Page 1

SERVICE MANUAL

A4 Full Color Laser Printer

EPSON AcuLaser C2600/2600

SEPG04005

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2005 SEIKO EPSON CORPORATION.

I&I CS/Quality Management & PL Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO

THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by -step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedu res for disassemb ling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Provides helpful tips and cautions on reassembly procedures, especially

when incorrect reassembling may affect the print quality.

Page 5

General Precautions

To prevent possible accidents during maintenance work, strictly observe the servicing warnings and cautions described in this manual.

Power Supply

W A R N I N G

Before starting any service procedure, turn the printer power off and unplug the power cord from the wall outlet.

When the power supply cable must be connected, be aware of the potential for electrical shock and do all tasks by following the procedures in this

manual.

Do not touch any live parts unless instructed to do so.

Make sure to ground the printer properly. Otherwise a short circuit may cause an electric fire or shock.

Handle the power cable with care observing the precautions listed below.

• Do not plug too many leads into a single socket.

• Do not damage or tamper with the power cable.

• Avoid putting heavy objects on the cable, plucking it, and bending it forcedly. To do so may damage the cable and cause an electric fire and shock.

• Do not insert or remove the power cable with wet hands to prevent electric shock.

• Never replace the fuse on the Power Supply Board (high pressure/low pressure) under any circumstances.

Mechanical Components

W A R N I N G

When servicing any driving assembly (e.g., gears), turn the power off and unplug the power cord to prevent injuries.

Do not touch the driving part (e.g., gears) while the assembly (printer) is operating.

Page 6

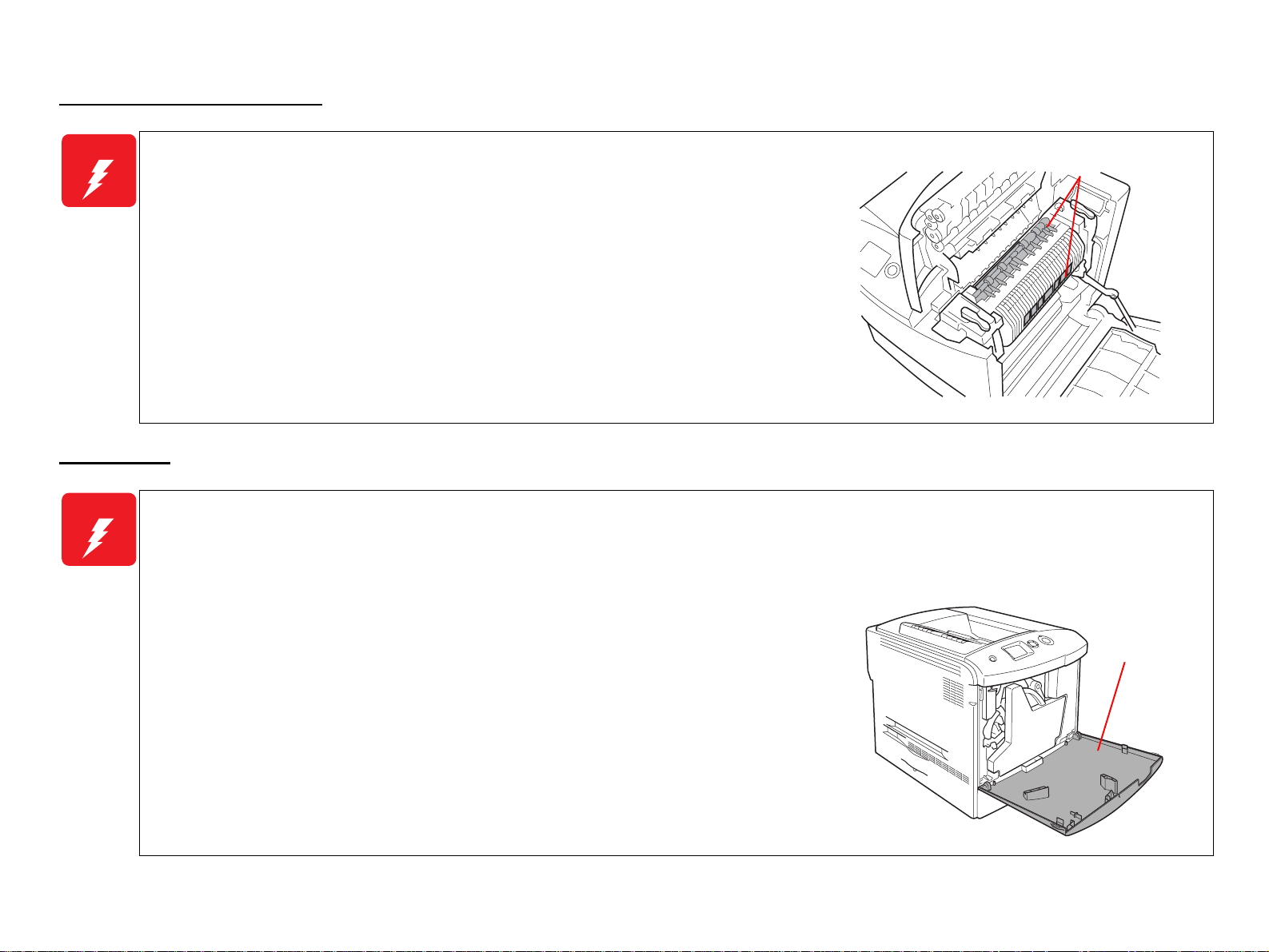

High Temperature Assembly

W A R N I N G

When working with hot parts (Fuser Unit etc.), turn the power off and unplug the power cord

Make sure to wait the hot section to cool enough especially when accessing near the section

Laser Beam

W A R N I N G

Understand hazardous nature of the laser beam, use extreme caution to avoid injury of yourself and anyone around you. Letting a laser beam get

HIGH

to prevent burns or injuries. After unplugging the power cable, wait until the part or unit

cools down before starting maintenance work.

immediately after printing.

directly into your eyes could result in loss of vision.

Since the laser beam has a narrower frequency band and more coherent phases than any other light (sunlight, electric light), the beam has excellent

monochromaticity and convergence, thus it reaches long distances. Because of these characteristics, the laser beam converges into one point, causing high

density and high temperature, which is harmful to the human bod y.

TEMPERATURE

00000101

Never turn the interlock switch on forcibly while servicing to prevent the laser beam from

emitting accidentally. The interlock switch is designed to be turned off when the cover D is

opened.

When performing maintenance work, be sure to turn the power off and unplug the power

cord.

If you need to work on the printer with power applied, strictly follow the instructions in this

manual.

Never disassemble the Laser Scanner Unit under any conditions.

Be sure to take off a wristw atch, ring or any ot her metal materials especially when working on

the printer with the power applied.

Cover D

00000201

Page 7

Handling Parts

W A R N I N G

Be careful not to throw out your back when handling heavy parts while taking care not to drop th ose parts.

Always wear gloves to perform maintenance work since the printer has many sharp edges.

Do not work with wet or oily hands, or may cause you to drop parts or affect the function of the printer.

Use only specified genuine parts for maintenance.

Do not repair or replace the ICs and other electrical components on the power circuit board (including fuse) under any circumstances.

Handling Consumables

W A R N I N G

To avoid dust explosion or ignition, never bring any consumables close to flame or throw them into fire.

Take extra care not to inhale the developing powder (such as toner), and get it into your mouth and eyes. Use extreme caution to avoid injury of yourself

and anyone around y ou.

Before starting your work, spread a sheet of paper over the working place to prevent interior of the product and the place becoming tainted.

If the developer or oil adheres to your skin or clothes, wipe it off thoroughly with dry rags before rinsing with water.

Do not disassemble the toner cartridges.

To prevent ignition, explosion, burn, injury, etc., do not use a general vacuum cleaner for

cleaning dropped toner. (To do so may cause the toner to catch fire by sparks in the vacuum

cleaner.)

Irregular Use of the Printer

W A R N I N G

Cautions when performing work with covers or parts removed

• As a general rule, do not power the printer while covers or parts are removed.

• If you need to remove covers or parts from the printer with power applied, take care o f yo ur fingers and clothes so as not to get entangled by moving

parts such as the driving belt, gears, and fans.

Altering the printer is banned under any circumstances.

00000301

Page 8

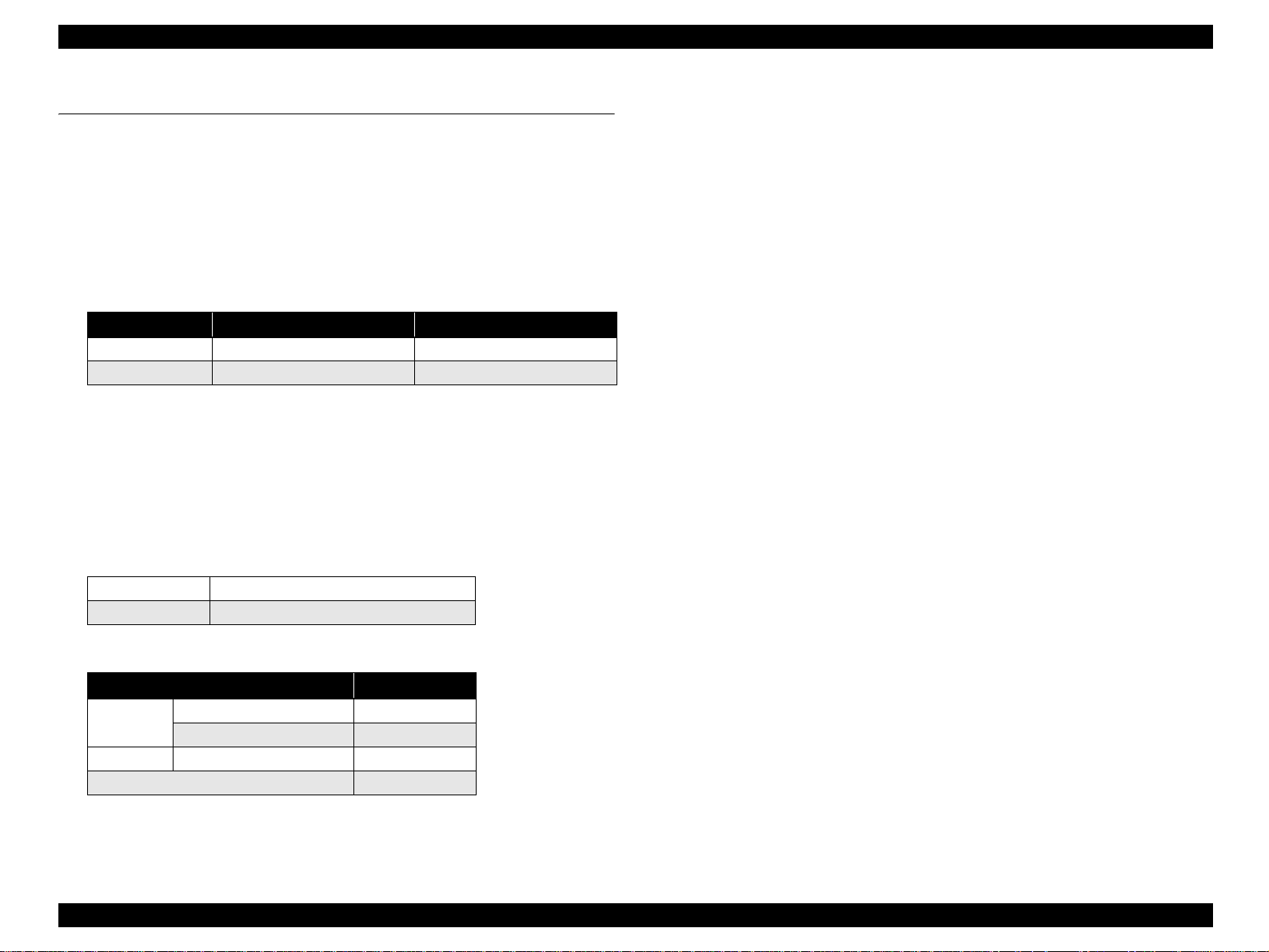

Revision Status

Revision Date of Issue Description

A APR. 28, 2005 First release

Page 9

EPSON AcuLaser C2600/2600 Revision A

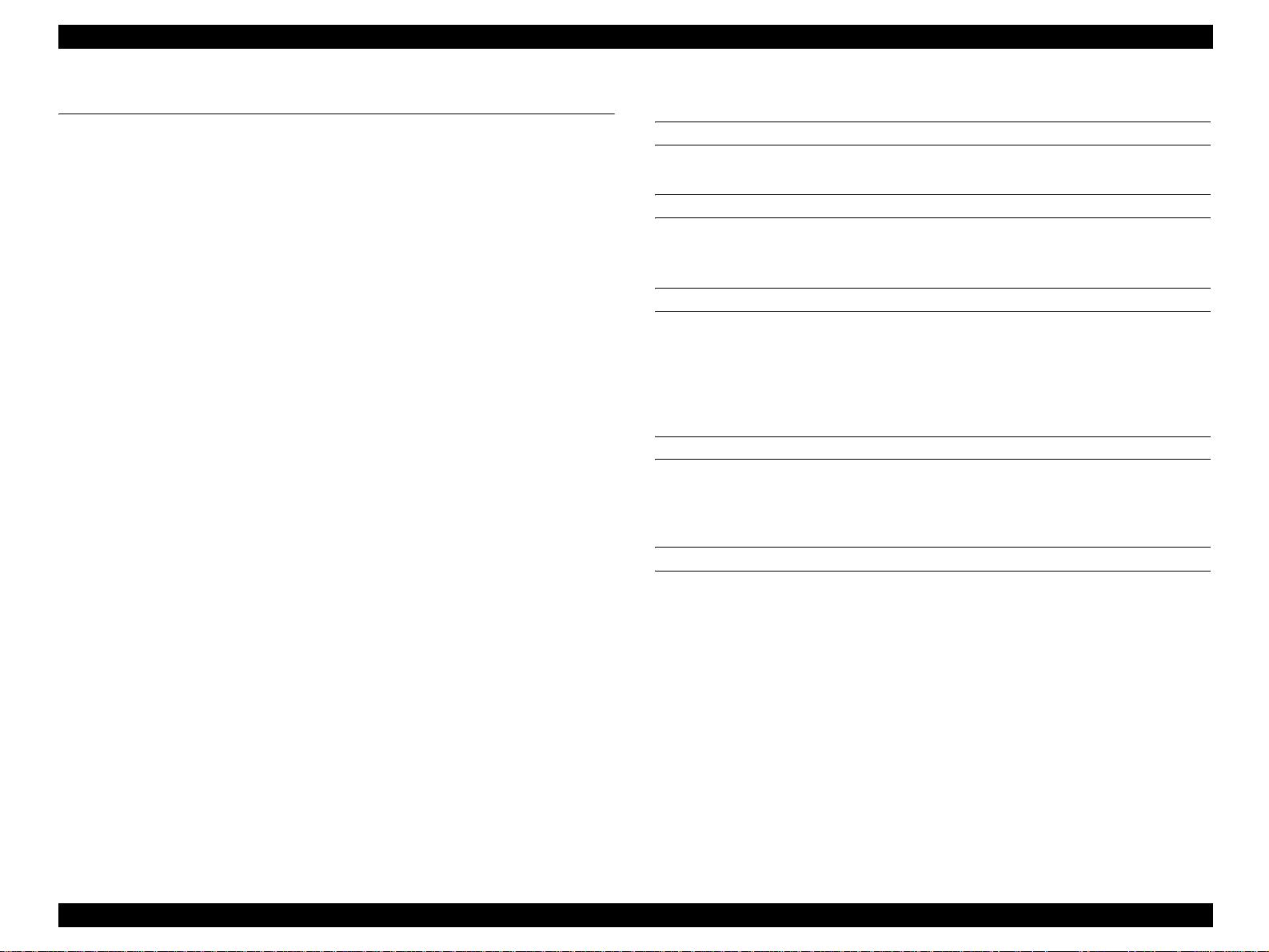

Contents

Chapter 1 Product Description

1.1 Overview ............................................................................................................. 13

1.1.1 Engine Features .......................................................................................... 13

1.1.2 Controller Features..................................................................................... 13

1.1.3 Software Features ....................................................................................... 13

1.2 Basic Specifications............................................................................................ 14

1.2.1 Process Specifications & System................................................................ 14

1.2.2 Printer Basic Specifications ........................................................................ 14

1.3 Paper Specifications ............................................................................................ 22

1.3.1 Paper Type.................................................................................................. 22

1.3.2 Paper That May Cause Printing Defects, Paper Jams or Printer Malfunction.

22

1.3.3 Paper Feed Types........................................................................................ 23

1.3.4 Printing Area............................................................................................... 23

1.4 Reliability and Serviceability.............................................................................. 24

1.4.1 Reliability ................................................................................................... 24

1.4.2 Durability.................................................................................................... 25

1.4.3 Serviceability.............................................................................................. 25

1.5 Service Conditions............................................................................................... 26

1.5.1 Space Requirements.................................................................................... 26

1.6 Conditions for Storage and Transport ................................................................. 27

1.7 Electrical Characteristics..................................................................................... 28

1.8 Compatible Specification .................................................................................... 29

1.9 Consumables/Periodic Replacement Unit........................................................... 30

1.9.1 Specifications.............................................................................................. 30

1.9.2 Conditions for Storage and Transport......................................................... 31

1.10 Maintenance ...................................................................................................... 32

1.11 External Appearance and Unit Names.............................................................. 33

1.11.1 Unit Names............................................................................................... 33

1.12 Engine Restrictions............................................................................................ 34

1.12.1 Factors Limiting Printing Speed............................................................... 34

1.12.2 Toner Duty Limiting Value...................................................................... 34

1.13 Notes When Replacing Consumables and Installing Optional Products .......... 35

1.13.1 Consumables............................................................................................. 35

1.13.2 Options...................................................................................................... 35

1.14 Notes on Fuser Pressure.................................................................................... 35

1.15 Life Details........................................................................................................ 36

1.16 Controller Specifications................................................................................... 40

1.16.1 Controller Basic Specifications................................................................ 40

1.16.2 Controller Configuration.......................................................................... 40

1.16.3 External Interface Specifications.............................................................. 41

1.17 Control Panel..................................................................................................... 43

1.17.1 External Appearance and Names.............................................................. 43

1.17.2 Panel Settings List.................................................................................... 45

1.17.3 Explanation of Menu and Settings............................................................ 56

1.17.4 Special Operations.................................................................................... 58

1.18 Printer Status..................................................................................................... 59

1.18.1 List of Printer Messages........................................................................... 59

1.18.2 Status Messages and Troubleshooting...................................................... 61

1.18.3 Warning Messages and Troubleshooting ................................................. 61

1.18.4 Error Messages and Troubleshooting....................................................... 62

1.18.5 Help Messages.......................................................................................... 65

1.18.6 Service Call Error Messages..................................................................... 71

1.19 Expanding the RAM.......................................................................................... 73

1.20 Handling Precautions ........................................................................................ 73

1.20.1 Precautions When Turning Off the Power ............................................... 73

1.20.2 Precautions for High Temperature Parts .................................................. 73

1.21 Status Sheet....................................................................................................... 74

1.22 Engine Status Sheet........................................................................................... 77

1.23 Paper Handling Algorithm................................................................................ 78

1.24 Toner Check Sheet............................................................................................ 79

1.24.1 For Color Mode........................................................................................ 79

1.24.2 For 4xB/W Mode...................................................................................... 79

1.25 Form Overlay List............................................................................................. 80

9

Page 10

EPSON AcuLaser C2600/2600 Revision A

1.26 Switching between Color Mode and Monochrome Mode ................................ 81

1.26.1 Switching of Operation Mode .................................................................. 81

1.26.2 Switching of Printer Driver ...................................................................... 84

Chapter 2 Operating Principle

2.1 Print Process........................................................................................................ 86

2.1.1 Print Process Overview............................................................................... 86

2.1.2 Print Process Diagram ................................................................................ 87

2.1.3 Technical Explanation of Print Process...................................................... 88

2.2 Paper Feed Mechanism...................................................................................... 104

2.2.1 Main Unit Paper Feed Mechanism........................................................... 105

2.2.2 Duplex Printing......................................................................................... 110

2.2.3 Paper Feed from Opt. Feeder Unit............................................................ 111

2.3 Drive................................................................................................................. 112

2.3.1 Main Drive Motor..................................................................................... 113

2.3.2 Photoconductor Drive Motor.................................................................... 115

2.3.3 Rotary Drive Motor.................................................................................. 115

2.3.4 Development Drive Motor........................................................................ 116

2.3.5 Duplex Motor............................................................................................ 117

2.3.6 Opt. Feeder Motor .................................................................................... 118

2.4 Electrical............................................................................................................ 119

2.4.1 Electronic Circuit Board / R/W Module................................................... 119

2.4.2 Motor........................................................................................................ 120

2.4.3 Solenoids and Clutches............................................................................. 121

2.4.4 Sensors and Switches................................................................................ 122

2.4.5 Interlock Switch........................................................................................ 123

2.4.6 Fan ............................................................................................................ 124

2.5 Control............................................................................................................... 125

2.5.1 Hardware for Control................................................................................ 125

2.5.2 Image-Stabilizing Control ........................................................................ 126

2.5.3 Operation Sequence.................................................................................. 131

2.5.4 Operating Mode........................................................................................ 133

2.5.5 Control of Consumables and Components Needing Periodic Replacement ...

134

2.6 Electrical Circuit Operation Principle............................................................... 136

2.6.1 Electric Circuit.......................................................................................... 136

2.6.2 Engine Control Circuit.............................................................................. 138

2.6.3 Controller.................................................................................................. 140

Chapter 3 Troubleshooting

3.1 Overview................... ...... ................................. ...... .................................. ...... ... 142

3.1.1 Procedure Outline for Troubleshooting.................................................... 142

3.1.2 Preliminary Check.................................................................................... 142

3.1.3 Precautions in Performing Troubleshooting Work................................... 143

3.1.4 Procedure for Troubleshooting................................................................. 143

3.2 Troubleshooting for Paper Jam ......................................................................... 144

3.3 Troubleshooting According to the Error Message............................................ 145

3.3.1 List of Error Message............................................................................... 145

3.3.2 List of Service Request............................................................................. 145

3.3.3 Troubleshooting for Error Message.......................................................... 147

3.3.4 Troubleshooting for Service Request Error.............................................. 157

3.4 Printing-quality troubleshooting (PQT) ............................................................ 184

3.4.1 Print Quality Trouble List......................................................................... 184

3.4.2 Printing-quality troubleshooting............................................................... 186

3.5 Test Print........................................................................................................... 208

Chapter 4 Disassembly and Assembly

4.1 Overview................... ...... ................................. ...... .................................. ...... ... 211

4.1.1 Precautions................................................................................................ 212

4.1.2 Prohibited Disassembly............................................................................ 214

4.1.3 Tools......................................................................................................... 215

4.1.4 Inspection After Assembling .................................................................... 215

4.2 Procedures for Disassembly and Assembly ...................................................... 216

4.3 Disassembly and Reassembly ........................................... ...... ...... .................... 217

4.4 Disassembling Flowchart.................................................................................. 219

4.5 Disassembling/Assembling the Main Unit........................................................ 234

4.5.1 Consumables............................................................................................. 234

4.5.2 Housing..................................................................................................... 240

4.5.3 Paper Transport......................................................................................... 253

4.5.4 Xerographic.............................................................................................. 263

4.5.5 Exposure................................................................................................... 268

4.5.6 Deve.......................................................................................................... 271

4.5.7 Transfer..................................................................................................... 276

4.5.8 Fusing....................................................................................................... 293

4.5.9 Drive......................................................................................................... 294

4.5.10 Electrical................................................................................................. 307

10

Page 11

EPSON AcuLaser C2600/2600 Revision A

4.5.11 MP Tray.................................................................................................. 323

4.5.12 Paper Cassette......................................................................................... 339

4.6 Disassembling/Assembling the Options............................................................ 342

4.6.1 Opt. Feeder ............................................................................................... 342

4.6.2 Duplex Unit .............................................................................................. 355

Chapter 5 Adjustment

5.1 Overview ........................................................................................................... 365

5.1.1 Precautions................................................................................................ 365

5.1.2 Reference Chapter .................................................................................... 365

5.1.3 Adjustment Execution Timing.................................................................. 366

5.2 Adjustment Program (LPssp)............................................................................ 367

5.2.1 Overview................................................................................................... 367

5.2.2 Setup before Adjustment.......................................................................... 367

5.2.3 Writing the model name........................................................................... 370

5.2.4 Writing USB ID........................................................................................ 371

5.2.5 Counter Reset............................................................................................ 372

5.2.6 Timing Adjustment................................................................................... 373

5.2.7 Registration Adjustment (Top)................................................................. 374

5.2.8 Registration Adjustment (Side)................................................................ 375

5.2.9 2nd Transfer Bias Adjustment.................................................................. 376

5.2.10 Vpp Setting............................................................................................. 377

5.3 Firmware Update............................................................................................... 378

5.3.1 Main Controller Firmware Update........................................................... 379

5.3.2 Engine Controller Firmware Update ........................................................ 381

6.5.2 Regular Replacement Parts....................................................................... 397

6.6 Gluing/Lubrication....................................................... ..... ................................ 398

6.6.1 Gluing....................................................................................................... 398

6.6.2 Lubrication................................................................................................ 398

Chapter 7 APPENDIX

7.1 Connector Summary.......................................................................................... 411

7.1.1 Connectors and Plug and Jack Layout...................................................... 411

7.2 Wiring Connection Diagrams....................................... .................................. ... 418

7.3 Parts List............................................................................................................ 433

7.4 Exploded Diagrams........................................................................................... 437

7.5 Circuit Diagrams............................................................................................... 449

Chapter 6 Maintenance

6.1 Overview ........................................................................................................... 385

6.2 Cleaning............................................................................................................. 387

6.3 Maintenance Menu............................................................................................ 389

6.3.1 Entry into Maintenance Mode.................................................................. 389

6.3.2 Maintenance Menu Items ......................................................................... 390

6.4 Sheet for Servicing............................................................................................ 391

6.4.1 Engine Status Sheet.................................................................................. 391

6.4.2 Print Log Report....................................................................................... 394

6.5 Consumables and Components That Need Periodic Replacement.................... 396

6.5.1 Consumables............................................................................................. 396

11

Page 12

PRODUCT DESCRIPTION

CHAPTER

1

Page 13

EPSON AcuLaser C2600/2600 Revision A

1.1 Overview

This printer is a non-impact color page printer that takes advantage of a laser and

electrophotographic technologies.

It provides 600 dpi of resolution and 7.5 ppm (A4, color printing) or 30 ppm (A4,

monochrome printing) of print speed.

1.1.1 Engine Features

High speed 4-cycle A4 engine

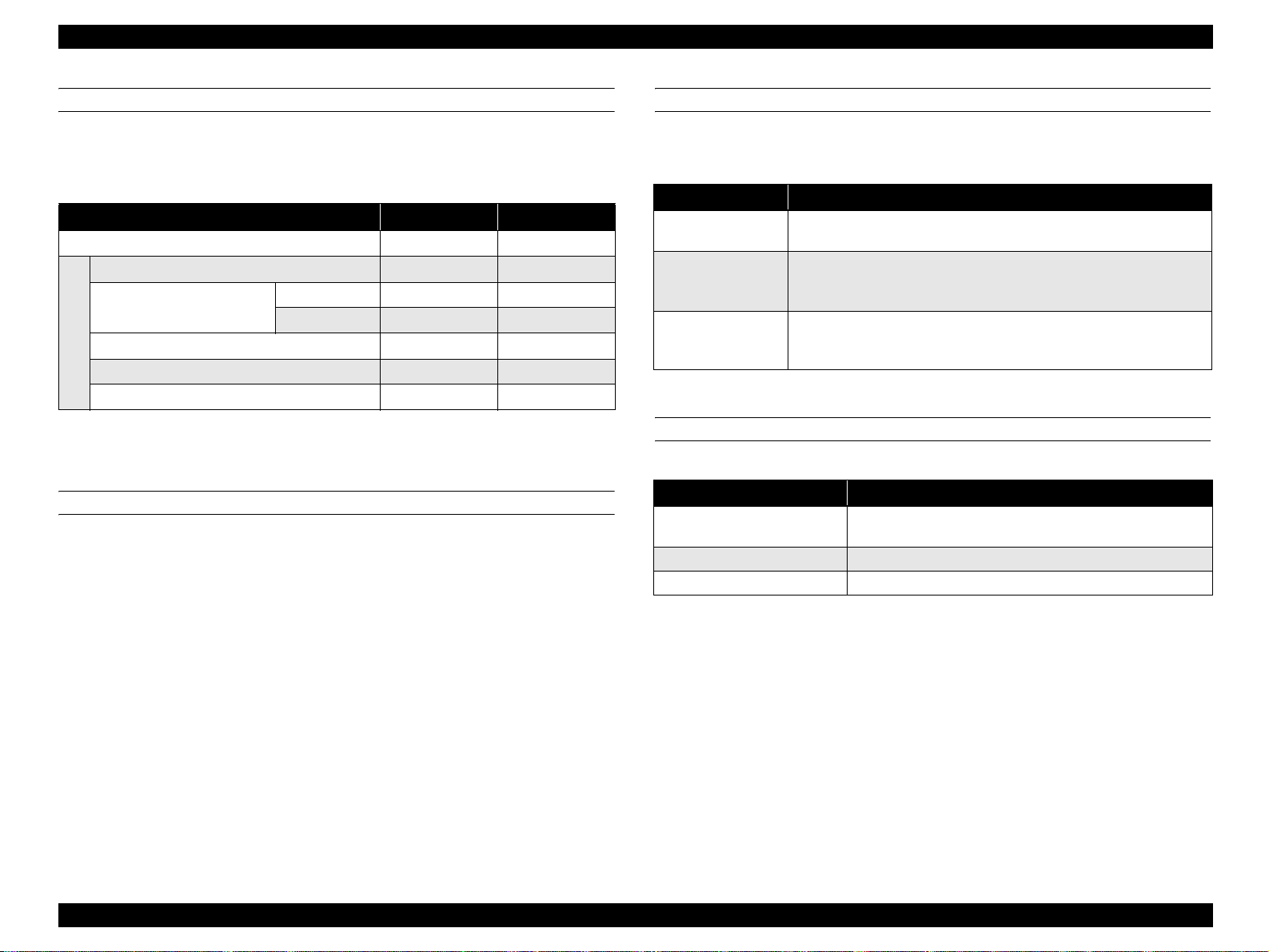

Table 1-1. Print Speed (When Printing A4)

Color printing Monochrome printing

Simplex printing 7.5 ppm 30 ppm

Duplex printing 7.5 ppm 20 ppm

Two models: color and monochrome

The monochrome model has one black toner cartridge bundled as standard.

Adding three black toner cartridges (option) allows the printer to print up to

20,000 copies. Furthermore, the monochrome model can be upgraded to color

model.

The color model can be operated as monochrome model by replacing the color

toners with black ones or removing them.

Compact and light weight, suitable for desktop placement

Dimension 435 mm (W) x 516 mm (D) x 425 mm (H)

Weight 35 kg

Paper supply (Maximum of 1150 sheets, 3-bin paper feed is possible)

1.1.2 Controller Features

High speed intelligent controller

CPU: VR5532A (350 MHz)

RAM

Standard RAM: 64 MB

Expanded RAM: 512 MB (When two 256 MB DIMMs are installed.)

Support for optional large capacity, 40 GB HDD.

Color technology

nPGI, which allows low price, high quality printing

Wide LCD panel with backlight

The new wide LCD panel supp orting a max imum of 2 2 digits a nd 5 lines (132 x 65

dots) provides improved operation and visibility.

Improved serviceability with the addition of the Help function (with description

and graphics).

Interface

USB interface (Rev. 2.0 HS, Supports bi-directional (D4))

Network interface (10Base-T/100Base-TX)

Parallel interface (IEEE1284)

Type-B interface

1.1.3 Software Features

Adobe PostScript 3 (17 fonts), PCL6 (monochrome) as standard

ESC/Page Color, PCL5e, FX, LQ, and IBM emulations are also provided

Paper cassette

Standard

Option Paper cassette unit 500 sheets

MP Tray 150 sheets

Lower paper cass et t e 500 sheets

Maximum 1150 sheets

Paper eject capacity is 250 sheets, face-down only.

Printer status and printer environment monitor with use of bi-directional EJL and

MIB

Version upgrade function for engine program ROM

Support for DCC command (DIAG command only)

Support for firmware overwrite using RCC (full or partial overwrite)

Support for manual duplex

Product Description Overview 13

Page 14

EPSON AcuLaser C2600/2600 Revision A

1.2 Basic Specifications

1.2.1 Process Specifications & System

Printing method: Semiconductor laser beam scan and

electrophotography with dry single component system.

Exposure light source: Semiconductor laser

Photoconductor: Organic photoconductor

Charging: Wire electrode scorotron

Development: 1-component non-contact development system

Toner: 1-component non-magnetic toner

Primary transfer: Intermediate transfer belt method

Fixing: Roller heat fixing system

1.2.2 Printer Basic Specifications

RESOLUTION

600 x 600 dpi

WARMING UP TIME

120 V: 80 seconds or less (at 23 °C, 55 % RH, rated voltage)

230 V: 80 seconds or less (at 23 °C, 55 % RH, rated voltage)

OPERATION MODE

This engine supports the following operation modes.

B/W mode: Supports Toner cartridge K x 1

4xB/W mode: Supports Toner cartridge K x 4

Color mode: Supports Toner cartridges Y x 1, M x 1, C x 1, and K x 1.

PRINT MODE

Color mode: Color mode using Y, M, C, K toner (color mode only)

Monochrome mode: Normal black and white mode, enabling printing at the

highest speed of the main unit.

PRINTING SPEED MODE

Std. mode (plain paper 1): Makes prints at the maximum speed of the engine.

Std. mode (plain paper 2): This mode is to make prints on papers with less

fixability (such as bond papers) at the maximum speed

of the engine. As the fuser unit takes a substantial

amount of time to increase its temperature for fixing

toner onto the papers firmly, the first print time

becomes slow. When it comes to a continuous printing,

however, the printing can be performed at the

maximum speed of the engine.

Low speed mode 1: Slows down the speed of printing on papers with

thickness of 90 g/m

fixability.

2

(24 lb) or more to sustain the

Low speed mode 2: Slows down the speed of printing on envelopes for the

better fixability or on transparents for the stable

permeability.

Product Description Basic Specifications 14

Page 15

EPSON AcuLaser C2600/2600 Revision A

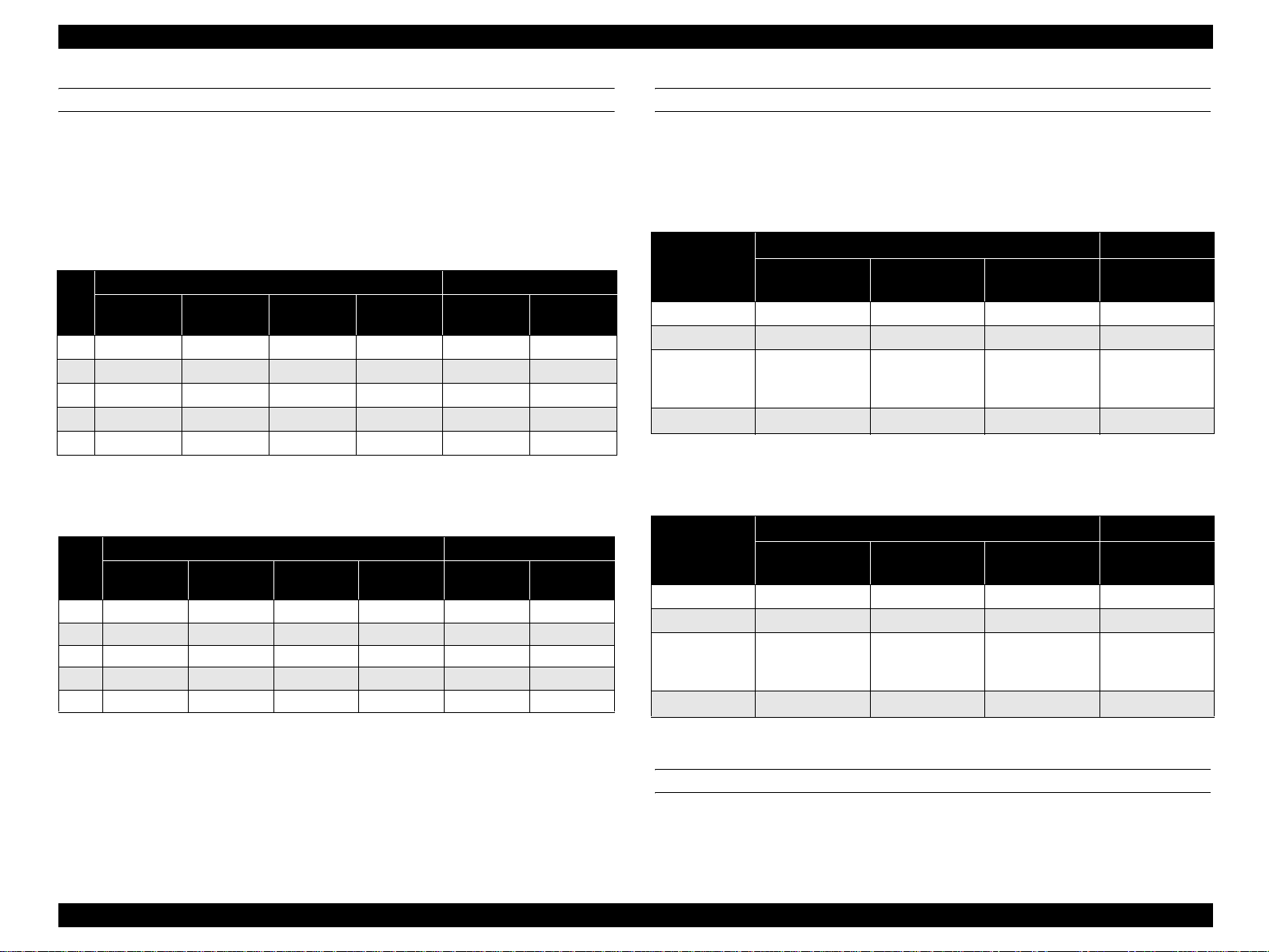

FIRST PRINT TIME

The following table shows the time from receiving a start command to when trailing

edge of the paper leaves the paper eject roller. Note that the time given in the tables

does not apply when the printer is in the conditions described in “1.12 Engine

Restrictions” (p.34).

Monochrome mode*

1

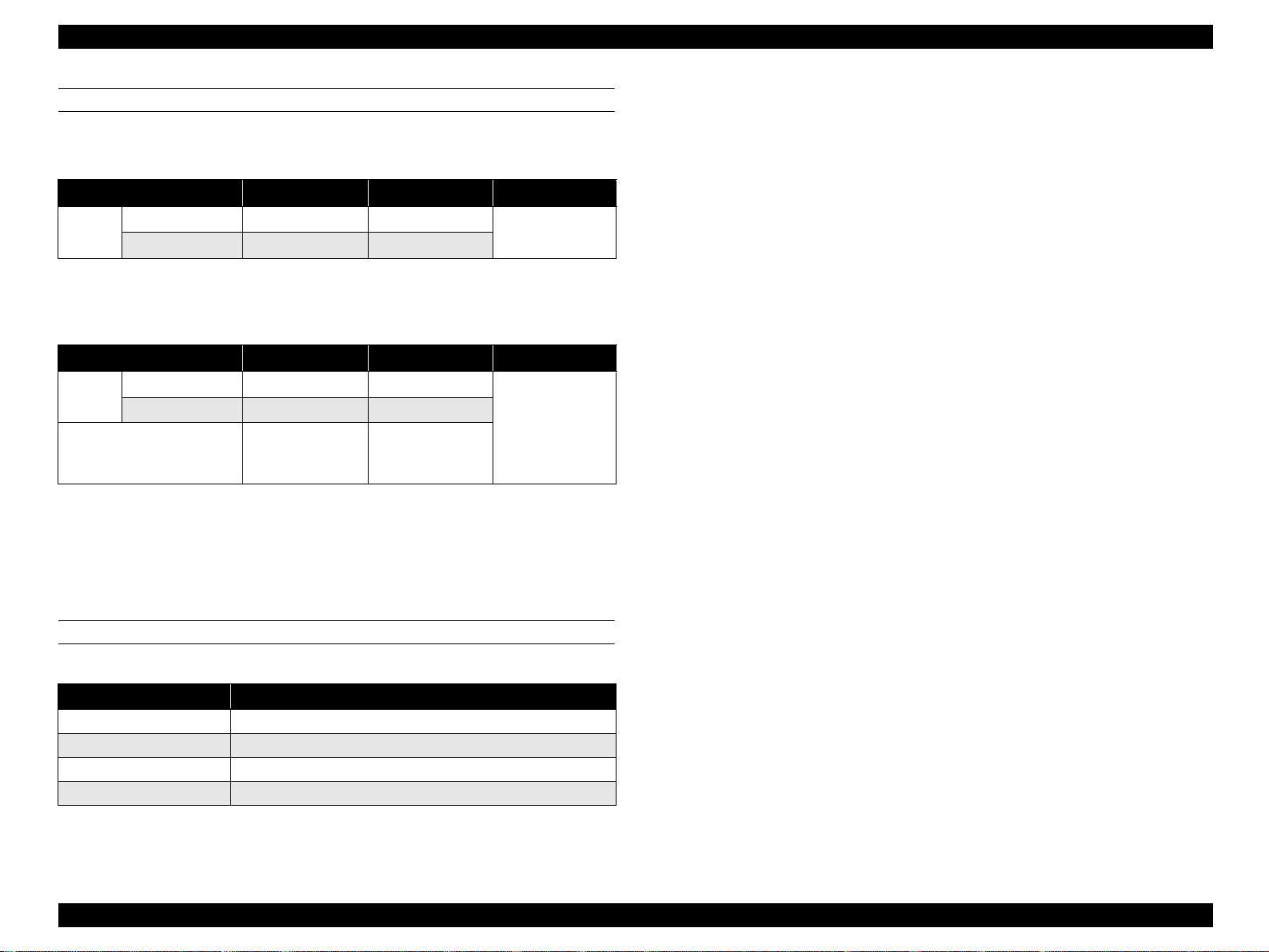

Table 1-2. Monochrome Mode (Unit: Seconds or Less)

Paper

size

A4

A5

B5

LT

EXE

Std. mode

(Plain paper 1)

9.3 19.3 17.9 26.6 13.3 23.3

8.9 18.9 17.1 25.0 12.9 22.9

9.1 19.1 17.6 25.9 13.1 23.1

9.2 19.2 17.8 26.3 13.2 23.2

9.2 19.2 17.7 26.1 13.2 23.2

Color mode*

1

Simplex printing Duplex printing

Std. mode

(Plain paper 2*2)

Low speed

mode 1

Low speed

mode 2

Std. mode

(Plain paper 1)

Std. mode

(Plain paper 2*2)

Table 1-3. Color Mode (Unit: Seconds or Less)

Paper

EXE 15.2 25.2 23.7 32.1 23.2 33.2

Std. mode

size

(Plain paper 1)

A4 15.3 25.3 23.9 32.6 23.3 33.3

A5 14.9 24.9 23.1 31.0 22.9 32.9

B5 15.1 25.1 23.6 31.9 23.1 33.1

LT 15.2 25.2 23.8 32.3 23.2 33.2

Simplex printing Duplex printing

Std. mode

(Plain paper 2*2)

Low speed

mode 1

Low speed

mode 2

Std. mode

(Plain paper 1)

Std. mode

(Plain paper 2*2)

CONTINUOUS PRINTING SPEED

This excludes operations that fall under the restrictions on printing speed explained in

“1.12 Engine Restrictions” (p.34).

Monochrome mode

Table 1-4. Monochrome Mode (Unit: PPM)

Simplex printing Duplex printing

Paper size

A4, B5, LT 30 4.2 2.6 20

A5, EXE 30 4.2 2.6 20

Envelope C6,

MON, DL, C5,

Com-#10

User define d s i z e 30

Std. mode

(Plain paper 1, 2)

––2.6–

Low speed mode 1 Low speed mode 2

4.2 2.6

Std. mode

(Plain paper 1, 2)

–

Color mode

Table 1-5. Color Mode (Unit: PPM)

Simplex printing Duplex printing

Paper size

A4, B5, LT 7.5 2.9 2.1 7.5

A5, EXE 7.5 2.9 2.1 7.5

Envelope C6,

MON, DL, C5,

Com-#10

User define d s i z e 7.5 2.9

Std. mode

(Plain paper 1, 2)

––2.1–

Low speed mode 1 Low speed mode 2

2.1

Std. mode

(Plain paper 1, 2)

–

Note *1: The above speed are the same for any paper feeder including the option cassette.

*2 : The mode to be used for papers that are hardly fixed.

As the temperature for the f ixation is set h igher than that o f the other modes , it takes relati v ely

long period of time until the t em p. rea ches the required level.

PAPER FEED REFERENCE

Center-line reference for each paper size and for both MP tray and 500-sheet cassette

(optional).

Product Description Basic Specifications 15

Page 16

EPSON AcuLaser C2600/2600 Revision A

PAPER FEED

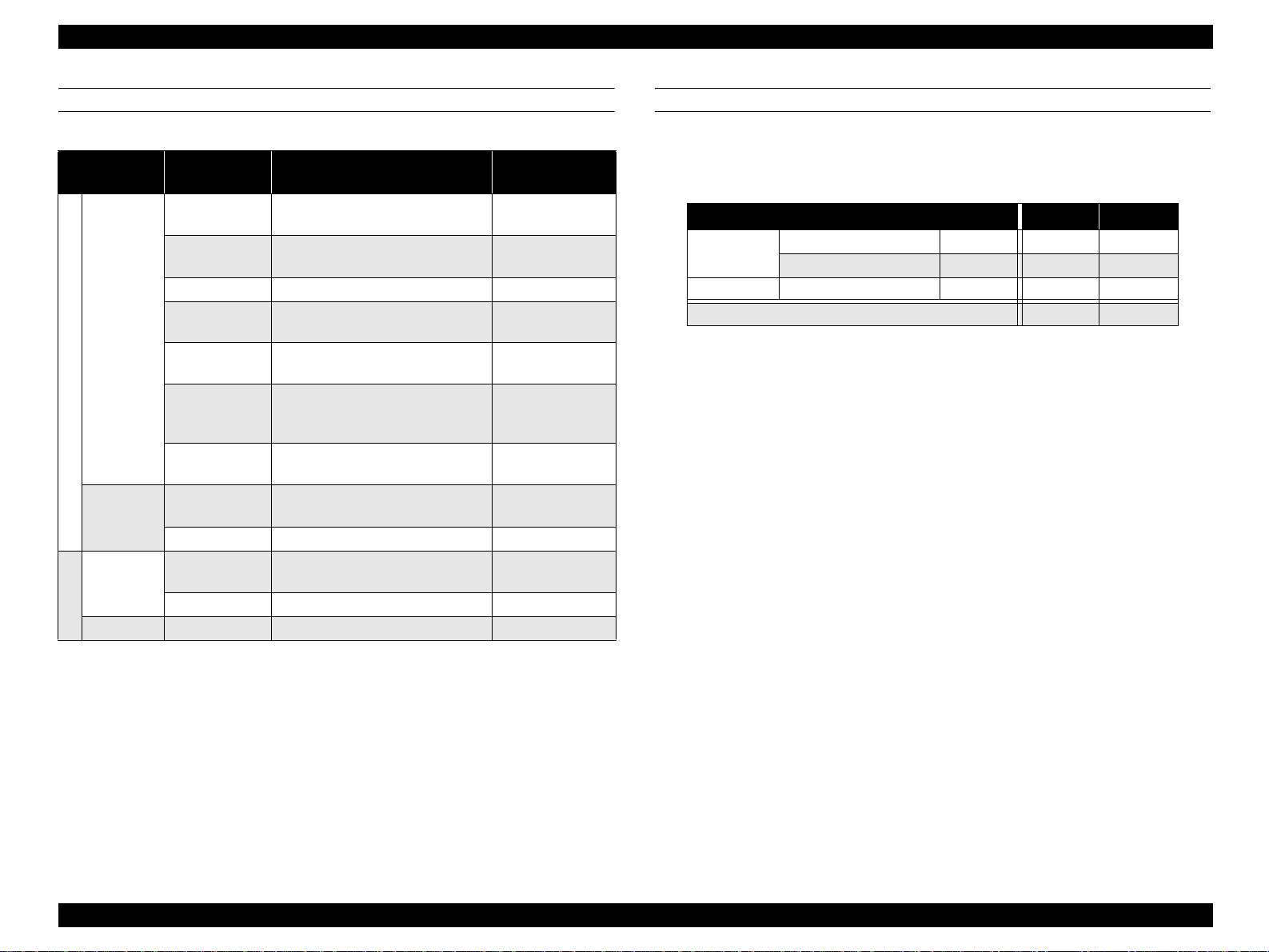

Table 1-6. Paper Feed

Paper feed

Sheet capacity

Height capacity

150 sheets

16.5 mm

Paper type/Paper size

Standard paper:

EPSON high quality plain paper

Plain paper/recycled paper:

A4, A5, B5, LT, GLT, HLT, EXE

60 sheets Transparency: A4, LT –

50 sheets

MP tray

75 sheets

Standard

15 sheets

Labels: A4, LT

EPSON coated papers: A4

Thick Paper:

A4, A5, B5, LT, GLT, HLT, EXE

Envelopes:

C5, C6, Com-#10, DL, Monarch,

ISO-B5

User defined size:

Width 98 to 216/ Length 148 to 297

Standard paper:

EPSON high quality plain paper

Standard paper:

EPSON high quality plain paper

Lower paper

cassette (C1)

Paper

cassette unit

(C2)

Option

16.5 mm

500 sheets

55 mm Plain paper: A4, L T 64 to 90 g/m

500 sheets

55 mm Plain paper: A4, L T 64 to 90 g/m

Duplex – A4, LT, B5, A5, EXE 64 to 90 g/m

Note *: Refer to “1.3 Paper Specifications” (p.22).

Acceptable paper

basis weight*

64 to 90 g/m

91 to 163 g/m

64 to 163 g/m

82 g/m

–

–

82 g/m

82 g/m

OPTIONAL PAPER SOURCE COMBINATION

Installing an optional paper cassette unit enables the printer to load the maximum

number of papers as shown in the table below.

Table 1-7. Optional Paper Source Combination

2

2

Standard

Option Paper cassette unit (C2) 500 sheets* – {

Note *: Standard pa per: EPSON high quality plain paper (82 g/m2)

2

2

2

2

2

2

2

Combination (1) (2)

MP tray 150 sheets* {{

Lower paper cassette (C1) 500 sheets* { {

Total number of sheet s 650 sheets 1150 sheets

Product Description Basic Specifications 16

Page 17

EPSON AcuLaser C2600/2600 Revision A

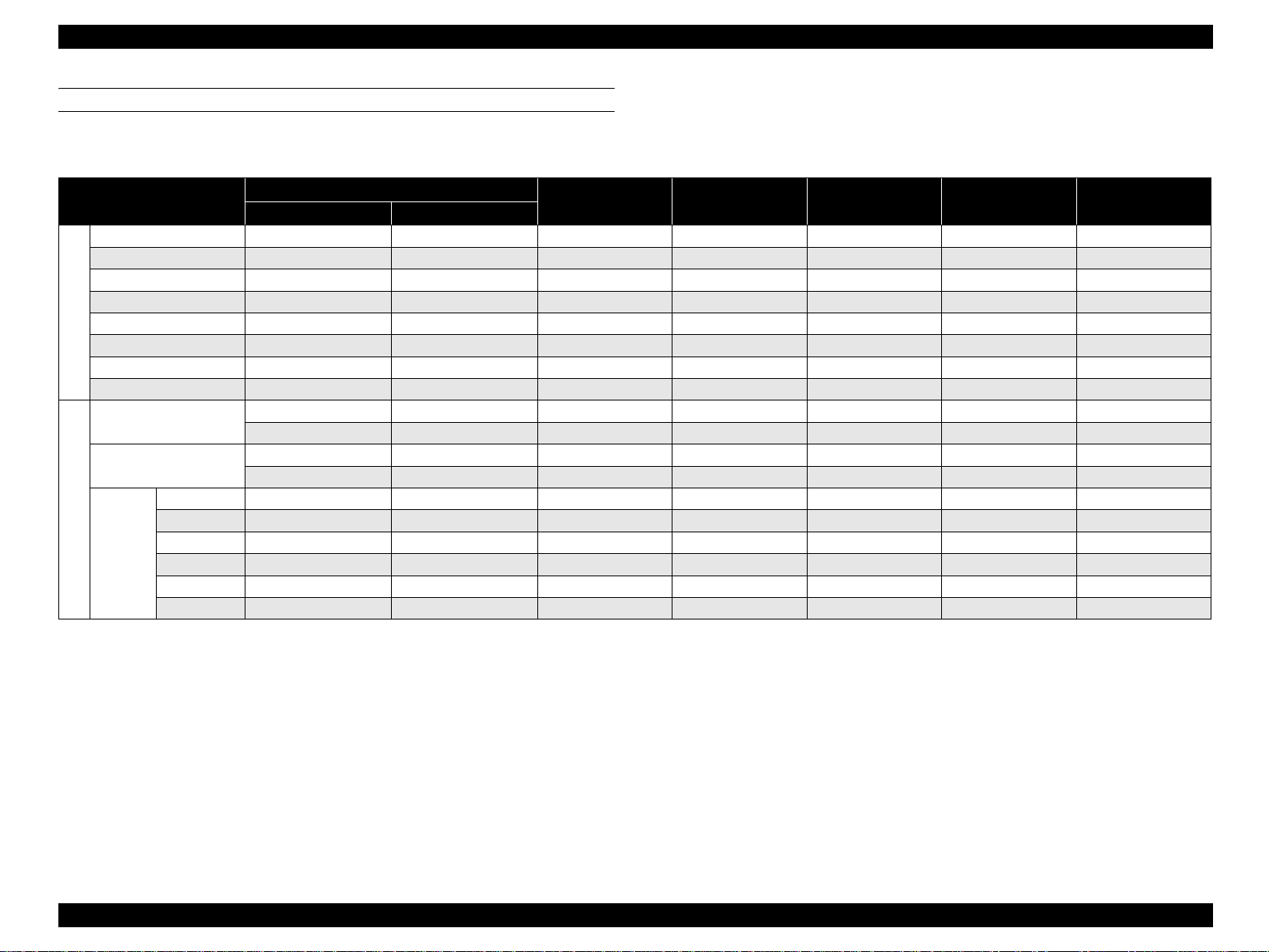

SUPPORTED PAPER SIZE, TYPE AND ORIENTATION

Supported paper

Table 1-8. List of Supported Paper Size, Type and Orientation

Paper

A4 297.00 210.00 {{{SEF {

A5 210.00 148.00 { – – SEF {

JIS-B5 257.00 182.00 { ––SEF{

LT 279.40 (11.00") 215.90 (8.50") { { { SEF {

HLT 215.90 (8.50") 139.70 (5.50") { ––SEF–

Standard

GLT 266.70 (10.50") 203.20 (8.00") { – – SEF –

EXE 266.70 (10.50") 184.15 (7.25") { ––SEF{

User defined pa p er s ize 148.00 to 297.00 98.00 to 216.00 { – – Free –

Transparency

Labels

MONARCH 190.50 (7 1/2) 98.43 (3 7/8) { ––SEF–

Com-#10 241.30 (9 1/2) 104.78 (4 1/8) { – – SEF –

Special paper

DL 220.00 110.00 { ––SEF–

C5 229.00 162.00 { – – SEF –

Envelopes

C6 162.00 114.00 { ––SEF–

ISO-B5 250.00 176.00 { – – SEF –

Paper size Dimensions in mm (inches)

Vertical (length) Horizontal (width)

A4: 297.00 A4: 210.00 { ––SEF–

LT: 279.40 LT: 215.90 { – – SEF –

A4: 297.00 A4: 210.00 { ––SEF–

LT: 279.40 LT: 215.90 { – – SEF –

MP tray

Standard lower

paper cassette

Optional pape r

cassette unit

Paper orientation Duplex printing

Note 1: SEF (Short Edge Feed): Set paper to be loaded from its short side.

2: The supported sizes differ depending on the destination.

3: For the orientation of envelopes, refer to

4: Curls must be straightened.

“Envelope orientation” (p.18).

Product Description Basic Specifications 17

Page 18

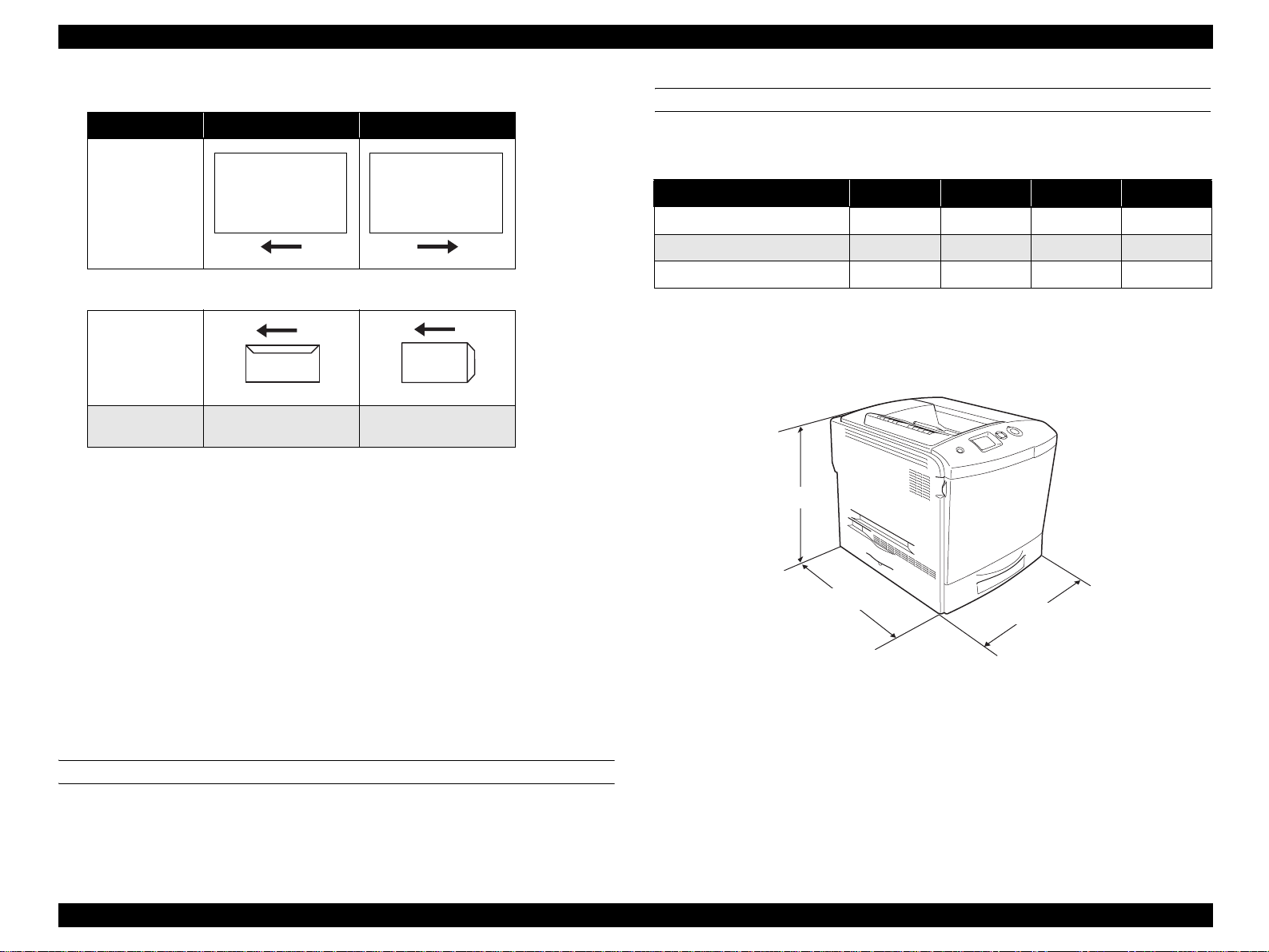

EPSON AcuLaser C2600/2600 Revision A

Paper orientation

Paper Feed MP Tray Cassette (C1/C2)

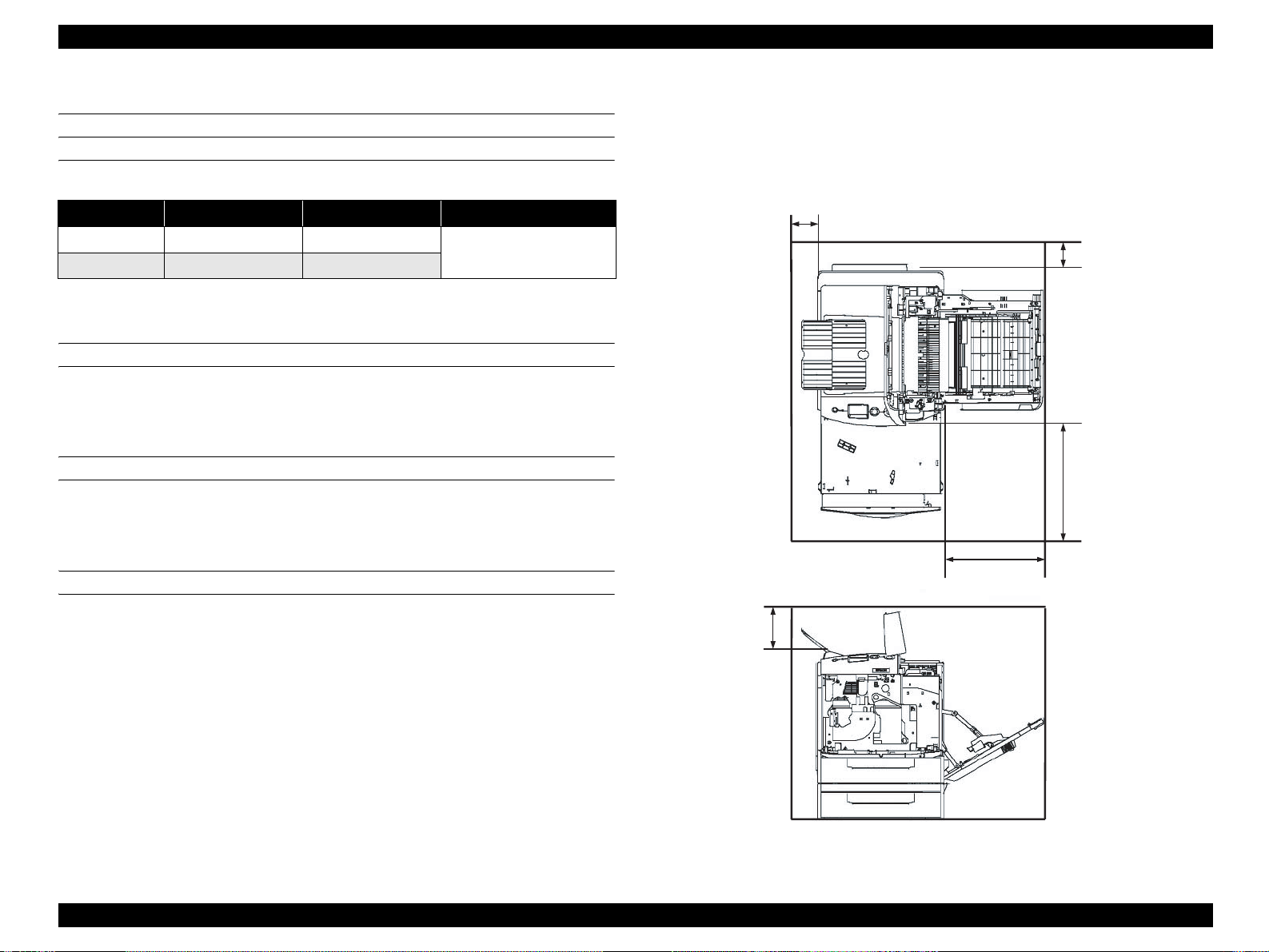

DIMENSIONS AND WEIGHT

Stand alone outline dimensions and weight

Table 1-9. Stand Al one Outline Di m e ns i ons and Weight

Paper Orientation/

Feeding Direction

Place Print Side Down. Place Print Side Up.

Width (mm) Depth (mm) Heigh t (mm) Weight (kg)

Main unit 431 518 425

500-sheet cassette unit (option)

Duplex unit (option)

408 482 140 5

132 282 220 0.9

37*1 / 33*

Envelope orientation

Note : Ma nufacturing tolerance is ± 5 mm in dimensions and ± 0.5 kg in weight.

Note *1: Includes consumables.

Feeding Direction

*2 : Initial condition (exc. Toner Cartridges)

2

01000201

C5

Envelope Types

01000101

MONARCH, DL,

Com- #10, C6

NOTE 1: Place papers in the MP tray with the printable side face down.

2: When the flap is closed, printing on the reverse (flap side) is not

available.

(The flap may adhere to the transfer belt and open, which may

result in paper wrinkles and paper jams.)

3: O nly envelop es without tape or glue can be used.

4: Change the fuser unit lever when printing envelopes.

(For details, refer to “1.14 Notes on Fuser Pressure” (p.35).)

5: Only envelopes with trapezoid shaped flaps can be fed with the

flap opened.

Envelopes with triangular shaped flaps should not be used. (It

may cause a slip off or stack defect.)

PAPER EJECT

Only for face-down (FD) 250 sheets

NOTE: Standard paper: EPSON high quality plain paper (82 g/m

2

)

425 mm

518 mm

431 mm

01000301

Figure 1-1. Dimensions (Main Unit)

Product Description Basic Specifications 18

Page 19

EPSON AcuLaser C2600/2600 Revision A

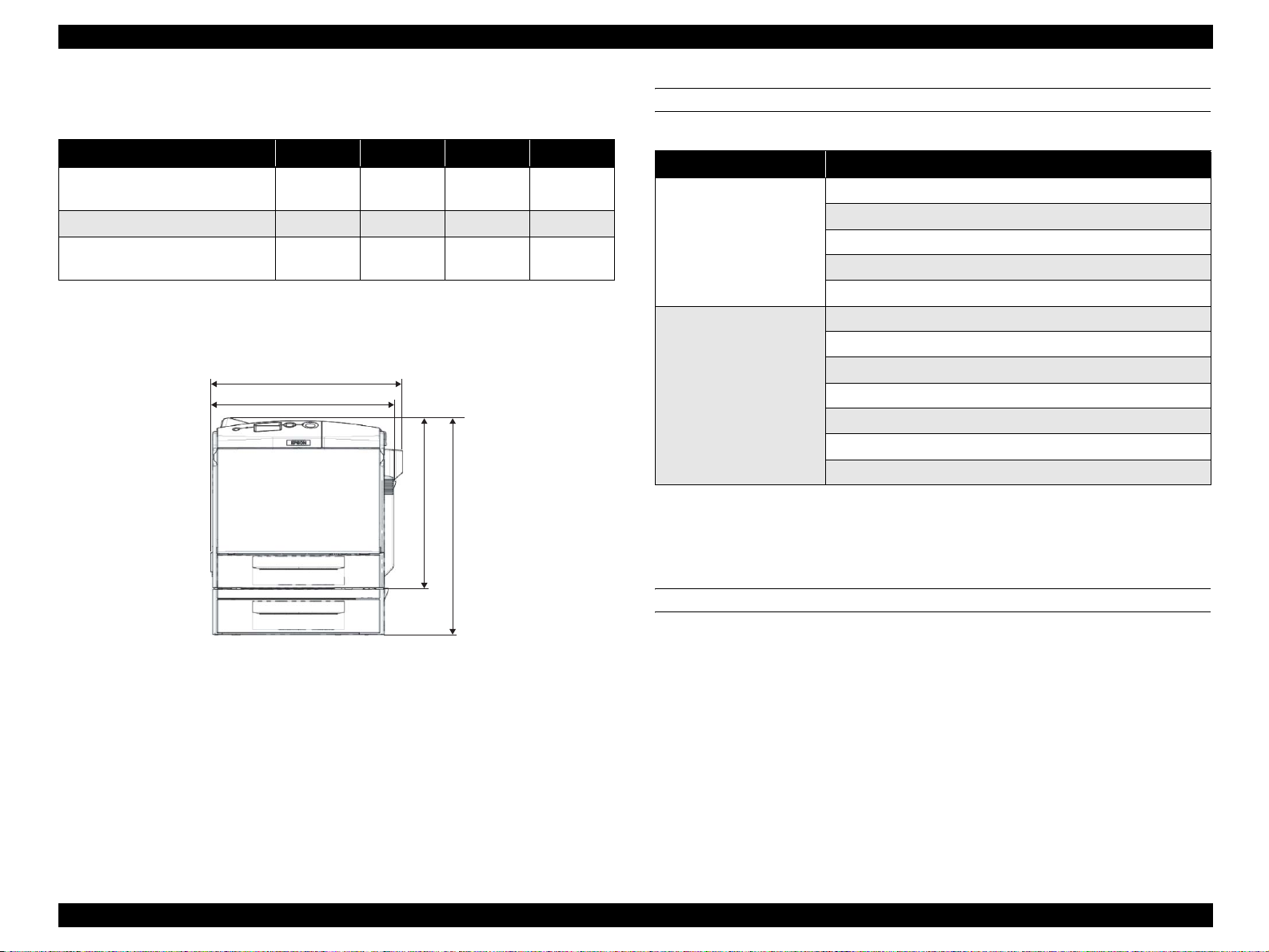

Outline dimensions and weight with options installed

Table 1-10. Outline Dimensions and Weight With Opti ons Installed

Width (mm) Depth (mm) Height (mm) Weight (kg)

Main unit + Optional paper cassette

unit

Main unit + Duplex unit

Main unit + Optional paper cassette

unit + Duplex unit

Note : Manufacturing tolerance is ± 5 mm in dimensions and ± 0.5 kg in wei ght.

Note *: Includes consumables.

431 518 538

447 518 425 38*

447 518 538 43*

447 mm

431 mm

42*

CONSUMABLES AND PERIODIC REPLACEMENT UNIT

Table 1-11. List of Consumables and Periodic Replacement Unit

Classification Replacement unit

Toner cartridge (Black, Cyan, Yellow, Magenta)

Photoconductor un it

Consumables

Periodic replacement units

Fuser unit

Waste toner collector

Filter

Transfer belt unit (TRANSFER, Assy; ASP)

Cleaning tape (MOUNTING PLATE, ANTI-STATIC; ASP)

Cleaner clutch (CLUTCH, CLEANER)

2nd transfer clutch (CLUTCH, 2ND TRANSFER)

Paper eject roller (COVER Assy., FU; ASP)

Post-fixing roller (COVER Assy., FU; ASP)

Pickup roller (ROLLER ASSY, PICK UP)

425 mm

538 mm

Replacement Unit” (p.30).

POWER SUPPLY

Power supply operating voltage/frequency

NOTE: For detailed specifica tions, refer to “1.9 Consumables/P eri od ic

01000401

Figure 1-2. Dimensions (Including Options)

AC 110 V to 120 V ± 10 %, 50 Hz / 60 Hz ± 3 Hz

AC 220 V to 240 V ± 10 %, 50 Hz / 60 Hz ± 3 Hz

Power supply for the controller

DC 5.0 V ± 5 %, 2A

DC 3.3 V ± 5 %, 5A

Product Description Basic Specifications 19

Page 20

EPSON AcuLaser C2600/2600 Revision A

POWER CONSUMPTION

The maximum rated current is measured with all engine options and controller options

installed.

Table 1-12. List of Power Consumption

120V 230V

Maximum rated curr ent 10 A or less 6 A or less

Maximum 880 W 900 W

Continuous printing average

Average during standby with the heater on 96 W 99 W

Sleep mode* 10 W or less 12 W or less

Power consumption

Power supply off 0 W 0 W

Note *: Refer to “Table 1-13. Operating State” (p.20).

Color 335 W 332 W

Monochrome 567 W 583 W

CONSUMPTION CURRENT

500-sheet cassette unit (op tion)

5 V / 0.3 A or less

24 V / 0.35 A or less

Du plex unit (option)

5 V / 0.1 A or less

24 V / 1.0 A or le ss

OPERATING STATE

This printer operates in the following 3 operating states.

Table 1-13. Operating State

Operational mode Explanation

Operating state

Standby state

Sleep state

Performs a print job in va rious printi ng mode upon receiv ing a comma nd

from the controller.

Standby state. Switches to this mode auto matic a lly after comp le tin g a

print job (exits out of the operating state) without receiving any

commands.

Switches to this mode on receiving a comman d from the con trol le r.

Supporting BAM and International Energy Star Program (power

consumption 21W or less within 30 minutes after the printing operation)

PRODUCT LIFETIME

Table 1-14. Product Lifetime

Product lifetime

1

Main unit

Optional paper cassette unit 400,000 pages*

Duplex unit 600,000 pages*

Note *1: 1,200,000 pages for single color images

*2: 480,000 pages when the ratio of color and monochr ome is 1:1 (1,200,000 images)

*3: 2/3 of the main unit max pages (Monochrome 600,000 pages)

*4: When all of the main unit m a x pages (Monochrome 600,000 pages) are made by

duplexing.

300,000 pages (color*

5 years; whichever comes first.

) or 600,000 pages (monochrome)*2 or

3

4

Product Description Basic Specifications 20

Page 21

EPSON AcuLaser C2600/2600 Revision A

NOISE

Sound pressure

Table 1-15. Sound Pressure

Operating state Standby state Sleep state

Main unit

Note : Reference values

Color mode 56 dB (A) 40 dB (A)

Monochrome mode 56 dB (A) 40 dB (A)

Background noise

Sound power

Table 1-16. Sound Power

Operating state Standby state Sleep state

Main unit

With all optional installations

(reference value)

Note *: The method of measu ring and calculation conforms to ISO-7779 and ISO-9296.

Color mode 68 dB (A)* 52 dB (A)

Monochrome mode 66 dB (A)* 52 dB (A)

Exceeds the main

unit values by less

than 1 db

(Employing standard values for RAL-UZ85 (BAM standard))

52 dB (A)

Background noise

Note : (A) indicates that the valu e has be en adju sted with c on side ra tio n of hu ma n sen sitiv ity

to frequencies (correction by A characteristic).

EXHAUST GAS

Table 1-17. Exhaust Gas

Value

3

Ozone Concentration 0.02 mg/m

Styrene Concentration 0.07 mg/m3 or less (the measurin g me thod conforms to BAM)

Fine Particles Concentration 0.075 mg/m

TVOC 0.40 mg/m3 or less

or less (the measurin g me thod conforms to BAM)

3

or less (the measuring met hod conforms to BAM)

Product Description Basic Specifications 21

Page 22

EPSON AcuLaser C2600/2600 Revision A

1.3 Paper Specifications

1.3.1 Paper Type

Standard paper

RX-80 paper (Monochrome), 4024 paper (20 lb) (Monochrome),

EPSON high quality plain paper (A4)

Plain paper

64 g/m

Recommended recycled paper: Recommended Recycling Copy classic

Special paper

EPSON transparency sheets (A4, LT)

Labels

Thick papers (91 g/m

Envelopes (75 g/m

EPSON coated papers (A4) (Guarantees only the paper feedability)

C H E C K

P O I N T

2

to 90 g/m2 (17 lb to 24 lb)

(General purpose copy papers and recycled papers.)

2

to 163 g/m2)

2

to 105 g/m2)

lb: Ream weight = Total weigh of 500 sheets of 17" x 22"

sized paper

g/m

2

:1 g/m2 = 0.2659763 lb

Before purchasing a large amount of paper, test the paper if it

can be printed normally.

1.3.2 Paper That May Cause Printing Defects, Paper Jams or Printer Malfunction

Transfer paper (carbon paper, non-carbon paper), thermal paper, impact paper,

acid paper

Paper that is too thin or too thick

Paper that is wet or damp

Paper with special coatings or color printer paper with processed surfaces

Glossy (too slick) paper, or paper with too rough surface

Paper that the roughness is significantly different by side

Paper with punch holes or perforations

Creased, curled or torn paper

Irregularly shaped paper or paper with non-perpendicular corners

Labels that peel off easily

Paper with glue, staples or paper clips attached to it

Special paper for ink jet applications (super-fine, glossy, glossy film, etc.)

Paper previously used in a thermal or ink jet printer

Transparencies for other color laser printers or color photocopiers

Paper that has been already printed with other color/monochrome laser printers or

photocopiers

Sheets of paper stuck together

Postcards for ink jet printers, unofficial postcards, and adhesive postcards

Iron print coated paper (for both ink jet and laser printers)

Paper that is deteriorated or discolored, due to temperatures lower than 235 ºC.

Product Description Paper Specifications 22

Page 23

EPSON AcuLaser C2600/2600 Revision A

1.3.3 Paper Feed Types

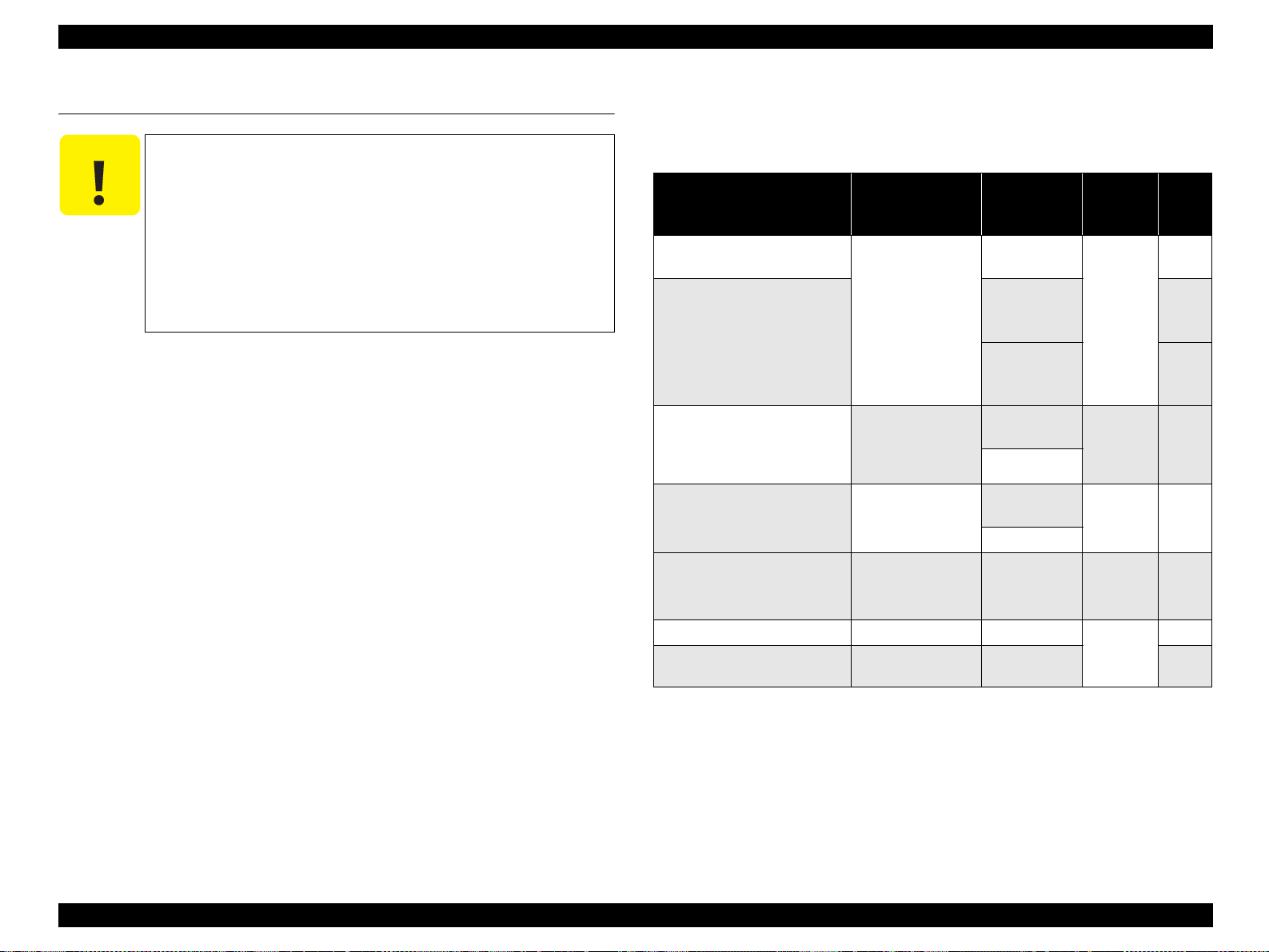

Table 1-18. Paper Feed Types

Special paper

Feeder

MP tray {

Paper

Standard

cassette

Paper

cassette unit

Option

Duplex unit { X X X X

Note :

{ : Paper feed and image quali ty is guaranteed.

: Paper feed and printing is possible. However, this is limited to types of paper for general

applications. Image quality is not guaranteed.

X : Paper feed is impossible.

Standard

paper

{ X X X X

{XXXX

Plain

paper

Transpar-

ency

Labels

Thick

paper,

Coated

paper

Envelopes

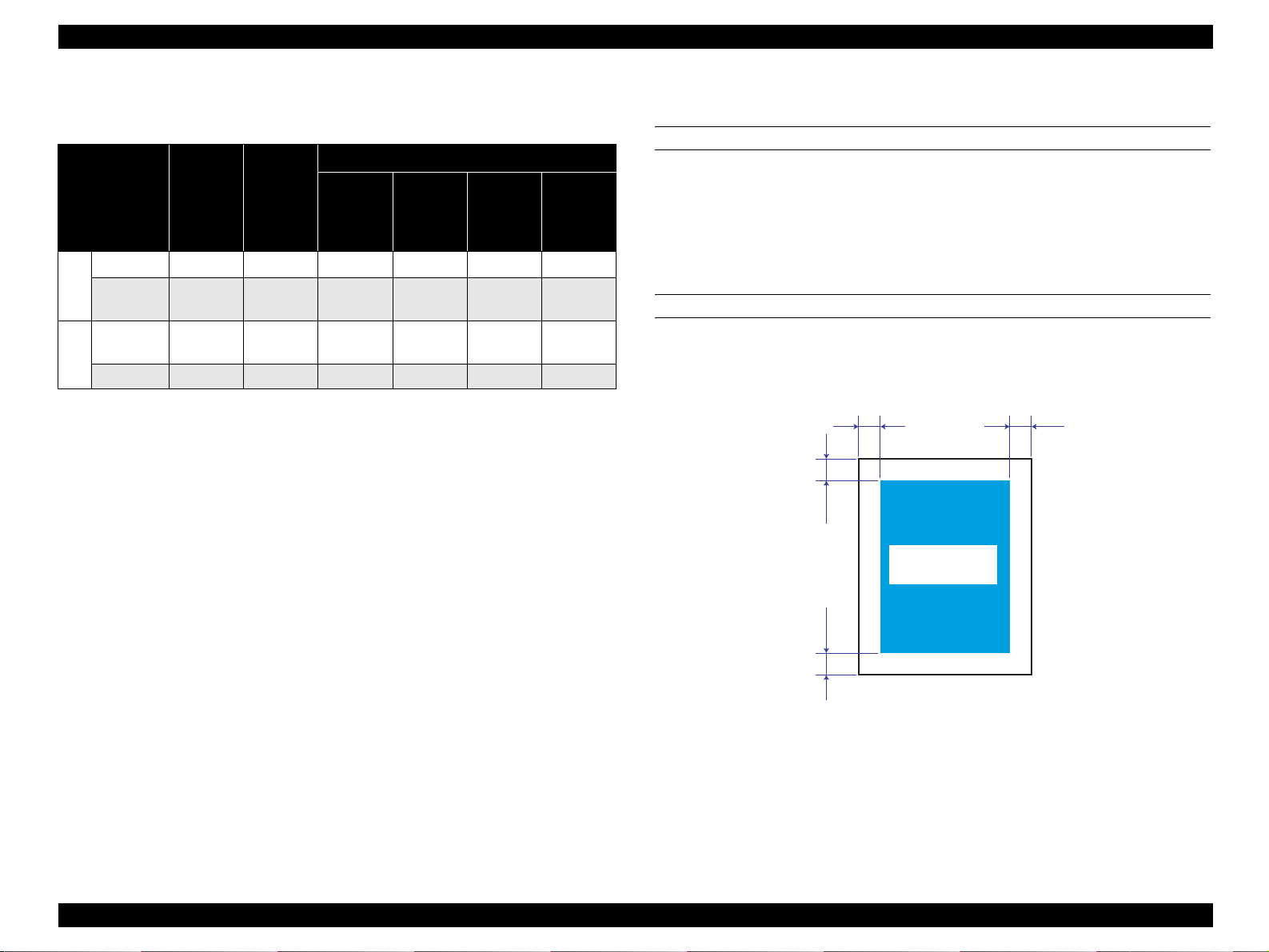

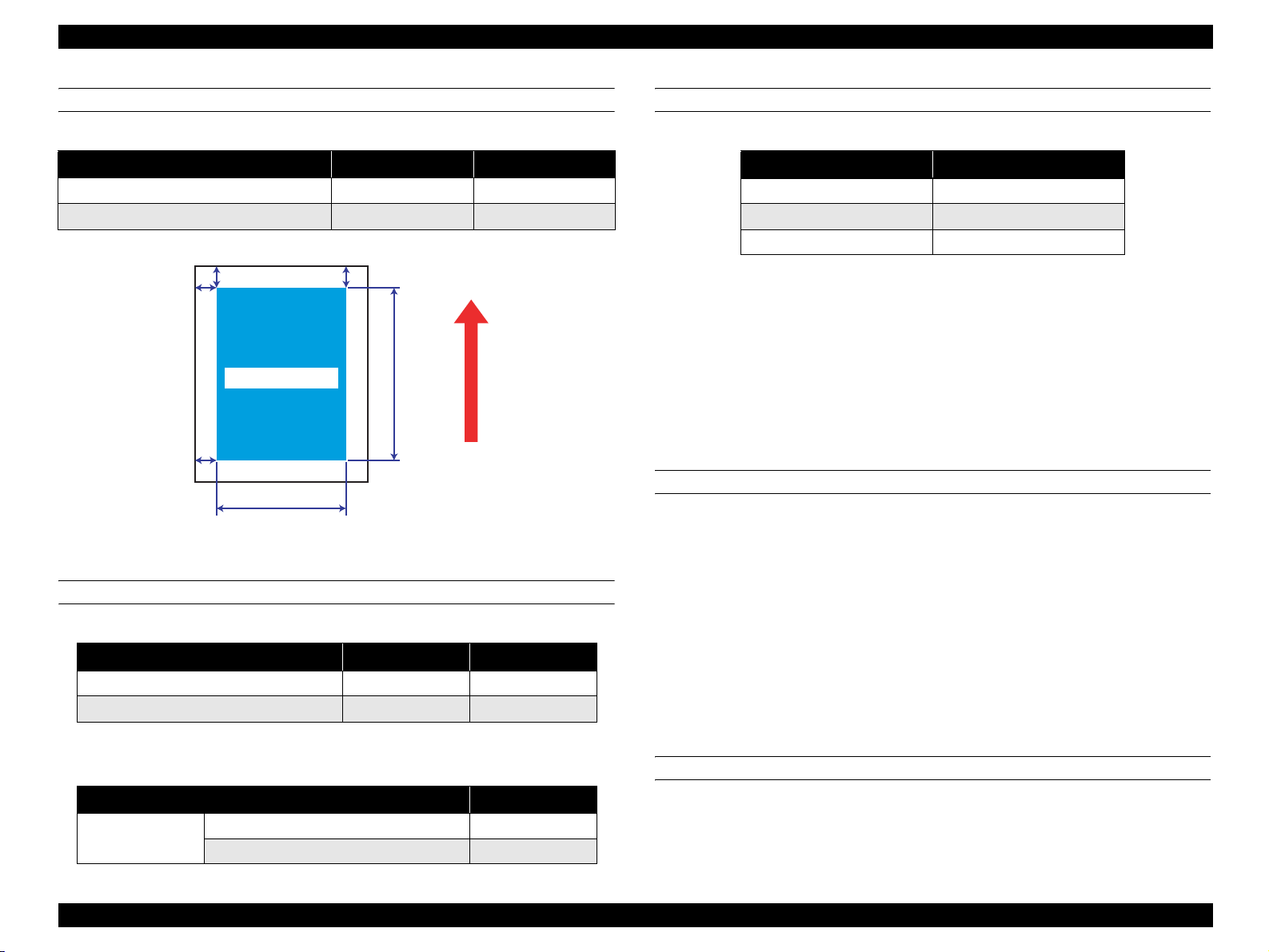

1.3.4 Printing Area

MAXIMUM PRINTABLE AREA

208 mm (width) x 289 mm (length)

NOTE: Although papers smaller than the maxi mum pr int abl e s ize ca n be printed

without margins, continuous printing on such papers, especially if the

left, right, top, and bottom margins beyond the paper exceed 4 mm,

causes contamination inside the printer and paper jam.

GUARANTEED PRINTING AREA

The guaranteed printing area is sho wn b elow. Th e min imum left, rig ht, to p an d bottom

margins are 4 mm for any type of paper.

4 mm4 mm

4 mm4 mm

Guaranteed

Printing Area

01000501

Figure 1-3. Guaranteed Printing Area

Product Description Paper Specifications 23

Page 24

EPSON AcuLaser C2600/2600 Revision A

1.4 Reliability and Serviceability

1.4.1 Reliability

MPBF/MTBF

60, 000 pages or more*

NOTE *1:

Assuming the ratio of color and monochrome is 1:1

*2:

Assuming an average power-on time is 300 hours per month.

1

/ 3,000 hours or more*

2

PAPER FEED RELIABILITY

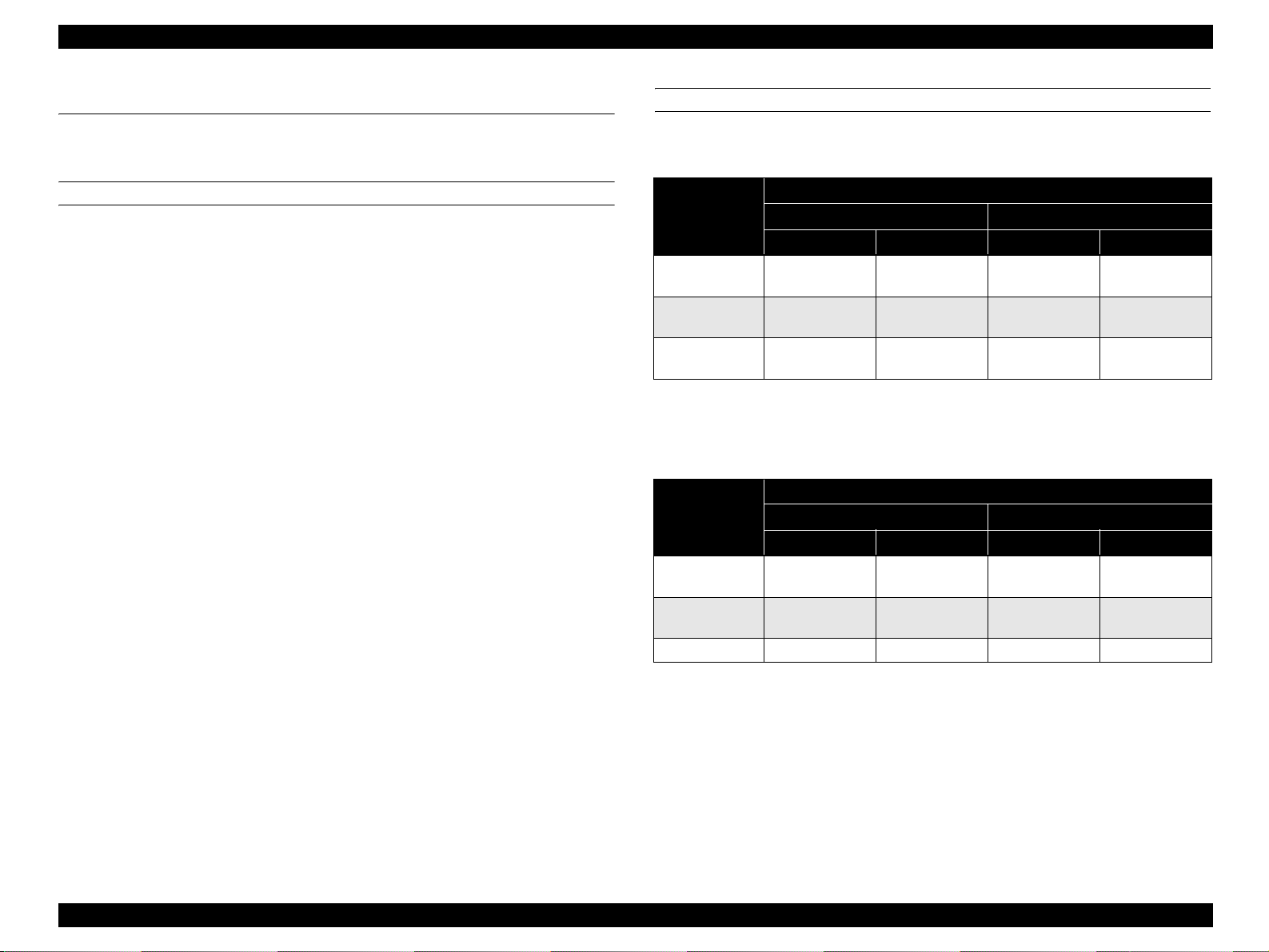

Jam r a te

Table 1-19. Jam Rate

Paper Type

Reliability issue

Standard paper

Plain paper

Special paper

Simplex printing Duplex printing Simplex printing Duplex printing

1/4000 sheets or

less

1/2000 sheets or

less

1/100 sheets or

less

Environment A*

Paper feed error / multiple sheet feeding*

Table 1-20. Paper Feed Error/Multiple Sheet Feeding/

Paper Wrinkles/Creased Corner Rate

Reliability issue

Simplex printing Duplex printing Simplex printing Duplex printing

Standard paper

Plain paper

Special paper 1/25 sheets or less – 3/25 sheets or less –

1/1000 sheets or

less

1/500 sheets or

less

Environment A*

1

2/4000 sheets or

less

2/2000 sheets or

less

–

3

/ paper wrinkles / creased corner rate*

Paper Type

1

2/1000 sheets or

less

2/500 sheets or

less

Environment B*

3/4000 sheets or

less

3/2000 sheets or

less

3/100 sheets or

less

Environment B*

3/1000 sheets or

less

3/500 sheets or

less

6/4000 sheets or

less

6/2000 sheets or

less

6/1000 sheets or

less

6/500 sheets or

less

2

–

4

2

Note *1: Conditions for environment A (15 to 28 °C / 35 to 70 % RH)

Paper size: Standard-size

Humidity control: no regulation

*2: Conditions for environment B (10 to 30 °C / 15 to 65, 85 % RH)

Paper size: Standard-size

Humidity control: uncontrolled packed papers

*3 : The multiple sheet feeding rate does not include the performance at the boundary of

the originally loaded papers and additionally replenished papers.

*4: Counts creases more than C1 mm.

Product Description Reliability and Serviceability 24

Page 25

EPSON AcuLaser C2600/2600 Revision A

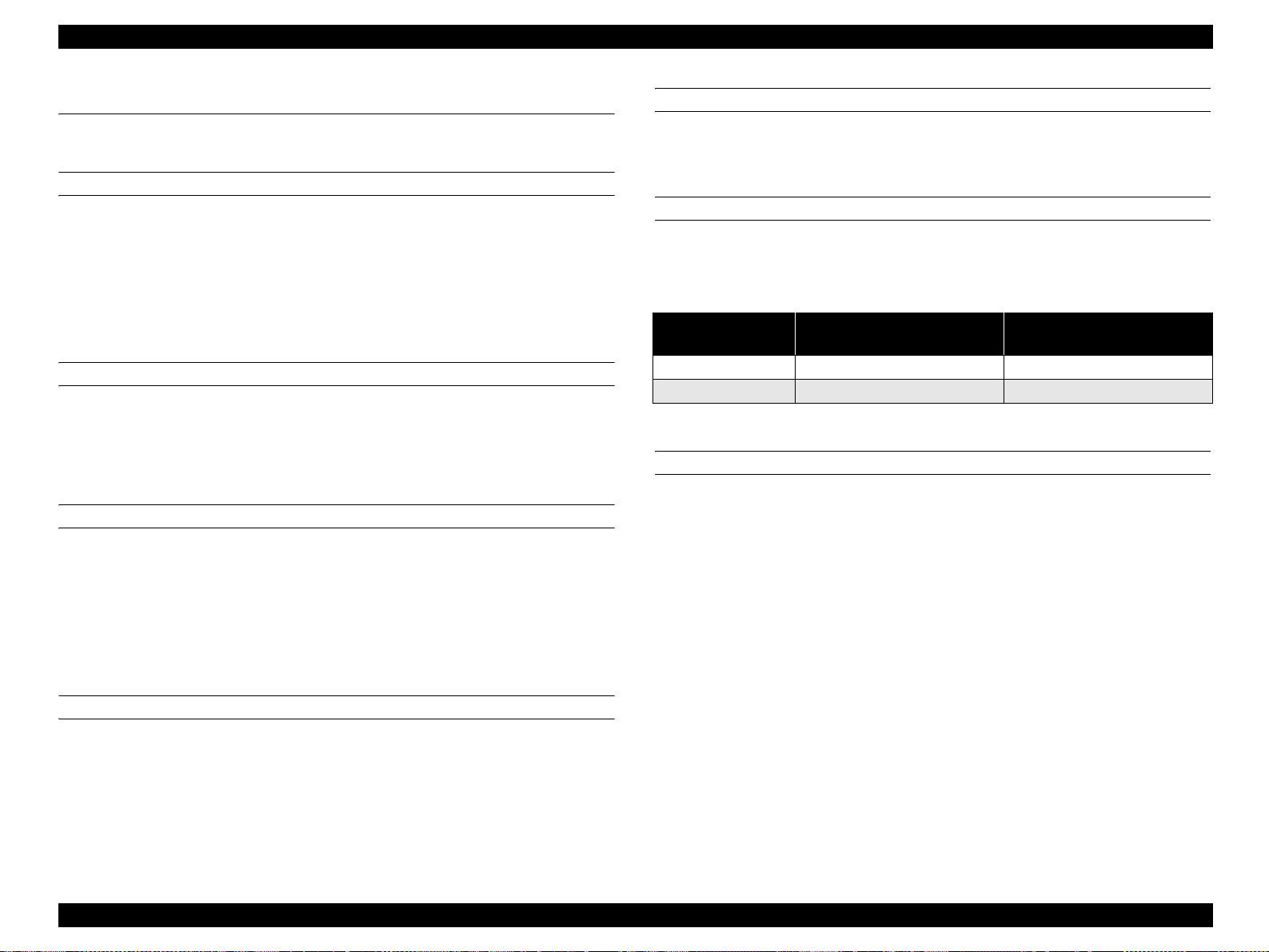

PRINTING START POSITION ACCURACY

Table 1-21. Printing Start Position Accuracy

A4/A3 Simplex printing Duplex printing

Main scanning direction Reference point (c)

Sub-scanning direction Reference point (a) ± 2.5 mm ± 2.5 mm

a

c

Printable Area

± 2.0 mm ± 3.0 mm

b

f

Feed Direction

d

e

01000601

Figure 1-4. Printing Start Position Accuracy

HEIGHT OF CURL ON OUTPUT PAPER

Table 1-24. Height of Curl on Output Paper

Paper type Height of Curl

Standard paper, P lain paper 30 mm or less

Transparency 15 mm or less

Other special papers No regulation

Note 1: The same for simplex and duplex printing

2: Measurement conditions:

Image occupation rate 5 % misaligned monochrome printing, or color

printing with 5 % of each color (total 20 %).

Print 10 sheets of 1p/J intermittent printing, then measure after an

interval of 1 minute.

Differs in accordance with the image occupation rate/array pattern

printing conditions.

1.4.2 Durability

PRINT VOLUME

Average: 8,000 pages/month*

Maximum: 48,000 pages/month (Color mode)*

120,000 pages/month (Monochrome mode)*

1

2

3

SKEW

Table 1-22. Skew

A4 Simp le x pr intin g Duplex printi ng

Main scanning direction (| a-b |) 1.47 mm 2.21 mm

Sub-scanning direction (| c-d |) 2.05 mm 3.07 mm

NOTE *1:

*2:

*3:

Product lifetime 480,000 pa ges as sumin g the ratio of color and mo nochro me

printing i s 1:1; 5 years assuming the usage is 8,000 page/months.

The ratio of color and monochrome printing is 1:1

Color printing only:30,000 pages/month

6,000 pages (MaxPV/day) x 20 day s

1.4.3 Serviceability

Table 1-23. Length Standard of Measurement

A4

Simplex printing

Duplex printing

Main scanning direction (e) 208 mm

Sub-scanning direct ion (f) 289 mm

Product Description Reliability and Serviceability 25

MTTR

Average 30 minutes or less

The MTTR value indicated above represents the time for service personnel to

locate and correct the malfunction only, and the time for ex amining malfunction is

not included.

Page 26

EPSON AcuLaser C2600/2600 Revision A

1.5 Service Conditions

AMBIENT TEMPERATURE AND HUMIDITY

Table 1-25. Ambient Temperature and Humidity

Temperature (ºC) Humidity (%RH) Other

Operating 1 0 to 35 15 to 85

Non-operating 0 to 35 10 to 85

AIR PRESSURE (ALTITUDE)

76 kPa or more (2,500 m or less)

LEVELNESS

Difference between front and back or left and right should be 1 º or less

No condensation allowed

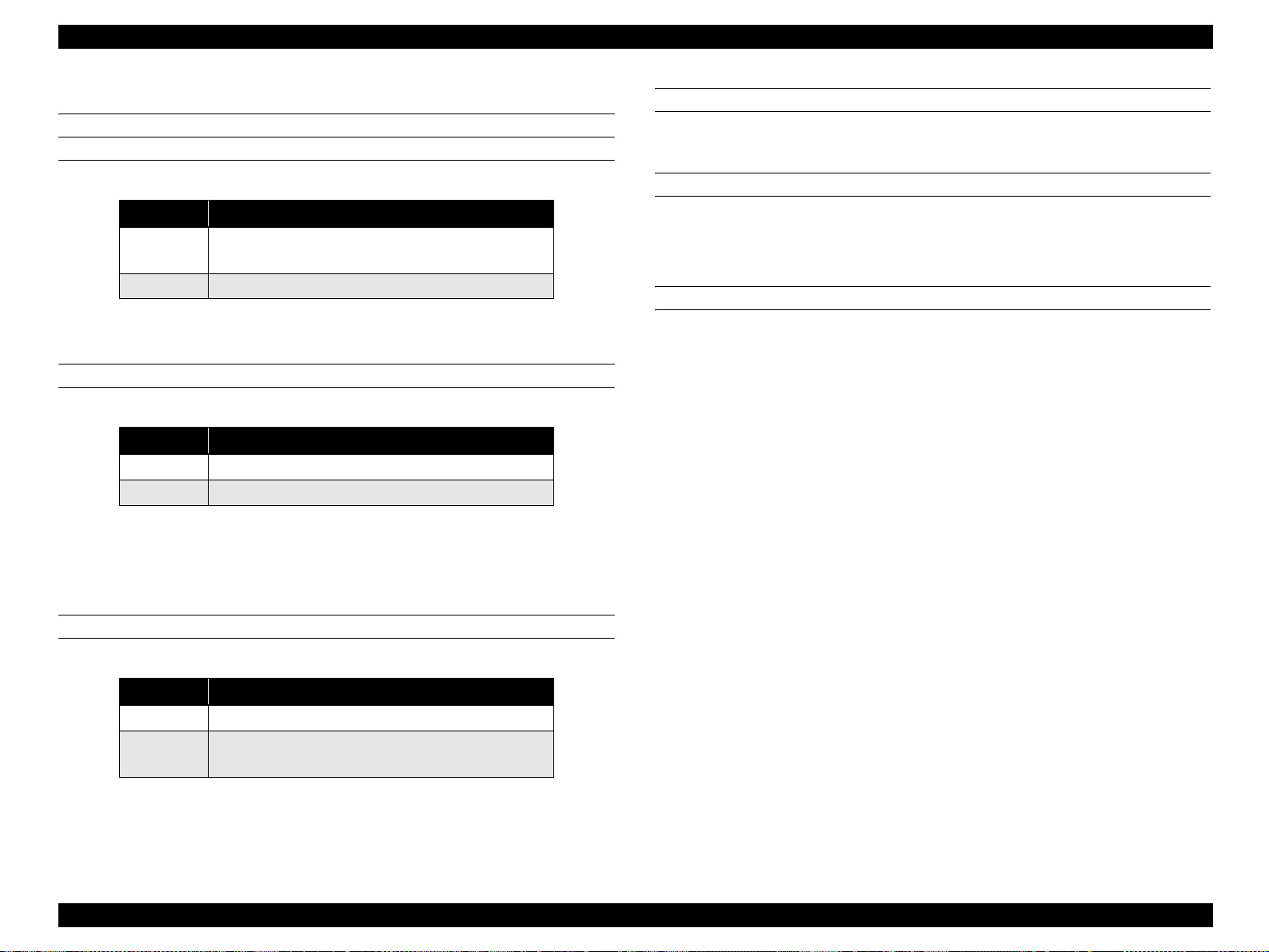

1.5.1 Space Requirements

In order to ensure that the printer operates properly, provide at least as much space as

shown in the diagram below.

100

100

430

ILLUMINATION

330

3,000 lx or less (do not expose to direct sunlight)

130

Unit: mm

01000701

Figure 1-5. Space Requirements

Product Description Service Conditions 26

Page 27

EPSON AcuLaser C2600/2600 Revision A

1.6 Conditions for Storage and Transport

AMBIENT TEMPERATURE AND HUMIDITY CONDITIONS

Table 1-26. Ambient Temperature and Humidity Conditions

Condition Tem perature (°C)

Normal conditions 0 to 35 15 to 80

Harsh condition s

High 35 to 40 High 80 to 95

Low -20 to 0 Low 5 to 15

Humidity (%RH)

(No condensation allowed)

RESISTANCE TO AIR PRESSURE (ALTITUDE)

0 to 2,500 m

(However, this is not applicable when pressurized to 70.9275 kPa or more during air

transportation.)

DROPPING

Guarantee

period

12 months after

manufacture

Maximum of

one month

VIBRATION

No damage under the following conditions

Conforms to divisional Assessment Standard of Transport (T-AE-05-001).

Frequency 5 to 55 Hz

1.5 G

Acceleration

Direction of application XYZ 3 directions

Frequency sweep Logarithmic sweep 10 minutes one way.

Number of cycles 3 cycles for each direction (1 hour each)

(However, constant 7.5 mm double amplitude is assumed between 5

and 10 Hz.)

COMPRESSION

Conforms to divisional Assessment Standard of Transport (T-AE-05-001).

No damage with 1 corner, 3 edges, and 6 sides dropping when packed.

Conforms to divisional Assessment Standard of Transport (T-AE-05-001).

Table 1-27. Dropping

Dropping height

Standard Main unit 42 cm 45.4 kg

Option

Duplex unit 82 cm 1.7 kg

500-sheet cassette unit 82 cm 6.8 kg

Package weight

(referential)

Product Description Conditions for Storage and Transport 27

Page 28

EPSON AcuLaser C2600/2600 Revision A

1.7 Electrical Characteristics

NOTE: The following sections do not include any optional units.

ELECTRICAL FAST TRANSIENT /BURSTS (AC LINE NOISE)

Ensure the following conditions using evaluation methods compliant with IEC610004-4.

1 kV: No errors excluding insignificant dot errors

2 kV: No damage to parts

INSTANTANEOUS OUTAGES

No effect on printing quality.

DIP: 1 cycle 100 % (at -10 % of rated current)

RESISTANCE TO STATIC ELECTRI CITY

Ensure the following conditions using evaluation methods compliant with IEC610004-2 and CISPR 24.

INSULATION RESISTANCE

10 MΩ or more

WITHSTAND VOLTAGE

No dielectric break down during application of the voltages shown below for a one

minute period.

Table 1-28. Withstand Voltage

Model Type

120 V AC 1250 V AC 1000 V

230 V AC 1500 V AC 3000 V

LEAK CURRENT

Between prima ry and s econd ary

supply transformers

Between power supply line and

chassis

120 V: 0.25 mA or less

230 V: 3.5 mA or less

Contact electric discharge 4.5 kV: No error on any device after applying

Aerial electric discharge 8.5 kV: No error on any device after applying

INRUSH CURRENT

100 A and 1/2 cycles or less for a cold start in an atmosphere at 23 ºC or more.

Product Description Electrical Characteristics 28

Page 29

EPSON AcuLaser C2600/2600 Revision A

1.8 Compatible Specification

SAFETY STANDARD

Table 1-29. Safety Standards

Model Type Applicable Sta nda r ds

120 V

230 V IEC60 95 0 3rd Edition

SAFETY STANDARD (LASER TRANSMISSION)

Table 1-30. Safety Standards (Laser Transmission)

Model Type Applicable Sta nda r ds

120 V FDA21CFR Chapter 1, Subchapter J, Section 1010, 1040

200 V series Compliant with IEC60825-1

Note : Refer to the Laser Specification

Wave length: 770-800 nm

Maximum output r a ting: 15 mW

UL60950 3rd Edition

CSA C22.2 No.60950

ELECTRICAL POWER HIGH FREQUENCY

230V: EN61000-3-3 (Flicker)

POWER CONSUMPTI O N

Conforms to International Energy Star Program standards

MISCELLANEOUS

Toner: Have no affect on the human body (conforms to OSHA,

TSCA, EINECS)

OPC: Have no affect on the human body (conforms to OSHA)

Ozone generation: Conforms to UL478 5th edition

Materials: Does not contain any materials prohibited in each country,

nor harmful substances above the permitted values

EMI STANDARDS

Table 1-31. EMI Standards

Model Type Applicable Sta nda r ds

120 V FCC Part 15 Subpart B, Class B

230 V

EN55022 (CIRSPR Publication 22), Class B

EN61000-3-2 (Harmonics) Class A

Product Description Compatible Specification 29

Page 30

EPSON AcuLaser C2600/2600 Revision A

1.9 Consumables/Periodic Replacement Unit

C A U T I O N

The print page-based service life values of the Consumables and

Periodical Replacement Parts are guidelines. The number of

printable pages changes depending on how they are printed. The

number of printable pages decreases depending on the intermittent

printing (where a few pages, one to several pages, are printed each

time), paper size, paper orientation, thick paper print ing, printed

document, frequent power-on/off, etc. Hence, the number of

printable pages of the consumables and periodical replacement

parts may become less than a half depending on the operating

conditions and environment of the user.

1.9.1 Specifications

Consumables (replaced by the user)

Table 1-32. Consumables

1

1

1

External

dimensions

(mm)

336 (W)

82 (D)

67 (H)

378 (W)

111 (D)

159 (H)

256 (W)

50 (D)

225 (H)

327 (W)

37 (D)

46 (H)

113 (D)

140 (H)

Weight

(kg)

0.9

0.8

0.9

1.3

0.2

0.1

2.3

Name Configuration

Toner cartridge (K)

(developer car tridge)

Toner cartridge (C)

Toner cartridge (M)

Toner cartridge (Y)

(developer car tridge)

Photoconductor unit

(a Waste toner collect or and a filter

unit are included in the package)

Waste toner collector*

(A filter is included in the package)

2

Filter*

Fuser unit (120V) Fuser 80,000 394 (W)

Fuser unit (230V) Fuser 80,000 2.3

Note *1: Approximate number of printed pages using A4 continuous printing at 5 % image

occupation rate.

The cartridge lifetime varies accordi ng to the paper size and type of printing (toner

save mode etc.).

*2: Rep laced at the same time as photoconductor unit o r the Waste toner collec tor.

2

Development,

Toner hopper

Waste toner

collection space

integrated drum

cartridge

Waste toner tank

Toner filter

Ozone filter

Lifetime

(pages)

5,000*

2,000*

5,000*

Monochrome:

40,000

Color: 10,000

Monochrome:

60,000

Color: 15,000

15, 000

Note : For details on the part life, see

“1.15 Life Details” (p.36).

Product Description Consumables/Periodic Replacement Unit 30

Page 31

EPSON AcuLaser C2600/2600 Revision A

Periodic replacement units (replaced by service personnel)

Table 1-33. Periodic Replacement Units

Name Lifetime (pages)

Transfer unit

Cleaning tape

Cleaner cl utc h 150,000

2nd transfer clutch 150,000

Paper eject roll e r 300,000

Post-fixing roller 300,000

Pickup roller 200,000

Monochrome: 100,000

Color: 60,000

1.9.2 Conditions for Storage and Transport

Ambient temperature and humidity cond itions

Table 1-34. Ambient Temperature and Humidity Conditions

Condition Temperature (°C)

Normal conditions 0 to 35 15 to 80

Harsh conditions

Note *: Storage time after opening is 12 months in the normal operating environment.

High 35 to 40 High 80 to 95

Low -20 to 0 Low 5 to 15

Humidity (%RH)

(No condensation allowed)

Resistance to Air Pressure (altitude)

Guarantee

period

18 months

(unopened*)

Maximum of

one month

740 to 1013 hPa (2,500 m or less)

(However, this is not applicable when pressurized to 70.9275 kPa or more during

air transportation.).

Package dropping

Direction of drop: 1 corn er, 6 sides, 3 edges

Dropping height: No damage with the conditions below

Table 1-35. Package Dropping

Package name Configuration

Toner cartridge (Y, M, C) 2,000 Toner cartridge 82 c m 1.2 kg

Toner cartridge (K, Y, M, C) 5,000 Toner cartridge 82 cm 1.3 kg

Photoconductor unit,

Photoconductor unit

Waste toner collector

Fuser unit Fuser unit 82 cm 3.2 kg

Waste toner collector,

Filter unit

Waste toner collector,

Filter unit

Dropping

height

82 cm 1.98 kg

82 cm 0.43 kg

Reference

(package

weight)

Product Description Consumables/Periodic Replacement Unit 31

Page 32

EPSON AcuLaser C2600/2600 Revision A

1.10 Maintenance

Table 1-36. Maintenance

Maintena nce item Period Maintenance method

• Paper f e ed roller

• Paper f e ed pad

• Retard roller

• Photoconductor wire cleaning

• Exposure window cleaning

• Patch sensor cleaning

When paper feed

problem occurs

When a warning is

issued (Clean Parts a)

When a warning is

issued (Clean Parts b)

When an error is

issued (Clean Sensor)

Wipe with a wet or dry cloth.

Clean by pulling out the cleaning knob

on the photocon ductor cartridge.

Clean by repeatedly pulling out the

cleaning knob.

Clean by opening and closing co ver D.

Product Description Maintenance 32

Page 33

EPSON AcuLaser C2600/2600 Revision A

1.11 External Appearance and Unit Names

1.11.1 Unit Names

Table 1-37. List of Unit Names

No. Name No. Name No. Name

1 Operation panel 7 Lock release lever (Cover A) 13 Rear cover

2 Cover B 8 MP tray 14 AC inlet

3 Output tray 9 Lock release lever (MP tray) 15 Duplex unit (Option)

4 Cover D 10 Handle (right) 16 Optional paper cassette unit

5 Lower paper cassette 11 Handle (left) 17 Cover E

6 Cover A 12 Power switch

<Top View>

2

3

1

<Front View> <Right Side View>

6

4

5

7 9

10

8

01000801

<Left Side View> <Rear View>

11

12

<Right Side View> Options installed

13

14

15

1617

01000901

Figure 1-6. External Appearance 1 Figure 1-7. External Appearance 2

Product Description External Appearance and Unit Names 33

Page 34

EPSON AcuLaser C2600/2600 Revision A

1.12 Engine Restrictions

1.12.1 Factors Limiting Printing Speed

Fuser cool down control

When the temperature of the Fusing roller edge reaches 235 °C, printing operation

stops for about 40 seconds until the temperature falls to 225 °C. If the temperature of

the Fusing roller edge reaches 194 °C when printing on smaller width papers, printing

operation stops for about 55 seconds until the temperature falls down enough.

(Monochrome printing speed becomes slow.)

Toner supply operations within a cartridge during a continuous Monochrome

printing.

When performing monochrome printing continuously, the rotary starts rotating in

process of print job in order to supply toner. (The speed of simplex monochrome

printing turns down.)

1. When the number of continuously printed pages reaches 255 (counted with

Vsync), the print process is interrupted while the rotary rotates 360° (until the

Vsync counts another 1) to supply toner.

2. When the integrated value of the toner counter reaches a certain level, the

print process is interrupted while the rotary rotates 360° (until the Vsync

counts another 1) to supply toner.

When performing duplex printing, the printing speed does not turn down as the rotary

rotates while the duplex unit is re-feeding the paper.

Patch Control (AIDC)

Patch control is activated by the engine factors on occasions described below.

At power on

When the Photoconductor unit is replaced

When the Toner cartridge is replaced

When the target value is changed due to the lifetime of the toner cartridge. (It

may affect printing speed.)*

Note *: Approximate frequency is as follows. (5 % duty or color printing with 5

% of each color, in case printing 5,000 pages continuously.)

•

In color mode of color model: Max. 16 times

•

In B/W mode (4xB/W mode) of color model: 4 times

•

B/W mode: 4 times

•

4xB/W mode: 1-2 times (4 times in

20,000 pages)

Printing stop time is as follows.

Color mode: 60 seconds

B/W mode: 22 seconds

4xB/W mode: 52 seconds

Toner supply control

After 3 hours have passed since the power-on without any printing operations,

developer rollers are rotated to stir toner inside of them in order to prevent banding on

printout from occurring. (This may cause delay in printing.)

1.12.2 Toner Duty Limiting Value

150 % (to prevent Fuser unit from twisting paper jam)

NOTE: Even if it exceeds 150 %, the engine (mechanical controller) does not

force a hard stop.

Product Description Engine Restrictions 34

Page 35

EPSON AcuLaser C2600/2600 Revision A

1.13 Notes When Replacing Consumables and Installing Optional Products

1.13.1 Consumables

Toner cartridge

When replacing the toner cartridges on occasion other than the toner end

occurs, move the toner cartridge to the replacement position using the control

panel.

Photoconductor unit

Can be replaced while the power supply to the main unit is either on or off.

Avoid replacing with a second hand u nit before the pro duct lifetime oth erwise

the lifetime will not be counted correctly.

Fuser unit

Can be replaced while the power supply to the main unit is either on or off.

Avoid replacing with a second hand u nit before the pro duct lifetime oth erwise

the lifetime will not be counted correctly.

1.13.2 Options

Duplex Unit

1.14 Notes on Fuser Pressure

Fuser unit is equipped with a pressure setting lever to switch between 2 levels of

pressures.

When the lever is not correctly set, toner offset, fix level reduction, paper wrinkle, or

OHP haze defects may be caused.

The relation between the fuser pressure and speed mode is as follows.

Table 1-38. The Relation between the Fuser Pressure and Speed Mode

Fuser pressure

Low pressure – – Envelopes

Standard

Std. mode Low speed mode 1 Low speed mode 2

Standard paper,

plain paper

Printing speed mode

Thick paper,

labels

Transparency

Turn off the main unit before installing.

When installed with the main unit power supply turned on, the unit will not be

detected.

Optional paper casse tte unit

Turn off the main unit before installing.

When installed with the main unit power supply turned on, the unit will not be

detected.

Option parts to expand the controller function

Turn off the main unit before installing, or the parts may be broken.

Product Description Notes When Replacing Consumables and Installing Optional Products 35

Page 36

EPSON AcuLaser C2600/2600 Revision A

1.15 Life Details

Regarding the lifetime of consumables and periodic replacement units:

Lifetime management methods

When the followings are fulfilled, it is required to replace the consumables or the

periodic replacement unit. (For more information, refer to “2.5.5 Control of

Consumables and Components Needing Periodic Replacement” (p.134).)

Table 1-39. Lifetime Management Methods

Unit Conditions

Toner cartridge

Photoconductor

unit

Fuser unit

Transfer belt unit

• Dot count value

• Development operation time

• Cumulative counted number of the Vsync.

• Cumulative number of pages counted per color.

• Waste toner full detection

• Cumulative time of rotation of the Gate roller (duration gate clutch is

ON)

• Cumulative time of rotation of the Main Drive Motor while the

temperature of the thermistor l ocated at the edge of the heat roller rises

above given level.

• Cumulative time of rotation of the Main Drive Motor.

• Cumulative time of rotation of the Main Drive Motor while the

temperature of the thermistor located at the center of the heat roller rises

above given level in Plain paper 2 mode.

• Cumulative number of cool -down cycles performed after print i ng on

narrow papers.

• Time period that the temperature of the center of the pressure roller is

kept above a prescribed level.

• Cumulative counted number of the Vsync.

• Number of paper feed for 2nd transfer

Product Description Life Details 36

Page 37

EPSON AcuLaser C2600/2600 Revision A

Life Details

Color Model

Table 1-40. Monochrome Mode (CMYK installed)

Print Volume: 1kp/M Print Volume: 8kp/M

Unit

Photoconductor unit*

Fuser uni t *

Transfer belt unit*

Cleaner clutch 150,000 cycle

2nd transfer clutch 150,0 00 cycle

2

Note *1: Print volume: 1 kp/M, 8kp/M

Average print r at i o is 5 %.

Power ON: Once a day

This indicates the value when the waste toner collector full is not detected in advance.

(If the average print ratio of all colors is 5 %, the collector still has room for waste toner when the part life is detected by the cumulative pages.)

*2: Print volume: 1 kp/M, 8kp/M

Power ON: Once a day

*3: 50 kp/j, ma k es a pa use fo r mor e tha n 1 minute.

*4: Shorten its l ife when the fusing roller has been used with its edges at high temp. for a long time due to the co ntinuous printing.

*5: Print volume: 1 kp/M, 8kp/M

Average print r at i o is 5 %.