Epson EPL-C8000 Service Manual

®

SERVICE MANUAL

Color Laser Printer

EPSON ColorPage EPL-C8000

4009762

Notice

o All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic,

mechanical, photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

o All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

o The contents of this manual are subject to change without notice.

o All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

o The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

EPSON WARRANTY.

About this manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of EPL-C8000. The

instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on

the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. DISASSEMBLY / ASSEMBLY AND ADJUSTMENT

Describes the step-by-step procedures for

disassembling/assembling and adjusting the product.

CHAPTER 4. DIAGNOSTICS

Provides Epson-approved methods for diagnostics.

CHAPTER 5. TROUBLESHOOTING

Provides the step-by-step procedures for

troubleshooting.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

APPENDIX Provides the following additional information for

reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Symbols Used in This Manual

Various symbols are used throughout this manual either to provide

additional information on a specific topic or to warn of possible danger

present during a procedure or an action. Be aware of all symbols when

they are used, and always read NOTE, CAUTION, or WARNING

messages.

Indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, could result in

injury or loss of life.

Indicates an operating or maintenance procedure, practice,

or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure,

practice or condition that is necessary to accomplish a task

efficiently. It may also provide additional information that is

NOTE

related to a specific subject, or comment on the results

achieved through a previous action.

Abbreviation

ADC = Automatic Density Control

AG = Analog Ground

ASSY = Assembly

AUX. = Auxiliary

B/W = Black and White

BCR = Bias Charge Roll

Bk = Black

BK = Black

BTR = Bias Transfer Roll

BUR = Back Up Roll

C = Cyan

CART. = Cartridge

CCW = Counterclockwise

CL. = Clutch

CLN = Cleaning (or Cleaner)

CLK = Clock

CONT. = Controller

CR = Charge Roll

CRU = Customer Replaceable Unit

CRUM = CRU Monitor

CW = Clockwise

DB = Developing Bias

DEVE. = Developer

DIAG. = Diagnostic

dpi = dots per inch

DTS = Detach Saw

ELEC. = Electric

EP = Electrophotography

FDR = Feeder

FG = Frame Ground

FRU = Field Replaceable Unit

GND = Ground

H/R = Heat Roll

Hex = Hexadecimal

HVPS = High Voltage Power Supply

I/F = Interface

IBT = Intermediate Belt Transfer

ID = Image Density (or Identification)

L = Left

L/H = Left Hand

L/P = Low Paper

LD = Laser Diode

LEF = Long Edge Feed

LVPS = Low Voltage Power Supply

M = Magenta

MAG. = Magnetic

MCU = Machine Control Unit

MECH. = Mechanical

MOT. = Motor

MSI = Multi Sheet Inserter

N/F = Normal Force

N/P = No Paper

NVM = Non Volatile Memory

O/H = Option Hinge

OHP = Overhead Projector

(In this manual, OHP means OHP film)

OPC = Organic Photo Conductor

P/H = Paper Handling

P/R = Pressure Roll

PCDC = Pixel Count Dispense Control

Pixel = Picture Cell

PPM = Prints Per Minute

PV = Print Volume

PWB = Printed Wiring Board

R = Right

R/H = Right Hand

REGI. = Registration

ROS = Raster Output Scanner

RTN = Return

SEF = Short Edge Feed

SG = Signal Ground

SNR = Sensor

SOL. = Solenoid

SOS = Start Of Scan

SPI = Scans Per Inch

SYNC. = Synchronous

TC = Toner Concentration

TEMP. = Temperature

TR = Transfer

TRANS. = Transport

WDD = Wide Range Dynamic Damper

XERO. = Xerographic

Y = Yellow

YMCBk = Yellow, Magenta, Cyan, Black

Safety Information

To prevent accidents during a maintenance procedure, strictly observe

the Warnings and Cautions. Do not do anything that is dangerous or not

within the scope of this document.

Do not do anything that is dangerous even if not specifically described

in this manual. In addition to the descriptions below and those given in

this manual, there are many situations and circumstances that are

dangerous. Be aware of these when you are working with the printer.

Power Supply

Before starting any service procedure, switch off the printer power and

unplug the power cord from the wall outlet. If you must service the

printer when the power is applied, be aware of the potential for electrical

shock and do all tasks by following the procedures in this manual.

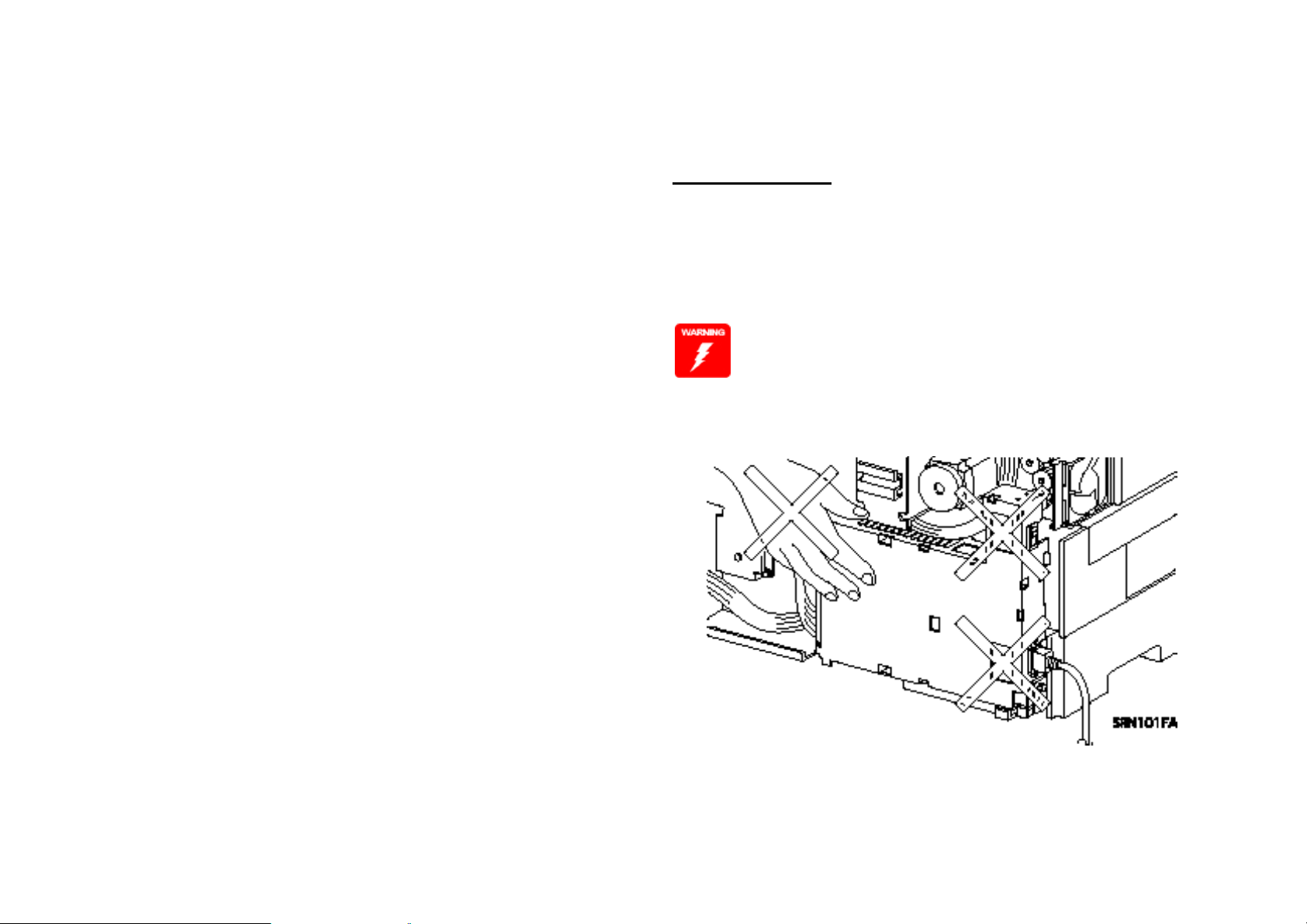

Do not touch any live part unless you are instructed to

do so by a service procedure. The LVPS power supply

switch/inlet part is live even when the power switch has

been turned off. Do not touch any live part.

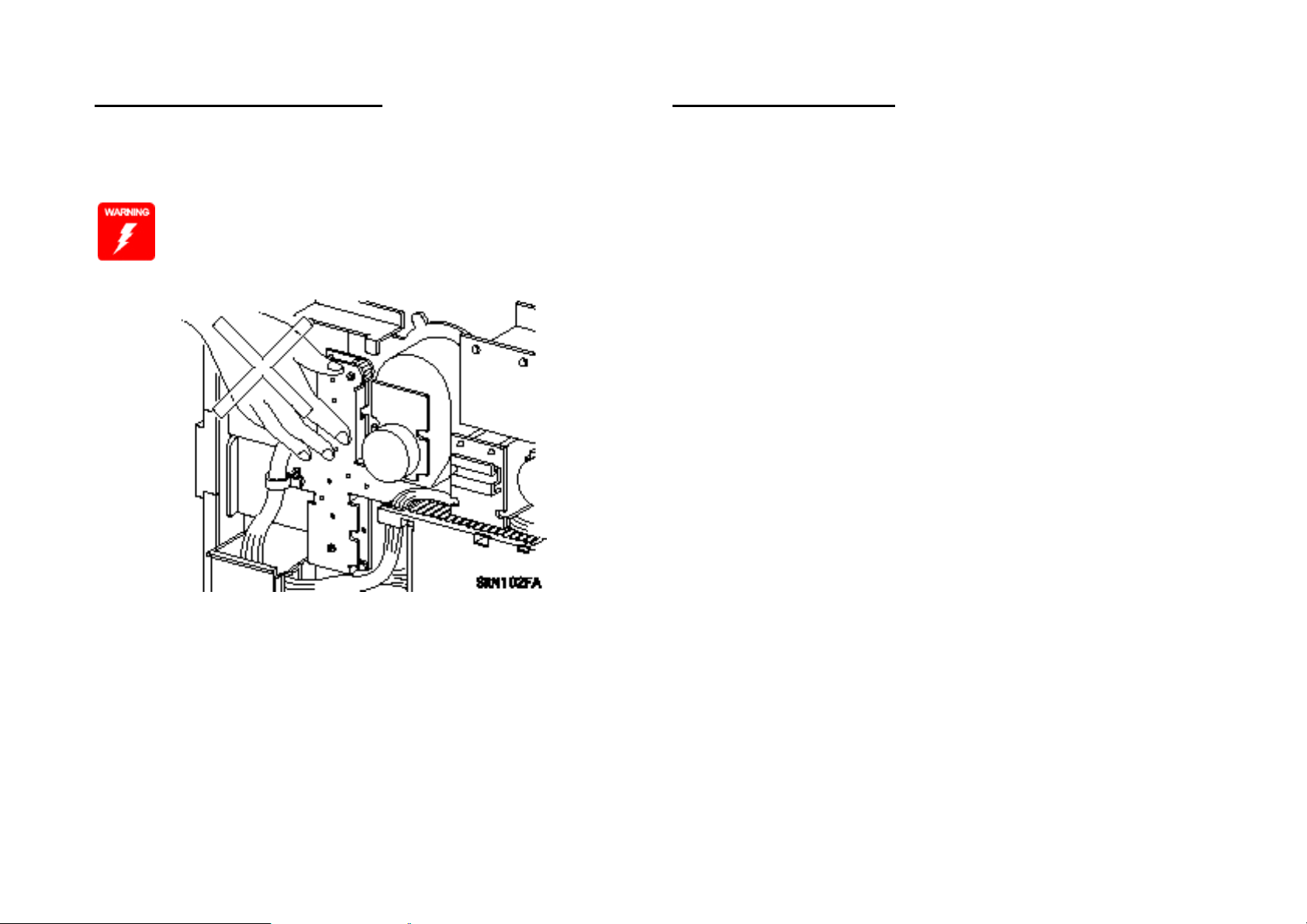

Mechanical Components

Safety Components

If you service a driving assembly (e.g., gears), first turn off the power

and unplug the power cord. Then manually rotate the assembly.

Do not touch the driving part (e.g., gears) while the

assembly (printer) is being driven.

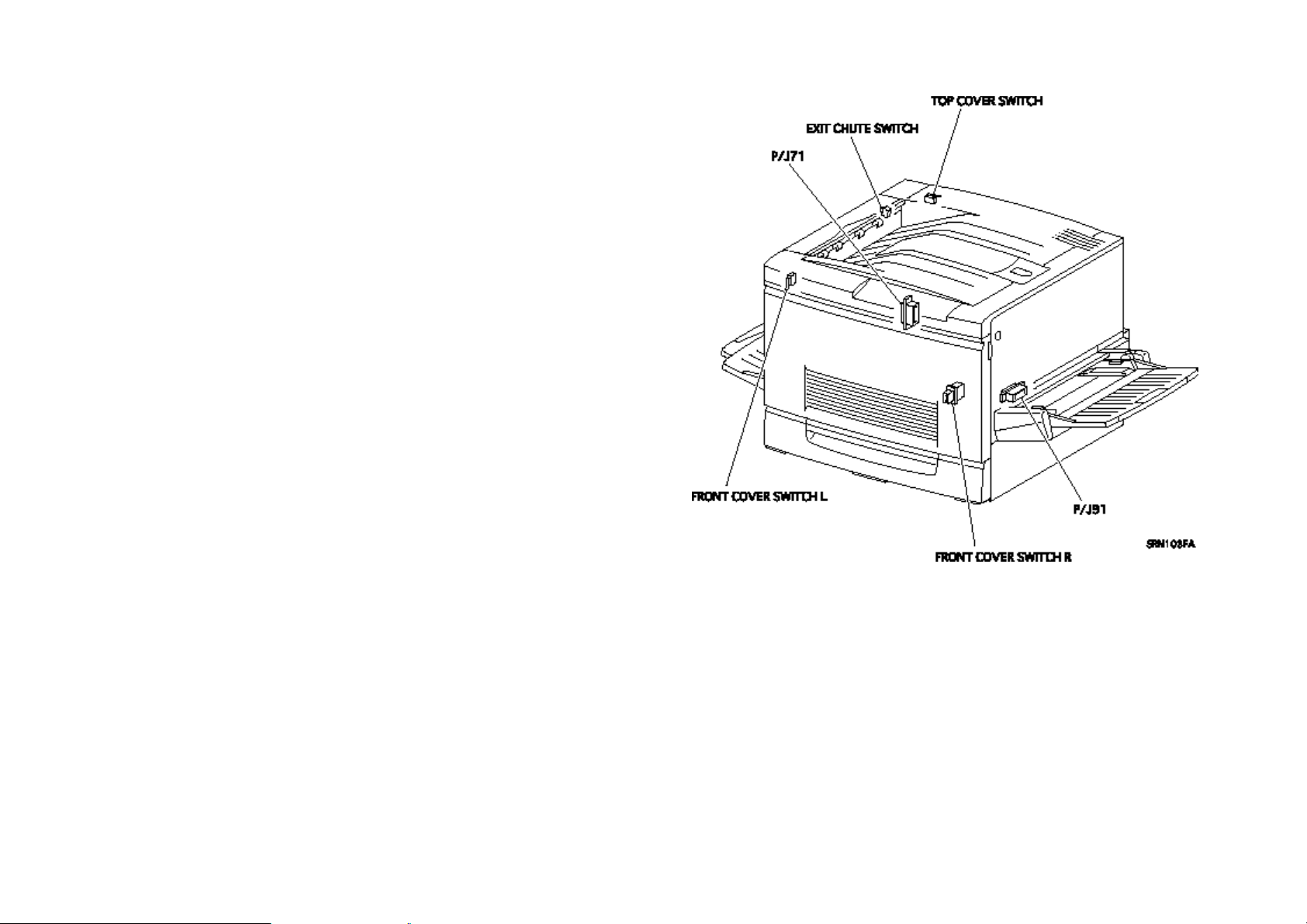

The printer is equipped with safety components (e.g., interlock

switches, fuses, thermostat) and safety switches for protecting users

and service personnel from injury and the equipment from damage.

The printer has two interlock switches, two safety switches and two

interlock connectors that serve as the main safety mechanism.

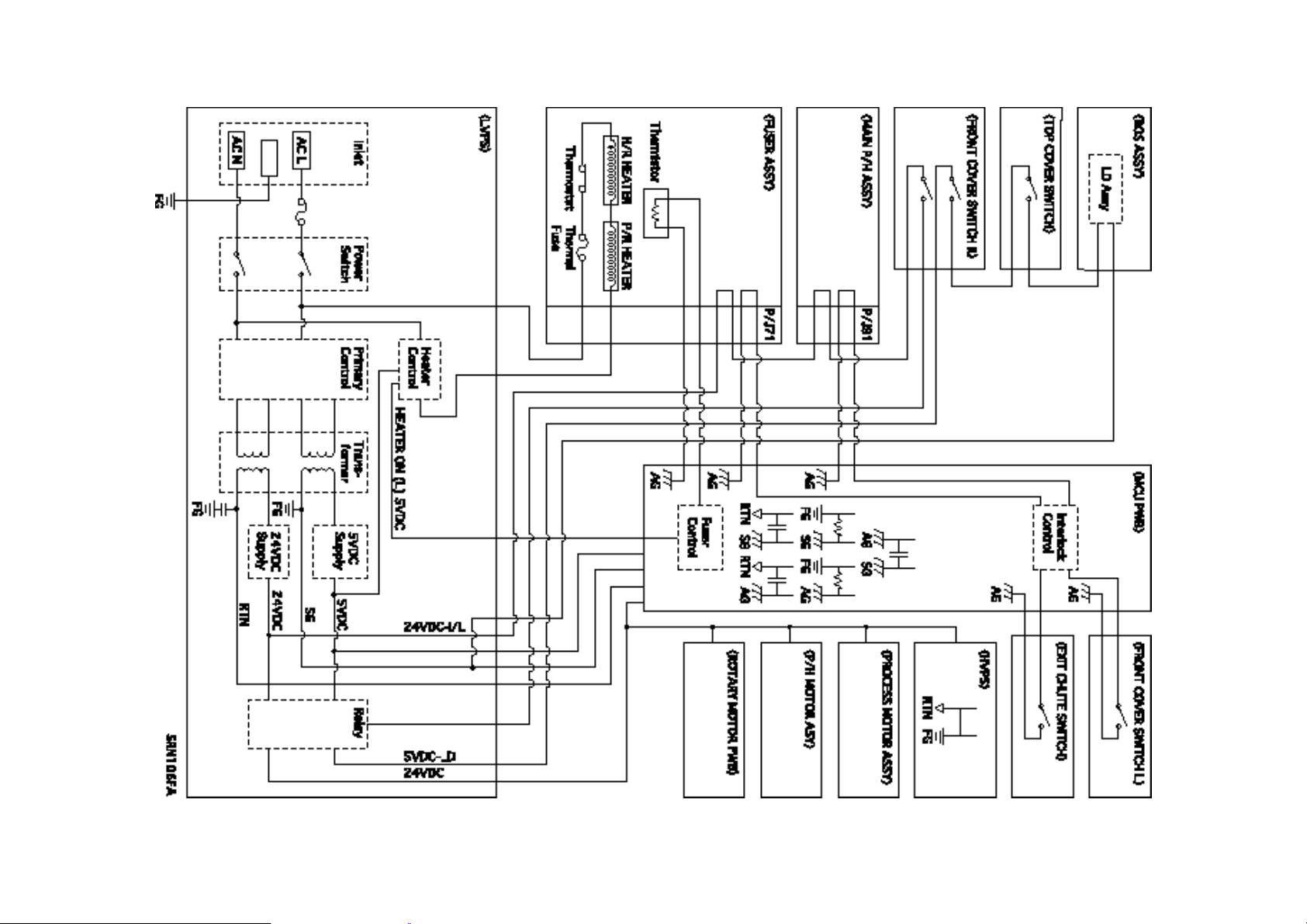

o Front Cover Switch R

This switch is turned off when the Front Cover Assembly is opened.

It cuts off the power supply (24VDC, 5VDC-LD) from the power

supply unit to stop all operations and disconnects the output (5VDCLD) circuit from the power supply and stops the laser beam

emission.

This switch consists of the following two switches:

n A switch that cuts off the power supply (24VDC, 5VDC-LD) to

the control circuits and related parts.

n A switch that directly cuts off the power supply circuit (5VDC-LD)

to the laser beam output circuit.

o Front Cover Switch L

This is a safety switch. This switch is turned off when the Front

Cover Assembly is opened, causing the printer without control units

to stop operating.

o Top Cover Switch

This is an interlock switch that directly cuts off the power supply

(5VDC-LD) circuit to the laser beam output circuit. This switch is

turned off when the Top Cover Assembly is removed, cutting off the

output (5VDC-LD) circuit from the power supply unit and stopping

the laser beam emission.

o Exit Chute Switch

This switch is a safety switch. This switch is turned off when the Exit

Upper Assembly (the cover on the upper left side of the printer) is

opened.

o P/J91 (Connector that connects the Main Harness Assembly and

Registration Harness Assembly)

This is an interlock connector that cuts off the power supply

(24VDC, 5VDC-LD) to the control circuit and related parts.

This connector is disconnected when the Main P/H Assembly (pullout type unit on the right side of the printer) is pulled out, cutting off

the output (24VDC, 5VDC-LD) from the power supply and stopping

the printer operation without control units.

o P/J71 (Connector that connects the Fuser Connector and Fuser

Harness Assembly)

This is an interlock connector that cuts off the power supply

(24VDC, 5VDC-LD) to the control circuit and related parts.

This connector is disconnected when the Fuser Assembly (pull-out

type unit on the left side of the printer) is pulled out, cutting off the

output (24VDC, 5VDC-LD) from the power supply and stopping the

printer operation without control units.

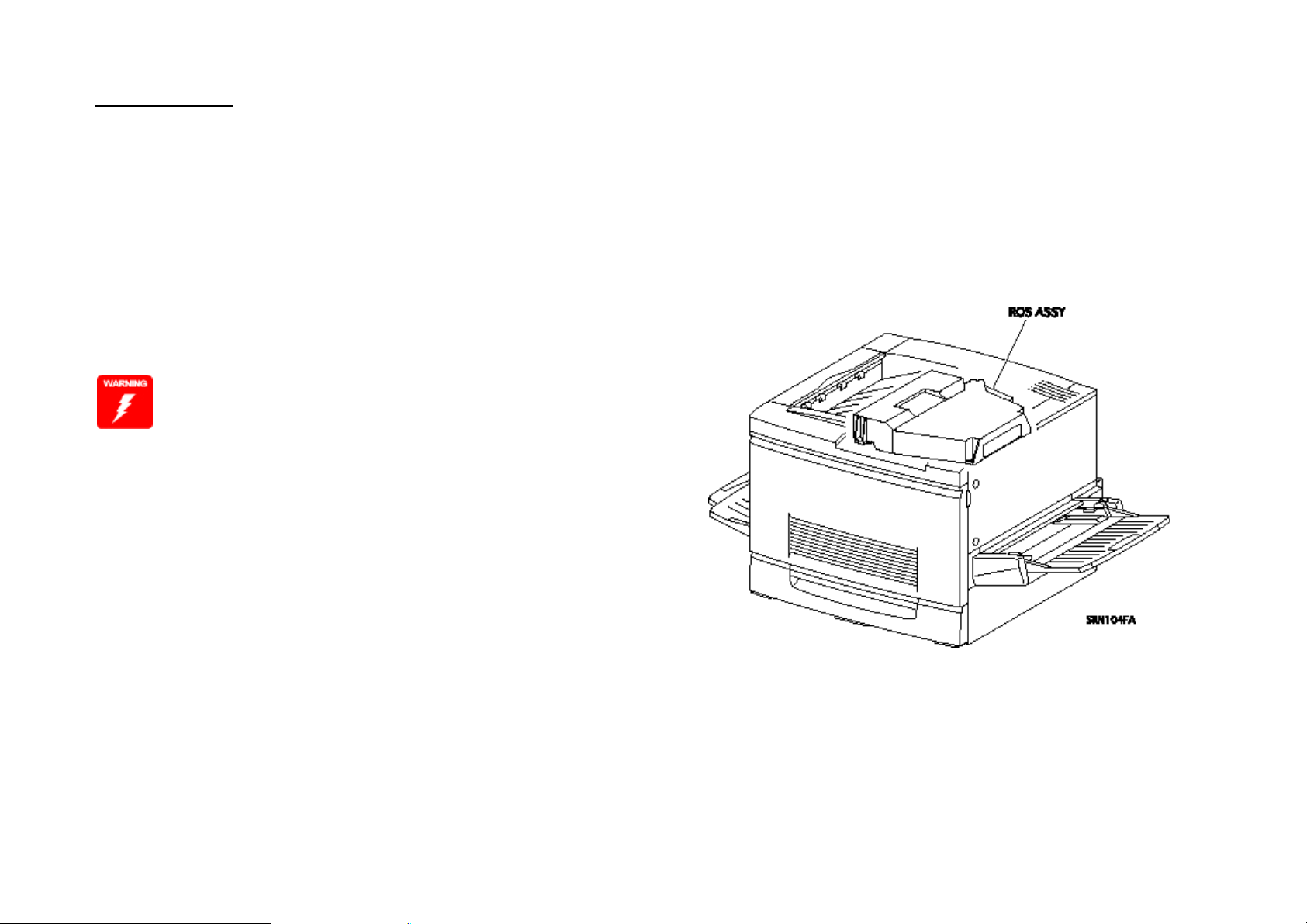

Laser Beam

The printer has two interlock switches: the Front Cover Switch R and

the Top Cover Switch. The purpose of these switches is to turn off the

laser beam emission if any of the printer covers have been opened; this

protects the user or service personnel from exposure to the laser beam

from the ROS Assembly.

NOTE:The laser beam has a narrower frequency band and more

coherent phases than any other light (sunlight, electric light).

It has excellent monochromaticity and convergence. A thin

laser beam reaches long distances. Because of its

convergence characteristic, the laser beam converges into

one point, causing high density and high temperature. A

laser beam is harmful to the human body.

A laser beam may be emitted during a maintenance operation. Do not

turn on these interlock switches simultaneously under any

circumstances except in a normal operation.

n Do not expose yourself to the laser beam to prevent

injury (blindness).

n Do not open the cover that has the laser beam

warning label.

n If you disassemble or assemble the printer, turn off

the power.

n If you need to work on the printer with power applied,

strictly follow the instructions in this manual.

n If you have to activate the printer while pressing the

Front Cover Switch R by hand or with a tool, remove

the Top Cover. (Do not turn on these interlock

switches simultaneously under any circumstances

except in a normal operation.)

n Understand how the laser beam functions and take

maximum precautions not to injure yourself or anyone

around you.

NOTE:The laser beam in this printer is invisible.

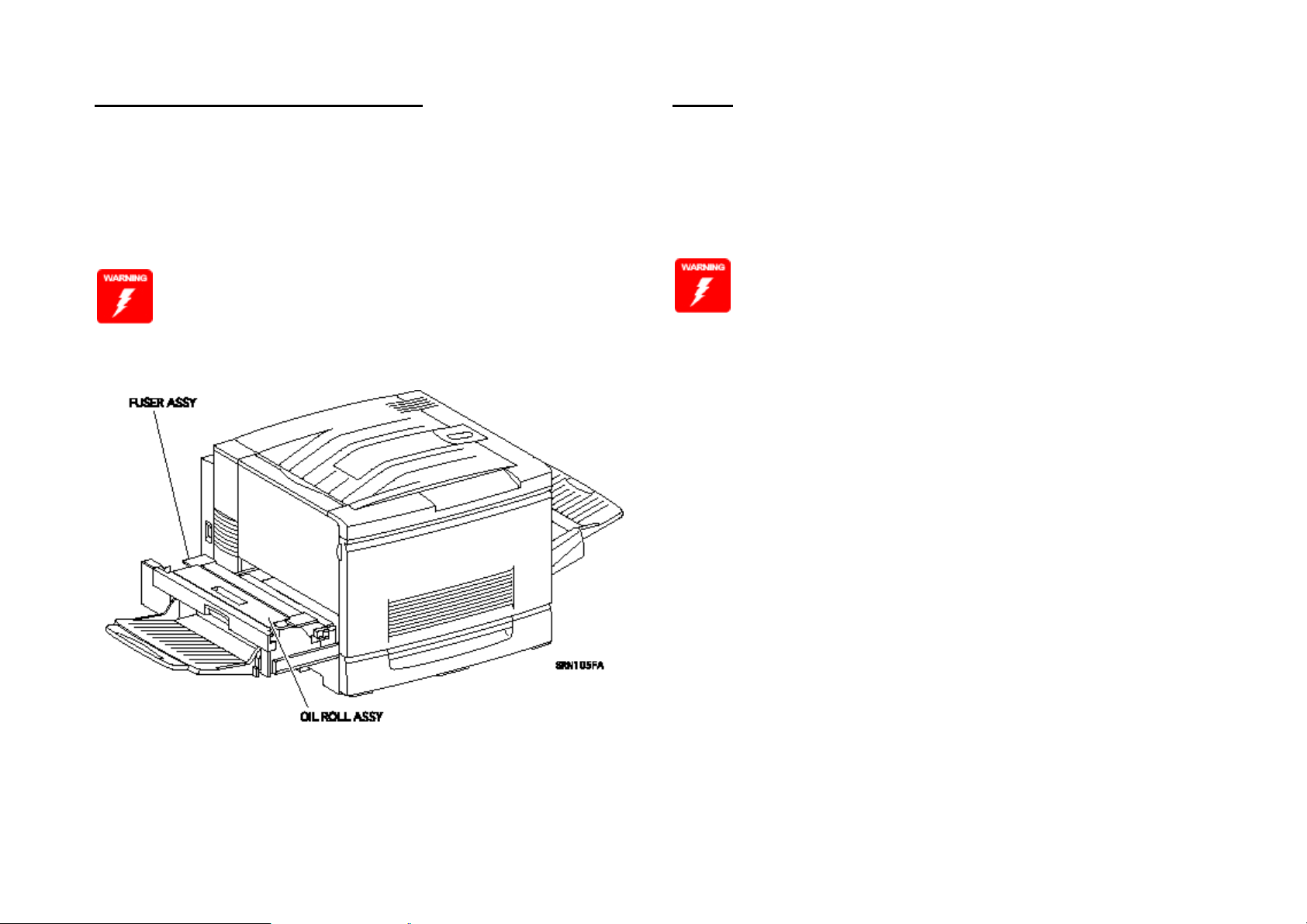

High Temperature Assembly

Parts

To prevent you from becoming injured or burned, do the following:

Before working with a high temperature Assembly (e.g., Fuser

Assembly), turn off the power, unplug the power cord and wait until it

cools down.

The high temperature Assembly is very hot

immediately after any printer operations. Wait at least

40 minutes before you start working on the printer.

To prevent you from becoming injured, keep the following in mind:

o When handling heavy parts (including the printer itself), use good

posture to protect your back whenever you lift, move or place parts.

Do not lift, move or place heavy parts in a body posture

that is likely to cause injury to yourself or cause the

part to drop.

o Be careful not to injure yourself with the sharp edges of the parts.

o Do not work with wet or oily hands-you may drop a part or injure

yourself. Dry your hands first.

o When pulling out a part (including a harness), do not use too much

force. Pull out the part carefully and slowly step by step.

Consumables

Improper Printer Use

Some parts may cause a particulate explosion or fire if handled

improperly. Do not handle these parts near fire or throw into a fire.

Some materials (e.g., Developer or Fuser Oil) may cause bodily injury.

Do not swallow or inhale these materials or allow them to come in

contact with the eyes.

Help to protect those around you and follow the prohibitions against

swallowing or inhaling those materials. Be careful to protect the eyes at

all times.

Place a sheet inside or under the printer so that the floor or workbench

is protected.

If the Developer or Fuser Oil gets on your clothing, dry it with a cloth and

wash with clean water.

NOTE:The printer has the following consumable parts:

•Drum Cartridge •Waste Toner Box

•Oil Roll Assembly •Toner Cartridge Y

•Toner Cartridge M •Toner Cartridge C

•Toner Cartridge Bk

Modifying, revising, tampering with the printer, especially to the safety

mechanism, is strictly prohibited in all circumstances.

Manual Contents

Chapter 1 PRODUCT DESCRIPTIONS

Chapter 2 OPERATING PRINCIPLES

Chapter 3 DISASSEMBLY AND ASSEMBLY / ADJUSTMENT

Chapter 4 DIAGNOSTICS

Chapter 5 TROUBLESHOOTING

Chapter 6 MAINTENANCE

Appendix

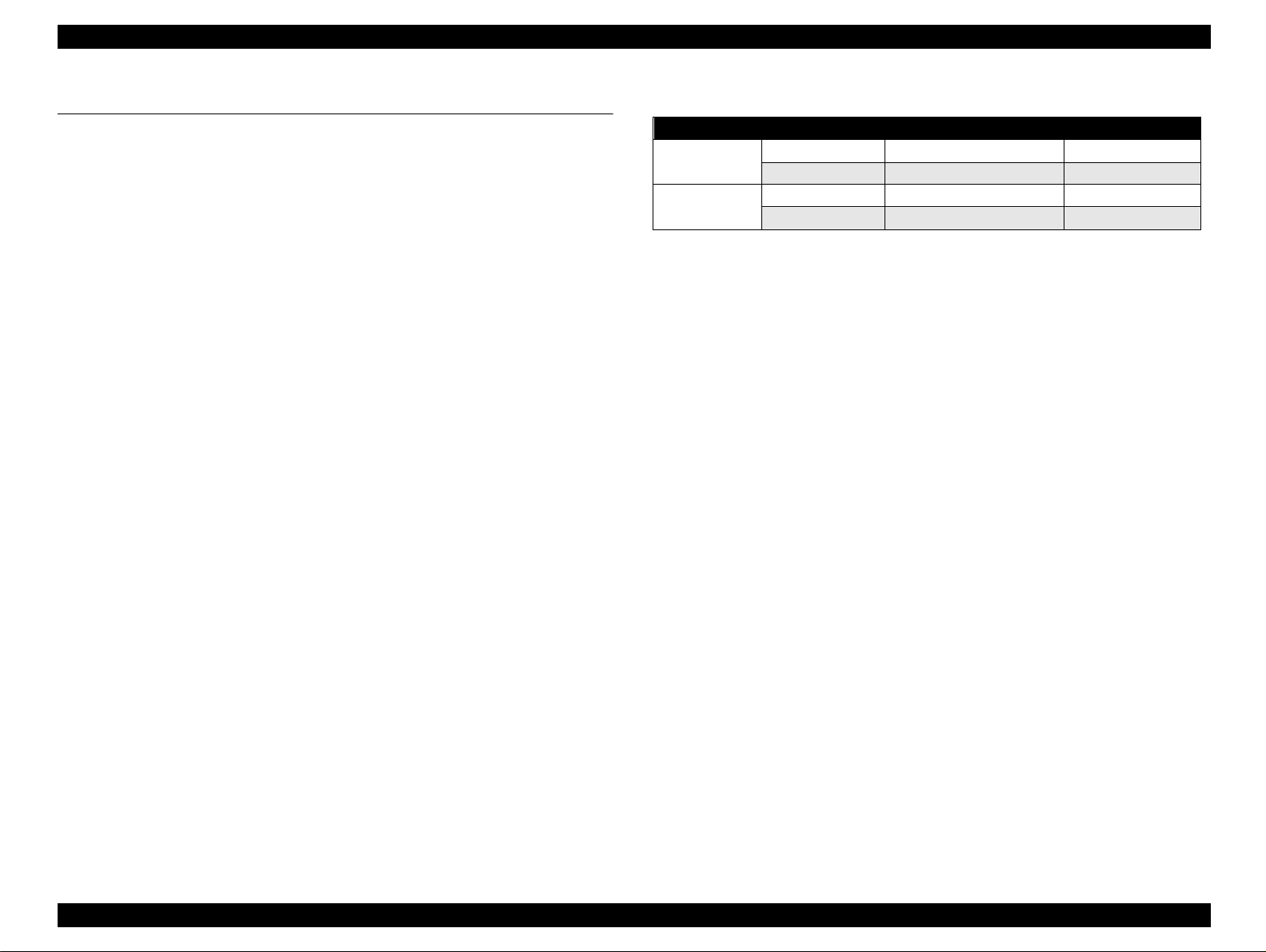

Revision Status

Revision Issued Date Description

Rev. 0

(Preliminary revision)

Rev. A September 28, 1998 2nd release

Rev. B August 23, 1999 The manual is mainly revised on the following points:

August 07, 1998

1st release

[Chapter 1]

• Page 1-4: Paper Out Sensor is added.

• Page 1-6: IBT Cleaner is eliminated from the regularly replaced parts.

• Page 1-30: NOTE is added to Section 1.5.4.

[Chapter 3]

• Page 3-2: Change in Table 3-1.

• Page 3-6: NOTE is added to Section 3.2.3.1 under “Preparation”.

• Page 3-96: Section 3.2.12.21 “FUSER IN SENSOR Removal” is added.

• Page 3-97: Section 3.2.12.22 “FUSER CHUTE FAN Removal” is added.

• Page 3-119: CHECK POINT box is added.

• Page 3-121: New adjustment item “DEVE. SPACER Selection” is added.

[Chapter 4]

• Page 4-1: Change in the procedure for Test Print my MCU PWB.

• Pages 4-3, 4-7, 4-61: DIAGNOSTIC DATA DISK is replaced by SELF

TRAINING KIT (#F728).

[Chapter 7:]

• Fuser relating exploded diagrams and controller are mainly replaced.

PRODUCT DESCRIPTIONS

CHAPTER

1

EPSON EPL-C8000 Revision B

Contents

FEATURES ........................ ...... ....... ............................................. ....... ...... ..... 1

SPECIFICATIONS ............................................. ....... ...... ....... ...... ....... ...... ..... 3

Basic Specifications ...................................... ............................................ 3

Paper Specification ................................................................................... 8

Reliability and Durability.......................................................................... 11

Operating Environment (including options) ............................................. 13

Environmental Conditions for Storage and Transportation ..................... 14

Electrical Specification ............................................................................ 15

Process Specifications ............................................................................ 16

Applicable Standards .............................................................................. 16

Consumables and Options...................................................................... 17

Toner cartridge ................................................................................... 17

DRUM CARTRIDGE ........................................................................... 18

Fuser Oil Roll ...................................................................................... 19

Waste Toner Box ................................................................................ 19

Regularly Replaced Parts........................................................................ 19

Exterior Dimensions ................................................................................ 20

Controller Specification ........................................................................... 21

Controller Board Jumper Settings........................................................... 21

INTERFACE SPECIFICATIONS........... ....... ...... ....... ................................... 22

Parallel Interface Specification................................................................ 23

Option Interface....................................................................................... 25

CONTROL PANEL....................................................................................... 26

Appearance and Descriptions................................................................. 26

LED Description ................................................................................. 27

Button Functions ..................................................................................... 28

SERVICE FUNCTIONS................... ...... ....... ...... ....... ...... ....... ...................... 30

Hex dump Mode...................................................................................... 30

EEPROM Initialization............................................................................. 30

Formatting the Flash ROM Module......................................................... 30

Updating the Program ROM.................................................................... 30

ROM Module Copy.................................................................................. 30

Panel Setting Initialization....................................................................... 31

Maintenance Mode.................................................................................. 31

Error Recovery Operation ....................................................................... 31

PANEL SETTING......................................................................................... 32

Setting Methods ...................................................................................... 32

SelecType Setting Menu List .................................................................. 35

Details of Menus and Settings ................................................................ 39

EPSON EPL -C 8000 Rev. B

1.1 Features

EPL-C8000 is a non-impact color page printer that makes the most use

of the semi -c onductor laser and elec tr ophotographic technology.

o Engine

1. Designe d f or performan c e in t rue business environme nt s . S upports

sizes from A5 to A3W. Printing speed (on A4/Let t er) is 4ppm for

color print ing, 16ppm for m onochro m e printing.

2. Supports high-resolut ion full color (T rue 600dpi) .

3. Can generate high-quality print s on s pecial (dedic at ed) paper.

4. Supports th ic k sh eets and OHP (dedicated OHP shee t s) .

5. Easy to ma int ain.

6. 2 Standard paper feed bins= paper t ray (150 sheets; A3W) a nd

standard universal cassette (250 sheets: A3).

When the optional Large Capacity Paper unit attached, total

capacity is up to 1150sheets with 5 bins.

7. Standard paper eject ion is face down (up to 250 sh eets). Face-up

ejection is al s o av ailable (up to 150 sheets ).

o Controller features

1. Newly dev eloped high -s peed controller

n New 64-bit RISC CPU: R4700 - 133MHz

n 64-bit high speed memory: SDRAM DIMM

n 64MB RAM standard: expanda ble up to 256MB (2 expans ion

slots)

2. Color management technology

n AcuL as er Color Halft oning includ ed

n RGB mu lt iv alue input proc es s ing (Controller carries out

binarization proce ssing: color m apping, colo r c orrection, and

screening.)

n Enhanced ASIC (AcuLaser Color Halfto ning, CCNV)

3. Data compression technology

n Multiv alue data compression: reduces RA M us e and incres es

host-I/F data transfer speed.

4. Firmware Program is executed on the RAM.

At the power on, compressed ROM program data is expanded into

RAM by lPL in the MASK ROM.

n RAM execution increases processing speed (fast access, 64-bit

proces s ing instead of 32-bit)

n Program compres s ion reduce s us age of program m emory in

ROM

5. Bi-d irectional I/F c onforms to IE EE1284 ECP

n ECP- based high-s peed data transfer (to/from host)

n Printer can return status to host.

6. Includes two Type-B interface slots.

7. inst allation of expansion RAM (DIMMs) provides improvements in

the follo w ing.

n Drawing area for Ac uLaser Color Halftoning, Enhanced Micro

Gray.

n Print data processing speed

n Resolution

8. Incl udes toner-sav e mode (color, monochrome)

Chapter 1 PRODUCT DESCRIPTIONS 1-1

EPSON EPL -C 8000 Rev. B

9. ROM update by flash-DIMM installation

10. Includes RIT and Enhanced Micro Gray monochrome technologies

o Software features

1. ESC/Page-Color

n Printer pages: High Speed priorit y . Color correction and col or

adjustment can be set for each object. (But 1 resolution and

screen typ e [ gradation=LPl] per page.)

n Driver page: Fast pro c es s ing (on fast PC ). Co lor correctio n and

color adjustment can be set for each object.

n Image: Full co lor (WYSIW YG).

2. Bidirecti onal EJL can re tr iev e printer sta t us and monitor the printer

environm ent.

3. The following emulation modes are fully compatible with EPL-5700:

LJ4, GL2, ESCP2, FX, I239X, and ESC/Page (monochrome).

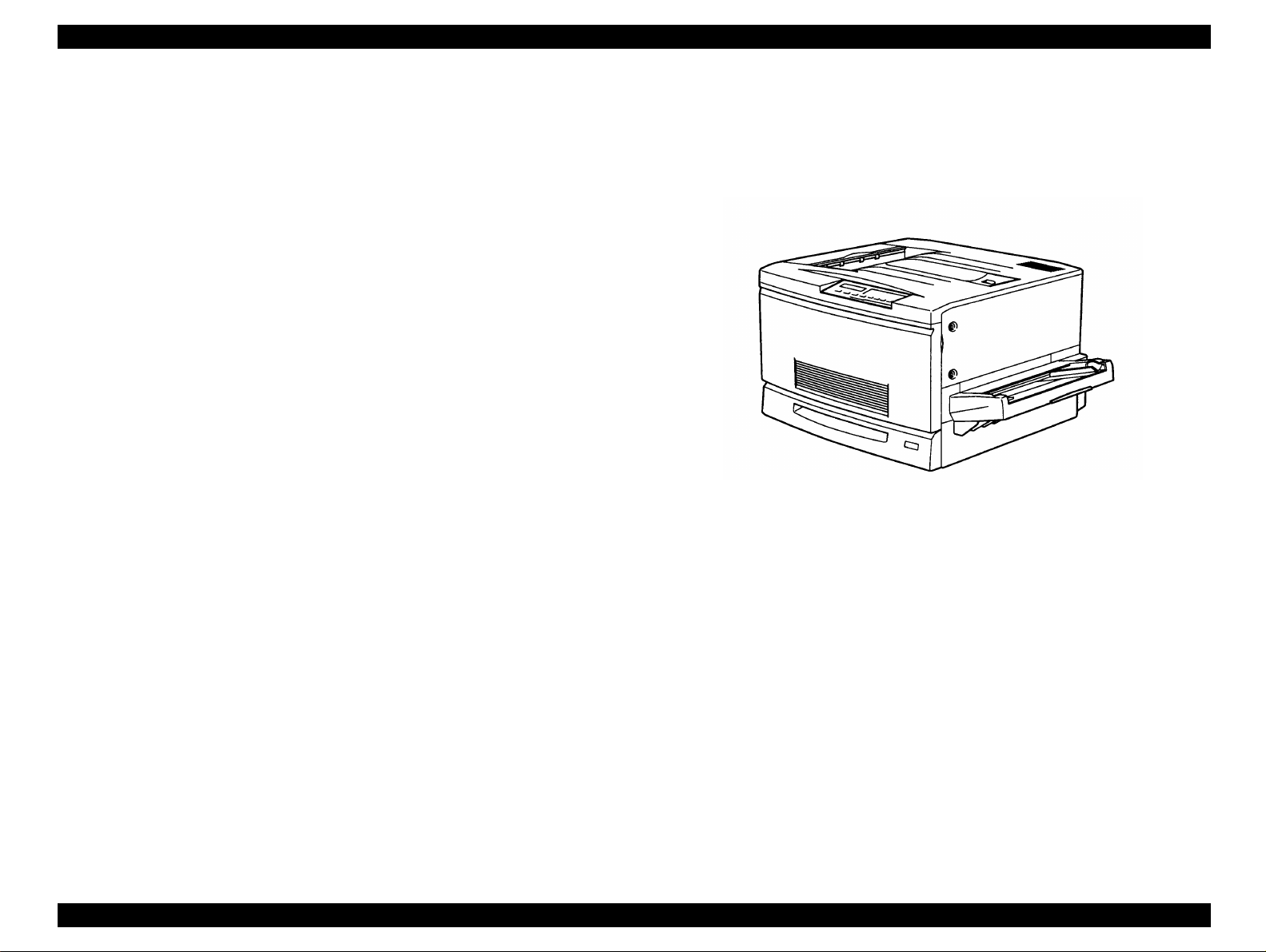

Figure 1-1. Exterior View of EPL-C8000

Chapter 1 PRODUCT DESCRIPTIONS 1-2

EPSON EPL -C 8000 Rev. B

1.2 Specifications

This section describe s sp ec if ic at ions for this printer.

1.2.1 Basic Specifications

o Method: Semi-conductive lase r beam scanning and dry

electrophotographic process

o Resolut ion: 600 DPI

o Print mode:

n B/W mo de: St andard monochrome p rint m ode that su pports

the fastest speed.

n Color mode: Color mode which uses the color toner of Y, M, C,

and BK.

o Speed m ode:

n Standa rd mode: Transport s paper at the high es t s peed

supporte d by the printer.

n Half speed mode: Low speed mode that enables better fusing

2

for thick pa per (over 105g/ m

and OHP s heet.

o Print Sp eed: See Table 1-1.

) envelopes,

Table 1-1. Speed Mode

Print mode Speed m ode LT/A4 LEF 2UP (*1) B(LD)/A 3 S E F (*2 )

B/W Standard mode 16 PPM or more 8PPM or more

Half speed mode 2.7 PPM or more 1.3PPM or more

Color Standard mode 4 PPM or more 2PPM or more

half speed mode 1.8 PPM or more 0.9PPM or more

Notes:

*1. In this mo de, the print er prints tow prin t im ages on the IB T belt and

the imag es are transfer red in sequenc e onto two sheet s of paper. It

is availa ble for LT/A4 (LEF) or smaller.

*2. [LEF, or Long Edge Feed]

The longer edge of the paper is the top toward the paper feed direction.

[SEF, or Short Edge Feed]

The shorter edge of the paper is the top toward the paper feed direction.

o First print*:

- Face-up B/W: 20 seconds or less (LT/A4 LEF)

Color: 42.6 seconds or less (LT/A4 LEF)

- Face-down B/W: 24.9 seconds or less (LT/A4 LEF)

Color: 47.6 seconds or less (LT/A4 LEF)

NOTE:Fist print is de fi ned as the duration taken af t er receiving t he

start command un ti l out putting the fi rs t p rint . It is applicable

when a feeder is selected in the standard mode. (Not applied

during the process cont rol operation.)

o Warm-up ti m e: Within 300 seco nds

(at 22 degree Celsius, 58% Rh, rated voltage)

Chapter 1 PRODUCT DESCRIPTIONS 1-3

EPSON EPL-C8000 Rev. B

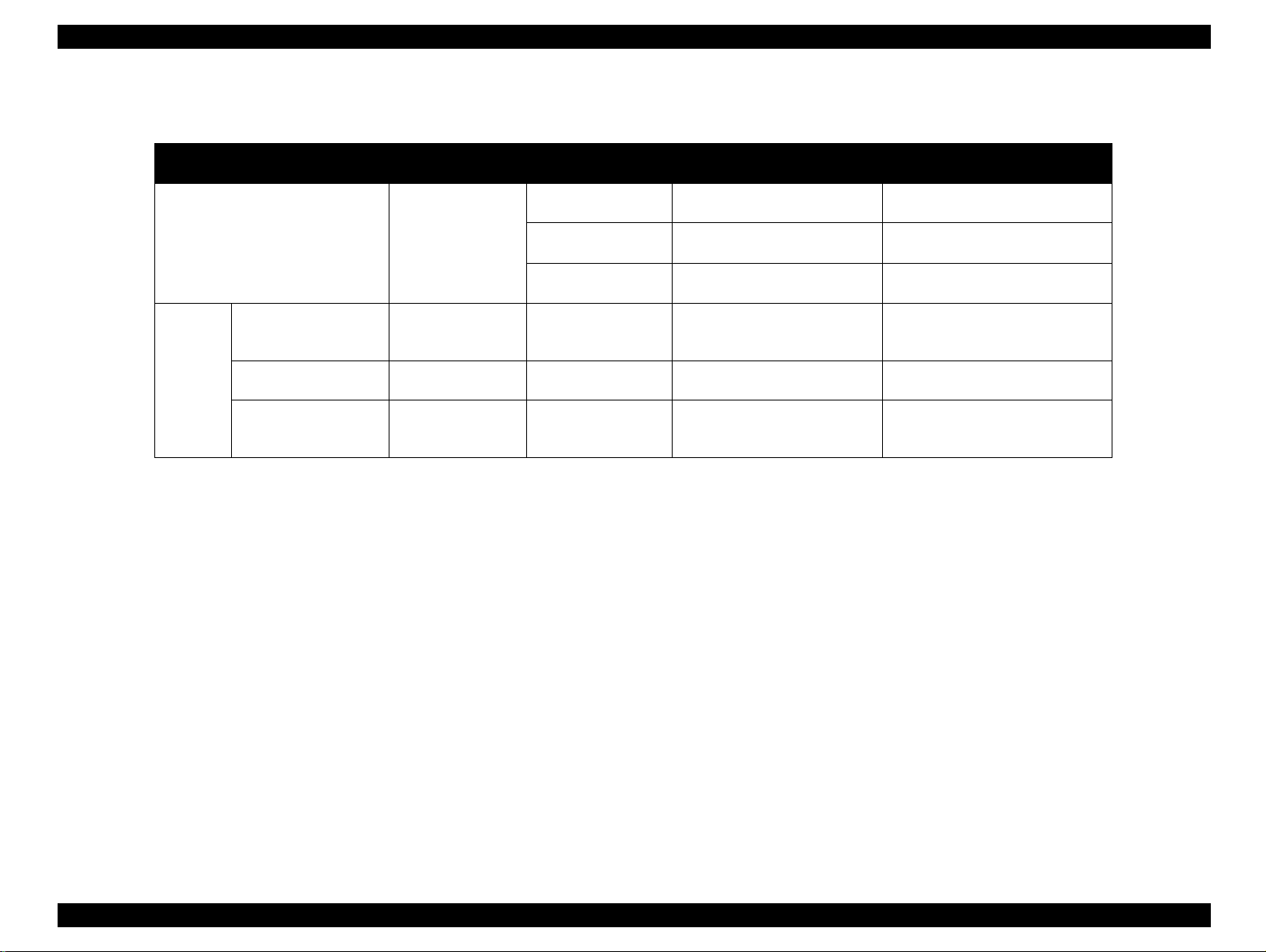

o Paper Handling: See Table 1-2.

Table 1-2. Paper Feeding

Capacity

Paper source Available feeder

Standard Tray (MSI) *1 *5

Cassette

Unit

*2 *6

Notes:

Standard universal

cassette

A3W cassette (option) Standard feeder 250 sheets (28mm) A3W (304.8 x 420 - 330.2 x

Large capacity paper

cassette unit (option)

*3

Standard feeder 250 sheets (28mm) B5 LEF, Letter LEF, A4 LEF,

250 x 3 feeder

(option)

*1. Change the side guide in the MSI tray for the paper whose width is more than 304.8mm (12”).

*2. Each paper cassette is equipped with 2 separate paper guides, side guide and end guide, which also serves to detect paper size.

They are adjusted by users. Maximum of 4 cassette unit including one standard and optional paper cassettes (250 sheets x 3) can

be used. With these installed, the printer can hold up to 1150 sheets.

*3. Composed of 3 paper cassettes (each holds 250 sheets). This paper cassette unit is compatible with the standard universal

cassette, and either paper cassette can accommodate it.

*4. Note the following points when setting envelopes:

- Must be loaded with the longer edge first.

- Set envelopes with their flaps open and set to the rear end toward paper feeding direction.

- The minimum length with a flap open is 143mm.

- The minimum width is 90mm.

*5. Out of paper sensor installed.

*6. Out of paper sensor and near end sensor installed. Near end sensor is actuated when the remaining paper is 40 ± 30 sheets*.

* Applicable to paper of 64g/m

2

.

(Thickness)

150 sheets (16mm) 90 x 139.7 - 330.2 x 457.2 mm 60 - 105g/m2 , 16 - 20 lb (Normal

75 sheets 90 x 139.7 - 330.2 x 457.2 mm

OHP sheet/Labels/Thick paper

20 sheets Envelopes *4

Monarch, C10, DL, C6

B4, A3, Legal, Executive LEF,

Ledger (B)

457.2 mm)

250 sheets (28mm) Letter LEF, A4LEF, B4, A3,

Legal LEF, Executive LEF,

Ledger (B)

Paper size Available paper thickness

paper, Recommended paper)

105 - 220g/m

(Thick paper, Special paper)

60 - 105g/m

Recommended paper)

60 - 105g/m2 (Normal paper,

Recommended paper)

60 - 105g/m

Recommended paper)

2

2

(Normal paper,

2

(Normal paper,

o Paper Size: See Tabl e 1-3 in t he next page.

Chapter 1 PRODUCT DESCRIPTIONS 1-4

EPSON EPL -C 8000 Rev. B

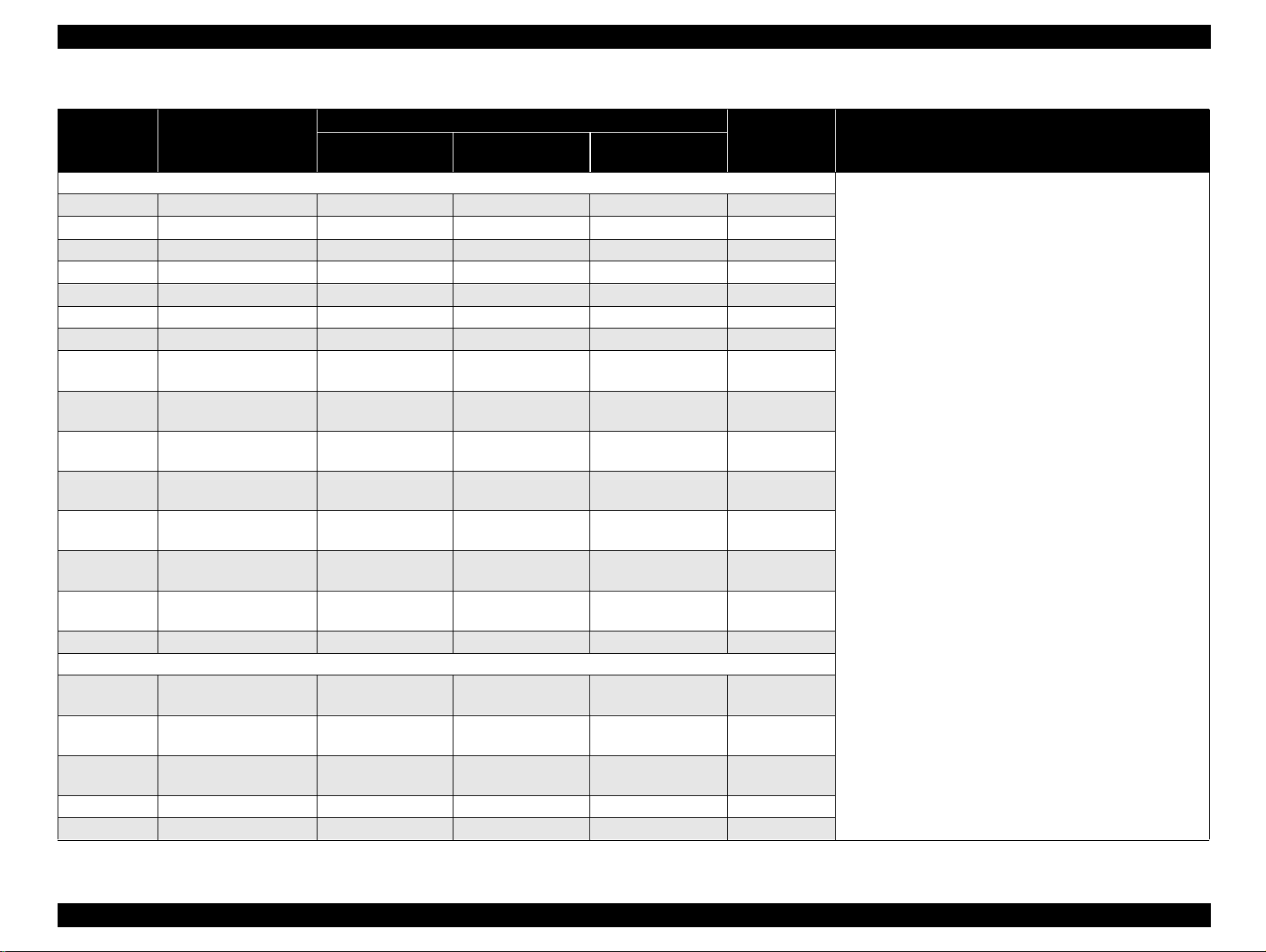

Table 1-3. Paper Size Availability

Paper setting ori entation

Paper Size

Standard tray

(MSI)

Standard cassette A3W cassette

Normal paper

A3W 328 x 453mm SEF SEF Unavailable

A3 297 x 420mm SEF SEF Unavailable

A4 210 x 297mm LEF LEF Available

A5 148 x 210mm LEF Available

B4 257 x 364mm SEF SEF Unavailable

B5 182 x 257mm LEF Available

I-B5 176 x 250 LEF Available

LT

HLT

LG

EXE

GLG

GLT

B (LD)

F4 210 x 330 SEF Unavailable

8.5 x 11”

(215.9 x 279.4mm)

5.5 x 8.5”

(139.7X215.9mm)

8.5 x l4”

(215.9X355.6mm)

7.25 x 10.5”

(184.15X266.7mm)

8.5 x 13”

(215.9X330.2mm)

8 x 10.5”

(203.2 x 266.7mm)

11 x 17”

(279.4 x 431.8mm)

LEF LEF Available

LEF Available

SEF SEF Unava ilable

LEF LEF Available

SEF Unava il able

LEF Available

SEF SEF Unavailable

Special paper

OHP Sheet

MON

C10

DL 110 x 220mm LEF* Available

C6 114 x 162 LEF* Available

8.5 x 11”

(210 x 297mm)

3 7/8” x 71/2”

(98.43 x 190.5mm)

41/8 x 91/2

(104.78 x 241.3mm)

LEF Available

LEF* Available

LEF* Available

2UP mode

availability

Notes

• LEF: Long edge is loaded first.

• SEF: Short edge is loaded first.

• 2UP is available only for paper size of LT(LEF) or

smaller. For custom size paper, paper length along

the loading direction must be 8.5 inch or short er. As

for envelopes, the total length including the opened

flap part must be 8.5 in ch or shorter.

• The minimum size of paper set in the standard

universal paper cassette is EXE (LEF).

• The maximum size of paper set in the MSI tray is

330.2 x 457.2 mm (13” x 18”).

• When setting envelopes (LEF*), open their flaps and

set the rear ends of the flaps toward paper feeding

direction.

• A3W cassette hav e capability for only A3W paper.

Chapter 1 PRODUCT DESCRIPTIONS 1-5

EPSON EPL -C 8000 Rev. B

o Paper aligning: Single side aligning (front side) fo r all s iz es

(both standard tray (MSI) and each cassette)

o Consumables:

n TONER CARTRIDGE (Black, Cyan, Magenta, Yellow)

n DRUM CARTRIDGE (including one WASTE TONER BOX)

n WASTE TONER BOX

n OIL ROLL

o Regula r replaced part s :

n MAIN FUSER ASSEMBLY

n Air filter (replaced with the MAIN FUSER ASSEMBLY

n 2ND BTR ASSEMBLY

o Paper Output:

n Face-down (FD):

2

250 sheet s (B5/EXE or larger, up to 105g/m

or 28lb

n Face-up (FU):

150 sheet s (s m aller than A4), 50 s heets (A4 or larger)

See Table 1-4 for the FD av ailability for eac h paper size.

Table 1-4. Face-Down Output Availability

Paper Size FD Availability Paper Size FD Availability *1

Normal paper A3W Available HLT Unavailable

A3 Availabl e LG Available

A4 Availabl e EXE Avail able

A5 Unavailabl e GLG Available

B4 Availabl e GLT Available

B5 Availabl e B(LD) Available

LT Available F4 Available

I-B5 Unavailable

Special paper OHP sheet FU *2 C10 FU *2

Card stock FU *2 DL FU *2

MON FU *2 C6 FU *2

Notes:

*1. The minimum size available for FD ejection is 182 mm toward paper

feeding direction.

*2. FU*2 means face-up ejection for OHP sheet, thick paper, and envelopes .

o Dimensions (without option):

728 (W)* m m x 641 (D)* mm x 49 0 (H ) mm (tolerances:

± 1%)

* When the standard tra y (M SI ) and Outpu t tra y (F U ) are stored.)

o W eight: 68.4 kg

o Voltage: 110V/120V

220V/240V

± 1% (without option)

± 10%, 50 / 60Hz ± 3Hz

± 10%, 50/6 0H z ± 3 Hz

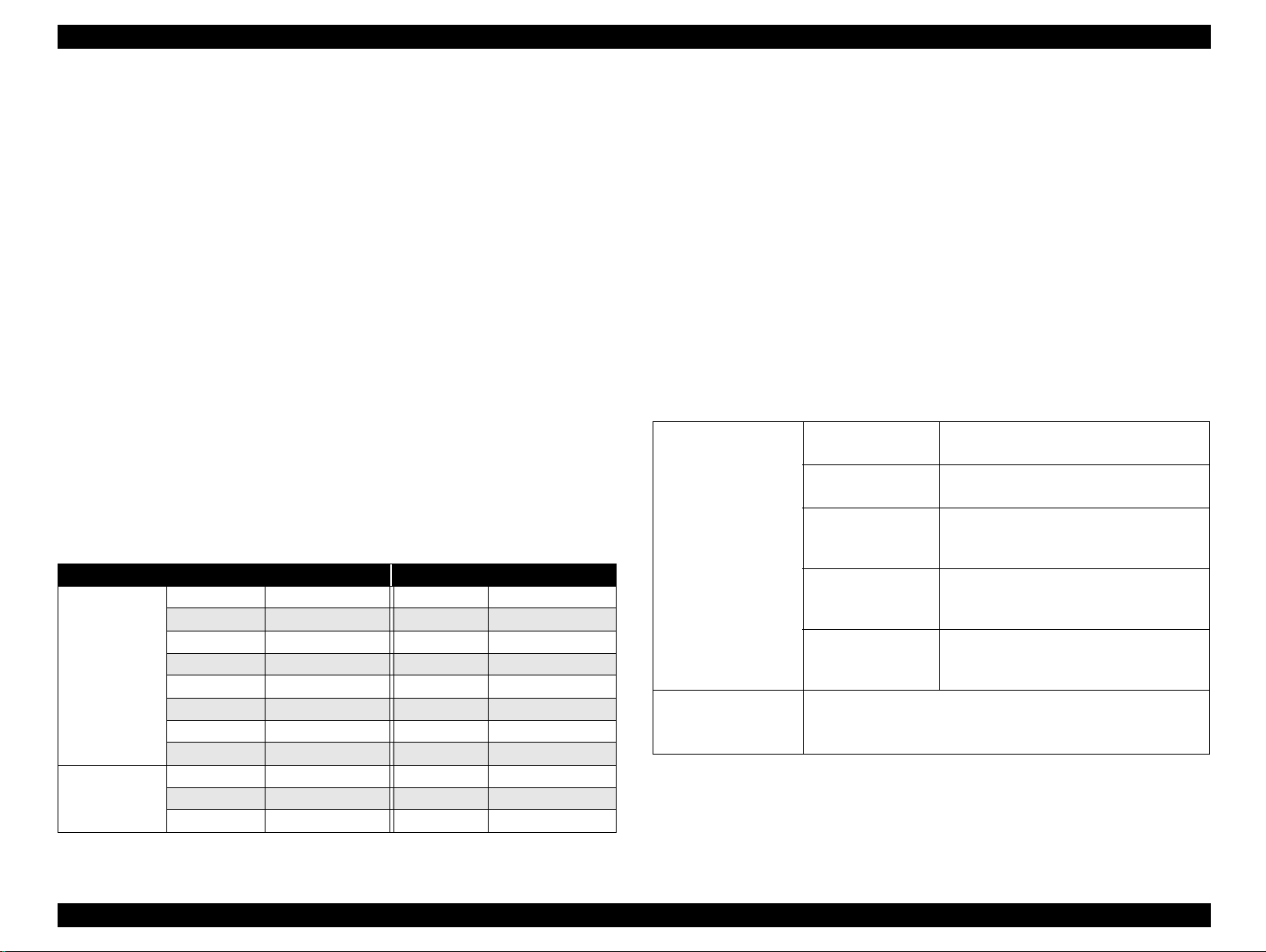

o Pow er consumption, Rated c urrent: S ee Table 1-5.

Table 1-5. Power Consumption Specifications

Power consumpt i o n

Rated current • 100 V:

Notes:

Operating (color)

Operating (B/W)

Standby mode

Energy save mode

*1

Energy save mode

*2

• 115V:

• 240V:

*1. Saves more energy than in standby mode.Time required for warning up is

shorter.

*2. Completely non-operating condition. Complies with the Energy Star.

• Average: 400Wh or less

• Maximum: 1100W or less (Fuser: On)

• Average: 500Wh or less

• Maximum: 1100W or less (Fuser: On)

• Average: 250Wh or less

• Maximum: 1000W or less (Fuser: On)

100W or less (Fuser: Off)

• Average: 200Wh or less

• Maximum: 1000W or less (Fuser: On)

100W or less (Fuser: Off)

• Average: 45Wh or less

• Maximum: 1000W or less (Fuser: On)

100W or less (Fuser: Off)

11A or less (at rated voltage)

10A or less (at rated voltage)

5A or less (at rated volt age)

Chapter 1 PRODUCT DESCRIPTIONS 1-6

EPSON EPL -C 8000 Rev. B

o Product life

n Printer:

Approxim ately 180,000 printed pages on A4 LEF (450,000

images) or five years, whichever comes first.

n Standard tray (MSI): 72,000 sheets

n 250 she et s x 3 fee ders: 135,000 sheet s (45,000 shee ts x 3)

o Acoost ic N ois e: Operating = 54. 8dB (A) or less

Stand-by = 3 8. 3dB (A) or les s

Energy Save mode 1 = 38. 3dB (A) or less

Energy Save mode 2 = 35. 0dB (A) or less

o Ozone em is s ion: 0.02 ppm (time waited av erage value) or less.

o Toxicity : Photo con ductor, tone r, ca rrier, plastic material

have no effect on human body.

Chapter 1 PRODUCT DESCRIPTIONS 1-7

EPSON EPL -C 8000 Rev. B

n

1.2.2 Paper Specification

Paper wit h labels that c om e off and stick eas ily .

o Paper s pec if ic ations: See Table 1-6.

Table 1-6. Paper Specifications

Paper Type

Recommended paper 4024 pape r (B/ W), X-pression paper (color )

Normal Paper Normal copier paper, Recycled paper,

Special Paper OHP film, Card stock, Labels, Color paper, Thick

2

60g/m

- 105g/m2 (16lb - 28lb)

paper (105g/m

2

- 220g/m2), DTP paper , Envelopes

NOTE:lb: Ream Weight = lb/500sheets/17” x 22”

2

g/m

= 0.2659763 lb

1

NOTE:Before purchasing a large amo unt of paper, try it out and chec k

that it is properly fed.

NOTE:Avoid usin g th e types of paper lis t ed below to prev ent abnorma l

printing, paper jam, and printer mal fu nc t ion.

n

Carbon paper, non- c arbon paper, t hermal pap er,

impact paperm, acid ic paper

n

Paper that has gone through a therm al or an ink-jet printer.

n

Paper wit h glue, stap les , or paper clips attached.

n

Special ink-jet paper (Super Fine Paper, g lossy film, and so

on.)

n

OHP sh eets for other c olor laser print ers, monochrome

printers, and photocopiers.

n

Paper that has gone through oth er color laser printers,

monochrome printers, and photocopiers.

n

Pasted paper

n

Paper that is to o t hic k or t hin.

n

Wet (damp) paper

n

Paper to which a special coating has been applied, or colored

paper that has gone through surface process .

n

Paper that has been lub ric ated (too sm oot h or slipper y ).

n

Paper whose texture is different o n t he f ront and ba ck.

n

Paper wit h holes for binders and perf orations.

n

Paper wit h irregular sh ape or not cut wi th right angles.

Chapter 1 PRODUCT DESCRIPTIONS 1-8

EPSON EPL -C 8000 Rev. B

G uaranteed

print area

4m m

4m m

4m m 4m m

o Paper path classific at ion: See Table 1-7.

Table 1-7. Paper Usability for Each Paper Path

Recom-

Paper path

Standard (MSI) tray RF P P P P P P

Standard univer sal cassette RF P N N N N N

A3W cassette *3 RF P N N N N N

Large capacity paper cassette *3 RF P N N N N N

Notes:

*1. 105 - 220g/m

2

mended

paper

Normal

paper

OHP sheet Postcard Label s

*2. MON, C10, DL, C6

*3. Option

*4. RF: Reliable feeding and good image quality

P: Possible, but limited to paper generally available

N: Not supported

Special paper

Thick

paper*1

Envelopes

*2

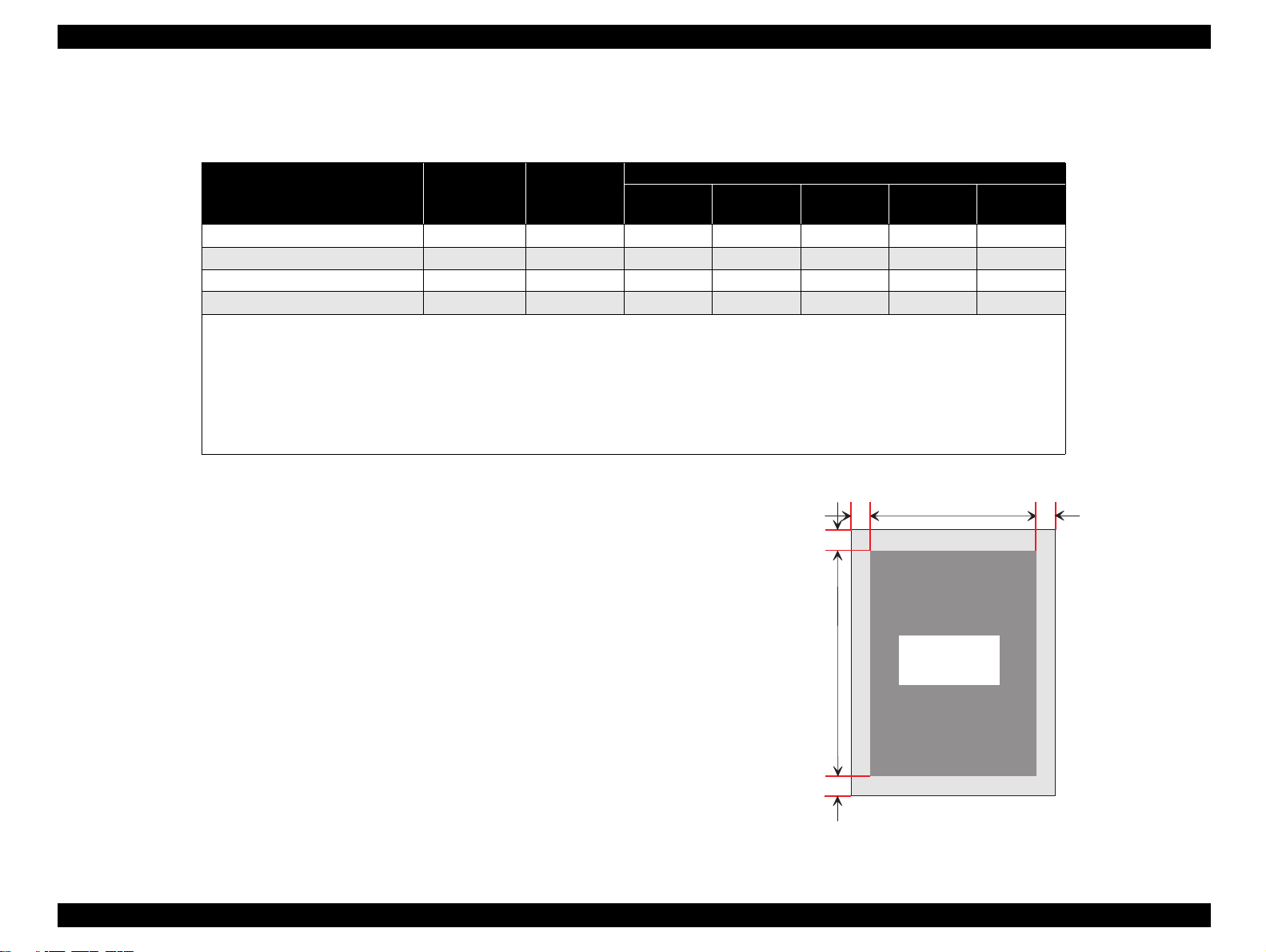

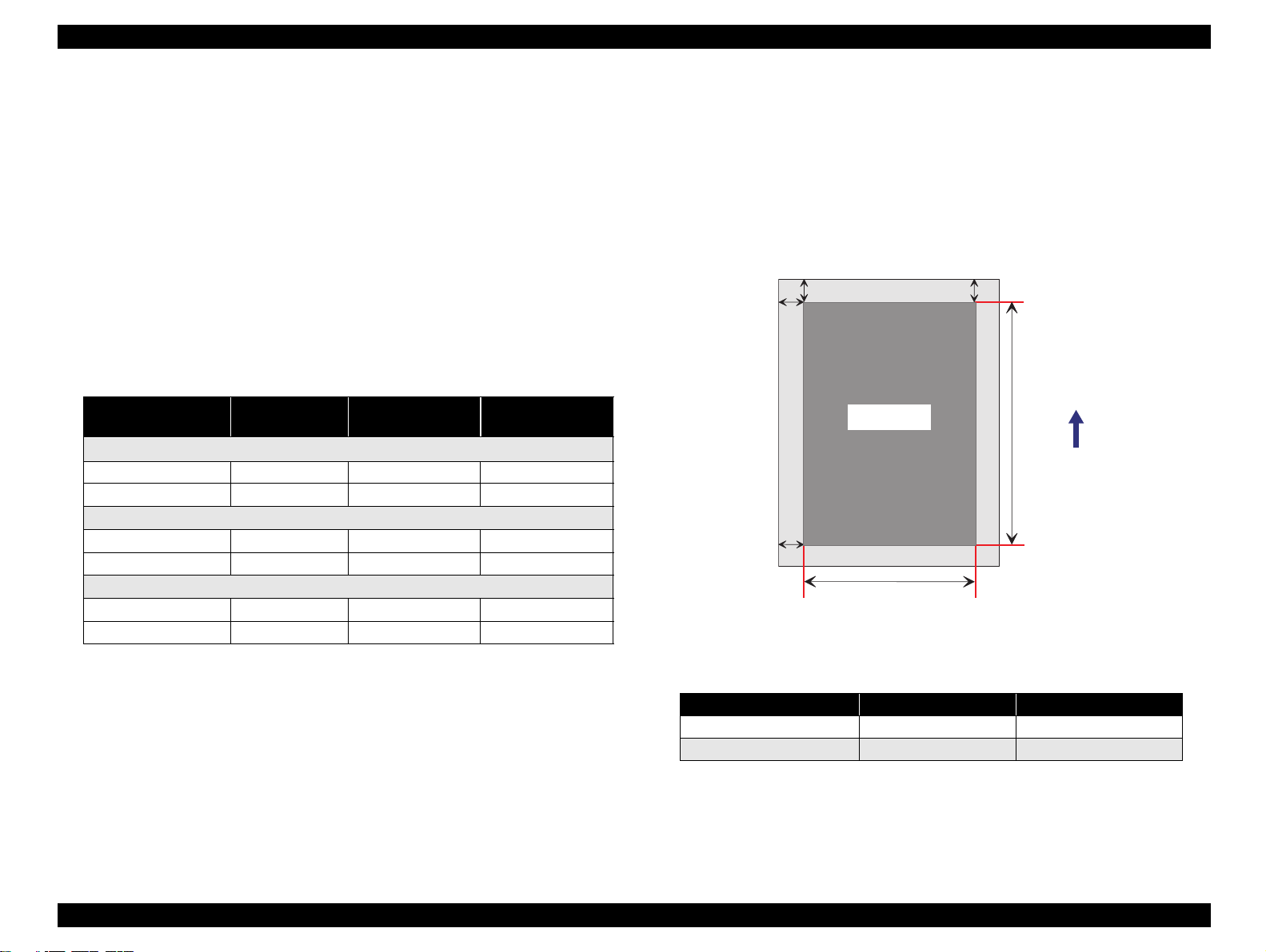

o Guarant eed print area: See Figure 1-2.

n Maxim um guaranteed print area :

Area with margins of 4 mm from each side

Applied to a paper size u p t o 297mm (11. 7”) width x 431. 8m m

(17”) leng th .

o Maxim um printable area:

320mm (1 2. 6”) width x 449. 2mm (17.7 ”) length

Figure 1-2. Guaranteed Print Area

Chapter 1 PRODUCT DESCRIPTIONS 1-9

EPSON EPL -C 8000 Rev. B

p

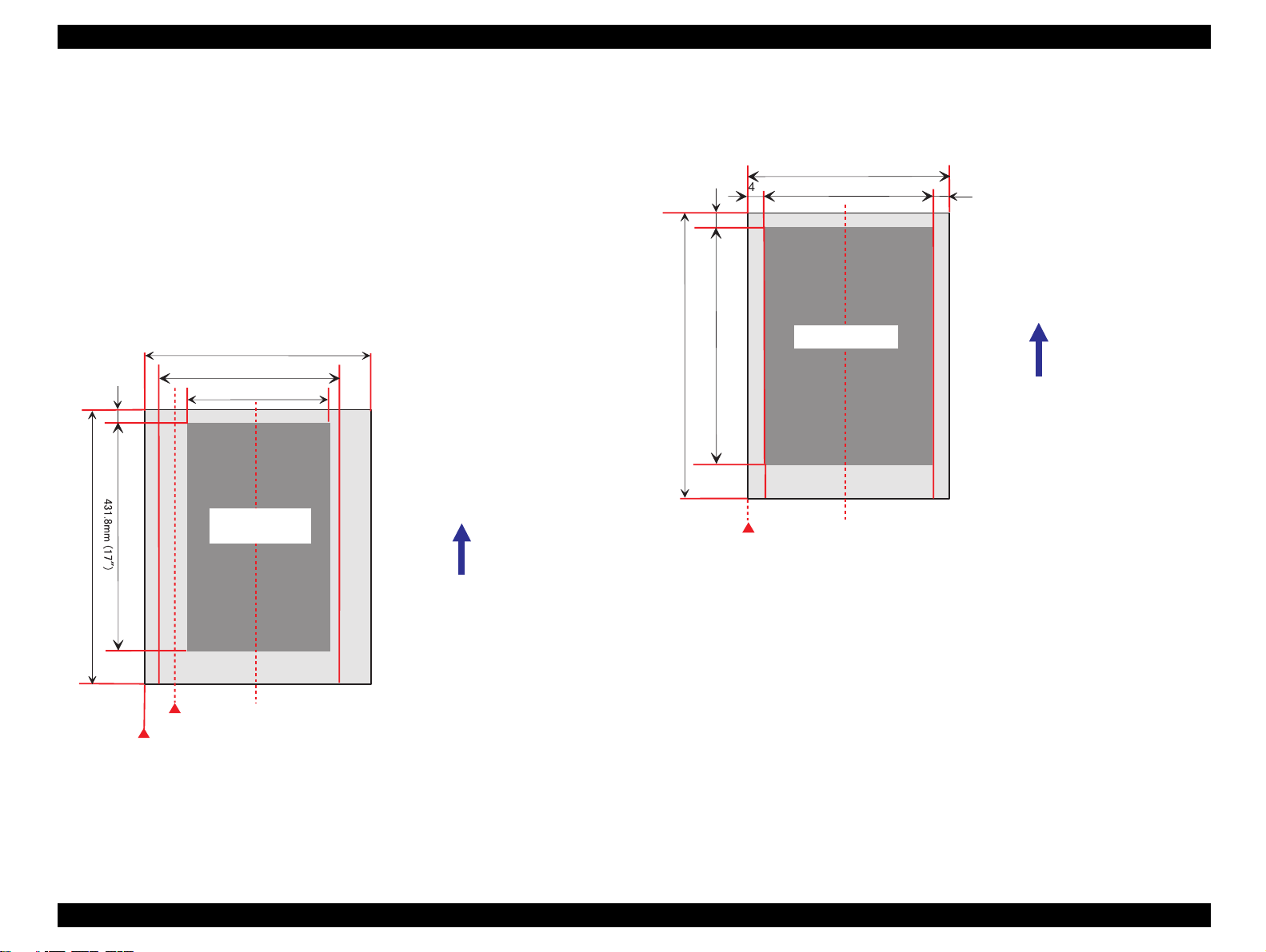

o Printab le area:

Paper whose width is 30 4. 8mm (12”) or shorter: Fro m th e edge

Paper whose width is lo nger than 30 4. 8m m (12”)*: Fro m th e point

with a margin of 5mm

* When loading paper whose width is more than 304.8 mm (12”), the

standard cassette (MSI) is shifted and print position starts with a

margin of 5 mm f rom t he paper edge (a). This ch ange is appl ied

to paper loaded from th e A3W cassett e.

n When the s t andard tray (MSI) or A3W cass et te is used.

330.2m m (13")

4m m

457.2m m (18")

(a )

320m m (12,6")

297m m (11.7")

Printable

area

Paper feeding direction

n When th e s t andard univers al cassett e or large capac it y paper

casset te unit is used.

304.8m m (12")

4m m

4m m

457.2m m (18")

431.8m m (17")

296.8m m (11.7")

Printable area

Side guide position for paper w hose w idth is 304.8 m m (12") or less

M axim um size of paper: 304.8 m m (12") w idth x 457.2 m m (18") length

Printable area: 296.8 m m (11.7") w idth x 449.2 m m (17.7") length

G uaranteed print area: 296.8 m m (11.7") w idth x 431.8 m m (17") length

4m m

Paper feeding direction

Figure 1-4. Printable Area 2

Side guide position for paper w hose w idth is 304.8 m m or shorter

Side guide position for paper w hose w idth is m ore than 304.8 m m

Length betw een the guides is 12.6m m

M axim um size of paper: 330.2 m m (13") w idth x 457.2 m m (18") length

Printable area: 320.0 m m (12.6") w idth x 449.2 m m (17.7") length

G uaranteed

rint area: 297 m m(11.7") w idth x 431.8 m m (17") le ngth

Figure 1-3. Printable Area 1

Chapter 1 PRODUCT DESCRIPTIONS 1-10

EPSON EPL -C 8000 Rev. B

a

b

c

d

e

f

Print area

Paper feeding direction

1.2.3 Reliability and Durability

o MPBF:

- Printer inc luding stand ard tray (MSI):

38,000 pages or more (95 , 000 images or more*)

- Printer inc luding optional 250 she et x 3 fee ders:

32,000 pages or more (80 , 000 images or more*)

o Print position accuracy:

n Main scan direction : Ref erence posit ion (c)

n Sub scan direction : Re f erence position (a)

± 2.5 mm

± 2.0 mm

See Figure 1-4.

o Paper skew: See Fi gure 1-4 and T able 1-9.

NOTE:Figured out based on the MPBF in condition that the job ratio

of the color and mono ch rome prints is 1 : 1, s inc e 1 page of

color print is for m ed with 4 imag es .

o Paper F eed Reliabilit y : See Table 1 -8.

Table 1-8. Paper Feed Reliability

Recommended

paper

Standard paper tray

o

Paper jam rate 1/500 or less 1/ 100 or less 1/100

Multiple feeding rate 1/80 or less 1/50 or less 1/50

Standard universal cassette/Large capacity paper cassette (option)

o

Paper jam rate 1/3,000 or less 1/2,000 or less

Multiple feeding rate 1/800 or less 1/500 or less

A3W cassette (option)

o

Paper jam rate 1/2,000 or less

Multiple feeding rate 1/500 or less

* Do not feed envelopes at high temperature to avoid adhering.

* Statistics for envelopes only applies to front face feeding under normal

temperature. ( back side feeding is not incl uded.)

NOTE:Paper jam or multiple feeding occurred to the top sheet of an

added sta c k of paper is ignor ed.

Normal paper Special paper *

Figure 1-5. Paper Skew

Table 1-9. Paper Skew

Direction A4 (landscape) A3

Main scan direction (|c-d|)

Sub scan directi on (|a-b|)±2.0mm(e=271mm)

1.5mm(f=196mm)

±

3.0mm(f=406mm)

±

2.0mm(f=271mm)

±

Chapter 1 PRODUCT DESCRIPTIONS 1-11

EPSON EPL -C 8000 Rev. B

o Durability:

n Printer itself:

180,000 sheets (450,000 images) A4 LEF or 5 years, whichever

comes first. Parts regularly replaced by the service is ignored.

* 450,000 for monochrome print only. In color printing, one page is formed

with 4 images, and the value “180,000” sheets is figured out in the

condition that the job ratio of monochrome and color printings is 1:1.

n Standard tray (MSI): 72,000 sheets

n 250she et s x 3 fe eders: 135, 000 sheets (45,000 sheets x 3)

o MTTR: Within 30 minutes (average)

o Curl heig ht at ejection:

Less than

± 15mm (Color printing with the image ratio of 5 % in non-

aligned condition, whic h varies depending on th e im age rate and

aligning pattern.)

Chapter 1 PRODUCT DESCRIPTIONS 1-12

EPSON EPL -C 8000 Rev. B

1.2.4 Operating Environment (including options)

o Temperature: 10 to 32 °C

o Humidit y : 15% to 85% RH (without co ndensation)

o Air pressure(altitud e): 760hPa or more (2500 meters o r les s )

o Levelness:

n Front- rear direction on t he table: 5m m or less (within 6 41mm)

n Right - lef t d irec t ion on the tabl e: 10mm or les s (w ith in 560mm)

o Lumino s it y : 3000 lux or less (not to ex posed to dire ct

sunlight )

o Surrounding environment:

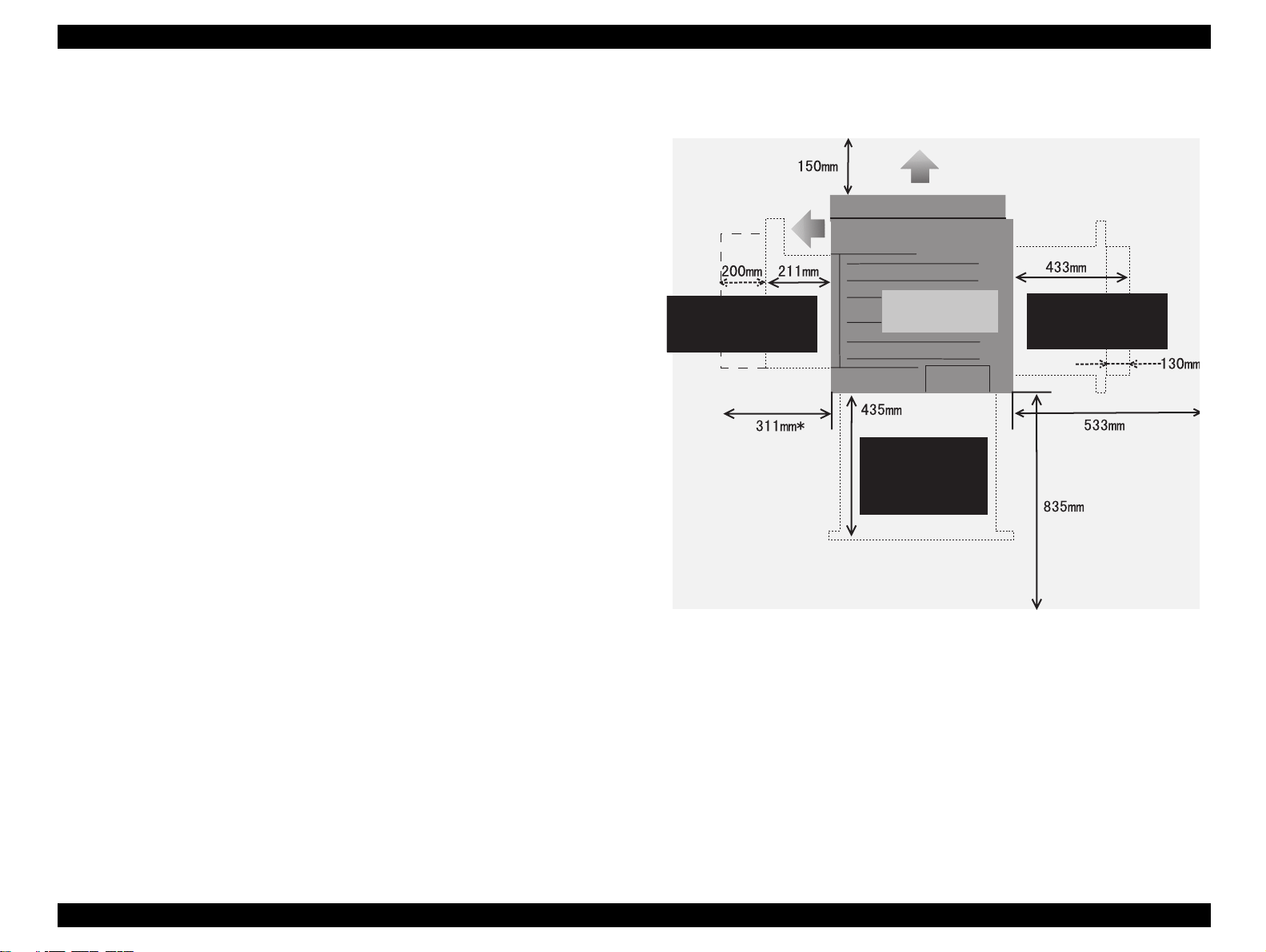

See Figure 1-6.

Ventilation

To pull out the FU SE R

UNIT to rem ove

jam m ed paper.

To P ull out the

standard paper

c a s s e tte u n it w h e n

putting paper.

* 511 m m w ith the face-up tray installed.

Ventilation

To pull out the paper

path unit to rem ove

jam m ed paper.

Figure 1-6. Space

Requirement........................................................................................

Chapter 1 PRODUCT DESCRIPTIONS 1-13

EPSON EPL -C 8000 Rev. B

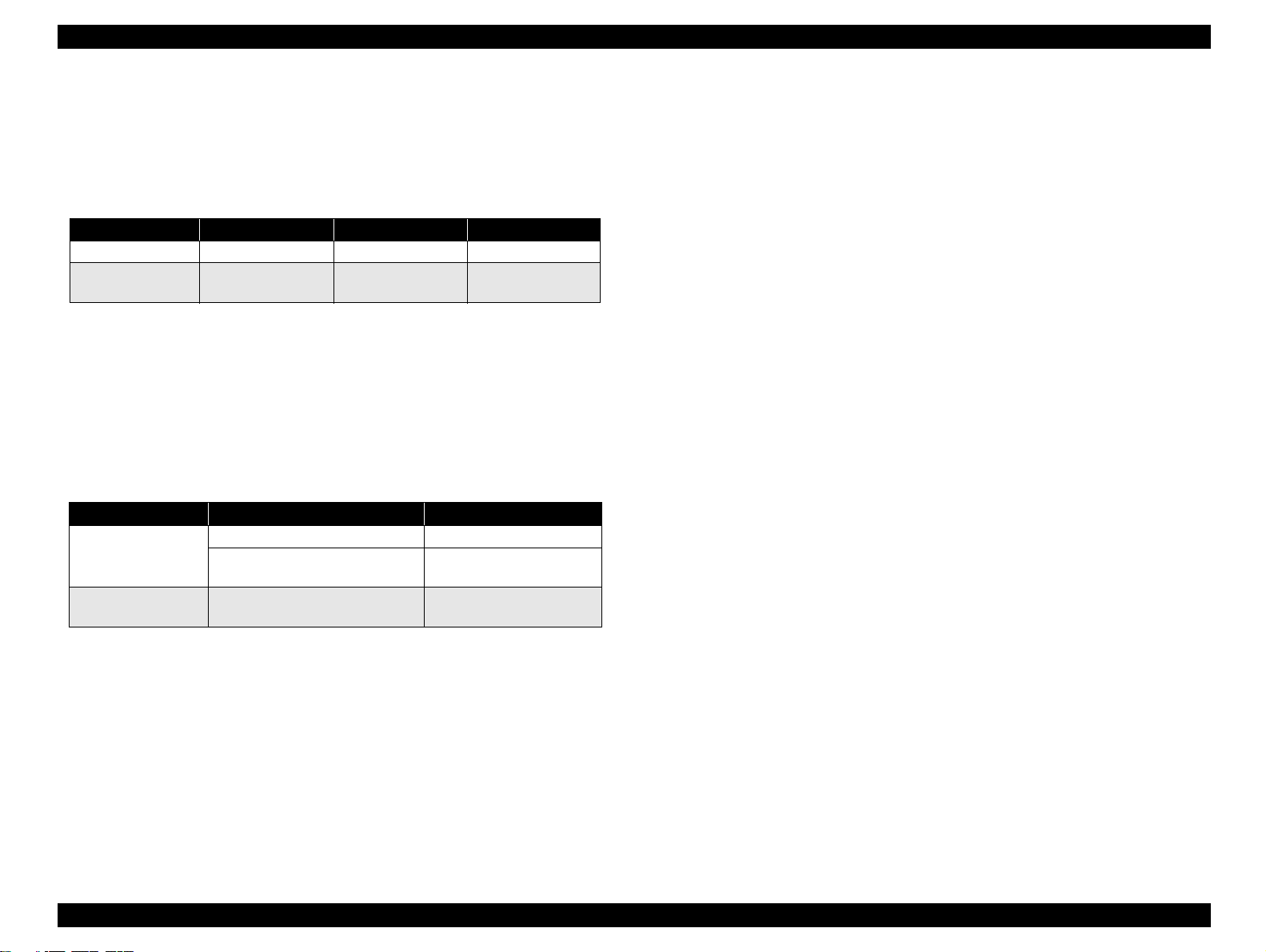

1.2.5 Environmental Conditi ons for Storage and Transportation

o temperature and Hu m idity: See Table 1-10.

Table 1-10. Environmental Conditions 1

Temperature Humidity Guaranty

Normal conditio n 0 - 35

Extreme condition High: 35 - 40 °C

* Without condensation.

o Storag e air pressure (a lt it ude):

0 - 2500m (0 up to 15000m is p os s ible during air shipping, but th e

air pressu re in the cargo ro om m ust be 0.7 hP A or more.)

o Drop test: See Table 1-11.

Free drop

Ridge drop 457 mm (18”)

C 15 - 80%RH* For 12 months

°

High: 80 - 95%RH*

Low: -20 - 0

C

°

Low: 5 - 15%RH*

Table 1-11. Drop Test

Height Test times

Bottom: 457 mm (18”) Once

Other than bottom: 305m m

(12”)

Once for each surface

(total of 5 times)

Once for each side (tot al

of 4 times)

One month (Max.)

o Resistance to vibration:

n Freque nc y : 2 - 500 Hz

n Acceleration: 12.6 m/s

2

(on a vibrat ing board)*1

n Directio n: 3 directio ns (X, Y, Z ) * 2

n Duration: 30 minutes (single way)

*1.Overall rms value

*2.Z: verti c al, X and Y: horizontal

Chapter 1 PRODUCT DESCRIPTIONS 1-14

Loading...

Loading...