Page 1

MICROCOM CORPORATION

MODEL 410

DIRECT THERMAL PRINTER

OPERATOR'S MANUAL

(6dpmm version)

January 1995 Software Version 3.35

Page 2

Operator's Manual

410 Direct Thermal Printer

- Revised 01/13/95 MSG -

Centronics is a registered trademark of Data Computer Corp.

Epson is a registered trademark of Seiko Epson Corporation.

FX-86e is a trademark of Seiko Epson Corporation.

HP and LaserJet II are trademarks of Hewlett-Packard Company.

Other products, names, and brands are trademarks of their respective holders.

This manual is subject to change without notice.

Copyright © 1995, Microcom Corporation, Westerville, Ohio - All rights reserved.

Printed in the U.S.A.

Page 3

Table of Contents

List of Tables

List of Figures

Introduction

CHAPTER 1: FEATURES AND SPECIFICATIONS

1.1 SPECIAL FEATURES ..............................................3

1.2 BAR CODES

1.3 FONTS ..........................................................4

1.4 PRINTING

1.5 INTERFACE COMMUNICATIONS .....................................4

1.6 PHYSICAL

1.7 ENVIRONMENT ...................................................5

1.8 ELECTRICAL

1.9 OPTIONS ........................................................5

1.10 PRINTER VARIATIONS

1.11 APPROVALS .....................................................6

CHAPTER 2: BASIC OPERATION ................................................9

2.1 UNPACKING THE 410 PRINTER .....................................9

2.2 FRONT PANEL SWITCH AND STATUS LIGHTS

2.3 THE STATUS LIGHT ..............................................11

2.4 LOADING PAPER

2.5 CLEARING LABEL MISFEEDS: DIAPHRAGM REMOVAL .................13

2.6 CLEANING INSTRUCTIONS

................................................................

................................................................

...................................................................

...................................

.....................................................

........................................................

.......................................................

.....................................................

.............................................

.........................

2.2.1 NORMAL MODE ............................................9

2.2.2 BATCH MODE

2.2.3 STATUS LABEL MODE .......................................9

2.2.4 PAPER-OUT MODE

2.4.1 NORMAL AND TAG/TEAR MODES ............................12

2.4.2 PEEL-AND-DISPENSE MODE

..............................................

........................................

................................................

................................

........................................

10

12

13

14

vi

vi

1

3

4

4

5

5

6

9

9

CHAPTER 3: COMMUNICATIONS

3.1 CABLE PINOUT ..................................................15

3.2 PRINTER CABLES

CHAPTER 4: DESIGNING LABELS USING LDS

4.1 CONTROL CHARACTERS .........................................17

4.2 GETTING STARTED

4.2.1 PC CONNECTION (SERIAL) ..................................17

4.2.2 PC CONNECTION (PARALLEL)

4.2.3 LEARNING LDS ............................................19

4.3 FORMATTING LABELS: AN OVERVIEW

4.3 LABEL HEADER .................................................21

4.3.1 A SAMPLE SESSION WITH A LABEL HEADER ...................25

4.4 LABEL FIELDS

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual

...............................................

...............................................

....................................

..............................................

...................................................

...............................

..............................

15

16

17

17

18

19

26

Page 4

Table of Contents

))))))))))))))))))))))))))))))))))))))))))))

4.4.1 A SAMPLE SESSION WITH A LABEL FIELD .....................33

CHAPTER 5: PRINTER COMMANDS .............................................34

5.1 SPECIAL PRINTER CONTROL CODES

..............................

34

5.2 PRINTER ENQUIRIES .............................................35

5.3 SENDING ^D PRINTER COMMANDS

.................................

36

5.3.1 SOFTWARE DIP SWITCHES AND EEPROM COMMANDS .........37

5.3.2 PRINTING COMMANDS

......................................

42

5.3.3 AUTO-SIZING and VALID GAP COMMANDS .....................43

5.3.4 REAL-TIME CLOCK

........................................

45

5.3.5 SERIAL NUMBER COMMANDS ...............................47

5.3.6 LABEL HEADER COMMANDS

................................

49

5.3.7 SAVING FORMAT FILES COMMANDS ..........................50

5.3.8 LABEL PRESENCE SENSOR CONTROL

.......................

53

5.3.9 TEXT STRINGS COMMANDS .................................55

5.3.10 MISCELLANEOUS PRINTER COMMANDS

......................

57

CHAPTER 6: LOGOS

.........................................................

59

6.1 PROCEDURE FOR USING THE PCX2410 SOFTWARE .................60

6.2 FORMAT OF LOGO FILES

CHAPTER 7: SPECIAL DESIGNS

................................................

.........................................

62

64

7.1 DESIGNING WITH BAR CODES .....................................64

7.1.1 HUMAN READABLES .......................................64

7.2 MAKING LINES

...................................................

67

7.3 REVERSE VIDEO ................................................68

CHAPTER 8: OPTIONS ........................................................69

8.1 LABEL SUPPORT RACK

..........................................

69

8.2 LARGE PAPER ROLL SUPPLY HOLDER .............................69

8.3 CLOCK/BATTERY BACKED RAM SOCKET

...........................

69

8.4 PCX2410 SOFTWARE ............................................69

8.5 WYSIWYG SOFTWARE PACKAGES

................................

70

8.6 PARALLEL CONVERSION BOARDS .................................70

8.7 CLEANING KIT

APPENDIX A: WARRANTY AND REPAIR PROCEDURES

APPENDIX B: CLEANING KIT & ACCESSORIES

..................................................

............................

...................................

70

71

73

APPENDIX C: CONFIGURATION GUIDE

..........................................

BATTERY BACKED RAM WITH REAL-TIME CLOCK ..........................74

ADDITION FORMAT AREA

...............................................

Graphic Images ........................................................74

APPENDIX D: INSTALLING THE LABEL SUPPORT RACK ...........................75

APPENDIX E: MORE LABEL SAMPLES ...........................................76

DEFAULT POWER-UP LABEL ............................................76

FONTS 410

))))))))))))))))))))))))))))))))))))))))))))

...........................................................

410 Operators Manual

74

74

77

Page 5

))))))))))))))))))))))))))))))))))))))))))))

Table of Contents

AIAG LABEL

APPENDIX F: SAMPLE BASIC PROGRAM

...........................................................

........................................

APPENDIX G: QUICK REFERENCE COMMAND SUMMARY

.......................................................................

Index

..........................

84

86

88

96

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual

Page 6

List of Tables

Status Light

Serial Port Configuration .......................................................15

Parallel Port Configuration

Print Speed ..................................................................23

Fonts

Bar code Symbologies .........................................................29

Graphic Images

Character Starting Positions ....................................................31

Enquiry Responses

Clock Field Parameters ........................................................45

.................................................................

......................................................

......................................................................

..............................................................

...........................................................

11

16

28

29

36

List of Figures

Front View

Rear View ....................................................................7

Status Label

Printer Feed Mechanism .......................................................12

Microcom Label

Label Header Parameters of a 4" X 3" Label ........................................21

Clock Option .................................................................46

European Date Format

U.S. Date Format .............................................................46

Time Format

Graphic Image in Four Rotations .................................................60

Two Graphic Images in Two Rotations

Bar Code Rotations ...........................................................64

Bar code Human Readables

Thick Lines ..................................................................67

Reverse Video

...................................................................

.................................................................

..............................................................

........................................................

.................................................................

............................................

....................................................

...............................................................

10

20

46

46

61

65

68

7

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual

Page 7

Introduction

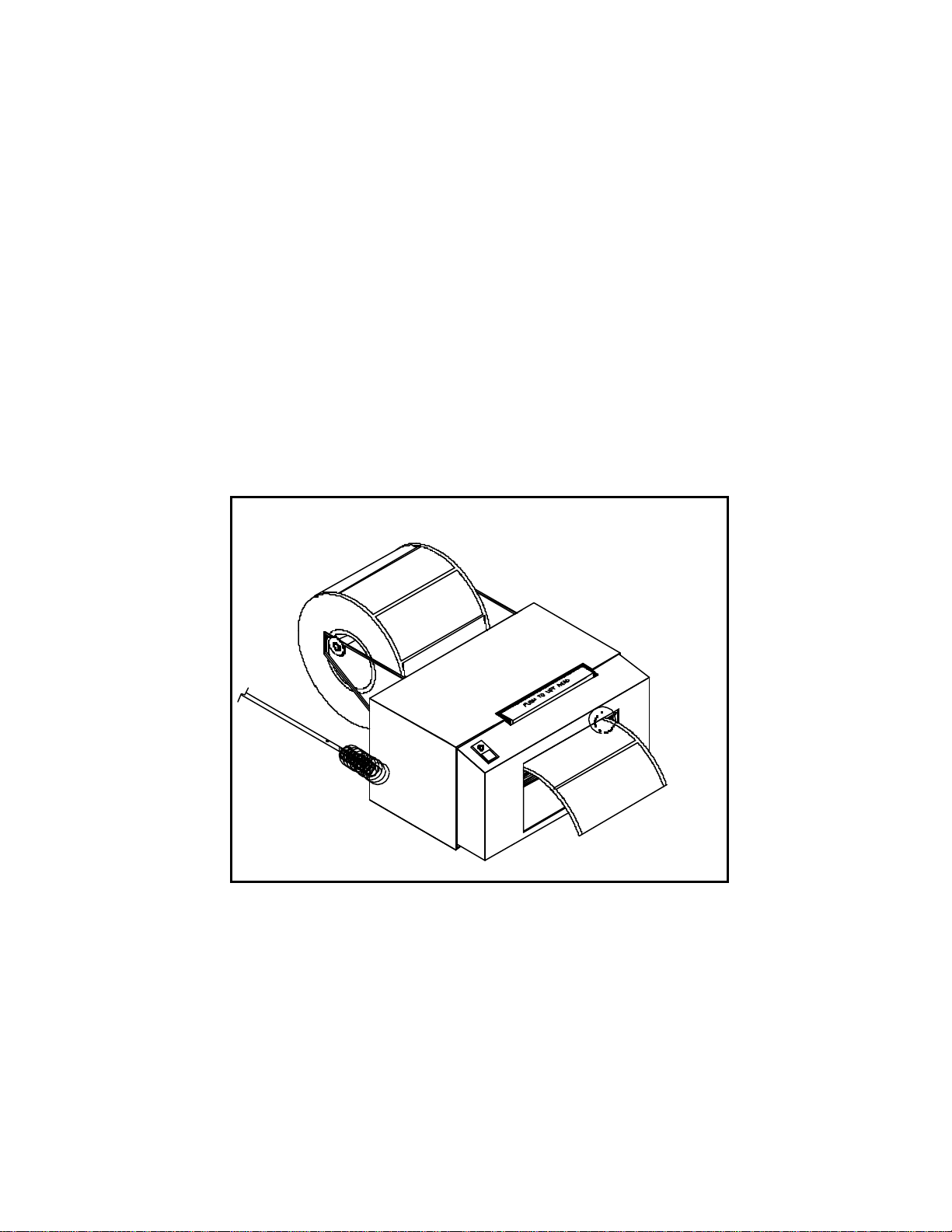

The Microcom Corporation model 410 (6 dots/mm version) is a direct thermal label printer with a

640 element, 4.16 inch wide print head. The economic size and price have no effect on the

printer's ability to handle a wide variety of labeling tasks - even the most demanding applications.

The resident Label Design Software (LDS) is a powerful and easy to use package that allows

the user to create personalized label formats. It can be driven from a PC, mini-computer,

mainframe and most special purpose computers.

Among many other features, LDS supports graphics functions and multiple serial numbering. It

offers 18 different text fonts in four rotations and all popular bar code symbologies. Graphic

images can also be loaded into the printer's memory. Fonts, bar codes and graphic images can

be multiplied in size to offer great flexibility in custom designing labels. Once the labels are

designed, they can be stored in printer memory for high speed access.

The 410 is capable of printing on most types of label stock or fax paper. It offers operation in a

tag/tear, peel-and-dispense, batch mode, and user-defined advance mode. It can handle blowhole, black-line, label gap and continuous stock.

Many thermal printer applications use the same label format, but change the data on every label.

This is not a problem for the Microcom Corporation model 410 printer. Data may be changed

without down-loading the same fixed format, or fixed data fields, time after time. This increases

data access time and productivity.

Various options are available for the Model 410 printer. Label creation software packages are

offered with database capabilities including quick and easy on-screen label design, custom

fonts, bar codes and graphics.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual

Page 8

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual2

Page 9

CHAPTER 1: FEATURES AND SPECIFICATIONS

The Microcom Corporation model 410 direct thermal printer is designed with many standard

features that are unique when compared to other printers. The 410 is built to meet the demands

of complicated applications and rigorous use. A guarantee of excellence in engineering is

provided by fulfilling the requirements for approval by UL, CSA and the FCC.

1.1 SPECIAL FEATURES

! Operates as tag or ticket feed

! Resolution of 6 dots/mm (.0065" per dot) and a print width of 640 dots (4.16")

! Print length is virtually unlimited

! WYSIWYG software compatible

! Print speeds up to 3.0"/sec (2"/sec for large supply roll, narrow stock or peel mode)

! Media supply rack allows roll size up to 5 inches OD (8 inch optional)

! Prints on die-cut, continuous, fax, or preprinted label stock

! Prints on tag stock up to 9.0 mil thickness (factory adjustment required)

! Software-controlled contrast adjustment

! Standard memory of 128K bytes ROM, 32K bytes RAM

! Easy to load label path with liner for easy misfeed removal

! Adjustable guides for easy label centering

! Preheated head for improved print quality and life

! Detects label gap, black line, or blow-hole stock

! Internal statistical counter for inches and labels printed

! Automatic label sizing on power up

! Logo/graphics capability in four rotations (with optional RAM)

! Incrementing and decrementing fields

! Machine state enquiries for security and maintenance

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 3

Page 10

Features and Specifications Chapter 1

))))))))))))))))))))))))))))))))))))))))))))

1.2 BAR CODES

! Code 39, Interleaved 2 of 5, CODABAR, Code 128, Code 93, Plessey, Modified Plessey,

UPC-A, UPC-E, EAN-8, EAN-13

! Selectable ratios for producing HIBC, AIAG, LOGMARS, and Bookland

1.3 FONTS

! 18 resident font styles, including OCR-A

! All fonts expandable in height and width up to 255 times

! Rotated fonts and bar codes: 0, 90, 180, and 270 degrees

1.4 PRINTING

! Peel function strips label off of backing

! Tag/tear mode advances label to the tear bar

! Batch mode printing

! User defined label advancement for special stock or application

! Label-presence sensor allows printer to dispense at operator's pace

! Label back-up to prevent wasted media in tag/tear and peel modes

1.5 INTERFACE COMMUNICATIONS

! Serial: RS-232C, 9 pin female D-Sub connector (DCE)

-Flow control: XON/XOFF, CTS

-Baud rate: 110 to 19200, user-selectable

-Parity: odd, even or none

-Data bits: 7 or 8

! Parallel: 25 pin female (optional)

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual4

Page 11

Chapter 1 Features and Specifications

))))))))))))))))))))))))))))))))))))))))))))

1.6 PHYSICAL

! Construction: Rigid painted steel construction

! Height: 5" (127mm)

! Width: 8.5" (216mm)

! Depth: 10.5" (267mm)

! Weight: 12 LBS (5.44 Kg)

1.7 ENVIRONMENT

! Temperature: 0" C to 40" C operating

! Humidity: 10-85% non-condensing

1.8 ELECTRICAL

! Voltage: 117 VAC nom.,60Hz

! Current: 3 AMPS maximum

1.9 OPTIONS

! Cleaning kit

! Assorted printer cables

! On-screen label design PC software packages

! Expandable memory: 128K bytes ROM, 64K bytes RAM or 256K bytes ROM, 32K bytes

RAM

! Media supply rack of 8 inch outer diameter (no charge option)

! Real-time clock that battery-backs RAM

! PCX to printer graphic conversion PC software

! Parallel interface

! On-demand label support rack

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 5

Page 12

Features and Specifications Chapter 1

))))))))))))))))))))))))))))))))))))))))))))

1.10 PRINTER VARIATIONS

! 230V European power supply

! Battery powered model (405)

1.11 APPROVALS

! UL, CSA, Complies with FCC, Class A

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual6

Page 13

Chapter 1 Features and Specifications

))))))))))))))))))))))))))))))))))))))))))))

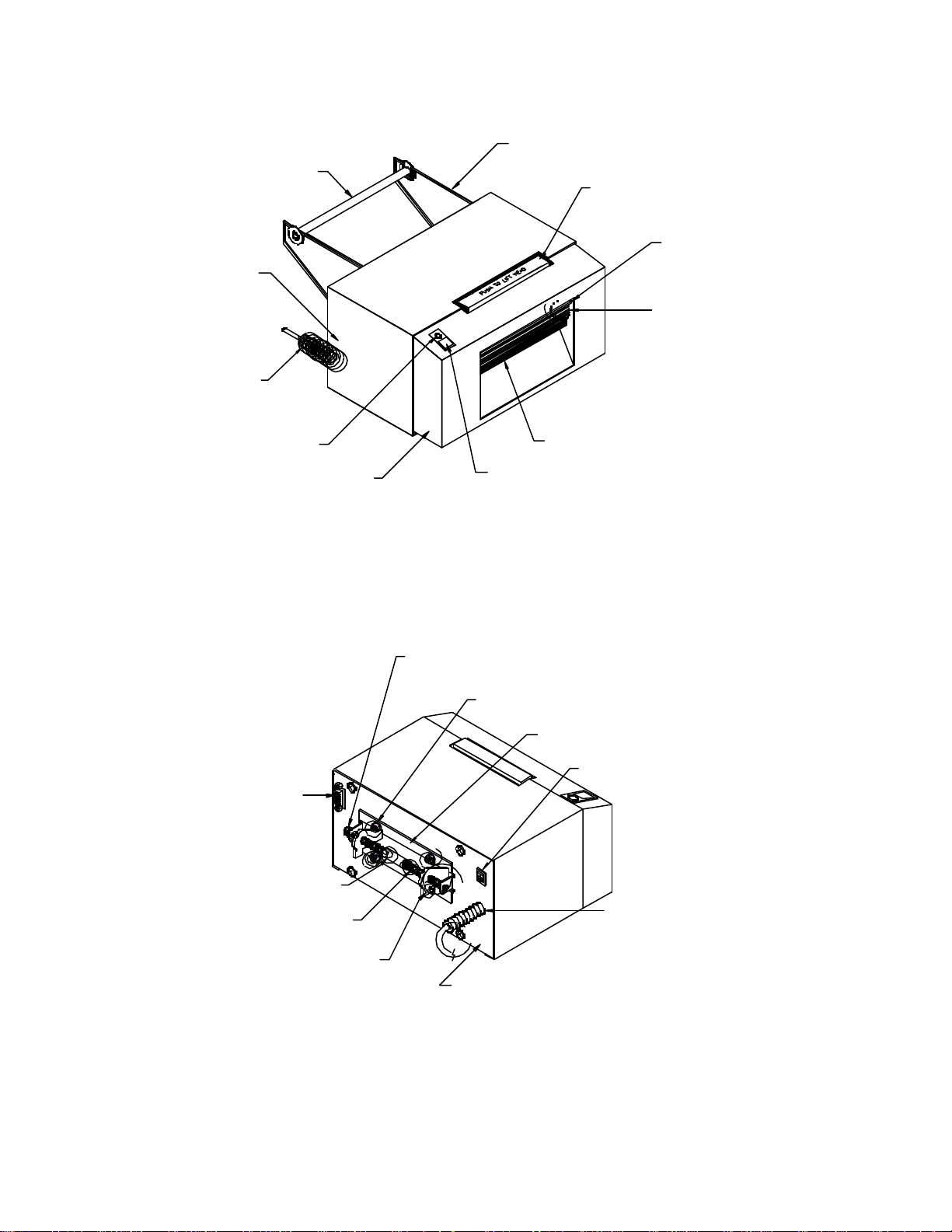

LABEL SUPPORT RACKS

LABEL SUPPLY SHAFT

PUSH TO LIFT HEAD LEVER

PEEL EDGE

TOP COVER

DRIVE ROLLER

POWER CORD

FRONT PANEL LED

SERIAL PORT

LINE GUIDE IDLER

LINE GUIDE SHAFT

FRONT PANEL

PINCH ROLLER

LABEL FEED AND LINE FEED BUTTON

Front View

Figure 1

LINE GUIDE ADJUSTMENT KNOB

THUMB NUTS

LABEL DIAPHRAGMS

POWER SWITCH

POWER CORD

PAPER LINE GUIDES

REAR PANEL

Rear View

Figure 2

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 7

Page 14

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual8

Page 15

CHAPTER 2: BASIC OPERATION

2.1 UNPACKING THE 410 PRINTER

While unpacking the printer, please check all packing materials closely to avoid misplacing any

necessary parts. After the printer is removed from the box, verify that all parts are present and in

good condition (see Figure 3). All packaging material should be kept and used if the printer is to

be shipped. The printer must be returned in the original container to insure proper warranty

coverage.

2.2 FRONT PANEL SWITCH AND STATUS LIGHTS

The front panel switch performs several different functions depending on the printer mode:

2.2.1 NORMAL MODE

The front panel switch (see figure 1) acts as both a paper feed button and a label request button.

If the button is pressed and then released within a half second, the unit will print a label using the

current label format. If the button is held for more than the half second, the unit will start to feed

paper until the button is released.

2.2.2 BATCH MODE

If the printer is in the process of printing a predetermined quantity of labels (see ^D73, section

5.3), pressing the button after the printer has started to print these labels will cause the unit to

pause. Pressing the button again will allow the printer to continue the batch.

2.2.3 STATUS LABEL MODE

When status label mode is accessed, the printer creates a status label and temporarily defaults

all serial communication settings.

To print a status label, hold the button while turning on the printer until the status light turns

orange. Release the button and a test pattern with statistical information will be printed (see

figure 3). When a status label is created, the communication settings will be temporarily set to

9600 baud rate, no parity, 8 data bits, and 1 stop bit. The printer will return to the old settings, if

different, after power down or a soft reset.

The printed labels and total labels represent the number of labels printed to date. The printed

labels and printed inches fields are user resetable while the total labels and total inches are not.

Printed inches and printed labels are reset using the ^D29 command (see section 5.3). Other

useful information on the power-up label is the unit serial number, the non-resetable power-on

hours, the previous serial parameters (not the default parameters caused by executing creating

a status label), and the revision number of the Label Design Software (LDS).

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 9

Page 16

Basic Operation Chapter 2

))))))))))))))))))))))))))))))))))))))))))))

The switch bank settings reflect the contents of the four software dip switches that configure the

operation of the printer. See section 5.3, specifically ^D21, ^D22, ^D23 and ^D24, for more

information on software dip switch settings.

PRINTER SERIAL #: 0-1083

PRINTED LABELS: 3097

TOTAL LABELS: 4937

PRINTED INCHES: 7150

TOTAL INCHES: 11885

POWER ON HOURS: 353

SWITCH BANK 1: 10001011

SWITCH BANK 2: 01010001

SWITCH BANK 3: 00000000

SWITCH BANK 4: 00000000

SERIAL PARAMETERS: 9600-N-8-1

LDS 410 REV 3.0 8/02/91

Status Label

Figure 3

2.2.4 PAPER-OUT MODE

After a paper-out condition, the front panel switch serves to load and realign the new label stock.

When a paper out condition occurs, the indicator light will turn red. Pressing the button and

holding it will cause the status light to go from red to yellow and feed paper. The status light will

then flash yellow until the button is pressed for a label request. It will then turn yellow and the

printer will print a duplicate of the last label printed and return to the blinking mode. This feature

was designed to facilitate batches with serial numbers or other variable data. This process can

be repeated as often as necessary to allow the paper to align itself. To return to the pre-paper

out condition, tap the button while the duplicate label is being printed. The status light will turn

green and normal printing may resume.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual10

Page 17

Chapter 2 Basic Operation

))))))))))))))))))))))))))))))))))))))))))))

2.3 THE STATUS LIGHT

The status light has different functions depending upon the mode of the printer. Table 1 shows

the relationship between the status light and the different modes.

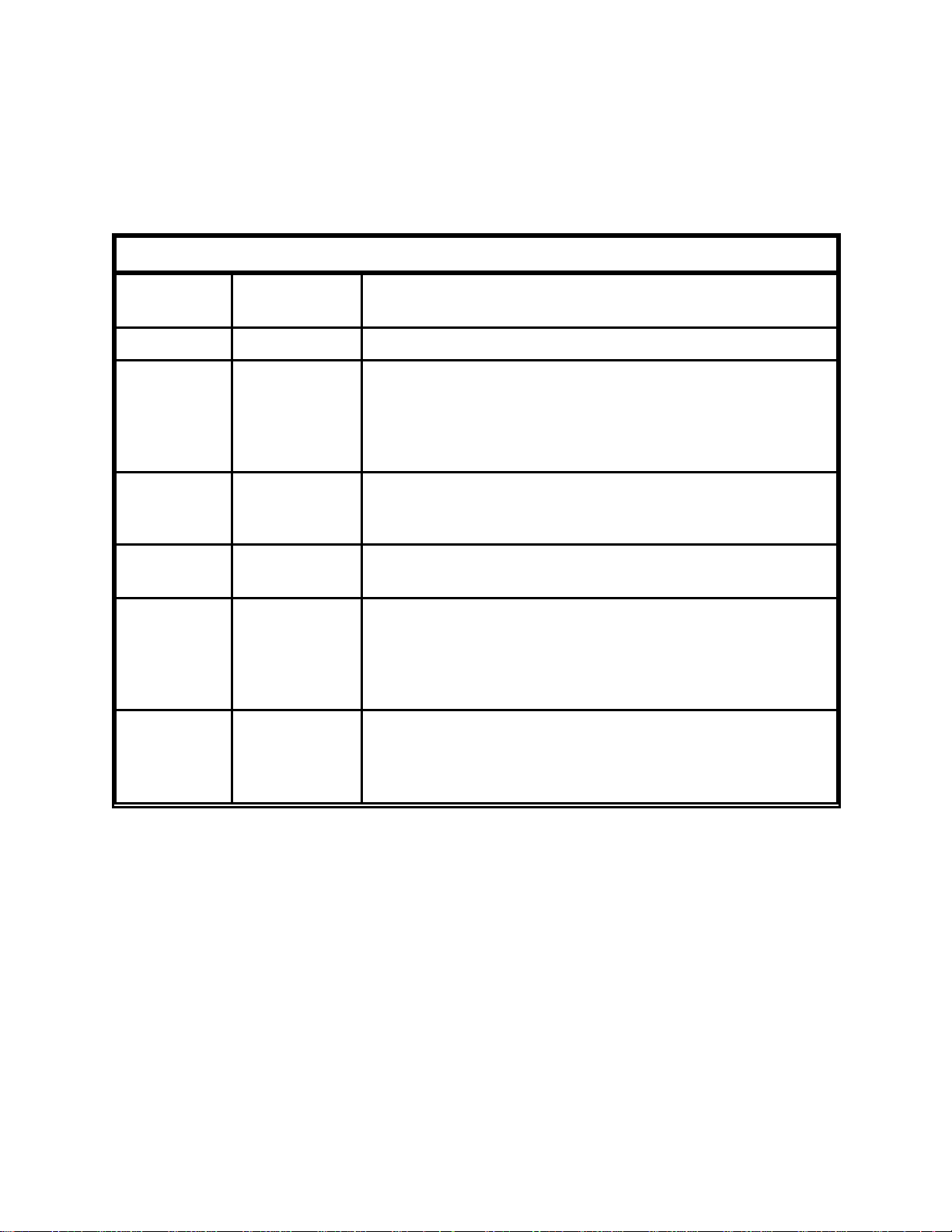

Status Light

Light

Mode Meaning

Color

Green All On-Line and ready to print

Red All Printer error:

Caused by a paper-out condition or a hardware failure. If

paper is out, follow instructions in section 2.3, otherwise

turn printer off and back on. If condition persists, contact

your service representative.

Flashing

Red

All Spike or low voltage on the AC line. The unit will remain in

this mode until the condition is removed and the printer is

powered off.

Yellow Tag/tear, Peel Label present. Label is ready to be removed from the printer

mouth

Flashing

Yellow

All Printer is paused or in standby mode and is waiting for the

front panel button to be pressed. If the paper was just

changed and the reprinted label look good, press the button

during the next print cycle to clear the repeat function and

flashing yellow light.

Flashing

Yellow and

Red

All A serial port buffer overflow has occurred. Check the host

flow control for problems. (Note: the serial buffer will only

accept 9 characters after the printer drops the clear to send

signal or optionally sends the XOFF character.)

Table 1

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 11

Page 18

Basic Operation Chapter 2

))))))))))))))))))))))))))))))))))))))))))))

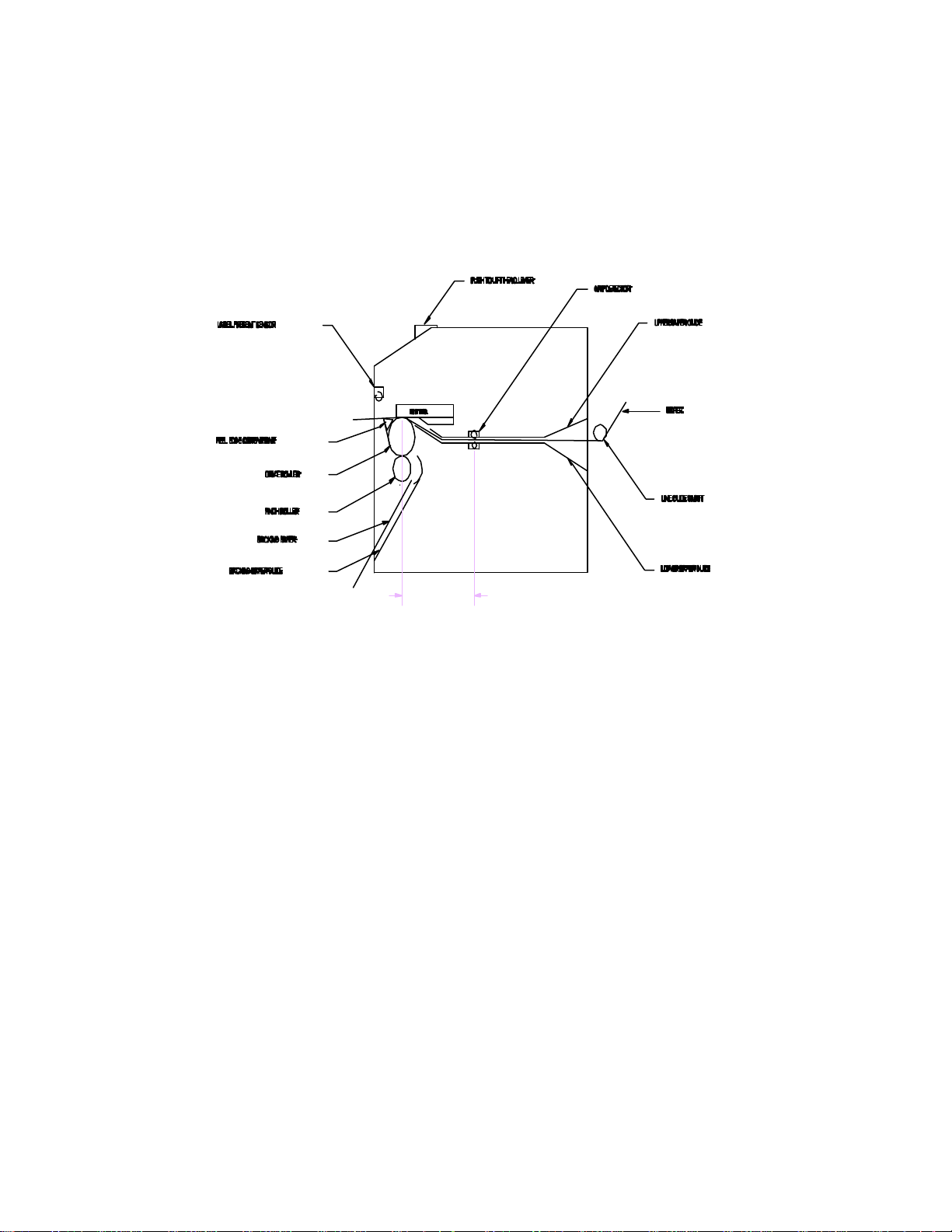

2.4 LOADING PAPER

The following two sections explain the dispensing modes. Refer to figures 1, 2 and 4 for the

printer components.

Printer Feed Mechanism

Figure 4

2.4.1 NORMAL AND TAG/TEAR MODES

Unwind about two feet of stock from the paper supply roll of paper. Set the roll behind the printer

on the table. Remove the label supply shaft. Insert the paper with the thermally sensitive side up,

under the rear threaded paper guide shaft, and into the printer until the paper stops. Turn the

paper guide adjust knob at the rear of the printer until the paper guides are slightly wider than the

label stock. Continue to apply pressure on the paper with your left hand. With your right hand

apply slight pressure to the printhead lift lever with your little finger. Press and hold the front

panel button with your pointing finger until the paper has advanced to a point past the printhead

and release the pressure of your little finger from the lift lever. To align the paper, press down on

the head lift lever and move the paper until the desired alignment is reached. Replace the label

supply roll shaft and stock onto the wire rack.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual12

Page 19

Chapter 2 Basic Operation

))))))))))))))))))))))))))))))))))))))))))))

2.4.2 PEEL-AND-DISPENSE MODE

1. Follow the paper loading in the normal and tag mode directions.

2. Remove enough labels to expose about two feet of backing paper.

3. Insert the stock into the printer and allow about three inches to protrude out of the

front.

4. Make sure the leading edge of the backing paper is square and straight. (Tear at

perforation or cut if necessary)

5. Insert the leading edge of the backing paper between the black drive roller and the

white pinch roller, making sure it is positioned evenly between the rollers.

6. Press and hold the print button and feed the backing paper completely through

the rollers until about three inches protrude out of the printer.

7. Firmly push the head lift lever and press the feed button until most of the slack is

taken out, then release the lift lever.

8. Continue feeding paper until labels are reached. To avoid a paper jam, remove

the labels as they start to peel.

9. Enable the peel-and-dispense mode using the ^A1^D98<CR> command

described in this manual.

*If the label height is over 2", a label support rack should be used. This rack will

support the peeled label until it is removed.

2.5 CLEARING LABEL MISFEEDS: DIAPHRAGM REMOVAL

The purpose of the label diaphragm is to provide a smooth path for labels through the printer and

provide an easy means of removing label misfeeds. If a label misfeed occurs, remove the supply

roll shaft at rear of printer. Remove the four black thumb nuts which hold the diaphragm sheets

in place. Gently slip the sheets off the threaded studs. Once the sheets are removed, clean all

foreign matter and any adhesive gum. To replace the sheets repeat this process in reverse.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 13

Page 20

Basic Operation Chapter 2

))))))))))))))))))))))))))))))))))))))))))))

2.6 CLEANING INSTRUCTIONS

The printer and printhead should be cleaned approximately every 5,000 labels or every two

weeks whichever occurs first. The printer should also be cleaned whenever a label roll is

changed. A Microcom Corporation cleaning kit should be used for cleaning and maintaining the

model 410 printer. It is important to note that the optimum printhead life is achieved by

maintaining a clean printer and printhead.

To clean the printer:

1) Turn the printer off.

2) Lift the printhead using the "PUSH TO LIFT HEAD" lever and remove any label stock that

remains inside the head mechanism.

3) Using the cleaning brush, sweep away all small label and adhesive particles that may be

in the area of the printhead.

4) Moisten a cleaning swab with the cleaning solution and wipe away any adhesive from the

rollers or the aluminum peel bar.

5) Dampen a swab with cleaning solution and lift the print head by pushing the lever in the

direction of the arrows. Take the moistened swab and gently wipe the underside of the

printhead. Repeat if necessary (if swab is extremely dirty).

6) Moisten the felt side of a cleaning card with the cleaning solution. Insert card with felt side

facing up into the rear of the printer as you would insert label stock. Hold down on the

print button to feed the card through the printer (see section 2.3). Do not lift the print head

for this operation. Allow the printhead to ride on the cleaning card. Repeat the process if

needed. The cleaning card may be used once at each end.

7) Remove the label diaphragm (see section 2.4).

WARNING: DO NOT TOUCH THE PRINTHEAD WITH ANY METAL OR SHARP OBJECTS

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual14

Page 21

CHAPTER 3: COMMUNICATIONS

The printer may be connected to PC's, mini-computers, main frames, and many other special

purpose machines. The following sections explain the communication interfaces.

3.1 CABLE PINOUT

Table 2 shows the signals of the 410's 9-pin RS-232 serial port. Out of the box, unless

otherwise requested, the printer communicates serially at 9600 baud, 8 data bits, 1 stop bit and

no parity with both hardware and software handshaking. This configuration may be changed

through software commands as explained in the programming section of this manual. Table 3

shows the optional parallel port configuration.

If XON/XOFF hand shaking is used, the only signals the 410 requires are RXD, TXD, and GND. If

hardware (CTS) hand shaking is used, a CTS signal is provided. XON/XOFF may be disabled

through the software dip switch #1 (see chapter 5). The other signals are offered in the event the

host computer requires them.

Serial Port Configuration

25 TO 9 PIN 9 TO 9 PIN

State 412 Direction PC

HI 1 DCD---->---- DCD 8

XX 2 TXD---->---- RXD 3

XX 3 RXD----<---- TXD 2

HI 4 DSR----<---- DTR 20

LO 5 GND---<->--- GND 7

HI 6 DTR---->---- DSR 6

DC 7 CTS----<---- RTS 4

XX 8 RTS---->---- CTS 5

HI 9 +5V

DE-9 DB-25

DC = Do Not Care

XX = Indeterminate

State 412 Direction PC

XX 1 DCD---->---- DCD 1

XX 2 TXD---->---- RXD 2

XX 3 RXD----<---- TXD 3

HI 4 DSR----<---- DTR 4

LO 5 GND---<->--- GND 5

HI 6 DTR---->---- DSR 6

DC 7 CTS----<---- RTS 7

XX 8 RTS---->---- CTS 8

HI 9 +5V---->---- +5V 9

DE-9 DE-9

DC = Do Not Care

XX = Indeterminate

Table 2

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 15

Page 22

Communications Chapter 3

))))))))))))))))))))))))))))))))))))))))))))

Parallel Port Configuration

1 = /STROBE

2 = D0

3 = D1

4 = D2

5 = D3

6 = D4

7 = D5

8 = D6

9 = D7

10 = /ACK

11 = BUSY

12 = PAPER OUT

13 = SLCT

14 = NC

15 = /ERROR

16 = /INIT

17 = NC

18-25 = GROUND

(25 PIN FEMALE)

Table 3

3.2 PRINTER CABLES

Warning: Connection of a serial printer to a parallel port may result in damage to the printer

and/or computer. Connection of a parallel printer to a serial port may result in damage to the

printer and/or computer.

The printer cables needed are standard and available through Microcom Corporation. You will

not need a NULL-modem cable because the printer is DCE equipment.

For parallel connection, use a straight 25 pin male to 25 pin male cable, connected from the

desired parallel port of the host computer to the 25 pin connector on the optional parallel board.

For serial connection, if your host computer has a...

25 pin serial com port - Use a standard 25 pin male to 9 pin male serial cable.

9 pin serial com port - Use a 9 pin female to 9 pin male video extension cable.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual16

Page 23

CHAPTER 4: DESIGNING LABELS USING LDS

Label Design Software (LDS) refers to the firmware language resident in the printer that is used

to process information sent by the host computer. All fonts, character sets and bar codes

symbologies are resident in the printer.

A label format is produced by a series of 5 steps:

1: Control commands to define printer operation

2: A header to define label height, width, print speed, etc..

3: Field data to define placement of text, bar code, graphic or line

4: Actual text data to place in the above text or bar code fields

5: Control commands to initiate printing

4.1 CONTROL CHARACTERS

Throughout this manual there are references to control characters. In order to print them in this

manual, they have been written using standard characters and icons. Escape characters are

represented by <ESC> and a carriage return is represented by the 5 symbol. It is important to

note that all printer functions, unless otherwise noted, must be followed with a carriage return5.

4.2 GETTING STARTED

There are many different machines that can send information to the printer: For example - main

frames, mini-computers, special purpose computers and PC's. However, if you are using the

printer for the first time, the easiest way to start is with a PC and terminal emulation software.

This will allow two-way, serial communication with the printer. You will be able to quickly upload

files and access label sizing and other features that will help considerably in formatting your first

labels.

4.2.1 PC CONNECTION (SERIAL)

Items required:

- A computer with at least one unused serial communications port. (COM1,COM2...)

- A serial interface cable. (See section 3.2 for cable information)

- A terminal emulation program.

Note: This communications test assumes that you have a standard serial printer.

Set the communication parameters in the PC terminal software program to 9600 baud, no parity,

8 data bits and 1 stop bit. Unless modified by the user, this is the printers' communication

configuration out of the box. Depress ^C (ASCII or control code) on the PC keyboard. If the

printer prints a label, proper PC to printer communications have been confirmed. Depress ^E to

verify printer to PC communication. You will receive a text response from the printer.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 17

Page 24

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

If a terminal program is not available, it is possible to send files to the printer using the DOS

COPY command. To do this you must first create a text file containing the information to be sent

(i.e. ^C ). You may use any text editor that does not add its own formatting characters).

Use the following DOS MODE command to set up the appropriate PC port.

Note: COM1 may be any available communications port on your PC.

C:>MODE COM1:9600,N,8,1,P

You must then send the file to the printer using the following DOS command.

C:>COPY FILENAME COM1

4.2.2 PC CONNECTION (PARALLEL)

Items required:

- A computer with at least one unused parallel communications port. (LPT1,LPT2...)

- A parallel interface cable. (See section 3.2 for cable information)

Create a text file containing the information to be sent. (^C is the print command.)

^C

You may use any text editor that does not add its own formatting characters. Send the file to the

printer using the following DOS command. Note: LPT1 may be any available printer port on your

PC.

C:>COPY FILENAME LPT1

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual18

Page 25

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

4.2.3 LEARNING LDS

You can test some of the control code functions (see section 5.1) directly through the keyboard.

Large label files, such as some of those illustrated in Appendix B, may be entered in a straight

ASCII text word editor and then up-loaded to the printer using a terminal emulation program or

the DOS copy command. (To use the DOS copy command, first use the DOS mode instruction

to configure the PC. For example, MODE COM1:9600,N,8,1,P).

There are some special features offered by the printer that will aid label design. For example, the

auto-size command (^A2^D395) will provide most of the header format information needed to

define the different properties of label stock. The state of the machine is accessed through the

enquiry command (^D55 or ^E). The statistical printer information is made available through the

^A0^D295 command.

The following sections of this chapter are designed to give an overview of a label format, define

the label header, and list the different types of field information available. Chapter 5 explains the

special functions of the control codes. Once some understanding of these basic concepts are

achieved, use the quick reference guide in Appendix D for expedient label design.

4.3 FORMATTING LABELS: AN OVERVIEW

A label format consists of a header record and field records, followed by the text data to be

printed. The records describe how the label is to be printed. The header contains information

about the label itself such as label height, width, print speed, etc. The field records refer to the

data section and contain information about positioning coordinates, the type of character

generators or bar codes to use, etc.. Below is a sample label format. We will refer to this format

as we break down the components of its structure.

(See figure 5)

^D57<CR>

4,615,153,,20,30,,70,4<CR>

1,100, 40, 4, 1,4<CR>

2,100, 60,17, 1,4<CR>

3,100,100, 5, 1,6<CR>

3,100,150, 5,16,2,,,,30<CR>

^D56<CR>

^D2<CR>

EASY<CR>

MICROCOM MAKES IT<CR>

HELLO<CR>

^D3<CR>

A format is coming

Header information

Field #1 information

Field #2 information

Field #3 information

Field #4 information

Select RAM Format

Text Data is Coming

Text String #1

Text String #2

Text String #3

Print

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 19

Page 26

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

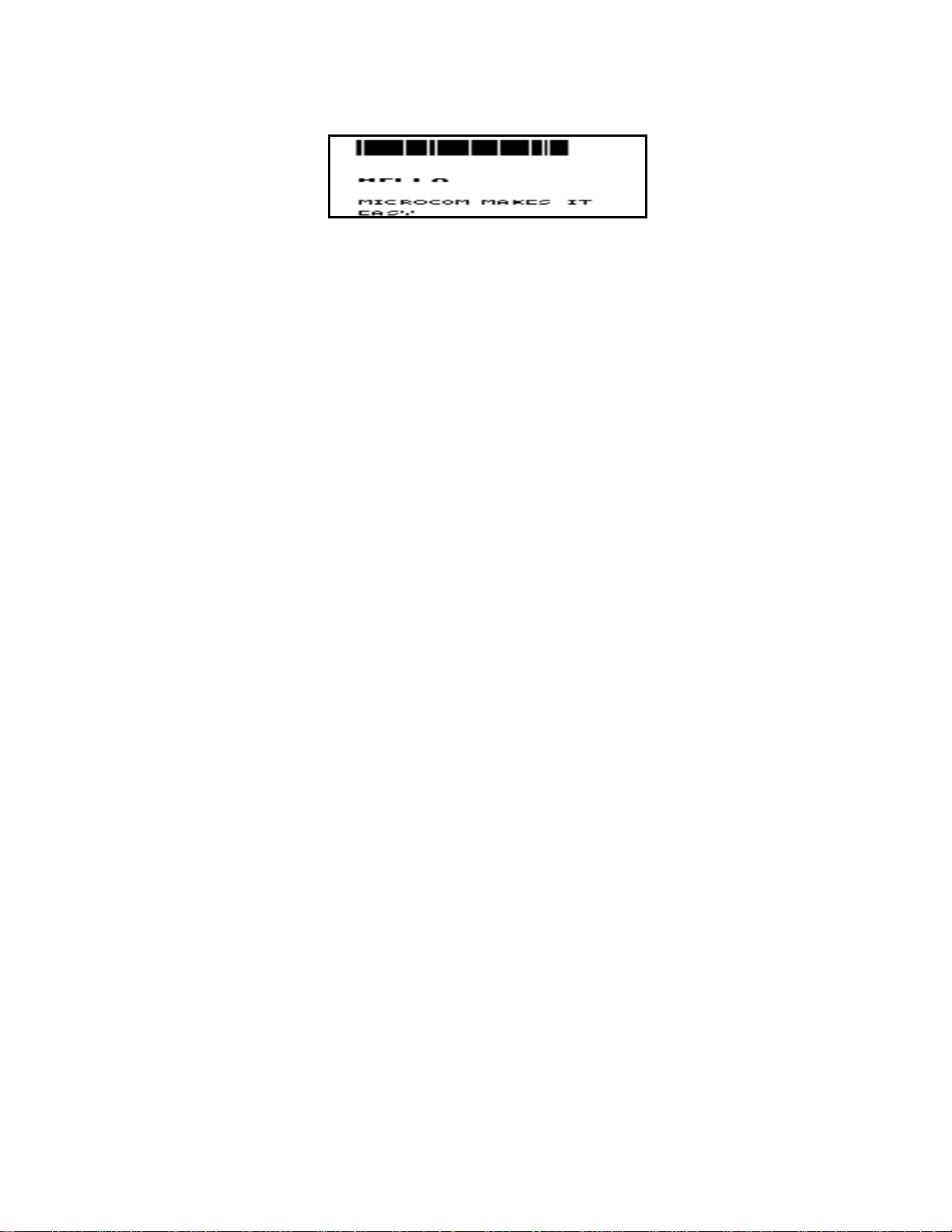

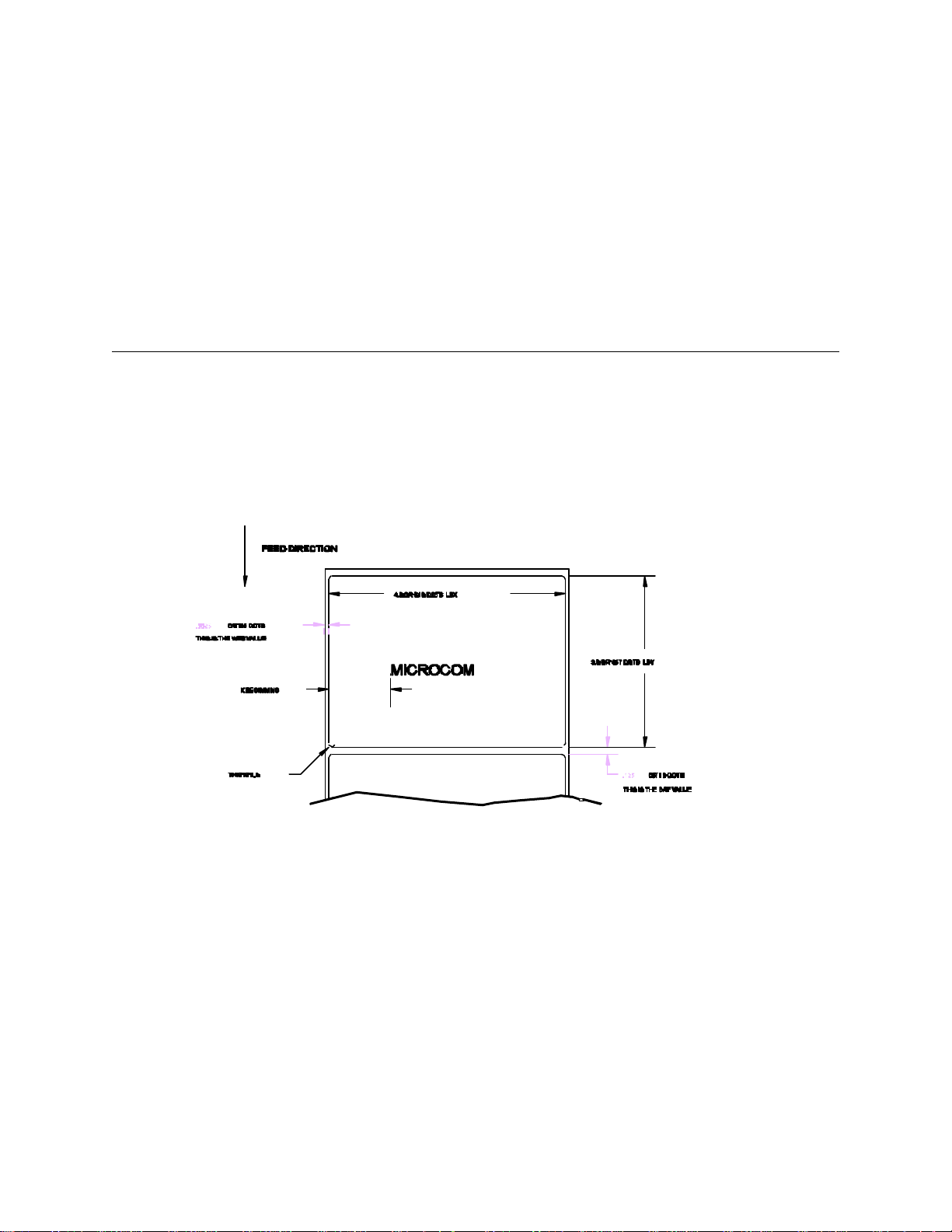

Microcom Label

Figure 5

The sequence ^D57<CR> puts the printer in format entry mode.

The next line is the header information: sizing the label (615 dots wide 153 dots high).

The next four lines are layout information for each printable text string.

The sequence ^D56<CR> selects the user layout.

The sequence ^D2<CR> tells the printer to start accepting text data for each defined field.

The next three lines contain the text for each field. The first string will be TSN# 1, the second will be

TSN#2 and so on.

Text string #3 is accessed twice. The format will print the word 'easy' and then the barcode

equivalent.

The sequence ^D3<CR> starts the print cycle (unless otherwise defined, it will print one copy).

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual20

Page 27

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

4.3 LABEL HEADER

The header is broken down into eleven different parameters. These parameters contain information

about the label. It is not necessary to enter information for all of the parameters: If a parameter is

left blank, then the default value will be used. A carriage return must follow the label header.

The value of measurement for many of the header elements is the dot. There are 154 dots per inch

across the print head (6 dots/mm). There is a maximum 640 dots in the X direction (width). Y

direction (length) is virtually unlimited.

Most of the header parameters can be supplied by auto-sizing the label stock (^D39 section 5.3.3).

Below is a list of the header element mnemonics and their default values:

HFM, LSX, LSY, WEB, GAP, DPS, LCB, AGD, SPG, OFX, OFY

0, 640, 443, 10, 10, 35, 0, 1, 352, 0, 0

Label Header Parameters of a 4" X 3" Label

Figure 6

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 21

Page 28

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

Refer to Figure 6 for a visual representation of most header parameters.

The following is a description of each header element:

HFM NUMBER OF FIELDS IN LAYOUT

This parameter is used to specify the number of fields in the layout. If more fields are defined

than what is specified for HFM, the extras will be ignored. To prevent software confusion, do

not set the HFM parameter to a number higher than the number of fields defined.

LSX LABEL SIZE X DIRECTION

Specifies the width of the label in dots. For example: A 3" wide label would have an LSX of

3 x 154 = 462 dots. (154 dots = 1 inch)

LSY LABEL SIZE Y DIRECTION

Specifies the height of the label in dots.

WEB WEB SIZE

The width, measured in dots, of the webbing that is found on the left side of the label.

GAP GAP SIZE

The height, measured in dots, of the gap between labels. Auto-sizing (See section 5.3.3) will

define this value.

DPS PRINT SPEED

The speed the printer actually prints a label. The printer will slow down in a dense area of

the label, if needed, to prevent the label from being garbled. If the printer must slow down in

an area, reducing the print speed will produce a better quality label.

The labels per minute a particular format will print can be calculated by the equation below:

IPS x 60 seconds

Labels per Minute = --------------- Label Height+Gap

The printer's default print speed is 2.1 inches per second (DSP value =34). To speed it up

or slow it down, the following DPS parameters can be inserted into the label header. Please

note that certain conditions such as large supply rolls, narrow label stock and tag/peel mode

may require slower print speeds (about 2"/sec.) in order to acheive reliable label feed.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual22

Page 29

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

See Table 3 for a list of print speeds, DPS values, and inches per second.higher value

slows the printer down and a smaller value speeds it up.

Print Speed

DPS MM/SEC INCHES PER

SECOND

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

76.8

74.2

71.7

69.1

66.6

64.0

61.4

58.9

56.3

53.8

51.2

48.6

46.1

43.5

41.0

38.4

3.0

2.9

2.8

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2.0

1.9

1.8

1.7

1.6

1.5

Table 4

INCHES PER

MINUTE

180

174

168

162

156

150

144

138

132

126

120

114

108

102

96

90

LCB LABEL CONTROL BYTE

The label control number defines the type of label stock that is used.

Continuous Stock: If set to a value of 2, the printer will not activate the gap detector

circuit. After all fields are printed, the printer will advance the extra distance in the SPG

header element.

Normal Stock (leading edge): If defaulted (value of 0), the printer will detect the trailing

edge of the label (the beginning of the gap).

Black Line Stock: If set to a value of 1, the printer will detect the leading edge of a black

line.

Blow Hole Stock (Slot-Cut): Use the default value (0) and set software dip switch #4

(^D24) for blow hole stock (see section 5.3).

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 23

Page 30

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

AGD NUMBER OF STEPS TO ACTIVATE GAP DETECTOR

The number of steps (dots) from the front edge of the label before the gap detector

circuitry is activated. This value is usually defaulted. It is not defaulted when using stock

that is smaller than 2.3 inches, the distance between the gap detector and the dot row, or

on larger labels, when skipping over pre-print, gaps, or paper flutter that may cause the

gap detector to trigger incorrectly. There is a long equation to manually calculate this

value for small labels, but auto-sizing (^D39) the label will produce this value accurately

and quickly.

SPG NUMBER OF STEPS PAST GAP

The steps (dots) to move the label after detection of a label gap. This facilitates using

very small label stock - less than 2.3 inches (the distance between the dot row and the

gap detector). Use auto-sizing (^A39) to quickly evaluate this parameter for small stock.

It may also be necessary to adjust this value if using special stock: For example, if using

black line stock with a perforation that is not on the black line. SPG would need to be

manipulated so that the printer can print the label between the perforations, yet still trigger

on the black line. In this case SPG would be calculated as the distance from the black

line to the perforation.

OFX X DIRECTION OFFSET

Equally moves all of the fields to the right. Useful for centering a label format on different

label stock. For example: Transferring a small label layout to a larger label stock. (Note:

This command consumes software time and may decrease the maximum print speed.)

OFY Y DIRECTION OFFSET

Equally moves all of the fields up on the label. Also useful for adjusting a label format to a

different stock. (Note: This command consumes software time and may decrease the

maximum print speed.)

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual24

Page 31

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

4.3.1 A SAMPLE SESSION WITH A LABEL HEADER

This is the label header from the sample label in section 4.2.

4,615,153,,20,30,,70,4<CR>

4 - 4 fields following the header

615 - Label width (LSX) of 615 (615/154= ~4 inches)

153 - Label length (LSY) of 153 (153/154 = ~1 inch)

- No entry in the WEB parameter means default value of 10

20 - A GAP between labels of 20 (20/154 = ~.13 inch)

30 - Label print speed (DPS) of 30 = 2.5 inches per second (from table)

- No entry for the LCN parameter means default value of 0, normal stock on

backing paper

70 - The AGD could not be defaulted because the stock was less than 2.3 inches in

length (LSY). This value was produced from auto-sizing (LDS command ^D39)

the label.

4 - SPG also could not be defaulted because of the small size of the stock. Auto-

sizing quickly produced this value.

<CR> A carriage return must follow the label header. There were two parameters left

that were not entered into the header - OFX and OFY. Because they were not

entered, the printer assumes the default values, 0 in their cases. Likewise, if the

AGD and SPG were defaulted, the carriage return could have followed the DPS.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 25

Page 32

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

4.4 LABEL FIELDS

A field is broken down into fourteen different parameters. These parameters contain the

information necessary to position data (text, bar codes, etc.) on the label. It is not

necessary to enter values for all of the field parameters; the default values will be used if

left blank. A carriage return must follow each label field. The following is a list of the field

element mnemonics and their default values:

TSN, XB, YB, CC,TCI,CGN, FO, FJ, CMX,CMY, CS, TSP,CLX,CLY

1, 0, 0, *, 1, **, 0, 0, 1, 1, *, 1, *, *

* The default depends on the character generator (CGN) used.

** The default depends on the TCI used.

TSN TEXT STRING NUMBER

Determines from which text string the field obtains the printable information. This allows

for more than one field to use the same text string. A TSN of 0 accesses the clock chip

text string (see section 8.3 for more details). A TSN of 1 accesses the first line of text

data. A TSN of 2 accesses the second line of text data, and so forth. (Note: Text data is

the information that follows the ^D2 command (section 5.3).)

XB X BEGINNING COORDINATE

The X coordinate of the field is measured in dots. The far left edge of the print head as

viewed from the front of the printer is X co-ordinate 1. There is no X co-ordinate 0. The X

coordinate increases in size from left to right (See figure 7). An XB of 154 would place

the text one inch from the left side of the print head.

YB Y BEGINNING COORDINATE

The Y coordinate of the field is measured in dots. A YB of one would be specified as the

first edge of the label coming out of the front of the printer during a label print. The Y

coordinate increases in size from the bottom to the top of the label (See figure 7). A YB of

154 would place text one inch from the bottom of the label.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual26

Page 33

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

CC CHARACTER COUNT

The number of characters that will be used in a field. If the number of characters in the

selected text string is more than the quantity specified by CC, then the remainder of the

text string is ignored. If the text string has less than the number of characters specified

by this parameter, then only those characters defined by the text string are printed. For

example, the text string - MICROCOM - would be 8 characters long.

TCI TEXT CONVERSION IDENTIFIER

The selected text string will be printed according to this chart. The values below define

which method is used:

1 Text

2 Text Surrounded by Asterisks (Code 3 of 9)

3 Text with UPC-A/UPC-E Checksum Digit Printed

7 Graphic Image (ROM and RAM)

12 UPC-A Bar code

13 UPC-E Bar code (SEND 11 DIGITS)

14 UPC-E Bar code (SEND 7 DIGITS)

15 Interleaved 2 of 5 Bar code

16 Code 3 of 9 Bar code

20 EAN-13 Bar code

21 EAN-8 Bar code

24 MSI 1 (Plessey)

25 MSI 2 (Plessey)

26 MSI 3 (Plessey)

*28 Text with MSI Checksum Added - Type 1

*29 Text with MSI Checksum Added - Type 2

*32 Text with UPC-A Checksum and Extended Bars Added

*33 Text with UPC-A With Extended Bars Added

40 Code 128 bar code

42 Codabar bar code

43 Code 93 bar code

44 AS-10 bar code

* Refer to section 7.1.1 on how to use these TCI's

Example: For the text string - 1234567

A TCI of one would print it as an ASCII string

A TCI of 42 would print it as a Codabar bar code

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 27

Page 34

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

CGN CHARACTER GENERATOR NUMBER

This refers to the character generator (font size, barcode size, etc.) that is used.

The character generators and specifications for the various fonts, barcodes, and logos

are shown below. Remember, there are 154 dots per inch.

Key For Tables:

CGN - Character Generator Number

FO - Field Orientation

Height - Y Direction, in Dots

Width - X Direction, in Dots

Spacing - Default Spacing Between Characters, in Dots

Font Type - Font Descriptor

'-' - Use Default Ratio

Fonts

CGN Dot

Height

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

5

5

6

7

7

7

8

9

9

12

15

18

40

40

9

18

17

18

19

20

16

8

Dot

Width

3

5

5

5

7

7

5

5

7

8

12

10

15

20

40

21

10

8

Spacing FO Font Type

1

1

1

1

1

1

1

1

1

2

2

2

3

3

4

2

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

01

01

0123

Standard

Standard

Standard

Standard

Standard

Bold

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Numeric

Custom #1

Custom #2

2

01

01

OCR-A

Upper/

Lowercase

Table 5

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual28

Page 35

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

This list constitutes the bar codes available on the 410 printer. Some bar codes offer different

ratios to accommodate different applications. See section 7.1 on designing with bar codes for

more information.

Bar code Symbologies

Bar code CGN Ratio Height Spacing FO

Code 3 of 9

(non-standard)

I 2 of 5

*UPC/EAN

*UPC Readable

*Code 128

Codabar

Code 93

AS-10

MSI (Plessy)

2

3

4

2

3

5

2:1

3:1

3:1 N

2:1

3:1

5:2

50%

50%

50%

2

3

2:1

3:1

2:1

2:1

1:1

Table 6

* These bar codes must be multiplied by 2 for a 100% ratio

1

1

1

1

1

1

1

1

1

1

1

1

1

-

-

Special

-

-

-

-

-

-

-

-

-

-

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

1

Graphic Images

CGN Height Width Spacing Graphic FO

1

3

4

2

X

X

255

X

X

0

0

0

Line

*RAM

*RAM

12

12

1

Table 7

X=Indeterminate

* See chapter 6 on RAM Graphic Images

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 29

Page 36

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

FO FIELD ORIENTATION

Defines the rotation of each field on the label. The point of rotation is determined from the

field justification. The positioning of data relative to field orientation and field justification

can sometimes be confusing. Refer to Table 8 for more detailed information on FO and

FJ interaction.

0 0 degrees (normal rotation).

1 180 degrees (upside-down rotation).

2 270 degrees (right rotation).

3 90 degrees (left rotation).

FJ FIELD JUSTIFICATION

The justification of each field on the label.

0 Right justified above base-line.

1 Left justified above base-line.

2 Right justified below base-line.

3 Left justified below base-line.

4 Centered above base-line.

5 Centered below base-line.

Whereas:

Right Justified - Text positioned right of X co-ordinate

Left Justified - Text positioned left of X co-ordinate

Centered - Text is centered on the X co-ordinate

Above Baseline - Text positioned above the Y co-ordinate

Below Baseline - Text positioned below the Y co-ordinate

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual30

Page 37

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

Starting position definitions:

Use the following to obtain proper character placement relative to orientations and justifications.

Character Starting Positions Relative to Field Orientations and Field Justifications

Rotation Field Orientation

0 Degrees 0 - Right justified above base-line

1 - Left justified above base-line

2 - Right justified below base-line

3 - Left justified above base-line

4 - Centered above base-line

5 - Centered below base-line

180 Degrees 0 - Left justified below base-line

1 - Right justified below base-line

2 - Left justified above base-line

3 - Right justified above base-line

4 - Centered below base-line

5 - Centered above base-line

270 Degrees 0 - Right justified below base-line

1 - Right justified above base-line

2 - Left justified below base-line

3 - Left justified centered on base-line

4 - Right justified centered on base-line

5 - Left justified centered on base-line

90 Degrees 0 - Left justified above base-line

1 - Left justified below base-line

2 - Right justified above base-line

3 - Right justified below base-line

4 - Left justified centered on base-line

5 - Right justified centered on base-line

Table 8

CMX CHARACTER MULTIPLIER X DIRECTION

Multiplies each character in the X direction. A 5 high by 3 wide character with a CMX of 2

would produce a 5 high by 6 wide character.

CMY CHARACTER MULTIPLIER Y DIRECTION

Multiplies each character in the Y direction. A 5 high by 3 wide character with a CMY of 2

would produce a 10 high by 3 wide character.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 31

Page 38

Designing Labels Using LDS Chapter 4

))))))))))))))))))))))))))))))))))))))))))))

CS CHARACTER SPACING

The spacing between each character. If this parameter is not used, then the default for

the selected character generator (CGN) is used. Bar codes have default spacing

according to the indicated multiplier. Multiplying a text string will not multiply the spacing

between characters. This element should be used to properly space the characters.

TSP TEXT STARTING POSITION

The starting position of the character in the text string to be used as data. This is useful

for allowing several fields to use sections of the same text string minimizing the amount

of data transmitted. For example, for the text string 0123456789 a TSP of 5 and a CC

(character count) of 2 would print 45. See section 5.3.4 for use of this parameter with

clock fields.

CLX CHARACTER CELL LENGTH X DIRECTION

This will override the width of the characters in the selected character generator. This

element is used only in special cases, such as drawing lines. It will form an incomplete

character.

CLY CHARACTER CELL LENGTH Y DIRECTION

This elements will over-ride the height of the characters in the selected character

generator. This element is used only in creating lines.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual32

Page 39

Chapter 4 Designing Labels Using LDS

))))))))))))))))))))))))))))))))))))))))))))

4.4.1 A SAMPLE SESSION WITH A LABEL FIELD

Looking at the sample label...

^D57<CR>

4,615,153,,20,30,,70,4<CR>

1,100, 40, 4, 1,4<CR>

2,100, 60,17, 1,4<CR>

3,100,100, 5, 1,6<CR>

3,100,150, 5,16,2,,,,30<CR>

^D56<CR>

^D2<CR>

EASY<CR>

MICROCOM MAKES IT<CR>

HELLO<CR>

^D3<CR>

... and referring to field #1.

1,100, 40, 4, 1,4<CR>

1 - Field refers to text string #1 - EASY. This field could have referred to HELLO, if

it had a TSN of three. The fields do not have to be in any kind of order with

respect to the data fields.

100 - Data X co-ordinate (XB) of 100 dots from left side of label

40 - Data Y co-ordinate (YB) of 40 dots from bottom of label

4 - Character count (CC) of 4 characters, the amount of characters in EASY.

1 - A TCI of 1 indicates that the data will appear on the label as text, an ASCII string,

as opposed to, for example, a bar code.

4 - This CGN selection of 4 selects a font size of 7 dots high by 5 dots wide. This is

the size of each character in the word EASY as it appears on the label.

<CR>- The carriage return (<CR>) signifies that this field is complete. The field

parameters that were not defined will accept the default values. A FO

(Field Orientation) and FJ (Field Justification) of 0 will place EASY to the

right of the X co-ordinate with a rotation of 0 degrees. CMX and CMY will

default to 1, so the character will be the size as defined by the font. The

TSN is 1, therefore we will print the entire EASY word (a TSN of 2 would

have printed ASY). CLX and CLY will default to 5 and 7, respectively, so a

full character will be printed.

A format is coming

Header Information

Field #1 information

Field #2 information

Field #3 information

Field #3 information

Select RAM Format

Text Data is Coming

Text String #1

Text String #2

Text String #3

Print

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 33

Page 40

CHAPTER 5: PRINTER COMMANDS

The Model 410 printer has a large and versatile collection of control codes to meet the special

needs of labeling applications. Most of the commands use a ^D control sequence, however the

printer also recognizes a selected number of other control sequences.

For all the commands listed in this manual, the printer will recognize either the one-character

control character or the two-character caret and alpha character sequence. In other words, for a

PC key board, the same command can be generated either by holding down the control key and

pressing the letter or by entering two characters - the ^ (a caret, the character generated if you

press the Shift key and the 6) and an alpha character (upper or lower case).

To protect against errors, in situations where two-character caret-alpha sequences are used

exclusively as printer commands, control character recognition can be disabled. This is done

either through software dip switch #1 (^D21) or command ^D93.

Some main-frame and mini-computers cannot use the ASCII '^' character. In these cases

substitute the ASCII pipe symbol '|' or use the one character control-code representation.

The caret symbol can be used in text or bar codes by preceding it with another caret.

5.1 SPECIAL PRINTER CONTROL CODES

The following control characters perform special functions. All other control characters are

ignored. Some of these instructions are also accessible through a ^D sequence.

^A Accumulator Mode: Used to supply parameters for ^D commands.

These parameters must be positive integers and are generally decimal numbers but they

can however be binary if preceded by an ASCII B. (^AB00000001^D21<CR> equals

^A1^D21<CR>>

^B Text entry mode: Instructs the printer to enter printable text entry mode. This command

(or the preferred ^D2<CR>) must be sent before the text information. This command is

equivalent to ^D2<CR> but does not require a <CR> after it (^Btext data string). Because

control B is shorter it is easier to use in direct terminal mode. In general it is better to use

^D2 inside a file or program.

^C Print a label: Starts the print cycle or batch. This command is equivalent to ^D3<CR>

but does not require a <CR> after it. Because control C is shorter than ^D3<CR> it is

easier to use in direct terminal mode. In general it is better to use ^D3<CR> inside a file

or program.

^D Command Mode: Used to issue commands to the printer. This command is normally

preceded by a ^A sequence (see above). ^D commands must be terminated with a

<CR> or another control sequence (^A9^D73^D3<CR> equals ^A9^D73<CR> and

^D3<CR>.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual34

Page 41

Chapter 5 Printer Commands

))))))))))))))))))))))))))))))))))))))))))))

^E Printer enquiry: See section 5.2 for more details (equivalent to ^D5<CR> but does not

require a <CR> after it). Because control E is shorter than ^D5<CR> it is easier to use in

direct terminal mode. In general it is better to use ^D5<CR> inside a file or program.

^M Terminate text or data string: Must be used to terminate a text or data string. (Same

as a carriage return or enter key on a PC keyboard.)

^H (or DEL) Deletes the last printable character entered: This is usually only used

when communicating to the printer through the keyboard. (Same as the backspace key

on a PC keyboard.)

^K Print test label: A test label consists of a series of diagonal lines. It is useful in

determining the condition of the dots on the print head (equivalent to ^D11<CR>).

^L Form Feed. (Equivalent to ^D12)

^Q XON: Instructs the printer to continue sending data.

^S XOFF: Instructs the printer to stop sending data.

5.2 PRINTER ENQUIRIES

It is important for the host computer to know the status of the printer as labels are produced.

This facilitates security in the system and flags electrical and mechanical errors. Enquiries also

aid the system designer in adjusting the pace of the printer with that of the operator.

The printer is capable of returning responses to enquiries in three different ways depending on

how the machine is programmed (see software dip switch #1, ^D21, section 5.3. The text

equivalent response returns a defining word, giving the state of the machine. The ^ equivalent

returns an ASCII '^' response followed by the defining alpha character. The control-code

equivalent returns an actual control code.

The printer will send to the host one of the following responses in response to a ^E or ^D5:

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 35

Page 42

Printer Commands Chapter 5

))))))))))))))))))))))))))))))))))))))))))))

Enquiry Responses

TEXT ^ALPHA or CONTROL

DEFINITION

CODE

>RESTARTED<

>READY<

>DATA ERROR<

>LOW STOCK<

>LOW TEMP<

>OVER TEMP<

>OVER VDD<

>TAKE LABEL<

^Z

^F

^U

^Y

^^

^[

^\

^V

Printer has been reset

Normal condition

Communication error

Out of labels

Head temperature is low

Head temperature is high

VDD voltage is high

Printer is waiting for a label to be taken

Table 9

5.3 SENDING ^D PRINTER COMMANDS

Unless otherwise specified, these commands are entered by sending a ^DXX where XX is the

command number. It is followed by a carriage return or another control code. Some commands

load data or control numbers and are preceded by a ^AXX, where XX represents the data or

control number. Unless otherwise specified, command codes should precede or follow the

actual format layout. They should be placed before the ^D57 or just before the print command

^D3.

All commands not listed in 5.3.1 (the EEPROM and dip switch section) are not retained when

the printer is turned off and if desired, must be sent again upon power-up.

When possible, the following commands are grouped by function. See the quick reference

command summary in Appendix G for a listing by number.

Some commands can be substituted with equivalent control-codes. If this is the case, there will

be an equivalence statement in the description.

Example of Command usage:

^A3^D75^D3<CR> (This sequence will print a batch of three labels).

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual36

Page 43

Chapter 5 Printer Commands

))))))))))))))))))))))))))))))))))))))))))))

5.3.1 SOFTWARE DIP SWITCHES AND EEPROM COMMANDS

The following commands are different from the other printer commands in that they are stored in

EEPROM, are non-volatile and configure the machine upon power-up. Once sent to the printer,

they do not need to be sent again.

The printer will only configure to the following commands after a the machine has been powered

off and then turned back on. The printer will not accept these commands until this is done.

^A ^D COMMAND

20 Change baud rate: Unless otherwise requested by the customer, the baud rate

of the printer is 9600. (To change baud to 19200 use ^A8^D20<CR>)

0 110 Baud

1 150 Baud

2 300 Baud

3 600 Baud

4 1200 Baud

5 2400 Baud

6 4800 Baud

7 9600 Baud

8 19200 Baud

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 37

Page 44

Printer Commands Chapter 5

))))))))))))))))))))))))))))))))))))))))))))

^A ^D COMMAND

21 Change SW1: Software dip switch #1. The dip switches are the only commands

that do not use the ^A parameters. Instead, they use a ^AB sequence followed by

an 8 digit 0 or 1 code.

For example: ^AB10101011^D21<CR> will configure the printer for a text

equivalent enquiry response, accept control codes, even parity, disable parity,

disable echo, 8 data bits and enable XON/XOFF flow control.

12345678

^ABxxxxxxxx

*******.Q

******.)Q

*****.))Q

****.)))Q

***.))))Q

**.)))))Q

*.)))))))))),

.)))))))))),*

1=XON/XOFF Enable, 0=Disable

1=8 Data Bits, 0=7 Data Bits

1=Echo Enable, 0=Disable

1=No Parity, 0=Enable Parity

1=Odd Parity, 0=Even Parity

1=Ignore Control Codes, 0=Accept

Enquiry Response

00 = Control Codes

10 = Text Equivalent

11 = ^ Equivalent

Position:

1,2 Enquiry Response: This determines what the printer will send back in response

to an enquiry. See chapter 5.

3 Control Codes: This switch setting will allow or disallow printer response to

control codes (below 20h).

4 Parity: Selects either even or odd parity error checking.

5 Enable Parity: Enables or disables parity error checking.

6 Echo: If this feature is enabled, the printer will echo all received characters to the

serial port.

7 Data Bits: Choose 7 or 8 bit data.

8 XON/XOFF: Enable or disable XON/XOFF software handshaking. Clear to Send

(CTS) hardware handshaking is always enabled.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual38

Page 45

Chapter 5 Printer Commands

))))))))))))))))))))))))))))))))))))))))))))

^A ^D COMMAND

22 Change SW2: Software dip switch #2. Below is the ^AB sequence:

12345678

^ABxxxxxxxx

*******.)))),

******.)))),*

*****.)))),**

*****

*****

*****

*****

*****

*****

*****

*****

*****

****.))))Q

***.)))))Q

**.))))))Q

*.)))))))Q

RRR

000=ALWAYS EPROM Format 1

001=ROM or Saved Format File 1

010=ROM or Saved Format File 2

011=ROM or Saved Format File 3

100=ROM or Saved Format File 4

101=ROM or Saved Format File 5

110=ROM or Saved Format File 6

111=ROM or Saved Format File 7

1=Use Saved Format File, 0=Rom Format

1=Print Button Enable, 0=Disable

1=Disable Button Use, 0=Enable

1=>RESTARTED< Response Enable,

Power-up Label Format

0=Disable

.))))))))Q

1=Clear Text Enable, 0=Disable

Position:

1 Clear Text Function: If enabled, all variable text strings will be erased when a

^D2<CR> is processed.

2 >RESTARTED< Response: If the printer has been reset and this switch has

been enabled, the printer will respond with to the first poll by sending the

>RESTARTED< message. If additional enquiries are made the printer will

respond normally. The >RESTARTED< message is only sent once after reset.

3 Button Use: Set to 1, the printer will not allow button use, even for paper feed.

4 Print Button: If this is 0, the button can be used for paper feed, but cannot be

used to initiate label printing.

5 Power-up Format Type: Defines the power-up label format. This parameter

determines whether to use a saved format file for the power-up label, or a ROM

format (defined by positions 6, 7, and 8). The saved format file must be battery

backed to use the saved format file feature. See Appendix C for configuration

instructions and section 5.3.7 for saved format file information. Please consult

your service organization if changes or additions to the fixed ROM formats are

required.

6,7,8 Power-up Label Format: These switches decide which format to use at power-

up.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 39

Page 46

Printer Commands Chapter 5

))))))))))))))))))))))))))))))))))))))))))))

^A ^D COMMAND

23 Change SW3: Software dip switch #3. Below is the ^AB sequence:

12345678

^ABxxxxxxxx

*******.

******.Q

*****.)Q

****.))Q

***.)))Q

**.))))Q

Not Used

Not Used

1=Enable 460 Emulation, 0=Disable

1=Enable 450 Emulation, 0=Disable

1=Enable Label Centering, 0=Disable

1=Send Response After a Print

** 0=No Response After a Print

Position:

1 Always 0

2 Always 0

3 Response After Print: If enabled, an enquiry response will be sent back through

4 Label Centering: The printer will center all label formats if this position is set to

5 450 Emulation: Only used if 450 format files are being sent to the printer.

6 460 Emulation: Used if 460 format files are being sent to the printer.

7 Always 0

8 Always 0

*.)))))Q

.))))))Q

the serial port after every print.

1. Label centering creates an X offset for the older formats that were left justified.

It will not center normal format fields on the label. It offsets a previously left

justified label. Not recommended for new applications.

Not Used

Not Used

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual40

Page 47

Chapter 5 Printer Commands

))))))))))))))))))))))))))))))))))))))))))))

^A ^D COMMAND

24 Change SW4: Change software dip switch #4. Below is the ^AB sequence.

12345678

^ABxxxxxxxx

Position:

1 4" Epson Emulation: When set, the printer executes the same commands as

2 Enable 2" Epson Emulation: Same as position 2, but prints in a 40 column

3 Blow-hole Stock: Enable this position when using blow-hole or cut-slot stock:

4 Auto-size on power-up: When enabled, the printer automatically sizes the label

5 Always 0

6 Always 0

7 Always 0

8 Always 0

*******.)Q

******.))Q

*****.)))Q

****.))))Q

***.)))))Q

**.))))))Q

*.)))))))Q

.))))))))Q

an Epson printer in an 80 column format. This parameter enables the emulation

on printer power-up (Also see the ^A1^D38 command in section 5.3). To exit this

mode, create a status label (see section 2.1.3) and clear (0) this position in this

software dip switch. This function is no longer supported.

format. (Also see the ^A2^D38 command in section 5.3.) This function is no

longer supported.

Stock that uses a hole instead of a gap to separate labels.

stock when turned on. The printer then uses these header values for all

subsequent label formats. See the ^D39 command in section 5.3 for more

information on auto-sizing.

Not Used

Not Used

Not Used

Not Used

1=Auto-size on Power-up, 0=Disable

1=Blow-hole Sensing Enable, 0=Disable

1=Enable 2" Epson Emulation, 0=Disable

1=Enable 4" Epson Emulation, 0=Disable

^A ^D COMMAND

XX 36 Adjust Contrast Base: Used to adjust the contrast base point for such things as

high-speed paper and printhead wear. This command is stored in the EEprom

and skews the entire contrast window (^D35). This command has a ^A range of

10 to 200%.

))))))))))))))))))))))))))))))))))))))))))))

410 Operators Manual 41

Page 48

Printer Commands Chapter 5

))))))))))))))))))))))))))))))))))))))))))))

5.3.2 PRINTING COMMANDS

The following commands initiate label printing or define the number of labels to be printed.

^A ^D Command

3 Print Command: Prints a single label or starts the printing of a batch of labels.

This is usually the last command in a format file.