Page 1

EPSON TER M INAL PR INTER

EPL-5500

SERVICE MANUAL

EPSON

4005431

Page 2

- ii -

Page 3

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever without SEIKO

EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual. However, should

any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above not withstandi ng SEIKO EPSON can assume no responsibil ity for any error s in this

manual or the consequence thereof.

Epson is a registered trademark of Seiko Epson Corporation.

General N ot ice:

be trademarks of their respective campanies.

Other product names used herein are for ident ication purposes only and may

Copyright © 1995 by SEIKO EPSON CORPORATION Nagano, Japan

- i -

Page 4

PRECAUTIONS

Precautionary not ati ons throughout t he t ext ar e c at egor ized relative to 1) personal injury and 2)

damage to equipment.

DANGER

WARN ING

The precautionary measures itemized below should always be observed when performing repair/

maintenance procedures.

Signals a precautio n which, if ignored, could result in seri ous or fatal personal injur y.

Great ca ution s hould be exercised i n performing procedures pr eceded by DANGER

Headi ngs.

Signals a precaution which , if ignored, could result in damage to equipment.

DANGER

1. ALWAY S D ISCON NECT T HE PRODU CT FROM B OT H THE P OWER SO URCE AN D PERI PHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICI ANS IN

THEIR LINE OF WO RK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT

THE UNI T TO A POW ER SOU RCE UNTIL IN STR UCTED TO DO SO. WHEN THE PO WER

SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWE R SUPPLY AND OTHER EL ECTRONI C COMPONENTS.

WAR NING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORM ED ONLY BY AN EPSON CERTIFIED REPAIR T ECHNICI AN.

2. MAKE C ERTAIN THAT THE SOURCE V OL TAGE IS THE SAME AS THE RAT ED VOLTAGE,

LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A

PRIMA RY AC R ATI NG D IFFE RENT FRO M AV AILA BLE POW ER SOUR CE , DO NOT C ON NECT IT TO THE POWER SOURCE.

3. ALWAY S VERIFY THAT THE EPSON PRO DUCT HAS BEEN DISCONN E CTED FROM T HE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/O R INDIVI DUAL CHI PS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC

DISCH ARGE EQ UIPM ENT, S UC H AS A NTI -STAT IC WRI ST S TRAPS, WH EN ACCES SIN G

INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE

MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER NONAPPROVED

COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

- ii -

Page 5

SAFET Y INFORMATION

This printer is a page printer which operates by means of a laser. There is no possibility of danger from

the laser, provided the printer is operated according to the instructions in this manual provided.

Since radiation em itted by the laser is completely confined with in protective housings, the laser beam

cannot escape from the machine during any phase of user operation.

For United States Users;

[Laser Safety]

This printer is certified as a Class 1 Laser product under the U.S. Department of Health

and Human Services (DHHS) Radiation Performance Standard according to the Radiation Control for Healt h and Safety Act of 1968. Thi s means that the printer does not

produce hazardous laser radiation.

[CDRH Reg u lations ]

The Center for Devices and Radiologica l Health (CDRH) of the U.S. Food a nd Drug

Administr ation implemented regul ati ons for laser product s on August 2, 1976. Compliance is mandatory for products marketed in the United States. The label shown below

indicates compliance with the CDRH regulations and must be at tached to laser products

marketed in the United States.

WARNING : Use of controls, adjustments or performance of procedures other

than those specified in this manual may result in hazardous radiation exposure.

[Internal Laser Radiation]

Maximum Radiation Power: 5.0 × 10-4 (W)

Wave Length: 790 ± 20 nm

This is a Class IIIb Laser Diode Assay that has an invisi ble la ser beam. The print head

unit is NOT A FIELD SERVICE ITEM. Therefore, the print head unit should not be opened

under any circumstances .

For Other Countr ies Users;

WARNING: Use of controls, adj ustments or performance of pro cedures other

than those specified in this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 5.0 ×

10-4 W and the wavelength is 790 ± 20 nm.

For Denmark Users;

ADVARSEL

Usynlig laserstr åling ved åbning , når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

Klasse 1 laser produkt der opfylder IEC825 sikkerheds kravene.

- iii -

Page 6

For Finland , Sweden User s;

VAROITUS

Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteiylle.

VARNING

Om apparaten används på annat sätt än i denna bruksanvisning specificerats,

kan användaren utsättas för osynlig laserstrålning, som överskrider gränsen för

laser klass 1.

For Finland , Sweden Ser vice Peop le

VAROITUS

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING

Osynlig laserstrålning när denna del är öppnad och spärren är urkopplad.

Betrakta ej strålen.

For Norway Users;

ADVARSEL

Dersom apparat et brukes på anne n m åte enn s pesi fi sert i denne br uksanv isning, kan brukeren utsettes for unsynlig laserstråling som overskrider grensen

for laser klasse 1.

Dette er en halvleder laser. Maksimal effeckt til laserdiode er 5.0 × 10-4 W og

bølgelengde er 790 ± 20 nm.

Laser Safety Labels

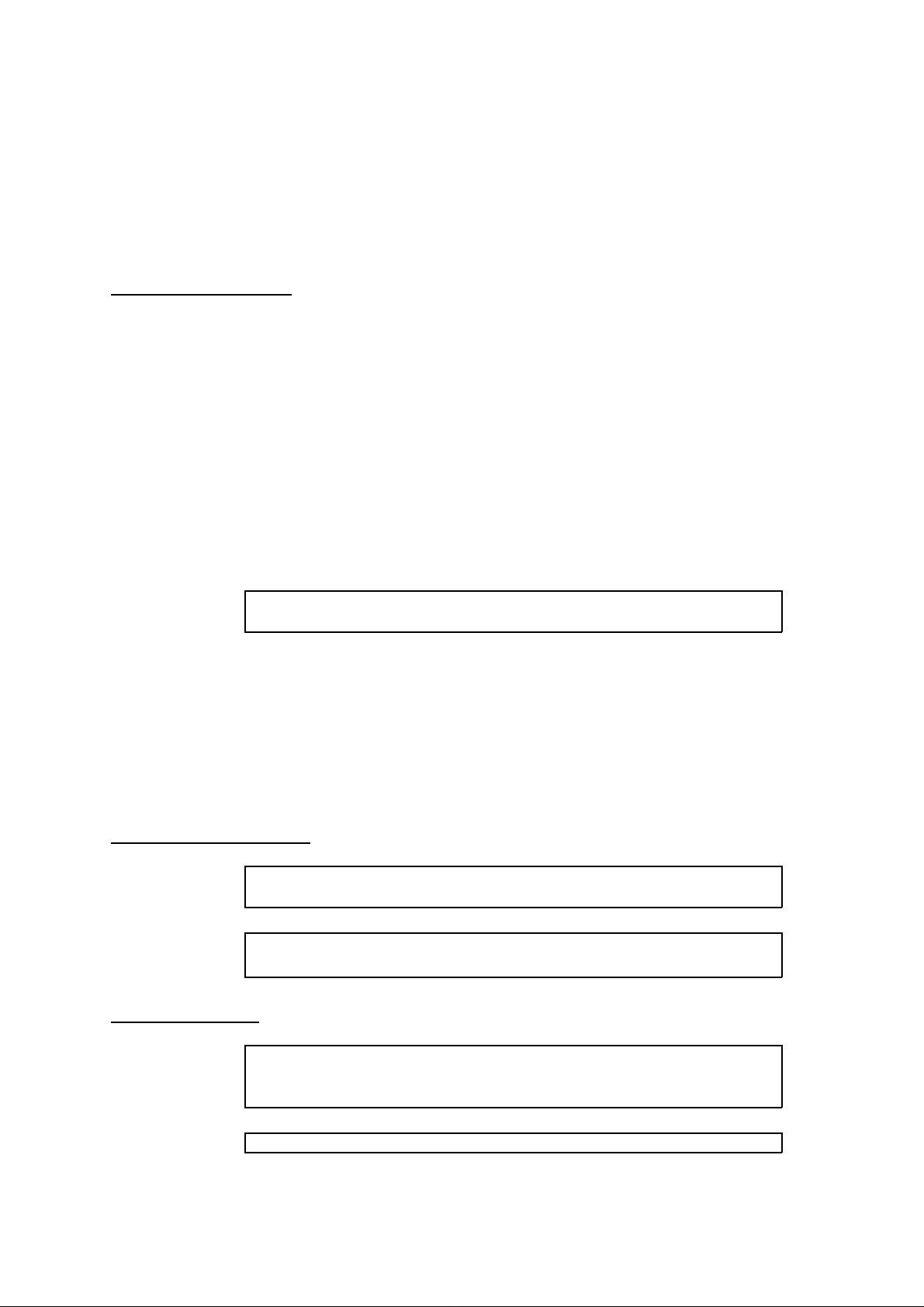

[Label on rear printer case]

A laser safety labels is attached on the outside of the printer shown below.

For United State

- iv -

Page 7

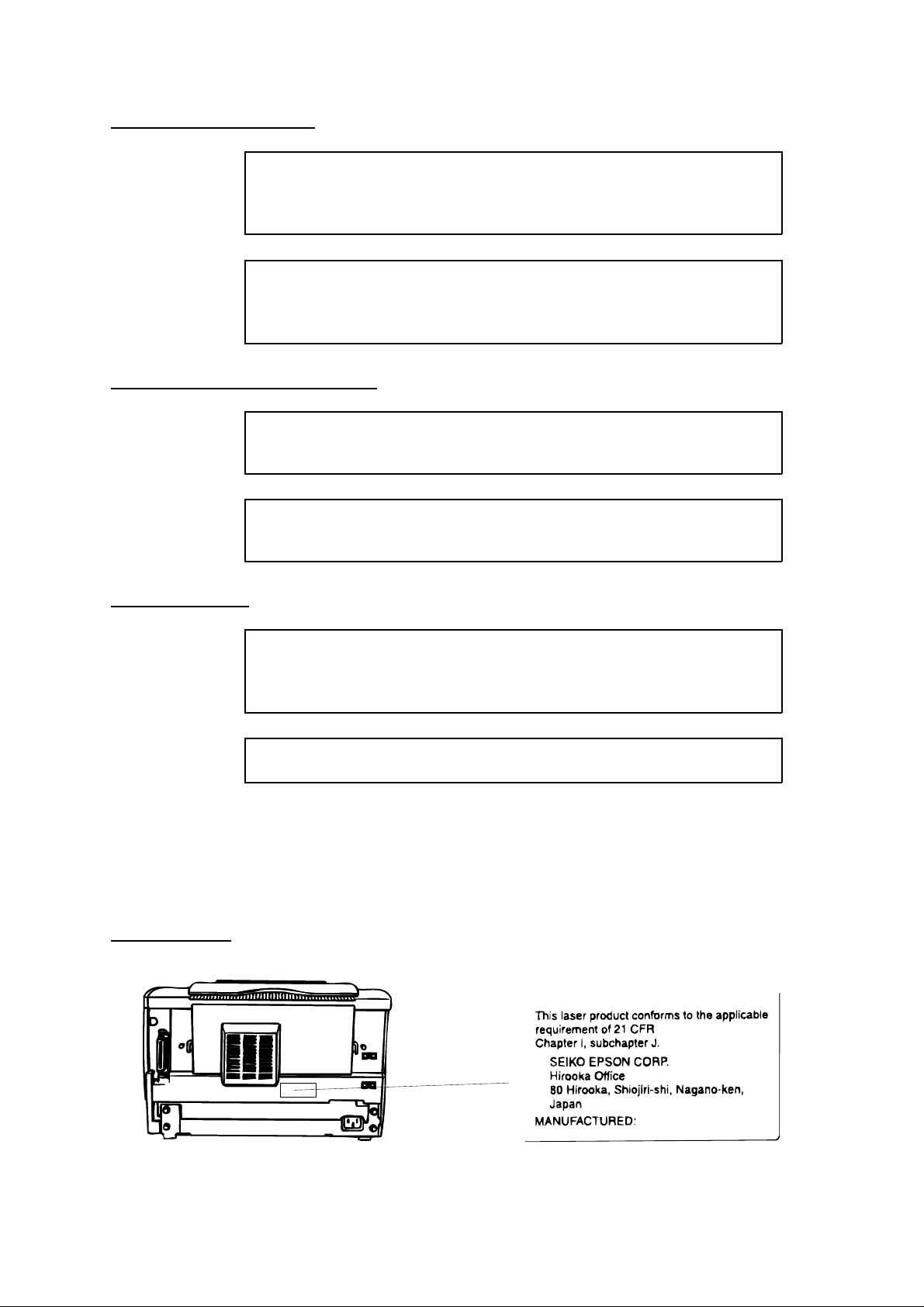

For Europe

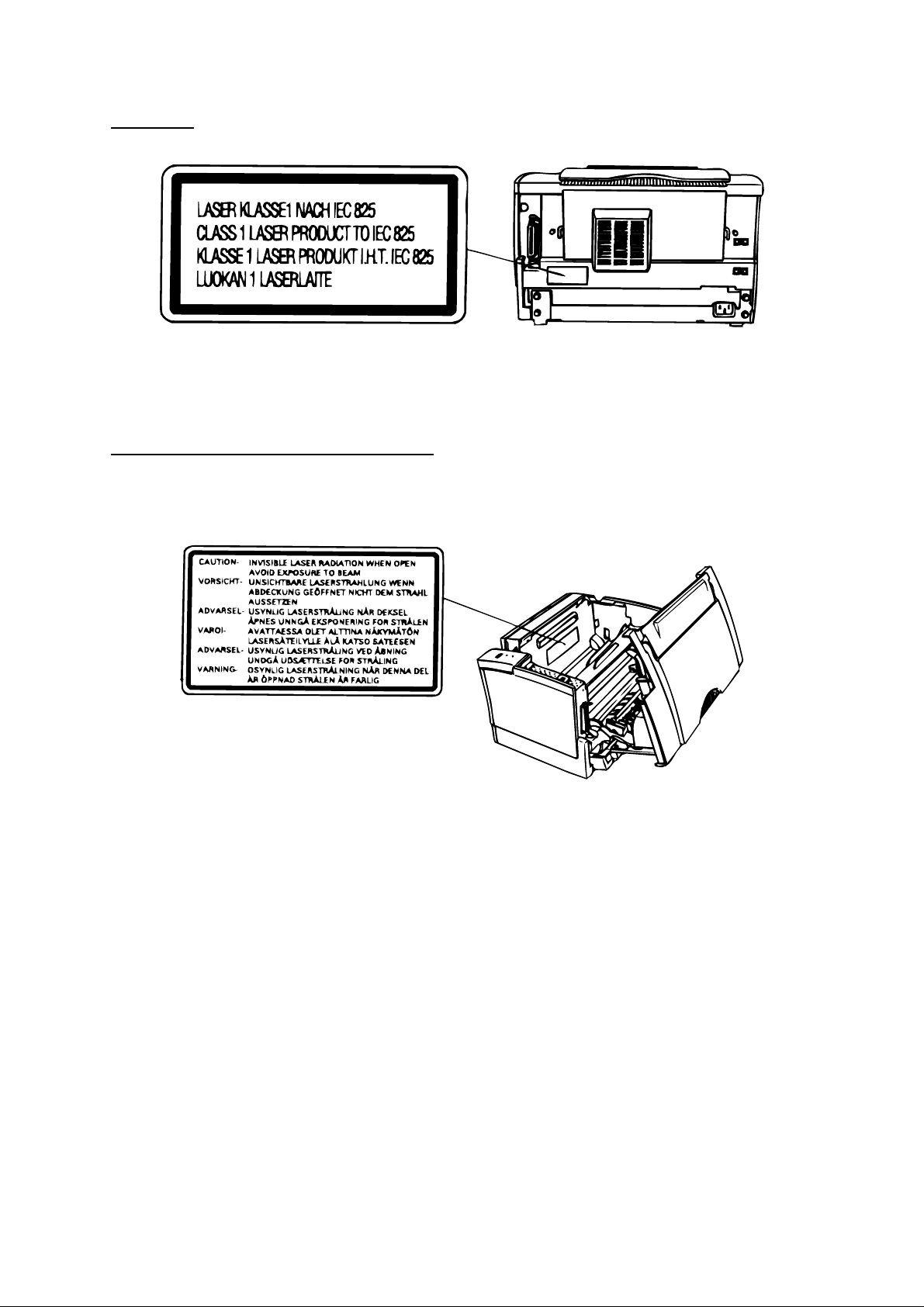

[Label inside printer]

The following laser safety label will be attached inside the printer as shown below.

For Denmark, Finl and, Sweden, and Norway

- v -

Page 8

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of EPL-5500.

The instruct ions and proc edur es included herein are intended f or the experi ence rep air technici an, and

attenti on should be given t o the prec autions on the preceding page. The chapters are o rganized as

follows:

CHAP TER 1. GENERAL DESC RIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the printer.

CHAP TER 2. OPERATING PR INCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMB LY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAP TER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAP TER 6. MAINT E NANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

- vi -

Page 9

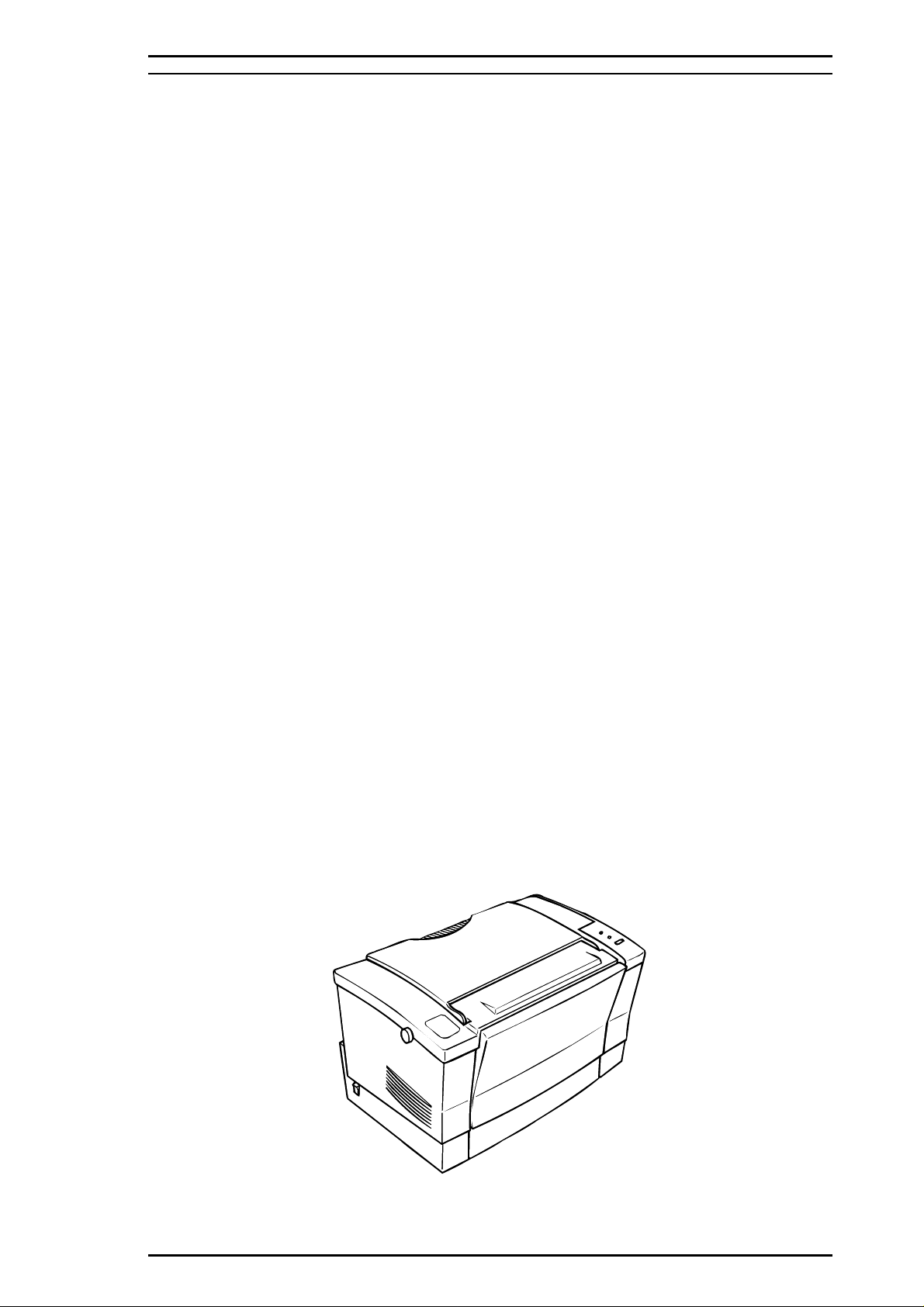

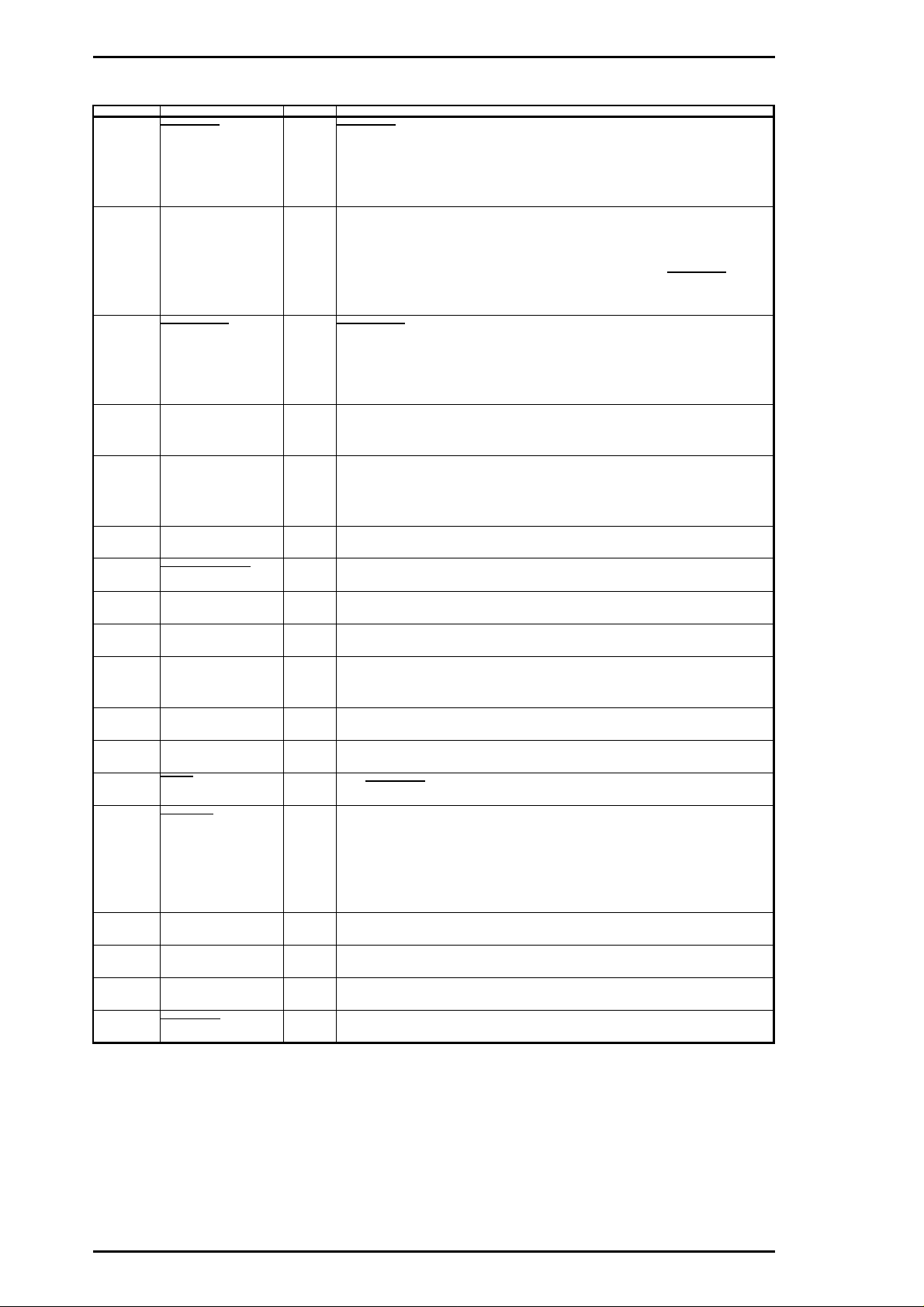

REVISION SHEET

Revision Issue Date Revision Page

Rev. A October 06, 1995 1st issue

Revise the whole pages of the

following chapters:

Chapter 1

Rev. B March 15, 1996

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

- vii -

Page 10

Chapter 1 General Description

Table of Contents

1.1 FEATURES 1-1

1.2 SPECIFICATIONS 1-3

1.2.1 Basic Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.2 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.3 Reliability Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.4 Environmental Conditions for Operating (Include Imaging Cartridge) . . . . 1-5

1.2.5 Environmental Conditions for Storage and Transportation . . . . . . . . . . . . 1-5

1.2.6 Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.7 Specifications for Consumable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.8 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.9 Software Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3 INTERFACE SPECIFICATIONS 1-9

1.3.1 Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.3.1.1 Compatibility Mode of Parallel Interface . . . . . . . . . . . . . . . . . . . . 1-9

1.3.1.2 Reverse ModeMode Signal Timing . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.3.2 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.3.3 Optional LocalTalk Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4 OPERATING INSTRUCTIONS 1-18

1.4.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.4.2 Printer Settings Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.4.3 Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.4.3.1 Heaxadecimal Dump Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.4.3.2 EEPROM Initialize Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.4.3.3 Factory Reset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.4.3.4 Default Setting Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.4.4 Display of Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1.4.4.1 Status Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1.4.4.2 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1.4.4.3 Service Call Error Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1.4.5 Printer Sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

1.4.5.1 Port Fixed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

1.4.5.2 Auto Sense Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

1.4.6 Emulation Mode Switch Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

1.4.6.1 Emulation Switch by SPL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

1.4.6.2 Intelligent Emulation Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

1.4.7 Bi Resolution Improvement Technology . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

1.4.8 Toner Save Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

1.4.9 Optional Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

1.5 MAIN COMPONENTS 1-32

1.5.1 C169 MAIN-B Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

1.5.2 PWB-E Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

1.5.3 PWB-F Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

1.5.4 Optical Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

1.5.5 FUSING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

1.5.6 Photoconductor Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Page 11

1.5.7 Developing Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

1.5.8 Lower Paper Cassette Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

List of Figures

Figure 1-1. Exterior View of the EPL-5500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Figure 1-2. Printable Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-3. Compatibility Mode Signal Timing . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Figure 1-4. Parallel Interface State Switch Diagram. . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-5. Negotiation Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-6. Timing Chart of Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-7. Termination Timing Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-8. Timing Chart of Interrupt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-9. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Figure 1-10. Port Fixed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Figure 1-11. Auto Sense Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Figure 1-12. Emulation Switch by SPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Figure 1-13. Intelligent Emulation Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Figure 1-14. Effect of RITech . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Figure 1-15. RITech Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Figure 1-16. Toner Save Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Figure 1-17. Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Figure 1-18. C169 MAIN - B Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Figure 1-19. PWB-E Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Figure 1-20. PWB-F Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Figure 1-21. Optical Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Figure 1-22. Fusing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Figure 1-23. Photoco nduct or Uni t. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Figure 1-24. Developing Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

List of Tables

Table 1-1. Options for the EPL-5500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Paper Feed Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-3. Paper Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-4. Usability of Special Papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-5. Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-6. Differences between EPSON GL/2 and GL/2 in the HP LaserJet 4

Emulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-7. Built-in Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-8. Parallel Interface Pin Assignment. . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-9. Parallel Interface Pin Assignment. . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Table 1-10. Serial Interface Connector Pin Assignments . . . . . . . . . . . . . . . . . 1-15

Table 1-11. LocalTalk Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . 1-17

Table 1-12. Printer Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Table 1-13. Service MOde Select Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-14. Default Settings Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-15. Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Table 1-16. Differences in Components for the C169 MAIN-B Board . . . . . . . 1-33

Page 12

Rev. A 1-iii

Page 13

EPL-5500 Service Manual General Description

1.1 FEATURES

The EPSON EPL-5500 is non-impact page printer that combines a semi-conductor laser with

electrophotographic technology. This printer is small and light, and features high-speed,

high-resol ut ion print ing. Mai nte nance is ver y easy as a result of various built-in di agnos t ic functions.

The main features are:

❏

No ozone

Printing speed — 6 ppm (pages per minute)

❏

Resolution — 600/300 dpi (dots per inch)

❏

Light weight — about 5 kg (11 lb)

❏

Small footprint

❏

Low running cost: separation of the development/toner cartridge and photoconductor unit

❏

HP LaserJet 4 emulation mode

❏

22 built-in scalable fonts (8 Agfa and 14 TrueType fonts)

❏

High-performance controller (the controller’s CPU is a 22.5 MHz SPARKlite (MB86933H))

❏

Bi Resolution Improvement Technology (BiRITech) refines the print quality by eliminating

❏

jagged edges from images and characters on 600 dpi and 300 dpi printing

Memory Improvement Technology suppor ted

❏

Optional EPSONScrip t Level 2 (PostScript compatible) module

❏

Optional WPS (Windows Printing System) ROM SIMM module

❏

❏

Optional I239X, ESC/P 2 , and FX emulation ROM SIMM module

EPSON Micro Gray Technology (EMGTech), which is available when using PCL and

❏

EPSONScript Level 2 mode, refines gray scale printing to be comparable to printing on a

1200-dpi printer

❏

Small and low-cost optional LocalTalk with ser ial interface module

1MB standar d RAM and memory expansion availabl e up to 32MB of RAM with the addition of

❏

opt ional SIM M s

Bidirectional parallel interface

❏

Toner-saver mode supported

❏

A multi-user, multi-emulation mode

❏

IES (Intel li gent Emul ation Switch) allows switching between EP SONScript mode and another

❏

mode

SPL (Shared Printer Language) enabl es switching of the printer mode by command

❏

Figure 1-1 shows an exterior view of the EPL-5500.

Figure 1-1. Exter ior View of the EPL-5500

Rev. B 1-1

Page 14

General Descript ion E PL-5500 Ser vice Manual

Table 1-1 lists the optional units available for the EPL-5500.

Table 1-1. Optio ns for the EPL-5500

Cat. No. Description Note

C83218✽

C83219✽

C83220✽

—

—

C812491

S050005 Developer cartridge Develo per and toner cartridge

S051029 Photoconductor unit —

C82334✽ LocalTalk with serial I/F module (see Note 3)

C83614✽ Interface cable RS-232C extens ion cable for C82334✽

C82335✽ Type-B EX box Type-B I/F card box (see Note 4)

Windows Printing System ROM SIMM Supports Window s Printi ng System

EPSONScript Level 2 ROM SIMM Supports EPSONScript Level 2 mode

(PostScript Level 2 compatible) fonts and

commands (see Note 1)

LQ/FX/I239X ROM SIMM Supports ESC/P 2, FX, and IBM

2390/2391 emulation modes

NLSP Bitmap 2 font ROM Supports local NLSP bitmap fonts

(see Note 2)

NLSP Scalable font ROM Suppor ts local NLSP scalable fonts

(see Note 2)

250-sheet lower paper cassette for the

EPL-5500 (A4/B5)

Lower paper cassette

C82307✽/

C82308✽

C82310✽/

C82311✽

C82312✽ LocalTalk card ( see Not e 5)

C82313✽ GPIB card (see Note 5)

C82314✽ COAX interface card (see Note 5)

C82315✽ TWINAX interface card (see Note 5)

C82324✽ Ethernet interface card for NetWare

C82328✽ FAX card (see Note 5)

C82331✽ Multi protocol Ethernet card (see Note 5)

Notes:

1. Requires added memory (RAM) over a total of 2 MB, including standard RAM.

2. NLSP font ROMs do not support ESC/P 2 and FX modes.

3. LocalTalk with ser ial I/F module (C82334✽ ) cannot be used with Type-B EX box (C82335✽).

4. Type-B EX box (C82335✽) cannot be used with LocalTalk with serial I/F module (C82334✽) .

5. Type-B EX box (C82335✽) must be installed while usin g the Type-B I/F card.

32 KB serial interface card (see Note 5)

32 KB parallel interface card (see Note 5)

(see Note 5)

1-2 Rev. B

Page 15

EPL-5500 Service Manual General Description

1.2 SP ECIFICAT IONS

This section provi des statisti cal data for the EPL-5500.

1.2.1 Basic Specifications

Printing method: Laser beam scanning and dry electrophotogra phy

Resolu tion: 600/300 dpi

Printing speed: 6 ppm (letter/A4)

First printing ti me (A4/LT): Less than 20 seconds (face-up output)

Warm-up time: Less than 35 seconds

(at rated current and 23° C (73° F) temperature)

Paper supply: See Table 1-2.

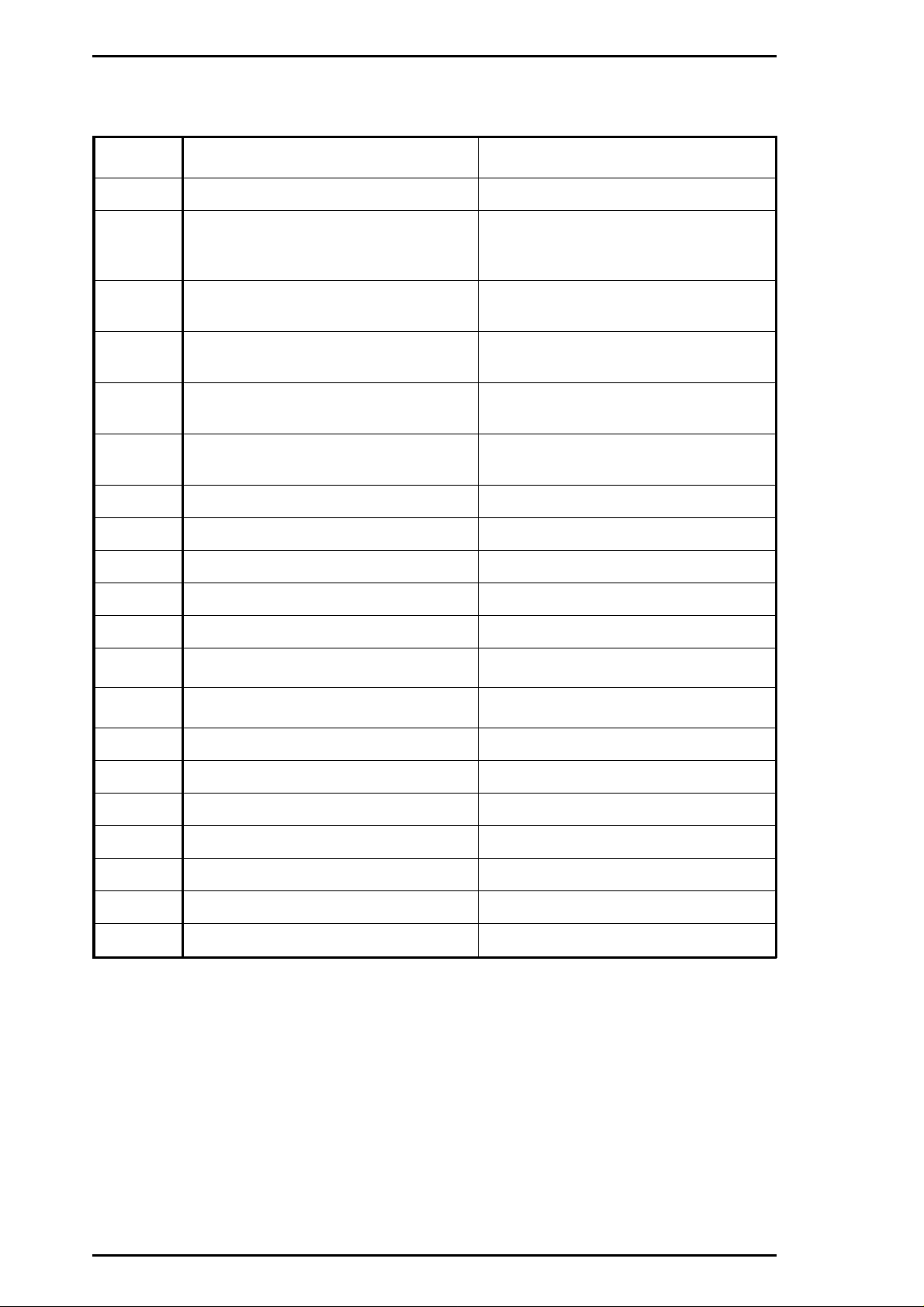

Table 1-2. Paper Feed Methods

Capacity Using

Paper Supply

Standard built-in paper tray 150 A5, B5, A4, LT,

Manual feed slot 1 Any size feedable

Lower paper cassette (optional) 250 A4, B5 16 to 24 lb.

Notes:

1.

The weight in pounds (lb) is determined by the weight of 500 sheets cut to 17 × 22 inches;

1 g/m2 = 0.2659763 lb.

2. Paper size range: width 3 to 8.5 inches (76 to 216 mm)

length 5 to 14.0 inches (127 to 356 mm)

20 lb. (75 g/m2)

Paper

5 to 10 Monarch,

Pap er Si z e

GLT, EXE, LGL,

GLG, F4, HL

DL, C5, C6,

International B5,

Commercial-10

(Note 2)

Usage Thick ness

(Ream Weight)

16 to 24 lb.

(60 to 90 g/m2)

Envelopes made

of 20 to 24 lb.

(75 to 90 g/m2)

paper

16 to 42 lb.

(60 to 157 g/m2)

(60 to 90 g/m2)

Paper types: See Table 1-3.

Table 1-3. Paper Types

Rev. B 1-3

Page 16

General Descript ion E PL-5500 Ser vice Manual

Standard paper Xerox 4024 DP paper

20 lb (75 g/m2)

Normal paper Regular photocopier paper

Bond paper

Recycled paper

16 to 24 lb (60 to 90 g/m2)

Special papers Card stock (90 to 157 g/m2)

Envelopes

Labels

Letterhead

Transparency (OHP) sheets

Colored paper

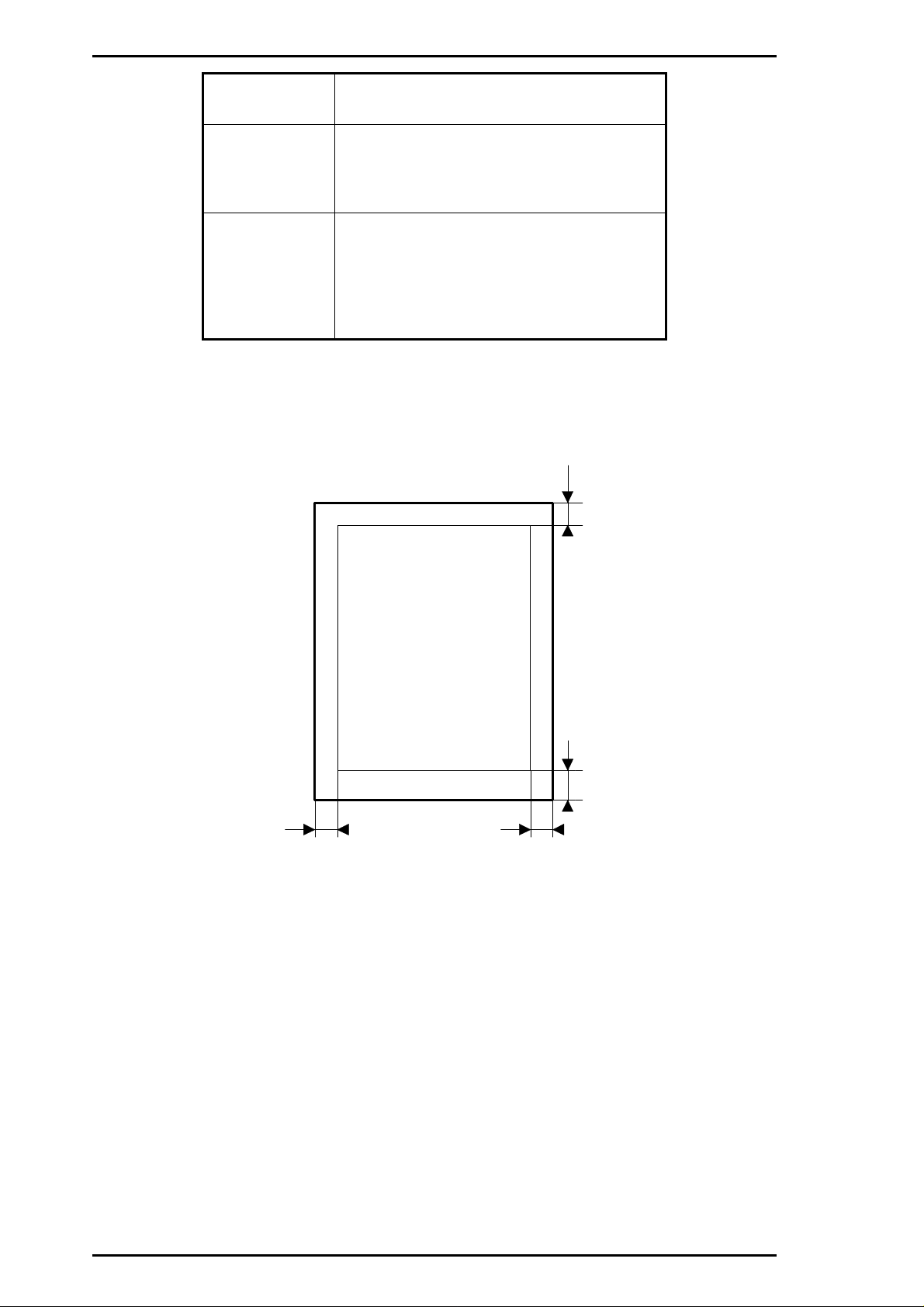

4.0 mm

Printable Area

4.0 mm4.0 mm

Figure 1-2. Printable Area

4.0 mm

1-4 Rev. B

Page 17

EPL-5500 Service Manual General Description

Usability of special papers: See Table 1-4.

Tab le 1- 4. Usabi li t y of S pecial Pa pers

Input OHP Envelopes Labels Card Stock Letterhead

Standard built-in

paper tray

Manual feed slot P P P P R

Lower paper cassette N N N N P

R: Reliable feeding and good image quality.

P: Possible, but better avoided.

N: Not supported.

Paper feed alignment and direction: Center alignment for all sizes

Paper ejection: Face down

Output tray capacity: 100 sheets (face down)

Printa ble area (standard paper): See Figure 1-2.

Note:

Noise: Less than 35 dB(A), standby

Ozone density: Less than 0.01 ppm

Toxici ty: No toxicity e xists i n organi c photoconduct or (OP C), toner,

The actual printable area depends on the printer mode.

PPPPR

Less than 47 dB(A), operating

or plastic material s

Rev. B 1-5

Page 18

General Descript ion E PL-5500 Ser vice Manual

1.2.2 Electrical Specifications

Table 1-5. Electrical Requirements and Ranges

Description 100 V Version 200 V Version

Rated voltage 100 ∼ 120 VAC 220 ∼ 240 VAC

Input voltage range

Rated frequency range

Input frequency range

Power consumption Less than 500 W Less than 600 W

Power consum ption while in

standby mode

90 ∼ 132 VAC 198 ∼ 264 VAC

50 ∼ 60 Hz

47 ∼ 63 Hz

Less than 15 W

(witho ut option)

1.2.3 Reliability Specifications

MPBF (Mean Prints Between Failures ): Over 25,000 sheets

Note:

MTBF (Mean Time Between Failures): 3000 power on hours (POH)

Jam rate: 1 out of 2,000 sheets or le s s (excluding multip le-s heet feeding)

Feed failure: 1 out of 2,000 sheets or le ss (excludi ng multip le-sheet fe eding)

Multiple paper feeds: 1 out of 500 sheets or less

Paper curl height: 30 mm (1.2 inches) or less

Leading edge bending (1 cm or more): 1 out of 1,000 sheets

MTTR (Mean Time To Repair): 30 minutes or less

Durability: 5 years or 180,000 sheets

MPBF indicates average number of pages printed bef ore occ urrence of pr oblem requiring

replacement or service.

1.2.4 Environmental Conditions for Operation (Including Imaging Cartridge)

Temperature:

Humidity: 15 to 85% RH

Altitude: 2,500 m (8,200 feet) or lower

Levelness:

Illuminance: 3,000 lux or less (Must not be exposed to direct sunl ight.)

Surrounding space: Printer should have at least 100 mm of clearance on its

10 to 35° C (50 to 95° F)

1°

sides and rear.

1.2.5 Environmental Conditions for Storage and Transportation

Temperature:

Humidity: 30 to 85% RH

Drop test: Clear to JIS Z0200-1987 Level 1

Vibration: Vibration frequency 5 to 100 Hz and 100 to 5 Hz

Resistance to atmospheric pressure: More than 61.3 KPa

Storage life: 18 m onths (followi ng date of manufactur e)

0 to 35° C (32 to 95° F)

Acceleration 1 G

Acceleration direction 3 direction

1-6 Rev. B

Page 19

EPL-5500 Service Manual General Description

1.2.6 Ap p licab le St andards

Safety Sta ndards

120 VAC model: UL 1950, CSA 22.2 No. 950 Deviation 3

220/240 VAC model: EN 60950 (IEC950), NEMKO (IEC950), SETI (IEC950),

SEMKO (IEC950), DEMKO (IEC950)

Safety Regulations (Laser Radiation)

12 0 VAC model: FDA (NCDRH) Class 1

220/240 VAC model: VDE 0837 (Laser Class 1) (IEC825), SETI (IEC 825) , SEMKO

(IEC825), DEMKO (IEC825)

EMI

120 VAC model: FCC Part 15 Subpart B Class B, DOC Class B

220/240 VAC model: Vfg 243 (VDE 0878 Part 3,3 0)

EN55022 Class B (CISPR Pub.22 Class B)

CE marking, EMC

Others

Toner: No effect on human health (OSHA-TSCA, EINE CS)

OPC: No effect on human health (OSHA)

Ozone: Less than 0.01 mmp

other UL478 (5th edition)

Materials: SWISS environmental law (must contain no CdS)

1.2.7 Specifications for Consumables

Life: Develo per and toner cartridge: 3,000 pages

Photo conductor unit : 20,000 pages

Note:

In continuous printi ng mode wit h A4/letter p aper at a 5% image ratio (black/whi te ratio).

The life varies, depending on the printing mode (continuous or intermittent) and/or the

image ratio.

Environmental Conditions for Storage and Transportation

Temperat ure:

Humidity: 30 to 85% RH

Drop test: Height 76 cm (30.4 inches)

Vibration: Same as printer

Resistance to atmospher ic pres sure: More than 74 Kpa

Storage term: 18 months (following date of manufacture)

0 to 3 5° C (32 to 95° F)

1.2.8 Physical Specifications

Dimensions (Width × Depth × Height):

Printe r: 352 × 264 × 299 mm (13.9 × 10.4 × 11.8 inches)

Weight: Approx. 5 kg (11 lb), with consumables, excluding all options

Rev. B 1-7

Page 20

EPL-5500 Service Manual General Description

1.2.9 Software Specifications

Built-in modes: HP LaserJet 4 emulation (P CL 5e)

EPSON GL/2 mode (GL-like mode)

Note:

EPSON GL/2 mode is similar to the GL/2 mode included in the HP LaserJet 4 emulation.

Table 1-6 shows the differences between EPSON GL/2 mode and the LJ4 GL/2 mode.

While in EPSON GL/2 mode, the operator can enter GL/2 mode without sending the

ESC %#B (Enter GL/2 mode) command. If the operator’s application software cannot

send the ESC %#B command, then use this mode.

Table 1-6. Differences between EPSON GL/2 and

GL/2 in the HP LaserJet 4 Emulation

EPSON GL/2 Mode

PCL mode Not available Initial mode

Paper eject Supports PG, AF commands Supported in PCL

Auto eject SelecType setting Not available

Reduced printing SelecType setting Available in PCL

Switch to PCL

(ESC %#A)

Reset (ES C E) Ejects paper and then initializes Ejects paper, switches to PCL,

PJL, EJL, and ES Supp orted Supported

Advance full page

(PG, AF)

Note:

Optional modes : EPSONSc r ip t Level 2 (PostScript Level 2 emulation) mode

Auxiliary software: Hex dump

Built-in fonts: See Table 1-7.

The EPL-5500 GL/2 mode features all the commands of the LJ4-GL/2 mode, plus a few

additional commands. The GL/2 mode emulates some of the HP-GL

etc.) commands. If the application software uses unsupported commands for the GL/2

mode, print cannot be assured.

FX (FX-870/ 1170, LX-100) emulation mod e

ESC/P 2 (Stylus 800/1000) emulation mode

WPS (Windows Printing System) mode

Status sheet

Font sample

Not supported Supported

Supported Not supported

GL/2 for HP LaserJet 4

Emulati on Mode

and then initializes

plotter (HP 7475A,

Table 1-7. Built-in Fonts

Resident Fon ts

Bitmap fonts

Line Printer16.66 cpi(Po rtrait)

Scalable fonts

Dutch

Dutch 801Bold SW C

Dutch 801Italic SW C

Dutch 801Bold Italic SWC

Swiss

Swiss 742Bold SWC

Swiss 742Medium Italic SW C

S: Supported, NS: Not Supported

801Roman SWC

742SWC

Applicable Mode

HP LJ4, GL/2

S

S

S

S

S

S

S

S

Rev. B 1-7

Page 21

General Description EPL-5500 Service Manual

Table 1-7. Built-in Fonts (Continued)

Applicable Mode

Resident Fon ts

Scalable fonts

Swiss 742Bold Italic SWC

Swiss 721Rom an SWM

Swiss 721Bold SWM

Swiss 721Oblique SWM

Swiss 721Bold Oblique SWM

Dutch 801Roman SWM

Dutch 801Bold SW M

Dutch 801Italic SW M

Dutch 801Bold Italic SWM

Symbol SetSWA

More WingBatsSWM

CourierSWC

CourierBold SW C

CourierItalic SWC

CourierBold Italic SWC

S: Supported, NS: Not Supported

HP LJ4

GL/2

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

1-8 Rev. B

Page 22

EPL-5500 Service Manual General Description

1.3 INTERFACE SPECIFICATIONS

The EPL-5500 is eq uip ped with the following externa l inter fac es :

❏ Par allel inte rfac e

❏ Optio n al Loca lTalk/serial interface

❏ Optio n al Type B interface with Type-B EX box

1.3.1 Parallel Interface

The parallel interface has the following two modes:

❏ Com patibility mod e (s ame as par allel in te rfac e for EPS ON’ s cu rre n t page prin te r)

❏ Rev er se mo de

1.3.1.1 Parallel Interface Compatibility Mode

System: STROBE synchronization, 8-bit par allel data tran sf er

Handshakin g: BUSY and

Connector type: P90-25027-1 (Amphenol) recept acle

Applicable plug: 57-30360 (A mph enol or equivalent)

Transfer spe e d : Approximat ely 400, 000 bytes/second (ma x.)

Signal timing: S ee F ig ur e 1-3.

Signal descript ion : See Table 1-8.

ACKNLG signals

DATA 1-8

STROBE

0.5

BUSY

ACKN LG

0.5 µ s

(minimum)

0.5 µ

s

(minimum)

VALID VALID

0.5

s (minimum)

µ

s (maximum)

µ

0 s

0.5 or 5 µ

s

(min.)

(minimum)

1 or 10

s

µ

(typical)

Figure 1-3. Compatibility Mode Signal Timing

Rev. B 1-9

Page 23

General Description EPL-5500 Service Manual

Table 1-8. Parallel Interface Pin Assignments

Pin No. Signal Name I/O Description

STROBE

1

STROBE is a strobe pulse used to read data from the host

computer. The pulse width must be more than 0.5 µsec.

IN

Normally it is HIGH, and data is latched at the trailing edge of

this signal.

2-9

10

11

12

13

14

15

16

DATA 1-8

ACKNLG

BUSY

PE

SLCT

AUTO-FEED

NC

GND

DATA 1 to 8 are parallel data bits. Whe n the sig nal is HIGH, the

data bit is 1, and when it is LOW, the data bit is 0. The most

IN

significant bit (MSB) is DATA 8. The signal state must be

maintained for 0.5 µsec. on either side of the

active edge.

ACKNLG is an acknowledge pulse with an approximate width

of 1 or 10 µsec. This signal goes LOW when the data reception is

OUT

completed, which indic ates tha t the printer c an ac ce pt new data.

Timing with the BUSY signal is specified through SelecType.

The BUSY signal informs the host computer of the printer state.

OUT

When the signal i s HIGH, the pr i nter cann ot accept d a ta.

The PE signal indicates paper empty for the standard tray

OUT

selected through SelecType or command, or for the optional

paper cassette. Paper empty is indicated by HIGH.

OUT

Used in reverse mode.

IN

Not used.

—

Not used.

—

Logic ground level.

STROBE signal

17

18

19-30

31

32

33

34

35

36

CHASSIS GND

NC

GND

INIT

ERROR

GND

NC

+5

SLCT IN

Connected to the pr inter chassis . The print er chassis GND and

—

the signal GND ar e c onn ec ted to each other.

—

Not connected.

—

Ground level for the twiste d pair r eturn signal.

IN

The

STROBE signal is ignored when this signal is LOW.

This level goes LOW whe n the pr inter is:

• Out of paper

OUT

• Paper jam

• In the error state

• Off line

—

Same as for pi n s 19 t o 30.

—

Not used.

—

Pulled up to +5 V throu gh 1. 0K -ohm resistance.

—

Used in reverse mode.

1-10 Rev. B

Page 24

EPL-5500 Service Manual General Description

1.3.1.2 Reverse Mode

Reverse mode for the EPL-5500 supports the IEEE-P1284 nibble mode. This printer can run in

reverse mode, in which the printer can inform the computer of its status with EJL and PJL

commands.

System: IEEE-P1284 nibble mode

Connector type: P90-25027-1 (Amphenol) recept acle

Applicable plug: 57-30360 (A mph enol or equivalent)

Signal descript ion : See Table 1-9.

Table 1-9. Parallel Interface Pin Assignment

Pin No. Signal Name I/O Description

1

STROBE

HostClk: This signal is a strobe pulse used to read extension

IN

request values from the host computer durin g n egot iat ion.

DATA 1-8

2-9

10

ACKNLG

BUSY

11

PE

12

SLCT

13

AUTO-FEED

14

15

NC

16

GND

CHASSIS GND

17

These signals are data bits of extension request values received

during negotiation. Th is printer suppo rts fo llowing v alues :

IN

0000 0100: Requ es t Device ID (sent in nibble mode)

0000 0000: Requ es t nibble mod e

OUT

PtrClk: Printer sends clock data.

PtrBusy: P rinter s ends da ta bits 3 and 7 during d ata tr ansfer to

OUT

host computer.

AckDataReq: Printer sends data bits 2 and 6 during data

OUT

transfer to host computer.

Xflag: Printer sends data bits 2 and 6 during data transfer to

OUT

host computer.

HostBusy: This signal informs the printer of the host computer’s

IN

state. When the signal is HIGH, the host computer cannot

accept data.

—

Not used.

—

Logic ground level.

Connected to the pr inter chassis . The print er chassis GND and

—

the signal GND ar e c onn ec ted to each other.

18

19-30

31

32

33

34

35

36

NC

GND

INIT

ERROR

GND

NC

+5

SLCT IN

—

Not connected.

—

Ground level for the twiste d pair r eturn signal.

IN

nInit: Fixed at HIGH level.

nDataAvail: Printer sending data bits 0 and 4 during data

OUT

transfer to host computer.

—

Same as for pi n s 19 t o 30.

—

Not used.

—

Pulled up to +5 V throu gh 1. 0K -ohm resistance.

1284Active: If this signal is set to HIGH, this printer is actively

IN

in P1284 (rev er se mode).

Rev. B 1-11

Page 25

General Description EPL-5500 Service Manual

Compatibility Mode

Forward

Data

Transfer

ERR=HIGH

No da ta se nt

Host Busy

Data Not

Available

AUTO

FEED=LOW

STROBE

ACK and BUSY

SLCT IN=HIGH

ERR=HIGH

No da ta se nt

Forward

Idle

Negotiation

Reverse

Data

Transfer

Failed

Negotiat ion

Sending data

ERR=LOW

Sending data

AUTO

FEED=LOW

Request to

send data

Terminate

SLCT IN=LOW

ERR=L OW

Host Busy

Data

Available

AUTO

FEED=HIGH

Reverse

Idle

ERR=LOW

Figure 1-4. Parallel Interface State Switch Diagram

Figure 1-4 shows the switch diagram for the parallel in te rf ac e st ate.

Interrupt

Host

1-12 Rev. B

Page 26

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

Peripheral Busy StatusBUSY

PE

SLCT

ERROR

HB DA Negotiation

HB DA or

HB DNA

(Note 3)

Idle or

Transfer

Bit 3 Bit 7

Bit 2 Bit 6

Bit 1 Bit 5

Bit 0 Bit 4

Peripheral Busy Status

Note 1

Note 1

Note 2

EPL-5500 Service Manual General Description

Figure 1-5 shows the negotiation timi ng char t .

DATA 00h or 04h

SEL-IN

STROBE

AUTO-FEED

ACKNLG

Peripheral Busy StatusBUSY

Current Peripheral StatusPE Note1

Note 2SLCT

Current Peripheral StatusERROR Note1

Compatibility Negotiation HB DA or

Figure 1-5. Negotiation Timing Chart

Notes:

1. This signal is set to HIGH when no data is being sent .

This signal is set to LOW during sending of data.

2. This signal is set to HIGH if the extension request value was 04h.

3. HB DA: Host Busy Data is Available

HB DNA: Host Busy Data is Not Available

Figure 1-6 shows the data transfer timing chart.

Notes:

HB DNA

(Note 3)

Idle or

Transfer

1. This signal is set to HIGH when no data is being sent .

This signal is set to LOW during sending of data.

2. This signal is set to HIGH, if extension request value was 04h.

3. HB DA: Host Busy Data is Available

HB DNA: Host Busy Data is Not Available

Rev. B 1-13

Figure 1-6. Timing Chart for Data Transfer

Page 27

General Description EPL-5500 Service Manual

Figure 1-7 shows the t i ming chart for termination.

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

PE

SLCT

ERROR

Note 3

Peripheral Busy StatusBUSY

Note 1

Note 2

HB DNA, Idle,

or HB DA

Termination Compatibility

Figure 1-7. Termina tion Timing Chart

Notes:

1. The signal is HIGH when HB DNA.

The signal is LOW when HB DA.

2. The signal is set to HIGH, if the extension reques t value was 04h .

3. Idle = LOW.

Figure 1-8 shows the t i ming cha rt for in terr u pts .

Peripheral Busy Status

Current Peripheral Status

Current Peripheral StatusNote 1

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

PE

SLCT

ERROR

Note:

Peripheral Busy StatusBUSY

Note 1

Reverse Idle Interrupt

Figure 1-8. Timing Chart for Interrupts

The signal is set to HIGH, if the extension re que st value was 04 h.

HB DA Transfer

1-14 Rev. B

Page 28

EPL-5500 Service Manual General Description

1.3.2 Serial Interfac e

This printer can use the optional LocalTalk/serial interface module.

Type: RS-232C/current loop

Transfer system: Full duplex

Synchronization: Asynchronous start-stop system

Start-bit: 1 bit

Stop-bit: 1 or 2 bits

Data length: 7 bits or 8 bits

Parity: Odd, even, or none

Protocol: X-ON/X-OFF (can be c ombined wit h D TR con t ro l)

DTR control (can be c ombin ed with X-ON/X-OFF)

Transfer speed: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, or 57600 bps

Error: Overrun error: Processed as missing data and replaced by “*”

Pari ty error: Repla ced by “*”

Framing error: Replaced by “*”

Breaking c h ar ac te r: Ignored

Signal descript ion : See Table 1-10.

Table 1-10. Serial Interface Pin Assignments

Pin No. Signal Name I/O Description

CHASSIS-GND

1

Connected to the pr inter chassis . The print er chassis GND and

—

signal GND are connected to each other.

TXD

2

RXD

3

5

CTS

7

SIGNAL-GND

TTY-TXD

17

DTR

20

Serial ASCII data output by the printer. It maintains the

“MARK” state (LOW level) between transmitted character

OUT

codes. Logic 0 is at HIGH level (SPACE) and logic 1 is at LOW

level (MARK).

Serial ASCII data input to the printer. It maintains “MARK”

IN

state (LOW leve l) betw een r ec eiv ed character codes.

IN

Always ignored.

—

Ground.

Current loop signal: HIGH impedance (SPACE) between pins

17 and 24 or X-ON signal sent across pins 17 and 24 indicates

OUT

that the printer is ready to accept data; LOW impedance

(MARK) or X-OFF signal being sent indicates that the printer is

busy.

Signal output by printer. When the DTR signal is HIGH, the

printer can receive the RXD signal. The SelecType settings do

not specify DTR control, the signal level is HIGH while printer

OUT

power is on. When the SelecType setting is used for DTR

control, DTR goes LOW in case of any error conditions. The

data (RXD) from host computer must be stopped within 128

characte r s after DTR goes LOW.

23

TTY-RXD Retu rn

24

TTY-TXD Retur n

25

TTY-RXD

Note :

Rev. B 1-15

The DTR state can be selected through printer settings.

—

Current loop signal: Current return for pin 17

—

Current loop sign a l : Inp u t data current loop

IN

Current loop signal: Current return for pin 25

Page 29

General Description EPL-5500 Service Manual

Handshaking

When the vacant area for data in the input buffer drops to 256 bytes, the printer outputs an X-OFF

code or sets the DTR signal level to LOW, indicating that the printer cannot receive more data.

Once the vacant area for data in the buffer recovers to 512 bytes, the printer outputs an X-ON code

or sets the DTR flag to HIGH, indicating that the printer is again ready to receive data.

Protocol

There are two types of protocols, as listed below, and each of them can be designated by SelecType

independentl y.

❏

DTR/DSR protocol

SelecType is used to execute the DTR/DSR control protocol. The DTR signal is set to HIGH when

the printer is ready to receive data, and to LOW when conditions indicate an error or that the

receiving buffer is full.

When the error is cleare d a nd the print e r ret urns to on-line mode, the signal returns to HIG H. When

SelecType is used to set the DTR control OFF, DTR is always set to HIGH. The printer transmits

TXD only when DSR is at the HIGH level (DSR is always considered HIGH when the SelecType

setting for DSR is OFF). X-ON/X-OFF tran sm issi on is indepen d en t of the DSR state.

❏ X-ON/X-OFF (DC1/DC3) protocol

SelecType is used to execute the X-ON/X-OFF protocol. The X-OFF (DC3) code is output if status

indicates an error, and the printer warns the host to stop data transmission within 256 characters.

No further X-OFF codes are sent in response to additional data received from the host after the

X-OFF code has been sent once. The X-ON (DC1) code is output after all conditions given in the

error are cleared .

When the remaining capacity of the receive buffer reaches 512 characters, X-OFF (DC3) is output

once. It is sent only once, even if there are multiple errors. The printer goes on line automatically at

power on, and outputs an X-ON code. Transmission of X-ON/X-OFF codes can be defined by

SelecType.

1-16 Rev. B

Page 30

EPL-5500 Service Manual General Description

1.3.3 Optional LocalTalk Interface

This printer can use the optional LocalTalk/ serial int er fac e mod ule.

Type: LocalTalk

Signal level: Same as RS-422 sign al level

Protocol: X-ON/X-OFF (can not be co mbin ed wit h DTR c on trol)

DTR control (cann ot be combined with X-ON/X-OFF)

Transfer speed: 230.4K bps

Signal descript ion : See Table 1-11.

Table 1-11. LocalTalk Interface Pin Assignments

Pin No. Signal Name I/O Description

DTR

1

Signal output by the printer. When the DTR signal is HIGH, the

OUT

printer can receive the RXD signal.

2

CTS

TXD-

3

4

GND

RXD-

5

6

TXD+

7

NC

8

RXD+

IN

The printer transmit s the data through T XD while CTS is HIGH.

Serial ASCII d a ta output f rom the pri n ter.

HIGH level; whe n SD+ voltag e is high er than t h e SD - voltage.

OUT

LOW level; when SD+ voltage is les s th an the SD - voltage.

Logic 0 is SPACE and logic 1 is MARK. The state must be

main tained be tween transmitted character codes.

—

Ground.

Serial ASCII data input fr om c ompu t er .

HIGH level; when RD+ voltage is high er than RD - voltage.

IN

LOW level; when RD+ voltage is les s th an RD - vo ltage .

Logic 0 is “SPACE” and logic 1 is “MARK” state must be

main tained be tween transmitted character codes.

OUT

Refer to TXD-.

—

No connect.

IN

Refer to RXD-.

Rev. B 1-17

Page 31

General Description EPL-5500 Service Manual

1.4 OPERATING INSTRUCTIONS

This section describes functions performed through the control panel, such as printing a status

sheet, hexadecimal dump, and printer settings functions.

1.4.1 Control Pane l

The printer control panel gives you easy control over most common printer operations. The panel

consists of indicator lights and a button.

LED (Yellow)

LED (Red)

Button

Figure 1-9. Control Panel

Indicator lights

❏

Yellow light

ON: Communication with the host is possible.

Fast flashing: Receiving data or warming up.

Slow flashing: Received data is stored in the printer but has not been printed.

OFF: Printer is power off.

❏

Red light

ON: Paper jam or cov er open .

Fast flashing: Feed jam, paper empty.

Slow flashing: One of these errors: SOFT ERROR, PRINT OVERRUN, MEMORY OVERFLOW,

CHECK PAPE R SIZE , IMA GE OP TIMUM

OFF: No error condition.

1-18 Rev. B

Page 32

EPL-5500 Service Manual General Description

Functions of Pressing the Button

❏

While the Red light flashe s slowly:

Function of button Clears an error.

Operation Hold down the button until the yellow and Red lights both go on

after release. The prin ter prin ts a status sheet in dicatin g the er r or

type.

❏

While the Red light flashes fast:

Function of button Prints any of the following page.

- Feed jam or paper empty page

- Manual feed page

Operation Load the pape r or c lear the jam, and then hold down the button

until the yellow and Red lights go on, then release to continue

printing.

❏

While yellow light is flashing slow ly (ex cep t in EPSONS cript mod e):

Function of button Prints out data in the printer’s memory.

Operation Hold down the button until the yellow and red lights go on, then

release the button to continue printing.

❏

While the yellow light is on (except in W PS mod e):

Function of button Prints a status sheet.

Operation Hold down the button until the yellow and red lights go on, then

release the button to continue printing. The yellow light flash while

the status sheet is being printed.

❏

Reset (always effective ex ce pt du ring w ar m up or status sheet print ing ):

Function of button Clears current port.

Operation Hold down the button until the yellow and red lights go on, and

when these lights start flas h in g altern at ely, release the button.

❏

Warm boot (always effective except during warm up or status sheet printing):

Function of button Warm boot (same as power on reset, except for engine initialization).

Operation Hold down the button until the yellow an d red ligh ts start flas h in g

at the same time, then release the button.

Rev. B 1-19

Page 33

General Description EPL-5500 Service Manual

1.4.2 Printer Settings Functions

The printer settings function from the Remote Control Panel (software) lets the user control most of

the printer’s functions, such as printing test pages, selecting a paper size, and changing the printer’s

configuration. Table 1-12 shows the prin ter se ttin gs options.

Table 1-12. Printer Settings

Menu It em Avai lab le Options

PRINTING COPIES 1 to 999

PAGE SIZE A4, A5, B5, LT, H LT, LGL, G LT, GLG, EXE ,

F4, MON, C10, DL, C5, IB5, CTM

ORIENTATION PORT, LAND

MANUAL FEED OFF, ON

RITech OFF, LIGHT, MEDIUM, DARK

TONER SAVE OFF, ON

LJ4 FONT SRC RESIDENT, SIMM, DOWN LO AD

FONT NUMBER 0 to (available)

PITCH 0.44 to 99.99 CPI (0.01 steps)

HEIGHT 4.00 to 999.75 PT. (0.25 steps)

SYMSET Roman-8, ECM94-1, 8859-2 ISO, 8859-2 ISO,

IBM-US, IBM-DN, PcMultiling, PcE.Europe,

PcTk437, WiAnsi, WiE.Europe, WiTurkish,

DeskTop, PsText, VeInternati, VeUS,

MsPublishin, Math-8, PsMath, VeMath,

PiFont, Legal, UK, ANSI ASCII, Swedis2,

Italian, Spanish, German, Norweg1,

French2, Windows

FORM 5 to 128 lines

SRC SYMSET* 0 to 3199

DEST SYMSET* 0 to 3199

PS* ERR SHEET OFF, ON

MicroGray OFF, ON

PROTECT LEV EL 1 to 5

ESCP2* Font Courier, Roman, Sans serif, Roman-T,

Sans-H, Script

Pitch 10 CPI, 12 CPI, 15 CPI, Prop

Condensed OFF, ON

T-Margin 0.40 to 1.50 Inch (0.05 steps)

Text 1 to (available) lines

CG Table Pc USA, Italic, PcMultilin, PcPortuguese,

PcCanFrenc, PcNordic, PcTurk2,

Pc.E.Europe, BpBRASCII, BpAbicomp

Country USA, France, Germany, UK, Denmak,

Sweden, Italy, Spain1, Japan, Norway,

Denmark2, Spain2, LatinAmeric, Korea,

Legal

* With option

Table 1-12. Printer Settings (Co ntinued)

Menu It em Avai lab le Options

1-20 Rev. B

Page 34

EPL-5500 Service Manual General Description

ESCP2 * (Con tinued) Auto CR ON, OFF

Auto LF OFF, ON

Bit Image Dark, Light, BarCode

Zero Char

FX* Font Courier, Prestige, Roman, Sans serif, Script

Pitch 10 CPI, 12 CPI, 15 CPI, Prop

Condensed OFF, ON

T-Margin 0.40 to 1.50 Inch (0.05 steps)

Text 1 to (available) lines

CG Table Pc USA, Italic, PcMultilin, PcPortuguese,

Country USA, France, Germany, UK, Denmak,

Auto CR ON, OFF

Auto LF OFF, ON

Bit Image Dark, Light, BarCode

Zero Char

I239X* Font Courier, Prestige, Gothic, Orator Script,

φ

0,

PcCanFrenc, PcNordic, PcTurk2,

Pc.E.Europe, BpBRASCII, BpAbicomp

Sweden, Italy, Spain1, Japan, Norway,

Denmark2, Spain2, LatinAmerica

φ

0,

Presentor

* With option

Pitch 10 CPI, 12 CPI, 15 CPI, 17 CPI, 20 CPI, 24

CPI, Pro p

Code Page 437, 850, 860, 863, 865

T-Margin 0.40 to 1.50 Inch (0.05 steps)

Text 1 to (available) lines

Auto CR OFF, ON

Auto LF OFF, ON

Alt.Graphics OFF, ON

Bit Image Dark, Light, BarCode

Zero Char

0,

φ

Rev. B 1-21

Page 35

General Description EPL-5500 Service Manual

Table 1-12. Printer Settings (Co ntinued)

Menu It em Avai lab le Options

JOB PAG E PROTECT AUTO, ON

RESOLUTION 600, 300

IMAGE OPTIMUM AUTO, OFF, ON

TIMEOUT 5 to 300

EMULATIO N PARALLEL LJ4, ESCP2*, FX*, I 239X*, PS*, GL2, AUTO*

SERIAL* LJ4, ESCP2*, FX* , I239X*, P S*, GL 2, AUTO*

L/T* LJ4, ESCP2*, FX*, I239X*, P S*, GL 2, AUTO*

AUX* LJ4, ESCP2*, FX* , I239X*, P S*, GL 2, AU TO *

CONFIG AUTO CON T OFF, ON

STANDBY ENABLE, DISABLE

DENSITY 3, 4, 5, 1, 2

INTERFACE AUTO, PARALLEL, SERIAL*, L/T*, AUX*

TOP OFFSET 0 to 99

LEFT OFFSET 0 to 99

PAGE COUNT 0 to 262143

PARALLEL SPEED FAST, LOW

BI-D ON, OFF

SERIAL WORD LENGTH 8, 7

BAUD RATE 9600, 19200, 38400, 57600, 300, 600, 1200,

2400, 4800

PARITY NONE, EVEN, ODD

STOP BIT 1, 2

DTR ON, OFF

XON/XOFF ON, OFF

TEST STATU S SHEET —

PS STATUS SHEET* —

PS FONT SAMPLE* —

PS FACT SHEET* —

EXT PRINTER INFO —

* With option

1-22 Rev. B

Page 36

EPL-5500 Service Manual General Description

1.4.3 Service Mode

This printer has the following four serv ice mod es:

❏

Hexadecimal dump mode

❏

EEPROM format mode

❏

Factory reset mode

❏

Default setting mode

Each service mode can be activatted selectively, by turning the printer on while hold down the

button and release it at the correspond ing tim in g shown in table below .

Table 1-13. Serv ice Mo de Se lect Tim ing

Order Pattern

1

2

3

4

5

6

*1: Can be performed by the user.

Pattern 0-0

Pattern 0-1

Pattern 1

Pattern 2

Pattern 3

Pattern 4

LED

(Yellow)

ON ON

OFF OFF

ON OFF

OFF ON

ON OFF

OFF OFF

LED

(Red)

Mode

NA

NA

Hexadecimal dump mode

EEPROM Initialize mode

Factory reset mode

Default setting mode *1

1.4.3.1 Hexadecimal Dump Mode

Hexadecimal dump mode is a useful tool in troubleshooting data control problems. To enter

hexadecimal dump mode, release the button at the mode select timing "Pattern-1". To quit the

hexadecimal dump mode, turn off the printer or perform the warm-boot operation.

1.4.3.2 EEPROM Initialize Mode

EEPROM initialize operations are required only when the main board or EEPROM is replaced and

these operations are spec ified in the accompanying documen ta tion.

This mode resets all user settings to the factory default settings and clears the printer status

information (page counter and jam counter). To perform EEPROM initialize mode, release the

button at the mode select timing "Pattern-2" and press the bottun again within 2 seconds from the

release. The LED lights flashes alternately during the initialization. If the button is not pressed

within 2 seconds afte r release, the printer enters nomal state wit h out init ialize operation.

1.4.3.3 Factory Reset Mode

The factory reset mode resets the printer settin gs to the factory def ault settings (the page counter

and jam co unte r are no t cl eare d). T o ent er fa ctory re set mode, releas e the but ton a t the mode s elec t

timing "Pattern-3" and press the button again within 2 seconds after release. The LED lights flashes

alternat ely during the rese t operation. If the button is no t p re ssed within 2 seco nds after releas e , the

printer enters the nomal state without r eset operatio n .

Rev. B 1-23

Page 37

General Description EPL-5500 Service Manual

1.4.3.4 Default Settings

The default settings function is used to enter printer settings. The procedure for entering default

settings is:

1. To enter the default settings mo de, turn on the printer whil e holdi ng down the button until

yellow and red lights turn off and on and off .

2. Press the button the number of times for the 1st code, while the yellow light is flas h ing .

3. Press the button the number of times for the 2nd code, while the red light is flashing.

4. Press the button the number of times for the 3rd code, while all lights flash.

5. If you need end the default settings mode, return step 2 and input the "111" code.

If you n e ed set th e other sett i ngs, return to ste p 2.

Thable 1-14 shows default settings co de s.

Table 1-14. Default Settings Codes

Default Settings

Menu Item Available Options

Code

End of default settings mode

Codes

1st

2nd

Code

111

3rd

Code

PARALLEL SPEED FAST

SLOW

Bi-D ON

OFF

SERIAL* WORD LENGT H 8

7

BAUD RAT E 960 0

19200

38400

27600

300

600

1200

2400

4800

PARITY NONE

EVEN

112

113

114

115

121

122

123

124

125

131

132

133

134

135

141

142

143

ODD

STOP BIT 1

2

DTR ON

OFF

XON/XOFF ON

OFF

* With option

Table 1-14. Defau lt Set tings Code (Continued )

Menu Item Available Options

1-24 Rev. B

144

145

151

152

153

154

155

Default Settings

Codes

1st

Code

2nd

Code

3rd

Code

Page 38

EPL-5500 Service Manual General Description

EMULATION PARALLEL LJ4

ESCP2*

FX*

I239X*

PS*

GL2

AUTO*

SERIAL* LJ4

LT*

AUX*

SERIAL* ESC/P2*

LT*

AUX*

SERIAL* FX*

LT*

AUX*

SERIAL* I239X*

211

212

213

214

215

221

222

232

233

234

235

* With option

LT*

AUX*

SERIAL* PS*

LT*

AUX*

SERIAL* GL/2

LT*

AUX*

SERIAL* AUTO*

LT*

AUX*

241

242

243

Rev. B 1-25

Page 39

General Description EPL-5500 Service Manual

Table 1-14. Default Settings Code (Continued)

Deafult Settings

Menu Item Available Options

Code

ESC/P2* / FX* C G Table PcUSA

Codes

1st

2nd

Code

253

3rd

Code

Italic

PcMultilin

PcPortugue

PcCanFrenc

PcNordic

PcTurkish

PcE.Europe

BpBRASCII

BpAbicomp

STATUS SHEET LANGUAGE ENGLI S H

FRENCH

GERMAN

ITALIAN

SPANISH

PRINTING PAGE SIZE A4

LT

LGL

254

255

311

312

313

314

315

321

322

323

324

325

331

332

351

352

353

CTM

ORIENTATION PORT

LAND

MANUAL FEED OFF

ON

TONER SAVE R OFF

ON

JOB RESOLUT I ON 600

300

CONFIG AUTO CONT OFF

ON

STANDBY ENABLE

DISABLE

INTERFACE AUTO

PARALLEL

SERIAL

LT

354

355

411

412

413

414

415

421

422

423

424

425

431

432

433

434

435

AUX

* With option

1-26 Rev. B

441

Page 40

EPL-5500 Service Manual General Description

1.4.4 Display of Messag es

This pr inte r ind ica tes t hree type s of messa ges w ith t he LED lig hts o r s tatus she et: stat us m ess ages ,

error messages, and the service call error message.

1.4.4.1 Status Messages

The LED lights normally indicate the printer’s status. (Refer to Section 1.4.1.)

1.4.4.2 Error Messages

If any of the following errors occurs, it will be printed on the status sheet (Refer to Section 1.4.2.).

Clear the error immediately using the measures shown in the following table.

Table 1-15. Error Messages

Message Status Measures

SOFT ERROR Print er detected a CPU error or soft

error. (Refer to Chapter 5.)

PAPER JAM A paper jam has occurred. Open the cover and remove the

PRINTER OPEN Cove r i s open. Close the c o ver.

MANUAL FEED Select manual feed and begin

printing data.

PAPER SET No paper is left in either the

standard tray or the optional

cassette.

PRINT OVERRUN Engine speed faster than print image

processing.

MEM OVERFLOW Data has filled the buffer. Confirm and press the button. And

CHECK PAPER SIZE The paper si ze in the tray is di fferen t

from the paper size chosen.

IMAGE OPTIMUM The printer uses a lower print

quality.

—

jammed paper. Then clo se th e cover.

Insert paper and press button.

Load paper in paper tray or optional

cassette and press button.

Press the button.

add optional SIMM.

Change the paper and print again.

Erase downloaded data or add a

SIMM.

1.4.4.3 Service Call Error Message

The LED lights flash r an d omly, wh en the printer detects a s er vice c all er ro r. (Refer to Chapter 5.).

Rev. B 1-27

Page 41

General Description EPL-5500 Service Manual

1.4.5 Printer Sharing

This section describes printer sharing. This printer has two methods of printer sharing, port fixed

mode and auto sense mode . These modes a re selected by “INTE RFACE” in the printer sett ings

menu.

1.4.5.1 Port Fixed Mode

When the printer is in port fixed mode, only one interface port is active. Data from other ports is

ignored.

1.4.5.2 Auto Sense Mode

HP mode

ESC/P2 mode

FX mode

GL2 mode

EPSONScript

mode

HP mode

ESC/P2 mode

FX mode

GL2 mode

EPSONScript

mode

Switc hed by

print er sett ings

Input buffer

Memory

User 1

User 2

Mode Assignment

Parallel

Mode Assignment

L/T or

Seri al or

AUX

Figure 1-10. Port Fixed Mode

It is possible to allocate each mode to parallel, serial, L/T, and AUX. The entire memory will be

allocated to the channels that are us ed . Th e interface that receives the data first will print first.

HP mode

ESC/P2 mode

FX mode

GL2 mode

EPSONScript

mode

Input buffer

Auto Sense

User 1

Mode Assignment

Parallel

User 2

Mode Assignment

Serial or

L/T or

AUX

Figure 1-11. Auto Sense Mode

HP mode

ESC/P2 mode

FX mode

GL2 mode

EPSONScript

mode

Memory

Input buffer

1-28 Rev. B

Page 42

EPL-5500 Service Manual General Description

1.4.6 Emulation Mode Switch Function

This section describes the emulat ion mode switch function.

1.4.6.1 Emulation Switch by SPL

The two types of emulation switch function described below are available on this printer. Together

they are referred to as SPL (Shared Printer Language).

EJL: EPSON Job Language

This is EPSON’s original language system. It is used to skip among various destinations, as shown

in Figure 1-12.

PJL: Printer Job Language

This is HP’s original language, which is available with LaserJet 4 printer. It is used to skip among

various destinations, as shown in Figure 1-12. The precise specifications for this language are based

on HP LaserJet 4.

The figure below shows three types of mode switchin g.

Neither EJL no r PJL swit ches the mode directly. They first exit the current mode and return to EJL

or PJL. Then they en t er an ot h er mode.

1.4.6.2 Intelligent Emulation Switch

LJ4

EJL

FX

EPSONScript

PJL

ESC/P 2

EPSON GL/2

Figure 1-12. Emulation Switch by SPL

Intelligent Emulation Switch (IES) automatically switches emulation mode, depending on the data

sent from the host computer through one of the interface channels. It is able to switch between

EPSONScript and other modes as shown in the figure below.

1.4.7 Bi Resolution Improvement Technology

LJ4

ESC/P 2

EPSONScript

FX EPSON GL/2

Figure 1-13. Intelligent Emulation Switch

The EPL-5500 printer has BiRITech (Bi Resolution Improvement Technology), which is designed to

improve print quality at 600 dpi and 300 dpi. By this method, the dot map data extracted from the

image data is reassembled to improve prin t data .

Rev. B 1-29

Page 43

A

B

General Description EPL-5500 Service Manual

The main improvement of this technique is in eliminating “jaggies” in diagonal lines. It is most

effective when the dot m ap data fi ts the development characteristic s o f the printer mechanism well .

It is therefore necessar y to set appropriat e value s in printer settings .

Note:

BiRITech is not as effective for printing a mesh pattern or gray scale. In such cases,

BiRITech must be set to OFF. (The default setting is MEDIUM.) Since the BiRITech effect

depends on the toner condition, ad jus ted it w hen the ima g ing cart ridge is repla ce d or after

the imaging cartridge is used for a long time .

1 inch

1 inch

1 2 600

1

2

3

4

5

6

7

8

34

R

600

(When 600 DPI printi ng)

Figure 1-14. Effect of BiRITech

The following settings are available in printer settings for RITech: DARK, MEDIUM, LIGHT, OFF.

The status sheet has the following RITech test image. When the toner density of area A is almost the

same as that of area B (as shown in the figure below), the RITech setting is at its optimum setting. In

other words, the optimum setting is achieved when it is difficult to distinguish the shape of area A

from that of B.

Figure 1-15. RITech Adjustment

1-30 Rev. B

Page 44

EPL-5500 Service Manual General Description

1.4.8 Toner Save Mode

The Ton e r Save Mode uses about 50% l e ss toner than normal . Th e printer saves tone r b y substiut i ng

a gray shade for the black inside of characters. the outlines of the characters are still printed in full

back.

1.4.9 Optional Memory

Upper Edge

Left Edge

Figure 1-16. Toner save Mode

If you have difficulty printing complex, graphics-intensive pages or if you regularly use

downloaded fonts, you may need to install one of the option al SIM M sets on this printer ’s contr oller

board. The printer’s controlle r board comes wit h 1MB of RAM inst alled .

By installing additional SIMMs, you can increase the printer’s memory to a total of 32MB, including

the residen t me mor y .

EPSON s upplies se veral types of memor y option (SI MMs). Other S IMMs can be p urchased fr om

other vendors. Be sure the SIMM meets the requirements listed below.

❏

72-pin type

❏

Capac ity is one of the following: 1, 2, 4, 8, 16 , 32MB

❏

Ac ce ss speed is less than 70 ns.

❏

Within the following dimensional size

36 mm (height) × 108 mm (wid th) × 10 mm (depth)

Rev. B 1-31

Page 45

General Description EPL-5500 Service Manual

1.5 MAIN COMPONENTS

To simplify maintenance and repair, the main components of the EPL-5500 have been designed for

easy removal and repla ce men t . Th e main c omponents are:

❏ C169 MAIN- B B oard Main board

❏ PWB-E Board Power supply cir c u it boar d

❏ P WB -F B oar d High-voltage supp ly c ir cuit boar d

❏ Optical Un it Printhead unit

❏ Fusing Unit

❏ Photoconductor u n i t

❏ Developer cartridge

❏ Housing

C169 M AIN-B Board

Fusing Unit

PWB-E Board

Optical Unit

PWB-F Board

Figure 1-17. Component Layout

1-32 Rev. B

Page 46

MB86933H

(IC1)

E05A91

(IC2)

(IC12)

(IC16)

(IC15)

(IC14)

(IC13)

M3807

(IC201)

E05A93

(IC4)

E05A92

(IC3)

EPL-5500 Service Manual General Description

1.5.1 C169 MAIN-B Boar d

The C169 MAIN-B board is a video c on troller and engine controller board . Th e prim ar y fun ction s of

this board are receiving print data from the host, generating the print image (video), and sending

the print image to the engine controller via the video interface. A 32-bit 22 MHz RISC MB86933H

SPARKlite CPU in location IC1 is used, and the following memory chips and custom ICs are

assigned to the 4GB memory space.

❏

Memory chips

Code and font ROM s: fou r 4M -bit E P ROM s (IC13, 14, 15, 16) or two 8M- bit mas k ROM s (IC 21, 22)

Optional NLSP font ROM : 4M- bit or 8M -bit RO M (IC 12). Not available in U.S. version.

4M-bit DRAMs (IC 17, 18)

EEPROM (IC11)

❏

Custom ICs

ASIC E05A91 (IC 2)

ASIC E05A92 (IC 3)

ASIC E05A93 (IC 4)

❏

Others

Reset IC M51953BFP (IC6)

The engine controller consists of an M3807x 8-bit CPU, including a MASK ROM. It controls laser

scanning (the polygon mirro r drive motor), image sync hronization, laser beam pulse wi dth, and

power.

There are two types of C169 MAIN-B boards used as after service parts. The following table shows

differences betw een t hem.

Table 1-16. Diff er en ces in Com pone nt s for the C169 MAIN - B Boar d

US version Other Version

IC12 None IC socket

Jumper J20 Open Sho rt

Figure 1-18. C169 MAIN- B Boar d

Rev. B 1-33

Page 47

CAUTION

CAUTION

VR3

General Description EPL-5500 Service Manual

1.5.2 PWB-E Board

The PWB-E is the power supply board, which consists of a switching regulator circuit. It converts

the AC line voltage into +24 V and +5 VDC voltages. There are two types of power supply board,

the 100/120 V type and 220/240 V type. The difference between the two circuits is only in the input

section.

Do not touch VR1 on PWB-E board. This volume is for factory setting only.

VR1

F1

Figure 1-19. PWB-E Board

1.5.3 PWB-F Board

The PWB-F is the high-vol tage supply circuit b oard. It conv erts the develo pment bia s, OPC drum

charge bias, and image tra n sfe r bias.

Do not touch VR3 on the PWB-F board. These volumes are for factory setting only.

Figure 1-20. PWB-F Board

1-34 Rev. B

Page 48

EPL-5500 Service Manual General Description

1.5.4 Optical Unit

The optica l u ni t consists of the l as e r diode (semi-conductor laser), the m i rro r m otor (scanner moto r)

which drives the pol ygon mirro r for l aser sca nning, an d sever al mirro rs and lenses. The lase r beam

generated by the laser diode is conducted to the OPC drum surface by way of the polygon mirror,

as well as several mirrors and lenses , to create a latent elec tro- photo graph ic ima ge on the d r um.

Figure 1-21. Optical Unit

1.5.5 Fusing Unit

The fusing unit fixes the toner to the paper using heat and pressure. This unit has a heater lamp,

thermistor, and thermal fuse. There are two types of fusing units, the 120 V type and the 220/240 V

type. The only differenc e bet ween them is the heater lamp.

Figure 1-22. Fusing Unit

Rev. B 1-35

Page 49

General Description EPL-5500 Service Manual

1.5.6 Phot oc on du cto r Uni t

Core mechanisms of the printing process, such as charging and imaging, are integrated into this

unit.

Figure 1-23. Photoconductor Unit

1.5.7 Developing Cartridge

Core mechanisms of the printing proce ss , such as de velopin g, are int egr ate d into this cartridg e.

1.5.8 Lower Paper Casste Unit

This optional paper cassete allows you to feed up an addtional 250 sheets of A4 or B5 paper into

this printer.

Note:

Figure 1-24. Developing Cartridge

While you use A4/B5 paper, jumper JP1 on the circuit board of lower paper casstte unit

should be set to 2-3. While you use letter/ executive paper, jumper JP1 should be set to

1-2. Jumper JP2 is fixed to 1-2.

1-36 Rev. B

Page 50

Chapter 2 Operating Principles

Table of Contents

2.1 ENGINE OPERATION 2-1

2.1.1 Print Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1.1 Paper Feeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.1.2 Drum Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1.1.3 Laser Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.1.4 Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.1.5 Image Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.1.6 Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.2 Engine Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.1.2.1 Main Motor Functions and Control . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.1.2.2 Paper Take-Up Sensor and Paper Exit Sensor. . . . . . . . . . . . . . . 2-9

2.1.2.3 Fuser Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.1.2.4 Scanner Mirror Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.1.2.5 Laser Diode Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.1.2.6 Bias Voltages and Laser Drive Timing . . . . . . . . . . . . . . . . . . . . 2-13

2.1.2.7 Fan Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.1.2.8 Power Supply Circuit Function and Safety Protection. . . . . . . . . 2-15

2.2 VIDEO CONTROLLER OPERATION 2-16

2.2.1 C169 MAIN-B Board Operat i on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.1.1 Reset Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.2.1.2 Bus Control Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.2.1.3 Interrupt Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.2.1.4 DRAM Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.2.1.5 Parallel Interface Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.2.1.6 Video Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

List of Figures

Figure 2-1. Main Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1