Page 1

EPSON TERMINAL PRINTER

EPL-5500W

SERVICE MANUAL

EPSON

4005668

Page 2

- ii -

Page 3

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever without SEIKO

EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual. However, should any

errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for any errors in this manual or

the consequence thereof.

Epson is a registered trademark of Seiko Epson Corporation.

GeneralNotice: Other product names used herein are for identicationpurposesonlyand may be trademarks

of their respective campanies.

Copyright © 1995 by SEIKO EPSON CORPORATION Nagano, Japan

- i -

Page 4

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2) damage to

equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/ maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great

caution should be exercised in performing procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE

POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING

ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLTAGE,

LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A

PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING

INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

EPSON WARRANTY.

- ii -

Page 5

SAFETY INFORMATION

This printer is a page printer which operates by means of a laser. There is no possibility of danger from the laser,

provided the printer is operated according to the instructions in this manual provided.

Since radiationemittedbythelaser is completely confinedwithinprotectivehousings,the laser beam cannot escape

from the machine during any phase of user operation.

For United States Users;

[Laser Safety]

This printer is certified as a Class 1 Laser product under the U.S. Department of Health and

Human Services (DHHS) Radiation Performance Standard according to the Radiation Control

for Health and Safety Act of 1968. This means that the printer does not produce hazardous laser

radiation.

[CDRH Regulations]

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented regulations for laser products on August 2, 1976. Compliance is mandatory

for products marketed in the United States. The label shown below indicates compliance with

the CDRH regulations and must be attached to laser products marketed in the United States.

WARNING : Use of controls, adjustments or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

[Internal Laser Radiation]

Maximum Radiation Power: 5.0 × 10

Wave Length: 790 ± 20 nm

This is a Class IIIb Laser Diode Assay that has an invisible laser beam. The print head unit is

NOT A FIELD SERVICE ITEM. Therefore, the print head unit should not be opened underany

circumstances.

For Other Countries Users;

WARNING: Use of controls, adjustments or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

This is a semiconductorlaser. The maximum power ofthelaser diode is 5.0 × 10

W and the wavelength is 790 ± 20 nm.

For Denmark Users;

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

-4

(W)

-4

Klasse 1 laser produkt der opfylder IEC825 sikkerheds kravene.

For Finland, Sweden Users;

- iii -

Page 6

VAROITUS

Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteiylle.

VARNING

Om apparaten används på annat sätt än i denna bruksanvisning specificerats, kan

användaren utsättas för osynlig laserstrålning, som överskrider gränsen för laser klass

1.

For Finland, Sweden Service People

VAROITUS

Avattaessa jasuojalukitusohitettaessaoletalttiina näkymättömälle laser-säteilylle. Älä

katso säteeseen.

VARNING

Osynlig laserstrålning när denna del är öppnad och spärren är urkopplad. Betrakta ej

strålen.

For Norway Users;

ADVARSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning, kan

brukeren utsettes for unsynlig laserstråling som overskrider grensen for laser klasse 1.

Dette er en halvleder laser. Maksimal effeckt til laserdiode er 5.0 × 10-4Wog

bølgelengde er 790 ± 20 nm.

Laser Safety Labels

[Label on rear printer case]

A laser safety labels is attached on the outside of the printer shown below.

For United State

For Europe

- iv -

Page 7

[Label inside printer]

The following laser safety label will be attached inside the printer as shown below.

For Denmark, Finland, Sweden, and Norway

- v -

Page 8

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair of

EPL-5500W.

The instructions and procedures included herein are intended for the experience repair technician, and attention

should be given to the precautions on the preceding page. The chapters are organized as follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques andlistslubricants and adhesives required toservice the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

- vi -

Page 9

REVISION SHEET

Revision Issue Date Revision Page

Rev. A November 24, 1995 1st issue

- vii -

Page 10

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENTS

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

- viii -

Page 11

Chapter 1 General Description

Table of Contents

1.1 FEATURES 1-1

1.2 SPECIFICATIONS 1-3

1.2.1 Basic Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.2 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.3 Reliability Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.4 Environmental Conditions for Operating (Include Imaging Cartridge) . . . . 1-5

1.2.5 Environmental Conditions for Storage and Transportation . . . . . . . . . . . . 1-5

1.2.6 Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.7 Specifications for Consumable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.8 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.9 Software Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3 INTERFACE SPECIFICATIONS 1-9

1.3.1 Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4 OPERATING INSTRUCTIONS 1-9

1.4.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.2 Display of Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.4.2.1 Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.4.2.2 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.4.3 Printing Resolution Host PC Capability Dependency. . . . . . . . . . . . . . . . 1-11

1.5 MAIN COMPONENTS 1-12

1.5.1 C180 MAIN Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.5.2 PWB-E Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.5.3 PWB-F Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.5.4 Optical Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.5.5 FUSING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.5.6 Photoconductor Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.5.7 Developing Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

List of Figures

Figure 1-1. Exterior View of the EPL-5500W . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Figure 1-2. Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-3. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Figure 1-4. Component Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-5. C180 MAIN Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-6. PWB-E Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-7. PWB-F Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-8. Optical Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure 1-9. Fusing Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure 1-10. Photoconductor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Figure 1-11. Developing Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Page 12

List of Tables

Table 1-1. Options for the EPL-5500W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Paper Feed Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-3. Paper Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-4. Usability of Special Papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-5. Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-6. Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-7. Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-8. Host PC Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Page 13

Rev. A 1-iii

Page 14

EPL-5500W Service Manual General Description

1.1 FEATURES

The EPSONEPL-5500W laser printer has a 300/600 dots per inch (dpi) resolution and 6 pages per minute

(ppm) printing speed in a dedicated Microsoft

Windows 3.1x and Windows 95, achieving very high performance due to the recent advances in PC

technology. The main features are:

❏ No ozone

❏ Printing speed — 6 ppm

❏ Resolution — 600/300 dpi

❏ Light weight — about 5 kg (11 lb)

❏ Small footprint

❏ Low running cost: separation of the development/toner cartridge and photoconductor unit

❏ Ease of use with Microsoft Windows Printing System (WPS)

❏ PCL4 software emulation mode

❏ High throughput, especially with fine-pitch halftone image output

❏ Freedom from the memory overflow

❏ Freedom from document incompatibility, True WYSIWYG

❏ Bidirectional parallel interface (ECP and Microsoft Peppy modes)

❏ Achieves high throughput with a very high-speed parallel interface. Maximum transmission speed is

approximately 2 MB/sec. (under ECP mode) or 600 KB/ sec. (under Peppy mode).

Figure 1-1 shows an exterior view of the EPL-5500W.

®

WindowsPrinting System. It works under Microsoft

Figure 1-1. Exterior View of the EPL-5500W

Rev. A 1-1

Page 15

General Description EPL-5500W Service Manual

Table 1-1 lists the optional units available for the EPL-5500W.

Table 1-1. Options for the EPL-5500W

Cat. No. Description Note

S050005 Developer cartridge Developer and toner cartridge

S051029 Photoconductor unit —

1-2 Rev. A

Page 16

EPL-5500W Service Manual General Description

1.2 SPECIFICATIONS

This section provides statistical data for the EPL-5500W.

1.2.1 Basic Specifications

Printing method: Laser beam scanning and dry electrophotography

Resolution: 600/300 dpi

Printing speed: 6 ppm (letter/A4)

First printing time (A4/LT): Less than 20 seconds (face-up output)

Warm-up time: Less than 35 seconds

(at rated current and 23° C (73° F) temperature)

Paper supply: See Table 1-2.

Table 1-2. Paper Feed Methods

Paper Supply

Standard built-in paper tray

Manual feed slot 1

Capacity Using

20 lb. (75 g/m2)

Paper

150

5 to 10

Paper Sizes

B5, A4, LT,

EXEC, LGL

Monarch,

DL, C5, Env #10,

11, 12, 14

Any size feedable

(Note 2)

Usage Thickness

(Ream Weight)

16 to 24 lb.

(60 to 90 g/m

Envelopes made of

20 to 24 lb.

(75 to 90 g/m

paper

16 to 42 lb.

(60 to 157 g/m

Notes:

1. The weight in pounds (lb) is determined by the weight of 500 sheets cut to 17 × 22 inches;

1 g/m

2

= 0.2659763 lb.

2. Paper size range: width 3 to 8.5 inches (76 to 216 mm)

length 5 to 14.0 inches (127 to 356 mm)

Paper types: See Table 1-3.

Table 1-3. Paper Types

Standard paper

Normal paper

Special papers

Xerox

20 lb (75 g/m

Regular photocopier paper

Bond paper

Recycled paper

16 to 24 lb (60 to 90 g/m

Card stock (90 to 157 g/m

Envelopes

Labels

Letterhead

Transparency (OHP) sheets

Colored paper

4024 DP paper

2

)

2

)

2

)

2

)

2

)

2

)

Rev. A 1-3

Page 17

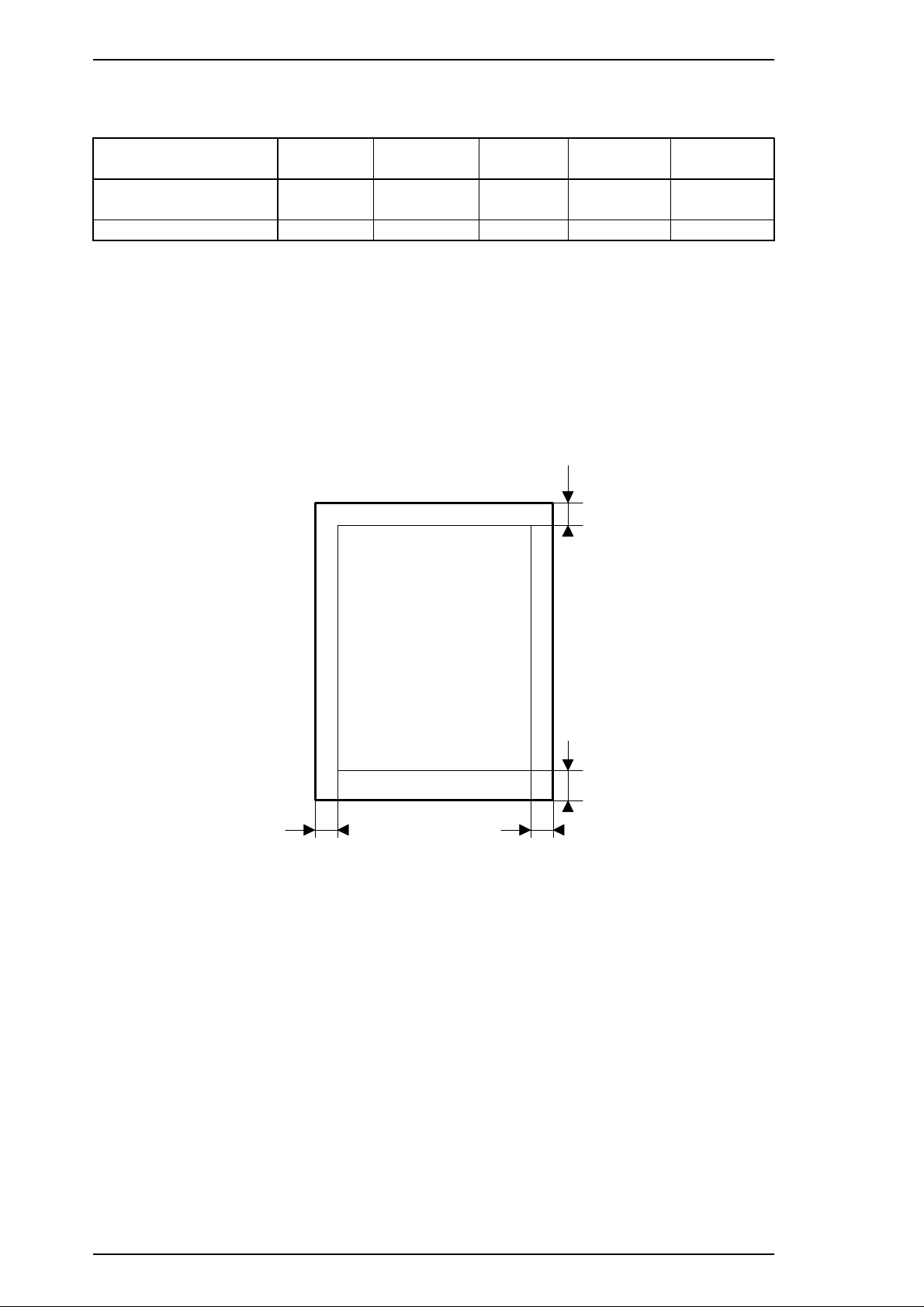

Printable Area

4.0 mm

4.0 mm

4.0 mm4.0 mm

General Description EPL-5500W Service Manual

Usability of special papers: See Table 1-4.

Table 1-4. Usability of Special Papers

Input OHP Envelopes Labels Card Stock Letterhead

Standard built-in

paper tray

Manual feed slot P P P P R

R: Reliable feeding and good image quality.

P: Possible, but better avoided.

N: Not supported.

Paper feed alignment and direction: Center alignment for all sizes

Paper ejection: Face down

Output tray capacity: 100 sheets (face down)

Printable area (standard paper): See Figure 1-2.

PPPPR

Figure 1-2. Printable Area

Note: The actual printable area depends on the printer mode.

Noise: Less than 35 dB(A), standby

Less than 47 dB(A), operating

Ozone density: Less than 0.01 ppm

Toxicity: No toxicity exists in organic photoconductor (OPC), toner, or

1-4 Rev. A

plastic materials

Page 18

EPL-5500W Service Manual General Description

1.2.2 Electrical Specifications

Table 1-5. Electrical Requirements and Ranges

Description 100 V Version 200 V Version

Rated voltage 100 ∼ 120 VAC 220 ∼ 240 VAC

Input voltage range 90 ∼ 132 VAC 198 ∼ 264 VAC

Rated frequency range 50 ∼ 60 Hz

Input frequency range 47 ∼ 63 Hz

Power consumption Less than 500 W Less than 600 W

Power consumption while

in standby mode

Less than 15 W

(without option)

1.2.3 Reliability Specifications

MPBF (Mean Prints Between Failures): Over 25,000 sheets

Note: MPBF indicates the average number of pages printed before an occurrence of a problem requiring

replacement or service.

MTBF (Mean Time Between Failures): 3000 power on hours (POH)

Jam rate: 1 out of 2,000 sheets or less (excluding multiple-sheet feeding)

Feed failure: 1 out of 2,000 sheets or less (excluding multiple-sheet feeding)

Multiple paper feeds: 1 out of 500 sheets or less

Paper curl height: 30 mm (1.2 inches) or less

Leading edge bending (1 cm or more): 1 out of 1,000 sheets

MTTR (Mean Time To Repair): 30 minutes or less

Durability: 5 years or 1,800,000 sheets

1.2.4 Environmental Conditions for Operation (Including Imaging Cartridge)

Temperature: 10 to 35° C (50 to 95° F)

Humidity: 15 to 85% RH

Altitude: 2,500 m (8,200 feet) or lower

Levelness: 1°

Illuminance: 3,000 lux or less (Must not be exposed to direct sunlight.)

Surrounding space: Printer should have at least 100 mm (4") of clearance on its sides

and rear.

1.2.5 Environmental Conditions for Storage and Transportation

Temperature: 0 to 35° C (32 to 95° F)

Humidity: 30 to 85% RH

Drop test: Clear to JIS Z0200-1987 Level 1

Vibration: Vibration frequency 5 to 100 Hz and 100 to 5 Hz

Acceleration 1 G

Acceleration direction 3 directions

Resistance to atmospheric pressure: More than 61.3 KPa

Storage life: 18 months (following date of manufacture)

Rev. A 1-5

Page 19

General Description EPL-5500W Service Manual

1.2.6 Applicable Standards

Safety Standards

120 VAC model: UL 1950, CSA 22.2 No. 950 Deviation 3

220/240 VAC model: EN 60950 (IEC950), NEMKO (IEC950), SETI (IEC950),

SEMKO (IEC950), DEMKO (IEC950)

Safety Regulations (Laser Radiation)

120 VAC model: FDA (NCDRH) Class 1

220/240 VAC model: VDE 0837 (Laser Class 1) (IEC825), SETI (IEC825), SEMKO

(IEC825), DEMKO (IEC825)

EMI

120 VAC model: FCC Part 15 Subpart B Class B, DOC Class B

220/240 VAC model: Vfg 243 (VDE 0878 Part 3,30)

EN55022 Class B (CISPR Pub. 22 Class B)

CE marking, EMC

Others

Toner: No effect on human health (OSHA-TSCA, EINECS)

OPC: No effect on human health (OSHA)

Ozone: Less than 0.01 mmp

other UL478 (5th edition)

Materials: SWISS environmental law (must contain no CdS)

1.2.7 Specifications for Consumables

Life: Developer and toner cartridge: 3,000 pages

Photoconductor unit: 20,000 pages

Note: In continuous printing mode with A4/letter paper at a 5% image ratio (black/white ratio). The life

varies, depending on the printing mode (continuous or intermittent) and/or the image ratio.

Environmental Conditions for Storage and Transportation

Temperature: 0 to 35° C (32 to 95° F)

Humidity: 30 to 85% RH

Drop test: Height 76 cm (30.4 inches)

Vibration: Same as printer

Resistance to atmospheric pressure: More than 74 Kpa

Storage term: 18 months (following date of manufacture)

1.2.8 Physical Specifications

Dimensions (Width × Depth × Height):

Printer: 352 × 264 × 299 mm (13.9 × 10.4 × 11.8 inches)

Weight: Approx. 5 kg (11 lb), with consumables, excluding all options

1-6 Rev. A

Page 20

EPL-5500W Service Manual General Description

1.2.9 Software Specifications

Built-in modes: Microsoft Windows Printing System

PCL4 (software emulation)

Rev. A 1-7

Page 21

General Description EPL-5500W Service Manual

1.3 INTERFACE SPECIFICATIONS

The EPL-5500W is equipped with the following external interfaces:

❏ Parallel interface

1.3.1 Parallel Interface

The parallel interface has the following two modes:

❏ ECP mode

❏ Microsoft Peppy mode

Pin assignments: Fully IEEE-1284 compliant

Connector type: P90-25027-1 (Amphenol) receptacle

Applicable plug: 57-30360 (Amphenol or equivalent)

1-8 Rev. A

Page 22

GREEN Light

RED Light

EPL-5500W Service Manual General Description

1.4 OPERATING INSTRUCTIONS

This section describes printer functions, including control panel operation and messages.

1.4.1 Control Panel

The printer control panel gives you easy control over most common printer operations. The panel consists of

the indicator lights described below.

Figure 1-3. Control Panel

Indicator Lights

❏ GREEN light

ON: Printer is ready or idle.

Blinking: Printer is currently receiving data.

❏ RED light

ON: Printer has detected errors.

Rev. A 1-9

Page 23

General Description EPL-5500W Service Manual

1.4.2 Display of Messages

This printer indicates two types of messages with the status message window for the printer driver on the PC.

1.4.2.1 Status Messages

This section describes the status messages.

Table 1-6. Status Messages

Message Status

Printer ready Printer is ready.

Printing Printer is printing.

Manual feed Printer is loading paper from manual feed slot.

Paused Printer is in pause mode.

Printing stopped Printer is stopping during printing of a job.

Please wait Printer is in the wait condition.

Paused printer warming up Printer is warming up.

Printer warming up Printer is warming up.

1.4.2.2 Error Messages

This section describes error messages, what they indicate, and what measures to take to eliminate the error.

Table 1-7. Error Messages

Message Status Measures

The user is unable to redirect

Configuration error

Low memory Memory in PC has run out. Add the memory to the PC.

No local printer

Status not available

a port, or system software

cannot find a file to complete

a request.

The printer is not connected

to the local port when you are

using PCL emulation.

The printer does not return

status information.

Check the printer connection

port, and reinstall the driver.

PCL emulation does not

support a network.

Check the printer connection.

Check printer/ cable

Service error Printer is damaged. Service required.

Clear paper jam A paper jam occurred.

1-10 Rev. A

The printer does not return

status information.

Check the printer connection.

Open the cover and remove

the jammed paper. Then

close the cover.

Page 24

EPL-5500W Service Manual General Description

Table 1-7. Error Messages (Continued)

Message Status Measures

Check Toner & Cover

Wrong paper loaded

Change paper Paper settings are wrong. Check the paper size settings.

Printer is cover open or no

toner cartridge is installed.

Paper in the tray to be fed into

the printer is different from the

specified paper size.

Check the cover and toner

cartridge.

Check the paper size.

1.4.3 Printing Resolution Host PC Capability Dependency

This printer driver calculates the host PC’s capability every time Windows starts up, and the driver drops the

printing resolution at the beginning of each job automatically if the value it detects will not allow complete

printing at the resolution the user has set. This printer can print pages at the resolution if the HOST PC fulfill

the following conditions.

Table 1-8. Host PC Conditions

Installed DRAM Quantity

CPU

Windows 3.1, WFW 3.11 Windows 95

< 8 MB ≥ 8 MB < 8 MB ≥ 12 MB

80386SX

16/20/25/33 MHz

or compatibles

80386DX

16/20/25/33 MHz

or compatibles

80486SX/DX

16/20 MHz

or compatibles

80486SX/DX

25/33/50 MHz

80486DX2

50/66 MHz

80486DX4

75/100 MHz

Pentium

60/66/75/90/100

120/133 MHz

300 DPI

(Note 1)

300 DPI

(Note 1)

300/600 DPI

(Note 2)

300/600 DPI

(Note 2)

300 DPI

(Note 1)

300 DPI

(Note 1)

300/600 DPI

(Note 2)

300/600 DPI

——

300 DPI

(Note 1)

300/600 DPI

(Note 2)

300/600 DPI

(Note 2)

300 DPI

(Note 1)

300/600 DPI

(Note 2)

300/600 DPI

Note 1: Some pages may be not be printed completely, depending on complexity of those pages.

Note 2: Some pages may not be printed at 600 DPI depending on complexity of those pages.

Rev. A 1-11

Page 25

General Description EPL-5500W Service Manual

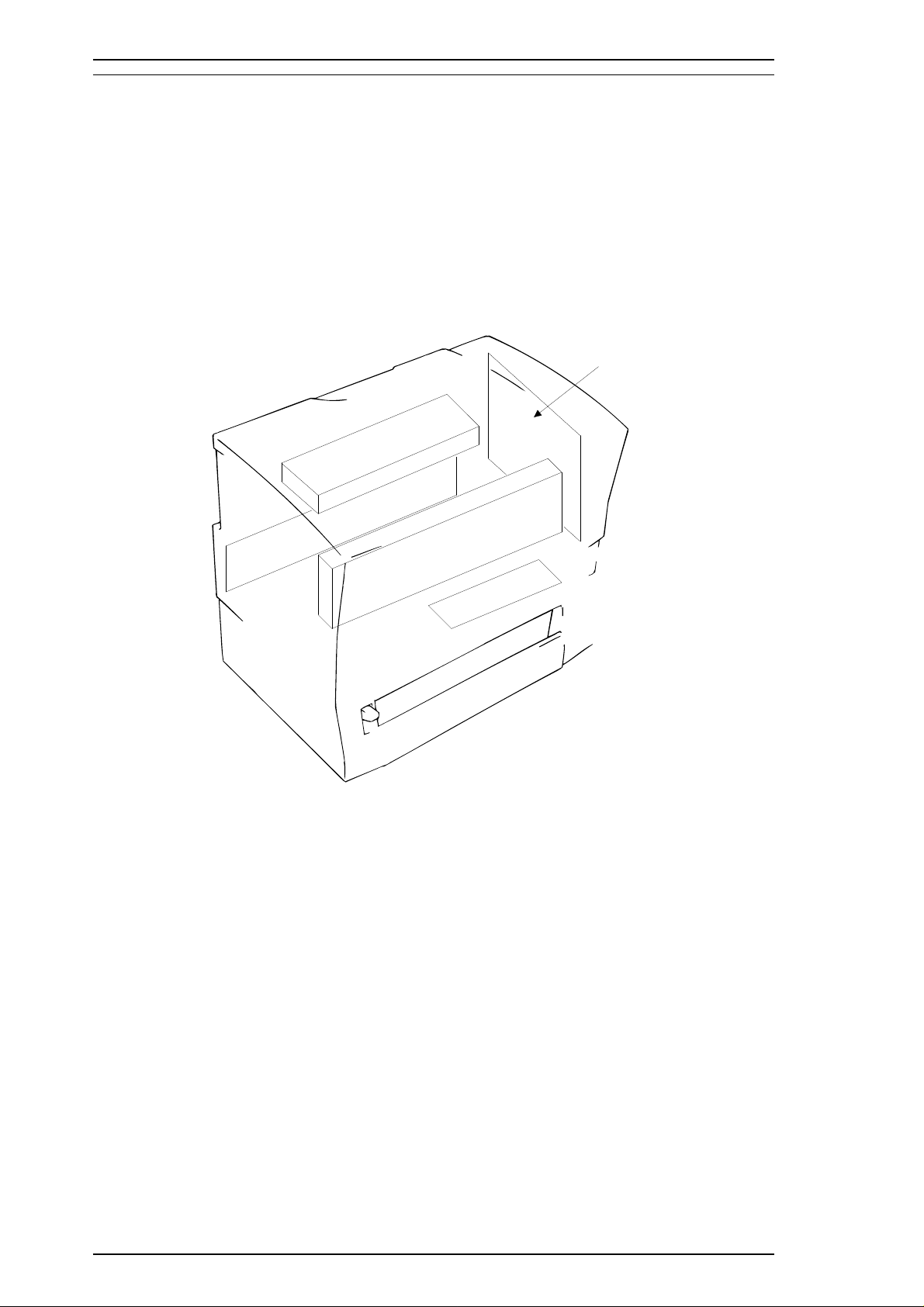

1.5 MAIN COMPONENTS

To simplify maintenance and repair, the main components of the EPL-5500W have been designed for easy

removal and replacement. The main components are:

❏ C180 MAIN Board Main board

❏ PWB-E Board Power supply circuit board

❏ PWB-F Board High-voltage supply circuit board

❏ Optical Unit Printhead unit

❏ Fusing Unit

❏ Photoconductor unit

❏ Developer cartridge

❏ Housing

C180 MAIN Board

Fusing Unit

PWB-E Board

Optical Unit

PWB-F Board

Figure 1-4. Main Components

1-12 Rev. A

Page 26

M3807

(IC201)

E05B23

(U6)

4M DRAM

(U4)

EPL-5500W Service Manual General Description

1.5.1 C180 MAIN Board

The C180 MAIN board contains a parallel interface controller and engine controller board. The primary

functions of this board are receiving print data from the host and sending the print image to the engine

controller via the video interface.

❏ Memory chips

4M-bit DRAM (U4)

❏ Custom ICs

ASIC E05B23 (U6)

The engine controller consists of an M3807 x 8-bit CPU, including a MASK ROM. It controls laser scanning

(the polygon mirror drive motor), image synchronization, laser beam pulse width, and power.

Figure 1-5. C180 MAIN Board

Rev. A 1-13

Page 27

VR3

General Description EPL-5500W Service Manual

1.5.2 PWB-E Board

The PWB-E is the power supply board, which consists of a switching regulator circuit. It converts the AC

line voltage into +24 V and +5 VDC voltages. There are two types of power supply board, the 100/120 V

type and 220/240 V type. The difference between the two circuits is only in the input section.

CAUTION

Do not touch VR1 on PWB-E board. This volume is for factory setting only.

VR1

F1

Figure 1-6. PWB-E Board

1.5.3 PWB-F Board

The PWB-F is the high-voltage supply circuit board. It converts the development bias, OPC drum charge

bias, and image transfer bias.

CAUTION

Do not touch VR3 on the PWB-F board. These volumes are for factory setting only.

Figure 1-7. PWB-F Board

1-14 Rev. A

Page 28

EPL-5500W Service Manual General Description

1.5.4 Optical Unit

The optical unit consists of the laser diode (semi-conductor laser), the mirror motor (scanner motor) which

drives the polygon mirror for laser scanning, and several mirrors and lenses. The laser beam generated by the

laser diode is conducted to the OPC drum surface by way of the polygon mirror, as well as several mirrors

and lenses, to create a latent electro-photographic image on the drum.

Figure 1-8. Optical Unit

1.5.5 Fusing Unit

The fusing unit fixes the toner to the paper using heat and pressure. This unit has a heater lamp, thermistor,

and thermal fuse. There are two types of fusing units, the 120 V type and the 220/240 V type. The only

difference between them is the heater lamp.

Figure 1-9. Fusing Unit

Rev. A 1-15

Page 29

General Description EPL-5500W Service Manual

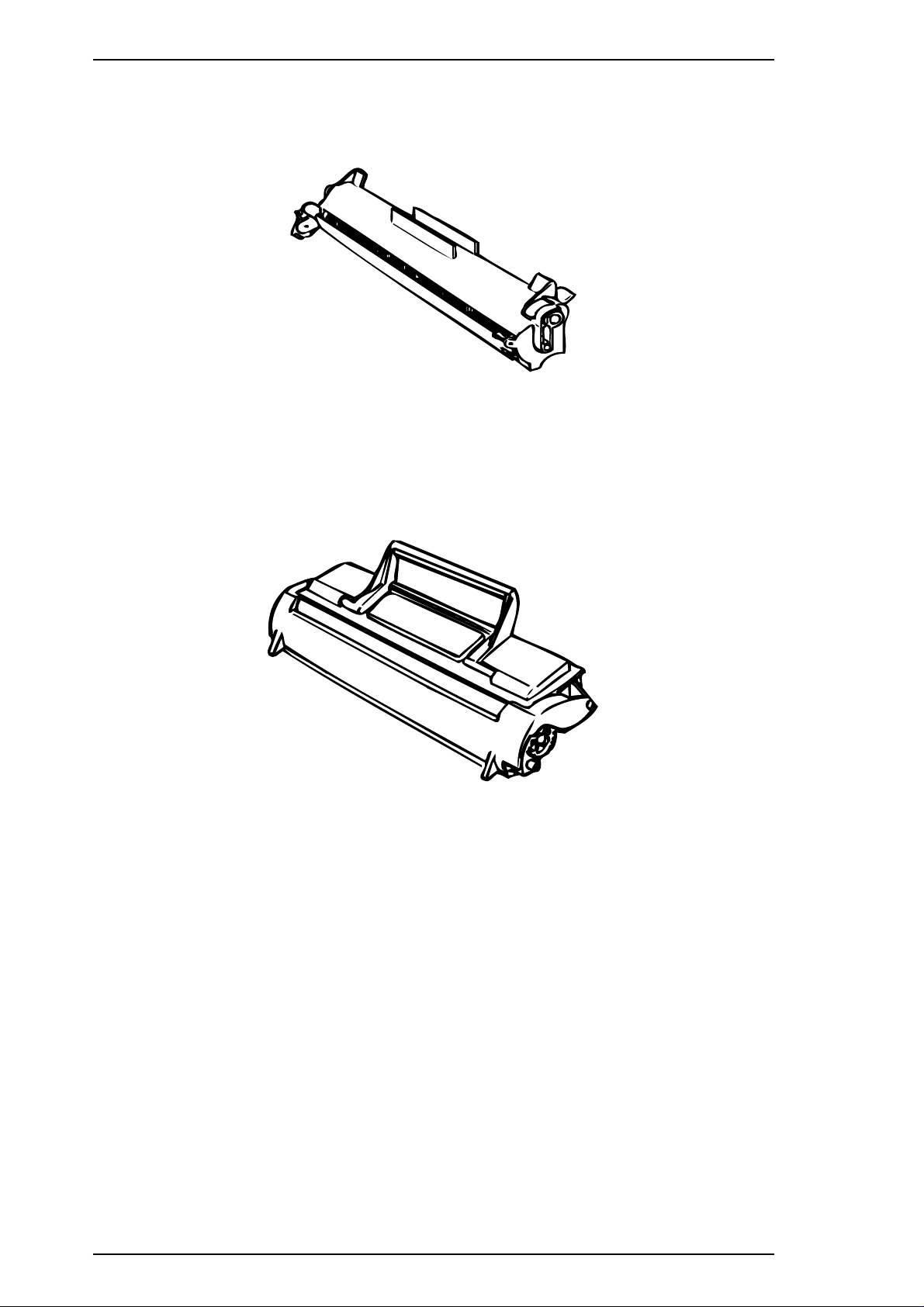

1.5.6 Photoconductor Unit

Core mechanisms of the printing process, such as charging and imaging, are integrated into this unit.

Figure 1-10. Photoconductor Unit

1.5.7 Developing Cartridge

The developing mechanism for the printing process is integrated into this cartridge.

Figure 1-11. Developing Unit

1-16 Rev. A

Page 30

Chapter 2 Operating Principles

Table of Contents

2.1 ENGINE OPERATION 2-1

2.1.1 Print Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1.1 Paper Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.1.2 Drum Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1.1.3 Laser Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.1.4 Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.1.5 Image Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.1.6 Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.2 Engine Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.1.2.1 Main Motor Functions and Control . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.1.2.2 Paper Take-Up Sensor and Paper Exit Sensor. . . . . . . . . . . . . . . 2-9

2.1.2.3 Fuser Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.1.2.4 Scanner Mirror Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.1.2.5 Laser Diode Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.1.2.6 Bias Voltages and Laser Drive Timing . . . . . . . . . . . . . . . . . . . . 2-13

2.1.2.7 Fan Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.1.2.8 Power Supply Circuit Function and Safety Protection. . . . . . . . . 2-15

2.2 PARALLEL INTERFACE CONTROLLER OPERATION 2-16

2.2.1 C180 MAIN Board Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

List of Figures

Figure 2-1. Main Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-2. Print Process Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-3. Paper Feeding from the Paper Feed Tray . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4. Drum Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-5. Laser Exposure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-6. Development. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-7. Image Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-8. Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-9. Engine Controller Connecting Diagram . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-10. Gear and Roller Positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-11. Main Motor Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-12. Paper Take-Up Sensor and Paper Exit Sensor On/Off Timing . . . 2-9

Figure 2-13. Fuser Control Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-14. Temperature for Fuser Control Procedure . . . . . . . . . . . . . . . . . . 2-10

Figure 2-15. Scanner Motor Control Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Figure 2-16. Laser Diode Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-17. LDATA Generation Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-18. Laser Emission Power Adjustment Timing . . . . . . . . . . . . . . . . . . 2-12

Figure 2-19. High-Voltage Supply Block Diagram. . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-20. Print Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-21. Print Sequence (Start) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-22. Print Sequence (End) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-23. Power Supply Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-24. Parallel Interface Controller Section . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-25. C180 MAIN Board Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Page 31

List of Tables

Table 2-1. Functions of C180 MAIN Board Main Elements. . . . . . . . . . . . . . . 2-18

Page 32

1

2

3

4 5

6

7

8

9

10

11

12

13

14

15

16

17

18

EPL-5500W Service Manual Operating Principles

2.1 ENGINE OPERATION

This section describes the functions and operating principles of the EPL-5500W engine. Figure 2-1 shows the

locations and names of the main engine components.

Figure 2-1. Main Components

1. Fan Motor (M3) 11. Paper Feeding Tray

2. Lower Fusing Roller 12. Paper Lift-up Plate

3. Paper Exit Sensor (PC3) 13. Paper Take-up Roller

4. Upper Fusing Roller 14. Paper Transport Roller

5. Heater Lamp (H1) 15. Paper Take-up Sensor (PC1)

6. Paper Exit Roller 16. Pre-image Transfer Roller

7. Print Tray 17. Electrode Comb

8. Optical Unit 18. Drum Cartridge

9. Toner Cartridge

10. Manual Feed Guide

Rev. A 2-1

Page 33

Optical Unit

Drum Cartridge

Toner Cartridge

Paper Feeding

Tray

Fusing

Image

Transfer

Print Exit

Drum

Charge

Toner

Hopper

Development

Multi Feeding

(150 sheets)

Manual Feed

(1 sheet)

Exposure

Operating Principles EPL-5500W Service Manual

2.1.1 Print Process

This section describes the print process from paper feeding to paper exit. Figure 2-2 shows a diagram of the

print process.

Figure 2-2. Print Process Diagram

2-2 Rev. A

Page 34

Upper Fusing Roller

Paper Exit Roller

Lower

Fusing

Roller

PC Drum

Pre-Image Transfer

Roller

Paper Lift-Up Plate

Fixed Separating

Pad

Transport Roller

Paper Take-Up Sensor (PC1)

Paper Exit Sensor

(PC3)

Paper Take-Up

Roller

Depression

Cam

Paper TakeUp Clutch

Paper Take-Up

Solenoid (SL1)

When SL1 is de-energized

When SL1 is energized

Paper Lift-Up Plate Paper

EPL-5500W Service Manual Operating Principles

2.1.1.1 Paper Feeding

Paper can be fed into the printer from the paper feed tray (150 sheets) or from the manual feed slot (1 sheet at

a time). Paper fed by the paper take-up roller is transported to the transport roller, pre-image transfer roller,

and then exit roller. After this, the paper is fed out onto the print tray. The starting position of an image is

decided by the paper take-up sensor (PC1). A photo sensor is used as the paper take-up sensor (PC1) and the

paper exit sensor (PC3).

Paper Feeding Tray (Standard Tray)

When the paper take-up solenoid is energized, the main motor (M1) drive is transmitted to the paper take-up

roller via the paper take-up clutch (a one-way clutch) to rotate the paper take-up roller one revolution. At the

same time, the depression cam rotates and releases the paper lift-up plate to feed the top (first) paper. The

fixed separating pad is used for the paper separation system. It prevents the second or later sheets from being

fed together with the top paper.

Figure 2-3. Paper Feeding from the Paper Feed Tray

Rev. A 2-3

Page 35

Operating Principles EPL-5500W Service Manual

2.1.1.2 Drum Charge

The PC drum is charged with static electricity before laser exposure. The rotating charge brush and pre-film

are used as the charging method. Less ozone is generated by the corona charge of the rotating charge brush

and the pre-film, and the PC drum can be charged with low voltage because the charge is directly applied to

the PC drum. The charge brush is rotated by the drive of the M1 main motor via its gear.

C180 MAIN

IC201

A

B Pre-film

A: Drum Charging Bias

B: Drum Ground

Drum Cartridge

Rotating Charge

Brush

PC Drum

Protecting

Shutter

Drum Charging

and Pre-film Bi as

PC Drum

Protecting

Shutter

Charged Su rface:

(approx. -800 V)

PC Drum

PWB-F

Figure 2-4. Drum Charge

2-4 Rev. A

Page 36

Charged Surface

Laser-Exposed Surface:

(Approx. -50 V)

PWB-D

SOS Sensor

Reflector Mirror

Laser Diode

M2

CN210

CN205

C180 MAIN

IC201

1

5

1

7

2

4

3

Vs Terminal

VB TerminalVBL Terminal

VB (Developing Bias)

VBL (Toner Blade Bias)

Vs (Lower Seal Bias)

PWB-F

CN1F

CN204

C180 MAIN

IC201

1

8

1

8

EPL-5500W Service Manual Operating Principles

2.1.1.3 Laser Exposure

The laser beam, emitted from the optical unit, makes an invisible static image. The SOS (start of scan)

sensor, installed on the laser diode control board (PWB-D), unifies the laser emission timing for each scan

line.

Figure 2-5. Laser Exposure

2.1.1.4 Development

Toner is applied to the invisible static image on the PC drum and a toner image is created on the surface.

When the PC drum starts to rotate (when the main motor is activated), the PC drum surface remains 0 V at

the position between the rotating charge brush and sleeve roller. At this time, a specified positive voltage is

applied to the sleeve roller to prevent toner from being attracted back onto the PC drum (reverse bias

control).

Figure 2-6. Development

1. Toner hopper: Contains toner.

2. Toner agitating screw:Stirs the toner in the hopper and sends the toner to the toner transport

3. Toner transport roller: Transports the toner to the sleeve roller.

4. Doctor blade: Spreads a thin, even coat of toner over the resin sleeve. The toner is

negatively charged by passing between this blade and resin sleeve.

roller.

5. Sleeve roller: Rotates the resin sleeve.

6. Resin sleeve: Carries the toner to the PC drum surface for development.

7. Bias seal: Collects the toner remaining on the resin sleeve.

8. PC drum: Is exposed to the laser to create an invisible image and rotates to carry

Rev. A 2-5

the developed image to the paper surface.

Page 37

Operating Principles EPL-5500W Service Manual

2.1.1.5 Image Transfer

The electrode comb is an image transfer system that transfers the toner image on the PC drum onto the paper.

Image Transfer Unit

Housing

Electrode Comb

Pre-Image Transfer Roller

Housing

Electrode Comb

Housing

Pre-Image Transfer

Roller

Housing Ground

Image Transfer Bias

PWB-F

CN1F

PWB-S

1

818

C180 MAIN

IC201

CN204

1

1

8

8

Figure 2-7. Image Transfer

2.1.1.6 Fusing

The toner image transferred onto the paper is fixed securely using a heat roller system as the fusing system.

The upper fusing roller, which is heated by the heater lamp, fuses the toner image, which is securely fixed by

the pressure between the upper and lower fusing rollers. Thermistor TH1 detects and controls the temperature

of the upper fusing roller. Thermal fuse TF1 blows when the temperature exceeds 200° C (392° F), shutting

down power to the heater lamp.

Thermal Fuse

Thermistor

Lower Fusing Roller

Upper Fusing

Roller

Paper

Figure 2-8. Fusing

Heater Lamp

2-6 Rev. A

Page 38

C180 MAIN Board

Main

Motor

(M1)

Polygon

Motor

(M2)

Fan

Motor

(M2)

Exit

Sensor

(PC3)

Paper

Take-up

Sensor

(PC1)

Paper

Take-up

Solenoid

(SL1)

Fusing

Roller

Thermistor

(TH1)

PWB-S

PWB-F

High

Voltage

Unit

Image Transfer

Housing

Image Transfer

Charger

PWB-D

Laser

Diode

Drive

PWB-E

Power

Unit

Heater Lamp

Interlock Switch

EPL-5500W Service Manual Operating Principles

2.1.2 Engine Control

This section describes engine control, the power supply board, and the high-voltage supply board. The

engine is controlled by the main board (C180 MAIN board). Figure 2-9 shows the engine controller

connection diagram.

Figure 2-9. Engine Controller Connection Diagram

Rev. A 2-7

Page 39

Toner Cartridge

Sleeve Roller

A

Paper Exit Roller

Upper Fusing Roller

Lower Fusing

Roller

PC Drum

Pre-image Transfer

Roller

Main Motor (M1)

Optional Second Paper Feeding Unit

Paper Take-Up Roller

Paper Transport Roller

A

Operating Principles EPL-5500W Service Manual

2.1.2.1 Main Motor Functions and Control

The M1 main motor transmits the drive to the printer rollers and the optional second paper feed unit (lower

cassette) via each gear, as shown below.

Figure 2-10. Gear and Roller Positions

2-8 Rev. A

Page 40

A

B

CN206

4

3

2

1

M1 Mai n Moto r

Board

C180 MAIN

B

A

EPL-5500W Service Manual Operating Principles

Figure 2-11 shows the main motor drive circuit. The M1 main motor is a four-phase stepping motor,

controlled by the CPU (IC201) on the main board (C180 MAIN). This board has a stepping motor driver IC

that drives the M1 main motor with a constant current.

Figure 2-11. Main Motor Drive Circuit

2.1.2.2 Paper Take-Up Sensor and Paper Exit Sensor

The paper take-up sensor has three functions:

1. To detect the top edge of paper. The engine starts printing when the detection signal

is received.

2. To detect paper size. The printer detects the time it takes for paper to pass the paper

take-up sensor during paper feeding. If this time is long, longer paper is feeding;

if the time is short, shorter paper is feeding.

3. To detect paper jams and feed jams.

If the paper take-up sensor does not turn on for paper feeding, the printer detects a feed jam or no paper. A

feed jam is a paper jam that occurs in the feed process.

If any of the following conditions is detected, the printer detects a paper jam. A paper jam is a jam that

occurs in the printing process area.

The paper take-up sensor (PC1) or the paper exit sensor (PC3) is on at power on or when the upper case

is closed.

The paper take-up sensor (PC1) or the paper exit sensor (PC3) is not turned on or off within the

specified time. (Refer to the following timing chart.)

PC1

(CN203-3)

PC3

(CN208-3)

Take Up Solenoid ON

2.0 11.0

3.5-4.5

3.4-4.7

[seconds]

Figure 2-12. Paper Take-Up Sensor and Paper Exit Sensor

On/Off Timing

Rev. A 2-9

Page 41

Operating Principles EPL-5500W Service Manual

2.1.2.3 Fuser Control

The heater lamp, powered by AC voltage, heats the fuser. When the power supply board receives a FUSER

signal from the main board (C180 MAIN), the power supply board (PWB-E) supplies the AC voltage to the

heater lamp. This AC voltage is cut by an interlock switch when the case is open.

Thermistor TH1 detects the surface temperature of the upper fusing roller and inputs that analog voltage to

the 77-pin chip, IC201. Based on this temperature data, the heater lamp on/off signal (the

output from the 54-pin chip, IC201, causing heater lamp H1 to turn on or off to control the fusing

temperature. When the heater lamp is not turned off even if the thermistor detects a high temperature

malfunction (which occurs if the surface temperature of the upper fusing roller exceeds 200º C), the signal

from the 75-pin chip, IC201, changes from H to L to turn off the heater lamp forcibly.

FUSER signal) is

C180 MAIN

IC201

77

54

75

H

L

IC202B

5

6

5 VDC

IC202A

H

2

3

H

4

L

1

H

3

4

L

Analog Voltage Detected by the

Thermistor (TH1)

CN202

1

2

CN207

1

5

CN1E

Heater Lamp

ON/OFF Signal

L

H1:ON

H

H1:OFF

Figure 2-13. Fuser Control Circuit

The following figure shows the fuser temperature control procedure.

Temperature

(Degrees C)

172

When a print is m ade immed iately a fter warm up

1

5

PWB-E

CN3E

1

2

3

TH1

Thermistor

Heater Lamp

H1

TF1

Thermal Fuse

156

112

Power On

Warm up Standby Standby with Low

Temperature

Time

Figure 2-14. Temperature for Fuser Control Procedure

1. Warm up: After printer initialization, printer warm up starts, and the heater lamp turns on until

the upper fusing roller’s temperature reaches approximately 172º C (342º F).

2. Standby: In standby mode, the upper fusing roller’s temperature is controlled to maintain 156º C

(313º F). When this condition continues for 3 minutes, the printer goes into standby

mode at low temperature.

3. Print cycle: When the printer receives the printing command from the controller, the upper

fusing roller is controlled to maintain 172º C (342º F).

4. Standby at low temperature: The upper fusing roller is controlled to maintain 112º C (234º F).

2-10 Rev. A

Page 42

+24V

GND2

5

4

3

2

1

CN210

C180 MAIN Board

M2 Scanner Motor

NC

+5V

P_CTL

EPL-5500W Service Manual Operating Principles

If any of the following conditions are detected, the printer indicates a fuser error:

1. If the thermistor detects the temperature has not risen by 20º C for 50 msec. within 12 to 30 sec.

after warm up. (This error applies only when the thermistor detects a temperature of 90º C (194º F)

or less.)

2. If the thermistor detects that the temperature has not reached 172º C (342º F) within 60 sec. after

warm up.

3. Except in pause mode (see the note below), if the thermistor detects that the temperature in the

idle state has fallen to 80º C (176º F) or lower for 50 msec., or the temperature during printing has

fallen to 133º C (271º F) or lower.

4. The thermistor detects that the temperature has exceeded 193º C (379º F) for 50 msec. during

temperature control.

Note: In Pause Mode, the control temperature is decreased to save power in the idle state, the

heater lamp is turned OFF.

Thermo fuse TF1 cuts power if the temperature of the fusing section rises to an abnormally high level (over

200° C, 392° F).

2.1.2.4 Scanner Motor Control

Figure 2-16 is the scanner motor (M2) control circuit. The scanner motor is driven while it receives the

POLYGON CTL signal. Motor rotation speed is 8622 rpm.

Figure 2-15. Scanner Motor Control Circuit

If the any of following conditions are detected, the printer indicates a scanner motor error:

1. The SSCAN signal has not been given once within 1 sec. after the scanner motor is energized.

2. The number of scanner motor rotations has not stabilized within ± 0.5 rpm by 4.2 sec. after the

motor is energized.

3. The number of scanner motor rotations has exceeded ± 3% for more than 0.5 sec. after the motor

is energized, even if the rotation number stabilizes within ± 0.5 rpm.

Rev. A 2-11

Page 43

SSCAN

LD_CTL

LDAPC1

LDAPC2

L DATA

C180 MAIN Boa rd

LD

SOS

(PWB-D)

Laser Diode

SOS Sensor

SOS Mirror

Scanner Motor On

LDATA

LDAPC1

LDAPC2

P_CTL

Operating Principles EPL-5500W Service Manual

2.1.2.5 Laser Diode Drive

Figure 2-16 shows the laser diode drive circuit. Laser diode emission is controlled by three signals (LDATA,

LDAPC1, and LDAPC2) from the main board (C180 MAIN).

Figure 2-16. Laser Diode Drive Circuit

The

LDATA signal is the laser on/off signal. When it is LOW, the laser emits, and when it is HIGH, the

laser stops emitting.

FORCED LASER DIODE ON signal is activated (LOW), the

signal is an image signal sent from the video controller circuit. The FORCED LASER DIODE ON signal is

a laser emission signal to apply the laser beam to the SOS sensor.

LDATA is the combination of the two signals in the figure below. If the VIDEO or the

LDATA signal will be active. The VIDEO

Forced Laser Diode ON

L DATA

VIDEO

from the Video

Controller Circuit

(C180 MAIN)

Figure 2-17. LDATA Generation Circuit

The laser diode is forcibly activated after scanner motor M2 turns on. At this time, laser emission power is

adjusted. LDAPC1 and LDAPC2 are the laser emission power adjust signals; they are analog signals.

LDAPC1 is a tuning, and LDAPC2 is a fine tuning signal.

If either of the following conditions is detected, the printer indicates a laser error:

The LDAPC1 signal or LDAPC2 signal has been out of the specified range while laser power is adjusted.

2-12 Rev. A

Figure 2-18. Laser Emission Power Adjustment Timing

Page 44

EPL-5500W Service Manual Operating Principles

2.1.2.6 Bias Voltages and Laser Drive Timing

Figure 2-19 is a diagram of the drum charge bias voltage, image transfer bias voltage, and the developing

bias voltage control circuit. These bias voltages are generated from the +24 VDC from the high-voltage

supply board (PWB-F). If the printer detects a case-open condition, the interlock switch is set to off, which

cuts the +24 VDC, which, in turn, cuts the bias voltages.

These bias voltages are controlled by the main board (C180 MAIN). The

HV-T signal is the image transfer

bias voltage control. While this signal is LOW, the image transfer electrode comb is charged to from +3 to

+6K VDC by the high-voltage supply circuit.

HV SEL1 and HV SEL2 are image transfer bias level control

signals.

The HVB signal is the digital signal for developing bias voltage control. This signal controls the bias on/off.

The BIAS MON signal controls the bias voltage level (–300 V to –375K VDC) using pulse data. The image

density is controlled by the developing bias voltage level.

Power Supply

Board

(PWB-E)

+24 VDC

Interlock

SW

Main

Board

(C180 MAIN)

+24 VDC

HV SEL1

HV SEL2

BIAS MON

HV-C

HV-T

HV B

PWB-S

High Voltage Supply

Board

(PWB-F)

Drum Charge

-2.0 K VDC

Image Transfer

Bias

3K to 6 K VDC

Developing

Bias

-270 to -370 VDC

Toner Doctor Blade

Bias -500 VDC

Seal Bias

-250 VDC

Figure 2-19. High-Voltage Supply Block Diagram

Rev. A 2-13

Page 45

Brush Roller Charging

Laser Exposure

PC Drum

Image Transfer

Development

[m sec.]

Print

Command

Polygon Motor

(M3)

Paper Take-up

Sensor (PC1)

Paper Take-up

Solenoid

(SL1/2)

Main Motor

(M1)

Drum Charge

Laser

Exposure

Development

Image

Transfer

20

200

500

300

2310

150

500

260

1st:770, 2nd:2820

1st: 790 to 1300

2nd: 2670 to 3080

480

1st: 1510

2nd: 1680

Normal M3 Rotation

4000

[m sec.]

Polygon Motor

(M3)

Main Motor

(M1)

Drum Charge

Laser

Exposure

Development

Image

Transfer

Paper Exit

Sensor (PC3)

5160

850

480

Operating Principles EPL-5500W Service Manual

Figure 2-20 shows the print process.

Figure 2-20. Print Process

Figure 2-21 shows the start print sequence. The printer’s engine starts printing when it receives the

signal from the video controller circuit.

Figure 2-21. Print Sequence (Start)

Figure 2-22 is the end of the print sequence.

PRINT

2-14 Rev. A

Figure 2-22. Print Sequence (End)

Page 46

AC IN

Interlock

SW

+24 VDC

+5 VDC

FG

SG

Power Supply Board

(PWB-E)

EPL-5500W Service Manual Operating Principles

2.1.2.7 Fan Motor Control

The fan motor (M3) rotates at engine initialization, and stops after 2 sec. The fan motor also rotates during

printing. When printing ends, the fan motor stops after 3 min.

If the following condition is detected, the printer indicates a laser error:

The voltage equivalent to the motor current of the fan motor remains 160 mV or lower for 2 sec.

2.1.2.8 Power Supply Circuit Function and Safety Protection

The printer’s power supply board (PWB-E) supplies the +5 VDC and +24 VDC. The +24 VDC is used as

the bias voltage supply, main motor (M1) drive, scanner motor (M2) drive, fan motor (M3) drive, and

solenoid drive. For safety protection, the +24 VDC line is cut when the interlock switch (case open switch)

is off.

Figure 2-23. Power Supply Circuit Block Diagram

Rev. A 2-15

Page 47

Operating Principles EPL-5500W Service Manual

2.2 PARALLEL INTERFACE CONTROLLER OPERATION

The parallel interface controller section converts from a bidirectional parallel interface to a video interface.

The parallel interface controller section is in the C180 MAIN board.

C180 MAIN Board

Parallel Interface

Controller Section

Engine Controller Section

Figure 2-24. Parallel Interface Controller Section

2.2.1 C180 MAIN Board Operation

Figure 2-25 shows a block diagram of parallel interface controller section of the C180 MAIN board.

Bidirectional

Parallel I/F

E05B23

(U8)

4M DRAM

(U4)

Engine Controller

Sectio n

Figure 2-25. C180 MAIN Board Block Diagram

2-16 Rev. A

Page 48

EPL-5500W Service Manual Operating Principles

Table 2-1 lists the functions of the main elements of the video controller section in the C180 MAIN board.

Table 2-1. Functions of C180 MAIN Board Main Elements

Element Location Function

This ASIC contains the following functions:

E05B23 ASIC U8

DRAM U4 These DRAMs are used as the working area of the E05B23.

Changing from parallel I/F to video I/F.

DRAM management (refresh control, RAS/CAS control).

Rev. A 2-17

Page 49

Chapter 3 Disassembly and Assembly

Table of Contents

3.1 GENERAL INFORMATION 3-1

3.1.1 Precautions for Disassembly/Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.3 Small Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.4 Service Checks after Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 DISASSEMBLY AND ASSEMBLY 3-4

3.2.1 Housing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.1.1 Case Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.2 Removal of the Controller Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.2.1 Main Board (C180 MAIN Board) Removal . . . . . . . . . . . . . . . . . . 3-5

3.2.3 Disassembling the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.3.1 Optical Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.3.2 Image Transfer Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.3.3 Upper Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.2.3.4 High-Voltage Supply Board (PWB-F) Removal. . . . . . . . . . . . . . 3-10

3.2.3.5 Power Supply Unit (PWB-E) Removal. . . . . . . . . . . . . . . . . . . . . 3-11

3.2.3.6 Fusing Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.2.3.7 Fusing Unit Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

List of Figures

Figure 3-1. Removing the Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-2. Removing the Shield Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-3. Removing the C169 MAIN-B Board . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-4. Removing the Optical Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-5. Removing the Image Transfer Unit -1. . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-6. Removing the Image Transfer Unit -2. . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-7. Moving the Image Transfer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-8. Reinstalling the Electrode Comb . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-9. Removing the Harness Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-10. Removing the Upper Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-11. Removing the PWB-F Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-12. Removing the PWB-F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-13. Removing the PWB-E Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-14. Removing the PWB-E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-15. Gear and Spring Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-16. Removing the Fusing Guide Plate . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-17. Removing the Harness Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-18. Removing the Fusing Entrance Guide . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-19. Removing the Fusing Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-20. Roller Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-21. Removing the Heater Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Figure 3-22. Removing the Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Figure 3-23. Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Figure 3-24. Removing the Paper Separator . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Figure 3-25. Paper Exit Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Figure 3-26. Removing the G-Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Page 50

Figure 3-27. Removing the Upper Fusing Roller . . . . . . . . . . . . . . . . . . . . . . . 3-18

Figure 3-28. Removing the Lower Fusing Roller . . . . . . . . . . . . . . . . . . . . . . . 3-19

Figure 3-29. Removing the Thermal Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

List of Tables

Table 3-1. Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3-2. Abbreviations Used for Screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-3. Screw Types and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-4. Checks after Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Page 51

EPL-5500W Service Manual Disassembly and Assembly

3.1 GENERAL INFORMATION

This chapter describes disassembly/assembly procedures to use to replace the main assemblies of the

EPL-5500W.

3.1.1 Precautions for Disassembly/Assembly

Follow the precautions below when disassembling/assembling the printer.

WARNING

❒Disconnect the power cord before disassembling/assembling the printer.

❒Be sure to handle the fusing unit carefully, because the unit remains hot for a while after

the printer stops printing.

❒If it is necessary to plug in the power cord and operate the printer after disassembling it,

please be careful of the following:

1.Keep your hands and clothing well away from operating or rotating parts (such as

rollers, fan motors, etc.).

2.Never touch electric terminals or high-voltage components (such as the charger and the

high-voltage unit).

CAUTION

❒Do not disassemble the photoconductor unit and toner cartridge.

❒If the photoconductor unit is removed from the printer, do not place it in direct sunlight.

❒Do not disassemble the optical unit.

❒Never turn power on if the optical unit is not installed.

❒To prevent damage to ICs from static electricity, do not touch the ICs on the circuit

board or the terminals of peripheral electrical components with your hands.

❒Use only the recommended tools to ensure safe and efficient maintenance work.

Inappropriate tools may damage the machine.

❒Never open the upper unit until the main motor stops completely. Otherwise, the gears

may be damaged.

❒When transporting the printer, remove the photoconductor unit and toner cartridge from

the printer.

❒When transporting the printer a long distance, pack up the printer using the original

packing material.

3.1.2 Tools

Use the tools listed in Table 3-1 for disassembling/assembling the printer and for troubleshooting.

Table 3-1. Tools

Name Commercially Available? Part No.

Philips screwdriver no. 2 Yes B743800200

Regular screwdriver Yes B743000100

Tweezers Yes B641000100

Soldering iron Yes B740200100

Round-nose pliers Yes B740400100

Rev. A 3-1

Page 52

Disassembly and Assembly EPL-5500W Service Manual

3.1.3 Small Parts

In the following sections, abbreviations are used for small parts, such as screws and washers. Tables 3-2 and

3-3 list these abbreviations.

Table 3-2. Abbreviations Used for Screws

Abbreviation Part Name

CP Cross-recessed Pan head

CC Cross-recessed Cup head

CP(O) Cross-recessed Pan head with Outside-toothed lock washer

CP(S)(P1) Cross-recessed Pan head with Spring lock washer and 1 Plain washer

CCB Cross-recessed Cup head Bind

SCB Slotted Cross-recessed B-tight

SCB(S)(P1) Slotted Cross-recessed Bind with Spring washer and 1 Plain washer

Table 3-3. Screw Types and Abbreviations

Top Side

Cross-recessed

1.

head

Slotted Cross-

2.

recessed head

Head

1.

2.

3.

Bind

Pan

Cup

1.Normal

—————-

2.

B-tight

Body

Washer

(Assembled)

1.

Plain washer 1

Outside-toothed

2.

lock washer

Spring washer

3.

3-2 Rev. A

Page 53

EPL-5500W Service Manual Disassembly and Assembly

3.1.4 Service Checks after Repair

Check the repaired unit using the following list on completion of servicing.

Table 3-4. Checks after Repair

Item Location Checkpoint Check

Control panel Do all LEDs and buttons function normally?

Operation

Adjustments Print position

Cleaning

Packing

Heater lamp Does the heaterlamp turn on normally?

Test Page Is the test page printed normally?

Data print Does data print in all modes?

Is the gap between the top edge of the paper and

the horizontal line in the adjustment printing sheet

print exactly 4.2 mm (0.17 inch).

Is toner and dust removed from the paper path?

Is the paper take-up roller cleaned?

Is the roller in the fusing unit cleaned?

Is the outer surface of the printer clean?

Are the consumables removed from the printer?

Is the unit packed securely?

Are accessories packed also?

Rev. A 3-3

Page 54

2. Front Cover

1. Left cover

3. Operation

Cover

4. Rear Cover

Upper unit

Upper unit lock

release button

Disassembly and Assembly EPL-5500W Service Manual

3.2 DISASSEMBLY AND ASSEMBLY

This section describes and illustrates procedures for removing and disassembling components of the

EPL-5500W. Cleaning is described in Chapter 6. The assembly procedures are not described, except for

special notes where necessary, because assembly can be accomplished by performing disassembly in reverse.

3.2.1 Housing Removal

This section describes how to remove the cases and the rear frame.

3.2.1.1 Case Removal

1. Push the upper unit lock release button, and open the upper unit.

2. Remove each cover in the following order.

ASSEMBLY POINT

When reinstalling each cover, securely insert the protrusions for the cover into the cutouts in the

printer frame.

3-4 Rev. A

Figure 3-1. Removing the Housing

Page 55

EPL-5500W Service Manual Disassembly and Assembly

3.2.2 Removal of the Controller Section

The control section is comprised of the controller board (the C180 MAIN board).

3.2.1.1 Main Board (C180 MAIN Board) Removal

1. Turn the printer so that its right side faces you.

2. Remove the right cover.

3. Remove 2 screws, and then remove the shield case.

Figure 3-2. Removing the Shield Case

4. Disconnect all connectors on the C180 MAIN board.

5. Remove the 5 screws for the C180 MAIN board.

6. Remove the C180 MAIN board.

Figure 3-3. Removing the C180 MAIN Board

Rev. A 3-5

Page 56

Disassembly and Assembly EPL-5500W Service Manual

3.2.3 Disassembling the Engine

This section describes disassembling the engine, including the high-voltage unit (PWB-F) and power supply

board (PWB-E).

3.2.3.1 Optical Unit Removal

CAUTION

❒Do not touch the optical unit, except during replacement.

❒Do not open the unit under any conditions.

❒Do not remove the circuit board from the optical unit under any conditions.

1. Open the top cover.

2. Remove the right cover, left cover, and front cover. (Refer to Section 3.2.1.1.)

3. Remove the cover shield plate.

4. Disconnect connectors CN205 and CN210 from the C180 MAIN board.

4. Remove the 6 screws from the optical unit.

5. Remove the optical unit.

Figure 3-4. Removing the Optical Unit

3-6 Rev. A

Page 57

EPL-5500W Service Manual Disassembly and Assembly

3.2.3.2 Image Transfer Unit Removal

1. Open the top cover.

2. Remove harness cover A. (Refer to Section 3.2.3.3.)

3. Remove the 2 screws and holders at both ends of the image transfer unit.

Figure 3-5. Removing the Image Transfer Unit - 1

4. Disconnect the 2 connectors and remove the unit.

Figure 3-6. Removing the Image Transfer Unit - 2

Rev. A 3-7

Page 58

Disassembly and Assembly EPL-5500W Service Manual

ASSEMBLY POINT

After reinstalling the image transfer unit, check that the unit smoothly moves up and down.

Figure 3-7. Moving the Image Transfer Unit

5. Remove the electrode comb.

ASSEMBLY POINT

When reinstalling the electrode comb, be careful of the direction of installation. Install the

electrode comb so that the comb terminal faces the image transfer roller drive gear.

Figure 3-8. Reinstalling the Electrode Comb

3-8 Rev. A

Page 59

A

B

EPL-5500W Service Manual Disassembly and Assembly

3.2.3.3 Upper Unit Removal

1. Open the upper unit.

2. Remove the right cover and left cover. (Refer to Section 3.2.1.1.)

3. Disconnect connectors CN202, CN208, and CN211 from the C180 MAIN.

4. Remove harness covers A and B, and pull CN1 out from the PWB-E board.

5. Remove the image transfer unit. (Refer to Section 3.2.3.2.)

Figure 3-9. Removing the Harness Cover

6. Slide and remove the unit as shown in the illustration.

Figure 3-10. Removing the Upper Unit

Rev. A 3-9

Page 60

Disassembly and Assembly EPL-5500W Service Manual

3.2.3.4 High-Voltage Supply Board (PWB-F) Removal

1. Open the top cover.

2. Remove 1 screw from the PWB-F cover.

3. Remove the PWB-F cover.

Figure 3-11. Removing the PWB-F Cover

4. Remove the 4 screws from the PWB-F board.

5. Disconnect 2 connectors.

6. Remove the PWB-F board.

Figure 3-12. Removing the PWB-F

3-10 Rev. A

Page 61

EPL-5500W Service Manual Disassembly and Assembly

3.2.3.5 Power Supply Unit (PWB-E) Removal

1. Remove the upper unit. (Refer to Section 3.2.3.3.)

2. Remove 6 screws, and remove the PWB-E cover.

Figure 3-13. Removing the PWB-E Cover

3. Disconnect connector CN207 from the C180 MAIN board.

4. Remove 4 screws and 2 screws, and then remove the PWB-E.

Figure 3-14. Removing the PWB-E

Rev. A 3-11

Page 62

Disassembly and Assembly EPL-5500W Service Manual

3.2.3.6 Fusing Unit Removal

1. Open the top cover. (Refer to Section 3.2.3.3.)

2. Remove the image transfer unit. (Refer to Section 3.2.3.2.)

3. Remove 1 screw, and remove the drive tension section of the fusing unit.

4. Remove the transport gear.

5. Release the hook for the spring and remove the drive gear section of the fusing unit.

ASSEMBLY POINT

When rehooking the spring, be sure to hook it in the correct position.

drive gear section

of the Fusing unit

drive transport

gear

hook of the

spring

Figure 3-15. Gear and Spring Position

6. Remove 2 screws, and remove the fusing guide plate.

drive tension section

of the Fusing unit

Figure 3-16. Removing the Fusing Guide Plate

3-12 Rev. A

Page 63

EPL-5500W Service Manual Disassembly and Assembly

7. Remove the harness cover.

Figure 3-17. Removing the Harness Cover

8. Remove the fusing entrance guide.

Figure 3-18. Removing the Fusing Entrance Guide

Rev. A 3-13

Page 64

Disassembly and Assembly EPL-5500W Service Manual

10. Remove 4 screws, and remove the fusing unit.

Figure 3-19. Removing the Fusing Unit

ASSEMBLY POINT

After reinstalling the fusing unit, check the direction of the bushings on the paper exit roller and

the connection between the roller and the ground plate.

Figure 3-20. Roller Position

3-14 Rev. A

Page 65

EPL-5500W Service Manual Disassembly and Assembly

3.2.3.7 Fusing Unit Disassembly

This section describes how to remove the paper exit sensor, heater lamp, lower fusing roller, and upper fusing

roller.

Heater Lamp

CAUTION

Do not touch the glass surface of the lamp with your bare hands.

1. Remove the fusing guide plate. (Refer to Section 3.2.3.8.)

2. Pull the heater lamp out of the lamp holder from the front side.

Figure 3-21. Removing the Heater Lamp

ASSEMBLY POINT

When reinstalling the lamp, position its voltage indicator to the left side (non-gear end.).

Rev. A 3-15

Page 66

Disassembly and Assembly EPL-5500W Service Manual

Thermistor

1. Remove the fusing unit. (Refer to Section 3.2.3.6.)

2. Remove the 1 screw, and remove the thermistor.

Figure 3-22. Removing the Thermistor

ASSEMBLY POINT

When reinstalling the thermistor, wire the harness as shown below.

Figure 3-23. Wiring

3-16 Rev. A

Page 67

EPL-5500W Service Manual Disassembly and Assembly

Paper Separator

1. Remove the fusing unit. (Refer to Section 3.2.3.6.)

2. Release the lock of the holder, and remove the 3 paper separators.

Figure 3-24. Removing the Paper Separators

ASSEMBLY POINT

When reinstalling the paper separators, be careful of their positions, because the middle one

differs from the others.

Paper Exit Sensor

1. Remove the fusing unit. (Refer to Section 3.2.3.6.)

2. Remove the paper exit sensor.

Figure 3-25. Paper Exit Sensor

Rev. A 3-17

Page 68

Disassembly and Assembly EPL-5500W Service Manual

Fusing Roller

1. Remove the fusing unit. (Refer to Section 3.2.3.6.)

2. Remove the 2 G-rings from the fusing unit.

Figure 3-26. Removing the G-Rings

CAUTION

When reinstalling the G-rings:

❒ Be careful of the direction.

❒ Securely position them into the grooves of the fusing roller.

3. Remove the upper fusing roller drive gear.

4. Remove the upper fusing roller.

Figure 3-27. Removing the Upper Fusing Roller

3-18 Rev. A

Page 69

EPL-5500W Service Manual Disassembly and Assembly

5. Take out the lower fusing roller.

Figure 3-28. Removing the Lower Fusing Roller

Thermal Fuse

1. Remove the fusing unit. (Refer to Section 3.2.3.6.)

2. Remove 2 screws, and remove the thermal fuse.

Figure 3-29. Removing the Thermal Fuse

Rev. A 3-19

Page 70

Chapter 4 Adjustment

Table of Contents

4.1 ADJUSTMENT 4-1

4.1.1 Print Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

List of Figures

Figure 4-1. Print Position Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Page 71

4-ii Rev. A

Page 72

EPL-5500W Service Manual Adjustments

4.1 ADJUSTMENTS

This section describes the adjustment procedures for the EPL-5500W. You must perform these adjustments

after servicing the printer, especially when any component or part is replaced.

4.1.1 Print Position Adjustment