Page 1

®

SERVICE MANUAL

A4 Color Page Printer

EPSON AcuLaser C1900

AcuLaser C900

SEPG02003

Page 2

Notice

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical,

photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2002 SEIKO EPSON CORPORATION.

Imaging & Information Product Division

TPCS Quality Assurance Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR

OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for servicing

the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Page 5

Safety Precautions for Inspection and Service

When performing inspection and service procedures, observe the

following precautions to prevent accidents and ensure utmost safety.

* Depending on the model, some of the precautions given in the

following do not apply.

Different markings are used to denote specific meanings as detailed

below.

W A R N I N G

C A U T I O N

The following graphic symbols are used to give instructions that need to

be observed.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

Used to call the service technician's attention to what is

graphically represented inside the marking (including a

warning).

Used to prohibit the service technician's from doing what is

graphically represented inside the marking.

Used to instruct the service technician's to do what is

graphically represented inside the marking.

W A R N I N G

WARNING

1.Always observe precautions.

Parts requiring special attention in this product will include a

label containing the mark shown on the left plus

precautionary notes. Be sure to observe the precautions.

Be sure to observe the “Safety Information” given in the

Operator's Manual.

2.Before starting the procedures, be sure to unplug the power

cord.

This product contains a high-voltage unit and a circuit with a

large current capacity that may cause an electric shock or

burn.

The product also contains parts that can jerk suddenly and

cause injury.

If this product uses a laser, laser beam leakage may cause

eye damage or blindness.

3.Use the specified parts.

For replacement parts, always use the genuine parts

specified in the manufacturer's parts manual. Installing a

wrong or unauthorized part could cause dielectric

breakdown, overload, or undermine safety devices resulting

in possible electric shock or fire.

Replace a blown electrical fuse or thermal fuse with its

corresponding genuine part specified in the manufacturer's

parts manual. Installing a fuse of a different make or rating

could lead to a possible fire. If a thermal fuse blows

frequently, the temperature control system may have a

problem and action must be taken to eliminate the cause of

the problem.

Page 6

4.Handle the power cord with care and never use a multiple outlet.

9.Do not remodel the product.

Do not break, crush or otherwise damage the power cord.

Placing a heavy object on the power cord, or pulling or

bending it may damage it, resulting in a possible fire or

electric shock.

Do not use a multiple outlet to which any other appliance or

machine is connected.

Be sure the power outlet meets or exceeds the specified

capacity.

5.Be careful with the high-voltage parts.

A part marked with the symbol shown on the left carries a

high voltage. Touching it could result in an electric shock or

burn. Be sure to unplug the power cord before servicing this

part or the parts near it.

6.Do not work with wet hands.

Do not unplug or plug in the power cord, or perform any kind

of service or inspection with wet hands. Doing so could

result in an electric shock.

7.Do not touch a high-temperature part.

A part marked with the symbol shown on the left and other

parts such as the exposure lamp and fusing roller can be

very hot while the machine is energized. Touching them

may result in a burn.

Wait until these parts have cooled down before replacing

them or any surrounding parts.

Modifying this product in a manner not authorized by the

manufacturer may result in a fire or electric shock. If this

product uses a laser, laser beam leakage may cause eye

damage or blindness.

10.Restore all parts and harnesses to their original positions.

To promote safety and prevent product damage, make sure

the harnesses are returned to their original positions and

properly secured in their clamps and saddles in order to

avoid hot parts, high-voltage parts, sharp edges, or being

crushed.

To promote safety, make sure that all tubing and other

insulating materials are returned to their original positions.

Make sure that floating components mounted on the circuit

boards are at their correct distance and position off the

boards.

8.Maintain a grounded connection at all times.

(This item may not apply in the USA.)

Be sure to connect the ground wire to the ground terminal

even when performing an inspection or repair. Without

proper grounding, electrical leakage could result in an

electric shock or fire.

Never connect the ground wire to a gas pipe, water pipe,

telephone ground wire, or a lightning conductor.

Page 7

C A U T I O N

CAUTION

1.Precautions for Service Jobs

A toothed washer and spring washer, if used originally,

must be reinstalled. Omitting them may result in contact

failure which could cause an electric shock or fire.

When reassembling parts, make sure that the correct

screws (size, type) are used in the correct places. Using the

wrong screw could lead to stripped threads, poorly secured

parts, poor insulating or grounding, and result in a

malfunction, electric shock or injury.

Take great care to avoid personal injury from possible burrs

and sharp edges on the parts, frames and chassis of the

product.

When moving the product or removing an option, use care

not to injure your back or allow your hands to be caught in

mechanisms.

2.Precautions for Servicing with Covers and Parts Removed

Wherever feasible, keep all parts and covers mounted when

energizing the product.

If energizing the product with a cover removed is absolutely

unavoidable, do not touch any exposed live parts and use

care not to allow your clothing to be caught in the moving

parts. Never leave a product in this condition unattended.

Never place disassembled parts or a container of liquid on

the product. Parts falling into, or the liquid spilling inside, the

mechanism could result in an electric shock or fire.

Never use a flammable spray near the product. This could

result in a fire.

Make sure the power cord is unplugged before removing or

installing circuit boards or plugging in or unplugging

connectors.

Always use the interlock switch actuating jig to actuate an

interlock switch when a cover is opened or removed. The

use of folded paper or some other object may damage the

interlock switch mechanism, possibly resulting in an electric

shock, injury or blindness.

3.Precautions for the Working Environment

The product must be placed on a flat, level surface that is

stable and secure.

Never place this product or its parts on an unsteady or tilting

workbench when servicing.

Provide good ventilation at regular intervals if a service job

must be done in a confined space for a long period of time.

Avoid dusty locations and places exposed to oil or steam.

Avoid working positions that may block the ventilation ports

of the product.

4.Precautions for Handling Batteries

(Lithium, Nickel-Cadmium, etc.)

Replace a rundown battery with the same type as specified

in the manufacturer's parts manual.

Before installing a new battery, make sure of the correct

polarity of the installation or the battery could burst.

Dispose of used batteries according to the local regulations.

Never dispose of them at the user's premises or attempt to

try to discharge one.

Page 8

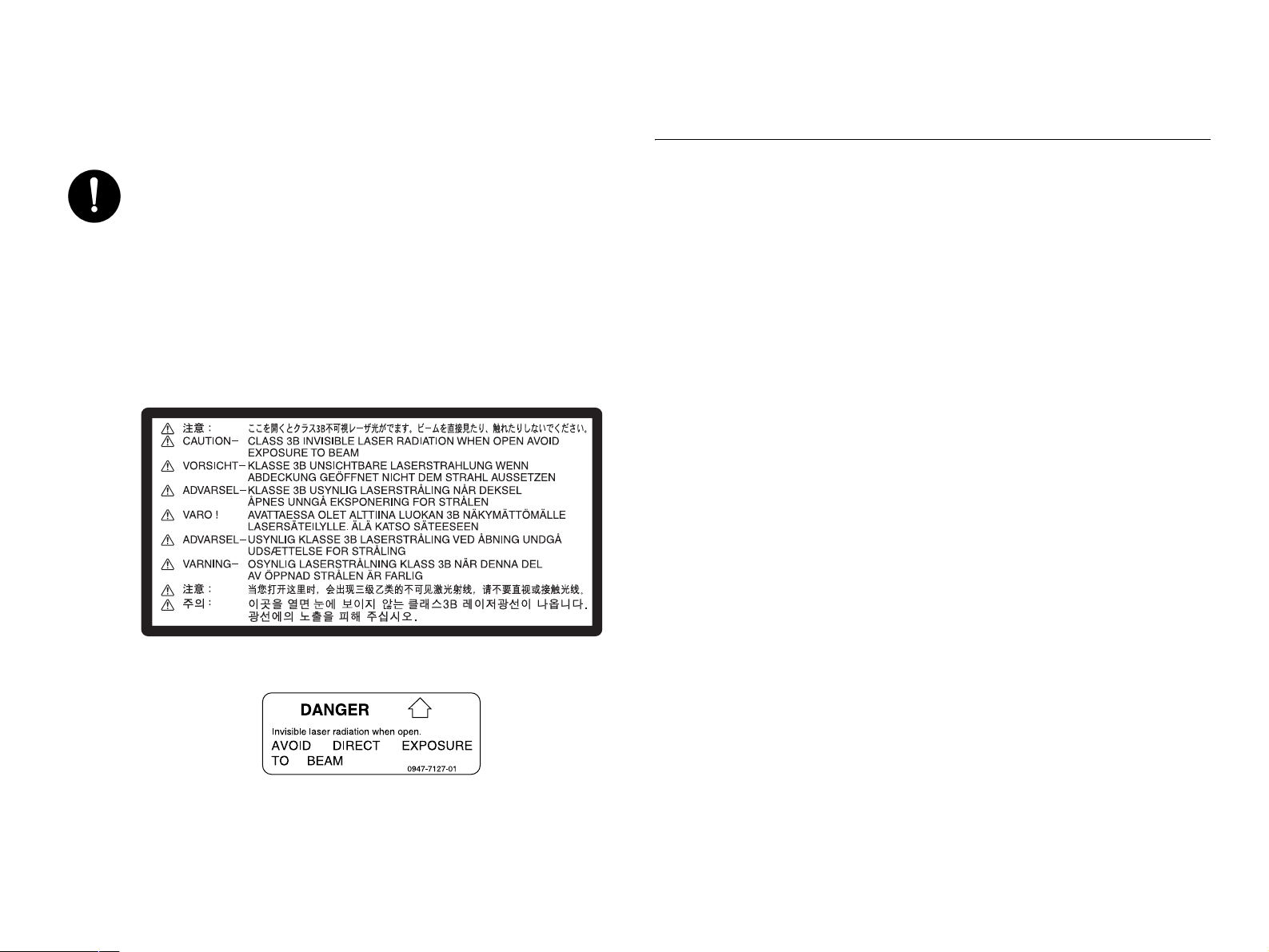

5.Precautions for the Laser Beam

(Only for Products Employing a Laser)

Removing the cover marked with the following caution label

could lead to possible exposure to the laser beam, resulting

in eye damage or blindness. Be sure to unplug the power

cord before removing this cover.

If removing this cover while the power is ON is unavoidable,

be sure to wear protective laser goggles that meet

specifications.

Make sure that no one enters the room when the machine is

in this condition.

When handling the laser unit, observe the “Precautions for

Handling Laser Equipment.”

Other Precautions

When handling circuit boards, observe the “HANDLING of PWBs”.

The PC Drum is a very delicate component. Observe the precautions

given in “HANDLING OF THE PC DRUM” because mishandling may

result in serious image problems.

Note that replacement of a circuit board may call for readjustments or

resetting of particular items, or software installation.

Page 9

Precautions for Service

When performing inspection and service procedures, observe the

following precautions to prevent mishandling of the machine and its

parts.

All troubleshooting procedures contained herein assume that

there are no breaks in the harnesses and cords and all

connectors are plugged into the right positions.

The procedures preclude possible malfunctions due to noise

and other external causes.

* Depending on the model, some of the precautions given in the

following do not apply.

PRECAUTIONS BEFORE SERVICE

When the user is using a word processor or personal computer from

a wall outlet of the same line, take necessary steps to prevent the

circuit breaker from opening due to overloads.

Never disturb the LAN by breaking or making a network connection,

altering termination, installing or removing networking hardware or

software, or shutting down networked devices without the

knowledge and express permission of the network administrator or

the shop supervisor.

HOW TO USE THIS BOOK

DIS/REASSEMBLY, ADJUSTMENT

To reassemble the product, reverse the order of disassembly

unless otherwise specified.

TROUBLESHOOTING

PRECAUTIONS FOR SERVICE

Check the area surrounding the service site for any signs of

damage, wear or need of repair.

Keep all disassembled parts in good order and keep tools under

control so that none will be lost or damaged.

After completing a service job, perform a safety check. Make sure

that all parts, wiring and screws are returned to their original

positions.

Do not pull out the toner hopper while the toner bottle is turning.

This could result in a damaged motor or locking mechanism.

If the product is to be run with the front door open, make sure that

the toner hopper is in the locked position.

Do not use an air gun or vacuum cleaner for cleaning the ATDC

Sensor and other sensors, as they can cause electrostatic

destruction. Use a blower brush and cloth. If a unit containing these

sensors is to be cleaned, first remove the sensors from the unit.

If a component on a PWB or any other functional unit including a

motor is defective, the text only instructs you to replace the

whole PWB or functional unit and does not give troubleshooting

procedures applicable within the defective unit.

Page 10

PRECAUTIONS FOR DISASSEMBLY/REASSEMBLY

PRECAUTIONS FOR CIRCUIT INSPECTION

Be sure to unplug the copier from the outlet before attempting to

service the copier.

The basic rule is not to operate the copier anytime during

disassembly. If it is absolutely necessary to run the copier with its

covers removed, use care not to allow your clothing to be caught in

revolving parts such as the timing belt and gears.

Before attempting to replace parts and unplug connectors, make

sure that the power cord of the copier has been unplugged from the

wall outlet.

Be sure to use the Interlock Switch Actuating Jig whenever it is

necessary to actuate the Interlock Switch with the covers left open

or removed.

While the product is energized, do not unplug or plug connectors

into the circuit boards or harnesses.

Never use flammable sprays near the copier.

A used battery should be disposed of according to the local

regulations and never be discarded casually or left unattended at

the user's premises.

When reassembling parts, make sure that the correct screws (size,

type) and toothed washer are used in the correct places.

Never create a closed circuit across connector pins except those

specified in the text and on the printed circuit.

When creating a closed circuit and measuring a voltage across

connector pins specified in the text, be sure to use the GND wire.

HANDLING OF PWBS

During Transportation/Storage:

During transportation or when in storage, new P.W. Boards must

not be indiscriminately removed from their protective conductive

bags.

Do not store or place P.W. Boards in a location exposed to

direct sunlight and high temperature.

When it becomes absolutely necessary to remove a Board from

its conductive bag or case, always place it on its conductive mat

in an area as free as possible from static electricity.

Do not touch the pins of the ICs with your bare hands.

Protect the PWBs from any external force so that they are not

bent or damaged.

During Inspection/Replacement:

If it becomes necessary to replace the thermal fuse or any other

fuse mounted on a board, be sure to use one of the rating marked

on the blown fuse. Always note the rating marked on the fuse, as

the rating and mounting site or number used are subject to change

without notice.

Avoid checking the IC directly with a multimeter; use connectors

on the Board.

Never create a closed circuit across IC pins with a metal tool.

Before unplugging connectors from the P.W. Boards, make sure

that the power cord has been unplugged from the outlet.

Page 11

When removing a Board from its conductive bag or conductive

case, do not touch the pins of the ICs or the printed pattern.

Place it in position by holding only the edges of the Board.

When touching the PWB, wear a wrist strap and connect its cord

to a securely grounded place whenever possible. If you cannot

wear a wrist strap, touch a metal part to discharge static

electricity before touching the PWB.

HANDLING OF THE PC DRUM

* Only for Products Not Employing an Imaging Cartridge.

During Transportation/Storage:

Use the specified carton whenever moving or storing the PC

Drum.

Note that replacement of a PWB may call for readjustments or

resetting of particular items.

HANDLING OF OTHER PARTS

The magnet roller generates a strong magnetic field. Do not bring it

near a watch, floppy disk, magnetic card, or CRT tube.

The storage temperature is in the range between -20°C and

+40°C.

In summer, avoid leaving the PC Drum in a car for a long time.

Handling:

Ensure that the correct PC Drum is used.

Whenever the PC Drum has been removed from the copier,

store it in its carton or protect it with a Drum Cloth.

The PC Drum exhibits greatest light fatigue after being exposed

to strong light over an extended period of time. Never, therefore,

expose it to direct sunlight.

Use care not to contaminate the surface of the PC Drum with oil-

base solvent, fingerprints, and other foreign matter.

Do not scratch the surface of the PC Drum.

Do not apply chemicals to the surface of the PC Drum.

Do not attempt to wipe clean the surface of the PC Drum.

Page 12

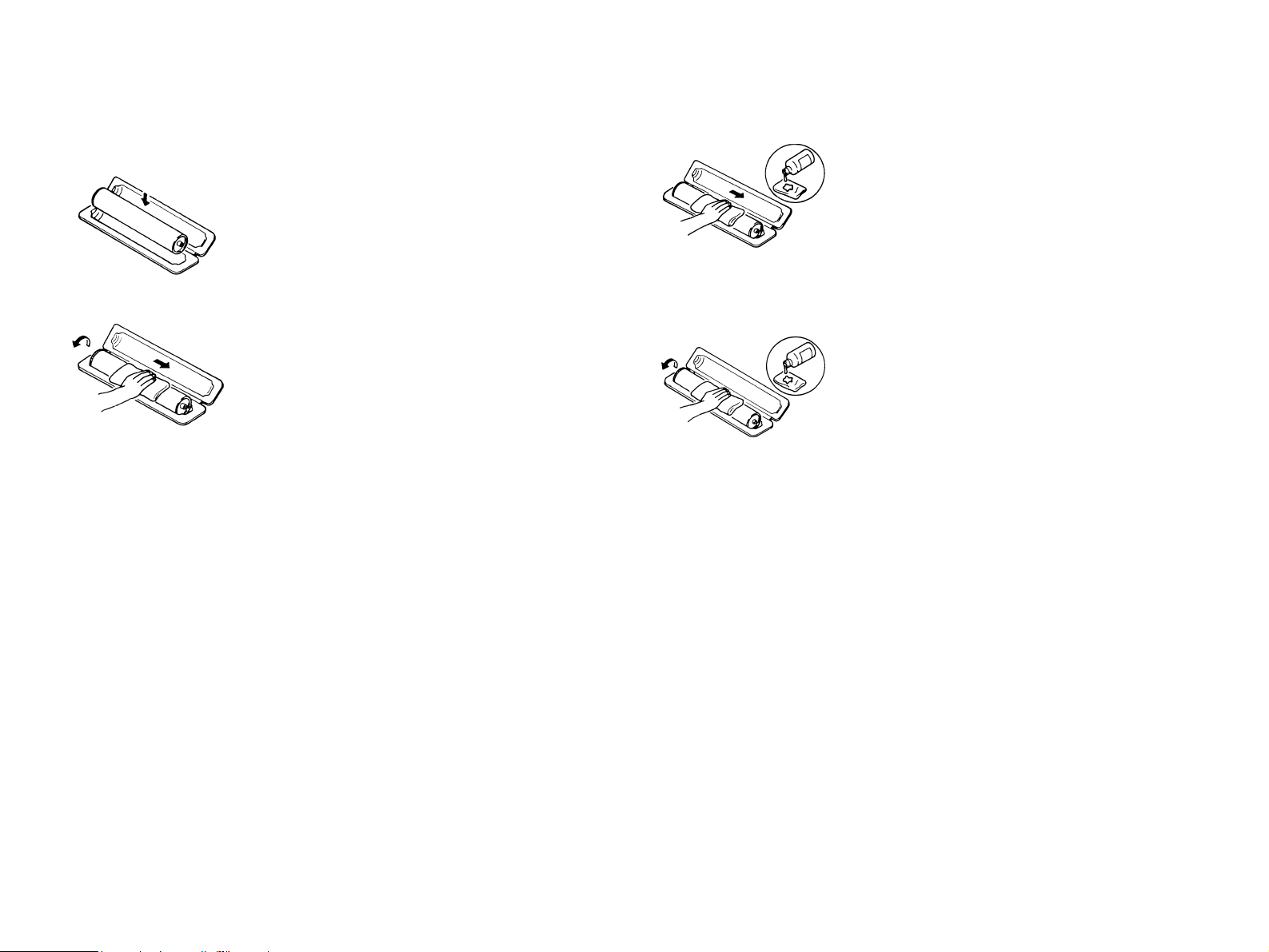

If, however, the surface is contaminated with fingerprints, clean it using

the following procedure.

1. Place the PC Drum into one half of its carton.

3. Soak a small amount of either ethyl alcohol

or isopropyl alcohol into a clean, unused

Dust-Free Cotton Pad which has been

folded over into quarters. Now, wipe the

surface of the PC Drum in one continuous

movement from its rear edge to its front

edge and off its surface one to two times.

2. Gently wipe the residual toner off the

surface of the PC Drum with a dry, DustFree Cotton Pad.

A.Turn the PC Drum so that the area of its

surface on which the line of toner left by the

Cleaning Blade is present is facing straight

up. Wipe the surface in one continuous

movement from the rear edge of the PC

Drum to the front edge and off the surface

of the PC Drum.

B. Turn the PC Drum slightly and wipe the

newly exposed surface area with a CLEAN

face of the Dust-Free Cotton Pad. Repeat

this procedure until the entire surface of the

PC Drum has been thoroughly cleaned.

*At this time, always use a CLEAN face of the dry

Dust-Free Cotton Pad until no toner is evident on

the face of the Pad after wiping.

*Never move the Pad back and forth.

4. Using the SAME face of the Pad, repeat the

procedure explained in the latter half of

step 3 until the entire surface of the PC

Drum has been wiped. Always OVERLAP

the areas when wiping. Two complete turns

of the PC Drum would be appropriate for

cleaning.

NOTE:

Even when the PC Drum is only locally dirtied, wipe the entire

surface.

Do not expose the PC Drum to direct sunlight. Clean it as

quickly as possible even under interior illumination.

If dirt remains after cleaning, repeat the entire procedure from

the beginning one more time.

Page 13

HANDLING OF THE IMAGING CARTRIDGE

* Only for Products Employing an Imaging Cartridge.

During Transportation/Storage:

The storage temperature is in the range between -20°C and

+40°C.

In summer, avoid leaving the Imaging Cartridge in a car for a

long time.

Handling:

Store the Imaging Cartridge in a place that is not exposed to

direct sunlight.

Precautionary Information on the PC Drum Inside the Imaging

Cartridge:

Use care not to contaminate the surface of the PC Drum with oil-

base solvent, fingerprints, and other foreign matter.

Do not scratch the surface of the PC Drum.

Do not attempt to wipe clean the surface of the PC Drum.

W A R N I N G

WARNING

Do not throw the toner cartridge or toner into an open

flame. The hot toner may scatter and cause burns or

other damage.

Page 14

SAFETY INFORMATION

LASER SAFETY

This is a digital machine certified as a class 1 laser product. There is no

possibility of danger from a laser, provided the machine is serviced

according to the instruction in this manual.

INTERNAL LASER RADIATION

semiconductor laser

Maximum average radiation power(*) 4.68 µW

Wavelength 770-795 nm

*:Laser Aperture of the Print Head Unit

This product employs a Class 3b laser diode that emits an invisible

laser beam. The laser diode and the scanning polygon mirror are

incorporated in the print head unit.

The print head unit is NOT A FIELD SERVICE ITEM. Therefore, the

print head unit should not be opened under any circumstances.

the U.S.A., Canada (CDRH Regulation)

This machine is certified as a Class I Laser product under

Radiation Performance Standard according to the Food, Drug

and Cosmetic Act of 1990. Compliance is mandatory for Laser

products marketed in the United States and is reported to the

Center for Devices and Radiological Health (CDRH) of the U.S.

Food and Drug Administration of the U.S. Department of Health

and Human Services (DHHS). This means that the device does

not produce hazardous laser radiation.

The label shown to page 15 indicates compliance with the

CDRH regulations and must be attached to laser products

marketed in the United States.

CAUTION

Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 5 mW

Wavelength 770-795 nm

Laser Aperture of the Print Head Unit

All Areas

CAUTION

Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 5 mW

Wavelength 770-795 nm

Page 15

Denmark

Finland, Sweden

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling. Klasse 1 laser produkt der opfylder IEC60825

sikkerheds kravene.

halvlederlaser

Laserdiodens højeste styrke 5 mW

bølgelængden 770-795 nm

Norway

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne

bruksanvisning, kan brukeren utsettes för unsynlig laserstrålning, som

overskrider grensen for laser klass 1.

halvleder laser

Maksimal effekt till laserdiode 5 mW

bølgelengde 770-795 nm

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VAROITUS!

Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla

saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle

lasersäteilylle.

puolijohdelaser

Laserdiodin suurin teho 5 mW

aallonpituus 770-795 nm

VARNING!

Om apparaten används på annat sätt än i denna bruksanvisning

specificerats, kan användaren utsättas för osynlig laserstrålning, som

överskrider gränsen för laserklass 1.

halvledarlaser

Den maximala effekten för laserdioden 5 mW

våglängden 770-795 nm

VARO!

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättomälle

lasersäteilylle. Älä katso säteeseen.

VARNING!

Osynlig laserstråining när denna del är öppnad och spärren är urkopplad.

Betrakta ej stråien.

Page 16

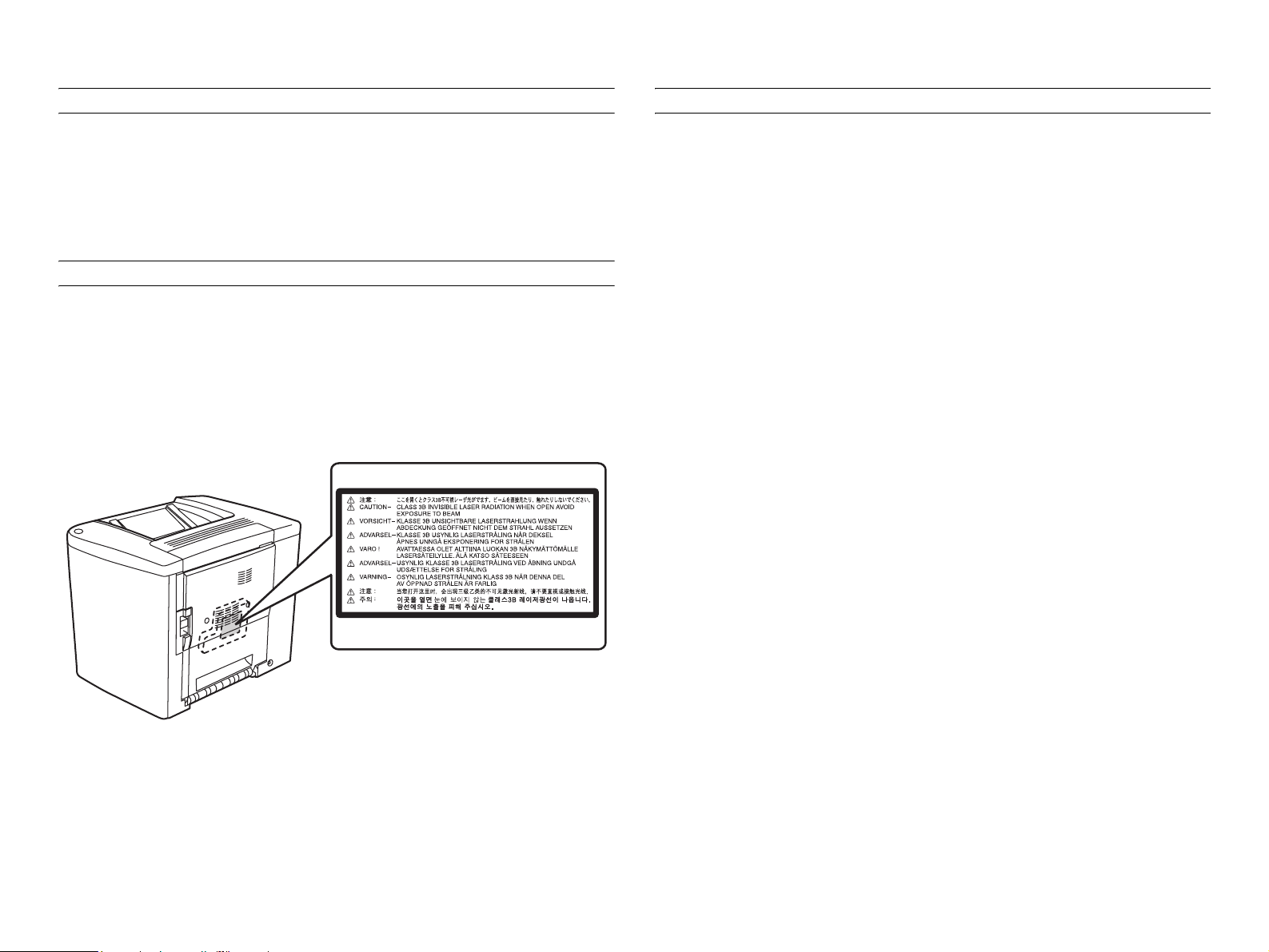

LASER SAFETY LABEL

PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT

A laser safety label is attached to the outside of the machine as shown

below.

LASER CAUTION LABEL

A laser caution label is attached to the inside of the machine as shown

below.

When laser protective goggles are to be used, select ones with a

lens conforming to the above specifications.

When a disassembly job needs to be performed in the laser beam

path, such as when working around the printerhead and PC Drum,

be sure first to turn the printer OFF.

If the job requires that the printer be left ON, take off your watch and

ring and wear laser protective goggles.

A highly reflective tool can be dangerous if it is brought into the laser

beam path. Use utmost care when handling tools on the user's

premises.

Page 17

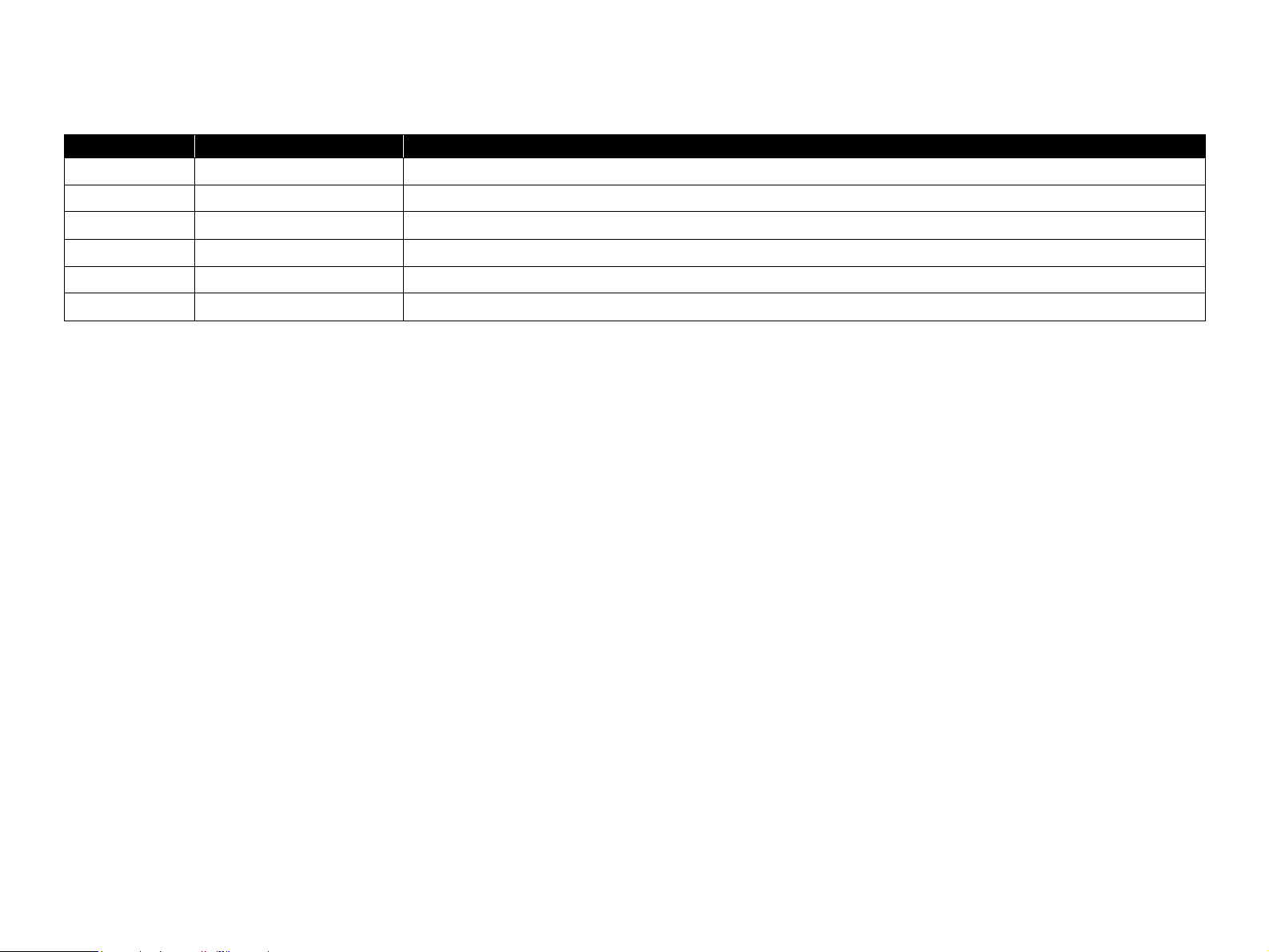

Revision Status

Revision Date of Issue Description

0 June 3, 2002 Partial release (Chapter 1/ Chapter4) (provisional)

A September 30, 2002 First release

Page 18

EPSON AcuLaser C1900/AcuLaser C900 Revision A

Contents

Chapter 1 Product Description

1.1 Product Description............................................................................................. 22

1.1.1 Features....................................................................................................... 22

1.2 Basic Specifications............................................................................................. 24

1.2.1 Process Specifications ................................................................................ 24

1.2.2 Printer Basic Specifications........................................................................ 24

1.2.3 Paper Specifications.................................................................................... 30

1.2.3.1 Paper type ............................................................................................ 30

1.2.3.2 Paper Feeding ...................................................................................... 31

1.2.3.3 Printing Area ....................................................................................... 31

1.2.4 Reliability and Maintainability ................................................................... 32

1.2.4.1 Reliability ............................................................................................ 32

1.2.4.2 Durability............................................................................................. 33

1.2.4.3 Maintenance ........................................................................................ 33

1.2.5 Operating Conditions (Including Consumables) ........................................ 33

1.2.6 Storage and Transport Environments of the Packaged Printer Main Unit and

Optional Products ...................................................................................... 35

1.2.7 Electrical Feature........................................................................................ 35

1.2.8 Compatible Standard .................................................................................. 36

1.2.9 Consumable / Regular Replacement Component Specifications ............... 37

1.2.9.1 Specifications ...................................................................................... 37

1.2.9.2 Storage and Transport Environments for Packages ............................ 38

1.2.9.3 Lives of Components........................................................................... 39

1.3 Controller Unit Specifications............................................................................. 41

1.3.1 Controller Basic Specifications .................................................................. 41

1.3.2 Differences in Jumper Settings between Designated Markets ................... 42

1.3.3 External I/F Specifications ......................................................................... 42

1.3.3.1 Parallel Interface Specifications.......................................................... 43

1.3.3.2 USB Interface Specifications .............................................................. 44

1.3.3.3 Ethernet Interface Specifications (AcuLaser C1900).......................... 45

1.3.3.4 Type B Interface Specifications .......................................................... 46

1.4 Control Panel....................................................................................................... 47

1.4.1 External Appearance and Names of Parts .................................................. 47

1.4.2 List of Panel Settings (Only with AcuLaser C1900).................................. 49

1.4.3 Explanation of Each Setting Menu and Items

(Only with AcuLaser C1900) .................................................................... 56

1.4.4 Special Operations (Only with AcuLaser C1900)...................................... 58

1.4.5 Printer Setting Items (Only with AcuLaser C900) ..................................... 59

1.4.5.1 Setting Items stored on the Printer Side .............................................. 59

1.4.5.2 Setting Items which are Valid only in the Job and are not

Stored in Printer................................................................................... 60

1.4.5.3 Setting Items Requiring Control by the Printer for

Each Printing or Status Change ........................................................... 62

1.4.5.4 Settings controlled by the mechanical controller, but requiring reading out

and changing the values....................................................................... 64

1.4.5.5 Settings specified regardless of Job and not stored in the printer ....... 65

1.4.6 Special Setting Operation (Only with AcuLaser C900) ............................. 66

1.4.7 Printer Status Checking .............................................................................. 69

1.4.7.1 Status sheet.......................................................................................... 69

1.4.8 Reserve Job List (Only for AcuLaser C1900)............................................ 72

1.4.9 Form Overlay List (Only for AcuLaser C1900)......................................... 72

1.4.10 Network Status Sheet (Only for AcuLaser C1900) .................................. 73

1.4.11 Engine Status Sheet .................................................................................. 75

1.5 RAM Expansion.................................................................................................. 79

1.6 Handling Precautions .......................................................................................... 80

1.6.1 Caution when there is a Power Failure....................................................... 80

1.6.2 Caution Regarding High Temperature Parts .............................................. 80

1.7 Network Environment (Only for AcuLaser C900).............................................. 81

1.8 Host Requirements (Only for AcuLaser C900)................................................... 82

1.9 AIDC Control...................................................................................................... 82

1.10 External Appearance and Parts Name............................................................... 83

1.10.1 Overall Dimensions .................................................................................. 83

1.10.2 Names of Parts.......................................................................................... 84

1.11 Differences in Specifications............................................................................. 85

1.11.1 Differences between AcuLaser C1900 and AcuLaser C2000.................. 85

1.11.2 Differences between AcuLaser C900 and AcuLaser C1000.................... 86

18

Page 19

EPSON AcuLaser C1900/AcuLaser C900 Revision A

Chapter 2 Operating Principles

2.1 Mechanism Overview.......................................................................................... 88

2.1.1 Locations of Electric Parts.......................................................................... 89

2.2 Operation Sequence............................................................................................. 92

2.3 Image Stabilization Control................................................................................. 93

2.3.1 Execution Conditions for Image Stabilization Control (Only for AcuLaser

C900) ......................................................................................................... 95

2.3.2 Engine Restrictions..................................................................................... 96

2.4 Description of Mechanisms................................................................................. 97

2.4.1 Paper Path ................................................................................................... 97

2.4.2 Photoconductor Unit................................................................................... 98

2.4.2.1 OPC Drum........................................................................................... 98

2.4.2.2 Charging Process................................................................................. 99

2.4.3 Exposure Process...................................................................................... 100

2.4.4 Development Process................................................................................ 101

2.4.4.1 Toner Cartridge Rack ........................................................................ 101

2.4.4.2 Development Position ....................................................................... 102

2.4.4.3 Toner Cartridge ................................................................................. 103

2.4.5 Transfer Process........................................................................................ 105

2.4.5.1 Transfer Belt Unit.............................................................................. 105

2.4.5.2 Secondary Transfer Roller Cleaning ................................................. 106

2.4.5.3 Transfer Belt Cleaner Mechanism..................................................... 107

2.4.5.4 Waste Toner Box............................................................................... 108

2.4.5.5 Waste Toner Box Detection .............................................................. 108

2.4.6 Fusing Process .......................................................................................... 109

2.4.6.1 Fuser Unit.......................................................................................... 109

2.4.7 Fusing Temperature Control..................................................................... 110

2.4.8 Paper Feed Mechanism............................................................................. 112

2.4.8.1 MP Tray............................................................................................. 112

2.4.8.2 500-sheet Cassette Unit (Option) ...................................................... 113

2.4.9 Other Mechanisms.................................................................................... 114

2.4.9.1 Duplex Unit (option) ......................................................................... 114

2.5 Controller Board Operating Principles.............................................................. 117

Chapter 3 Troubleshooting

3.1 Overview ........................................................................................................... 122

3.2 Status Display (AcuLaser C1900)..................................................................... 123

3.2.1 Service Call Error Status .......................................................................... 123

3.2.1.1 Details of Service Call Errors and Remedy ...................................... 124

3.2.2 Printer Status............................................................................................. 130

3.2.3 Details of Status Messages and Treatment Method.................................. 132

3.2.4 Details of Error Status and Remedy ......................................................... 134

3.2.5 Details of Warning Status and Remedy.................................................... 139

3.3 Status Display (AcuLaser C900)....................................................................... 142

3.3.1 Service Call Error Status .......................................................................... 142

3.3.1.1 Details of Service Call Errors and Remedy ...................................... 144

3.3.2 Printer Status............................................................................................. 150

3.3.3 Details of Status Messages and Treatment Method.................................. 151

3.3.4 Details of Error Status and Remedy ......................................................... 152

3.3.5 Details of Warning Status and Remedy.................................................... 155

3.4 Check Points and Remedy for Paper Jam ......................................................... 158

3.4.1 Initial Checking ........................................................................................ 158

3.4.2 Locations of Jam Detection Sensors......................................................... 158

3.4.3 Jam Detection Timing / Action to be Taken............................................. 159

3.4.4 Checking Method for Electric Parts ......................................................... 161

3.5 Details of Print Quality Trouble and Remedy................................................... 163

Chapter 4 Disassembly and Assembly

4.1 Overview ........................................................................................................... 166

4.1.1 Precautions................................................................................................ 166

4.1.2 Tools ......................................................................................................... 168

4.1.3 Screws....................................................................................................... 168

4.2 Main Unit Disassembly..................................................................................... 169

4.2.1 Before Disassembling the Printer ............................................................. 171

4.2.1.1 Toner Cartridge Removal.................................................................. 171

4.2.1.2 Removal of Other Units .................................................................... 172

4.3 Periodical Replacement Parts Removal ............................................................ 174

4.3.1 Secondary Transfer Roller........................................................................ 174

4.3.2 Fuser Unit ................................................................................................. 174

4.4 Cover Removal.................................................................................................. 176

4.4.1 Upper Front Cover.................................................................................... 176

4.4.2 Top Cover................................................................................................. 176

4.4.3 Front Door ................................................................................................ 177

4.4.4 Rear Cover................................................................................................ 177

4.4.5 Upper Rear Cover..................................................................................... 177

4.4.6 Left Cover................................................................................................. 178

19

Page 20

EPSON AcuLaser C1900/AcuLaser C900 Revision A

4.4.7 Front Cover............................................................................................... 178

4.4.8 Right Door ................................................................................................ 179

4.5 Printer Main Parts Disassembly and Assembly................................................. 182

4.5.1 Main Board (C485MAIN/C494MAIN).................................................... 182

4.5.2 Engine Board (PWB-A)............................................................................ 183

4.5.3 Exhaust Fan Motor (M6) .......................................................................... 184

4.5.4 Power Supply Fan Motor (M4)................................................................. 184

4.5.5 Power Supply Unit (PU)........................................................................... 185

4.5.6 AIDC Sensor............................................................................................. 186

4.5.7 High Voltage Unit (HV) ........................................................................... 187

4.5.8 Cleaner Pressure Flapper Solenoid (SL4)................................................. 188

4.5.9 Rack Motor (M2)...................................................................................... 189

4.5.10 Main Motor Ass’y................................................................................... 190

4.5.11 Multi Purpose Tray................................................................................. 191

4.5.12 Paper Empty Sensor................................................................................ 192

4.5.13 Fuser Unit Removal................................................................................ 193

4.5.14 Fusing Cooling Fan Motor (M5) ............................................................ 195

4.5.15 Paper Load Roller................................................................................... 196

4.5.16 Separation Roller .................................................................................... 196

4.5.17 Printer Head Unit (PH) ........................................................................... 197

4.5.18 Manual Paper Feed Solenoid (SL1)........................................................ 199

4.5.19 Fuser Deceleration Drive Assy............................................................... 200

4.5.20 Rack ........................................................................................................ 201

4.6 Extension Unit Disassembly and Assembly...................................................... 203

4.6.1 The 2nd Paper Load Roller....................................................................... 203

4.6.2 500-sheet Cassette Unit Control Board (PWB-A).................................... 204

4.7 Duplex Unit Disassembly and Assembly.......................................................... 205

4.7.1 Duplex Unit Control Board (PWB-A)...................................................... 205

4.7.2 Paper Feed Sensor..................................................................................... 205

4.7.3 Reverse Motor / Transfer Motor............................................................... 206

5.3.1 Overview .................................................................................................. 211

5.3.1.1 Operating Environment ..................................................................... 211

5.3.1.2 Conditions for Use ............................................................................ 211

5.3.2 How to Use the Service Utility................................................................. 212

5.3.2.1 Starting the Service Utility ................................................................ 212

5.3.2.2 Functions ........................................................................................... 214

5.3.3 Operation .................................................................................................. 214

5.3.3.1 Engine Status Sheet........................................................................... 214

5.3.3.2 Reset Counter .................................................................................... 214

5.3.3.3 USB ID.............................................................................................. 215

Chapter 6 Maintenance

6.1 Maintenance ...................................................................................................... 217

6.1.1 Consumables and Regular Replacement Parts ......................................... 217

6.1.2 Cleaning.................................................................................................... 217

Chapter 7 Appendix

7.1 Schematic Wiring Diagram............................................................................... 219

7.2 Connectors and Jumpers on Circuit Boards ...................................................... 220

7.3 ASP List ............................................................................................................ 248

7.4 Circuit Diagram................................................................................................. 258

Chapter 5 Adjustment

5.1 Overview ........................................................................................................... 208

5.2 USB ID Input..................................................................................................... 209

5.2.1 Installation Procedure for Program........................................................... 209

5.2.2 Procedure for Program Operation............................................................. 209

5.2.3 USB ID Confirmation............................................................................... 210

5.3 Service Utility (AcuLaser C900)....................................................................... 211

20

Page 21

PRODUCT DESCRIPTION

CHAPTER

1

Page 22

EPSON AcuLaser C1900/AcuLaser C900 Revision A

1.1 Product Description

AcuLaser C1900/AcuLaser C900 are non-impact color page printer that takes

advantage of the laser and electrophotographic technology.

1.1.1 Features

ENGINE FEATURES

True 600 dpi high resolution full color printing engine. (AcuLaser C900)

New, low-price color engine supporting A4-size paper (AcuLaser C1900)

4.0 ppm (A4 color) /16.0 ppm (A4 monochrome) print speed.

Duplex printing supported (A4/LT).

Compact and light weight, with body size about 70%, weight about 65%, and foot

print about 85% of AcuLaser C2000

Resolution

AcuLaser C1900 : 600dpi

AcuLaser C900 : 600dpi / 300dpi

Paper feed

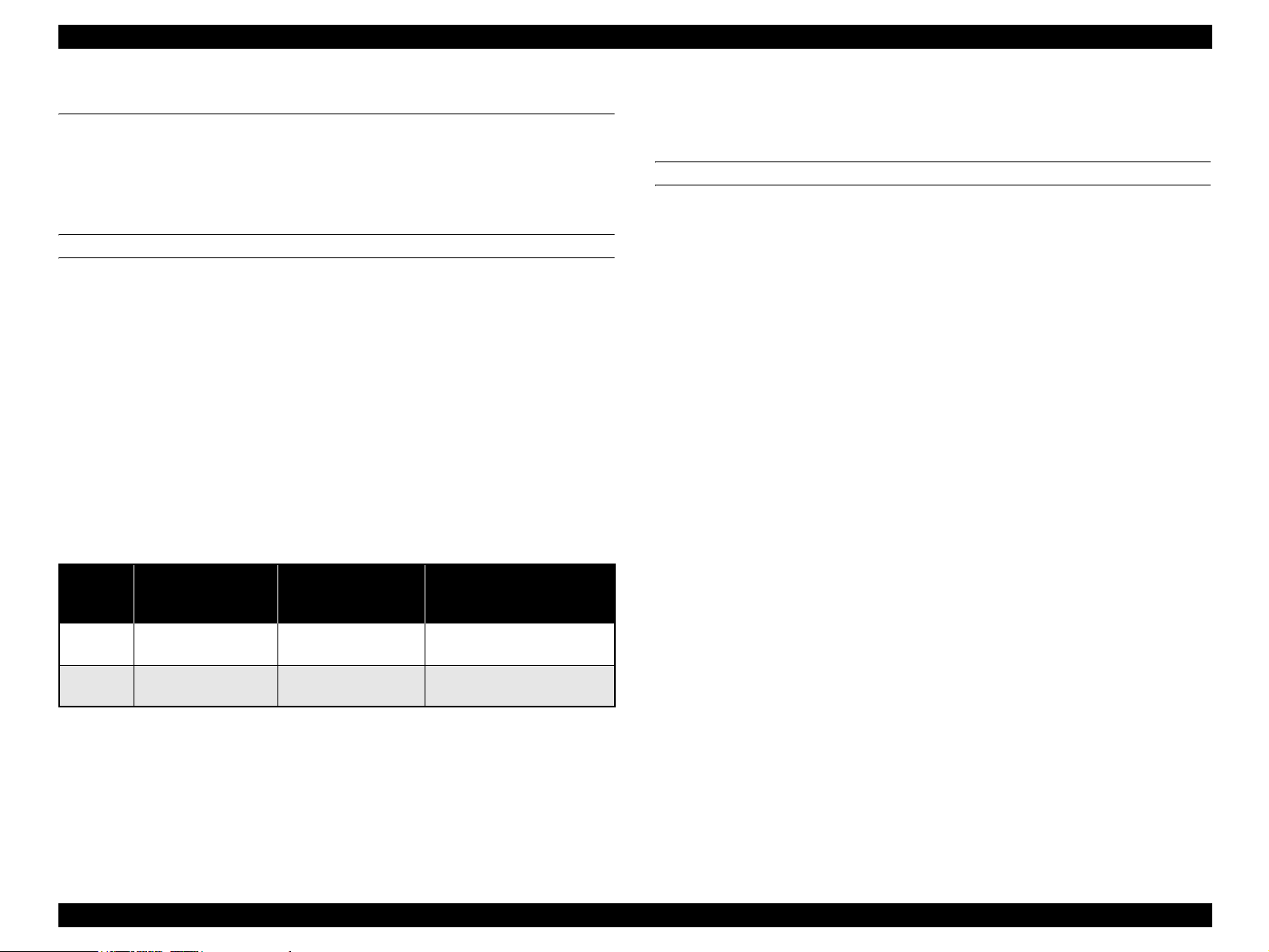

Table 1-1. Paper feed

Postcards,

Model Standard paper feed

AcuLaser

C1900

AcuLaser

C900

MP Tray (200 sheets) -

MP tray (200 sheets) MP tray (50 sheets)

Transparencies, Thick

Paper, or Labels

A maximum of 200 sheets can be output face-down.

Optional (Lower Cassette Unit)

Paper Source (500 sheets)

An optional paper cassette unit

(500 sheet, A4/LT only)

option

1.5 K pre-installed toner

1.5 K toner for each color included with package

4.5 K toner for Optional use

CONTROLLER FEATURES

<AcuLaser C1900>

New RISC CPU: PowerPC 300 MHz (SPC603ei)

RAM: Standard 32MB

Expandable up to a maximum of 1GB

SDRAM DIMM supporting standard PC100 and PC133 (32, 64, 128, 256, or

512 MB) can be used. For memory expansion of 544 MB or more, the standard

32 MB DIMM must be replaced.

Color technologies

AcuLaser Color Halftoning installed

Three types of standard interfaces installed

10/100baseTx Ethernet

IEEE1284 parallel interface (Compatibility, Nibble, ECP)

USB 1.1 (2.0 FS 12Mbps Certified)

NOTE:

Support for optional Type-B interface

RAM expansion can increase the performance and speed of the AcuLaser Color

Halftoning drawing area, print speed, resolution, receive buffer size, and collated

printing (Collate in Printer).

HDD (optional) can be installed

New HDD that is also used by AcuLaser C8600 is supported.

(The old type of HDD cannot be used)

Improved color stability brought by new AIDC control Color stability matching or

exceeding AcuLaser C1000 is targeted.

Low noise level (target)

Sleep Mode : 39dB (A)

While printing : 54dB (A)

Use of newly developed polymerized toner, making oil-less fixing possible

Product Description Product Description 22

Page 23

EPSON AcuLaser C1900/AcuLaser C900 Revision A

<AcuLaser C900>

Host based controller

CPU: VR4305-48MHz

Standard RAM: 16 MB,

with additional RAM DIMM expanding to a maximum of 144 MB

Color technologies

CPGI, CRIT (Color RIT) installed

Two types of standard interfaces installed

IEEE1284 compatible parallel interface supporting ECP

USB I/F

SOFTWARE FEATURE

<AcuLaser C1900>

Emulation included as standard

ESC/Page Color mode

LJ4, GL2, ESC/P2, FX, I239X, ESC/Page (monochrome mode)

Optional emulation

Adobe PostScript 3

<AcuLaser C900>

ESC/PageS installed

Color supported

Duplex printing supported

Network compatibility

Use of background job commands establish network connections.

Ability to update the firmware

Supply of program on Flash DIMM makes update of firmware possible

(no MASK during mass production).

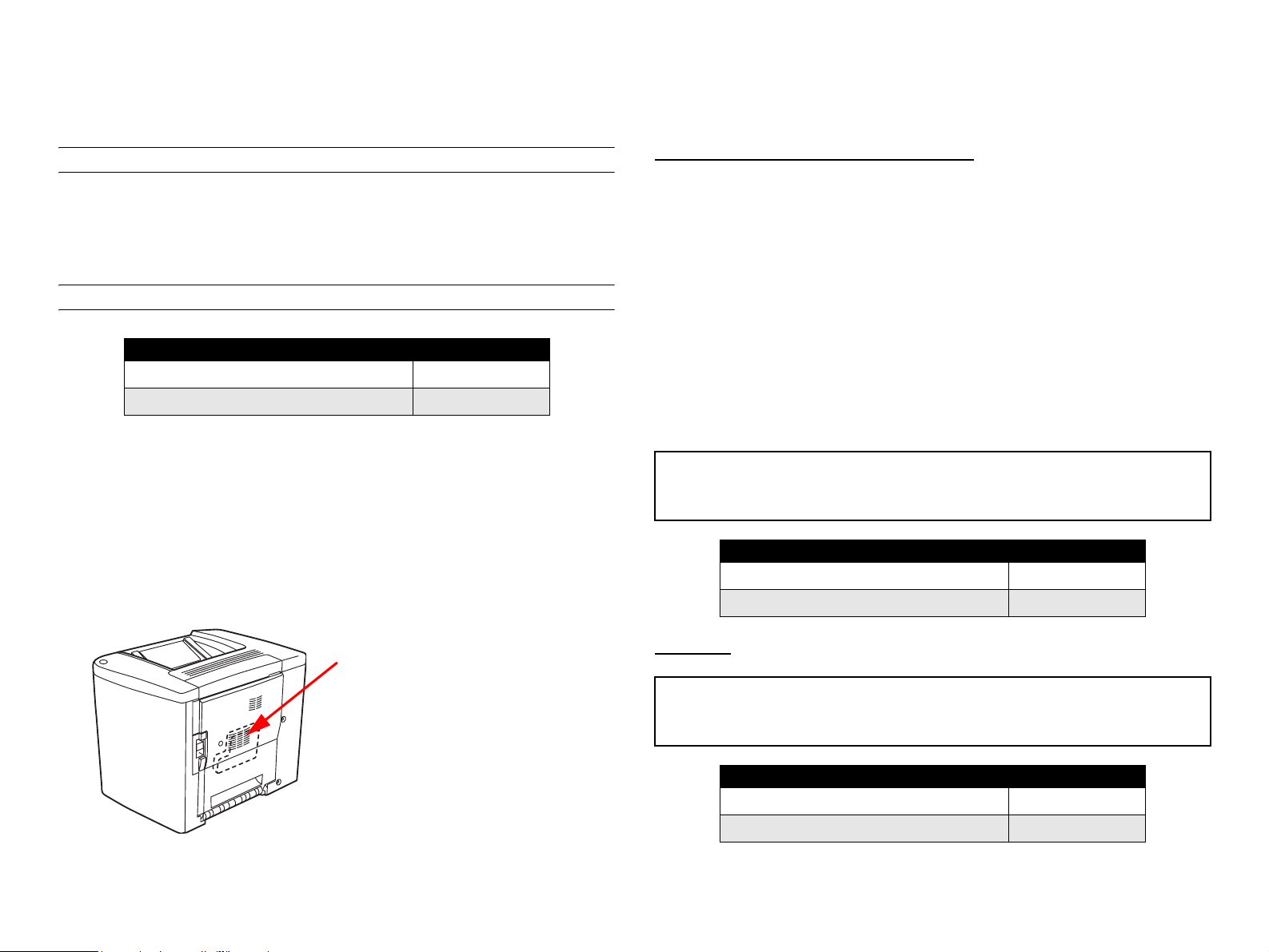

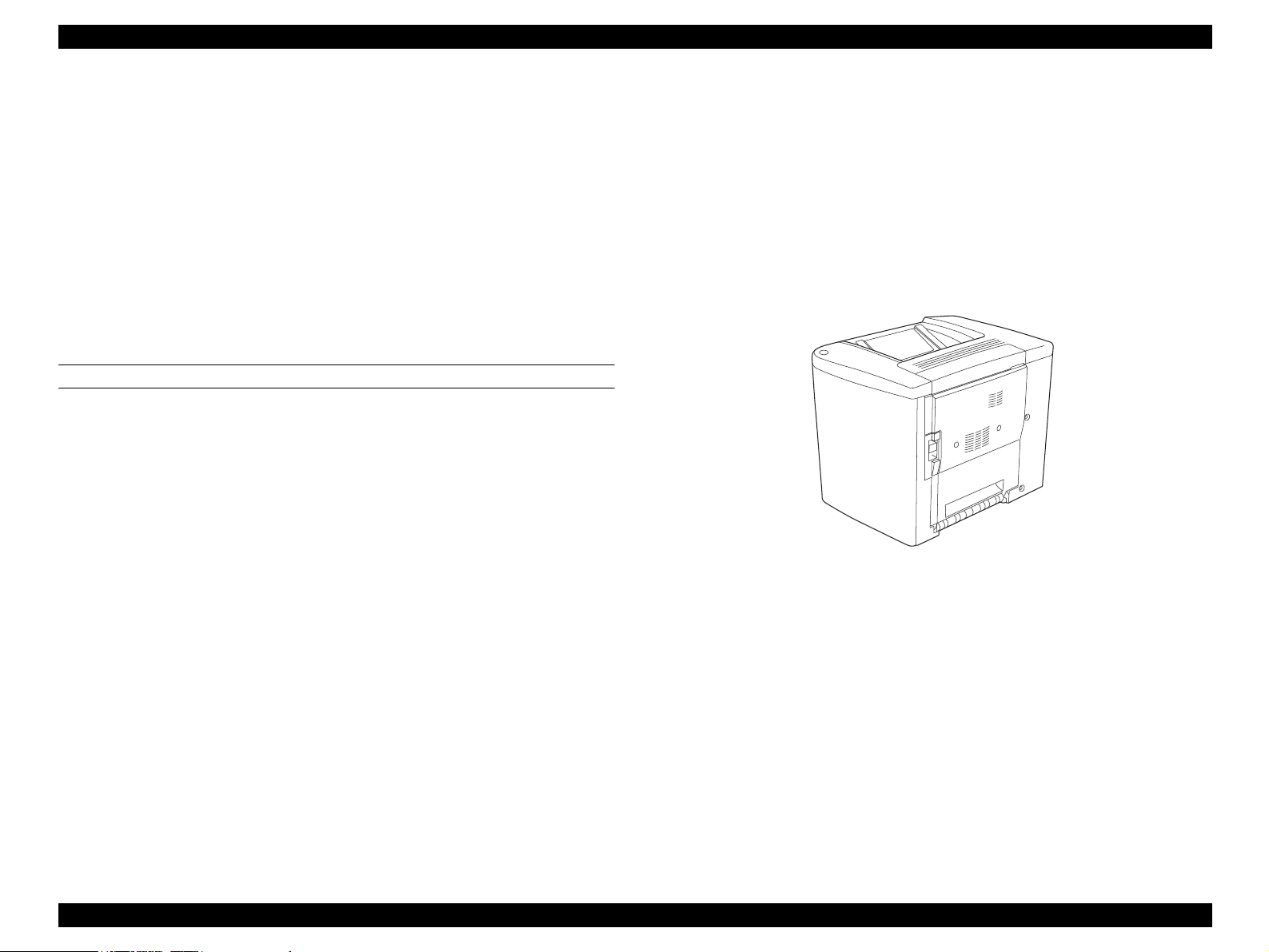

Figure 1-1. External Appearance

Ability to update the engine controller program.

This function is only supported for the evaluation sample.

DCC command support.

Diag command only.

Product Description Product Description 23

Page 24

EPSON AcuLaser C1900/AcuLaser C900 Revision A

1.2 Basic Specifications

1.2.1 Process Specifications

Printer formula

Semi-conductor laser beam scan and elector photography with dry single

component no electromagnetic toner.

Light Source

Semi-conductor laser

Photoconductor Unit

OPC (organic photoconductive conductor) drum

Charging

Needle electrode scorotron charger

Development

Exposed area development

Toner

Nonmagnetic one-component toner

Primary Transfer

Electrode roller transfer method

Intermediate Transfer

Intermediate transfer belt method

1.2.2 Printer Basic Specifications

Resolution

600 dpi

Warming Up Time

100 V, 120 V : 180 seconds or less (in 23 °C 55%RH, rated voltage)

220~240 V : 180 seconds or less (in 23 °C 55%RH, rated voltage)

Printing Mode

B/W mode : A regular monochrome mode that prints fastest.

Color mode : A color mode that uses Y, M, C, K toners.

Speed Mode

Standard mode : Paper feeding at the main unit's fastest speed.

Low-speed <1> mode : Reduce the envelope feeding speed to retain the

quality.

Low-speed <2> mode : Reduces paper feeding speed to ensure satisfactory

fusing at printing on thick paper, label sheets or

coated paper exceeding 90g/m

Low-speed <3> mode : Reduce the paper feeding speed to retain the fixity of

printing on transparencies.

2

(24 lb).

Secondary Transfer

Roller transfer method

Fixing

Heated roller fuser method

Density Adjustment

Automatic adjustment (not adjustable by user)

Product Description Basic Specifications 24

Page 25

EPSON AcuLaser C1900/AcuLaser C900 Revision A

First Printing Time

*1

B/W mode

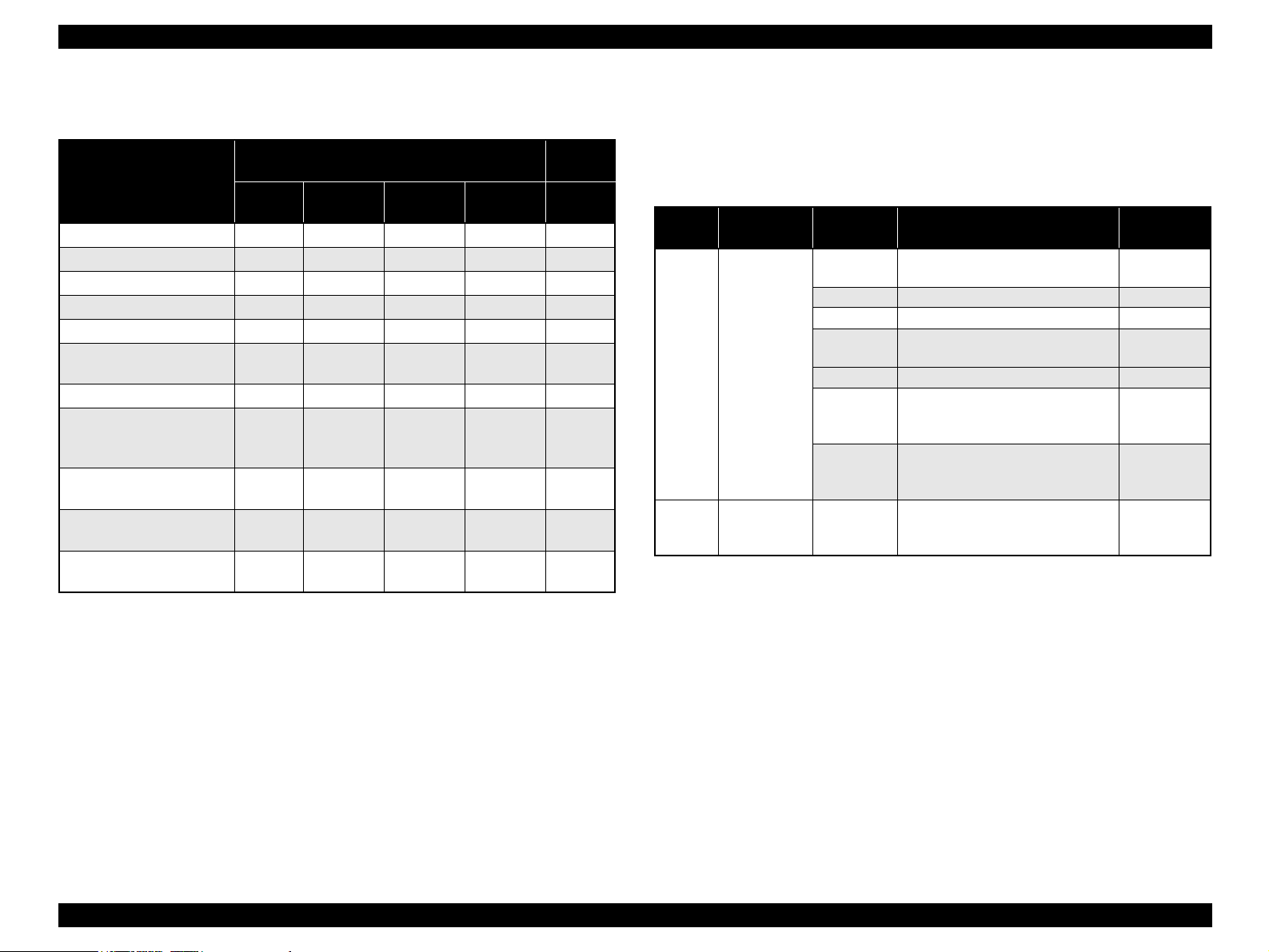

Table 1-2. First Printing Time (Unit: seconds max.)

Printing mode

\

Paper size

A4 14.0 23.0 28.0 25.0

A5 14.0 23.0 - -

B5 14.0 23.0 - -

Letter 14.0 23.0 28.0 25.0

Japanese official postcard - 22.0 - -

Japanese official returned

postcard

Standard

mode

- 23.0 - -

Simplex printing

Low-speed

<2> mode

Low-speed

<3> mode

Duplex

printing

Standard

mode

Color mode

Table 1-3. First Printing Time (Unit: seconds max.)

Printing mode

\

Paper size

A4 25.0 34.0 40.0 39.0

A5 25.0 34.0 - -

B5 25.0 34.0 - -

Letter 25.0 34.0 40.0 39.0

Japanese official postcard - 33.0 - -

Japanese official returned

postcard

Standard

mode

- 34.0 - -

Simplex printing

Low-speed

<2> mode

Low-speed

<3> mode

Duplex

printing

Standard

mode

Continuous Printing Speed

B/W mode

Table 1-4. Continuous Printing Speed (Unit: ppm)

*2

*2

Printing mode

\

Paper size

A4 16.0 - 3.3 2.5 10.0

A5 16.0 - 3.5 - -

B5 16.0 - 3.4 - -

Letter 16.0 - 3.3 2.5 10.0

Japanese official postcard - - 3.6 - -

Japanese official returned

postcard

Envelope C6 Yokei #6

/MON/DL

Envelope Yokei #0

/Yokei #4

User defined

148 mm ≤ L<210 mm

User defined

210 mm ≤ L ≤ 297 mm

User defined

297 mm <L ≤ 356 mm

Note *: JIS envelope

NOTE 1:

*

C5/Com-#10

L: Paper length

2:

Paper width is between 92 mm and 216 mm

Standard

mode

- - 3.5 - -

*

-4.1 - - -

- 4.0 - - -

- - 3.5 - -

16.0 - 3.3 - -

8.0----

Simplex printing

Low-speed

<1> mode

Low-speed

<2> mode

Low-speed

<3> mode

Duplex

printing

Standard

mode

Note *1: The above values are periods from when the printer receives the start command to

when it completes ejecting the first sheet.

*2: The above periods are the same in all the paper feed bins.

Product Description Basic Specifications 25

Page 26

EPSON AcuLaser C1900/AcuLaser C900 Revision A

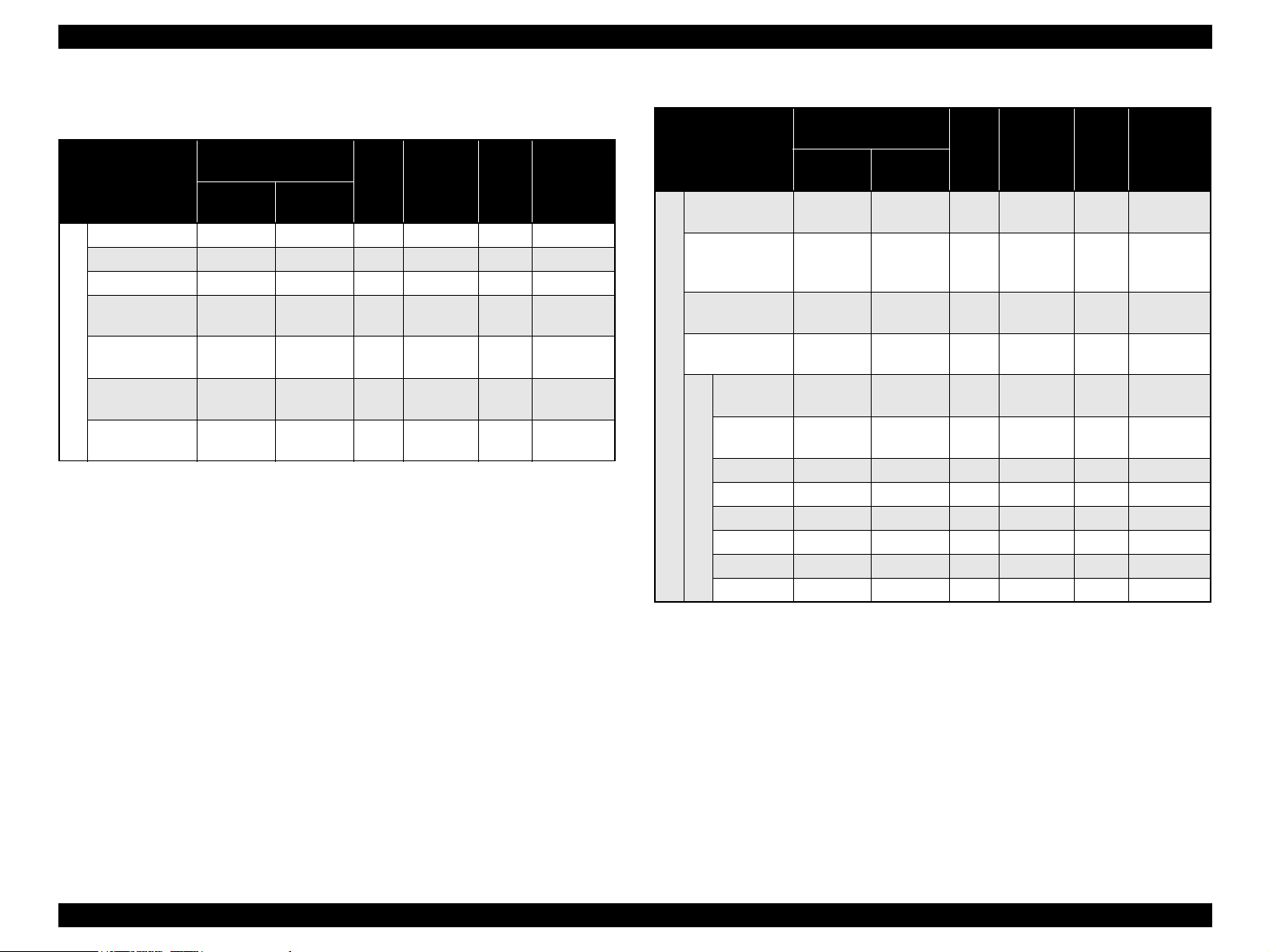

Color mode

Table 1-5. Continuous Printing Speed (Unit: ppm)

Printing mode

\

Paper size

A4 4.0 - 2.0 1.6 4.0

A5 4.0 - 2.0 - -

B5 4.0 - 2.0 - -

Letter 4.0 - 2.0 1.6 4.0

Japanese official postcard - - 2.1 - -

Japanese Official both-way

postcard

Envelope C6 - 2.3 - - -

Envelope MON/C5/Com#10/DL Yokei #0*/Yokei #4*

Yokei #6

User defined

148 mm

User defined

210 mm ≤ L ≤ 297 mm

User defined

297 mm < L ≤ 356 mm 2.0

*

≤ L<210 mm

Standard

mode

- - 2.0 - -

- 2.2 - - -

- - 2.0 - -

4.0 - 2.0 - -

2.0 - - - -

Simplex printing

Low-speed

<1> mode

Low-speed

<2> mode

Low-speed

<3> mode

Duplex

printing

Standard

mode

Paper Feed Reference

Centerline reference for each paper size, and for both the MP tray and optional

cassette unit (option).

Paper Feed

Table 1-6. Paper Feed

Paper source

Standard MP tray 200 sheets

Optional Optional

500sheets

cassette unit

Note *: JIS envelope

Capacity

(Height)

(23mmMax)

50 sheets Transparency: A4, Letter 50 sheets Label: A4, Letter -

50 sheets

50 sheets Label: A4, Letter -

10 sheets

50 sheets

500 sheets

(57mmMax)

Paper size for paper feed

A4,A5,B5,Letter,GLT,HLT,Exective Plain paper

Thick paper:

A4,A5,B5,Letter,GLT,HLT,Exective

Envelope:

C5, C6, Com-10, DL, Monarch,

Yokei #0

Postcard (for domestic models):

Japanese official postcard,

Japanese official returned postcard

A4 or Letter

(fixed on the factory default) 60 ~ 90 g/m

*

,Yokei #4 *,Yokei #6

*

Applicable

paper type

60 ~ 90 g/m

91 ~ 163 g/m

-

190 g/m

2

2

2

2

Note *: JIS envelope

NOTE 1:

L: Paper length

2:

Paper width is between 92 mm and 216 mm

Product Description Basic Specifications 26

Page 27

EPSON AcuLaser C1900/AcuLaser C900 Revision A

Applicable Paper Sizes, Paper Types, and Paper Orientation

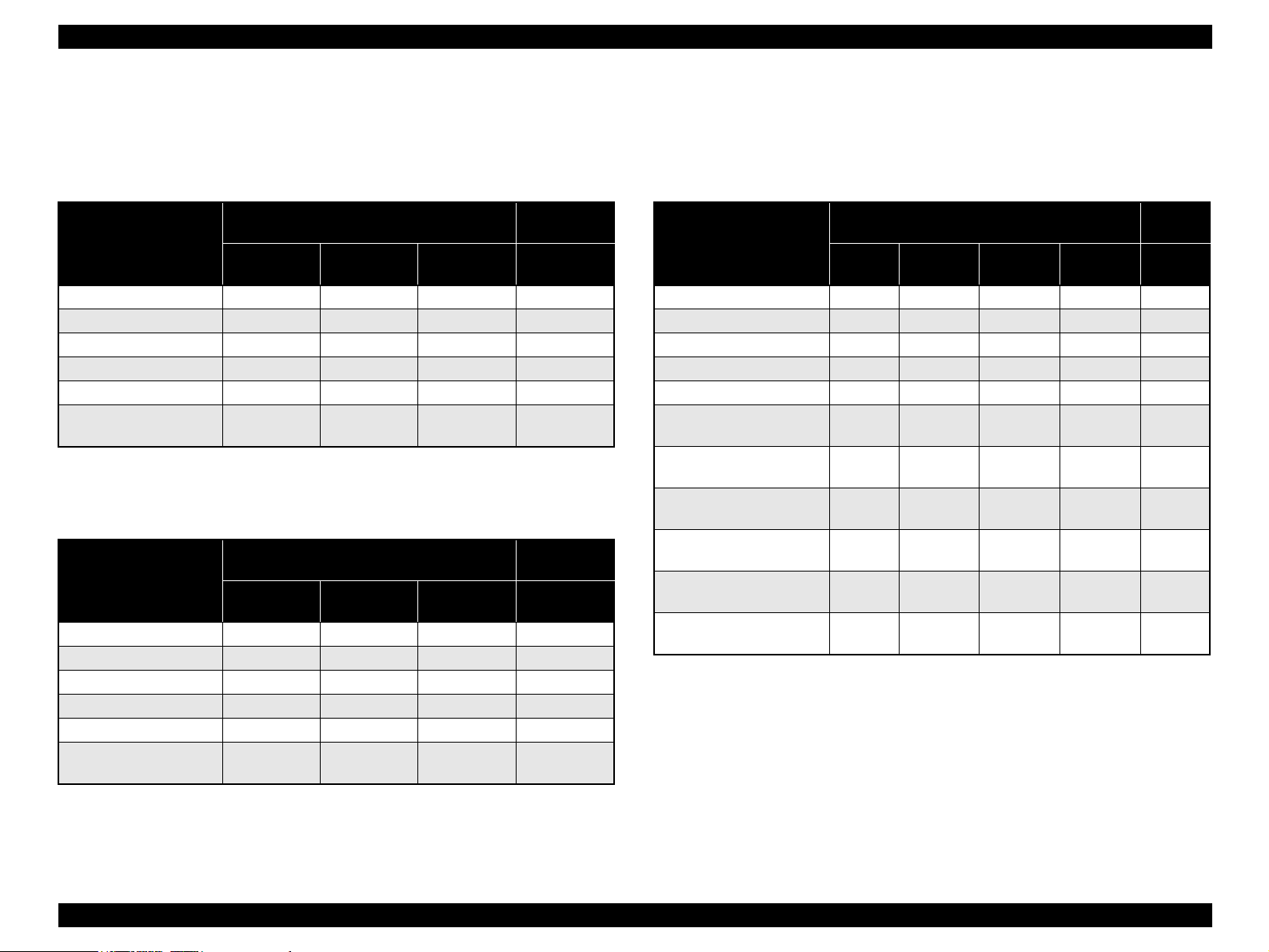

Table 1-7. Applicable Paper Sizes, Paper Types, and Paper Orientation

Paper size Unit mm

Paper Size

Vertical

(length)

(inch)

Horizontal

(width)

A4 297.00 210.00 {{ {SEF

A5 210.00 148.00 { - - SEF

B5 257.00 182.00 { --SEF

Letter 279.40

(11.00)

Half Letter 215.90

Plain paper

(8.50)

EXECUTIVE 266.70

(10.50)

G.Letter 266.70

(10.50)

215.90

(8.50)

139.70

(5.50)

184.15

(7.25)

203.20

(8.00)

MP

tray

Optional*1

cassette

unit

Duplex

print

unit

Paper

Orientation

{ { { SEF

{ --SEF

{ - - SEF

{ --SEF

Table 1-7. Applicable Paper Sizes, Paper Types, and Paper Orientation (continued)

Paper size Unit mm

Paper Size

Japanese official

postcard

*4

Japanese official

returned postcard

*4

148.00 100.00

200.00 148.00

Transparency A4:297.00

LT:279.40

Label A4:297.00

LT:279.40

MONARCH 190.5

(7 1/2)

Com-10 241.30

Special applications

*2

DL 220.00 110.00 { - - SEF

(9 1/2)

Vertical

(length)

(inch)

Horizontal

(width)

A4: 210.00

LT:215.90

A4: 210.00

LT:215.90

98.43

(3 7/8)

104.78

(4 1/8)

C5 229.00 162.00 { --SEF

Envelope

C6 162.00 114.00 { - - SEF

Yokei #0 *5235.00 120.00 { --SEF

Yokei #4 *5235.00 105.00 { - - SEF

Yokei #6 *5190.00 98.00 { --SEF

MP

tray

Optional*1

cassette

unit

Duplex

print

unit

Paper

Orientation

{ - - SEF

{ --SEF

{ - - SEF

{ --SEF

{ - - SEF

{ --SEF

*3

*3

*3

*3

*3

*3

*3

*3

Note *1: The dedicated cassette for A4 only or Letter only (by factory default).

*2: The supported envelope sizes differ depending on destination.

*3: Refer to “Envelope Orientation” (p.28) for details on feeding direction of envelopes.

*4: Curls must be straightened.

*5: JIS envelope.

NOTE 1:

SEF (Short Edge Feed): The short edge of the paper is fed to the printer.

2:

“-”: Not supported.

Product Description Basic Specifications 27

Page 28

EPSON AcuLaser C1900/AcuLaser C900 Revision A

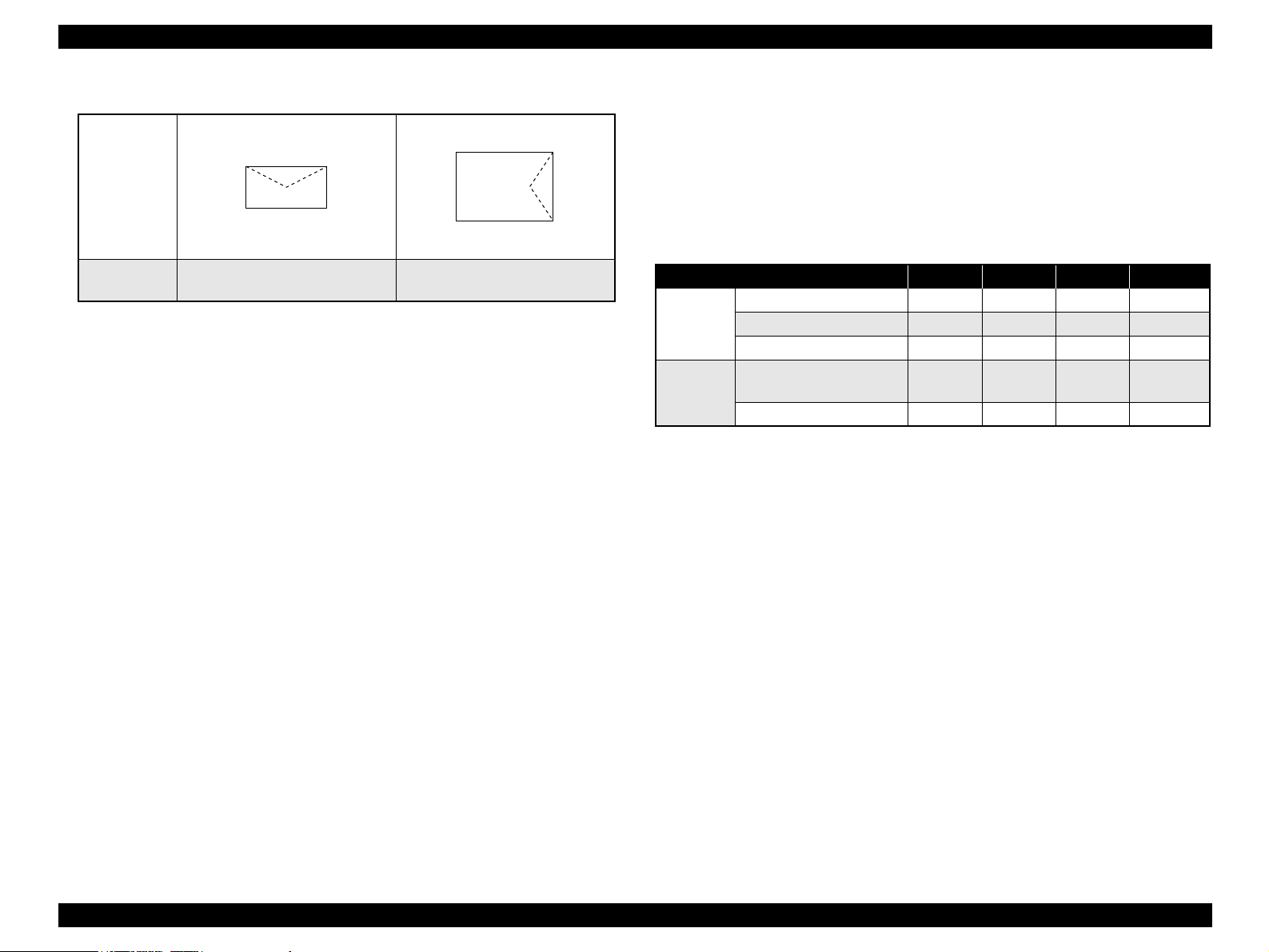

Envelope Orientation

Optional 500-sheet cassette unit

Paper size: Fixed on A4 or Letter

Feeding

direction

→

Paper thickness: 60 g/m

Output Paper Capacity

Face-down (FD) tray only 200 sheets

2

~ 90 g/m

2

Dimensions and Weights

Table 1-8. Outline Dimensions and Weight

Envelope types

Note *: JIS envelope.

NOTE 1:

Envelopes must be loaded facing the printing side up with the flaps heading

MONARCH, DL Com-#10, C6

Yokei #0*, Yokei #4* Yokei #6

*

C5

forward or backward to the paper feed direction.

2:

Opened flaps must be closed.

3:

Printing on the backside (where a flap seal is being sealed) is not possible.

4:

Only envelopes without adhesive or adhesive tapes can be used.

Paper Sizes for Feeding

Regular paper sizes or user defined paper sizes within applicable paper sizes below.

Main unit

Paper width: 92.00 mm ~ 216.00 mm

Paper length: 148.00 mm

Paper thickness: 60 g/m

*1

~ 356.00 mm

2

~ 163 g/m2 (190 g/m2: Japanese official postcard)

Note *1: 148.00 mm ~ 356.00 mm in low-speed <2> mode only and

210.00 mm ~ 356.00 mm in standard mode

Duplex print unit

Paper size: A4, Letter

Paper thickness: 60 g/m

NOTE:

Only regular sizes are supported, while user defined paper size

cannot be used.

2

~ 90 g/m

2

Stand-alone

Options

Installed

Note *1: This value includes the height of the right-side paper path.

*2: This value includes the weight of the consumables, controller circuit board and

Note : Dimensions have a tolerance of ±5mm and weights have a tolerance of ±0.5kg.

Consumables

Developer cartridge (Black, Cyan, Yellow, Magenta)

Photoconductor unit

Transfer belt unit

Waste toner collector

Regular Replacement Parts

Fuser unit

Second transfer roll

Power Supply

Paper source Width Depth Height Weight

Main unit 429 mm 521 mm 406 mm 29 kg

Optional cassette unit 380 mm 485 mm 178 mm 5.3 kg

Duplex print unit 96 mm 340 mm 330 mm 2.0 kg

Main unit+

Optional cassette unit

Main unit + Duplex print unit 473 mm 521 mm 406 mm 31.0 kg

operation panel.

100 V

± 10% : 50Hz

120 V ± 10% : 50Hz

220 ~ 240 V ± 10% : 50Hz

469 mm 521 mm 526 mm 34.3 kg

±3Hz

±3Hz

±3Hz

/ 60 Hz

/ 60 Hz

/ 60 Hz

±3Hz

±3Hz

±3Hz

*2

Product Description Basic Specifications 28

Page 29

EPSON AcuLaser C1900/AcuLaser C900 Revision A

Power supply to the controller

5.0 V

± 5%, 2 A or less

3.3 V

± 5%, 5 A or less

Power Consumption

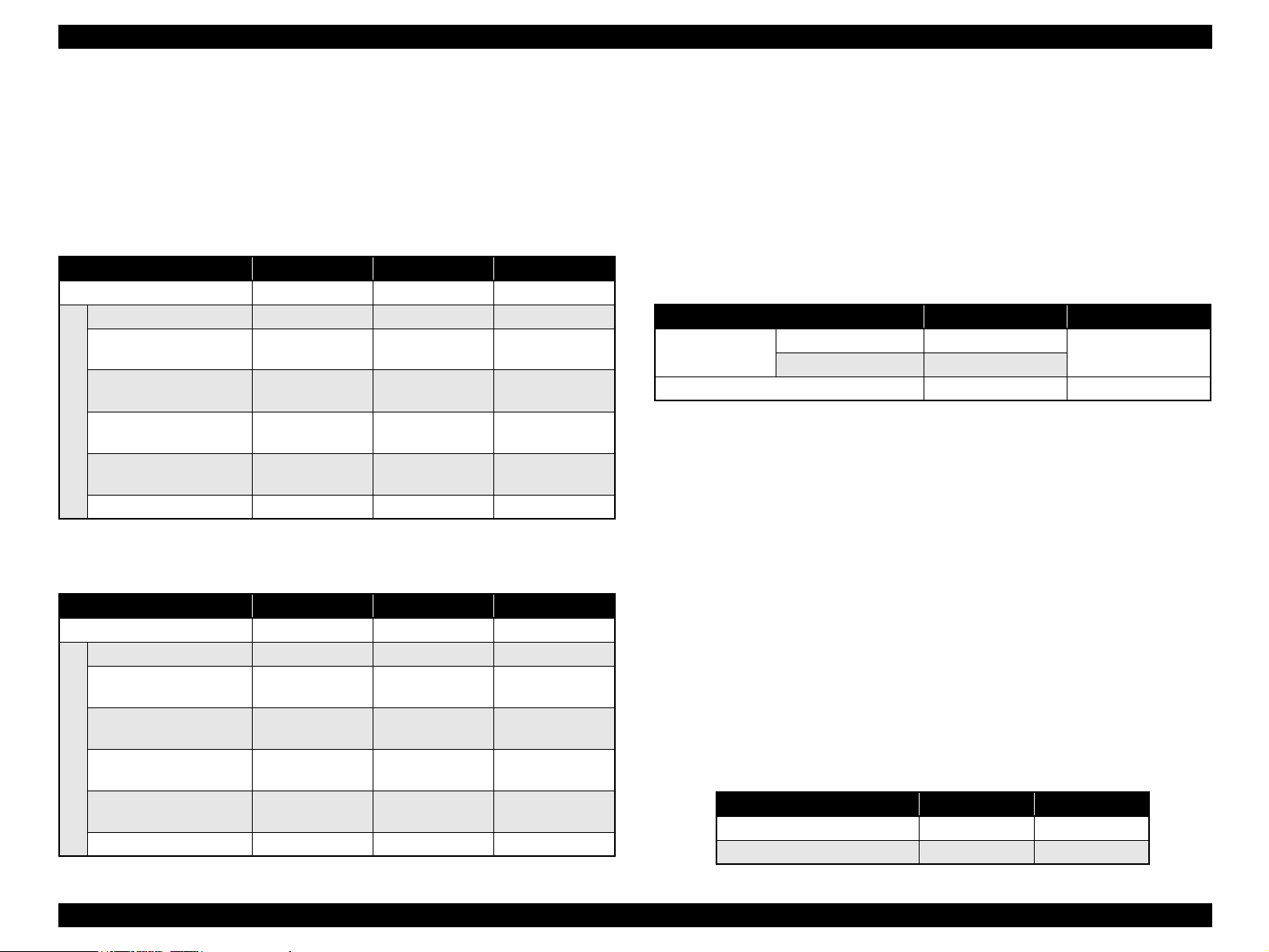

<AcuLaser C1900>

Table 1-9. Power Consumption (AcuLaser C1900)

100 V 120 V 230 V

Maximum current rated 100 V:13 A or less 11 A or less 7 A or less

Maximum 1100 W 1100 W 1100 W

Average at continuous

printing in B/W

Average at continuous

printing in color

Average during standby

with heating ON

Average during sleep mode

Power Consumption

with heater OFF

Powered off mode 0Wh 0Wh 0Wh

- 372 Wh 352 Wh

- 247 Wh 241 Wh

- 108 Wh 107 Wh

30 W or less 15 W or less 12 W or less

<AcuLaser C900>

Table 1-10. Power Consumption (AcuLaser C900)

100 V 120 V 230 V

Maximum current rated 100 V:13 A or less 11 A or less 7 A or less

Maximum 1100 W 1100 W 1100 W

Average at continuous

printing in B/W

Average at continuous

printing in color

Average during standby

with heating ON

Average during sleep mode

Power Consumption

with heater OFF

Powered off mode 0Wh 0Wh 0Wh

352Wh 351 Wh 352 Wh

253Wh 243 Wh 243 Wh

108Wh 111 Wh 100 Wh

10 W or less 11 W or less 8 W or less

Product Lifetime

Main unit : 200 k pages printed or five years, whichever

comes first

Optional cassette unit : 200 k pages printed or five years, whichever

comes first

Duplex print unit : 200 k pages printed or five years, whichever

comes first

Noise

Table 1-11. Noise

In printing In standby

Main unit Color mode 54 dB(A) or less

B/W mode 54 dB(A) or less

When full-options are installed

Note *: The noise with all options installed is the value actually measured.

*

54 dB(A) or less 39 dB(A) or less

39 dB(A) or less

Exhaust Gas

Ozone concentration : 0.02m g/m

(New Blue Angel standard compliance)

Styrene concentration : 0.07m g/m

(New Blue Angel standard compliance)

Dust concentration : 0.150m g/m

(New Blue Angel standard compliance)

Nitrogen dioxide : 5 ppm or less

Carbon monoxide : 30 ppm or less

3

or less

3

or less

3

or less

Hazardous Materials

None of the Photoconductor (OPC), toners, or plastic contains is hazardous

material.

NOTE: Note: For the standards, refer to “1.2.8 Compatible Standard (p. 36)”.

Current Consumed (Rating)

Table 1-12. Current Consumed

5V 24V

Optional 500-sheet Cassette Unit 0.2A 1A

Duplex Unit 0.1A 0.4A

Product Description Basic Specifications 29

Page 30

EPSON AcuLaser C1900/AcuLaser C900 Revision A

1.2.3 Paper Specifications

Paper that Causes Printing Defects, Paper Jams or Printer

Malfunctions if Used

• Copy papers (carbon papers, non-carbon papers), thermal papers,

impact papers, acid-based papers

• Papers that are too thin or too thick

• Papers that are wet or damp

• Papers with special coatings or paper for color printers with processed

surfaces

• Papers that are too smooth (slick and slippery) or too rough on its

surfaces

• Papers with significantly different roughness on each surface of front

and back side

• Papers with punch holes for binders or perforations

• Creased, curled or torn paper

• Irregularly shaped paper or paper with non-perpendicular corners

• Labels that peel off easily

• Papers with glue, staples or paper clips attached to it

• Special applications for ink jet papers

(super-fine, glossy paper or film, etc.)

• Papers that were previously used in a thermal or ink jet printer

• Transparencies for other color/monochrome laser printers or

photocopiers

• Sheets already printed on other color / monochrome laser printers or

photocopiers

• Sheets of paper stuck together

• 4-page jointed postcard, and Japanese official postcard, nonofficial

postcard, sealed postcard for ink jet printers

• Iron print coated paper (for both inkjet and laser printers)

• Sheets deteriorate or discolor by at 180

°

C or cooler

1.2.3.1 Paper type

Standard Paper

Domestic:

FX P paper (B/W), EPSON high-quality plain paper (A4/LT)

Overseas:

4024 paper (20 lb) (B/W), EPSON high-quality plain paper (A4/LT)

Plain paper

2

60 g/m

Generally applied copy paper, recycled paper

Special Applications

EPSON Dedicated transparency sheet (A4/LT)

EPSON dedicated coated paper (A4)

Japanese official postcard (for domestic models)

Japanese official returned postcard (for domestic models) with no crease

Label

Thick paper (91 g/m

Envelope

NOTE 1:

~ 90 g/m2 (16 lb ~ 24 lb)

2

~ 163 g/m2)

lb: Ream weight = lb / 500 sheets / 17” × 22”

2

g/m

: 1 g/m2 = 0.2659763 lb

2:

When purchasing bulk paper, be sure to check that the paper can be properly

fed beforehand.

C A U T I O N

C H E C K

P O I N T

When “Kamo mail” Japanese official postcards or illustrated

postcards are used, paper feed roller may be soiled with paper

dust, causing difficulties in feeding these postcards properly. In

this case cleaning is required following the “6.1.2 Cleaning”

(p.217).

Product Description Basic Specifications 30

Page 31

EPSON AcuLaser C1900/AcuLaser C900 Revision A

1.2.3.2 Paper Feeding

Table 1-13. Paper Feeding

Special applications

)

2

Paper source

Recommended paper

Standard MP tray {

Optional Optional 500-sheet

cassette unit

Duplex print unit

{ : The paper feed reliability and image quality assured.

∆

: Paper feeding and printing are possible, however only for the use of generally applied types

of paper.

The Image quality is not assured.

{

{

× : Paper feeding is impossible.

Plain paper

∆∆∆∆ ∆ ∆

∆

∆

Transparency

Japanese official

postcard

Label

Thick paper

(91 ~ 163 g/m

Coated paper

× × × × ×

ЧЧЧЧЧ

Envelope

1.2.3.3 Printing Area

Maximum Printable Area: Width 208 mm / length 348 mm

Guaranteed Printing Area: All area of a sheet, which is up to the paper size 216

mm × 297 mm or less, except 4 mm of vertical and

horizontal margins

NOTE:

A Paper that exceeds the paper length 297 mm is not supported

(refer to the diagram below).

Guaranteed

printing area

Figure 1-2. Guaranteed printing area

NOTE: The printing area may differ depending on each printer product

specification (emulation mode).

Product Description Basic Specifications 31

Page 32

EPSON AcuLaser C1900/AcuLaser C900 Revision A

1.2.4 Reliability and Maintainability

1.2.4.1 Reliability

MPBF/MTBF

Main unit: 35,000 pages or more / 3,000 hours or more

NOTE:

Paper Feed Reliability

Paper jam rate 1/2000 sheets or less 1/1000 sheets or less

Miss-feed 1/2000 sheets or less -

Multiple-sheet feed rate

Wrinkled paper 1/1000 sheets or less 1/500 sheets or less

Creased paper at the top edge

(for 1 c or more

Note *1: Standard environment: 15 ~ 25°C, 35 ~ 70%RH

*2: Multiple-sheet feed rate does not include performance at the boundary between the

*3: 1 C indicates 1 mm of crease at a corner.

*1: Monthly operating hours: Over 300 hours (average)

*1

Table 1-14. Paper Feed Reliability

Simplex printing Duplex printing

*2

*3

)

Defines the reliability of humidity-no adjusted paper of the plain paper (A4, Letter).

original paper and the replenished paper that occurs after replenishing paper.

1/500 sheets or less -

1/1000 sheets or less 1/500 sheets or less

*1

Printing Start Position Accuracy

Main scanning

Simplex

printing

Duplex

printing

direction

reference

position (c)

Sub scanning

direction

reference

position (a)

Main scanning

direction

reference

position (c)

Sub scanning

direction

reference

position (a)

±2.0mm

±2.5mm

Printing Area

±3.0mm

±2.5mm

Skew

The table below shows specification values converted to dot-2 pattern reference.

Table 1-15. Skew

A4

Simplex

printing

Duplex

printing

Main scanning direction (|c-d|)

Sub scanning direction (|a-b|)

Main scanning direction (|c-d|)

Sub scanning direction (|a-b|)

2.12 mm

1.56 mm

3.19 mm

2.60 mm

Paper Feed Direction

Metric length

Table 1-16. Skew

A4

Simplex

printing

Duplex

printing

Main scanning direction (|c-d|)

Sub scanning direction (|a-b|)

Main scanning direction (|c-d|)

Sub scanning direction (|a-b|)

195.58 mm

281.61 mm

195.58 mm

281.61 mm

Product Description Basic Specifications 32

Page 33

EPSON AcuLaser C1900/AcuLaser C900 Revision A

Height of Curl of Printed Pages

1.2.5 Operating Conditions (Including Consumables)

Table 1-17. Height of Curl of Printed Pages

Paper type Height of curl

Standard paper, plain paper 30 mm or less

Transparency 15 mm or less

Other special applications Not regulated

NOTE 1:

Same in both simplex printing and duplex printing

2:

Measuring conditions

Non arrayed monochrome printing with 5% of image occupation rate, or

color printing with 5% of image occupation rate for each color (20% in

total). Measured after 1 p/J of intermittent printing for 10 sheets and leaving

unattended for one minute.

Image occupation rate and alignment pattern differ depending on printing

condition.

1.2.4.2 Durability

Printing Volume

Average 3,000 pages / per month

Maximum 35,000 pages / per month

NOTE: The standard mode provides print ratio between color <2P/J> and

monochrome <3P/J> as color: monochrome = 1: 3

Air Temperature and Humidity

Table 1-18.

Temperature (°C) Humidity (%RH) Others

Printer is in operation 10 ~ 35 15 ~ 85 With no condensation

Printer is stopped

0 ~ 35 10 ~ 85

Unattended time:

72 hours or less

Air Pressure (Altitude)

741 hPa or more (2,500 m or less)

Level

1° difference or less in front and back, or left and right.

Lighting

3,000 lx or less (no exposure to direct sunlight)

1.2.4.3 Maintenance

MTTR Within 30 minutes in average.

(Time required for service personnel to determine and correct the cause of the

malfunction)

Product Description Basic Specifications 33

Page 34

EPSON AcuLaser C1900/AcuLaser C900 Revision A

Space Requirements

In order to ensure that the printer operates properly, provide at least as sufficient

space as shown in the figure below.

NOTE: The space height required above the top cover is 200 mm or more.

1225 mm

426 mm

200 mm