Page 1

®

Color Image Scanner

EPSON Perfection 610

SESC990016

Page 2

EPSON Perfection 610 Rev. B

g

g

g

g

g

g

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopyin

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate bein

informed of them.

, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a re

General Notice: Other product names used herein are for identification purpose only and may be trademarks or re

Copyri

ht © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

istered trademark of SEIKO EPSON CORPORATION.

respective owners. EPSON disclaims any and all ri

hts in those marks.

istered trademarks of their

Page 3

EPSON Perfection 610 Rev. B

g

g

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

in performin

WARNING

The precautionary measures itemized below should always be observed when performin

procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised

Signals a precaution which, if ignored, could result in damage to equipment.

repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO

DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER

ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE

ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

Page 4

EPSON Perfection 610 Rev. B

g

g

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of EPSON Perfection 610. The

instructions and procedures included herein are intended for the experienced repair technicians, and attention should be

e. The chapters are organized as follows:

pa

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

iven to the precautions on the preceding

CHAPTER 5. ADJUSTMENTS

This product reqires no adjusment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector Pin Assignments

• Parts List

• Exploded Diagrams

Page 5

EPSON Perfection 610 Rev. B

g

Revision Status

Revision Issued Date Description

A June 16, 1999 First Release

BAu

ust 2, 1999 Parts list and exploded digrams have been added to Appendix.

Page 6

EPSON Perfection 610 Rev. B

Contents

Product Description

Features ................................... ....... ...... ....... ...... ....... ..................................... 8

Specifications ..................... ...... ....................................... ....... ...... ....... ...... ..... 8

Interface Specifications ................................................................................ 11

USB Specifications.................................................................................. 11

Control Codes............................................................................................... 12

Lamp Descriptions........................................................................................ 12

Error Indications ........................................................................................... 13

Manuscript Table.......................................................................................... 14

Operating Principles

Engine Mechanism....................................................................................... 16

Carriage Unit ........................................................................................... 16

Carriage Drive Mechanism...................................................................... 17

Power Supply Circuit............................................................................... 18

Control Circuit.......................................................................................... 20

Troubleshooting

Overview....................................................................................................... 22

Self-Diagnostic Function............................................................................... 22

Troubleshooting............................................................................................ 23

Document Cover Removal ...................................................................... 28

Upper Housing Removal ......................................................................... 29

Inverter Lamp / Inverter Board Removal................................................. 30

Carriage Unit Removal............................................................................ 32

Carriage Motor / Timing Belt Removal.................................................... 36

Main Board Removal............................................................................... 38

Panel Board Removal ............................................................................. 40

Power Supply Board Removal ................................................................ 41

Adjustment

Maintenance

Overview ...................................................................................................... 46

Cleaning.................................................................................................. 46

Lubrication............................................................................................... 46

Appendix

Overview ...................................................................................................... 48

Interconnection........................................................................................ 48

Connector Assignment............................................................................ 48

Parts List and Explode Diagrams................................................................. 50

Assembly and Disassembly

Overview....................................................................................................... 26

Precautions ............................................................................................. 26

Tools........................................................................................................ 26

Screws..................................................................................................... 26

Disassembly Procedures.............................................................................. 27

Releasing the Carriage Lock................................................................... 27

Page 7

PRODUCT DESCRIPTION

Page 8

EPSON Perfection 610 Revision B

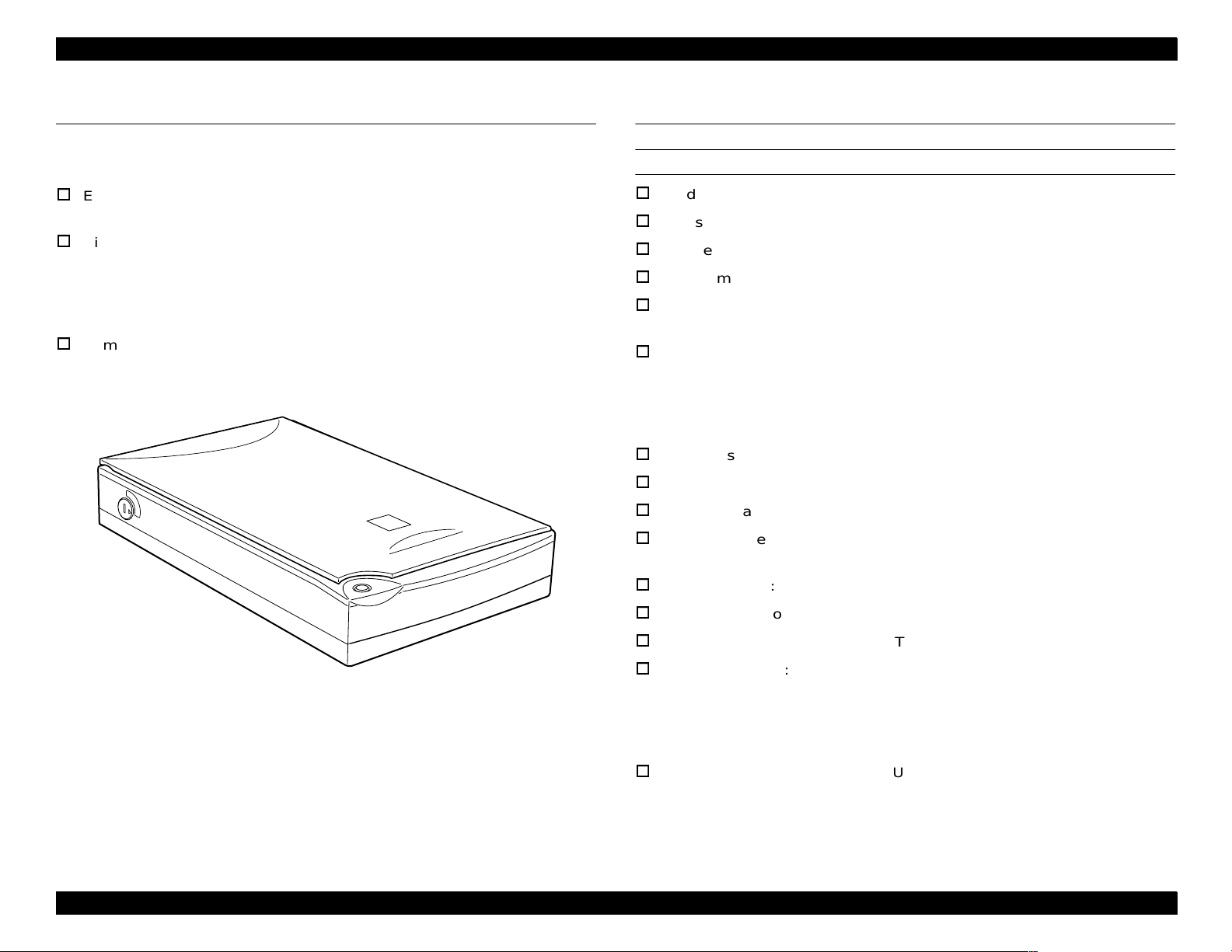

1.1 Features

The major features of the EPSON color image scanner Perfection 610 are as

follows.

Easy to use: USB I/F, Friendly user interface TWAIN

Start Button (Ease of use with Page Manager)

High quality:

Resolution: 600 dpi (Optical resolution by 3 line CCD with

15300 pixels)

Gray scale levels: 12bits (In: 12bits, Out: 8bits)

Command level: ESC/I-D1

1.2 Specifications

GENERAL SPECIFICATIONS

Product type: Flatbed color image scanner

Sub-scanning method: Movement of the scanning head

Photoelectric device: Color CCD line sensor

Maximum read area: 8.5 x 11.7” (216 x 297 mm)

Maximum effective picture element:

5100 x 7020 pixels (600 dpi)

Scanning resolution:

Main: 600 dpi (Optical resolution by 3 line CCD with

15300 pixels)

Sub: 2400 dpi with micro step

Output resolution: 75, 150, 300, 600, 1200, 2400 dpi

Gray scale levels: 12bits/pixel (In: 12bits, Out: 8bits)

Color separation: By the color filter of CCD

Scanning speed (600 dpi): Color: 16 msec/line

Monochrome (bi-level):5.3 msec/line

Command level: ESC/I-D1

Gamma correction: User defined 1 level

Interface: USB (Type-B Receptacle Connector)

Operating system: Microsoft Windows 98 (pre-install model only)

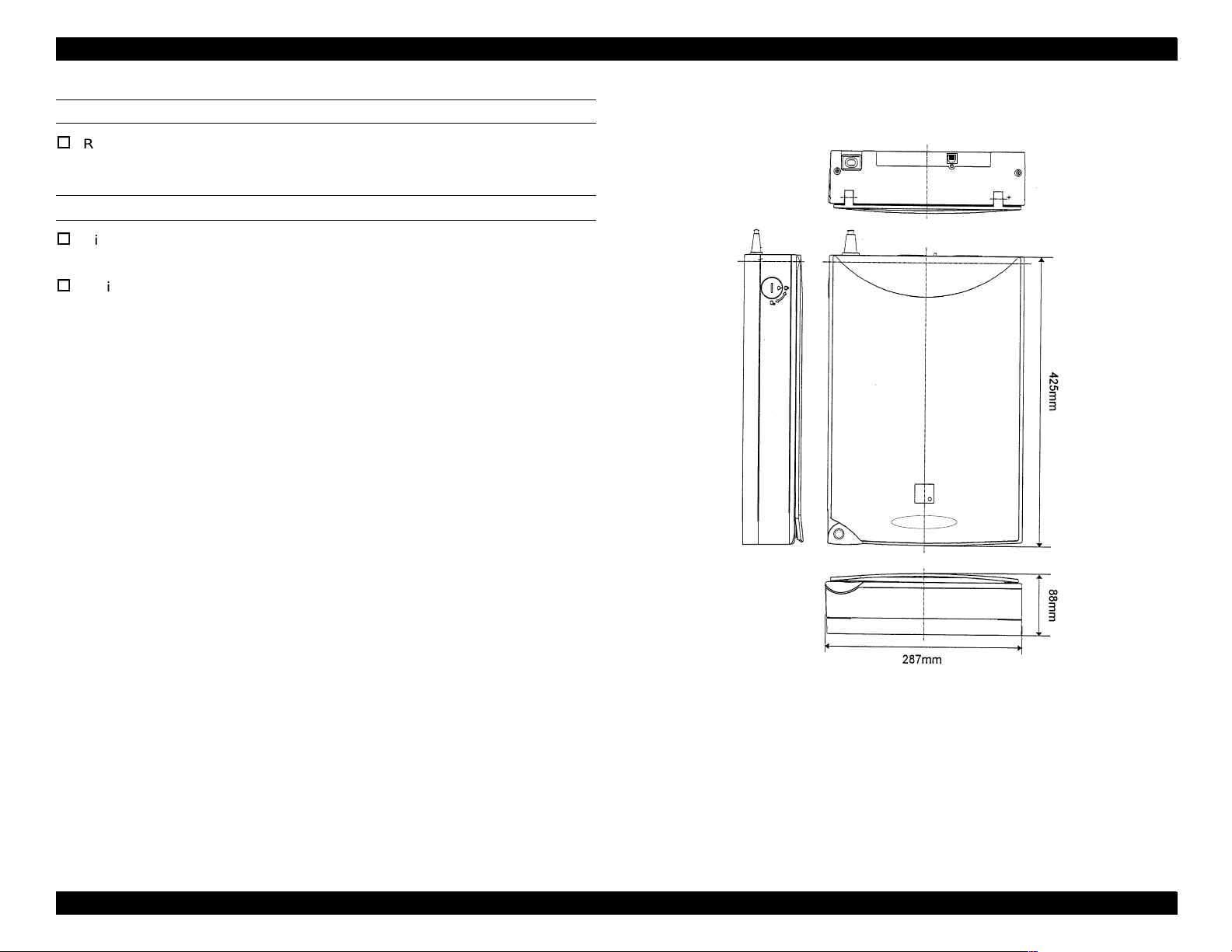

Figure 1-1. Exterior View of the Perfection 610

USB hosts: All of USB ports work correctly. (The

Microsoft Windows2000 will be supported.

iMac (AppleSystem8.5 or later, AppleSystem-

8.1 w/iMac Update 1.0)

PowerMacintosh G3 (AppleSystem8.5 or later)

functinality of the USB port(s) must be ensured

by the vendor of the Host.)

Product Description Features 8

Page 9

EPSON Perfection 610 Revision B

Number of hubs: This device must be in the Tier 1 or 2 with a

recommended USB cable.

(Tier 1: Host - this device, Tier 2: Host - Hub this device)

Light source: White cold cathode fluorescent lamp

Option: None

Operate switch: None

LED indicator: None

Start button: Ease of use with Page Manager

Scanning time: Color A4, Pentium 300MHz

300 dpi: 60 seconds

600 dpi: 280 seconds

EMC: FCC Part15 Subpart B Class B

CSA C108.8 Class B

AS/NZS3548 Class B

CISPR Pub22 Class B

CNS13438 Class B

CE Marking:

Low Voltage Directive 73/23/EEC EN60950

EMC Directive 89/336/EEC EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC 801-2/801-3/801-4

EPA: Energy Star Program

RESISTANCE TO ELECTRIC NOISE

ELECTRICAL SPECIFICATIONS

Static electricity: Panel: 10kV

Rated voltage: AC100-120V or AC220-240V

Input voltage: AC 100-120V ± 10% or AC 220-240V ± 10%

Rated current: 0.5A (Input AC 100V) or 0.3A (Input AC 200V)

Rated frequency range: 50-60Hz

Input frequency range: 49.5-60.5 Hz

Power consumption: Approximately 20 W

Insulation resistance: 10 M Ω at 500 VDC

(between AC line and chassis)

Dielectric strength: AC 1.5kV, 1 min

(between AC line and chassis)

Metal: 7kV / 150pF, 150

ENVIRONMENTAL CONDITIONS

Temperature: Operating: 5°C to 35 °C

Storage: -25

Humidity: Operating: 10 to 80%, no condensation

Storage: 10 to 85%, no condensation

°C to 60 °C

RELIABILITY

MCBF: 10,000 cycles

Ω

SAFETY, EMC, EPA

OPERATING CONDITIONS

Safety: UL1950 (UL)

CSA C22.2 No.950 (CSA)

EN60950 (VDE)

IEC950 (ROTEST, PSB)

Dust: Ordinary office or home conditions.

Extreme dust should be avoided.

Illumination: Operation under direct sunlight or near strong

light source is not guaranteed and should be

avoided.

Product Description Specifications 9

Page 10

EPSON Perfection 610 Revision B

DOCUMENT

Reflective type: Documents which has a smooth surface such as

printing and photograph.

DIMENSION

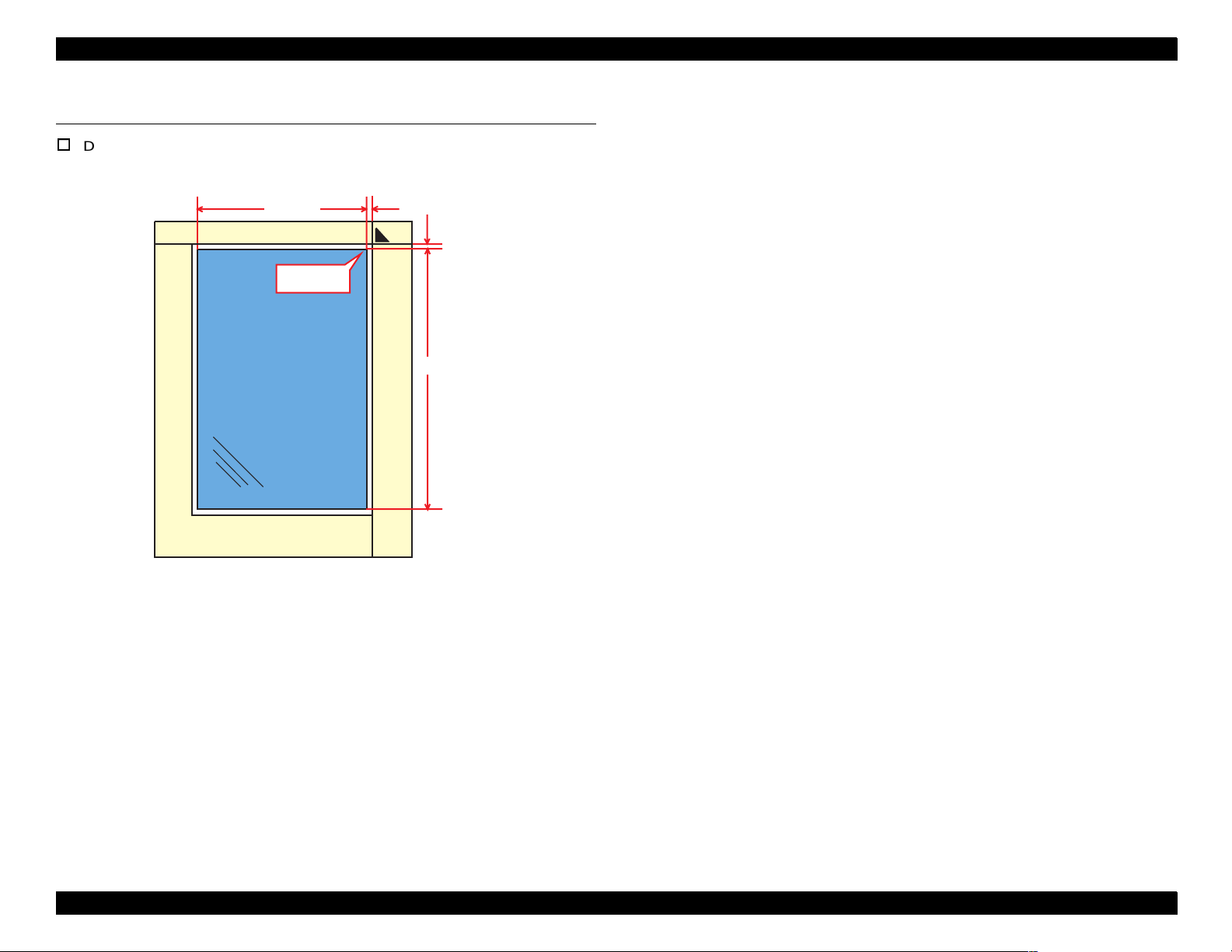

Dimension: 287(W) x 425(D) x 88(H) mm

Refer to Figure 1-2.

Weight: 4.5 Kg

Figure 1-2. Exterior Dimension of the Perfection 610

Product Description Specifications 10

Page 11

EPSON Perfection 610 Revision B

1.3 Interface Specifications

This section provides specifications of the USB, the only interface supported by

the Perfection 610.

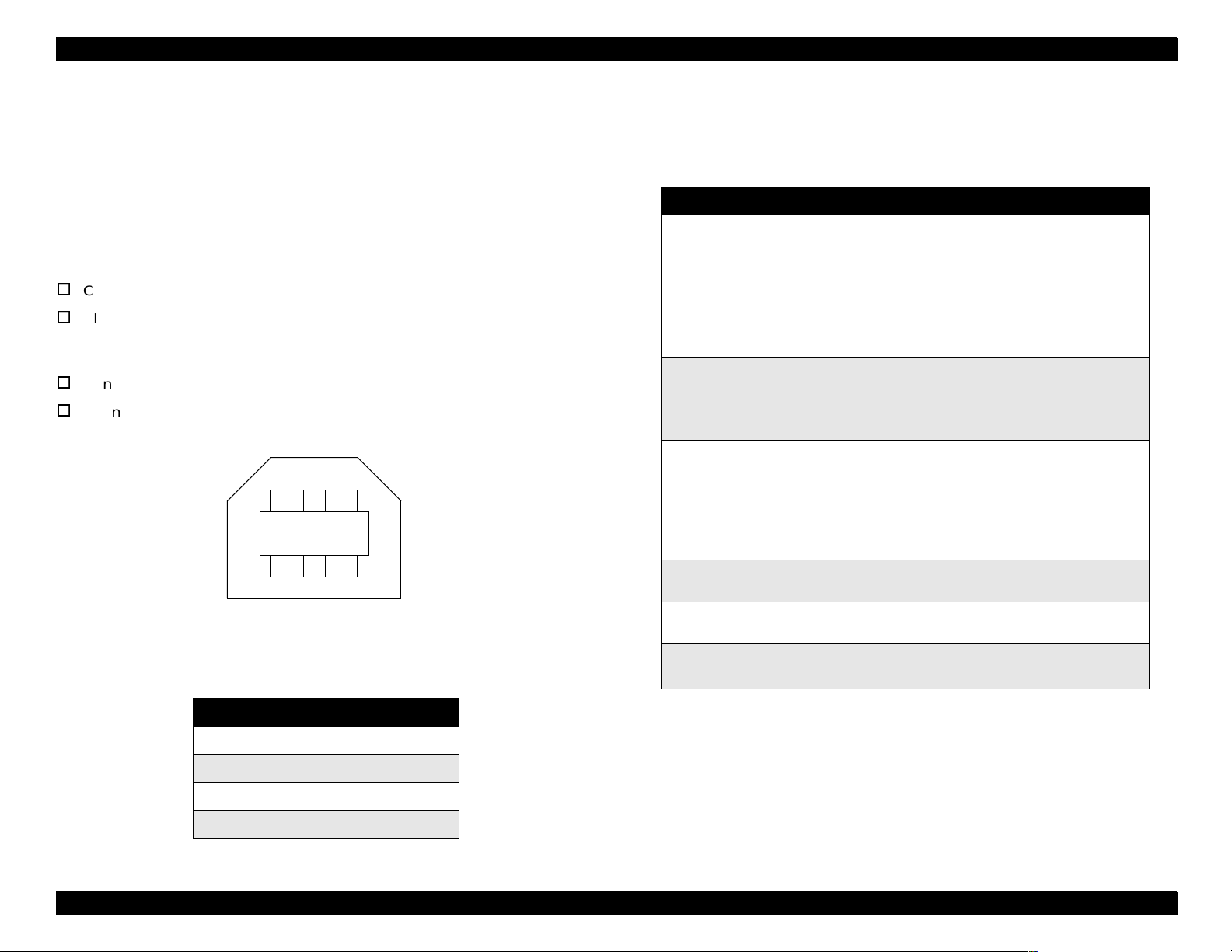

Table 1-2. Configuration

1.3.1 USB Specifications

Any items not included in this specification shall be in compliance with

Universal Serial Bus Specification Revision 1.0.

Configuration: See Table 1-2.

Electric specification: Compliant to Full Speed mode (12Mbit/s) of

Universal Serial Bus Specification Revision

1.0.

Connector: One Receptacle (Series B)

Connector Pin Assignment: See the following figure.

2

3

Figure 1-3. Connector Pin Location

Table 1-1. Connector Pin Assignment

1

4

Element Description

• Class: Vendor specific

• Subclass: Vendor specific

• Protocol: Vendor specific

Device

Configuration

Interface

Endpoint 1

Endpoint 2

String

Descriptor

• Maximum packet size for endpoint 0: 8byte

• Vendor ID: 0x04B8 (Seiko EPSON Corp.)

• Product ID: 0x0103

• Number of possible configurations: 1

• Number of interfaces supported by this configuration: 1

• Characteristics: Self-powered

• Remote wake up feature: Not supported

• Maximum of possible consumption: 2mA

• No Alternate setting

• Number of endpoints used by

this interface (excluding endpoint 0): 2

• Class: Vendor specific

• Subclass: Vendor specific

• Protocol: Vendor specific

• Bulk IN transfer

• Maximum data trans fer size: 64 byte

• Bulk OUT transfer

• Maximum data trans fer size: 64 byte

• iManufacturer: “EPSON”

• iProduct: “Scanner GT-6600” or “Perfection610”

Pin No. Signal

1VCC

2-Data

3+Data

4 GND

Product Description Interface Specifications 11

Page 12

EPSON Perfection 610 Revision B

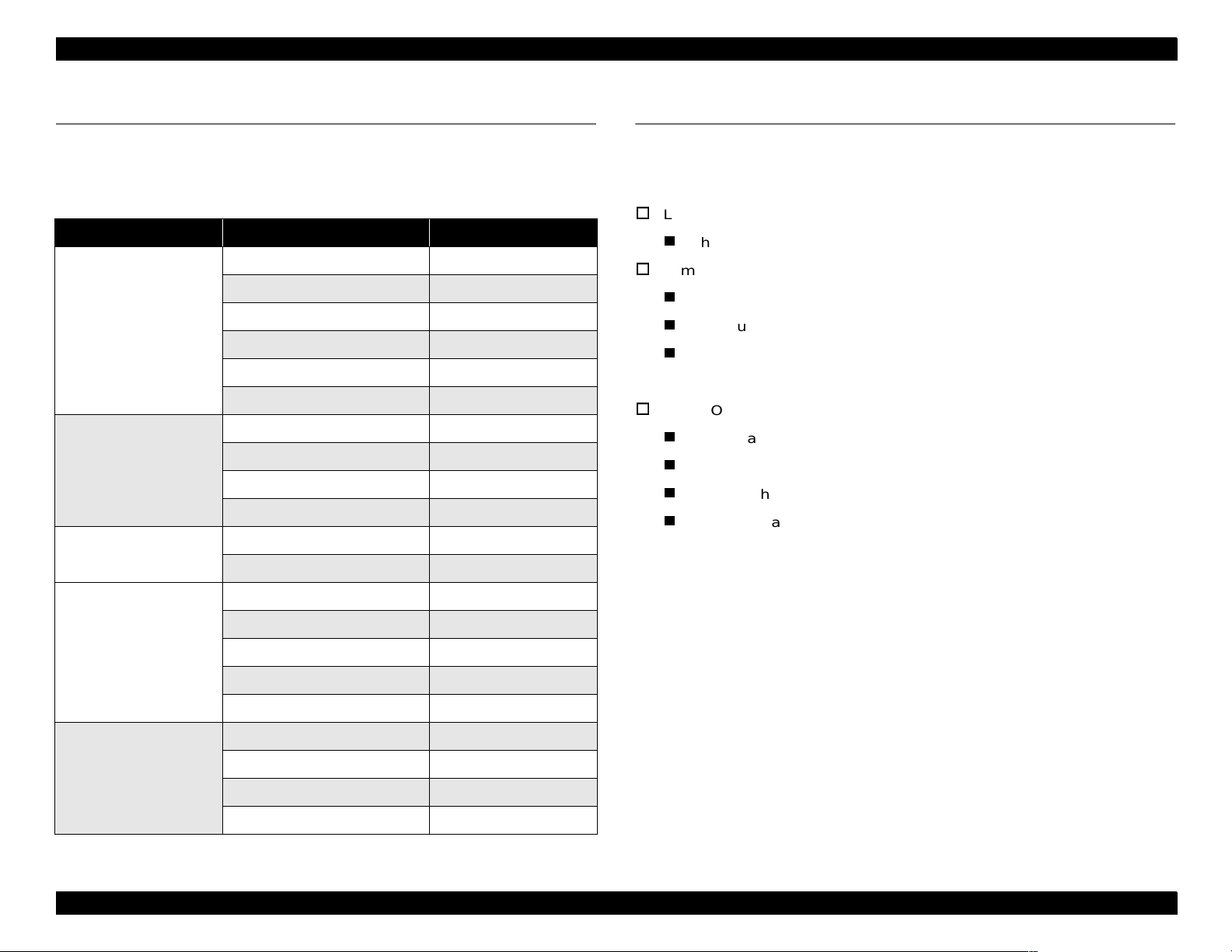

1.4 Control Codes

The command level of this scanner is ESC/I-D1. The commands supported

are shown in the table below.

Table 1-3. Control Codes

Category Command Name Code

Request Identity ESC I

Request Identity 2 ESC i

Request Status ESC F

Execute Command

Request Extended Status ESC f

Start Scanning ESC G

Request Push Button Status ESC!

Set Data Format ESC D i

Set Resolution ESC R n1 n2

Set Data Format

Set Scanning Area ESC A n1 n2 n3 n4

Set Color ESC C i

Set Gamma Correction ESC Z i

Image Correction

Download Gamma Table ESC z i d[256]

1.5 Lamp Descriptions

Since this scanner does not have any LED indicator, it shows the various

conditions by turning on/off or blinking the lamp. Conditions indicated by the

lamp are as listed below:

Lamp: On

The scanner is in a normal condition.

Lamp: Blinking

The scanner is turned on before the transportation screw is unlocked.

Communication error

Fatal error except for lamp break has occurred.

NOTE:

Lamp: Off

The lamp goes off after 30 minutes.

Power save mode (Command is not received for 10 minutes.)

Power is not supplied.

The lamp has blown out.

The lamp was left blinking for 30 minutes.

Set Color Correction Factor ESC m d[9]

Set Threshold ESC t i

Auxiliary

Control

Set Scanning Mode ESC g i

Initialize ESC @

Set Line Counter ESC d i

Normal Response ACK

Abnormal Response NACK

Abort Scanning CAN

Header STX

Product Description Control Codes 12

Page 13

EPSON Perfection 610 Revision B

1.6 Error Indications

Refer to Section 1.5 for the error indications.

COMMAND ERROR

Cause: Undefined command is detected.

Disposition: The scanner ignores a wrong command and

parameter(s), so it keeps the current settings or

default value effective. The scanner sends

NACK and waits for the next command and

parameter(s).

Indicator: No effect

Remedy: Error condition is cleared when the scanner

receives a correct command.

Indicator: The lamp starts blinking. (The lamp goes off after

30 minutes.)

The lamp does not light up when it has blown.

Remedy: (After the cause of the error is removed)

Turn the scanner off and then back on.

Connect the USB cable again.

Receiving of ESC@

Acceptable command: [ESC F, ESC f, ESC @]

COMMUNICATION ERROR

Cause: Wrong procedure is detected in the interface

communication.

USB cable was removed during communication.

Disposition: The scanner stops the ongoing job.

Indicator: The lamp starts blinking. (The lamp goes off in

30 minutes.)

Remedy: Turn the scanner off and then back on.

Connect the USB cable again.

Acceptable command: None

FATAL ERROR

Cause: The lamp is broken.

The scanner is turned on before the

transportation lock is released.

System breakdown

Disposition: The scanner stops the ongoing job.

Product Description Error Indications 13

Page 14

EPSON Perfection 610 Revision B

1.7 Manuscript Table

Dimension: 216 mm (Horizontal) x 297 mm (Vertical)

216 mm

Origin Point

Front

3 ± 2 mm

3 ± 2 mm

297 mm

Product Description Manuscript Table 14

Page 15

OPERATING PRINCIPLES

CHAPTER

2

Page 16

EPSON Perfection 610 Rev. B

CCD Sensor Board

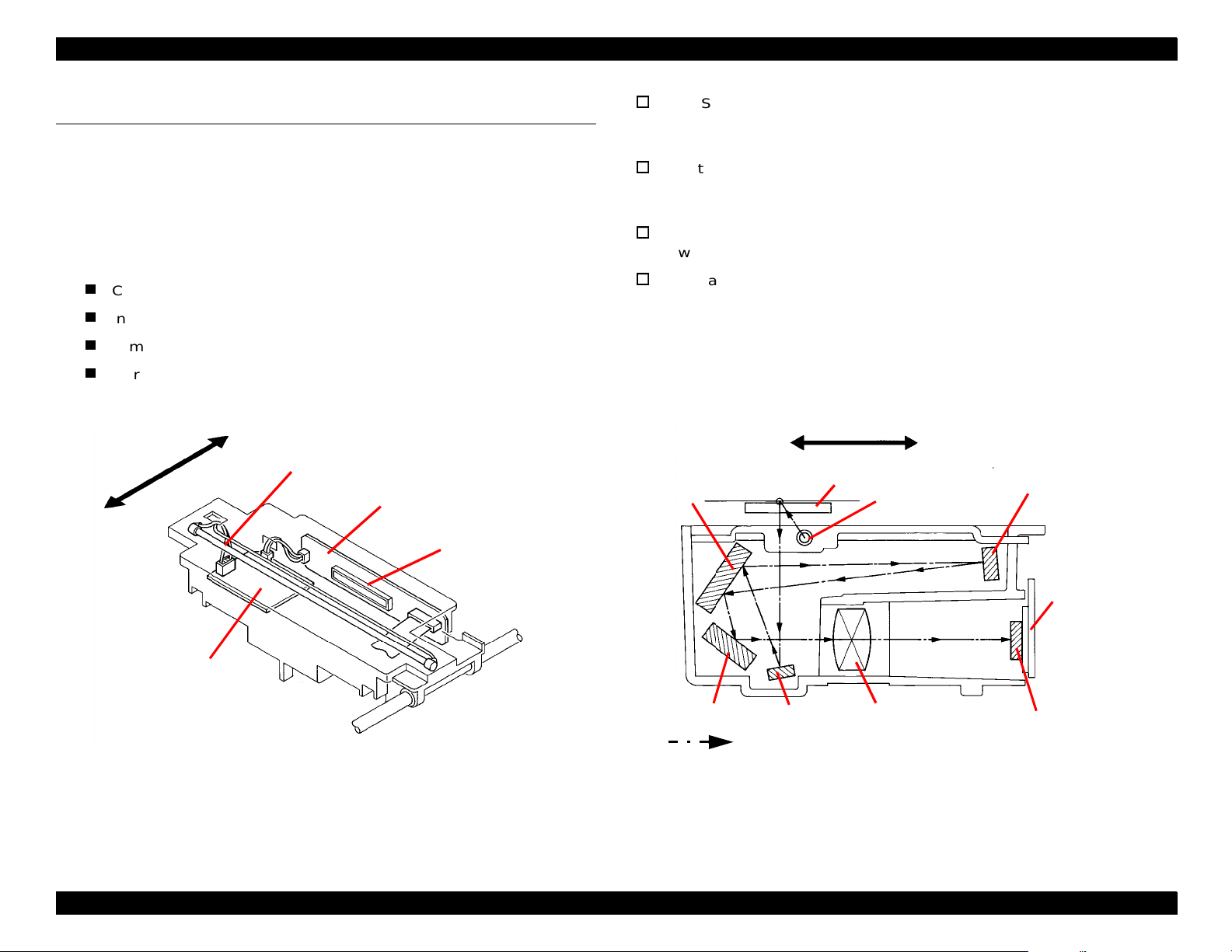

2.1 Engine Mechanism

This section explains the engine functions and operating principles of the

EPSON Perfection 610. The engine mechanism has the two major parts; the

carriage unit (=scanning head) and the carriage move mechanism.

2.1.1 Carriage Unit

The carriage unit is composed of the following:

CCD sensor board (containing the CCD sensor)

Inverter board

Lamp (the light source)

Mirror and lens mechanism

This board includes the Color CCD line sensor (independent R,G,B) and

the sensor’s control and driver circuits.

Inverter Board

This board generates voltage used to drive the lamp. The board pressures

up +24VDC and converts it from direct current to alternating current.

Lamp

A white cold fluorescent lamp is used as the light source.

Mirror and Lens Mechanism

Light emitted to the document reaches the CCD sensor via the mirror and

lens mechanism in the carriage unit, where the light’s optical axis is

corrected. Note other scanners separates R/G/B components by switching

the light source between R, G, and B. In this scanner, however, it is

performed by the CCD sensor itself.

Front

Rear

Lamp

CCD Sensor Board

Inverter Board

Figure 2-1. Carriage Unit Component

CCD Sensor

Mirror 2

Mirror 4

Front

Mirror 1

Scanned Ima ge

Document

Lamp

Lens

Rear

Figure 2-2. Mirror, Lens Mechanism

Mirror 3

CCD Sensor

Board

CCD Sensor

Operating Principles Engine Mechanism 16

Page 17

EPSON Perfection 610 Rev. B

2.1.2 Carriage Drive Mechanism

A line-type color CCD sensor, which is included in the carriage unit, scans one

line at a time in the main scan direction (parallel to the carriage unit). To scan

next lines in the sub-scan direction after the first line, the scanner moves the

carriage unit with the CCD sensor in it along the sub-scan direction. The

scanned data is sent to the control board. Reading image for “n” line and

processing data for “N-1” line are simultaneously performed one after another.

1 Pixel

Second Line

Main Scan

Direction

Sub Scan Direction by CR Movement

First Line

The carriage unit slides in the sub-scan direction along the guide rail. To slide

the carriage, the carriage (CR) motor drives the timing belt attached to the

carriage unit by conveying torque via the drive pulley and transmission gear.

Scanning start position is determined by CR HP sensor, which is located on the

control board. Since the CR motor is a stepping motor, it is controlled under the

open loop system. (See Figure 2-4.)

CR HP Sensor

Carriage Unit

Drive Pulley

Timing Belt

Rear

CR Motor

Transmission

Gear

Driven Pulley

Figure 2-3. Carriage Movement

Front

Figure 2-4. Carriage Operation

Operating Principles Engine Mechanism 17

Page 18

EPSON Perfection 610 Rev. B

2.1.3 Power Supply Circuit

Power supply circuit board in this scanner generates direct current necessary

for driving the controller board and scanner engine.

See Table 2-1 and Table 2-2 for the power supply circuit board specifications

and the protection circuits for each output voltage/current, respectively. Figure

2-5 shows the power supply circuit diagram.

Table 2-1. Power Supply Circuit Board Specifications for Each Destinati o n

Specification Unit Part No. Fuse

100 -120 VAC Range 2031592 2.5 A / 125 VAC

220 -240 VAC Range 2031593 T2.5AH / 250 VAC

Table 2-2. Protection Circuits for Output Voltages/Curr ents

Output

Voltage

5 VDC 1.2A

12 VDC 0.2A

24 VDC 0.7A

*: Re covers within 5 minutes.

NOTE:

Output

Current

• The current is held 1A or less by the

fold-bac k characteristic.

• Recovers automatically*.

• The current is held 0.5 or less by the

fold-bac k characteristic of the

generator.

• Recovers automatically*.

• Shut down.

• To restore, turn the scanner power off

and then back on.

If any of the outputs is shut down, all the other outputs are also shut down.

Over Current Protection Over Voltage Protection

• Shut down.

• To restore, turn the scanner off and

then back on.

• The protection circui t becomes active

when the voltage rises to 5.5 - 7.5

VDC.

• Shut down.

• To restore, turn the scanner power off

and then back on.

• The protection circui t becomes active

when the voltage rises to 14 -17 VDC.

• Shut down.

• To restore, turn the scanner power off

and then back on.

• The protection circui t becomes active

when the voltage rises to 28 -33 VDC.

Operating Principles Engine Mechanism 18

Page 19

EPSON Perfection 610 Rev. B

F u ll W a v e

R e c tifie r C irc u it

F ilte r C ir c u it

AC Voltge Input

Sm oothing

Circuit

S w itc h in g

Circuit

Sm oothing

Circuit

+12VD C

R egulator IC

+5VD C

R egulator

Circuit

O v e r C u rre n t

Protection

Circuit

Sm oothing

Circuit

+24VD C

C o n tro l C irc u it

+24VD C O ver

C urrent Protectio n C irc u it

+ 5 /+ 1 2 /+ 2 4 V D C

O ver Voltage

Protection C ircuit

+12 VD C

+5 VD C

+24 VD C

To the M ain B oard To the S tart B utton

Figure 2-5. Power Supply Circuit Block Diagram

Operating Principles Engine Mechanism 19

Page 20

EPSON Perfection 610 Rev. B

(

)

2.1.4 Control Circuit

The CPU (IC11) of this scanner is a one-tip 16-bit bus CPU operating at

20MHz. ASIC (IC7) manages input signal correction, image processing, and

controlling the CCD sensor board and USB interface. Table 2-3 shows the

major IC functions.

Table 2-3. Major ICs

IC Location Functions

CPU

M37920 IC11

SDM4260CLU-6S IC3 DRAM 256k x 16bit

BA033FP-E2 IC9 Regulator IC (3.3 VDC)

NJM78M05DLA-TE1 IC12 Regulator IC (5 VDC)

E02A32SA IC7

A3957SLBTR IC1, 2 CR motor driver IC

M51953A IC8 Reset IC

AD9816JS IC24 12-bit A/D converter

M27C1001-10F1 IC5 Program ROM (128k x 8bit)

24-bit Address Bus

16-bit Data Bus

ASIC: Manages the following:

• Input image signal correction

• CCD control

• USB interface control

• Image processing

• Memory control

• Data in/output control

CCD Board

Lam p

&

Inverter B oard

R e g u la to r (IC 9 )

3.3V D C

DRAM

(IC 3 )

Im age D ata

(R /G /B )

E02A 32 (IC 7)

Address B us

D a ta B u s

CPU (IC11)

CLK

CR2

CR

Motor

AMP.

CR Motor

D river

(IC 1 , 2 )

H.P. Sensor

(P C 1 )

Figure 2-6. Control Circuit Diagram

R e g u la to r (IC 1 2 )

5VD C

CLK

(CR1)

USB

PRO M

(IC 5 )

Reset IC

(IC 8 )

SG-8002PHC CR1 48MHz clock for E02A32SA

CSTCS20.00 CR2 20MHz clock for CPU.

EE-SX1041 PC1 CR home position sensor

Operating Principles Engine Mechanism 20

Page 21

TROUBLESHOOTING

Page 22

EPSON Perfection 610 Revision B

3.1 Overview

This chapter describes troubleshooting procedures for this scanner.

3.2 Self-Diagnostic Function

The self-diagnostic function of the scanner let s the scanner it self det ect

abnormal conditions. When the scanner detects an abnormality, it

shows an error using the lamp. See Table 3-1 for the error s detected by

the self-diagnostic function.

Table 3-1. Errors Detected by the Self-Diagnostic Function

Lamp Condition Error Type (Cause Remedy)

No effect

Blinking

(Goes off after 30

minutes.)

Off

(=the lamp ha s

blown out.)

Blinking

(=error except the

lamp has blown

out.)

Command Error

Cause:

Disposition:

Remedy:

Communication Error

Cause:

Disposition:

Remedy:

Acceptable command:

Fatal Error

Cause:

Disposition:

Remedy:

Acceptable command:

Undefined command

The scanner ignores the wrong command and

parameters, and returns NACK and waits for the

next command and parameters.

The scanner clears the error when it receives a

correct command and parameters.

Wrong communication procedure is detected.

USB is disconnected during communication.

The scanner turns the lamp off and stops

operating.

Turn the scanner off and back on.

Disconnect the USB cable and then connect it

properly.

The lamp has blown out.

The scanner is turned on or receives a

command with the transportation screw

locked.

The scanner is broken.

The scanner turns the lamp off and stops

operating.

After removing the cause of the problem,

Turn the scanner off and back on.

Send a ESC@ command.

Disconnect the USB cable and connect it

again.

None

[ESC F, ESC f, ESC @]

Troubleshooting Overview 22

Page 23

EPSON Perfection 610 Revision B

3.3 Troubleshooting

This section describes how to troubleshoot probl ems according to

exhibited phenomenons.

See Table 3-2 that enables you to find the defective part to the unit

level. Then refer to the corresponding table for checkpoints and

solutions.

Table 3-2. Problems and Corresponding Tables to Refer to

Phenomenon Problem Refer to:

The scanner is turned on but

does not operate.

“Fatal Error” occurs. The

scanner is turned off and back

on but still shows the same

error.

Image is not read clearly. Image is not read clearly. Table 3-7

“Communication Error” occurs .

Communication with the host

is attempted again, but the

same error occurs.

Table 3-3. The scanner is not Initialized.

Cause Step Checkpoints Finding Remedy

CN1 on the power

supply board is

disconnected.

1

The scanner is not initialized. Table 3-3

The carriage unit does not

operate.

The carriage unit operates but

the error is indicated.

The lamp does not light up. Table 3-6

USB interface error Table 3-8

Is CN1 on the power

supply board

disconnect ed?

Yes

Connect CN1 to the

power supply

board.

Table 3-4

Table 3-5

Table 3-4. The carriage unit does not operate.

Cause Step Checkpoints Finding Remedy

The PS

(Power

Supply)

board is

defective.

The carriage

drive

mechanism

is defective.

The CR

motor is

defective.

The main

board is

defective.

1 With scanner power on, ch eck

CN101 for the output voltage at

the pins below.

• Pins: 8/9 (+) and 6/7 (-)

• Voltage: +24VDC

Is grease (G-26) properly

applied?

2

(See Chapter 6.)

3 • With the upper housing

removed, turn the scanner on,

and check that the CR motor is

live.

• Remove the CR motor, and

check that the carriage unit

moves smoothly.

4 Disconnect CN6 on the main

board. Then, using a tester,

check that the coil resistance at

each point below is 6.2

1. Between Pins 2 and 4

2. Between Pins 1 and 3

5 Follow the steps below to check

for the CR motor driver circuit.

1. Set the meter to

2. Place the (-) terminal of the

tester on Pins 1, 2, 3, and then

4 of the CN6 on the main

board.

3. Place the (+) terminal of the

tester on Pin 6 or 7 of the CN4

on the main board.

4. Turn the scanner off, and

check that the meter shows

“for each pi n.

“

∞

6 --- --- Replace the main

.

Ω

.

Ω

No Replace the PS

board.

No Apply grease to

the specified

points properly.

No Check the

carriage unit, and

replace any

defective part or

disassemble an d

assemble the

scanner again.

No Replace the CR

motor and go to

step 4.

No Replace the main

board.

board.

Troubleshooting Troubleshooting 23

Page 24

EPSON Perfection 610 Revision B

Table 3-5. The carriage unit operates but the error is indicated.

Cause Step Checkpoints Finding Remedy

The CR home

position sensor

is defective.

Check the signal levels

1

between the collector (+)

and emitter (-) of PC1. The

signal level should change

depending on the conditio n

below:

•HIGH (4.5V) = Light is

blocked in PC1.

•LOW (0.3V) = Light

passes in PC1.

--- Replace the CR

home position

sensor (PC1) on

the main board.

Table 3-6. The lamp does not light up.

Cause Step Checkpoints Finding Remedy

CN5 on the

main board is

disconnect ed.

CN1 or CN2 on

the CCD sensor

board is

disconnected.

The connector

for the lamp is

not properly

connected to

the inverter

board.

The lamp is

defective.

The inverter

board is

defective.

The main board

is defective.

1 Check tha t CN5 is

disconnect ed.

2 Check that CN1 or CN2 on

the CCD sensor board is

disconnected.

3 Check that the co nnector is

properly connected to the

inverter board.

4 After replacing the lamp,

check that the lamp lights

up.

5 After replacing the inverter

board, check that the lamp

lights up.

6 --- --- Replace the main

Yes Connect CN5 on

the main board

properly.

Yes Connect CN1 or

CN2 on the CCD

sensor board

properly.

No Connect the

connector

properly.

Yes Replace the

lamp.

Yes Replace the

inverter board.

board.

Table 3-7. Image is not read clearly.

Cause Step Checkpoints Finding Remedy

Any mirror in the

carriage unit or

the surface of

the lamp is dirty.

The CCD

sensor board is

defective.

The main board

is defective.

1 After cleaning the mirror(s ),

check that image is read

clearly.

2 --- --- Replace the CCD

3 --- --- Replace the main

No Clean the

surface of the

lamp.

sensor board.

board.

Table 3-8. USB Interface Error

Cause Step Checkpoints Finding Remedy

The host or O/S

(Windows’98/

NT) does not

support USB.

The TWAIN

driver attached

for the scanner

is not prope rly

installed.

The USB cable

is defective.

The main board

is defective.

1 On the Windows, access

My Computer > Property >

Device Manager, and

check that Universal Serial

Bus Controller is effective.

2 Check that the driver for

the scanner is installed

properly.

3 After replacing the USB

cable, check that the error

is not indicated.

4 --- --- Replace the main

No Replace the host.

No Instal the correct

driver properly.

No Replace the USB

cable.

board.

Troubleshooting Troubleshooting 24

Page 25

ASSEMBLY AND DISASSEMBLY

CHAPTER

4

Page 26

EPSON Perfection 610 Revision B

4.1 Overview

This chapter describes procedures for disassemb li ng the EPSON

Perfection 610. Unless otherwise specified, the scanner can be

disassembled by reversing the disassembly procedures.

4.1.1 Precautions

W ARNING

CAUTION

The directions used in this chapter are defined as shown in Figur e 4-1.

Disconnect the power cable before disassembling or

assembling the scanner.

When servicing, note the points below:

Consider the size of the scanner and make enough

room for servicing.

Since this scanner is a precision equipement,

service it on a flat, level, heavy-duty table.

In s id e

R ear (B ack)

R ight

Left

Front

EPSON

4.1.2 Tools

Use the tools specified in Table 1-1.

Table 4-1. Tools

Names Availabi lity Part Number

Phillips screw driver (#2)

Standard screw driver

Pliers

Tweezers

B743800200

B743000100

B740400100

B641000100

4.1.3 Screws

The screws used in the scanner are as shown in Table 4-2. Make sure

you always use the correct type and number of screws for the

assembling part. See Table 4-3 for the screw appearances.

Table 4-2. Screw Specifications

Abbreviation Description

CP Cross-recessed Pan Head sc rew

CBS Cross-recessed Binding Head S-tite screw

CCP Cross-recessed Cup Head P-tite screw

Table 4-3. Screw Appearances

Head appearance

Top Side

Crossrecessed

Binding

Pan

Cup

Standard

- - - S-tite

B-tite

P-tite

Type Washer

With Outside Toot hed

lock washer

With Spring lock

washer

Figure 4-1. Directions

Assembly and Disassembly Overview 26

Page 27

EPSON Perfection 610 Revision B

4.2 Disassembly Procedures

4.2.1 Releasing the Carriage Lock

1. Using a standard screw driver, release the Carri age Lock locat ed at

the left side of the scanner body.

CAUTION

: Released

When locking the carriage for transporting the

scanner, make sure the carriage is at the home

position.

: Locked

Figure 4-2. Carriage Lock Location

Assembly and Disassembly Disassembly Procedures 27

Page 28

EPSON Perfection 610 Revision B

4.2.2 Document Cover Removal

1. Open the Document Cover.

2. Holding the Document Cover by the edges, release the two hooks

by pushing the cover to the rear as shown in Figure 4-4.

Document Cover

Hooks

Figure 4-3. Document Cover Removal (1)

Figure 4-4. Document Cover Removal (2)

Assembly and Disassembly Disassembly Procedures 28

Page 29

EPSON Perfection 610 Revision B

4.2.3 Upper Housing Removal

1. Release the Carriage Lock. (See Section 4.2.1.)

2. Remove the Document Cover. (See Section 4.2.2.)

3. Remove the two screws (gold, CBS, M3x6) at the back of the

scanner body.

4. Lifting up the rear end of the Upper Housing, release the three

hooks at the front end, and then remove the Upper Housing toward

the front.

Figure 4-6. Upper Housing Removal (2)

Three Hooks on the Front

CBS Screws (M3x6)

Figure 4-5. Upper Housing Removal (1)

Figure 4-7. After Removing the Upper Housing

Assembly and Disassembly Disassembly Procedures 29

Page 30

EPSON Perfection 610 Revision B

4.2.4 Inverter Lamp / Inverter Board Removal

1. Release the Carriage Lock. (See Section 4.2.1.)

2. Remove the Document Cover. (See Section 4.2.2.)

3. Remove the Upper Housing. (See Section 4.2.3.)

4. Remove the two screws (CCP, M3x8) on the Carriage Unit. (See

Figure 4-8.)

5. Using a standard screw driver, lift up the carriage cover in the

Carriage Unit, and then move it to the front to remove it. (See Fi gure

4-9.)

CCP Screws (M3x8)

Figure 4-8. Carriage Unit Disassembly (1)

Figure 4-9. Carriage Unit Disassembly (2)

Assembly and Disassembly Disassembly Procedures 30

Page 31

EPSON Perfection 610 Revision B

6. Disconnect the connector for the Inverter Lamp from the Inverter

Board.

7. Remove the black screw and disconnect the 2-pin connecto r for the

CCD sensor, and then remove the Inverter Board.

8. Remove the Inverter Lamp from the carriage cover.

CHECK

POINT

When installing the Inverter Lamp, locate the

connectors correctly as shown in the following

figures.

Connector

Inverter Board

Black Screw

Connector (2-pin)

Figure 4-10. Inverter Board Removal

Carriage Cover

Connector (2-pin)

Inverter Lamp

Figure 4-11. Inverter Lamp Removal

Assembly and Disassembly Disassembly Procedures 31

Page 32

EPSON Perfection 610 Revision B

4.2.5 Carriage Unit Removal

1. Release the Carriage Lock. (See Section 4.2.1.)

2. Remove the Document Cover. (See Section 4.2.2.)

3. Remove the Upper Housing. (See Section 4.2.3.)

4. Using a standard screw driver, remove the timing belt clamp

securing the timing belt and the carriage.

Timing Belt Clamp

Figure 4-12. Metal Clamp Removal

Assembly and Disassembly Disassembly Procedures 32

Page 33

EPSON Perfection 610 Revision B

5. Remove the hexagon nut at the rear end of the carriage guide shaft.

6. Remove the tension spring and the screw (gold, CBS, M3x4)

securing the driven pulley assembly.

Tension Spring

Figure 4-14. Driven Pulley Assembly Removal (1)

Hexagon Nut

Figure 4-13. Hexagon Nut Removal

CBS Screw (M3x4)

Figure 4-15. Driven Pulley Assembly Removal (2)

Assembly and Disassembly Disassembly Procedures 33

Page 34

EPSON Perfection 610 Revision B

7. Release the timing belt from the driven pulley.

8. Remove the driven pulley assembly by pushing it in the direction

indicated with the arrow. (See Figure 4-17.)

9. Remove the CR shaft from the Carriage Unit.

7.

Figure 4-17. Driven Pulley Assembly Removal (3)

Driven Pulley

Timing Belt

Carriage Unit

Figure 4-16. Timing Belt Removal

CR Shaft

Figure 4-18. Carriage Guide Shaft Removal

Assembly and Disassembly Disassembly Procedures 34

Page 35

EPSON Perfection 610 Revision B

10. Inserting a standard screw driver from the back, remove the FFC

metal clamp.

Carriage Unit

FFC Metal Clamp

FFC Cable

11. Release the FFC (white) from the connect or and the two guide tabs

in the Carriage Unit, and then remove the Carriage Unit.

Carriage Unit

Figure 4-20. Carriage Unit

Guide Tabs

Connector

Figure 4-19. FFC Metal Clamp and FFC Removal

Assembly and Disassembly Disassembly Procedures 35

Page 36

EPSON Perfection 610 Revision B

4.2.6 Carriage Motor / Timing Belt Removal

1. Release the Carriage Lock. (See Section 4.2.1.)

2. Remove the Document Cover. (See Section 4.2.2.)

3. Remove the Upper Housing. (See Section 4.2.3.)

4. Remove the Carriage Unit. (See Section 4.2.5.)

5. Remove the two screws (CBS, M3x4) securing t he FFC fi xing plate,

and then remove the FFC fixing plate.

6. Remove the three screws (gold, CBS, M3x4/M3x6) and the two

hooks at the rear edge, and then remove the main board cover.

7. Remove the two screws (gold, CBS, M3x4) securing the CR Motor

Unit, and then shift the CR Motor Unit inward.

8. Disconnect the cable for the CR Motor Unit from the connector on

the main board, and then remove the CR Motor Unit.

6. Hooks

5. FFC Fixing Plate

6. CBS Screws M3x6)

CR Motor Unit

Connector

CBS Screws (M3x4)

Figure 4-22. CR Motor Unit Removal (1)

6. Main Board Cover

6. CBS Screw (M3x4)

5. CBS Screws (M3x4)

Figure 4-23. CR Motor Unit Removal (2)

Figure 4-21. Shield Plate Removal

Assembly and Disassembly Disassembly Procedures 36

Page 37

EPSON Perfection 610 Revision B

9. Follow the steps below to remove the Timing Belt from the CR Motor

Unit.

1) Remove the E-ring.

2) Remove the transmission gear.

3) Disengage the timing belt from the drive pulley.

E-ring

Figure 4-24. Timing Belt Removal

Timing Belt

Timing Belt

E-ring

Transmission Gear

Drive Pulley

Transmission Gear

Figure 4-25. Parts in the CR Motor Unit

Assembly and Disassembly Disassembly Procedures 37

Page 38

EPSON Perfection 610 Revision B

4.2.7 Main Board Removal

1. Release the Carriage Lock. (See Section 4.2.1.)

2. Remove the Document Cover. (See Section 4.2.2.)

6. Hooks

3. Remove the Upper Housing. (See Section 4.2.3.)

4. Slide the Carriage Unit slowly until you see the whole main board

cover.

5. Remove the two screws (CBS, M3x4) securing t he FFC fi xing plate,

and then remove the FFC fixing plate.

6. Remove the three screws (gold, CBS, M3x4/M3x6), release t he two

hooks at the rear edge, and then remove the main board cover.

6. Main Board Cover

6. CBS Screws (M3x6)

5. CBS Screws (M3x4)

6. CBS Screw (M3x4)

4. Carriage Unit

5. FFC Fixing Plate

Figure 4-26. Main Board Removal (1)

Assembly and Disassembly Disassembly Procedures 38

Page 39

EPSON Perfection 610 Revision B

7. Remove the screw (CP, M3x5) near the I/F connector and the one

(CBS, M3x5) securing the Main Board.

Carriage FFC Connector

CN4 (Power Supply Unit)

8. Disconnect the followi ng cables f rom the corr esponding connectors;

CR Motor - CN6, carriage FFC, Power Supply Board - CN4.

9. Remove the Main Board.

CP Screw (M3x5)

Figure 4-27. Main Board Removal (2)

CN6 (CR Motor)

Figure 4-28. Main Board Removal (3)

CBS Screw (M3x5)

Figure 4-29. Main Board

Assembly and Disassembly Disassembly Procedures 39

Page 40

EPSON Perfection 610 Revision B

4.2.8 Panel Board Removal

1. Release the Carriage Lock. (See Section 4.2.1.)

2. Remove the Document Cover. (See Section 4.2.2.)

3. Remove the Upper Housing. (See Section 4.2.3.)

4. Remove the screw (gold, CBS, M3x4).

CHECK

POINT

In the following steps, manually move the carriage

back and forth slowly if necessary.

5. Disconnect the locking connector (pull and rel ease) for the Panel

Board from the Power Supply Board, and then remove the Panel

Board.

Connector

CBS Screw (M3x4)

Panel Board

Figure 4-30. Panel Board Removal

Assembly and Disassembly Disassembly Procedures 40

Page 41

EPSON Perfection 610 Revision B

4.2.9 Power Supply Board Removal

1. Release the Carriage Lock. (See Section 4.2.1.)

2. Remove the Document Cover. (See Section 4.2.2.)

3. Remove the Upper Housing. (See Section 4.2.3.)

CAUTION

In the following steps, manually move the carriage

back and forth slowly if necessary.

4. Release the locking connector (pull and releas e) for the Panel

Board, and then disconnect the cable from t he Power Supply Board.

(Refer to Figure 4-30.)

5. Disconnect the locking connector (pick and release) for the AC

cable from the Power Supply Board.

AC Cable

Connector for the AC Cable

Figure 4-31. Connectors for the Power Supply Board

Assembly and Disassembly Disassembly Procedures 41

Page 42

EPSON Perfection 610 Revision B

6. Remove the two screws (gold, CBS, M3x4) securing the shield

plate, and then remove it toward the inside.

7. Disconnect the cable from the locking connector (push and release) ,

remove the five screws (gold, CBS, M3x4), and then remove the

Power Supply Board from the shield plate.

CBS Screws (M3x4)

Shield Plate

Figure 4-32. Power Supply Board Removal (1)

CBS Screws (M3x4)

Connector

Figure 4-34. Power Supply Board

CBS Screws (M3x4)

Figure 4-33. Power Supply Board Removal (2)

Assembly and Disassembly Disassembly Procedures 42

Page 43

ADJUSTMENT

Page 44

EPSON Perfection 610 Revision B

This scanner needs no adjustment at the level of the service, including part replacement,

specified in Chapter 4 “Disassembly and Assembly”.

Adjustment 44

Page 45

MAINTENANCE

CHAPTER

6

Page 46

EPSON Perfection 610 Rev. B

6.1 Overview

This chapter provides information necessary to keep the scanner function in

optimum condition constantly and to prevent troubles.

6.1.1 Cleaning

Perform cleaning when stain is noticeable. Stain on the document glass,

particularly, has a direct effect on scanned images. Therefore, be sure to clean

the glass well to remove stain thoroughly.

CAUTION

Outer Cases

Wipe dirt off with a clean cloth, moistened with water and squeezed tightly.

To remove severe stains, use a neutral detergent.

Document Glass

Remove dust and paper debris with a dry, clean cloth. If the dirt is severe

or foreign matter is stuck on the glass, use a cloth soaked with neutral

detergent. If any trace is left, wipe it off with a dry, clean cloth again.

Never apply any organic solvents such as thinner or

benzene, since these may deteriorate plastic and rubber

parts.

Table 6-2. Lubrication Points

Figure Lubrication Points Lubrication

Table 6-1 Transmission gear shaft of the CR motor and

drive pulley shaft.

Figure 6-1 Driven pulley shaft G-26 (1x3 mm)

CAUTION

Excessive lubrication may cause the carriage

G-26 (1x3 mm) for

each

mechanism to be damaged or operate abnormally.

G-26

6.1.2 Lubrication

You need to lubricate the carriage unit if you have replaced it or notice it

making abnormal noise. See the following tables for the recommended grease

type and points to apply it.

Table 6-1. Recommended Grease

Grease Type Content s Pa rt Number Availability

G-26 40g B702600001 E *

*: EPSON exclusive (Not on the market)

Maintenance Overview 46

G-26

Figure 6-1. Lubrication Points

Page 47

APPENDIX

CHAPTER

7

Page 48

EPSON Perfection 610 Rev. B

7.1 Overview

This section provides useful information for servicing this sca nner.

7.1.1 Interconnection

Following figures shows interconnection of the scanner.

Lam p

(2 -p i n )

CN2

CN1

B071 ISN

B o a r d

(2 -p i n )

CN1

Inverter Board

B103MAIN Board

(18-pin) (4-pin)

CN5

CN4

CN2

CN6

CN7

(4 -p i n )

CR

Motor

USB

7.1.2 Connector Assignment

Table 7-1. Connector Summary- B103MAIN

Connector

Number

B103MAIN Board

CN4 To the Power Supply Board 12 Table 7-2

CN5 To the CCD Sensor Board 18 Table 7-3

CN6 To the CR Motor 4 Table 7-4

CN7 To the USB Cable 4 Table 1-1

Power Supply Board

CN1 AC Input 2 Table 7-5

CN101 To the Control Board 12 Table 7-2

CN102 To the Panel Board 5 Table 7-6

CCD Sensor Board

CN1 To the Control Board 18 Table 7-3

CN2 To the Inverter Board 2 Table 7-7

Inverter Board

CN1 To the CCD Sensor Board 2 Table 7-7

CN2 To the Lamp 4 Table 7-8

Description

Number

of Pins

Refer to:

(12-pin)

CN101

Power Supply Board

CN1

CN102

(5 -p i n )

CN1

(2 -p i n )

B103PNL

AC Plug

Figure 7-1. Interconnection (USB)

Appendix Overview 48

Page 49

EPSON Perfection 610 Rev. B

Table 7-2. Main Board - CN4

Pin No. Signal I/O

1, 2, 6, 7, 11, 12 GND -

3 +12V I

4, 5 +5V I

8, 9 +24V I

10 PM-SW I

Table 7-3. Main Board - CN5

Pin No. Signal I/O

1, 3, 5, 7, 8, 9, 10, 18 GND -

2 B I

4RI

6GI

11 SH O

12 12V O

13 F1X O

14 F2X O

15 RS O

16 5V O

17 24V O

Table 7-4. Main Board - CN6

Pin No. Signal I/O

1BXO

2AX O

3BO

4AO

Table 7-5. Power Supply Board - CN1

Pin No. Signal I/O

1AC (H)I

2AC (L) I

Table 7-6. Power Supply Board - CN102

Pin No. Signal I/O

1NC2NC 3 Push-SW I

4 NC 5GND-

Table 7-7. CCD Sensor Board - CN2

Pin No. Signal I/O

124VO

2GND I

Table 7-8. Inverter Board - CN2

Pin No. Signal I/O

1LAMPO

2LAMP O

Appendix Overview 49

Page 50

EPSON Perfection 610 Rev. B

7.2 Parts List and Explode Diagrams

Table 7-9. Parts List

Ref. # Description Ref. # Description Ref. # Description

100 FRAME,BASE 122 LOGO PLATE;E 146 MOTOR ASSY.,CR

101 HOUSING ASSY.,UPPER;ASP 123 EXTENSION SPRING,18.4 147 C.B.S. SCREW

102 KNOB,MOUNT,CARRIAGE 124 FOOT 148 C.B.(O) SCREW,4X4,F/ZG

103 MAT,COVER,DOCUMENT 125 BUSHING,HOUSING 14 9 TAPE,HOUSING

104 COVER,DOCUMENT 126 SHEET,COVER,25 180 LABEL,CARRIAGE LOCK

105 COVER,MAIN BOARD 127 SHEET,COVER,18 200 BOARD ASSY.,MAIN

106 KEYTOP,FUNCTION SWITCH 128 COVER,INLET 331 HARNESS

107 COMPRESSION SPRING,1.32 130 FERRITE CORE 300 BOARD ASSY.,POWER SUPPLY

108 HOUSING,PANEL 131 DOUBLE SIDE TAPE,28X10 330 HARNESS

109 SUPPORT,F-SW 132 COVER,FERRITE 400 POWER CABLE

110 LEVER,MOUNT,CARRIAGE 133 6N,5,F/ZN 401 I/F CABLE

111 COVER,P/S BOARD 134 SHAFT,CR 500 CARRIAGE ASSY.

112 SHEET,P/S BOARD 135 SHEET,SLIDE 502 BOARD ASSY.,INVERTER

113 TIMING BELT 136 RAIL,CR 503 LAMP ASSY.

114 PULLEY,DRIVE 137 COVER,SWITCH BOARD 504 COVER,CARRIAGE

115 FRANGE,PULLEY 138 BOARD ASSY.,PANEL 505 CLAMP,FERRITE CORE

116 PULLEY,IDLE 139 DOUBLE SIDE TAPE,22X50 506 FERRITE CORE

117 HOLDER ASSY.,PULLEY,DRIVE 140 SHEET,COVER,P/S BOARD 507 DOUBLE SIDE TAPE,28X10

118 CLAMP,TIMING BELT 141 C.B.S. SCREW 508 C.C.P-TITE,3X8,F/ZB

119 6N,3,F/ZN 143 C.P.SCREW 509 HARNESS

120 HOLDER ASSY.,PULLEY,DRIVEN 144 RETAINING RING 510 HARNESS

121 PULLEY,DRIVEN 145 C.B.S. SCREW 511 TAPE,HOUSING

Appendix Parts List and Explode Diagrams 50

Page 51

145

300

112

140

400

See P.2

500

104

141

138

137

330

139

145

124

140

141

100

124

135

136

145

111

145

145

128

145

132

130

131

145

143

120

127

147

123

141

145

105

200

115

121

145

134

144

146

117

145

119

133

119

114

115

113

116

118

144

122

106

107

108

109

148

148

103

101

181

331 (for 220/240V)

400 (for 120V)

180

102

183

147

147

149

149

110

401

125

127

127

127 126

126

127

GT-6600/PERFECTION 610 No.1 Rev.01 10123

Page 52

508

504

503

509

511

508

508

505

507

(NOT ASP.)

506

510

GT-6600/PERFECTION 610 No.2 Rev.01 10123

502

Loading...

Loading...