Page 1

Rev.6 EM07ZS1647F

EPSON RC+ Option

Fieldbus I/O

Page 2

E

PSON RC+ Option Fieldbus I/O Rev.6

Page 3

EPSON RC+ Option

Fieldbus I/O

Rev.6

Copyright © 2005-2007 SEIKO EPSON CORPORATION. All rights reserved.

Fieldbus I/O Rev.6 i

Page 4

FOREWORD

This manual contains important information necessary to use the EPSON RC+ option

Fieldbus I/O properly and safely. This manual is intended for personnel who perform any

operations that use the pendant, such as teaching robot points.

Please thoroughly read this and other related manuals before and while using the

equipment.

WARRANTY

The robot and its optional parts are shipped to our customers only after being subjected to

the strictest quality controls, tests, and inspections to certify its compliance with our high

performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please ask your Regional Sales Office for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

1. Damage or malfunction caused by improper use which is not described in the manual,

2. Malfunctions caused by customers’ unauthorized disassembly.

3. Damage due to improper adjustments or unauthorized repair attempts.

or careless use.

4. Damage caused by natural disasters such as earthquake, flood, etc.

Warnings, Cautions, Usage:

1. If the robot or associated equipment is used outside of the usage conditions and

product specifications described in the manuals, this warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this manual

cannot warn the user of all possible hazards.

ii Fieldbus I/O Rev.6

Page 5

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® 2000 Operating system

Microsoft® Windows® XP Operating system

Throughout this manual, Windows 2000, and Windows XP refer to above respective

operating systems. In some cases, Windows refers generically to Windows 2000, and

Windows XP.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

INQUIRIES

Contact the following service center for robot repairs, inspections or adjustments.

If service center information is not indicated below, please contact the supplier office for

your region.

Please prepare the following items before you contact us.

- Your controller model and its serial number

- Your manipulator model and its serial number

- Software and its version in your robot system

- A description of the problem

SERVICE CENTER

Fieldbus I/O Rev.6 iii

Page 6

MANUFACTURER & SUPPLIER

Japan & Others SEIKO EPSON CORPORATION

Suwa Minami Plant

Factory Automation Systems Dept.

1010 Fujimi, Fujimi-machi,

Suwa-gun, Nagano, 399-0295

JAPAN

TEL : +81-266-61-1802

FAX : +81-266-61-1846

SUPPLIERS

North & South America EPSON AMERICA, INC.

Factory Automation/Robotics

18300 Central Avenue

Carson, CA 90746

USA

TEL : +1-562-290-5900

FAX : +1-562-290-5999

E-MAIL : info@robots.epson.com

Europe EPSON DEUTSCHLAND GmbH

Factory Automation Division

Otto-Hahn-Str.4

D-40670 Meerbusch

Germany

TEL : +49-(0)-2159-538-1391

FAX : +49-(0)-2159-538-3170

E-MAIL : robot.infos@epson.de

iv Fieldbus I/O Rev.6

Page 7

Before Reading This Manual

This section describes what you should know before reading this manual.

Safety Precautions

Installation and transportation of robots and robotic equipment shall be performed by

qualified personnel and should conform to all national and local codes.

Please carefully read this manual and other related manuals before installing the robot

system or before connecting cables.

Keep this manual handy for easy access at all times. Please read the Safety chapter in

User’s Guide to understand safety requirements before installing the robot system.

Conventions

Important safety considerations are indicated throughout the manual by the following

symbols. Be sure to read the descriptions shown with each symbol.

This sign indicates that a danger of serious injury or death will

WARNING

exist if those instructions are not followed.

WARNING

CAUTION

This sign indicates that a danger of possible harm to people

caused by electric shock will exist if those instructions are not

followed.

This sign indicates that ignoring these instruction may cause

harm to people or physical damage to equipment and facilities.

Fieldbus I/O Rev.6 v

Page 8

vi Fieldbus I/O Rev.6

Page 9

Table of Contents

1. Introduction ...................................................................... 1

1.1 Overview of Fieldbus I/O............................................................ 1

1.2 DeviceNet .................................................................................. 2

Overview of DeviceNet ............................................................................ 2

Features of DeviceNet............................................................................. 2

General Specifications............................................................................. 4

1.3 PROFIBUS DP ..........................................................................5

Overview of PROFIBUS DP .................................................................... 5

Features of PROFIBUS DP ..................................................................... 5

General Specifications............................................................................. 7

1.4 EtherNet/IP ................................................................................ 8

Overview of EtherNet/IP .......................................................................... 8

Features of EtherNet/IP .......................................................................... 8

General Specifications........................................................................... 10

2. Installation...................................................................... 11

2.1 How to Setup a DeviceNet Network......................................... 11

2.2 DeviceNet Network Construction ............................................. 12

2.3 How to Setup a PROFIBUS DP Network.................................19

2.4 PROFIBUS DP Network Construction ..................................... 20

2.5 How to Setup a EtherNet/IP Network....................................... 24

2.6 EtherNet/IP Network Construction ...........................................25

2.7 DeviceNet Board Installation.................................................... 26

2.7.1 Board Appearance........................................................................ 26

2.7.2 Specifications................................................................................ 27

2.7.3 Software Installation ..................................................................... 27

2.7.4 Board Installation.......................................................................... 29

2.7.5 Master Mode................................................................................. 31

2.7.6 Slave Mode................................................................................... 37

2.8 PROFIBUS DP Board Installation............................................ 41

2.8.1 Board Appearance........................................................................ 41

2.8.2 Specifications................................................................................ 42

2.8.3 Software Installation ..................................................................... 42

2.8.4 Board Installation.......................................................................... 44

2.8.5 Master Mode................................................................................. 46

2.8.6 Slave Mode................................................................................... 51

2.8.7 GSD File ....................................................................................... 53

Fieldbus I/O Rev.6 vii

Page 10

Table of Contents

2.9 DeviceNet Board Installation ................................................... 54

2.9.1 Board Appearance ........................................................................54

2.9.2 Specifications................................................................................ 54

2.9.3 Software Installation...................................................................... 55

2.9.4 Board Installation .......................................................................... 57

2.9.5 Master Mode .................................................................................60

2.9.6 Slave Mode ...................................................................................64

2.10 EPSON RC+ Fieldbus I/O Installation ................................... 67

Fieldbus I/O Software Configuration ......................................................67

3. Operation....................................................................... 69

3.1 Fieldbus I/O Addressing in SPEL+ .......................................... 69

3.2 SPEL+ Fieldbus I/O Commands.............................................. 69

3.3 Outputs Off by Emergency Stop and Reset Instruction ........... 70

3.4 Waiting for Input or Output Status............................................ 70

3.5 Using FbusIO_SendMsg ......................................................... 71

3.6 Using Slave Mode ................................................................... 72

3.7 Remote Control Slave ............................................................. 72

3.8 Devices available for Fieldbus I/O Option................................ 73

3.9 Fieldbus I/O Response Performance....................................... 73

DeviceNet ..............................................................................................73

PROFIBUS DP....................................................................................... 75

4. Troubleshooting ............................................................. 77

4.1 DeviceNet Troubleshooting ..................................................... 77

Exclusion................................................................................................ 77

Tools ...................................................................................................... 77

4.1.1 Examining a Problem .................................................................... 78

4.1.2 Problems and Countermeasures................................................... 80

4.1.3 Procedures for Examining Possible Causes ................................. 98

4.2 PROFIBUS DP Troubleshooting............................................. 111

Exclusion...............................................................................................111

Tools .....................................................................................................111

4.2.1 Examining a Problem .................................................................. 112

4.2.2 Problems and Countermeasures................................................. 114

4.2.3 Procedures for Examining Possible Causes ............................... 130

4.3 EtherNet/IP Troubleshooting.................................................. 140

Exclusion.............................................................................................. 140

4.3.1 Examining a Problem ..................................................................141

4.3.2 Problems and Countermeasures................................................. 143

4.3.3 Procedures for Examining Possible Causes ............................... 144

viii Fieldbus I/O Rev.6

Page 11

Table of Contents

5. Maintenance Parts List ................................................ 151

Appendix A applicomIO Upgrade.................................... 153

Fieldbus I/O Rev.6 ix

Page 12

Table of Contents

x Fieldbus I/O Rev.6

Page 13

1. Introduction

1.1 Overview of Fieldbus I/O

The Fieldbus I/O option is an integrated I/O system that supports DeviceNet, PROFIBUS DP,

and EtherNet/IP fieldbuses.

A fieldbus is a standard of signal communications between field devices operating in a

factory (sensor, actuator, robot controller, etc.) and controller (PLC or robot controller) using

serial communications. Compared to signal communications using analog signals, a fieldbus

has the following features:

• Access to signals from multiple devices and multiple data from each device using

one cable.

1. Introduction

• Precise signal transmission since there is no need for A/D conversion and D/A

conversion.

• Less wiring costs, including signal relay board costs and installation area due to

several dozen (or a hundred) devices connected on one fieldbus.

• More flexible modification and expansion of a system because multiple devices are

simply added to one fieldbus without additional wiring.

• Slave devices can transmit self-diagnostics information.

For each fieldbus on the RCxxx controller, there is at least one board installed. You can use

more that one fieldbus type on the same controller. You can also use multiple boards for the

same fieldbus type. The EPSON RC+ software key Fieldbus I/O Option must be enabled to

use this option.

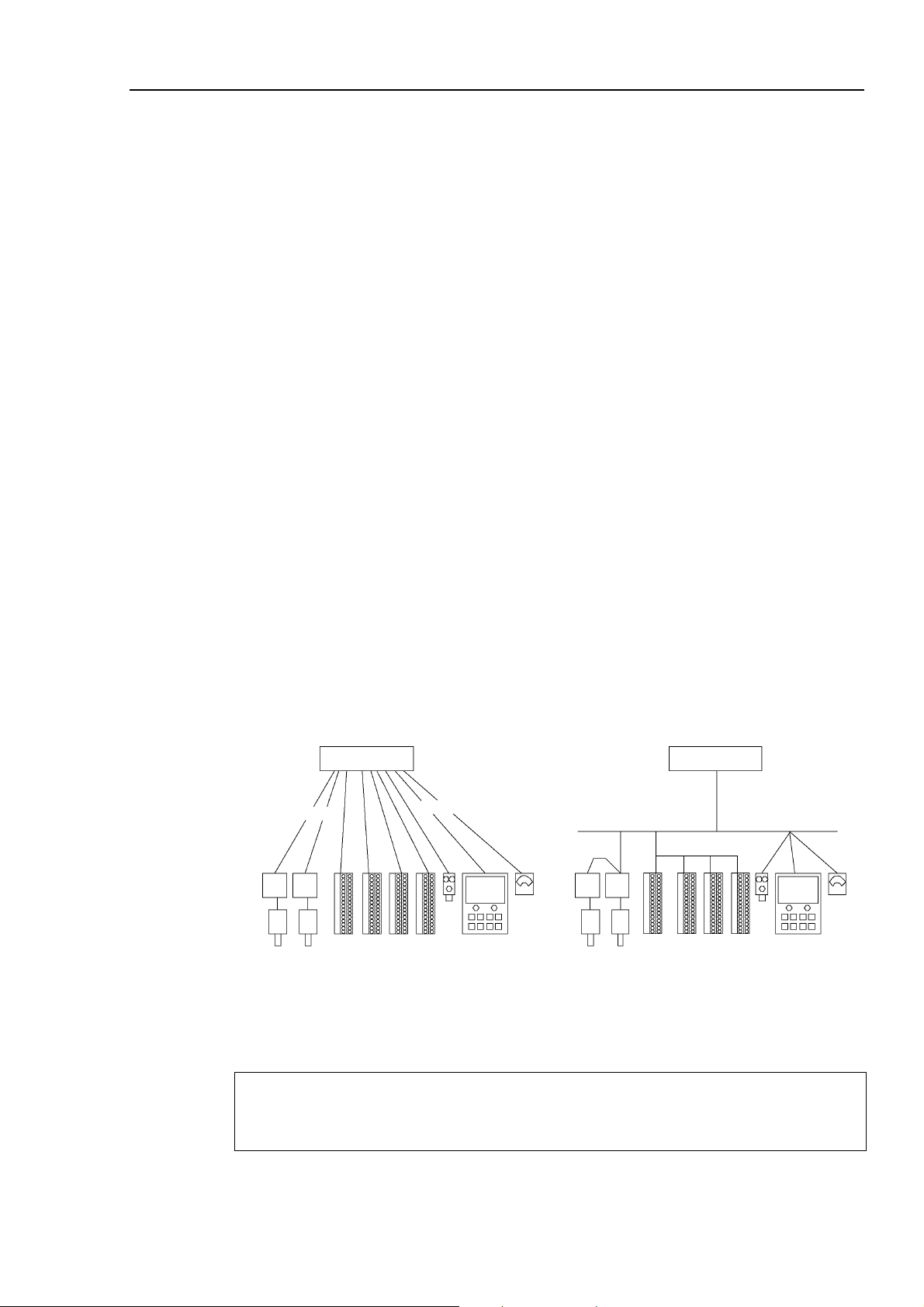

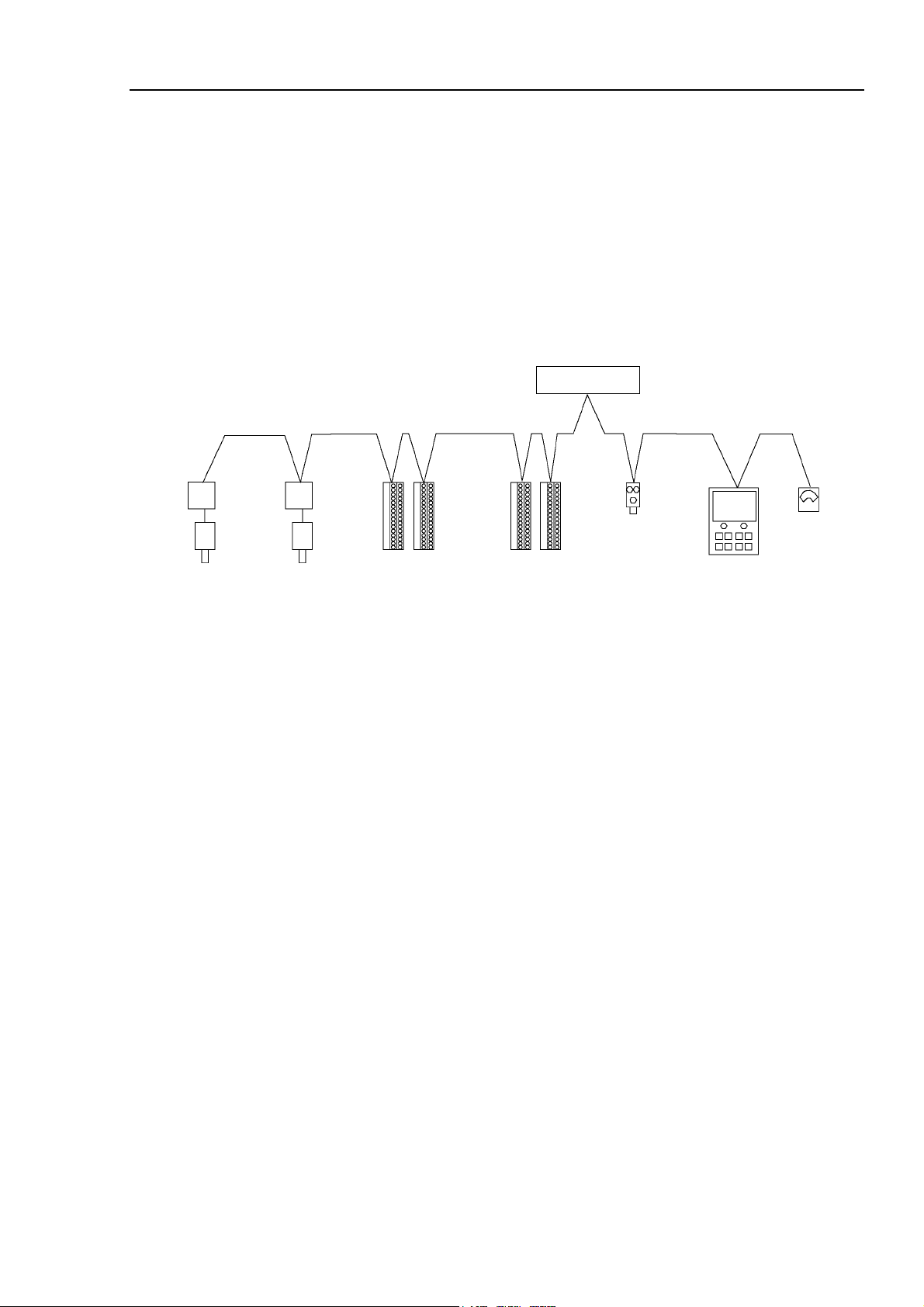

Controller

RS-232c

Sample Parallel Connection Sample Fieldbus Connection

RS-232c

Controller

Fieldbus

NOTE

)

Fieldbus I/O Rev.6 1

Response times for Fieldbus I/O can vary and depend on several factors, including baud rate,

scan rate, number and types of devices, number of SPEL+ tasks, etc. When the fastest and

most consistent response times are required, please use EPSON standard digital I/O, which

incorporates interrupt driven inputs and outputs.

Page 14

1. Introduction

1.2 DeviceNet

Overview of DeviceNet

DeviceNet is a fieldbus network that provides easy interconnection between control devices

(PLC, PC, sensor, actuator, etc.).

DeviceNet was developed by Allen-Bradley as an open communication standard to connect

various field devices (sensor, actuator, robot controller, etc.). Because of the open

communication standard, DeviceNet users can easily construct a multi-vendor system with

various devices developed around the world.

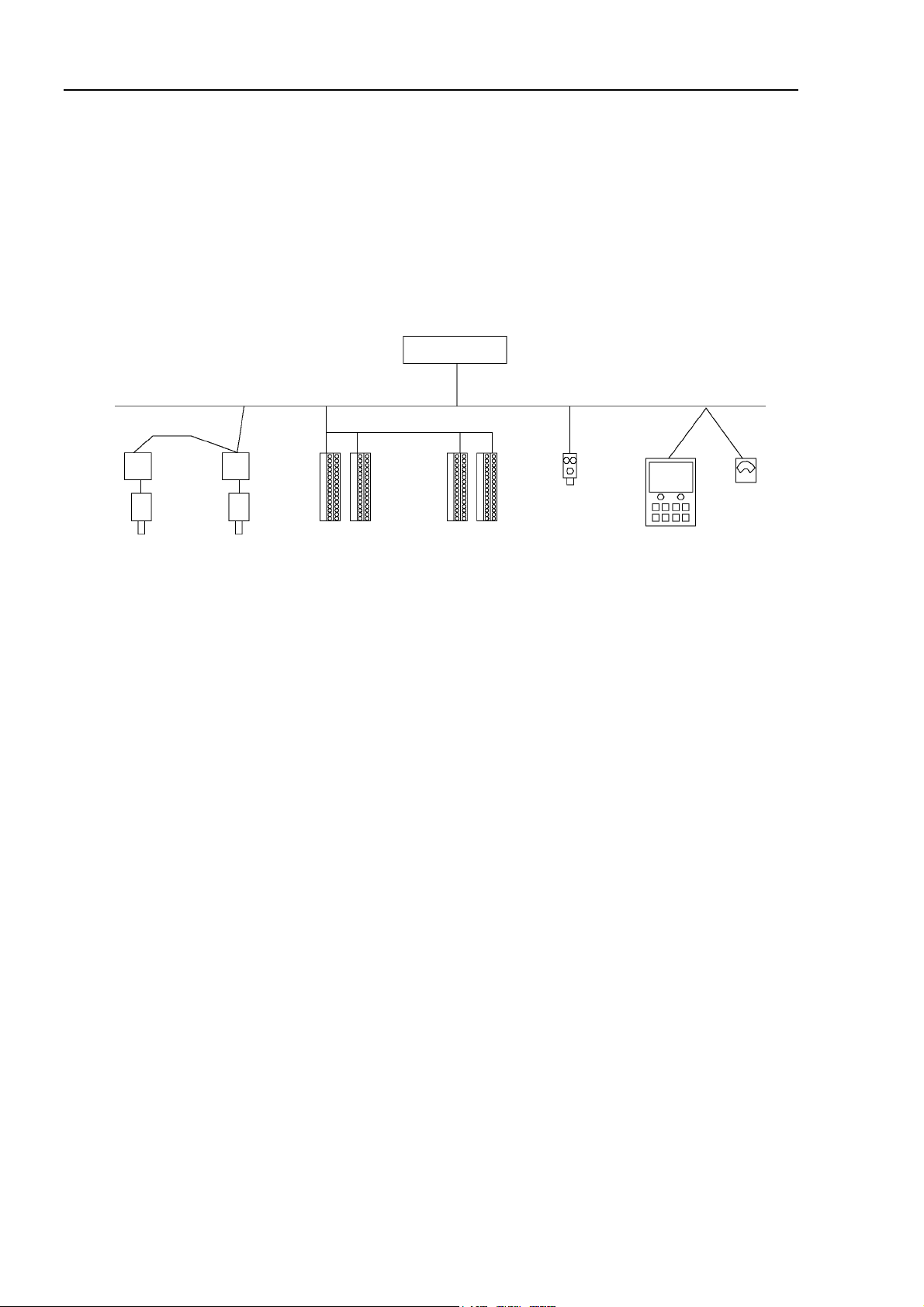

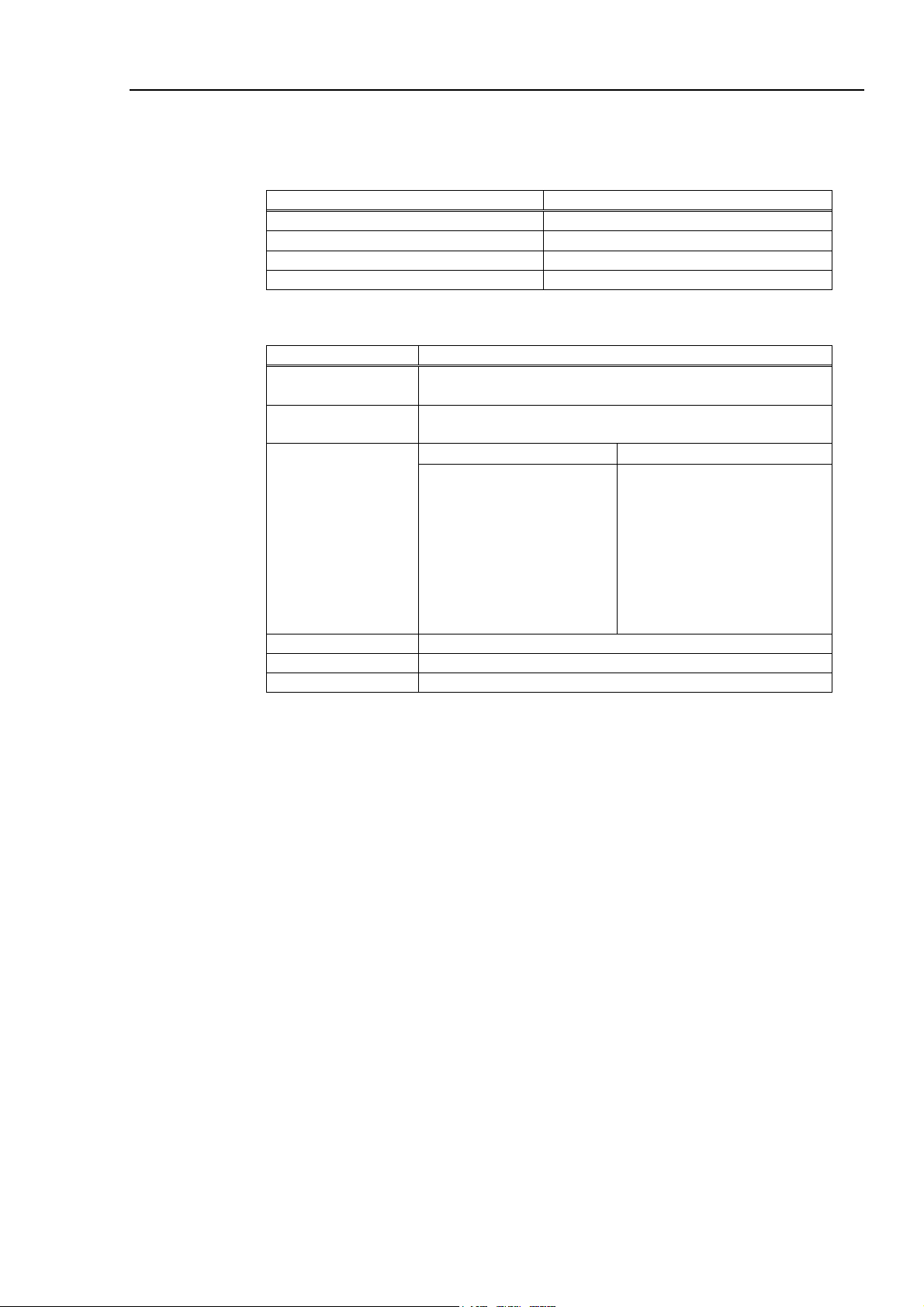

Controller

DeviceNet Network

Motor Driver

from Company A

Analog Device

from Company G

Motor Driver

from Company B

Intelligent I/O

from Company C

Intelligent I/O

from Company D

Photo Sensor

from Company E

HMI Device

from Company F

Features of DeviceNet

Reduced Wiring

Compared with parallel wiring, DeviceNet employs a dedicated 5-wire cable (signal wires

and power wires) which substantially reduces the number of necessary wires, wiring time and

cost.

Detachable communication connectors provide you with simple wiring between nodes and

easy network separation or reconstruction.

Specified environment-resistance cables allow you to construct an environment-resistant

system at low cost.

Open Standard (Multi-vendor)

Due to an open communication standard, various devices from many manufacturers are

available. Standardized communication connectors provide you with easy network

construction.

The maintenance spare parts stored on site (factory, etc.) can be reduced because different

manufacturers’ devices are used in case of a breakdown. Similar products are available

around the world due to a global standard DeviceNet.

Large Numbers of Inputs/Outputs

For EPSON RC+ standard I/O and expansion I/O, the number of inputs/outputs is limited to

512 inputs and 512 outputs. When configuring a device to be a master of fieldbus I/O, you

can control more than 16,000 total inputs and outputs.

For a slave device, 2,040 inputs (255 bytes) and 2,040 outputs (255 bytes) are available.

2 Fieldbus I/O Rev.6

Page 15

1. Introduction

Different Connection Types

There are two messaging connections: I/O messaging connection and explicit messaging

connection. The I/O messaging connection includes polling, strobe, cyclic, and change of

state. I/O messaging connections are explained below:

Polling: First, a master device sends output data to a slave device and then the slave device

responds. Data is normally exchanged in every communication cycle. The

communication frequency can be changed by setting. This connection type is the

most often used.

Strobe: First, a master device requests slave devices to send data with multicast messages,

and then, each slave device responds separately.

Data from many sensors on the system can be effectively gathered. When the master

does not receive responses from all requested slave devices, a timeout error occurs.

Change Of State:

A device sends data whenever it changes. Signals for device diagnosis are sent

regularly in the background. This connection type is useful for remedying DeviceNet

communication traffic.

Cyclic: A slave device transfers data regularly according to its internal timer. This

connection type is typically used for communicating with a temperature controller.

The data transfer frequency is defined by master configuration.

NOTE

)

For Change of State and Cyclic, you can disable the ACK that is for verifying that

communication is completed. Never disable ACK, since communication errors cannot be

detected.

Functions of Master

The Master device gathers and controls all nodes on one network.

A DeviceNet master can control up to 64 nodes (max. 2 kbytes) on one network.

A PLC is typically configured as a master and controls all nodes in factory automation system,

but EPSON RC+ is also capable of being a master.

DeviceNet network configuration is specified by configuration management software. This

software is normally provided by a master device manufacturer. The configuration

management software determines parameters for each slave device via an Electronic Data

Sheet (EDS).

Available connection types are Polling, Strove, Cyclic, Change Of State, and explicit

messaging.

Available baud rates are 125 kbps, 250 kbps, and 500 kbps.

Functions of Slave

A slave can exchange data with a master device.

The configuration management software identifies parameters of each slave device via

Electronic Data Sheet (EDS) where the parameters are registered.

Available connection types are Polling, Strobe, Cyclic, and Change of State.

Available baud rates are 125 kbps, 250 kbps, and 500 kbps.

Fieldbus I/O Rev.6 3

Page 16

1. Introduction

General Specifications

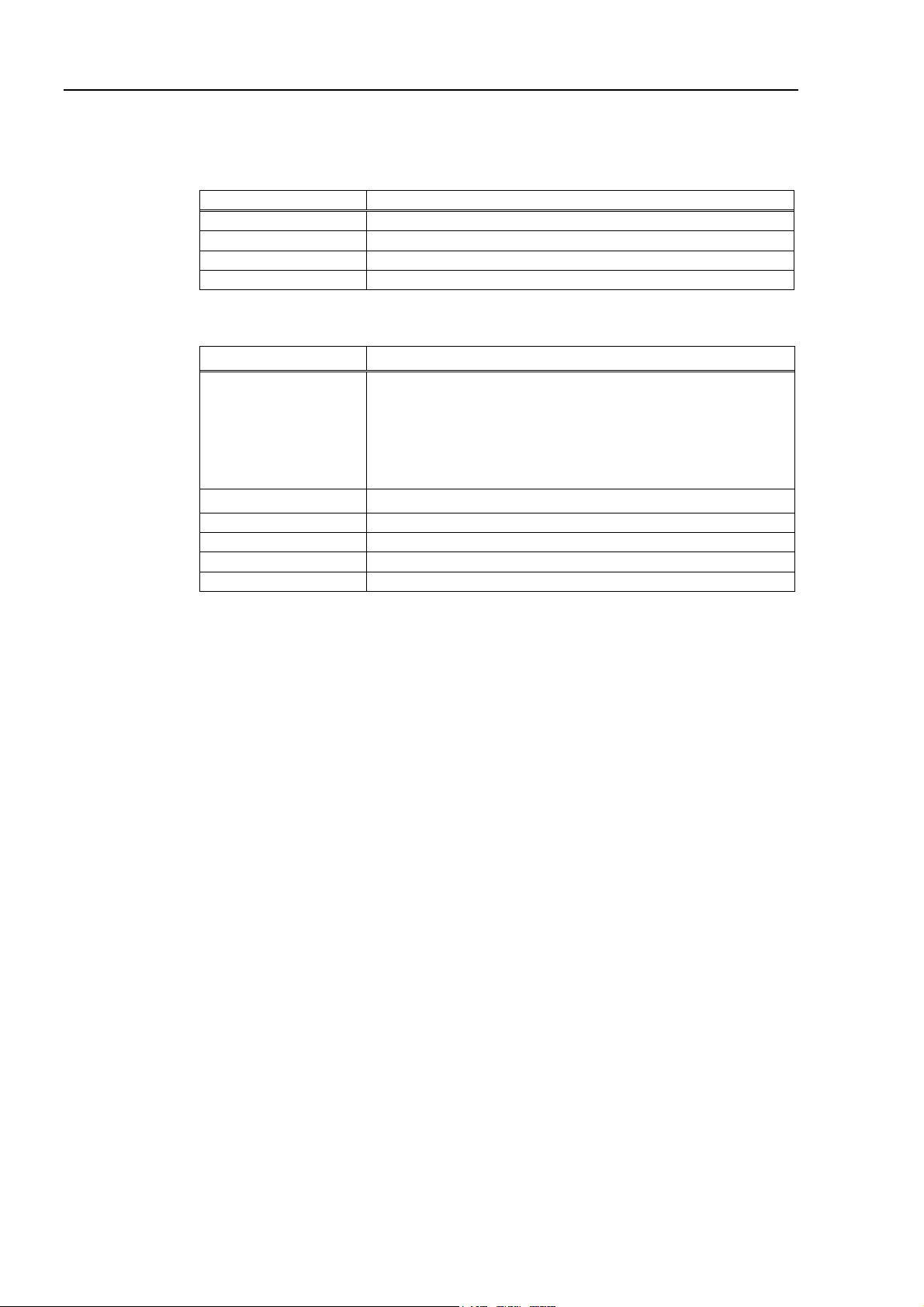

Electrical Specifications

Item Specification

Supply Voltage 5 V DC (supplied from a controller)

Power Consumption 7 W

Ambient Temperature 5-40 deg C

Relative Humidity 20-80%

DeviceNet Communication Specifications

Item Specification

Supported Connection - I/O messaging connection

(Polling, Strove, Cyclic, Change of State)

- Explicit messaging connection

All connections are conformed to DeviceNet communication

protocol.

Baud Rates 125 kbps, 250 kbps, 500 kbps

Transfer Distance

Maximum Nodes 64 (including master unit)

Data Length / Frame 8 byte (The data can be divided and transferred.)

Bus Access CSMA/NBA

Error Detection CRC error / Duplicate node address check

Cable 5-wire cable dedicated to DeviceNet (2 wires for signal,

Communications

Power Supply Voltage

Baud Rates

500 kbps

250 kbps

125 kbps

2 wires for power supply, 1 shield wire)

24 V DC (supplied from a connector)

Max. Network

Length

100 m

250 m *

500 m *

Drop Length

6 m or under

6 m or under

6 m or under

Total Drop

Line Length

39 m or under

78 m or under

156 m or under

* When thin cable is used for trunk line, the maximum network length is 100 m.

4 Fieldbus I/O Rev.6

Page 17

A

1.3 PROFIBUS DP

Overview of PROFIBUS DP

PROFIBUS DP is one of fieldbus networks that provide easy interconnection between control

devices (PLC, PC, sensor, actuator, etc.).

PROFIBUS DP was co-developed by Siemens, Bosch, and ABB as an open communication

standard to connect various field devices (sensor, actuator, robot controller, etc.). Because of

the open communication standard, PROFIBUS DP can easily construct multi-vendor system

with various devices developed around the world.

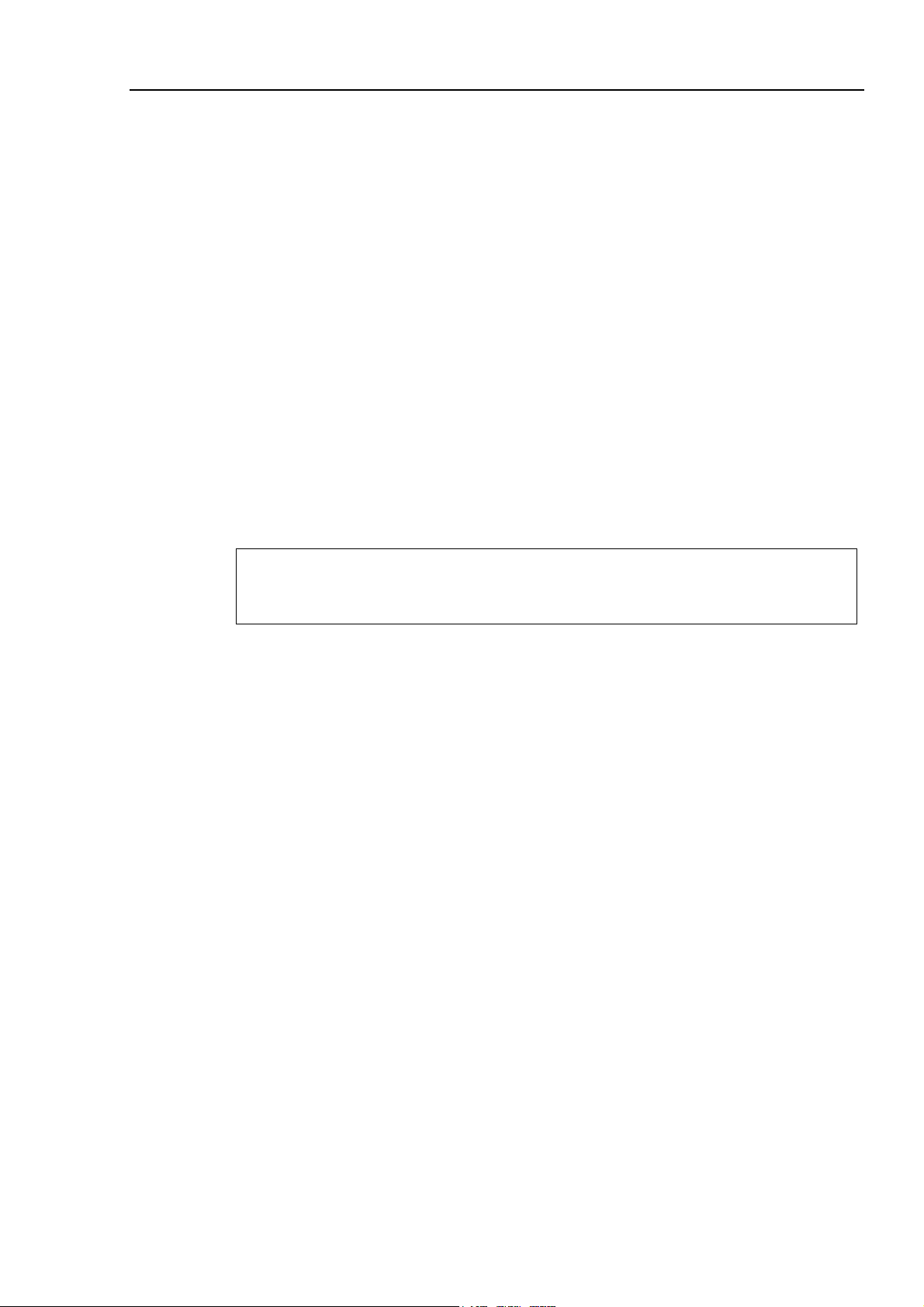

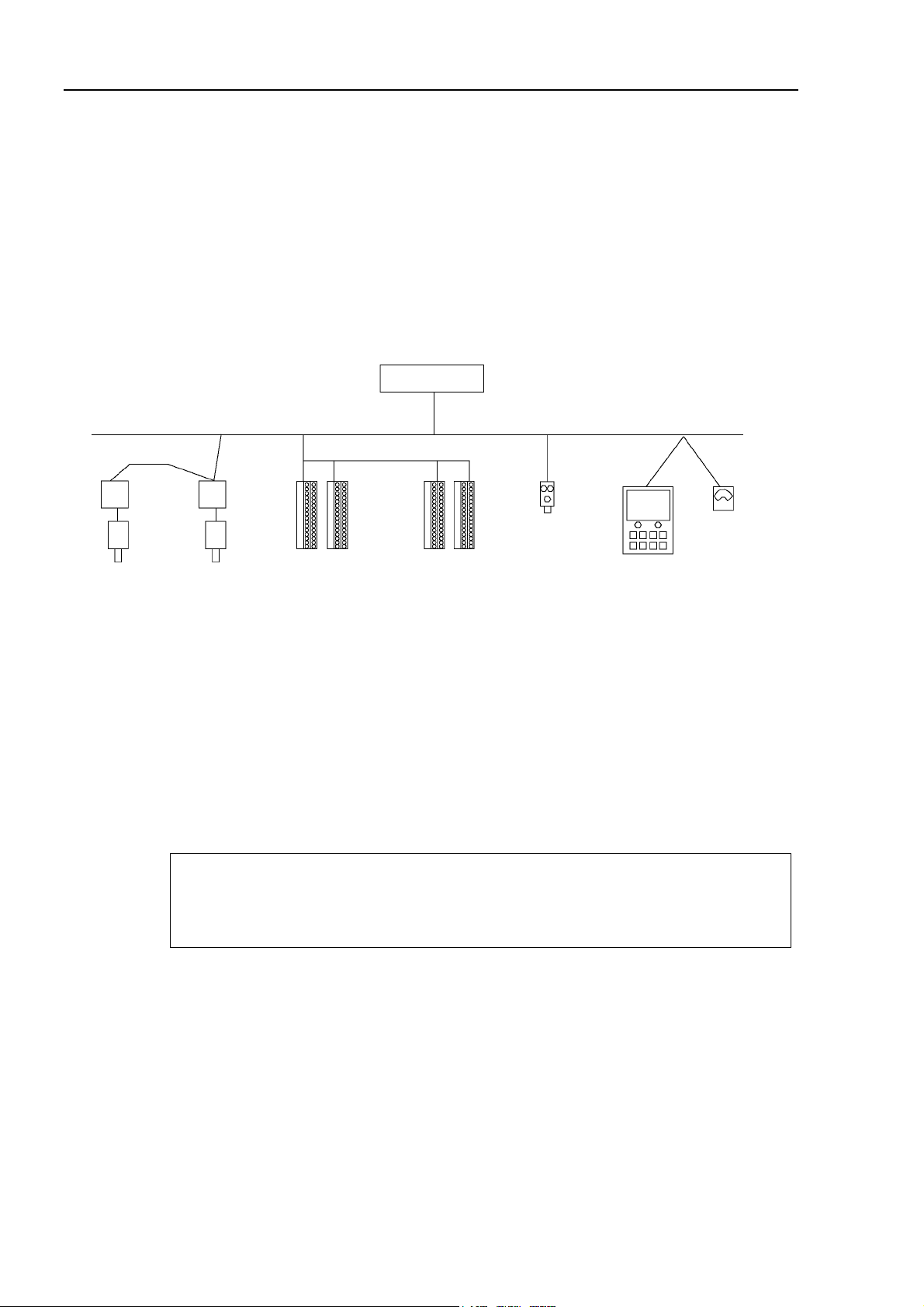

PROFIBUS DP Network

1. Introduction

Controller

Motor Driver

from Company A

nalog Device

from Company G

Motor Driver

from Company B

Intelligent I/O

from Company C

Intelligent I/O

from Company D

Photo Sensor

from Company E

HMI Device

from Company F

Features of PROFIBUS DP

Reduced Wiring

Compared with a parallel wiring, PROFIBUS DP employing dedicated 2-wire cable

substantially reduces the number of necessary wires, wiring time and cost.

Detachable communication connector provides you a simple wiring between devices

(stations) and an easy network separation or reconstruction.

Fast Communication

PROFIBUS DP communication speed can be set up to 12Mbps. This is faster than

DeviceNet, another communication standard supported by the fieldbus I/O.

Open Standard (Multi-vendor)

Due to an open communication standard, various devices from many manufacturers are

available. Standardized communication connectors allow you to reconstruct your network

easily.

The sort of maintenance parts stored on site (factory, etc.) can be reduced because different

manufacturers’ devices are used in case of a breakdown. Similar products are available

around the world due to a global standard PROFIBUS DP.

Large Numbers of Inputs/Outputs

For the standard I/O and expansion I/O, the number of inputs/outputs is limited to up to 512

inputs and 512 outputs. When configuring a device to be a master of fieldbus I/O, you can

control more than 16,000 total inputs and outputs.

For a slave device, 1,952 inputs (244 bytes) and 1,952 outputs (244 bytes) are available.

Fieldbus I/O Rev.6 5

Page 18

1. Introduction

Functions of Master

There are two types of PROFIBUS DP master: DPM1 and DPM2. DPM1 (DP Master Class

1) gathers and controls all stations on one PROFIBUS DP network. DPM2 (DP master Class

2) operates network configurations, network maintenance, and diagnosis.

PROFIBUS DP master can control up to 126 stations (max. 2 kbytes) on one network.

A PLC is typically configured as a master and controls all devices in factory automation

system, but EPSON RC+ is also capable of being a master.

PROFIBUS DP network configuration is specified by configuration management software.

This software is normally provided by a master device manufacturer. The configuration

management software determines parameters for each slave device via an Electronic Data

Sheet (GSD).

The connection type is token passing procedure and master-slave communication. The token

passing procedure is applied to the PROFIBUS DP network with more than two master

devices to transfer network control between masters. The master-slave communication is

applied to the communication between the master device with network control and its slave

devices.

Available baud rates are 9.6 kbps, 19.2 kbps, 93.75 kbps, 187.5 kbps, 500 kbps, 1500 kbps, 3

Mbps, 6 Mbps, and 12 Mbps.

Functions of Slave

A slave can exchange data with a master device.

The configuration management software identifies parameters of each slave device via an

electronic data sheet (GSD) file where the parameters are registered.

The communication type is a cyclic master-slave communication.

The input/output data of each station is up to 244 bytes.

Available baud rates are 9.6 kbps, 19.2 kbps, 93.75 kbps, 187.5 kbps, 500 kbps, 1500 kbps, 3

Mbps, 6 Mbps, and 12 Mbps.

6 Fieldbus I/O Rev.6

Page 19

1. Introduction

General Specifications

Electrical Specifications

Item Specification

Supply Voltage 5 V DC (supplied from a controller)

Power Consumption 5.5 W

Ambient Temperature during Operation 5-40 deg C

Relative Humidity during Operation 20-80%

PROFIBUS DP Communication Specifications

Item Specification

Connection Method Hybrid

(token passing procedure and master-slave communication)

Baud Rates 9.6 kbps, 19.2 kbps, 93.75 kbps, 187.5 kbps, 500 kbps,

1500 kbps, 3 Mbps, 6 Mbps, and 12 Mbps.

Baud Rates Cable Length Transfer Distance

12 Mbps

6 Mbps

3 Mbps

1500 kbps

500 kbps

187.5 kbps

93.75 kbps

19.2 kbps

9.6 kbps

Maximum Stations 126 (including master unit and repeater)

Data Length / Frame 244 bytes

Cable 2-wire cable dedicated to PROFIBUS (2 wires for signal)

100 m

100 m

100 m

200 m

400 m

1000 m

1200 m

1200 m

1200 m

Fieldbus I/O Rev.6 7

Page 20

1. Introduction

1.4 EtherNet/IP

Overview of EtherNet/IP

EtherNet/IP is a fieldbus network that provides easy interconnection between control devices

(PLC, PC, sensor, actuator, etc.).

EtherNet/IP was developed by Allen-Bradley as an open communication standard to connect

various field devices (sensor, actuator, robot controller, etc.). Because of the open

communication standard, EtherNet/IP users can easily construct a multi-vendor system with

various devices developed around the world.

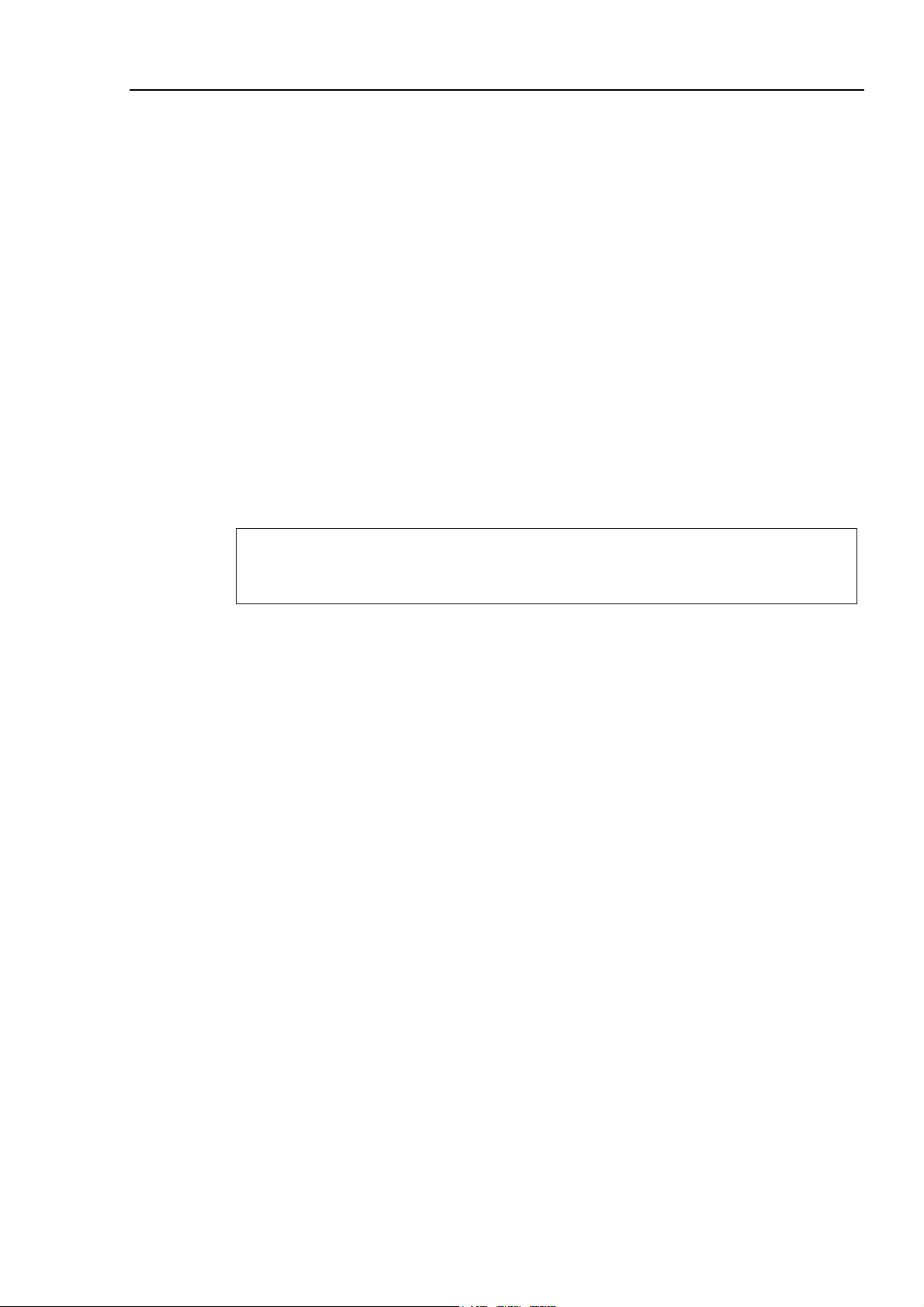

Controller

Ethernet/IP Network

Motor Driver

from Company A

NOTE

)

Analog Device

from Company G

Motor Driver

from Company B

Intelligent I/O

from Company C

Intelligent I/O

from Company D

Photo Sensor

from Company E

HMI Device

from Company F

Features of EtherNet/IP

Reduced Wiring

Compared with parallel wiring, EtherNet/IP employs a standard Ethernet cable which

substantially reduces the number of necessary wires, wiring time and cost.

Detachable communication connectors provide you with simple wiring between nodes and

easy network separation or reconstruction.

Specified environment-resistance cables allow you to construct an environment-resistant

system at low cost.

You can use the generic Ethernet hub or Ethernet switch for the EtherNet/IP. However, be

sure to a use product complying with the industrial standards or noise resistant Ethernet

cable (STP cable). If you use an office use product or UTP cable, it may causes

communication errors and may not offer the proper performance.

Open Standard (Multi-vendor)

Due to an open communication standard, various devices from many manufacturers are

available. Standardized communication connectors provide you with easy network

construction.

The maintenance spare parts stored on site (factory, etc.) can be reduced because different

manufacturers’ devices are used in case of a breakdown. Similar products are available

around the world due to a global standard EtherNet/IP.

8 Fieldbus I/O Rev.6

Page 21

NOTE

)

1. Introduction

Large Numbers of Inputs/Outputs

For EPSON RC+ standard I/O and expansion I/O, the number of inputs/outputs is limited to

512 inputs and 512 outputs. When configuring a device to be a master of fieldbus I/O, you

can control more than 16,000 total inputs and outputs.

For a slave device, 4,040 inputs (505 bytes) and 4,072 outputs (509 bytes) are available.

Different Connection Types

There are two messaging connections: I/O messaging connection and explicit messaging

connection. The I/O messaging connection includes cyclic and change of state. I/O

messaging connections are explained below:

Change Of State:

A device sends data whenever it changes. Signals for device diagnosis are sent

regularly in the background. This connection type is useful for remedying

EtherNet/IP communication traffic.

Cyclic: A slave device transfers data regularly according to its internal timer. This

connection type is typically used for communicating with a temperature controller.

The data transfer frequency is defined by master configuration.

For Change of State and Cyclic, you can disable the ACK that is for verifying that

communication is completed. Never disable ACK, since communication errors cannot be

detected.

Functions of Master

The Master device gathers and controls all nodes on one network.

A EtherNet/IP master can control up to 127 nodes (max. 14 kbytes) on one network.

A PLC is typically configured as a master and controls all nodes in factory automation system,

but EPSON RC+ is also capable of being a master.

EtherNet/IP network configuration is specified by configuration management software. This

software is normally provided by a master device manufacturer. The configuration

management software determines parameters for each slave device via an Electronic Data

Sheet (EDS).

Available connection types are Cyclic, Change Of State, and explicit messaging.

Available baud rates are 100 Mbps and 10 Mbps. (auto-detect)

Functions of Slave

A slave can exchange data with a master device.

The configuration management software identifies parameters of each slave device via

Electronic Data Sheet (EDS) where the parameters are registered.

Available connection type is Cyclic.

Available baud rates are 100 Mbps and 10 Mbps. (auto-detect)

Fieldbus I/O Rev.6 9

Page 22

1. Introduction

General Specifications

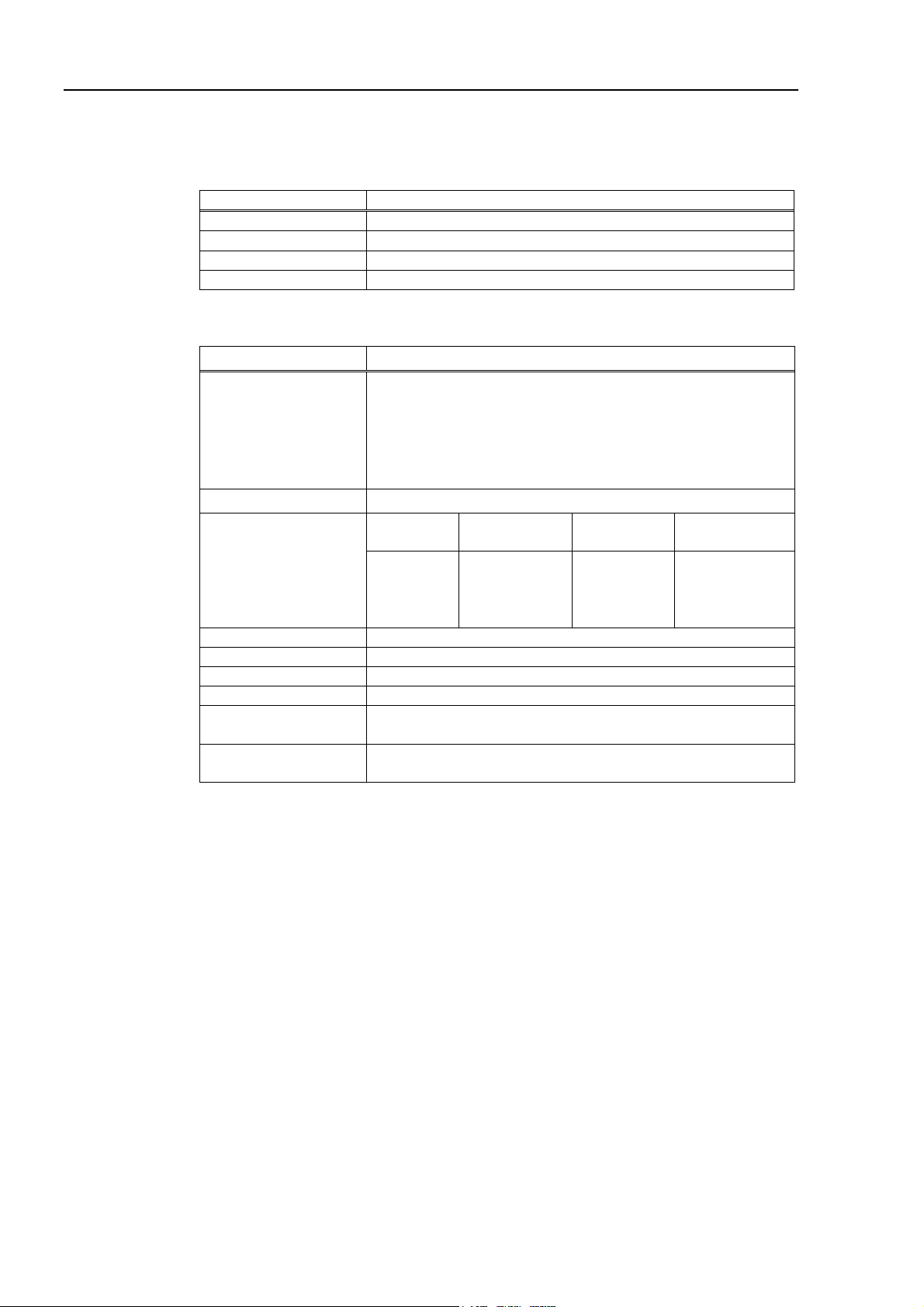

Electrical Specifications

Item Specification

Supply Voltage 5 V DC (supplied from a controller)

Power Consumption 5.5 W

Ambient Temperature 5-40 deg C

Relative Humidity 20-80%

EtherNet/IP Communication Specifications

Item Specification

Supported Connection - I/O messaging connection

(Cyclic, Change of State)

- Explicit messaging connection

All connections are conformed to EtherNet/IP communication

protocol.

Baud Rates 100 Mbps, 10 Mbps

Maximum Nodes 128 (including master unit)

Data Length / Frame 244 bytes

Access Control Type CSMA/CD

Cable Universal Ethernet cable

10 Fieldbus I/O Rev.6

Page 23

2. Installation

This chapter contains procedures for installing a DeviceNet, PROFIBUS DP, or EtherNet/IP

network. Refer to the sections that correspond to the type of network you are installing.

2.1 How to Setup a DeviceNet Network

The following is a basic procedure for setting up a DeviceNet network:

1. Choose node distribution and distribution route on your network.

For details, refer to the following section 2.2 DeviceNet Network Construction.

2. Choose power supply method for communication.

For details, refer to the following section 2.2 DeviceNet Network Construction.

2. Installation

3. Choose baud rate.

Choose the baud rate based on the network length. Select the fastest baud allowed

for the length. Increasing network load due to slow baud rate may cause trouble

including communication failure.

4. Lay cables.

For details, refer to the following section 2.2 DeviceNet Network Construction.

5. Configure nodes.

For details, refer to respective manuals of your desired nodes.

6. Turn ON the communications power supply and nodes.

Turn ON the communications power supply. After that or simultaneously, turn ON

the nodes to supply power. When the power to the nodes is supplied earlier than the

power to the communications power supply, communication with the nodes may fail.

7. Install the scanner board in your controller.

Refer to the section 2.7 DeviceNet Board Installation later in this chapter.

8. Configure a master and slaves.

Use the configuration management software for configuring a master and slaves

(scan list). For details, please refer to the configuration management software

manual.

To configure EPSON RC+ as a master, refer to the section 2.7 DeviceNet Board

Installation later in this chapter.

9. Configure EPSON RC+.

Refer to the section 2.10 EPSON RC+ Fieldbus I/O Installation later in this chapter.

10. Operate the DeviceNet network.

Fieldbus I/O Rev.6 11

Page 24

2. Installation

p

y

A

A

r

r

2.2 DeviceNet Network Construction

Network Configuration

A DeviceNet network is configured as shown in the following figure.

ttach a terminating

resistor on each end

of the trunk line.

Trunk Line

T-branch

Tap

Drop Line

Node

Drop

Line

Node

Node

There are two types of the node: master and slave. The master controls a network and gathers

data from its slaves. The slaves, including external I/O and other devices, output data in

response to the master’s output order and informs the master of its input status.

You can install masters anywhere in the network. You can connect up to 64 nodes (including

the master) on your network.

Ground to

100 Ω or less.

Trunk Line

Drop

Line

Communications

ower suppl

24 V DC

Trunk Line

T-branch

Tap

Drop Line

Node

Drop Line

Node

Use DeviceNet cables.

Power Supply Tap or

T-branch Tap

Trunk

T-branch Tap

Drop Line

Drop Line

Node

Node

T-branch

Connector

Line

T-branch Tap

Node

Trunk

Line

Drop

Line

Waterproof

slave

ttach a terminating

resistor on each end

of the trunk line.

T-branch

Connector

Connector with

Line

terminating

resistor

Waterproof

slave

Drop

Trunk Line and Drop Line

A trunk line is a backbone cable of DeviceNet network with a terminating resistor on the both

ends.

A drop line is a branch of the trunk line.

Terminating

resisto

Trunk Line

T-branch

These are all drop Lines.

Terminating

resisto

- No limits on the number of T-branch

- Limits on the length of drop lines

For DeviceNet, 5-wire cables are used for trunk lines and drop lines. The DeviceNet cables

on the market can be used for such cables. There are two types of the DeviceNet cable: Thick

cable and Thin cable. Environment-resistant cable and flexible cable are available. For

details of cables, see ODVA’s Web site (http://www.odva.org/).

12 Fieldbus I/O Rev.6

Page 25

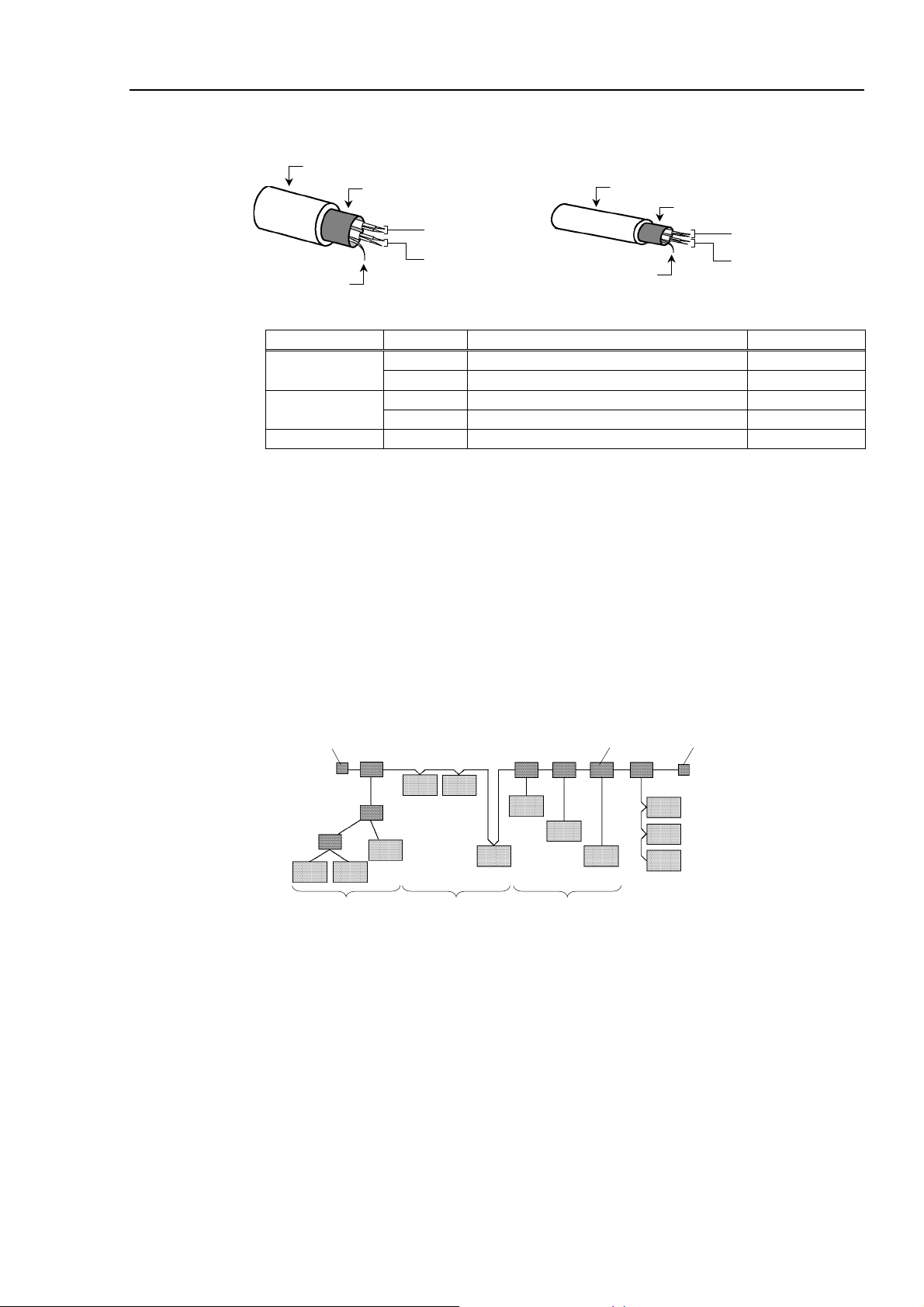

2. Installation

Thick Cable Thin Cable

11.2 to 12.1 mm outside diameter

Braid Shield

Signal Wire

(Blue/White)

Power Wire

Shield Wire

(Red/Black)

Shield Wire

6.9 mm outside diameter

Braid Shield

Signal Wire

(Blue/White)

Power Wire

(Red/Black)

Communication Cable Signal

Wire Type Color Details of Signal Wire Identity

Signal wire

Power wire

Blue Signal Low CAN L

White Signal High CAN H

Red Communications Power Positive V+

Black Communications Power Negative V

Shield wire - Shield S

Terminating Resistor

To reduce reflections of communication signal, terminating resistors should be attached on

both ends of the trunk line. For DeviceNet, nodes have no terminating resistor on the ends.

Attach 121 Ω +/-1%, 1/4W terminating resistors between the signal wires (CAN-H and CANL) of the trunk line cable. Some T-branch taps and connectors can accept terminal resistors.

Molded terminating resistors with connectors are also available to attach to environmentresistant T-branch taps and connectors.

Node Connection

Nodes can be connected to a DeviceNet network by the following topologies: tree, multi-drop,

T-branch, daisy chain. For tree topology, there is no limitation of daisy chain layer but drop

line length is limited. For details of drop line length, refer to the following section “Drop

Line Length”.

Terminating

Resistor

Tree

Trunk Line

Branch Tap

Multi-drop T-branch

Terminating

Resistor

Daisy Chain

Communications Power Supply

DeviceNet supplies 24V DC communications power to each node via 5-wire cables. You can

install the communications power supply at any location on the DeviceNet network. We

recommend providing a dedicated communications power supply on the network separately

even though it is possible to share power among the communications power supply, node

internal circuit power supply, and I/O power supply.

Shield Ground of Signal Wire

Ground the DeviceNet network at one point with 100 Ω or less.

As a noise countermeasure, you can leave the network ungrounded. For details, refer to the 4.

Troubleshooting.

Fieldbus I/O Rev.6 13

Page 26

2. Installation

Maximum Network Length (Maximum Trunk Length)

The maximum network length is the longest distance either between terminating resistors or

between the two most distant nodes on the network.

The longest distance is the maximum network length.

Trunk Line

Terminating

Resistor

Terminating

Resistor

The maximum network length is restricted by the type of cable and the baud rate.

Baud Rate

500 kbps

250 kbps

125 kbps

Thick Cable Thin Cable

Maximum Network Length

100 m

250 m

500 m

100 m

100 m

100 m

Both Thick Cable and Thin Cable can be combined and used for trunk lines. In this

case, the maximum network length is calculated using the following formulas.

Baud Rate Maximum Network Length

500 kbps Thick Cable Length + Thin Cable Length ≤ 100m

250 kbps Thick Cable Length + 2.5 × Thin Cable Length ≤ 250m

125 kbps Thick Cable Length + 5.0 × Thin Cable Length ≤ 500m

Drop Line Length

The drop line length is the distance from a branch on the trunk line to the end of that branch.

2 m

3 m

Trunk Line

4 m

Node 3

1 m

1 m

Node 1 Node 2

In figure above, each drop line length is as follows:

Drop Line to Node 1: 4 m

Drop Line to Node 2: 6 m

Drop Line to Node 3: 6 m

One drop line length should be 6m or less.

14 Fieldbus I/O Rev.6

Page 27

2. Installation

Total Drop Line Length

The total drop line length is the total distance of all drop lines on one network.

2 m

Trunk Line

Terminating

Resistor

4 m

Terminating

Resistor

1 m

1 m

3 m

2 m

4 m

In the figure above, the total drop line length is 17 m.

The maximum total drop line length is restricted by baud rate as shown in the table below.

The cable thickness is not related to the restriction.

Baud Rate Max. Total Drop Line Length

500 kbps

250 kbps

125 kbps

39 m

78 m

156 m

Cable Current Capacity

The current-carrying capacity of the DeviceNet network cable is restricted as shown below:

Thick Cable Thin Cable

Trunk Line

Drop Line (Unit: A)

Current Capacity 8A 3A 4.57 / Drop Line Length (m) ≤ 3A

The following figures illustrate power supply configuration examples.

When an external power supply is installed on the network as shown in the figure below, the

current capacity is 11A and it exceeds the permissible current of the cable.

Terminating

Resistor

External Power

Supply 24 V DC

Power Supply Tap

1A

1A

1A

2A

Trunk Line

2A2A

Terminating

Resistor

2A

If the location of the external power supply is changed on the network as shown in the figure

below, the power supply can be used on the network because the current capacity on the left

side of the power supply tap is 5 A and that on the right side is 6 A.

Terminating

Resistor

Power Supply Tap

1A

1A

1A

2A

External

Power Supply

24 V DC

Trunk Line

2A2A

Terminating

Resistor

2A

Fieldbus I/O Rev.6 15

Page 28

2. Installation

Ω

A

If the current capacity consumed on the network exceeds the restriction of cable current

capacity, it is possible to install more than one power supply on the network. If you attempt

to install two or more power supplies on the network, take necessary measures (pulling out a

fuse on the power supply tap, etc.) to avoid conflicts between power outputs from multiple

power supplies.

CAUTION

Terminating

Resistor

1A 1A

Power Supply Tap

2A

1A

External

Power Supply

24 V DC

Trunk Line

2A2A

2A

Power Supply Tap

Terminating

Resistor

2A

1A

1A 1A

The following figure illustrates a sample wiring. An OMRON power supply tap is shown in

the figure.

Trunk Line

Pull out

the fuse.

Ground the

network at

only one point.

Ground 100

Ground 100 Ω or less.

If you cannot ground the network with 100 Ω or less,

do not connect V- and FG wires.

Carefully connect the wires. Incorrect wiring may cause node malfunction and

severe damage to the entire DeviceNet network.

V+ V+

L CAN L

S Shield

H CAN H

V- V-

or less.

Procedure for Modifying and Installing Communication Cables

Follow the steps described below to modify communication cables and connect them to

connectors.

Be careful not to injure your hands or fingers on any sharp blades or tools used

to modify the cable.

CAUTION

Use appropriate blades and/or other tools to modify the cable. Using

inappropriate blades and/or other tools may result in bodily injury and/or

equipment damage.

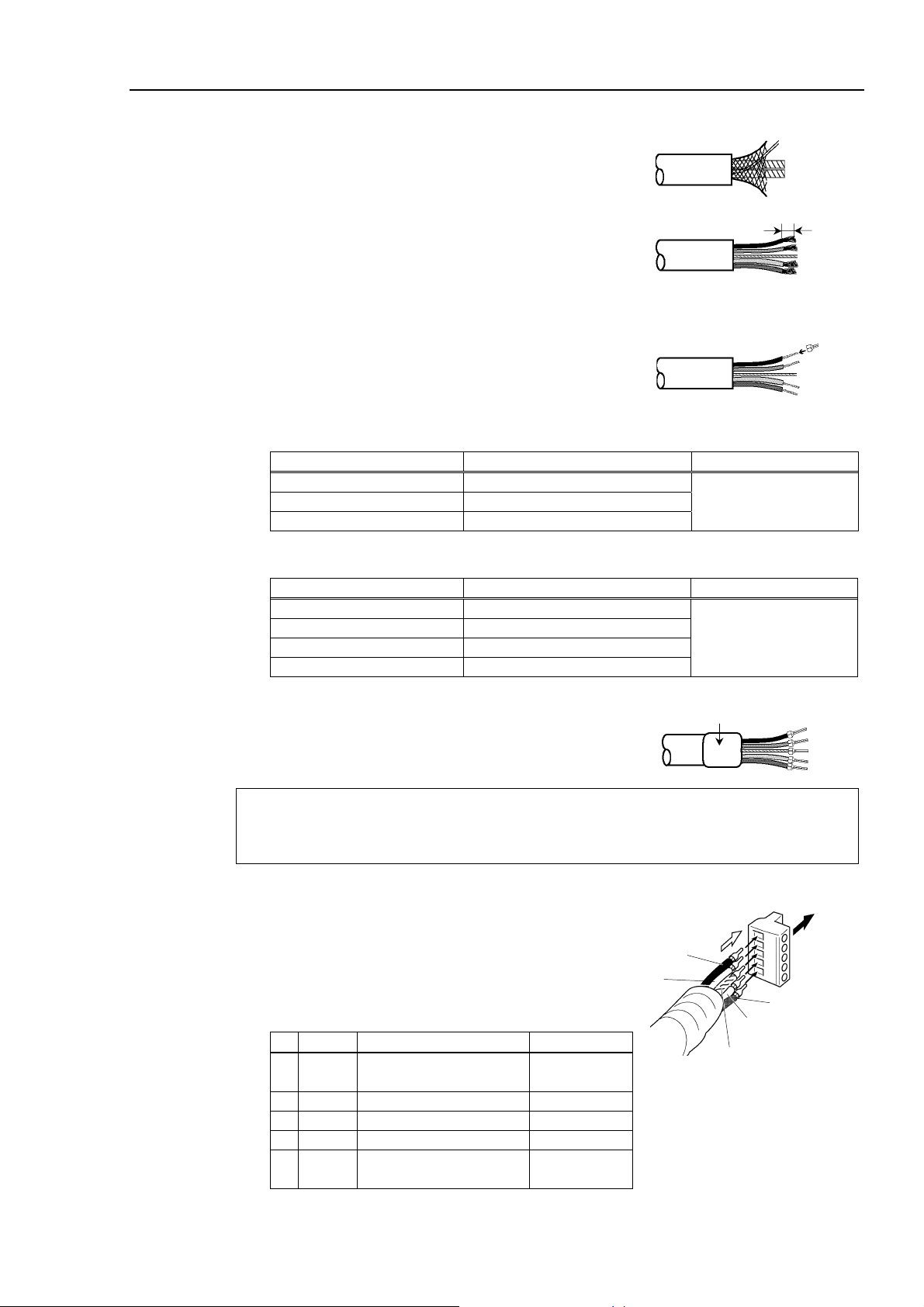

(1) Strip approx. 30 mm of the cable covering with extra

pprox. 30 mm

care so that you do not scratch on the braided shield

underneath. Do not strip the cable covering more than

necessary. Excess stripping may cause short-circuit

and/or make the cable more sensitive to noise.

16 Fieldbus I/O Rev.6

Page 29

2. Installation

(2) Carefully expand the meshes of the braided shield.

Shield Wire

Under the braided shield, there is one exposed bare

twisted shield wire other than the signal wires and

power wires that are wrapped with aluminum tape. The

shield wire is slightly harder than the mesh.

(3) Cut off the expanded braided shield and remove the

aluminum tape around the signal wires and power

wires. Then, strip the insulation from the signal wires

and power wires for a length sufficient to connect them

to crimp terminals.

Twist each stripped signal wire and power wire.

(4) Set the crimp terminal on the stripped part of the wire

and crimp it with a crimp tool. The following crimping

Peel the coverings in enough

length to connect the wires to

crimping terminals.

Crimping

Te rm i na l

terminals are recommended products.

NICHIFU TC series

Model Number Specifications Special Tool

TMEV TC-0.5 For Thin Cable

TMEV TC-2-11 For Thick Cable (power wire)

MH-32

TMEV TC-1.25-11 For Thick Cable (signal wire)

Phoenix Contact AI series

Model Number Specifications Special Tool

AI 0.5-8WH For Thin Cable (power cable)

AI 0.25-8YE For Thin Cable (signal wire)

AI 2.5-8BU For Thick Cable (signal wire)

CRIMPFOX UD6

AI 1-8RD For Thick Cable (signal wire)

NOTE

)

(5) Wrap or cover the cable with vinyl tape or heat-shrink

Heat-shrinkable Tube, etc.

tubing.

Loosen the screws securing the cables on the connector. If the screws are not loosened, the

wires go into different openings on the rear of connector instead of the correct openings

and the wires cannot be secured.

(6) Ensure the correct connector orientation and insert the

signal wires and shield wire to their respective holes

on the connector.

As shown in the figure, insert the wires (black, blue,

shield, white, and red) into the holes in the order

named.

The following table shows the specified colors of the

cables.

Color Details of Signal Wire Identity

a Black Communications Power

V-

Supply (negative)

Insert wires in

this direction.

a

b

c

Insert the

connector

in this

direction.

e

d

b Blue Signal (Low) CAN L

c - Shield S

d White Signal (High) CAN H

e Red Communications Power

Supply (positive)

V+

Fieldbus I/O Rev.6 17

Page 30

2. Installation

(7) Tighten each screw securing the wires on the connector.

Tighten the screw securing the wire at a correct tightening torque (0.25 to 0.3 N·m). To

prevent thick cable from coming out due to cable tension, install enough thick cable

length to allow for stretch.

Use a small flat blade screwdriver that has the correct

width and thickness. If you use a typical screwdriver

Thickness

Width

whose point is narrow, you cannot deeply insert it into

the hole on the connector.

Specific screwdriver for DeviceNet connector screw:

OMRON : XW4Z-00C

Phoenix Contact : SZF-1 0.6×3.5

0.6 mm 3.5 mm

18 Fieldbus I/O Rev.6

Page 31

2.3 How to Setup a PROFIBUS DP Network

The following is a basic procedure for setting up a PROFIBUS DP network:

1. Choose station distribution and distribution route on your network.

For details, refer to the following section 2.4 PROFIBUS DP Network Construction.

2. Choose baud rate.

Choose the baud rate based on the network length. Select the fastest baud rate

allowed for the length. Increasing network load due to slow baud rate may cause

trouble including communication failure.

3. Lay cables.

For details, refer to the following section 2.4 PROFIBUS DP Network Construction.

4. Configure stations.

For details, refer to respective manuals of your desired stations.

5. Turn ON the stations.

6. Install the scanner board in your controller.

Refer to the section 2.8 PROFIBUS DP Board Installation later in this chapter.

7. Configure a master and slaves.

Use the configuration management software for configuring a master and slaves

(scan list). For details, please refer to the configuration management software

manual.

To configure EPSON RC+ as a master, refer to the section 2.8 PROFIBUS DP Board

Installation later in this chapter.

2. Installation

8. Configure EPSON RC+.

Refer to the section 2.10 EPSON RC+ Fieldbus I/O Installation later in this chapter.

9. Operate the PROFIBUS DP network.

Fieldbus I/O Rev.6 19

Page 32

2. Installation

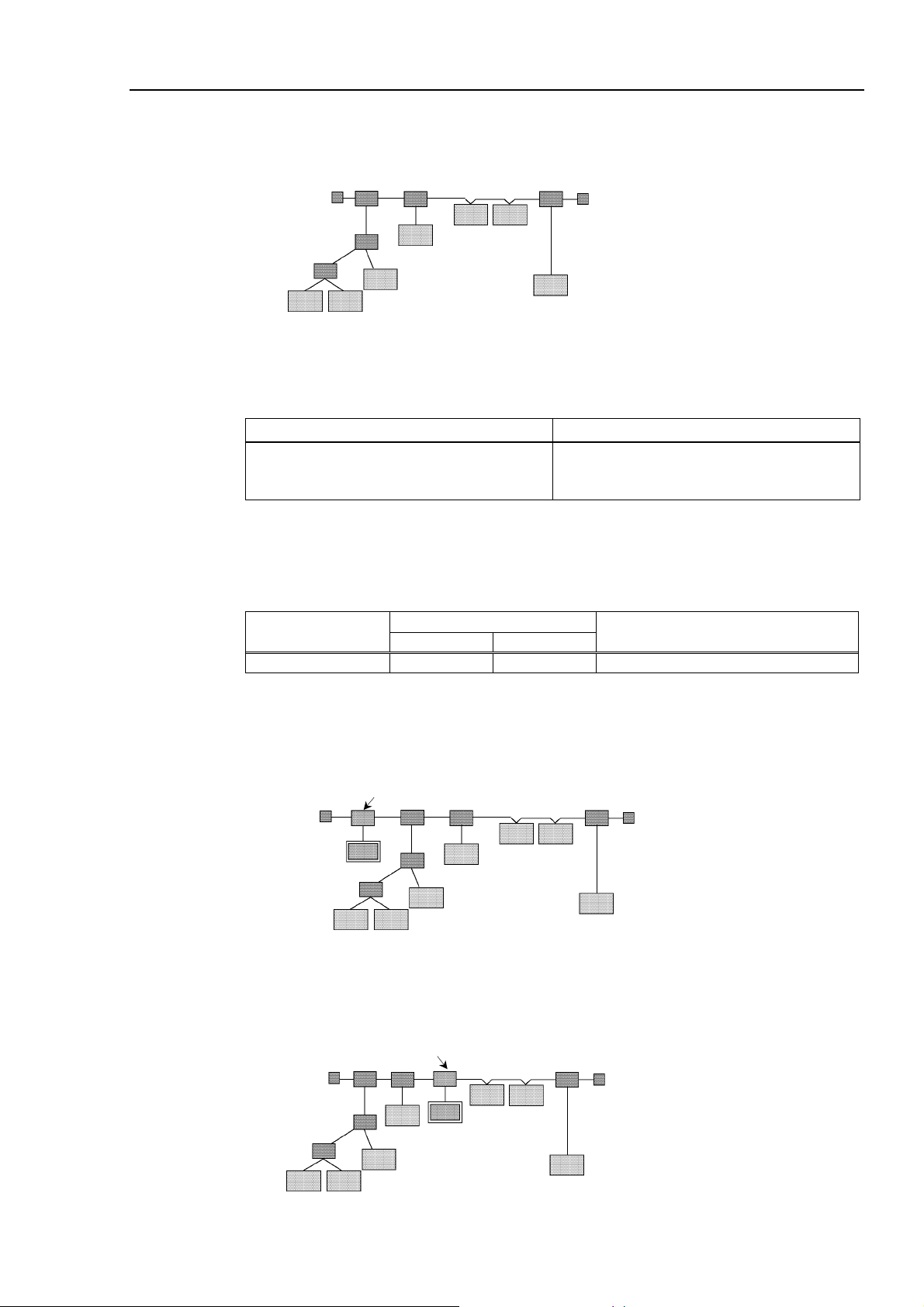

2.4 PROFIBUS DP Network Construction

Network Configuration

A PROFIBUS DP network is configured as shown in the following figure.

Terminating

Resistor ON

Terminating

Resistor ON

Master 1 Master 2

Slave

Slave Slave Slave Slave Slave

Slave Slave

Network

Cable

Slave

Slave

Terminating

Resistor ON

Repeater

Terminating

Resistor ON

Station

There are four types of stations (devices): master, slave, repeater, and configurator.

The master controls a network and gathers its slaves.

The slave, including external I/O and other devices, outputs data as a response to a master’s

output order and informs the master of its input status.

The repeater is necessary for a network with more than 32 slaves to separate network

segments.

The configurator, used only for network installation, configures a scan list of the slaves on the

master device.

You can install masters anywhere on the network. You can connect up to 126 stations

including server and repeater on your network. However, we recommend you to use one

device for the engineering device.

Network Cable

The PROFIBUS cable can be used as a network cable. There are four types (A, B, C, D) of

PROFIBUS cables. Normally, cable type A is used for a PROFIBUS DP network. The cable

type A specifications are shown in the table below.

Item Specification

Impedance

135 to 165 Ω

Capacity < 30 pf/m

Loop resistance 110 Ω/km

Wire diameter 0.64 mm

Core cross-section > 0.34 mm

2

20 Fieldbus I/O Rev.6

Page 33

2. Installation

It is recommended that a 9-pin D-Sub connector be used for protecting rating IP 20. For IP

65/67, M12 connector in accordance with IEC 947-5-2, Han-Bird connector in accordance

with DESINA, and Siemens hybrid connector are available.

Pin assignment (9-pin D-Sub)

Pin No. Signal Assignment

1 Shield Shield / Protective ground

2 M24 Ground of output voltage (24 V)

3 RxD/TxD-P Data line B

4 CNTR-P Repeater control signal (directional control)

5 DGND Communications power supply (5 V)

6 VP Supply voltage to terminating resistor (P5V)

7 P24 Output voltage (24 V)

8 RxD/TxD-N Data line A

9 CNTR-N Repeater control signal (directional control)

Use pins 2 and 7 for connecting a maintenance device without any power supply.

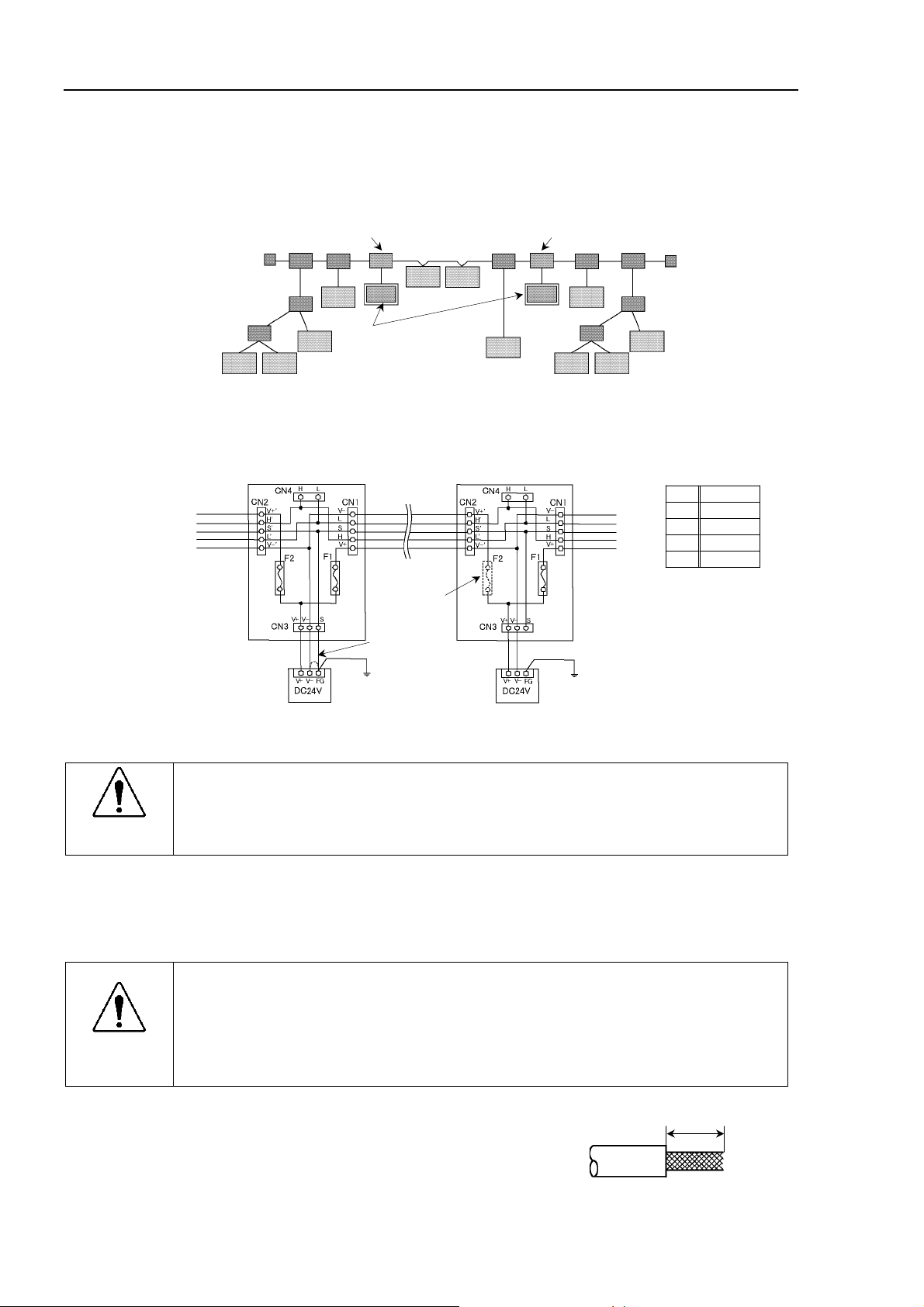

The following figure illustrates wiring.

RxD/TxD-P (3)

DGND (5)

RxD/TxD-N (8)

Station 1 Station 2

VP (6)

Shield

Protective Ground Protective Ground

(3) RxD/TxD-P

(5) DGND

(6) VP

(8) RxD/TxD-N

Different manufacturers produce a wide range of PROFIBUS cables. For details of the

PROFIBUS cables, see PROFIBUS International’s website (http://www.profibus.com/).

Terminating Resistor

To reduce reflections of communication signal, terminating resistors should be attached on

both ends of each segment. Attach the terminating resistor as shown below.

Data Line B

Data Line A

VP (6)

390

Ω

RxD/TxD-P (3)

Ω

220

RxD/TxD-N (8)

Ω

390

DGND (5)

Some PROFIBUS 9-pin D-Sub connectors on the market have functions of terminating

resistor and they can enable / disable the terminating resistor. (Example: Woodhead

MA9D00-32)

Molded terminating resistors with connector are also available to attach them to environmentresistant M12 connector.

Baud Rate and Maximum Cable Length

Available baud rates are 9.6 kbps, 19.2 kbps, 93.75 kbps, 187.5 kbps, 500 kbps, 1500 kbps, 3

Mbps, 6 Mbps, and 12 Mbps.

Fieldbus I/O Rev.6 21

Page 34

2. Installation

PROFIBUS DP requires approximately 1ms at 12 Mbps for the transmission of 512 bits input

data and 512 bits output data distributed over 32 stations. The following figure shows typical

PROFIBUS DP transmission times depending on the number of stations and baud rate.

Bus Cycle Time [ms]

18

14

10

500 kbps

6

2

2 10 20 30

1.5 Mbps

12 Mbps

Number of Slaves

The maximum cable length is restricted by the baud rate.

Baud Rate Maximum Cable Length

12 Mbps

6 Mbps

3 Mbps

1500 kbps

500 kbps

187.5 kbps

93.75 kbps

19.2 kbps

9.6 kbps

100 m

100 m

100 m

200 m

400 m

1000 m

1200 m

1200 m

1200 m

Multi-Master Configuration

PROFIBUS DP allows you to install multiple masters on a single physical network.

All slave devices on the network can be accessed by different masters. Only one master on

the network can be used for device configuration.

The following figure illustrates the communication procedure for a multi-master

configuration.

Master 1

Slave Slave Slave Slave Slave

Token-passing Procedure

Master 2

Master 3

Master-slave communication

Slave Slave

When the master receives the logic token, it inquires data from its slaves. After all

communications are completed, the master passes the token to another master. In this way,

the master can only communicate with its slaves while it is holding the token. The slaves

respond to only the inquiry from the master. No slave can output any messages.

22 Fieldbus I/O Rev.6

Page 35

A

CAUTION

2. Installation

Procedure for Modifying and Installing Communication Cables

The following procedure explains how to modify and install a Woodhead 9-pin D-Sub

connector (MA9D00-32).

Follow the steps described below to modify communication cables and connect them to the

connector.

Be careful not to injure your hands or fingers on any sharp blades or tools used

to modify the cable.

Use appropriate blades and/or other tools to modify the cable. Using

inappropriate blades and/or other tools may result in bodily injury and/or

equipment damage.

(1) Strip approx. 47.5 mm of the cable covering with extra

care so that you do not scratch on braided shield

underneath.

Do not strip the cable covering more than necessary.

Excess stripping may cause short-circuit and/or make

the cable more sensitive to noise.

pprox. 47.5 mm

(2) Carefully expand meshes of the braided shield and fold

back the shield over the cable covering. Cut off the

shield at approx. 10 mm from the stripped side of the

cable covering.

(3) Strip the covering of the signal wire as shown in the

figure.

(4) Insert the signal wires into the terminal block on the connector and secure the signal

wires. Carefully connect the same signal wire to the same terminal on both ends.

To prevent faulty wiring, make a rule of connection. For instance, connect the green

signal wire to the A1/A2 terminal and the red signal wire to the B1/B2 terminal.

10 mm

40 mm 7.5 mm

Fieldbus I/O Rev.6 23

Page 36

2. Installation

2.5 How to Setup a EtherNet/IP Network

The following is a basic procedure for setting up a EtherNet/IP network:

1. Choose node distribution and distribution route on your network.

For details, refer to the following section 2.6 EtherNet/IP Network Construction.

2. Lay cables.

For details, refer to the following section 2.6 EtherNet/IP Network Construction.

3. Configure nodes.

For details, refer to respective manuals of your desired nodes.

4. Turn ON the nodes.

5. Install the scanner board in your controller.

Refer to the section 2.9 EtherNet/IP Board Installation later in this chapter.

6. Configure a master and slaves.

Use the configuration management software for configuring a master and slaves

(scan list). For details, please refer to the configuration management software

manual.

To configure EPSON RC+ as a master, refer to the section 2.9 EtherNet/IP Board

Installation later in this chapter.

7. Configure EPSON RC+.

Refer to the section 2.10 EPSON RC+ Fieldbus I/O Installation later in this chapter.

8. Operate the EtherNet/IP network.

24 Fieldbus I/O Rev.6

Page 37

2.6 EtherNet/IP Network Construction

Network Configuration

A EtherNet/IP network is configured as shown in the following figure.

Network inside

the factory, etc

Ethernet switch

Node

Node

Node

Node

Ethernet switch

Node

Node

Node

2. Installation

Waterproof

Ethernet switch

Node

Node

NOTE

)

Waterproof

slave

Waterproof

slave

Node

There are two types of the node: master and slave. The master controls a network and gathers

data from its slaves. The slaves, including external I/O and other devices, output data in

response to the master’s output order and informs the master of its input status.

You can install masters anywhere in the network. One master node can control up to 127

nodes.

Universal Ethernet cable is used for EtherNet/IP. Use a proper cable such as environmental

resistance and refraction resistance that fulfills the environment.

For details, see the website of ODVA. (http://www.odva.org/)

Wiring

Wirings are conformed to EtherNet/IP connection protocol.

You can use the generic Ethernet hub or Ethernet switch for the EtherNet/IP. However, be

sure to a use product complying with the industrial standards or noise resistant Ethernet

cable (STP cable). If you use an office use product or UTP cable, it may causes

communication errors and may not offer the proper performance.

Fieldbus I/O Rev.6 25

Page 38

2. Installation

2.7 DeviceNet Board Installation

Following two types can be used for the fieldbus I/O option DeviceNet.

- PCU-DVNIO

- PCI-DVNIO

2.7.1 Board Appearance

Part names and functions of the scanner board are shown in the following figure.

For details of the status display LEDs (Module/NetWork LED and IO LED), refer to the 4.

Troubleshooting in this manual.

PCU-DVNIO

4-pin Terminal

Watchdog Port

(Do not use this port.)

Status Display LED (2)

DeviceNet Port

(Not in use)

RJ45 Connector

(Not in use)

PCI-DVNIO

4-pin Terminal

Watchdog Port

(Do not use this port.)

Male 9-pin D-Sub

Port for Board Configuration

Status Display LED (2)

Left: Module/NetWork LED

Right: IO LED

DeviceNet Port

LED (2)

Jumper for Board Address

JP1

JP1

0

1

C0 C1 C2

Jumper for Board Address

JP1

JP1

0

1

C0 C1 C2

26 Fieldbus I/O Rev.6

Page 39

2. Installation

2.7.2 Specifications

Part Number applicom PCI-DVNIO / PCU-DVNIO

Modes Master/Slave

Baud rates 125, 250, 500 kbps

Interface

Supported Devices

Maximum Nodes

Connection Types

Explicit Messaging

EDS Support

Input Data Size

Output Data Size

Automatic Detection

1 DeviceNet port

Group 2 Only Server and U.C.M.M. capable

63

Strobe, Polling, Cyclic and Change of State

Yes

Yes

1 to 255 bytes

1 to 255 bytes

Yes. Devices can be detected automatically.

2.7.3 Software Installation

Before installing any boards in your controller, you must install the applicomIO console

application and drivers for the type of board you will be using.

(1) Start the controller.

(2) Run the C:\Install\FieldBus\Install\applicomIO\Disk1\Setup.EXE from the install

folder in the controller to start the installation.

(3) Select the desired language for the installer.

(4) Select Install Products.

(5) Select applicomIO. Do not select applicomIO ActiveX.

Fieldbus I/O Rev.6 27

Page 40

2. Installation

(6) Allow the default components to be installed.

(7) Select the protocol: DeviceNet you will be using. If you also use PROFIBUS DP,

select Profibus-DP as well. Select which type of device data files to install (EDS for

DeviceNet, GSD for PROFIBUS DP).

(8) Complete the installation.

(9) The message to ensure the restart appears. Click the Yes button.

(10) Start the C:\Install\FieldBus\Install\SP\Setup.EXE and install the service pack.

No installation is necessary when a service pack is not attached to controller.

(11) After completing the installation of the service pack, shutdown the computer.

(12) Proceed to 2.5.4 Board Installation.

28 Fieldbus I/O Rev.6

Page 41

2. Installation

t

WARNING

2.7.4 Board Installation

Make sure that the power is turned OFF before installing/removing any boards

or connecting/disconnecting any cables. Installing/removing any boards or

connecting/disconnecting any cables with the power ON is extremely hazardous

and may result in electric shock and/or malfunction of equipment.

(1) Configure the board address jumper (JP1) on each board. The board number must

start with 1 consecutively. Refer to the following table for JP1 configuration.

Short Socke

Board No.

1 0: Short 0: Short 0: Short

2 1: Short 0: Short 0: Short

3 0: Short 1: Short 0: Short

4 1: Short 1: Short 0: Short

5 0: Short 0: Short 1: Short

6 1: Short 0: Short 1: Short

7 0: Short 1: Short 1: Short

8 1: Short 1: Short 1: Short

(2) Install the board(s) in any available PCI slot in the controller.

(3) Connect the board(s) to the Fieldbus.

C0 C1 C2

(4) Start the controller.

(5) The Windows Hardware Wizard will display a message that the applicomIO board

was found and prompt you to restart the computer.

The applicomIO console application will automatically start for this first start after

installation. Close this application for now and restart the controller.

(6) Start the applicomIO console application.

(7) Click the Add Board button on the upper left of the console window to add a board.

(8) The following dialog will appear.

Check that “PCI-DVNIO” (“PCI-DPIO” or “PCU-DPIO” in case of PROFIBUS DP)

Fieldbus I/O Rev.6 29

Page 42

2. Installation

is shown in the Board Type: box. Then, click the OK button.

When installing more than two fieldbus boards in the system, add all the boards

using this dialog.

The following dialog will appear when no board is detected. Ensure that the board is

correctly inserted and that the board configuration is correct.

(9) After all the boards are added, the system should be restarted.

Close the applicomIO Console application and click the OK button on the Save

modification dialog. Click the OK button on the following dialog to restart

Windows.

(10) After restarting the system, continue with the following 2.5.5 Master Mode or 2.5.6

Slave Mode sections.

30 Fieldbus I/O Rev.6

Page 43

2. Installation

2.7.5 Master Mode

(1) Ensure that the board is connected to the fieldbus. Then, start the applicomIO

console application.

(2) Register the device information (EDS file) that is necessary for the network setup.

Select the [Equipment Library] tab at the center of the dialog’s right side and click

the Add icon.

(3) Following dialog appears. Specify the EDS file that is supplied from the device

manufacturer.

(4) Click on the “Protocol list” under the board that was just added.

(5) Select Protocol | Property.

Fieldbus I/O Rev.6 31

Page 44

2. Installation

(6) Configure the baud rate, MAC ID (master address), and so on for the DeviceNet

network.

NOTE

)

The load on a bus can be controlled by the baud rate and interscan delay settings.

When the load exceeds 60%, the DeviceNet network communication will be unstable, for

example: more communication errors. Set the configuration to minimize the load.

For the procedure for verifying the load on the bus using the applicomIO Console

application, refer to the 4. Troubleshooting in this manual.

(7) Click the Network Detection tab on the center left of the console window.

(8) Click the Read Network Configuration button to display the Network Detection

dialog and read in the devices on the Fieldbus.

32 Fieldbus I/O Rev.6

Page 45

2. Installation

(9) Drag each device you want to scan from the Network Detection tab to the Master

item in the list on the right.

(10) The following dialog will appear.

NOTE

)

Select the Connection Configuration tab to verify the connection configuration.

Change the configuration if necessary.

Not every slave device supports all connection types. Understand the

specifications of the slave device you want to use and configure the connection

correctly.

Fieldbus I/O Rev.6 33

Page 46

2. Installation

The Expert Mode button will appear when the applicomIO Console application is

used in the expert mode.

To configure details of “Change Of State” and “Cyclic”, click the Expert Mode

button and display the Expert Mode dialog.

NOTE

)

Never disable Ack. When the [Ack] checkbox is unchecked, a failed connection is

not regarded as an error.

(11) When the system cannot identify the device you want to use (its EDS file is not

registered), the following dialog will appear. In this case, obtain the EDS file from

the device manufacturer and register it. Then, start from step 5 (Network Detection)

of this procedure.

34 Fieldbus I/O Rev.6

Page 47

2. Installation

To create a new EDS file based on the data from the device, click the Create New

EDS File button.

When a new EDS file is created, the following dialog will appear to verify the

contents of the file.

(12) Select the Equipment Library tab on the center left of the console window and

click the Add button to register the new EDS file in the system.

Fieldbus I/O Rev.6 35

Page 48

2. Installation

(13) Select File | Download in Flash to register the configuration in the fieldbus board.

After a few seconds, the board's state will show green in the status bar.

(14) Now, the fieldbus board is ready to operate as a master. Close the applicomIO

Console application.

36 Fieldbus I/O Rev.6

Page 49

2. Installation

2.7.6 Slave Mode

(1) Ensure that the board is connected to the fieldbus. Then, start the applicomIO

console application.

(2) Click on the “Protocol list” under the board that was just added.

(3) Select Protocol | Properties.

(4) Configure the baud rate, MAC ID (slave address), and so on for the DeviceNet

network. In this example, the MAC ID (slave address) is set to 005.

NOTE

Specify an unused address on the network for a slave device as well as other devices.

)

(5) Double-click the “DeviceNet Local Slave” item.

Fieldbus I/O Rev.6 37

Page 50

2. Installation

(6) The DeviceNet Local Slave property sheet will appear. Select the Equipment

(device) ID. It must be the same number as the Master ID in step (4).

(7) Click on the Connection Configuration tab. Check the Polling check box and

configure how many inputs and outputs for the slave device. In this example, the

Output Size and Input Size are set to 8 bytes.

NOTE

)

The load on a bus varies depending on the input/output size settings.

When the load exceeds 60%, the DeviceNet network communications will be

unstable, for example: more communication errors. Restrict the input/output sizes

to the minimum necessary to minimize the load. The load is also controlled by

baud rate in the master configuration.

For the procedure for verifying the load on the bus using the applicomIO Console

application, refer to the 4. Troubleshooting in this manual.

The input/output sizes of each node may be restricted depending on the master.

For details of the permitted data size, refer to the respective manuals of the masters.

(8) Click OK.

38 Fieldbus I/O Rev.6

Page 51

2. Installation

(9) Select File | Download in Flash to register the configuration in the fieldbus board.

After a few seconds, the board's state will show green in the status bar.

(10) Close the applicomIO console application.

(11) The default slave EDS file is created.

The path is: C:\Program Files\Woodhead\Direct-link\ApplicomIO2.3\ConfigIO

\Config01\applicomio.eds.

You may make a copy of the default slave EDS file and modify it to create your

original EDS file if necessary.

Edit the copy of the slave EDS file using Notepad. You may want to change the

VendName and ProductTypeStr.

Fieldbus I/O Rev.6 39

Page 52

2. Installation

$ EDS File Generated by applicomIO® Console Version : 2.2

[File]

DescText = "EDS for applicomIO Scanner";

CreateDate = 02-01-2004;

CreateTime = 08:14:41;

ModDate = 02-01-2004;

ModTime = 08:14:41;

Revision = 1.0;

[Device]

VendCode = 579;

ProdType = 12;

ProdCode = 1;

MajRev = 1;

MinRev = 2;

VendName = "applicom international";

ProdTypeStr = "Communication Adapter";

ProdName = "applicomIO Scanner";

Catalog = "";

[IO_Info]

Default = 0x0000;

Copy the EDS file to the system where the master is located. Add the new slave

device to the master using the new EDS file.

(12) On the master system, scan the network for new devices. The new slave device

should be detected.

Use the EDS file created in previous steps for the slave device.

40 Fieldbus I/O Rev.6

Page 53

2.8 PROFIBUS DP Board Installation

Following two board types can be used for the fieldbus I/O option PROFIBUS DP.

- PCU-DPIO

- PCI-DPIO

2.8.1 Board Appearance

Part names and functions of the scanner board are shown in the following figure. For details

of the status display LEDs, refer to the 4. Troubleshooting in this manual.

PCU-DPIO

2. Installation

4-pin Terminal

Watchdog Port

(Do not use this port.)

Status Display LED (2)

PROFIBUS-DP Port

LED (2)

(Not in use)

RJ45 Connector

(Not in use)

PCI-DPIO

Configuration Port

Communication Status LED

Male 9-pin D-Sub

Port for Board Configuration

Status Display LED (2)

Left: Communication Status LED

Right: Physical Error LED

Female 9-pin D-Sub

PROFIBUS DP Port

4-pin Terminal

Watchdog Port

(Do not use this port.)

Jumper for Board Address

JP1

JP1

0

1

C0 C1 C2

Jumper for Board Address

JP1

JP1

0

1

C0 C1 C2

Fieldbus I/O Rev.6 41

Page 54

2. Installation

2.8.2 Specifications

Part Number applicom PCI-DPIO / PCU-DPIO

Modes Master/Slave

Baud Rates 9.6, 19.2, 93.75, 187.5, 500, 1500, 3000, 6000, 12000 kbps

Interface 1 PROFIBUS port (EN 50 170)

Output Current Capacity Maximum 150mA

Supported Devices All DP Devices

Maximum Stations 126 (32 per segment)

GDS Support Yes

PROFIBUS DP Class 1 Yes

PROFIBUS DP Class 2 Yes

Input Data Size 1 to 244 bytes

Output Data Size 1 to 244 bytes

Automatic Detection Yes. Devices can be detected automatically.

2.8.3 Software Installation

Before installing any boards in your controller, you must install the applicomIO console

application and drivers for the type of board you will be using.

(1) Start the controller.

(2) Run the C:\Install\FieldBus\Install\applicomIO\Disk1\Setup.EXE from the install

folder in the controller to start the installation.

(3) Select the desired language for the installer.

(4) Select Install Products.

(5) Select applicomIO. Do not select applicomIO ActiveX.

42 Fieldbus I/O Rev.6

Page 55

2. Installation

(6) Allow the default components to be installed.

(7) Select the protocol: PROFIBUS DP you will be using.

If you also use DeviceNet, select DeviceNet as well. Select which type of device

data files to install (GSD for PROFIBUS DP, EDS for DeviceNet).

(8) Complete the installation.

(9) The message to ensure the restart appears. Click the Yes button.

(10) Start the C:\Install\FieldBus\Install\SP\Setup.EXE and install the service pack.

No installation is necessary when a service pack is not attached to controller.

(11) After completing the installation of the service pack, shutdown the computer.

(12) Proceed to 2.6.4 Board Installation.

Fieldbus I/O Rev.6 43

Page 56

2. Installation

t

WARNING

2.8.4 Board Installation

Make sure that the power is turned OFF before installing/removing any boards

or connecting/disconnecting any cables. Installing/removing any boards or

connecting/disconnecting any cables with the power ON is extremely hazardous

and may result in electric shock and/or malfunction of equipment.

(1) Configure the board address jumper (JP1) on each board. The board number must

start with 1 consecutively. Refer to the following table for JP1 configuration.

Short Socke

Board No.

1 0: Short 0: Short 0: Short

2 1: Short 0: Short 0: Short

3 0: Short 1: Short 0: Short

4 1: Short 1: Short 0: Short

5 0: Short 0: Short 1: Short

6 1: Short 0: Short 1: Short

7 0: Short 1: Short 1: Short

8 1: Short 1: Short 1: Short

(2) Install the board(s) in any available PCI slot in the controller.

(3) Connect the board(s) to the Fieldbus.

C0 C1 C2

(4) Start the controller.

(5) The Windows Hardware Wizard will display a message that the applicomIO board

was found and prompt you to restart the computer.

The applicomIO console application will automatically start for this first start after

installation. Close this application for now and restart the controller.

(6) Start the applicomIO console application.

(7) Click the Add Board button on the upper left of the console window to add a board.

44 Fieldbus I/O Rev.6

Page 57

2. Installation

(8) The following dialog will appear.

Check that “PCI-DPIO” or “PCU-DPIO” (“PCI-DVNIO” in case of DeviceNet) is

shown in the Board Type: box. Then, click the OK button.

When installing more than two fieldbus boards in the system, add all the boards

using this dialog.

The following dialog will appear when no board is detected. Ensure that the board is

correctly inserted and that the board configuration is correct.

(9) After all the boards are added, the system should be restarted.

Close the applicomIO Console application and click the OK button on the Save

modification dialog. Click the OK button on the following dialog to restart

Windows.

(10) After restarting the system, continue with the following 2.6.5 Master Mode or 2.6.6

Slave Mode sections.

Fieldbus I/O Rev.6 45

Page 58

2. Installation

2.8.5 Master Mode

(1) Ensure that the board is connected to the fieldbus. Then, start the applicomIO

console application.

(2) Register the device information (GSD file) that is necessary for the network setup.

Select the [Equipment Library] tab at the center of the dialog’s right side and click

the Add icon.

(3) Following dialog appears. Specify the GSD file that is supplied from the device

manufacturer.

(4) Select Description | Properties.

46 Fieldbus I/O Rev.6

Page 59

2. Installation