Page 1

Installation and Assembly:

Universal Projector Ceiling Mount

Model: ELPMBPJF

This product is UL Listed. It must be

installed by a qualihed professional

C

US installer.

Maximum UL Load Capacity: 50 lb (22.7 kg)

Manufactured by Peerless Industries, Inc.

3215W.North Ave. • MelrosePark,IL 60160 • (800)865-2112or(708)865-8870 • Fax:(708)865-2941 • www.peerlessmounts.com

Page 2

NOTE: Read entire instruction sheet before you start instaiiation and assembiy.

A WARNING

Do not begin to instaii your product untii you have read and understood the instructions and warnings contained in

this Instaiiation Sheet. If you have any questions regarding any of the instructions or warnings, caii Peeriess cus

tomer care at 1-800-729-0307.

This product shouid oniy be instaiied by someone of good mechanicai aptitude, has experience with basic buiiding

construction, and fuiiy understands these instructions.

Make sure that the supporting surface wiii safeiy support the combined ioad ofthe equipment and aii attached hard

ware and components.

Never exceed the Maximum UL Load Capacity.

Aiways use an assistant or mechanicai iifting equipment to safeiy iift and position equipment.

This product is intended for indoor use oniy. Use of this product outdoors couid iead to product faiiure and personai

injury.

Tighten screws firmiy, but do not overtighten. Overtightening can damage the items, greatiy reducing their hoiding

power. See suggested torque vaiues where appiicabie within these instructions.

When instaiiing or adjusting the ceiiing mount, do not use adhesives, iubricants, or oiis to prevent the screws from

ioosening. Ifyou use adhesives, iubricants, or oiis to prevent the screws from ioosening, the casing may crack and

the projector may faii, causing serious injury and damage to the projector.

Tools Needed for Assembly

• stud finder ("edge to edge" stud finder is recommended)

• phiiiips screwdriver

• driii

• 1/4" bit for concrete surface

• 5/32" bit for wood joist

Table of Contents__________________

Parts List.............................................................

Instaiiation to Extension Coiumn

Instaiiation to Wood Joist Ceiiings

Instaiiation to Concrete Ceiiings..........................

Fiush Mount Appiication......................................

Attaching Adapter Piate to Projector

Attaching Adapter Piate to Projector Mount.

Projector Aiignment and Accessories..................

Warranty Information

...........................................

.........................

......................

...................

...

...

...

....

...

7-8

...

...

.. 10

3

4

5

6

7

8

9

Visit the Peeriess Web Site atwww.peeriessmounts.com ForTechnicai Support Contact Peeriess Mounts at 1-800-729-0307 or708-865-8870.

2 oflO

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 3

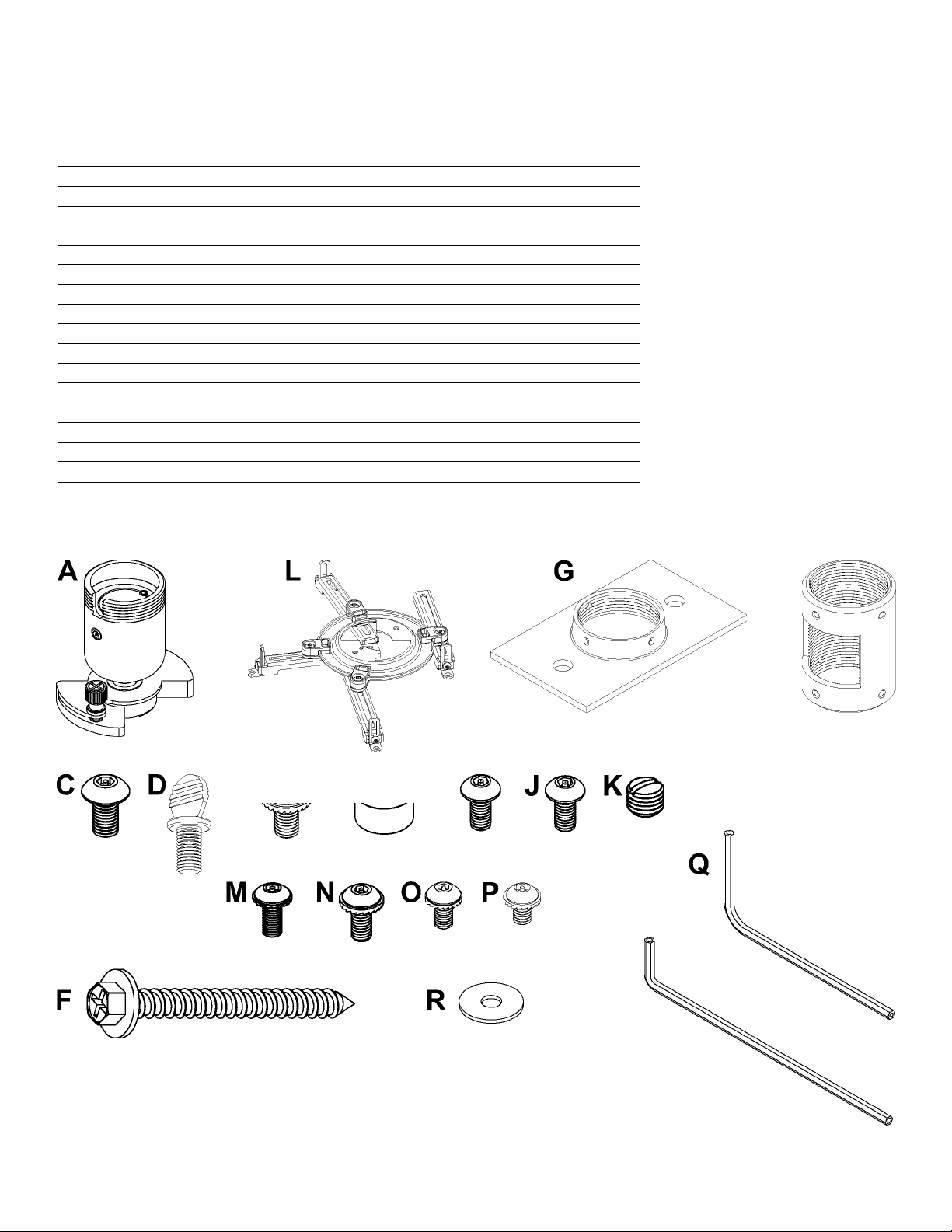

Before you start check the parts list to ensure all of the parts shown are included.

Parts List

Description

A projector mount 1

B 4 mm security allen wrench 1

M5x.8x10 mm socket pin type F screw 1

C

D #10-32 x 3/8" spade thumb screw 1 560-2107

E #10-32 x 3/8" serrated washer head socket pin screw 1

F #14 x 2.5" phillips hex head wood screw 2 5S1-015-C04

ceiling plate 1 580-4042

G

H

.25"IDx.56" ODx.26 spacer

1 extension column connectorwith cord management 1

#10-32 x 3/8" socket pin screw 2 520-2084

J

K #10-32 x 3/16" slotted set screw

L adapter plate 1

M M3x8 mm serrated washer head socket pin screw 4 510-2004

N M4x10 mm serrated washer head socket pin screw 4

M5x10 mm serrated washer head socket pin screw 4

0

P M6x10 mm serrated washer head socket pin screw 4

2 mm security allen wrench 1 560-1097

Q

R washer 4

NOTE: Actual parts may appearslightly different than illustrated.

Qty.

2

3

Part Number

055-0016

560-9646

520-2031

520-2151

590-2071

580-4025

520-2187

055-KUNV-S-3

510-2060

510-2063

510-2066

540-2025

B

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

3 of10

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 4

Installation to Extension Column

Screw extension column (sold separately) to ceiling plate (G). Align the notch with one ofthe four holes in the

o

ceiling plate (G) and secure extension column with aM5x10 mm socket pin screw (C) using security allen

wrench (B). See detail 1.

Screw extension column connector (I) to extension column. Align slot in extension column with one of the top

holes in extension column connector (I). Insert and tighten one #10-32 x 3/8" socket pin screw (J) through

extension column connector (I) into slot on extension column using security allen wrench (B). See detail 2.

Screw projector mount (A) into extension column connector (I). Align slot in projector mount (A) to one ofthe

bottom holes in extension column connector (I). Insert and tighten one #10-32 x 3/8" socket pin screw (J) through

extension column connector into slot in projector mount (A) using security allen wrench (B). See detail 3.

*NOTE: Slotted set screws (K) are used to jam against the threads of each connecting joint to prevent any excess

movement. Do not overtighten screws; overtightening screws will damage threads making it difficult to separate

the products.

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

4 of10

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 5

Installation To Wood Joist Ceilings

Drill two 5/32" (4 mm) dia. holes to a minimum

o

depth of2.5" (64 mm). Attach ceiling plate (G)with

two #14x 2.5" (6 mm x 65 mm) wood screws (F)

as shown using 3/8" (10 mm) socketwrench.

Skip to step 2.

A WARNING

Tighten wood screws (F) so that wall plate (G) is

firmly attached, but do not overtighten. Overtighten

ing can damage the screws, greatly reducing their

holding power.

Never tighten in excess of 80 in • lb (9 N.M.).

Make sure that mounting screws are anchored into

the center of the studs. The use of an "edge to edge"

stud finder is highly recommended.

A WARNING

It is the responsibility of the installer to verify that the

supporting surface will safely support the combined

load of all attached hardware and components.

IMPORTANT: Be sure to drill holes into thejoist CENTER!

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

5 of10

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 6

Installation to Solid Concrete or Cinder Block

A WARNING

When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortarjoints! Be sure to mount in a solid

partofthe block, generally 1" minimum from the side ofthe block. Cinder block must meetASTM C-90 specifica

tions. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill to

avoid breaking out the back ofthe hole when entering a void or cavity.

Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

Make sure that the supporting surface will safely support the combined load ofthe equipment and all attached hard

ware and components.

NOTE: ACC233 (concrete anchors are not included)

o

are recommended.

Drill two 5/16" (8 mm) dia. holes to a minimum depth of

2.5" (64 mm). Attach ceiling plate (G) using two concrete

anchors and #14x 2.5" wood screws (F) as shown in

Illustration A and 1, 2 and 3. Tighten all fasteners.

IMPORTANT: It is the responsibility of the installer to

verify that the ceiling will safely support the

combined load of all attached hardware and

components.

Skip to step 2.

A WARNING

Tighten screws so that wall plate is firmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

Never tighten in excess of 80 in. • lb (9 N.M.).

A WARNING

Always attach concrete anchors directly to load

bearing concrete.

Never attach concrete anchors to concrete covered

with plaster, drywall, orotherfinishing material.

If mounting to concrete surfaces covered with a

finishing surface is unavoidable (not evaluated by

UL), the finishing surface must be counterbored

as shown below. Be sure concrete anchors do

not pull away from concrete when tightening

screws. If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer (not

evaluated by UL).

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

6 oflO

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 7

Flush Mount Application

Screw projector mount (A) into ceiling plate (G). Align the notch with one ofthe four holes ofthe ceiling

o

plate (G) and secure projector mount (A) with aM5x10 mm socket pin screw (C) using security allen

wrench (B) as shown in detail 1.

NOTE: Slotted set screw (K) is used tojam against the threads of mount to prevent any excess movement of

the projector mount (A). Do not overtighten screw; overtightening screwwill damage threads making it difficult to

Attaching Adapter Plate to Projector

NOTE: The projector you are installing may differ

©

in appearance from the sample illustrated below.

NOTE: Some projectors may have three orfour

attachment points. If projector has three attach

ment points, the unused leg may be removed.

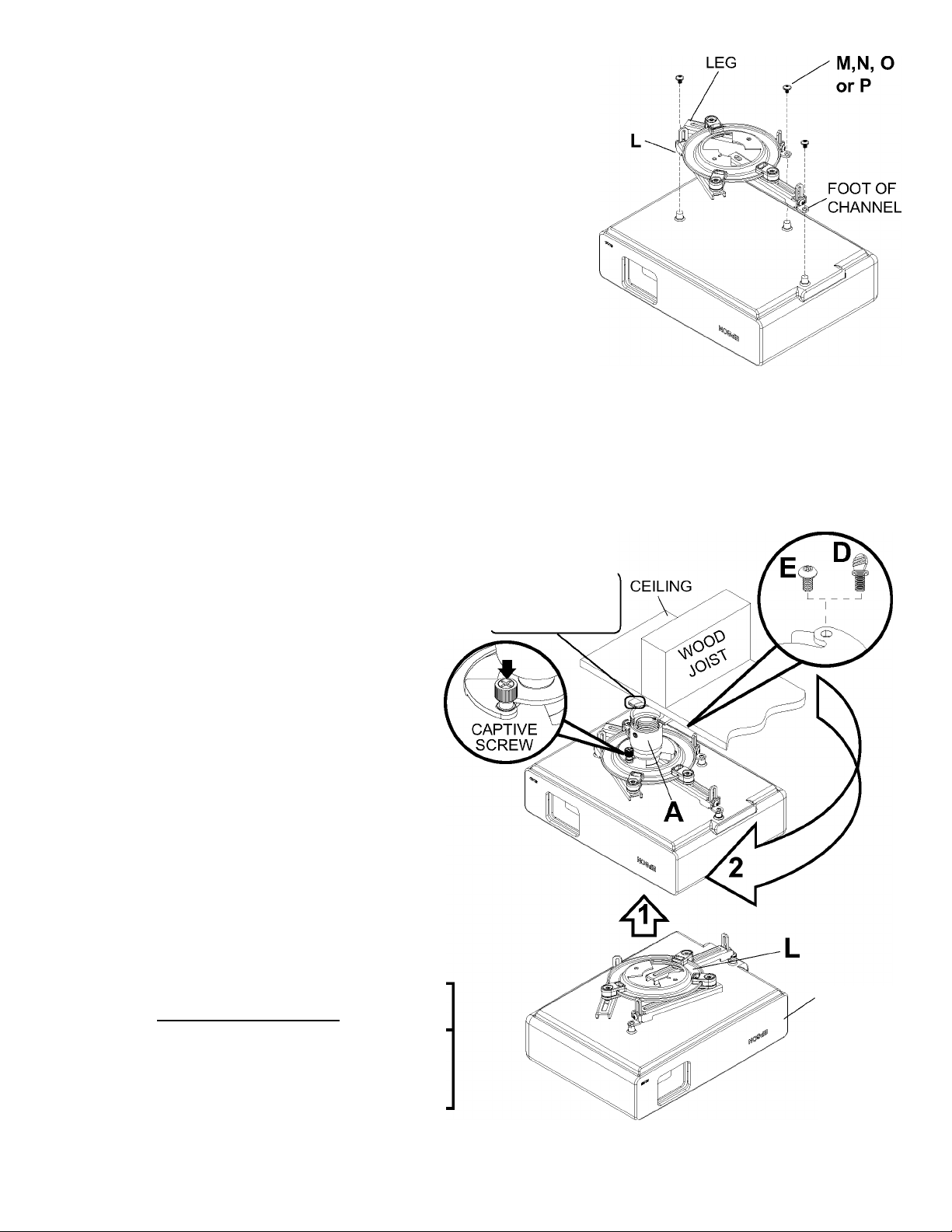

Place projector upside down. Locate adapter

plate (L) with notch* facing forward as close to

projector center of gravity as possible without

covering any mounting holes. Loosen channels,

and ifthere are only three mounting holes re

move fourth channel. Using one channel for each

mounting hole, position feet of channels over

mounting holes as shown. Important: If projector

does not have at least three mounting holes, do

not use this adapter plate. Once channels are in

position retighten fasteners.

NOTE: Some projectors have feet which can be

removed and the corresponding threaded insert

can be used for a mounting hole.

*Notch indicates front of projector.

CAUTION

It is the responsibility of the installer to ensure that

the projector is properly ventilated. Feet of channels

are used to raise the mount off the projector surface.

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

7 of10

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 8

o

Attach adapter plate (L) to projector using one

screw (M, N, O or P) for each channel as shown.

Tighten all screws, while keeping the center ofgravity.

Be sure that adapter plate (L) is straight. Adjust the

feet ofthe channels to keep the adapter plate level.

Tighten all screws with 4 mm security allen wrench

(B) orwrench provided with projector mount, while

keeping the center of gravity. If M3 screws are used,

tighten using 2 mm security allen wrench (Q).

NOTE: Projectors may require different size screws

for mounting. Use a combination ofscrews (M, N, O

or P) and foot adjustment that will result in channels

of adapter plate (L) fitting tightly against projector.

Important: In order to properly engage the threads in

the mounting holes, the screw must be turned at least

3 full turns.

NOTE: If using screw (M), place washer (R) between

screw (M) and foot of channel.

Attaching Adapter Plate to Projector Mount

Attach projector, with adapter plate already on

O

it, to the projector mount (A) by inserting the

projector mount (A) into the adapter plate

connection and twisting until the adapter plate

will no longer turn (about 75°). The spring

loaded captive screw should line up with a

corresponding hole on the adapter plate (this

should line up automatically when the two are

connected). Push down and tighten the spring

loaded captive screw to secure the adapter

plate to the mount. If not using the optional

security feature, fasten thumb

screw (D) in the hole opposite the spring loaded

captive screw.

OPTIONAL: For security option, use #10-32 x

3/8" security screw (E) in the hole opposite

the spring loaded captive screw. Tighten with

security allen wrench (B). This will prevent the

projectorfrom being removed.

NOTE: Be sure to only use the #10-32 x 3/8"

screw (E) (or the thumb screw (D) opposite

the spring loaded captive screw.

CUTAWAY VIEW

OF CEILING

PLATE (G)

PROJECTOR

A WARNING

Do not lift more weight than you can handle! Use

additional man power or mechanical lifting equip

ment to safely handle placement ofthe projector!

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

8 of10

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 9

Projector Alignment

To adjust roll, pitch and yaw loosen the set screw

o

(shown below) using alien wrench (B). You should be

able tojust slightly loosen the screw so that your adjust

ments can be set without having to hold the projector.

Move projector to desired position and slowly tighten set

screw.

IMPORTANT: Allen wrench is your key for projector removal. Store it in a safe place.

PROJECTOR

NOTE: All accessories are available for purchase through Epson (www.epson.com)

ELPMBP01

Adjustable Suspended Ceiling

Channel Kit

• Adjustable carriage allows for ideal

projector positioning below a2'x2' or 2'

X 4' standard ceiling tile

• Pre-assembled, easy to install design

reduces installation time

• Knockouts are provided for electrical

outlet boxes and antenna leads

• Escutcheon ring leaves a clean finish

• Compact and lightweight

• Includes Kwik-LocTM self locking cable

joiners for simple cable support set-up

ELPMBP03

Structural Round Ceiling Plate

• Mounts to wood joist or structural concrete ceiling

• Features cable management access hole

• 1 %" -11.5" NPT fitting for attachment of

adjustable extension column

• Max weight load: 150 lb (68 kg.)

• Color: White

Accessories

ELPMBP02

False Ceiling Plate Kit

• Replaces a2'x2' ceiling tile and mounts to

structural ceiling with tie wires

• Two-piece design offers five different points

for mount attachment

• Includes tie wire supports and fiush mount

tube

• 1 -11.5" NPT fitting for attachment of

adjustable extension column

• Two knockout panels for electrical outlet

boxes

• Max weight load: 50 lb (23 kg.)

• Color: White

ELPMBC01

Adjustable Extension Column (Pipe)

8"- 11"

• 8"-11" adjustable extension in 1" increments

• Specially designed to allow internal cable

management

• 1 %" -11.5" NPT pipe threaded on both ends

• Notched ends for use with set screw to provide

safety and security

• Color: White

Uus

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

9 of10

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

Page 10

LIMITED FIVE-YEAR WARRANTY

Peerless Industries, Inc. establishes a warranty period offive years for products manufactured or supplied by Peerless. This period commences from the date of

sale ofthe productto the original consumer, butwill in no case lastfor more than sixyears afterthe date ofthe product’s manufacture. During the warranty period

such products will be free from defects in material and workmanship, provided they are installed and used in compliance with the instructions established by

Peerless Industries, Inc. Subject to applicable legal requirements, during the warranty period Peerless will repair or replace, or refund the purchase price of, any

Any otherwarranties prescribed by the law which may apply with respect to such products also are limited in duration to the warranty period specified in this

This warranty does not cover damage caused by (a) service or repairs by the customer or a person who is not authorized for such service or repairs by Peerless

Industries, Inc., (b) the failure to utilize proper packing when returning the product, (c) incorrect installation or the failure to follow Peerless’ instructions or warnings

when installing, using or storing the product, or (d) misuse or accident, in transit or otherwise, including in cases ofthird party actions and force majeure.

In no event shall Peerless be liable for incidental or consequential damages or damages arising from the theft of any product, whether or not secured by a security

This Limited Five-Year Warranty is in lieu of all other warranties, expressed or implied, and is the sole remedy with respect to product defects. No retailer, dealer,

distributor, installer or other person is authorized to modify or extend this warranty or impose any obligation on Peerless in connection with the sale of any product

This warranty gives specific legal rights, and you may also have other rights provided bythe national legislation ofthe country in which you purchased such

such product which fails to conform with this warranty.

Limited Five-YearWarranty.

device which may be included with the product.

manufactured or supplied by Peerless.

product.

teerless*

www.peerlessmounts.com

© 2008 Peerless Industries, Inc.

Visit the Peerless Web Site atwww.peerlessmounts.com For Technical Support Contact Peerless Mounts at 1-800-729-0307 or708-865-8870.

10 oflO

All other brand and product names are trademarks or registered trademarks oftheir respective owners.

ISSUED:01-23-07 SHEET #:055-9498-4 05-20-10

© 2008 Peerless Industries, Inc. All rights reserved.

Loading...

Loading...