Page 1

nualck Innova® 2000/2050 Shaker

EN) manual

New Brunswick™ Innova®

2000/2050 Shaker

Operating manual

Page 2

Copyright © 2014 Eppendorf AG, Germany. No part of this publication may be reproduced without the

prior permission of the copyright owner.

Eppendorf

®

and the Eppendorf logo are registered trademarks of Eppendorf AG, Germany.

New Brunswick™ and the New Brunswick™ logo are trademarks of Eppendorf AG, Germany.

®

Innova

Trademarks are not marked in all cases with ™ or

is a registered trademark of Eppendorf, Inc., USA.

®

in this manual.

M1190-0050-R/012014

Page 3

Table of contents

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Hazard symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Degrees of danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 User profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Main Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.3 Platforms and accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Universal power module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4.1 LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.2 Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.3 Status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.4 Function indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Platform assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6 Heavy duty construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6.1 Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6.2 Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6.3 Triple eccentric drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.7 Electronic boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.8 Optional features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.8.1 Temperature/monitor option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.8.2 Capacity upgrade option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Checking voltage configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Install the platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Install flask clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Continuous/unlimited run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Checking setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Timed functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.1 Setting the timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.2 Canceling the timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 4

Table of contents

New Brunswick Innova® 2000/2050 Shaker

4

English (EN)

5.5 Alarm functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.1 Stopping the alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.2 Deactivating the alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.3 Reactivating the alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.6 Total running time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.7 Temperature monitor option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.8 Recorder adaptation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Cleaning external and internal surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Fuse replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.1 Innova 2000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.2 Innova 2050. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1 Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2 Accessory flask clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.3 Service parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.4 Clamp hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.1 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10 Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Page 5

Operating instructions

New Brunswick Innova® 2000/2050 Shaker

English (EN)

1 Operating instructions

1.1 Using this manual

Carefully read this operating manual before using the device for the first time.

Also observe the operating manual enclosed with the accessories.

The operating manual should be considered as part of the product and stored in a location that is easily

accessible.

When passing the device on to third parties, be sure to include this operating manual.

If this manual is lost, please request another one. The latest version can be found on our website

www.eppendorf.com (international) or www.eppendorfna.com (North America).

1.2 Danger symbols and danger levels

1.2.1 Hazard symbols

5

Electric shock Hazard point

Crushing Material damage

Heavy loads Explosion

1.2.2 Degrees of danger

The following degree levels are used in safety messages throughout this manual. Acquaint yourself with

each item and the potential risk if you disregard the safety message.

DANGER Will lead to severe injuries or death.

WARNING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

Page 6

Operating instructions

New Brunswick Innova® 2000/2050 Shaker

6

English (EN)

1.3 Symbols used

Example Meaning

You are requested to perform an action.

1.

2.

• List.

Perform these actions in the sequence described.

References useful information.

Page 7

2 Safety

2.1 User profile

CAUTION!

This equipment must be operated as described in this manual. If operational guidelines are

not followed, equipment damage and personal injury can occur. Please read the entire

Operating Manual before attempting to use this unit.

Do not use this equipment in a hazardous atmosphere or with hazardous materials for

which the equipment was not designed.

Eppendorf is not responsible for any damage to this equipment that may result from the

use of an accessory not manufactured by Eppendorf.

Safety

New Brunswick Innova® 2000/2050 Shaker

English (EN)

7

2.2 Warnings for intended use

WARNING! Heavy!

Do not attempt to lift the Innova 2000/2050 Shaker by yourself.

Ask for assistance or use suitable equipment when raising or handling the device.

WARNING! Risk of explosion and injury or death!

Do not use equipment with flammable substances or organisms with flammable

by-products.

WARNING! Risk of electric shock and/or damage to the device!

Use a grounded power supply.

WARNING! Risk of electric shock and/or damage to the device!

Before cleaning device, turn off and unplug from mains/power supply.

WARNING! Risk of electric shock when replacing fuses!

Turn off shaker and disconnect from mains/power supply.

CAUTION!

A minimum load is required to safely operate the Innova 2000/2050.

Without a minimum load there is risk of instability that may cause serious injuries.

Page 8

Safety

New Brunswick Innova® 2000/2050 Shaker

8

English (EN)

Page 9

3 Product description

SE

LECT

ST

ART

ST

O

P

MAINT

S

E

T

TIME

MUTE

RP

M

HRS

°

C

*

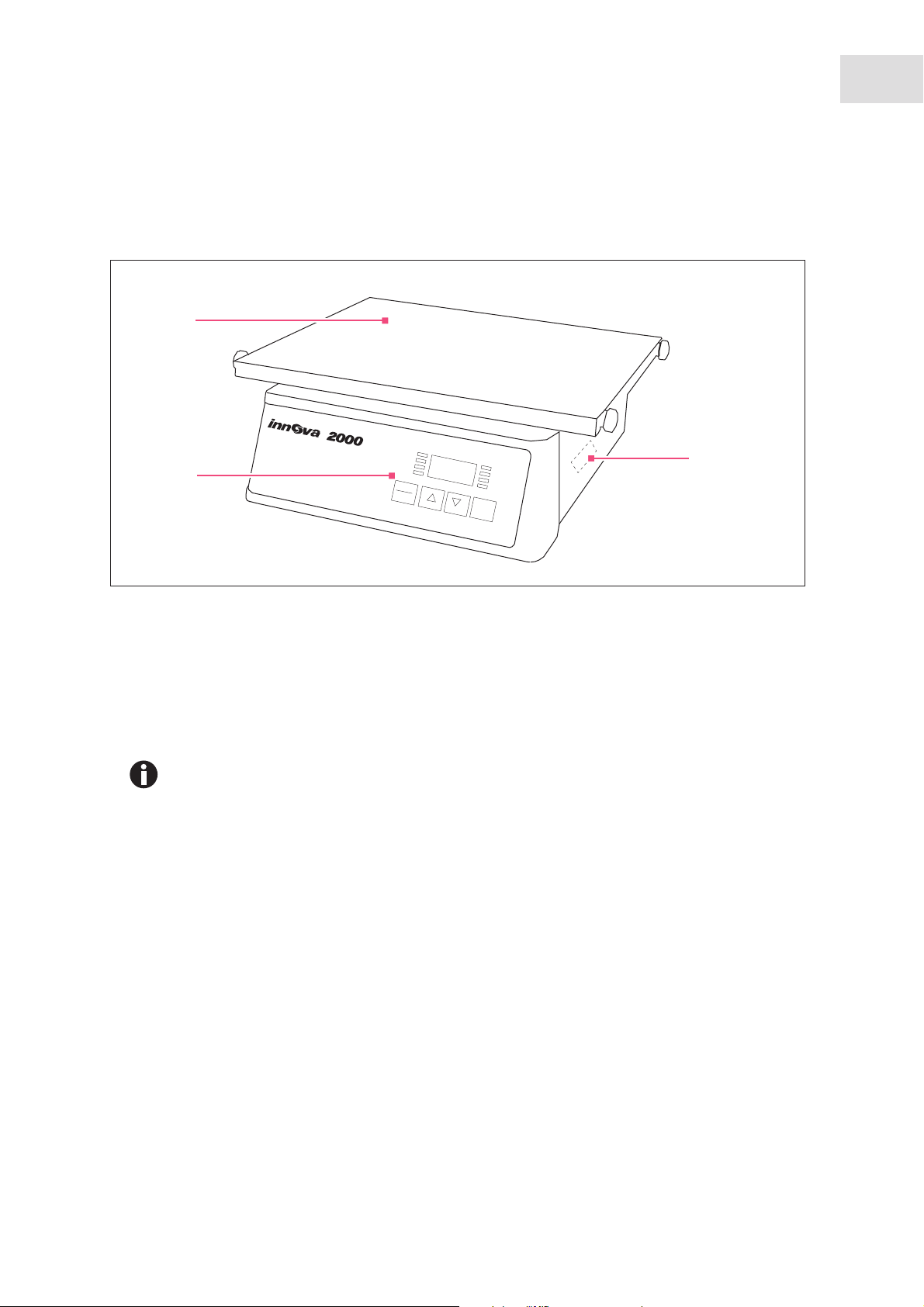

3.1 Main Illustration

Abb. 3-1: Innova 2000/2050 front view

1

3

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

2

9

Fig. 3-1: Innova 2000/2050 front view

1 Platform

2 Temperature/monitor RTD probe and bracket

Optional

Unless otherwise indicated, all drawings represent both Innova 2000 and Innova 2050 models.

3 Control panel

Page 10

10

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

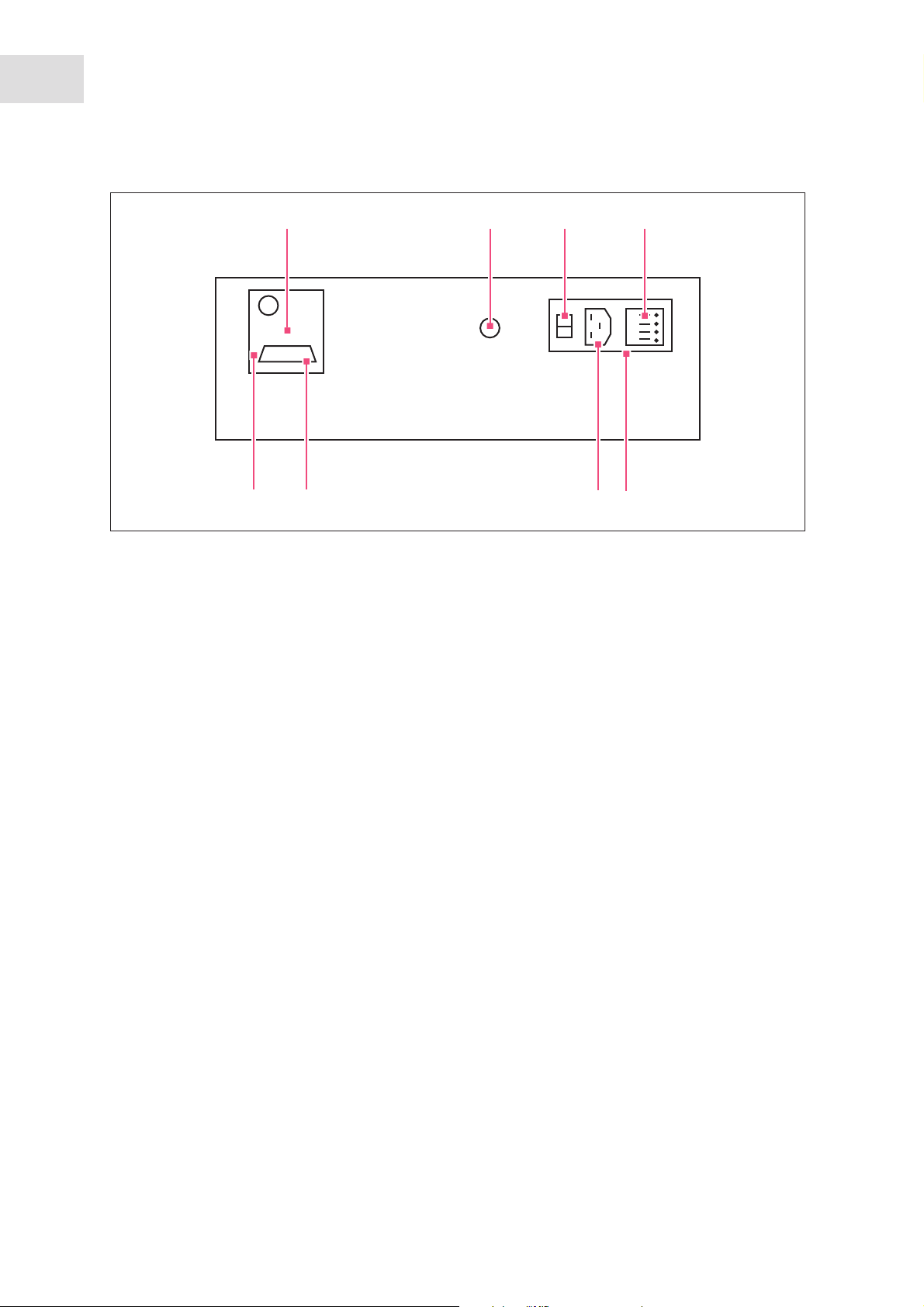

Abb. 3-2: Innova 2000/2050 rear view

1

8

7

Fig. 3-2: Innova 2000/2050 rear view

1 RTD connectos

Optional

2 Fuse

Control circuit

3 On/Off switch

4 Voltage selector

2 3 4

56

5 Universal power module

6 Power cord connection

7 Chart recorder connection

Optional

8 Cover plate

3.2 Features

The Innova 2000/2050 is a portable benchtop shaker utilizing a triple eccentric counterbalanced drive to

provide horizontal plane rotary motion in a 19 mm (3/4 in) circular orbit. A Proportional/Integral (PI)

microprocessor controller with instantaneous digital feedback controls the speed over a range of 25 – 500

RPM.

3.2.1 Operation

The shaker may be operated either continuously or in a timed mode via a programmable timer for shaking

periods of 0 hr 1 min – 99.9 hr. A Temperature Monitoring option is available for the measurement, display

and documentation of sample temperature.

Page 11

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

3.2.2 Alarms

The Innova 2000/2050 is equipped with audible and visible alarms that alert the user to the following

conditions:

• The end of a timed run

• Deviation of shaking speed outside the tolerance limits

3.2.3 Platforms and accessories

To accommodate customer needs, a wide variety of platforms can be used with the Innova 2000/2050.

Dedicated platforms are available for a variety of flask sizes. Universal platforms are also available (see

Platforms on p. 31).

3.3 Universal power module

11

The power module contains a voltage card and fuse holder which are used to select the appropriate voltage

and fusing. This universal power entry system adapts to worldwide power requirements. Voltage and fusing

has been set prior to shipment. Innova shakers are available in 100 V, 120 V, 220 V and 240 V

configurations that accommodate both 50 and 60 Hz frequencies.

WARNING! Risk of electric shock and/or damage to device!

Do not plug the shaker into a power source until you check the voltage and frequency

settings.

Check the voltage selection on the power entry module against the serial tag located either

on the side or rear of the device.

3.4 Control panel

The control panel is located on the front of the instrument. It serves as the operator interface, and consists

of:

• A START/STOP key

• An up arrow ( )

• A down arrow ( )

• A SELECT key

• A 3-digit LED display that provides numeric values, and some letter codes

• 4 function indicator lights

• 4 status indicator lights

Page 12

12

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Abb. 3-3: Control panel

MAINT

MUTE

Fig. 3-3: Control panel

SET

TIME

START

STOP

2

31

RPM

HRS

° C

*

SELECT

4

1 Status indicators

2 LED display

3 Function indicators

4 Keypad

3.4.1 LED display

The Innova control panel has a 3-digit LED display. During normal shaker operation, the display will

indicate:

• Shaker status (ON/OFF)

• Shaking speed

• Setpoints

• Hours remaining (timed run)

• Measured temperature (when temperature/monitor option is installed)

3.4.2 Keypad

START/STOP • Starts and stops the drive

• Activates or stops timer when timed run is desired

Keys

• Adjusts the setpoint of a displayed parameter up or down

• Used to enter the SET mode for setpoint changes

Page 13

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

SELECT • Changes the displayed parameter

• Temperature (°C) cannot be selected unless the temperature/remote monitoring

option is installed.

3.4.3 Status indicators

MAINT • Illuminates after 10000 hours of use. Indicates need for routine maintenance (see

Routine maintenance on p. 25)

SET Illuminates to indicate that:

• Shaker is in SET mode

• Setpoints are being displayed

• Setpoints can be altered

TIME • Illuminates to indicate that the timer is in operation

MUTE • Illuminates to indicate that the audible alarm is disabled

13

3.4.4 Function indicators

RPM Revolutions per minute shaking speed

HRS Time remaining

°C Temperature function (only activated of the temperature/monitor option is installed)

* This function is not active in the Innova 2000/2050

3.5 Platform assemblies

Neither the Innova 2000 nor the 2050 can be used without a platform. One must be purchased and installed

on your shaker prior to operation (see Platforms on p. 31).

The Innova 2000 can be used with a wide range of New Brunswick 28 cm x 33 cm (11 in × 13 in) platforms,

which will accept a variety of clamps for flasks, test tubes, etc (see Tab. on p. 31).

The Innova 2050 can accommodate an even wider range of New Brunswick 30.5 cm × 40.6 cm (12 in x

16 in) platforms, which will accept a variety of clamps for flasks, test tubes, etc (see Tab. on p. 31).

3.6 Heavy duty construction

3.6.1 Bearings

Innova shakers employ sealed lubricated ball bearings of the highest quality. Sealed bearings minimize the

generation of airborne particles that could be disadvantageous in clean rooms or controlled environment

areas.

Page 14

14

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

3.6.2 Motor

The Innova 2000/2050 Shaker uses a brushless ball bearing DC motor. This low profile motor provides high

torque along with quiet, efficient operation and low maintenance. The motor has a rating of 1/20

horsepower.

3.6.3 Triple eccentric drive

The drive mechanism utilizes a counterweight system to stabilize the rotary motion produced during

operation. When the workload moves in one direction, opposing forces are generated to stabilize the

shaker. This action will help eliminate the problem of “walking” which may occur with less precisely

balanced instruments. Vibration is minimized and the life of the unit is extended.

Abb. 3-4: Counterbalanced drive mechanism

1

Fig. 3-4: Counterbalanced drive mechanism

1 Platform

2 Spongepad

3 Sub-platform

2

6

5

4

5 Eccentric drive shaft

6 Lower bearing housing

7 Upper bearing housing

37

4 Pulley with counterweight

3.7 Electronic boards

The main control board for Innova shakers has the following functions:

• Non-volatile memory for storage of key parameters during power interruption;

• Speed sensing, electronic commutation, and power control for the brushless DC drive motor;

• Maintains an elapsed running time clock;

• Contains firmware for shaker control as well as recognition of an expansion connector for option

Page 15

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

modules;

• Provides an operator interface via displays, audible alarm, and connection to the keypad module

(keypad buttons and display graphics).

The optional Temperature Monitor module is designed to “piggyback” onto the main board via an

expansion connector. It has the following functions:

• Control of analog power supplies;

• Signal conditioning of RTD sensor readings;

• Provide remote monitoring capabilities by supplying analog outputs for speed and temperature that are

compatible with chart recorders and analog data acquisition systems.

3.8 Optional features

3.8.1 Temperature/monitor option

A Temperature/Monitor Option is available for installation on the Innova 2000/2050. The ambient

temperature or the temperature of the liquid in any vessel can be measured using the RTD

electronics-based measuring device supplied with this option.

15

When the option is installed, the LED will display the measured temperatures in 0.1 °C increments. This

option also allows the connection of a chart recorder so that shaking speed and temperature can be

documented. The analog output for shaking speed is 0 – 5 V: 1 V per 100 rpm. For temperature, the output

is 0 – 5 V (0.05 V per °C).

The output can also be connected to a data logging computer with an analog data acquisition card.

3.8.2 Capacity upgrade option

It is possible to significantly increase the capacity of an Innova 2000 shaker with an available capacity

upgrade package (M1190-9910). This option will simply and easily convert an Innova 2000 to an Innova

2050.

This package consists of a 30.5 cm x 40.6 cm (12 in x 16 in) subplatform to replace the 25 cm x 33 cm

(11 inch x 13 inch) subplatform, and the appropriate counterweight and hardware.

Large capacity Innova 2050 platforms must be used with the increased capacity configuration

(see Platforms on p. 31).

Page 16

16

Product description

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Page 17

Installation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

4 Installation

4.1 Unpacking

When you unpack the unit, inspect it carefully for any apparent damage that may have occurred during

transit. Report any damage to the carrier and to Eppendorf Service Department.

Verify against the packing list that you have received everything; report any missing items to your

Eppendorf representative.

Do not discard the crate or packing material.

4.2 Checking voltage configuration

17

WARNING! Risk of electric shock and/or damage to device!

Do not plug the shaker into a power source until you check the voltage and frequency

settings.

Determine the voltage of your unit by checking the voltage selector and the label on the rear of the unit,

and confirm that the correct electrical service package is included with the unit.

4.3 Space requirements

It is essential that the unit be situated in an area where there is sufficient space for the shaker and platform

to clear walls and other potential obstructions during operation.

The dimensions, including a platform but excluding glassware, are:

Model Width Depth Height

Innova 2000 35 cm (14 in) 36 cm (14 ¼ in) 13.9 cm (5 3/8 in)

Innova 2050 43 cm (17 in) 36 cm (14 ¼ in) 13.9 cm (5 3/8 in)

The required surface area required for operation is:

Model Width Depth

Innova 2000 43 cm (17 in) 43 cm (17 in)

Innova 2050 50 cm (20 in) 50 cm (20 in)

Page 18

18

SEL

ECT

ST

A

R

T

ST

OP

MA

INT

SET

TI

ME

MUT

E

RP

M

H

R

S

°

C

*

SEL

EC

T

ST

A

R

T

ST

OP

MA

INT

SET

TI

ME

MUT

E

R

P

M

HR

S

°

C

*

Installation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Abb. 4-1: Innova 2000 operating space

35 cm

(17 in)

35 cm

(17 in)

Fig. 4-1: Innova 2000 operating space

Abb. 4-2: Innova 2050 operating space

50 cm

(20 in)

Fig. 4-2: Innova 2050 operating space

WARNING!

50 cm

(20 in)

Do not position the equipment so that it is difficult to operate the disconnecting device

(main plug).

For service reasons and for cases of emergencies, sufficient space must be provided for

easy access to the main power cord/power switch (located at the back of the unit).

Page 19

Installation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

4.4 Electrical connections

WARNING! Risk of electric shock and/or damage to device!

Use a grounded power supply.

CAUTION!

A detachable main power cord has been provided with your unit.

Only use the cord provided with the unit.

Before making electrical connections, be sure to follow these instructions:

1. Check the voltage selector in the Universal Power Module at the rear of the unit to ensure that it is set to

the appropriate voltage.

2. Remove the CAUTION label from the universal power module.

3. Make sure the power switch on the back of the unit is set in the OFF position.

ONLY THEN:

19

4. Connect the power cord to the universal power module and to a grounded electrical outlet.

4.5 Install the platform

A platform (purchased separately) must be installed on the unit prior to use.

NOTICE! Risk of damage to device!

Never run shaker without a platform.

1. Set the mains/power switch to off.

2. Place the platform on the subplatform. Make sure that all four slots are seated over the four knob

screw-shafts. Be sure to use a platform of the proper size for your particular shaker.

3. Tighten the four knobs to secure the platform.

Page 20

20

Installation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

4.6 Install flask clamps

WARNING!

Do not overfill flasks (i.e., more than 50% of the flask volume).

If you have purchased flask clamps for use with a universal platform, they will require installation. All

clamps are shipped complete with hardware.

1. Clamps are installed by securing the base of the

clamp to the platform with the correct type and

number of screws (see Clamp hardware on p. 33).

Page 21

Operation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

5 Operation

5.1 Getting started

To start the instrument, turn the ON/OFF switch on the back of shaker to the ON position.

If the shaker is running, the LED display will track the speed as it accelerates to the last entered setpoint.

The shaking action may be stopped or started by pressing the START/STOP key on the control panel.

5.2 Continuous/unlimited run

1. If the LED displays OFF, press the START/STOP key.

2. Press the SELECT key to illuminate RPM.

3. Press either or to enter SET mode (SET indicator will illuminate).

21

4. Set the speed by using the or key until the desired setpoint is displayed.

Holding the or key will cause the setting to change more rapidly.

The setpoint may be changed at any time during a run without stopping the shaker by following steps 2 – 4.

During speed changes, the alarm may sound until the speed returns to within 5 rpm of the setpoint.

5.3 Checking setpoints

To check any setpoint:

1. Press the SELECT key to illuminate the desired indicator.

2. Press either or to enter the SET mode and display the current setpoint.

Holding the or key for more than 0.5 s causes the setpoint to change. Should this occur,

resetting will be necessary.

5.4 Timed functions

The shaker may be programmed to stop automatically after a preset time period of 0.1 to 99.9 hr. There

must be power to the shaker in order to set the timer. However, a timed run can be initiated while the unit

is either shaking or stopped.

5.4.1 Setting the timer

1. Press the SELECT key to light HRS.

2. Press either or to enter the SET mode, then set a time period of 0.1 – 99.9 hr.

3. While SET light is illuminated, press the START/STOP key to program the time (and start the run).

Page 22

22

Operation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

The TIME indicator will illuminate and remain on for the duration of the run. At the end of the timed run:

• The display will read OFF

• The time indicator will flash

• The audible alarm will sound

The setpoint may be changed during a run without stopping the shaker by following steps 1 and 2 above.

5.4.2 Canceling the timer

To cancel the timer without stopping the shaker:

1. Press the SELECT key to illuminate HRS.

2. Press either or to enter the SET mode, then immediately press the START/STOP key.

The Time indicator will go out and the display will read “OFF”.

5.5 Alarm functions

Innova shakers have an audible alarm which is activated at predetermined times. It is possible to deactivate

and reactivate the alarm, according to your needs.

5.5.1 Stopping the alarm

When the alarm sounds, you can stop it by pressing the SELECT key and changing to any other function.

5.5.2 Deactivating the alarm

The alarm may be deactivated in the following way:

1. Press SELECT to illuminate HRS.

2. Simultaneously press the and keys.

The SET and MAINT indicators will flash.

3. While the SET and MAINT indicators are flashing, press the START/STOP key.

The MUTE indicator will illuminate to advise that the audible alarm is deactivated.

5.5.3 Reactivating the alarm

The alarm may be reactivated in the following way:

1. Press SELECT to illuminate HRS.

2. Simultaneously press the and keys.

The SET and MAINT indicators will flash.

3. While the SET and MAINT indicators are flashing, press the START/STOP key.

Page 23

Operation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

The MUTE indicator will extinguish to advise that the audible alarm is active.

The shaker may be stopped or started by pressing the START/STOP key. When starting, the

unit will automatically return to the last function and speed setting.

The audible alarm will sound until the speed is within 5 rpm of the setpoint.

The alarm will not sound while the shaker is accelerating immediately following turning on the power.

5.6 Total running time

The control modules of the Innova shakers keep track of the time the shaker has been on, tracking the

hours of usage.

To display the accumulated running time:

1. Select HRS using the SELECT key.

23

2. Simultaneously press the and keys.

The SET and MAINT indicators will flash and the accumulated running time will be displayed in

hundreds of hours (i.e., “02” equals 200 hours; “102” equals 10,200 hours). This display will continue

for 10 seconds and then default to the previous mode readout.

After 10,000 hours of operation, the MAINT indicator will light. Preventive maintenance is

recommended at this point. The Eppendorf Service Technician will deactivate the light when

the technician performs the required maintenance.

5.7 Temperature monitor option

This option consists of an internal electrical interface, an RTD temperature probe and an analog output for

chart recorder or data acquisition sytem. When this option is installed, either the ambient temperature or

the temperature of any vessel on the shaker platform can be measured with the probe:

1. Remove the probe from its holder and insert it into the vessel to be monitored.

2. Use the SELECT key to indicate °C.

The °C indicator will only function when the temperature/monitor option is installed.

Since the Temperature Monitor option does not provide temperature control, any attempt to enter a

temperature setpoint results in Err (“Error”) being displayed.

Page 24

24

Operation

New Brunswick Innova® 2000/2050 Shaker

English (EN)

5.8 Recorder adaptation

To record speed or temperature, an auxiliary recorder (not supplied, but available from Eppendorf) can be

used. The recorder should have the following capabilities:

Abb. 5-1: Recorder connector as seen from the rear of the unit

4

5

Fig. 5-1: Recorder connector as seen from the

Pin number Signal name Scale

6 Speed 1 V = 100 rpm

2 Ground

7 Temperature 1 V = 20 °C

3 Ground

3

7

8

9

rear of the unit

21

6

• For speed, each channel should have signal

conditioning that accepts 0 – 5 V input.

• For temperature, each chanel should have a

signal conditioning that accepts 0 – 5 V input

• A mating connector is required on the recorder

cable (not supplied, but available from

Eppendorf). This is a 9-pin male D subminiature

connector, AMP Amplimite HDP-20 series or

equivalent.

Page 25

Maintenance

New Brunswick Innova® 2000/2050 Shaker

English (EN)

6 Maintenance

WARNING!

Before performing any service, turn off the power, using the ON/OFF switch on the rear

panel, and disconnect the power cord.

6.1 Routine maintenance

No routine maintenance is required for the Innova 2000/2050 Shaker.

The MAINT indicator light illuminates at the end of 10000 hours of use. At that time, contact your local

Eppendorf Service Engineer, or call the Eppendorf Service Department. This periodic maintenance will

keep your unit in premium condition.

25

6.2 Cleaning external and internal surfaces

WARNING! Personnel injury and equipment damage!

When cleaning the unit, always turn off the shaker and disconnect the power cord from the

power supply.

The unit may be cleaned using a damp cloth or any standard household or laboratory cleaner to wipe down

its outer surfaces. Do not use abrasive or corrosive compounds to clean this instrument, as they may

damage the unit.

6.3 Fuse replacement

WARNING! Risk of electric shock when replacing fuses!

Turn off shaker and disconnect from mains/power supply.

CAUTION!

A detachable main power cord has been provided with your unit.

Only use the cord provided with the unit.

Page 26

26

Maintenance

New Brunswick Innova® 2000/2050 Shaker

English (EN)

To replace fuses (without changing the fusing arrangement):

1. Disconnect the unit from the power source.

2. Using a small screwdriver, remove the cover/fuse block located on the rear of the unit.

3. Remove the old fuse.

4. Insert a new one of the same type.

5. Replace the cover/fuse block into the power module.

Spare fuses are supplied with the unit.

Abb. 6-1: Power entry module

321

Fig. 6-1: Power entry module

1 Housing

2 Voltage selector card

3 Indicator pin

5

4

4 Cover

5 Fuse block

Page 27

Technical data

New Brunswick Innova® 2000/2050 Shaker

English (EN)

7 Technical data

7.1 Specifications

7.1.1 Innova 2000

Tab. 7-1: Shaking

Speed 25 – 500 rpm

Control accuracy ±1 rpm

Indication 3-Digit LED, in 1 rpm increments

Stroke/Orbit 1.9 cm (¾ in)

Setpoint and

control

Operating ambient 0 – 60 °C, 90 % humidity, non-condensing. Up to 2000 m

Timer Programmable shaking periods from 0.1 to 99.9 hours by a digital timer that shuts

Alarms Warning signal (audible and visual) indicates when shaking speed deviates more

LED display Indicates speed, running time alarm conditions, and displays readout of internal

Automatic restart Automatic restart after power is restored, indicated by flashing display.

Setpoint retention All setpoints and operating status are retained in non-volatile memory.

Drive Triple-eccentric counterbalanced ball bearing drive.

Drive motor 1/20 hp 3-phase brushless ball bearing DC motor.

Electrical

requirements

Electrical

protection

Dimensions Width: 35.5 cm (14 in) with knobs

Platform 28 × 33 cm (11 × 13 cm)

Weight Net: 15 kg (33 lb)

Cabinet Heavy gauge steel, phosphate coated and texture painted.

Remote monitoring

(optional)

Temperature

monitor (optional)

Digital adjustment with PI microprocessor control and instantaneous visual

feedback.

off at the end of period and energizes status light.

Timer counts down and digital display indicates remaining time. Can be

deactivated for continuous operation. Additionally, unit will display total

accumulated running time for service information.

than 5 rpm from setpoint and when timed operation has expired. Audible alarm can

be deactivated/activated by the operator.

clock (actual accumulated operating time).

100 / 120 / 220 / 240 VAC, 50/60 Hz.

35 VA universal power entry system adapts to U.S. or international needs.

Main fuses in power entry module. Control circuits provided with separate fuse.

Depth: 37 cm (14 ½ in)

Height: 13.7 cm (5 ⅜ in)

Interchangeable without tools.

Gross: 19 kg (41 lb)

0 – 5 V chart recorder output for speed: 1 V per 100 rpm. Accuracy ±25 mV.

RTD digital temperature monitor displays individual flask or ambient temperature

in 0.1 °C increments. Chart recorder output provided.

27

Page 28

28

Technical data

New Brunswick Innova® 2000/2050 Shaker

English (EN)

At 25 – 400 rpm, the unit will perform to specifications with up to ±10 % line voltage

fluctuation. To attain speed accuracy at 401 – 500, the line voltage cannot be lower than 5 %

of the rated voltage.

The Innova 2000 can be upgraded to a larger capacity platform with a kit that converts this

shaker to an Innova 2050. This kit can be installed in the field.

7.1.2 Innova 2050

Tab. 7-2: Shaking

Speed 25 – 500 rpm

Control accuracy ±1 rpm

Indication 3-Digit LED, in 1 rpm increments

Stroke/Orbit 1.9 cm (¾ in)

Setpoint and

control

Operating ambient 0 – 60 °C, 90 % humidity, non-condensing. Up to 2000 m

Timer Programmable shaking periods from 0.1 to 99.9 hours by a digital timer that shuts

Alarms Warning signal (audible and visual) indicates when shaking speed deviates more

LED display Indicates speed, running time alarm conditions, and displays readout of internal

Automatic restart Automatic restart after power is restored, indicated by flashing display.

Setpoint retention All setpoints and operating status are retained in non-volatile memory.

Drive Triple-eccentric counterbalanced ball bearing drive.

Drive motor 1/20 hp 3-phase brushless ball bearing DC motor.

Electrical

requirements

Electrical

protection

Dimensions Width: 43.4 cm (17 in) with knobs

Platform 30.5 × 40.6 cm (12 × 16 in)

Weight Net: 16 kg (35 lb)

Digital adjustment with PI microprocessor control and instantaneous visual

feedback.

off at the end of period and energizes status light.

Timer counts down and digital display indicates remaining time. Can be

deactivated for continuous operation. Additionally, unit will display total

accumulated running time for service information.

than 5 rpm from setpoint and when timed operation has expired. Audible alarm can

be deactivated/activated by the operator.

clock (actual accumulated operating time).

100 / 120 / 220 / 240 VAC, 50/60 Hz.

35 VA universal power entry system adapts to U.S. or international needs.

Main fuses in power entry module. Control circuits provided with separate fuse.

Depth: 37 cm (14½ in)

Height: 13.7 cm (5⅜ in)

Interchangeable without tools.

Gross: 19.5 kg (43 lb)

Page 29

New Brunswick Innova® 2000/2050 Shaker

Cabinet Heavy gauge steel, phosphate coated and texture painted.

Remote monitoring

(optional)

Temperature

monitor (optional)

At 25 – 400 rpm, the unit will perform to specifications with up to ±10 % line voltage

fluctuation. To attain speed accuracy at 401 – 500 rpm, the line voltage cannot be lower than

5 % of the rated voltage.

0 – 5 V chart recorder output for speed: 1 V per 100 rpm. Accuracy ±25 mV.

RTD digital temperature monitor displays individual flask or ambient temperature

in 0.1 °C increments. Chart recorder output provided.

Technical data

29

English (EN)

Page 30

30

Technical data

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Page 31

New Brunswick Innova® 2000/2050 Shaker

8 Ordering information

8.1 Platforms

Tab. 8-1: Innova 2000 platforms

Part number Number of clamps Description

28 x 33 cm (11 x 13 in ) Platform

AG2-UT --- Utility Carrier

AG2-00 --- Utilility Tray

M1001-0240 --- Universal Platform

AG2-10 60 for 10 ml Erlenmeyer flasks

AG2-25 32 for 25 ml Erlenmeyer flasks

M1190-9915 20 for 50 ml Erlenmeyer flasks

M1190-9916 12 for 125 ml Erlenmeyer flasks

M1190-9917 8 for 250/300 ml Erlenmeyer flasks

M1190-9918 6 for 500 ml Erlenmeyer flasks

AG2-TA25 18 Test Tube Rack, Slant

Ordering information

31

English (EN)

Tab. 8-2: Innova 2050 platforms

Part number Number of clamps Description

30.5 x 40.6 cm (12 x 16 in) Platform

M1190-9907 --- Utility Carrier

M1190-9908 --- Utilility Tray

M1190-9900 --- Universal Platform

M1190-9901 86 for 10 ml Erlenmeyer flasks

M1190-9902 48 for 25 ml Erlenmeyer flasks

M1190-9903 33 for 50 ml Erlenmeyer flasks

M1190-9904 20 for 125 ml Erlenmeyer flasks

M1190-9905 12 for 250/300 ml Erlenmeyer flasks

M1190-9906 8 for 500 ml Erlenmeyer flasks

M1190-9911 6 for 1 L Erlenmeyer flasks

M1190-9912 3 for 2 L Erlenmeyer flasks

Page 32

32

Ordering information

New Brunswick Innova® 2000/2050 Shaker

English (EN)

8.2 Accessory flask clamps

All clamps listed are made of stainless steel.

Catalog number Clamp type

ACE-105 10 mL Erlenmeyer

ACE-255 25 mL Erlenmeyer

ACE-505 50 mL Erlenmeyer

ACE-125S 125 mL Erlenmeyer

ACE-250S 250 mL Erlenmeyer

ACE-500S 500 mL Erlenmeyer

ACE-1000S 1.0 L Erlenmeyer

ACE-2000S 2.0 L Erlenmeyer

ACE-4000S 4.0 L Erlenmeyer

ACE-6000S 6.0 L Erlenmeyer

ACFE-2800S 2.8 L or 2800 mL Fernbach

ACSB-500S 500 mL Media Bottles

ACSB-1000S for 1 L Media Bottles

Page 33

Ordering information

New Brunswick Innova® 2000/2050 Shaker

8.3 Service parts

Model Part number Description Quantity

Innova 2000/2050 P0380-3830 0.2 A / 250 V / Time

Delay - Fuse

P0380-3410 1.0 A / 250 V Time Delay

/ 5 × 20 mm - Fuse

EF-104 1.0 A / 250 V / Time

Delay - Fuse

P0420-1610 10 VA Transformer 1

M1190-5300 80 VA Transformer 1

P0320-0340 4100 uF Capacitor 1

P0460-4091 Diode Bridge 1

P0360-4040 130 V Varistor 2

M1190-5320 Small Motor Assembly 1

M1190-9940 Main Control PCB 1

M1190-5000 Membrane Sw. Panel 1

P0460-2200 Power Entry Module 1

P0720-2053 Power Cord 120 V 10 A1

P0720-2021 Power Cord 220 V1

P0180-0020 Bearing, Shielded, lower 6

M1190-6340 Bearing Assembly 3

R-243 Drive Belt 1

M1190-6330 Bearing Housing

Assembly

H-1386 Knob 4

M1194-8000 Stainless Steel RTD

(optional)

Innova 2000 only M1190-9501 Foam Pad 1

Innova 2050 only M1190-9502 Foam Pad 1

1

1

1

1

1

33

English (EN)

8.4 Clamp hardware

Eppendorf flask clamps are used on a variety of shaker platforms. Flat Phillips and flat head screws of

different lengths and thread pitch are used to secure the clamp. The following tables identify the proper

screw for your shaker application by reference to the head style.

Page 34

34

Ordering information

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Tab. 8-3: 10 – 500 mL clamp hardware application chart

Description Part number Qty. Application

10-24 x 5/8 (15.87 mm) flat

Phillips (+) head screw

10-24 x 5/16 (7.9 mm) flat

Phillips (+) head screw

10-32 x 5/16 (7.9 mm) flat

slotted (-) head screw

Tab. 8-4: 1 – 6 Liter clamp hardware application chart

Description Part number Qty. Application

10-24 x 5/8 (15.87 mm)

flat Phillips (+) head screw

10-24 x 5/16 (7.9 mm) flat

Phillips (+) head screw

10-32 x 5/16 (7.9 mm) flat

slotted (-) head screw

S2116-3101 1 19.05 mm (3/4 in) thick wood platform

S2116-3051 1

S2117-3050 1 All stainless steel platforms

S2116-3101 5 19.05 mm (3/4 in) thick wood platform

S2116-3051 5 7.9 mm (5/16 in) thick aluminum,

S2117-3050 5 All stainless steel platforms

7.9 mm (5/16 in) thick aluminum,

phenolic and stainless steel platforms

phenolic and stainless steel platforms

The 1 – 6 liter chart also applies to 2800 mL Fernbach flask clamps.

Page 35

Transport, storage and disposal

New Brunswick Innova® 2000/2050 Shaker

English (EN)

9 Transport, storage and disposal

9.1 Disposal

In case the product is to be disposed of, the relevant legal regulations are to be observed.

Information on the disposal of electrical and electronic devices in the European Community:

Within the European Community, the disposal of electrical devices is regulated by national regulations

based on EU Directive 2012/19/EU pertaining to waste electrical and electronic equipment (WEEE).

According to these regulations, any devices supplied after August 13, 2005, in the business-to-business

sphere, to which this product is assigned, may no longer be disposed of in municipal or domestic waste. To

document this, they have been marked with the following identification:

35

Because disposal regulations may differ from one country to another within the EU, please contact your

supplier if necessary.

In Germany, this is mandatory from March 23, 2006. From this date, the manufacturer has to offer a

suitable method of return for all devices supplied after August 13, 2005. For all devices supplied before

August 13, 2005, the last user is responsible for the correct disposal.

Page 36

36

Transport, storage and disposal

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Page 37

10 Certifications

Declaration of Conformity

The product named below fulfills the requirements of directives and standards listed. In the case of

unauthorized modifications to the product or an unintended use this declaration becomes invalid.

Product name:

Innova® 2100 and 2150

including accessories

Certifications

New Brunswick Innova® 2000/2050 Shaker

English (EN)

37

Product type:

Benchtop open air shaker

Relevant directives / standards:

2006/95/EC: EN 61010-1

2004/108/EC: EN 61000-6-1, EN 61000-6-4

2011/65/EU

2012/19/EU

Date: October 28, 2013

tnemeganaM oiloftroPdraoB tnemeganaM

Your local distributor: www.eppendorf.com/contact

Eppendorf AG · 22331 Hamburg · Germany

eppendorf@eppendorf.com

Eppendorf and the Eppendorf Logo are registered trademarks of Eppendorf AG Hamburg/Germany.

All rights reserved incl. graphics and pictures. Copyright 2013 © by Eppendorf AG.

www.eppendorf.com

ISO 9001

Certified

ISO 13485

Certified

ISO 14001

Certified

M1194-2115-00

Page 38

38

Index

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Index

A

Accessories............................................................11

Alarm ...................................................11, 22, 22, 22

B

Bearings ................................................................13

C

Clamps...................................................................32

Cleaning ................................................................25

Construction ..........................................................13

Continuous run......................................................21

Control board.........................................................14

Control panel .........................................................11

D

Display...................................................................12

Disposal .................................................................35

K

Keypad .................................................................. 12

M

Main illustration...................................................... 9

Mains/power ......................................................... 11

Maintenance .........................................................25

Manual conventions................................................ 6

Measuring temperature ........................................ 23

Motor ....................................................................14

O

Operation .............................................................. 10

Optional features................................................... 15

P

Platform assemblies.............................................. 13

Platform installation.............................................. 19

Platforms............................................................... 11

E

Eccentric drive ......................................................14

Electrical connections ...........................................19

F

Features.................................................................10

Flask clamp hardware ...........................................33

Flask clamp installation.........................................20

Front view................................................................9

Fuse replacement ..................................................25

I

Indicators.........................................................13, 13

R

Run time................................................................ 23

S

Setpoints ............................................................... 21

Specifications........................................................ 27

Speed .............................................................. 27, 28

Speed/monitor option ........................................... 24

Starting the shaker................................................ 21

Symbols used.......................................................... 6

T

Temperature monitor............................................ 23

Timer............................................................... 21, 22

Page 39

U

Universal power module .......................................11

Unpacking .............................................................17

Using this manual....................................................5

V

Voltages.................................................................17

Index

New Brunswick Innova® 2000/2050 Shaker

English (EN)

39

Page 40

40

Index

New Brunswick Innova® 2000/2050 Shaker

English (EN)

Page 41

Page 42

Evaluate your manual

Give us your feedback.

www.eppendorf.com/manualfeedback

Your local distributor: www.eppendorf.com/contact

Eppendorf AG · 22331 Hamburg · Germany

eppendorf@eppendorf.com · www.eppendorf.com

Loading...

Loading...