Page 1

®

SERVICE MANUAL

Monochrome Page Printer

EPSON EPL-5900 / EPL-5900L

SEPG01005

Page 2

Notice

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical,

photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2001 SEIKO EPSON CORPORATION.

Imaging & Information Product Division

TPCS Quality Assurance Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR

OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for servicing

the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

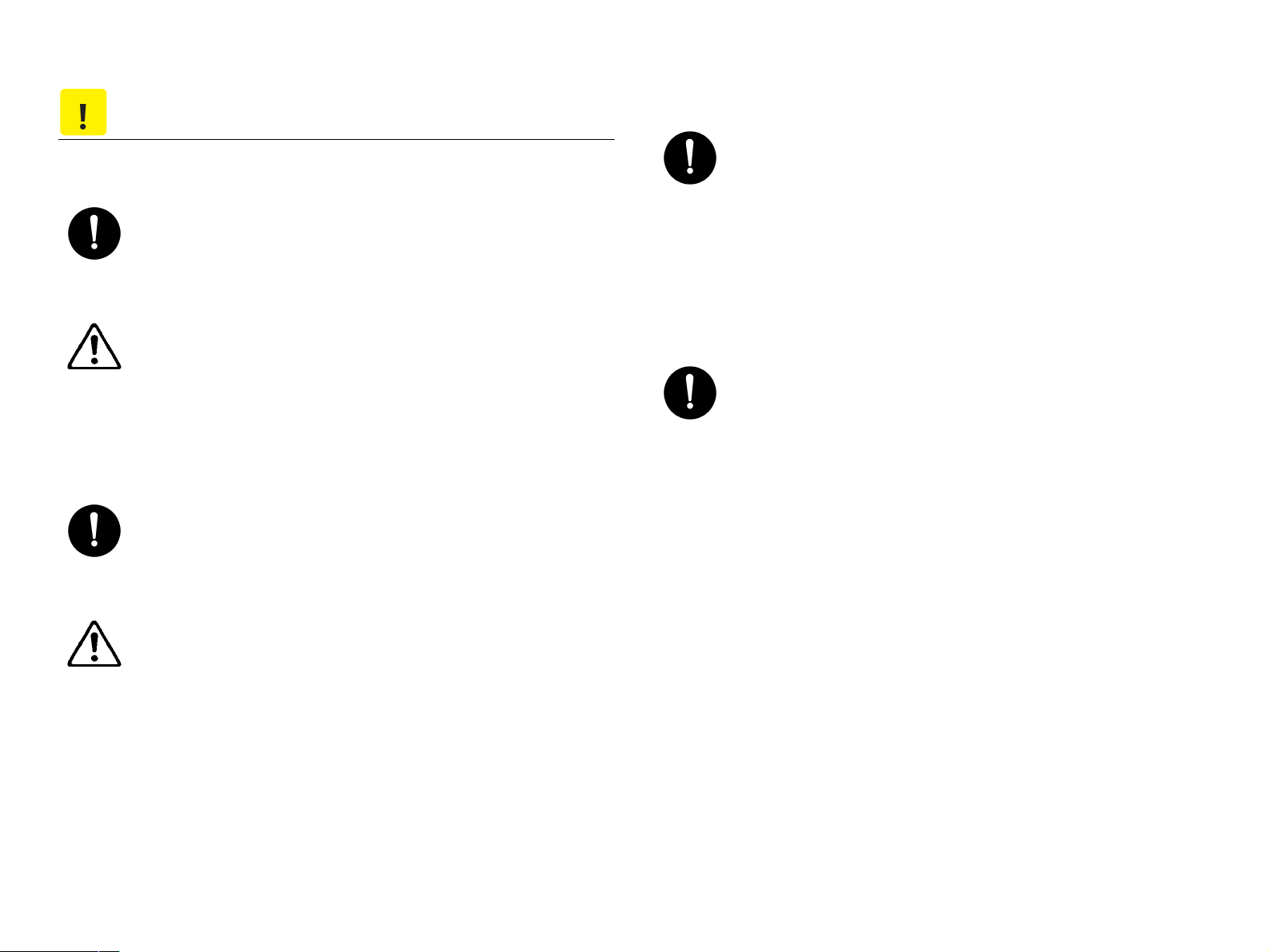

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Page 5

Safety Precautions for Inspection and Service

When performing inspection and service procedures, observe the

following precautions to prevent accidents and ensure utmost safety.

* Depending on the model, some of the precautions given in the

following do not apply.

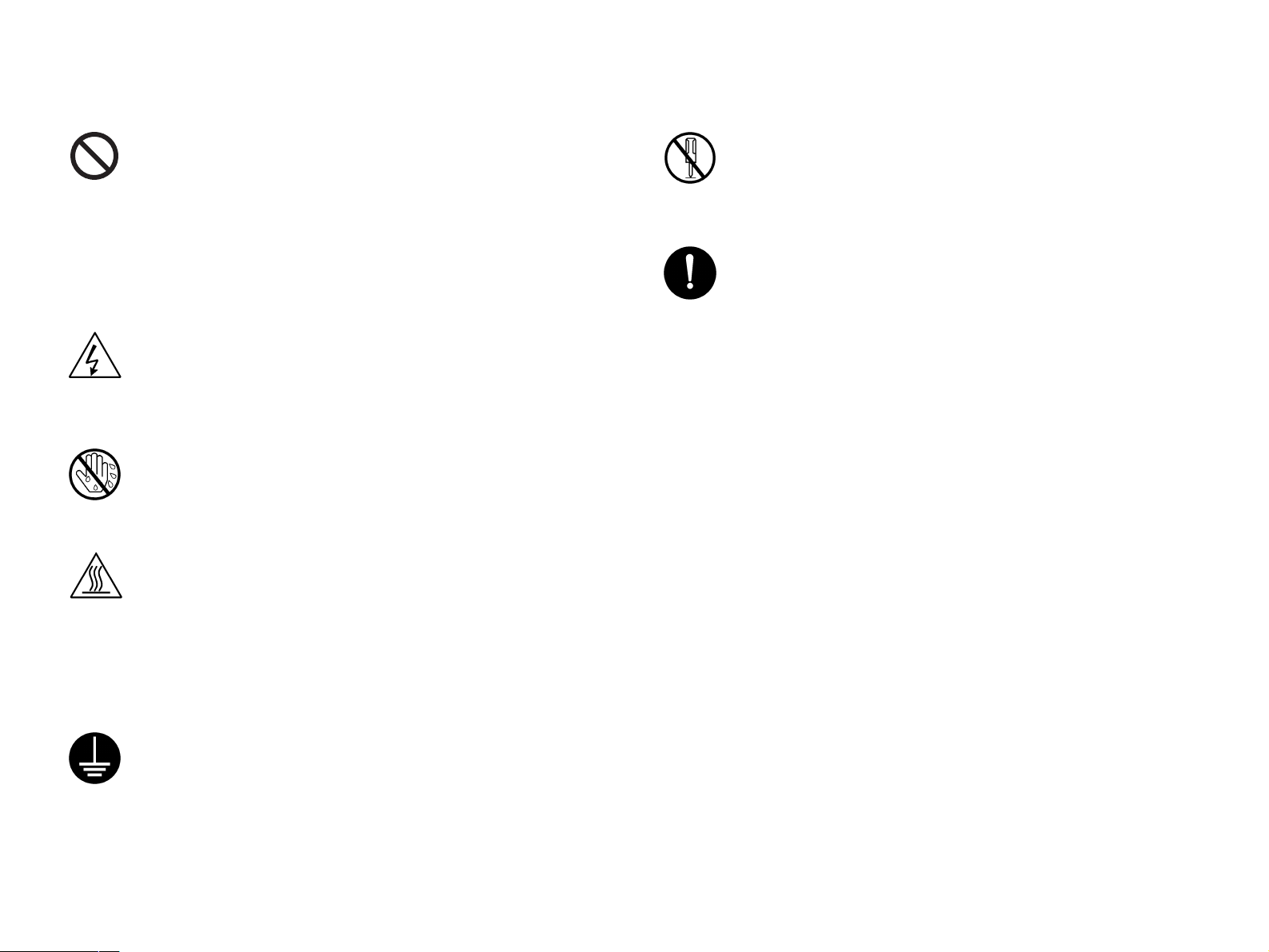

Different markings are used to denote specific meanings as detailed

below.

W A R N I N G

C A U T I O N

The following graphic symbols are used to give instructions that need to

be observed.

fIndicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

Used to call the service technician's attention to what is

graphically represented inside the marking (including a

warning).

Used to prohibit the service technician's from doing what is

graphically represented inside the marking.

Used to instruct the service technician's to do what is

graphically represented inside the marking.

W A R N I N G

WARNING

1.Always observe precautions.

Parts requiring special attention in this product will include a

label containing the mark shown on the left plus

precautionary notes. Be sure to observe the precautions.

Be sure to observe the “Safety Information” given in the

Operator's Manual.

2.Before starting the procedures, be sure to unplug the power

cord.

This product contains a high-voltage unit and a circuit with a

large current capacity that may cause an electric shock or

burn.

The product also contains parts that can jerk suddenly and

cause injury.

If this product uses a laser, laser beam leakage may cause

eye damage or blindness.

3.Use the specified parts.

For replacement parts, always use the genuine parts

specified in the manufacturer's parts manual. Installing a

wrong or unauthorized part could cause dielectric

breakdown, overload, or undermine safety devices resulting

in possible electric shock or fire.

Replace a blown electrical fuse or thermal fuse with its

corresponding genuine part specified in the manufacturer's

parts manual. Installing a fuse of a different make or rating

could lead to a possible fire. If a thermal fuse blows

frequently, the temperature control system may have a

problem and action must be taken to eliminate the cause of

the problem.

Page 6

4.Handle the power cord with care and never use a multiple outlet.

9.Do not remodel the product.

Do not break, crush or otherwise damage the power cord.

Placing a heavy object on the power cord, or pulling or

bending it may damage it, resulting in a possible fire or

electric shock.

Do not use a multiple outlet to which any other appliance or

machine is connected.

Be sure the power outlet meets or exceeds the specified

capacity.

5.Be careful with the high-voltage parts.

A part marked with the symbol shown on the left carries a

high voltage. Touching it could result in an electric shock or

burn. Be sure to unplug the power cord before servicing this

part or the parts near it.

6.Do not work with wet hands.

Do not unplug or plug in the power cord, or perform any kind

of service or inspection with wet hands. Doing so could

result in an electric shock.

7.Do not touch a high-temperature part.

A part marked with the symbol shown on the left and other

parts such as the exposure lamp and fusing roller can be

very hot while the machine is energized. Touching them

may result in a burn.

Wait until these parts have cooled down before replacing

them or any surrounding parts.

Modifying this product in a manner not authorized by the

manufacturer may result in a fire or electric shock. If this

product uses a laser, laser beam leakage may cause eye

damage or blindness.

10.Restore all parts and harnesses to their original positions.

To promote safety and prevent product damage, make sure

the harnesses are returned to their original positions and

properly secured in their clamps and saddles in order to

avoid hot parts, high-voltage parts, sharp edges, or being

crushed.

To promote safety, make sure that all tubing and other

insulating materials are returned to their original positions.

Make sure that floating components mounted on the circuit

boards are at their correct distance and position off the

boards.

8.Maintain a grounded connection at all times.

(This item may not apply in the USA.)

Be sure to connect the ground wire to the ground terminal

even when performing an inspection or repair. Without

proper grounding, electrical leakage could result in an

electric shock or fire.

Never connect the ground wire to a gas pipe, water pipe,

telephone ground wire, or a lightning conductor.

Page 7

C A U T I O N

CAUTION

1.Precautions for Service Jobs

A toothed washer and spring washer, if used originally,

must be reinstalled. Omitting them may result in contact

failure which could cause an electric shock or fire.

When reassembling parts, make sure that the correct

screws (size, type) are used in the correct places. Using the

wrong screw could lead to stripped threads, poorly secured

parts, poor insulating or grounding, and result in a

malfunction, electric shock or injury.

Take great care to avoid personal injury from possible burrs

and sharp edges on the parts, frames and chassis of the

product.

When moving the product or removing an option, use care

not to injure your back or allow your hands to be caught in

mechanisms.

2.Precautions for Servicing with Covers and Parts Removed

Wherever feasible, keep all parts and covers mounted when

energizing the product.

If energizing the product with a cover removed is absolutely

unavoidable, do not touch any exposed live parts and use

care not to allow your clothing to be caught in the moving

parts. Never leave a product in this condition unattended.

Never place disassembled parts or a container of liquid on

the product. Parts falling into, or the liquid spilling inside, the

mechanism could result in an electric shock or fire.

Never use a flammable spray near the product. This could

result in a fire.

Make sure the power cord is unplugged before removing or

installing circuit boards or plugging in or unplugging

connectors.

Always use the interlock switch actuating jig to actuate an

interlock switch when a cover is opened or removed. The

use of folded paper or some other object may damage the

interlock switch mechanism, possibly resulting in an electric

shock, injury or blindness.

3.Precautions for the Working Environment

The product must be placed on a flat, level surface that is

stable and secure.

Never place this product or its parts on an unsteady or tilting

workbench when servicing.

Provide good ventilation at regular intervals if a service job

must be done in a confined space for a long period of time.

Avoid dusty locations and places exposed to oil or steam.

Avoid working positions that may block the ventilation ports

of the product.

4.Precautions for Handling Batteries

(Lithium, Nickel-Cadmium, etc.)

Replace a rundown battery with the same type as specified

in the manufacturer's parts manual.

Before installing a new battery, make sure of the correct

polarity of the installation or the battery could burst.

Dispose of used batteries according to the local regulations.

Never dispose of them at the user's premises or attempt to

try to discharge one.

Page 8

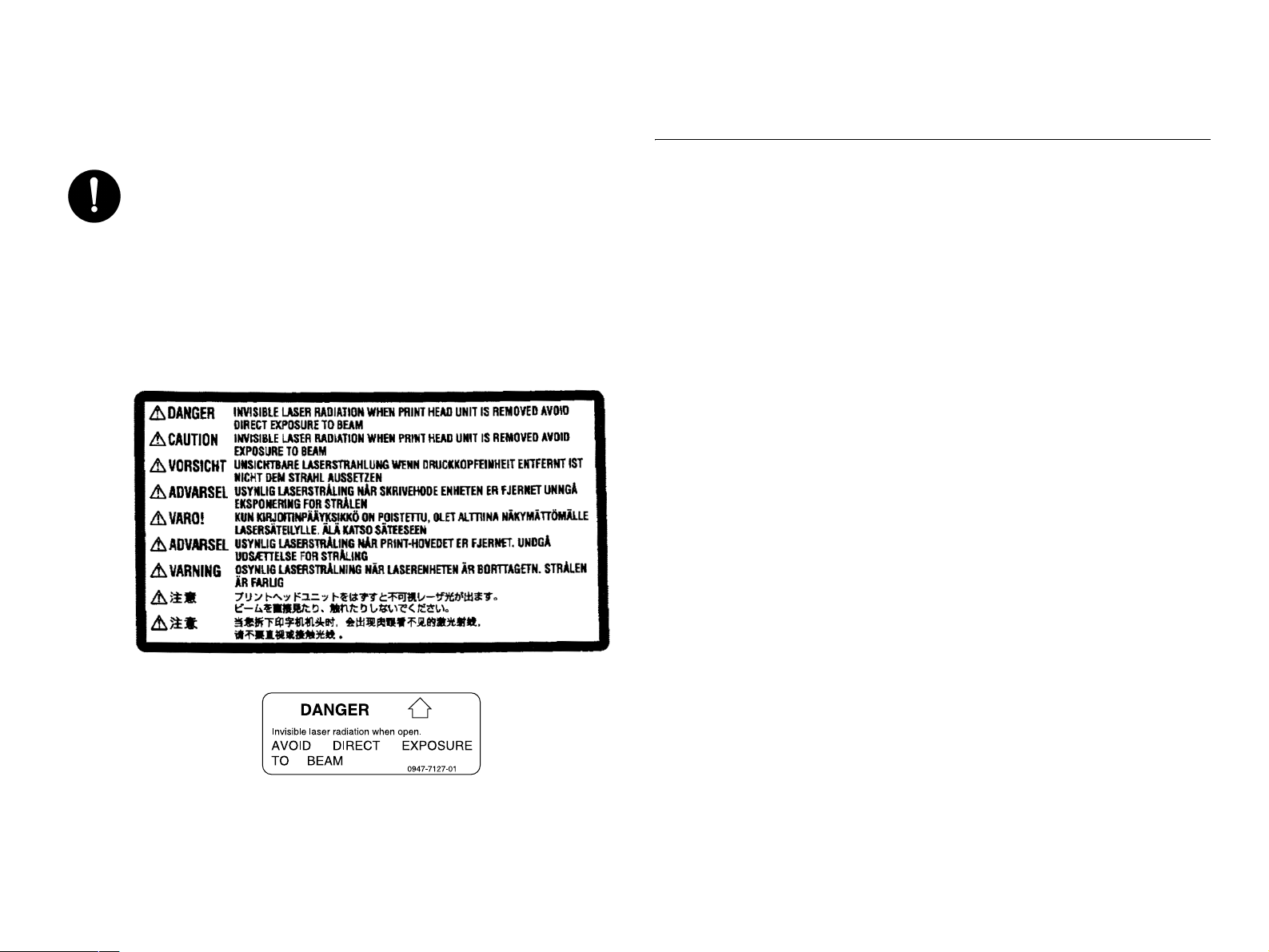

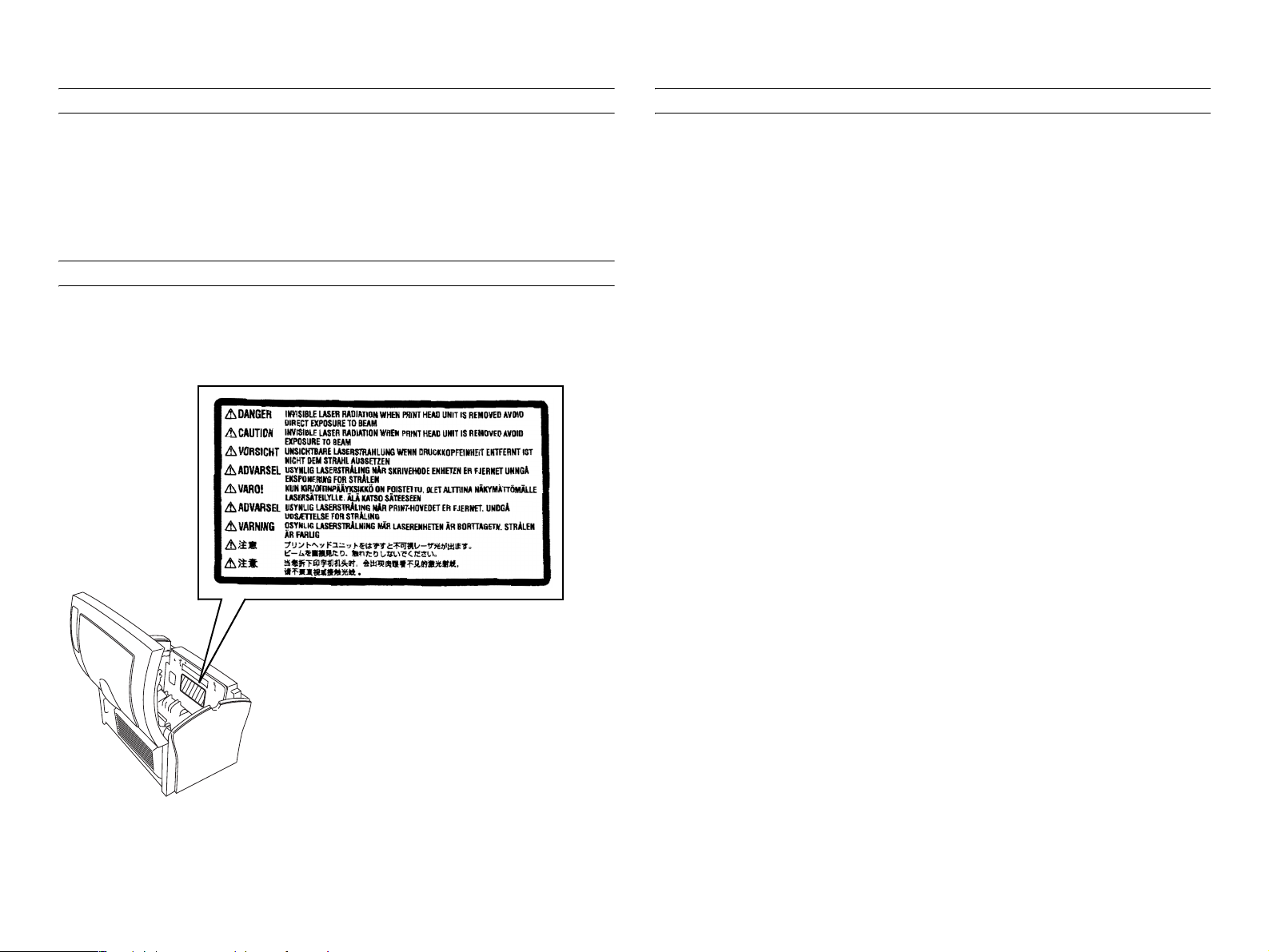

5.Precautions for the Laser Beam

(Only for Products Employing a Laser)

Removing the cover marked with the following caution label

could lead to possible exposure to the laser beam, resulting

in eye damage or blindness. Be sure to unplug the power

cord before removing this cover.

If removing this cover while the power is ON is unavoidable,

be sure to wear protective laser goggles that meet

specifications.

Make sure that no one enters the room when the machine is

in this condition.

When handling the laser unit, observe the “Precautions for

Handling Laser Equipment.”

Other Precautions

When handling circuit boards, observe the “HANDLING of PWBs”.

The PC Drum is a very delicate component. Observe the precautions

given in “HANDLING OF THE PC DRUM” because mishandling may

result in serious image problems.

Note that replacement of a circuit board may call for readjustments or

resetting of particular items, or software installation.

Page 9

Precautions for Service

When performing inspection and service procedures, observe the

following precautions to prevent mishandling of the machine and its

parts.

All troubleshooting procedures contained herein assume that

there are no breaks in the harnesses and cords and all

connectors are plugged into the right positions.

The procedures preclude possible malfunctions due to noise

and other external causes.

* Depending on the model, some of the precautions given in the

following do not apply.

PRECAUTIONS BEFORE SERVICE

When the user is using a word processor or personal computer from

a wall outlet of the same line, take necessary steps to prevent the

circuit breaker from opening due to overloads.

Never disturb the LAN by breaking or making a network connection,

altering termination, installing or removing networking hardware or

software, or shutting down networked devices without the

knowledge and express permission of the network administrator or

the shop supervisor.

HOW TO USE THIS BOOK

DIS/REASSEMBLY, ADJUSTMENT

To reassemble the product, reverse the order of disassembly

unless otherwise specified.

TROUBLESHOOTING

PRECAUTIONS FOR SERVICE

Check the area surrounding the service site for any signs of

damage, wear or need of repair.

Keep all disassembled parts in good order and keep tools under

control so that none will be lost or damaged.

After completing a service job, perform a safety check. Make sure

that all parts, wiring and screws are returned to their original

positions.

Do not pull out the toner hopper while the toner bottle is turning.

This could result in a damaged motor or locking mechanism.

If the product is to be run with the front door open, make sure that

the toner hopper is in the locked position.

Do not use an air gun or vacuum cleaner for cleaning the ATDC

Sensor and other sensors, as they can cause electrostatic

destruction. Use a blower brush and cloth. If a unit containing these

sensors is to be cleaned, first remove the sensors from the unit.

If a component on a PWB or any other functional unit including a

motor is defective, the text only instructs you to replace the

whole PWB or functional unit and does not give troubleshooting

procedures applicable within the defective unit.

Page 10

PRECAUTIONS FOR DIS/REASSEMBLY

PRECAUTIONS FOR CIRCUIT INSPECTION

Be sure to unplug the copier from the outlet before attempting to

service the copier.

The basic rule is not to operate the copier anytime during

disassembly. If it is absolutely necessary to run the copier with its

covers removed, use care not to allow your clothing to be caught in

revolving parts such as the timing belt and gears.

Before attempting to replace parts and unplug connectors, make

sure that the power cord of the copier has been unplugged from the

wall outlet.

Be sure to use the Interlock Switch Actuating Jig whenever it is

necessary to actuate the Interlock Switch with the covers left open

or removed.

While the product is energized, do not unplug or plug connectors

into the circuit boards or harnesses.

Never use flammable sprays near the copier.

A used battery should be disposed of according to the local

regulations and never be discarded casually or left unattended at

the user's premises.

When reassembling parts, make sure that the correct screws (size,

type) and toothed washer are used in the correct places.

Never create a closed circuit across connector pins except those

specified in the text and on the printed circuit.

When creating a closed circuit and measuring a voltage across

connector pins specified in the text, be sure to use the GND wire.

HANDLING OF PWBS

During Transportation/Storage:

During transportation or when in storage, new P.W. Boards must

not be indiscriminately removed from their protective conductive

bags.

Do not store or place P.W. Boards in a location exposed to

direct sunlight and high temperature.

When it becomes absolutely necessary to remove a Board from

its conductive bag or case, always place it on its conductive mat

in an area as free as possible from static electricity.

Do not touch the pins of the ICs with your bare hands.

Protect the PWBs from any external force so that they are not

bent or damaged.

During Inspection/Replacement:

If it becomes necessary to replace the thermal fuse or any other

fuse mounted on a board, be sure to use one of the rating marked

on the blown fuse. Always note the rating marked on the fuse, as

the rating and mounting site or number used are subject to change

without notice.

Avoid checking the IC directly with a multimeter; use connectors

on the Board.

Never create a closed circuit across IC pins with a metal tool.

Before unplugging connectors from the P.W. Boards, make sure

that the power cord has been unplugged from the outlet.

Page 11

When removing a Board from its conductive bag or conductive

case, do not touch the pins of the ICs or the printed pattern.

Place it in position by holding only the edges of the Board.

When touching the PWB, wear a wrist strap and connect its cord

to a securely grounded place whenever possible. If you cannot

wear a wrist strap, touch a metal part to discharge static

electricity before touching the PWB.

HANDLING OF THE PC DRUM

* Only for Products Not Employing an Imaging Cartridge.

During Transportation/Storage:

Use the specified carton whenever moving or storing the PC

Drum.

Note that replacement of a PWB may call for readjustments or

resetting of particular items.

HANDLING OF OTHER PARTS

The magnet roller generates a strong magnetic field. Do not bring it

near a watch, floppy disk, magnetic card, or CRT tube.

The storage temperature is in the range between -20°C and

+40°C.

In summer, avoid leaving the PC Drum in a car for a long time.

Handling:

Ensure that the correct PC Drum is used.

Whenever the PC Drum has been removed from the copier,

store it in its carton or protect it with a Drum Cloth.

The PC Drum exhibits greatest light fatigue after being exposed

to strong light over an extended period of time. Never, therefore,

expose it to direct sunlight.

Use care not to contaminate the surface of the PC Drum with oil-

base solvent, fingerprints, and other foreign matter.

Do not scratch the surface of the PC Drum.

Do not apply chemicals to the surface of the PC Drum.

Do not attempt to wipe clean the surface of the PC Drum.

Page 12

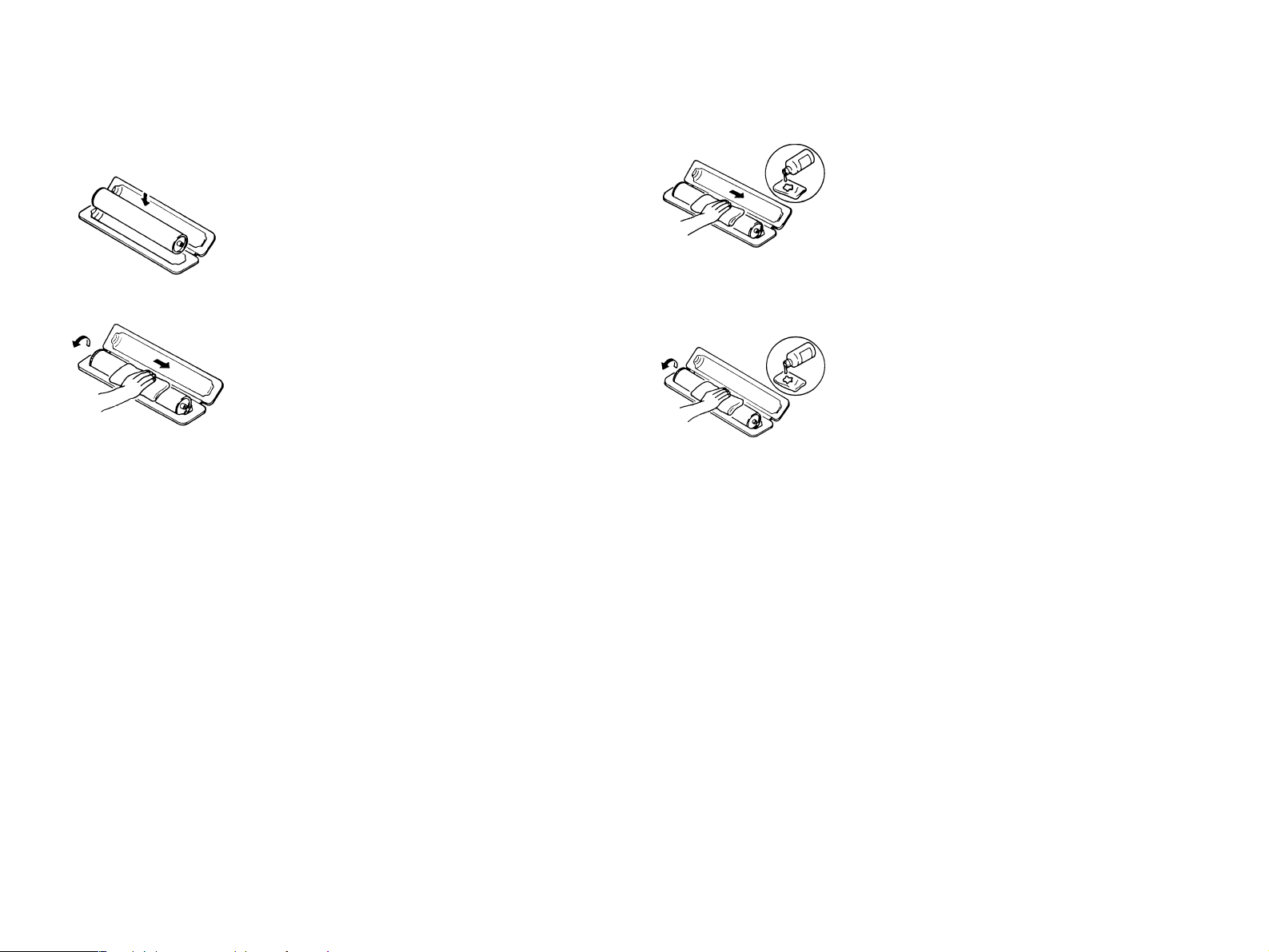

If, however, the surface is contaminated with fingerprints, clean it using

the following procedure.

1. Place the PC Drum into one half of its carton.

3. Soak a small amount of either ethyl alcohol

or isopropyl alcohol into a clean, unused

Dust-Free Cotton Pad which has been

folded over into quarters. Now, wipe the

surface of the PC Drum in one continuous

movement from its rear edge to its front

edge and off its surface one to two times.

2. Gently wipe the residual toner off the

surface of the PC Drum with a dry, DustFree Cotton Pad.

A.Turn the PC Drum so that the area of its

surface on which the line of toner left by the

Cleaning Blade is present is facing straight

up. Wipe the surface in one continuous

movement from the rear edge of the PC

Drum to the front edge and off the surface

of the PC Drum.

B. Turn the PC Drum slightly and wipe the

newly exposed surface area with a CLEAN

face of the Dust-Free Cotton Pad. Repeat

this procedure until the entire surface of the

PC Drum has been thoroughly cleaned.

*At this time, always use a CLEAN face of the dry

Dust-Free Cotton Pad until no toner is evident on

the face of the Pad after wiping.

*Never move the Pad back and forth.

4. Using the SAME face of the Pad, repeat the

procedure explained in the latter half of

step 3 until the entire surface of the PC

Drum has been wiped. Always OVERLAP

the areas when wiping. Two complete turns

of the PC Drum would be appropriate for

cleaning.

NOTE:

Even when the PC Drum is only locally dirtied, wipe the entire

surface.

Do not expose the PC Drum to direct sunlight. Clean it as

quickly as possible even under interior illumination.

If dirt remains after cleaning, repeat the entire procedure from

the beginning one more time.

Page 13

HANDLING OF THE IMAGING CARTRIDGE

* Only for Products Employing an Imaging Cartridge.

During Transportation/Storage:

The storage temperature is in the range between -20°C and

+40°C.

In summer, avoid leaving the Imaging Cartridge in a car for a

long time.

Handling:

Store the Imaging Cartridge in a place that is not exposed to

direct sunlight.

Precautionary Information on the PC Drum Inside the Imaging

Cartridge:

Use care not to contaminate the surface of the PC Drum with oil-

base solvent, fingerprints, and other foreign matter.

Do not scratch the surface of the PC Drum.

Do not attempt to wipe clean the surface of the PC Drum.

W A R N I N G

WARNING

Do not throw the toner cartridge or toner into an open

flame. The hot toner may scatter and cause burns or

other damage.

Page 14

SAFETY INFORMATION

LASER SAFETY

This is a digital machine certified as a class 1 laser product. There is no

possibility of danger from a laser, provided the machine is serviced

according to the instruction in this manual.

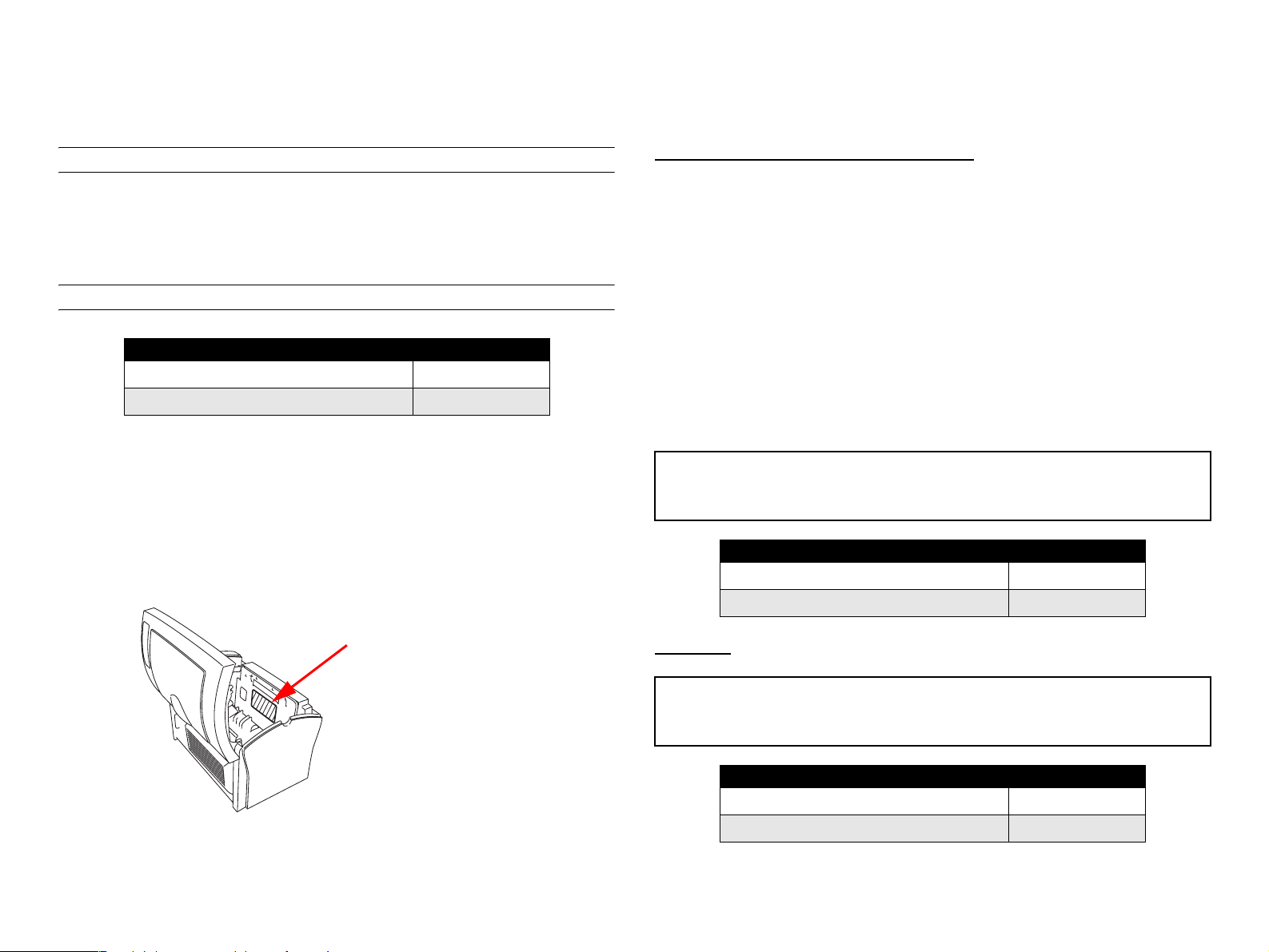

INTERNAL LASER RADIATION

semiconductor laser

Maximum average radiation power(*) 27.1 µW

Wavelength 770-810 nm

*:Laser Aperture of the Print Head Unit

This product employs a Class 3b laser diode that emits an invisible

laser beam. The laser diode and the scanning polygon mirror are

incorporated in the print head unit.

The print head unit is NOT A FIELD SERVICE ITEM. Therefore, the

print head unit should not be opened under any circumstances.

the U.S.A., Canada (CDRH Regulation)

This machine is certified as a Class I Laser product under

Radiation Performance Stan-dard according to the Food, Drug

and Cosmetic Act of 1990. Compliance is mandatory for Laser

products marketed in the United States and is reported to the

Center for Devices and Radiological Health (CDRH) of the U.S.

Food and Drug Administration of the U.S. Department of Health

and Human Services (DHHS). This means that the device does

not produce hazardous laser radiation.

The label shown to page 15 indicates compliance with the

CDRH regulations and must be attached to laser products

marketed in the United States.

CAUTION

Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 5 mW

Wavelength 770-810 nm

Laser Aperture of the Print Head Unit

This figure shows the view inside the Top Cover with the Toner Cartridge and the Drum Cartridge removed.

All Areas

CAUTION

Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 5 mW

Wavelength 770-810 nm

Page 15

Denmark

Finland, Sweden

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling. Klasse 1 laser produkt der opfylder IEC60825

sikkerheds kravene.

halvlederlaser

Laserdiodens højeste styrke 5 mW

bølgelængden 770-810 nm

Norway

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne

bruksanvisning, kan brukeren utsettes för unsynlig laserstrålning, som

overskrider grensen for laser klass 1.

halvleder laser

Maksimal effekt till laserdiode 5 mW

bølgelengde 770-810 nm

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VAROITUS!

Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla

saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle

lasersäteilylle.

puolijohdelaser

Laserdiodin suurin teho 5 mW

aallonpituus 770-810 nm

VARNING!

Om apparaten används på annat sätt än i denna bruksanvisning

specificerats, kan användaren utsättas för osynlig laserstrålning, som

överskrider gränsen för laserklass 1.

halvledarlaser

Den maximala effekten för laserdioden 5 mW

våglängden 770-810 nm

VARO!

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättomälle

lasersäteilylle. Älä katso säteeseen.

VARNING!

Osynlig laserstråining när denna del är öppnad och spärren är urkopplad.

Betrakta ej stråien.

Page 16

LASER SAFETY LABEL

PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT

A laser safety label is attached to the outside of the machine as shown

below.

LASER CAUTION LABEL

A laser caution label is attached to the inside of the machine as shown

below.

When laser protective goggles are to be used, select ones with a

lens conforming to the above specifications.

When a disassembly job needs to be performed in the laser beam

path, such as when working around the printerhead and PC Drum,

be sure first to turn the printer OFF.

If the job requires that the printer be left ON, take off your watch and

ring and wear laser protective goggles.

A highly reflective tool can be dangerous if it is brought into the laser

beam path. Use utmost care when handling tools on the user's

premises.

CAUTION

Page 17

Revision Status

Revision Date of Issue Description

0 July 2, 2001 Partial release (Chapter 1/ Chapter4) (provisional)

A September 20, 2001 Formal first release

B February 7, 2002 [Revised] The sections listed below are revised.

Chapter 1: Table 1-47. Printer Messages (Only with EPL-5900)

Chapter 3: Table 3-1. Service Call Error (Engine-Related)

Chapter 7: 7.4 Exploded Diagrams

Chapter 7: 7.5 ASP List

Page 18

EPSON EPL-5900/EPL-5900L Revision B

Contents

Chapter 1 Product Description

1.1 Outline ...................................................................................................... 5

1.1.1 Features............................................................................................. 5

1.1.2 “EPL-5900” Differences from EPL-5800 ........................................ 7

1.1.3 “EPL-5900L” Differences from EPL-5800L ................................... 7

1.1.4 “EPL-5900L” Differences from EPL-5900...................................... 7

1.1.5 Restrictions on Use of “EPL-5900L”............................................... 8

1.2 Basic Specifications.................................................................................. 8

1.2.1 Process Specifications ...................................................................... 8

1.2.2 Printer Basic Specifications.............................................................. 8

1.2.3 Various Sensors .............................................................................. 16

1.2.4 Paper Specification......................................................................... 17

1.2.4.1 Paper Type........................................................................................... 17

1.2.4.2 Paper Feedings .................................................................................... 17

1.2.4.3 Printable Area...................................................................................... 17

1.2.5 Reliability, Durability, Serviceability............................................. 18

1.2.6 Operating Conditions (Including Imaging Cartridge) .................... 20

1.2.7 Storage and Transport of the Printer Main Unit and Optional Products

(Consumables Packaged)......................................................................... 21

1.2.8 Electrical Features .......................................................................... 22

1.2.9 Compliance with Standards and Regulations ................................. 22

1.2.10 Consumable Components............................................................. 23

1.2.10.1 Specifications .................................................................................... 23

1.2.10.2 Packing Storage and Transport Environments .................................. 24

1.3.1 Overall Dimensions of EPL-5900 .................................................. 25

1.3.2 Overall Dimensions of EPL-5900L................................................ 26

1.3.3 Names of Parts of EPL-5900.......................................................... 27

1.3.4 Names of Parts of EPL-5900L ....................................................... 29

1.4 Controller Specification.......................................................................... 31

1.4.1 Basic Controller Specifications ...................................................... 31

1.4.2 External I/F Specifications ............................................................. 32

1.4.2.1 Parallel Interface Specifications.......................................................... 33

1.4.2.2 USB Interface...................................................................................... 34

1.4.2.3 Type B Interface (Not Available with EPL-5900L)............................ 34

1.5 Control Panel........................................................................................... 36

1.5.1 External Appearance and Names of Parts....................................... 36

1.5.2 List of Panel Settings (Only with EPL-5900)................................. 38

1.5.2.1 Setting Items (Model-dependent) (Only with EPL-5900)................... 43

1.5.3 Printer Messages (Only with EPL-5900)........................................ 45

1.5.3.1 Status Specifications (Model-dependent)............................................ 47

1.7 System Requirements (Only for EPL-5900L)......................................... 50

1.9 Paper Feed Specifications (Only for EPL-5900L).................................. 52

1.9.1 Paper Size ....................................................................................... 52

1.9.2 Paper Feed Specifications............................................................... 52

1.9.3 Case List ......................................................................................... 53

1.9.4 Special Notes .................................................................................. 53

1.10 Notes on Operation ............................................................................... 54

1.10.1 Powering Off (EPL-5900) ............................................................ 54

1.10.2 Caution About Hot Parts (EPL-5900/EPL-5900L)....................... 54

1.10.3 About the Moist Environment Mode Select Jumper (EPL-5900L) 54

1.11 Engine Environment Setting ................................................................. 55

1.12 Ambient Conditions .............................................................................. 55

1.13 Differences in Specifications between Intended Markets..................... 56

1.13.1 Differences in Specifications ........................................................ 56

1.13.2 Jumper Setting .............................................................................. 57

Chapter 2 Operating Principles

2.1 Overview................................................................................................. 59

2.1.1 EPL-5900 Major Components ........................................................ 59

2.1.2 EPL-5900L Major Components...................................................... 60

1

Page 19

EPSON EPL-5900/EPL-5900L Revision B

2.1.3 Drive System .................................................................................. 61

2.1.4 Names and Functions of Electrical Parts (Printer Body)................ 62

2.1.5 Names and Functions of Electrical Parts (Lower Cassette)

(Not Applicable to EPL-5900L).............................................................. 63

2.1.6 Timing Chart .................................................................................. 64

2.2 Description of Mechanisms .................................................................... 65

2.2.1 Paper Path....................................................................................... 65

2.2.2 Paper Feed Mechanism................................................................... 66

2.2.2.1 Paper Tray ........................................................................................... 66

2.2.2.2 Lower Cassette Unit (Option for EPL-5900) ...................................... 67

2.2.3 Charging Process ............................................................................ 69

2.2.4 Exposure Process............................................................................ 70

2.2.5 Development Process ..................................................................... 71

2.2.6 Transfer Process ............................................................................. 72

2.2.7 Fusing Process ................................................................................ 73

2.2.8 Paper Eject Process......................................................................... 75

2.3 Operating Principles of Electric Circuitry .............................................. 76

2.3.1 Operation Overview of the Main Control Circuit Board................ 76

Chapter 3 Troubleshooting

3.1 Overview................................................................................................. 80

3.1.1 Specified Tools............................................................................... 80

3.1.2 Procedure for Troubleshooting....................................................... 80

3.1.3 Printer Messages (EPL-5900)......................................................... 80

3.1.3.1 Service Call Error................................................................................ 80

3.1.4 Printer Messages (EPL-5900L) ...................................................... 84

3.1.4.1 Printer Status. ...................................................................................... 84

3.1.4.2 Engine Error ........................................................................................ 84

3.1.5 Paper Jam Detection ....................................................................... 85

3.1.5.1 Overview ............................................................................................. 85

3.1.5.2 Paper Jam Conditions .......................................................................... 85

3.1.5.3 Resetting the Paper Jam ...................................................................... 85

3.1.6 Detection of Abnormal Operations ................................................ 86

3.2 Troubleshooting for Paper Jam............................................................... 87

3.2.1 Paper Jam when the Power is ON .................................................. 87

3.2.2 Paper Jam in Paper Feed to Paper Transport.................................. 87

3.2.3 Paper Jam in Paper Transport to Paper Eject.................................. 88

3.3 Troubleshooting for Abnormal Operations............................................. 89

3.3.1 Abnormal Laser .............................................................................. 89

3.3.2 Abnormal Polygon Motor............................................................... 89

3.3.3 Abnormal Main Motor.................................................................... 89

3.3.4 Abnormal Fusing ............................................................................ 89

3.3.5 Power Cannot be Turned ON.......................................................... 90

3.4 Troubleshooting for Print Quality Problems........................................... 91

3.4.1 All White......................................................................................... 91

3.4.2 All Black ......................................................................................... 91

3.4.3 White Out........................................................................................ 92

3.4.4 Back of Paper Gets Dirty ................................................................ 92

3.4.5 Low Image Density......................................................................... 92

3.4.6 Foggy Background.......................................................................... 92

3.4.7 White Line / Black Line.................................................................. 93

3.4.8 Offset Image ................................................................................... 93

Chapter 4 Disassembly and Assembly

4.1 Overview................................................................................................. 95

4.1.1 Precautions...................................................................................... 95

4.1.2 Tools ............................................................................................... 97

4.1.3 Screws............................................................................................. 97

4.2 Main Unit Disassembly........................................................................... 98

4.2.1 Preparation before Disassembling .................................................. 99

4.2.2 Imaging Cartridge and Drum Cartridge Removal .......................... 99

4.3 Disassembly and Reassembly of the Printer Body ............................... 100

4.3.1 Transfer Roller Removal .............................................................. 100

4.3.2 Paper Separator Unit Removal ..................................................... 101

4.3.3 Right Cover Removal ................................................................... 101

4.3.4 Control Panel Removal................................................................. 102

4.3.5 Main Board Assy Removal........................................................... 103

4.3.6 Interface Board (C409I/F) Removal............................................. 104

4.3.7 Left Cover Removal...................................................................... 105

4.3.8 Front Cover Removal.................................................................... 105

4.3.9 Paper Feed Roller Removal .......................................................... 106

2

Page 20

EPSON EPL-5900/EPL-5900L Revision B

4.3.10 Printing Head Unit Removal ...................................................... 106

4.3.11 Paper Empty Sensor (PE1) Removal.......................................... 107

4.3.12 Top Cover and Rear Cover Removal ......................................... 107

4.3.13 Fuser Unit Removal.................................................................... 108

4.3.14 Fuser Unit Disassembly.............................................................. 109

4.3.15 Power Supply Unit and High Voltage Board Removal.............. 113

4.3.16 Main Motor Assy (M1) Removal ............................................... 115

4.4 500-sheet Lower Cassette Unit (Optional) ........................................... 117

4.4.1 Second Paper Feed Roller Removal ............................................. 117

4.4.2 Second Paper Feed Unit Removal................................................ 118

4.4.3 Relay Board (PWB-A) Removal .................................................. 119

4.4.4 Cassette Type Detect Switch (SW21) Removal........................... 119

4.4.5 Second Paper Feed Solenoid (SL21) Removal ............................ 120

Chapter 5 Adjustment

5.1 Overview............................................................................................... 122

5.2 USB ID Input........................................................................................ 123

5.2.1 Installation Procedure for Program .............................................. 123

5.2.2 Procedure for Program Operation ................................................ 123

5.2.3 USB ID Confirmation................................................................... 125

7.1.1.5 HV1 (High Voltage Unit) Board....................................................... 131

7.2 Circuit Board Component Layout......................................................... 132

7.3 Circuit Diagrams ................................................................................... 137

7.4 Exploded Diagrams............................................................................... 145

7.5 ASP List ................................................................................................ 158

Chapter 6 Maintenance

6.1 Overview............................................................................................... 127

6.1.1 Cleaning........................................................................................ 127

6.1.2 Maintenance ................................................................................. 127

Chapter 7 Appendix

7.1 Connectors ............................................................................................ 129

7.1.1 Circuit Boards............................................................................... 129

7.1.1.1 Connectors on Main Board Assy (EPL-5900) .................................. 129

7.1.1.2 Connectors on Main Board Assy (EPL-5900L)................................ 130

7.1.1.3 Interface Board (C409I/F)................................................................. 131

7.1.1.4 PU1 (Power Supply Unit) Board....................................................... 131

3

Page 21

PRODUCT DESCRIPTION

CHAPTER

1

Page 22

EPSON EPL-5900/EPL-5900L Revision B

1.1 Outline

EPSON EPL-5900 and EPL-5900L are non-impact page printer with semi-conductor

laser and electrophotographic technology.

1.1.1 Features

ENGINE FEATURES

New compact and lightweight, A4 support engine

Resolution/ printing speed: See table below.

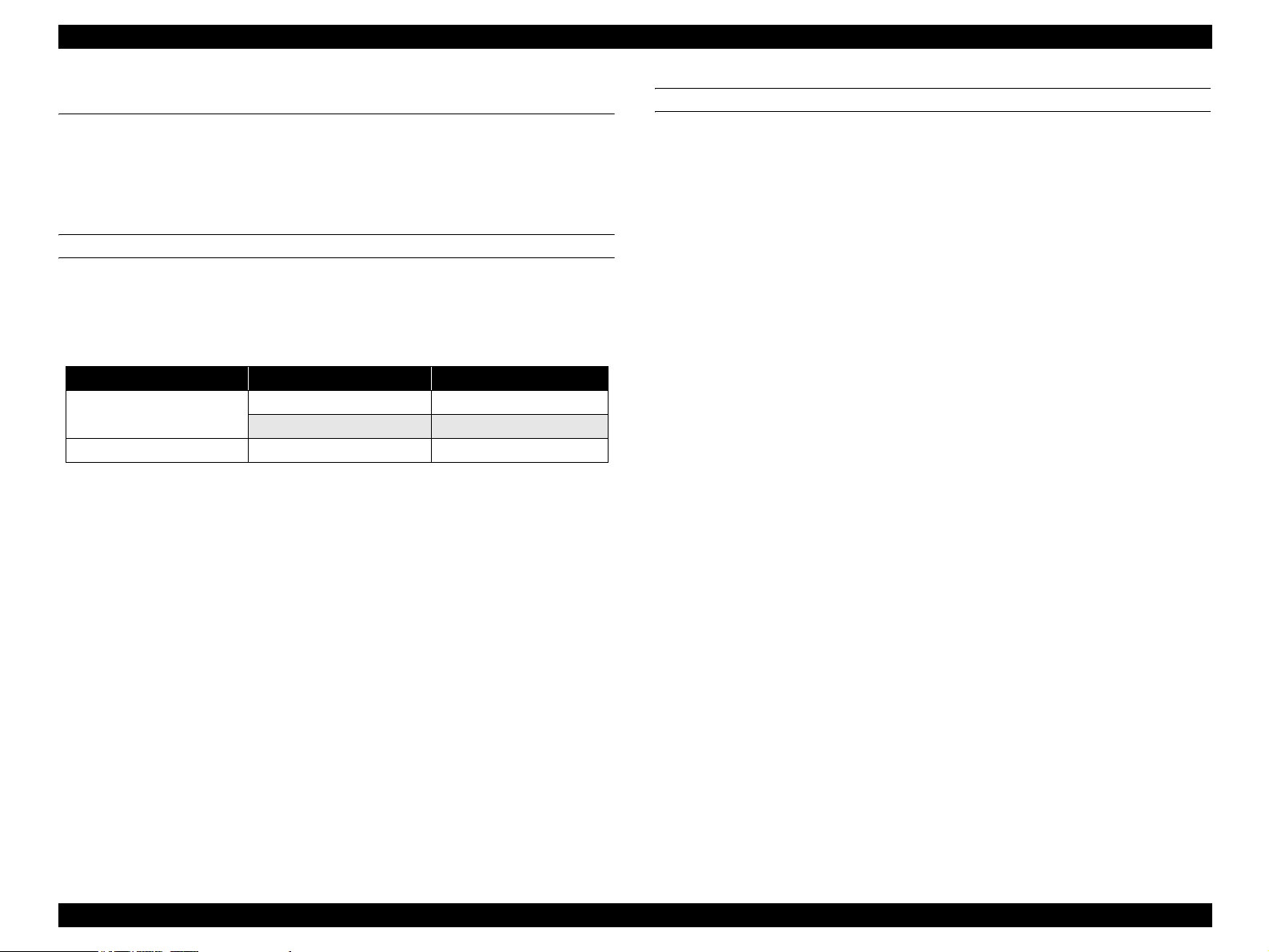

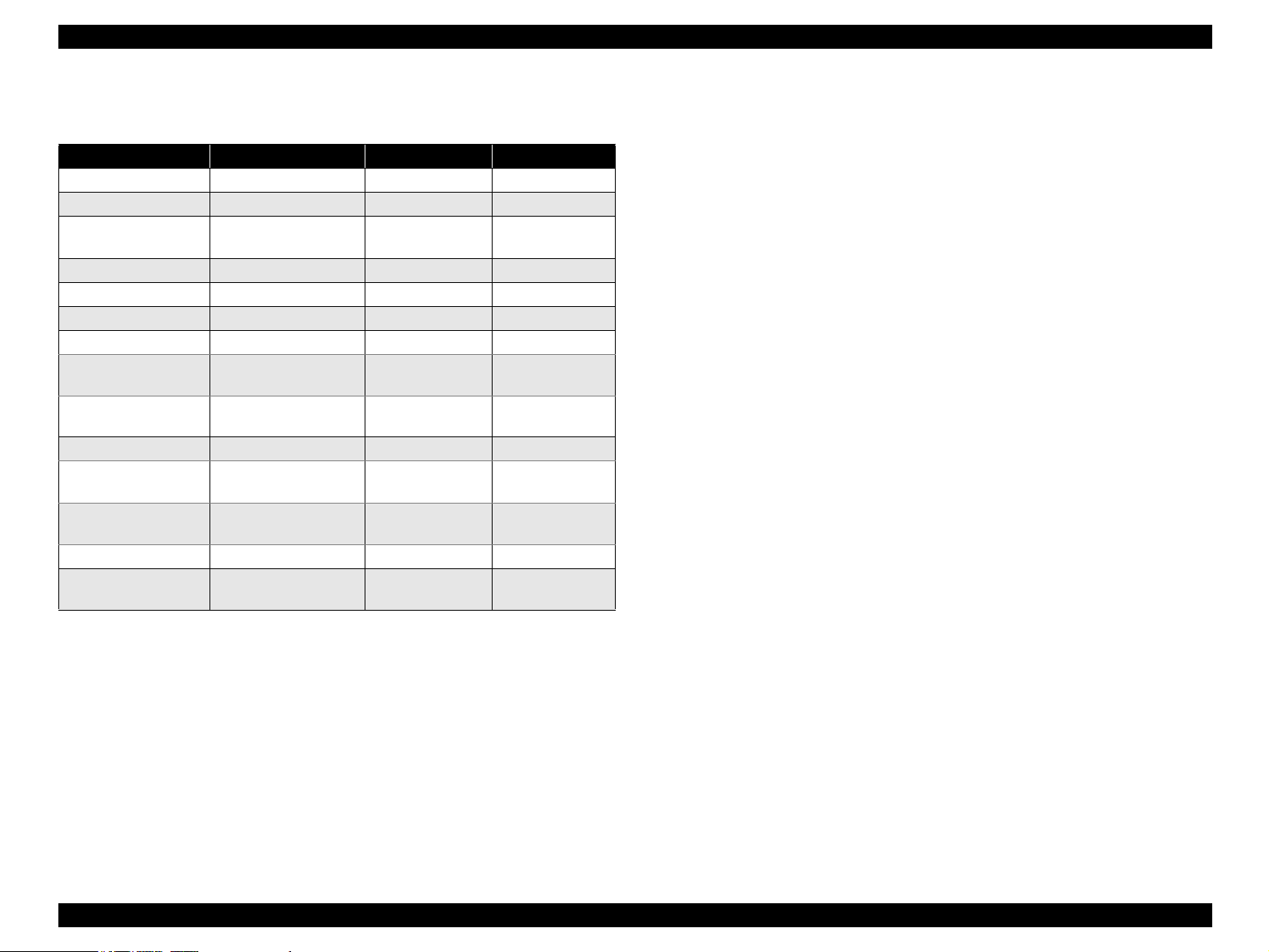

Table 1-1. Resolution and Printing Speed

Model Resolution Printing Speed

EPL-5900

EPL-5900L 600 dpi 12 ppm

Note: The engine itself supports True 1200 dpi, but 1200 dpi is not

supported with EPL-5900L.

With EPL-5900, the standard paper supply consists of the cassette-like universal

paper tray (250 sheets) and manual feed tray (one sheet).

EPL-5900L is equipped with a 150-sheet paper feed tray.

EPL-5900 supports an optional 500-sheet lower cassette (A4).

Toner life: 3,000 pages with the pre-installed Imaging Cartridge and 6,000 sheets

with a replaced Imaging Cartridge.

Neither the pre-installed Imaging Cartridge nor replaced Imaging Cartridge is

interchangeable with that for EPL-5800 or EPL-5800L series.

300 dpi / 600 dpi 12 ppm

1200 dpi 6 ppm

CONTROLLER FEATURES

<EPL-5900>

High-speed controller, employing new CPU

CPU = TMPR4955AF / Clock = 200 MHz

8 MB fitted as standard RAM and Expandable up to 136 MB Max.

PCL6 emulation installed

Two standard interfaces

IEEE1284 parallel interface

USB interface

Equipped with one Type B interface slot (Level 3 supported)

Real 1200dpi supported (Only in ESC/Page, PCL6, PostScript 3. Up to 600 dpi

supported in other modes)

Note: 1200dpi printing needs much memory then the possibility of running

short of memory is high with standard memory.

Recommendation: Extension of 16MB or more.

EnhancedMicroGray installed (available only in 600dpi and 300dpi.

Automatically switched Off when 1200dpi is selected.)

RITech installed (available only in 600dpi and 300dpi. Automatically switched

Off when 1200dpi is selected.)

New control panel design with 3 switches and 6 LEDs

The Photoconductor Unit is common to EPL-5900 Series and EPL-5800 Series.

The face down tray attachment is available as an option.

Note: This attachment is not a general option. It is supplied on user request

or tender request. The capacity depends on user environment. This

attachment is not described in manuals or catalogs.

Product Description Outline 5

Page 23

EPSON EPL-5900/EPL-5900L Revision B

<EPL-5900L>

Host based controller

CPU Toshiba TMP95C001 24MHz

RAM Standard 2MB

Expandable up to a maximum of 13 MB (EDO RAM SIMM,

access speed 60 ns).

Two standard interfaces

IEEE1284 parallel interface (ECP supported)

USB interface (UBS Revision 1.1, USB ID supported)

RITech, EnhancedMicroGray functions installed

Data Compression Technologies

By sending compressed data from the host computer, almost all data can be

printed only with the standard memory.

High speed processing is realized by use of the expansion circuit hardware.

Expansion of RAM will enhance the following functions and speed up printing.

EnhancedMicroGray printing

Increasing the size of the receiving buffer

High-speed printing

SOFTWARE FEATURE (ONLY WITH EPL-5900)

The following modes and resolution are supported.

Table 1-2. Supported Modes

Mode 1200dpi 600dpi 300dpi Note

ESC/Page {{{

PCLXL { { {

PCL5e x {{

ESC/P2 x { {

FX x {{

1239X x { {

PostScript {{{Optional (New)

NLSP is included in the main unit font ROM

Compatible with USB Revision 1.1

Job cancellation by panel switch

Product Description Outline 6

Page 24

EPSON EPL-5900/EPL-5900L Revision B

1.1.2 “EPL-5900” Differences from EPL-5800

Table 1-3. EPL-5900 Differences from EPL-5800

Item EPL-5900 EPL-5800 Note

Engine speed 12 ppm 10 ppm

CPU performance TMPR4955AF-200MHz R4310-133MHz

RAM capacity

(Standard / Maximum)

Paper size at shipment A4 only A4/Letter

Control Panel 3 switches, 6 LEDs 4 switches, 6 LEDs

LED Status New specifications

Status Sheet New format

Photoconductor Unit

life indicator

Consumables

information

Selectype

Preprinted: LC Type/

MP Type

Parallel Menu Bi-D

default value

Standby time 15 minutes 5 minutes

Optional Letter cassette

unit

8MB / 136MB 16MB / 256 MB

Included Not included

Indicated Not indicated

Deleted Available

ECP Nibble

None Available

1.1.4 “EPL-5900L” Differences from EPL-5900

Compatible with Windows (Windows 95/98/2000, NT 4.0) and Macintosh (Mac

OS 8.1 or later) OS only.

Not compatible with the other operating systems, such as DOS, Unix or Linux.

As for Macintosh, EPL-5900L is compatible with only those models which

support the standard USB port.

Even in Windows environments, EPL-5900L is not compatible with any machine

with a connection port other than the standard USB port.

EPL-5900L is not equipped with fonts and emulations.

No emulations are offered as options.

In image printing, output results may differ, since the ROP and filling methods as

well as the half-tone screen, etc. differ.

1200 dpi resolution is not supported.

Only EDO RAM SIMM (with an access speed of 60 ns or less) is supported for

expansion RAM.

Not compatible with direct connection to a network.

Can be used as a Shared Printer in both Windows environments and Macintosh

environments.

The standard paper feeder is a folding tray type.

No optional lower cassette is available.

No switches on the control panel

1.1.3 “EPL-5900L” Differences from EPL-5800L

The standard paper feeder is a folding tray type.

Printing speed 12 ppm (EPL-5800L: 10 ppm)

“Toner Out” setting added (already employed with EPL-1220)

“Invalid Size” error added (already employed with EPL-1220)

The Check Paper Size error and Check Multi Copy P-Size error are not

implemented.

Product Description Outline 7

Page 25

EPSON EPL-5900/EPL-5900L Revision B

1.1.5 Restrictions on Use of “EPL-5900L”

The Status Sheet can not be printed out with the printer unit in the stand alone

state.

If the printer is connected to the parallel interface through a printer switching

device, LAN-Parallel switching device, USB-Parallel switching device or any

other like device, printing performance is not guaranteed.

⇒ Direct connection to the host's printer port via an ECP compatible cable is

premised.

For USB connection, use of a switching device is not covered by the warranty.

With a host computer that does not permit ECP connection, printing with the

standard memory may be impossible in some cases.

The maximum RAM size is 13 MB (even when 16/32 MB RAM SIMM is

installed).

EPL-5900L can not be used in a system incorporating a terminal server or any

other device which does not support bidirectional communication.

1.2 Basic Specifications

1.2.1 Process Specifications

Printer Type

Semi-conductor laser beam scan and dry one-component electromagnetic toner

electrophotography

Light Source

Semi-conductor laser

Photoconductor Unit

OPC (organic photoconductor) drum

Charging

Rotary-brush charging method

Development

Exposed area development

Toner

One-component magnetic toner

Transfer

Roller transfer method

Fixing

Heated roller method

Density Adjustment

Variable development bias method (adjustable by user)

1.2.2 Printer Basic Specifications

Resolution:

<EPL-5900> 600dpi / 1200dpi

(1200dpi is half speed control)

<EPL-5900L> 600 dpi

Warming Up Time:

21 or less seconds ....... Time from power-on to “Ready” display

11 or less seconds ........Warm-up time from sleep mode

(23°C environment, at rated voltage)

Product Description Basic Specifications 8

Page 26

EPSON EPL-5900/EPL-5900L Revision B

First Printing Time: Continuous Printing Speed:

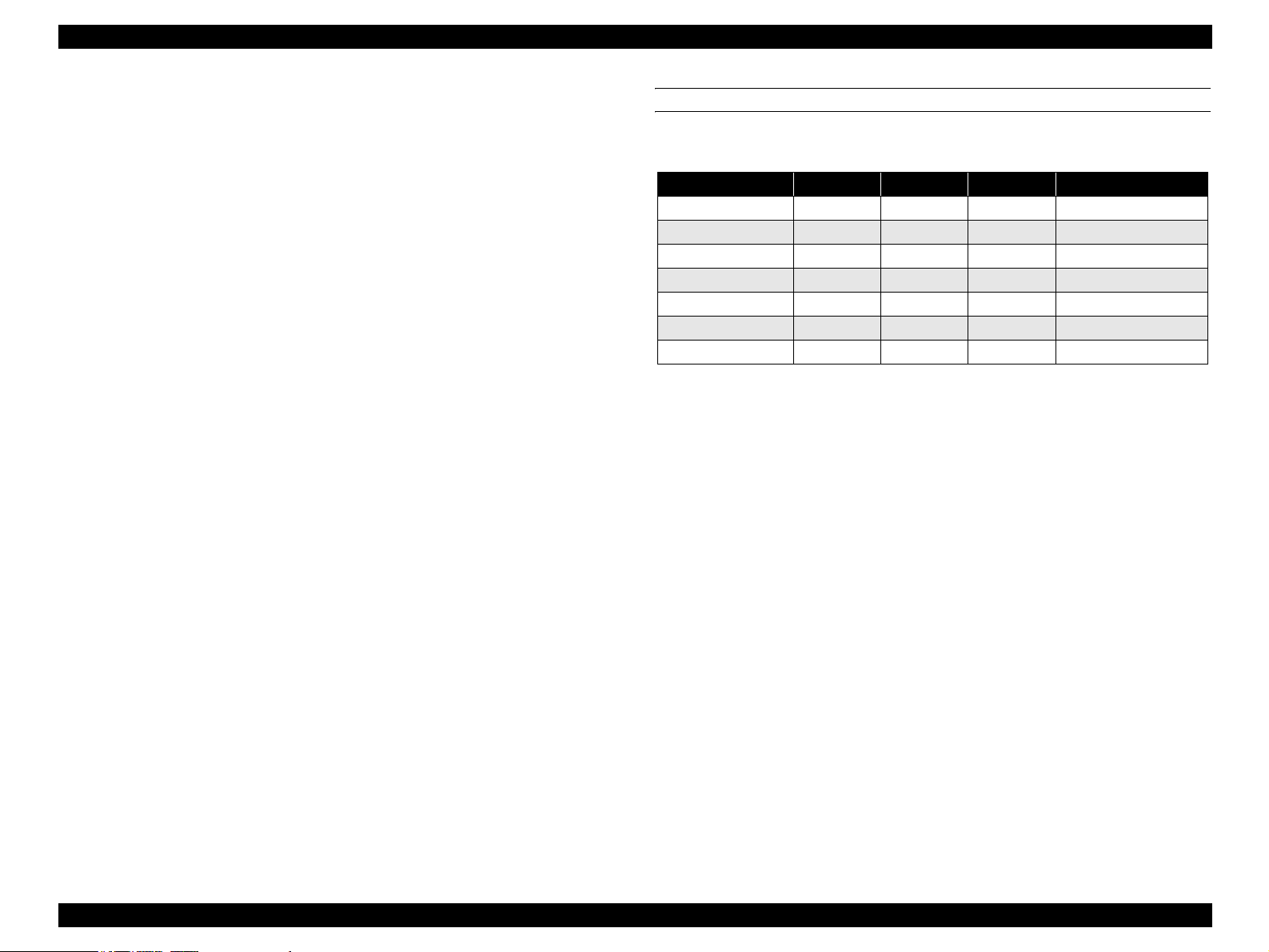

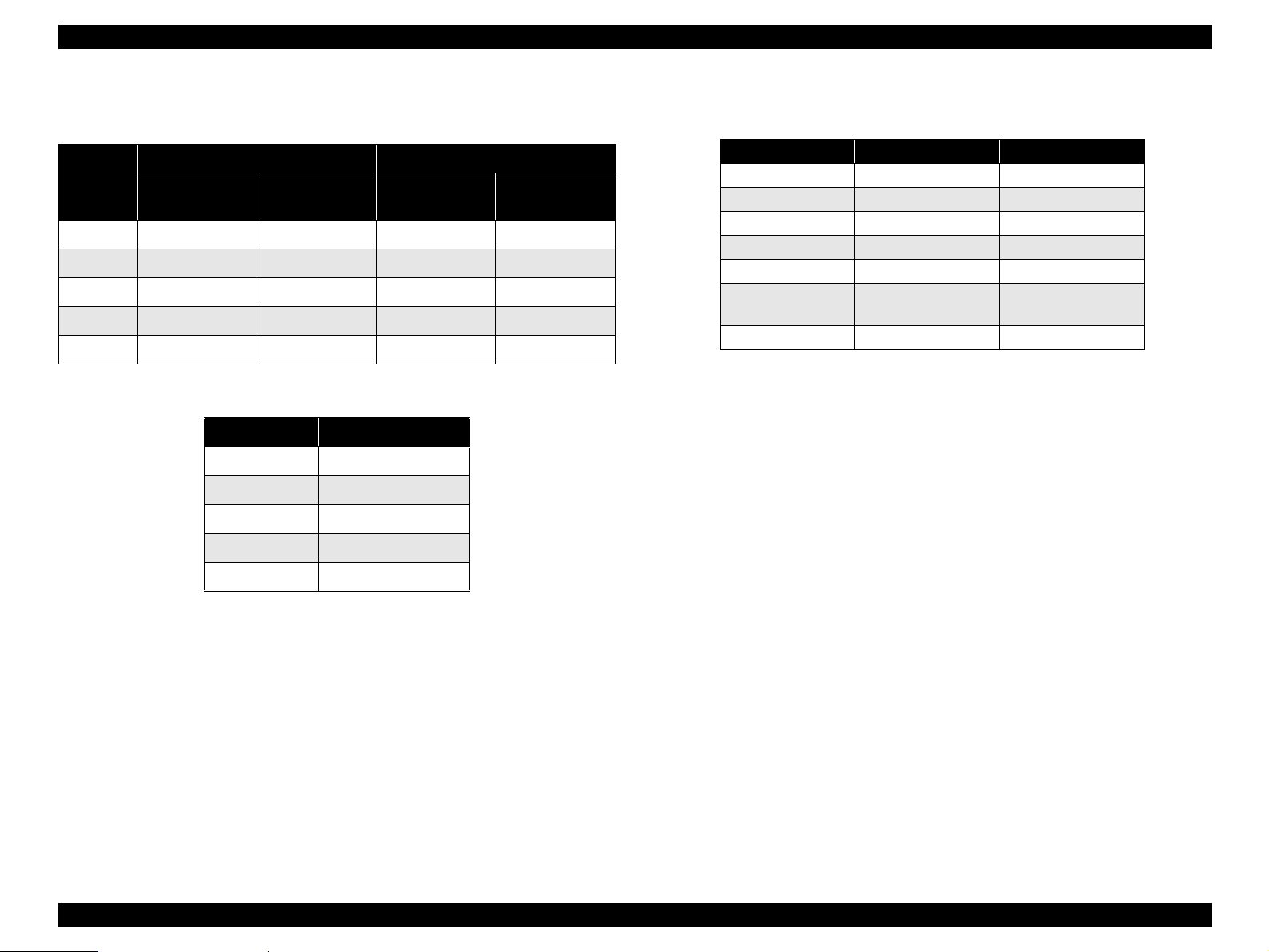

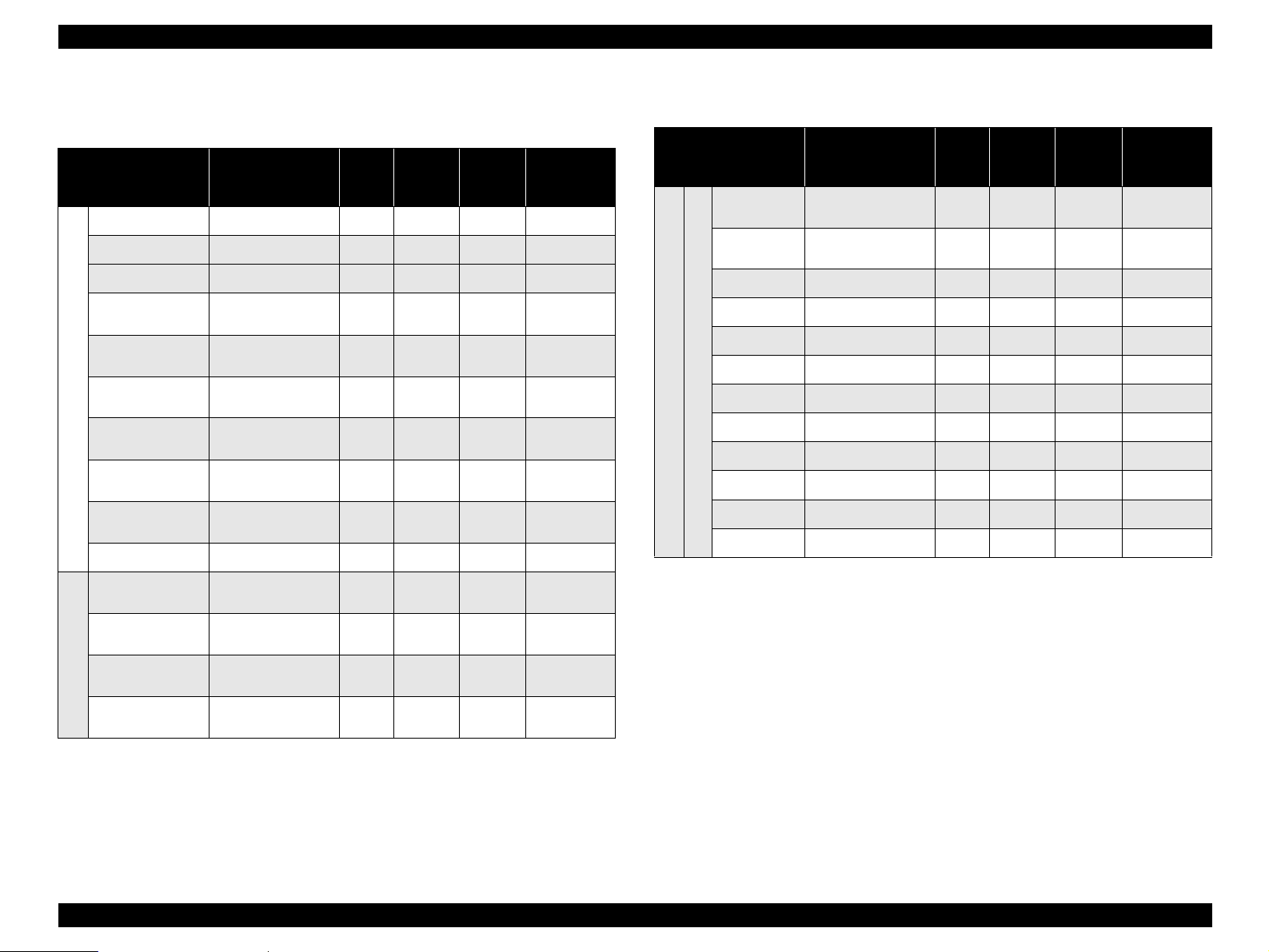

Table 1-4. First Printing Time with “EPL-5900”

600dpi 1200dpi

Paper Size

Main Unit

A4 15 sec. maximum 16 sec. maximum 24 sec. maximum 26 sec. maximum

LGL 16 sec. maximum -- 25 sec. maximum --

LT 15 sec. maximum 16 sec. maximum 24 sec. maximum 26 sec. maximum

B5 15 sec. maximum -- 23 sec. maximum --

A5 14 sec. maximum -- 22 sec. maximum --

Lower Cassette

Unit

Main Unit

Lower Cassette

Unit

Table 1-5. First Printing Time with “EPL-5900L”

Paper Size 600dpi

A4 15 sec. maximum

LGL 16 sec. maximum

LT 15 sec. maximum

B5 15 sec. maximum

A5 14 sec. maximum

Table 1-6. Continuous Printing Speed

Paper Size 600dpi 1200dpi

A4 12.0 ppm minimum 6.0 ppm minimum

LGL 10.3 ppm minimum 5.1 ppm minimum

LT 12.5 ppm minimum 6.2 ppm minimum

B5 12.5 ppm minimum 6.2 ppm minimum

A5 12.5 ppm minimum 6.2 ppm minimum

Japanese official

postcard

Kakugata #3

*1: 1200 dpi is not available with EPL-5900L.

*2: JIS envelope

NOTE 1:

The continuous printing speeds indicated above are common to all the paper

*2

12.5 ppm minimum 6.2 ppm minimum

11.0 ppm minimum 5.5 ppm minimum

feeders.

2:

For printing of custom size paper, printing speed will be lower because

automatic cleaning is carried out. In addition, paper sheets of custom size

will be printed at the same speed irrespective of the paper size.

Paper Feed Reference

Centerline reference for each paper size and each paper feeder.

*1

Product Description Basic Specifications 9

Page 27

EPSON EPL-5900/EPL-5900L Revision B

Paper Feed:

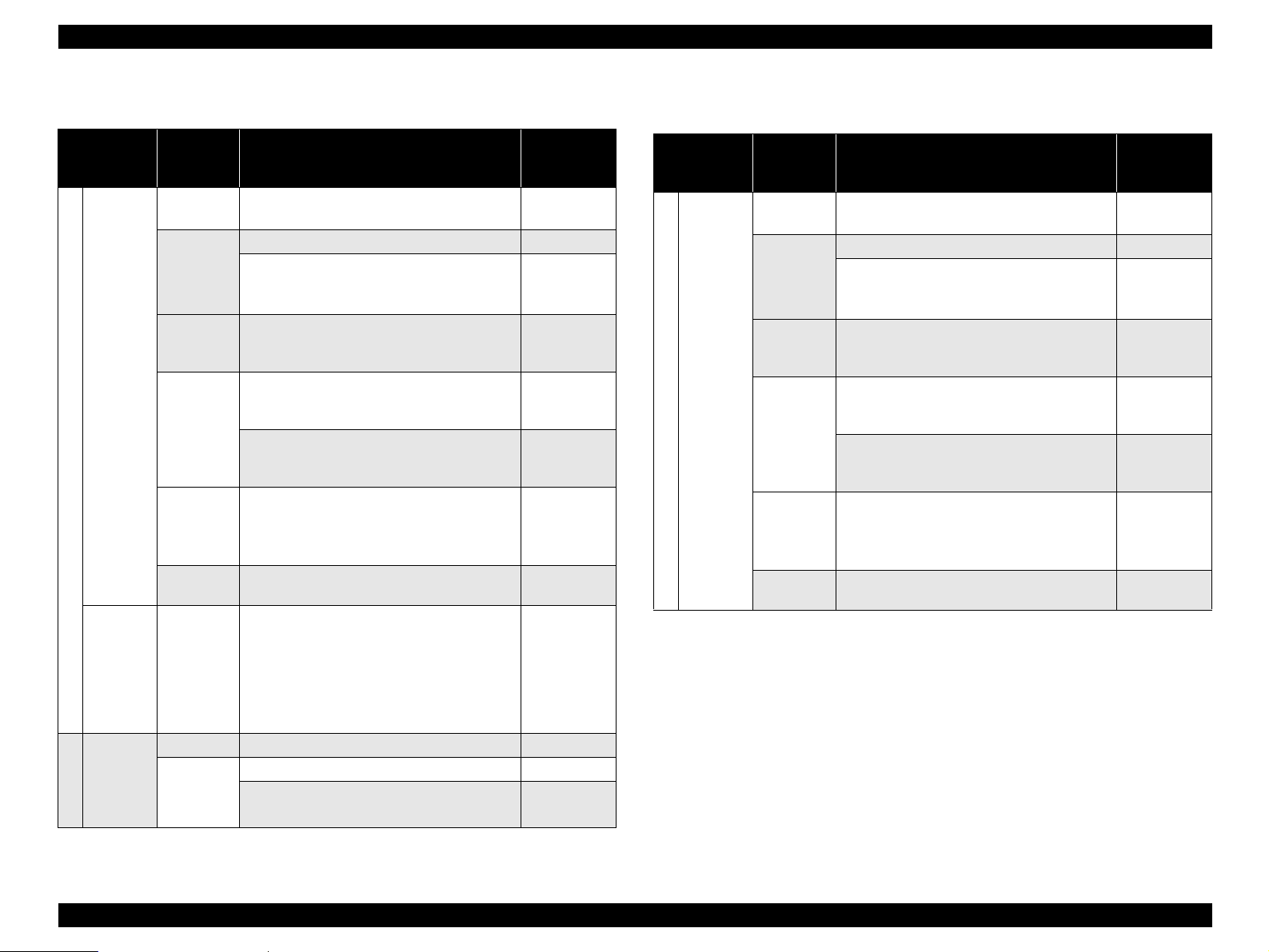

Table 1-7. Paper Feed with “EPL-5900”

Paper Source Capacity Paper Type *1 and Paper Size

Paper Tray

Standard

Manual

feed slot

500-sheet

lower

cassette

(paper size

Optional

fixed)

300 sheets

(TBD)

250 sheets

5 sheets

10 sheets

10 sheets

50 sheets

1 sheet

TBD sheets

500 sheets

Standard paper: FX P Paper: A4

Standard paper: XEROX 4024DP 20lb: Letter

Plain paper or regenerated paper:

A4, B5, A5, Letter, GLT, Executive, LGL

GLG, F4, Half Letter, Custom size paper

Transparencies:

A4, B5, A5, Letter, GLT, Executive, LGL,

GLG, F4, Half Letter, Custom size paper

Labels:

A4, B5, A5, Letter, GLT, Executive, LGL,

GLG, F4, Half Letter, Custom size paper

Thick paper:

A4, B5, A5, Letter, GLT, Executive, LGL,

GLG, F4, Half Letter, Custom size paper

Envelope:

Monarch, Com-10

ISO-B5, Yokei #0

*4

, Chokei #3 *4, Chokei #4 *4, Kakugata #3

Japanese official postcard *2,

*3

Japanese official prepaid postcard

, DL, C5, C6

*4

, Yokei #4 *4, Yokei #6

*2

Standard paper, plain paper, special

applications:

A4, A5, Letter, GLT, Executive, LGL, GLG

F4, Half Letter, B5, Monarch, Com-10 DL,

*4

C5, C6, ISO-B5, Yokei #0

*4

Yokei #6

, Chokei #3 *4, Chokei #4 *4,

, Yokei #4 *4,

Kakugata #3 *4, Custom size paper

*

Standard paper: FX P Paper: A4

Standard paper: XEROX 4024DP 20lb: Letter

Plain paper or regenerated paper: A4 or Letter

Thickness

60 ~ 90 g/m

90 ~ 163 g/m

70 ~ 105 g/m

*4

60 ~ 163 g/m

60 ~ 90 g/m

Feedable

Paper

2

64 g/m

2

75 g/m

---

---

190 g/m

2

64 g/m

2

75 g/m

*1

2

Paper Source Capacity Paper Type *1 and Paper Size

Paper Tray

Standard

2

2

2

*1: Refer to 1.2.4 "Paper Specification".

2

*2: Curl must be straightened, especially before feeding a postcard for printing of its back

side in consideration of manual duplex printing. (Set the postcard so that its side to be

printed faces up and its curl is directed upward.)

*3: For the second side printing, set not more than 20 sheets.

*4: JIS envelope

NOTE: For custom size paper, refer to Paper Feed Sizes and Paper Thickness

2

(p13).

Table 1-8. Paper Feed with “EPL-5900L”

300 sheets

(TBD)

150 sheets

5 sheets

10 sheets

10 sheets

50 sheets

Standard paper: FX P Paper: A4

Standard paper: XEROX 4024DP 20lb: Letter

Plain paper or regenerated paper:

A4, B5, A5, Letter, GLT, Executive, LGL

GLG, F4, Half Letter, Custom size paper

Transparencies:

A4, B5, A5, Letter, GLT, Executive, LGL,

GLG, F4, Half Letter, Custom size paper

Labels:

A4, B5, A5, Letter, GLT, Executive, LGL,

GLG, F4, Half Letter, Custom size paper

Thick paper:

A4, B5, A5, Letter, GLT, Executive, LGL,

GLG, F4, Half Letter, Custom size paper

Envelope:

Monarch, Com-10

ISO-B5, Yokei #0

*4

, Chokei #3 *4, Chokei #4 *4, Kakugata #3

Japanese official postcard *2,

*3

, DL, C5, C6

*4

, Yokei #4 *4, Yokei #6

Japanese official prepaid postcard

Feedable

Paper

Thickness

64 g/m

75 g/m

60 ~ 90 g/m

---

---

90 ~ 163 g/m

70 ~ 105 g/m

*4

*2

190 g/m

*1

2

2

2

2

2

2

Product Description Basic Specifications 10

Page 28

EPSON EPL-5900/EPL-5900L Revision B

Applicable Paper Sizes, Paper Types, and Paper Orientation

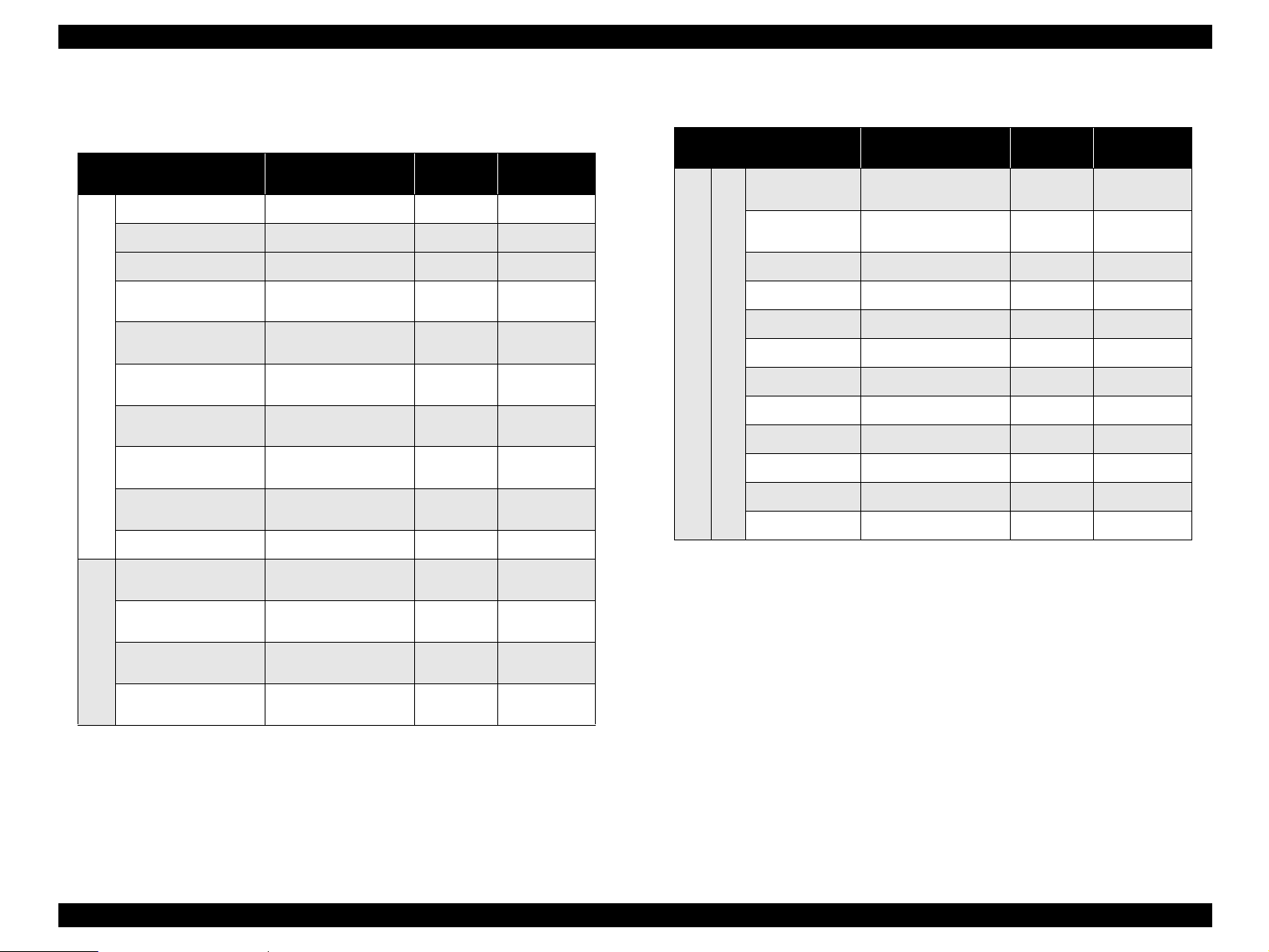

Table 1-9. Applicable Paper Sizes, Paper Types, and Paper Orientation

with “EPL-5900”

Paper Size

A4 210.00

A5 148.00× 210.00

B5 182.00 × 257.00

LT

HLT

LGL)

Plain Paper

EXE

GLG

GLT

F4 210.00

Japanese official

postcard

Japanese official

prepaid postcard

Transparencies

Special Applications

Labels

*4

*4

Dimensions

in mm (inches)

215.90

(8.50× 11.00")

139.70× 215.90

(5.50× 8.50")

215.90

×14.00")

(8.50

184.15× 266.70

(7.25× 10.50")

215.90× 330.20

×13.00")

(8.50

203.20× 266.70

(8.00× 10.50")

100.00× 148.00

200.00× 148.00

A4: 210.00×297.00

LT: 215.90×279.40

A4: 210.00×297.00

LT: 215.90×279.40

×297.00

×279.40

×355.60

×330.00

Paper

Tray

Manual

Feed

Slot

{{{

{ {

{ {

{{{

{ {

{{

{ {

{{

{ {

{{

{ {

{{

{ {

{{

Lower

Cassette

*4

*3

- SEF

- SEF

*3

-SEF

- SEF

-SEF

- SEF

-SEF

- SEF

-SEF

- SEF

-SEF

Paper

Orientation

SEF

SEF

SEF

Table 1-9. Applicable Paper Sizes, Paper Types, and Paper Orientation

with “EPL-5900” (continued)

Paper Size

Monarch

Com-10

DL 110.00×220.00

C5 162.00 × 229.00

C6 114.00 × 162.00

*3, *4

ISO-B5 176.00×250.00

Yokei #0

Envelope

Yokei #4

Special Applications

Yokei #6

Chokei #3 *5120.00×235.00

Chokei #4 *590.00×205.00

Kakugata #3 *5216.00×277.00

*1: Curls must be straightened.

*2: Refer to Envelope Orientation (p.13) for details on feeding direction of envelopes.

*3: The lower cassette is available with a fixed paper size.

*4: Option

*5: JIS envelope

*5

*5

*5

Dimensions

in mm (inches)

98.43×190.50

(3 7/8”×7 1/2”)

×241.30

104.78

×9 1/2”)

(4 1/8”

120.00×235.00

105.00×235.00

98.00×190.00

Paper

Tray

Manual

Feed

Slot

{ {

{{

{ {

{{

{ {

{{

{ {

{{

{ {

{{

{ {

{{

Lower

Cassette

*4

- SEF

-SEF

- SEF

-SEF

- SEF

-SEF

-SEF

-SEF

Paper

Orientation

SEF

SEF

SEF

SEF

NOTE: LEF (Long Edge Feed): the long edge of the paper is fed to the printer.

SEF (Short Edge Feed): the short edge of the paper is fed to the printer.

*2

*2

*2

*2

*2

*2

*2

*2

*2

*2

*2

*2

Product Description Basic Specifications 11

Page 29

EPSON EPL-5900/EPL-5900L Revision B

Table 1-10. Applicable Paper Sizes, Paper Types, and Paper Orientation

Table 1-10. Applicable Paper Sizes, Paper Types, and Paper Orientation

with “EPL-5900L”

Paper Size

A4 210.00

A5 148.00 ×210.00

B5 182.00× 257.00

LT

HLT

LGL)

Plain Paper

EXE

GLG

GLT

F4 210.00

Japanese official

postcard

Japanese official prepaid

postcard

Transparencies

Special Applications

Labels

*4

*4

in mm (inches)

215.90

×11.00")

(8.50

139.70×215.90

(5.50×8.50")

215.90×355.60

(8.50×14.00")

184.15×266.70

×10.50")

(7.25

215.90×330.20

(8.50×13.00")

203.20×266.70

×10.50")

(8.00

100.00×148.00

200.00×148.00

A4: 210.00×297.00

LT: 215.90

A4: 210.00×297.00

LT: 215.90×279.40

Dimensions

×297.00

×279.40

×330.00

×279.40

Paper Tray

{

{

{

{

{

{

{

{

{

{

{

{

{

{

Paper

Orientation

SEF

SEF

SEF

SEF

SEF

SEF

SEF

SEF

SEF

SEF

SEF

SEF

SEF

SEF

Paper Size

Monarch

Com-10

DL 110.00×220.00

C5 162.00×229.00

C6 114.00×162.00

*3, *4

ISO-B5 176.00×250.00

Yokei #0

Envelope

Special Applications

*1: Curls must be straightened.

*2: Refer to Envelope Orientation (p.13) for details on feeding direction of envelopes.

*3: JIS envelope

Yokei #4

Yokei #6

Chokei #3

Chokei #4

Kakugata #3

NOTE: LEF (Long Edge Feed): the long edge of the paper is fed to the printer.

SEF (Short Edge Feed): the short edge of the paper is fed to the printer.

with “EPL-5900L” (continued)

Dimensions

in mm (inches)

98.43×190.50

(3 7/8”×7 1/2”)

×241.30

104.78

(4 1/8”×9 1/2”)

*3

*3

*3

*3

*3

120.00×235.00

105.00×235.00

98.00×190.00

120.00×235.00

90.00×205.00

*3

216.00×277.00

Paper Tray

{

{

{

{

{

{

{

{

{

{

{

{

Paper

Orientation

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

*2

SEF

Product Description Basic Specifications 12

Page 30

EPSON EPL-5900/EPL-5900L Revision B

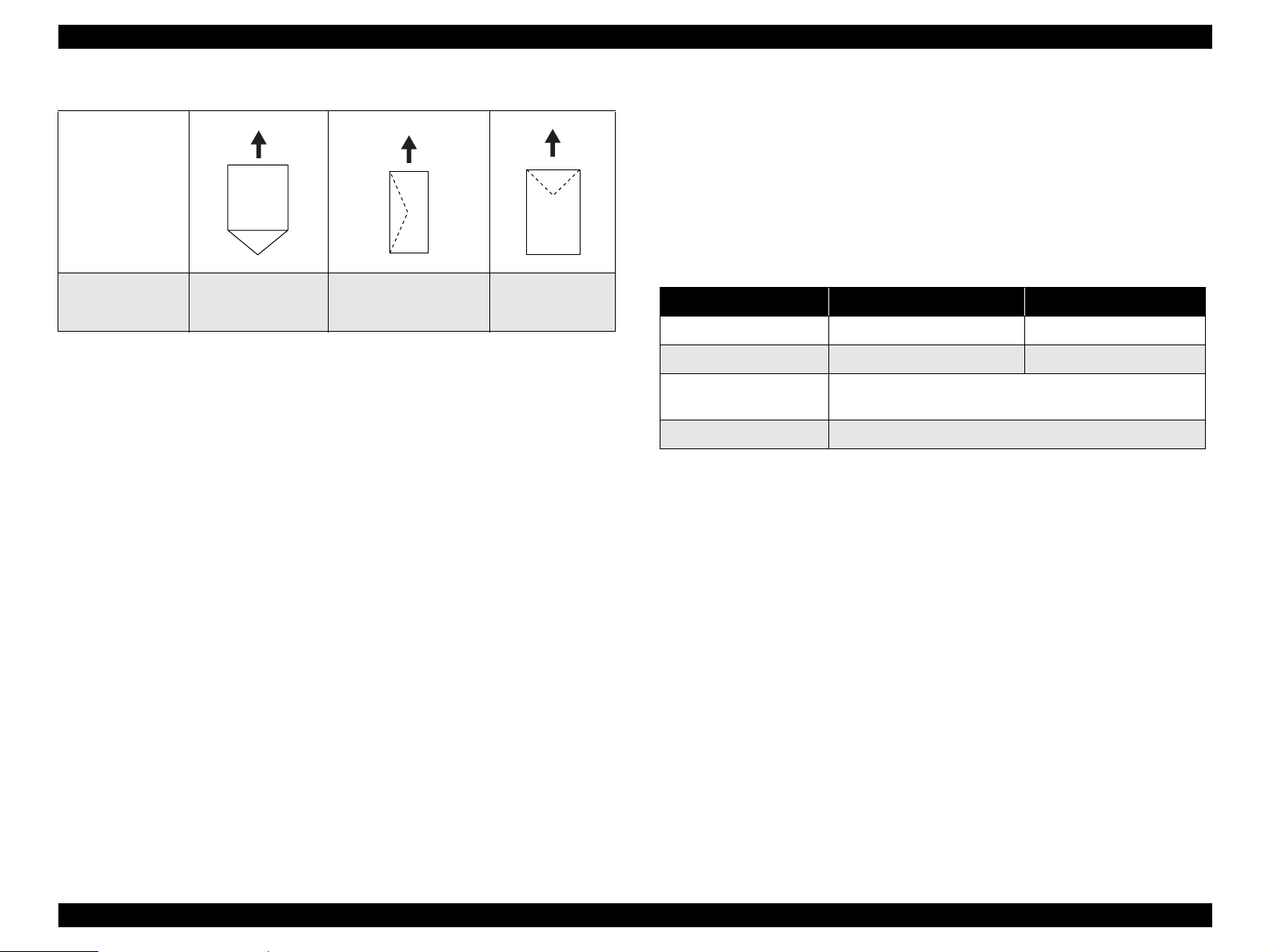

Envelope Orientation

<EPL-5900L>

Paper tray:

Regular types of paper or custom size paper within the following feedable

paper size range

Feeding Direction

Paper width 76.00 to 216.00 mm

Paper length 127.00 to 356.00 mm

Paper thickness 60 to 163 g/m

2

Output Paper Capacity:

Table 1-11. Output Paper Capacity

Standard Optional

*1

100 sheets 20 sheets

All sizes which can be fed through the printer body

(Regular or custom sizes)

Standard paper, plain paper, special applications

Envelope Types

*1: JIS envelope

Chokei #3 *1,

Chokei #4 *1,

Kakugata #3

Yokei #0 *1, Yokei #4 *1,

*1

Yokei #6 *1, Monarch,

Com-10, DL, C6

C5, ISO-B5

NOTES:1. Only envelopes without adhesive or adhesive tapes can be used.

2. Set the envelope with its side to be printed facing up.

Paper Feed Sizes and Paper Thickness

Paper exit bin Face-down Face-up

Output paper capacity

Paper sizes

Paper types

*2

<EPL-5900>

Printer body and Paper tray:

Regular types of paper or custom size paper within the following feedable

*1: In Environment A (see p.55). With standard paper immediately after unpacked

*2: Refer to 1.2.4 "Paper Specification".

paper size range

Paper width 76.00 to 216.00 mm

Paper length 127.00 to 356.00 mm

Paper thickness 60 to 163 g/m

2

Manual feed slot:

Regular types of paper or custom size paper within the following feedable

paper size range

Paper width 76.00 to 216.00 mm

Paper length 148.00 mm to 356.00 mm

Paper thickness 60 to 163 g/m

2

Lower cassette unit (option):

Supported paper size = Either A4 or Letter (fixed to only one size)

Paper thickness 60 to 90 g/m

2

Product Description Basic Specifications 13

Page 31

EPSON EPL-5900/EPL-5900L Revision B

Dimensions

Stand Alone Outline Dimensions and Weights

Table 1-12. Stand Alone Outline Dimensions and Weights of

“EPL-5900”

Standard

Optional

Standard

Optional

NOTE 1:

Face-down tray in storage position

Face-down tray in use position

Face-up tray

Lower cassette unit

Table 1-13. Stand Alone Outline Dimensions and Weights of

“EPL-5900L”

Face-down tray in storage position

Face-down tray and Paper tray in

use position

Face-up tray

Unpacked dimensions are stated.

2:

Dimensions have a tolerance of ±5mm and weights have a tolerance of

±

0.5kg.

3:

The dimensions of the Main Unit does not include those of the controller and

consumables.

Width

(mm)

399 435 265 7.5

399 435 378 7.5

248 32 248 0.2

382 444 137 4

Width

(mm)

399 263 256 7

399 406 368 7

248 32 248 0.2

Depth

(mm)

Depth

(mm)

Height

(mm)

Height

(mm)

Weight

Weight

(kg)

(kg)

Outline Dimensions and Weights with Options Installed

Table 1-14. Outline Dimensions and Weights with Options Installed of

“EPL-5900”

Main Unit +

Face-up tray

Main Unit +

Lower cassette unit

Main Unit +

Lower cassette unit +

Face-up tray

Main Unit +

Paper eject tray

attachment

NOTE 1:

Dimensions have a tolerance of ±5mm and weights have a tolerance of

±

0.5kg.

2:

The dimensions of the Main Unit does not include those of the controller and

consumables.

Face-down and

Face-up trays in

storage position

Face-up tray in use

position

Face-down tray in

storage position

Face-down tray in

use position

Face-down tray in

use position

Face-down tray in

storage position

Face-down tray in

use position

Width

(mm)

399 435 269 7.7

399 569 428 7.7

399 444 377 11

399 444 491 11

399 578 541 11.2

399 435 276 7.1

399 435 287 7.1

Depth

(mm)

Height

(mm)

Weight

(kg)

Product Description Basic Specifications 14

Page 32

EPSON EPL-5900/EPL-5900L Revision B

Consumables:

Table 1-15. Outline Dimensions and Weights with Options Installed of

“EPL-5900L”

Main Unit +

Face-up tray

Main Unit +

Paper eject tray

attachment

NOTE 1:

2:

Width

(mm)

Face-down and

Face-up trays and

Paper tray in storage

position

Face-up tray and

Paper tray in use

position

Face-down tray and

Paper tray in storage

position

Face-down tray and

Paper tray in use

position

399 397 280 7.2

399 540 418 7

399 263 267 7.1

399 406 278 7.1

Dimensions have a tolerance of ±5mm and weights have a tolerance of

±

0.5kg.

The dimensions of the Main Unit does not include those of the controller and

Depth

(mm)

consumables.

Height

(mm)

Weight

(kg)

Imaging Cartridge (black toner)

Drum Cartridge (Photoconductor Unit)

Note: Refer to 1.2.10 "Consumable Components".

Regular Replacement Parts

Without taking into account replacement by the user, the lives of regular

replacement parts are as follows:

Fuser Unit..........................50,000 pages (5% pattern continuous printing)

Transfer Roller ..................50,000 pages (5% pattern continuous printing)

Power Supply:

100V ±10% 50 ∼ 60Hz ±3Hz

110V

−

10% 50 ∼ 60Hz ±3Hz

127V

+6

% 50 ∼ 60Hz ±3Hz

220

∼

240V ±10%50 ∼ 60Hz ±3Hz

Applicable low-voltage power supplies are 100~120 V and 220~240 V only.

Power Consumption

Table 1-16. Power Consumption

100V 120V 200V System

Maximum current rated

Maximum

Average at continuous

Power

Consumption

printing

Average during standby

with heating on

Average during power save

mode with heating off

8.6A 7.2A 3.8A

810W 840W 850W

330Wh 330Wh 330Wh

75Wh 75Wh 75Wh

15Wh 15Wh 15Wh

Product Lifetime

Main Unit

180,000 printed pages or 5 years, whichever comes first. (with periodic part

replacement) → See Table 6-2 Regular Replacement Parts and Consumables

Product Description Basic Specifications 15

Page 33

EPSON EPL-5900/EPL-5900L Revision B

Noise

Table 1-17. Noise

During standby During printing

Main Unit only 30.0dB (A) 49.0dB (A)

Exhaust Gas

Ozone Concentration: 0.02 mg/m

(by blue angel mark measurement method)

Styrene Concentration: 0.07 mg/m

(by blue angel mark measurement method)

Dust Concentration: 0.15 mg/m

(by blue angel mark measurement method)

3

max.

3

max.

3

max.

1.2.3 Various Sensors

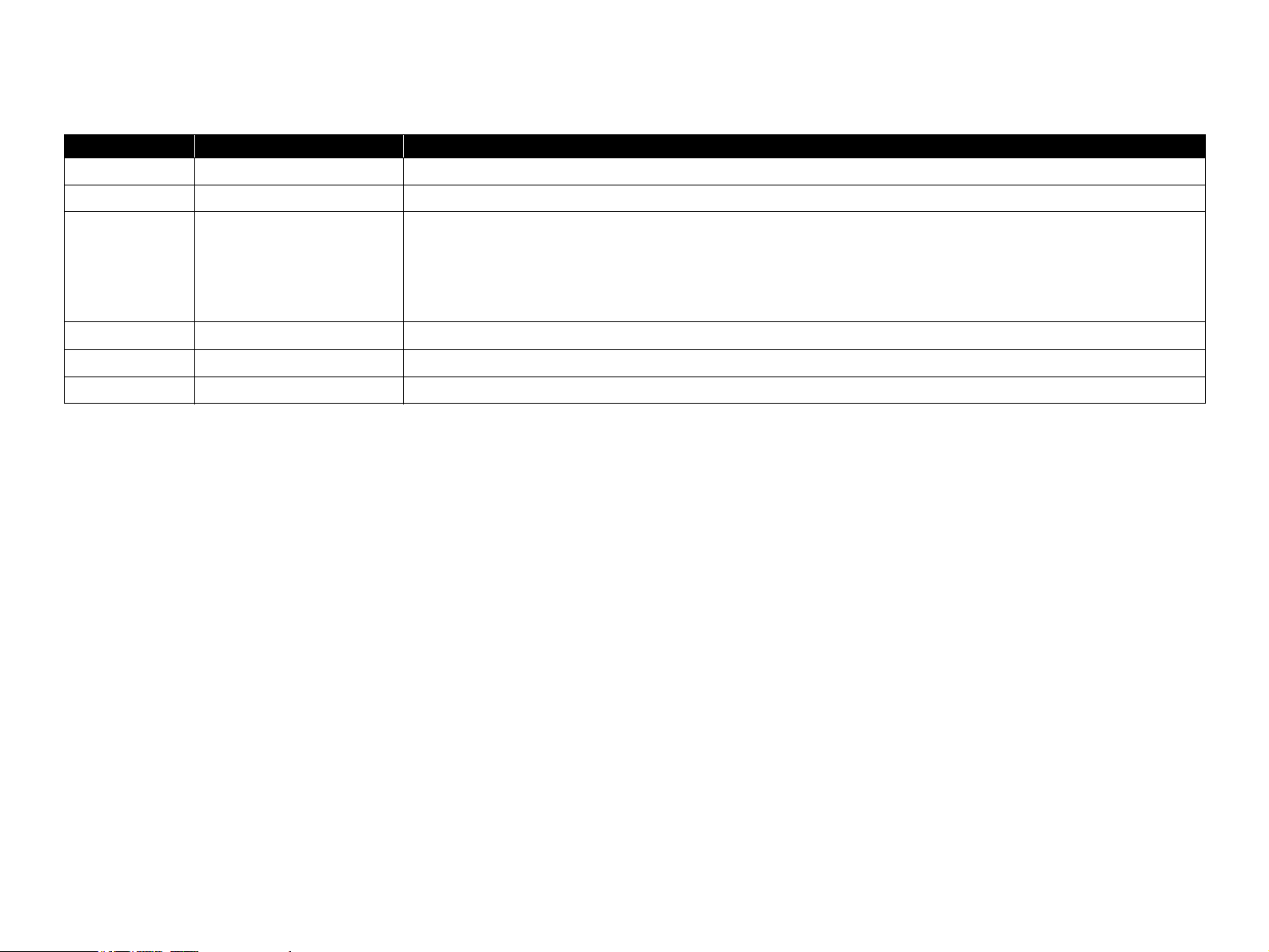

Table 1-18. Various Sensors of “EPL-5900”

Unit Detectable Matter Sensors Remarks

Standard Paper Tray

Lower

Cassette

Unit

Out of paper

Out of paper

Paper size

Cassette mounted/

unmounted

Automatic detection

by sensor

Automatic detection

by sensor

Automatic setting

with projection on

cassette

Combination of both

detections for “out of

paper” and “paper

size”

Cassette dedicated to A4

or LT

Hazardous Materials

None of the OPC, toner and plastics contains hazardous materials.

Note: For safety standards, refer to 1.2.9 "Compliance with Standards and

Regulations".

Unit Detectable Matter Sensors Remarks

Standard Paper Tray

Table 1-19. Various Sensors of “EPL-5900L”

Out of paper

Automatic detection

by sensor

Product Description Basic Specifications 16

Page 34

EPSON EPL-5900/EPL-5900L Revision B

•

1.2.4 Paper Specification

Four-leaf printed postcard, postcards made for inkjet printing, or presssealed postcards

•

1.2.4.1 Paper Type

Standard Paper

XEROX 4024 DP 20 lb: Letter paper

Plain Paper

2

60 g/m

∼ 90 g/m2 (16 lb ∼ 24 lb)

generally applied copy paper, recycled paper

Iron print coated paper (for inkjet or laser printing)

•

Sheets deteriorate or discolor by heat of the Fuser Unit of approximately 200

°

C

3:

When the Japanese “Kamo mail” post card or official / non-official

postcards with illustrations are used, paper feed roller may be soiled with

paper dust, and these postcards are not fed properly. In this case, cleaning is

required following Table 6-1 Cleaning Items.

Special Applications

Labels

Transparencies

Thick paper (90 ∼ 163 g/m

Envelopes

NOTE 1:

lb: Ream weight = lb / 500 sheets/ 17” ×22” (431.8X558.8mm)

2

g/m

: 1 g/m2 = 0.2659763 lb

2:

The following types of paper should not be used with this printer.

They could cause printing defects, paper jams or printer malfunctions.

•

Carbon paper, non-carbon paper, thermal paper, impact paper, acid-based

paper

•

Paper that is too thin or too thick

•

Paper that is wet or damp

•

Paper with special coatings or colored paper with processed surfaces

•

Glossy (too slick on its surface) paper, or paper with too smooth/rough

surfaces

•

Paper with significantly different roughness on each surface

•

Paper with punch holes or perforations

•

Creased, curled or torn paper

•

Irregularly shaped paper or paper with non-perpendicular corners

•

Labels that peel off easily

•

Paper with glue, staples or paper clips attached to it

•

Ink jet paper for special applications (super-fine, glossy, glossy film, etc.)

•

Paper that was previously used in a thermal or ink jet printer

•

Transparencies for color photocopiers or color laser printers

•

Sheets already printed on other color / monochrome laser printers or

photocopiers

•

Sheets of paper stuck together

2

)

1.2.4.2 Paper Feedings

Table 1-20. Paper Feedings

Standard

Paper

Standard Paper Tray {

Optional

*1: Use of Lower Cassette is not supported with EPL-5900L.

{ : Paper feed reliability and image quality assured.

: Paper feed reliability and image quality assured, but only for the use of generally applied

∆

Lower

Cassette

types of paper.

: Paper feed and printing are possible for only generally applied types of paper.

*1

{ × × × ×

Plain

Paper

Transparencies Labels

Special Applications

Thick

paper

∆∆∆∆

Envelope

× : Sheets cannot be fed.

1.2.4.3 Printable Area

Available Printing Area

208.0 mm × 348.0 mm

Product Description Basic Specifications 17

Page 35

EPSON EPL-5900/EPL-5900L Revision B

Guaranteed Printing Area

All area of the sheet except vertical and horizontal margins of 4 mm (See

illustration below)

4 m m 4 m m