Page 1

383823-01/DW870 5/3/02 1:33 PM Page 1

Page 2

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in China (MAY00-1) Form No. 383823-01

DW870 Copyright © 2000

The following are trademarks for one or more DeWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of

pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

383823-01/DW870 5/3/02 1:33 PM Page 2

Page 3

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW870

14" (355 mm) Heavy Duty Chop Saw

Scie fendeuse de 355 mm (14 po) et de service intensif

Cortadora de metales de 355 mm (14")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us on the World Wide Web at www.dewalt.com

383823-01/DW870 5/3/02 1:33 PM Page 3

Page 4

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

WARNING: FOR YOUR OWN SAFETY READ INSTRUCTION

MANUAL BEFORE OPERATING CHOP SAW.

Important Safety Instructions

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep work

area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe

distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches,

or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for

which it was not designed.

• USE PROPER EXTENSION CORD. Make sure your extension

cord is in good condition. When using and extension cord, be sure

to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. The following table shows the

correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord.

1

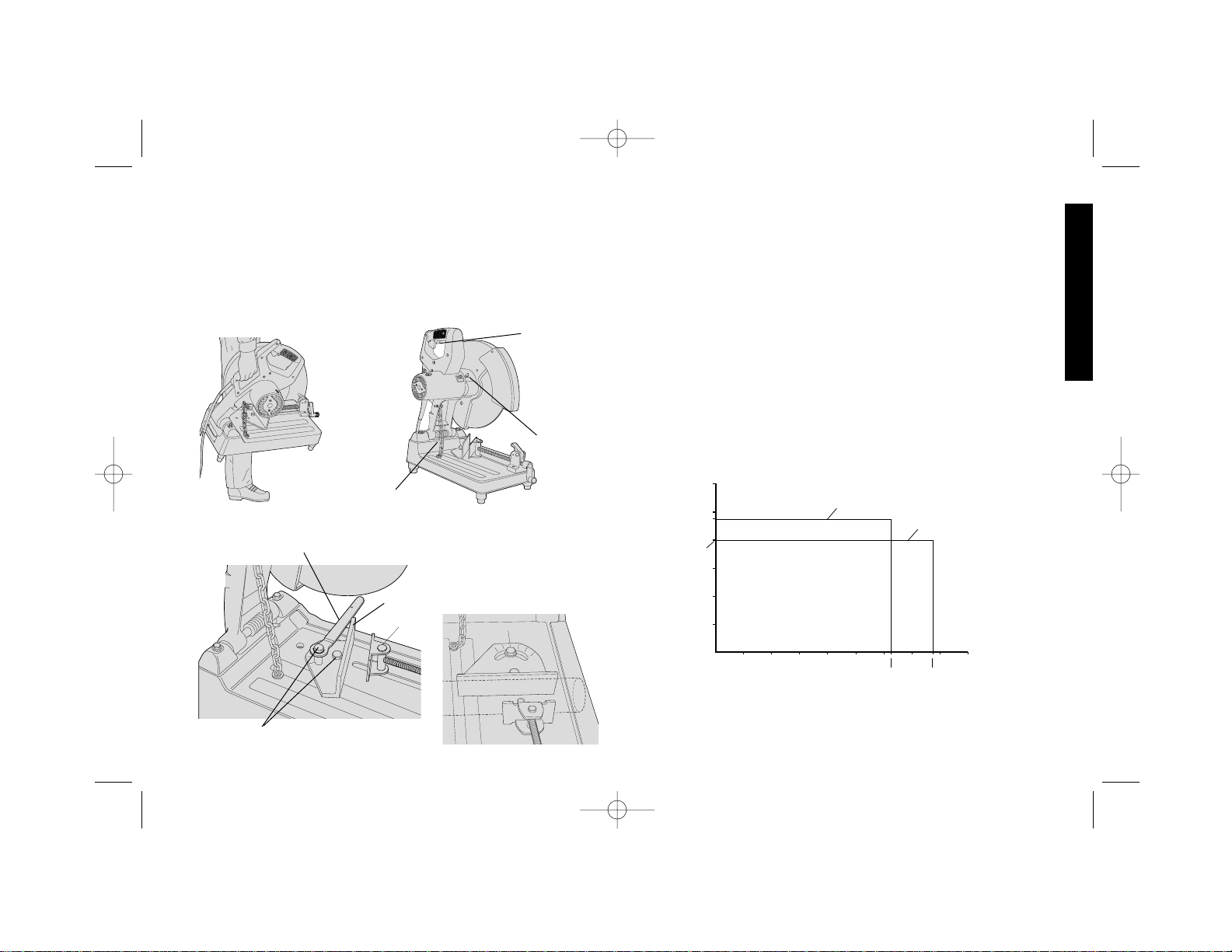

STOPPER PIN

TRIGGER

SWITCH

LOWER

GUARD

RELEASE

LEVER

BLADE LOCK

LEVER

FENCE

VISE

UPPER GUARD

383823-01/DW870 5/3/02 1:33 PM Page 4

Page 5

English

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0- 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

• WEAR PROPER APPAREL.Do not wear loose clothing, neckties,

rings, bracelets, or other jewelry which may get caught in moving

parts. Nonslip footwear is recommended. Wear protective hair

covering to contain long hair.

Air vents often cover moving parts and

should also be avoided.

• ALWAYS USE SAFETY GLASSES.Also use face or dust mask if

cutting operation is dusty. Everyday eyeglasses only have impact

resistant lenses, they are not safety glasses.

• SECURE WORK. Use clamps or a vise to hold work when

practical. It’s safer than using your hand and it frees both hands to

operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

best and safest performance. Follow instructions for lubricating and

changing accessories.

• DISCONNECT TOOLS before servicing; when changing acces-

sories, such as blades, bits, cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure switch is in off position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction

manual for recommended accessories. The use of improper

accessories may cause risk of injury to persons.

• NEVER STAND ON T OOL.Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function — check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

• DIRECTION OF FEED. Feed work into a blade or cutter against

the direction of rotation of the blade or cutter only.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don’t leave tool until it comes to a complete stop.

• REPLACEMENT PARTS. When servicing use only identical

replacement parts.

• TO REDUCE THE RISK OF ELECTRIC SHOCK, this equipment

may have a polarized plug (one blade is wider than the other.)

This plug will fit in a polarized outlet only one way. If the plug does

not fit, contact a qualified electrician to install the proper outlet.

DO NOT CHANGE THE PLUG IN ANY WAY.

• The tool may be equipped with a 3-prong grounding type plug. This

plug is to be used in a grounded outlet only. If the plug does not fit,

contact a qualified electrician to install the proper outlet. DO NOT

CHANGE THE PLUG IN ANY WAY.

Additional Safety Rules for Chop Saw

• Always wear safety goggles or other eye protection when using this tool.

• Before using, inspect each cutting wheel for cracks or flaws. If a crack

or flaw is evident—discard the wheel! The wheel should also be

inspected whenever you think the tool may have been dropped.

• When starting the tool (with a new or replacement wheel installed)

place the tool in a well protected area. If the wheel has an undetected

crack or flaw, it should burst in less than one minute. Never start the

tool with a person in line with the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment.

If this occurs, stop the tool and inspect the wheel.

2

383823-01/DW870 5/3/02 1:33 PM Page 5

Page 6

3

English

• Clean your chop saw periodically following the procedure in this manual.

• Do not remove wheel guard.

• ALW AYS USE THE VISE OR SPECIAL FIXTURE TO CLAMP

WORK SECURELY. Other aids such as the, spring, bar, or C-clamps

may be appropriate for certain sizes and shapes of workpiece. Use

care in selecting and placing these clamps and make a dry run before

making a cut.

• Use only 14” type 1 wheels rated at 4100 rpm or higher.

• Allow cut off parts to cool before handling.

• Do not attempt to cut wood or plastic with this tool.

• NEVER CUT MAGNESIUM WITH THIS TOOL.

• Use chop saw in a well-ventilated area.

• Turn chop saw off before removing any pieces from the base.

• DO NOT CUT ELECTRICALLY LIVE MATERIAL.

• NEVER USE A CIRCULAR SAW BLADE IN THIS CHOP SAW.

do not use toothed blades.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE LIQUIDS,

GASES OR DUST. Sparks or hot chips from cutting or arcing motor

brushes may ignite combustible materials.

• Do not use the side of the abrasive wheel as a deburring grinder.

This will substantially weaken the wheel creating an unsafe

condition. The wheel may come apart .

CAUTION: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do

this type of work. T o reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water.Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

Power Supply

Be sure your power supply agrees with the nameplate marking. 120

volts, “60 Hz” means alternating current (normal 120 volt, 60 Hz

house current).

A voltage decrease of more than 10% will cause a loss of power and

overheating.

Cutting Capacity

The wide vise opening and high pivot point provide cutting capacity

for many large pieces. Use the cutting capacity chart to determine

total maximum size of cuts that can be made with a new wheel.

CAUTION: CERTAIN LARGE, CIRCULAR OR IRREGULARLY

SHAPED OBJECTS MAY REQUIRE ADDITIONAL HOLDING

MEANS IF THEY CANNOT BE HELD SECURELY IN VISE.

CAUTION: DO NOT CUT MAGNESIUM WITH THIS TOOL.

Maximum Cutting Capacity

NOTE: CAPACITY SHOWN ON CHART ASSUMES NO WHEEL WEAR

AND OPTIMUM FENCE POSITION.

Standard Equipment

1 14” Metal Cutting Abrasive Wheel. Use only high strength Type 1

organic bonded wheels rated 4,100 rpm or higher.(Aluminum

Oxide)

1 Wheel Wrench

383823-01/DW870 5/3/02 1:33 PM Page 6

Page 7

4

English

FIG. 1

FIG. 2

S

T

O

P

P

E

R

P

I

N

TRIGGER

SWITCH

BLADE

LOCK

LEVER

FENCE AT FORWARD

POSITION

FENCE AT REAR

POSITION

6”

5”

4”

3”

2”

1”

0” 1” 2” 3” 4” 5” 6” 7” 8”

9”

4.75”

3.93”

6.25” 7.75”

HEIGHT

WIDTH

CHAIN

To Carry

Fold down unit to position where you can attach chain to pin on tool

arm (Fig. 1).

Unlocking

To unlock tool and raise head, depress motor arm slightly and

remove chain. Motor arm will then pivot upward (see Figure 2).

Material Clamping and Supporting

• Angles are best clamped and cut with both legs resting against

base

• A spacer block slightly narrower than the work space

can be used to increase wheel utilization.

• Long workpieces must be supported by a block so it will be

level with top of base. The cut off end should be free to fall

downward to avoid wheel binding.

Vise Operation

Vise has a quick travel feature. To release the vise when it is clamped

tightly, turn the crank counterclockwise one or two times to remove

clamping pressure. Lift vise lever up. Pull crank assembly out as far

as desired. Vise may be shoved into work without cranking. Lower

vise lever then tighten vise on work by using crank (see Figure 5).

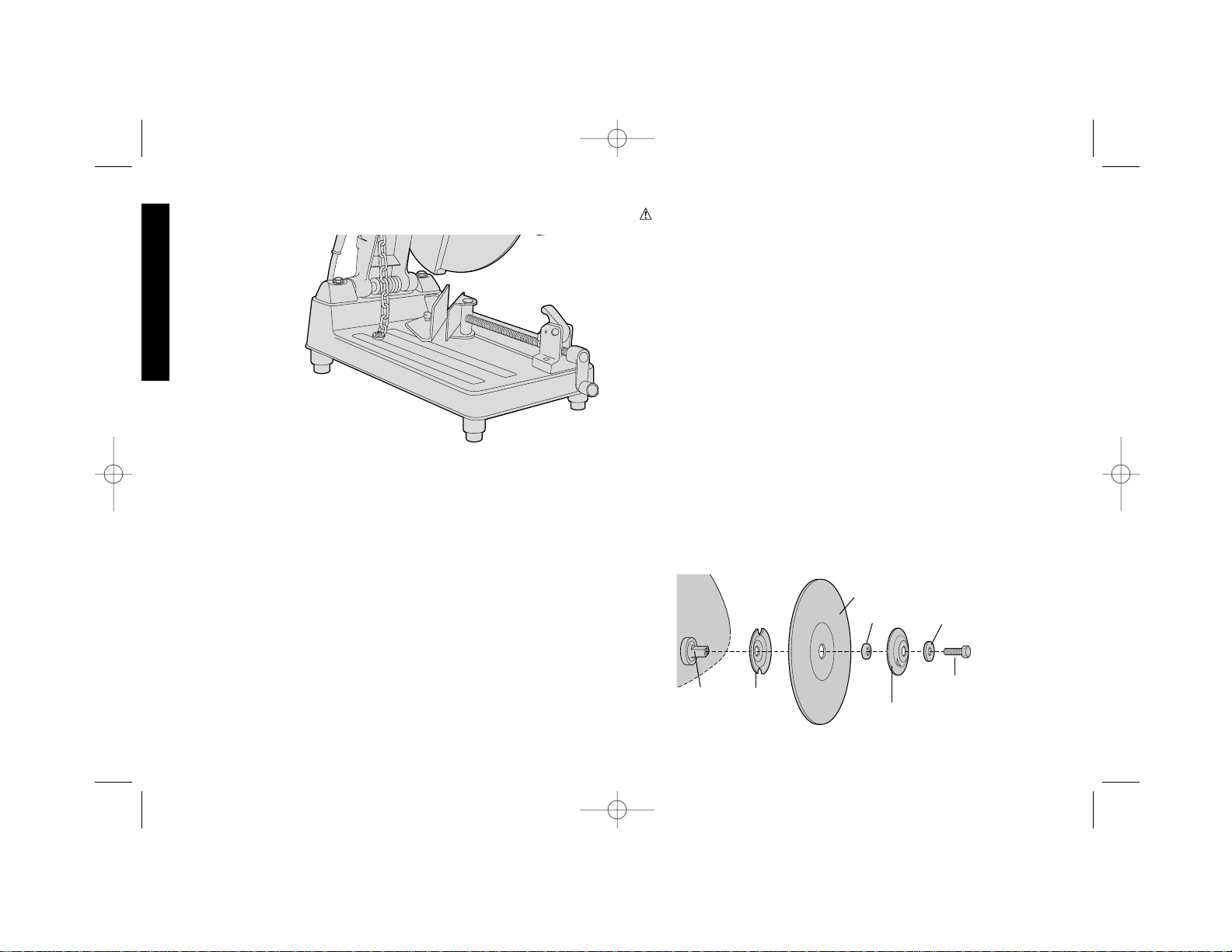

FIG. 3

WRENCH

FENCE

FENCE BOLTS

VISE

FIG. 4

383823-01/DW870 5/3/02 1:33 PM Page 7

15

30

15

0

30

5

1

45

30

Page 8

5

English

To Adjust Vise Stop

CUTTING ANGLE

Use the wrench to

loosen the two hex

bolts (Fig. 3). (Do

not remove the

bolts). The fence

can be rotated in

either direction.

Securely tighten

both the bolts

before use.

Switch

To start the tool,

depress the trigger switch shown in Figure 2. To turn the tool off,

release the trigger switch. Keep hands and material from wheel until it

has coasted to a stop.

Removal and Installation of Wheels

1. Be sure tool is disconnected from power supply.

2. Push in wheel lock lever (Figure 6) and rotate wheel by hand until

wheel lock lever engages slot in inside flange to lock wheel.

Loosen the bolt counterclockwise in the center of the abrasive

wheel with the 8 mm hex wrench found in the holder in the base.

Bolt has right hand thread.

3. Remove the bolt, washer, outside flange, adapter and old wheel

(Fig. 10).

4. Install the new abrasive wheel by reversing the above steps.

Make sure the adapter is on the shaft and centered on the wheel.

5. Do not over tighten bolt.

DO NOT MAKE ANY ADJUSTMENT WHILE THE WHEEL IS IN MOTION.

DO NOT MAKE ANY ADJUSTMENT WHILE CHOP SAW IS PLUGGED

INTO POWER SUPPLY.

WARNING: CHECK THE WORK SURFACE THAT THE CHOP

SAW RESTS ON WHEN REPLACING WITH A NEW ABRASIVE

WHEEL. IT IS POSSIBLE THAT THE WHEEL MAY CONTACT ANY

ITEMS OR STRUCTURE THAT EXTENDS ABOVE WORK SURFACE

(UNDER THE BASE) WHEN THE ARM IS FULL Y LOWERED.

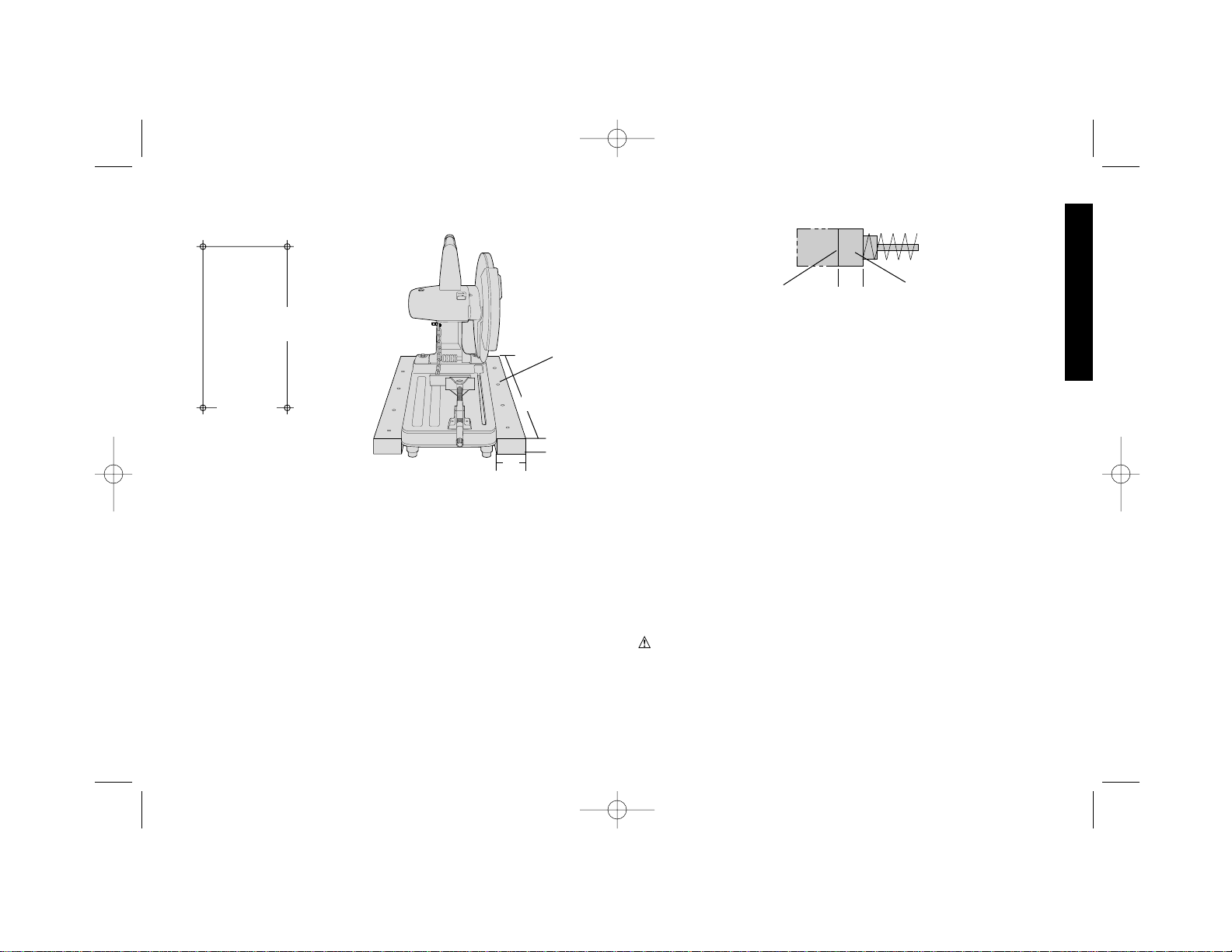

Procedure For Permanent Mounting

1. Drill four holes, 5/16" diameter minimum, through the work

surface (Fig. 7).

2. Remove screws from feet.

3. Insert 1/4-20 screws through underside of work surface,

through feet, into holes in tool base. The proper screw length is

equal to the thickness of the work surface plus 1 inch

(25 mm).

CRADLE MOUNTING

1. Cut two boards approximately 20" long x 2" high x 4" wide.

2. Place chop saw at desired work location.

3. Place boards tightly along side, and nail to work surface,

(Figure 8).

FIG. 5

FIG. 6

GEAR

SHAFT

FLANGE,

INSIDE

ABRASIVE WHEEL

ADAPTER

FLANGE, OUTSIDE

WASHER

HEX HEAD BOLT

383823-01/DW870 5/3/02 1:33 PM Page 8

Page 9

6

English

Motor Brush Inspection and

Replacement

Be sure tool is unplugged before inspecting brushes. Brushes should

be regularly inspected for wear. To inspect brushes, unscrew the

two end cap screws and remove end cap. T o remove each brush, first

unplug the shunt wire terminal connection. Then carefully back the

brush spring out of the brush box and remove brush. Brushes should

slide freely in brush box. If brushes are worn down to .3” they should

be replaced (see Figure 9). To reinstall each brush carefully back

the spring out of the brush box, insert the brush and return the spring

making sure it is pressing on the brush and not touching the brush

box. Then replace the end cap and two screws.

Operation Tips for More Accurate Cuts

• Allow the wheel to do the cutting. Excessive force will cause the

wheel to glaze reducing cutting efficiency and/or to deflect causing

inaccurate cuts.

• Adjust fence angle. (Figure 3)

• Make sure material is laying flat across base.

• Properly clamp material to avoid movement and vibration.

Cleaning

Blowing dust and grit out of the main housing by means of an air hose

is recommended and may be done as often as dirt is seen collecting

in and around the air vents.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, contact:

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286

CAUTION: The use of any other accessory not recommended

for use with this tool could be hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by authorized service centers

or other qualified service organizations, always using identical

FIG. 7

FIG. 8

16-3/8"

(416 mm)

8-1/2"

(216 mm)

20"

2"-3"

NAIL

4"

FIG. 9

0.3"

7.62 mm

BRUSH

WEAR LINE

383823-01/DW870 5/3/02 1:33 PM Page 9

PIN

R

PE

P

O

ST

Page 10

7

English

replacement parts. ALWAYS WEAR SAFETY GLASSES. ALWAYS

SECURE WORK IN VISE. DISCONNECT TOOL FROM POWER

SUPPLY BEFORE CHANGING WHEEL.

Lubrication

Closed-type, grease-sealed ball bearings are used throughout. These

bearings have sufficient lubrication packed in them at the factory to last

the life of the chop saw.

Gears should be relubricated every 60 to 90 days, depending upon

use. This lubrication should only be attempted by experienced power

tool repair persons like the mechanics at D

EWAL T service centers. The

gear case should be wiped clean and 1/2 oz. (16 grams) of D

EWALT

Lubricant Part No. 790206 (6 oz. tube) placed in the gear case.

Full Warranty

D

EWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-4-D

EWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

383823-01/DW870 5/3/02 1:33 PM Page 10

Page 11

11

English

Trouble Shooting Guide

TROUBLE! TOOL WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1. Tool not plugged in. 1.Plug in saw.

2. Fuse blown or circuit breaker tripped. 2.Replace fuse or reset circuit breaker.

3. Cord damaged. 3.Have cord replaced by authorized service center.

4. Brushes worn out. 4.Have brushes replaced by qualified service person.

TROUBLE! TOOL MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1. Glazed wheel. 1.Dress the wheel or replace with a new one.

2. Workpiece incorrectly placed or clamped. 2.Firmly clamp and support workpiece.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1. Extension cord too light or too long. 1.Replace with adequate size cord. See chart on page 2.

2. Low voltage. 2.Contact your electric company.

3. Low generator voltage. 3.Check generator output voltage. Reduce number of tools powered by the generator.

TROUBLE! TOOL VIBRATES EXCESSIVELY DURING CUT

WHAT’S WRONG? WHAT TO DO…

1. Tool not mounted securely to stand or work bench. 1.Tighten all mounting hardware. See page 5, Procedures for Permanent Mounting.

2. Damaged wheel. 2.Replace wheel.

3. Workpiece not clamped properly. 3.Refer to Material Clamping and Supporting page 4.

TROUBLE! DOES NOT MAKE ACCURATE CUTS

WHAT’S WRONG? WHAT TO DO…

1. Fence not adjusted correctly. 1.Check and adjust. See Fence Operation on page 5.

2. Wheel is not square to fence. 2.Check and adjust.

3. Excessive force used to make cut. 3.Reduce cutting force, let the wheel do the work.

4. Work piece moving. 4.Clamp workpiece securely. See Material Clamping and Supporting page 4. Make sure

material is laying flat against the base.

TROUBLE! CANNOT MOVE ARM

WHAT’S WRONG? WHAT TO DO…

1. Auto-retracting wheel guard will not move. 1.Check for damaged parts. Check for excessive chips in guard. Replace or repair as needed.

2. Chain is engaged. 2.Push down slightly on the arm, remove chain from pin. Raise arm.

TROUBLE! MATERIAL MOVES DURING CUT

WHAT’S WRONG? WHAT TO DO…

1. Fence slipping or workpiece incorrectly placed or clamped. 1.See Material Clamping and Supporting, page 4.

2. Vise too loose 2.Tighten vise clamping.

3. Excessive cutting force. 3.Reduce cutting force.

383823-01/DW870 5/3/02 1:33 PM Page 11

Page 12

12

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE

PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU

TOUT AUTRE OUTIL DEWALT, COMPOSEZ SANS FRAIS LE :

1 800 433-9258.

Mesures de sécurité importantes

AVERTISSEMENT! LIRE ET COMPRENDRE TOUTES LES

DIRECTIVES, car le non-respect des directives suivantes pourrait

entraîner un choc électrique, un incendie ou des blessures graves.

CONSERVER CES DIRECTIVES

· GARDER LES DISPOSITIFS DE PROTECTION EN PLACE et en

bon état de fonctionnement.

· RETIRER LES CLÉS DE RÉGLAGE; prendre l’habitude de s’assurer

que les clés de réglage soient retirées de l’outil avant de démarrer ce

dernier.

· GARDER LA ZONE DE TRAVAIL PROPRE; les espaces de travail

et les établis encombrés sont propices aux accidents.

· NE PAS UTILISER DANS DES ENDROITS DANGEREUX; ne pas

utiliser l’outil électrique dans des endroits humides ou mouillés, ni

l’exposer à la pluie. Garder la zone de travail bien éclairée.

· TENIR LES ENFANTS À L’ÉCART; s’assurer que personne ne se

tienne trop près de la zone de travail.

· S’ASSURER QUE L’ATELIER SOIT SÛR POUR LES ENFANTS;

utiliser des cadenas, des interrupteurs centraux ou enlever les

commandes de démarrage.

· NE PAS FORCER L’OUTIL; pour obtenir de meilleurs résultats et

réduire les risques de blessure, laisser l’outil couper à la vitesse pour

laquelle il a été conçu.

· UTILISER L’OUTIL APPROPRIÉ; ne pas forcer l’outil ni les

accessoires, ni les utiliser pour des travaux autres que ceux pour

lesquels ils ont été conçus.

· UTILISER LES RALLONGES APPROPRIÉES; s’assurer que la

rallonge électrique soit en bon état et qu’elle soit en mesure de porter

le courant nécessaire à l’outil. Une rallonge de calibre inférieur

entraînera une chute de tension se traduisant par une perte de

puissance et une surchauffe. Le tableau ci-dessous illustre les calibres

que l’on doit utiliser selon la longueur de la rallonge et l’intensité

nominale indiquée sur la plaque signalétique. En cas de doute, utiliser

Français

PROTÈGE-LAME SUPÉRIEUR

PROTÈGE-LAME

INFÉRIEUR

LEVIER DE

DÉGAGEMENT

ÉTAU

GUIDE

LEVIER DE

VERROUILLAG

E DE LA LAME

INTERRUPTEUR

À GÂCHETTE

AVERTISSEMENT : POUR ASSURER VOTRE PROTECTION,

LIRE LE MANUEL D’UTILISATiON AVANT DE FAIRE FONCTIONNER L’OUTIL

CHAÎNE

383823-01/DW870 5/3/02 1:33 PM Page 12

N

I

P

R

E

P

P

O

T

S

Page 13

le calibre suivant. Plus le calibre est petit, plus la rallonge peut porter

de courant.

Calibre minimal des cordons de rallonge

Longueur totale du cordon

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Intensité

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

· PORTER DES VÊTEMENTS APPROPRIÉS; ne pas porter de

vêtements amples ni de cravate, de bague, de bracelet ou d’autres

bijoux, car ceux-ci peuvent rester coincés dans les pièces mobiles.

On recommande le port de chaussures antidérapantes. Couvrir les

cheveux longs. Se tenir éloigné des évents puisque ces derniers

pourraient camoufler des pièces mobiles.

· TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ; porter aussi

un masque lorsqu’on soulève de la poussière. Les lunettes ordinaires

protègent uniquement les yeux contre les chocs et ne sont pas des

lunettes de protection.

· IMMOBILISER L’OUVRAGE; au besoin, retenir l’ouvrage au moyen

d’un étau ou de brides de serrage, et non pas avec une main, afin de

pouvoir manipuler l’outil des deux mains.

· NE PAS TROP ÉTENDRE LES BRAS; les pieds doivent rester

ancrés fermement sur le sol afin de maintenir son équilibre en tout

temps

· BIEN ENTRETENIR L’OUTIL; afin d’obtenir de meilleurs résultats et

faire preuve de prudence, garder l’outil propre et bien aiguisé. Suivre

les consignes lorsqu’on lubrifie ou qu’on remplace les accessoires.

· DÉBRANCHER L’OUTIL avant de procéder à l’entretien ou de

remplacer un accessoire (lame, mèche, organe de coupe, etc.).

· RÉDUIRE LES RISQUES DE DÉMARRAGE ACCIDENTEL;

s’assurer que l’interrupteur soit en position d’arrêt avant de brancher

l’outil.

· UTILISER LES ACCESSOIRES RECOMMANDÉS; consulter le

manuel d’utilisation pour savoir quels accessoires sont appropriés.

L’utilisation d’accessoires autres que ceux recommandés pourrait

entraîner des blessures.

· NE JAMAIS METTRE LES PIEDS SUR L ’OUTIL;si l’outil se renverse

ou est accidentellement mis en marche, il pourrait entraîner des

blessures graves.

· VÉRIFIER LES PIÈCES ENDOMMAGÉES; avant de poursuivre les

travaux, on doit examiner attentivement les dispositifs de protection, ou

toute autre pièce endommagée, afin de s’assurer qu’il fonctionne

toujours adéquatement et qu’il est en mesure d’effectuer les travaux

pour lesquels il a été conçu. Vérifier les pièces mobiles afin de

s’assurer qu’elles soient bien alignées et qu’elles ne restent pas

coincées; vérifier également les pièces et les assemblages afin de

s’assurer qu’il n’y ait aucun bris ni aucune autre condition susceptible

de nuire au bon fonctionnement de l’outil. On doit réparer ou remplacer

toute pièce endommagée, y compris les dispositifs de protection.

· TOUJOURS RESPECTER LE SENS D’AVANCE; ne jamais faire

avancer l’ouvrage dans le sens de rotation de la lame ou de l’organe

de coupe.

· NE JAMAIS LAISSER L’OUTIL FONCTIONNER SANS SURVEILLANCE; COUPER L’ALIMENTATION et attendre que l’outil s’arrête

complètement avant de quitter les lieux.

· PIÈCES DE RECHANGE; seules des pièces de rechange identiques

doivent être utilisées lorsqu’on effectue l’entretien.

· AFIN DE RÉDUIRE LES RISQUES DE CHOC ÉLECTRIQUE, cet

outil est muni d’une fiche polarisée (c’est-à-dire que l’une des lames

est plus large que l’autre), et ne peut être raccordé qu’à une rallonge

polarisée et ce, dans un seul sens. Si la fiche ne s’adapte pas à la

prise, on doit demander à un électricien qualifié d’installer la prise

appropriée. ON NE DOIT JAMAIS MODIFIER LA FICHE.

Règles de sécurité additionnelles

concernant la scie fendeuse

· Toujours porter des lunettes de sécurité ou tout autre dispositif de

protection oculaire lorsqu’on utilise l’outil.

13

Français

383823-01/DW870 5/3/02 1:33 PM Page 13

Page 14

14

· Avant d’utiliser l’outil, vérifier chaque lame afin de s’assurer qu’il n’y

ait ni bris ni fissure. Si on y trouve de tels défauts, mettre la lame au

rebut!! Inspecter également la lame chaque fois qu’elle subit un choc.

· Lorsqu’on démarre l’outil (après y avoir installé une lame neuve ou de

rechange), se tenir dans un endroit bien protégé. Si la lame est

fissurée ou brisée, elle pourrait éclater et ce, en moins d’une minute.

Ne jamais démarrer l’outil lorsque quelqu’un, y compris l’opérateur, se

tient directement devant la lame.

· Éviter de faire rebondir la lame durant son fonctionnement ou de

l’utiliser sans ménagement. Si la lame subit de tels traitements, arrêter

l’outil et inspecter cette dernière.

· Bien nettoyer l’outil périodiquement, conformément aux directives

contenues dans le présent manuel.

· Ne pas retirer le protège-lame.

· TOUJOURS IMMOBILISER L’OUVRAGE AU MOYEN D’UN ÉTAU

OU D’UNE FERRURE APPROPRIÉE. D’autres dispositifs de fixation

tels que la ferrure fournie ou un ressort, une barre ou un serre-joint en

C peuvent convenir pour certains ouvrages, selon la dimension et la

forme. On doit choisir et positionner ces dispositifs avec soin et

effectuer un essai à vide avant de réaliser une coupe.

· N’utiliser que des lames de type 1 de 355 mm (14 po) ayant une

vitesse nominale égale ou supérieure à 4100 tr/min.

· Laisser les pièces coupées se refroidir avant de les manipuler.

· Ne pas utiliser l’outil pour couper du bois ou du plastique.

· NE JAMAIS UTILISER L’OUTIL POUR COUPER DES PIÈCES DE

MAGNÉSIUM.

· Utiliser l’outil dans un endroit bien ventilé.

· Arrêter l’outil avant de retirer des pièces de sa base.

· NE PAS COUPER DE MATÉRIAUX QUI POURRAIENT ÊTRE

SOUMIS À UN COURANT ÉLECTRIQUE.

· NE JAMAIS UTILISER DE LAMES POUR SCIE CIRCULAIRE AVEC

CET OUTIL, ni de lames dentées.

· NE PAS UTILISER L’OUTIL À PROXIMITÉ DE LIQUIDES, DE GAZ

OU DE POUSSIÈRES INFLAMMABLES; le moteur peut créer des

étincelles ou projeter des particules chaudes et enflammer des

matières environnantes.

MISE EN GARDE : porter un dispositif de protection personnel

anti-bruit approprié durant l’utilisation. Sous certaines conditions et

pendant toute la durée de l’utilisation, le bruit émanant de ce produit

pourrait contribuer à la perte d’audition.

AVERTISSEMENT : Certains outils, tels que les sableuses

électriques, les scies, les meules, les perceuses ou certains autres

outils de construction, peuvent soulever de la poussière contenant des

produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de

maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence

avec laquelle on effectue ces travaux. Pour réduire l’exposition à de

tels produits, il faut travailler dans un endroit bien ventilé et utiliser

l’équipement de sécurité approprié tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par

cet outil ou autres outils électriques. Porter des vêtements

de protection et nettoyer les parties exposées du corps avec

de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits

chimiques nocifs.

Français

383823-01/DW870 5/3/02 1:33 PM Page 14

Page 15

Alimentation électrique

S’assurer que l’alimentation corresponde aux valeurs nominales

inscrites sur la plaque signalétique de l’outil.

L’étiquette portant la mention «120 volts, 60 Hz» signifie qu’on doit

seulement utiliser une prise à courant alternatif (prise résidentielle

standard). Une diminution de tension de 10 % ou plus entraînera une

chute de puissance et une surchauffe.

Capacité de coupe

La grande ouverture de l’étau et le point de pivotement élevé permettent la

coupe de pièces de grande dimension. En présence d’une nouvelle lame, se

reporter au tableau ci-contre pour déterminer la dimension maximale de

coupe.

MISE EN GARDE : IL PEUT S’AVÉRER NÉCESSAIRE D’IMMOBILISER

AU MOYEN DE FERRURES SUPPLÉMENTAIRES CERTAINS

MATÉRIAUX DE GRANDE DIMENSION OU DE FORME CIRCULAIRE OU

IRRÉGULIÈRE S’IL NE PEUVENT ÊTRE MAINTENUS SOLIDEMENT AU

MOYEN DE L’ÉTAU.

MISE EN GARDE : NE PAS UTILISER CET OUTIL POUR COUPER DES

PIÈCES DE MAGNÉSIUM.

Capacité de coupe maximale

REMARQUE : POUR OBTENIR LES RENDEMENTS CI-DESSOUS, ON

DOIT S’ASSURER QUE LA LAME NE SOIT PAS TROP USÉE ET QUE LE

GUIDE SOIT PLACÉ TEL QU’INDIQUÉ.

Équipement standard

• Une (1) lame pour la coupe des métaux de 355 mm (14 po).

Utiliser seulement des lames à liants organiques de type 1 (en

oxyde d’aluminium) à haute résistance ayant une vitesse

nominale égale ou supérieure à 4 100 tr / min.

• Une (1) clé pour lame.

Transport

Rabattre l’outil de manière à pouvoir fixer la chaîne à la goupille

située sur le levier (fig. 1).

Déverrouillage

Pour déverrouiller l’outil et soulever la tête, abaisser légèrement le levier du

moteur et retirer la chaîne; le levier pivotera ensuite vers le haut (fig. 2).

15

Français

GUIDE EN POSITION AVANT

GUIDE EN

POSITION

ARRIÈRE

LARGEUR

HAUTEUR

6 PO

5 PO

12,1 CM

(4,75 PO)

10 CM

(3,93 PO)

15,9 CM

(6,25 PO)

19,7 CM

(7,75 PO)

3 PO

2 PO

1 PO

4 PO

0

1 PO

2 PO

3 PO

4 PO

5 PO

6 PO

7 PO

FIG. 1

FIG. 2

383823-01/DW870 5/3/02 1:33 PM Page 15

N

I

P

R

E

P

P

O

T

S

Page 16

FIG. 3

16

Immobilisation et support de l’ouvrage

· On recommande de bien appuyer les deux pattes de l’outil à la

base afin de procéder à la coupe de cornières.

· Une cale d’écartement légèrement plus étroite que l’espace de

travail peut être utilisée en vue d’augmenter la utilization de la

lame.

· Les longues planches doivent être soutenues au moyen d’un

bloc afin qu’elles soient de niveau avec le dessus de la base. La

section coupée doit pouvoir se détacher complètement afin

d’éviter que la lame ne se coince.

Fonctionnement de l’étau

L’étau est pourvu d’un mécanisme de serrage ou de desserrage

rapide. Pour relâcher l’étau, tourner la manivelle vers la gauche à

une ou deux reprises, puis soulever le levier. Sortir la manivelle

jusqu’à la position voulue pour pouvoir

utiliser l’étau sans se servir de la

manivelle. Abaisser le levier de l’étau,

puis fixer ce dernier sur l’ouvrage au

moyen de la manivelle (figure 5).

Réglage de la butée de

l’étau

ANGLE DE COUPE

Au moyen de la clé, desserrer les deux boulons hexagonaux (sans les retirer)

(fig. 3), afin de pouvoir faire pivoter le guide dans un sens ou dans l’autre.

S’assurer de resserrer les deux boulons avant d’utiliser l’outil.

Interrupteur

Pour mettre l’outil en marche, enfoncer l’interrupteur à gâchette (fig.

2); le relâcher pour arrêter l’outil. Garder les mains et l’ouvrage à

l’écart de la lame jusqu’à ce que celle-ci se soit arrêtée complètement.

Retrait et installation des lames

1. Débrancher l’outil avant de procéder.

2. Enfoncer le levier de verrouillage de la lame (fig. 6) et tourner

manuellement cette dernière jusqu’à ce que la fente du levier

s’engage dans la bride interne, bloquant ainsi la lame. Desserrer

le boulon (à filetage droit) situé au centre de la lame en le

tournant vers la gauche au moyen de la clé à six pans de 8 mm

qui se trouve dans le compartiment de rangement de la base.

3. Retirer le boulon, la rondelle, la bride externe, l’adaptateur ainsi

que la lame (fig. 10).

4. Installer la lame neuve en inversant les étapes ci-dessus.

S’assurer que l’adaptateur soit bien inséré dans la tige et placée

au centre de la lame.

5. Ne pas trop serrer le boulon.

Français

FIG. 5

LAME

ADAPTATEUR

RONDELLE

BOULON À

TÊTE

HEXAGONALE

BRIDE

EXTERNE

BRIDE

INTERNE

TIGE

D’ENGRENAGE

FIG. 6

FIG. 4

383823-01/DW870 5/3/02 1:33 PM Page 16

15

30

1

0

5

3

0

15

45

0

3

Page 17

NE PAS EFFECTUER DE RÉGLAGE PENDANT QUE LA LAME EST EN

MOUVEMENT, NI LORSQUE L’OUTIL EST BRANCHÉ DANS UNE PRISE

ÉLECTRIQUE.

AVERTISSEMENT : VÉRIFIER LA SURFACE DE TRAVAIL SUR

LAQUELLE REPOSE L’OUTIL LORSQU’ON INSTALLE UNE LAME NEUVE;

LORSQUE LE LEVIER EST ABAISSÉ COMPLÈTEMENT , LA PARTIE DE LA

LAME SITUÉE SOUS LA BASE RISQUE D’ENTRER EN CONTACT AVEC

DES OBJETS OU DES SAILLIES.

Installation permanente

1. Percer quatre trous d’au moins 0,8 cm (5/16 po) de diamètre

dans la surface de travail (fig. 7).

2. Enlever les vis retenant les pattes.

3. Insérer des vis de type 1/4 po-20 sous la surface de travail, à

travers les pattes puis dans les orifices de la base de l’outil. La

longueur de vis utilisées doit correspondre à l’épaisseur de la

surface de travail, plus 25 mm (1 po).

MONTAGE EN BERCEAU

1. Préparer deux planches d’environ 50 cm (20 po) de longueur, 5

cm (2 po) de hauteur et 10 cm (4 po) de largeur.

2. Mettre la scie fendeuse à l’endroit voulu.

3. Placer les planches contre les côtés, et clouer à la surface de

travail (fig. 8).

Inspection et remplacement des balais

de moteur

S’assurer que l’outil soit débranché avant de procéder à l’inspection

des balais. Ces derniers doivent être vérifiés périodiquement afin de

s’assurer qu’il n’y ait aucun signe d’usure. Pour ce faire, dévisser les

deux vis du capuchon et retirer ce dernier. Avant d’enlever un des

balais, débrancher le fil de dérivation de la borne, puis sortir

lentement le ressort du balai hors de son boîtier et retirer le balai (ce

dernier devrait pouvoir glisser librement dans le boîtier). Si les balais

ont réduit de plus de 7,62 mm (0,3 po), on doit les remplacer (fig. 9).

Pour réinstaller un balai, sortir doucement le ressort du boîtier du

balai, insérer le balai et réinsérer le ressort en s’assurant qu’il soit

bien appuyé contre le balai, sans entrer en contact avec le boîtier.

Réinstaller le capuchon et serrer les deux vis.

Conseils visant à obtenir une coupe

précise

· Laisser la lame travailler librement; une force excessive pourrait

la rendre lisse, ce qui pourrait à son tour réduire son efficacité

ou la faire dévier, produisant ainsi des coupes inexactes.

· Régler l’angle du guide selon le travail à effectuer (fig. 3).

· S’assurer que l’ouvrage soit à plat et perpendiculaire à la base.

Fixer l’ouvrage solidement afin de l’empêcher de bouger ou de

vibrer.

17

Français

FIG. 7

FIG. 8

416 MM

(16-3/8 PO)

216 M

(8-1/2 PO)

FIG. 9

7,62 MM

(0,3 PO)

LIGNE

D’USURE

BALAI

383823-01/DW870 5/3/02 1:33 PM Page 17

N

I

P

R

E

P

P

O

T

S

Page 18

18

Nettoyage

On recommande de nettoyer le logement principal de l’outil au moyen d’un jet

d’air lorsque la poussière et les particules s’accumulent à l’intérieur et autour

des évents.

Accessoires

Les accessoires recommandés pour chaque outil sont vendus chez les

dépositaires locaux ou les centres de service autorisés. Pour obtenir plus

d’information sur les accessoires, communiquer avec D

EWALT Industrial

Tool Co., 701 East Joppa Road, Baltimore, MD 21286 aux États-Unis.

MISE EN GARDE : l’usage d’un accessoire non recommandé peut

présenter un danger.

Important

Pour assurer la SÉCURITÉ et la FIABILITÉ de cet outil, toutes les

opérations de réparation, d’entretien et de réglage doivent être

effectuées par un centre de service autorisé ou qualifié; seules des

pièces de rechange identiques doivent être utilisées. TOUJOURS

PORTER DES LUNETTES DE SÉCURITÉ. TOUJOURS

IMMOBILISER L’OUVRAGE DANS UN ÉTAU. DÉBRANCHER

L’OUTIL AVANT DE REMPLACER LA LAME.

Lubrification

Cet outil est doté de roulements à billes de type fermé et scellés à la

graisse en usine, et sont en conséquence lubrifiés pour la durée de

vie de la scie.

Les engrenages doivent être lubrifiés tous les 60 à 90 jours, selon

l’utilisation, par le personnel d’entretien qualifié seulement, comme

un mécanicien d’un centre de service DeWALT. Le carter

d’engrenages doit être essuyé au moyen d’un linge propre et lubrifié

au moyen de 16 g (1/2 oz) de lubrifiant DeWALT (tube no 790206

rangé dans le carter d’engrenages).

Garantie complète

DeWALT garantit les outils industriels de service intensif contre tout

défaut de matériel ou de fabrication pour une période d’un an à

compter de la date d’achat; le produit défectueux sera réparé sans

frais. Pour obtenir de plus amples renseignements sur les

réparations couvertes par la présente garantie, composer le 1 800

433-9258. Cette garantie ne s’applique pas aux accessoires et ne

vise pas les dommages causés par des réparations effectuées par

un tiers. Cette garantie confère des droits légaux particuliers à

l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits

différant d’un territoire à l’autre. En plus de la présente garantie, la

s’applique également aux outils DeWALT.

GARANTIE SANS RISQUE DE 30 JOURS EN CAS

DE NON-SATISFACTION

Si vous n’êtes pas entièrement satisfait(e) du rendement de l’outil industriel

de service intensif DeWALT, il suffit de le retourner au vendeur participant

dans les 30 jours pour obtenir un remboursement intégral. Retourner l’outil au

complet en payant le transport à l’avance; une preuve d’achat peut être

requise.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE

Si vos étiquettes d'avertissement deviennent illisibles ou sont

manquantes, composez le 1-800-4-D

EWAL T pour obtenir une étiquette

de remplacement gratuite.

Français

383823-01/DW870 5/3/02 1:33 PM Page 18

Page 19

19

Guide de dépannage

PROBLÈME : L’OUTIL NE DÉMARRE PAS

QUE SE PASSE-T-IL ? QUOI FAIRE…

1.La scie n’est pas branchée. 1.Brancher la scie.

2.Le fusible a sauté ou le disjoncteur le disjoncteur. 2.Remplacer le fusible ou réenclencher s’est déclenché.

3.Le cordon est endommagé. 3.Faire remplacer le cordon par un centre de service autorisé.

4.Les balais sont usés. 4. Faire remplacer les balais par un centre de service autorisé.

PROBLÈME : L’OUTIL NE COUPE PAS DE MANIÈRE SATISFAISANTE.

QUE SE PASSE-T-IL? QUOI FAIRE…

1.La lame est lisse. 1.Rectifier la lame ou la remplacer par une lame neuve.

2.L’ouvrage n’est pas bien immobilisé ou fixé. 2.Fixer solidement l’ouvrage et le supporter adéquatement.

PROBLÈME : LA LAME N’ATTEINT PAS SA VITESSE MAXIMALE

QUE SE PASSE-T-IL? QUOI FAIRE…

1.La rallonge est trop longue ou de calibre 1.La remplacer par une rallonge appropriée insuffisant. (tableau de la page 2).

2.L’alimentation électrique est insuffisante. 2.Appeler la compagnie d’électricité.

3.La tension de la génératrice utilisée est 3.Vérifier la tension de sortie de la génératrice insuffisante. Réduire le nombre d’outils y étant raccordés.

PROBLÈME : L’OUTIL VIBRE EXCESSIVEMENT DURANT LA COUPE

QUE SE PASSE-T-IL? QUOI FAIRE…

1.La scie n’est pas fixée solidement sur le support ou l’établi. 1.Serrer tous les éléments de fixation. Consulter la section Installation permanente à la page 5.

2. La lame est endommagée. 2.Remplacer la lame.

3.L’ouvrage n’est pas fixé solidement. 3.Consulter la section Immobilisation et support de l’ouvrage à la page 4.

PROBLÈME : L’OUTIL NE COUPE PAS AVEC PRÉCISION

QUE SE PASSE-T-IL? QUOI FAIRE…

1.Le guide n’est pas réglé correctement. 1.Le vérifier et le régler correctement. Consulter Fonctionnement de l’étaula page 5.

2.La lame n’est pas perpendiculaire au guide. 2.La vérifier et la régler.

3.L’outil est forcé pendant la coupe. 3.Réduire la force de coupe et laisser la lame travailler librement.

4.L’ouvrage bouge. 4.Fixer solidement l’ouvrage. Consulter la section Immobilisation et support de l’ouvrage à la page 4.

S’assurer que l’ouvrage soit à plat et perpendiculaire à la base.

PROBLÈME : LE LEVIER REFUSE DE BOUGER

QUE SE PASSE-T-IL? QUOI FAIRE…

1.Le protège-lame auto-escamotable refuse de 1.Vérifier l’outil pour s’assurer bouger. qu’aucune pièce ne soit endommagée. S’assurer qu’aucune particule ne soit restée

coincée dans le protège-lame. Remplacer le protège-lame ou le faire réparer, le cas échéant.

2.La chaîne s’est engagée dans la goupille. 2. Appuyer légèrement sur le levier et sortir la chaîne de la goupille. Soulever le levier.

PROBLÈME : L’OUVRAGE BOUGE DURANT LA COUPE

QUE SE PASSE-T-IL? QUOI FAIRE…

1.Le guide glisse ou l’ouvrage n’est pas bien 1. Consulter la section Immobilisation et placé ou fixé. Support de l’ouvrage à la page 4.

2. L’étau n’est pas bien serré. 2. Serrer les ferrures de l’étau.

3. La force de coupe est excessive. 3. Réduire la force de coupe.

Français

383823-01/DW870 5/3/02 1:33 PM Page 19

Page 20

20

SI TIENE ALGUNA PREGUNTA O COMENTARIO ACERCA DE

ESTA O CUALQUIER OTRA HERRAMIENTA DEWALT,

LLÁMENOS GRATIS AL SIGUIENTE NÚMERO: 1-800-433-9258

Instrucciones generales de seguridad

¡ADVERTENCIA! Lea y asegúrese de entender todas las

instrucciones. El no hacerlo puede originar riesgos de choque

eléctrico, incendio y/o lesiones personales de gravedad.

CONSERVE ESTAS

INSTRUCCIONES

· MANTENGA LOS DISPOSITIVOS DE SEGURIDAD EN SU SITIO y

en buen funcionamiento.

· RETIRE LAS LLAVES DE AJUSTE O PRESIÓN. Desarrolle el hábito

de verificar que las llaves, incluyendo las llaves de ajuste, hayan sido

retiradas del eje antes de poner en marcha la herramienta.

· CONSERVE SU ÁREA DE TRABAJO LIMPIA. Las áreas y las bancas

desordenadas propician los accidentes.

· NO UTILICE LAS HERRAMIENTAS EN AMBIENTES PELI-

GROSOS, como tampoco en áreas húmedas o mojadas, ni las

exponga a la lluvia. Mantenga el área de trabajo bien iluminada.

· MANTENGA A LOS NIÑOS ALEJADOS. Todos los visitantes deben

ser mantenidos a una distancia segura del área de trabajo.

· ASEGÚRESE DE MANTENER EL TALLER BAJO LLAVE CON EL

FIN DE EVITAR QUE LOS NIÑOS TENGAN ACCESO,ya sea con el

uso de candados, interruptores maestros o retirando las llaves de

arranque.

· NO FUERCE LA HERRAMIENTA. Esto le permitirá ejecutar mejor el

trabajo, de manera más segura y al ritmo para el cual ésta ha sido

diseñada.

· UTILICE LA HERRAMIENTA ADECUADA. No fuerce la herramienta

ni intente realizar un trabajo para el cual no ha sido diseñada.

· UTILICE EXTENSIONES ADECUADAS. Asegúrese de que su

extensión se encuentre en buenas condiciones. Cuando utilice una

extensión, asegúrese de que su calibre sea adecuado para soportar la

corriente necesaria para su herramienta. Una extensión cuyo calibre

sea inferior al requerido causará una caída en el voltaje de la línea,

Español

¡ADVERTENCIA! PARA SU PROPIA SEGURIDAD LEA ESTE MANUAL

DE INSTRUCCIONES ANTES DE UTILIZAR LA CORTADORA DE

METALES.

INTERRUPTOR

DEL GATILLO

PROTECTOR

SUPERIOR

PROTECTOR

INFERIOR

PALANCA DE

ASEGURAMIENTO

PRENSA

GUÍA

PALANCA

DEL SEGURO

DEL DISCO

DE CORTE

383823-01/DW870 5/3/02 1:33 PM Page 20

STOPPER PIN

Page 21

provocando así una pérdida de potencia y el recalentamiento. El

siguiente cuadro presenta el calibre que debe utilizarse según la

longitud de la extensión y el amperaje mencionado en la placa de

especificaciones. Si tiene dudas, utilice el siguiente calibre. Mientras

más pequeño sea el número del calibre, mayor será su capacidad.

Calibre mínimo requerido (AWG) para cables de extensión

Longitud total del cable de extensión

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Calibre promedio del alambre

18 AWG18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

· VÍSTASE ADECUADAMENTE. No utilice ropa floja, corbatas, anillos,

brazaletes u otro tipo de joyas que puedan ser atrapadas por las

partes móviles. Se recomienda la utilización de zapatos

antideslizantes. Utilice un protector para cubrir su cabello y contenerlo.

Las rejillas de ventilación cubren partes móviles y también deben

evitarse.

· UTILICE SIEMPRE GAFAS DE SEGURIDAD. Utilice igualmente

mascarillas para proteger su cara y protegerse contra el polvo, si el

corte lo produce. Los lentes de las gafas de uso diario tan sólo resisten

al impacto, pero no son gafas de seguridad.

· ASEGURE LA PIEZA DE TRABAJO. Utilice abrazaderas o prensas

para asegurar la pieza de trabajo cuando esto resulte práctico. Esto es

más seguro que utilizar una de sus manos para ello, liberando así las

dos manos para manejar la herramienta.

· NO SE INCLINE DEMASIADO. Conserve siempre los pies bien

apoyados, al igual que su equilibrio.

· DÉ UN MANTENIMIENTO ADECUADO A SUS HERRAMIENTAS.

Mantenga las herramientas afiladas y limpias, con el fin de lograr

mejores resultados y una mayor seguridad de funcionamiento. Siga

las instrucciones con relación a la lubricación y al cambio de

accesorios.

· DESCONECTE LA HERRAMIENTA antes de realizar cualquier

reparación o cambio de accesorios, tales como discos de corte,

brocas, cortadores y similares.

· EVITE EL ENCENDIDO ACCIDENTAL. Asegúrese de que el

interruptor esté apagado antes de conectar la herramienta.

· UTILICE SOLAMENTE ACCESORIOS RECOMENDADOS. Consulte

para ello el manual de instrucciones. La utilización de accesorios

inadecuados puede causar lesiones personales.

· NUNCA SE PONGA DE PIE SOBRE UNA HERRAMIENTA. Golpear

o tocar accidentalmente una herramienta cortante puede causarle

lesiones graves.

· VERIFIQUE LAS PARTES DAÑADAS. Antes de utilizar nuevamente

la herramienta, el protector o cualquier otra parte averiada, éstas

deberán ser verificadas cuidadosamente con el fin de determinar si

funcionan adecuadamente y si ejecutan el trabajo para el cual han sido

diseñadas. Verifique la alineación de las partes móviles, su

articulación, las roturas, la instalación y cualquier otra condición que

pueda afectar su funcionamiento. El protector o cualquier otra parte

averiada deberán ser reparados adecuadamente o reemplazadas.

· DIRECCIÓN DE ALIMENTACIÓN. Introduzca la pieza que desea

cortar únicamente contra la dirección de rotación el disco de corte o de

la sierra.

· NUNCA DEJE UNA HERRAMIENTA FUNCIONANDO SIN SUPERVISIÓN: APÁGUELA. No se retire hasta que la herramienta se haya

detenido completamente.

· ACCESORIOS. Cuando efectúe reparaciones a cualquier

herramienta, utilice tan sólo repuestos idénticos.

· PARA DISMINUIR EL RIESGO DE CHOQUE ELÉCTRICO, este

equipo cuenta con un clavijero polarizado (un borne es más ancho que

el otro). Esta clavija se acoplará tan sólo de una manera a una toma

de corriente polarizada. Si la clavija no se acopla correctamente a la

toma de corriente, comuníquese con un electricista calificado para que

le instale una toma de corriente polarizada apropiada. NO ALTERE LA

CLAVIJA DE NINGINA MANERA.

21

Español

383823-01/DW870 5/3/02 1:33 PM Page 21

Page 22

22

Reglas adicionales de seguridad para

cortadora de metales

· CUANDO UTILICE ESTA HERRAMIENTA, UTILICE SIEMPRE

GAFAS DE SEGURIDAD O CUALQUIER OTRO PROTECTOR

PARA SUS OJOS.

· ANTES DE UTILIZAR LA HERRAMIENTA, VERIFIQUE QUE LOS

DISCOS DE CORTE NOS PRESENTEN FISURAS O DEFECTOS.

Si observa una fisura o defecto evidente, deshágase del disco de

corte. El disco también debe ser revisado cada vez que usted crea que

ha sido golpeado.

· CUANDO ENCIENDA LA HERRAMIENTA CON UN DISCO NUEVO

O REEMPLAZADO, COLOQUELA EN UN AREA BIEN

PROTEGIDA. Si el disco tiene una fisura no detectada o una

imperfección, éste se romperá en menos de un minuto. Nunca

encienda la herramienta cuando una persona se encuentre frente a

ella, incluyendo al usuario.

· DURANTE SU FUNCIONAMIENTO, EVITE EL HACER REBOTAR

EL DISCO O DARLE UN TRATAMIENTO BRUSCO. Si esto ocurre,

apague la herramienta e inspecciónela.

· LIMPIE SU CORTADORA DE METALES PERIODICAMENTE

SIGUIENDO LAS INSTRUCCIONES DADAS EN ESTE MANUAL.

· No retire el protector del disco de corte.

· UTILICE SIEMPRE LA PRENSA O UN ELEMENTO ESPECIAL

PARA SUJETAR LA PIEZA DE TRABAJO DE MANERA SEGURA.

La utilización de otros tipos de prensas adecuadas tales como de

resorte, de barra o prensas en C, podría ser adecuada para sujetar

algunas formas y tamaños de piezas. Seleccione y coloque las

prensas cuidadosamente y planifique su corte antes de realizarlo.

· UTILICE TAN SOLO DISCOS DE 14”, TIPO 1, DE 4.100 R.P.M. O

MAS.

· PERMITA QUE LAS P ARTES COR TADAS SE ENFRIEN ANTES DE

COGERLAS CON SUS MANOS.

· NO INTENTE CORTAR MADERA O PLASTICO CON ESTA

HERRAMIENTA.

· NUNCA CORTE MAGNESIO CON ESTA HERRAMIENTA.

· UTILICE LA CORTADORA DE METALES EN UN AREA BIEN

VENTILADA.

· APAGUE LA CORTADORA DE METALES ANTES DE RETIRAR

CUALQUIER PIEZA DE LA BASE.

· NO CORTE MATERIAL QUE SE ENCUENTRE CONECTADO A UN

CIRCUITO ELÉCTRICO ENCENDIDO.

· NUNCA UTILICE UN DISCO DE CORTE P ARA SIERRA CIRCULAR

CON ESTA CORTADORA PARA METALES. No utilice discos de

corte dentados.

· NO UTILICE HERRAMIENTAS ELÉCTRICAS EN ATMÓSFERAS

EXPLOSIVAS, COMO EN PRESENCIA DE LÍQUIDOS O GASES

INFLAMABLES. Las chispas y las esquirlas calientes provenientes de

los cortes y del arco voltaico de las escobillas del motor, pueden

causar la ignición de los materiales combustibles.

PRECAUCION: utilice la protección auditiva apropiada durante el

uso. Bajo ciertas condiciones de duración de uso, el ruido producido

por este producto puede contribuir a la pérdida auditiva.

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar, moler

o perforar con máquina, así como al realizar otras actividades de la

construcción, contiene substancias químicas que se sabe producen

cáncer, defectos congénitos u otras afecciones reproductivas. Algunos

ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de

albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia

en que se haga este tipo de trabajo. Para reducir la exposición a esas

substancias químicas: trabaje en un área bien ventilada, y trabaje con

equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

Español

383823-01/DW870 5/3/02 1:33 PM Page 22

Page 23

• EVITE EL CONTACTO PROLONGADO CON POLVOS

ORIGINADOS POR LIJAR, ASERRAR, ESMERILAR,

TALADRAR Y OTRAS ACTIVIDADES CONSTRUCTIVAS.

VISTA ROPAS PROTECTORAS Y LAVE LAS AREAS

EXPUESTAS CON AGUA Y JABON. Permitir que el polvo se

introduzca en su boca, ojos, o dejarlo sobre la piel promueve la

absorción de químicos dañinos.

Suministro de energía

Asegúrese de que el suministro de energía concuerde con el

señalado en la placa de especificaciones. 120 voltios, “60 Hz”,

significa corriente alterna (la corriente doméstica normal es de 120

voltios, 60 Hz.). Una disminución de voltaje en un 10% ó más,

causará la pérdida de energía y el recalentamiento de la

herramienta.

Capacidad de corte

La amplia apertura de la prensa y el alto punto de giro permiten una

capacidad de corte para una gran variedad de piezas grandes.

Utilice la tabla de capacidad de corte para determinar el máximo

tamaño de cortes que pueden ser realizados con un disco de corte

nuevo.

[ ADVERTENCIA: CIERTOS OBJETOS GRANDES CIRCULARES

O DE FORMA IRREGULAR PUEDEN REQUERIR DE UNA

SUJECIÓN ADICIONAL EN CASO DE QUE

NO PUEDAN SER SOSTENIDOS

FÍRMEMENTE EN LA PRENSA.

ADVERTENCIA: NO CORTE MAGNESIO

CON ESTA HERRAMIENTA.

Máxima capacidad de

corte

NOTA: EN EL GRÁFICO, LA CAPACIDAD

MOSTRADA ASUME QUE EL DISCO DE CORTE

NO PRESENTA DESGASTE Y QUE LA GUÍA SE

ENCUENTRA EN UNA ÓPTIMA POSICIÓN.

Equipo estándar

1. Disco metálico de corte abrasivo de 14”. Utilice solamente discos

para corte de aglomerante orgánico tipo 1, de alta resistencia, de

4.100 r.p.m. o más, (de óxido de aluminio).

2. Llave para el disco.

Transporte

Pliegue la unidad en una posición

que le permita atar la cadena al

pasador del brazo de la

herramienta (Fig. 1).

Desaseguramiento

Para desasegurar la herramienta y

levantar su cabeza, presione

ligeramente el brazo del motor y

retire la cadena. El brazo del

motor girará entonces hacia arriba

(Ver Fig. 2).

23

Español

GUÍA EN POSICIÓN HACIA ADELANTE

GUÍA EN

POSICICÓN

HACIA ATRÁS

ALTURA

AMPLITUD

6”

5”

4”

3”

2”

1”

0 1” 2” 3” 4” 5” 6” 7”

6,25” 7,75”

4,75”

3,93”

FIG. 1

FIG. 2

INTERRUPT

OR DEL

GATILLO

PALANCA

DEL

SEGURO DE

CORTE

CADENA

383823-01/DW870 5/3/02 1:33 PM Page 23

N

I

P

R

E

P

P

O

T

S

Page 24

24

Sujetamiento y apoyo del material

· Los ángulos se sujetan y cortan mejor cuando los dos lados

descansan sobre la base.

· Si es necesario, puede utilizar un bloque suplementario

ligeramente más angosto que la pieza de trabajo con el fin de

aumentar la utilización del disco de corte.

· Los materiales largos deben estar apoyados por medio de un

bloque, de manera que queden nivelados con relación a la

superficie de la base. El pedazo cortado no debe estar sujeto

para permitir que caiga sin enredarse con el disco de corte.

Funcionamiento de la prensa

La prensa cuenta con una característica que permite accionarla con

un rápido movimiento. Para soltar la prensa cuando la pieza se

encuentra firmemente sujeta, voltee la manivela en el sentido

contrario al de las manecillas del reloj una o dos veces para reducir

la presión de la prensa. Levante luego la palanca de la prensa hacia

arriba y tire la manivela hacia afuera tanto como lo desee.

Inicialmente la prensa debe apretar la pieza sin utilizar la manivela.

Luego, baje la palanca de la prensa y apriete la pieza con la prensa

utilizando para ello la manivela.

Ajuste del freno de la prensa

CORTE A ÁNGULO

Utilice la llave para aflojar los dos tornillos hexagonales (Fig. 3). (No

retire los tornillos). La guía debe girar en cualquier dirección.

Asegure firmemente los dos tornillos antes de utilizar la herramienta.

Interruptor

Para prender la herramienta, apriete el interruptor del gatillo tal como

se muestra en la Figura 2. Para apagar la herramienta, suelte el

interruptor del gatillo. Mantenga sus manos y la pieza alejadas del

disco de corte hasta tanto éste se haya detenido completamente.

Español

FIG. 3

FIG. 4

FIG. 5

LLAVE

TORNILLOS

DE LA GUÍA

PRENSA

GUÍA

EJE DE ENGRANAJE

ANILLO

INTERIOR

DISCO ABRASIVO

ADAPTADOR

ANILLO EXTERIOR

ARANDELA

TORNILLO DE

CABEZA HEXAGONAL

FIG. 6

383823-01/DW870 5/3/02 1:33 PM Page 24

15

30

15

0

3

0

15

4

0

5

3

Page 25

Remoción e instalación del disco de

corte

1. Asegúrese de que la herramienta no esté conectada al

suministro de energía.

2. Empuje la palanca del seguro del disco de corte (Figura 6) y gire

el disco manualmente hasta que la palanca encaje en la ranura

de la anillo interior para asegurar el disco. Afloje el tornillo en el

sentido opuesto al de las manecillas del reloj en el centro del

disco abrasivo, utilizando para ello una llave hexagonal de 8

mm que se encuentra en la base. El tornillo es de rosca derecha.

3. Retire el tornillo, la arandela, el anillo exterior, el adaptador y el

disco desgastado (Fig. 10).

4. Instale el nuevo disco abrasivo y siga los pasos dados

anteriormente pero esta vez en sentido contrario. Asegúrese de

que el adaptador se encuentre en el eje y centrado en la rueda.

5. No apriete demasiado el tornillo.

NO REALICE NINGÚN AUSTE MIENTRAS QUE EL DISCO SE

ENCUENTRE EN MOVIMIENTO.

NO REALICE NINGÚN AUSTE MIENTRAS QUE LA CORTADORA

DE METALES SE ENCUENTRE CONECTADA A UNA TOMA DE

CORRIENTE.

ADEVERTENCIA: CUANDO REEMPLACE UN DISCO

ABRASIVO, VERIFIQUE LA SUPERFICIE DE TRABAJO SOBRE

LA CUAL SE ENCUENTRA INSTALADA LA CORTADORA DE

25

Español

METALES. ES POSIBLE QUE EL DISCO PUEDA TOCAR

CUALQUIER ELEMENTO O ESTRUCTURA QUE SE EXTIENDA

SOBRE LA SUPERFICIE DE TRABAJO (BAJO LA BASE),

CUANDO EL BRAZO SE ENCUENTRA EN SU POSICIÓN MÁS

BAJA.

Procedimiento para el montaje

permanente

1. Realice cuatro orificios de un diámetro mínimo de 5/16” en la

superficie de trabajo (Fig. 7).

2. Retire los tornillos de las patas

3. Introduzca 20 tornillos de _” por la parte inferior de la superficie

de trabajo, a través de las patas, dentro del orificio de la base de

la herramienta. La longitud adecuada del tornillo es igual al

espesor de la superficie de trabajo más 1 pulgada (25 mm).

FIG. 7

16-3/8”

416 MM

8-1/2”

216 MM

FIG. 8

PUNTILLA

LÍNEA DE DESGASTE

ESCOBILLA

FIG. 9

0.3”

7.62 MM

383823-01/DW870 5/3/02 1:33 PM Page 25

N

I

P

R

E

P

P

O

T

S

Page 26

26

MONTAJE DE LA PLATAFORMA

1. Corte dos tablas de madera de aproximadamente 20” de largo x 2”

de espesor y 4 de ancho”.

2. Coloque la cortadora de metales en la posición de trabajo

deseada.

3. Coloque las tablas firmemente sobre sus lados y clávelas a la

superficie de trabajo, (Figura 8).

Inspección y reemplazo de las escobillas

del motor

Antes de inspeccionar las escobillas, asegúrese de que la herramienta se

encuentre desconectada. Verifique las escobillas de carbón con frecuencia.

Para ello, desconecte la herramienta, retire la tapa de inspección de las

escobillas y retire el conjunto de escobillas. Para retirar cada una de las

escobillas, primero retire la conexión del terminal del cable de derivación,

luego, retire con cuidado el resorte de la escobilla de la caja de la misma y

retire la escobilla. Las escobillas deben deslizarse libremente dentro de la

caja de escobillas. Si las escobillas están desgastadas hasta la línea de

desgaste de 0.3” (7.62 mm), éstas deben ser remplazadas (ver Figura 9).

Para reinstalar cada escobilla, retire cuidadosamente cada resorte de la caja

de escobillas, inserte la escobilla e inserte de nuevo el resorte asegurándose

de que éste ejerza una presión suficiente sobre la escobilla sin tocar la caja

de la misma. Coloque de nuevo la tapa y los dos tornillos.

Recomendaciones para realizar cortes

más precisos

· Permita que el disco realice el corte. Una fuerza excesiva hará

que el disco se vitrifique, reduciendo así su eficiencia de corte y/o

se desvíe, produciendo cortes inexactos.

· Ajuste el ángulo de la guía (Figura 3).

· Asegúrese de que el material se encuentre bien sentado sobre la

base

· Asegure adecuadamente el material con el fin de evitar su

movimiento y vibración.

Español

Limpieza

Se recomienda limpiar el polvo y los residuos del cuerpo principal de

la herramienta por medio de un chorro de aire, a medida en que la

suciedad se acumule alrededor de las rejillas de ventilación.

Accesorios

Usted puede adquirir los accesorios recomendados para su

herramienta en su centro local de servicio, por medio de un pago

adicional. En caso de requerir asistencia para localizar cualquier

accesorio para su herramienta, tome contacto con nosotros en:

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286.

PRECAUSIÓN: La utilización de cualquier accesorio no

recomendado para esta herramienta puede ser peligrosa.

Importante

Para garantizar la SEGURIDAD y la FIABILIDAD del producto, las

reparaciones, el mantenimiento y los ajustes (incluyendo la revisión

y el cambio de escobillas), deberán ser realizados en los centros

autorizados de servicio u otras organizaciones de servicio

calificadas que utilicen siempre accesorios originales. UTILICE

SIEMPRE GAFAS PROTECTORAS. ASEGURE SIEMPRE LA

PIEZA DE TRABAJO CON LA PRENSA. ANTES DE CAMBIAR EL

DISCO DE CORTE, DESCONECTE LA HERRAMIENTA DE LA

TOMA DE CORRIENTE.

Lubricación

Esta herramienta está diseñada con cojinetes herméticos de

lubricación sellada. Estos cojinetes cuentan con una lubricación de

fábrica suficiente para toda la vida útil de la cortadora de metales.

Los engranajes deben ser lubricados cada 60 ó 90 días, según la

intensidad de su utilización. Esta lubricación debe ser llevada a cabo

tan sólo por personal experimentado en herramientas eléctricas

tales como los mecánicos de los centros de servicio D

EWALT. La

caja de engranajes debe ser empacada limpia y con 12 oz. (16

383823-01/DW870 5/3/02 1:33 PM Page 26

Page 27

27

Español

gramos) de lubricante DEWALT N° 790206 (tubo de 6 oz.) colocado

al interior de la caja de engranajes.

Garantía completa

Las herramientas industriales DEWALT cuentan con una garantía de

un año a partir de la fecha de compra. Cualquier falla debida al

material o a una mano de obra defectuosa, será reparada sin costo.

Para obtener información acerca de las reparaciones, llame al 1800-443-9258. Esta garantía no se aplica a los accesorios o a los

daños causados por reparaciones efectuadas por terceras personas.

Esta garantía le otorga a usted derechos legales específicos, y otros

derechos que pueden variar según el Estado o la Provincia.

Además de la garantía, las herramientas D

EWALT están amparadas

por nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el

desempeño de su herramienta industrial D

EWALT, sencillamente

devuélvala a uno de los vendedores autorizados, a más tardar 30

días después de la fecha de compra, y su dinero le será

reembolsado completamente. Por favor devuelva la unidad completa

y agregue el valor del transporte para su envío. La prueba de compra

podrá ser requerida.

REEMPLAZO DE LAS ETIQUETAS DE ADVERTENCIA

GRATUITO: Si sus etiquetas de advertencia se tornan ilegibles o se

pierden, llame al 1-800-4-D

EWALT para que se las reemplacen sin

cost.

383823-01/DW870 5/3/02 1:33 PM Page 27

Page 28

28

Español

Guía para la detección de problemas

¡PROBLEMA¡ LA SIERRA NO ENCIENDE

¿QUÉ SUCEDE? ¿QUÉ HACER?

1. La sierra no está conectada 1. Conecte la sierra

2. Un fusible se quema, o un cortacircuitos salta 2. Reemplace el fusible o conecte de nuevo el cortacircuitos

3. Cable dañado 3. Haga reemplazar el cable en un centro de servicio autorizado

4. Las escobillas están desgastadas 4. Haga reemplazar las escobillas en un centro de servicio autorizado

¡PROBLEMA¡ LA SIERRA REALIZA CORTES DEFICIENTES

¿QUÉ SUCEDE? ¿QUÉ HACER?

1. Disco de corte desgastado 1. Reemplace el disco de corte

2. Incorrecta posición o sujeción de la pieza de trabajo 2. Sujete y apoye firmemente la pieza de trabajo

¡PROBLEMA¡ EL DISCO DE CORTE NO ALCANZA LA VELOCIDAD REQUERIDA

¿QUÉ SUCEDE? ¿QUÉ HACER?

1. La extensión es muy delgada o demasiado larga 1. Reemplace la extensión por una de un tamaño adecuado. Consulte el cuadro en la página 2

2. Baja de tensión 2. Contacte su compañía de electricidad

3. Bajo voltaje del generador 3. Verifique el voltaje de salida del generador. Reduzca el número de herramientas alimentadas por el generador.

¡PROBLEMA¡ LA MÁQUINA VIBRA EXCESIVSAMENTE CUANDO CORTA

¿QUÉ SUCEDE? ¿QUÉ HACER?

1. La sierra no está firmemente sujeta a la superficie o al banco de trabajo 1. Apriete todos los accesorios de montaje. Consulte la página 5, Procedimiento para el montaje permanente

2. Disco de corte averiado 2. Reemplace el disco de corte

3. La pieza de trabajo no se encuentras firmemente sujeta 3. Consulte las instrucciones sobre el Sujetamiento y apoyo del material, en página 4.

¡PROBLEMA¡ LA SIERRA NO HACE CORTE PRECISOS

¿QUÉ SUCEDE? ¿QUÉ HACER?

1. La guía no está ajustada correctamente 1. Verifíquela y ajústela. Consulte el Funcionamiento de la guía en la página 5

2. El disco de corte no se encuentra a escuadra con la guía 2. Verifíquelo y ajústelo

3. Fuerza excesiva para hacer el corte 3. Reduzca la fuerza de corte. Deje que el disco de corte haga el trabajo

4. La pieza de trabajo se mueve 4. Sujete firmemente la pieza de trabajo. Consulte la sección Sujetamiento y apoyo del material, en página 4. Asegúrese de que el

material esté bien sentado sobre la base.

¡PROBLEMA¡ NO PUEDE MOVER EL BRAZO

¿QUÉ SUCEDE? ¿QUÉ HACER?

1. El protector de autorepliegue del disco no se mueve 1. Verifique las partes averiadas. V erifique que no haya demasiadas esquirlas en el protector . Reemplace o repare las partes necesarias

2. La cadena está trabada 2. Empuje ligeramente el brazo, retire la cadena del pasador. Levante el brazo

¡PROBLEMA¡ EL MATERIAL SE MUEVE DURANTE EL CORTE

¿QUÉ SUCEDE? ¿QUÉ HACER?

1. La pieza de trabajo se encuentra mal localizada o sujetada1. Ver, Sujetamiento y apoyo del material, página 4.

2. Tornillo muy flojo 2. Apriete el tornillo de la prensa

3. Excesiva fuerza de corte 3. Reduzca la fuerza de corte

383823-01/DW870 5/3/02 1:33 PM Page 28

Loading...

Loading...