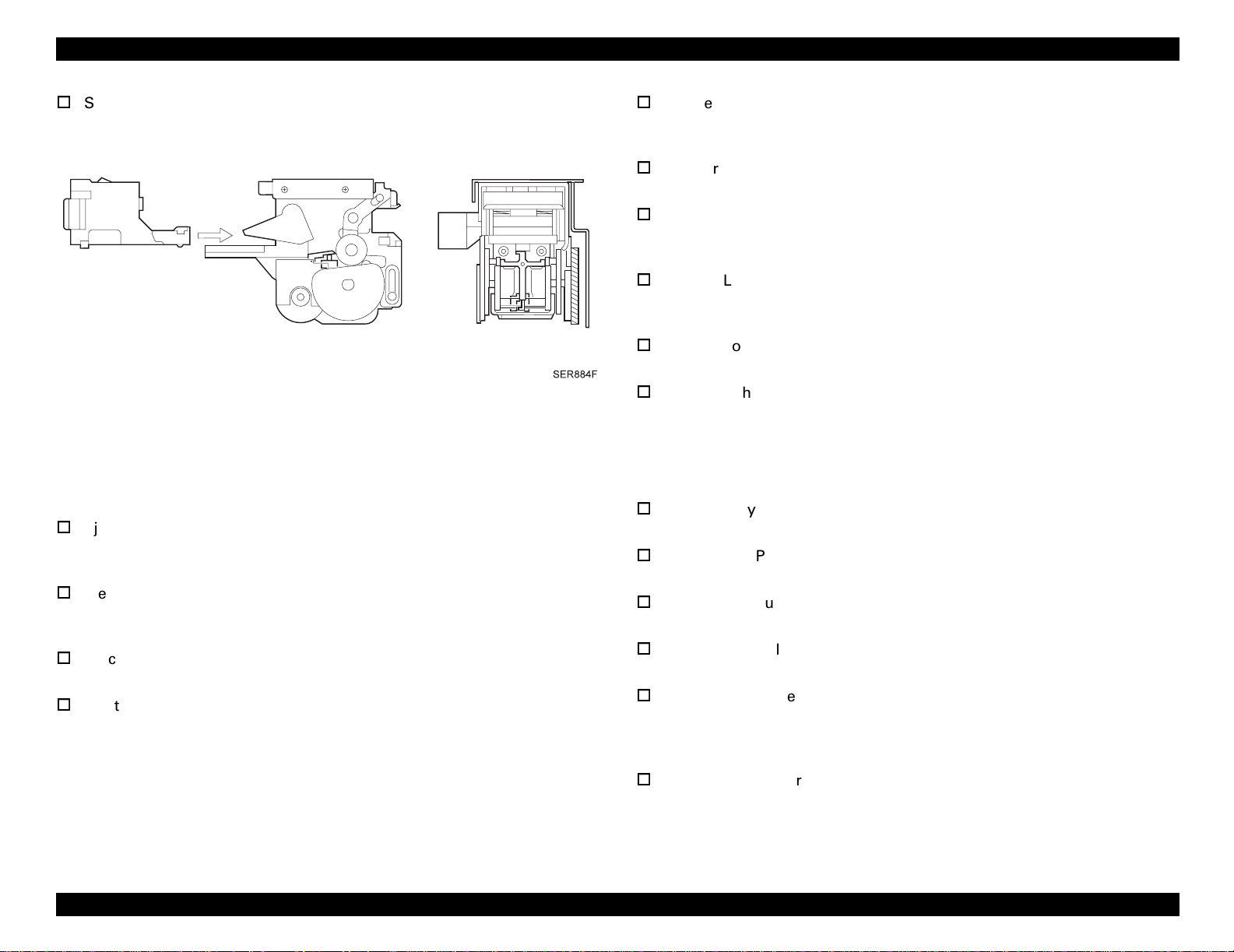

Figure 2-5. Stapler

Stacker Tray Elevator Motor

Revolves Stacker Drive shaft clockwise or counterclockwise and shifts

Stacker Tray up and down.

Stacker Tray ID Sensor

Supervises the right position of the Tray.

Stacker Upper Limit Switch

Detects the upper limit of the Stacker Tray. The switch shut off the DC

power supply to the Elevator Motor.

Stacker Lower Limit Switch

Detects the lower limit of the Stacker Tray. The switch shut off the DC

power supply to the Elevator Motor.

Stacker Lower Safety Switch

Supervises the obstruction under the Bottom Tray.

Stack Height Sensor

Supervises the Tray position.

2.1.2.4 Eject and Offset

Eject and Offset carries paper compiled on the Stacker Tray and ejects offset

paper.

Eject Clamp and Offset Motor

Drives Eject Chute and Pinch Roll by shifting Eject Chute and Pinch

Roll up and down.

Eject Clamp Sensor

Supervises if Eject Roll is at the upper position or at the lower

position.

Stacker Offset Home Sensor

Supervises if Eject Roll is at the home position.

Eject Motor

Drives Eject Shaft Assembly.

2.1.2.5 Stacker Unit

Provides function to shift three Stacker Tray up and down.

2.1.2.6 Stacker Top Tray

Provides function to shift Top Stacker Tray up and down.

Stacker Tray 1 Motor

Shifts Top Tray up and down.

Stacker Top Paper Sensor

Detects if there are paper on the Top Tray.

Stacker Top Full Sensor

Detects if paper on the Top Tray is full.

Stacker Top Half Sensor

Detects if paper on the Top Tray is 50% full.

Stacker Top Upper Limit Sensor

Detects the upper limit of the Top Tray. The sensor sends signal to

Finisher Stacker PWB to shut off the DC power supply to the Stacker

Tray 1 Motor.

Stacker Top Lower Limit Sensor

Detects the lower limit of the Top Tray. The sensor sends signal to

Finisher Stacker PWB to shut off the DC power supply to the Stacker

Tray 1 Motor.

Operating Principles Power Supply 18

Page 19

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.1.2.7 Stacker Middle Tray

Provides function to shift Middle Stacker Tray up and down.

Stacker Middle Motor

Shifts Middle Tray up and down.

Stacker Middle Paper Sensor

Detects if there are paper on Middle Tray.

Stacker Middle Full Sensor

Detects if paper on Middle Tray is full.

Stacker Middle Half Sensor

Detects if paper on Middle Tray is 50% full.

Stacker Middle Upper Limit Sensor

Detects the upper limit of Middle Tray. The sensor sends signal to

Finisher PWB to shut off the DC power supply to the Stacker Middle

Motor.

Stacker Middle Lower Limit Sensor

Detects the lower limit of Middle Tray. The sensor sends signal to

Finisher PWB to shut off the DC power supply to the Stacker Middle

Motor.

Stacker Low Lower Limit Sensor

Detects the upper limit of Bottom Tray. The sensor sends signal to

Finisher PWB to shut off the DC power supply to the Stacker Bottom

Motor.

2.1.2.8 Stacker Bottom Tray

Provides function to shift Bottom Stacker Tray up and down.

Stacker Low Motor

Shifts the Bottom Tray up and down.

Stacker Low Paper Sensor

Detects if there are paper on the Bottom Tray.

Stacker Low Full Sensor

Detects if paper on the Bottom Tray is full.

Stacker Low Half Sensor

Detects if paper on the Bottom Tray is 50% full.

Stacker Low Upper Limit Sensor

Detects the upper limit of Bottom Tray. The sensor sends signal to

Finisher PWB to shut off the DC power supply to the Stacker Bottom

Motor.

Operating Principles Power Supply 19

Page 20

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.2 Transmission of the Driving Force

2.2.1 Transport Motor

Transport Motor is in the Compiler of the Finisher Stapler.

Figure 2-6. Transport Driving Mechanism

2.2.2 Eject Motor

Finisher PWB revolves the Eject Motor clockwise to eject paper to the Stacker

Tray. Finisher PWB also revolves the Eject Motor counterclockwise to pull

paper back to the Compiler Tray.

Figure 2-8. Eject Motor

Figure 2-7. Driving Force Transmission Outline

Operating Principles Transmission of the Driving Force 20

Page 21

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

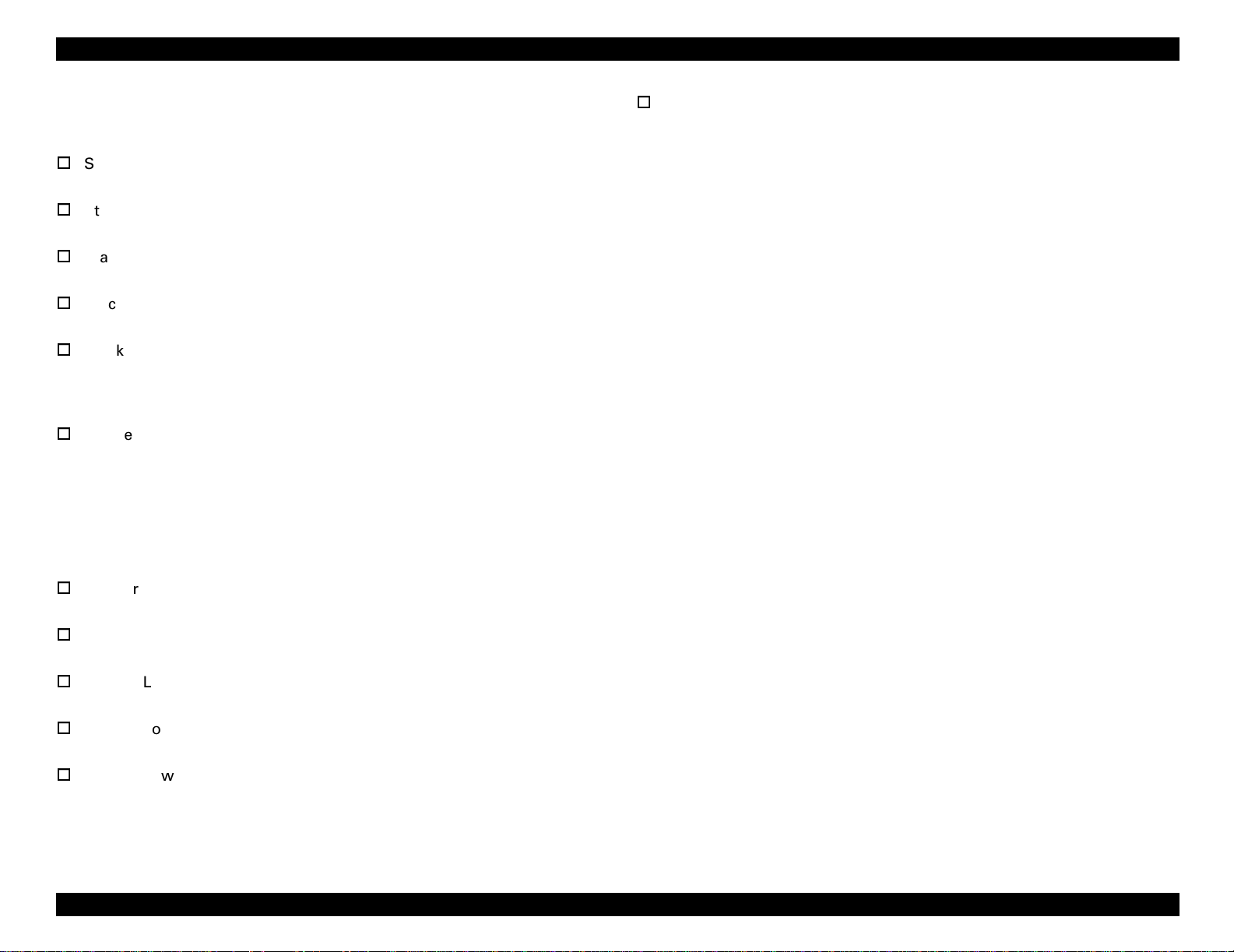

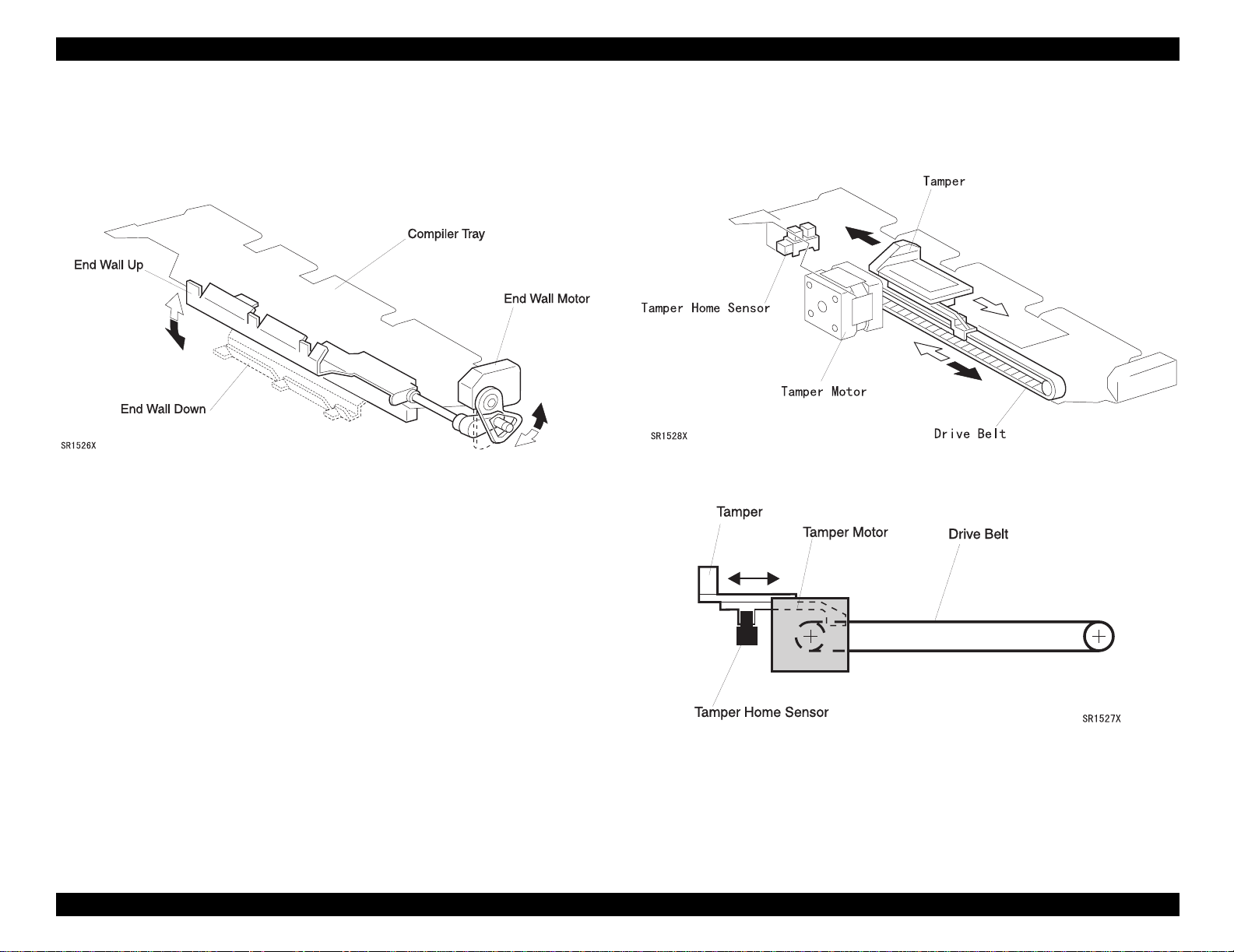

2.2.3 End Wall Motor

End Wall Motor shifts the End Wall of the Compiler Tray. When paper is sent

to the Compiler Tray, End Wall Motor shifts up the End Wall. When paper is

stapled, End Wall Motor shifts down the End Wall.

Figure 2-9. End Wall Motor

2.2.4 Tamper Motor

Tamper Motor drives the Tamper.

Figure 2-10. Tamper Motor Working Part

Figure 2-11. Tamper Motor Operational Outline

Operating Principles Transmission of the Driving Force 21

Page 22

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

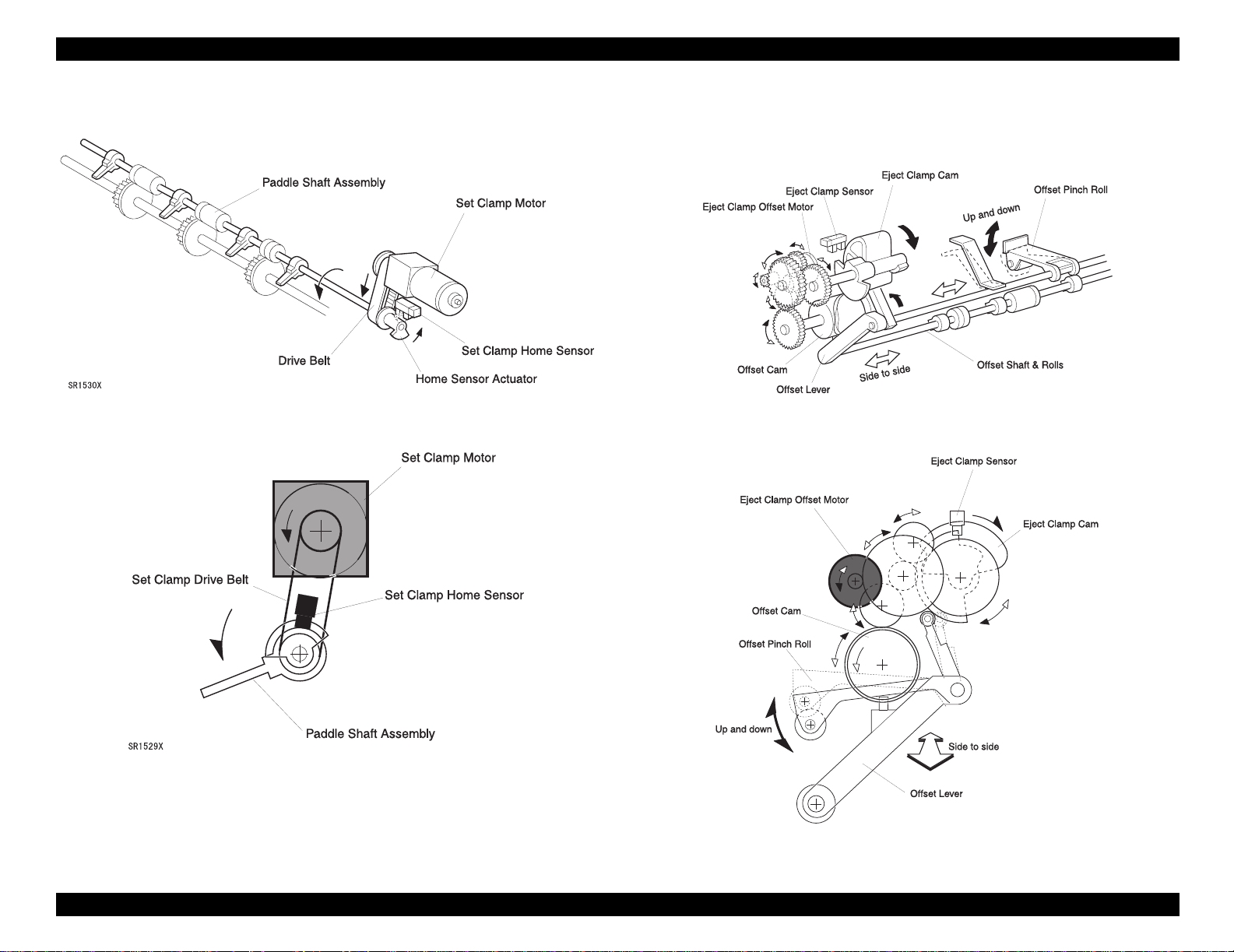

2.2.5 Set Clamp Motor

Figure 2-12. Set Clamp Motor Working Part

2.2.6 Offset Motor

Eject Clamp Offset Motor drives Offset Cam and Eject Clamp Cam.

SR1532X

Figure 2-14. Offset Motor Working Part

Figure 2-13. Set Clamp Motor Operational Outline

SR1531X

Figure 2-15. Offset motor Operational Outline

Operating Principles Transmission of the Driving Force 22

Page 23

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.2.7 Stacker Elevator Motor

SR1533X

Figure 2-17. Stacker Elevator Motor Operational Outline

SR1534X

Figure 2-16. Stacker Elevator Motor Working Part

Operating Principles Transmission of the Driving Force 23

Page 24

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.2.8 Tray Motors

SR1536XA

Figure 2-18. Tray Motor Working Part

SR1535X

Figure 2-19. Tray Motor Operational Outline

Operating Principles Transmission of the Driving Force 24

Page 25

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.3 Paper Path

Paper goes through four main components of DOC, Transport, Compiler, and

Stacker Tray.

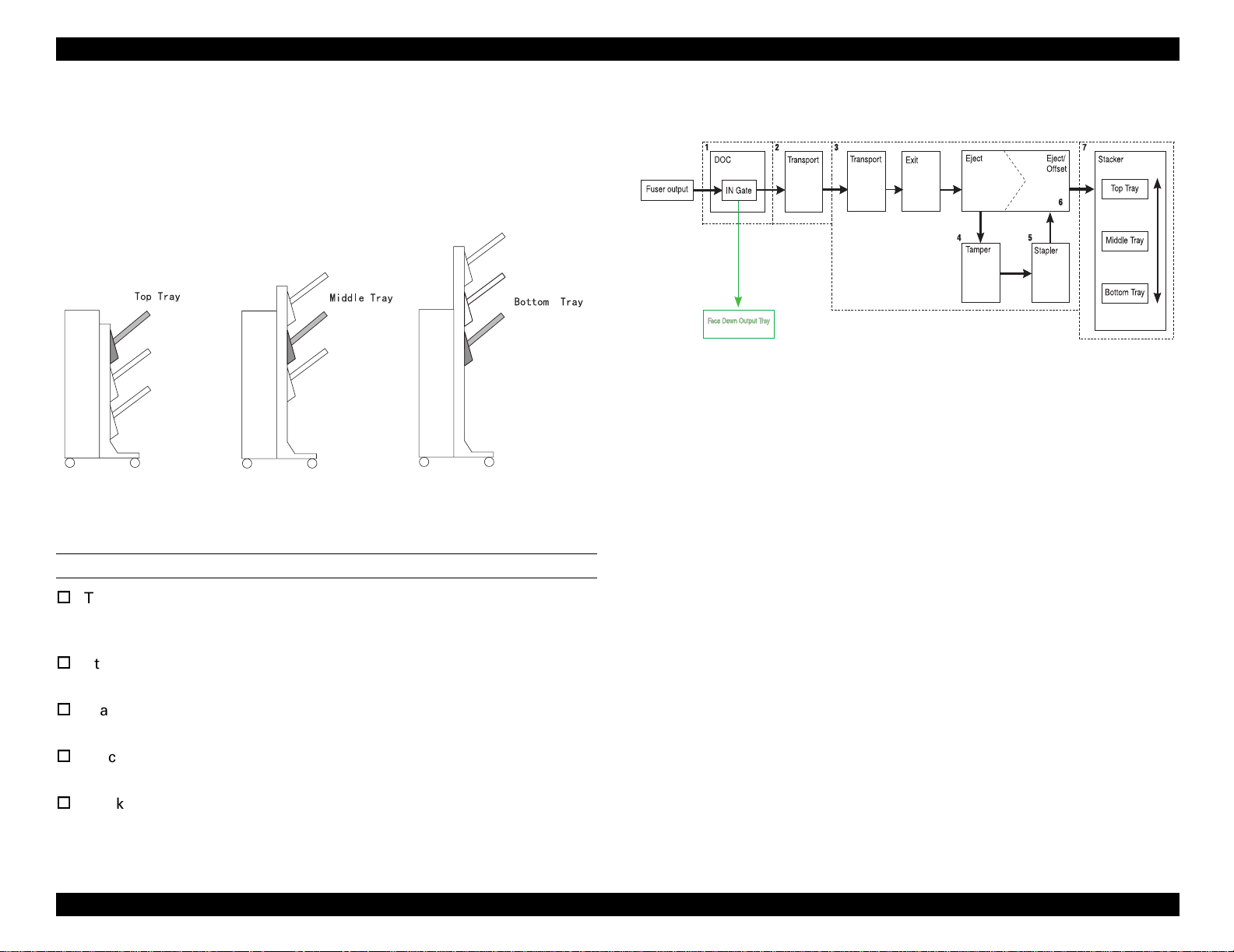

2.3.1 Paper Path on the Unstaple Mode

2.3.1.1 DOC

DOC is at the exit of the Fuser of the printer. DOC includes IN Gate. When

Finisher Stapler is selected, the Finisher PWB drives the IN Gate Solenoid to

alternate the direction of the IN Gate and carries paper to the HCS Transport

Assembly.

SR1503X

Figure 2-21. DOC

DOC PAPER PATH MAIN COMPONENTS

IN Gate

On normal mode, IN Gate faces up. When selected to send paper to

Staple Stacker, IN Gate Solenoid commands IN Gate to face down.

Upper Chute

Carries paper to the Transport Rolls.

IN Gate Solenoid

Controlled by Finisher PWB.

SR1502X

Figure 2-20. Main Components

Operating Principles Paper Path 25

Page 26

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

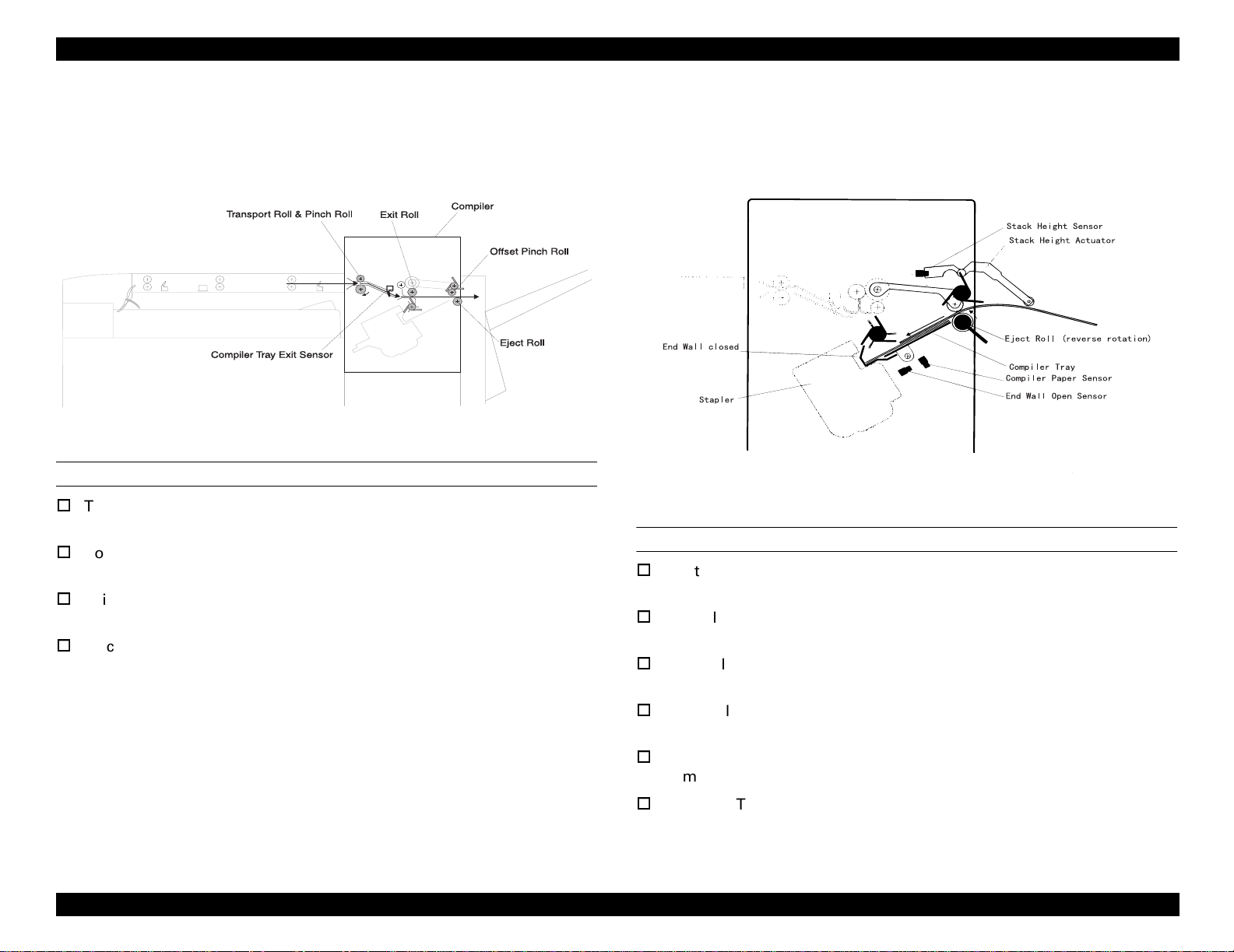

2.3.1.2 Transport

Three sets of Transport Rolls send paper through Transport Assembly to

Compiler. Transport Entrance Sensor and Transport Exit Sensor supervises

paper passing.

SR1515X

Figure 2-22. Transport

TRANSPORT PAPER PATH MAIN COMPONENTS

Transport Rolls and Pinch Rolls (3 sets)

Carries paper to the Compiler.

Transport Entrance Sensor

Supervises paper entering to the Transport.

Transport Exit Sensor

Supervises paper exiting from the Transport.

IOT Full Paper Sensor

Supervises the amount of paper on the Face Down Output Tray of the

printer. When the Finisher Stapler is installed, IOT Full Paper Sensor

supervises on behalf of the printer Full Stack Sensor.

2.3.1.3 Exit/Eject

SR1518X

Figure 2-23. Exit / Eject

EXIT/EJECT PAPER PATH MAIN COMPONENTS

Transport Rolls and Pinch Rolls

Carries paper to the Compiler.

Complier Tray Exit Sensor

Supervises paper passing to the entrance of the Compiler.

Exit Roll / Paddle Assembly

Carries paper to the Offset/Eject Rolls.

Eject Roll / Paddle Assembly

Ejects paper to the Stacker Tray.

Offset Pinch Roll

Offsets and ejects paper to the Stacker Tray.

Operating Principles Paper Path 26

Page 27

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.3.1.4 Stacker Trays

Eject Toll and Paddle Assembly ejects paper to the Stacker Tray. Stacker

Elevator shifts three Trays up and down as one of the Trays faces Eject Rolls.

ID Sensor informs the Finisher PWB that the selected Tray is at the right

position. Respective sensors supervise the amount of paper on each Tray.

SR1512X

Figure 2-24. Stacker Tray

2.3.2 Paper Path on the Staple Mode

SR1501X

Figure 2-25. Paper Path Outline

2.3.2.1 DOC

Operating principle of DOC on the staple mode is the same as on the unstaple

mode. (“DOC” on page 25)

2.3.2.2 Transport

Operating principle of Transport on the staple mode is the same as on the

unstaple mode. (“Transport” on page 26)

OFFSET PAPER PATH MAIN COMPONENTS

Top, Middle, Bottom Tray

Shifted up and down as one unit. Selected Tray stops in front of the

Eject Rolls.

Stacker Motor (Top, Middle, Bottom)

Shifts each Tray up and down.

Stacker Paper Sensor (Top, Middle, Bottom)

Supervises if there are paper on each Tray.

Stacker Full Sensor (Top, Middle, Bottom)

Supervises if paper on each Tray is 100% full.

Stacker Half Full Sensor (Top, Middle, Bottom)

Supervises if paper on each Tray is 100% full.

Operating Principles Paper Path 27

Page 28

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.3.2.3 Exit/Eject

Paper sent from the Transport is compiled and jogged on the Compiler Tray

by specified amount. Paper is bundled by stapler at the specified corner and is

ejected to the Stacker.

SR1518X

Figure 2-26. Exit/Eject

EXIT/EJECT PAPER PATH MAIN COMPONENTS

Transport Rolls and Pinch Rolls

Carries paper to the Compiler.

Complier Tray Exit Sensor

Supervises paper entering to the Compiler.

Exit Roll / Paddle Assembly

Carries paper to the Offset/Eject Rolls.

Eject Roll / Paddle Assembly

Eject Roll counter-revolves and sends paper to the Compiler Tray.

2.3.2.4 Compiler/Tamper

Eject Roll counter-revolves and sends paper to the Compiler Tray. When

paper is sent to the Compiler Tray, End Wall Motor lifts End Wall.

SR1520X

Figure 2-27. Compiler/Tamper

COMPILER /TAMPER PAPER PATH MAIN COMPONENTS

Eject Roll

Eject Roll counter-revolves and sends paper to the Compiler Tray.

Compiler Tray

Paper is compiled and jogged on the Compiler Tray by specified amount.

End Wall

Jogs paper. Lowered when stapling.

End Wall Motor

Shifts End Wall up and down.

Tamper

Tamps paper one by one.

Compiler Tray Solenoid

When amount of paper on the Compiler Tray reaches twenty five,

Compiler Tray Solenoid shifts Compiler Tray down.

Operating Principles Paper Path 28

Page 29

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

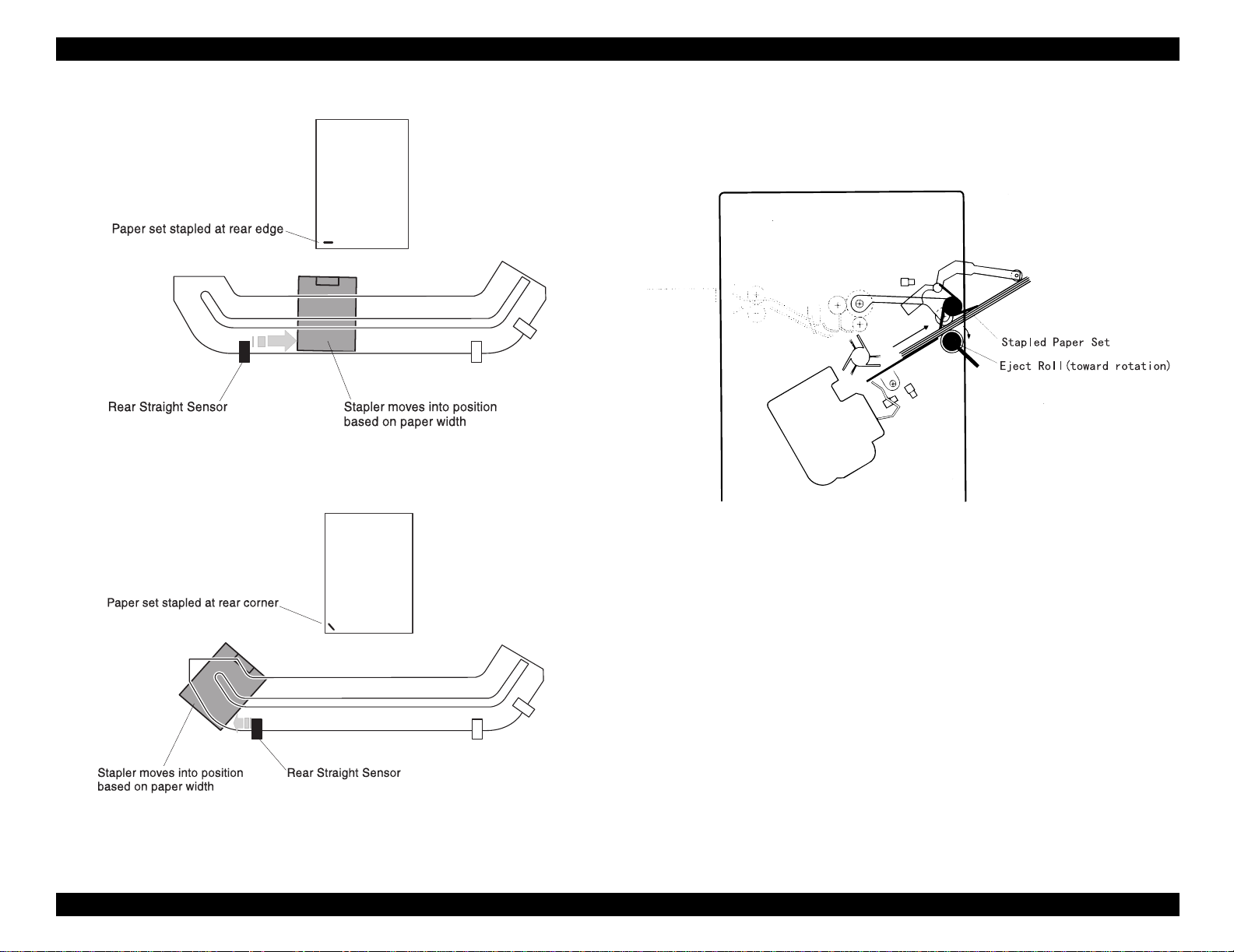

2.3.2.5 Stapler

End Wall is shifted down when stapling. Stapler Motor shifts Stapler Unit

along the rail. Sensors along rail supervises the position of the Stapler Unit.

SR1507X

Figure 2-29. Front Corner Staple

SR1522X

Figure 2-28. Stapler

STAPLER PAPER PATH MAIN COMPONENTS

Stapler Front Corner Sensor

Detects the front corner position of the Stapler Unit.

Stapler Front Straight Sensor

Detects the front straight position of the Stapler Unit.

Stapler Rear Straight Sensor

Detects the rear straight position of the Stapler Unit.

Stapler Assembly

Includes Stapler Head and Stapler Cartridge.

SR1508X

Figure 2-30. Dual (Front and Rear Edge) Staple

Operating Principles Paper Path 29

Page 30

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

2.3.2.6 Eject/Offset

Eject Roll revolves counterclockwise and Eject Roll and Offset Roll eject paper

from the Compiler Tray.

SR1509X

Figure 2-31. Rear Edge Staple

SR1521X

Figure 2-33. Eject/Offset

SR1510X

Figure 2-32. Rear Corner Staple

Operating Principles Paper Path 30

Page 31

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

The following figure is paper ejecting mechanism when offsetting paper.

SR1523X

Figure 2-34. Paper Eject When Offsetting Paper

2.3.2.7 Stacker Trays

Operating Principle of Stacker Tray on staple mode is the same as on the

unstaple mode. (“Stacker Trays” on page 27)

Operating Principles Paper Path 31

Page 32

DISASSEMBLY AND ASSEMBLY

CHAPTER

3

Page 33

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.1 Outline

This chapter explains main installation and removal procedures of staple

cartridge or Finisher Stapler.

3.1.1 Preparation

Before starting removal and installation;

1. Turn off the printer.

2. Remove AC power code from the plug.

3. Wear eliminate-static wrist band to avoid damaging any electronic parts

on the print circuit board which can be easily damaged by static

electricity.

3.1.2 Attention for Handling

CAUTION

Parts name here may not match the name on the parts list

precisely. For example, MSI Tray Assembly is the same as

Tray Assembly MSI on parts list.

Use the screw with right type and right size when

installing the parts.

Wrong screws may damage threaded holes.

Do not inflict any unnecessary force for removing and

installing parts.

3.1.3 Notation for Removal and Installation

1. The position (R for right) on the removal and installation is noted,

provided that an operator faces printer Console Panel.

2. The arrows on the figure indicates the direction to move a component

when removing it.

3. Slash on the parts name indicates that several components share the

same initial word and have the same function. For example, “Gear In/

Feed/Out indicates “Gear In, Gear Feed, Gear Out”.

Disassembly and Assembly Outline 33

Page 34

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.2 Up and Down of Finisher Stapler

When the stop button is pressed, the LED of the switch lights on and

the panel indicates “warm up”.

Finisher Stapler moves up when outputting to the bin 3. This is due to for

paper eject bin to move up.

For the safety measures, the paper eject bin can be lowered.

Finisher Stapler moves up and down under the following condition.

1. When applying the power;

When the Finisher Stapler is at bin 2 or bin 3, it moves down to bin1.

Stop button is unavailable.

No panel indication during the move.

2. When ejecting the paper to the staple Stacker;

Move to the target bin.

The panel indication during the move is the same as at the normal

printing operation.

When the EPL-N4000/EPL-N4000+ generates an error, Finisher Stapler

moves to the target position. If the printer does not start printing

again after the Finisher Stapler has moved for about one minute, the

Finisher Stapler moves down to bin 2 or bin 1 as same as in the case

of 3.

3. After ejecting paper to the Finisher Stapler;

About one minute after paper went out of compile tray, the Finisher

Stapler moves down to the bin 2. If there are no paper on bin 2 nor on

bin 3, the Finisher Stapler moves down to bin 1.

About one minute after the Finisher Stapler moves down to bin 1, or

when the stop button is pressed again, the LED of the switch lights off

and then printer will be on line again.

If the paper on bin 2 and bin 3 is removed after the Finisher Stapler

moved down to bin 2, the Finisher Stapler moves down to bin 1 after

about one minute.

No panel indication during the move.

4. When pressing the stop button of the Finisher Stapler;

The Finisher Stapler moves down to bin 1.

When the stop button is pressed during the printing procedure, bin

moves down after the job finishes or after the certain set of copies

has done.

Disassembly and Assembly Up and Down of Finisher Stapler 34

Page 35

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.3 Installation and Removal of Finisher

Stapler and Stapler Cartridge

3.3.1 Finisher Stapler

3.3.1.1 Installation

1. Install the DOC HCS (High Capacity Stacker).

2. Lock 2 casters in the front of HCF.

3. Install the Docking Rail into the left side of the printer’s bottom.

4. Install the Docking Rail into the right side of the printer’s bottom.

5. Install the Bracket Assembly EMI.

6. Raise the Transport Assembly horizontally and raise the ShaftTransport and support the Transport Assembly.

7. Move the Finisher Stapler close to the right side of the printer.

8. Connect HCS AC power cord to the right side of the printer.

9. Push the Finisher Stapler toward to the printer, making sure that a

positioning pin goes into the positioning hole of DOC HCS.

CAUTION

10. Fix the Docking Rail with a screw.

11. Connect the HCS interface cable to the back side of the printer.

Be careful not to shut in AC power cable between the

staple Stacker and the printer.

Figure 3-1. Installing the Finisher Stapler

Disassembly and Assembly Installation and Removal of Finisher Stapler and Stapler Cartridge 35

Page 36

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

ADJUSTMENT

REQUIRED

After installing the Finisher Stapler, adjust the height of the

caster (two). The adjustment procedure is as follows.

Lock nutFixed axis

Table 3-1. Height Adjustment

1. Loosen the lock nut.

2. Adjust the height by moving up and down the Finisher

Stapler with revolving the caster fixed axis.

NOTE: Be careful not to leave any gap between Finisher

Stapler and the printer body.

3. After adjustment, fix the lock nut.

Disassembly and Assembly Installation and Removal of Finisher Stapler and Stapler Cartridge 36

Page 37

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.3.2 Removal

1. Disconnect the HCS interface cable from the printer.

2. Remove a screw from the edge of the Docking Rail.

3. Slide the Finisher Stapler away from the printer.

4. Disconnect HCS AC power cable from the printer.

5. Put the Shaft-Transport back and face down the Transport Assembly.

6. Remove Bracket Assembly EMI.

7. Remove the Docking Rail from the right side of the printer’s bottom.

8. Remove the Docking Rail from the left side of the printer’s bottom.

9. Remove DOC HCS.

Figure 3-2. Removing the Finisher Stapler

Disassembly and Assembly Installation and Removal of Finisher Stapler and Stapler Cartridge 37

Page 38

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.3.3 Installing and Replacing Stapler Cartridge

1. Put staple into the cartridge.

2. Pull the sticker straight out to the arrow direction in the figure 2.

3. Open the Front Cover Assembly and set the cartridge with staple

inside.

4. Close the Front Cover Assembly.

Figure 3-3. Installing the Staple Cartridge

Disassembly and Assembly Installation and Removal of Finisher Stapler and Stapler Cartridge 38

Page 39

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.3.4 Replacing the Stapler Cartridge

1. Open the Front Cover Assembly.

2. Turn the lever and take out the cartridge.

3. Take out the cartridge and remove the empty staple case.

4. Put the staple to the case.

5. Pull out the sticker straight to the arrow direction in the figure 5.

6. Open the Front Cover Assembly and set the cartridge with staple

inside.

7. Close the Front Cover Assembly.

Figure 3-4. Exchanging the Staple Cartridge

Disassembly and Assembly Installation and Removal of Finisher Stapler and Stapler Cartridge 39

Page 40

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.4 Disassembly and Assembly

Front Cover Assembly

3.4.1 Front Cover Assembly

Refer to the exploded diagram (Figure 4-25, "HCS Covers Front" on page 166).

3.4.1.1 Removal

1. Open the Front Cover Assembly.

2. Remove E ring from the upper hinges where Front Cover Assembly and

Front Cover Inner Assembly are connected on.

3. Lift Front Cover Assembly off.

3.4.1.2 Installation

1. Install Front Cover Assembly, inserting two pairs of hinges of Front Cover

Inner Assembly into holes of Front Cover Assembly.

2. Put E ring around the upper hinges and secure Front Cover Assembly on

Front Cover Inner Assembly.

3. Close Front Cover.

Front Cover Inner Assembly

Figure 3-5. Front Cover Assembly

E ring

Disassembly and Assembly Disassembly and Assembly 40

Page 41

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.4.2 Front Cover Inner Assembly

Refer to the exploded diagram (Figure 4-25, "HCS Covers Front" on page 166).

3.4.2.1 Removal

1. Open Top Cover.

2. Open Front Cover Assembly.

3. Remove the screw securing Front Cover Inner Assembly to HCS frame.

4. Securing Unload While Run button pressed, lift Front Cover Inner

Assembly and remove it from HCS frame.

5. Remove Front Cover Assembly. (Refer to “Front Cover Assembly” on

page 40)

3.4.2.2 Installation

1. Install Front Cover Assembly. (Refer to “Front Cover Assembly” on

page 40)

2. Install Front Cover Inner Assembly to the body by inserting two tabs at

the bottom of Front Cover Inner Assembly into cutouts in HCS frame.

3. Securing Unload While Run button pressed, insert the top part of Front

Cover Inner Assembly to HCS frame.

4. Set Front Cover Inner Assembly as Unload While Run button can move

smoothly when pressed and unpressed.

5. Secure Front Cover Inner Assembly to HCS frame with a screw.

Unload While Run button

Cutouts in HCS frame

FR

O

N

T

Front Cover Inner Assembly

6. Close the Front Cover Assembly.

7. Close Top Cover.

Figure 3-6. Front Cover Inner Assembly

Disassembly and Assembly Disassembly and Assembly 41

Page 42

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.4.3 Front Low Cover

Refer to the exploded diagram (Figure 4-25, "HCS Covers Front" on page 166).

3.4.3.1 Removal

1. Remove HCS from the printer. (Refer to “Finisher Stapler” on page 35)

2. Remove three screws securing Front Low Cover to HCS frame.

3. Pull Front Low Cover to the right and remove it from the frame.

3.4.3.2 Installation

1. Place Front Low Cover as shown in the Figure 3-7.

2. Parallel Front Low Cover to the frame as three tabs on the frame fall into

rectangular cutouts on Front Low Cover.

3. Insert Front Low Cover to HCS frame.

4. Secure Front Low Cover to HCS frame with three screws.

5. Connect HCS and the printer. (Refer to “Finisher Stapler” on page 35)

Figure 3-7. Front Low Cover

Disassembly and Assembly Disassembly and Assembly 42

Page 43

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.4.4 L/H Cover

Refer to the exploded diagram (Figure 4-25, "HCS Covers Front" on page 166).

3.4.4.1 Removal

1. Remove Transport Assembly. (Refer to “Transport Assembly” on

page 130)

2. Remove Rear Cover (Refer to “Rear Cover” on page 46)

3. Remove three screws securing L/H Cover to HCS frame.

4. Remove L/H Cover.

3.4.4.2 Installation

1. Install L/H Cover by first siding L/H Cover front end into the Front Cover.

2. Place L/H Cover to the frame as threaded holes of the frame and those of

L/H Cover be at the same position.

3. Secure L/H Cover to HCS frame with three screws.

4. Install Rear Cover. (Refer to “Rear Cover” on page 46)

5. Install Transport Assembly. (Refer to “Transport Assembly” on page 130)

Figure 3-8. L/H Cover

Disassembly and Assembly Disassembly and Assembly 43

Page 44

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.4.5 L/H Cover Low

Refer to the exploded diagram (Figure 4-25, "HCS Covers Front" on page 166).

3.4.5.1 Removal

1. Remove HCS from the printer. (Refer to “Finisher Stapler” on page 35)

2. Remove Transport Assembly (Refer to “Transport Assembly” on

page 130)

3. Remove six screws securing L/H Cover Low to HCS frame.

4. Remove L/H Cover Low from the frame.

3.4.5.2 Installation

1. Place L/H Cover Low to HCS frame.

2. Secure L/H Cover Low to the HCS frame with six screws.

3. Install Transport Assembly. (Refer to “Transport Assembly” on page 130)

4. Connect HCS and the printer. (Refer to “Finisher Stapler” on page 35)

Figure 3-9. L/H Cover Low

Disassembly and Assembly Disassembly and Assembly 44

Page 45

EPSON EPL-N4000/EPL-N4000+ Optional Finisher Stapler Revision A

3.4.6 Eject Cover