Page 1

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW073 Cordless Rotary Laser

Laser rotatif sans fil DW073

DW073 Láser rotatorio inalámbrico

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

Page 2

Page 3

1

English

• Use battery operated tool only with the specifically designated

battery pack. Use of any other batteries may create a risk of fire.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothing, jewelry, or long hair can be caught

in moving parts. Air vents often cover moving parts and should also

be avoided.

• Avoid accidental starting. Be sure switch is in the locked or off

position before inserting battery pack. Carrying tools with your

finger on the switch or inserting the battery pack into a tool with the

switch on invites accidents.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to a loss of control.

• Do not use tool if switch does not turn it on or off. A tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments, changing accessories, or storing the tool. Such preventative safety

measures reduce the risk of starting the tool accidentally.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

Introduction

The DW073 Cordless Rotary Laser is a manually leveled laser tool

that can be used both inside and outside for horizontal (level) and vertical (plumb) alignment projects. This tool comes fully assembled.

Applications range from acoustical ceiling installation and wall layout

to foundation leveling and deck building. This tool has been designed

with many innovative features that allow for quick and easy set-up and

adjustment which will increase your productivity on the job. Please

read and understand all instructions within this manual prior to use.

General Safety Rules For Battery

Operated Tools

WARNING! Read and understand all instructions.

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• A battery operated tool with integral batteries or a separate

battery pack must be recharged only with the specified charger for the battery. A charger that may be suitable for one type of

battery may create a risk of fire when used with another battery.

Page 4

2

English

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• When battery pack is not in use, keep it away from other metal

objects like: paper clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another. Shorting the battery terminals together may

cause sparks, burns, or a fire.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one

tool, may create a risk of injury when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified person-

nel may result in a risk of injury.

Additional Safety Rules

WARNING! DO NOT DISASSEMBLE LASER LEVEL. There are

no user serviceable parts inside. Disassembling the laser level will void

all warranties on the product. Do not modify the product in any way.

These devices comply with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio and television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different

from that which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

These Class B digital devices comply with Canadian ICES-003.

CAUTION: Some tools with large battery packs will stand upright

on the battery pack but may be easily knocked over. When not in use,

place tool on its side on a stable surface where it will not cause a tripping or falling hazard.

• The label on your tool may include the following symbols.

V ................volts A ................amperes

Hz ..............hertz W ..............watts

min..............minutes ..............alternating current

............direct current

n

o ..............no load speed

................

Class II

................

earthing

....................Construction ....................

terminal

................safety alert .../min..........revolutions or

....................symbol ....................reciprocations

.................... ....................per minute

Important Safety Instructions for

Battery Packs

Your tool uses a 9.6, 12.0, 14.4 or an 18 Volt DEWALT battery pack.

When ordering replacement battery packs, be sure to include catalog

number and voltage. Extended Run-Time battery packs deliver more

Page 5

3

English

run-time than standard battery packs. Consult the chart at the end of

this manual for compatibility of chargers and battery packs.

NOTE: Your tool will accept either standard or Extended Run Time

battery packs. However, be sure to select proper voltage. Batteries

slowly lose their charge when they are not on the charger, the best

place to keep your battery is on the charger at all times.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below. Then

follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely damaged or is completely worn out. The battery pack can explode in

a fire.

• A small leakage of liquid from the battery pack cells may

occur under extreme usage or temperature conditions. This

does not indicate a failure. However, if the outer seal is broken and

this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water

for a minimum of 10 minutes and seek immediate medical attention. (Medical note: The liquid is 25-35% solution of potassium

hydroxide.)

• Charge the battery packs only in D

EWALT chargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations

where the temperature may reach or exceed 105°F (40˚) (such

as outside sheds or metal buildings in summer).

DANGER: Electrocution hazard. Never attempt to open the battery

pack for any reason. If battery pack case is cracked or damaged, do

not insert into charger. Electric shock or electrocution may result.

Damaged battery packs should be returned to service center for recycling.

NOTE: Battery storage and carrying caps are provided

for use whenever the battery is out of the tool or charger.

Remove cap before placing battery in charger or tool.

WARNING: Do not store or carry battery so that

metal objects can contact exposed battery terminals.

For example, do not place battery in aprons, pockets, tool boxes,

product kit boxes, drawers, etc., with loose nails, screws, keys, etc.

without battery cap. Transporting batteries can possibly cause

fires if the battery terminals inadvertently come in contact with

conductive materials such as keys, coins, hand tools and the

like. The US Department of Transportation Hazardous Material

Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes (i.e., packed in suitcases and carry-on luggage)

UNLESS they are properly protected from short circuits. So when

transporting individual batteries, make sure that the battery terminals

are protected and well insulated from materials that could contact

them and cause a short circuit.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corp

oration) Seal on the nickel-cadmium battery (or battery

pack) indicates that the costs to recycle the battery (or battery pack) at the end of its useful life have already been

paid by D

EWALT. In some areas, it is illegal to place spent nickel-

cadmium batteries in the trash or municipal solid waste stream and the

RBRC program provides an environmentally conscious alternative.

RBRC in cooperation with D

EWALT and other battery users, has

established programs in the United States to facilitate the collection of

spent nickel-cadmium batteries. Help protect our environment and

conserve natural resources by returning the spent nickel-cadmium

battery to an authorized D

EWALT service center or to your local retail-

er for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery.

RBRC™ is a registered trademark of the

Rechargeable Battery

Recycling Corporation.

Page 6

4

English

Important Safety Instructions for Battery

Chargers

SAVE THESE INSTRUCTIONS: This manual contains important

safety instructions for battery chargers.

• Before using charger, read all instructions and cautionary markings

on charger, battery pack, and product using battery pack.

DANGER: Electrocution hazard. 120 volts are present at charging

terminals. Do not probe with conductive objects. Electric shock or

electrocution may result.

WARNING: Shock hazard. Do not allow any liquid to get inside

charger. Electric shock may result.

CAUTION: Burn hazard. To reduce the risk of injury, charge only

D

EWALT nickel cadmium rechargeable batteries. Other types of bat-

teries may burst causing personal injury and damage.

CAUTION: Under certain conditions, with the charger plugged in to

the power supply, the exposed charging contacts inside the charger

can be shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, steel wool, aluminum foil, or any

buildup of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is

no battery pack in the cavity. Unplug charger before attempting to

clean.

• DO NOT attempt to charge the battery pack with any chargers

other than the ones in this manual. The charger and battery

pack are specifically designed to work together.

• These chargers are not intended for any uses other than

charging D

EWALT rechargeable batteries. Any other uses may

result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger.

This will reduce risk of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped on,

tripped over, or otherwise subjected to damage or stress.

• Do not use an extension cord unless it is absolutely necessary. Use of improper extension cord could result in risk of fire,

electric shock, or electrocution.

• An extension cord must have adequate wire size (AWG or

American Wire Gauge) for safety. The smaller the gauge number

of the wire, the greater the capacity of the cable, that is 16 gauge

has more capacity than 18 gauge. When using more than one

extension to make up the total length, be sure each individual

extension contains at least the minimum wire size.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

• Do not place any object on top of charger or place the charg-

er on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a position

away from any heat source. The charger is ventilated through slots

in the top and the bottom of the housing.

• Do not operate charger with damaged cord or plug — have

them replaced immediately.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassembly

may result in a risk of electric shock, electrocution or fire.

• Disconnect the charger from the outlet before attempting any

cleaning. This will reduce the risk of electric shock. Removing

the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household

electrical power (120 Volts). Do not attempt to use it on any

other voltage. This does not apply to the vehicular charger.

Page 7

5

English

Using Automatic Tune-Up™ Mode

The Automatic Tune-Up™ Mode equalizes or balances the individual

cells in the battery pack allowing it to function at peak capacity. Battery

packs should be tuned up weekly or after 10 charge/discharge cycles

or whenever the pack no longer delivers the same amount of work. To

use the Automatic Tune-Up™, place the battery pack in the charger

and leave it for at least 8 hours. The charger will cycle through the following modes.

1. The red light will blink continuously indicating that the 1-hour

charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on

continuously and will no longer blink. This indicates that the pack

is fully charged and can be used at this time.

3. Whenever the pack is left in the charger after the initial 1-hour

charge, the charger will begin the Automatic Tune-Up™ Mode.

This mode continues up to 8 hours or until the individual cells in the

battery pack are equalized. The battery pack is ready for use and

can be removed at any time during the Tune-Up™ Mode.

4. Once the Automatic Tune-Up™ Mode is complete the charger will

transition to a maintenance charge; the indicator light shuts off

when the Automatic Tune-Up™ Mode is complete.

Chargers

Your tool uses a 7.2, 9.6, 12.0, 14.4, or 18.0 Volt DEWALT charger.

Your battery can be charged in D

EWALT 1 Hour Chargers, 15 Minute

Chargers or Vehicular 12 Volt Charger. Be sure to read all safety

instructions before using your charger. Consult the chart at the end of

this manual for compatibility of chargers and battery packs.

Charging Procedure

DANGER: Electrocution hazard. 120 volts present at charging ter-

minals. Do not probe with conductive objects. Danger of electric shock

or electrocution.

1. Plug the charger into an appropriate outlet before inserting battery

pack.

2. Insert the battery pack into the charger making sure the pack is

fully seated. The red (charging) light will blink continuously indicating that the charging process has started.

3. The completion of charge will be indicated by the red light remaining ON continuously. The pack is fully charged and may be used

at this time or left in the charger.

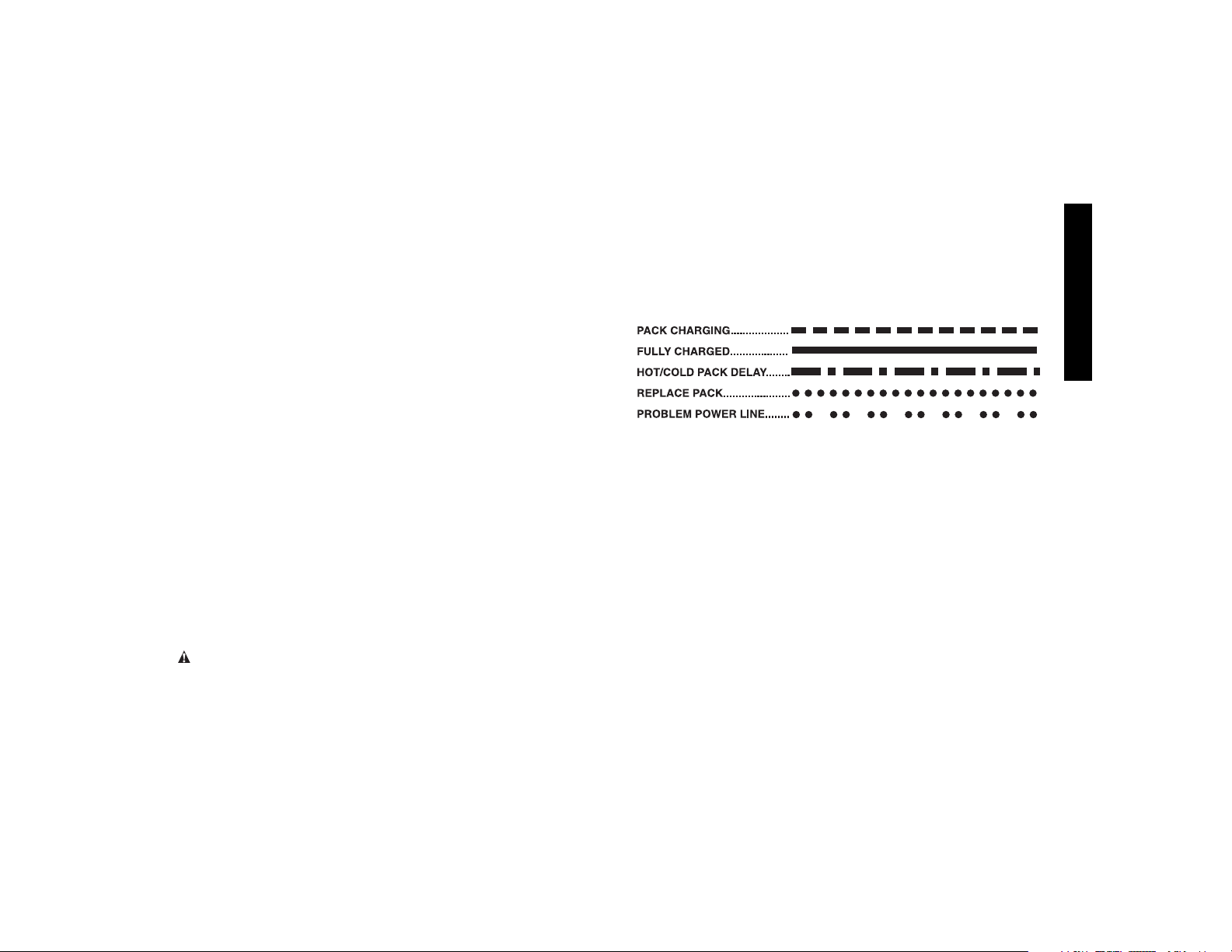

Indicator Light Operation

Charge Indicators

Some chargers are designed to detect certain problems that can arise

with battery packs. Problems are indicated by the red light flashing at a

fast rate. If this occurs, re-insert battery pack into the charger. If the

problem persists, try a different battery pack to determine if the charger is OK. If the new pack charges correctly, then the original pack is

defective and should be returned to a service center or other collection

site for recycling. If the new battery pack elicits the same trouble indication as the original, have the charger tested at an authorized service

center.

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when the charger detects a battery that is hot, it automatically starts a Hot Pack Delay,

suspending charging until the battery has cooled. After the battery has

cooled, the charger automatically switches to the Pack Charging

mode. This feature ensures maximum battery life. The red light flashes long, then short while in the Hot Pack Delay mode.

Page 8

6

English

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the charger is used with some portable power sources such as generators or

sources that convert DC to AC, the charger may temporarily suspend

operation, flashing the red light with two fast blinks followed by a

pause. This indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light

glowing indefinitely. The charger will keep the battery pack fresh and

fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of the

charger. If the battery pack has not been kept on maintenance charge,

it may need to be recharged before use. A battery pack may also slowly lose its charge if left in a charger that is not plugged into an appropriate AC source.

WEAK BATTERY PACKS: Chargers can also detect a weak battery.

Such batteries are still usable but should not be expected to perform

as much work. In such cases, about 10 seconds after battery insertion, the charger will beep rapidly 8 times to indicate a weak battery

condition. The charger will then go on to charge the battery to the highest capacity possible.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65°F and

75°F (18°- 24°C). DO NOT charge the battery pack in an air temperature below +40°F (+4.5°C), or above +105°F (+40.5°C). This

is important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a problem. To facilitate the cooling of the battery pack after use, avoid

placing the charger or battery pack in a warm environment such

as in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or other

appliance

b. Check to see if receptacle is connected to a light switch which

turns power off when you turn out the lights.

c. Move charger and battery pack to a location where the sur-

rounding air temperature is approximately 65°F - 75°F (18°24°C).

d. If charging problems persist, take the tool, battery pack and

charger to your local service center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT

CONTINUE to use under these conditions. Follow the charging

procedure. You may also charge a partially used pack whenever

you desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can be

shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, steel wool, aluminum foil, or any

buildup of metallic particles should be kept away from charger

cavities. Always unplug the charger from the power supply when

there is no battery pack in the cavity. Unplug charger before

attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING: Shock hazard. Don’t allow any liquid to get inside

charger. Electric shock may result.

CAUTION: Never attempt to open the battery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, return to a

service center for recycling.

CHARGER CLEANING INSTRUCTIONS

WARNING: Shock hazard. Disconnect the charger from the AC

outlet before cleaning. Dirt and grease may be removed from the exterior of the charger using a cloth or soft non-metallic brush. Do not use

water or any cleaning solutions.

Page 9

7

English

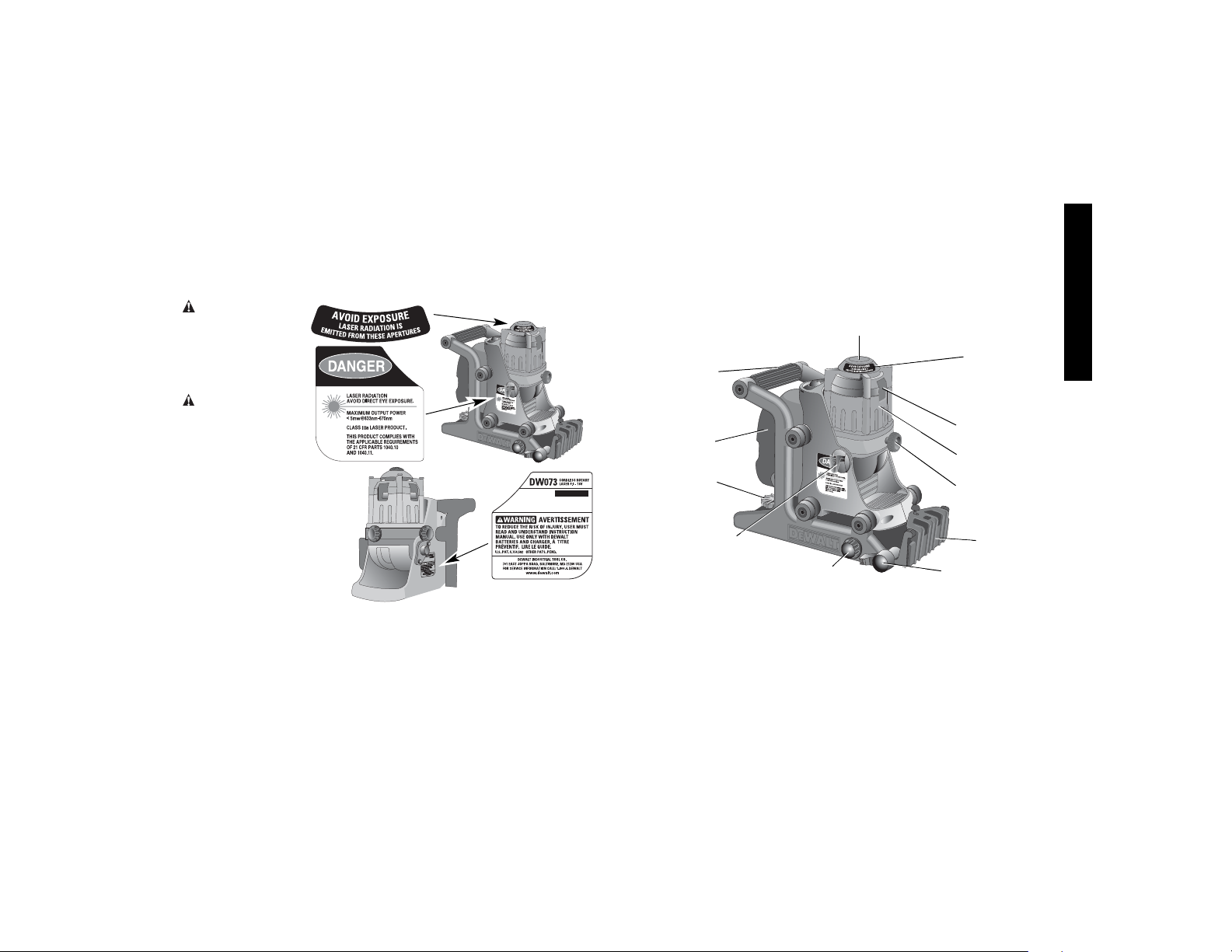

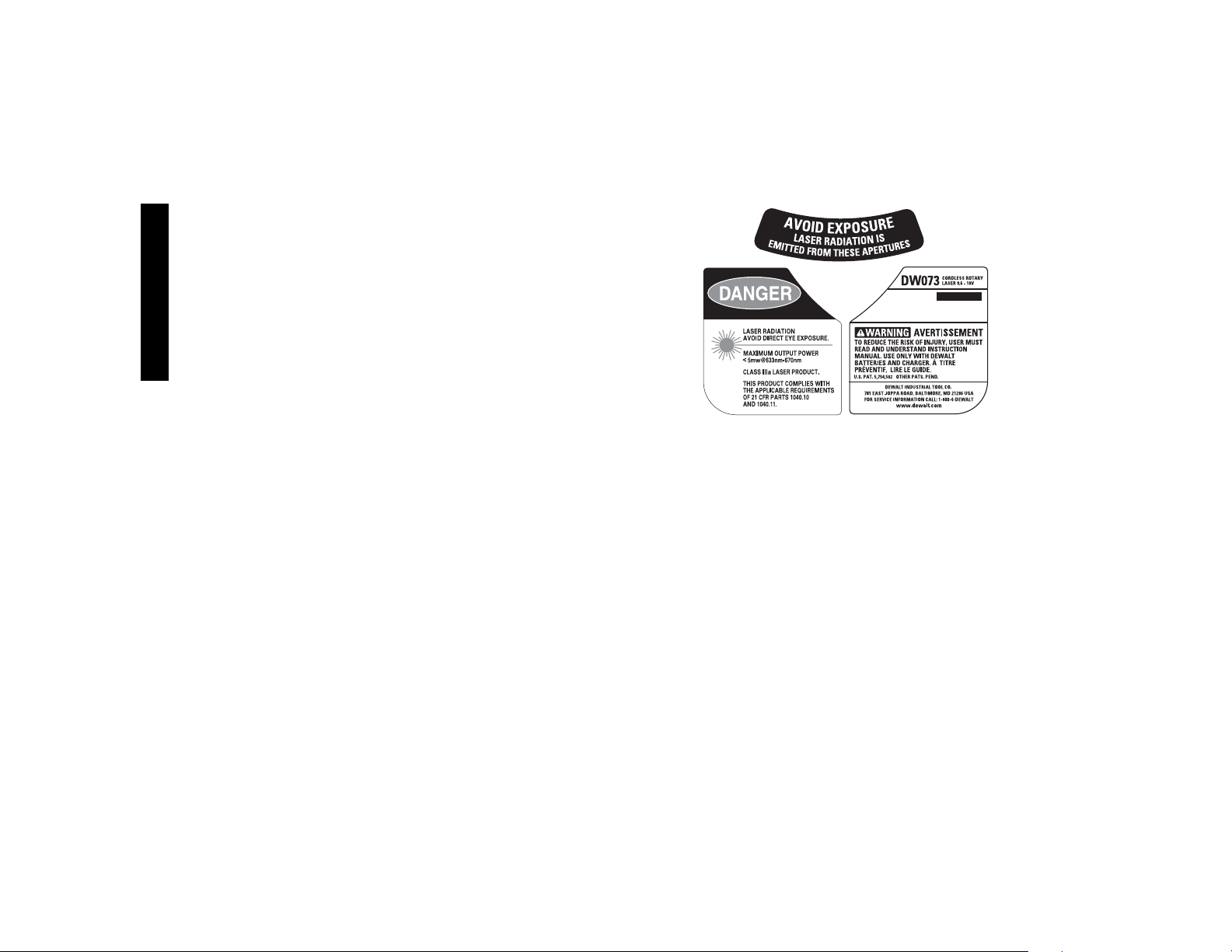

Laser Safety

The DW073 Cordless Rotary Laser is listed as a CLASS IIIa LASER

PRODUCT and complies with the applicable requirements of title 21

of the Code of Federal Regulations set forth by: the Department of

Health, Education, and Welfare; the Food and Drug Administration;

the Center for Devices and Radiological Health.

DANGER: THIS

PRODUCT EMITS

LASER RADIATION - DO NOT

STARE INTO THE

LASER BEAM.

CAUTION: The

use of optical

instruments with this

product will increase

eye hazard.

• Set the laser at a

position above or

below eye level.

• DO NOT disas-

semble the laser

tool. There are

no user serviceable parts inside.

• When using the

laser overhead, always use a ceiling wire hanger or equivalent

material in addition to the wall mount clamp to help secure the

laser level while mounting it to a wall. See “Wall Mount” section for

instructions.

• The use of controls or adjustments or procedures other than those

specified herein may result in Hazardous Radiation Exposure.

• DO NOT modify the laser in any way. Modifying the tool may result

in Hazardous Laser Radiation Exposure.

• Repairs and servicing must be performed by a qualified repair

facility.

•

DO NOT allow children to operate the laser tool.

• DO NOT operate the laser around children.

• DO NOT Remove warning labels from the tool.

• Your operating conditions may require that you post a Laser

“DANGER” sign. One has been provided with this product.

Operating Tips

• Ensure battery is properly charged. If the “Power” LED light is flashing, the battery needs to be charged.

• To extend battery life per charge, turn laser off when not working

with or marking the beam.

• To ensure the accuracy of your work, check to make sure your laser

is calibrated often. See “Field Calibration” section.

• Before attempting to level the laser, make sure the tool is positioned

on a relatively smooth surface.

BATTERY

PACK

DUAL

LASER

ROTARY

HEAD

LEVELING

VIAL

BASE

LEVELING

KNOB

LEVELING

KNOB

PIVOTING

HEAD

CARRYING

HANDLE

TWO-POSITION

PIVOTING HEAD

ADJUSTMENT

LEVER

WALL MOUNT

CLAMP

MANUAL HEAD ROTATION BUTTON

WALL MOUNT

CLAMP LOCK

RACK ‘N PINION

ADJUSTMENT KNOB

Page 10

8

English

• The more accurately centered the bubbles are in the vials, the

more accurate the laser beam will be for working.

• Your D

EWALT laser is equipped with 2, side by side laser diodes

which produce an extremely bright, visible beam when the laser

head is rotated.

• Always mark the center of the laser line or dot.

• To increase working distance and accuracy, set up the laser in the

middle of your working area.

• When attaching to a tripod or wall, mount the laser securely.

• When working indoor a slow rotary head speed will produce a visibly brighter line, a faster rotary head speed will produce a visibly

solid line.

• To increase beam visibility, wear the Laser Enhancement Glasses

provided and/or use the Laser Target Card to help find the beam.

• To transfer a laser dot mark use the Manual Rotation Button on the

top of the laser head for quick and easy control. See “Manual Head

Rotation Button” section for instructions.

• Extreme temperature changes can cause movement of internal

parts that can effect accuracy. Check your accuracy often while

working.

• When working with the D

EWALT Digital Laser Detector set the

laser variable speed control to the highest setting (600 RPM).

• Utilize the Bump Sensor feature on the laser to warn you if the tool

has been bumped after set up.

• If the laser has been dropped or has tipped over while set up on a tripod, have the calibration system checked by a qualified service center before continuing use.

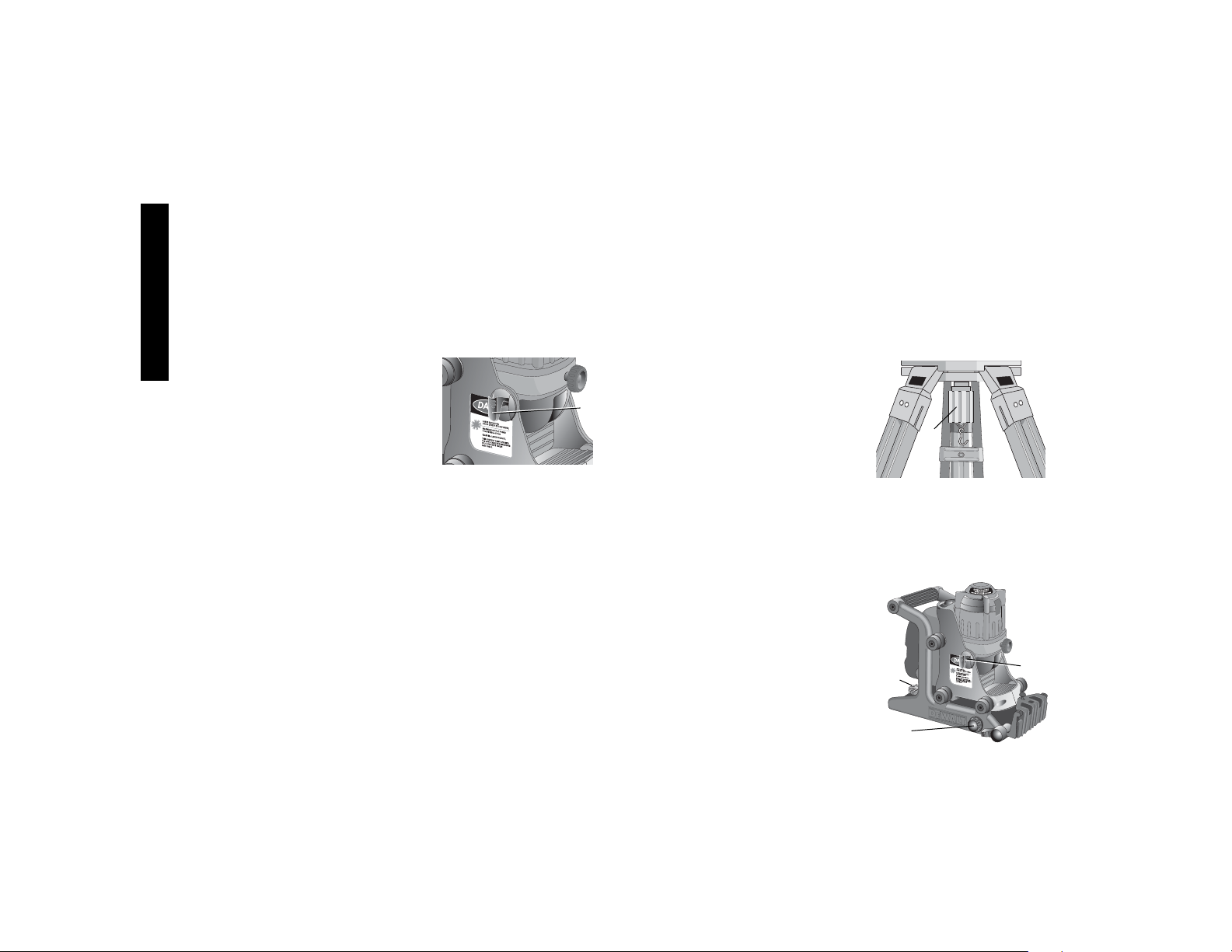

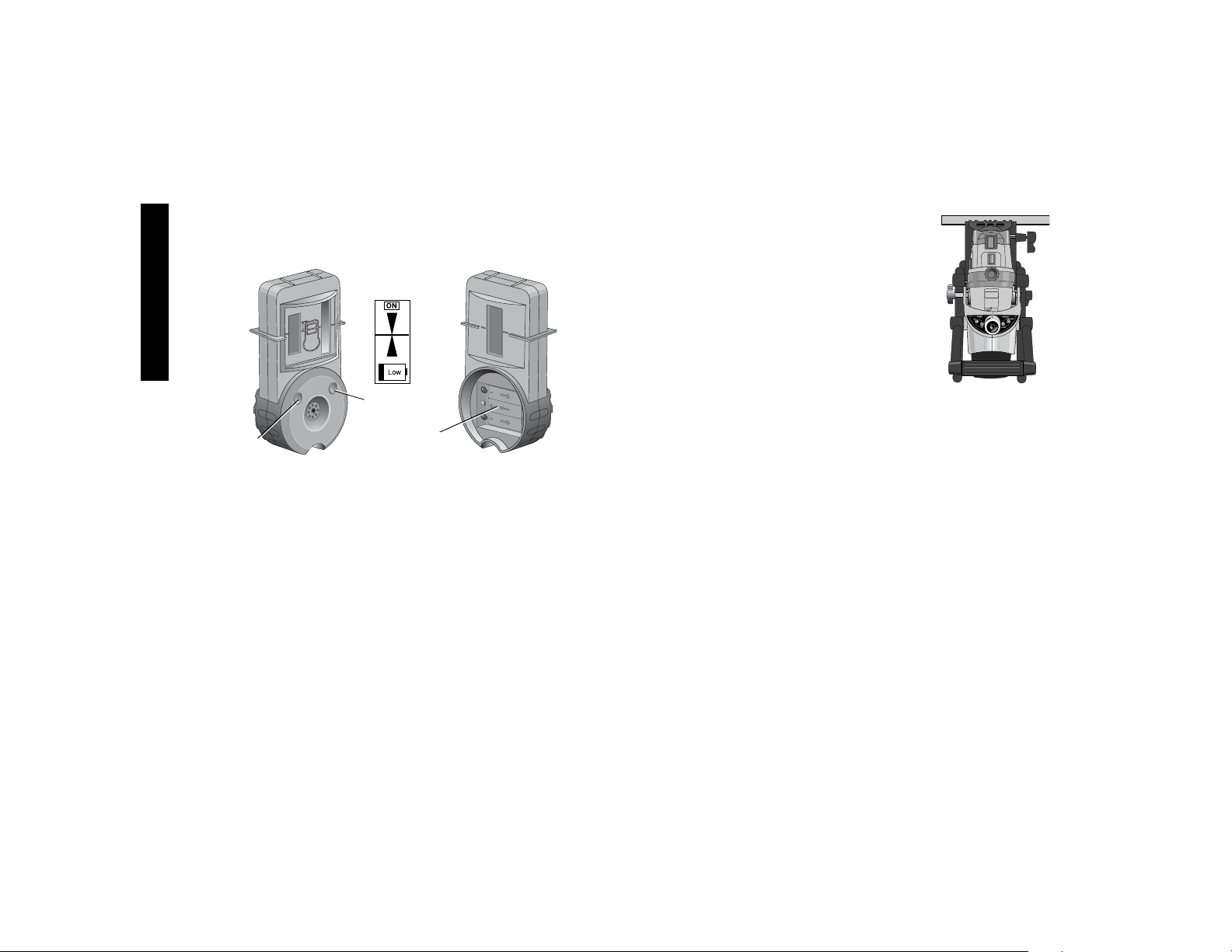

Installing and Removing the Battery Pack

NOTE: Make sure your battery pack is fully charged.

To install the battery pack

into the rotary laser, rotate the battery

adapter plate (A) with applicable cut out for 9.6, 12, 14.4 volt pack (B)

or the other for the 18 volt pack (C) aligned with the battery contacts

facing inside the cut out and slide the battery pack in firmly until you

hear the battery pack lock in place.

To remove the battery pack

from the tool, push the battery in

slightly, then press the release buttons, and firmly pull the battery pack

out of the receptacle. The battery

ejector pin (D) will aid in removing

the pack. To recharge the battery

pack, insert it into the charger as

described in the charger section of

this manual.

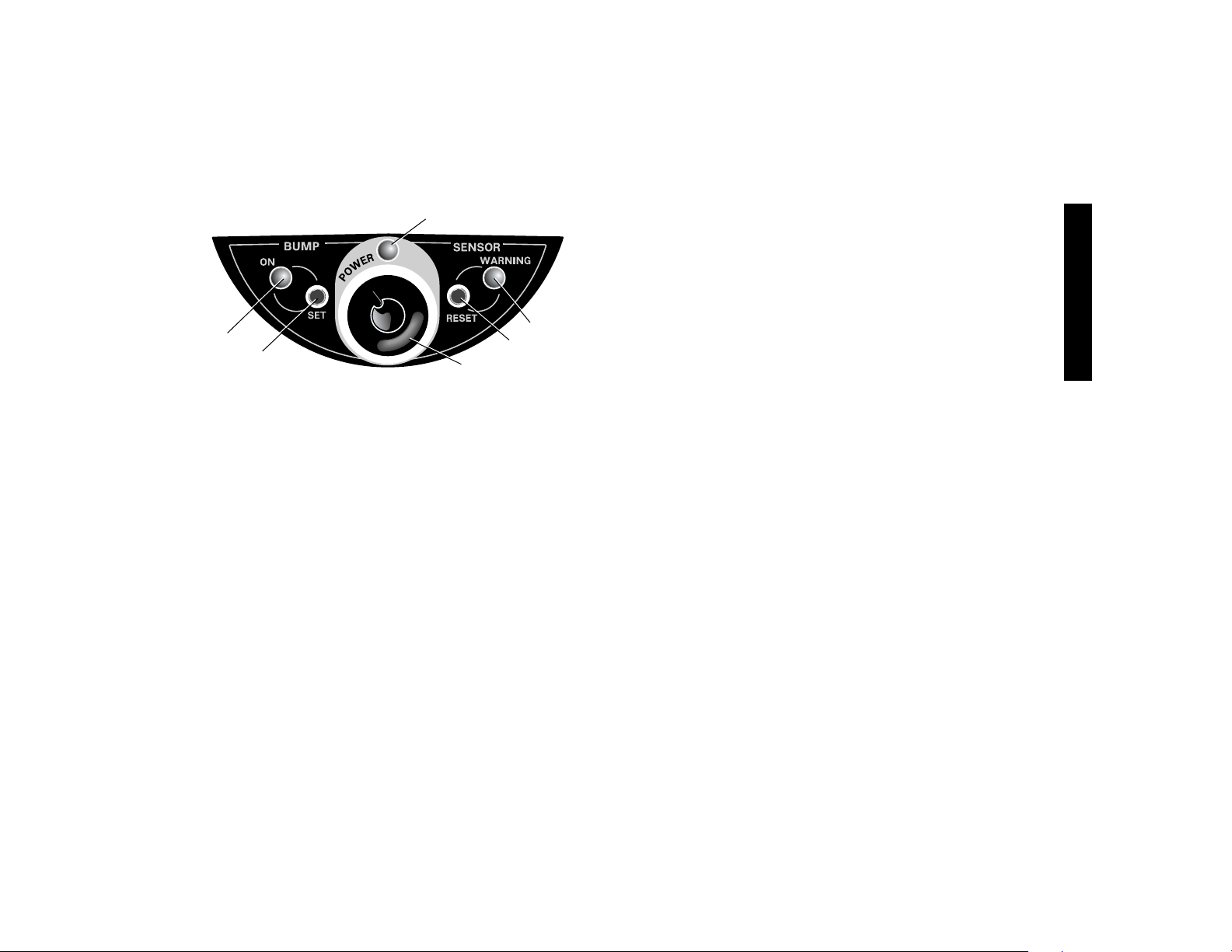

Control Panel

The Control Panel contains the

ON/OFF/Variable Speed Switch,

ON/LOW Battery Indicator LED

Light, and Bump Sensor Control

Buttons and LED Indicator Lights.

To Turn the Laser On:

Insert fully charged battery pack through proper cut out in battery

adapter plate. Ensure battery is firmly engaged.

Rotate the ON/OFF knob (A) clockwise to power the laser ON. The

dual laser diodes will turn on and the POWER LED (B) Light will illuminate. The rotary head will remain stationary during the first 1/4 turn

of the knob. Rotation of the laser head will begin as the Variable

Speed knob continues to be turned clockwise. The rotary head speed

is variable from 0-600 RPM. The POWER LED Light will remain lit as

long as the switch is turned ON and the battery remains charged.

Low Battery Indicator:

The DW073 is equipped with a Low Battery Indicator. A flashing

POWER LED Light indicates that the battery pack needs to be

recharged. All other electronic functions of the tool will shut down,

including the laser diodes. Follow recharging instructions for battery

packs as mentioned in this manual.

A

B

C

D

Page 11

9

English

To Turn the Laser Off:

Rotate the ON/OFF Knob counterclockwise until it clicks OFF and the

laser diodes shut down. The POWER LED Light will no longer be illuminated.

ROTATION SPEEDS

The Variable Speed Knob can be used to improve your visibility or

detection of the laser beam. The slower the rotation speed, the brighter

the laser line will appear. The faster the rotation speed, the more solid

the laser line appears. Always remember to operate your laser in HIGH

(600 RPM) speed when working with the Digital Laser Detector.

Remember: Slow Speed = Bright Beam; Fast Speed = Solid Beam.

Bump Sensor

The DW073 Cordless Rotary Laser is equipped with a BUMP SENSOR that will warn you if the laser level has been bumped after set up

and leveling. If properly used, this feature can help increase the accuracy of your work by insuring that you continue to work off of the same

level/plumb position that you initially set the laser to. The Bump Sensor

IS NOT AN OUT OF LEVEL SENSOR. It can not and will not warn you

if the laser has gone out of level without being bumped. Check your

level/plumb position often to ensure the accuracy of your work.

A

B

C

D

E

F

BUMP SENSOR CONTROLS

The Bump Sensor is activated as soon as you turn the laser power ON

and will remain active until you turn the laser power OFF. Through the

use of the Bump Sensor Controls, you can choose how the laser

warns you in the event it has been bumped. There are two settings to

choose from.

SETTING 1

FLASHING LED WARNING LIGHT ONLY

With a fully charged battery properly inserted, turn the laser power

ON. The Bump Sensor is automatically activated.

• Level the laser to establish a benchmark.

• Choose your rotation speed.

• If the laser level is bumped, the Bump Sensor WARNING LED (E)

will flash to warn you.

• To continue working, recheck the laser to your benchmark and relevel if necessary.

• Press the Bump Sensor RESET Button (F) to clear the flashing

LED light and reset the Bump Sensor circuit.

SETTING 2

FLASHING LED WARNING LIGHT, FLASHING LASER DIODES,

AND ROTATION STOP

With a fully charged battery properly inserted, turn the laser power

ON. The Bump Sensor is automatically activated.

• Level the laser and establish a benchmark.

• Choose your rotation speed.

• Press the Bump Sensor SET Button (C) to activate the second

operating mode. The Bump Sensor ON LED Light (D) will illuminate.

• If the laser level is bumped, the Bump Sensor WARNING LED (E)

will flash, the dual laser diodes will flash and rotation of the laser

head will stop, if the rotary head was spinning.

• To continue working, recheck the laser to your benchmark and relevel if necessary.

Page 12

10

English

• Press the Bump Sensor RESET Button (F) to clear the flashing

LED light and reset the Bump Sensor circuit. The laser diodes will

stop flashing and the rotary head will begin spinning again. The

Bump Sensor ON LED Light will remain lit and the tool will remain

in this operating mode.

To return the circuit to setting 1, press the Bump Sensor SET Button

(C) once again. The ON LED Light (D) will shut off indicating that the

laser is in operating mode 1.

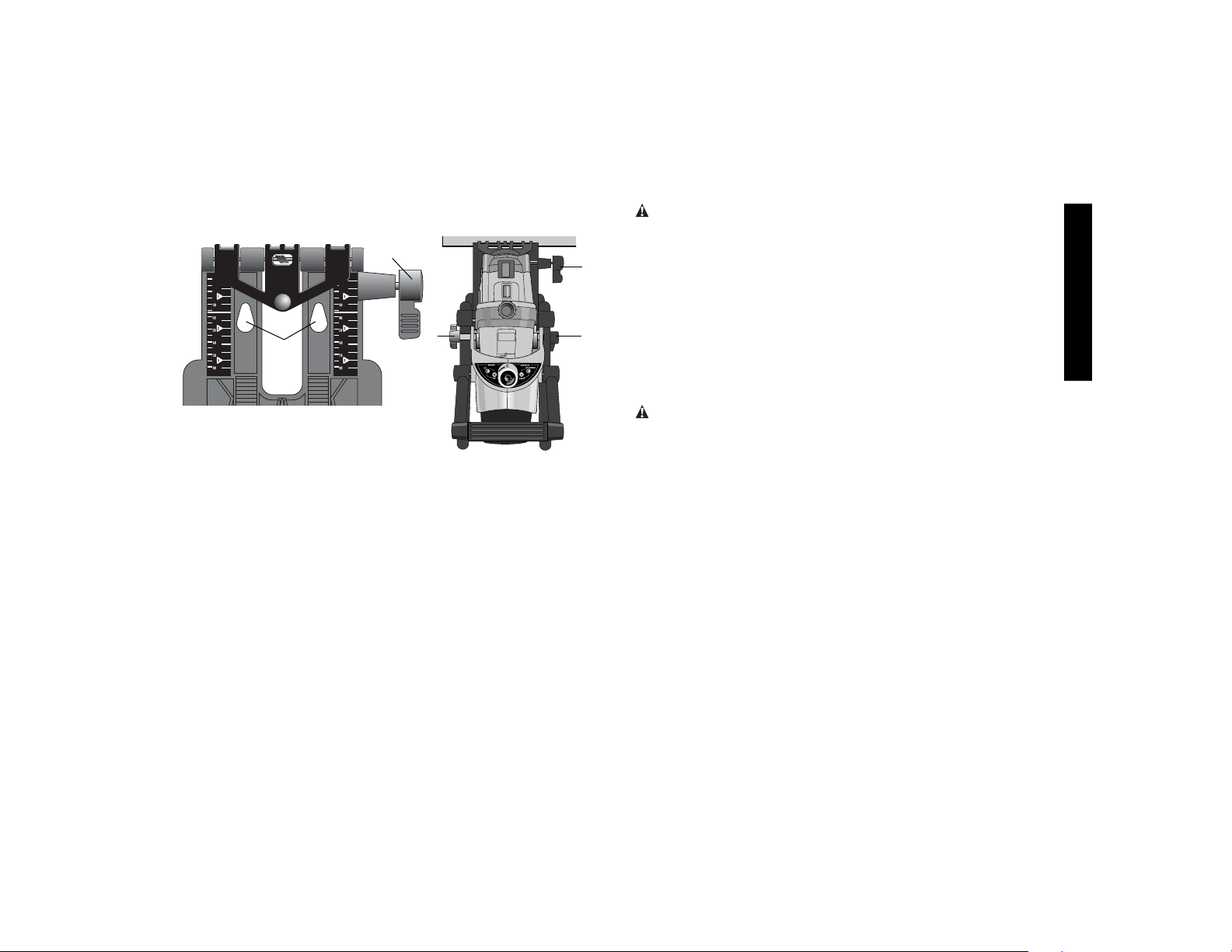

Two-Position Pivoting Head

This tool has been designed with a

Two-Position Pivoting Head for quick and

easy adjustments on the job. The TwoPosition Pivoting Head can be used to

position the laser for both horizontal (level)

and vertical (plumb) applications and to

adjust the laser for use with the built in Wall

Mount. The Two-Position Pivoting Head is

designed to lock the laser level into two predetermined positions (level

& plumb) through the use of a spring-loaded detent pin. To make

adjustments to the position of the laser head follow these instructions.

1. Locate the Two-Position Pivoting Head Adjustment Lever (A) on

the side of the laser level, next to the “DANGER” warning label.

2. To pivot the laser head lift the Adjustment Lever approximately

one quarter of the way open, enough to disengage the springloaded detent pin holding the laser head in position. DO NOT

ATTEMPT to fully open the Adjustment Lever, you may damage

the spring-loaded detent mechanism. The Adjustment Lever has

been designed to release the Pivoting Head when opened only

one quarter of the way.

3. While lifting the Adjustment Lever approximately one quarter of

the way open with one hand, pivot the laser head with your other

hand until it travels 90º to a stop.

4. Release the Adjustment Lever and make sure that the springloaded detent pin locks into place. The laser head should now be

locked into position and ready for use.

A

5. Follow the instructions for leveling or plumbing the laser. For positioning the tool for use on a wall see the Wall Mount section.

6. To return the laser head to its original position repeat steps 2-4.

Wall, Floor & Tripod Mounts

The DW073 Cordless Rotary Laser has been designed with the most

common accessories built directly into the base of the tool. These

accessories allow the laser to be mounted onto tripods, positioned

directly on the floor, and attached to walls for drop ceiling installation

or other leveling jobs.

MOUNTING ON A TRIPOD

1. Position the tripod on a smooth and

level surface. Set tripod to desired

height.

2. Secure the laser to the tripod base

by screwing the threaded knob (A)

on the tripod into the 5/8" x 11

threaded insert on the bottom of the

laser level. NOTE: Be sure the tripod you are working with has a 5/8" x 11 threaded screw.

3. Use the Two-Position Pivoting Head Adjustment Lever to pivot the

laser head for a level or plumb setting.

4. Follow the instructions for leveling or plumbing the laser.

5. Turn the laser on; adjust rotation speed and controls as needed.

FLOOR MOUNT

The laser level can be positioned directly on the floor for leveling and plumbing

applications. Follow the instructions

below for using the floor mount.

1. Place the laser on a relatively

smooth and level surface

2. Use the Two-Position Pivoting

Head Adjustment Lever (A) to

pivot the laser head for a level or

plumb setting.

A

B

C

A

Page 13

11

English

3. Use the Base Leveling Knob (B) located under the battery pack

to stabilize the tool and aid in rough leveling.

4. In a plumb orientation the laser can be positioned over a mark and

fine adjustments of the laser position can be made using the Base

Rack 'N Pinion Knobs.

TIP:

It may be helpful to turn the power ON

and spin the rotary head to set your mark. The Base Rack 'N

Pinion Locking Knob (D) is a wing nut style knob that will lock and

unlock the sliding base bracket. The Rack 'N Pinion Adjustment

Knob (C) rotates to slide the tool forward and back.

TIP:

You may

need to hold the laser base down while adjustments are made to

the tool while on the floor.

5. Follow the instructions for leveling or plumbing the laser.

6. Turn the laser on if not on already; adjust rotation speed and controls as needed.

WALL MOUNT

The DW073 Cordless Rotary Laser has been designed with a built-in

Wall Mount for attaching the tool to wall track to aid in acoustical ceiling installation and other specialty leveling projects. Follow the instructions below for using the Wall Mount.

A

B

A

D

C

CAUTION: Before attaching the laser level to wall track ensure that

the track is properly secured to the wall.

1. Use the Two-Position Pivoting Head Adjustment Lever to pivot the

laser head into a plumb orientation.

2. Rotate the entire tool so that the battery pack is positioned at the

bottom of the tool and the Wall Mount Clamp is in position to be

attached to the wall track. See illustration at left for proper set-up.

3. With the Base Plate Measuring Scale facing you, rotate the Wall

Mount Clamp Locking Knob (A) towards you to open the clamp

jaws. Position the clamp jaws around the wall track and rotate the

Wall Mount Clamp Locking Knob away from you to close the

clamp jaws shut on the track. Ensure that the Wall Mount Clamp

Locking Knob is securely locked before proceeding.

CAUTION: Always use a ceiling wire hanger or equivalent materi-

al, in addition to the wall mount clamp, to help secure the laser level

while mounting it to a wall. Thread the wire through the holes in the roll

cage above the Rack 'N Pinion Adjustment Knob (C) or above the

Rack 'N Pinion Locking Knob (D). Additionally, screws or nails can be

used to fasten the tool directly to the wall as a back up. Screw/Nail

holes (B) are located in the Base Plate next to the Base Plate

Measuring Scales.

4. The tool can be adjusted up and down to the desired offset height

for working. To change the height, loosen the Rack 'N Pinion

Locking Knob (D) located to the left of the laser head.

TIP:

You

may need to support the weight of the tool while the Rack 'N

Pinion Locking Knob is loosened. Turn the Rack 'N Pinion

Adjustment Knob (C) located to the right of the laser head to move

the laser level up and down to set your height. Use the Base Plate

Measuring Scale to pinpoint your mark.

TIP:

It may be helpful to

turn the power ON and spin the rotary head to set your height.

Once you have positioned the laser at your desired offset height,

tighten the Rack 'N Pinion Locking Knob to maintain your mark.

5. Use the Base Leveling Knob (behind the battery) at the bottom of

the base plate to aid in positioning the tool against the wall.

Page 14

12

English

6. Follow the instructions for leveling the laser.

TIP:

Remember the

front leveling knob controls the movement of the bubble in the

front vial, the side leveling knob controls the movement of the

bubble in the side vial.

7. Turn the laser on if not on already; adjust rotation speed and controls as needed.

Horizontal Leveling

1. Set the laser on a relatively smooth and

level surface such as a Tripod or prepare the laser level to be attached to

wall track using the built-in Wall Mount

feature. See “Wall Mount” section.

2. Use the Two-Position Pivoting Head

Adjustment Lever to pivot the laser

head to a level setting for projecting a

horizontal reference beam. In this

position the Manual Head Rotation

Button (A) should be pointing up

towards the ceiling or sky.

3. The leveling knobs (B) control the

orientation of the laser head on the metal leveling plates and effect

the movement of the bubbles in the vials (C). When the laser level

is placed in a level position the front leveling knob controls the

movement of the bubble in the front vial. The side leveling knob

controls the movement of the bubble in the side vial. NOTE: The

same leveling rules apply to the tool when being used with the

Wall Mount feature.

4. To level the laser, the bubbles in both the front and side vials need

to be centered within the vials.

TIP:

The more accurately you can

center the bubbles within the vials the more accurate your horizontal laser reference beam will be.

5. To level the laser, turn the leveling knob towards the bubble until

the bubble is centered in the vial.

TIP:

To move the bubble in the

front vial to the right, turn the front leveling knob to the left. To

A

B

C

move the bubble in the front vial to the left, turn the leveling knob

to the right. Repeat the procedure for the side vial.

6. Turn the laser on if not on already; adjust rotation speed and controls as needed.

7. To project a level laser reference plane, adjust the rotation speed

for preferred visibility. Remember: Slow Speed = Bright Beam;

Fast Speed = Solid Beam.

Vertical Plumbing

1. Set the laser on a relatively

smooth and level surface. The

tool should be positioned on the

large base plate under the battery

pack. Utilize the Base Leveling

Knob (A) to roughly position the

laser.

2. Use the Two-Position Pivoting

Head Adjustment Lever to pivot

the laser head to a plumb setting for projecting a vertical reference

beam. In this position the pivoting laser head should be directly

over the Wall Mount Clamp and the Control Panel should be facing up towards the ceiling or sky.

3. To plumb the laser, only the bubble in the Plumb Vial (D) needs to

be centered.

TIP:

The more accurately you can position the bubble within the vial the more accurate your vertical laser reference

beam will be.

4. Looking over the top of the laser, turn the Plumb Leveling Knob (B)

(which is located on the side of the pivoting laser head in this orientation) to move the bubble within the Plumb Vial (D). Turn the

plumb leveling knob towards the bubble until the bubble is centered in the vial.

TIP:

Turn the knob in the opposite direction you

need the bubble to move.

5. Use the Plumb Beam Alignment Knob (C )(which is the knob next

to the Plumb Vial) to adjust the plumb laser reference plane over

your mark.

A

B

C

D

Page 15

13

English

6. Turn the laser on if not on already; adjust rotation speed and controls as needed.

7. To project a plumb laser reference plane, adjust the rotation speed

for preferred visibility. Remember: Slow Speed = Bright Beam;

Fast Speed = Solid Beam.

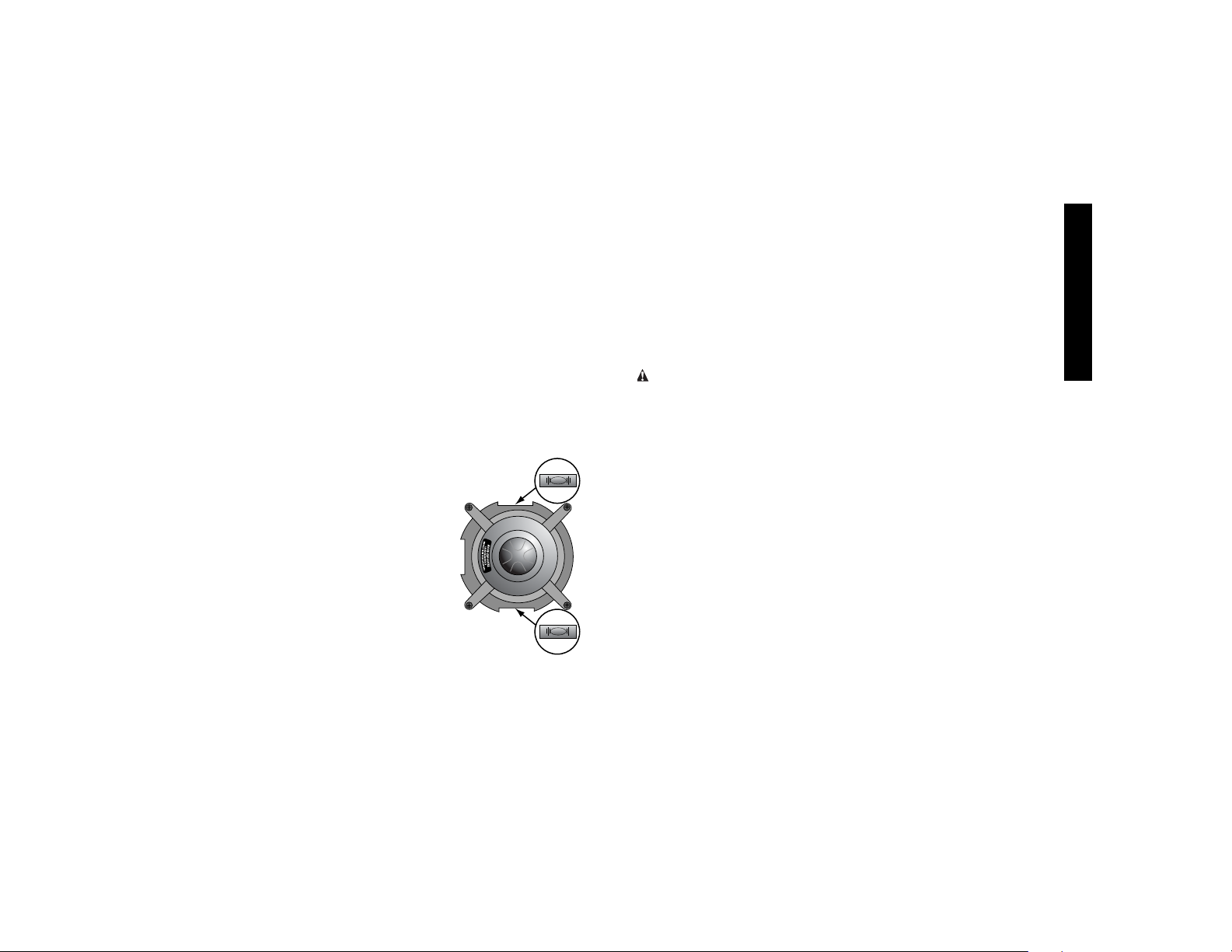

Manual Head Rotation Button

The laser has been designed with a

protective cap over the rotary head to prevent accidental damage from work site activities. You can still access the rotary head

and manually direct the beam to establish or

transfer a mark. To manually rotate the laser

beam follow the instructions below.

If the laser is turned OFF, rotate the ON/OFF knob clockwise a 1/4 turn

or less. Ensure that the laser diodes are powered on and that the rotary

head is not spinning. If the laser is ON and spinning, rotate the ON/OFF

knob counterclockwise until rotation of the head stops.

Depress the spring loaded Manual Head Rotation Button (A) on the

top of the protective cap. The button will make contact with the rotary

laser head. While maintaining pressure on the Manual Head Rotation

Button, you can now turn the button and direct the laser beams in the

direction of your mark.

Since the laser has been designed with dual, side by side laser

diodes, you may see 2 laser dots on the object you are projecting the

beam onto. Marks can be made using either laser dot. Mark the center of the dot.

DO NOT attempt to use the Manual Head Rotation Button while the

rotary head is spinning.

While using the Manual Head Rotation Button, it is recommended that

you set the Bump Sensor to Setting 1. See Bump Sensor operation.

NOTE: After storing this product in extremely cold conditions, the laser

head may not immediately rotate when turned on. The rotary head

may be started by depressing and turning the Manual Rotation Button

counterclockwise.

A

Laser Enhancement Glasses

The DEWALT Laser Kit includes a pair of Laser

Enhancement Glasses. These red lens glasses improve the visibility of the laser beam

under bright light conditions or over long distances. These glasses are not required to operate the laser but are

helpful. Working best indoors, the lens filters out ambient light and

intensifies the red laser dot or line to your eyes.

CAUTION: These glasses are not ANSI approved safety glasses

and should not be worn while operating other tools. These glasses do

not keep the laser beam from entering your eyes.

DANGER: NEVER STARE DIRECTLY INTO THE LASER BEAM,

WITH OR WITHOUT THESE GLASSES.

Target Card

The DEWALT Rotary Laser Kit includes a Laser

Target Card to aid in locating and marking the laser

beam. The target card enhances the visibility of the

laser beam as the beam crosses over the card. The

card is marked with inch and metric scales. The

laser beam passes through the red plastic and

reflects off of the reflective tape on the reverse side.

The magnets at the top hold the target card to ceiling track or steel studs to determine plumb and level

positions.

Digital Laser Detector

The DEWALT Digital Laser Detector enables you to locate a laser

beam emitted by a Rotary Laser in bright light conditions or over long

distances. The detector can be used in both indoor and outdoor situations where it is difficult to see the laser beam. The detector is not for

use with non-rotating lasers.

The detector gives both visual and audio signals as to the location of

the laser beam as the beam crosses over the detector. The D

EWALT

Digital Laser Detector is compatible with most rotary lasers on the

Page 16

14

English

market today. The clamp attaches the Digital Laser Detector to grade

rods, leveling poles, wall studs or posts. The detector can also be

mounted to ceiling track by attaching the magnets on the top of the

detector to the track.

If this laser kit contains a D

EWALT Digital Laser Detector, a separate

instruction manual has been included. For proper use and operation

read and understand the Detector manual before use.

Applications

The DW073 Cordless Rotary Laser is a versatile and accurate tool

that can be used for both interior and exterior construction and remodeling projects. The laser level can be adjusted and positioned for use

on dozens of horizontal (level) and vertical (plumb) applications. A few

of the most common applications are listed below. General user steps

are listed for each application to serve as a guide. They are not intended to provide you with detailed instructions to complete each leveling

or plumbing project.

Ceiling Installation

1. Follow the instructions in this manual for operating the built-in Wall

Mount.

2. Securely attach the tool to the wall track and adjust the laser to

your offset height.

POWER

ON

VOLUME

LEVEL

BATTERY

COMPARTMENT

3. Follow the instructions for leveling the laser.

TIP:

Remember the front leveling knob controls the front bubble vial, the side leveling

knob controls the side bubble vial.

4. Turn the laser on if not on already; adjust rotation speed and controls as needed.

Remember: Slow Speed = Bright Beam; Fast

Speed = Solid Beam.

5. Use the Laser Target Card to help you find the

rotating laser beam reference plane. Attach

the magnetic base of the Laser Target Card to

the ceiling track cross sections.

TIP:

Wear the

Laser Enhancement Glasses to help improve the visibility of the

laser beam to your eyes.

6. You can now begin to accurately level the ceiling grid/track for

ceiling installation.

Wall Layout

1. Follow the instructions in this manual for operating the built-in

Floor Mount.

2. Use the Two-Position Pivoting Head Adjustment Knob to pivot the

laser head for a plumb setting.

3. Position the laser over a predetermined benchmark on the floor

and adjust the tool by utilizing the Rack 'N Pinion Adjustment

Knobs.

4. Follow the instructions for plumbing the laser.

5. Turn the laser on if not on already; adjust rotation speed and controls as needed. Remember: Slow Speed = Bright Beam; Fast

Speed = Solid Beam.

6. Use the Laser Target Card to help you find the rotating laser beam

reference plane and to transfer your mark.

TIP:

Wear the Laser

Enhancement Glasses to help improve the visibility of the laser

beam to your eyes.

7. You can now begin to plumb and layout your walls by accurately

transferring the reference points on the floor to the ceiling.

Page 17

15

English

Foundations

1. Follow the instructions in this manual for setting up the laser on a

Tripod.

2. Use the Two-Position Pivoting Head Adjustment Knob to pivot the

laser head for a level setting.

3. Follow the instructions for leveling the laser.

4. Turn the laser on if not on already; adjust rotation speed and controls as needed. Remember: When working with the DEWALT

Digital Laser Detector set the variable control speed to the highest

setting (600 RPM).

5. Mount the DEWALT Digital Laser Detector to the Detector Clamp

and attach the clamp onto a Grade Rod or other leveling rod.

6. Adjust the clamp to the proper height on the rod for detecting the

rotating laser beam and for leveling the foundation.

7. You can now begin to level the area for the foundation.

Deck Building

1. Follow the instructions in this manual for

setting up the laser on a Tripod.

2. Use the Two-Position Pivoting Head

Adjustment Knob to pivot the laser head

for a level setting.

3. Follow the instructions for leveling the

laser.

4. Turn the laser on if not on already; adjust

rotation speed and controls as needed.

Remember: When working with the

DEWALT Digital Laser Detector set the

variable control speed to the highest setting (600 RPM).

5. Use the D

EWALT Digital Laser Detector to locate the rotating laser

beam and to set your marks on the posts.

6. You can now begin to lay out and level the deck.

Maintenance

• To maintain the accuracy of your work, have the laser checked

often to make sure it is properly calibrated.

• Calibration checks and other maintenance repairs can be performed by D

EWALT service centers. Two free calibration checks

are included under the D

EWALT One Year Free Service Contract.

• When not in use, store the laser in the kit box provided.

• Do not store your laser in the kit box if the laser is wet. Allow laser

to air dry and dry exterior parts with a soft dry cloth.

• Do not store your laser at temperatures below 0˚ F or above 105˚F.

CLEANING: Exterior plastic parts may be cleaned with a damp

cloth and mild detergent. Although these parts are highly solvent resistant, NEVER use solvents. Use a soft dry cloth to remove moisture

from tool and accessories before storage. Never use compressed air

to clean the laser.

Field Calibration Check

This section provides instructions by which you can perform simple

field calibration checks of your D

EWALT Rotary Laser. These checks

cannot take the place of professional calibration done by a D

EWALT

service center.

These instructions will help you check for the three types of out-of-

level errors.

• Tilt Error - checks that rotation of the head in your Rotary Laser

is perfectly level.

• Cone Error - checks that the laser beams are not at an angle

relative to the level head.

• Plumb Error - checks the calibration of the plumb leveling vial.

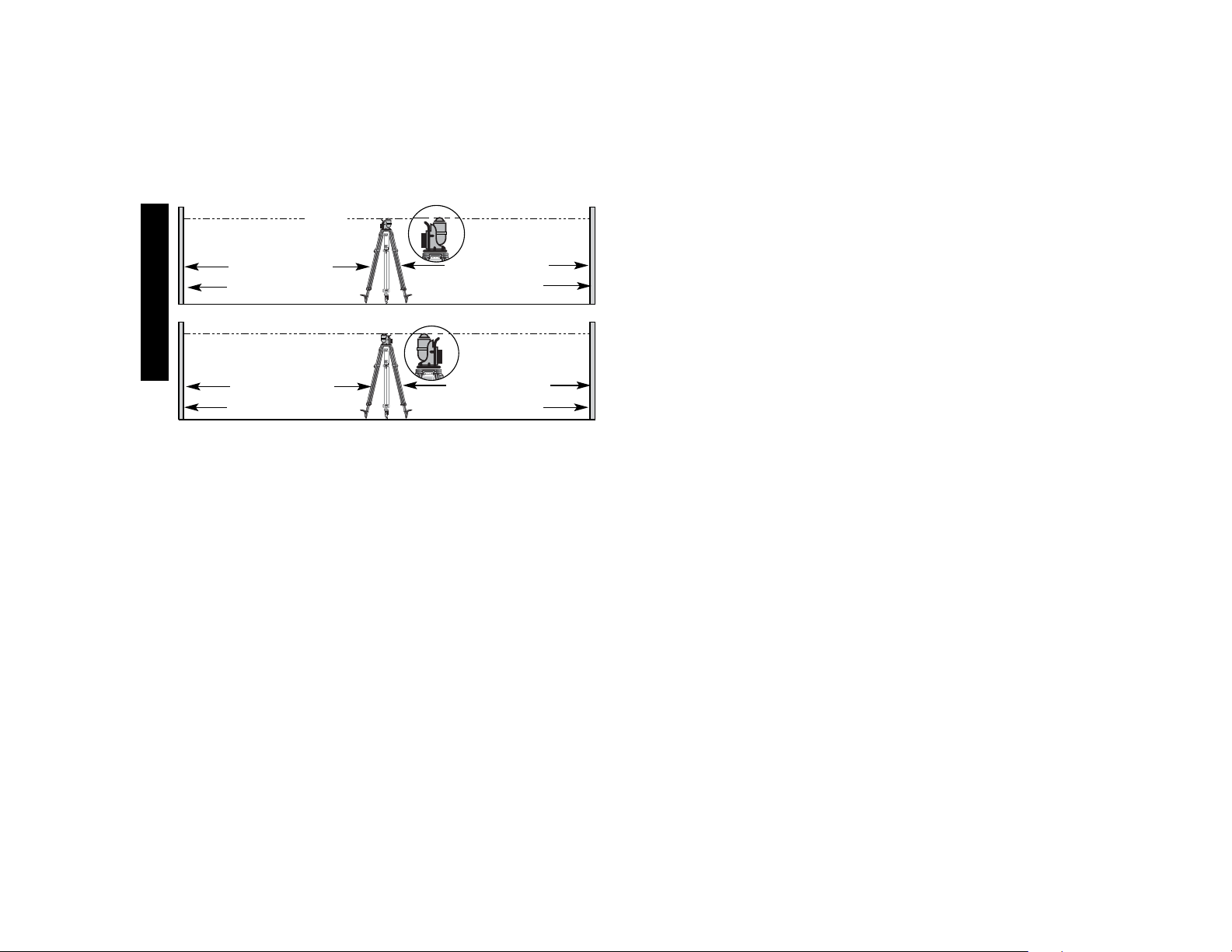

TILT ERROR CHECKS

Horizontal Checking for Front to Back Tilt Error

• Set up a tripod midway between 2 vertical surfaces about 100'

apart.

Page 18

16

English

• Mount your Rotary Laser on a tripod so it is aimed front-to-back

toward the vertical surfaces. (next page)

• Level the Laser, following the procedure in the “Horizontal

Leveling” section of this manual.

• Quick Check:

1. Compare the position of the bubbles in the front and rear vials

(Fig. AA).

2. If the two bubbles are not in about the same position in their

vials, (both about centered) have your Rotary Laser calibrated

at a D

EWALT service center.

• Turn the unit on so that the lasers are on and rotating.

• Go to surface #1 and mark the center of the beam. If it is difficult

to see the beam, use your Laser Enhancement Glasses, Target

Card or optional DW0732 Digital Laser Detector.

• Go to surface #2 and mark the center of the beam.

• Loosen the screw holding the Laser to the tripod, but do not

remove the Laser.

• Rotate the Laser 180˚ (Fig. BB)

• Level the Laser again, following the procedure in the “Horizontal

Leveling” section of this manual.

• Turn the unit on if it is not already on, so the lasers are on and

rotating.

• Go to surface #1 and mark the center of the beam.

• Go to surface #2 and mark the center of the beam.

• Measure the difference between the marks on surface #1.

• Measure the difference between the marks on surface #2.

• The difference between the marks on surface #1 must equal the

difference between the marks on surface #2. If these are not

equal, there was user set up or marking error.

• If the difference between the marks on surface #1 is 1/4" or less,

the Laser is properly calibrated.

• If the difference between the marks on surface #1 is more than

1/4", have your Rotary Laser calibrated at a D

EWALT service

center.

HORIZONTAL CHECKING FOR SIDE-TO-SIDE TILT ERROR

• Set up tripod midway between 2 vertical surfaces 100' from each

other.

• Mount your Rotary Laser on a tripod so that it is aimed side-to-side

toward the vertical surfaces.

• Level the Laser, following the procedure in the “Horizontal

Leveling” section of this manual.

• Turn the unit on so that the lasers are on and rotating.

• Go to surface #1 and mark the center of the beam. If is difficult to

see the beam use one of the aids mentioned earlier.

• Go to surface #2 and mark the center of the beam.

• Loosen the screw holding the Laser to the tripod but do not

remove the Laser.

• Rotate the Laser 180˚.

• Level the Laser again, following the procedure in the “Horizontal

Leveling” section.

APPROX. 50 FT.APPROX. 50 FT.

APPROX. 50 FT.APPROX. 50 FT.

BEAM

BEAM

FIG. AA - UNIT FACING RIGHT

FIG. BB - UNIT FACING LEFT

SURFACE 1 SURFACE 2

SURFACE 1 SURFACE 2

Page 19

17

English

• Turn the unit on if not already on, so that the lasers are on and

rotating.

• Go to surface #1 and mark the center of the beam.

• Go to surface #2 and mark the center of the beam.

• The difference between the marks on surface #1 must equal the

difference between the marks on surface #2. If these are not

equal, there was user set up or marking error.

• If the difference between the marks on surface #1 is 1/4" or less,

the Laser is properly calibrated.

• If the difference between the marks on surface #1 is more than

1/4", have your Rotary Laser calibrated at a D

EWALT service

center.

CONE ERROR CHECK

• Your D

EWALT Rotary Laser contains 2 laser diode assemblies. It

is highly unlikely that both lasers would have shifted by identical

amounts. The easiest way to test for possible “cone error” is to

compare the two laser beams.

• Level the laser, following instructions in the “Horizontal Leveling”

section of this manual.

• Quick Check:

1. Turn the unit on so that the lasers are on and rotating.

2. You should see a single red line on a vertical surface. If you see

a double line, have your Rotary Laser calibrated by a DEWALT

service center.

• Turn unit on so that the lasers are on but NOT rotating.

• Using the Manual Rotation Button, rotate the head so that the

lasers appear as two dots on a vertical surface about 25 feet

away.

• Compare the vertical position of the center of each laser beam.

The centers should be within 3/32"(vertically) of each other.

• If the centers of the two beams differ by more than 3/32" (vertically), then have your Rotary Laser calibrated at a D

EWALT ser-

vice center.

PLUMB ERROR CHECK

• Set up a tripod about 25 feet from a vertical surface.

• Mount your Rotary Laser on the tripod.

• Following the procedure in the “Two Position Pivoting Head”

section of this manual, set the Rotary Laser head in the plumb

position.

• Hang a plumb bob from the vertical surface.

• Level the laser, following instructions in the “Vertical Plumbing”

section of this manual.

• Turn the unit on so that the lasers are on and rotating.

• Rotate the laser on the tripod so that the beam is in the line with

the plumb bob.

• Ensure that the laser is still level.

• If the beam lies along the same line as the plumb bob string, then

the calibration is acceptable.

• If the beam does not lie along the same line as the plumb bob

string, have your Rotary Laser calibrated at a D

EWALT service

center.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local service center. If you need any assistance

in locating any accessory, please contact D

EWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286 or call 1-800-4-D

EWALT.

(1-800-433-9258) See our catalog on the World Wide Web at www.

D

EWALT.com.

CAUTION: The use of any non-recommended accessory may be

hazardous.

Repair

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by certified service centers or

other qualified service organizations, always using identical replacement parts.

Page 20

18

English

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by nor-

mal use, for free, any time during the first year after purchase.

2 YEARS FREE SERVICE ON

XRP

™ BATTERY PACKS

DC9096, DC9091 and DC9071

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in

Latin America. For products sold in Latin America, see country specific warranty information contained either in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

Troubleshooting Guide

This guide is intended to assist you in determining why the laser is not

operating to your expectations. These are some of the most commonly asked questions or observances. If you still have questions or

problems with your D

EWALT laser after completely reading through

this Troubleshooting Guide and instruction manual, call our toll free

Hot Line at 1-800-4-DEWALT or visit one of our service centers.

THE BATTERY WILL NOT LOCK IN PLACE

See “Installing the Battery Pack”

THE LASER WILL NOT TURN ON

Ensure that a fully charged battery is properly inserted into the tool.

TIP:

See “Installing the Battery Pack” section. Rotate the ON/OFF

VARIABLE SPEED Knob clockwise to turn the power on.

TIP:

See

“Control Panel” section. If the laser still doesn't turn on, take the tool

to a D

EWALT service center.

Page 21

AFTER TURNING THE LASER ON, 2 LASER DOTS ARE

PROJECTED FROM THE ROTARY HEAD

The DW073 Cordless Rotary Laser has been designed with dual, side

by side laser diodes. Two diodes allows the laser to avoid blind spots

which could potentially be created by the protective cap over the rotary

head and also produce an extremely bright beam when the rotary

laser head is spun.

THE LASER IS PROJECTING 2 LASER LINES WHEN THE LASER

HEAD IS ROTATED

Take the laser to a DEWALT service center for calibration.

THE POWER LED LIGHT IS FLASHING, THE ROTARY HEAD HAS

STOPPED SPINNING AND THE LASER DIODES HAVE SHUT

DOWN.

This indicates that the battery pack needs to be recharged.

TIP:

See

“Removing the Battery Pack” and “Charging Procedures.”

THE BUMP SENSOR WARNING LED LIGHT IS FLASHING

See “Bump Sensor” section for operating instructions.

THE BUMP SENSOR WILL NOT TURN THE LASER OFF AFTER

THE TOOL HAS GONE OUT OF LEVEL

The Bump Sensor is NOT AN OUT OF LEVEL SENSOR. See “Bump

Sensor” section.

THE ROTATING LASER BEAM IS DIFFICULT TO SEE INDOORS

Ambient light conditions will influence the visibility of the laser beam.

To aid in beam visibility, adjust the rotation speed using the ON/OFF

VARIABLE SPEED SWITCH. Remember: Slow Speed = Bright

Beam; Fast Speed = Solid Beam. Wearing the Laser Enhancement

Glasses can also help you see the beam better.

I NEED TO ADJUST THE LASER FOR A VERTICAL / PLUMB ORIENTATION

See “Two-Position Pivoting Head” section.

I NEED TO ADJUST THE LASER FOR MOUNTING ON A WALL

See “Wall Mount” section.

THE LASER ROCKS WHEN POSITIONED ON THE FLOOR

The laser is designed to sit on 3 contact points for maximum stability.

Two of these contact points are stationary while the third is adjustable.

To roughly position the tool on the floor adjust the Base Leveling Knob,

which is located under the battery pack.

I NEED TO STOP THE ROTARY HEAD ROTATION TO DIRECT

THE LASER DOT ONTO A MARK OR TO SET A MARK

See “Manual Head Rotation” section.

THE BUBBLE(S) IN THE VIAL(S) WILL NOT MOVE WHEN

ATTEMPTING TO LEVEL THE LASER

The tool must be positioned on a relatively smooth and level surface

before being leveled. The laser cannot be leveled if the tool is set up

outside of its leveling range.

TIP:

Use the Base Leveling Knob to

roughly level the tool before attempting to level the laser with the leveling knobs.

TIP:

Make sure that the Two-Position Pivoting Head is

locked into either the plumb or level setting before attempting to level

the laser. See “Two-Position Pivoting Head” section.

I CAN ONLY ADJUST THE BUBBLE IN THE PLUMB VIAL WHEN

ATTEMPTING TO PROJECT A VERTICAL LASER LINE

See “Vertical Plumbing” section for instructions on projecting a vertical

laser line.

COLD STORAGE INFORMATION

After storing this product in extremely cold conditions, the laser head

may not immediately rotate when turned on. The rotary head may be

started by depressing and turning the Manual Rotation Button counterclockwise.

19

English

Page 22

20

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE PART

DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU TOUT

AUTRE OUTIL D

EWALT, COMPOSEZ SANS FRAIS LE :

1 800 433-9258.

Introduction

Le laser rotatif sans fil DW073 est un outil laser à nivellement manuel

pouvant être utilisé tant à l’intérieur qu’à l’extérieur pour réaliser des

travaux d’alignement vertical et horizontal. L’outil est complètement

assemblé au moment de sa livraison. Il peut accomplir toute une variété de tâches, depuis l’installation d’un plafond insonorisant, jusqu’au

nivellement d’un mur par rapport à une fondation, en passant par la

construction d’une terrasse. Cet outil novateur présentant de nombreuses caractéristiques permet d’effectuer les opérations d’installation et de réglage rapidement et aisément, permettant du même coup

d’augmenter la productivité de l’utilisateur. On recommande de lire et

de comprendre toutes les directives et consignes contenues dans le

présent manuel avant d’utiliser cet outil.

Règles générales de sécurité

concernant les outils à piles

AVERTISSEMENT! Lire et comprendre toutes les

directives, car le non-respect des directives suivantes

pourrait entraîner un choc électrique, un incendie ou des

blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

• Garder la zone de travail propre et bien éclairée; les établis

encombrés et les endroits sombres sont propices aux accidents.

• Ne pas utiliser les outils électriques dans une atmosphère

explosive, comme à proximité de liquides, de gaz ou de poussières inflammables; le moteur peut créer des étincelles et

enflammer les vapeurs ou les poussières environnantes.

• Tenir les enfants, les visiteurs ou toute autre personne à

l’écart lorsqu’on utilise un outil électrique; les distractions peuvent faire perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ : ÉLECTRICITÉ

• Un outil à piles intégrées ou à bloc-piles externe doit être

rechargé seulement au moyen du chargeur approprié, car un

chargeur destiné à une pile particulière pourrait entraîner un risque

d’incendie lorsqu’il est utilisé avec une autre.

• N’utiliser l’outil à piles qu’avec le bloc-piles désigné, car l’utili-

sation d’un autre type de piles pourrait entraîner un risque

d’incendie.

SÉCURITÉ PERSONNELLE

• Rester vigilant en tout temps et faire preuve de jugement

lorsqu’on utilise un outil électrique; ne pas utiliser l’outil

lorsqu’on est fatigué ou sous l’influence de drogues, d’alcool ou de

médicaments, car un moment d’inattention pourrait entraîner des

blessures graves.

• Porter des vêtements appropriés; ne pas porter de vêtements

amples ni de bijoux. Couvrir ou attacher les cheveux longs. Garder

les cheveux, les vêtements, les bijoux et les gants éloignés des

pièces mobiles, car ceux-ci peuvent s’y coincer. Se tenir éloigné

des évents puisque ces derniers pourraient camoufler des pièces

mobiles.

• Éviter les démarrages accidentels; s’assurer que l’interrupteur

soit placé en position de verrouillage ou d’arrêt avant d’insérer le

bloc-piles. Ne pas transporter l’outil en laissant le doigt sur l’interrupteur ni insérer le bloc-piles lorsque l’outil est en position de

marche, car cela pourrait causer un accident.

• Ne pas trop étendre les bras; les pieds doivent rester ancrés fer-

mement sur le sol afin de maintenir son équilibre en tout temps et

de mieux maîtriser l’outil dans des situations imprévues.

• Utiliser le matériel de sécurité approprié; toujours porter des

lunettes de protection. Porter un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la situation le requiert.

Français

Page 23

UTILISATION ET ENTRETIEN DE L’OUTIL

• Fixer et soutenir l’ouvrage sur une plate-forme stable au

moyen d’une bride de serrage ou de tout autre dispositif semblable; l’ouvrage est instable lorsqu’on le retient manuellement ou

qu’on l’appuie contre le corps, ce qui pourrait faire perdre la

maîtrise de l’outil.

• Ne pas utiliser l’outil lorsque l’interrupteur de marche-arrêt ne

fonctionne pas; tout outil qui ne peut être commandé au moyen

de l’interrupteur est dangereux et doit être réparé.

• Débrancher le bloc-piles de l’outil ou mettre l’interrupteur en

position de verrouillage ou d’arrêt avant d’effectuer un

réglage, de changer les accessoires ou de ranger l’outil; ces

mesures de sécurité préventives réduisent les risques de démarrage accidentel.

• Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des

enfants ou des personnes non qualifiées; les outils sont dangereux entre les mains de personnes inexpérimentées.

• Lorsqu’on n’utilise pas le bloc-piles, le ranger à l’écart des

objets métalliques tels que les trombones, les pièces de monnaie, les clés, les clous, les vis ou autres petits objets susceptibles

de conduire l’électricité entre les bornes et d’occasionner ainsi des

étincelles, des brûlures ou un incendie.

• Vérifier les pièces mobiles afin de s’assurer qu’elles soient

bien alignées et qu’elles ne restent pas coincées; vérifier

également les pièces afin de s’assurer qu’il n’y ait aucun bris ni

aucune autre condition susceptible de nuire au bon fonctionnement de l’outil. Faire réparer l’outil si ce dernier est endommagé

avant de s’en servir à nouveau, car les accidents sont souvent

causés par des outils mal entretenus.

• N’utiliser que les accessoires recommandés par le fabricant

pour le modèle concerné; un accessoire destiné à un outil particulier peut devenir dangereux lorsqu’il est utilisé avec un autre.

ENTRETIEN

• L’outil doit être entretenu ou réparé par le personnel qualifié

seulement; toute maintenance effectuée par une personne non

qualifiée pourrait entraîner des risques de blessure.

Règles de sécurité additionnelles

AVERTISSEMENT! NE PAS DÉMONTER LE NIVEAU LASER.

L’outil ne comprend aucune pièce interne destinée à être entretenue

par l’utilisateur. Le fait de démonter ce niveau laser annulera toute

garantie appuyant ce produit; on ne doit jamais modifier ce dernier de

quelque manière que ce soit.

Ces dispositifs sont conformes aux dispositions de la partie 15 des

règlements de la FCC. Le fonctionnement doit respecter les deux conditions suivantes : (1) ce dispositif ne doit pas causer de brouillage

nuisible, et (2) ce dispositif doit accepter tout brouillage qu’il reçoit, y

compris celui qui cause un fonctionnement indésirable. REMARQUE

: les essais ont démontré que cet appareil respecte les limites régissant un dispositif numérique de classe B, conformément aux dispositions de la partie 15 des règlements de la FCC. Le but de ces limites

est de fournir une protection raisonnable contre le brouillage nuisible

dans une installation résidentielle. Cet appareil génère, utilise et peut

produire une énergie radiofréquence rayonnée et, lorsqu’il n’est pas

installé et utilisé conformément aux directives, peut causer le brouillage nuisible des communications radio. Cependant, il n’existe

aucune garantie que le brouillage ne se produira pas dans une installation particulière. Si cet appareil entraîne le brouillage nuisible de la

réception radio ainsi que celle des programmes de télévision, ce qui

peut être déterminé en allumant et en éteignant l’appareil, on invite

l’utilisateur à tenter de corriger le problème relié au brouillage au

moyen de l’une des deux méthodes suivantes : en réorientant ou en

déplaçant l’antenne de réception, en augmentant l’espace entre

l’appareil et le récepteur ou en raccordant l’appareil à une prise

murale reliée à un circuit autre que celui dans lequel le récepteur est

branché. Communiquer avec le distributeur ou un technicien de radio

ou de téléviseur qualifié pour obtenir de l’aide.

21

Français

Page 24

22

Cet appareil numérique de la classe B est conforme à la norme NMB003 du Canada" there are marks over the 1st e in “numerique” and

the a after conforme.

ATTENTION : Quelques outils avec de grands paquets de batterie

se tiendront droits sur le paquet de batterie mais peuvent être facilement frappés plus de. Quand pas en service, placez l'outil de son côté

sur une surface stable où il ne causera pas un risque de déclenchement ou en chute.

• L’étiquette de l’outil peut comporter les symboles suivants.

V......................volts A ....................ampères

Hz....................hertz W ....................watts

min ..................minutes ..................courant alternatif

..............courant continuno.................... sous vide

....................construction …/min ............tours ou courses

........................de classe II ........................à la minute

....................borne de mise ..................symbole

........................à la terre ........................d´avertissement

Consignes de sécurité importantes

concernant les bloc-piles

L’outil est alimenté au moyen d’un bloc-pile DEWALT de 9,6, de 12,0

de 14,4 ou de 18 volts. Au moment de commander un bloc-pile de

rechange, s’assurer d’inclure le numéro de catalogue et la tension

appropriée. Les bloc-piles à durée prolongée durent plus longtemps

que les bloc-piles standard. Consulter le diagramme à la fin du

présent manuel afin de vérifier la compatibilité du chargeur avec le

bloc-pile.

REMARQUE : Bien que l’outil puisse fonctionner au moyen de l’un ou

l’autre de ces bloc-piles, on doit s’assurer d’en choisir un de tension

appropriée. Un bloc-pile perd graduellement sa charge s’il n’est pas

laissé dans le chargeur; il est donc recommandé de le laisser dans le

chargeur en tout temps.

Le bloc-pile n’est pas complètement chargé au moment de sa livraison. Avant d’utiliser le bloc-pile et le chargeur, lire attentivement toutes

les consignes de sécurité énumérées ci-dessous et suivre les méthodes de chargement précisées ci-dessous.

LIRE TOUTES LES DIRECTIVES

• NE PAS incinérer le bloc-pile même s’il est gravement endommagé ou complètement usé, car il pourrait exploser en présence

de flammes.

• Les cellules peuvent subir une fuite légère par suite d’un

usage extrême ou d’une exposition à certaines températures;

cela n’indique pas un problème. Cependant, si le scellant externe

est percé et le liquide entre en contact avec la peau, on doit:

a. se laver rapidement la partie du corps touchée avec de l’eau

savonneuse;

b. neutraliser l’effet au moyen d’un acide doux tel que du jus de

citron ou du vinaigre;

c. si les yeux sont touchés, les rincer à fond avec de l’eau propre

pendant au moins 10 minutes et consulter immédiatement un

médecin. (REMARQUE AUX FINS MÉDICALES : ce liquide

contient une solution composée de 25 à 35 % d’hydroxyde de

potassium).

• Ne recharger les blocs-piles que dans des chargeurs D

EWALT.

• NE PAS immerger le chargeur ou le bloc-pile dans l’eau ou tout