Page 1

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

DW930/DW935/DW936/DW939

Cordless Circular Saws

Scie circulaire sans fil

Sierras circulares inalámbricas

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us in the World Wide Web at www.dewalt.com

Page 2

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Rules – For All Battery

Operated Tools

WARNING! Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

•

Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

•

Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

•

Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

•

Do not abuse the cord. Never use the cord to carry the tool.

Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately

.

Damaged cords may

create a fire.

•

A battery operated tool with integral batteries or a separate

battery pack must be recharged only with the specified

charger for the battery. A charger that may be suitable for one

type of battery may create a risk of fire when used with another

battery.

•

Use battery operated tool only with the specifically

designated battery pack. Use of any other batteries may create a

risk of fire.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

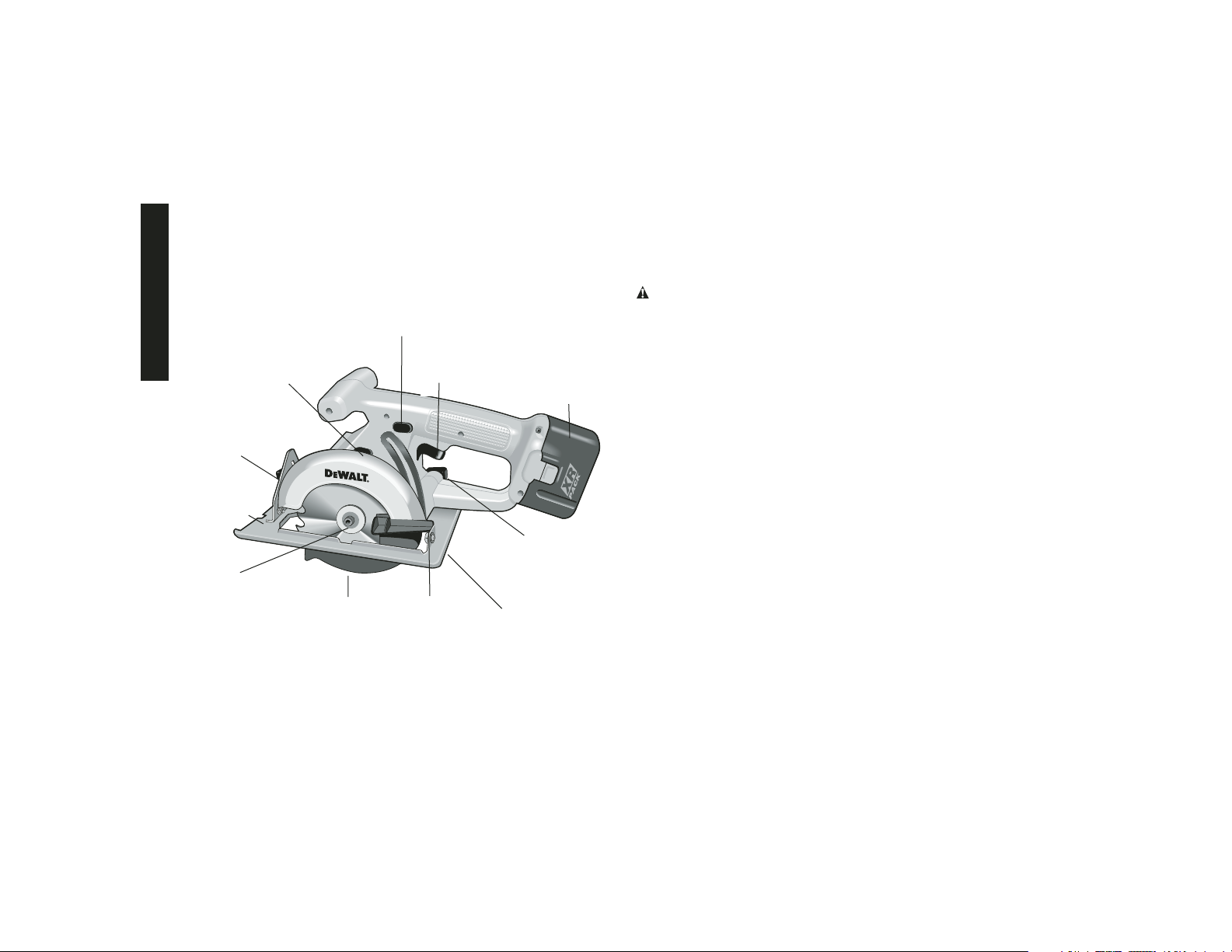

SWITCH LOCK OFF

BUTTON

BATTERY

PACK

SHOE

TRIGGER

SWITCH

DEPTH

ADJUSTMENT

KNOB

LOWER

GUARD

RETRACTING

LEVER

LOWER

GUARD

BLADE LOCK

BUTTON

BEVEL

ADJUSTMENT

KNOB

KERF

INDICATOR

BLADE CLAMPING

SCREW

DW930 12.0 Volt Cordless Trim Saw 2500 RPM

DW935 14.4 Volt Cordless Trim Saw 3000 RPM

DW936 18.0 Volt Cordless Trim Saw 3200 RPM

DW939 18.0 Volt Cordless Circular Saw 3700 RPM

DW935 shown

R

Page 3

1

English

PERSONAL SAFETY

•

Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury,

•

Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothing, jewelry, or long hair can be caught

in moving parts.

Air vents often cover moving parts and should also

be avoided.

•

Avoid accidental starting. Be sure switch is in the locked or

off position before inserting battery pack. Carrying tools with

your finger on the switch or inserting the battery pack into a tool

with the switch on invites accidents.

•

Remove adjusting keys or wrenches before turning the tool

on. A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

•

Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

•

Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions.

TOOL USE AND CARE

•

Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to a loss of control.

•

Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for which

it is designed.

•

Do not use tool if switch does not turn it on or off. A tool that

cannot be controlled with the switch is dangerous and must be

repaired.

•

Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments,

changing accessories, or storing the tool. Such preventative

safety measures reduce the risk of starting the tool accidentally.

•

Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

•

When battery pack is not in use, keep it away from other metal

objects like: paper clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one

terminal to another. Shorting the battery terminals together may

cause sparks, burns, or a fire.

•

Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less likely

to bind and are easier to control.

•

Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

•

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool, may create a risk of injury when used on another tool.

SERVICE

•

Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel may result in a risk of injury.

•

When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of shock or injury.

Additional Safety Rules for Circular

Saws

DANGER: Keep hands away from cutting area and blade. Keep

your second hand on auxiliary handle or motor housing. If both

hands are holding the saw, they cannot be cut by the blade.

Page 4

2

• Keep your body positioned to either side of the blade, but not in line

with the saw blade. KICKBACK could cause the saw to jump

backwards. (See KICKBACK)

• Do not reach underneath the work. The guard can not protect you

from the blade below the work.

• Check lower guard for proper closing before use. Do not operate

saw if lower guard does not move freely and close instantly. Never

clamp or tie the lower guard into the open position. If saw is

accidentally dropped, lower guard may be bent. Raise the lower

guard with the Retracting Handle and make sure it moves freely and

does not touch the blade or any other part, in all angles and depths

of cut.

• Check the operation and condition of the lower guard spring. If the

guard and the spring are not operating properly, they must be

serviced before use. Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a buildup of debris.

• Lower guard should be retracted manually only for special cuts such

as “Pocket Cuts” and “Compound Cuts.” Raise lower guard by

Retracting Handle. As soon as blade enters the material, lower

guard must be released. For all other sawing, the lower guard

should operate automatically.

• Always observe that the lower guard is covering the blade before

placing saw down on bench or floor. An unprotected, coasting blade

will cause the saw the walk backwards, cutting whatever is in its

path. Be aware of the time it takes for the blade to stop after switch

is released.

• NEVER hold piece being cut in your hands or across your leg. It is

important to support the work properly to minimize body exposure,

blade binding, or loss of control.

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring. Contact

with a “live” wire will also make exposed metal parts of the tool “live”

and shock the operator.

• When ripping always use a rip fence or straight edge guide. This

improves the accuracy of cut and reduces the chance for blade

binding.

• Always use blades with correct size and shape (diamond vs. round)

arbor holes. Blades that do not match the mounting hardware of the

saw will run eccentrically, causing loss of control.

• Never use damaged or incorrect blade washers or bolts. The blade

washers and bolt were specially designed for your saw, for optimum

performance and safety of operation.

Causes and Operator Prevention of

Kickback

•

KICKBACK is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw to lift up and

out of the workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing

down, the blade stalls and the motor reaction drives the unit rapidly

back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth at

the back edge of the blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and jump back toward

operator.

• KICKBACK is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

• Maintain a firm grip with both hands on the saw and position your

body and arm to allow you to resist KICKBACK forces.

KICKBACK forces can be controlled by the operator, if proper

precautions are taken.

• When blade is binding, or when interrupting a cut for any reason,

release the trigger and hold the saw motionless in the material until

the blade comes to a complete stop. Never attempt to remove the

saw from the work or pull the saw backward while the blade is in

motion or kickback may occur. Investigate and take corrective

actions to eliminate the cause of blade binding.

• When restarting a saw in the workpiece, center the saw blade in

the kerf and check that the saw teeth are not engaged into the

material. If saw blade is binding, it may walk up or KICKBACK

from the workpiece as the saw is restarted.

English

Page 5

• Support large panels to minimize the risk of blade pinching and

KICKBACK. Large panels tend to sag under their own weight.

Support must be placed under the panel on both sides, near the

line of cut and near the edge of the panel.

• Do not use dull or damaged blade. Unsharpened or improperly

set blades produce narrow kerf causing excessive friction, blade

binding, and KICKBACK.

• Blade depth and bevel adjusting locking levers must be tight

and secure before making cut. If blade adjustment shifts while

cutting, it may cause binding and KICKBACK.

• Use extra caution when making a “Pocket Cut” into existing

walls or other blind areas. The protruding blade may cut objects

that can cause kickback.

Additional Specific Safety Instructions

• AVOID CUTTING NAILS. Inspect for and remove all nails from

lumber before cutting.

CAUTION: When sawing into walls, floors, or wherever “live”

electrical wires may be encountered, DO NOT TOUCH ANY METAL

PARTS OF THE TOOL! Hold the saw only by its plastic handles to

prevent electric shock is you accidentally saw into a live wire.

CAUTION: Some tools with large battery packs will stand upright

on the battery pack but may be easily knocked over. When not in use,

place tool on its side on a stable surface where it will not cause a

tripping or falling hazard.

CAUTION: Wear appropriate personal hearing protection during

use. Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out

microscopic particles.

•

Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

• The label on your tool may include the following symbols.

V..............volts A ............amperes

Hz............hertz W ..........watts

min ..........minutes ..........alternating current

........direct current

n

o ..........no load speed

..........

Class II Construction …/min ....revolutions per minute

............

earthing terminal

..........safety alert symbol

Important Safety Instructions for Battery

Packs

The battery pack is not fully charged out of the carton! First read the

safety instructions below. Then follow charging notes and procedures.

READ ALL INSTRUCTIONS.

Your tool uses a 12.0 Volt, a 14.4 Volt or an 18 Volt DEWALT battery

pack. When ordering replacement battery packs, be sure to include

catalog number and voltage.

• Do not incinerate the battery pack even if it is severely damaged or

is completely worn out.The battery pack can explode in a fire.

• A small leakage of liquid from the battery pack cells may occur

under extreme usage or temperature conditions. This does not

indicate a failure. However, if the outer seal is broken and this

leakage gets on your skin:

3

English

Page 6

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corp

oration) Seal on the nickel-cadmium battery (or battery

pack) indicates that the costs to recycle the battery (or

battery pack) at the end of its useful life have already

been paid by D

EWALT. In some areas, it is illegal to place

spent nickel-cadmium batteries in the trash or municipal

solid waste stream and the RBRC program provides an

environmentally conscious alternative.

RBRC in cooperation with D

EWALT and other battery users, has

established programs in the United States to facilitate the collection of

spent nickel-cadmium batteries. Help protect our environment and

conserve natural resources by returning the spent nickel-cadmium

battery to an authorized D

EWALT service center or to your local retailer

for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery.

Important Safety Instructions for Battery

Chargers

SAVE THESE INSTRUCTIONS - This manual contains important

safety instructions for D

EWALT battery chargers.

• Before using battery charger, read all instructions and cautionary

markings on battery charger, battery and product using battery.

4

English

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water

for a minimum of 10 minutes and seek immediate medical

attention. (Medical note: The liquid is 25-35% solution of

potassium hydroxide.)

• Do not carry extra battery packs in aprons, pockets, or tool boxes

along with other metal objects. Battery pack could be short

circuited causing damage to the battery pack and possibly causing

severe burns or fire.

• Charge the battery packs only in D

EWALT chargers.

• NOTE: The batteries in your battery pack are the nickel–cadmium

type. Cadmium is considered to be a toxic material by the

Environmental Protection Agency. Before disposing of damaged or

worn out Nickel–Cadmium battery packs, check with your state

Environmental Protection Agency to find out about special

restrictions on the disposal of these battery packs or return them to

a D

EWALT certified service center for recycling.

• DO NOT store or use the tool and battery pack in locations where

the temperature may reach or exceed 105°F (such as outside sheds

or metal buildings in summer).

DANGER: Never attempt to open the battery pack for any reason.

If battery pack case is cracked or damaged, do not insert into

charger. Danger of electric shock or electrocution. Damaged battery

packs should be returned to service center for recycling.

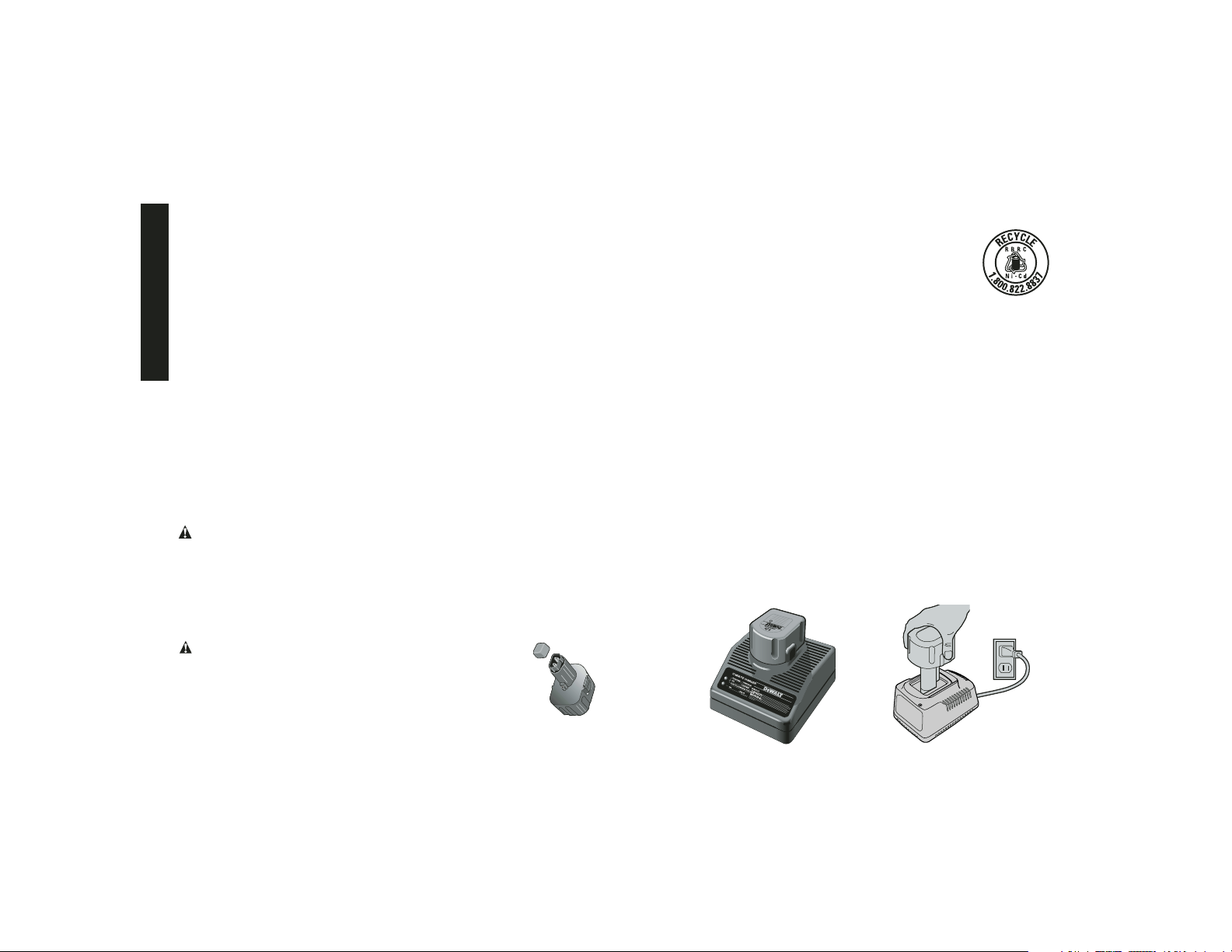

NOTE: Battery storage and carrying caps are provided for use

whenever the battery is out of the tool or charger. Remove cap before

placing battery in charger or tool.

WARNING: Do not store or carry battery so that

metal objects can contact exposed battery

terminals. For example, do not place battery in aprons,

pockets, tool boxes, product kit boxes, drawers, etc. with

loose nails, screws, keys, etc. without battery cap.

Without cap in place, battery could short circuit causing

fire or burns or damage to battery.

15 MINUTE CHARGER

1 HOUR CHARGER

Page 7

CAUTION:To reduce the risk of injury, charge only DEWALT nickel

cadmium rechargeable batteries. Other types of batteries may burst

causing personal injury and damage.

CAUTION: Under certain conditions, with the charger plugged in to

the power supply, the exposed charging contacts inside the charger

can be shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, steel wool, aluminum foil, or any

buildup of metallic particles should be kept away from charger cavities.

Always unplug the charger from the power supply when there is no

battery pack in the cavity. Unplug charger before attempting to clean.

DANGER: 120 volts present at charging terminals. Do not probe

with conductive objects. Danger of electric shock or electrocution.

WARNING: Don’t allow any liquid to get inside charger. Electric

shock may result.

• The charger and battery pack are specifically designed to work

together. DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual.

• These chargers are not intended for any uses other than charging

D

EWALT rechargeable batteries. Any other uses may result in risk

of fire, electric shock or electrocution.

• To reduce risk of damage to electric plug and cord, pull by plug

rather than cord when disconnecting charger.

• Make sure cord is located so that it will not be stepped on, tripped

over, or otherwise subjected to damage or stress.

• An extension cord should not be used unless absolutely necessary.

Use of improper extension cord could result in risk of fire, electric

shock, or electrocution.

• An extension cord must have adequate wire size (AWG or

American Wire Gauge) for safety. The smaller the gauge number of

the wire, the greater the capacity of the cable, that is 16 gauge has

more capacity than 18 gauge. When using more than one

extension to make up the total length, be sure each individual

extension contains at least the minimum wire size.

5

English

Recommended Minimum AWG Size for Extension Cords

Total Extension Cord Length (feet)

25 50 75 100 125 150 175

Wire Gauge

18 18 16 16 14 14 12

• The charger is ventilated through slots in the top and the bottom of

the housing. Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a position

away from any heat source.

• Do not operate charger with damaged cord or plug — have them

replaced immediately.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way; take it to an authorized

service center.

• Do not disassemble charger; take it to an authorized service center

when service or repair is required. Incorrect reassembly may result

in a risk of electric shock, electrocution or fire.

• To reduce risk of electric shock, unplug charger from outlet before

attempting any cleaning. Removing the battery pack will not reduce

this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household electrical

power (120 Volts AC). Do not attempt to use it on any other voltage!

This does not apply to vehicular charger.

Chargers

Your battery can be charged in DEWALT 1 Hour Chargers, 15 Minute

Chargers or Vehicular 12 volt charger. Be sure to read all safety

instructions before using your charger.

Consult chart on back cover for compatibility of chargers and battery

packs.

Page 8

charged if the red light is continuously ON. The charger and battery

pack can be left connected with the red light glowing indefinitely. The

charger will keep the battery pack fresh and fully charged. A battery

pack will slowly lose its charge when kept out of the charger. If the

battery pack has not been kept on maintenance charge, it may need

to be recharged before use. A battery pack may also slowly lose its

charge if left in a charger that is not plugged into an appropriate AC

source.

TROUBLE INDICATORS: These chargers are designed to detect

certain problems that can arise with battery packs which would be

indicated by the red light flashing at a fast rate (and continuous beeping

for 15 Minute Chargers). If this occurs, re-insert battery pack. If

problem persists, try a different battery pack to determine if the charger

is OK. If the new pack charges correctly, then the original pack is

defective and should be returned to a service center for recycling. If the

new battery pack elicits the same trouble indication as the original,

have charger tested at an authorized service center.

PROBLEM POWER LINE

If your charger has a Problem Power Line indicator: When the charger

‘is used with some portable power sources such as generators or

sources that convert DC to AC, the charger may temporarily suspend

operation, flashing the red light with two fast blinks followed by a

pause. This indicates the power source is out of limits.

HOT PACK DELAY

If your charger has a Hot Pack Delay feature: When the charger detects

a battery that is hot, it automatically starts a Hot Pack Delay, suspending

charging until the battery has cooled. After the battery has cooled, the

charger automatically switches to the Pack Charging mode. This

feature ensures maximum battery life. The red light flashes long, then

short while in the Hot Pack Delay mode.

BATTERY PERFORMANCE

Some chargers have a tune-up feature optimizes battery pack

performance. Your charger may provide Automatic Tune-Up™ Mode

or manual (i.e. push button) Tune-Up™ mode. For information on this

6

English

Charging Procedure

1 HOUR CHARGERS

1. Plug the charger into an appropriate power outlet.

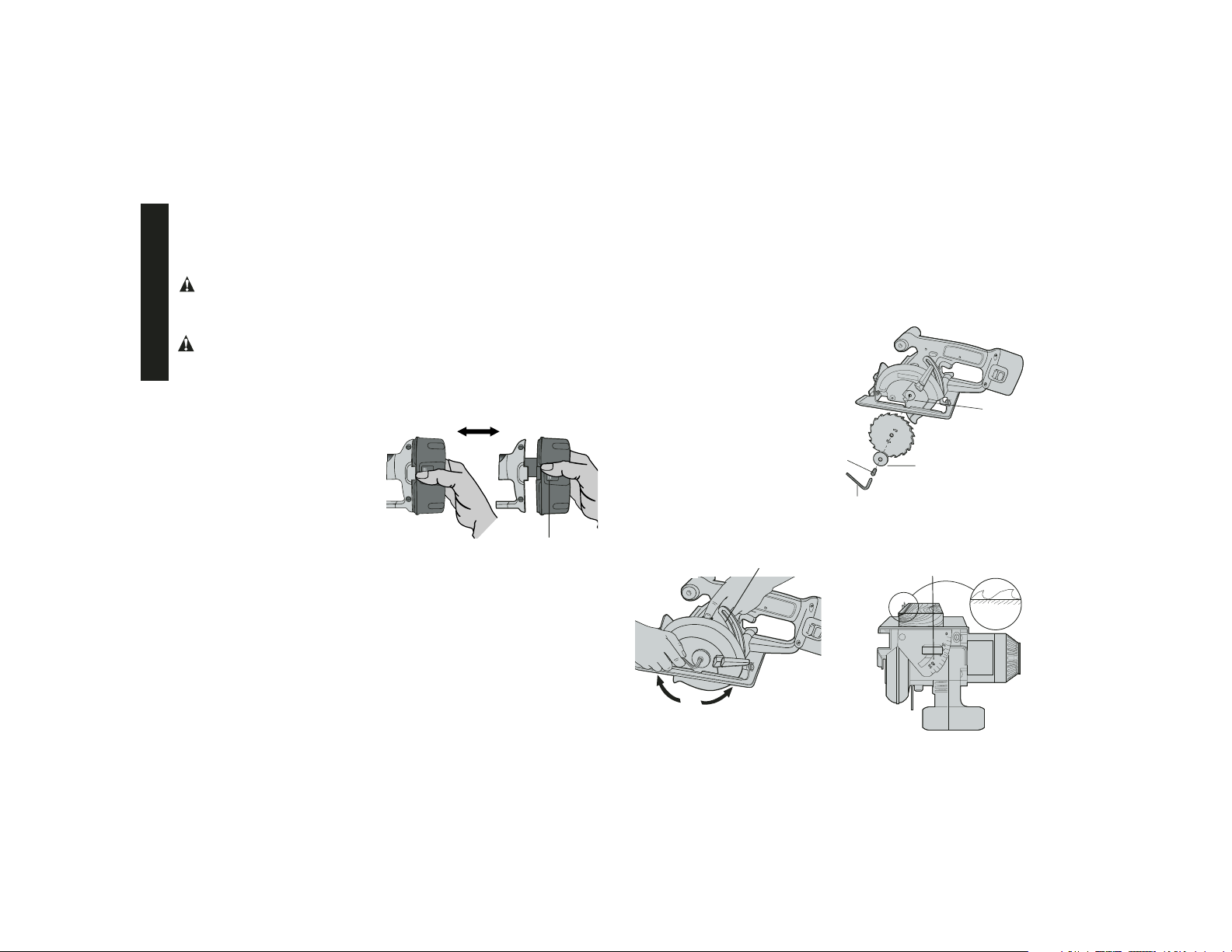

2. Insert the battery pack into the charger, as shown in FIG.1, making

sure the pack is fully seated in the charger. The red (charging) light

will blink continuously indicating that the charging process has

started.

3. The battery pack will be fully charged in about 1 hour. The

completion of charge will be indicated by the red light remaining ON

continuously. The pack is fully charged and may be used at this time

or left in the charger.

15 MINUTE CHARGERS

1. Plug the charger into an appropriate power outlet. The charger will

beep twice, the red light will blink and go off.

2. Insert the battery pack into the charger, as shown in FIG. 1, making

sure the pack is fully seated in the charger. The red light will blink

and the charger will beep once indicating the charging process has

started.

3. The battery pack will be fully charged in less than 15 minutes under

most conditions. This will be indicated by the red light remaining ON

and 3 beeps. The pack is fully charged and may be used at this time

or left in the charger.

WEAK BATTERY PACKS: The charger can also detect a weak

battery. Such batteries are still usable but should not be expected to

perform as much work. In such cases, about 10 seconds after battery

insertion, the charger will beep rapidly 8 times to indicate a weak

battery condition. The charger will then go on to charge the battery to

the highest capacity possible.

ALL CHARGERS

LEAVING THE BATTERY PACK IN THE CHARGER: When the red

light remains ON, the charger has switched to its "equalize charge"

mode which lasts approximately 4 hours, after which the charger will

switch to "maintenance charge" mode. The battery pack can be

removed at any time during these charge cycles, but will only be fully

Page 9

feature, please see the appropriate section below. Because batteries

slowly lose their charge when they are not on the charger, the best

place to keep your battery pack is on the charger at all times.

Using Automatic Tune-Up™ Mode

The Automatic Tune-Up™ Mode equalizes or balances the individual

cells in the battery pack allowing it to function at peak capacity.

Battery packs should be tuned up after every 10th charge/ discharge

cycle or whenever the pack no longer delivers the same amount of

work. To use the automatic tune-up mode, simply place the battery

pack in the charger and leave it for at least eight hours. The charger

will cycle through the following modes.

1. The red light will blink continuously indicating that the 1-hour

charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on

continuously and will no longer blink. This indicates that the pack

is fully charged and can be used at this time.

3. Whenever the pack is left in the charger after the initial 1-hour

charge, the charger will begin the Automatic Tune-Up™ Mode.

This mode continues up to 8 hours or until the individual cells in

the battery pack are equalized. The battery pack is ready for use

and can be removed at any time during the Tune-Up™ Mode.

4. Once the Automatic Tune-Up™ Mode is complete the charger

will transition to a maintenance charge; no indicator light shows

the completion of the Automatic Tune-Up™ Mode.

Using the Manual Tune-Up™ Mode

The manual Tune-up™ mode equalizes or balances the individual

cells in the battery pack at its peak capacity. This mode takes up to 8

hours to complete. Battery packs should be tuned up weekly or after

10 to 20 charge/discharge cycles or whenever the pack no longer

delivers the same amount of work.

1. To tune up your battery pack, place the battery in the charger as

usual. The red light will blink continuously indicating that the

charge cycle has started.

7

English

2. Press the Tune-Up™ Mode button any time after the charge cycle

has started. The red light will stop blinking momentarily, blink

quickly 3 times, and then resume blinking continuously. The

charger is now tuning up the cells in your battery.

3. When the Tune-Up™ mode cycle is complete, the light will stay on

continuously. The pack is fully charged and may be used at this

time or left in the charger.

4. If you select Tune-Up™ Mode and then change your mind,

remove the battery from the charger. After 5 seconds, insert the

battery into the charger. The normal charge cycle will begin.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65°F and 75°F

(18°- 24°C). DO NOT charge the battery pack in an air temperature

below +40°F(+4.5°C), or above +105°F (+40.5°C). This is important

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem.

3. If the battery pack does not charge properly — (1) Check current at

receptacle by plugging in a lamp or other appliance, (2) Check to see

if receptacle is connected to a light switch which turns power off

when you turn out the lights. (3) Move charger and battery pack to a

location where the surrounding air temperature is approximately

65°F - 75°F (18°- 24°C). (4) If charging problems persist, take or

send the tool, battery pack and charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously. DO NOT

CONTINUE to use under these conditions. Follow the charging

procedure. You may also charge a partially used pack whenever you

desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can be

shorted by foreign material. Foreign materials of a conductive nature

Page 10

such as, but not limited to, steel wool, aluminum foil, or any buildup

of metallic particles should be kept away from charger cavities.

Always unplug the charger from the power supply when there is no

battery pack in the cavity. Unplug charger before attempting to clean.

6. Do not immerse charger in water or any other liquid.

WARNING: Don't allow any liquid to get inside charger. Electric

shock may result. To facilitate the cooling of the battery pack after use,

avoid placing the charger or battery pack in a warm environment such

as in a metal shed, or an uninsulated trailer.

CAUTION: Never attempt to open the battery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, return to a

service center for recycling.

Installing and Removing the Battery

Pack

NOTE: Make sure your battery

pack is fully charged. To install the

battery pack into the tool handle,

align the base of the tool with the

notch inside the tool’s handle and

slide the battery pack firmly into the

handle until you hear the lock snap

into place as shown in FIG. 2.

To remove the battery pack from

the tool, press the release buttons and firmly pull the battery pack out

of the tool handle. Insert it into the charger as described in the charger

section of this manual.

OPERATION

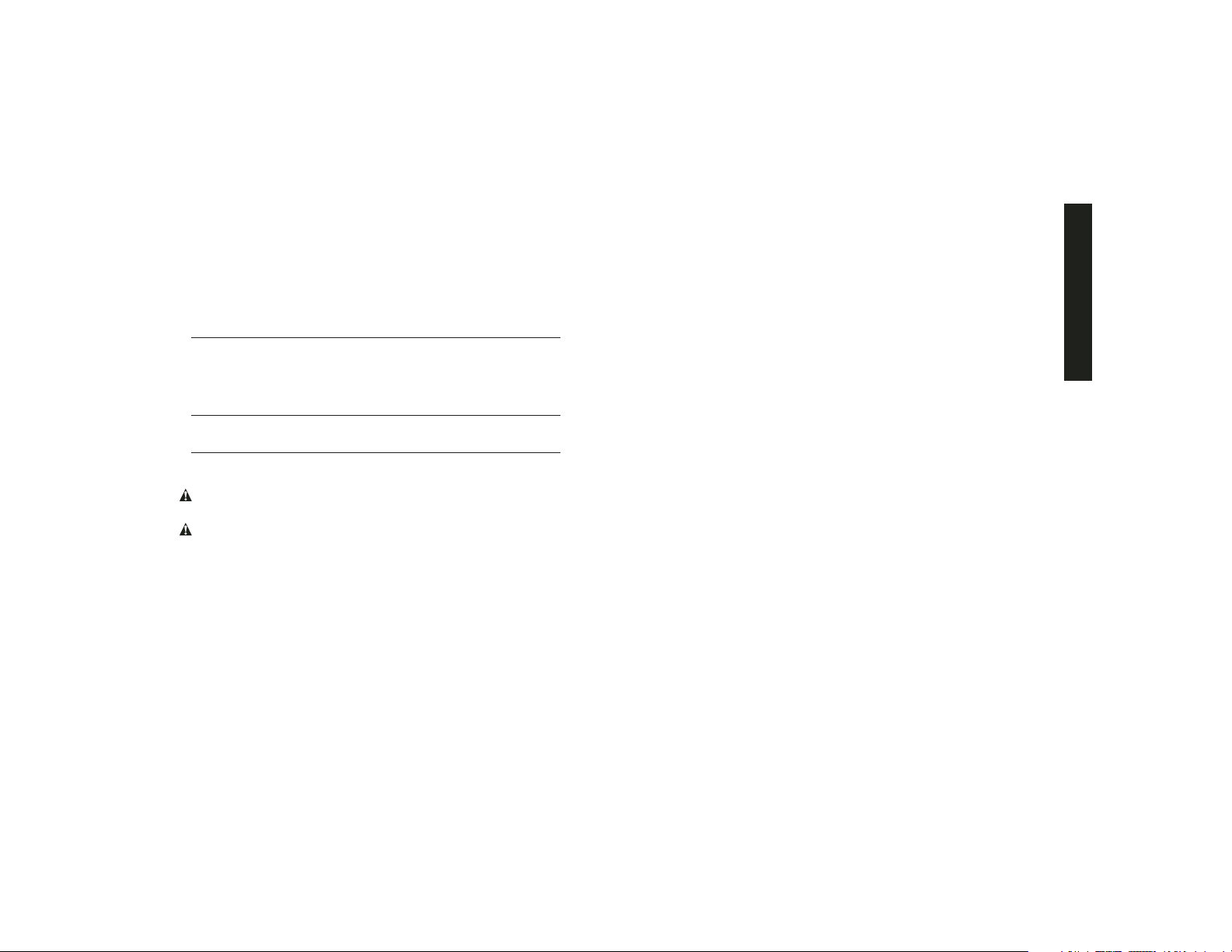

Changing Blades

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. To attach blade, retract lower blade guard and place blade over

spindle and against the inner clamp washer. Place outer clamp

washer against the blade. (Blade must go on with the printed side

out- teeth at bottom of blade pointing forward—FIG. 3).

3. Thread on blade clamping screw firmly by hand to hold washer in

position. (Screw has left hand threads and must be turned

counterclockwise to tighten).

4. Lightly depress the blade lock (FIG. 4) while turning the spindle until

the blade stops rotating.

5. Tighten blade clamping screw (counterclockwise) firmly with the

blade wrench.

6. To remove blade, TURN

OFF TOOL AND

REMOVE BATTERY

PACK. Engage the blade

lock and unscrew the

blade clamping

screw by turning it

clockwise with the

blade wrench.

NOTE: Never engage

blade lock while saw is

running, or engage in an

effort to stop the tool.

8

English

LOOSEN

clockwise

TIGHTEN

counterclockwise

BEVEL

ADJUSTMENT

KNOB

FIG. 4

FIG. 5

BLADE LOCK

BUTTON

RELEASE BUTTON

FIG. 2

INNER CLAMP

WASHER

OUTER

CLAMP

WASHER

BLADE

CLAMPING

SCREW

WRENCH

FIG. 3

Page 11

9

English

Never turn switch on when blade lock is engaged. Serious damage to

your saw will result.

Blades

A dull blade will cause slow, inefficient cutting overload on the saw

motor, excessive splintering, and could increase the possibility of

kickback. Please refer to the table on next page for to determine the

correct size replacement blade for your model saw.

Model Blade Dia. Teeth Application

DW930 DW9055 5-3/8" 16 General Purpose Cutting

DW935 DW9054 5-3/8" 24 Smooth/Finish Cutting

DW936 DW9052 5-3/8" 30 Aluminum Cutting

DW9053 5-3/8" 78 Thin Material Cutting

DW939 DW9155 6-1/2" 16 General Purpose Cutting

DW9154 6-1/2" 24 Smooth/Finish Cutting

If you need assistance regarding blades, please call 1-800-4-D

EWALT

(1-800-433-9258).

CAUTION: Do not use abrasive discs or blades for cutting ferrous

(steel) materials, masonry, glass or tile materials.

WARNING: To minimize the risk of eye injury, always use eye

protection. Carbide is a hard but brittle material. Foreign objects in the

work piece such as wire or nails can cause tips to crack or break. Only

operate saw when proper saw blade guard is in place. Mount blade

securely in proper rotation before using, and always use a clean,

sharp blade.

Cutting Depth Adjustment

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. Hold the saw firmly and loosen (counterclockwise) the depth

adjustment knob and move shoe to obtain the desired depth of cut.

3. Make sure the depth adjustment knob has been retightened

(clockwise) before operating saw.

For the most efficient cutting action, set the depth adjustment so that

one tooth of the blade will project below the material to be cut. This

distance is from the tip of the tooth to the bottom of the gullet in front of

it. This keeps blade friction at a minimum, removes sawdust from the

cut, results in cooler, faster sawing and reduces the chance of

kickback. A method for checking for correct cutting depth is shown in

FIG. 5. Lay a piece of the material you plan to cut along the side of the

blade, as shown, and observe how much tooth projects beyond the

material.

NOTE: When using carbide-tipped blades, make an exception to the

above rule and allow only one-half of a tooth to project below the

material to be cut.

Bevel Angle Adjustment

The full range of the bevel adjustment is from 0˚ to 50˚. The quadrant

is graduated in increments of 5˚. On the front of the saw is a bevel

angle adjustment mechanism (FIG. 5) consisting of a calibrated

quadrant and a knob. To set the saw for a bevel cut:

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. Loosen (counterclockwise) the quadrant knob and tilt shoe to the

desired angle by aligning the pointer with the desired angle mark.

Retighten knob firmly (clockwise).

NOTE: The quadrant pointer, located between the quadrant knob and

the quadrant, can be adjusted after loosening its screw. Retighten

firmly after adjustment.

Shoe Adjustment for 90˚ Cuts

If additional adjustment is needed:

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. Adjust the saw to 0˚ bevel.

3. Retract blade guard. Place the saw on blade side.

4. Loosen bevel adjustment knob. Place a square against the blade

and shoe to adjust the 90˚ setting.

5. Move the adjustment screw so that the shoe will stop at the proper

angle.

Page 12

10

English

6. Confirm the accuracy of the setting by checking the squareness of

an actual cut on a scrap piece of material.

Kerf Indicator

The front of the saw shoe has a kerf indicator for vertical and bevel

cutting. This indicator enables you to guide the saw along cutting lines

penciled on the material being cut. The indicator lines up with the left

(outer) side of the saw blade, which makes the slot or “kerf” cut by the

moving blade fall to the right of the indicator. Guide along the penciled

cutting line so that the kerf falls into the waste or surplus material..

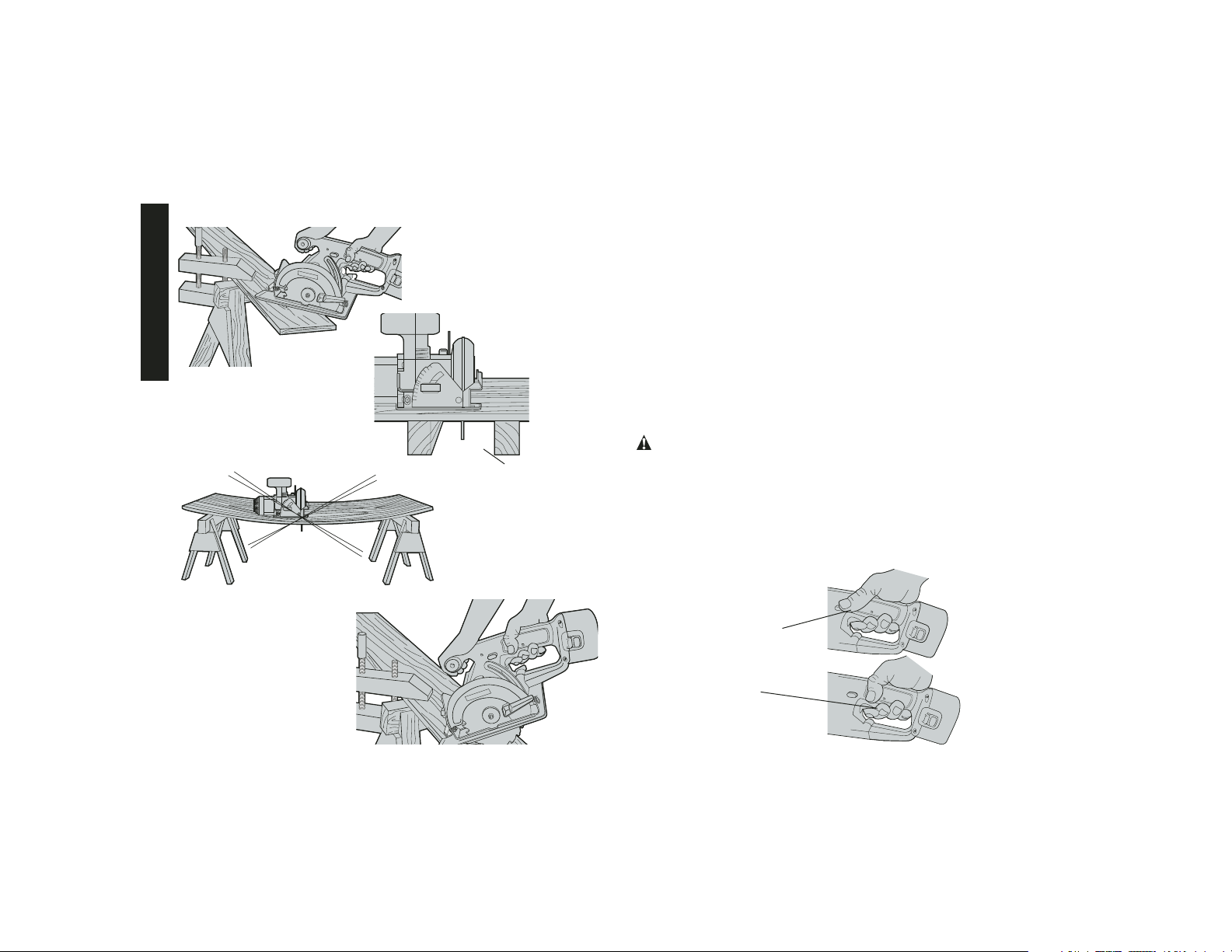

Work Piece Support

Figure 6 shows proper sawing position. Note that hands are kept away

from cutting area. To avoid kickback, DO support board or panel NEAR

the cut, (FIG. 7). DON’T support board or panel away from the cut,

(FIG. 8).

WARNING: It is important to support the work properly and to hold

the saw firmly to prevent loss of control which could cause personal

injury. FIG. 6 illustrates typical hand support of the saw. ALWAYS

TURN OFF TOOL AND REMOVE BATTERY BEFORE MAKING ANY

ADJUSTMENTS!

Place the work with its “good” side–the one on which appearance is

most important–down. The saw cuts upward, so any splintering will be

on the work face that is up when you cut it.

SWITCH LOCK

OFF RELEASE

BUTTON

TRIGGER

SWITCH

FIG. 10

SUPPORT

DO support board or

panel NEAR the cut.

DON’T support board or

panel AWAY from the cut.

FIG. 6

FIG. 7

FIG. 8

FIG. 9

50

4

0

3

0

20

15

0

50

40

30

20

15

0

Page 13

11

English

Switch

Release lock off by pressing button as shown (Fig. 10). Pull the trigger

switch to turn the motor ON. Releasing the trigger turns the motor OFF.

Releasing the trigger also automatically actuates lock off button.

NOTE: This tool has no provision to lock the switch in the ON position,

and should never be locked ON by any other means

Cutting

Place the wider portion of the saw shoe on that part of the work piece

which is solidly supported, not on the section that will fall off when the

cut is made. As examples, FIG. 6 illustrates the RIGHT way to cut off

the end of a board. Always clamp work. Don’t try to hold short pieces

by hand! Remember to support cantilevered and overhanging material.

Use caution when sawing material from below.

Be sure saw is up to full speed before blade contacts material to be cut.

Starting saw with blade against material to be cut or pushed forward into

kerf can result in kickback. Push the saw forward at a speed which

allows the blade to cut without laboring. Hardness and toughness can

vary even in the same piece of material, and knotty or damp sections

can put a heavy load on the saw. When this happens, push the saw

more slowly, but hard enough to keep working without much decrease

in speed. Forcing the saw can cause rough cuts, inaccuracy, kickback,

and over-heating of the motor. Should your cut begin to go off the line,

don’t try to force it back on. Release the switch and allow blade to come

to a complete stop. Then you can withdraw the saw, sight anew, and

start a new cut slightly inside the wrong one. In any event, withdraw the

saw if you must shift the cut. Forcing a correction inside the cut can stall

the saw and lead to kickback.

IF SAW STALLS, RELEASE THE TRIGGER AND BACK THE SAW

UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN THE CUT

AND CLEAR OF THE CUTTING EDGE BEFORE RESTARTING.

As you finish a cut, release the trigger and allow the blade to stop

before lifting the saw from the work. As you lift the saw, the springtensioned telescoping guard will automatically close under the blade.

Remember the blade is exposed until this occurs. Never reach under

the work for any reason. When you have to retract the telescoping

guard manually (as is necessary for starting pocket cuts) always use

the retracting lever.

NOTE: When cutting thin strips, be careful to ensure that small cutoff

pieces don’t hang up on inside of lower guard.

RIPPING

Ripping is the process of cutting wider boards into narrower stripscutting grain lengthwise. Hand guiding is more difficult for this type of

sawing and some type of guide should be used.

POCKET CUTTING (FIG. 9)

TURN OFF TOOL AND REMOVE BATTERY PACK BEFORE

ADJUSTING.

A pocket cut is one that is made in a floor, wall, or other flat surface.

Adjust saw shoe so blade cuts at desired depth. Tilt saw forward and

rest front of the shoe on material to be cut. Using the retracting lever,

retract blade guard to an upward position. Lower rear of shoe until blade

teeth almost touch cutting line. Now release the blade guard (its contact

with the work will keep it in position to open freely as you start the cut).

Start the motor and gradually lower the saw until its shoe rests flat on

the material to be cut. Advance saw along the cutting line until cut is

completed. Release trigger and allow blade to stop completely before

withdrawing the blade from the material. When starting each new cut,

repeat as above. Never tie the blade guard in a raised position. Never

move the saw backwards when pocket cutting. This may cause the

unit to raise up off of the work surface which could cause injury.

Cleaning

Use only mild soap and a damp cloth to clean the tool. Many household

cleaners contain chemicals which could seriously damage plastic. Also,

do not use gasoline, turpentine, lacquer or paint thinner, dry cleaning

fluids or similar products. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid.

Page 14

12

Lubrication

Self lubricating ball and roller bearings are used in the tool and

relubrication is not required. However, it is recommended that, once a

year, you take or send the tool to a certified service center for a thorough

cleaning, inspection, and lubrication of the gear case.

Accessories

Recommended accessories for use with your tool are available at extra

cost from your local service center.

If you need any assistance in locating any accessory, please contact

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286 or call 1-800-732-4441.

CAUTION: The use of any other accessory or attachment may be

hazardous. Water feed attachments are not recommended for use with

this tool.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258). This

warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

– no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

English

Page 15

13

Français

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE PART

DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU TOUT

AUTRE OUTIL DeWALT, COMPOSEZ SANS FRAIS LE :

1 800 433-9258.

Règles générales de sécurité

concernant les outils à piles

AVERTISSEMENT! Lire et comprendre toutes les directives, car le

non-respect des directives suivantes peut entraîner un choc

électrique, un incendie ou des blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

• Garder la zone de travail propre et bien éclairée; les établis

encombrés et les endroits sombres sont propices aux accidents.

• Ne pas utiliser les outils électriques dans une atmosphère

explosive, comme à proximité de liquides, de gaz ou de

poussières inflammables; le moteur peut créer des étincelles et

enflammer les vapeurs ou les poussières environnantes.

• Tenir les enfants, les visiteurs ou toute autre personne à

l’écart lorsqu’on utilise un outil électrique; les distractions

peuvent faire perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ : ÉLECTRICITÉ

• Ne pas utiliser le cordon de manière abusive; on ne doit pas

transporter l’outil en le tenant par le cordon. On doit tenir le

cordon à l’écart des sources de chaleur, de l’huile, des bords

tranchants ou des pièces mobiles. Remplacer immédiatement les

cordons endommagés, car ces derniers augmentent les risques

d’incendie.

• Un outil à piles intégrées ou à bloc-piles externe doit être

rechargé seulement au moyen du chargeur approprié, car un

chargeur destiné à une pile particulière peut entraîner un risque

d’incendie lorsqu’il est utilisé avec une autre.

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO :

1 800 4-DEWALT (1-800-433-9258)

BOUTON DE

VERROUILLAGE DE

L’INTERRUPTEUR

ENSEMBLE

DE PILES

PATIN

INTERRUPTEUR

À DÉTENTE

BOUTON DE

RÉGLAGE DE LA

PROFONDEUR DE

COUPE

RESSORT DE

RAPPEL DU

PROTÈGE-

LAME

INFÉRIEUR

PROTÈGE-

LAME

INFÉRIEUR

BOUTON DE

VERROUILLAGE

DE LA LAME

BOUTON DE

RÉGLAGE

DES COUPES

EN BISEAU

INDICATEUR

DE VOIE

VIS DE FIXATION

DE LA LAME

DW930 Ébouteuse sans fil de 12,0 volts 2 500 trs/min

DW935 Ébouteuse sans fil de 14,4 volts 3 000 trs/mi

DW936 Ébouteuse sans fil de 18,0 volts 3 200 trs/min

DW939 Scie Circulare sans fil de 18,0 volts 3 700 trs/min

R

Page 16

14

Français

• Ne pas forcer l’outil ni l’utiliser pour des travaux autres que

ceux pour lesquels il a été conçu. Pour obtenir de meilleurs

résultats et prévenir les risques de blessure, laisser l’outil couper

à la vitesse pour laquelle il a été conçu.

• Ne pas utiliser l’outil lorsque l’interrupteur de marche-arrêt ne

fonctionne pas; tout outil qui ne peut être commandé au moyen

de l’interrupteur est dangereux et doit être réparé.

• Débrancher le bloc-piles de l’outil ou mettre l’interrupteur en

position de verrouillage ou d’arrêt avant d’effectuer un

réglage, de changer les accessoires ou de ranger l’outil; ces

mesures de sécurité préventives réduisent les risques de

démarrage accidentel.

• Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des

enfants ou des personnes non qualifiées; les outils sont

dangereux entre les mains de personnes inexpérimentées.

• Lorsqu’on n’utilise pas le bloc-piles, le ranger à l’écart des

objets métalliques tels que les trombones, les pièces de

monnaie, les clés, les clous, les vis ou autres petits objets

susceptibles de conduire l’électricité entre les bornes et

d’occasionner ainsi des étincelles, des brûlures ou un incendie.

• Bien entretenir l’outil; s’assurer qu’il soit toujours bien propre et

aiguisé. Les outils bien entretenus et dont les bords sont bien

tranchants sont moins susceptibles de rester coincés et sont plus

faciles à maîtriser.

• Vérifier les pièces mobiles afin de s’assurer qu’elles soient

bien alignées et qu’elles ne restent pas coincées; vérifier

également les pièces afin de s’assurer qu’il n’y ait aucun bris

ni aucune autre condition susceptible de nuire au bon

fonctionnement de l’outil. Faire réparer l’outil si ce dernier est

endommagé avant de s’en servir à nouveau, car les accidents sont

souvent causés par des outils mal entretenus.

• N’utiliser que les accessoires recommandés par le fabricant

pour le modèle concerné; un accessoire destiné à un outil

particulier peut devenir dangereux lorsqu’il est utilisé avec un autre.

• N’utiliser l’outil à piles qu’avec le bloc-piles désigné, car

l’utilisation d’un autre type de piles peut entraîner un risque

d’incendie.

SÉCURITÉ PERSONNELLE

• Rester vigilant en tout temps et faire preuve de jugement

lorsqu’on utilise un outil électrique; ne pas utiliser l’outil

lorsqu’on est fatigué ou sous l’influence de drogues, d’alcool ou

de médicaments, car un moment d’inattention peut entraîner des

blessures graves.

• Porter des vêtements appropriés; ne pas porter de vêtements

amples ni de bijoux. Couvrir ou attacher les cheveux longs. Garder

les cheveux, les vêtements, les bijoux et les gants éloignés des

pièces mobiles, car ceux-ci peuvent s’y coincer. Se tenir éloigné

des évents puisque ces derniers pourraient camoufler des pièces

mobiles.

• Éviter les démarrages accidentels; s’assurer que l’interrupteur

soit placé en position de verrouillage ou d’arrêt avant d’insérer le

bloc-piles. Ne pas transporter l’outil en laissant le doigt sur

l’interrupteur ni insérer le bloc-piles lorsque l’outil est en position de

marche, car cela pourrait causer un accident.

• Retirer les clés de réglage avant de démarrer l’outil; une clé

laissée sur une pièce rotative peut entraîner des blessures.

• Ne pas trop étendre les bras; les pieds doivent rester ancrés

fermement sur le sol afin de maintenir son équilibre en tout temps

et de mieux maîtriser l’outil dans des situations imprévues.

• Utiliser le matériel de sécurité approprié; toujours porter des

lunettes de protection. Porter un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des

protecteurs auditifs lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Fixer et soutenir l’ouvrage sur une plate-forme stable au

moyen d’un étau ou de tout autre dispositif semblable;

l’ouvrage est instable lorsqu’on le retient manuellement ou qu’on

l’appuie contre le corps, ce qui peut faire perdre la maîtrise de l’outil.

Page 17

15

Français

• On ne doit escamoter manuellement le protège-lame inférieur que

pour réaliser une coupe spéciale, complexe ou à partir de l’intérieur

d’un matériau. Pour ce faire, on doit le soulever au moyen du levier

d’escamotage, relâchant ce dernier dès que la lame mord dans

l’ouvrage. Le protège-lame s’escamote automatiquement pour

tous les autres types de coupe.

• Toujours s’assurer que le protège-lame inférieur recouvre la lame

avant de déposer la scie sur le plancher ou sur un établi, car, sans

protection, une lame qui tourne encore fait reculer la scie, coupant

tout ce qui se trouve sur son passage. Il est en outre bon de savoir

combien de temps la lame prend pour s’arrêter une fois

l’interrupteur relâché.

• Ne JAMAIS tenir l’ouvrage dans ses mains ou le placer de travers

sur ses jambes pour le couper. Il est important de soutenir

l’ouvrage correctement afin d’éviter d’exposer des parties du corps

à la lame, de coincer cette dernière ou encore, de perdre la

maîtrise de l’outil.

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il

risque d’entrer en contact avec des fils cachés, car de tels contacts

peuvent mettre les pièces métalliques de l’outil sous tension,

engendrant des risques de choc électrique.

ENTRETIEN

• L’outil doit être entretenu ou réparé par le personnel qualifié

seulement; toute maintenance effectuée par une personne non

qualifiée peut entraîner des risques de blessure.

• Lors de l’entretien, n’utiliser que des pièces de rechange

identiques et suivre les directives de la section «Entretien» du

présent manuel afin de prévenir les risques de choc électrique ou

de blessure.

Règles de sécurité additionnelles

concernant les scies

DANGER! Garder les mains éloignées des zones de coupe et de

la lame. Toujours tenir l’outil en plaçant une main sur la poignée

auxiliaire ou le carter du moteur; on protège ses mains en les utilisant

toutes les deux pour tenir l’outil.

• Toujours se placer d’un côté ou de l’autre de la lame en évitant de

se tenir dans son trajet, car la scie pourrait reculer brusquement

par suite d’un

REBOND

. (Voir la section «

REBOND

» du présent

manuel).

• Ne pas mettre les mains sous l’ouvrage car il n’y a aucune

protection contre la lame à cet endroit.

• Vérifier le protège-lame inférieur afin de s’assurer qu’il soit bien

fermé avant d’utiliser l’outil; ne pas faire fonctionner ce dernier si le

protège-lame ne se déplace pas librement ou s’il ne se ferme pas

instantanément. Ne jamais le bloquer en position ouverte. Si on

échappe la scie, soulever le protège-lame inférieur au moyen du

levier d’escamotage et le vérifier afin de s’assurer qu’il n’y ait

aucun dommage, qu’il se déplace librement et qu’il n’entre pas en

contact avec la lame ou toute autre pièce de l’outil, quel que soit

l’angle et la profondeur de coupe.

• S’assurer que le ressort du protège-lame inférieur soit en bon état

de fonctionnement; sinon, on doit lui faire subir un entretien avant

d’utiliser l’outil. Le protège-lame peut être difficile à déplacer en

présence de pièces endommagées, de dépôts gommeux ou de

débris accumulés.

CHARGEUR EN 15 MINUTES

FIG. 1

CHARGEURS EN UNE HEURE

Page 18

16

Français

• Toujours utiliser un guide de refend ou de bord droit lorsqu’on

effectue une coupe en long afin d’assurer la précision de cette

dernière et d’éviter de coincer la lame.

• Toujours utiliser une lame munie d’un arbre dont les orifices sont de

dimension et de forme appropriées (ronds ou en losanges); les

lames qui ne correspondent pas aux éléments de fixation de la

scie tourneront de manière excentrique, faisant perdre la maîtrise

de l’outil.

• Ne jamais utiliser de rondelles ou de boulons endommagés ou

autres que ceux qui ont été conçus pour la scie, afin d’obtenir un

rendement optimal et de travailler en toute sécurité.

Causes du rebond et mesures préventives

• Le

REBOND

est une réaction soudaine de l’outil causée par une

lame pincée, bloquée ou mal alignée, occasionnant la perte de

maîtrise de la scie, qui se soulève et se détache de l’ouvrage en

direction de l’opérateur.

• Lorsque la lame reste coincée ou est immobilisée par une entaille

qui se referme, l’arrêt de la lame et la réaction du moteur entraîne

un recul brusque de l’outil vers l’opérateur.

• Si la lame se tord ou est mal alignée, les dents arrière peuvent

s’engager sur le dessus de l’ouvrage, faisant grimper la lame hors

de l’entaille et rebondir l’outil en direction de l’opérateur.

• Le rebond découle d’une mauvaise utilisation ou du mauvais

fonctionnement de l’outil; on peut l’éviter en prenant les

précautions suivantes.

• Tenir fermement l’outil des deux mains et placer le corps et les bras

de manière à pouvoir maîtriser les effets du rebond; le rebond peut

être maîtrisé si l’opérateur prend les précautions nécessaires.

• Lorsque la lame se coince ou qu’on veut interrompre une coupe pour

quelle que raison que ce soit, relâcher l’interrupteur à gâchette et

maintenir la scie immobile dans l’ouvrage, jusqu’à ce que la lame

s’arrête complètement. Ne jamais tenter de retirer la scie de

l’ouvrage ou de la tirer vers soi avant que la lame ne se soit

immobilisée complètement afin d’éviter le rebond. Vérifier l’ouvrage

afin de déterminer la cause du coincement et de prendre les

mesures correctives qui s’imposent.

• Lorsqu’on remet la scie en marche, centrer la lame dans l’entaille

et s’assurer que les dents ne soient pas engagées dans l’ouvrage.

Si la lame se coince, la scie peut grimper hors de l’entaille ou faire

un rebond lorsqu’on la redémarre.

• Soutenir les grands panneaux afin d’éviter autant que possible de

coincer la lame et d’engendrer un REBOND. Les grands panneaux

tendent à s’affaisser sous leur poids et doivent être soutenus de

chaque côté, près de la ligne de coupe et du bord du panneau.

• Ne pas utiliser de lames usées ou endommagées, car celles-ci

produisent des entailles plus étroites, ce qui peut causer une

friction excessive, coincer la lame et engendrer un rebond.

• Bien verrouiller les leviers de réglage de profondeur et d’angle de

biseau avant d’amorcer une coupe; si ces leviers se déplacent

durant la coupe, la lame peut se coincer et entraîner un REBOND.

• On doit faire particulièrement attention lorsqu’on effectue une coupe

«interne» dans un mur ou endroit difficile à voir, car la lame peut

couper des objets cachés qui risquent d’occasionner un rebond.

Consignes de sécurité additionnelles

• ÉVITER DE COUPER DES CLOUS; s’assurer que le bois de

sciage soit exempt de clous avant de procéder à la coupe.

MISE EN GARDE : lorsqu’on effectue une coupe dans un mur, un

plancher ou dans un endroit où l’on risque d’entrer en contact avec des

fils cachés, toujours tenir l’outil par les poignées en plastique prévues

à cette fin, car de tels contacts peuvent mettre les pièces métalliques

de l’outil sous tension et engendrer des risques de choc électrique.

ATTENTION: Quelques outils avec de grands paquets de batterie

se tiendront droits sur le paquet de batterie mais peuvent être

facilement frappés plus de. Quand pas en service, placez l'outil de

son côté sur une surface stable où il ne causera pas un risque de

déclenchement ou en chute.

MISE EN GARDE : porter un dispositif de protection personnel

anti-bruit approprié durant l’utilisation. Sous certaines conditions et

Page 19

17

Français

Importantes consignes de sécurité

concernant le bloc-piles

Le bloc-piles n’est pas complètement chargé au moment de sa

livraison! Avant de le charger, lire attentivement toutes les consignes

de sécurité énumérées ci-dessous, ainsi que les remarques, les notes

et les méthodes de chargement.

L'outil fonctionne sur un bloc-piles D

EWALT de 12,0, 14,4 ou 18 volts.

Lorsqu’on commande un bloc-piles de rechange, on doit indiquer le

numéro de catalogue et la tension requise.

• Ne pas incinérer le bloc-piles, même s’il a subi des dommages

importants ou s’il est usé complètement, car il pourrait exploser en

présence de flammes.

• Les cellules du bloc-piles peuvent subir une fuite légère par suite

d’un usage extrême ou d’une exposition à certaines températures;

ceci n’indique pas un problème. Cependant, si le scellant externe

est percé et le liquide entre en contact avec la peau, on doit :

a) se laver rapidement la partie du corps touchée avec de l’eau

savonneuse;

b) neutraliser l’effet au moyen d’un acide doux tel que du jus de

citron ou du vinaigre;

c) si les yeux sont touchés, les rincer à fond avec de l’eau propre

pendant au moins 10 minutes et consulter immédiatement un

médecin. (Remarque aux fins médicales : ce liquide contient

une solution composée de 25 à 35 % d’hydroxyde de potassium.)

• Ne pas transporter de bloc-piles supplémentaires dans un tablier,

une poche ou une boîte à outils contenant des objets métalliques,

car le bloc-pile pourrait causer un court-circuit et s’endommager, ou

risquer de provoquer de graves brûlures ou un incendie.

• Ne charger les bloc-piles qu’au moyen d’un chargeur D

EWALT.

REMARQUE : le bloc-piles contient des piles au nickel-cadmium. Le

cadmium est considéré comme une substance toxique par les

agences de protection de l’environnement, dont le ministère de

l’Environnement; on recommande donc de vérifier auprès de l’agence

concernée avant de mettre au rebut des bloc-piles au nickel-cadmium

pendant toute la durée de l’utilisation, le bruit émanant de ce produit

pourrait contribuer à la perte d’audition.

AVERTISSEMENT : Certains outils, tels que les sableuses

électriques, les scies, les meules, les perceuses ou certains autres

outils de construction, peuvent soulever de la poussière contenant des

produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits

de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique.

Le risque associé à de telles expositions peut varier selon la fréquence

avec laquelle on effectue ces travaux. Pour réduire l’exposition à de

tels produits, il faut travailler dans un endroit bien ventilé et utiliser

l’équipement de sécurité approprié tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par

cet outil ou autres outils électriques. Porter des vêtements

de protection et nettoyer les parties exposées du corps avec

de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits

chimiques nocifs.

• L’étiquette de l’outil peut comporter les symboles suivants.

V ............volts A............ampères

Hz ..........hertz W ..........watts

min..........minutes ........courant alternatif

........courant continu no ..........sous vide

............Construction de ..........borne de mise à la minute

................classe II ..........symbole d´avertissement

.../min ....tours ou à la minute

Page 20

18

Français

usés ou endommagés afin de se renseigner sur les dispositions

particulières qui s’appliquent dans votre région à ce sujet, ou de

retourner les bloc-piles usés ou endommagés à un centre de service

qualifié D

EWALT afin qu’ils puissent être recyclés.

• NE PAS ranger ni utiliser l’outil ou le bloc-piles dans des endroits où

la température peut atteindre ou dépasser 40,5 ºC (105 ºF), comme

les cabanons ou les bâtiments en revêtement métallique durant

l’été.

DANGER : ne jamais tenter d’ouvrir le bloc-piles pour quelle que

raison que ce soit. Si le compartiment se rupture ou subit des

dommages, ne pas l’insérer dans le chargeur afin d’éviter les risques

de choc électrique ou d’électrocution. On doit retourner les bloc-piles

endommagés à un centre de service afin qu’ils puissent être recyclés.

REMARQUE : un capuchon est fourni avec la pile en vue d’être utilisé

chaque fois qu’on retire cette dernière de l’outil ou du chargeur en vue

de la ranger ou de la transporter; enlever le capuchon

avant de remettre la pile dans le chargeur ou dans l’outil.

AVERTISSEMENT : s’assurer, au moment de ranger

ou de transporter la pile, qu’aucun objet métallique

n’entre en contact avec les bornes à découvert de la

pile. Par exemple, il faut éviter de placer une pile sans

capuchon dans un tablier, une poche, une boîte à outils ou

un tiroir (etc.) contenant des objets tels que des clous, des vis ou des

clés, car la pile pourrait causer un court-circuit et s’endommager, ou

risquer de provoquer des brûlures ou un incendie.

Le Sceau RBRC

mc

Le sceau RBRCmcde l’ensemble de piles au nickel-cad

mium indique que D

EWALT participe volontairement à

un programme du monde industriel qui a pour objet de

ramasser et de recycler ces ensembles de piles à la fin

de leur vie utile, si on s’en débarrasse aux États-Unis. Le

programme RBRCmcoffre une solution de rechange pratique à la

mise au rebut des ensembles de piles au nickel-cadmium usés, que ce

soit à la poubelle ou dans le système municipal car cette mise au rebut

est illégale dans certains endroits.

Grâce à la contribution de DEWALT au RBRCmc, il suffit de laisser un

ensemble de piles usé chez les détaillants qui vendent des piles au

nickel-cadmium de rechange ou dans un centre de service D

EWALT

autorisé. On peut également se renseigner auprès de son centre local

de recyclage pour savoir comment se débarrasser d’un ensemble de

piles usé. D

EWALT fait partie de ce programme en raison de son

engagement à protéger l’environnement et à préserver les ressources

naturelles.

RBRCmcest une marque de commerce de l’organisme américain

Rechargeable Battery Recycling Corporation.

Importantes consignes de sécurité

concernant les chargeurs

CONSERVER CES DIRECTIVES –

Le présent manuel contient

d’importantes consignes de sécurité concernant les chargeurs

D

EWALT.

• Avant d’utiliser le chargeur, lire toutes les directives et

étiquettes de mise en garde apposées sur le chargeur, la pile et le

produit utilisant la pile.

MISE EN GARDE : afin de réduire les risques de blessure, ne

charger que des piles au nickel-cadmium rechargeables D

EWALT, car

les autres pourraient éclater et entraîner des blessures ou des

dommages matériels.

MISE EN GARDE : dans certaines conditions, lorsque le chargeur

est enfiché, les raccords de charge à nu situés à l’intérieur du chargeur

peuvent subir un court-circuit lorsqu’ils entrent en contact avec une

matière étrangère. Les matières conductives comme la laine d’acier, la

feuille d’aluminium ou les particules métalliques, mais sans toutefois

s’y limiter, doivent être tenus à l’écart des cavités du chargeur. Toujours

débrancher celui-ci lorsque le bloc-piles n’y est pas inséré ou avant

de le nettoyer.

DANGER : les bornes du chargeur conduisent une tension de 120

volts; on ne doit pas les toucher au moyen d’objets conducteurs afin

d’éviter les risques de choc électrique ou d’électrocution.

Page 21

19

Français

d’obstruer les fentes de ventilation, ce qui pourrait causer une

chaleur interne excessive. Tenir le chargeur éloigné de toute source

de chaleur.

• Ne pas faire fonctionner le chargeur lorsque le cordon ou la fiche

est endommagé. Si tel est le cas, les remplacer immédiatement.

• Ne pas faire fonctionner le chargeur s’il a subi un coup important,

une chute ou des dommages quelconques. Si cela se produit,

l’emporter à un centre de service autorisé.

• Ne pas démonter le chargeur, car un mauvais assemblage pourrait

occasionner des risques de choc électrique, d’électrocution ou

d’incendie. Le chargeur doit être retourné à un centre de service

autorisé aux fins d’une réparation ou d’un entretien, le cas échéant.

• Afin de réduire les risques de choc électrique, débrancher le

chargeur de la prise murale avant de procéder au nettoyage; le seu

l

fait d’enlever le bloc-piles ne réduit pas ce risque.

• Ne JAMAIS brancher deux chargeurs ensemble.

• Le chargeur est conçu pour être utilisé sur une prise résidentielle

standard de 120 volts c.a. Ne pas tenter de le brancher sur une

prise autre que celle pour laquelle il a été conçu (cette directive ne

s’applique pas aux chargeurs pour véhicules).

Chargeurs

Les piles DEWALT peuvent être chargées au moyen d’un chargeur

D

EWALT d’une heure ou de 15 minutes, ou d’un chargeur pour

véhicules de 12 volts. S’assurer de lire toutes les consignes de sécurité

avant d’utiliser le chargeur.

Consulter le diagramme apparaissant sur le couvercle arrière afin de

vérifier la compatibilité du chargeur avec le bloc-piles.

Méthode de chargement

CHARGEURS D’UNE HEURE

1. Enficher le chargeur dans une prise appropriée.

2. Insérer le bloc-piles dans le chargeur, tel qu’illustré à la FIG. 1, en

s’assurant de bien l’enfoncer. Le voyant (de charge) rouge

clignotera, indiquant que le cycle de charge est amorcé.

AVERTISSEMENT : ne jamais laisser de liquide s’infiltrer à

l’intérieur du chargeur afin d’éviter les risques de choc électrique.

• Le chargeur et le bloc-piles sont conçus spécialement pour être

utilisés ensemble; NE PAS charger le bloc-piles au moyen d’un

chargeur autre que ceux décrits dans le présent manuel.

• N’utiliser ces derniers que pour charger les piles rechargeables

D

EWALT; tout autre usage peut entraîner des risques d’incendie, de

choc électrique ou d’électrocution.

• Afin de réduire les risques de dommage à la fiche ou au cordon

électrique, débrancher le chargeur en saisissant la fiche, non le

cordon.

• S’assurer que le cordon soit placé de manière à éviter qu’il ne

subisse des dommages ou des contraintes ou que les personnes

s’y prennent les pieds et trébuchent.

• Ne pas utiliser de rallonge à moins que cela ne soit absolument

nécessaire, car l’usage d’une rallonge ayant une puissance

inadéquate pourrait causer des risques d’incendie, de choc

électrique ou d’électrocution.

• Afin d’assurer la sécurité de l’utilisateur, la rallonge doit être de

calibre AWG approprié. Plus le calibre est petit, plus la capacité est

grande; autrement dit, une rallonge de calibre 16 est plus puissante

qu’une rallonge de calibre 18. Lorsqu’on utilise plusieurs rallonges

pour obtenir la longueur voulue, s’assurer que chacune d’elles

présente les valeurs minimales requises.

Calibre minimal des cordons de rallonge

Longueur totale du cordon

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Intensité

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• Le chargeur s’aère par l’entremise de fentes situées sur le dessus

et le dessous du logement; ne jamais mettre un objet sur le dessus

du chargeur ni placer celui-ci sur une surface molle risquant

Page 22

20

Français

3. Le bloc-piles est complètement chargé après environ une heure. Le

voyant rouge restera allumé, indiquant que le bloc-piles est

complètement rechargé; on peut alors le réutiliser ou le laisser dans

le chargeur.

CHARGEURS DE 15 MINUTES

1. Enficher le chargeur dans une prise appropriée; une fois alimenté,

il émet deux signaux sonores et le voyant rouge clignote puis

s’éteint.

2. Insérer le bloc-piles dans le chargeur, tel qu’illustré à la FIG. 1, en

s’assurant de bien l’enfoncer. Le voyant rouge clignotera

continuellement et le chargeur émettra un seul signal sonore pour

indiquer que le cycle de charge est amorcé.

3. Dans la plupart des cas, le bloc-piles requiert moins de 15 minutes

pour se charger complètement. Le voyant rouge reste allumé et le

chargeur émet trois signaux sonores pour indiquer que le bloc-piles

est complètement rechargé; on peut alors le réutiliser ou le laisser

dans le chargeur.

BLOC-PILES FAIBLE : on peut aussi utiliser le chargeur pour

déterminer si une pile est faible. Bien qu’on puisse continuer à utiliser

une pile faible, elle ne procurera pas un plein rendement. Si tel est le

cas, 10 secondes après l’insertion de la pile, le chargeur émettra

rapidement huit signaux sonores pour indiquer qu’il s’agit d’une pile

faible, puis chargera la pile jusqu’à sa pleine capacité.

CHARGEURS DE TOUT TYPE

BLOC-PILES LAISSÉ DANS LE CHARGEUR. Lorsque le voyant

rouge reste allumé, cela signifie que le chargeur s’est placé en mode

d’égalisation de charge, lequel peut rester ainsi pendant environ 4

heures. Après ce délai, le chargeur se placera en mode de tenue de

charge. Bien que le bloc-piles puisse être retiré pendant n’importe quel

de ces cycles, il n’est complètement chargé que lorsque le voyant

rouge reste allumé continuellement. On peut laisser le chargeur (avec

un bloc-piles inséré) raccordé à une prise tant que le voyant rouge

reste allumé; le chargeur maintient alors la charge du bloc-piles afin

que ce dernier soit prêt à être utilisé. Un bloc-piles perd graduellement

sa charge s’il n’est pas gardé dans le chargeur. Un bloc-piles n’étant

pas maintenu en mode de tenue de charge devra probablement être

rechargé avant son utilisation. Un bloc-piles peut graduellement perdre

sa charge s’il est laissé dans un chargeur qui n’est pas enfiché dans

une source d’alimentation à courant alternatif appropriée.

INDICATEURS D’ANOMALIE.

Les chargeurs sont conçus pour détecter certains problèmes pouvant

être reliés aux bloc-piles. Ces problèmes sont indiqués par le

clignotement rapide du voyant rouge et, dans le cas des chargeurs de

15 minutes, par un signal sonore continu. Si un tel problème survient,

réinsérer le bloc-piles dans le chargeur. Si le problème persiste,

remplacer le bloc-piles afin de déterminer si le chargeur fonctionne

bien. Si le bloc-piles de rechange se charge correctement, cela signifie

que le bloc initial est défectueux et qu’on doit le retourner à un centre

de service afin qu’il puisse être recyclé. Si le bloc-piles neuf affiche le

même problème que le bloc initial, on doit faire vérifier le chargeur à un

centre de service autorisé.

PROBLÈMES RELIÉS À LA SOURCE DE COURANT

Les chargeurs munis d’un voyant d’indication de problème au niveau

de la source de courant peuvent suspendre temporairement le

chargement s’ils sont branchés dans une source d’alimentation

portative, comme une génératrice ou un convertisseur de courant

continu en courant alternatif. En présence d’un tel problème, le voyant

rouge émet deux clignotements rapides, suivis d’une pause, indiquant

que le problème se situe au niveau de la source de courant.

DISPOSITIF DE DÉTECTION DE PILES CHAUDES

Si le chargeur est muni d’un dispositif visant à détecter les piles

chaudes, le chargement sera retardé jusqu’à ce que la pile se soit

refroidie et le chargeur se placera automatiquement en position de

chargement; ce dispositif sert à maximiser la durée de vie des piles. Le

voyant rouge s’allume longuement, et ensuite brièvement lorsque ce

dispositif est en marche.

Page 23

21

Français

L'EXÉCUTION de BATTERIE

L'EXÉCUTION de BATTERIE que quelques chargeurs ont un

dispositif de mise au point optimalise l'exécution de paquet de

batterie. Votre chargeur peut fournir automatique Accordent-Up™ le

mode ou manuel (c.-à-d. bouton de poussée) Accordez-Up™ le

mode. Pour l'information sur ce dispositif, voir s'il vous plaît la section

appropriée ci-dessous. Puisque les batteries détruisent lentement