Page 1

HIGH S

PEED

BUSINESS

USER’S

GUIDE

EPSON AMERICA INC. SERVICE DIVISION

PRINTER

Page 2

EPSON

420i

HIGH SPEED BUSINESS PRINTER

Epson America, Inc.

Computer Products Division

2780 Lomita Blvd.

Torrance, CA 90505

(213) 539-9140

Page 3

WARNING:

“This equipment has been certified to comply with the limits for a Class b

computing device, pursuant to Subpart J of Part 15 of FCC Rules. Only com-

puters certified to comply with the Class B limits may be attached to this printer.

Operation with noncertified computers is likely to result in interference to radio

and TV reception.”

“This equipment generates and uses radio frequency and if not installed and

used properly, that is, in strict accordance with the manufacturer’s instructions,

may cause interference to radio and television reception. It has been tested

and found to comply with the limits for a Class B computing device in accor-

dance with the specifications in Subpart J of Part 15 of FCC Rules, which are

designed to provide reasonable protection against such interference in a

residential installation. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause interference

to radio or television reception, which can be determinded by turning the equip-

ment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient the receiving antenna.

• Relocate the computer with respect to the receiver.

• Move the computer away from the receiver.

• Plug the computer into a different outlet so that computer and

receiver are on different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user may find the following

booklet prepared by the Federal Communications Commission helpful:

“How to Identify and Resolve Radio-TV Interference Problems.”

This booklet is available from the US. Government Printing Office, Washington,

D.C. 20402, Stock No. 004-000-00345-4.

IBM-PC® is a registered trademark of International Business Machines

Corporation.

©

Copyright

1985 by Epson America, Inc., Torrance, California 90505

ii

Page 4

INTRODUCTION

The Epson 420i is a high speed business printer which is usable with almost all commercial software, including word processing and graphics programs. By changing one switch

on the back of the printer, either the Epson Printer mode or the IBM Graphics Printer

mode is selectable. The two modes differ in character sets and some printer commands.

In contrast with the IBM Graphics Printer, the Epson 420i prints italic characters. Most

programs written for the IBM Graphics Printer do not attempt to print them.

The IBM Graphics Printer mode is selected when extended characters are to be used,

or when software is limited for use with the IBM Graphics Printer.

Refer to the sections tied ‘DIP Switch Setting” (page 26), “Code Table” (pages 30 through

32) and “Differences between the Epson Printer Mode and the IBM Graphic Printer Mode”

(page 36) for details on use of each mode.

iii

Page 5

PRECAUTIONS FOR USE

• When using fan fold paper, the friction lever should be positioned to the front.

• Do not apply undue force to the transparent printer cover.

• Do not use a power supply voltage which is out of the specified range.

• Do not touch the printhead immediately after printing because it is too hot.

•

Never close the openings of the upper enclosure or place the printer where these

openings are next to a wall.

• Be careful not to twist the ribbon while installing it.

•

Insert the ribbon between the ribbon guide and the printhead as shown in Figure 3.

•

Wait at least two seconds after turning power off before turning it back on again.

The initialization process may not be performed correctly if this is not done.

•

The printer should be used where the humidity is low, there is little dust, and where

it is not in direct sunlight.

•

Do not perform printing without the ribbon cassette and paper properly installed.

EPSON reserves the right to change the contents as stated herein at any time and

without notice. Although every effort has been made to insure that the contents as

stated herein are complete and without error, EPSON cannot be responsible for any

damage that may occur should this not be the case.

iv

Page 6

CONTENTS

OUTLINE

SWITCHES AND LAMPS

REPLACEMENT OF THE RIBBON CASSETTE

PAPER SETTING

MAIN FUNCTIONS

PARALLEL INTERFACE

SERIAL INTERFACE

DIP SWITCH SETTING

CODE TABLE

CONTROL CODE

PRINT MODE FLOWCHART

CONTROL CODE EXPLANATION

PROGRAM EXAMPLES

APPENDIX

...............................................................................

......................................................

...................................................................

................................................................

........................................................

..............................................................

..........................................................

........................................................................

SUMMARY

.........................................................

........................................................................

............................................... 33

.................................................

........................................ 38

....................

1

4

6

9

13

18

22

26

30

37

50

77

v

Page 7

OUTLINE

PRINTING OPERATION

1. Printing Method

Impact dot matrix

Bidirectional logic seeking printing

2. Printhead

8 Pins

3. Character Fonts

Standard

Italic

High quality (correspondence)

Italic high quality

Superscript / subscript

Italic superscript

IBM graphics fonts

4. Graphic Printing

Standard

Double-Density

High-Density

5. Print Mode

Any one of 17 fonts may be selected from the five available print modes. Each font

may be used exclusively or intermixed within any given line. When a mode change

is indicated, data already input is printed in the mode first selected, the printer skips

a few spaces, changes mdoes, and then receives new data.

Speed of printout (CPS) is slightly different in each mode depending on operational

complexity, e.g., the bold print and double-strike mdoes are created with two passes

of the printhead, thus requiring a slightly greater printout time.

See the “Detailed Summary of Character Fonts” Table on page 2 for print

specifications and CPS for each mode.

/

(140 characters in each font)

subscript

Horizontal x Vertical

n

n

n

x 8

x 8

x 16

(maximum value of n is 816)

(maximum value of n is 1632)

(maximum value of n is 1632)

1

Page 8

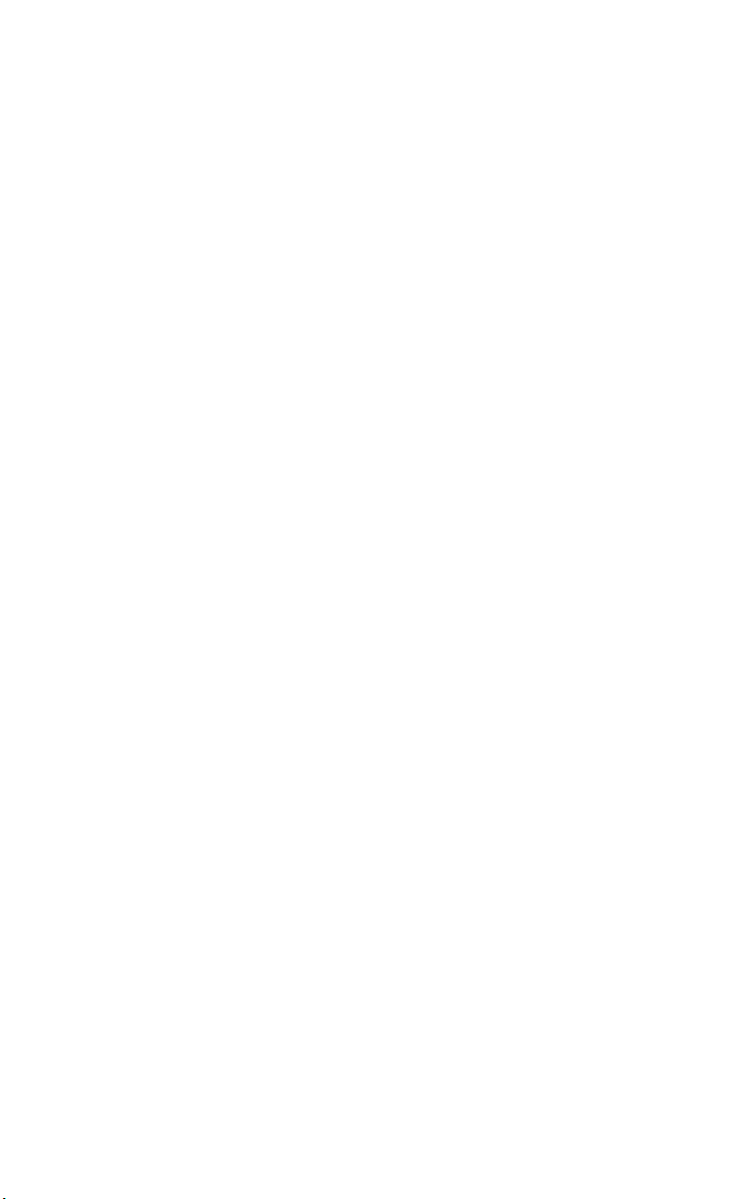

Detailed Summary of Character Fonts

2

Page 9

6.

Paper Feed Function and Form Width

Pin feed method (form width may vary) 5”-15.5”

Friction feed method

11”

7. Line Feed Pitch

Minimum 1/180”

8. Line Feed Speed

60 lines/second - when 6 lines/inch is selected

75 lines/second - when 7.5 lines/inch is selected

9. Copies

Original plus 4 copies, non-carbon, total thickness 0.3mm or less

10. Ribbon

Cassette style, single color

Other Specifications

1. Power Supply

2. Temperature (during operation)

3. Humidity (during operation)

4. External Dimensions

117VAC

5°C - 40°C (41°F - 104°F)

20% - 80%

595 mm (width) x 194 mm (height) x 405 mm

±

10%, 220-240VAC ± 10%, 50/60Hz

(depth)

(23.4 x 7.6 x 15.9 inches)

(The depth is 580mm when the paper rack is

attached.)

5. Weight

6. Power Consumption

27kg (60lb)

Printing 250 watts

Stand-by 5.5 watts

3

Page 10

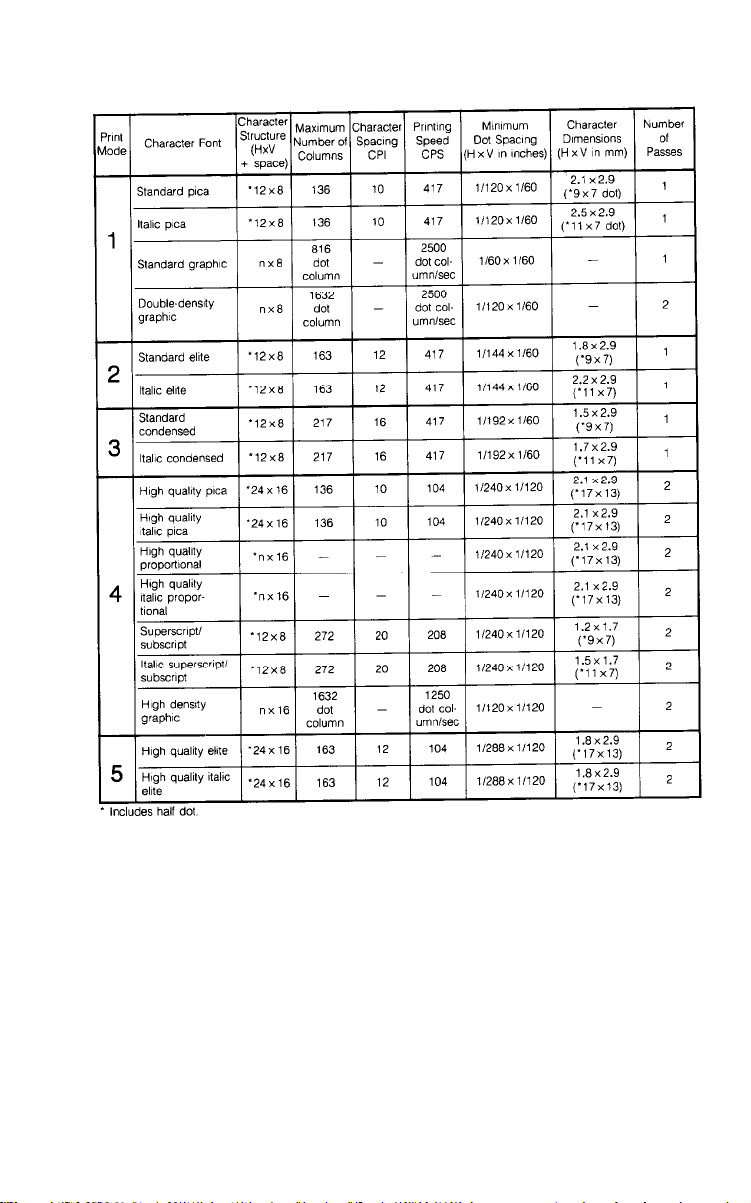

SWITCHES AND LAMPS

1. POWER Switch

The power switch is located at the rear,

right-hand side of the printer.

2. ON-LINE Switch

Pressing this switch selects either ON-LINE (green indicator on) or OFF-LINE (green

indicator off) state. If in the OFF-LINE state, the printer outputs a busy signal. The

print-head returns to the home position when entering the ON-LINE state from the

OFF-LINE state.

3. LF Switch (LINE FEED)

Each time this switch is pressed, a 1/6 inch line feed is performed. If held down,

continuous line feeds are performed. This command is valid only in the OFF-LINE

state.

Note: Refrain from performing continuous line feed for one minute or more. It may

affect the longevity of the line feed motor.

4. FF Switch (FORM FEED)

If the FF switch is pressed in the OFF-LINE state, a one page form feed is performed.

The page length is selected by the FORM dial switch or by code designation.

5. TOF SET Switch (TOP OF FORM)

If the TOF SET switch is pressed in the OFF-LINE state, the existing paper position

becomes the TOP OF FORM. The page length is designated by the FORM dial switch.

The buzzer sounds for 0.1 second after this switch is pressed.

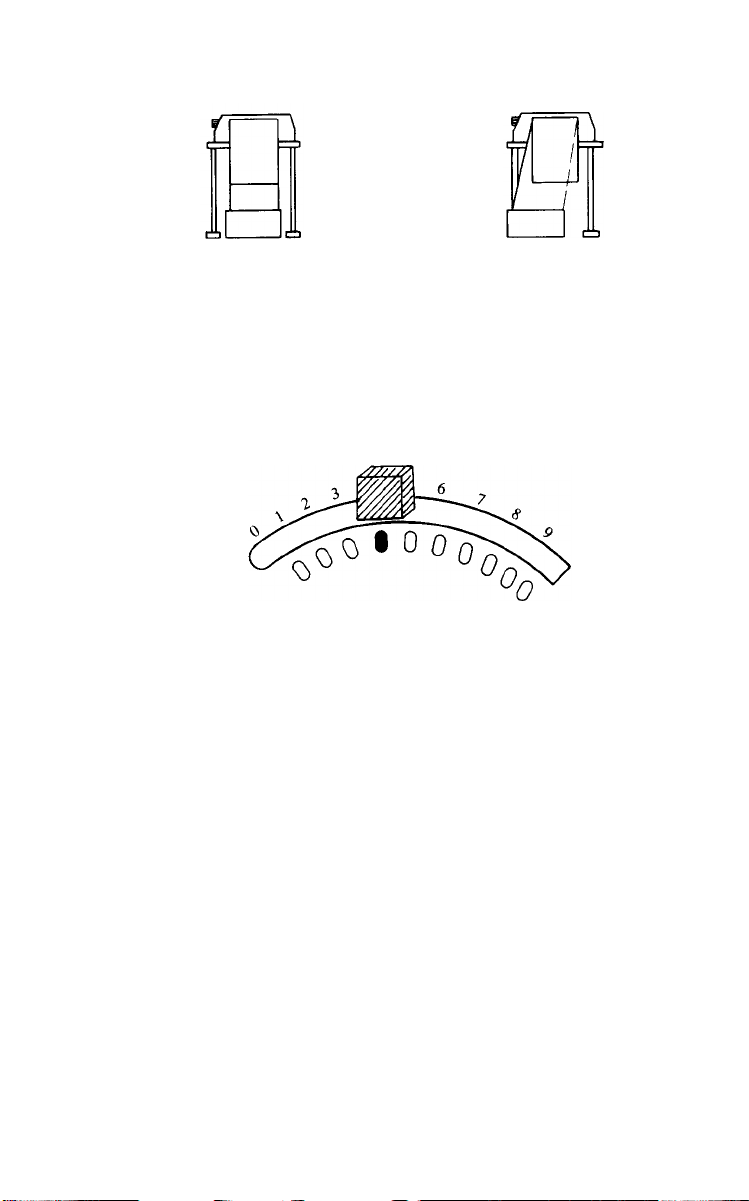

6. FORM Dial Switch

This switch selects the length of the page. If the switch is set to “0”, the page length

designated by an external device code, becomes valid. The page length can be

altered by pressing the TOF SET switch in the OFF-LINE state. A page length of

11 inches is automatically selected when the TOF SET switch is pressed for a dial

setting of “0”.

Dial

Dial

Page Length

CODE SET 5

0

1

2

3

4

7. MODE Dial Switch

Each character font may be selected by this switch.

8 INCH 6

8.5 INCH

11 INCH

12 INCH

Dial

Page Length

14 INCH

15 INCH

7

8

9

16 INCH

17 INCH

22 INCH

Code Selected Character Font

4

Page 11

Settings 1 to 9 have priority over the software designation. Software selection will be

9. If the switch selection is altered during prin-

ignored after setting this switch to

1~

ting, it will become effective after the current print command is executed.

RESET Switch

8.

When this switch is pressed, the printer enters the reset state. When released, the initialization operation is performed once again, This puts the printer in the same condition as at power-on.

9.

POWER Lamp (Green)

Lights up when power is on. Blinks if an error has been generated.

10. ON-LINE Lamp (Green)

Data can be input when the printer is the ON-LINE state. The ON-LINE lamp is lit when

the printer is ON-LINE, off when the printer is OFF-LINE. When the printer is OFF-

LINE, a BUSY signal is output by the printer.

11. P. EMPTY Lamp (Red)

When a paper-empty signal is detected, the P.E. indicator lights and the buzzer sounds

for 3 seconds. At this time, the printer goes OFF-LINE, and the BUSY and P. EMP

signals are output. If paper-empty is detected during printing, operation is terminated

at completion of the line in which the signal is received.

If the ON-LINE switch is pressed after paper is inserted, the P. EMP state is terminated.

If the ON-LINE switch is pressed without new paper inserted, a single line is printed

(during printing the ON-LINE lamp is lit) and the OFF-LINE state is entered again. This

operation can be repeated as many times as desired.

5

Page 12

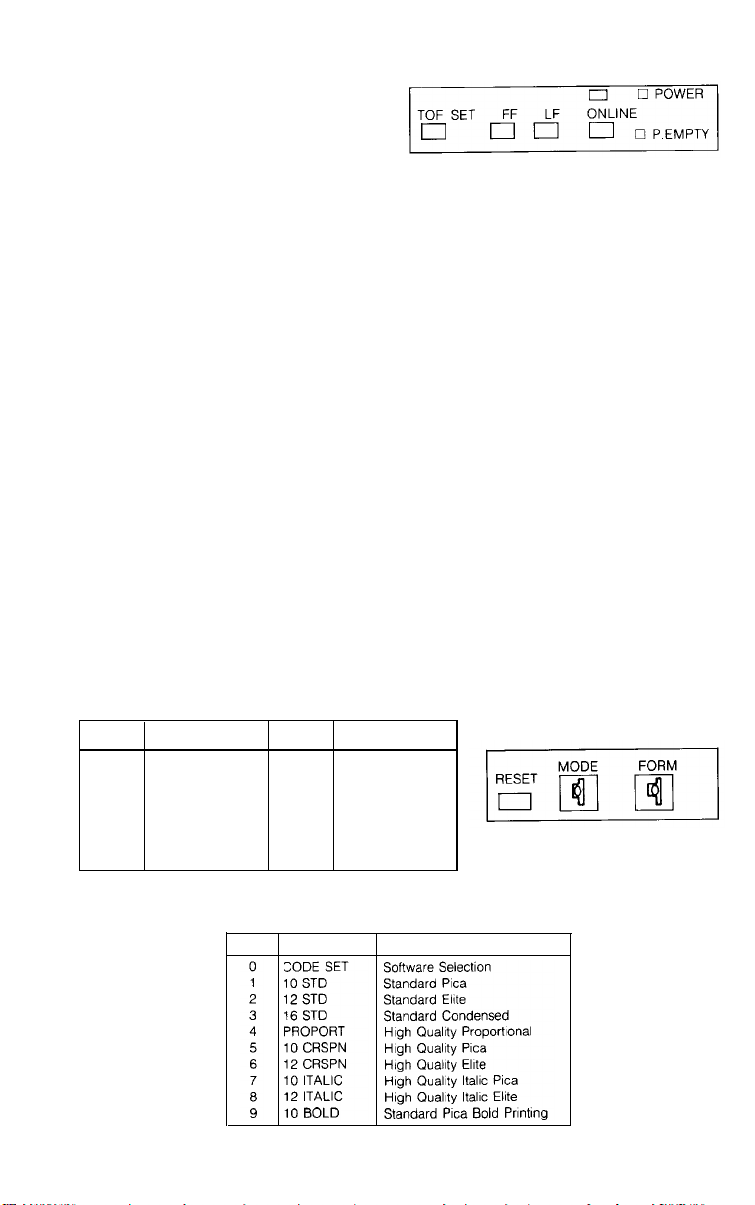

RIBBON CASSETTE REPLACEMENT

Installing the Ribbon Cassette

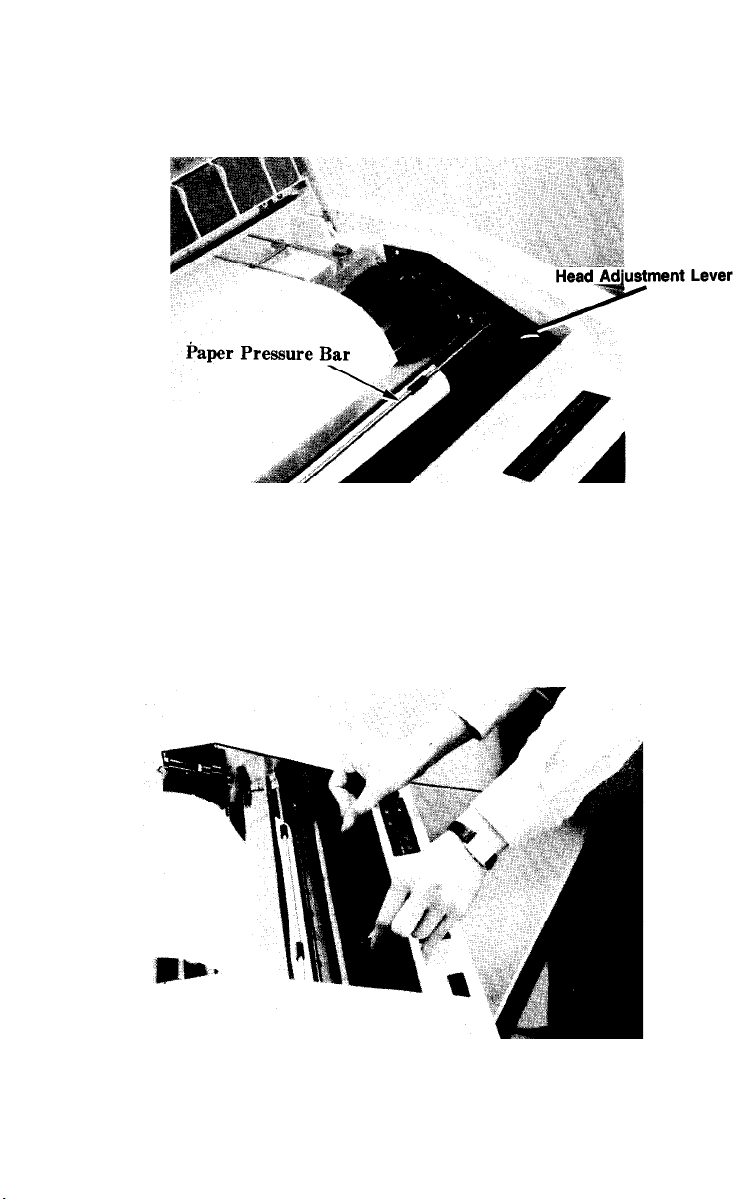

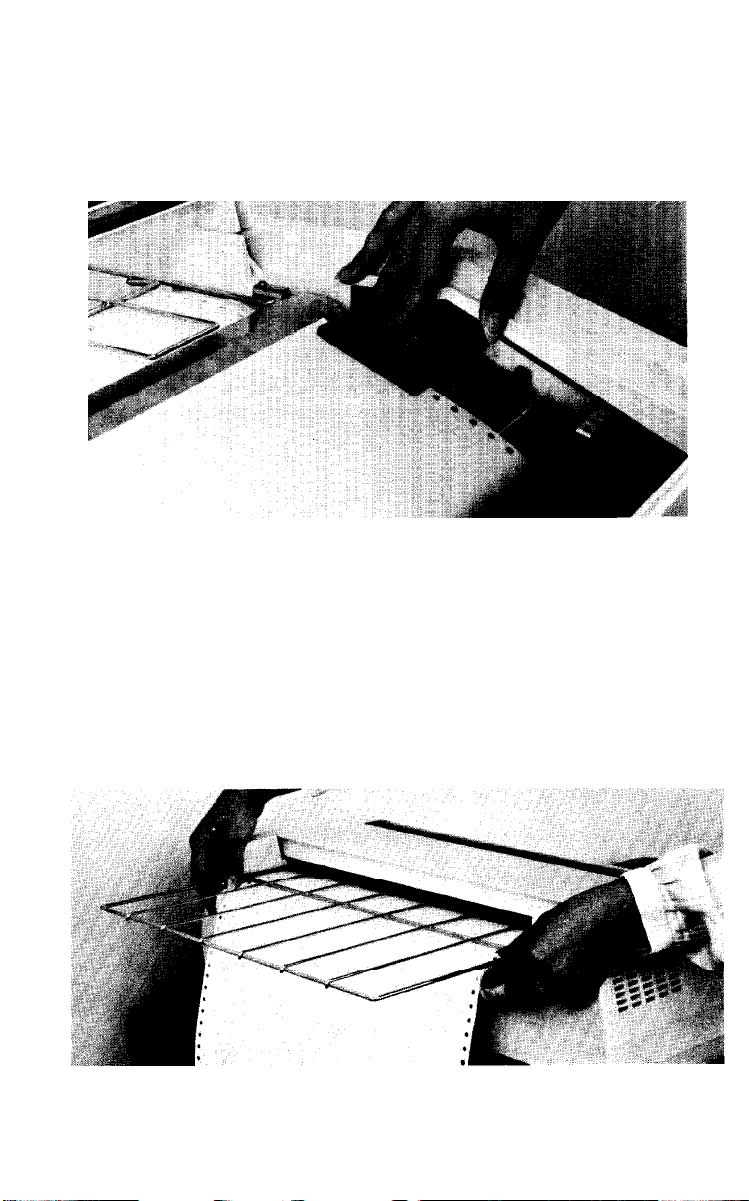

1. Open the printer cover and push the paper pressure bar toward the platen as

shown in Fig. 1.

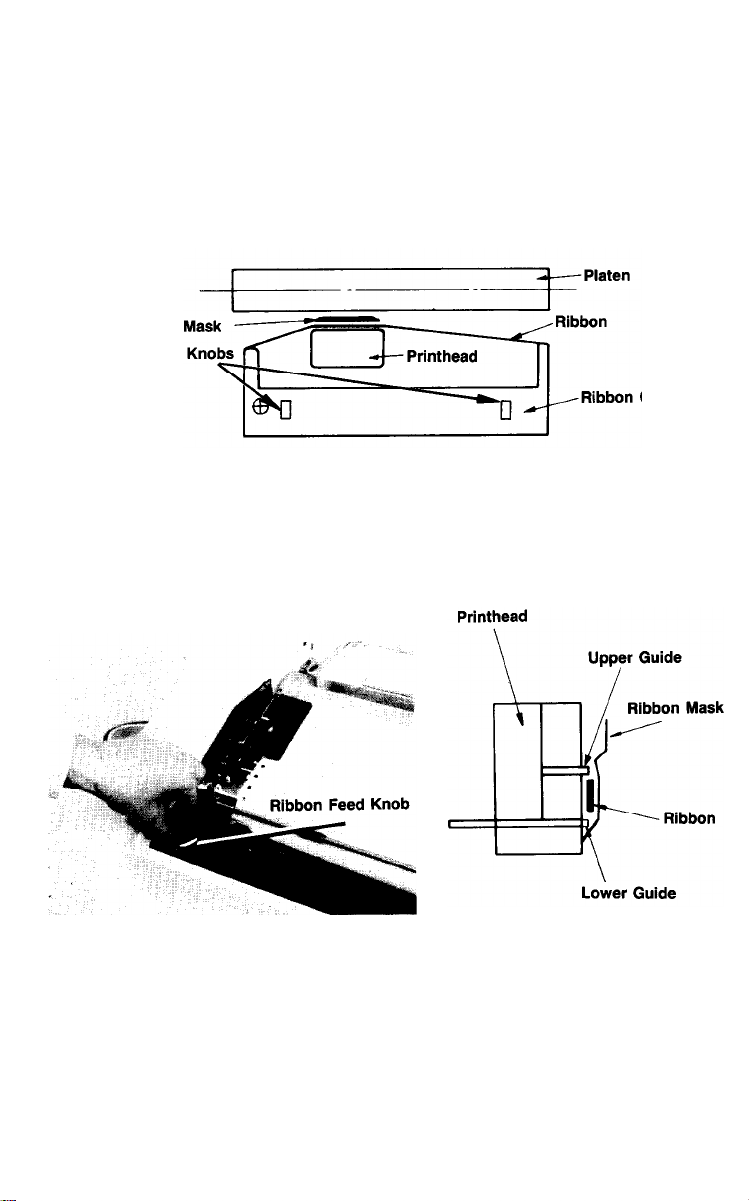

Fig. 1

6

Page 13

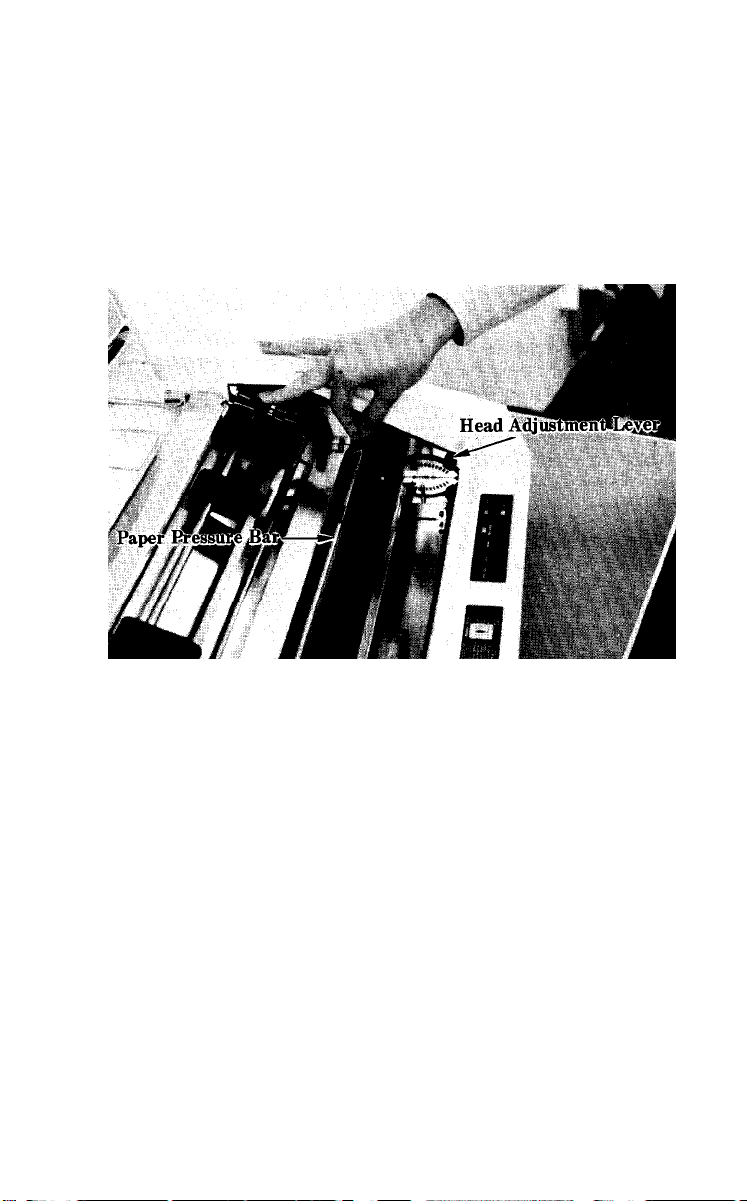

2. Set the head adjustment lever all the way forward. This lever may be moved easily

by pushing it outward.

3. To attach the ribbon cassette to the printer, hold the ribbon cassette knobs in both

hands and press the ribbon into position between the ribbon mask and the printhead.

Make sure that the ribbon is not twisted.

Fig. 2

4. Tighten the ribbon by twisting the ribbon feed knob in the direction of the arrow

(Fig. 3). Make sure that the ribbon is properly positioned in the guide as shown below.

Fig. 3

Fig. 4

5. The installation is complete once the head adjustment lever has been returned to

position 2, 3 or 4, any of which is a position for a single sheet of paper. The higher

the number that the lever is set on, the greater the distance between head and platen.

This greater distance is desirable since it reduces ribbon wear.

7

Page 14

Removing the Ribbon Cassette

1. Push the paper pressure bar towards the platen side. Pull the head adjustment

lever forward.

Fig. 5

2. As shown in Fig. 6, hold the ribbon cassette in both hands and pull the ribbon

cassette upward.

Fig. 6

8

Page 15

PAPER SETTING

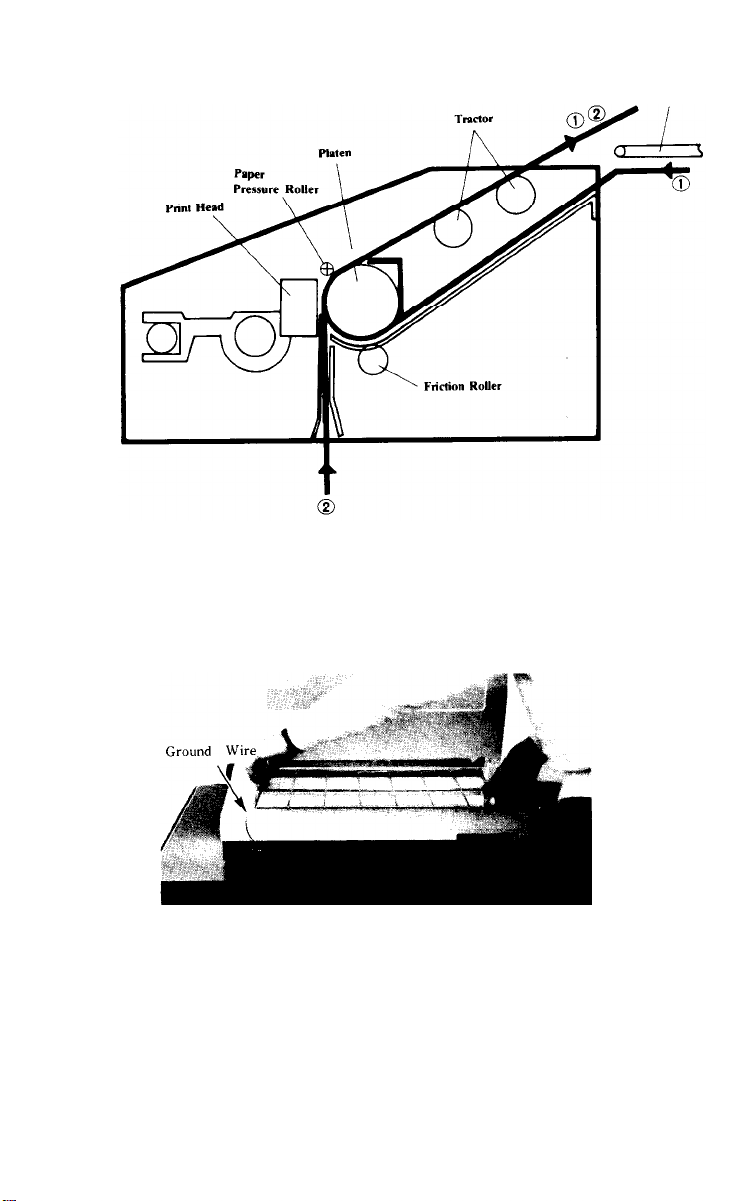

1. Rear feed (friction/tractor type)-used for fan-fold form, multiple copy sheets

2. Bottom feed (tractor type)-used for fan-fold, multiple copy sheets

Fig. 7

Fig. 8

Rear Feed Tractor Paper Setting

1. Attach the paper rack to the rear of the printer by inserting it into the two holes

located there, as shown in Fig. 8. Connect the ground wire. It is located between

the paper rack and the power cable receptacle’s right-hand screw (shown in Fig.

8). Failure to do so may cause malfunction of the printer. The purpose of this ground

connection is to eliminate static electricity formed by the paper.

9

Page 16

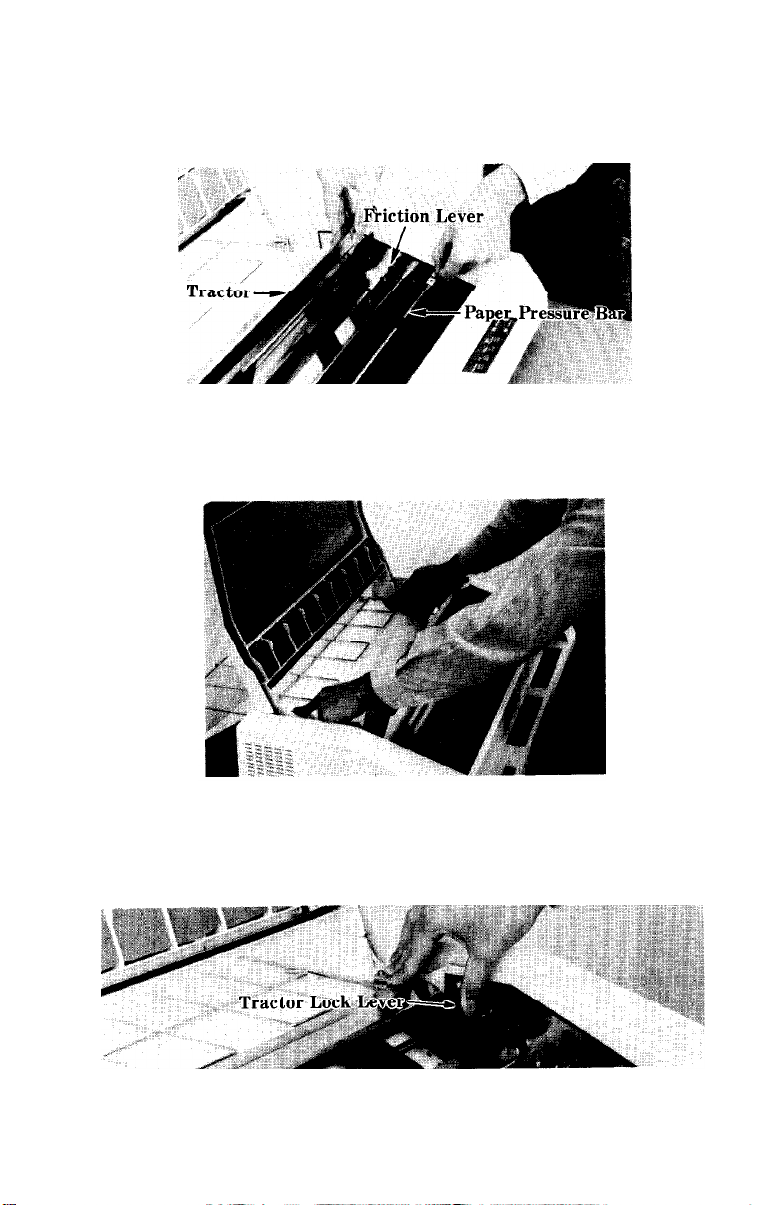

2. Pull the paper pressure bar forward. Pull the tractor forward until it clicks. At this

time make sure that the friction lever is in the forward position marked as “PIN FEED.”

(The form is free to move.)

Fig. 9

3. Insert the paper into the back of the printer following the paper feed path 1

as shown in Fig. 7.

Fig. 10

4. Push the tractor into its original position (until it clicks). If the tractor lock levers, located

at either side of the tractor shaft, are pushed up as shown in Fig. 11, the tractor can

be moved horizontally to adjust it to match the width of the form being used.

Fig. 11

10

Page 17

5. Open both tractor lids, adjust the form holes so they match the tractor pins, and

then close the tractor lids.

6. Determine the proper horizontal positions of the tractors, and then pull the tractor

lock lever forward to lock it into this position.

Fig. 12

7. Push the paper pressure bar towards the platen

8. For one part fan fold paper, the head adjustment lever is usually set at position

2. However, when printing an original plus 4 copies, it should be moved 3 or 4 clicks

forward.

9. As shown in Fig. 13, the side stoppers located at each side of the paper rack’s

form feed roller should be adjusted to match the width of the form being used.

Fig. 13

11

Page 18

Note 1: Recommended paper position is shown below.

CORRECT

Failure to position the paper correctly as shown above may result in a paper jam.

Note 2:

The head adjustment lever on the right base plate is used to find the best

printing quality by shifting it back and forth in line with the paper thickness.

INCORRECT

Bottom Feed Tractor Paper Setting

The bottom feed tractor paper setting is illustrated as path 2 in Fig. 7. Because the

form is fed in from the bottom, a special type of desk is required.

1. Pull the paper pressure bar forward and make sure that the friction lever is also

in the forward position marked “PIN FEED”. (Fig. 9)

2. Insert the form as done for path 2 of Fig. 7

3. Move the tractor lock lever upward. (Fig. 11)

4. Perform steps 5-8 for the rear feed tractor type (path 1).

5. Move the side stoppers, located at the bottom of the printer at the paper insertion

opening, to match the width of the paper to be used.

12

Page 19

MAIN FUNCTIONS

Detection Functions

1. Cover Switch

The printer cover open/close detection switch puts the printer in the OFF-LINE state.

It outputs a BUSY signal when the cover is opened. If the cover is opened during

printing, printing is terminated after the current line is finished, and the OFF-LINE

state is entered. When the cover is closed and the ON-LINE switch is pressed, the

ON-LINE state is entered and printing is resumed. For easier paper and ribbon installation, the printhead moves to the position which is approximately 10 cm away

from the home position when the printer cover is opened.

2. Right Overrun Switch

This switch detects the printhead carrier when it reaches the right most limit.

3. Temperature Detection Function

This detector recognizes abnormal temperature levels within the printer.

Note:

In the case of 2) or 3) if an abnormality is detected, the ERROR and BUSY

signals are output. The printer mechanism’s power supply is also turned

To reset this condition, an INITIAL signal must be input, the RESET switch

pressed, or power must be turned off and then on again.

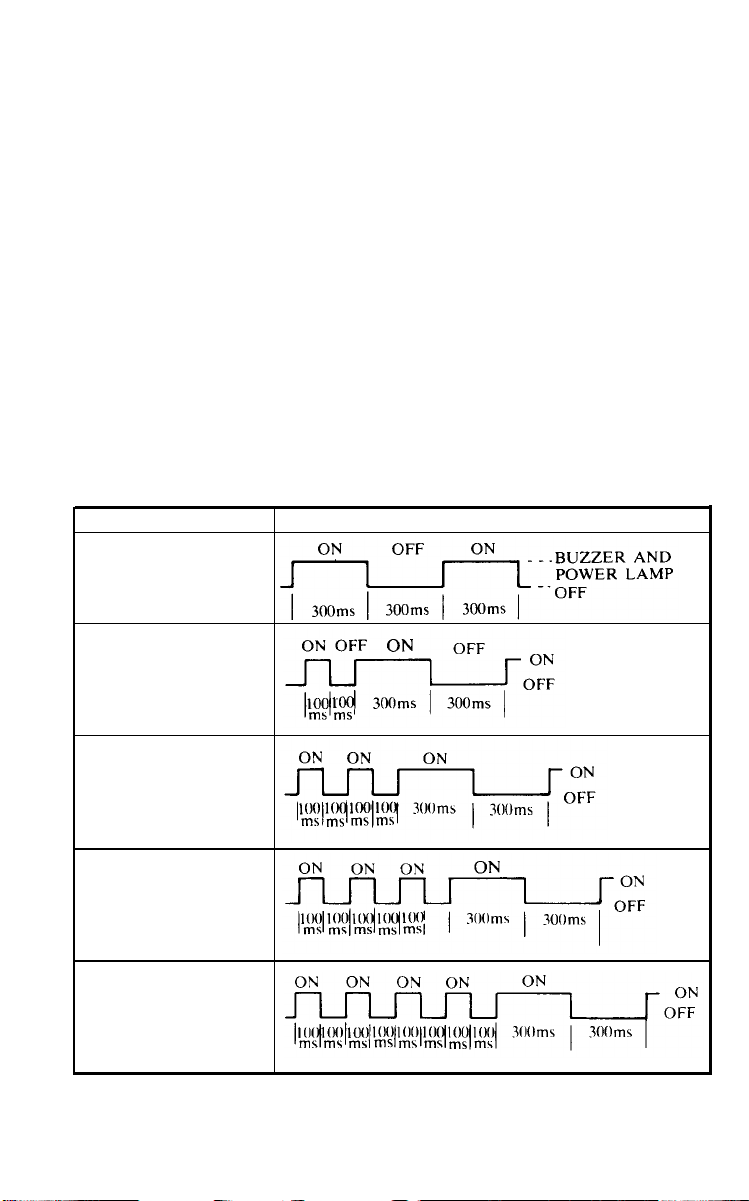

Errors

• Abnormal temper-

ature rise

• Pin fires abnormally

• Head carrier

overrun error

• Home sensor

• RAM error

Address (0000) H

(3FFF)H

• RAM error

Address (4000)H

(7FFF)H

off.

Buzzer and Power Lamp Blinking

You can identify which section is malfunctioning by the buzzer sound or POWER

lamp blinking as shown above.

13

Page 20

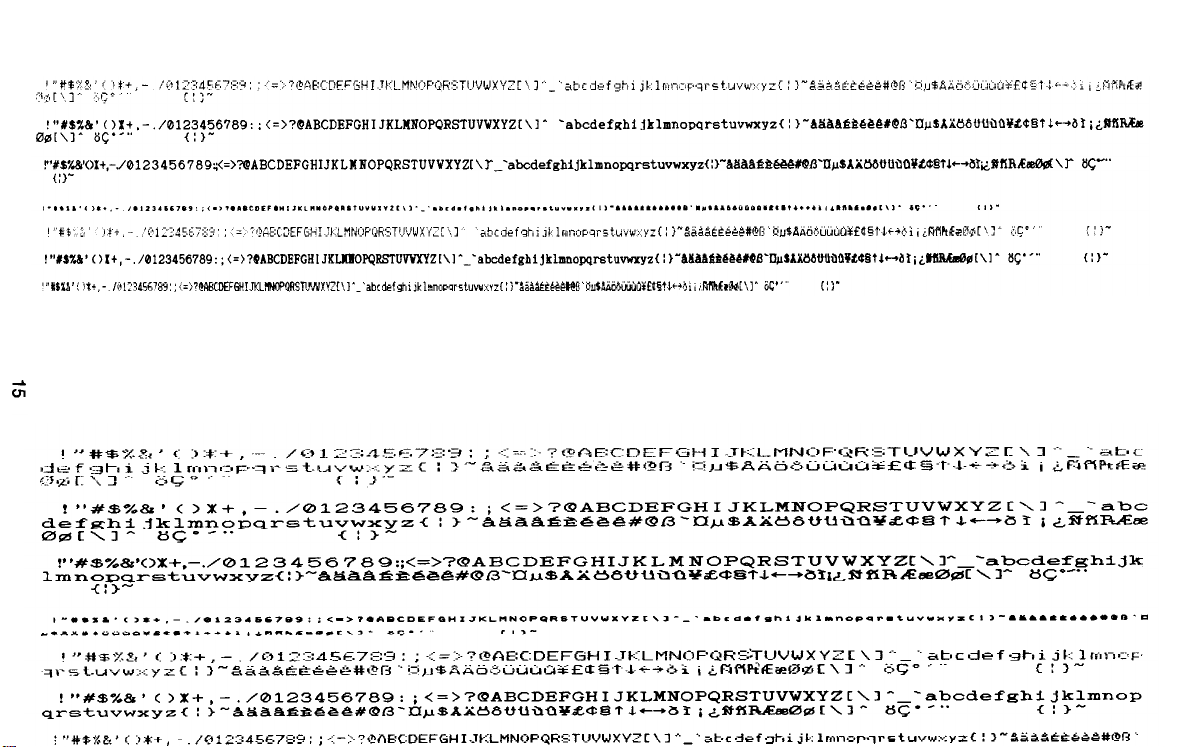

Self Test Printing

If the ON-LINE switch is pressed at power-on and held until the initialization opera-

tion ends, a given pattern is printed repeatedly. During printing, the printer is in the

OFF-LINE state. To terminate printing, press the ON-LINE switch until the printing

stops. When the switch is released, the printer performs the initialization operation,

enters the ON-LINE state, and the ON-LINE lamp goes on.

If paper-empty or cover-open is detected, printing is terminated while the printer is

still in the OFF-LINE state. When printing is terminated due to a paper-empty condi-

tion, the P.EMP lamp is lit, the buzzer sounds for 3 seconds, and the P.EMP signal

is output. This state can be reset by loading paper and pressing the RESET or ONLINE switch once. The printer then starts the initialization operation and enters the

ON-LINE state. If the RESET or ON-LINE switch is pushed though no paper has been

inserted, the printer enters the OFF-LINE state, the P.EMP lamp lights, and the buzzer

rings for 3 seconds after executing the initialization operation.

When printing is halted because of a cover-open condition, the printer performs initialization and enters the ON-LINE state only after the printer cover is closed and the

RESET or ON-LINE switch is pressed.

The self test print examples in the two modes (Epson Printer and IBM Graphics Printer)

are shown on pages 15 and 16.

Automatic Printing

When data input exceeds one line of data, printing is automatically carried out without

a print command unless the data are graphics data; there is no automatic print signal

with graphics data. After automatic printing,

it was prior to printing except when the

the printer is in the same condition as

function is cleared.

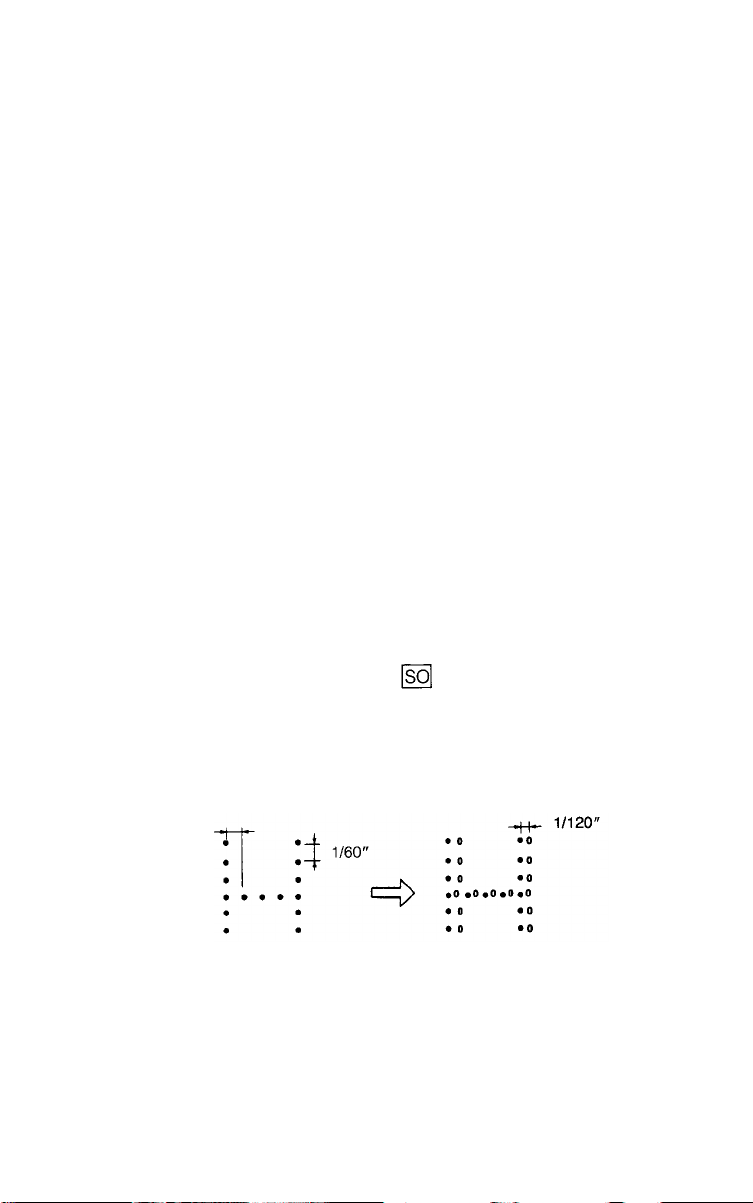

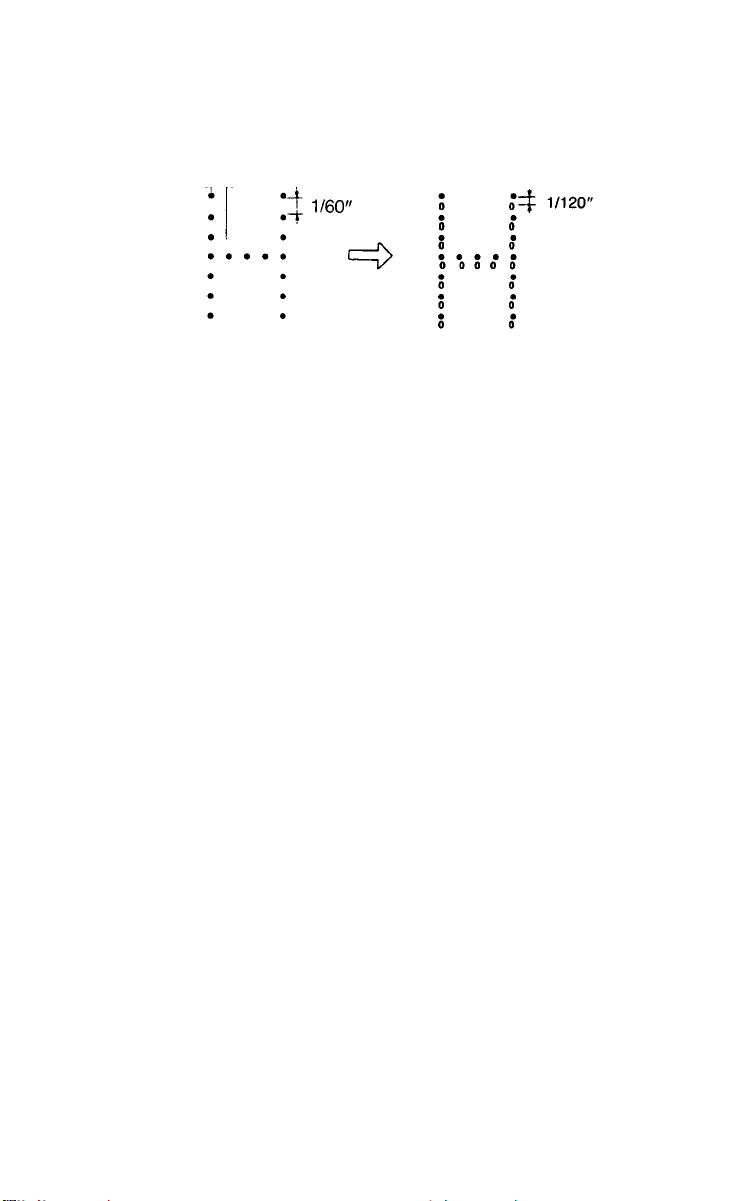

Bold Printing

In order to create bold print, a 1/120 inch dot is printed to the right of the initial dot.

Example:

(STANDARD)

14

(BOLD)

Page 21

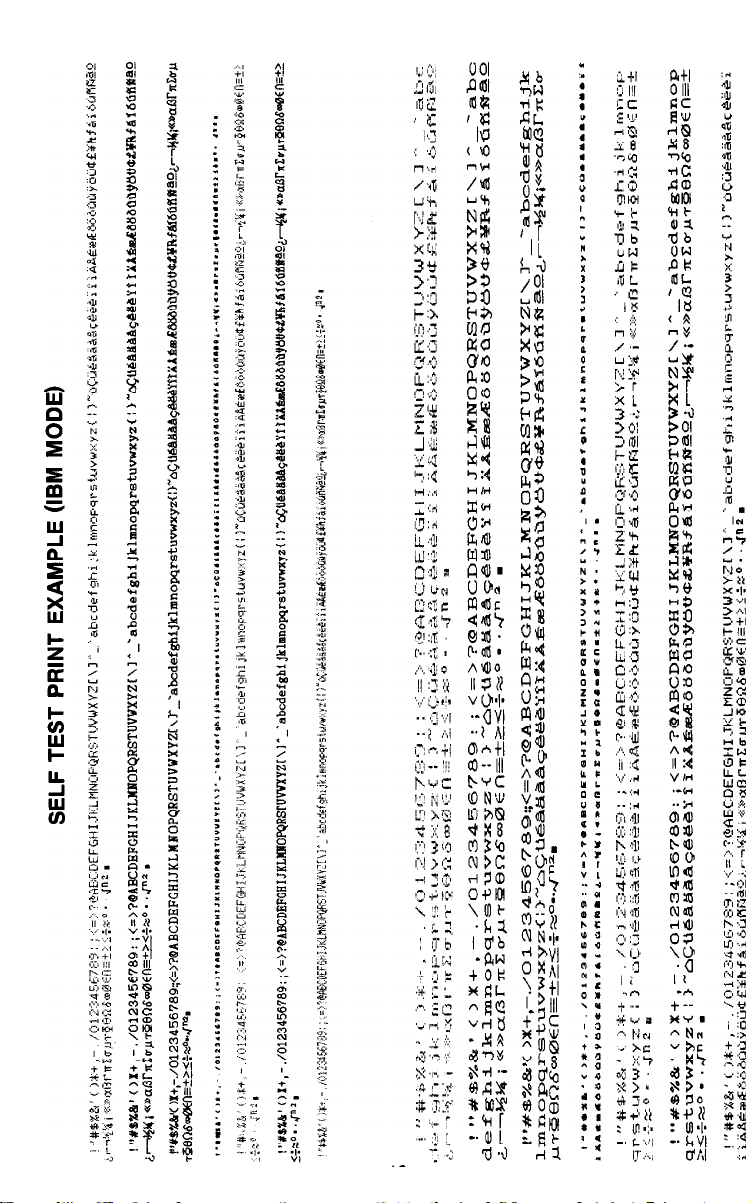

SELF TEST PRINT EXAMPLE (EPSON MODE)

Page 22

16

Page 23

Double-Strike Printing

In the double-strike mode, the second dot is printed 1/120 inch down from the initial

dot on a vertical line. The double-strike process requires 2 passes of the printhead.

Example:

(STANDARD)

(DOUBLE-STRIKE)

Buffer

This printer is equipped with an 18K-byte communication buffer which allows the

reception of data during printing. Thus, even for large data transfers the computer

is free to perform other tasks.

Printhead Protection

During high-density printing, a heat detector within the printhead protects the coils

from damage due to overheating, by reducing print speed. The sensor recognizes

two temperature warning levels. At level one, a 200 ms pause in the print cycle occurs before the next line is printed. At temperature level two, a 5-second pause in

the print cycle will occur, allowing the heat to dissipate. The ON-LINE lamp blinks

during the 5-second halt.

RAM (Memory) Error Detection

(performed only during the initialization operations)

When a RAM error is detected, the buzzer sounds, the POWER lamp blinks, and

the error state is entered.

17

Page 24

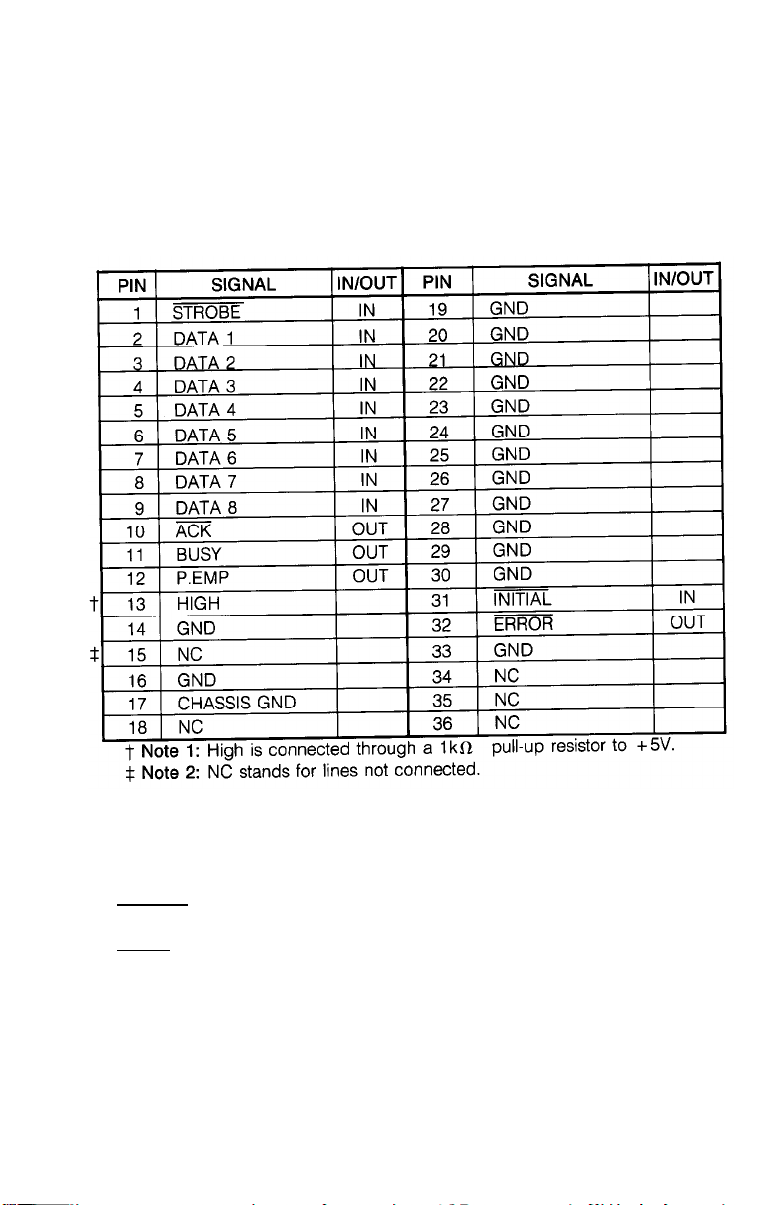

PARALLEL INTERFACE

Input Connector

Cable side connector

Printer side connector

Signal Diagram

DDK 36 pin 57-30360-D8 or equivalent

DDK 36 pin 57-40360-12 or equivalent

Signal Descriptions

1. Input Signals to the Printer.

* DATA 1-DATA 8

8-bit data signal, with “1” being HIGH.

* STROBE

Strobe signal used to read 8 bits of data. Data is input when the signal is LOW.

* INITIAL

Puts the printer into its initial state. This signal is usually HIGH. When it goes

LOW and then HIGH again, the printer is initialized.

2. Signals from the Printer

* BUSY

This signal shows that the printer is in the BUSY state. When it is HIGH, data

cannot be received. The following are conditions for which a HIGH BUSY signal

is output:

18

Page 25

(a) While performing initialization operations.

(b) While the printer is inputting data with the STROBE signal.

(c) During self test printing.

(d) When the printer is in the OFF-LINE state. (At this time, the ON-LINE lamp

is not lit: 1) If the printer cover is open; 2) paper supply is depleted or

P.EMPTY lamp is lit; 3) an error is detected or the POWER Lamp is blinking;

4) the ON-LINE switch is pressed.)

An ACK signal is output if the BUSY signal goes LOW only when BUSY is

generated due to conditions l), 2) or 3).

* ACK

This signal that is synchronized with the falling edge of the BUSY signal is output

after the initialization operations at power-on or after data is input.

* P.EMP

This signal goes HIGH when the printer is out of paper.

* ERROR

This signal shows that the printer is in the error state and occurs in the following

circumstances:

(a)

If the circuit component’s temperature increases to an abnormal level.

(b)

If the right overrun switch is activated.

(c)

If current flows through a pin of the printhead when printing is not required.

(d) If the home sensor is not operating properly, during initialization

operations.

(e)

If the RAM error is detected, while performing initialization operations.

The sequence of events when an error occurs are as follows:

(a) POWER lamp blinks

(b) ERROR signal goes LOW

(c) BUSY signal goes HIGH

(d) Buzzer is sounded

(e) Power for motion is turned off to terminate operations.

To terminate the error condition:

(a) Turn the power switch OFF and then ON again,

(b) Input the INITIAL signal.

(c) Press the RESET switch.

Electrical Conditions

1. Signal Levels

All signals are TTL level.

HIGH

LOW

. . . . . . . . . . . . . . . . . . . . . . . . . .

level

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

level

+2.4~5.0V

0~0.4V

19

Measured at the input pins on

the printer.

Page 26

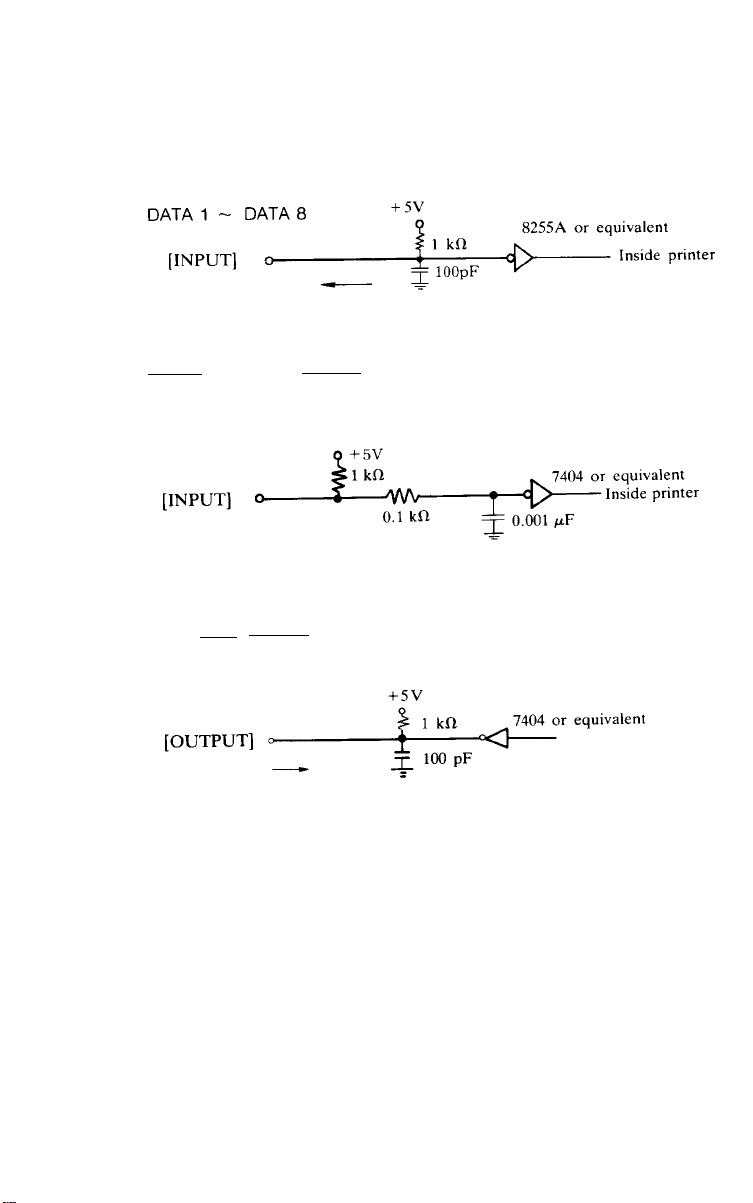

2. Input / Output Conditions

(a) Input Signals

•

INITIAL signal and STROBE signal

(b) Output Signals

•

BUSY, ACK, ERROR, P.EMP signals.

3. Signal Cable Length

The maximum length is 2 meters. All the signal lines should be run as twisted pairs

with the GND lines.

20

Page 27

Timing Chart

(a) Data input

(b) Initialization

DIP Swtich Setting

The parallel interface is selected when DIP switches 1-1 and 1-2 are set as follows:

21

Page 28

SERIAL INTERFACE

Input Connector

Cable side connector 25 pin (male)

Printer side connector 25 pin D-SUB type (female)

Note 2)

Note 2)

Note 1)

Note 1)

Note 1: As shipped from the factory CTS, DSR, and DC are NC (NO CONNECTION).

If DSR or CD is to be used, perform the following to the jumpers J1, J2, J4 and J5

on the circuit board in the printer.

• If DSR is to be used, cut J2 and connect a jumper at J5.

• If CD is to be used, cut J1 and connect a jumper at J4.

Note 2: RTS and CTS are connected within the printer.

If CTS is to be used, cut J3 and connect a jumper at J6.

CAUTION: Changes in jumper connections should only be made by an authorized

Epson Service representative.

22

Page 29

Input/Output Signal Descriptions

1. Printer Input Signals

* RD (RECEIVED DATA)

This line is the data reception line for the serial signals from the computer. The data

consists of a start bit, data (parity bit), and stop bit.

Data length 7/8 bits.

With/without parity bit.

Odd/even parity

* CTS (CLEAR TO SEND)

A data transmission control signal, NC (No Connection).

OFF: Data transmission may not be performed.

ON: Data transmission is possible.

* DSR (DATA SET READY)

A signal that displays the state of the modem, NC.

OFF: The modem cannot receive/transmit data.

ON: The modem can receive/transmit data.

CD (CARRIER DETECT)

A signal that indicates whether or not the carrier is detected, NC

OFF: No Carrier

ON: Carrier

2. Output Signals from the Printer

Selectable by DIP switches

*TR (TRANSMIT DATA)

Employed for the X-ON/X-OFF and ETX/ACK control.

* RTS (REQUEST TO SEND)

On (SPACE) state is continuously output.

*SRTS

This is a handshaking signal representing the printer’s BUSY state.

OFF: BUSY

ON: READY

* DTR (DATA TERMINAL READY)

This signal controls the state of the modem.

OFF: Modem transmitting/receiving cannot be performed.

ON: Modem transmitting/receiving can be performed.

23

Page 30

Electrial Conditions

1. Signal Level

ON

OFF

2. Input/Output Conditions

Space

Mark

+3V ~ +15V

-3V~-15V

• Input signal

• Output signal

Handshake Protocol

Handshake protcol is selected by the DIP switch settings as show in in the table below

1. READY/BUSY Protocol

The DTR line indicates the READY/BUSY state of the printer. It outputs an ON

(+ 12V) in the READY state, and an OFF (-12V) in the BUSY state. When the

remaining space of the 18K-byte communication buffer goes below 4K bytes, the

DTR line turns OFF, terminating the transmission of data from the computer. Then

when the buffer space increases to above the 10K-byte level, the DTR line turns ON,

allowing data to be sent from the computer.

When the printer is in the paper empty state or the cover has been opened, the DTR

line goes OFF. The SRTS line output is identical to the DTR output. The printer can

receive up to 4K bytes more after the DTR line goes OFF.

2. X-ON /X-OFF Protocol

When the printer is receiving data, X-ON is output. When the printer is not able to

receive data, X-OFF is output. When the computer receives the X-OFF signal, transmission of data to the printer is terminated. If the X-ON signal is then received, data

is transmitted once again, When the communication buffer space goes below 4K

bytes, X-OFF is sent. When the buffer space goes beyond 10K bytes, X-ON is sent.

X-ON is DC1 (11 HEX), and X-OFF is DC3 (13HEX). These signals are output through

the TR line. The data format is the same as the input data structure.

24

Page 31

3. ETXlACK Protocol

The printer sends an ACK (O6HEX) to the computer in response to the data block

separated by ETX (03HEX) which was sent by the computer. If the communication

buffer space goes below 4K bytes, ACK is not sent. If the buffer space is more than

4K bytes, ACK is sent through the TR line. The ACK’s output data format is the same

structure as the input data.

Baud Rate

The following four baud rates are selected by DIP switches,

Data Length 7/8 Bit Selection

A 7 bit or 8 bit data length may be selected by DIP switch 1-3. When the switch

is ON, the 7 bit length is selected. When the switch is OFF, the 8 bit length is selected.

Stop Bit

One bit or more are required for the stop bits. However, when DIP switch 1-3 is ON

and is set to 7 bits, and when there is no parity setting by SW 1-6 and SW 1-7, there

is a need for 2 or more stop bits.

Parity

Whether a parity bit is to be used, and whether odd or even parity is to be used

is selected by SW 1-6 and SW 1-7. If a parity error is generated during the input

of data, whether the data is ignored or a

1-8. If ON, the data is ignored. If OFF, the

No parity

Odd parity

Even parity

Note: All DIP switch selections should be performed with the power OFF.

“*” is to be printed, is selected by SW

“*” mark is printed.

SW1 -6

OFF

ON

OFF

ON

25

SW1-7

OFF

ON

ON

OFF

Page 32

DIP SWITCH SETTING

The Epson 420i has two banks of eight DIP switches located on the back of the printer

next to the interface connectors. The switch banks are labeled 1 and 2, with the individual switches in each bank labeled from 1 to 8. To identify a particular switch

we use a two part number consisting of the bank number followed by the switch

number. For example, 2-4 identifies the fourth switch from the top in bank number 2.

BANK 1

All DIP switch selections should be performed with the power OFF. The switches

are located at the rear of the printer next to the input connector. As shipped

from the factory, all switches are turned OFF.

DIP Switch Bank 1

DIP Switch Bank 1 controls the selection of the interface that you want to use. If you

are using a parallel interface, then you should be able to leave this bank of switches

alone (they should be all set to OFF). If you are using the serial (RS-232-C)

interface, then the settings of this bank of switches must be set to match the serial

interface settings of your computer.

BANK 2

DIP switches.

• Interface and Protocol Selection

* Number of Data Bits Selection

26

Page 33

* Baud Rate Selection

* Parity Selection

* Parity Error Selection

DIP Switch Bank 2

This bank of switches selects some of the other features of the Epson 420i. These

switches may be left in the OFF position as they come from the factory, or you may

wish to change some of the switch settings to select different features. First you must

decide if you want to use the Epson FX mode or the IBM Graphics Printer mode,

determined by Switch 2-4.

* LF (Line Feed) Command Selection

A carriage return is executed when the printhead returns to the print start or left margin

position.

* CR (Carriage Return) Command Selection

Auto-CR

Execute a carriage return upon

receiving a line feed

If SW2-1 and SW2-2 are both set on ON, the CR command and the LF command

perform the same function.

Disabled

Enabled

27

SW 2-2

OFF

ON

Page 34

* Skip-over Perforation Selection

Skip Perforation

Skip-over perforation

* Operating Mode Selection

Select operating mode

Note: Switch 2-4 changes several functions of the printer. See the differences be-

tween the Epson Printer mode and the IBM Graphics Printer mode (page 36 .)

* International Character Set Selection

Disabled

Enabled

Printer Mode

Epson Printer

IBM Graphics

Printer

SW 2-3

OFF

ON

SW 2-4

OFF

ON

Note: Switch 2-8 is not used.

28

Page 35

The international character set selection does not become valid until the printer

is turned ON once again. The table below shows the international characters:

International Characters

29

Page 36

CODE TABLE

The control code tables for the Epson and IBM (character set 1 and 2) modes are

shown below.

CODE TABLE (EPSON MODE)

30

Page 37

CODE TABLE (IBM CHARACTER SET 1)

31

Page 38

CODE TABLE (IBM CHARACTER SET 2)

Note: Encircled characters are selected by the DIP switches.

32

Page 39

CONTROL CODE SUMMARY

CATEGORY

PRINT

COMMANDS

CHARACTER

DESIGNATIONS

CHARACTER

FORMAT

DESIGNATIONS

DOUBLE-WIDTH

MODE

ITEM

SYMBOLS

HEX (DECIMAL) CODE

FUNCTION

33

Page 40

34

Page 41

Relationship among the font, bold, double-strike and double-width functions is shown

in the table below.

0: Can be used simultaneously

The bold and double-strike modes may not be entered simultaneously. The last mode

input has priority.

In all print modes, the double-width mode may be used simultaneously with the bold

or double-strike print modes.

x: Cannot be used simultaneously

35

Page 42

Differences between the Epson Printer mode and the IBM

Graphics Printer mode

Selecting one of the two mode (Epson Printer or IBM Graphics Printer mode) changes

several things about the way the Epson 420i operates. The following functions change

when you change the setting of Switch 2-4.

1.

The character set changes. The IBM Graphics Printer mode supports the extended IBM Graphics Printer character set. There are two versions of this

character set and you choose the one you want with Switch 2.7, or with soft-

ware commands

characters than the lBM set 1 but, otherwise the two sets are the same. The

software commands and are Ignored if you are using the

Epson FX printer mode.

The Epson printer mode includes 8 international character sets. Within each set,

12 characters may be different from country to country. You can choose the

set that you want with Switches 2-5, 2-6, and 2-7, or with a software command

. The software command

Graphics Printer mode.

and . The IBM character set 2 includes more

is ignored if you are using the IBM

2.

Two of the commands to set line spacing

ferently with each option.

When you choose the Epson printer mode, the

1/6-inch line spacing, and the command selects n/60-inch line

spacing.

When you choose the IBM Graphics Printer mode the

the line spacing to that defined by the

command has not been used, then the

ing to 1/16-inch. The

must be followed by an

3.

When you are using the IBM Graphics Printer mode, the commands to control

the state of the eighth-bit and are ignored.

command defines a line spacing of n/60, (but

command to actually use that spacing.)

and

work dif-

command selects

command sets

command. If an

command sets the line spac-

36

Page 43

PRINT MODE FLOWCHART

* 16 CPI refers to condensed printing

Note: 1) Italic print mode is set by

2) This flow chart is valid only when the MODE dial switch is set to ‘0’. If any other

is selected, the software designations of the above are ignored.

and terminated by

37

Page 44

CONTROL CODE EXPLANATION

Print Commands

1. (0D)H (13)D, (8D)H (141)D

Input of this code initiates printing. DIP SW2-2 indicates whether or not a line-feed

is to be performed after printing. When no print data is input, the printhead does

not move. Print data input after this print command has been performed is printed

at the beginning of the line.

If a line-feed is to be performed and if the

mode) is set, that mode is deleted.

2. (0A)H (10)D, (8A)H (138)D

Input of this code results in printing and line-feed. The line-feed width is set by the

line-feed amount command. If no print data has been input, only a line-feed is performed. By setting DIP SW2-1, it is possible to have the data print out start at the

beginning of the next line.

This command terminates the double-width character mode set by the

command.

3. (0C)H (12)D, (8C)H (140)D

Input of this code results in line-feeds after printing until the top of the next page

is reached. The setting for one page is performed by the switch located at the front

of the printer or by the software designation.

Print data following the command is printed at the beginning of the line.

The double-width character mode set by the command is terminated.

4. (0B)H (11)D, (8B)H (139)D

Input of this code results in a paperfeed until the next vertical tab. If a vertical tab

is not set, this command performs the same operation as the code. If at least

one vertical tab is set and there is no setting until the next page, a paper-feed is

carried out until the top of the next page is reached.

If the (double-width character mode) is set, it is terminated.

command (double-width character

Setting of a vertical tab is performed by the

5. (1 B, 4A, n)H (27, 74, n)D, (9B, CA, n)H (155, 202, n)D

0 [ n

[

255.n is a binary 8-bit code. Input of this code results in a n/180 inch paperfeed after printing. This line-feed value is not stored within the printer. This starting

position of the next line is at the right side of the line printed previously.

When n

IS not 0, the mode is canceled if it is set.

38

or

command.

Page 45

Character Designation Commands

6. (1B, 50)H (27, 80)D, (9B, D0)H (155, 208)D

Input of this code selects the 10 CPI pica print mode.

7. (1B, 4D)H (27, 77)D, (9B, CD)H (155, 205)D

Input of this code selects the 12 CPI elite print mode.

8. (0F)H (15)D, (8F)H (143)D

Input of this code selects the 16 CPI standard condensed print mode

9.

Same

as

10. (1B, 70, n)H (27, 112, n)D, (9B, F0, n)H (155, 240, n)D

This code selects and cancels the proportional print mode.

n = (01)H or (31)H

n = (00)H or (30)H

When the proportional print mode is set, the code and code are ignored.

11. (12)H (18)D, (92)H (146)D

This code terminates the condensed print mode.

12. (1B, 53,00)H (27,83,0)D, (9B,D3,OO)H (155,211,0)D

This code selects the superscript print mode.

13. (1B, 53,01)H (27, 83, 1)D, (9B,D3,01)H (155,211,1)D

This code selects the subscript print mode.

14. (1B, 54)H (27, 84)D, (9B, D4)H (155, 212)D

This code terminates superscript / subscript print modes.

(1B, 0F)H (27, 15)D, (9B, 8F)H (155, 143)D

Selects proportional print mode.

Cancels proportional print mode.

39

Page 46

15. (1B, 21, n)H (27, 33, n)F

This code allows you to select multiple print styles (i.e., pica-italic-underlined) with

one command. The value of n determines the style selected. To determine a value

of n, add the values given for the print styles that you want to use from the table

below. (Note that some styles can’t be combined.)

Style

Pica

Elite

Proportional

Compressed

Emphasized

Double-Strike

Enlarged

Italic

Underlined

For example, if you want to select elite double-strike Italic print, you would calculate

the value of n like this:

Elite

Double-strike

Italic

n=

Value

0

1

2

4

8

16

32

64

128

1

16

64

81

Character Format Commands

16. (1B, 45)H (27, 69)D, (9B, C5)H (155, 197)D

This code selects the bold print mode.

This code is invalid in the superscript / subscript print mode. The double-strike mode

is cleared when this code is selected.

17. (1B, 46)H (27, 70)D, (9B, C6)H (155, 198)D

This code terminates the bold print mode.

18. (1B, 47)H (27, 71)D, (9B, C7)H (155, 199)D

This code selects the double-strike mode. This code is only valid in pica, elite and

condensed printing of standard and Italic characters. It is invalid in high quality and

superscript / subscript modes. Bold print mode is canceled if it is set.

40

Page 47

19. (1B, 48)H (27, 72)D, (9B, C8)H (155, 200)D

This code terminates double-strike mode.

20. (1B, 58, n)H (27, 88, n)D, (98, D8, n)H (155, 216, n)D

This code selects high quality (correspondence) print mode.

n = (01)H or (31)H

n = (00)H or (30)H

This code is valid only in standard pica and standard elite print modes.

21. (1B, 78, n)H (27,120,n)D

This code selects correspondence quality print (n = 1) or draft print (n = 0).

22. (1B, 34)H (27, 52)D, (9B, B4)H (155, 180)D

This code selects italic print mode.

23. (1B, 35)H (27, 53)D, (9B, B5)H (155, 181)D

This code terminates italic print mode.

24. (1B,36)H (27,54)D (IBM mode only)

In the IBM Graphics Printer mode, this command selects the IBM Graphics Printer

character set 2 which includes characters not contained in character set 1.

Selects high quality print mode.

Terminates high quality print mode

25. (1B,37)H (27,55)D (IBM mode only)

In the IBM Graphics Printer mode, this command selects the IBM Graphics Printer

character set 1.

Double-Width Character Printing Commands

26. (0E)H (14)D, (8E)H (142)D

This code selects double-width print mode. This command is only valid for a single

line of printing. If more than a single line worth of print data is input, the automatic

printing function prints the data. However, after the line-feed is performed, the doublewidth print mode is terminated.

This command is terminated by a linefeed, or code

27. (1B, 0E)H (27, 14)D, (9B, 8E)H (155, 142)D

Same as the code.

41

Page 48

28. (14)H (20)D, (94)H (148)D

This code terminates the double-width print mode code.

29. (1B, 57, n)H (27, 87, n)D, (9B, D7, n)H (155, 215, n)D

This code is a double-width print mode code that is not terminated by the line-feed.

This code clears them mode.

n = (01) or (31)

n = (00) or (30)

Selects double-width print mode.

Terminates double-width print mode.

Graphic Printing Commands

Do not select 7-bit mode in graphic printing.

30. (1B, 4B, n1, n2)H (27, 75, n1, n2)D,

(9B, CB, n1, n2)H (155, 203, n1, n2)D

This code is a standard graphic select command. There are a maximum of 816

horizontal dots. The n1 and n2 are binary numbers that indicate the number of bytes

of graphic data. The number is n2x256 + n1 The n1 is the low byte and the n2

is the high byte. After this code has been performed all settings remain unchanged.

The amount of printable data per line is 816 dots maximum. If a printing designation

input exceeds this amount, the remainder is ignored. The automatic printing function does not operate in this case.

The relationship between graphic data and printed dots is shown below.

31. (1B, 4C, n1, n2)H (27, 76, n1, n2)D, (9B, CC, n1, n2)H

(155, 204, n1, n2)D

This code selects double-density graphic mode. The maximum number of horizontal dots is 1632. The n1 and n2 are binary numbers that indicate the number of bytes

of graphic data. The n1 is a low byte and n2 is a high byte. The others are the

same as the code.

42

Page 49

32. (1B, 6B, n1, n2)H (27,107, n1, n2)D, (9B, EB, n1, n2)H

(155, 235, n1, n2)D

This code selects high density graphic mode. The maximum number of vertical dots

is 16 and the maximum of horizontal dots is 1632. The n1 and n2 are binary numbers

that display the graphic data number. Note that 16 vertical dots require 2 bytes of

data, but they are considered as a single data block.

The relationship between graphic data and the printed dots is shown below

33. (1B, 2A, 6D, n1, n2)H (27, 42, 109, n1, n2)D

This command prints dot graphics in a density determined by the value of m (see

table below). The values of n1 and n2 are determined as in the other graphics com-

mands (i.e. n1 + n2* 256 = the number of dot columns). This command must be

followed by the correct number of graphic data (1 byte per column for m = 0 to

6, 2 bytes per column for m = 7).

Value of m Function of Command

0

1

2

3

4

5

6

7

34. (1B, 59, n1, n2)H (27, 89, n1, n2)D

This code prints high-speed, double-density dot graphics at 120 dots per inch. The

values of n1 and n2 define the number of bytes of data according to the formula

n1 + n2*256. Each byte of data controls the printhead pins in one vertical row of

dots. The maximum number of bytes of data is 1632.

Same as ESC k

Same as ESC L

Same as ESC Y

Same as ESC Z

Same as ESC K

Same as ESC K

Same as ESC K

Same as ESC k

43

Page 50

35. (1B, 5A, n1, n2)H (27, 90, n1, n2)D

This code prints quadruple-density dot graphics at 240 dots per inch. The values

of n1 and n2 define the number of bytes of data according to the formula n1 +

n2*256. Each byte of data controls the printhead pins in one vertical row of dots.

The maximum number of bytes of data is 3264.

Horizontal Tab Commands

36. (1B, 44, n1, n2, .... nk, 00)H (27, 68, n1, n2,

. . .

nk, 0)D, (9B, C4, n1, n2, .... nk, 00)H, (155, 196, n1, n2, .... nk, 0)D

This code sets the horizontal tab. The maximum number of horizontal tab settings

is 28. At power-on, the horizontal tabs are automatically set for every 8th column.

When this code is input, these tabs are cleared.

The n is a binary number that designates the column number. The horizontal tabs

are set in present character width. The horizontal tabs are set in sequence with the

smallest first. The command ends with a code. However, if the sequence

is made in the reverse order, the setting is terminated at that point. When the horizontal

tabs are set in pica print mode, elite print mode, or condensed print mode, and the

mode is changed, the position of the tabs on the paper remains the same.

When the left or the right margin is set, the tab position already set is cleared. The

left margin position is considered to be the home position, and horizontal tabs are

automatically placed every 8th column in the same manner as they were at power-on.

[ k [

28

l

n ranges

Pica

Standard character

Double-width character 1 [ n [ 67

37. (09)H (9)D, (89)H (137)D

This code causes a move to the next horizontal tab position.

36. (1B, 51, n)H (27, 81, n)D, (9B, D1, n)H (155, 209, n)D

This code sets the right margin. The n selects the column with the present character

width as the base. This code is ignored if the value of n exceeds a single line. This

code is also ignored if the width between the left and right margins is less then 2

pica double-width print mode characters. This command deletes the print data and

horizontal tabs.

1 [ n [ 135 1 [ n [ 162 1 [ n [ 216

44

Elite

1 [ n [ 80 1 [ n [ 107

Condensed

Page 51

39. (1B, 6C, n)H (27,108, n)D, (9B, EC, n)H (155, 236, n)D

This code sets the left margin, The n selects the column with the present character

width as the base. This code is ignored if the value of n exceeds a single line. This

code clears the print data input already and the horizontal tabs..

If the left and right margins overlap, the one input first is considered valid

Page Length Setting Commands

The length of the page at power-on is selected by the FORM switch.

The following two codes, 40 and 41, are valid only when the FORM switch is set to ”0”,

40. (1B, 43, n)H (27, 67, n)D, (9B, C3, n)H (155, 195, n)D

[ 127. If n [ 128, this is ignored.

1 n

This code selects the page length in line units. The n is the line number. The length

of a page is set by multiplying n by the present line-feed setting for a line. The maximum length of a page allowed to be set is 91 inches.

The paper position at the time this command is performed becomes the head of

the first page. The page length will not change even if a line-feed amount is altered.

41. (1B, 43, 00, n)H (27, 67, 0, n)D, (9B, C3, 00, n)H (155,

195, 0, n)D

[ n [ 22. When n m 23 or n = 0, this is ignored. This code sets the page length

1

in inches. The n is the number of inches,

Vertical Tab Commands

42. (1B, 42, n1, n2, ....

n2, .... nk, 0)D, (9B, C2, n1, n2, .... nk, 00)H (155, 194, n1, n2, .... nk, 00)D

This code sets the vertical tab positions. The n selects the number of lines. The vertical tab is positioned by multiplying the present single line-feed setting for a line by

the set number of lines, The vertical tabs are set in sequence, with the smallest set

first. The code sequence ends with the code.

A vertical tab is also automatically set at the head of the page

43. (1B, 62, m, n1, n2, .... nk, 00)H (27, 98,

m, n1, n2, .... nk, 0)D, (9B, E2, m, n1, n2, .... nk, 00)H (155, 226, m, n1, n2,

....

nk, 0)D

0 [ m [ 7. This code sequence set the vertical tabs per channel. The m specifies the

channel. When m = 0, this code becomes the same as the

method of setting is the same as is done with

45

nk, 00)H (27, 66, n1,

code. The

Page 52

44. (1B, 2F, m)H (27, 47, m)D, (9B, AF, m)H (155, 175, m)D

0 [ m [ 7. This code selects the vertical tab channel. When m = 0, the vertical tabs

set by are used. The code is used to move to the vertical tab positions.

Line-Feed Value Setting Commands

45. (1B, 30)H (27, 48)D, (9B, B0)H (155, 176)D

This code sets the line-feed pitch to 1/8 inch.

46. (1B, 31)H (27, 49)D, (9B, B1)H (155, 177)D

This code sets the line-feed pitch to 7/60 inch.

47. (1B, 33)H (27, 50)D

In the IBM Graphics Printer mode, this command sets the line spacing to the spacing selected with the command. If the command has not been

used, this command sets the line spacing to 1/6 inch.

48.

This code sets the line-feed pitch to n/180 inch.

49. (1B, 41, n)H (27, 46, n)D

In the IBM Graphics Printer mode, this command only defines a line spacing of n/60

inch. This command must be followed by the command to actually set

the selected line spacing.

In the Epson Printer mode, this command sets the line spacing to n/60 inch.

50. (1B, 2E)H (27, 46, n)D

This code sets the line spacing for subsequent line feed commands to n/120 inch.

(1B,

33,

n)H

(27, 51,

n)D,

(9B,

B3, n)H

(155, 179,

n)D

Underline Commands

51. (1B, 2D, n)H (27, 45, n)D, (9B, AD, n)H (155, 173, n)D

This code performs the setting and termination of underlining.

n = (01)H or (31)H

n = (00)H or (30)H

An underline is not output when the printing position is moved due to a tab. The

underline is printed in 9th vertical dot position.

Sets underline.

Termination of underline.

46

Page 53

Buffer Clear Command

52. (18)H (24)D, (98)H (152)D

This code deletes the print data that has already been input. However, the control

codes are still valid.

Back Space Commands

53. (08)H (08)D, (88)H (136)D

This code prints the contents of the buffer. The printing initiation position is moved

to the left by a single character width, determined by the present character width

setting. This code is ignored in proportional print mode.

54. (1B, 3D)H (27, 61)D (Epson mode only)

In the Epson Printer mode, this code sets the eighth data bit to 0.

55.

In the Epson Printer mode, this code sets the eighth data bit to 1.

56. (Epson mode only)

In the Epson Printer mode, this command cancels control of the eighth data bit set

by either the set eighth-bit or clear eighth-bit command.

(1B, 3E)H (27, 62)D (Epson mode only)

(1B, 23)H (27, 35)D

Skip-Over Perforation Commands

57. (1B, 4E, n)H (27, 78, n)D, (9B, CE, n)H (155, 206, n)D

This code sets skip-over perforation line-feed mode. The n is set in line units. A form

feed to the top of the next page is automatically performed when the remaining lines

on the present page is less than n.

Setting DIP SW2-3 allows the selection of a 1 -inch skip-over perforation mode. This

command has priority over the DIP switch setting.

58. (1B, 4F)H (27, 79)D, (9B, CF)H (155, 207)D

This code terminates the skip-over perforation mode.

47

Page 54

Data Delete Command

59. (7F)H (127)D, (FF)H (255)D

This code deletes one character worth of data. This code is ignored during the proportional print mode.

Home Position Command

60. (1B, 3C)H (27, 60)D, (9B, BC)H (155, 188)D

This code moves the print head to the home position.

International Character Set Command

61. (Epson mode only)

In the Epson Printer mode, this command selects from one of the 8 international

character sets as shown in the table below.

(1B, 52, n)H (27, 82, n)D

n

Country

0

U.S.A.

1

France

2

Germany

3

U.K.

4

Denmark

5

Sweden

6 Italy

7

Spain

n is binary number.

Buzzer Command

62. (07)H (07)D, (87)H (135)D

This code causes the buzzer to sound for approximately 1/3 second.

Reset Command

63. (1B, 40)H (27, 64)D (9B, C0)H (155, 192)D

This code initializes the printer. Data input after this code is not deleted

48

Page 55

Print Direction Command

64. (1B, 55, n)H (27, 85, n)D, (9B, D5, n)H (155, 213, n)D

This code selects unidirectional printing from the left to the right. Graphic mode is

also printed unidirectionally.

n = (01)H or (31)H

n = (00)H or (30)H

When power is turned on, or when the RESET switch is pressed, the bidirectional

printing is selected. This function can also be selected by operating switches. If the

FF switch is pressed in the ON-LINE state, the unidirectional printing is selected after

buzzing for 0.1 second. If the LF switch is pressed in the ON-LINE state, the bidirec-

tional printing is selected after 0.1 second of sounding the buzzer.

Selects unidirectional printing

Selects bidirectional logic seeking printing

Paper-Out Sensor On/Off Commands

65. (1B, 38)H (27, 56)D

This code turns the paper-out sensor off and allows you to print to the bottom of

single sheets of paper.

66. (1B, 39)H (17, 57)D

This code turns the paper-out sensor on so that it will report when the printer runs

out of paper. This is the default condition.

49

Page 56

PROGRAM EXAMPLES

50

Page 57

Page 58

52

Page 59

Page 60

Page 61

11.

Termination of condensed

13.

14.

Subscript

Termination of superscript/subscript

Refer to 13.

55

Page 62

15.

Elite, double-strike, italic

16.

17.

Bold

Termination of bold

Refer to 16.

56

Page 63

18.

Double-strike

19.

Termination of Double-strike

Refer to 18.

57

Page 64

20.

High quality

21.

High quality ON/OFF

56

Page 65

22.

Italic

23.

Termination of Italic

Refer to 22.

59

Page 66

24. IBM character Set 1

25.

IBM character Set 2

60

Page 67

26. Double width

27.

Refer to 26.

26.

Refer to 26.

29. Double width

Double-width

Termination of double-width

61

Page 68

30.

Standard graphic

31.

32.

Double-density graphic

High density graphic

62

Page 69

33.

Selected density dot graphics

63

Page 70

34.

High-speed, double-density dot graphics

35.

Quadruple-density dot graphics

64

Page 71

36.

Horizontal tab setting

37.

38.

Horizontal tab

Right margin

65

Page 72

40.

Page length in lines

41.

42.

Page length in inches

Refer to 3.

Vertical tab setting

Refer to 4.

66

Page 73

43.

Channel vertical tab setting

44.

Channel selection of vertical tab

Refer to 43

67

Page 74

45.

1/8 inch line feed

46.

47.

7/60 inch line feed

1/6

inch line

feed

88

Page 75

Page 76

50.

n/120 line spacing

70

Page 77

51.

52. Buffer clear

Underline

53.

Back space

71

Page 78

54.

8th bit 0 (Epson only)

55.

8th bit 1 (Epson only)

72

Page 79

56.

8th bit valid (Epson only)

57.

skip-over perforation

73

Page 80

Page 81

56.

Termination of skip-over perforation

Refer to 57.

59.

60.

Data delete

Home positioning

61.

International character (Epson only)

75

Page 82

62.

Buzzer

63.

Reset

76

Page 83

APPENDIX

INPUT DATA DUMP IN HEXADECIMAL

There is a function of printing input data from a computer in hexadeciamal codes.

Therefore, it is possible to check the data the printer has received. To perform this

function, keep pushing both the LF and the FF switches at power-on till the initialization operation ends. Hereafter, 16 bytes of input data will be printed a line at a time

due to the function of the automatic printing provided. If the number of input data

is less than 16 bytes and it is necessary to print them all, press the ON-LINE switch.

After printing, push the ON-LINE switch again to return to the dump function from

the OFF-LINE state. This function can be terminated by either of the 3 ways shown

below.

(1) Turn power off, wait 2 seconds and then turn it back on again.

(2) Push the RESET switch.

(3) Input the INITIAL signal.

77

Page 84

LIMITED WARRANTY

may reguest information on how to obtain service under this warranty by contacting the Dealer from

Epson America, Inc. hereby warrants that it will repair or replace, at its option, any part of the Epson

product with which this warranty is enclosed which proves defective by reason of improper workmanship

and/or material, without charge for parts or labor, for a period of one (1) year. This warranty period com

mences on the date of original purchase by the buyer other than for purposes of resale, and this warranty

applies only if such original purchase by the buyer was made in the United States,

To obtain service under this warranty you must return your Epson product, properly packaged in its origins

container or an equivalent, to the nearest authorized Epson Service Center or the Dealer from whom the

product was purchased. Any postage, insurance and shipping costs incurred in presenting or sending

your Epson product for service are your responsibility.

The dealer’s original bill of sale or other satisfactory proof of the date of the original buyer purchase o

your Epson product must be made available to obtain service under this warranty.

This warranty applies only if your Epson product fails to funtion properly under normal use and within

the manufacturer’s specifications. Batteries, as well as optional software packages (ROMs) not contained

in the original container of your Epson product, are excluded from coverage under this warranty. This

warranty does not apply if the Epson label or logo, or the rating label or serial number, has been removed

from your Epson product, or if, in the sole opinion of Epson, your Epson product has been damaged

by faulty or leaking batteries not supplied by Epson, or by accident, misuse, neglect, or improper

packing, shipping, modification or servicing by other than Epson or an authorized Epson Service Center

SOME EPSON PRODUCTS HAVE A COMPARTMENT CONTAINING STATIC-SENSITIVE ELECTRONIC

CIRCUITRY. THIS COMPARTMENT IS CLEARLY LABELED. DO NOT OPEN IT! THIS WARRANTY WILL

BECOME VOID IF YOU ATTEMPT TO ADD OR INSERT ANY ROM OR OTHER PART OR DEVICE. IF

ANY OF THESE STEPS IS REQUIRED, BRING YOUR EPSON PRODUCT TO AN AUTHORIZED

EPSON DEALER.

THE DURATION OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, ON YOUR EPSON PRODUCT SHALL BE LIMITED TO THE DURATlON

OF THE EXPRESS WARRANTY SET FORTH ABOVE. IN NO EVENT SHALL EPSON AMERICA, INC

OR ITS AFFILIATES BE LIABLE FOR ANY LOSS, INCONVENIENCE OR DAMAGE WHETHER DIRECT

INCIDENTAL, CONSEQUENTIAL OR OTHERWISE, AND WHETHER CAUSED BY NEGLIGENCE OF

OTHER FAULT RESULTING FROM BREACH OF ANY EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR OTHERWISE, WITH RESPECT TO

YOUR EPSON PRODUCT, EXCEPT AS SET FORTH HEREIN. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS AND SOME STATES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU.

OU

Y

whom your Epson product was purchased, or by contacting Epson America, Inc. at the address printed

below:

Epson America, inc.

Service Division

23610 Telo Avenue

Torrance, CA 90505

(213) 534-0360

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

79

Page 85

EPSON

EPSON AMERICA INC.

Loading...

Loading...