Page 1

SERVICE MANUAL

A3 Color Laser Printer

EPSON AcuLaser C9200N

Page 2

Manual Configuration

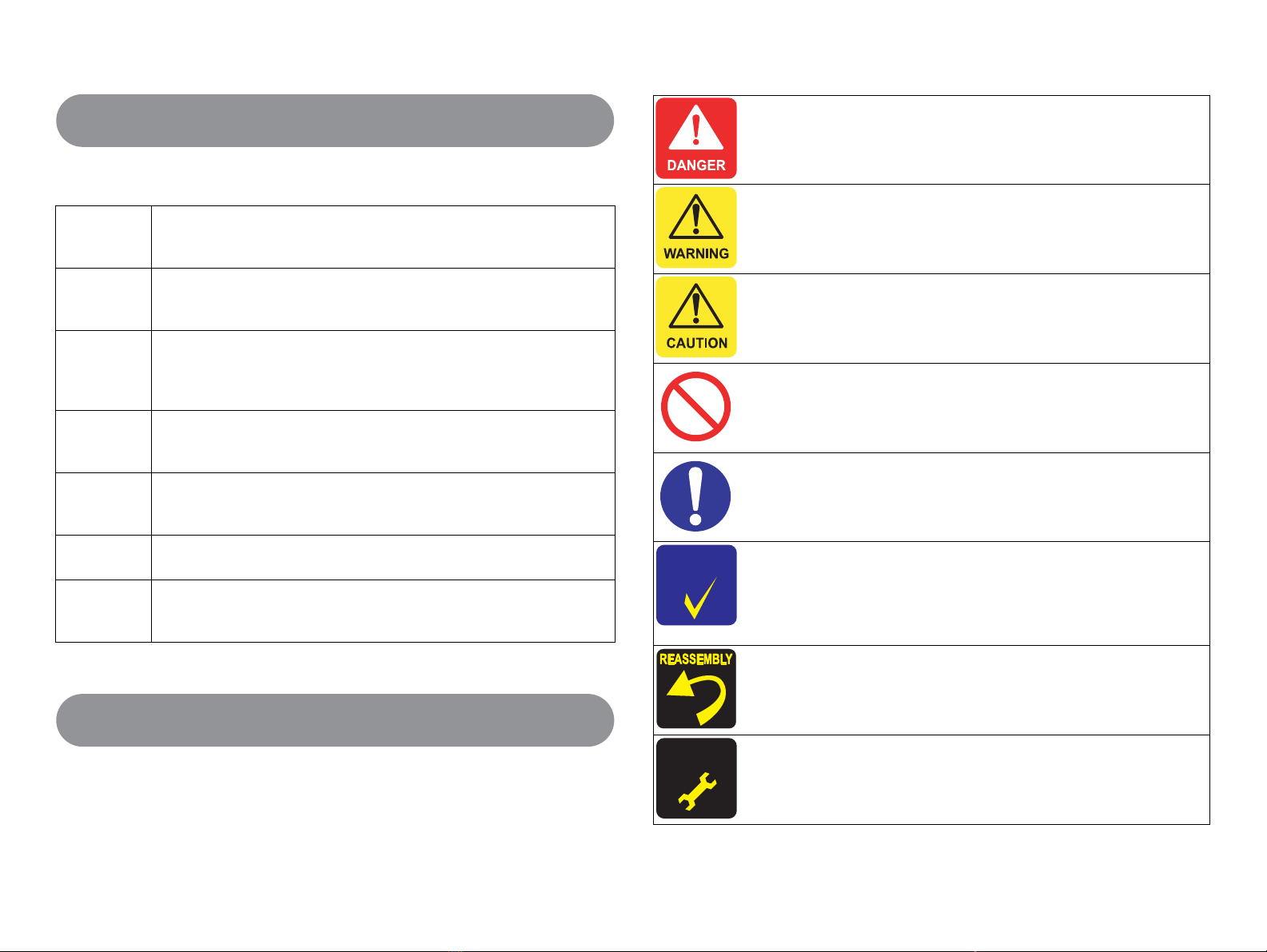

Symbols Used in this Manual

Indicates an operating or maintenance procedure, practice or

C H E C K

P O I N T

A D J U S T M E N T

R E Q U I R E D

condition that, if not strictly observed, would result in injury or loss

of life.

This manual consists of the following seven chapters:

CHAPTER 1 PRODUCT DESCRIPTIONS

Describes the main features, basic specifications, consumable produ cts,

periodic replacement parts, and controller interface of the product.

CHAPTER 2 OPERATING PRINCIPLES

Describes each mechanism configurations and explains fundamental

operating principle of major components including the control system.

CHAPTER 3 TROUBLESHOOTING

Describes the troubleshooting procedures that can help you diagnose and

resolve problems. The problems are sorted by displayed error codes and

phenomena of abnormal image output.

CHAPTER 4 DISASSEMBLY/ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

of the product.

CHAPTER 5 ADJUSTMENT

Describes the settings and the adjustments to be performed during the

maintenance work.

CHAPTER 6 MAINTENANCE

Describes preventive maintenance procedures.

CHAPTER 7 APPENDIX

Provides the additional information such as panel operations, connector

pin layouts, parts list, and exploded diagrams for reference.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in personal

injury or may cause damage to, or destruction of equipment.

Indicates a prohibited action during maintenance work.

Indicates a mandatory action during maintenance work.

Indicates an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently .

Provides addi tional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates a product reassembly procedure, practice or condition

that must be executed in accordance with the specified standards to

maintain the product’s quality.

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be sure to read and understand the information with these

symbols.

Indicates an operating or maintenance procedure, practice or

condition that must be executed in accordance with the specified

standards to maintain the product’s quality.

Confidential

Page 3

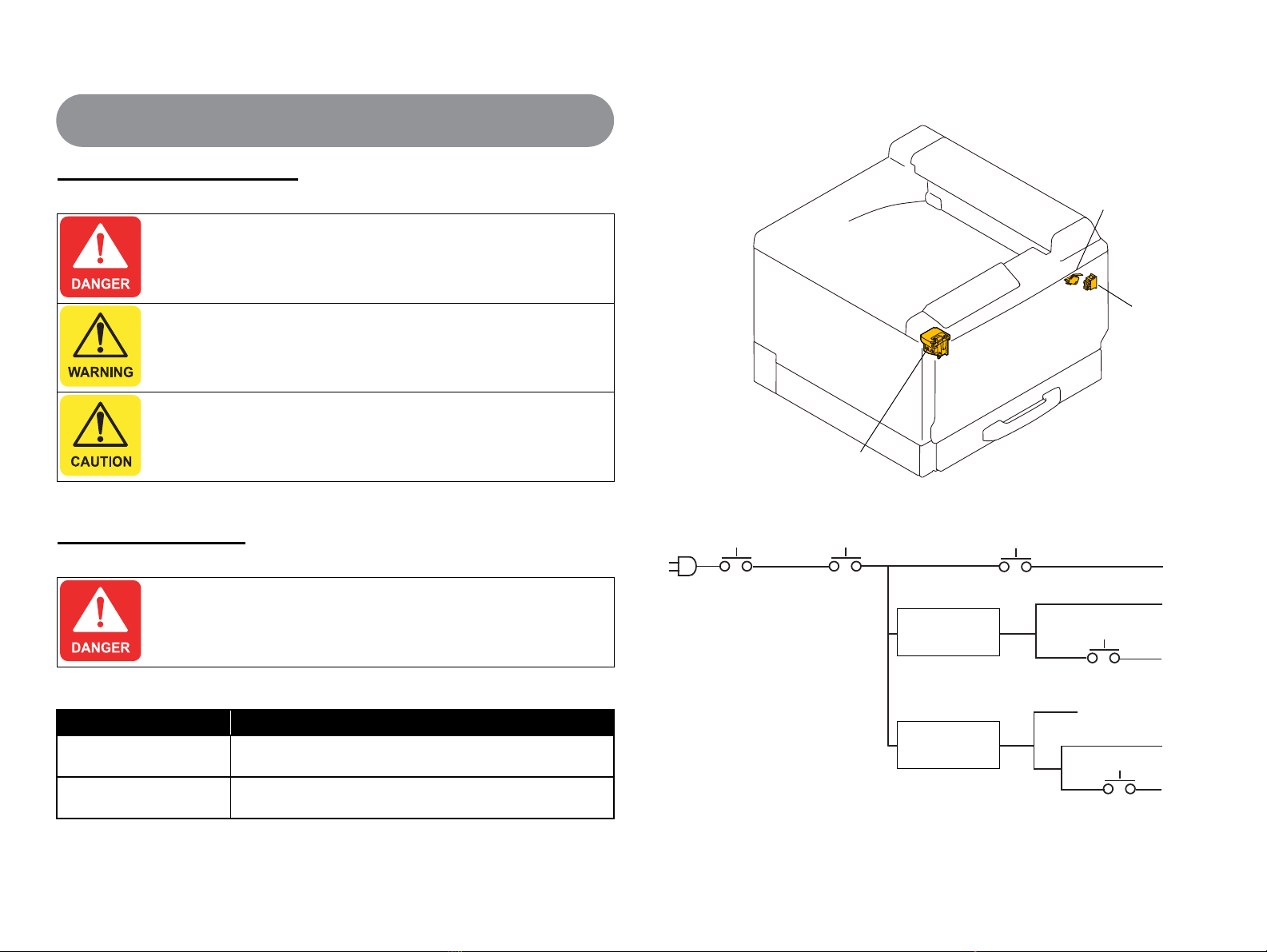

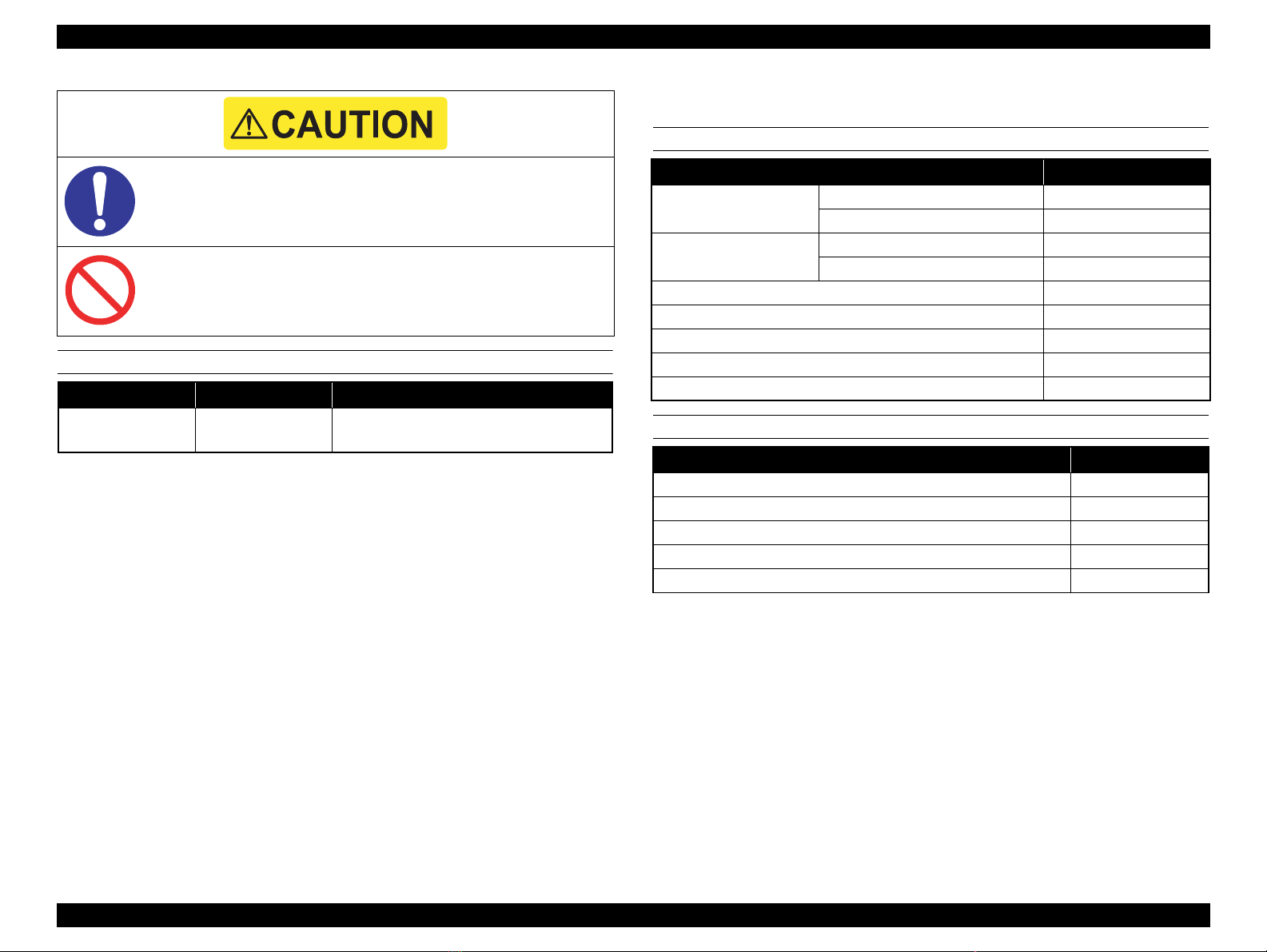

Safety-related Symbols

Safety

Right Door SW

Front Door SW

Front Door SW

Main Power Switch Sleep Relay Heater Relay

1

2

3

Front Door SW

/Right Door SW

Main DC Power

Supply

Sub DC Power

Supply

24V

3.3V

5V

Power supply to board

Front Door SW

4

5

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, would result in injury or loss

of life.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in personal

injury or may cause damage to, or destruction of equipment.

Safety Equipment

Location of Safety Equipment

Safety System Wiring Schematic

Never deactivate the safety equipment installed on the product for

any reason whatsoever. (e.g. Making a connection circuit bypasses

the safety equipment.)

List of Safety Equipment

Name Function/Purpose

Interlock switch (Front Door

SW/Right Door SW)

Interlock switch (Front Door

SW)

Shuts off 24 V DC power line when the Front Door or Right Door

is opened.

Shuts off 5V/3.3V DC power line when the Front Door is opened.

4039T2C133AA

Confidential

Page 4

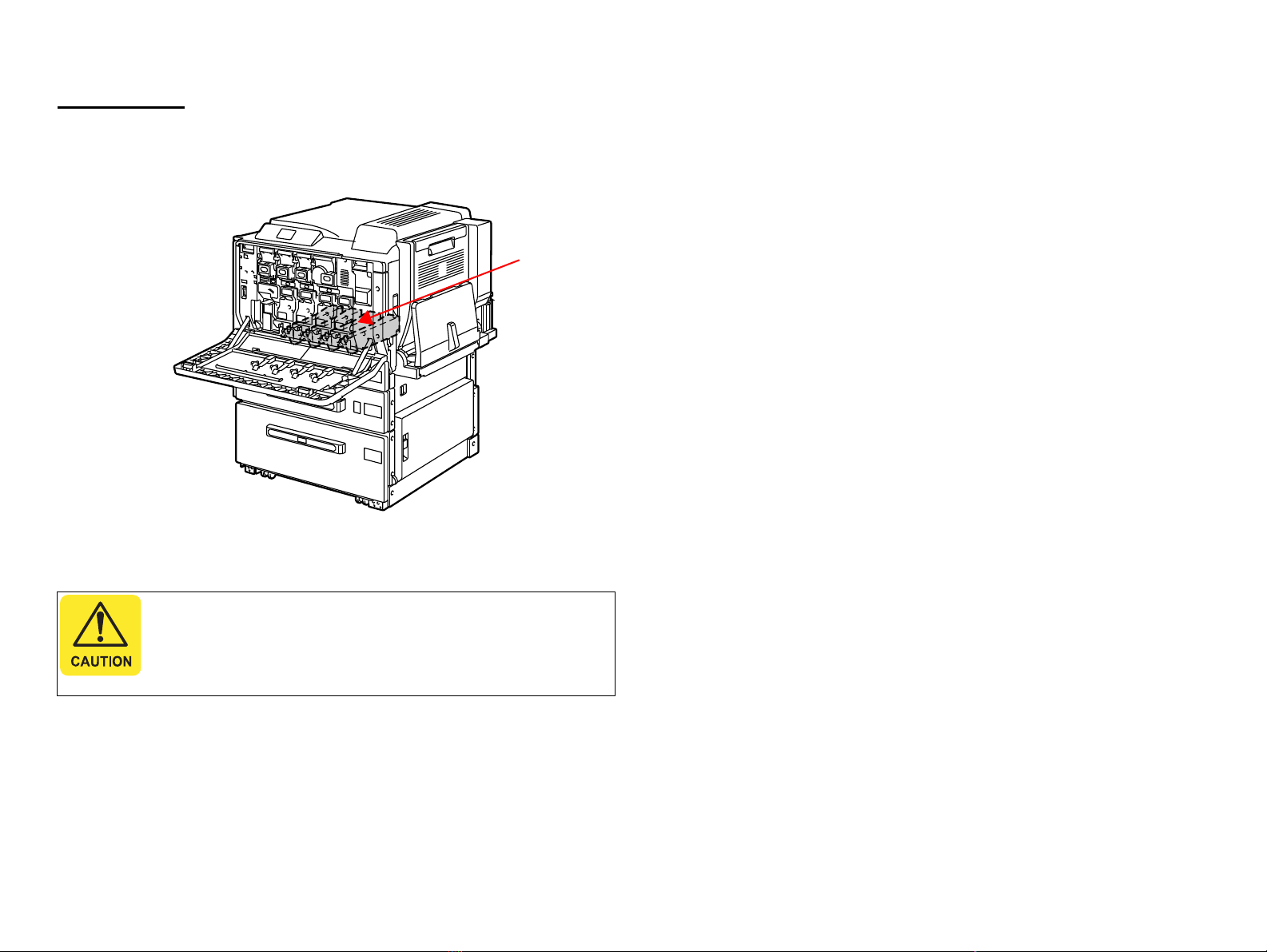

Laser Beam

Laser Openings

Laser Opening Location

Handling Precautions

Disassembling and adjustment procedures not specified herein

may result in hazardous radiation exposure.

Do not d isassemb le or at tempt to adjust the PH unit for any

reason whatsoever. When the PH unit malfunctions, replace it

with a new one.

Confidential

Page 5

Prohibited Matters

Never deactivate the safety equipment installed on the product for any reason

whatsoever.

Never modify the safety equipment or replace it with part not approved by

EPSON. Doing so may cause the safety functions to stop working properly, and

may result in fire or injury.

Never modify the product. If you are instructed to do so, however, fully

understand the instruction and perform the modification.

To prevent an electric shock, burn, injury, etc., always turn the

printer off and unplug the power cord before starting maintenance

work. When the power supply cable must be connected to measure

voltage or for any other task, strictly follow the instructions and use

extreme caution in working on electronic components.

Pay particular attention to the high-voltage part indicated with the

symbol on the left.

Do not touch the high temperature parts indicated with the symbol

on the left. Those parts are extremely hot immediately after use. If

you need to replace those parts, leave the printer until it cools.

Connect the printer to an electrical outlet that matches the printer’s

rated voltage and power requirements.

Do not connect any other devices to the electrical outlet supplying

the printer. Doing so can cause overloading of the electrical circuit

and may cause a fire.

Do not use extension cords or power adapters to plug multiple

devices into the same outlet. Power plug and electrical outlet should

be free from dust or foreign objects.

The printer should be properly grounded to prevent electric shock.

The grounding terminal should be one of the followings:

a. One of the electrical outlet

b. One that is grounded by a D-type grounding construction.

(The former third-type grounding construction; grounding

resistance under 100 Ω).

Power cord should not be deformed or damaged. If the cord is

damaged, replace it with a new one dedicated for the product.

Use the specified service parts for repair and maintenance.

When using compressed air products; such as air duster, for

cleaning during repair and maintenance, the use of such products

containing flammable gas is prohibited.

After replacing the Fuser Unit or any other parts to which AC

voltage is applied, be sure to check the part is properly installed and

the connecting cables are not caught between metal parts.

Otherwise a fire or an electric shock may occur.

Fuse on the Power Supply Unit must not be replaced under any

circumstances.

Confidential

Page 6

Before performing repair and maintenance work, read and

understand the documents of the product (e.g. service manual).

Be sure to follow the specified steps and use the prescribed tools

described in the documents.

When disassembling or assembling the product, make sure to wear

gloves to avoid injury from metal parts with sharp edges.

Take care not to drop any screws, washers, or clips inside the

printer body. Should it fall in, do not boot up your printer until the

part has been safely removed.

After reassembling the printer, make sure all the parts and the

screws are put back in place and the cables are not caught between

metal parts.

Do not use vacuum cleaner for home use to clean up spills of

powdered toners. The very fine particles can cause fire/explosion.

Sweep them thoroughly with a broom or wipe them with a cloth

moistened with neutral detergent. If a large amount of toner is

spilled, use a toner vacuum designed specifically to clean toner.

Ozone gas is generated by the printer as a by-product of the

printing process. The amount of gas is too small to be harmful,

however, some users may feel uncomfortable under the following

conditions. It is desirable to advice the users to ventilate the room

when using the printer.

When using the printer for a long period of time in a room with

poor ventilation.

When printing a large amount of documents at a time.

When using multiple printers in the same room.

In order to protect sensitive microprocessors and circuitry, use

static discharge equipment, such as anti-static wrist straps, when

accessing internal components.

Though toner and developer are safe for human body, they may

cause irritation to skin and eyes. If toner gets into your eyes, wash it

away immediately with water. If irritation continues, see a physician.

If toner gets in your mouth, rinse immediately with plenty of water.

If swallowed, induce vomiti ng and consult a physician.

Do not throw used toner cartridges or toner into the flames.

Do not use thinner or alcohol when cleaning the product as it may

result in discoloration or deformation.

Make sure an antivirus software is installed on the computer used

for service support. Be sure to have the latest virus definition file for

the software.

Confidential

Page 7

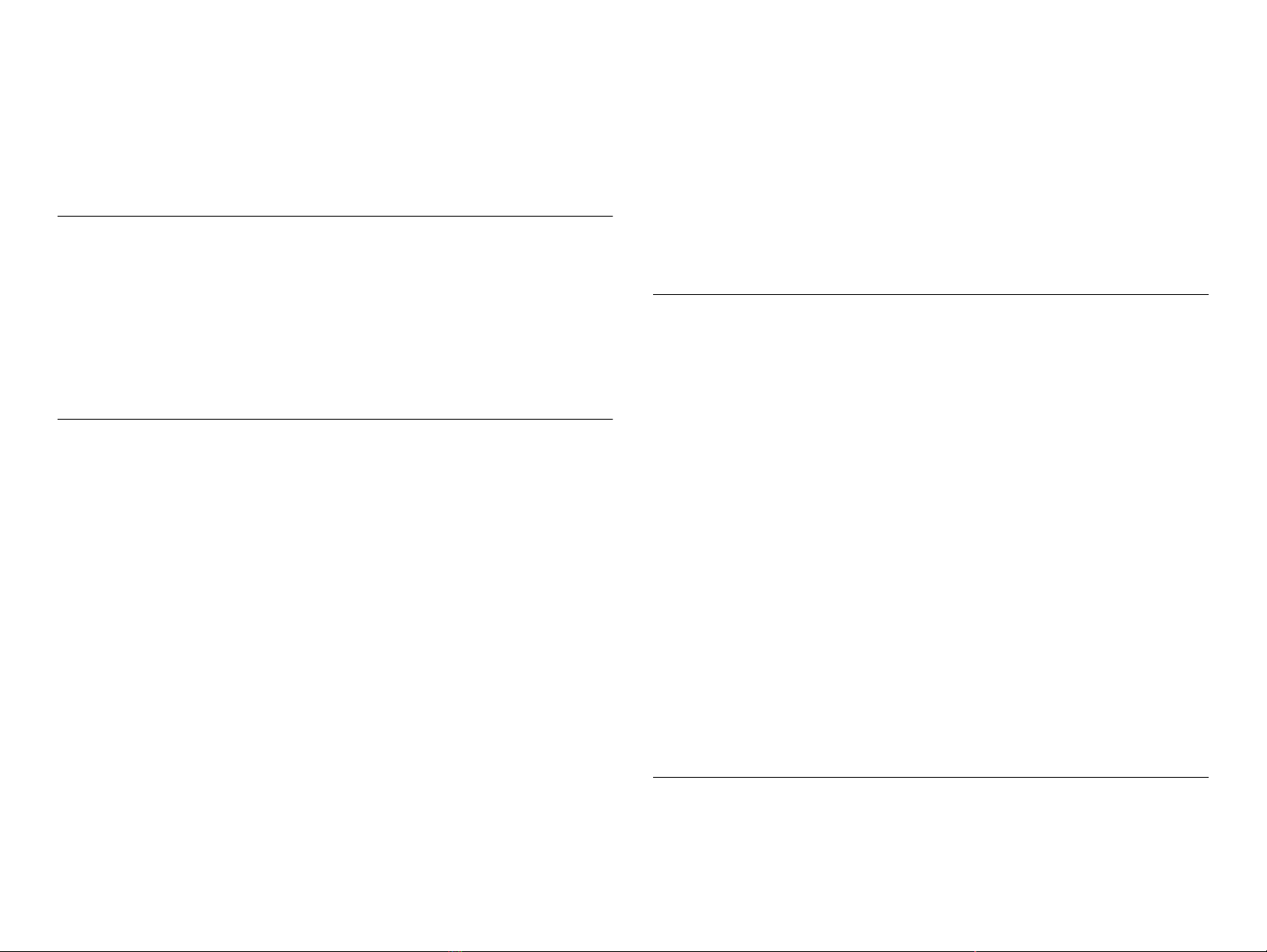

This manual is revised when the system, component, or part of the product is modified as a result of continuing improvements to the product’s performance and fu nctions.

Revision History

See the table below for recent updates.

Revision Date of Issue Description

A July 25, 2008 First Release

B October 14, 2008 Revision:

Chapter 2

2.2.2 Parts layout drawing: revised the contents partially.

Chapter 3

Table 3-17 Error Code List: revised the contents partially.

Revised E555.

Chapter 5

Table 5-3 Update method for Firmware: revised the contents.

Chapter 7

In 7.2 Wiring Diagram: added connector CNDM3.

7.5.5 Maintenance Status Sheet: revised the contents partially.

C May 17, 2010 Revision:

Chapter 1

1.2.1 Error Message and Troubleshooting was added.

1.2.2 Warning Message and Troubleshooting was added.

Chapter 3

3.3.4 Other Errors was added.

Chapter 4

Mechanical Control Board (PWB-M): revised the assembling directions partially.

D September 8, 2010 Revision:

Chapter 3

3.3.2 Solution to Engine-Related Error revised the contents partially. (E553)

Chapter 7

7.6 Exploded Diagram / Parts List: revised the contents partially.

Confidential

Page 8

Contents

Chapter 1PRODUCT DESCRIPTION

1.1 Product Specifications........................................................... ............................. 12

1.1.1 Basic Specifications................................................................................. 12

1.1.2 Paper Specifications ................................................................................ 17

1.1.3 Replacement Parts................................................................................... 20

1.1.4 Controller Specifications......................................................................... 21

1.2 List of Printer Messages..................................................................................... 22

1.2.1 Error Message and Troubleshooting ....................................................... 25

1.2.2 Warning Message and Troubleshooting.................................................. 28

Chapter 2OPERATING PRINCIPLES

2.1 Print Process....................................................................................................... 32

2.2 Operating Principle of Main Unit Mechanism................................................... 33

2.2.1 Center cross section................................................................................. 33

2.2.2 Parts layout drawing................................................................................ 35

2.2.3 PH Unit........................................ .................................. .......................... 38

2.2.4 Photoconductor Unit section (PU section).............................................. 41

2.2.5 Photo Conductor section.......................................................................... 43

2.2.6 Charge Corona section ............................................................................ 44

2.2.7 Developing section.................................................................................. 46

2.2.8 Toner Supply section........................................................................ ....... 51

2.2.9 Transfer Corona section .......................................................................... 54

2.2.10 Toner Collecting section........................................................................ 63

2.2.11 Paper feed section (Standard Cassette)............... .................................. . 66

2.2.12 Bypass section (MP tray)....................................................................... 69

2.2.13 Registration Roller section................ .................................. .................. 72

2.2.14 Fusing section...................................................................... .................. 74

2.2.15 Paper exit section............................................. .................................. .... 81

2.2.16 Image stabilization control............. ....................................................... 82

2.2.17 Life management................................................ .................................. . 83

2.3 Operating principle of Option mechanism ......................................................... 85

2.3.1 Optional Cassette..................................................................................... 85

2.3.2 Duplex Unit............................................................................................. 89

2.4 Other Control............................... ................................................................ ....... 94

2.4.1 Fan Control.............................................................................................. 94

2.4.2 Engine Section Parts Operated When the Main Power Switch is Turned ON

95

Chapter 3Troubleshooting

3.1 Overview............................................................................................................ 97

3.1.1 Procedure Outline for Troubleshooting................................................... 97

3.1.2 Preliminary Check................................................................................... 97

3.1.3 Precautions in Performing Troubleshooting Work ................................. 98

3.1.4 Troubleshooting Flowchart ..................................................................... 98

3.2 Jam Display........................................................................................................ 99

3.2.1 Checking a paper jam type and jammed location.................................... 99

3.2.2 Sensor layout......................................................................................... 101

3.2.3 Solution ..................................................... .................................. .......... 102

3.3 Service Call Error............................................................................................. 107

3.3.1 Error code.............................................................................................. 107

3.3.2 Solution to Engine-Related Error.......................................................... 113

3.3.3 Controller Related Error............................................. ........................... 129

3.3.4 Other Errors................................................................................. .......... 131

3.4 Power supply trouble........................................................................................ 134

3.4.1 Machine is not energized at all (PU1 operation check)......................... 134

3.4.2 Control panel indicators do not light..................................................... 134

3.4.3 Fusing Heaters do not operate............................................................... 135

3.4.4 Power is not supplied to option ............................................................. 135

3.5 Image quality problem...................................................................................... 136

3.5.1 Initial Check Items ................................................................................ 136

3.5.2 Image Trouble List.............. .................................................................. 136

3.5.3 Solution ..................................................... .................................. .......... 139

Chapter 4DISASSEMBLY AND ASSEMBLY

4.1 Preliminary Check............................................................................................ 157

4.1.1 Tool List................................................................................................ 157

4.1.2 Parts/Units that Should Not be Disassembled....................................... 157

4.1.3 How to Read this Chapter .................................................................... 158

Confidential

Page 9

4.2 List of Disassembly/Reassembly Parts/Units ................................................... 160

4.3 Main Unit Disassembly/Reassembly................................................................ 162

4.3.1 Group 1........................................ .................................. ........................ 162

4.3.2 Group 2........................................ .................................. ........................ 169

4.3.3 Group 3........................................ .................................. ........................ 175

4.3.4 Group 4........................................ .................................. ........................ 193

4.3.5 Group 5........................................ .................................. ........................ 198

4.3.6 Group 6........................................ .................................. ........................ 206

4.3.7 Group 7........................................ .................................. ........................ 210

4.3.8 Group 8........................................ .................................. ........................ 221

4.3.9 Group 9........................................ .................................. ........................ 226

4.3.10 Group 10.............................................................................................. 230

4.3.11 Group 11.............................................................................................. 246

4.3.12 Group 12.............................................................................................. 260

4.3.13 Group 13.............................................................................................. 271

4.3.14 Group 14.............................................................................................. 275

4.3.15 Group 15.............................................................................................. 279

4.3.16 Group 16.............................................................................................. 286

4.3.17 Group 17.............................................................................................. 291

4.4 Others ............................................................................................................... 297

Chapter 5ADJUSTMENT

5.1 Adjustment Item.......................................... .................................. ................... 314

5.2 Adjustment ....................................................................................................... 315

5.2.1 Skew Adjustment................................................................................... 315

5.2.2 MP Tray Mechanical Adjustment ......................................................... 316

5.2.3 Reset Life Counter................................................................................. 317

5.2.4 Writing USB ID..................................................................................... 318

5.3 Firmware Update.............................................................................................. 320

7.4.2 Special Menu................................................ .................................. ....... 349

7.5 Information Sheet............................................................................................. 352

7.5.1 Configuration Status Sheet..................................................... .. ............. 352

7.5.2 Supplies Status Sheet............................................................................. 353

7.5.3 Usage History Sheet.............................................................................. 354

7.5.4 Support Status Sheet.............................................................................. 355

7.5.5 Maintenance Status Sheet...................................................................... 356

7.5.6 Error Log Sheet ..................................................................................... 363

7.6 Exploded Diagram / Parts List ............................. ............................................ 364

Chapter 6MAINTENANCE

6.1 Cleaning............................................................................................................ 332

Chapter 7APPENDIX

7.1 Connection Diagram......................................................................................... 338

7.2 Wiring Diagram ................................................................................................ 339

7.3 Connector Layout Drawing.............................................................................. 346

7.4 Control Panel Special Operations..................................................................... 347

7.4.1 Operation Method & Functions............................................................. 347

Confidential

Page 10

PRODUCT DESCRIPTION

CHAPTER

1

Confidential

Page 11

EPSON AcuLaser C9200N Revision D

1.1 Product Specifications

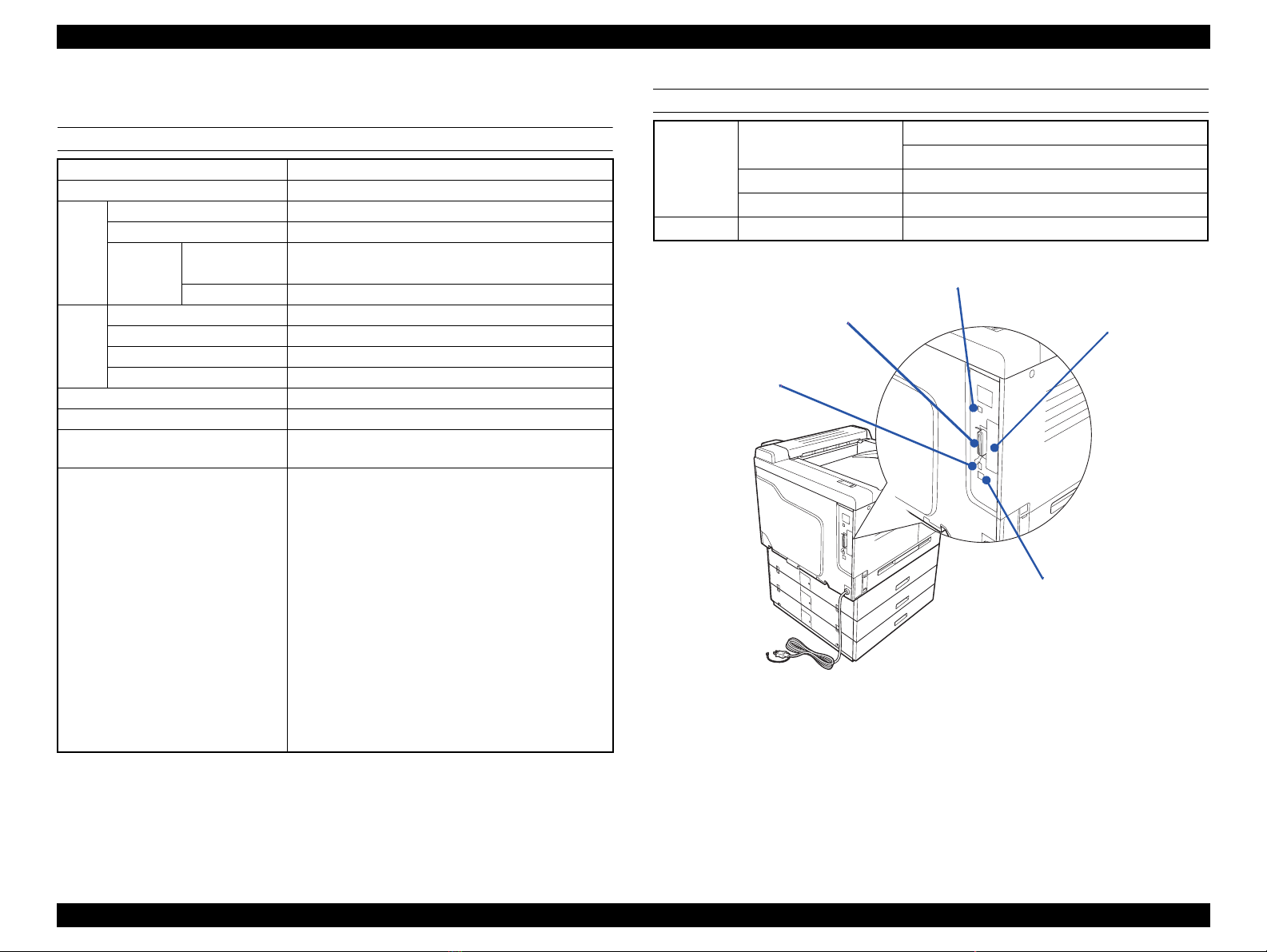

AcuLaser C9200N is a PDL model of a color page printer utilizing laser and

electrophotographic technologies.

1.1.1 Basic Specifications

PRINTER SPECIFICATIONS

Item Specification

Resolution 600 dpi

Print speed*

(Single-sided / Duplex)

Warm-up time 23°C, 55% RH Less than 109 seconds*

First Print Out*

Dimensions (W x D x H) 648 mm x 608 mm x 477 mm

Weight (excluded consumables) 49.5 kg

Power supply AC 110 ~ 120 V: 50 Hz / 60 Hz ± 3 Hz

Power consumption Max. 110 ~ 120 V: Less than 1340 W

Life*

Durability Average: 4,000 pages / month

1

3

4

Color 25.6 ppm / 23.8 ppm

Monochrome 25.6 ppm / 23.8 ppm

Less than 109 seconds*

Color 11.4 seconds

Monochrome 8.1 seconds

AC 220 ~ 440 V: 50 Hz / 60 Hz ± 3 Hz

220 ~ 240 V: Less than 1390 W

Color printing 110 ~ 120 V: 581 W

220 ~ 240 V: 576 W

Monochrome printing 110 ~ 120 V: 543 W

220 ~ 240 V: 522 W

Ready (Heater ON)

(Average)

Sleep Less than 11 W

Stand by 0 W

110 ~ 120 V: 139 W

220 ~ 240 V: 146 W

600,000 pages or five years, whichever

comes first

Max: 10,000 pages / month

2

(120 V)

2

(230 V)

Item Specification

Noise Printing 52 dB

Standby 40 dB

Storage and

transportation

conditions

*1: Conditions: A4, plain paper, continuous printing

The values vary depending on paper type and size.

*2: Less than 109 seconds from sleep mode. (120 V)

Less than 109 seconds from sleep mode. (230 V)

*3: Paper feeder = MP tray, Standard Cassette or Optional Cassette 1

Paper size = A4

*4: A4, continuous printing, independent of color/monochrome ratio.

*5: No condensation

Temperature and

humidity

Temperature: 0 ~ 35 °C

Humidity: 30 ~ 85 % RH*

5

OPTIONAL UNIT

Optional

cassette

Duplex Unit Paper size: A3F, A3, A4, A5, B4, B5, Letter, LGL, B, GLG, GLT, EXE,

Capacity: Up to 500 sheets

Paper size: A3, A4, B4, B5, Letter, LGL, B, F4

F4, Double postal card, 4-sided postal card

PRODUCT DESCRIPTION Product Specifications 12

Confidential

Page 12

EPSON AcuLaser C9200N Revision D

1

9

8

7

6

5

4

2

3

3

4

5

7

8

6

2

1

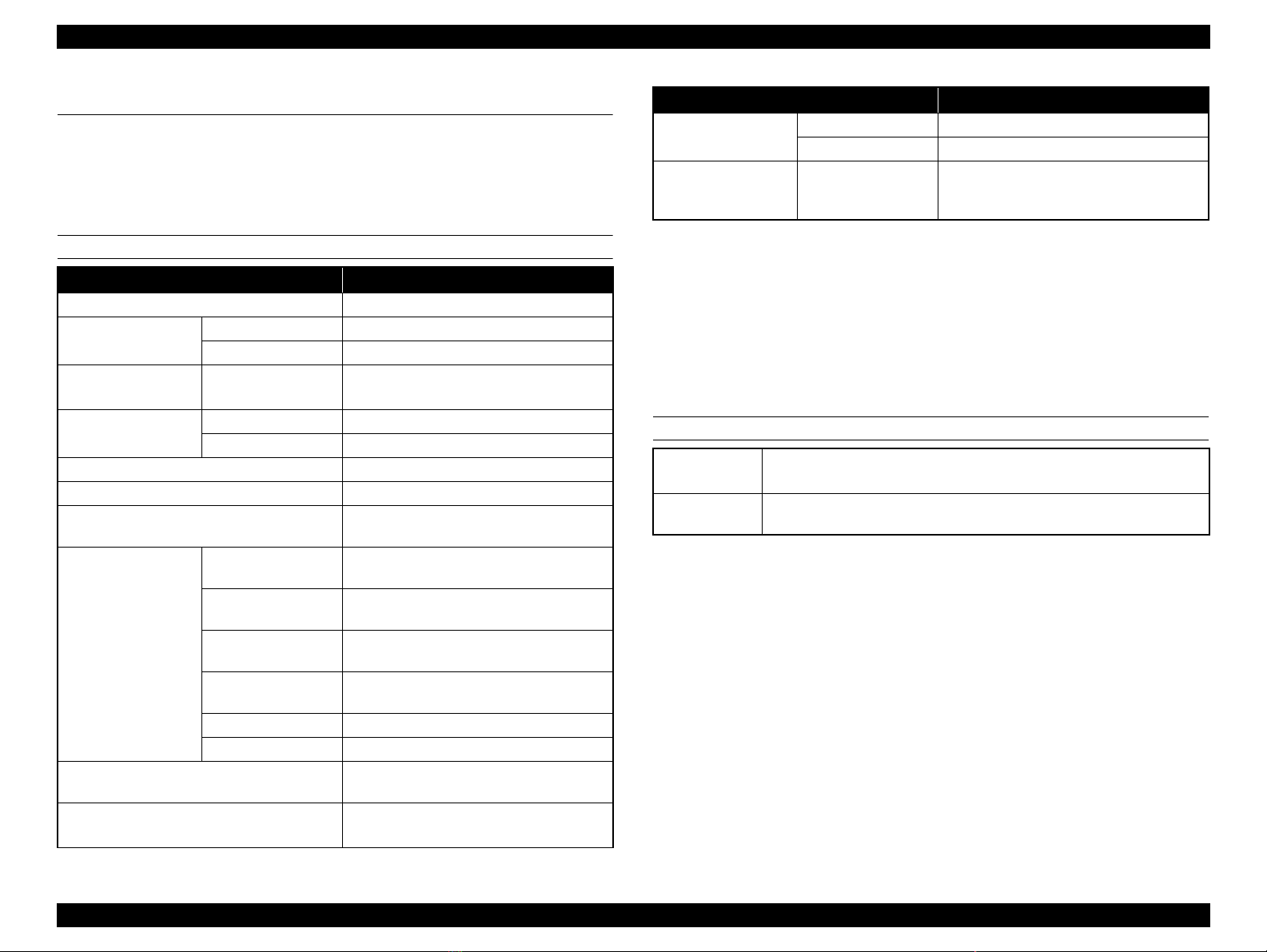

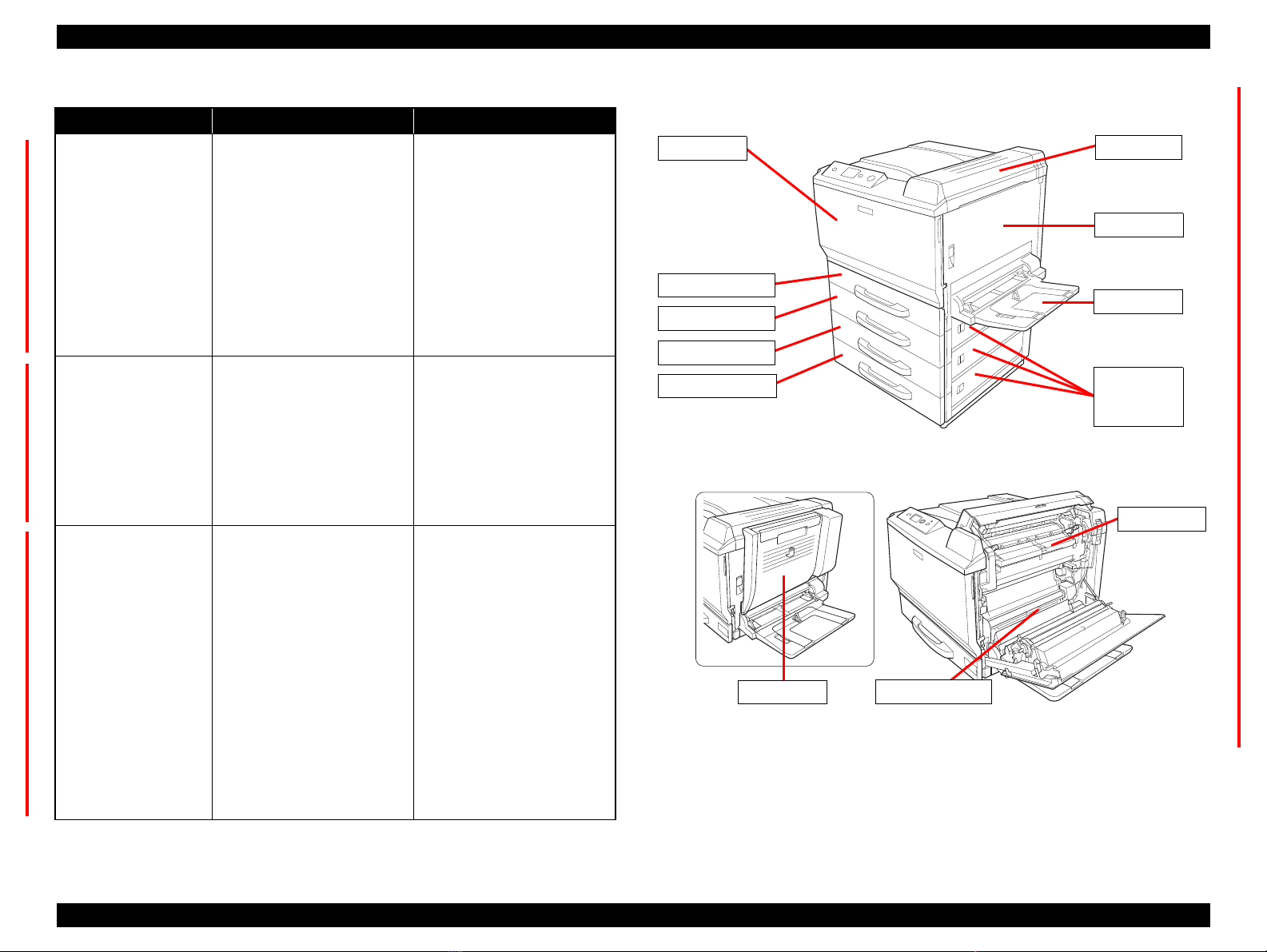

EXTERNAL VIEW AND PART NAMES

Table 1-1. Part Names

No. Name No. Name

1 Control Panel 6 MP Tray

2 Output Tray 7 Paper Indicator

3 Cover B 8 Standard Cassette

4 Odor filter 9 Cover F (Front Door)

5 Cover A (Right Door)

Table 1-2. Part Names

No. Name No. Name

1 Exhaust filter 5 AC inlet

2 Left side cover 6 Service connector

3 Type-B interface card slot cover 7 Parallel interface connector

4 Ethernet interface connector 8 USB interface connector

Figure 1-2. Rear view

Figure 1-1. Front view

PRODUCT DESCRIPTION Product Specifications 13

Confidential

Page 13

EPSON AcuLaser C9200N Revision D

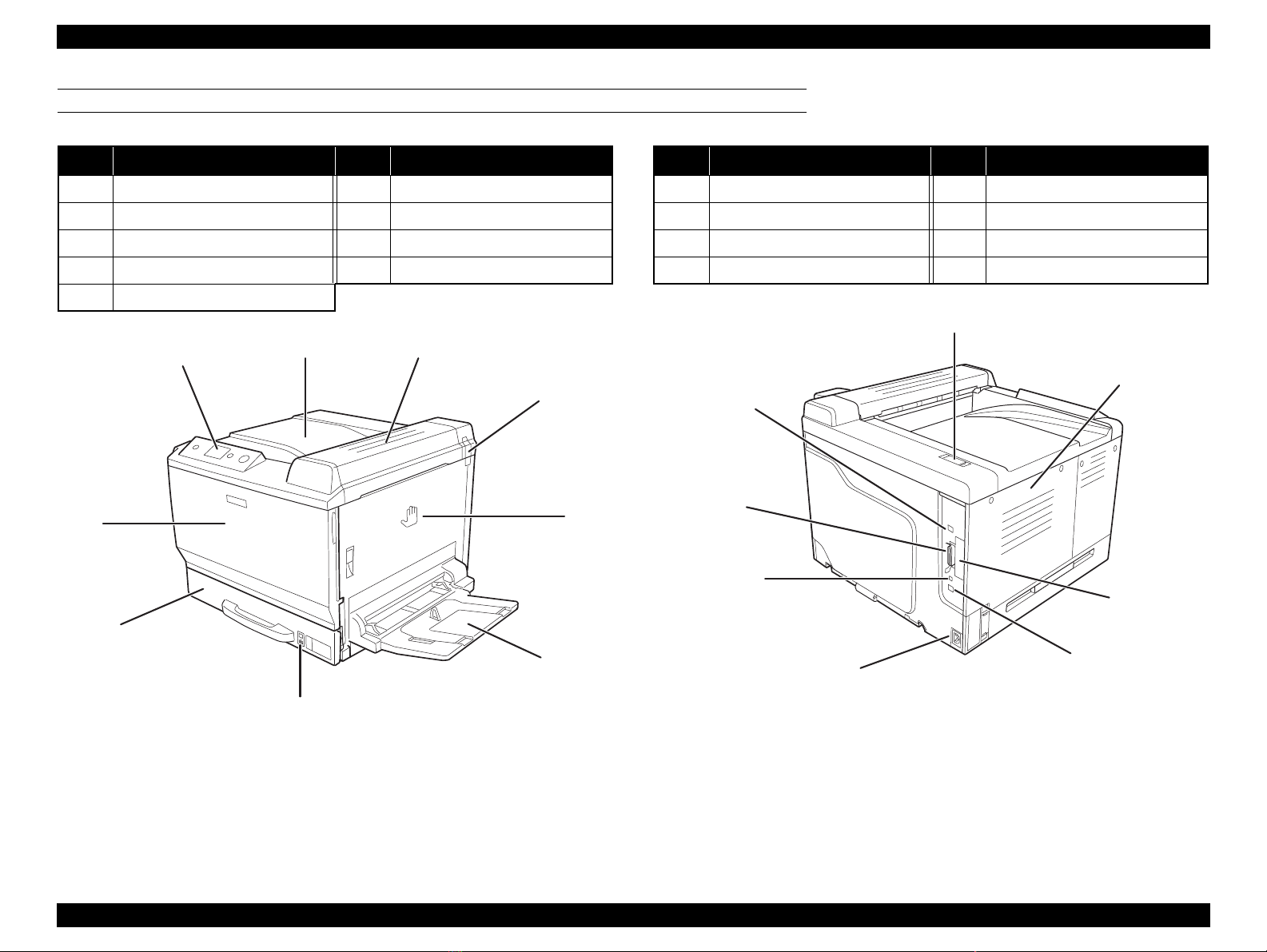

12

13

Table 1-3. Part Names

No. Name No. Name No. Name

1 Toner Cartridge (Yellow) 6 Photoconductor unit (Black) 11 Power switch

2 Toner Cartridge (Magenta) 7 Photoconductor unit (Cyan) 12 Cover H

3 Toner Cartridge (Cyan) 8 Photoconductor unit (Magenta) 13 Paper path G

4 Toner Cartridge (Black) 9 Photoconductor unit (Yellow)

5 Exposure window cleaning bar 10 Waste toner collector

1

2

3

4

5

11

10

9

6

7

8

Figure 1-3. Inside the printer

PRODUCT DESCRIPTION Product Specifications 14

Confidential

Page 14

EPSON AcuLaser C9200N Revision D

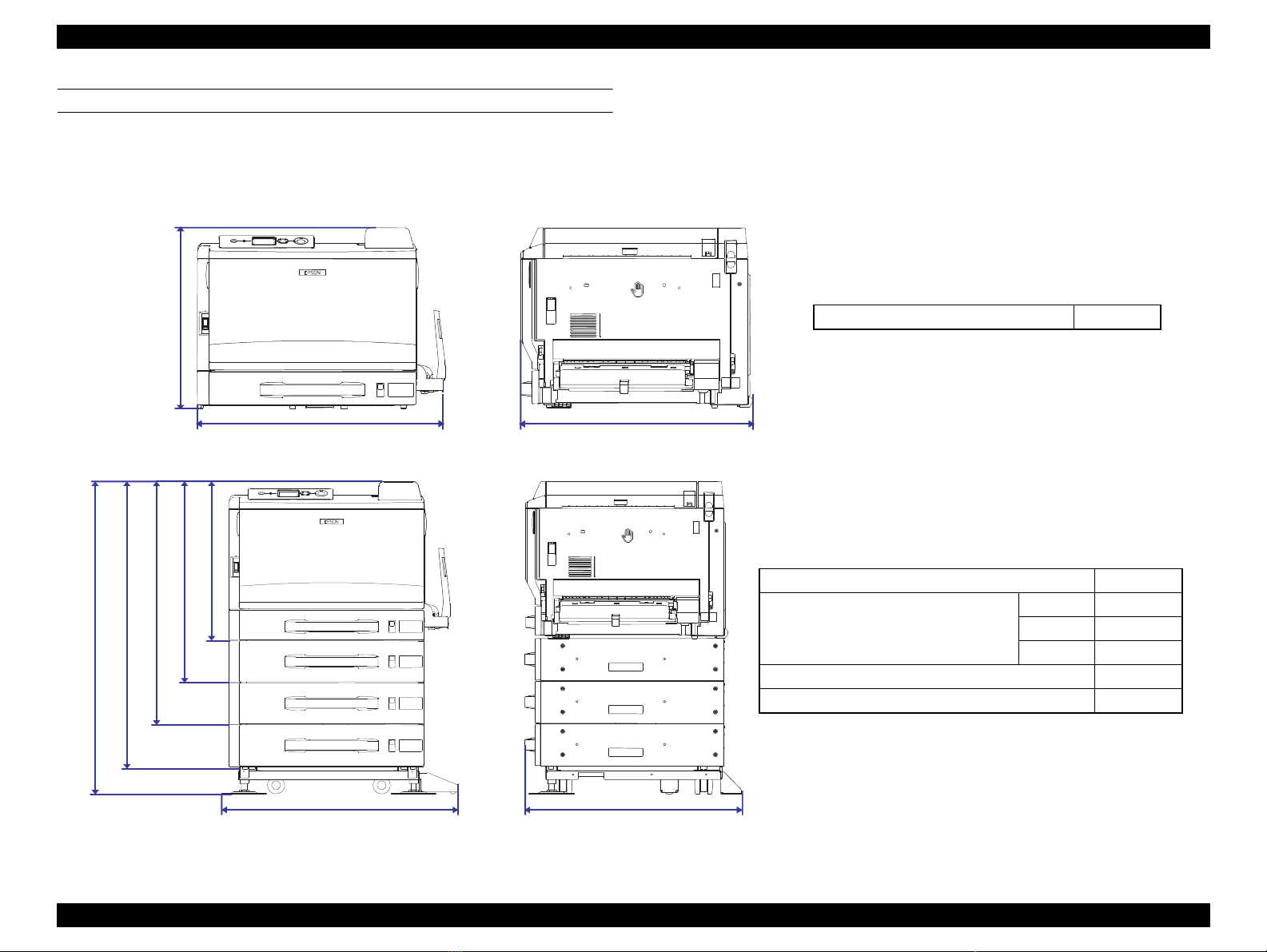

608 mm648 mm

477 mm

Main Unit 49.5 kg

629 mm699 mm

937 mm

Optional Cassette 14.8 kg

Main Unit + Optional Cassette 1 level 64.3 kg

2 levels 79.1 kg

3 levels 93.9 kg

Main Unit + Duplex Unit 52.8 kg

Main Unit + Optional Cassettes (3 levels) + Printer stand 102.4 kg

849 mm

725 mm

601 mm

477 mm

DIMENSIONS AND WEIGHT

The following figure shows the dimensions and weight of the printer.

NOTE 1 : Manufacturing tolerance is ±5 mm in dimensions and ±0.5 kg in weight.

2 : Consumables are not included in the weight of the main unit.

Figure 1-4. Main Unit

Figure 1-5. Main Unit with Optional Units Installed

PRODUCT DESCRIPTION Product Specifications 15

Confidential

Page 15

EPSON AcuLaser C9200N Revision D

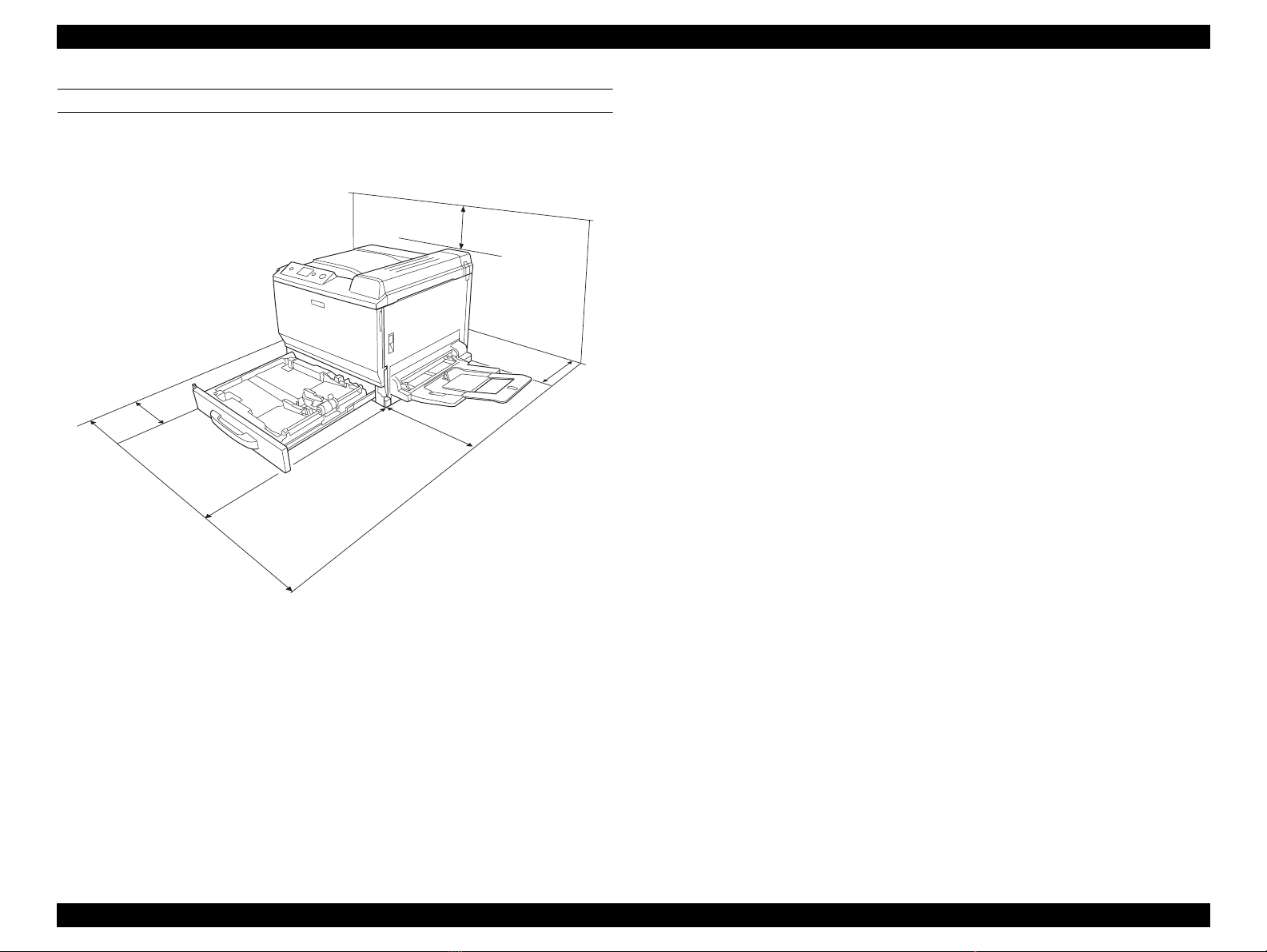

300 mm

200 mm

450 mm

820 mm

1125 mm

100 mm

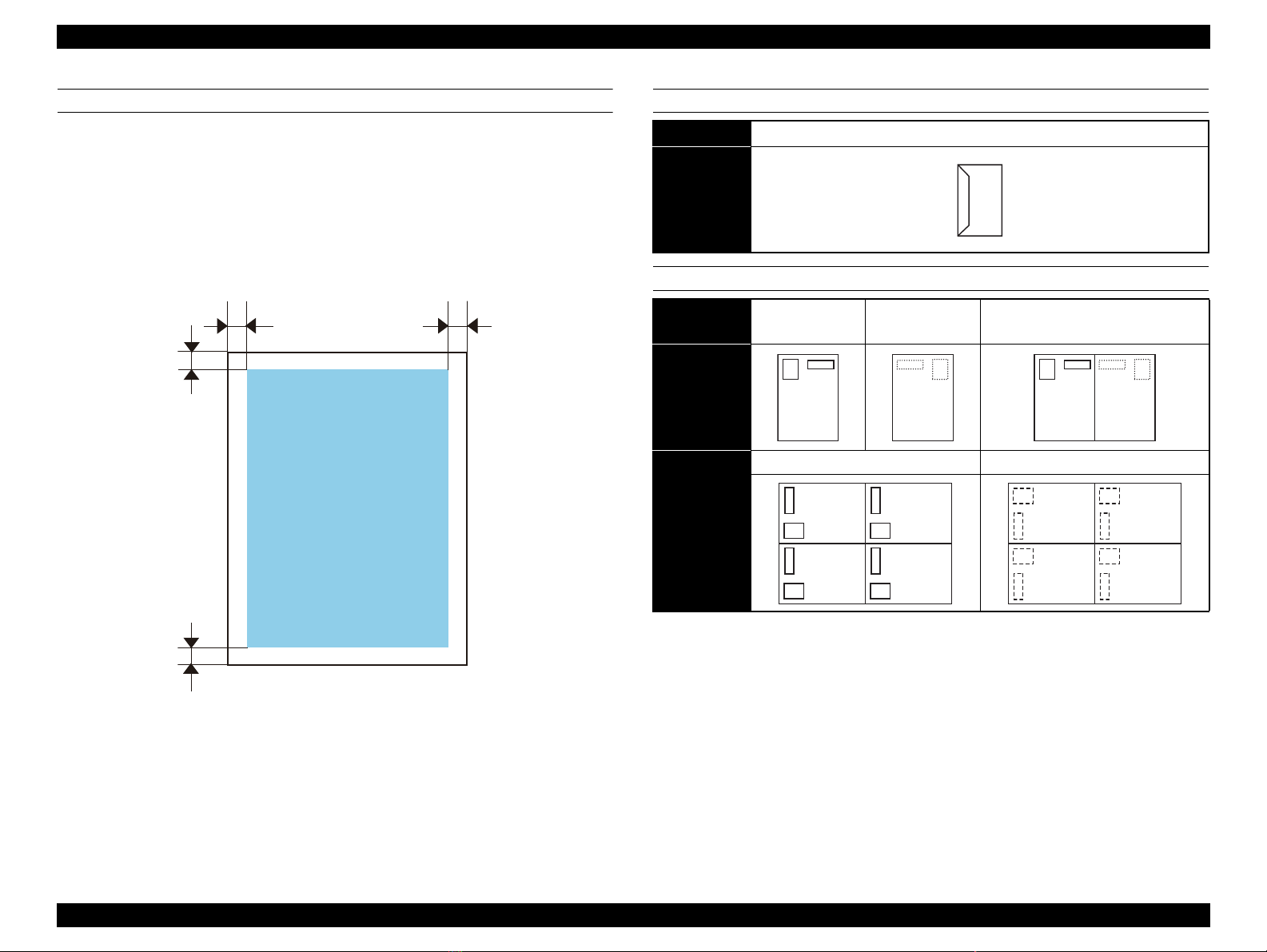

INSTALLATION SPACE REQUIREMENTS

The following figure shows the dimensions of the space required around the printer.

Be sure to provide the space for installation, operation, and maintenance.

Figure 1-6. Installation Space Requirements

PRODUCT DESCRIPTION Product Specifications 16

Confidential

Page 16

EPSON AcuLaser C9200N Revision D

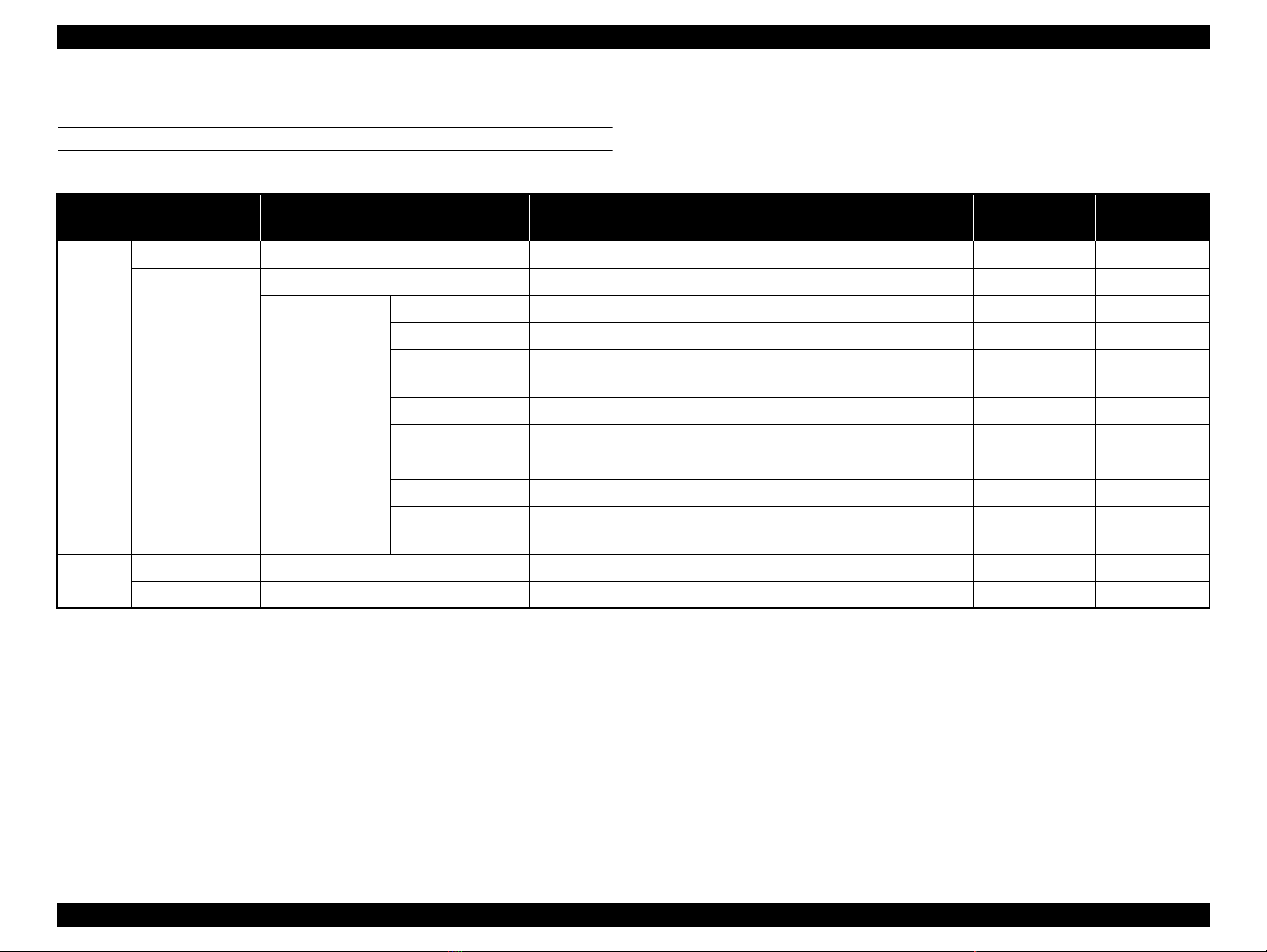

1.1.2 Paper Specifications

SUPPORTED PAPERS

Table 1-4. Supported Papers

Paper Feeder Paper Type* Paper Size

Capacity

(Height)

Weight

Standard Standard Cassette Plain paper / Recycled paper A3F, A3, A4, A5, B4, B5 250 sheets 64 ~ 90 g/m

MP tray Plain paper / Recycled paper A3F, A3, A4, A5, B4, B5, LT, HLT, GLT, LGL, GLG, EXE, B, F4 100 sheets 64 ~ 90 g/m

Special media Transparency A4, LT 10 sheets ---

Coated Paper A3F, A3, A4 10 sheets --Long Paper Width: 210 mm ~ 297 mm

Length: 458 mm ~ 1,200 mm

1 sheets 127 ~ 160 g/m

Postcard Postcard, Double postal card, 4-sided postal card 10 sheets 190 g/m

Labels A4, LT 10 sheets 91 ~ 209 g/m

Thick paper A3F, A3, A4, A5, B4, B5, LT, HLT, GLT, LGL, GLG, EXE, B, F4 10 sheets 91 ~ 256 g/m

Envelope Monarch, COM-#10, DL, IB5, C5, C6 10 sheets 91 ~ 256 g/m

User defined Width: 90.00 mm ~ 311.20 mm

Length: 139.70 mm ~ 1200.00 mm

--- 64 ~ 256 g/m

Option Optional Cassette Plain paper / Recycled paper A3, A4, B4, B5, LT, LGL, B, F4 500 sheets 64 ~ 90 g/m

Duplex unit Plain paper / Recycled paper / Thick paper A3F, A3, A4, A5, B4, B5, Letter, LGL, B, GLG, GLT, EXE, F4 --- 64 ~ 256 g/m

*: Plain Paper: FX-P (64g/m2), Epson color laser paper (82g/m2)

2

2

2

2

2

2

2

2

2

2

PRODUCT DESCRIPTION Product Specifications 17

Confidential

Page 17

EPSON AcuLaser C9200N Revision D

UNSUITABLE PAPERS

The following types of paper should not be used, otherwise decreased print quality,

paper misfeeds, or damage to the printer may occur.

Specially-treated papers, such as carbon-backed, non-carbon, heat-sensitive,

pressure-sensitive, or acid paper

Extremely thick or extremely thin papers

Damp paper

Art paper, coated paper for color printers

Extremely smooth or extremely rough paper, or paper with uneven surface

Perforated paper or paper with punched hole

Folded, curled, wrinkled, or torn paper

Paper of a non-standard shape (not rectangular)

Label that peels off easily

Papers with glue, staples, or paper clips

Inkjet printer paper (Photo Quality Ink Jet Paper, Glossy Paper, Glossy Film, etc.)

Printouts printed by a heat-transfer printer or an inkjet printer

Transparency for other color laser printers or color photocopiers

Printouts printed by another color/monochrome laser printer or a photocopier

Sheets of paper stuck together using glue or the like

Postcards for inkjet printers

Iron-on Transfer Paper (for inkjet printers or laser printers)

Paper that deteriorates or discolors at 200 °C or lower

When using illustrated postcards, paper feed rollers may be soiled with paper dust

and these cards may not be fed properly. In this case, clean the rollers with

reference to Chapter 6 “MAINTENANCE” (p.331)

PRODUCT DESCRIPTION Product Specifications 18

Confidential

Page 18

EPSON AcuLaser C9200N Revision D

5 mm (7 mm)

5 mm5 mm

5 mm (7 mm)

PRINTABLE AREA

Maximum print area (Printing is guaranteed)

Area excluding 4.2 mm margins on all four edges

(For A3F, all areas except 2 mm from the left and right edges)

Guaranteed print area

Area excluding 5 mm margins on all four edges

(Values in parenthesis ( ) are for A3F)

ENVELOPE ORIENTATION

Envelope Size

Feeding

Direction

↑

POSTCARD ORIENTATION

Postcard type

Feeding

Direction

↑

Feeding

Direction

↑

Postcard Front

side printing

Front side of 4-sided postal card Back side of 4-sided postal card

Monarch, COM-#10, DL, C5, C6

Postcard Reverse

side printing

Front side of double postal card

Back side of double postal card

Table 1-5. Guaranteed Print Area

PRODUCT DESCRIPTION Product Specifications 19

Confidential

Page 19

EPSON AcuLaser C9200N Revision D

1.1.3 Replacement Parts

CONSUMABLES

Load envelopes on the MP tray with the side to be printed face

down.

Before printing on envelopes, set the release lever to envelope

position.

Do not use envelopes that have a tape or glue.

PAPER EJECT/CAPACITY

Paper eject Capacity Remarks

Face down 500*1 sheets

*1: Calculated on FX-P paper (64 g/m2)

*2: Calculated on EPSON color laser paper (82 g/m2)

350

*2

sheets

Applicable to simplex printing only.

Name Life

Toner Cartridge (K) Included in the initial package 5,000 pages

Replacement 21,000 pages

Toner Cartridge (Y/M/C) Included in the initial package 3,500 pages

Replacement 14,000 pages

Photoconductor Unit (K) 50,000 pages

Photoconductor Unit (Y/M/C) 30,000 pages

Waste toner collector 21,000 pages

Odor filter (Included in the K toner cartridge) 15,000 pages

Exhaust fan filter (Included in the waste toner collector) 18,000 pages

PRODUCTS THAT REQUIRE PERIODIC REPLACEMENT

Name Life

Fusing Unit 120,000 pages

Transfer belt unit 120,000 pages

2nd transfer roller (Included in the Transfer belt unit) 120,000 pages

Maintenance Unit (Feed roller for MP tray and Standard cassette) 200,000 pages

Feed roller, Separation roller 200,000 pages

PRODUCT DESCRIPTION Product Specifications 20

Confidential

Page 20

EPSON AcuLaser C9200N Revision D

USB 2.0HS Device Interface

Parallel Interface

USB 2.0HS Host Interface

Ethernet Interface

Type-B Interface

1.1.4 Controller Specifications

BASIC SPECIFICATIONS

CPU 32bit RISC CPU

Enhanced Technology NPGI, PGI, CRIT, RIT

RAM Standard (on-board) 256 MB

Maximum 768 MB

Expansion Type DDR333 CL=2.5

(128 MB, 256 MB, 512 MB)

Numbers of slot 1 slot

ROM Type 32-bit width (3.3V)

Program 32 MB (DIMM)

Font Included in the program

Expansion ROM ROM for Adobe PS3 as a standard

EEPROM Serial type 512 kbit

Control panel 22 digits x 5 lines LCD, three LEDs and seven buttons

Printer language ESC/Page-Color, ESC/Page, FX, ESCP2, I239X,

PCL5c, PCL6, Adobe PostScript3 and PDF1.6

Auxiliary software

Configuration Status Sheet

Supplies Status Sheet

Usage History Sheet

Reserve Job List

Form Overlay List

Network Status Sheet

EpsonNet Config (Web)

USB Ext I/F Status Sheet (only when connected to

D4 compliant USB devices)

AUX Status Sheet (only when Type-B level 3 is

installed)

PS3 Status Sheet

PS3 Font List

ROM A Information (only when optional DIMM

is installed)

EXTERNAL INTERFACES

Standard USB interface

Parallel interface

Ethernet interface

Option Type-B interface

Figure 1-7. External Interfaces

USB 2.0HS Device Interface

Service connector (USB 2.0HS Host Interface)

IEEE1284 compliant

100BaseTX/10BaseT

---

PRODUCT DESCRIPTION Product Specifications 21

Confidential

Page 21

EPSON AcuLaser C9200N Revision D

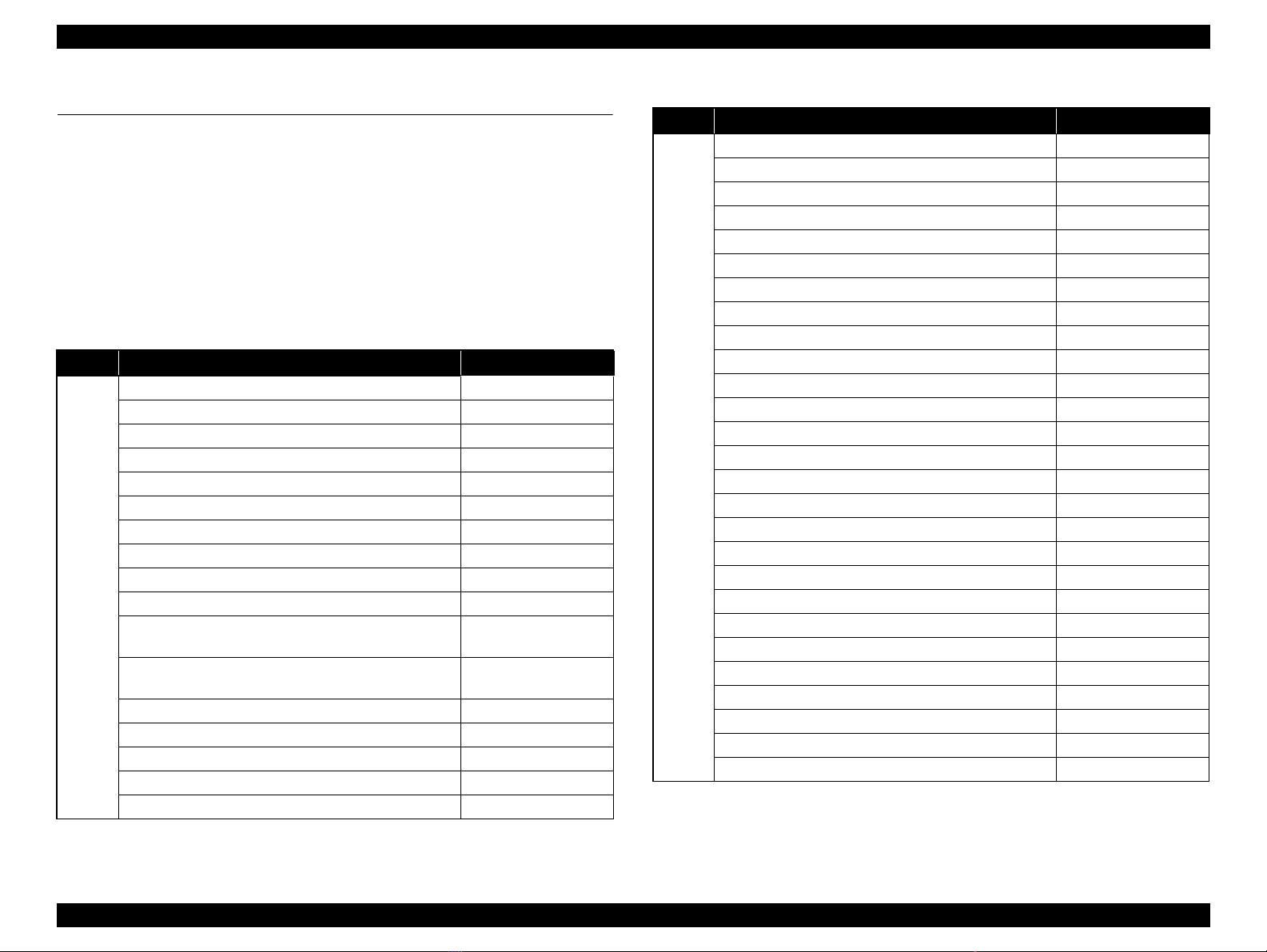

1.2 List of Printer Messages

The following table shows the printer’s LEDs indications in each printer status.

The meanings of the symbols used in the table are as follows.

O: Lights

---: Lights or flashes depending on the conditi on

X: Off

Δ1: Flashes on and off at intervals of 0.3 seconds

Δ2: Flashes on and off at intervals of 0.6 seconds

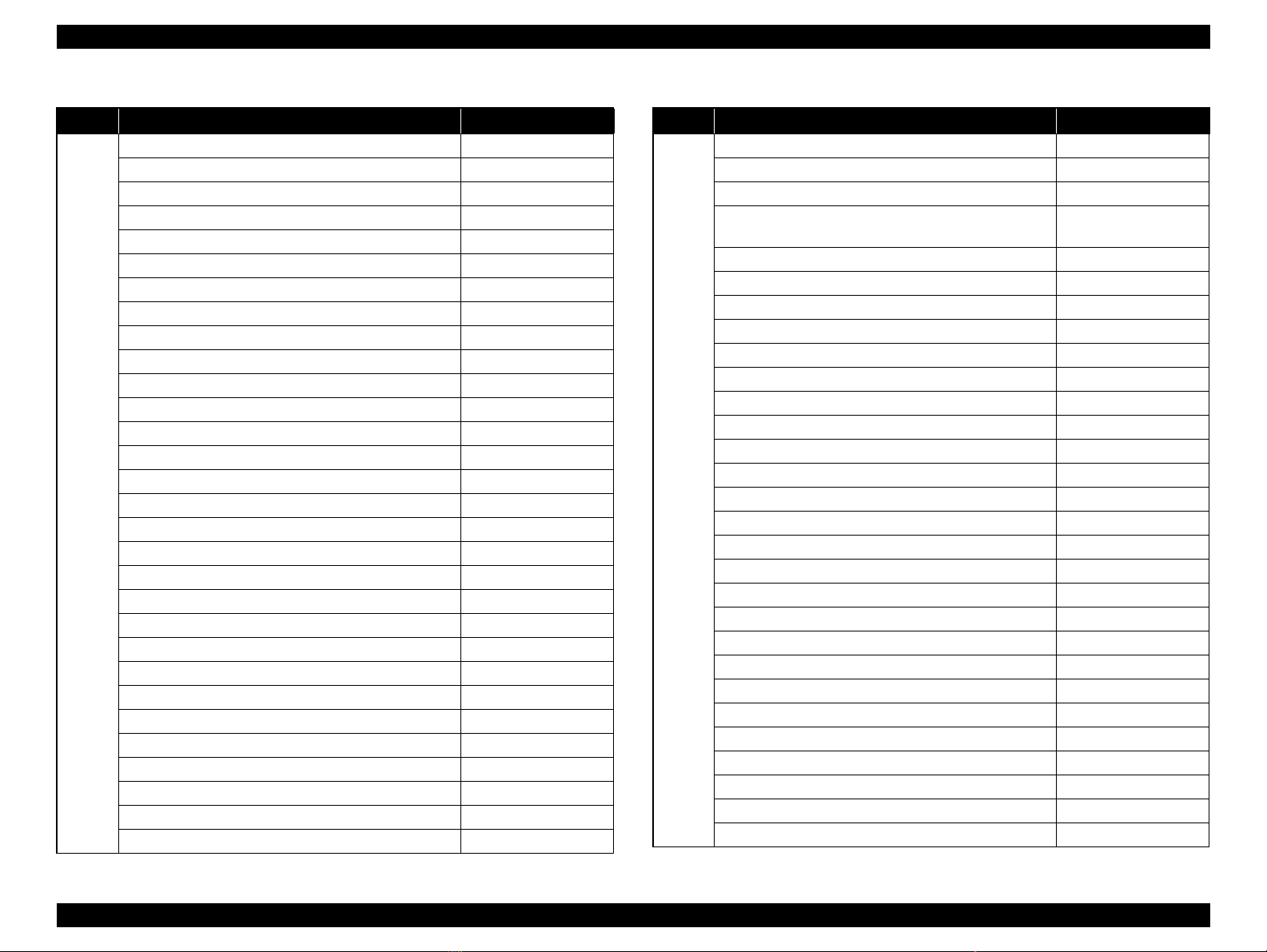

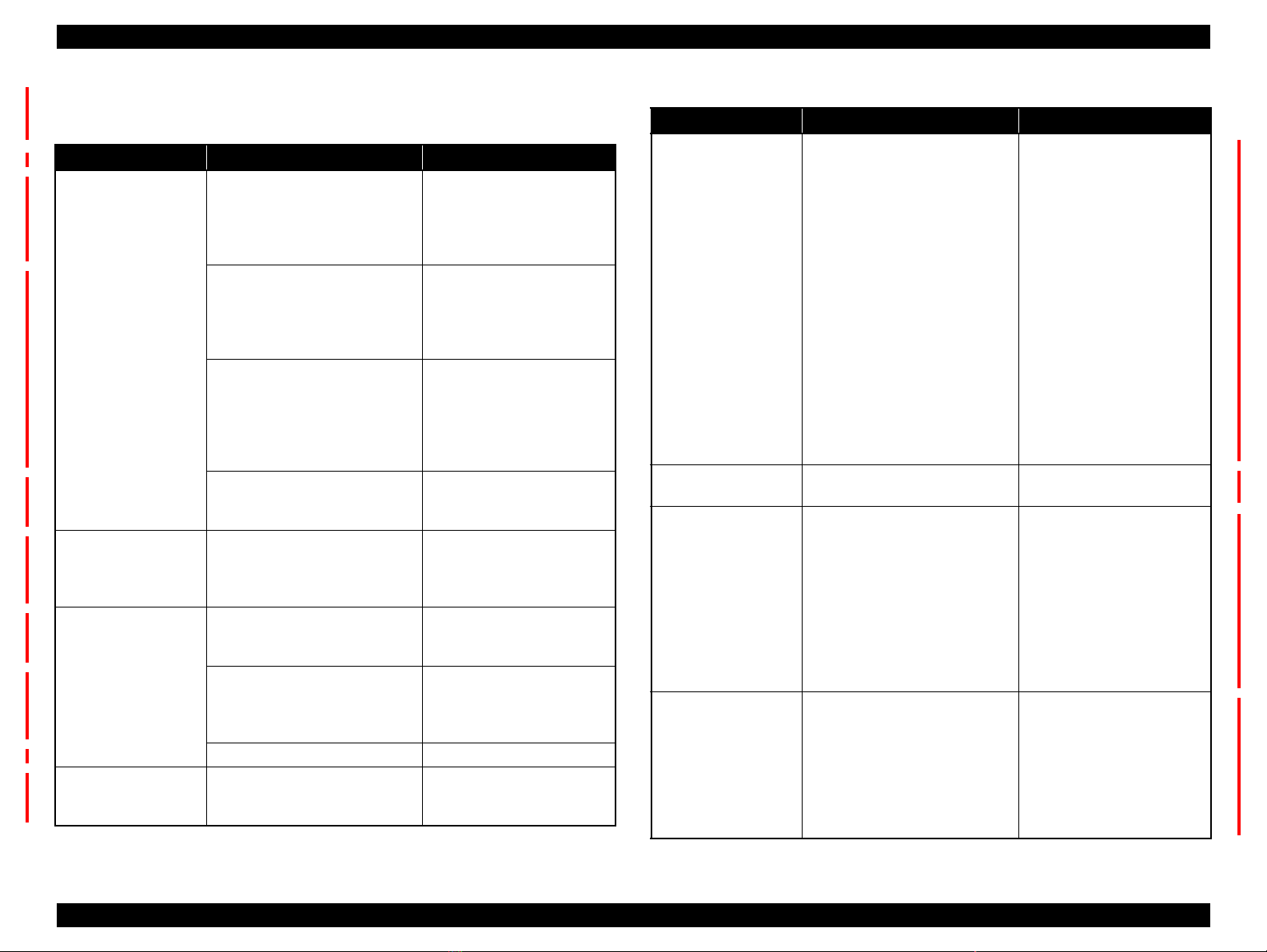

Table 1-6. List of Printer Messages

Class Printer Status Error LED status

Formatting CF X

ROM CHECK X

RAM CHECK X

CF CHECK X

O

All flashing

---

---

Status

Unable Clear Error

SELF TEST X

Reset All

Reset X

Cancel All Print Job X

Cancel Print Job X

Writing ROM A

Don’t poweroff nnn/mmm

Writing ROM P

Don’t poweroff nnn/mmm

Reset to Save X

Please Select File --Please wait for print --USB Memory Searching Files : nnn --Can't Print File ---

*1

*1

Table 1-6. List of Printer Messages

Class Printer Status Error LED status

X

Status

Form Feed

Printing Configuration Status Sheet X

Printing Supplies Status Sheet X

Printing Usage History Sheet X

ESC/Page Font Sample X

PCL Font Sample X

ESCP2 Font Sample X

FX Font Sample X

I239X Font Sample X

PS3 Status Sheet printing X

PS3 Font List X

Printing Support Status Sheet X

Printing Maintenance Status Sheet X

ROM A Information X

Reserve Job List X

Form Overlay List X

Color Diagnosis Sheet X

Warming Up X

Calibrating Printer X

Offline X

Cancel Print Job X

Sleep X

Preheat Mode X

Ready X

(Printing) X

(Communication with inactive I/F) --(Job being executed (printing OK)) ---

PRODUCT DESCRIPTION List of Printer Messages 22

Confidential

Page 22

EPSON AcuLaser C9200N Revision D

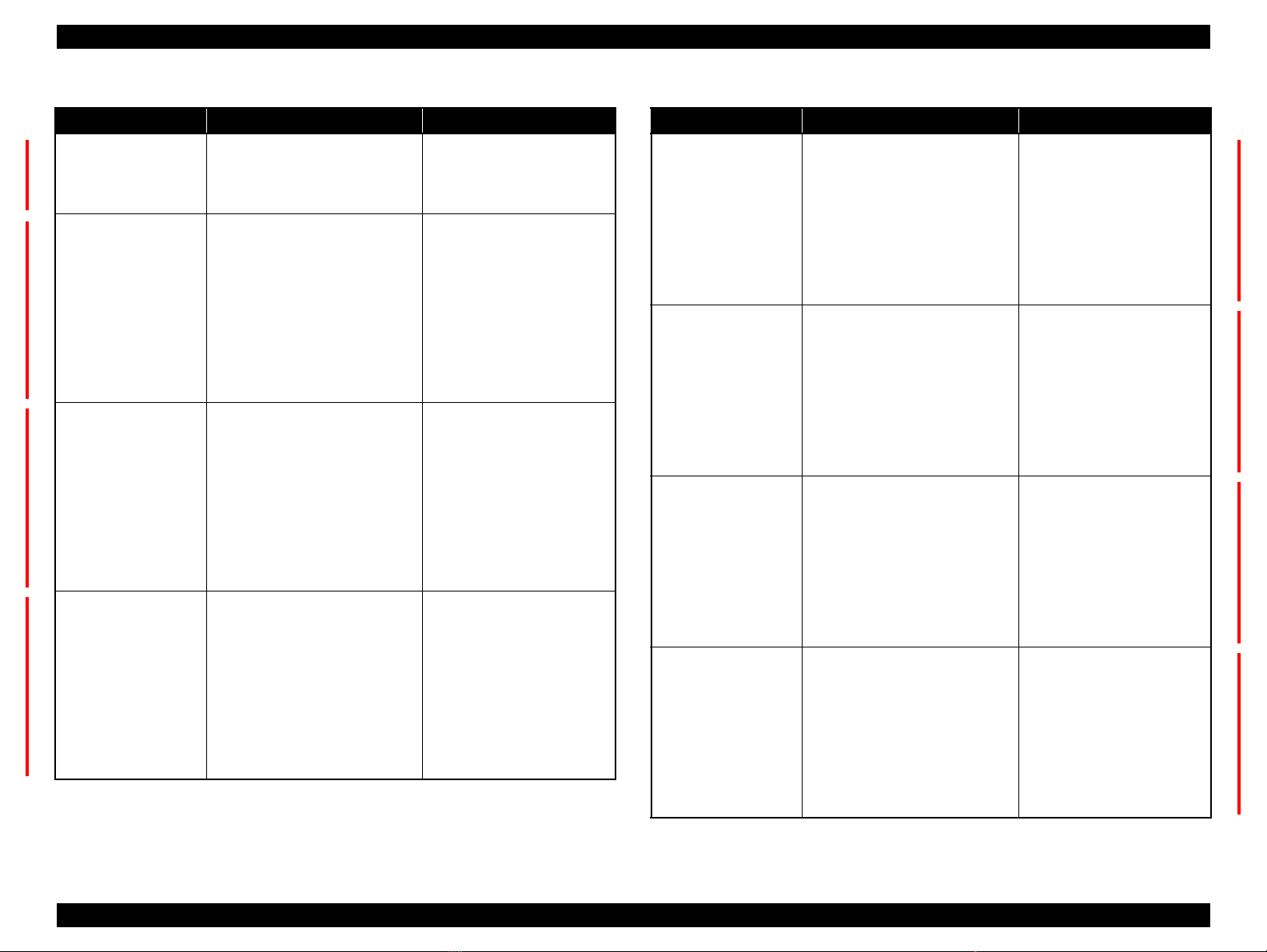

Table 1-6. List of Printer Messages

Class Printer Status Error LED status

X

X

X

Δ2

Warning

Reserve Job Canceled

CompactFlash Full X

Form Data Canceled X

PS3 CompactFlash Full X

Can't Print X

Collate Disabled X

Check Paper Size X

Image Optimum X

Check Paper Type X

Need Memory X

Not Supported USB Device XXX

*2

Format Error ROM A X

Correct time using Time Setting X

Replace Photocon uuuu

*3

Toner Low X

uuuu

Photocon uuuu

*3

*3

Needed Soon X

Waste Toner Box Near Full X

Replace Fuser

Replace Transfer Unit Δ2

Replace Maintenance Unit Δ2

Replace Feed Roller C2 Δ2

Replace Feed Roller C3 Δ2

Replace Feed Roller C4 X

Fuser Needed Soon X

Transfer Unit Needed Soon X

Maintenance Unit Needed Soon X

Feed Roller C2 Needed Soon X

Feed Roller C3 Needed Soon X

Feed Roller C4 Needed Soon X

Non-Genuine Toner Cartridge X

Table 1-6. List of Printer Messages

Class Printer Status Error LED status

*3

*3

All flashing

All flashing

O

*4

*5

*5

*5

*5

*5

*5

*5

*5

*5

*5

O

O

O

O

O

O

O

Δ2

O

O

O

Error

Service Req Cffff

Service Req Eggg

Optional RAM Error O

Format Required

No=LeftSW Yes=OK SW

Write Error ROM A O

Write Error ROM P O

Jam Paper Size Error O

Check Transparency O

Paper Jam w w w w w

Wrong Toner Cartridge uuuu

Toner Cart Error uuuu

Install Photocon uuuu

Install uuuu*5 TnrCart O

Install Waste Toner Box O

Wrong Photocon uuuu

Photocon Trouble uuuu

Replace Photocon uuuu

Replace Photocon uuuu

Replace Toner uuuu

Replace Toner uuuu

NonGenuineToner uuuu

Replace Waste Toner Box O

Replace Fuser O

Replace Fuser Δ2

Replace Transfer Unit Δ2

Replace Maintenance Unit Δ2

Replace Feed Roller C2 Δ2

Replace Feed Roller C3 Δ2

Replace Feed Roller C4 Δ2

PRODUCT DESCRIPTION List of Printer Messages 23

Confidential

Page 23

EPSON AcuLaser C9200N Revision D

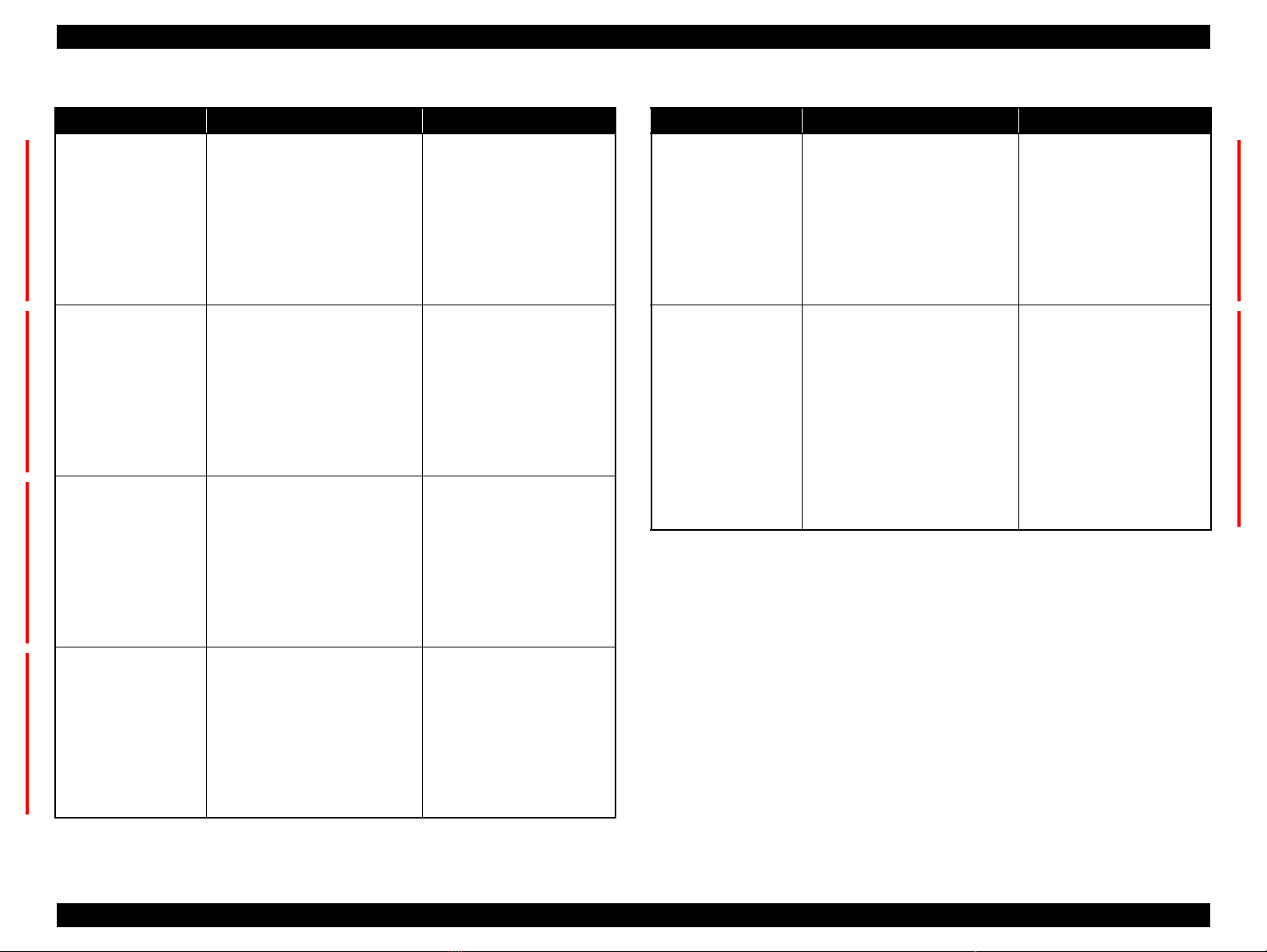

Table 1-6. List of Printer Messages

Class Printer Status Error LED status

Set Release Lever to ppp*6 Position O

w w w w*7 Open O

Manual Feed sss Δ2

Turn Paper Cassette1 O

Turn Paper Cassette2 O

Turn Paper Cassette3 O

Turn Paper Cassette4 O

Can’t Print Duplex Δ1

*9

*9

O

Δ1

Error

Paper Out ttt*8 sss

Paper Set ttt*8 sss

Print Overrun Δ1

Memory Overflow Δ1

Duplex Memory Overflow Δ1

Invalid Data Δ1

CompactFlash Error O

Invalid N/W Module O

Invalid PS3 O

Invalid AUX I/F Card O

Invalid ROM A O

Note : Messages in the table are sor ted in the order descending priorities. The message shown

at top of the table has the highest priority.

*1: nnn = Number of written blocks, mmm = total number of blocks

*2: "XXX" is replaced with “Hub” when a USB memory with a hub is in stalled. Otherwise,

it is displayed as a blank.

*3: See

*4: “WWWWW” indicates the jammed or opened point. See

*5: uuuu = Either of the following will appear: C, M,Y, K, Cyan (C), Magenta (M), Yellow

*6: ppp = Either of the following will appear: Envelope, Normal.

*7: Error location

*8: Displays relevant values of the paper source in the panel setting except Auto.

*9: Displays relevant values of each paper feed size of the Tray menu in the panel setting.

“3.3.3 Controller Related Error” (p.129) for details.

“3.2.1 Checking a paper

jam type and jammed location” (p.99)

(Y), Black (K). Only when a message exceeds the display digit in full spelling,

abbreviated forms (C, M, Y, K) will appear.

.

PRODUCT DESCRIPTION List of Printer Messages 24

Confidential

Page 24

EPSON AcuLaser C9200N Revision D

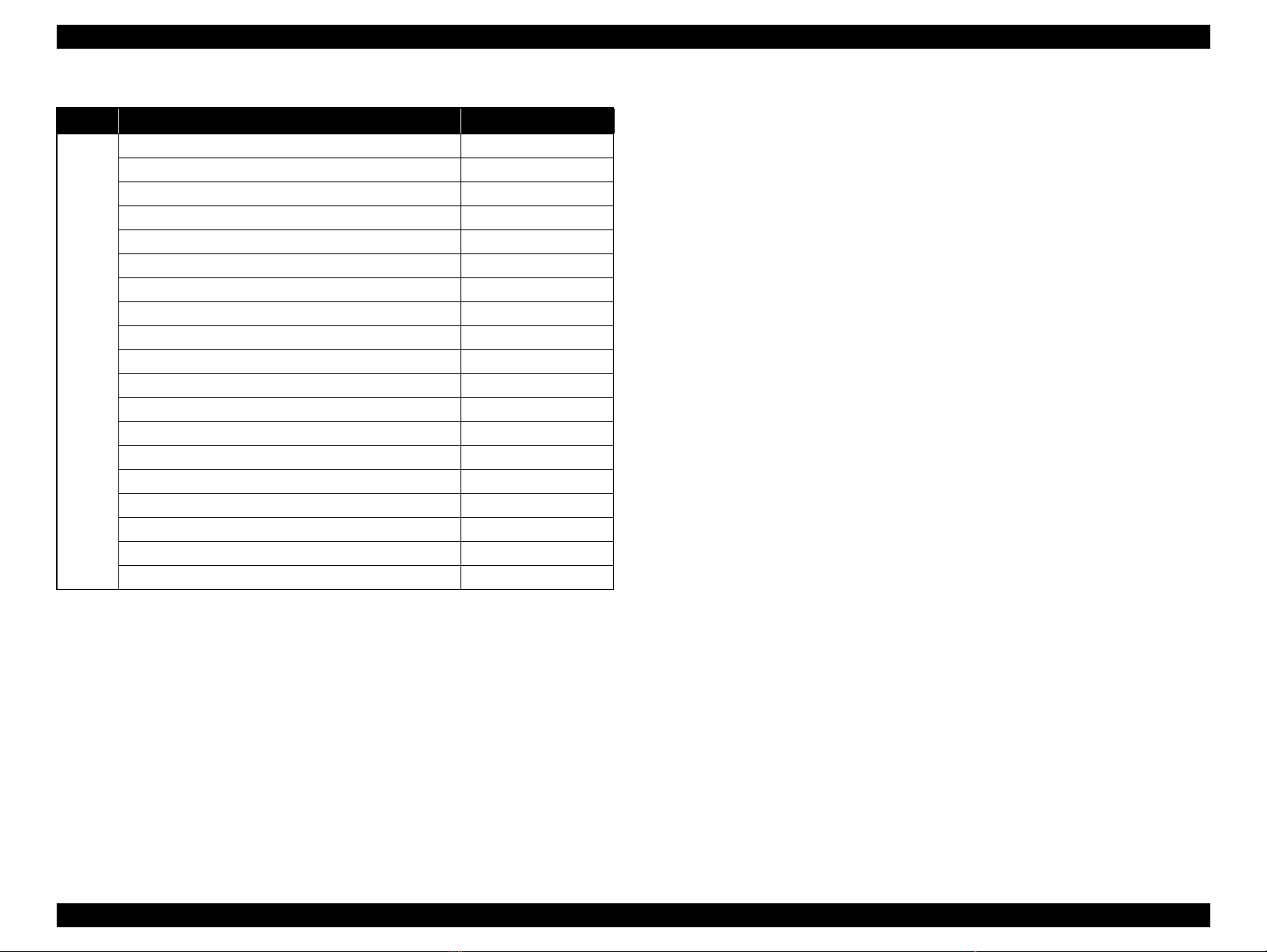

1.2.1 Error Message and Troubleshooting

Table 1-7. Error Message and Troubleshooting

Message Explanation Remedy

A CompactFlash which does not

have two partitions has been

installed.

Format Required

No=LeftSW

Yes=OK SW

Paper Jam

W W W W W

Check Transparency

NonGenuineToner uuuu

Toner Cartridge Error

uuuu

An unformatted CompactFlash

has been installed.

The printer is turned on after

executing "Format

CompactFlash" or "Delete All

CompactFlash Data" of the

Support Menu.

Paper jam in the displayed area.

Transparency is specified, but

media other than transparencies

were fed. Or transparency is not

specified, but transparencies was

fed.

The toner cartridge of the

specified color is non-genuine.

The toner cartridge of the

specified color is out of order.

l

Press the OK button to

format the CompactFlash.

Turn off the printer without

any operation and remove

the CompactFlash.

Remove the jammed paper and

close the cover. Printing will be

started again from where the jam

occurred. Refer to Figure 1-8.

Remove the media from the MP

Tray. Open and close cover F.

Load the correct media to start

printing again from where the

jam occurred.

The error is cleared either by

replacing it with a genuine toner

or selecting continuing use

according to the user

confirmation flow.

1. Replace the ton er cartridge of

the specified color with a

normal one.

2. Replace with a new toner

cartridge.

If the error is not cancelled, turn

the printer off and on again.

Table 1-7. Error Message and Troubleshooting

Message Explanation Remedy

1. Replace the photoconductor

Photocon Trouble uuuu

Install uuuu TnrCart

Install Photocon uuuu

Wrong Toner uuuu

Replace Toner uuuu

Install Waste Toner Box

Wrong Photocon uuuu

The photoconductor unit of the

specified color is out of order.

The toner cartridge of the

specified color is not

installed. Or it is not

installed correctly.

The tape has not been

removed from the toner

cartridge of the specified

color.

The photoconductor unit of

the specified color is not

installed. Or it is not

installed correctly.

The tape has not been

removed from the

photoconductor unit of the

specified color.

The toner cartridge of the

specified color is invalid

(different destination).

Printing has stopped because

the toner cartridge of the

specified color has reached

its lifetime.

Cannot be cleared by the

Start/Stop switch.

The waste toner box is not

installed. Or it is not installed

correctly.

The photoconductor unit of the

specified color is invalid

(different destination).

2. Replace with a new

If the error is not cancelled, turn

the printer off and on again.

Install the toner cartridge for

If a toner cartridge is

Install the photoconductor

If a photoconductor unit is

Replace with a legitimate toner

cartridge.

Replace with a new toner

cartridge of the specified color.

Install a waste toner box.

Replace with a legitimate

photoconductor unit.

unit of the specified color

with a normal one.

photoconductor unit.

the specified color.

installed, remove it, remove

the tape, and reinstall it.

unit for the specified color.

installed, remove it, remove

the tape, and reinstall it.

PRODUCT DESCRIPTION List of Printer Messages 25

Confidential

Page 25

EPSON AcuLaser C9200N Revision D

Table 1-7. Error Message and Troubleshooting

Message Explanation Remedy

Error LED flashing

Printing has stopped because

the photoconductor unit of

Replace Photocon uuuu

Replace Waste Toner

Box

Replace Fuser

Replace Transfer Unit

Replace Maintenance

Unit

the specified color has

reached its lifetime.

Cannot be cleared by the

Start/Stop switch.

The waste toner box is at the

end of its product lifetime.

Cannot be cleared by the

Start/Stop switch.

Printing has stopped because

the fuser unit has reached its

lifetime.

Can be cleared by the Start/

Stop switch.

Printing has stopped because

the transfer unit has reached

its lifetime.

Can be cleared by the Start/

Stop switch.

Printing has stopped because

the maintenance unit has

reached its lifetime.

Can be cleared by the Start/

Stop switch.

Error LED On

Replace with a new waste toner

box.

Error LED flashing

Error LED On

Replace with a new transfer

Press the Start/Stop switch to

Replace with a new

Press the Start/Stop switch

Replace with a new

photoconductor unit of

the specified color.

Press the Start/Stop

switch to clear the error

and continue printing.

Replace with a new

photoconductor unit of the

specified color.

Replace with a new fuser

unit.

Press the Start/Stop

switch to clear the error

and continue printing.

Replace with a new fuser

unit.

unit.

clear the error and continue

printing.

maintenance unit. After

replacement, perform Reset

Maint Counter on the panel.

to clear the error and

continue printing.

Table 1-7. Error Message and Troubleshooting

Message Explanation Remedy

Contact Service and replace

Printing has stopped because

the paper feed roller has

Replace Feed Roller xxx

Set Release Lever to ppp

Position

wwww Open A cover is open.

reached its lifetime.

Can be cleared by the Start/

Stop switch.

Displayed when there is an

envelope print request after

printing plain paper, or a plain

paper print request after printing

envelopes, prompting the user to

set the release lever to the

correct position.

Press the Start/Stop switch to

Open cover A, set the release

lever to the position shown in

the message, and close cover A.

The error is cleared by closing

the cover specified. Refer to

Figure 1-8.

the paper feed roller. After

replacement, perform Reset

xxx Counter on the panel.

clear the error and continue

printing.

PRODUCT DESCRIPTION List of Printer Messages 26

Confidential

Page 26

EPSON AcuLaser C9200N Revision D

cover F

cassette 1 (C1)

cassette 2 (C2)

cassette 3 (C3)

cassette 4 (C4)

cover E2

cover E3

cover E4

MP tray

cover A

cover B

cover D

cover H

paper path G

Table 1-7. Error Message and Troubleshooting

Message Explanation Remedy

The installed CompactFlash

cannot be used on this printer or

it is a CompactFlash of less than

Invalid CompactFlash

Error

Can't Print Duplex

Turn Paper Cassette 1

(2,3,4)

4 GB, or "No" is selected when

"Format Required" occurred.

This error also occurs under the

following conditions for a

CompactFlash with the

password lock function.

Password lock has failed.

Could not unlock the

password lock.

An error resulted as printing was

specified with conditions where

duplex printing is not possible.

An error occurred because the

width of the paper set in the

feeder device was narrower than

the width set for printing. With

this printer, the error occurs

when the following conditions

are met at the same time.

The width of the paper size

specified for printing is

210.00mm or more.

The paper set is less than

210.00 mm wide.

The envisioned situation is when

normally horizontally set A4,

A5, B5, or LT is mistakenly set

vertically.

Turn off the printer, remove

the CompactFlash, and turn

on the printer.

Select "Yes" to format the

CompactFlash when "Format

Required" occurs.

This error is cleared by

pressing the Start/Stop

switch and the printer prints

in simplex.

When Auto Continue is on,

simplex printing starts after a

certain interval.

If printing does not continue,

cancel the job.

When the specified paper

size is correct

Remove the paper from the

cassette displayed and set the

correct paper. The error is

cleared and printing starts.

When the set paper is correct

Cancel the job for which the

error occurred, and resend

the data with the correct

paper size specified.

Figure 1-8. cover

PRODUCT DESCRIPTION List of Printer Messages 27

Confidential

Page 27

EPSON AcuLaser C9200N Revision D

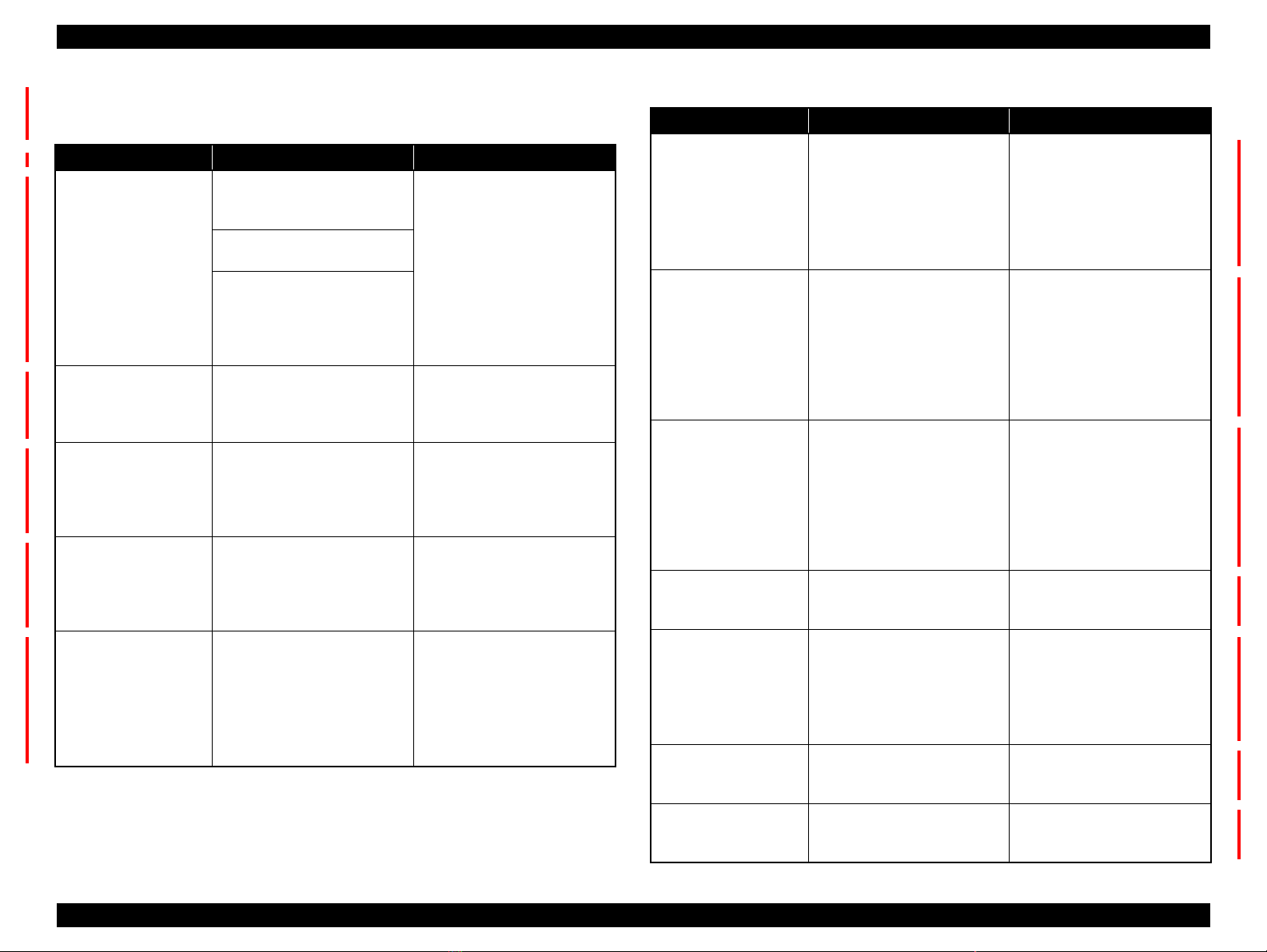

1.2.2 Warning Message and Troubleshooting

Table 1-8. Warning Message and Troubleshooting

Message Explanation Remedy

Reserve Job Canceled

CompactFlash Full

Form Data Canceled

PS3CompactFlash Full

An attempt has been made to

register a new Re-Print Job, Verify

Job, Stored Job or Confidential Job

though the number of registrations

has reached the maximum.

When the user attempted to register

a Re-Print Job or Verify Job, there

was already a Stored Job registered

by same user name or job name.

Insufficient capacity of RAM disk.

Or, RAM Disk is set to Off.

Insufficient capacity of

CompactFlash. Or, a

CompactFlash is not installed.

The CompactFlash memory is full

and collated print jobs, form data,

reserve jobs etc. cannot be saved.

The user attempted registration

after reaching the maximum

number.

The USB memory is not installed,

or was removed while registering.

Or, the capacity of the USB

memory is insufficient.

A CompactFlash is not installed. Install a CompactFlash.

When downloading PS3 fonts, the

CompactFlash memory is full and

the fonts cannot be saved.

Delete or print the registered

Re-Print Jobs, Verify Jobs,

Stored Jobs or Confidential

Jobs.

When there is another Stored

Job with the same user name or

job name, either change the job

name and register it or delete

the Stored Job.

Set RAM Disk to Normal or

Maximum if RAM Disk is set

to Off. Increase the RAM Disk

capacity or add more RAM if

RAM Disk is already set to

Normal or Maximum.

Install a CompactFlash if a

CompactFlash is not installed.

Delete unnecessary form data

and Reserve Jobs (Re-Print,

Verify, Stored, and

Confidential).

Delete registered forms. Or,

replace the USB memory.

Check if the USB memory is

installed. Or, replace with

another USB memory with a

larger capacity.

Delete previously downloaded

fonts to empty the

CompactFlash memory.

Table 1-8. Warning Message and Troubleshooting

Message Explanation Remedy

Data was disregarded and not

printed due to a problem in the

data. The following are conditions

of this warning.

Bandwidth of the received data

Can't Print

Check Paper Size

Image Optimum

Not Supported USB

Device xxx

does not match the value

determined by the paper size.

The received data contains

undefined intermediate codes or

compression format.

Checksums attached to the

intermediate code data using

ESC/Page and ESC/Page-Color

do not match checksums of the

actual data.

Data cannot be read from the

USB memory where print data

is stored.

The paper size for the loaded paper

and specified paper do not match.

Printing with PS

This warning occurs when

memory is insufficient, and the

resolution is reduced.

Printing with the ESC/Page-

Color driver or EPSON PCL

driver

This warning occurs when data

is compressed with a higher

level of compression.

The USB device (other than a

memory device) or a USB memory

with a hub currently connected to

the USB port is not supported. A

file check is performed whenever a

new device is found on the USB

port, and this error occurs at the

point.

This error occurs when a

printer driver for a different

printer is used. Check the

printer and reinstall it if it is an

incorrect driver. When printing

from a USB memory, check

and reinsert the USB memory.

Set the paper of the specified

size.

Printing with PS

ESC/Page-Color driver or

Disconnect the USB memory

from the USB port, or specify

Clear Warning to clear the

warning.

Add memory.

EPSON PCL driver

Set the priority of the driver

data compression method

to quality.

PRODUCT DESCRIPTION List of Printer Messages 28

Confidential

Page 28

EPSON AcuLaser C9200N Revision D

Table 1-8. Warning Message and Troubleshooting

Message Explanation Remedy

Correct time using

Time Setting

Replace Photocon uuuu

uuuu Toner Low

Photocon uuuu Needed

Soon

The printer has not been turned on

for 10 days or longer and the

capacitor has been

discharged.

The photoconductor unit for the

specified color has reached its

lifetime when it has been

continuously used after the

"Replace Photocon uuuu" error.

The print quality is not guaranteed

while this message is being

displayed.

Message warning that remaining

toner is low for the specified color.

Message warning that the

photoconductor unit of the

specified color is approaching the

end of its lifetime.

Set the date and time again

from Time Setting. This

warning recurs until they are

set again.

Replace with a new

This message is cancelle d

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replace with a new toner

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replace with a new

photoconductor unit of the

specified color.

by one of the following.

Executing Clear All

Warnings in the Reset

Menu.

Executing Reset in the

Reset Menu.

Warnings in the Reset

Menu.

Reset Menu.

cartridge of the specified

color.

Warnings in the Reset

Menu.

Reset Menu.

photoconductor unit of the

specified color.

Table 1-8. Warning Message and Troubleshooting

Message Explanation Remedy

This message is cancelled by

one of the following.

Executing Clear All

Waste Toner Box Near

Full

Replace Fuser

Replace Transfer Unit

Replace Maintenance

Unit

Message warning that the waste

toner box is approaching the end of

its lifetime.

Message warning that the fuser

unit has reached the end of its

lifetime when it has been

continuously used after the

"Replace Fuser" error. The print

quality is not guaranteed while this

message is being displayed.

Message warning that the transfer

unit has reached the end of its

lifetime when it has been

continuously used after the

"Replace Transfer Unit" error. The

print quality is not guaranteed

while this message is being

displayed.

Message warning that the

maintenance unit has reached its

lifetime when it has been

continuously used after the

"Replace Maintenance Unit" error.

The print quality is not guaranteed

while this message is being

displayed.

Executing Reset in the

Replacing the waste toner

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replacing the fuser unit

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replacing the transfer unit

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replacing the maintenance

Warnings in the Reset

Menu.

Reset Menu.

box with a new one.

Warnings in the Reset

Menu.

Reset Menu.

with a new one.

Warnings in the Reset

Menu.

Reset Menu.

with a new one.

Warnings in the Reset

Menu.

Reset Menu.

unit with a new one.

PRODUCT DESCRIPTION List of Printer Messages 29

Confidential

Page 29

EPSON AcuLaser C9200N Revision D

Table 1-8. Warning Message and Troubleshooting

Message Explanation Remedy

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replacing the feed roller

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replacing the fuser unit

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replacing the transfer unit

This message is cancelled by

one of the following.

Executing Clear All

Executing Reset in the

Replacing the maintenance

Replace Feed Roller

xxx

Fuser Needed Soon

Transfer Unit Needed

Soon

Maintenance Unit

Needed Soon

Message warning that the paper

feed roller has reached the end of

its lifetime when it has been

continuously used after the

"Replace Feed Roller xxx" error.

The print quality is not guaranteed

while this message is being

displayed.

The fuser unit is approaching its

lifetime.

The transfer unit is approaching its

lifetime.

This message appears when the

maintenance unit is approaching its

lifetime.

Warnings in the Reset

Menu.

Reset Menu.

with a new one.

Warnings in the Reset

Menu.

Reset Menu.

with a new one.

Warnings in the Reset

Menu.

Reset Menu.

with a new one.

Warnings in the Reset

Menu.

Reset Menu.

unit with a new one.

Table 1-8. Warning Message and Troubleshooting

Message Explanation Remedy

This message is cancelled by

one of the following.

Executing Clear All

Feed Roller xxxNeeded

Soon

Non-Genuine Toner

Cartridge

Message warning that the paper

feed roller is approaching the end

of its lifetime.

Warning message that the toner

cartridge is non-genuine when

selecting continued use in the user

confirmation flow.

Executing Reset in the

Replacing the feed roller

This message is cancelled by

one of the following.

Replacing with a genuine

Executing Clear All

Executing Reset in the

The message occurs when the

power is turned on again until

the cartridge is replaced with a

genuine product.

Warnings in the Reset

Menu.

Reset Menu.

with a new one.

toner cartridge.

Warnings.

Reset Menu.

PRODUCT DESCRIPTION List of Printer Messages 30

Confidential

Page 30

OPERATING PRINCIPLES

CHAPTER

2

Confidential

Page 31

EPSON AcuLaser C9200N Revision D

DrumBk

1.Charging

2.Exposure

3.Developing

5.Cleaning

DrumC

1.Charging

2.Exposure

3.Developing

5.Cleaning

DrumM

1.Charging

2.Exposure

3.Developing

5.Cleaning

DrumY

1.Charging

2.Exposure

3.Developing

5.Cleaning

4. Primary transfer (Drum→Intermediate Transfer Belt)

Transfer belt

8. Cleaning

Paper

7.Electrical discharge

9.Fusing

6. Secondary transfer (Intermediate

Transfer Belt

→Paper)

2.1 Print Process

This printer is a "Full color page printer" that uses the principle of

electrophotographic recording. Each YMCK color (yellow, magenta, cyan,

black) has its own special drum (Photoconductor (PC) drum) and developer

that are used in tandem. Since each color is developed simultaneously, the

color image can be printed at high speed comparing to the four cycles engine

printer. The transfer intermediate is coordinated, and at the end of the process

the layered color toner images produce a full color print. The major steps of the

print process are described below.

1. Charging: The PC Drum surfaces are charged with electricity.

2. Exposure: Imag e areas are exposed on PC Drum with laser radiation.

3. Developing: Image areas on drums are developed with toner.

4. Primary transfer: The toner image on PC Drum is transferred to Intermediate

Transfer Belt.

5. Cleaning: PC Drum are cleaned.

6. Secondary transfer: The complete four-color toner image on the Intermediate

7. Electrical discharge:The electrical charge of the paper is discharged.

Transfer Belt is transferred to the paper.

8. Cleaning: Intermediate Transfer Belt are cleaned.

9. Fusing: Ton e r on the paper is fused with heat and pressure.

OPERATING PRINCIPLES Print Process 32

Figure 2-1. Print Process

Confidential

Page 32

EPSON AcuLaser C9200N Revision D

[1]

[3]

[4]

[5]

[6]

[2]

[7][8][9][10]

[11]

[12]

[13]

[14]

[15]

[17]

[16]

[18]

[19]

4039T1C102AA

1. Fusing Unit

2. Transfer Belt Unit

3. 2nd Transfer Roller

4. MP tray

5. Standard Cassette

6. Optional Cassette

7. Print Head Unit (PH Unit) /K

8. Print Head Unit (PH Unit) /C

9. Print Head Unit (PH Unit) /M

10. Print Head Unit (PH Unit) /Y

11. Waste Toner Collector

12. Photoconductor Unit/Y

13. Photoconductor Unit/M

14. Photoconductor Unit/C

15. Photoconductor Unit/K

16. Toner Cartridge/Y

17. Toner Cartridge/M

18. Toner Cartridge/C

19. Toner Cartridge/Y

2.2 Operating Principle of Main Unit Mechanism

2.2.1 Center cross section

Figure 2-2. Center cross section

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 33

Confidential

Page 33

EPSON AcuLaser C9200N Revision D

4039T1C103AA

PAPER PATH

Normally, papers are supplied from 2 bins. MP tray (100 papers) and Standard

cassette (250 papers).

5 bins of paper supply can be available by setting maximum three optional

cassette (500 papers).

A Paper supplied from each Tray is transported to the Vertical Transport

then an image is transferred in the 2nd Transfer Roller and fused in the

Fusing Unit. Finally, the paper is exited with face down.

Duplex mechanism of this machine uses circuit system. The major steps of

Duplex are described below (When two documents are printed in Duplex).

1. Firstly, printing back up (back side of the paper) is executed. After an image

is fused, the transfer route is switched at Paper exit section and the paper is

drawn back inside the Duplex Unit.

2. The paper is reversed and transported from the Duplex Unit to the paper

route in front of the Registration Roller.

3. Printing the front page (surface of the paper) is executed and after an image

is fused, papers are exited to the Exit tray.

Figure 2-3. Paper path

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 34

Confidential

Page 34

EPSON AcuLaser C9200N Revision D

4039F5C501DA

[1]

[10]

[9]

[8]

[7]

[2]

[3]

[4]

[5]

[6]

4039F5C502DA

[1]

[2]

[3]

[4]

[5]

[7]

[6]

[8]

[9]

[10]

[11]

[12]

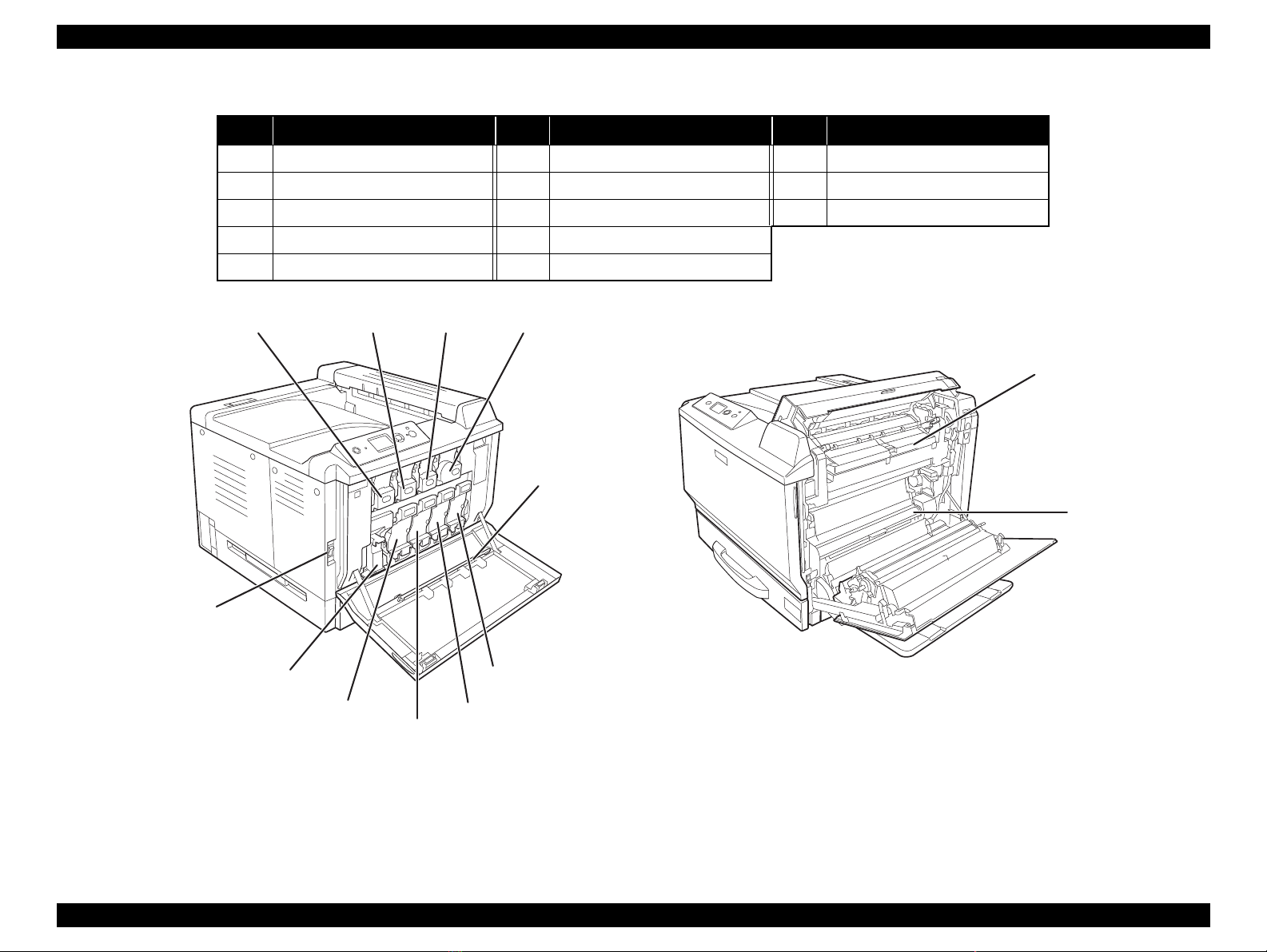

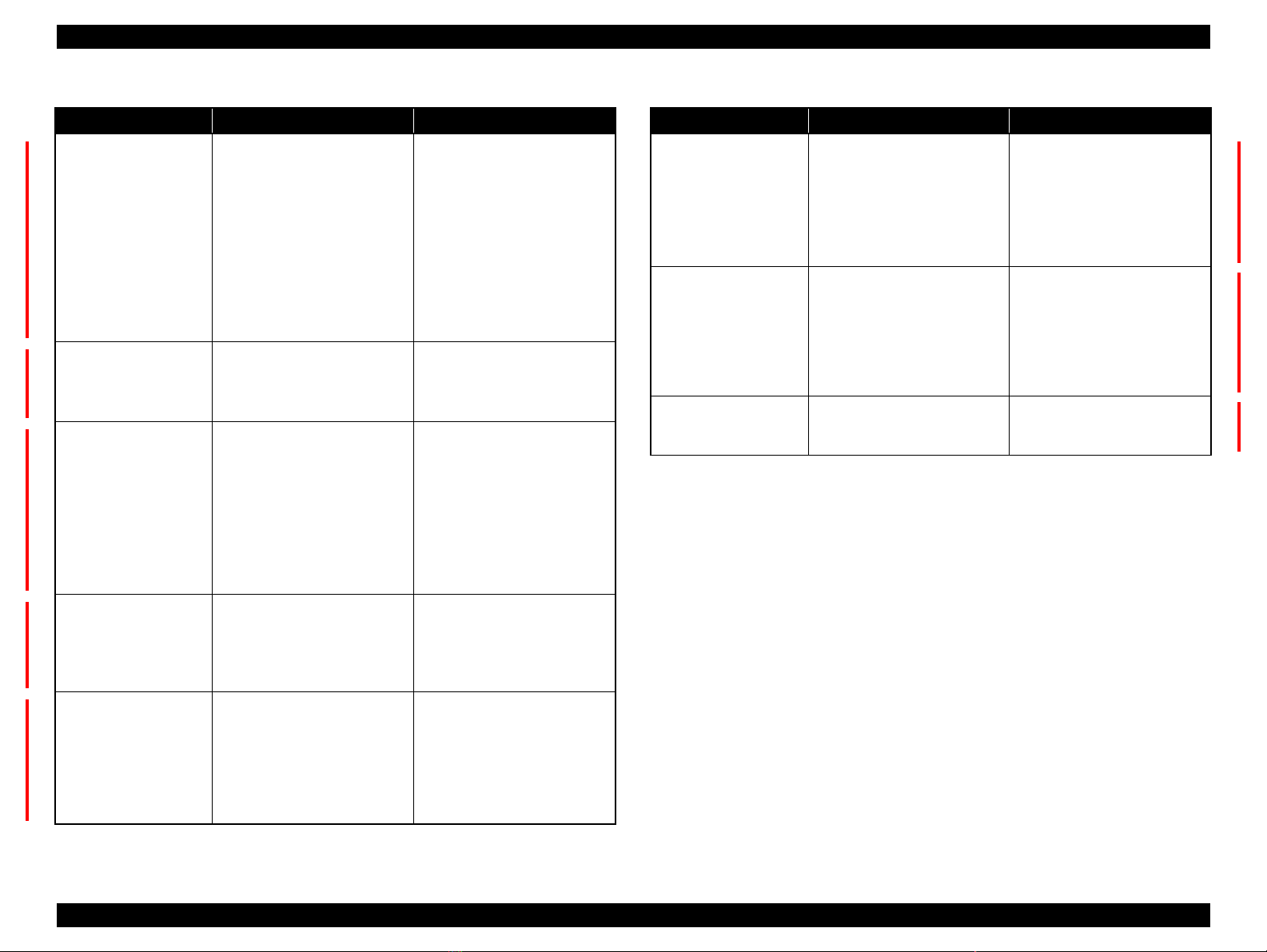

2.2.2 Parts layout drawing

ENGINE SECTION

[1] IDC/Registration Sensor/2 (SE2) [6] Controller Board (PWB-P)

[2] IDC/Registration Sensor/1 (SE1) [7] Program ROM DIMM (WORK0)

[3] Control Panel (PWB-OP) [8] RTC Board (PWB-RTC)

[4] PH Interface Board (PWB-D) [9] Mechanical Control Board (PWB-M)

[5] DC Power Supply (PU1) [10] High Voltage Unit (HV1)

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 35

[1] Fusing Drive Motor (M4) [7] Cooling Fan Motor/1 (M12)

[2] Main Motor (M1) [8] Toner Supply Motor Y/M (M6)

[3] Fusing Cooling Fan Motor/2 (M11) [9] Cooling Fan Motor/2 (M22)

[4] Power Supply Cooling Fan Motor/1 (M8) [10] Toner Supply Motor C/K (M7)

[5] Ozone Ventilation Fan Motor (M14) [11] Color PC Drum Motor (M2)

[6] Color Developing Motor (M3) [12] Fusing Cooling Fan Motor/1 (M13)

Confidential

Page 35

EPSON AcuLaser C9200N Revision D

4039F5C503DA

[3]

[1]

[2]

[4]

[5]

[6]

[10]

[9]

[8]

[7]

4039F5C504DA

[5]

[3]

[1]

[2]

[4]

[6]

[8]

[10]

[9]

[7]

[12]

[13]

[11]

[1] Right Door Switch (S5) [6] Front Door Switch/2 (S4)

[2] Primary Interlock Switch (S2) [7] Main Erase Lamp/Y (LA4)

[3] PH Unit [8] Main Erase Lamp/M (LA3)

[4] Main Power Switch (S1) [9] Main Erase Lamp/C (LA2)

[5] Front Door Switch/1 (S3) [10] Main Erase Lamp/K (LA1)

[1] Developing Clutch/K (CL4) [8] Waste Toner Full Sensor (PC8)

[2] Exit Sensor (PC2) [9] Color PC Drive Main Sensor (PC17)

[3] Temperature/Humidity Sensor (SE3) [10] Color PC Drive Sub Sensor (PC18)

[4] Registration Roller Sensor (PC1) [11] Black PC Drive Main Sensor (PC15)

[5] OHP Sensor (PC4) [12] Black PC Drive Sub Sensor (PC16)

[6] Registration Roller Clutch (CL1) [13] 1st Image Trans f er P ressure/Retraction

[7] 1st Image Transfer Pressure/Retraction

Clutch (CL3)

Position Sensor (PC6)

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 36

Confidential

Page 36

EPSON AcuLaser C9200N Revision D

A

4038T2C171AA

[1]

[3]

[2]

4039T2C113AA

4038T2C026DB

[4]

[5]

[7]

[10]

[9]

[11]

[8]

[6]

STANDARD CASSETTE

4038T2C111A

[1] Registration Roller Sensor (PC1) [7] Standard Cassette CD Paper Size Sensor

(PC9)

[2] Standard Cassette Feed Roller [8] Standard Cassette Separation Roller

[3] Standard Cassette Separation Roller [9] Standard Cassette Feed Roller (Bypass)

[4] Standard Cassette Device Detection

Sensor (PC12)

[5] Standard Cassette Paper Near-Empty

Sensor (PC11)

[6] Standard Cassette Paper Size Board

(PWB-I)

[10] Standard Cassette Paper Empty Sensor

(PC10)

[11] Standard Cassette Paper Feed Clutch

(CL2)

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 37

Confidential

Page 37

EPSON AcuLaser C9200N Revision D

4039T2C106AA

4038T2C008AA

PH Unit

4038T2C034AA

SOS Mirror

Laser Diode

Polygon Motor

SOS Sensor

4038t2J005AB

Transfer Belt

2nd Transfer

Roller

LD/K

LD/Y LD/M

LD/C

PC Drum

YM

C

K

Beam A

Beam B

PC Drum

Return Mirror 1Return Mirror 2

Laser Diode

Beam A

Beam B

Direction

of rotation

of the PC

Drum

Two lines

One scan

Surface of the PC Drum

Polygon

Mirror

G2 Lens

G1 Lens

2.2.3 PH Unit

2.2.3.1 Composition

2.2.3.2 Operation

OUTLINE

4 types of the PH Unit are used for exposure process.

The surface of the Photo Conductor is irradiated with a laser light and an

electrostatic latent image is thereby formed.

2 Beam Array LD is used to prevent the rotation speed from increasing

caused by decreasing the number of the sides comparing to Polygon Mirror

which has four sides.

2 Beam Array LD scans in two lines two lasers irradiated by two LD

electrical components set up vertically with one side of Polygon Mirror.

Figure 2-4. Composition

Figure 2-5. Overview

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 38

Confidential

Page 38

EPSON AcuLaser C9200N Revision D

Shutter

Shutter Guide

Void width: 4 mm/0.157 inch

Void width: 4 mm/0.157 inch

Void width: 4.2 mm/

0.165 inch

Void width: 4.2 mm/

0.165 inch

LASER SHUTTER MECHANISM

There is a shutter mechanism provided to prevent the PH from being

contaminated with foreign matter such as dust when the front cover is opened,

or prevent the emission laser from leaking outside for any reason.

The Shutter operates relative to the removing and inserting Photoconductor

Unit because PH Unit is not exposed concerning the layout of the unit when

Photoconductor Unit is inserted. The shutter opens by pressing shutter guide at

insertion of the Photoconductor Unit, and closes at de-installation of the

Photoconductor Unit.

LASER EMISSION AREA

Main scan direction (CD)

The print start position is determined by the start signal for main scan

print and the range of the paper size output from the Mechanical

Control Board (PWB-P).

The laser emission area is determined by the paper size. The area of 4 mm/

0.157 inch on both edges of the paper is, however, the void image area.

Sub scan direction (FD)

The print start position is determined by the writing image signal and the

range of the paper size output from the Mechanical Control Board (PWB-P).

The laser emission area is determined by the paper size. The area of 4.2

mm/0.165 inch on the leading and trailing edges and 4 mm/0.157 inch

on both the side edges of the paper are, however, the void image area.

Start signal

for main

scan print

Writing

image

signal

Figure 2-6. Laser shutter mechanism

4138to2595c0

Figure 2-7. Laser emission area

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 39

Confidential

Page 39

EPSON AcuLaser C9200N Revision D

Transfer Belt

IDC/Registration Sensor/1 and /2

(SE1, SE2)

4038T2C033DA

REGISTRATION CONTROL (COLOR SHIFT CORRECTION) SYSTEM

In a tandem engine, in which an independent image reproduction process is

provided for each of the four different colors of toner. Incorrect color

registration, or color shift, is therefore more likely to occur due to each of

the PH Units being out of correct position. The color shift correction

system automatically detects any misalignment among the different colors,

correcting it both in the main scanning and sub scanning directions.

The color shift correction is made when the Front Door is opened and

closed, the Transfer Belt is removed and reinstalled, the Main Power

Switch is turned OFF and ON, or "Calibration" is carried out from the

Control Panel.

SKEW CONTROL MECHANISM

When the PH Unit is mounted on the main body installation plate, image

distortion (skew) occurs due to mounting error. Therefore the PH Unit

adopts the correction system.

Figure 2-9. Skew Control Mechanism 1

The main body skew can be corrected by adjusting the dial of the

corresponding PH Unit (Y, M, C).

Figure 2-8. Registration Control (Color Shift Correction) System

Figure 2-10. Skew Control Mechanism 2

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 40

Confidential

Page 40

EPSON AcuLaser C9200N Revision D

4038T2C010AA

4038T2C009AA

4039T2C107AA

Photoconductor Unit/Y, M, C

Photoconductor Unit/K

Cleaning Blade

PC Drum/Y, M, C, K

Toner Collecting Screw

Developing Unit/

Y, M, C, K

PC Drum Charge Corona/

Y, M, C, K

Developing

Clutch/K (CL4)

Color PC Drum

Motor (M2)

Color Developing

Motor (M3)

Main Motor (M1)

2.2.4 Photoconductor Unit section (PU section)

2.2.4.1 Composition

2.2.4.2 Drive

Figure 2-12. Drive Overview

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 41

Figure 2-11. Composition

Confidential

Page 41

EPSON AcuLaser C9200N Revision D

0

Operation when a new PU is detected

Transfer Belt

is retracted

TCR

automatic

adjustment

Transfer Belt

cleaning

1st image transfer/

auto transfer

voltage control

adjustment

Image

stabilization

Transfer

Belt is

retracted

Transfer Belt

cleaning

1st image transfer/

auto transfer

voltage control

adjustment

Operation when a new PU is not detected

Image

stabilization

2.2.4.3 Operation

PU LIFE CONTROL

Each PU has IC chip that detects a new PU, keeps track of the service life of

the PU and installation.

New PU detection

New PU is detected when the Main Power Switch is turned ON and the

Front Door is closed.

When a new PU is detected, a TCR adjustment sequence is carried out.

When life is reached

PU Life is detected by the PU Life counter value.

When the PU Life counter value is reached to the near life value, the

warning message "Photocon xxxx Needed Soon" is displayed.

When the PU Life counter value is reached to the life value, the

warning message "Replace Photocon xxxx" is displayed.

4036ma2133c

4038T2C009AA

Figure 2-13. Detection of new PU

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 42

Confidential

Page 42

EPSON AcuLaser C9200N Revision D

4036ma2338c0

Charge Transport Layer (CTL)

Charge Generating Layer (CGL)

Aluminum Cylinder

PC Drum

Main Motor (M1)

PC Drum/K

PC Drum/C

PC Drum/M

PC Drum/Y

Color PC Drum Motor (M2)

2.2.5 Photo Conductor section

2.2.5.1 Composition

2.2.5.2 Drive

PC DRUM DRIVE MECHANISM

Two independent PC Drum Motors (for color and monochrome) are used for

the drive mechanism.

The Color PC Drum Motor drives the PC Drums/Y, M, and C, while the Main

Motor drives the PC Drum/K.

.

4038T2C013AA

OPERATING PRINCIPLES Operating Principle of Main Unit Mechanism 43

Figure 2-14. Composition

Figure 2-15. Drive overview

Confidential

Page 43

EPSON AcuLaser C9200N Revision D

4038T2C027AA

4039T2C108AA

Comb

Electrode

Grid Mesh

Grid Mesh

Cleaning Blade

Comb Electrode/Y, M, C, K