Page 1

BA00064S/04/EN/17.18

71393076

Valid from version

SWG70-xx-1: 03.00.xx (firmware)

SWG70-xx-2: 03.00.xx (firmware)

SWG70-xx-3: 01.00.xx (firmware)

Products Solutions Services

Operating Instructions

WirelessHART Fieldgate SWG70

Intelligent WirelessHART gateway

with Ethernet and RS-485 interface

Page 2

Page 3

WirelessHART Fieldgate SWG70 Table of Contents

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . 3

Revision history . . . . . . . . . . . . . . . . . . . . 5

Registered Trademarks. . . . . . . . . . . . . . 5

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Installation, commissioning and operation . . . . . . 6

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 IT security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . 7

1.6 Technical improvement . . . . . . . . . . . . . . . . . . . . . . 7

1.7 Conventions and icons . . . . . . . . . . . . . . . . . . . . . . . 8

2 Identification . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.1 Visual inspection . . . . . . . . . . . . . . . . . . . . . 9

2.1.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . 9

2.1.3 Storage and transport . . . . . . . . . . . . . . . . . 9

2.2 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Ordering information . . . . . . . . . . . . . . . . . . . . . . 10

3 Function and system design. . . . . . . . . 11

3.1 WirelessHART protocol . . . . . . . . . . . . . . . . . . . . 11

3.2 WirelessHART network . . . . . . . . . . . . . . . . . . . . 12

3.2.1 Network management . . . . . . . . . . . . . . . 12

3.2.2 WirelessHART security management . . 12

3.3 Connecting to HART-compatible host systems . 13

3.3.1 Instrument list . . . . . . . . . . . . . . . . . . . . . 13

3.3.2 Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Installation . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Mounting considerations . . . . . . . . . . . . . . . . . . . 15

4.1.1 Positioning the Fieldgate . . . . . . . . . . . . 15

4.1.2 Antenna range . . . . . . . . . . . . . . . . . . . . . 16

4.1.3 Examples of good and poor positioning 17

4.2 Mounting the antenna . . . . . . . . . . . . . . . . . . . . . 17

4.2.1 Mounting the antenna supplied . . . . . . . 18

4.2.2 Connecting a remote antenna . . . . . . . . 18

4.3 Mounting the Fieldgate . . . . . . . . . . . . . . . . . . . . 19

5 Electrical Installation . . . . . . . . . . . . . . 20

5.1 Connections and interfaces . . . . . . . . . . . . . . . . . 20

5.2 Connecting to power supply and grounding . . . 21

5.3 Connecting to Ethernet . . . . . . . . . . . . . . . . . . . . 22

5.3.1 Connecting the "Modbus" or "Modbus

+ OPC" versions to Ethernet . . . . . . . . . . 22

5.3.2 Connecting the "EtherNet/IP"

version to Ethernet . . . . . . . . . . . . . . . . . 23

5.4 Connecting to RS-485 . . . . . . . . . . . . . . . . . . . . . 24

5.5 Cable glands and housing cover . . . . . . . . . . . . . 25

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1 Operating and display elements . . . . . . . . . . . . . . 26

6.1.1 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.2 Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.3 DIP switches . . . . . . . . . . . . . . . . . . . . . . . . 29

7 Commissioning . . . . . . . . . . . . . . . . . . . 31

7.1 Ethernet connection . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1.1 Establishing the connection

between the host computer

and the Fieldgate SWG70 Web server . . 33

7.2 RS-485 connection . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3 Creating a FieldCare project . . . . . . . . . . . . . . . . . 34

7.3.1 Adding the HART IP CommDTM . . . . . . . 34

7.3.2 Adding the Fieldgate SWG70 . . . . . . . . . . 36

7.3.3 Parameterizing Fieldgate SWG70 . . . . . . 37

7.3.4 Scanning for wireless devices

in the network . . . . . . . . . . . . . . . . . . . . . . 38

7.3.5 Scanning for devices connected

to adapters . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.4 User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 Fieldgate configuration . . . . . . . . . . . . 42

8.1 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.2 Wireless Communication . . . . . . . . . . . . . . . . . . . . 43

8.2.1 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2.2 Advanced Setup . . . . . . . . . . . . . . . . . . . . . 45

8.2.3 Operating Modes . . . . . . . . . . . . . . . . . . . . 47

8.3 Interfaces (wired communication) . . . . . . . . . . . . 48

8.3.1 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.3.2 Serial (RS-485) . . . . . . . . . . . . . . . . . . . . . . 49

8.4 Protocols (wired communication) . . . . . . . . . . . . 50

8.4.1 Modbus via Ethernet or RS-485 . . . . . . . 50

8.4.2 EtherNet/IP via Ethernet . . . . . . . . . . . . . 51

8.4.3 HART via Ethernet or RS-485 . . . . . . . . . 51

8.4.4 AMS via Ethernet . . . . . . . . . . . . . . . . . . . . 52

9 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . 53

9.1 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.2 Wireless Communication . . . . . . . . . . . . . . . . . . . . 54

9.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.2.2 Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.2.3 Burst Lists . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.2.4 Topology View (Diagnostics) . . . . . . . . . . 57

9.3 Wired Communication . . . . . . . . . . . . . . . . . . . . . . 58

9.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.3.2 HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10 Engineering . . . . . . . . . . . . . . . . . . . . . . 62

10.1 Instrument List . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.1.2 Creating and editing an Instrument List . 63

10.2 Topology View (Engineering) . . . . . . . . . . . . . . . . 65

Endress+Hauser 3

Page 4

WirelessHART Fieldgate SWG70 Table of Contents

10.3 Configuring Modbus . . . . . . . . . . . . . . . . . . . . . . . 68

10.3.1 Modbus Settings . . . . . . . . . . . . . . . . . . . . 68

10.3.2 Input Status . . . . . . . . . . . . . . . . . . . . . . . . 69

10.3.3 Input Register . . . . . . . . . . . . . . . . . . . . . . 73

10.4 Configuring a WirelessHART OPC server . . . . . . 76

10.4.1 System architecture of an

OPC WirelessHART network . . . . . . . . . . 77

10.4.2 Configuring the WirelessHART

OPC server with "WirelessHART

Fieldgate OPC Configurator" . . . . . . . . . . 78

10.4.3 Description of the WirelessHART

Fieldgate OPC Configurator . . . . . . . . . . 81

10.4.4 Configuring bursts using

the WirelessHART OPC server . . . . . . . . 84

10.5 EtherNet/IP configuration . . . . . . . . . . . . . . . . . . 88

10.5.1 Setting up an EtherNet/IP connection . . 88

10.5.2 Assigning data exchange connections

via HART descriptors . . . . . . . . . . . . . . . . 88

10.5.3 Burst commands

for cyclic data exchange . . . . . . . . . . . . . 89

10.5.4 Integrating SWG70 into a PLC

via EtherNet/IP . . . . . . . . . . . . . . . . . . . . . 90

10.5.5 Cyclic data exchange

via the ControlLogix® controller system 90

10.5.6 Connection parameters

for cyclic data exchange . . . . . . . . . . . . . 95

10.5.7 Diagnostic bits in cyclic data exchange . 98

10.6 Downstream Communication

(for discreet field devices) . . . . . . . . . . . . . . . . . . 99

10.7 Substitution value (substitution value to DCS) 100

10.7.1 Burst message monitoring . . . . . . . . . . 101

10.7.2 Factory Acceptance Test (FAT) . . . . . . 103

10.8 Security – Whitelist, Temporary Join Key . . . . 103

14 Troubleshooting . . . . . . . . . . . . . . . . . 114

14.1 Faults indicated by Fieldgate LEDs . . . . . . . . . . 114

14.2 Wired Communication Faults . . . . . . . . . . . . . . 114

14.3 Wireless Communication Faults . . . . . . . . . . . . 115

14.4 Error messages of the WirelessHART

OPC server in the "Event Viewer" window . . . . 116

15 Technical data. . . . . . . . . . . . . . . . . . . 117

16 Modbus Interface . . . . . . . . . . . . . . . . 118

16.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

16.1.1 Modbus protocol . . . . . . . . . . . . . . . . . . 118

16.1.2 Modbus in Fieldgate . . . . . . . . . . . . . . . 119

16.1.3 Data types . . . . . . . . . . . . . . . . . . . . . . . . 122

16.2 Rules for mapping . . . . . . . . . . . . . . . . . . . . . . . 123

16.2.1 Automatic mapping of analog devices

(HART CMD 3) . . . . . . . . . . . . . . . . . . . . 123

16.2.2 Digital input/output devices . . . . . . . . . 124

16.3 Mapping formats . . . . . . . . . . . . . . . . . . . . . . . . 125

16.3.1 Dynamic process variables . . . . . . . . . . 125

16.3.2 Status mapping . . . . . . . . . . . . . . . . . . . 125

16.3.3 HART CMD48

Read Additional Status Information . . 126

16.3.4 Read Digital Inputs . . . . . . . . . . . . . . . . 127

17 CSV file formats . . . . . . . . . . . . . . . . . 128

17.1 Structure of the CSV files . . . . . . . . . . . . . . . . . . 128

17.2 Modbus Mapping CSV files . . . . . . . . . . . . . . . . 128

17.3 Instrument List CSV files . . . . . . . . . . . . . . . . . . 129

17.4 Topology View CSV file . . . . . . . . . . . . . . . . . . . 129

17.5 Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

11 Additional Functions . . . . . . . . . . . . . 106

11.1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.2 Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.3 Firmware Upgrade (Web Server) . . . . . . . . . . . 107

11.4 Change Password (Web Server) . . . . . . . . . . . . 108

11.5 Set DTM Addresses (DTM) . . . . . . . . . . . . . . . . 108

11.6 Set Device Addresses (DTM) . . . . . . . . . . . . . . . 109

11.7 Upload Certificate (Web server) . . . . . . . . . . . . 110

11.7.1 Self-signed security certificate . . . . . . . 110

11.7.2 Trusted security certificate . . . . . . . . . . 110

11.8 Auto Refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12 Measurement. . . . . . . . . . . . . . . . . . . . 112

13 Maintenance and repair. . . . . . . . . . . 113

13.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.2 Return to Endress+Hauser. . . . . . . . . . . . . . . . . 113

13.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.4 Contact addresses . . . . . . . . . . . . . . . . . . . . . . . . 113

13.5 Accessories and spare parts . . . . . . . . . . . . . . . . 113

18 Table Device Variable Classification

and Unit Code . . . . . . . . . . . . . . . . . . . 131

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4 Endress+Hauser

Page 5

WirelessHART Fieldgate SWG70 Revision history

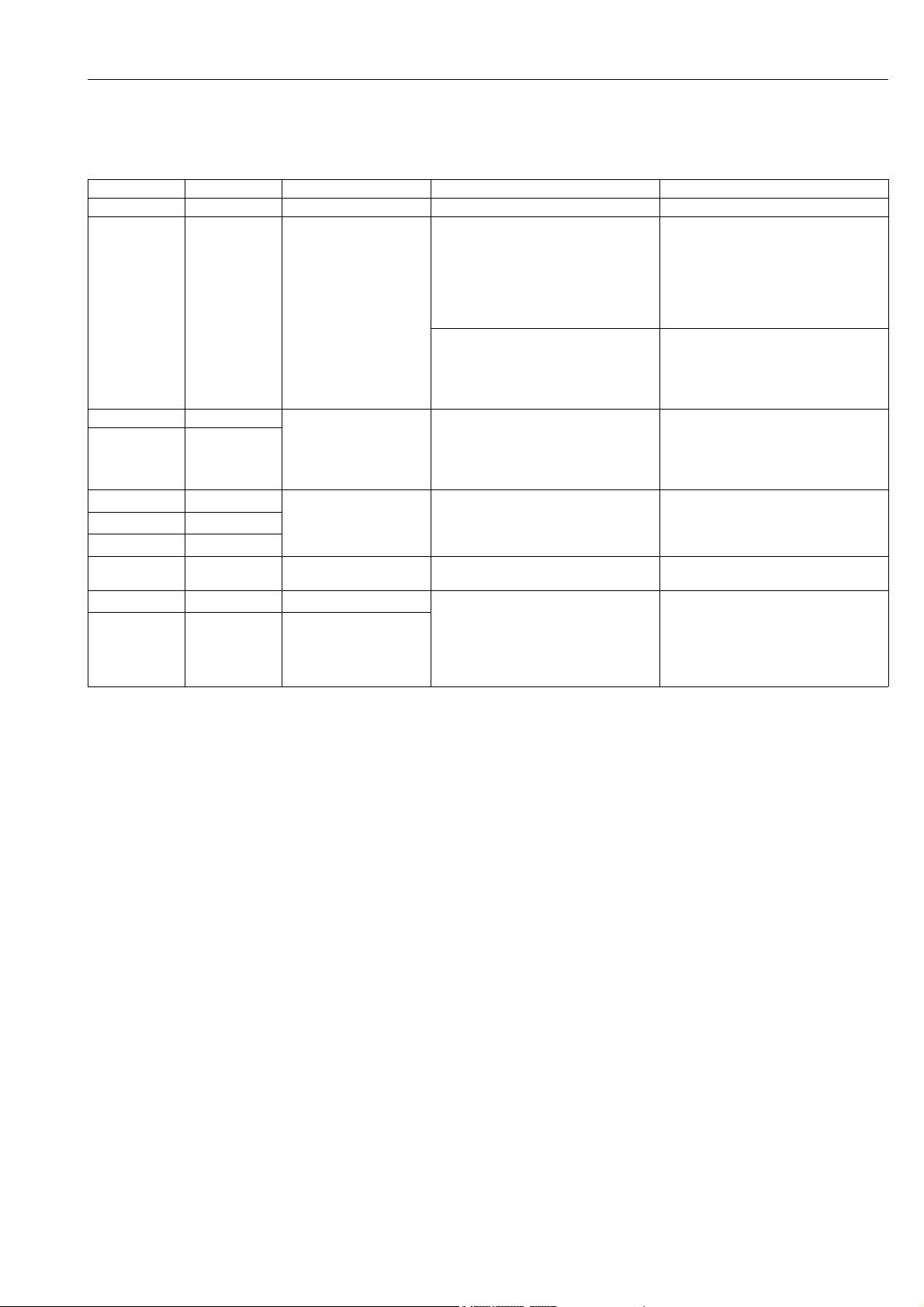

Revision history

Order code Product version Manual Changes Remarks

SWG70-xx-1 1.00.xx BA064S/04/en/06.10 – First version of Operating Instructions

SWG70-xx-1 1.01.xx BA00064S/04/en/13.13 New Functions • Navigation changed, Chapter 7.6

• Channel Blacklisting possible,

Chapter 8.2.2

• Topology with signal strength,

Chapter 9.2.4 and 10.3

• Network tables revised, e.g.

Chapter 8.2.3

Manual Restructuring • Chapter 8 Fieldgate configuration =>

Chapters 8 to 12

• Chapter 10 Modbus => Appendix A

• Chapter 9 HART OPC Server =>

Appendix B

SWG70-xx-1 2.00.xx BA00064S/04/en/14.14 Description of the WirelessHART

SWG70-xx-2 2.00.xx

SWG70-xx-1 2.03.xx BA00064S/04/en/15.15 New Functions

SWG70-xx-2 2.03.xx

SWG70-xx-3 1.01.xx

SWG70-xx-3 1.00.xx BA00064S/04/en/16.16 Correction of product version with order

SWG70-xx-1 3.00.xx BA00064S/04/en/17.18 New functions

SWG70-xx-2 3.00.xx

Fieldgate OPC Configurator and burst

configuration

Manual Restructuring

code SWG70-xx-3 from 1.01.xx to 1.00.xx

The new functions are not included in

version SWG70-xx-3.

• New Chapter 1.4 "IT security"

• New Chapter 11 "WirelessHART

Fieldgate OPC Configurator"

• Deleted Appendix C "HART OPC

Connection"

• EtherNet/IP amended

• Technical data moved to Technical

Information for "WirelessHARTFieldgate SWG70" (TI00027S)

• Editorial changes, removal of all

references to "CD-Rom"

• Notice in Chapter 1.1 added

• Chapter 7.1.1 edited

• Chapter 8.2.1 edited

• New chapters 10.6, 10.7, 10.8

• Chapter 11.4 edited

•New Chapter 11.9

Registered Trademarks

HART® and WirelessHART

Registered trademarks of the HART Communication Foundation, Austin/Texas, USA

Microsoft

®

and Windows

Registered trademarks of the Microsoft Corporation.

PC Easy Connect Suite

Registered trademark of Softing AG

ControlLogix

®

Registered trademark of Rockwell Automation

MatrikonOPC Tunneller

Registered trademark of MatrikonOPC

All other brand and product names are trademarks or registered trademarks of the companies and organizations in question.

®

®

®

TM

Endress+Hauser 5

Page 6

Safety WirelessHART Fieldgate SWG70

1Safety

1.1 Designated use

Fieldgate SWG70 serves as a gateway for WirelessHART networks. It enables WirelessHART

devices to communicate with each other and manages security and connectivity. The

Fieldgate converts wireless device data to a format that is compatible with host systems.

NOTICE!

• The WirelessHART protocol may not be used to replace the wiring in the case of safety

applications with a control function.

1.2 Installation, commissioning and operation

The WirelessHART Fieldgate can be operated safely in compliance with the current

guidelines for technical safety and the latest EU directives. Wireless field devices and

adapters connected to the WirelessHART Fieldgate must also be operated in accordance

with the current guidelines for technical safety and the latest EU directives.

If the WirelessHART Fieldgate is installed incorrectly or used in applications for which it is

not intended, it is possible that dangers may arise.

Installation, connection to the electricity supply, commissioning, operation and

maintenance of the WirelessHART Fieldgate may only be carried out by trained, qualified

technical specialists authorized to perform such work by the facility's owner-operator. The

specialist staff must have read and understood these Operating Instructions and must follow

the instructions they contain. It is not permitted to modify or repair the devices in any way.

NOTICE!

• Changes or modifications to the Fieldgate not expressly approved by Endress+Hauser will

void the user’s authority to operate the equipment.

1.3 Operational safety

Location Fieldgate SWG70 fulfills the requirements of EU Guidelines for a number of applications.

The associated environmental conditions must be upheld. See the Technical Information

document for "WirelessHART Fieldgate SWG70" (TI00027S).

The device must not be installed at locations where corrosive vapors may be present.

Hazardous areas Fieldgate SWG70 is available in a version that can be mounted in an explosion hazardous

area. In order to ensure the necessary degree of protection:

• All seals must be undamaged and have been correctly fitted.

• All screws of the housing/housing cover must have been tightened with the appropriate

torque.

• Only cable of the appropriate size must be used in the cable glands.

• All cable glands must have been tightened with the appropriate torque, see (Chapter 5.5).

• All empty cable glands must have been sealed with sealing plugs.

6 Endress+Hauser

Page 7

WirelessHART Fieldgate SWG70 Safety

When installing components in explosion hazardous areas:

• Ensure that all installation and maintenance personnel are suitably qualified.

• Check that all equipment has the appropriate safety certificates.

• Observe the specifications in the device certificates as well as national and local

regulations.

Coexistence of wireless

technologies

Operation CAUTION!

WirelessHART networks use the frequency spectrum between 2400 ... 2483.5 MHz according to IEEE 802.15.4. Various other wireless technologies also use this frequency spectrum,

for example WLAN and Bluetooth. Depending upon the situation, it is possible that these

different wireless technologies will affect each other.

When wireless technologies are used in an industrial environment, they must coexist without interfering with each other. If you find that systems are interfering with each other, take

appropriate measures to ensure the operation of all wireless systems, e.g. by reconfiguring,

enforcing a wireless compatibility policy, etc.

Maintain a minimum distance of 20 cm between the device antenna and the body of the user

and all persons in the vicinity at all times and for all applications and uses.

1.4 IT security

The Fieldgate SWG70 is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings. Additional IT security measures in line with

operators' security standards and designed to provide additional protection for the device

and device data transfer must be implemented by the operators themselves.

The Fieldgate offers the following functions that increase IT security:

• WirelessHART security management (See Chapter 3.2.2 "WirelessHART security

management" on page 12 and see Chapter 8.2.1 "Basic Setup" on page 43.)

• Password for Web server (See Chapter 11.4 "Change Password (Web Server)" on

page 108.)

• Security certificate for Web server (See Chapter 11.7 "Upload Certificate (Web server)" on

page 110.)

See the Technical Information document "WirelessHART Fieldgate SWG70" (TI00027S) for

system-specific firewall configurations such as TCP/IP ports and services.

1.5 Declaration of Conformity

All Declarations of Conformity can be found on www.endress.com.

CE Mark The WirelessHART Fieldgate SWG70 meets the legal requirements of the relevant EC direc-

tives. Endress+Hauser confirms successful testing of the WirelessHART Fieldgate SWG70 by

affixing to it the CE mark. An EC Declaration of Conformity has been issued for the Ex-versions and non-Ex versions of the device.

1.6 Technical improvement

Endress+Hauser reserves the right to make technical improvements to its software and

equipment at any time and without prior notification. Where such improvements have no

effect on the operation of the equipment, they are not documented. If the improvements

effect operation, a new version of the operating instructions is normally issued.

Endress+Hauser 7

Page 8

Safety WirelessHART Fieldgate SWG70

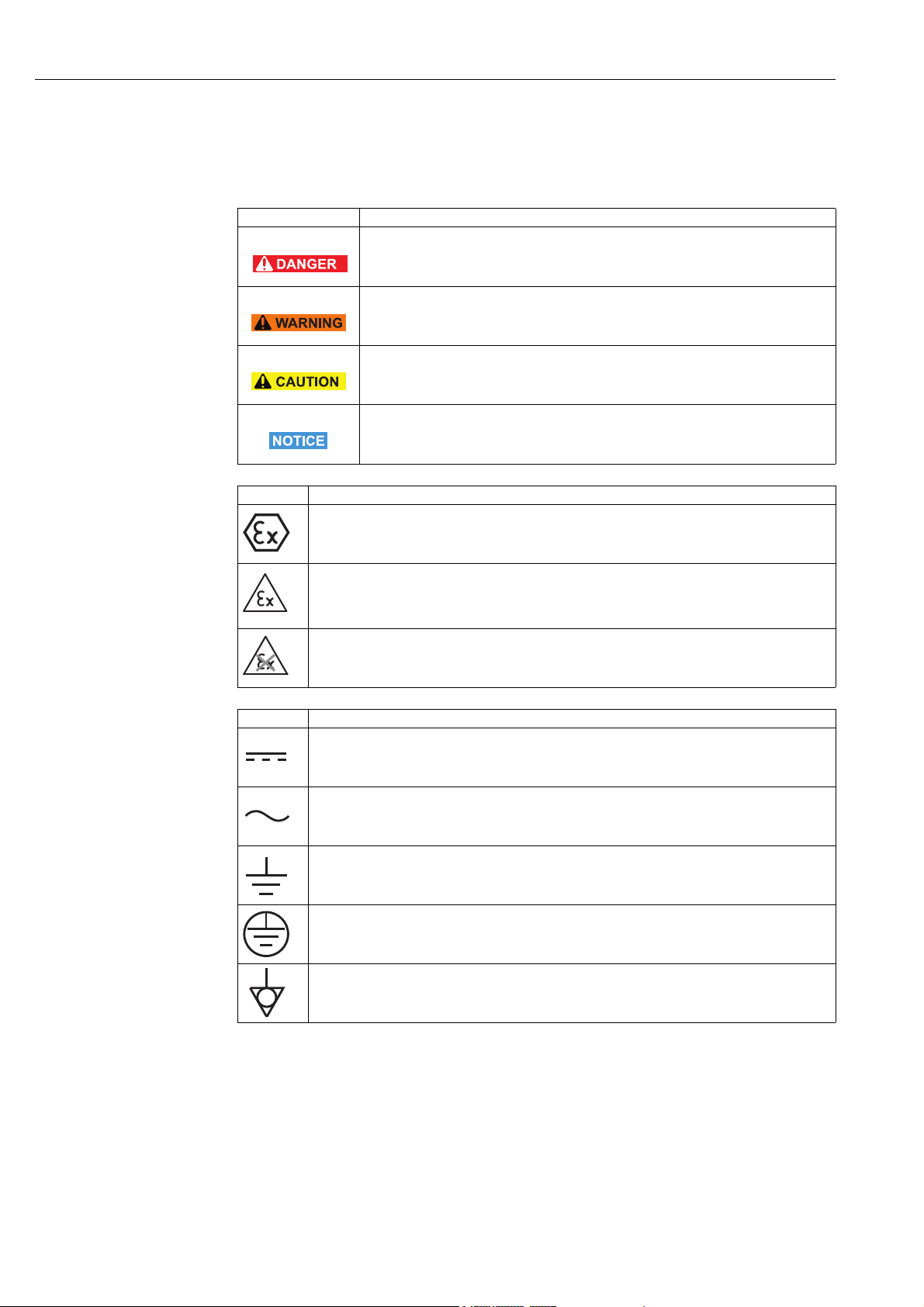

1.7 Conventions and icons

In order to highlight safety relevant or alternative operating procedures in the manual, the

following conventions have been used, each indicated by a corresponding icon in the margin.

Safety conventions

Type of protection .

Icon Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result

in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result

in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result

in minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Icon Meaning

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an explosion

hazardous area in accordance with the specifications in the certificate or in a safe area.

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas. Devices located in and wiring

entering areas with the designation “explosion hazardous areas” must conform with the stated type

of protection.

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas. Devices located

in safe areas still require a certificate if their outputs run into explosion hazardous areas.

Electrical symbols .

Icon Meaning

Direct voltage

A terminal to which or from which a direct current or voltage may be applied or supplied.

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or voltage may be applied or

supplied.

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is already grounded by means of an

earth grounding system.

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making any other connection to the

equipment.

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type e.g. neutral star or

equipotential line according to national or company practice.

8 Endress+Hauser

Page 9

WirelessHART Fieldgate SWG70 Identification

1

2

4

3

x

Made in Germany

CH-4153 Reinach, Switzerland

Order code:

SWG70-1056/0

Ser. no.:

60011009001

Ext. ord. cd.:

SWG70-BG3

WirelessHART Fieldgate SWG70

U:

P:

Ta:

Dev.Rev.:

CMIIT-ID:

FCC-ID:

Contains:

IC-ID:

5853A-M2140

SJC-M2140

2.4 GHz

Dat./Insp.:

2015-07-06

XA00C01S

II 3 G Ex nA nC IIC T4 Gc

НАНИО “ЦСВЭ”

No.: TC RU C-CH.ГБ05.В.00043

2ExnAIIT4 X

DC 20...30 V

< 5 W

-20 °C...+60 °C

R

202-SMD11

0976

IP 66 / IP 67 / NEMA 4

MAC:

DD-DD-BE-DD-DD-BB

FW:

1

2011DJ5310

Anatel ID: HHHHFF-AAAA

FW:

HW:

01.00.01

01.00.00

Order code:

Ser. no.:

Ext. ord. cd.:

2 Identification

2.1 Unpacking

2.1.1 Visual inspection

During unpacking:

• Check the packing materials for signs of transportation damage.

• Remove the packaging material with care, so as not to damage the Fieldgate.

• Store the original packing material, in case the Fieldgate must be shipped again.

• Keep the documentation supplied with the Fieldgate in a safe place.

• Keep the accompanying documents.

2.1.2 Scope of delivery

Please check that the delivery is complete and free of defects before starting installation.

The scope of delivery comprises the following parts:

• WirelessHART Fieldgate SWG70

•Antenna

• Short instructions

• Depending upon order, FieldCare Device Setup DVD

2.1.3 Storage and transport

Always store and transport the device in the original packaging.

Always store the device in a clean, dry environment.

Keep within the permitted storage temperature range. See the Technical Information

document for "WirelessHART Fieldgate SWG70" (TI00027S).

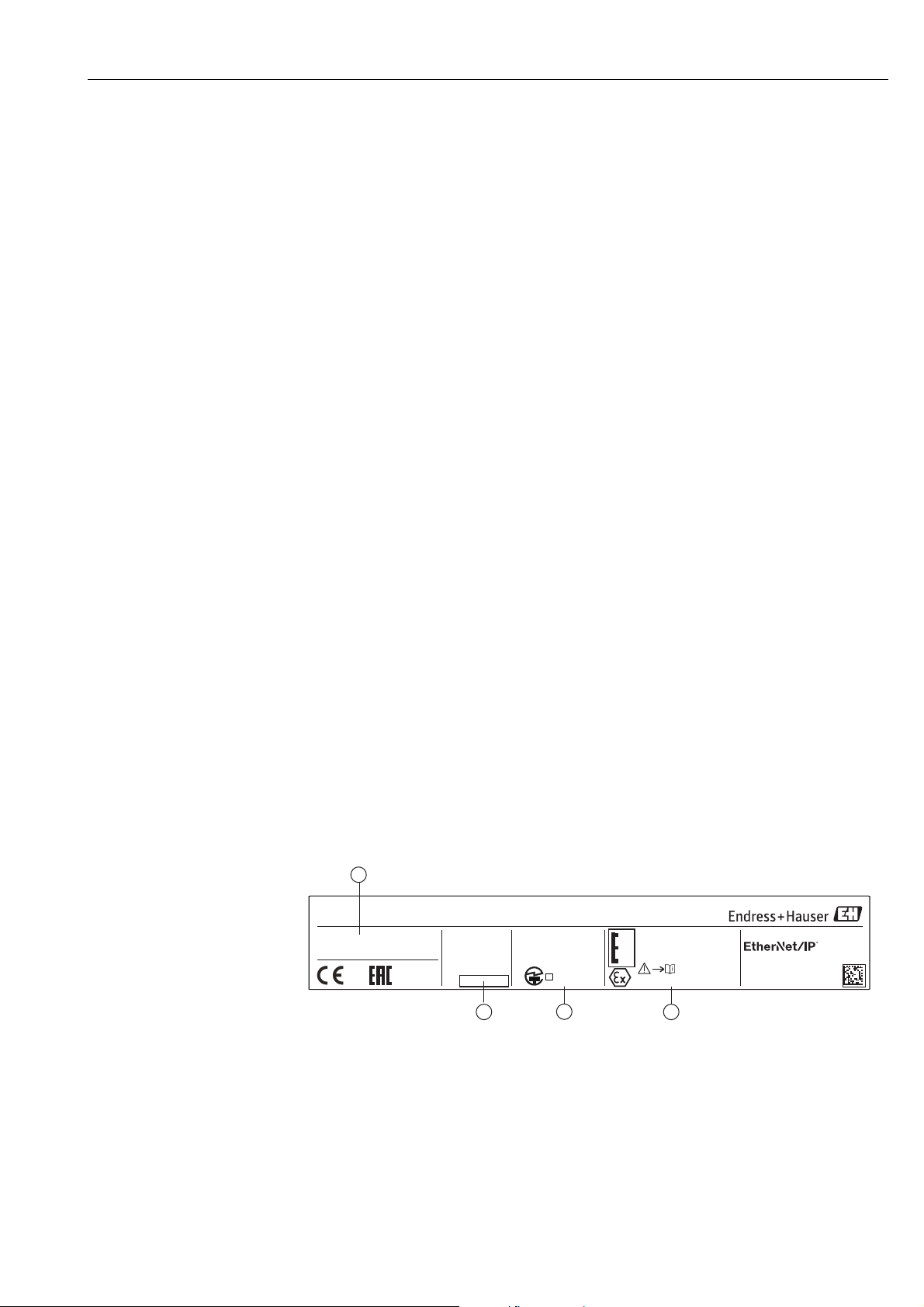

2.2 Nameplate

The device designation together with other information can be found on the nameplate

affixed to the front of the Fieldgate.

Fig. 2-1: Nameplate (example)

Endress+Hauser 9

1 Order number and serial number

2 Type of protection, if any

3 Telecommunication compliance

4 Version information

Page 10

Identification WirelessHART Fieldgate SWG70

2.3 Ordering information

Detailed information about the product structure is available:

• On the Endress+Hauser website: www.endress.com/SWG70

• From your Endress+Hauser Sales Center: www.addresses.endress.com

10 Endress+Hauser

Page 11

WirelessHART Fieldgate SWG70 Function and system design

3 Function and system design

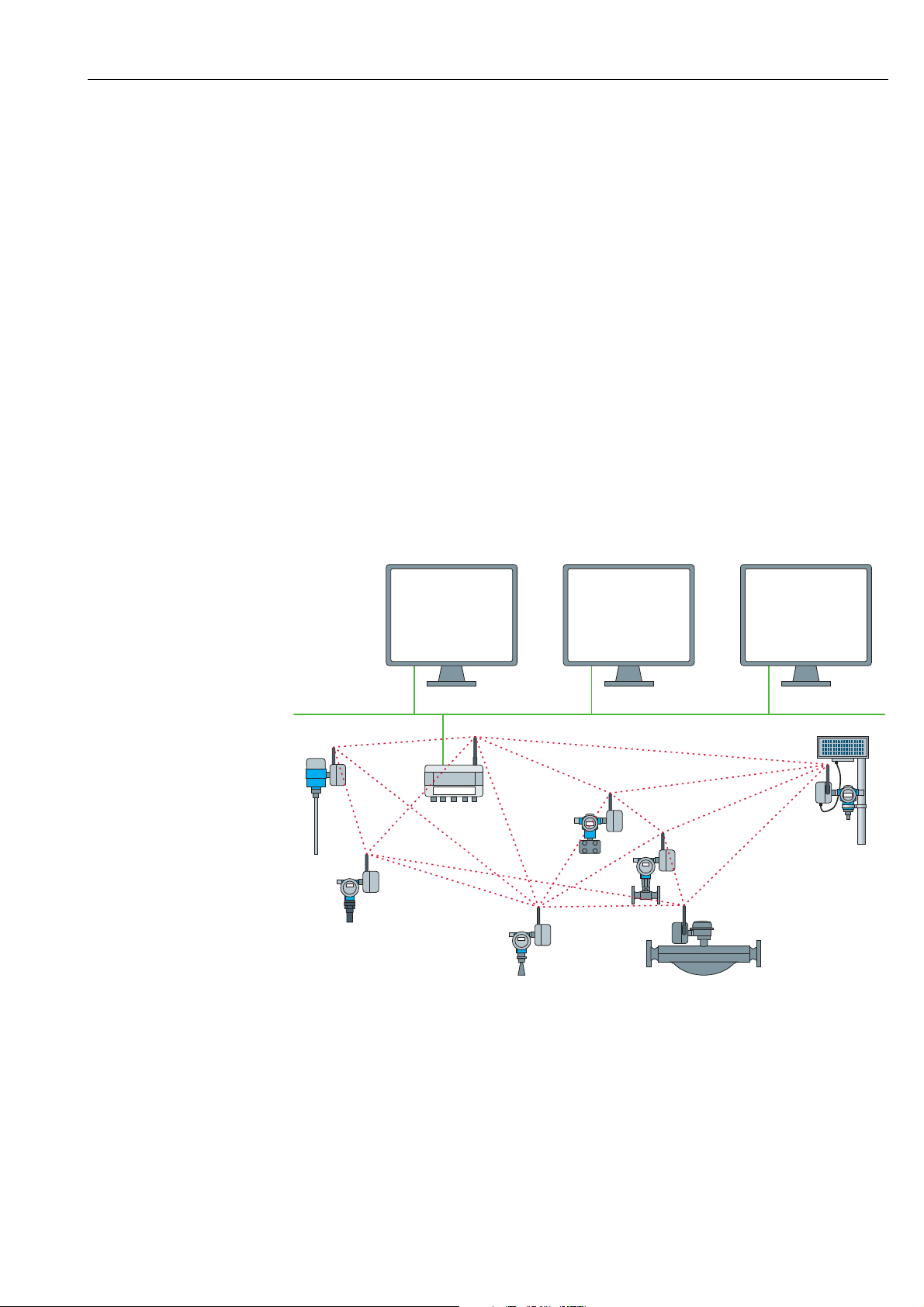

3.1 WirelessHART protocol

The HART protocol has until now used the wired 4–20 mA loop with a superimposed digital

signal as physical layer.

WirelessHART enables the wireless transmission of HART data. To be employable worldwide, WirelessHART utilizes the 2.4 GHz Band (IEEE 802.15.4 wireless network) as physical

layer. The WirelessHART devices form a mesh network in which every device is not just a

measurement point, but also a repeater. This results in a wider range for the whole network

as well as increased reliability through redundant communication paths.

The network may comprise three types of device:

• WirelessHART gateway (Fieldgate SWG70)

• WirelessHART field devices

• WirelessHART Adapters (SWA70): either connected to 4–20 mA/HART devices or acting

as repeaters.

The WirelessHART network is built up, organized and maintained by the Fieldgate, which

also takes care for connection to different HOST systems through different bus interfaces.

1

Ethernet

4

4

3

2

4

4

4

4

Fig. 3-1: WirelessHART network

1 Host applications

2Ethernet

3 WirelessHART Fieldgate

4 Field devices with wireless

Endress+Hauser 11

Page 12

Function and system design WirelessHART Fieldgate SWG70

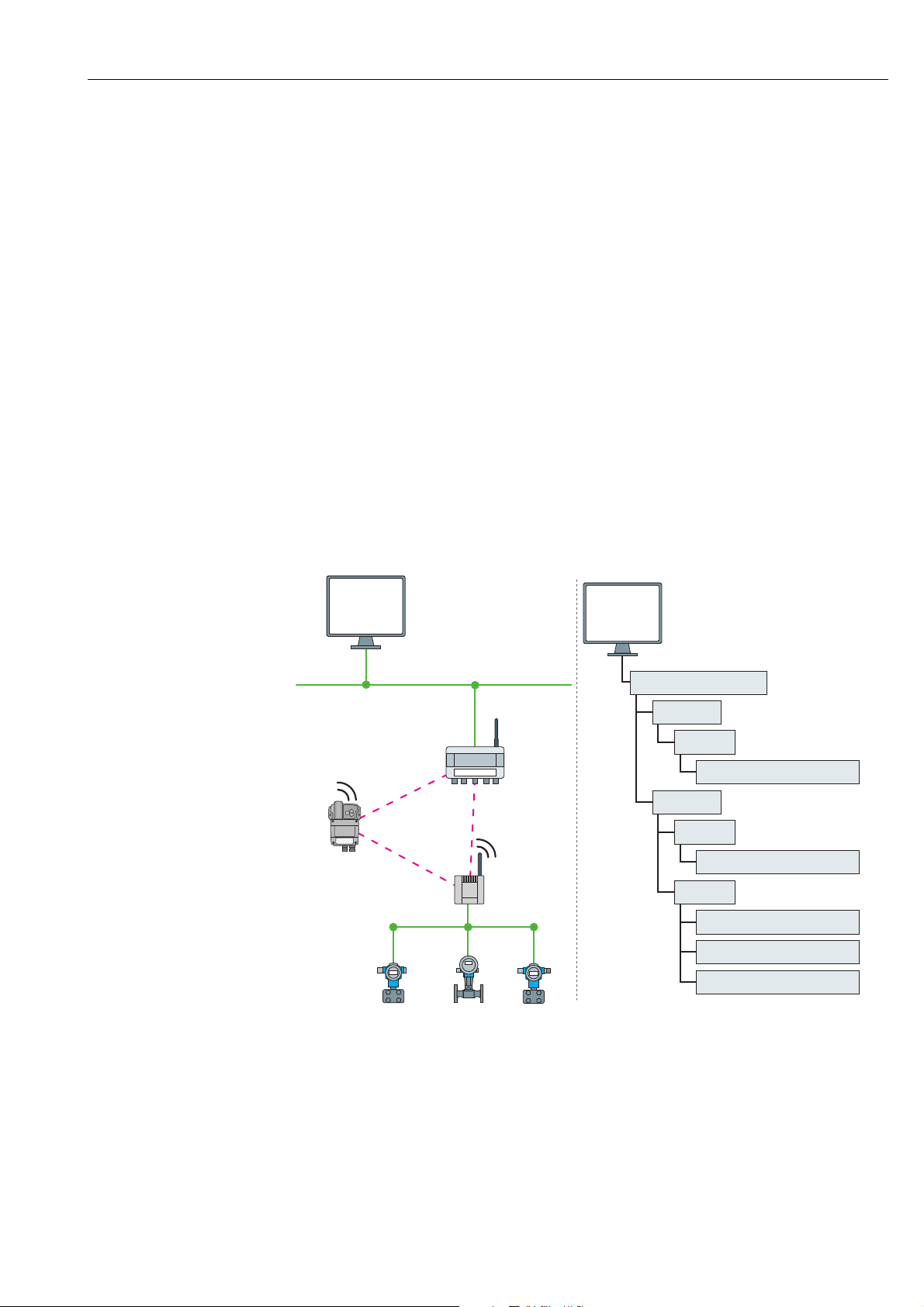

1

2

4

5

3

3.2 WirelessHART network

Fieldgate SWG70 is the master device in the WirelessHART network. Acting as network

manager, it recognizes other devices wanting to join the network. It makes contact with each

in turn and initiates the procedures required for them to join. The network organizes itself

without any intervention on the part of the user. Fieldgate SWG70 also acts as security manager and collects the data sent by the network participants, converting it into a form which

can be used by other systems connected to it.

3.2.1 Network management

In its role as network manager, Fieldgate SWG70 organizes the wireless communication

between the WirelessHART field devices.

Fig. 3-2: Network management

1Step 1: Advertising

2Step 2: Join Request

3 Step 3: Authorization, Session & Network Keys,

Scheduling and Routing

4 WirelessHART gateway (Fieldgate SWG70)

5 WirelessHART device or adapter

After the Fieldgate has started up the network, devices can join. To this end, it first sends out

a call for devices to join the network. Then, the device sends a join request to announce its

wish to join the network. If the WirelessHART field device can identify itself with the same

network ID and join key as stored in the WirelessHART Fieldgate, the field device is authorized to join the network. Otherwise, the field device will be rejected.

In the next step, the WirelessHART Fieldgate sends session and network keys as well as

scheduling and routing information to the field device. The field device is told how to participate in the network and receives various information from the WirelessHART Fieldgate:

• Number and identity of neighboring WirelessHART field devices,

• When to send messages and which channels to use,

• When to repeat messages for other WirelessHART field devices,

• The optimal communication path for messages as well as alternative communication

paths in case of failure.

During this process, the WirelessHART device or adapter may also apply to send messages

in certain intervals and ask the network manager for the appropriate resources. The network

manager then takes care that these resources are available. For example, the network manager informs other WirelessHART field devices when to repeat messages.

3.2.2 WirelessHART security management

Fieldgate SWG70 also acts as security manager. To make communication safe, all messages

are encrypted with industry-standard AES-128 block ciphers with symmetric keys. Therefore, messages are unreadable for external listeners. The encryption keys are distributed by

the security manager.

The Join Key is used to join the network. Subsequently, the Join Key is automatically

exchanged against the Session Key and the Network Key, i.e. two new additional keys.

12 Endress+Hauser

Page 13

WirelessHART Fieldgate SWG70 Function and system design

1

2

3

4

5

WirelessHART-Gateway

I/O card 1

I/O card 2

Channel 0

WirelessHART Field device

WirelessHART Adapter

Channel 0

Channel 1

WirelessHART Field device1

WirelessHART Field device2

WirelessHART Field device3

Network structure

1

2

3

4

5

5

5

Instrument list I/O structure

3.3 Connecting to HART-compatible host systems

Fieldgate SWG70 also makes wireless communication accessible to HART-capable host systems via its Ethernet interface or serial interfaces (RS-485) and the following functions.

Depending on the version ordered, Fieldgate SWG70 can also be integrated into Modbus,

OPC or Ethernet/IP host systems.

3.3.1 Instrument list

The WirelessHART devices in the network are made available to the host systems via an

instrument list. This list contains one or more I/O cards. Every I/O card has one or more

channels. Up to 6 field devices can be connected in multidrop mode to each channel. See

Figure 3-3 on page 13. The list itself can be up and downloaded. See Chapter 10.1 "Instrument List" on page 62.

Fieldgate SWG70 assigns a virtual I/O card to each WirelessHART device. The I/O cards are

assigned to the WirelessHART devices in the order in which they join the network. New

WirelessHART devices in the network are assigned to the next available I/O card, which is

added to the end of the instrument list (First-in-First-Out principle).

Within an I/O card, the WirelessHART device itself as well as status information is assigned

to Channel 0. If the WirelessHART device is an adapter, all field devices connected to it are

assigned to channel 1 (multi-drop mode). The list of the connected field devices is also called

sub-device list.

If a WirelessHART device loses communication to the Fieldgate, it stays assigned to the I/O

card initially allocated to it. When communication is established again, the device thus has

the same position in the instrument list that it had before.

The same principle applies to the field devices connected to the WirelessHART Adapter

(SWA70). When communication to the Fieldgate is lost, the long tags of the filed devices are

Fig. 3-3: Instrument list

stored. After communication has been established again, the field devices regain their previous position in the instrument list.

Endress+Hauser 13

Page 14

Function and system design WirelessHART Fieldgate SWG70

3.3.2 Cache

The WirelessHART Fieldgate stores information received over the WirelessHART network

and makes it available to the host for further processing. This ensures that information is

available immediately for the host system without having to send a request to the device and

wait for the response. The following commands and answers to requests are cached in the

Fieldgate.

Information cached in the

WirelessHART Fieldgate

Cache HART Command Description

Static: cached upon

read

Static: cached upon

read & write

confirmation

Dynamic: cached on

publication only

0, 11, 21 Read unique identifier (associated with tag or long tag)

12, (17) Read (Write) Message

13, (18) Read (Write) Short Tag, Descriptor, Date

20, (22) Read (Write) Long Tag

50 (51) Read (Write) Dynamic Variable Assignments

1 Read Primary Variable

2 Read Current and Percentage

3 Read All Variables

9 Read Device Variables and Status

33 Read Device Variables

38 Read Additional Device Status

48 Reset Configuration Change Counter

93 Read Trend

Each listed command has its own cache memory. Static commands are stored in the cache

upon the first request. Dynamic variables are stored each time a field device sends a burst

message so that up-to-date values are available at all times.

With the exception of write commands 17, 18, 22 and 51, when the WirelessHART

Fieldgate receives a request from a host system which is embedded in Command 77, the

response is sent immediately (provided that the response is available in the cache).

Long Tag Emulation WirelessHART uses the long tag for addressing devices. Not every HART device supports

long tags, for example, older HART devices with HART Protocol Version 5 or less, do not support long tag addressing.

If a HART 5.0 device is connected to a WirelessHART Adapter (SWA70), the WirelessHART

Fieldgate emulates the long tag using the "Message" field. When a host system addresses a

HART 5 device, the emulation translates Command 20(22) directly into Command 12 (17)

which the HART 5 understands. The response is stored in the Fieldgate cache for CMD

12(17) and for CMD 20(22).

14 Endress+Hauser

Page 15

WirelessHART Fieldgate SWG70 Installation

4Installation

NOTICE!

• It is recommended that Fieldgate SWG70, adapters and devices be setup on the test bench

and the network be tested before the components are installed in the field.

4.1 Mounting considerations

4.1.1 Positioning the Fieldgate

Install the Fieldgate before installing other WirelessHART devices. This way you can check

for proper operation of new devices as they are installed. Nevertheless, consider the location

of future WirelessHART devices that will be routed through the Fieldgate to ensure good

connectivity.

Guidelines for Planning a

WirelessHART Network

• Mark the positions of the various measuring points on a scale overview of the plant. It is

important that the overview shows likely obstacles to the propagation of the radio waves.

• Make sure that a minimum of 2 other WirelessHART devices are well within the antenna

range of the device. If necessary, consider using an adapter as an additional stand-alone

repeater. Please refer to the following section for more information about the antenna

properties.

• Where a lot of metal, grids or walls prevent a device from being in line-of-sight of its

nearest neighbor, the maximum distance between two devices is 30 m. Install wireless

devices at least 1m above the ground or the floor.

• Where there are fewer structural elements and one or more neighbors are in direct lineof- sight, the maximum distance between two devices for planning purposes is 200 m. In

this case, install wireless devices at least 3m above the ground or the floor.

• Consider moving objects that could affect the device's antenna range.

• Make sure that the device's antenna is aligned vertically.

• If possible, position the Fieldgate at or near the center of the network - it should be in

contact with at least 20% of the devices in the network.

• Do not position WirelessHART devices directly below or above each other as they will be

outside each other's antenna range. See Chapter 4.1.3 "Examples of good and poor

positioning" on page 17.

• If possible, do not position the device next to metal surfaces, pipes or walls containing

metal (minimum distance: 6 centimeters). There should be as little metal around the

device as possible.

• Do not position other 2.4 GHz devices like cordless phone bases or WLAN routers near

WirelessHART devices. Wireless technologies used in an industrial environment must be

able to coexist without disrupting each other. If multiple networks operate in one facility,

wireless frequency management may be required.

Endress+Hauser 15

Page 16

Installation WirelessHART Fieldgate SWG70

1

2

2

1

α

α

α

α

100%

100%

50%50%

50%50%

0%

0%

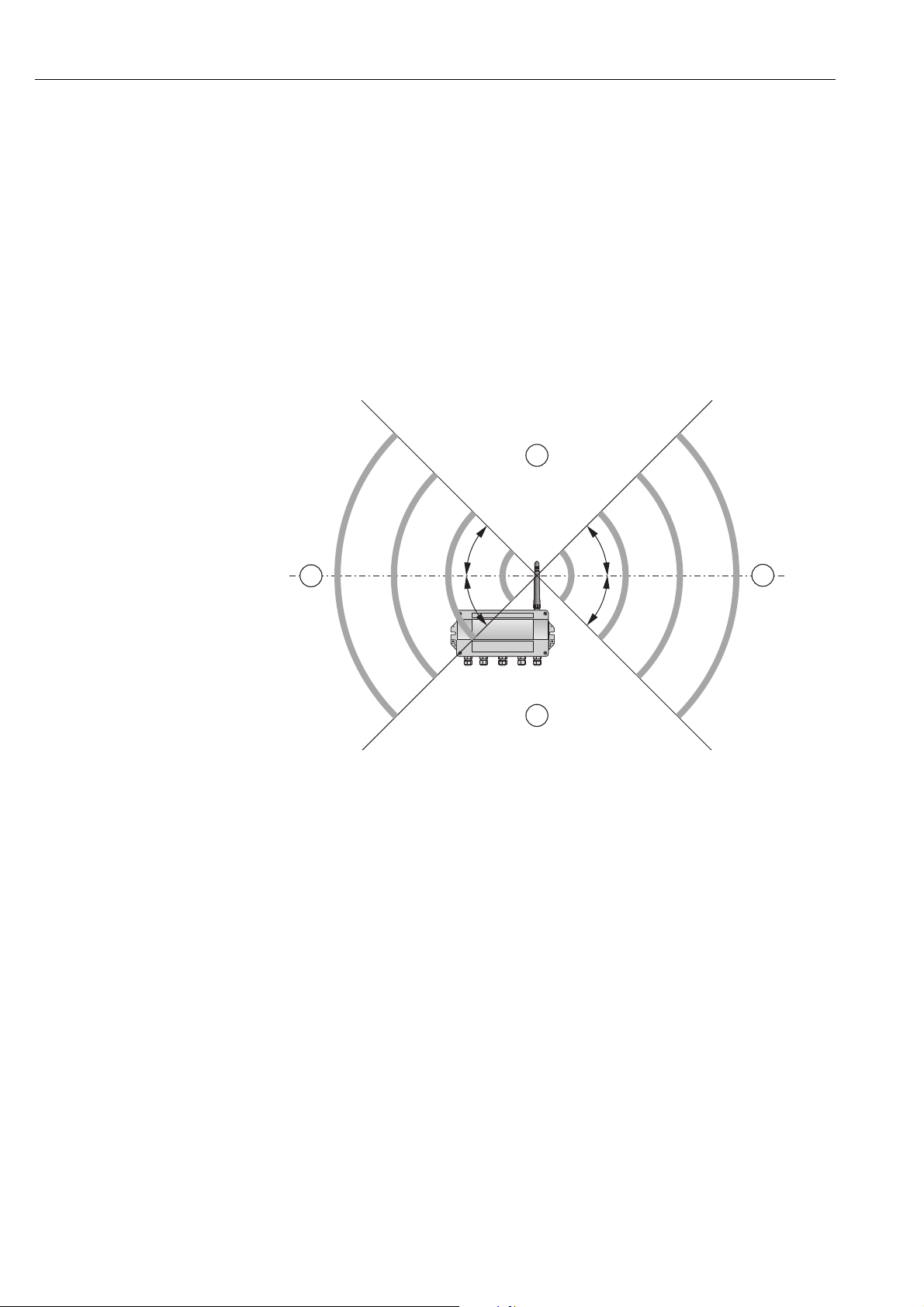

4.1.2 Antenna range

The antenna supplied is an omni-directional dipole antenna.

A schematic representation of the wave propagation is provided in the following graphic.

If the antenna is pointed upwards, the signal is emitted horizontally. The transmission and

reception quality decreases by up to 50% as of an angle of approx. 39°. Almost no signal will

be radiated directly above and below the antenna.

We therefore recommend that you mount the wireless devices on one plane where possible.

If you must mount the wireless devices on very different planes, we recommend you use a

remote antenna. See Chapter 4.2 "Mounting the antenna" on page 17. Different coverage is

achieved with a remote antenna. For the associated requirements, please see the Technical

Information document for "WirelessHART Fieldgate SWG70" (TI00027S).

Fig. 4-1: Wave propagation, schematic representation (alpha = approx. 39°)

1 No signal above and below 2 Stronger signal sideways

16 Endress+Hauser

Page 17

WirelessHART Fieldgate SWG70 Installation

PWR

COM

FLT

-

Height

Distance

/

Height

Distance

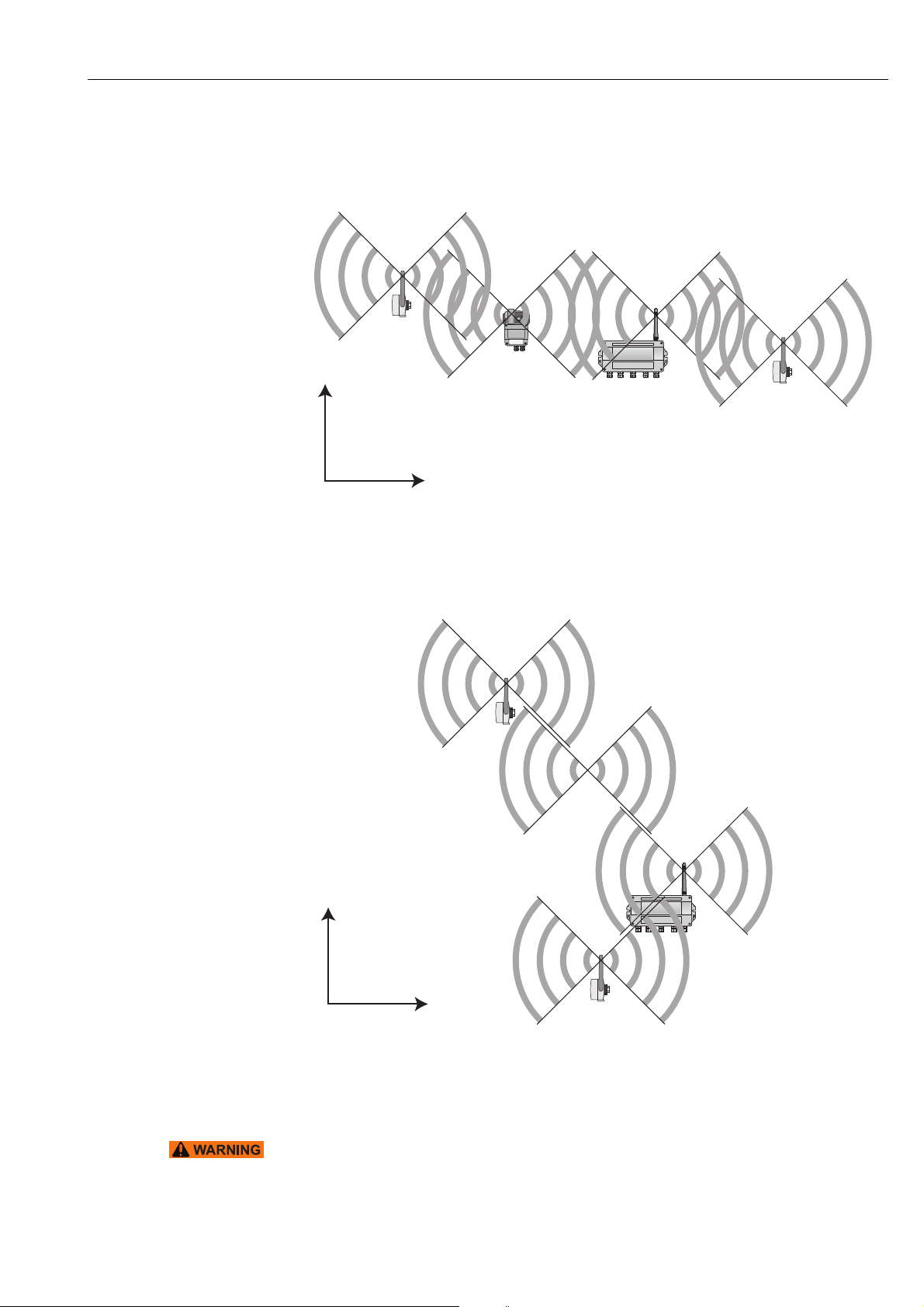

4.1.3 Examples of good and poor positioning

The positioning is good when the network participants are within the antenna range:

Fig. 4-2: Example of good positioning

The positioning is poor when neighbors are not in the antenna range or within the weaker

signal zone of the antenna:

Fig. 4-3: Example of poor positioning

Endress+Hauser 17

4.2 Mounting the antenna

WARNING!

• If Fieldgate SWG70 is installed in a hazardous area Zone 2, you may only connect or

disconnect the antenna and cables in the absence of any potentially explosive atmosphere

or if the Fieldgate is not connected to the power supply.

Page 18

Installation WirelessHART Fieldgate SWG70

2

1

6

7

53 4

NOTICE!

• Use only the antenna supplied or a remote antenna that meets the requirements. For

the associated requirements, please see the Technical Information document for

"WirelessHART Fieldgate SWG70" (TI00027S).

4.2.1 Mounting the antenna supplied

1. Switch off the power supply to the Fieldgate.

2. Firmly screw the antenna to the device's antenna terminal.

See Figure 5-1 on page 20, Item 6.

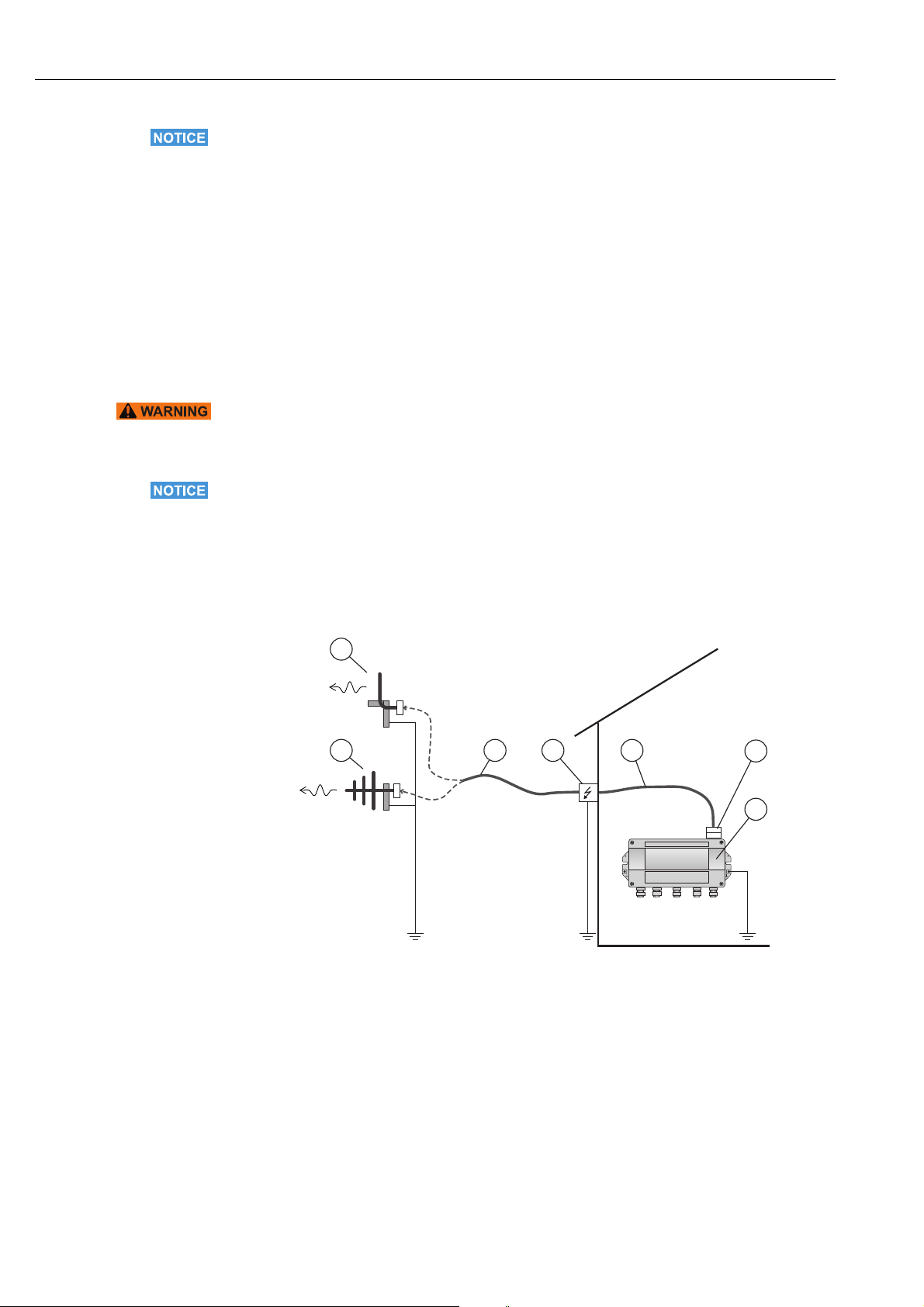

4.2.2 Connecting a remote antenna

WARNING!

• Outdoor installations can be subject to lightning strikes. Install a surge arrester to protect

the installation against transients or damage caused by lightning strikes.

NOTICE!

• Only use antennas, cables and surge arresters that are listed in the Technical Information

document "WirelessHART-Fieldgate SWG70" (TI00027S).

• Ensure adequate strain relief for the cables.

• Pay attention to the bending radii of the cables. Do not drop below the permitted bending

radii.

Fig. 4-4: Installation of an remote antenna

1 Omnidirectional antenna

2 Directional antenna

3 Coaxial cable with connector

4Surge arrester

5 Coaxial cable with connector

6 Coaxial adapter

7 Fieldgate SWG70

1. Switch off the supply voltage to the Fieldgate.

2. Install the antenna where it is within the antenna range of other WirelessHART

devices. See Chapter 4.1.3 "Examples of good and poor positioning" on page 17.

18 Endress+Hauser

Page 19

WirelessHART Fieldgate SWG70 Installation

2

1 1

2

3. Mount the surge arrester indoors. The coaxial cable between the surge arrester and

Fieldgate may only be routed indoors.

4. Connect the antenna to the surge arrester using a coaxial cable.

5. Connect the antenna, the surge arrester and the Fieldgate to the protective grounding

as illustrated in Figure Fig. 4-4.

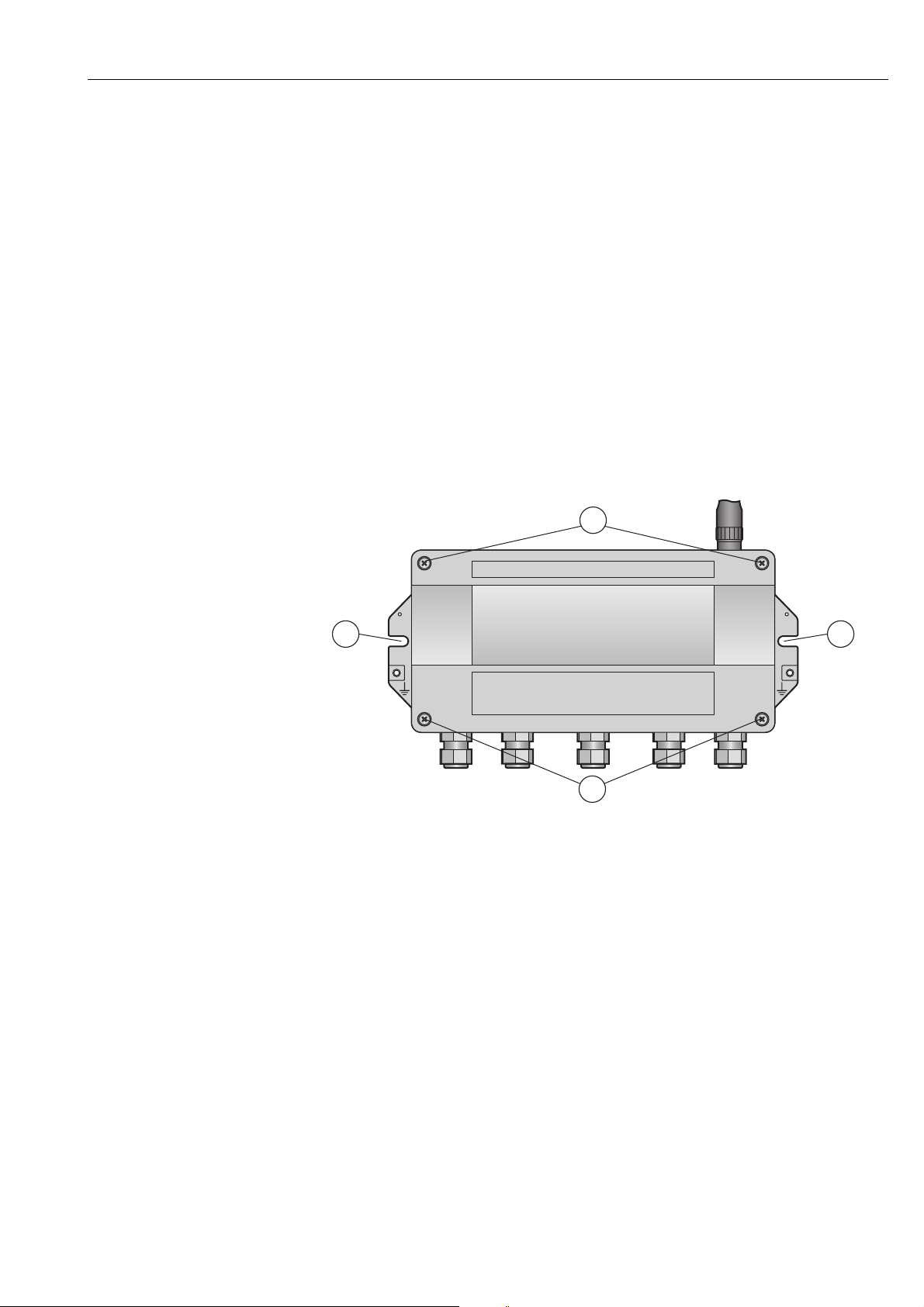

4.3 Mounting the Fieldgate

In addition to fulfilling the conditions for good wireless communication, the mounting location should be well accessible for mounting and electrical installation. Make sure that there

is enough space to open the housing cover and to access the terminals, switches, and cable

glands. Choose a mounting location that meets the climatic limits specified and radio

requirements in the technical data.

Required tools:

• 2 screws (M6)

• Drill

• Screwdriver

Fig. 4-5: Mounting holes and housing screws

1 Mounting holes 2 Housing screws

Mounting the Fieldgate 1. Drill 2 holes in the mounting surface so that they match the holes of the housing

(centers 240 mm to 250 mm apart). See the Technical Information document for

"WirelessHART Fieldgate SWG70" (TI00027S).

2. Screw the device to the mounting surface.

Endress+Hauser 19

Page 20

Electrical Installation WirelessHART Fieldgate SWG70

5

1

6

1

2 3 4

7

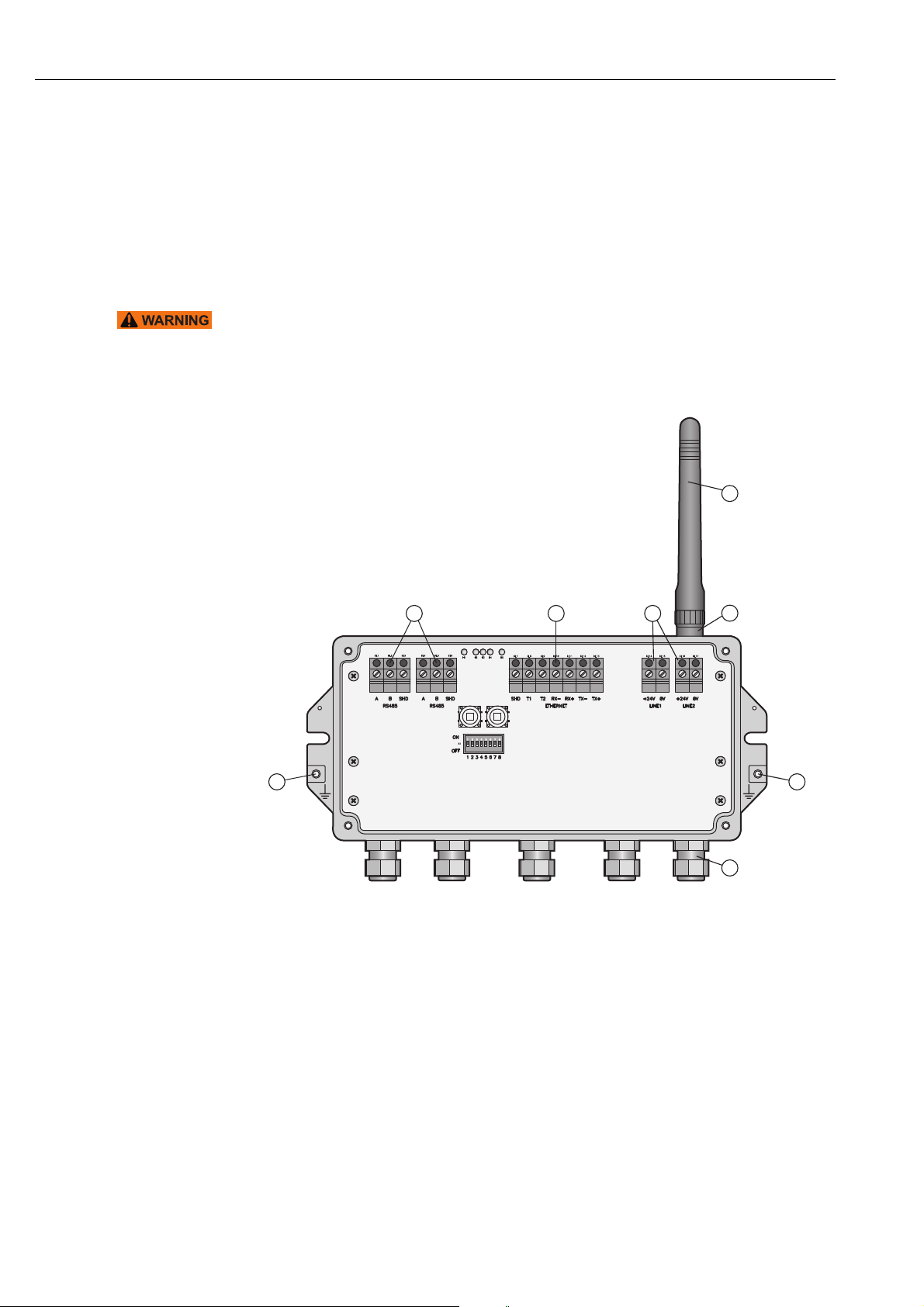

5 Electrical Installation

5.1 Connections and interfaces

The connections and interfaces are only accessible with an open enclosure. In the case of the

DIP switches, the user has the choice of using the switch settings, or overriding the settings

by software. See Chapter 8 "Fieldgate configuration" on page 42.

WARNING!

• If Fieldgate SWG70 is installed in a hazardous area Zone 2, you may only connect or

disconnect the antenna and cables in the absence of any potentially explosive atmosphere

or if the Fieldgate is not connected to the power supply.

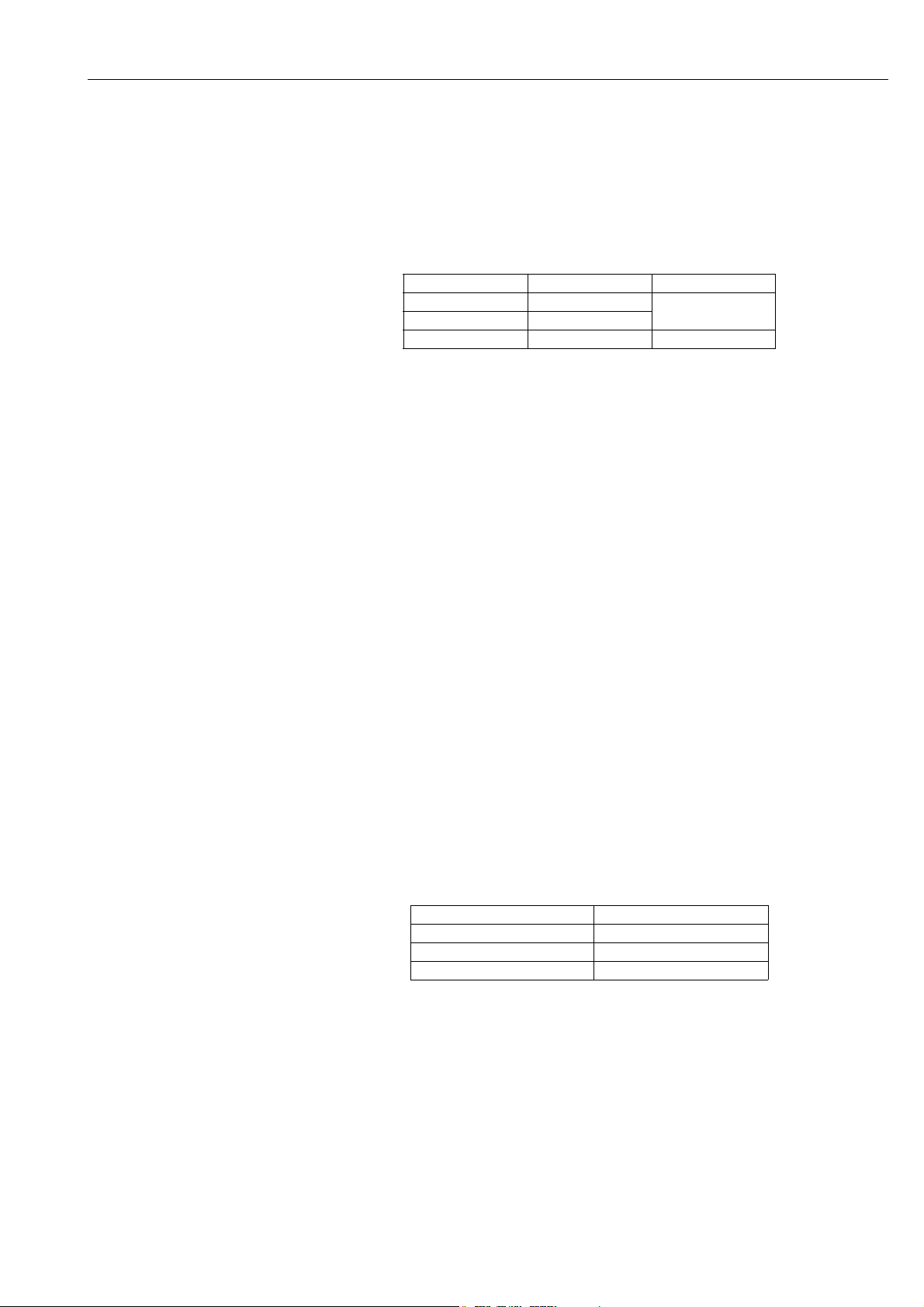

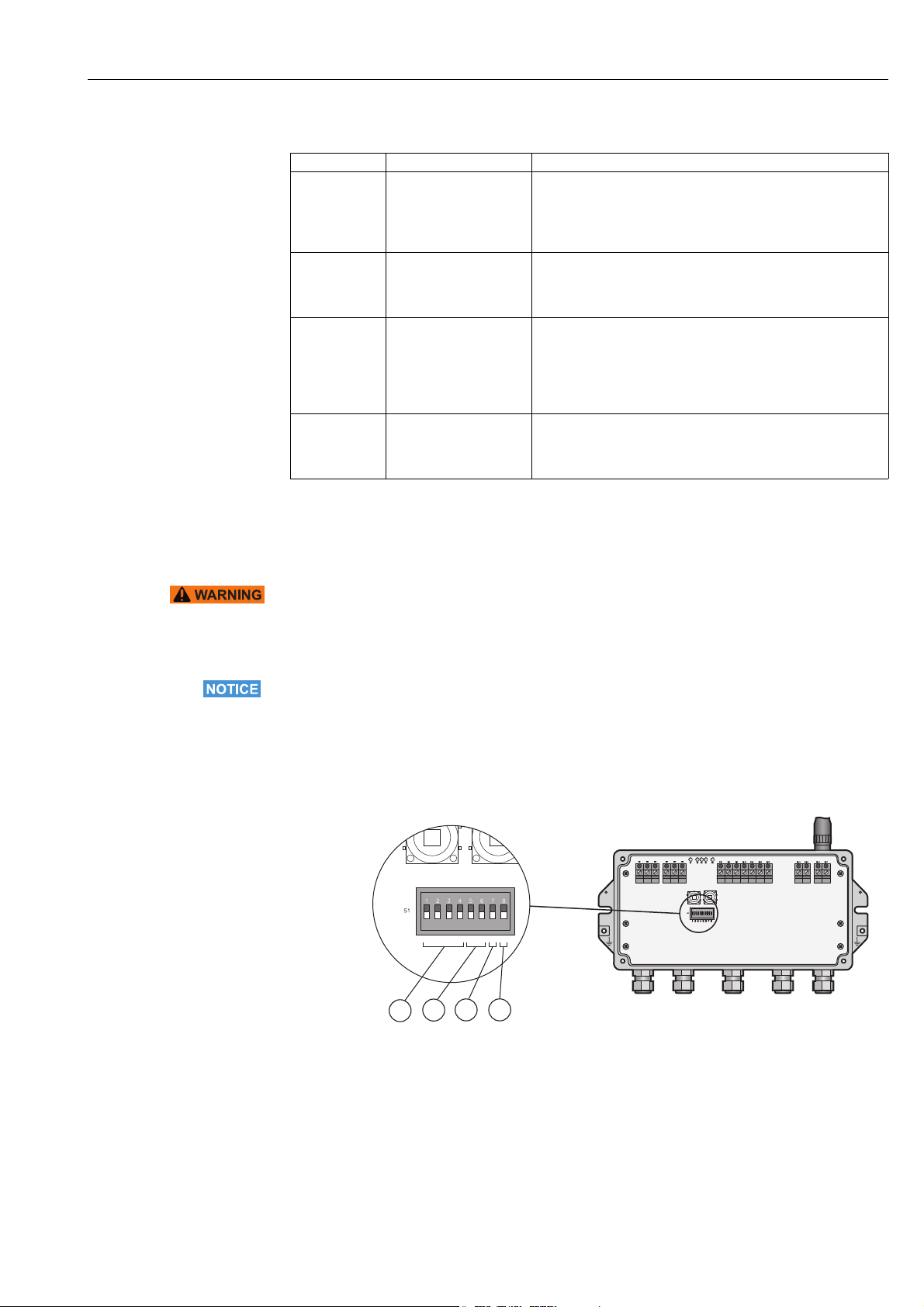

Fig. 5-1: Connections and interfaces

1Grounding terminal

2 RS-485 interfaces, duplicated terminal block for

daisy-chain capability

3 Ethernet interface

4 Power supply connections (redundant)

5 Antenna

6 Antenna terminal

7 Cable glands

20 Endress+Hauser

Page 21

WirelessHART Fieldgate SWG70 Electrical Installation

1

2

KL14

KL15 KL16

KL17

+24V +24V0V 0V

LINE1

LINE2

+24V +24V

0V 0V

LINE1 LINE2

A

B

SHD

RS485

T1

T2

RX–

RX+

TX–

TX+

ON

OFF

SHD

A

B

SHD

RS485

ETHERNET

3 3

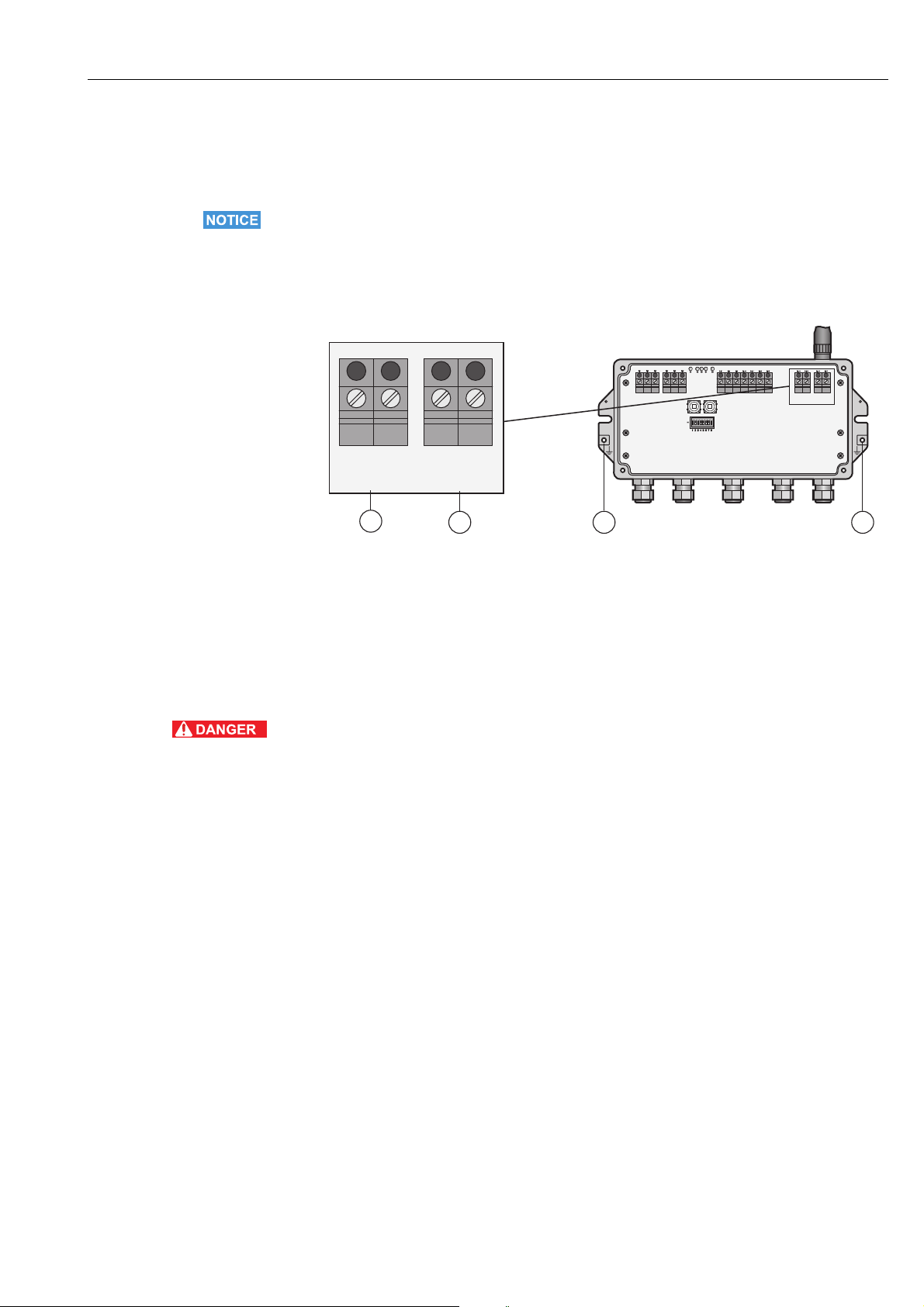

5.2 Connecting to power supply and grounding

There are two 24 VDC power supply terminal blocks located inside Fieldgate SWG70, allowing for redundant power supply. Open the housing cover to access the terminal blocks.

NOTICE!

• Ensure adequate strain relief for the cables.

• Pay attention to the bending radii of the cables. Do not drop below the permitted bending

radii.

Connecting to 24 VDC

power supply and

grounding

Fig. 5-2: Power supply

1 First power supply connection

3Grounding terminals

2 Second (redundant) power supply connection

Fieldgate SWG70 must be connected to a 24 VDC power supply. For details, see the

Technical Information document for "WirelessHART Fieldgate SWG70" (TI00027S).

DANGER!

Risk of electric shock if the wrong power unit is used.

• Always use a SELV/PELV power unit to guarantee electrical safety.

1. Switch off the power supply.

2. Connect the protective ground to one of the two ground terminals.

3. Unscrew the 4 screws of the housing cover and remove the housing cover. See

Figure 4-5 on page 19.

4. Route the 24 VDC power cable through the second cable gland from right.

The permissible cable diameter lies between 6 mm and 10 mm.

5. Connect the 24 VDC power cable to the first power supply connection "Line 1" observing

polarity. See Figure 5-1 on page 20.

6. If you want to connect a redundant power supply (optional), route the second 24 VDC

power cable through the cable gland on the far right of the housing.

7. Connect the second power cable to the second power supply connection "Line 2"

observing polarity.

8. Switch on the power supply. The green power LED should light up immediately.

9. Tighten the cable gland with appropriate torque. See Chapter 5.5 "Cable glands and

housing cover" on page 25.

Endress+Hauser 21

Page 22

Electrical Installation WirelessHART Fieldgate SWG70

KL7 KL8 KL9 KL10

+24V +24V

0V 0V

LINE1 LINE2

A

B

SHD

RS485

T1

T2

RX–

RX+

TX–

TX+

ON

OFF

SHD

A

B

SHD

RS485

ETHERNET

T1 T2 RX– RX+ TX– TX+SHD

ETHERNET

KL11 KL12 KL13

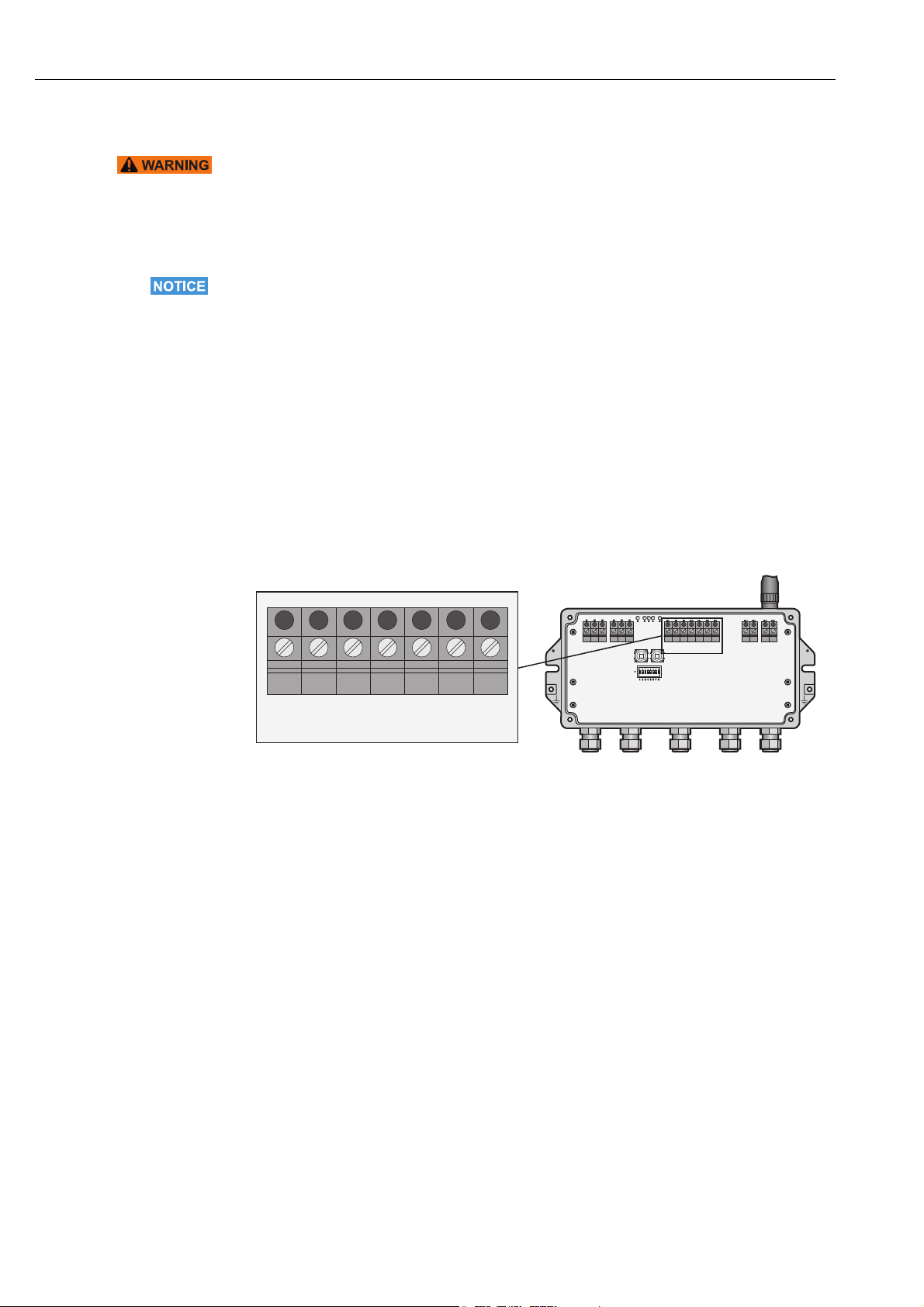

5.3 Connecting to Ethernet

WARNING!

• If Fieldgate SWG70 is installed in a hazardous area Zone 2, you may only connect or

disconnect the antenna and cables in the absence of any potentially explosive atmosphere

or if the Fieldgate is not connected to the power supply.

NOTICE!

• Keep in mind that an access point of the Ethernet network has to be available. The

maximum length of the cable running from the Fieldgate to the access point is 100 m,

depending on the cable type and communication speed.

• Please note that older computers, hubs, switches or routers might not feature automatic

TX/RX detection. In this case, use a crossover cable.

• Ensure adequate strain relief for the cables.

• Pay attention to the bending radii of the cables. Do not drop below the permitted bending

radii.

5.3.1 Connecting the "Modbus" or "Modbus + OPC" versions to

Ethernet

The Ethernet cable is connected directly to the Ethernet terminal block in the Fieldgate.

Fig. 5-3: Fieldgate with 5 cable entries and Ethernet terminal block

1. Switch off the power supply.

2. Unscrew the screws of the housing cover and remove the housing cover. See Figure 4-5

on page 19.

3. Route the Ethernet cable through the cable gland in the middle of the Fieldgate

housing. The permissible cable diameter is between 6 mm and 10 mm.

22 Endress+Hauser

Page 23

WirelessHART Fieldgate SWG70 Electrical Installation

123 45 678

KL7 KL8 KL9 KL10

A

B

SHD

RS485

T1

T2

ON

OFF

SHD

A

B

SHD

RS485

ET

T1 T2 RX– RX+ TX– TX+SHD

ETHERNET

KL11 KL12 KL13

4. Connect the Ethernet cable to the terminal block labeled "Ethernet" according to the

following table.

Computer Fieldgate

Pin Numbering Connector Crossover cable Normal cable

Pin 1 TX+ RX+

Pin 2 TX– RX–

Pin 3 RX+ TX+

Pin 4 T2 T2

Pin 5 T2 T2

Pin 6 RX– TX–

Pin 7 T1 T1

Pin 8 T1 T1

5. Screw the housing cover on the housing.

6. Tighten the cable gland with appropriate torque. See Chapter 5.5 "Cable glands and

housing cover" on page 25.

7. Switch on the power supply.

5.3.2 Connecting the "EtherNet/IP" version to Ethernet

The Ethernet cable with a D-coded M12 connector is connected to the M12 socket of the

Fieldgate housing.

Fig. 5-4: Fieldgate with M12 socket in the middle

1 Ethernet terminal block wired internally to M12

socket

2 M12 socket, D-coded for connection to an

Ethernet or Ethernet/IP network

1. Switch off the power supply.

2. Plug the D-coded M12 connector into the Ethernet socket of the Fieldgate. See

Figure 5-4 on page 23.

3. Tighten the coupling nuts on the M12 connector. The Fieldgate is connected to the

Ethernet network.

4. Switch on the power supply.

Endress+Hauser 23

Page 24

Electrical Installation WirelessHART Fieldgate SWG70

3

4

2

1

KL1 KL2 KL3 KL4

+24V +24V

0V 0V

LINE1 LINE2

A

B

SHD

RS485

T1

T2

RX–

RX+

TX–

TX+

ON

OFF

SHD

A

B

SHD

RS485

ETHERNET

KL5 KL6

A B SHD

RS485

A B SHD

RS485

1

2

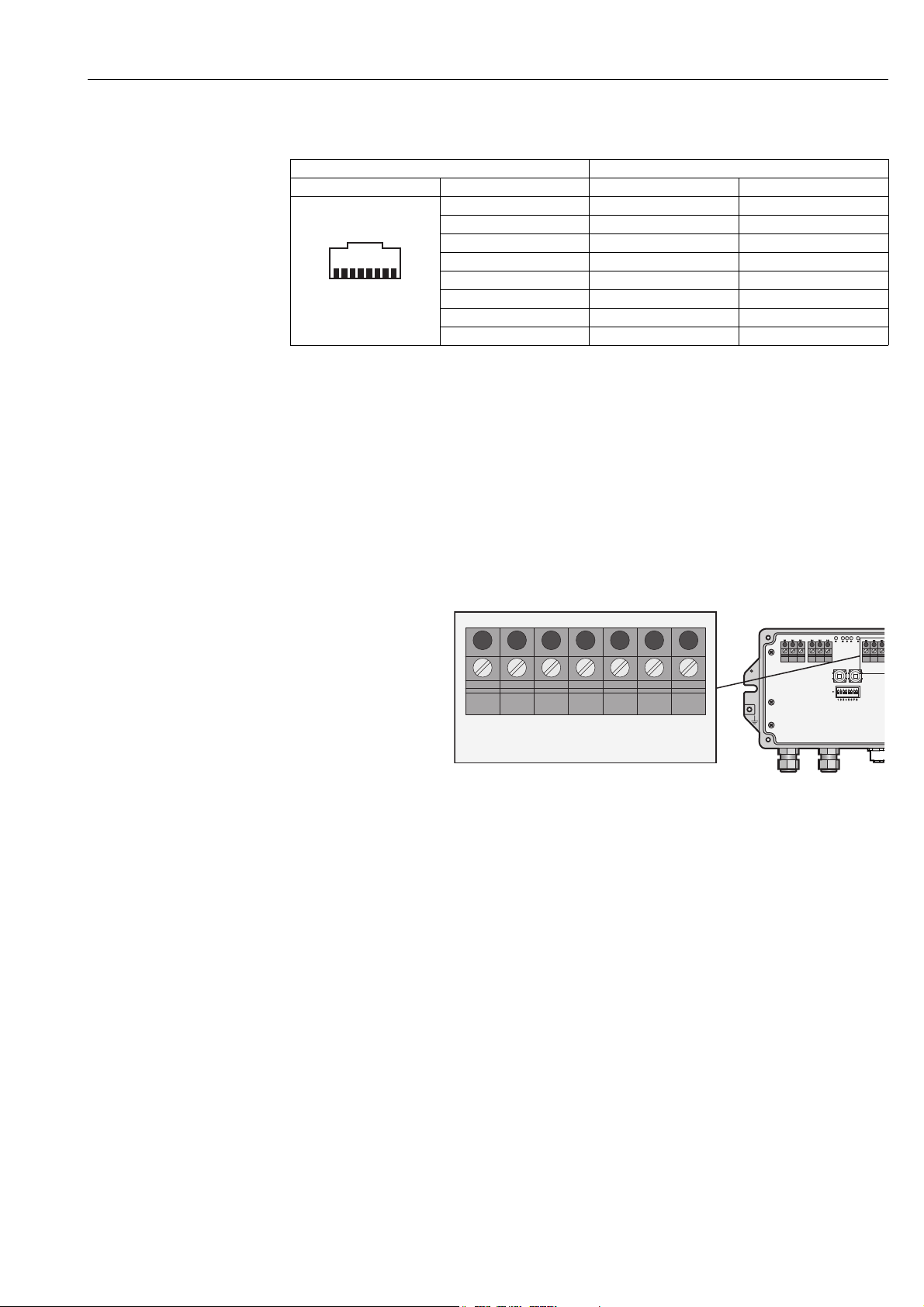

Internal wiring The Ethernet socket is wired to the Ethernet terminal block. The internal wiring may not be

modified.

Pin Numbering Connector Signal Internal Wire Colors

Pin 1 TX+ Yellow

.

Pin 2 RX+ White

Pin 3 TX– Orange

Pin 4 RX– Blue

5.4 Connecting to RS-485

Fieldgate SWG70 is equipped with a fully galvanic isolated RS-485 interface. A second

RS-485 terminal block allows several Fieldgates to be connected through a daisy chain.

A terminating resistor is required at each end of the RS-485 cable. If the RS-485 cable is not

routed to other devices (no daisy-chain connection), activate the terminating resistor using

the corresponding DIP switches in the fieldgate. See Chapter 6.1.3 "DIP switches" on page 29.

NOTICE!

• The maximum length of the cable from the Fieldgate is 1200m (at reduced

communication speed).

• Use shielded twisted pair (STP) cables only.

• If the cable shield is grounded, only connect the grounding to one cable end. This avoids

potential equalization currents.

• Ensure adequate strain relief for the cables.

• Pay attention to the bending radii of the cables. Do not drop below the permitted bending

radii.

Fig. 5-5: RS-485 interface

1 First RS-485 connection 2 Second RS-485 connection for daisy chaining

24 Endress+Hauser

Page 25

WirelessHART Fieldgate SWG70 Electrical Installation

Connecting to RS-485 1. Switch off the power supply.

2. Unscrew the screws of the housing cover and remove the housing cover. See Figure 4-5

on page 19.

3. Route the RS-485 cable through the first cable gland from left.

The permissible cable diameter is between 6 mm and 10 mm.

4. Connect the RS-485 cable to the left terminal block labeled "RS-485" as follows (see the

graphic above):

Wire RS-485 cable Fieldgate terminal Remarks

RxD/TxD– (RS-485 A) A RS-485 differential

RxD/TxD+ (RS-485 B) B

Shield SHD Cable shielding

signal

5. For a daisy-chain connection, route the second RS-485 cable through the second cable

gland from left and connect it to the right terminal block labeled "RS-485", see table

above.

6. To activate the RS-485 termination, set DIP switch number 7 to "ON". See Chapter 6.1.3

"DIP switches" on page 29.

7. Screw the housing cover on the housing.

8. Tighten the cable gland with appropriate torque. See Chapter 5.5 "Cable glands and

housing cover" on page 25.

5.5 Cable glands and housing cover

The degree of protection cannot be achieved if the cables and cable glands are not fitted

correctly.

To ensure the IP degree of protection

• all screws of the housing / housing cover must have been tightened with the appropriate

torque,

• only cables of the appropriate size must be used in the cable glands,

• all cable glands must be tightened with the appropriate torque,

• all seals must be undamaged and fitted correctly,

• all empty cable glands must be sealed with appropriate plugs.

The tightening torques of cable glands depend on what type of cable is used and must therefore be determined by the user. The cap nuts must be securely tightened. Tightening the cap

nuts too tight can have a negative effect on the protection class. The following figures can

be taken as rough guides.

Type of cable gland Approx. installation torque

Plastic 2.5 Nm

Nickel-plated brass 4.1 Nm

Stainless steel 4.1 Nm

The Fieldgate housing cover must be tightened with a torque of 2.5 Nm.

Endress+Hauser 25

Page 26

Operation WirelessHART Fieldgate SWG70

1

2 3

4

6Operation

6.1 Operating and display elements

Inside the fieldgate housing there are LED indicators, DIP switches and reset buttons. The

controls and indicators are accessible with open enclosure.

WARNING!

• If Fieldgate SWG70 is installed in a hazardous area Zone 2, you may only operate the DIP

switches and the keys and only connect or disconnect the cables in the absence of any

potentially explosive atmosphere or if the Fieldgate is not connected to the power supply.

1LEDs

2Button P1

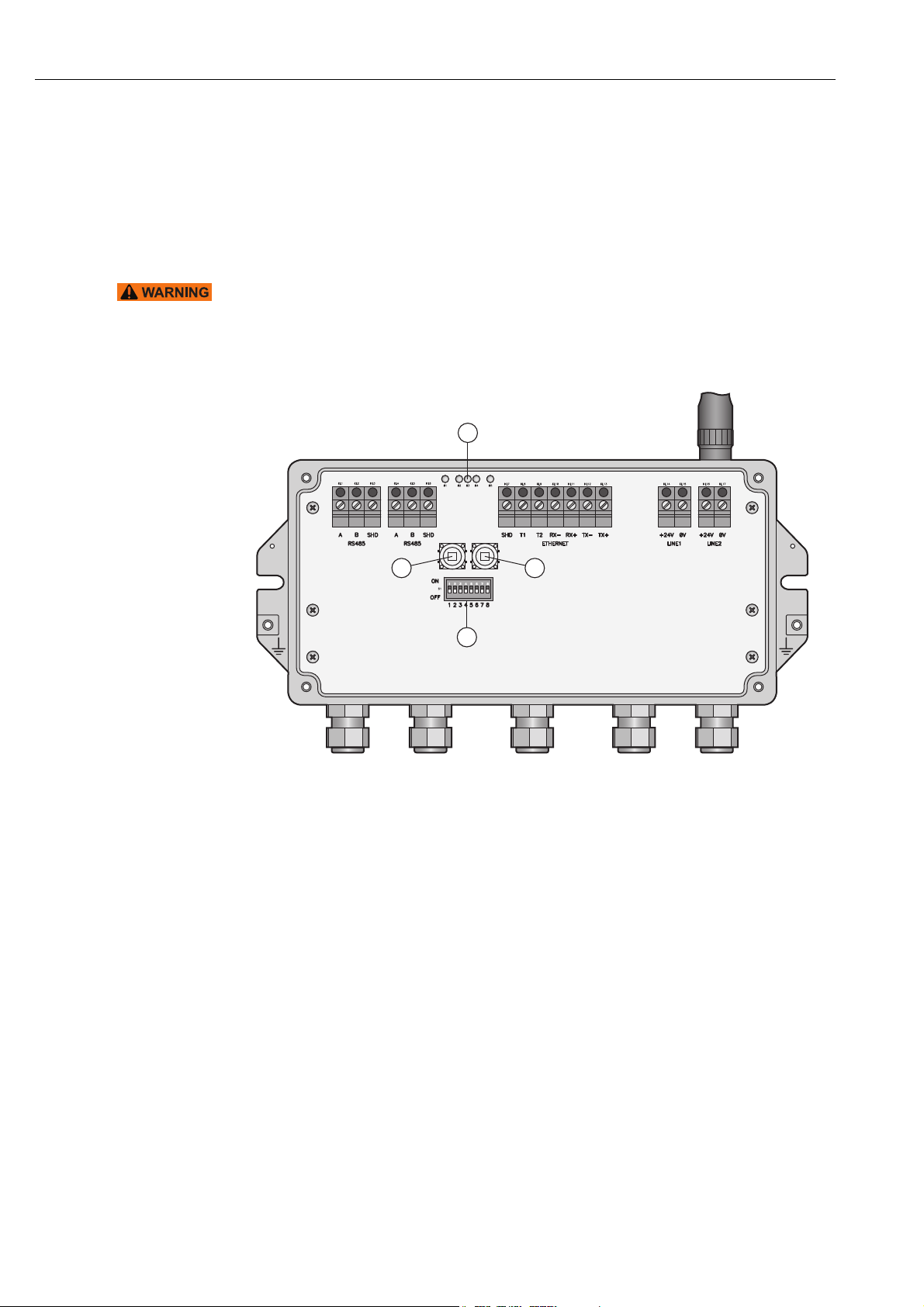

Fig. 6-1: Operating and display elements

3Button P2

4 DIP switches

26 Endress+Hauser

Page 27

WirelessHART Fieldgate SWG70 Operation

+24V +24V0V 0V

LINE1 LINE2

A

B

SHD

RS485

T1

T2

RX–

RX+

TX–

TX+

ON

OFF

SHD

A

B

SHD

RS485

ETHERNET

1

2

3

4

5

6.1.1 LEDs

Five LEDs indicate the status of Fieldgate SWG70.

Fig. 6-2: LED indicators

Yellow LED: RS-485

communication status

Green LED: Power supply

and operation status

Yellow LED: WirelessHART

communication status

1 Yellow LED: RS-485 communication status

2 Green LED: Power supply

4 Red LED: Device status

5Yellow LED: Ethernet communication status

3 Yellow LED: WirelessHART communication status

Mode Status Meaning

Flashes – Flashes briefly whenever a valid message is received by the

Fieldgate on the RS-485 communication line.

– The LED does not flash if the message is not addressed to the

Fieldgate or if a communication error was detected within the

message.

Off – Currently no communication on the RS-485 line.

Mode Status Meaning

On OK Fieldgate SWG70 is powered up and running

Flashes Not ready On power-up, indicates that the Fieldgate application is running

but the Fieldgate is not yet ready to answer HART commands.

Off No power The power supply is not connected/Fieldgate is not ready.

Mode Status Meaning

Flashes – Flashes shortly whenever a valid WirelessHART message is

received by the Fieldgate on the WirelessHART communication

interface.

– Messages include simple commands but not published bursts

and event notifications.

Off – Currently no communication on the WirelessHART interface.

Red LED: Device status

Mode Status Meaning

On Hardware fault Fieldgate has detected a hardware fault that makes normal

operation impossible.

Flashes Recovering from hardware

fault.

The Fieldgate application is trying to recover from the fault (not

possible for all faults).

Off No hardware fault –

Endress+Hauser 27

Page 28

Operation WirelessHART Fieldgate SWG70

+24V +24V

0V 0V

LINE1 LINE2

A

B

SHD

RS485

T1

T2

RX–

RX+

TX–

TX+

ON

OFF

SHD

A

B

SHD

RS485

ETHERNET

1

2

12345678

Yellow LED: Ethernet

communication status

Mode Status Meaning

On – The connection to the Ethernet line is established.

Flashing

irregularly

– Fieldgate is receiving a message via the Ethernet interface. The

LED does not flash in the following instances:

• The message is not addressed to the Fieldgate.

• A communication error was detected in the message.

Flashing (every

second)

– A conflict has been detected in the IP address. The Fieldgate IP

address is already being used by another device in the Ethernet

network

Assign another IP address to the Fieldgate. See Chapter 7.1

"Ethernet connection" on page 31.

Off – There is no connection to the Ethernet network. This is often due

to a bad cable connection. See Chapter 5.3 "Connecting to Ethernet"

on page 22.

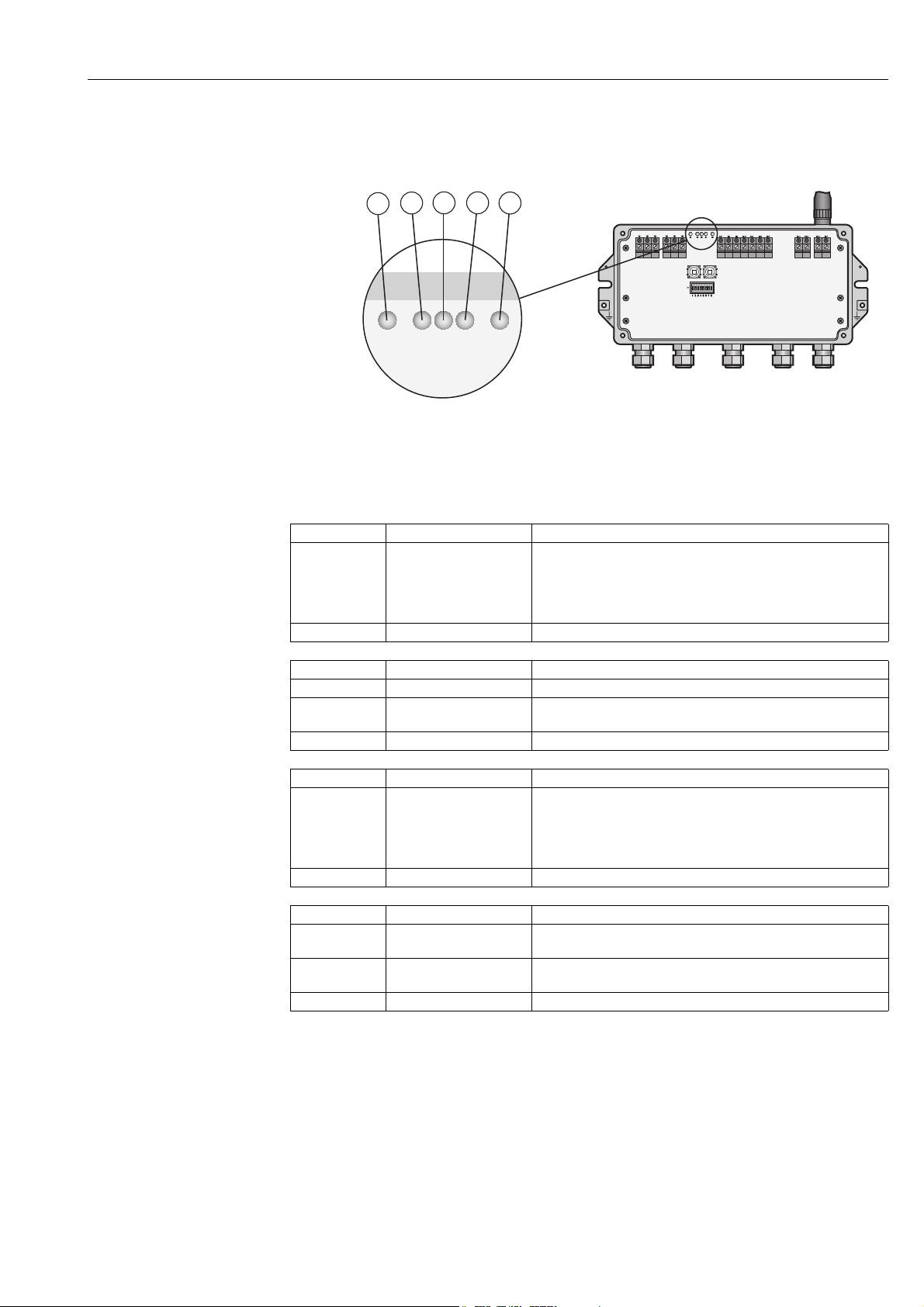

6.1.2 Buttons

Fieldgate has two pushbuttons.

WARNING!

• When Fieldgate SWG70 is installed in Ex-Zone 2 and the power is switched on, the

operation of the pushbuttons is permitted only in the absence of any potentially explosive

atmosphere.

Fig. 6-3: Pushbuttons

1Button P1 2Button P2

28 Endress+Hauser

Page 29

WirelessHART Fieldgate SWG70 Operation

+24V +24V

0V 0V

LINE1 LINE2

A

B

SHD

RS485

T1

T2

RX–

RX+

TX–

TX+

ON

OFF

SHD

A

B

SHD

RS485

ETHERNET

1

2

3

4

ON

OFF

1 234 5678

The function of the buttons is as follows:

Buttons

Buttons Function Procedure

Button P1 Configuration reset Press the button for more than 3 seconds.

– All Fieldgate SWG70 configuration parameters are reset to

factory settings with exception of the parameters set by button

P2 and button P1 + P2.

– After approx. 3 seconds, all LEDs light up to confirm the reset.

Button P2 Communication reset Press the button for more than 3 seconds.

– All Fieldgate SWG70 configuration parameters related to the

wired communication channels are reset to factory settings.

– After approx. 3 seconds, all LEDs light up to confirm the reset.

Button P1 + P2

DIP switch 8 OFF

Password reset Press buttons P1 and P2 simultaneously for more than 3 seconds.

– All Fieldgate SWG70 passwords are reset to the factory settings.

– Passwords are used for access to the Command Line Interface

and the Web Server (HTTPS).

– For Web Server User name: admin; Password: admin

– After approx. 3 seconds, all LEDs light up to confirm the reset.

Button P1 + P2

DIP switch 8 ON

Network manager reset Press buttons P1 and P2 simultaneously for more than 3 seconds.

– The Fieldgate SWG70 join key, network ID, radio power and

access mode are reset to factory settings.

– After approx. 3 seconds, all LEDs light up to confirm the reset.

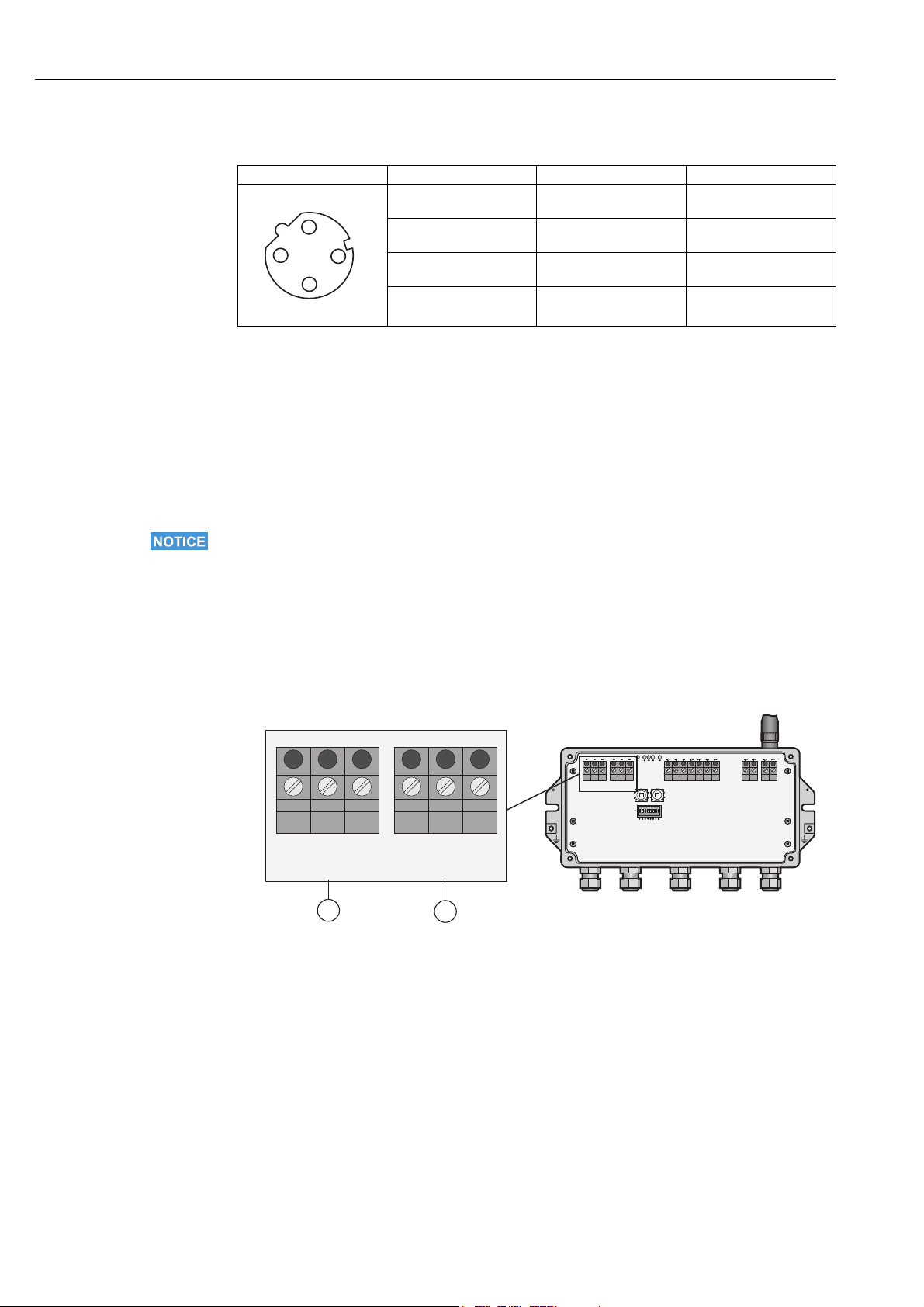

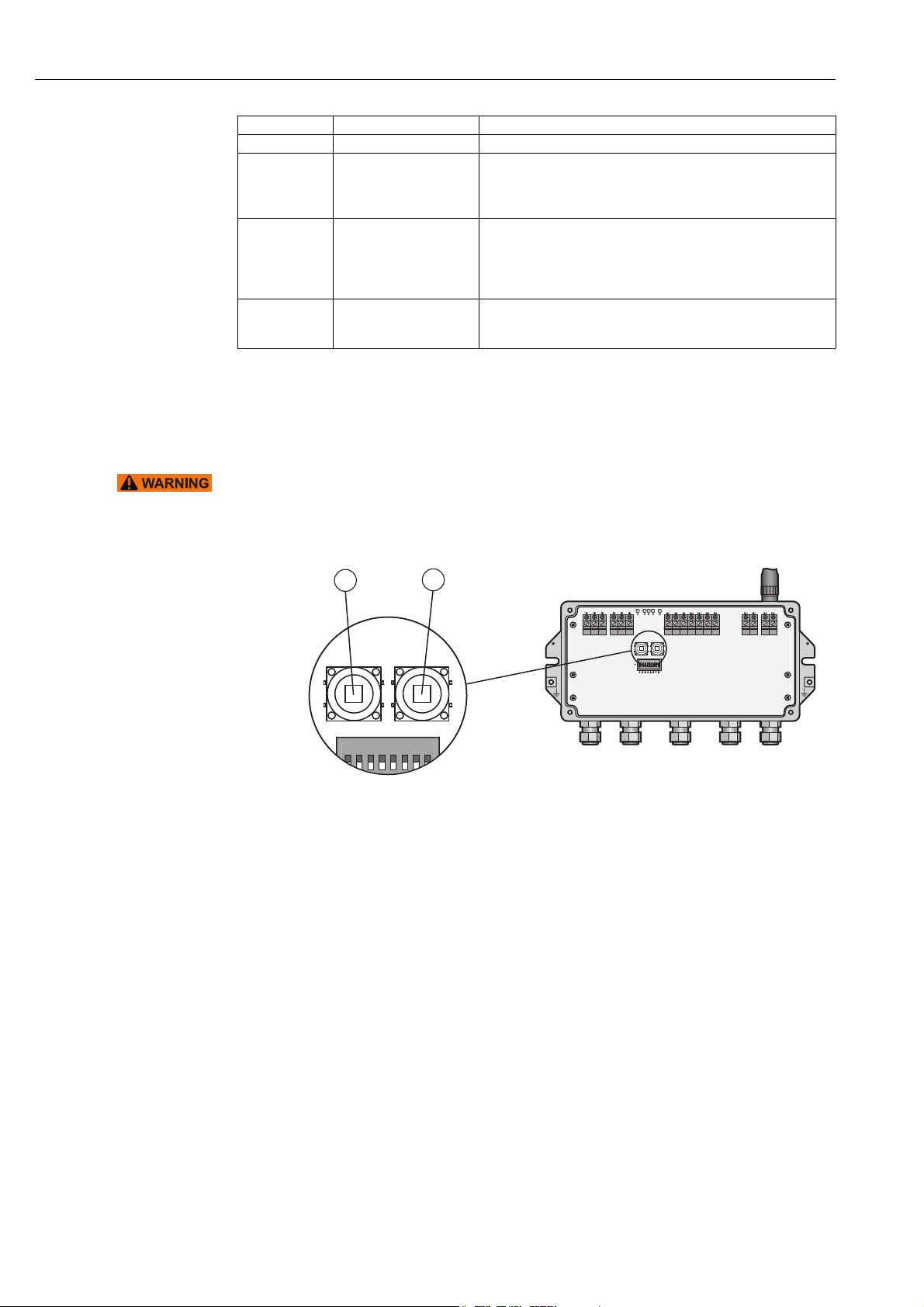

6.1.3 DIP switches

WARNING!

• When Fieldgate SWG70 is installed in Ex-Zone 2 and connected to the power supply, the

operation of DIP switches is permitted only in the absence of any potentially explosive

atmosphere.

NOTICE!

• The same functions can be initiated from the Fieldgate SWG70 Web interface and DTM.

See Chapter 8.3 "Interfaces (wired communication)" on page 48.

Fieldgate SWG70 has one 8-gang DIP switch. Fieldgate SWG70 is delivered with all DIP

switches set to ON and with all DIP switch functions set by software controls.

Fig. 6-4: DIP switches

1 DIP switches 1 to 4: HART device address

2 DIP switches 5 and 6:

Baud rate of RS-485 interface

3 DIP switch 7: RS-485 terminating resistor

4 DIP switch 8: Security mode

Endress+Hauser 29

Page 30

Operation WirelessHART Fieldgate SWG70

DIP switch positions

Switch Function 1234Value1234Value

1 – 4 HART device address

5 and 6 Baud rate of RS-485

interface

7 RS-485 termination • OFF = disconnected • ON = connected

8 Download

Join Key/Network ID

1) You can set up HART device addresses from 0 to 63 by software.

1)

OFF OFF OFF OFF 0 OFF OFF OFF ON 8

ON OFF OFF OFF 1 ON OFF OFF ON 9

OFF ON OFF OFF 2 OFF ON OFF ON 10

ON ON OFF OFF 3 ON ON OFF ON 11

OFF OFF ON OFF 4 OFF OFF ON ON 12

ON OFF ON OFF 5 ON OFF ON ON 13

OFF ON ON OFF 6 OFF ON ON ON 14

ON ON ON OFF 7 ON ON ON ON 15

56Value 56Value

OFF OFF 9600 bit/s OFF ON 38400 bit/s

ON OFF 19200 bit/s ON ON 57600 bit/s

• OFF = disabled • ON = enabled

Security mode When DIP switch 8 is OFF, it is not possible to download the Network ID and the Join Key to

the Fieldgate. See Chapter 8.3.2 "Serial (RS-485)" on page 49. Fieldgate SWG70 is delivered

with the download enabled by default, i.e. DIP switch 8 is ON.

30 Endress+Hauser

Page 31

WirelessHART Fieldgate SWG70 Commissioning

7 Commissioning

NOTICE!

• We recommend that you first set up the Fieldgate SWG70, the WirelessHART Adapters

and the HART devices on a test bench and test the network.

The Fieldgate SWG70 can be set up in the following ways:

• Via the Ethernet connection using the Web server

• Via the Ethernet connection using FieldCare and Fieldgate-DTM

• Via the RS-485 connection using FieldCare and Fieldgate-DTM

The structure of the parameter blocks and the parameters in the Fieldgate DTM and the Web

server in the Fieldgate are identical.

Web server The Fieldgate SWG70 has an integrated Web server.

You can set up the Fieldgate and the associated WirelessHART network via the Web server.

See Chapter 7.1 for details on setting up the Fieldgate SWG70 via the Web server.

FieldCare You can set up the Fieldgate and the associated WirelessHART network via FieldCare. In

addition, you can also configure the WirelessHART Adapters SWA70 and the connected

devices via FieldCare.

A prerequisite is that the WirelessHART Adapters and devices already use the same join key

and network identifier as Fieldgate SWG70 and have joined the network. Configure

connected WirelessHART Adapters and field devices via the relevant DTMs.

NOTICE!

• It is advisable to configure the adapters and connected HART devices via a direct

connection. See Operating Instructions BA00061S/04/en. If FieldCare accesses the

devices via the Fieldgate SWG70 DTM, the response times may be considerably longer

than for a direct connection.

See Chapter 7.1 and Chapter 7.3. for details on setting up the Fieldgate SWG70 via

FieldCare.

7.1 Ethernet connection

The Ethernet connection of Fieldgate SWG70 allows communication with a computer via the

integral Web Server or via FieldCare.

The following requirements must be met:

• Internet Protocol TCP/IP is installed on your computer and is active.

• You have administration rights for your computer and network.

• You have an set of IP addresses that have been authorized by your IT department.

• Any proxy server for your Internet Browser is disabled.

• Firewalls allow communication on port 80, 433, 502, 3333 and 5094.

Fieldgate SWG70 is delivered with the default IP address:

• 192.168.1.1

Endress+Hauser 31

Page 32

Commissioning WirelessHART Fieldgate SWG70

NOTICE!

• By default, the IP address of the WirelessHART Fieldgate EtherNet/IP version is

automatically assigned via DHCP. Please contact your network administrator to identify

the automatic set IP address, if necessary.

rd

•Alternative 3

party IP scanner software i.e. "BOOTP Utility Software" from Rockwell

Automation enables you to scan the Ethernet network and being able to assign a dedicated

IP address i.e. 192.168.1.1 to the WirelessHART Fieldgate. Please consider WirelessHART

Fieldgate MAC address is required to be able to set a dedicated IP address with "BOOTP

Utility Software" from Rockwell Automation.

• Please find below path to Rockwell Automation "BOOTP Utility Software" download and

instruction page:

1. Go to http://www.rockwellautomation.com

2. Click "Products"

3. Click "Reliance Electric Drives"

4. Click "Software”"

32 Endress+Hauser

Page 33

WirelessHART Fieldgate SWG70 Commissioning

7.1.1 Establishing the connection between the host computer and the Fieldgate SWG70 Web server

Prerequisite

The Fieldgate SWG70 is connected to the Ethernet network. See Chapter 5.3 "Connecting

to Ethernet" on page 22.

Procedure 1. Check that the computer can reach the Fieldgate via ports 80, 443, 502, 3333 and

5094. Please contact your network administrator if necessary.

2. Note the current settings for the IP address and network/subnet mask of the computer

to restore them if necessary.

3. Change the IP address and the network/subnet mask of your computer:

– IP address 192.168.1.200

– Network/subnet mask 255.255.255.0.

4. The simplest way to check the connection is to call up the Fieldgate SWG70 Web

server. For this, enter the default IP address of the Fieldgate SWG70 in your Internet

browser: 192.168.1

5. Accept the site certificate in the dialog which now appears.

6. The Login of the Web page appears.

– To open the Fieldgate SWG70 Web page, enter the User name

(default: admin) and the Password (default: admin) and click OK.

– You must change the password after logging in for the first time.

7. If the connection to the Fieldgate Web server fails, check the following points:

– Are all the proxy servers in the browser switched off or not used for this address

range?

– Are ports 80, 443, 502, 3333 and 5094 open in all the firewalls?

– Are you using the correct Ethernet cable? See Chapter 5.3 "Connecting to Ethernet" on

page 22.

– Is the Ethernet cable correctly connected? See Chapter 5.3 "Connecting to Ethernet" on

page 22.

Endress+Hauser 33

Page 34

Commissioning WirelessHART Fieldgate SWG70

7.2 RS-485 connection

Prerequisite

The Fieldgate SWG70 is connected to the RS-485 bus. See Chapter 5.4 "Connecting to

RS-485" on page 24.

Procedure 1. Connect the RS-485 bus to your computer via an RS-485/RS-232 signal converter or

an RS-485/USB signal converter.

2. If you are using an RS-485/USB signal converter, install the correct driver.

3. Open the Windows device manager to find out which COM port the converter is

connected to. For this purpose, enter "Device manager" in the search window in the

Windows Start menu.

4. The signal converter and the assigned COM port are displayed under "Ports (COM &

LPT)".

5. Note the COM port (in this case USB Serial Port (COM5)) and the baudrate etc. as you

will need them to set up communication.

7.3 Creating a FieldCare project

Creating a FieldCare project will allow you to configure Fieldgate SWG70 and any HART

device (field device or adapter) in the wireless network via its DTM. The configuration of a

field device can be taken from the manufacturer’s operating manual, the configuration of

the adapter is described in Operating Instructions BA00061S/04/en, SWA70 Wireless

Adapter.

7.3.1 Adding the HART IP CommDTM

The HART IP CommDTM is required for communication via Ethernet with FieldCare.

NOTICE!

• If you wish to connect to FieldCare via the RS-485 interface, the HART Communication

CommDTM must be added and configured instead of the HART IP CommDTM.

• The procedure is similar to that described here, whereby the configuration involves other

parameters such as selection of multiplexer option, COM port and baudrate.

34 Endress+Hauser

Page 35

WirelessHART Fieldgate SWG70 Commissioning

1. In the FieldCare project workspace, right-click on the Host Computer node and select

Add Device:

2. The Add New Device dialog opens:

– Select HART IP Communication and press OK.

– The dialog closes and the HART IP Communication DTM is added below the Host

node.

3. If desired, the HART IP Communication DTM can be now configured offline.

– Right-click on the node and select Configuration.

– The node name and timeout (default 10000 ms) can be changed.

– The changes are accepted when the Apply button is pressed.

Endress+Hauser 35

Page 36

Commissioning WirelessHART Fieldgate SWG70

7.3.2 Adding the Fieldgate SWG70

1. Right-click HART IP Communication and select Add Device:

2. The Add New Device dialog opens:

– Select WirelessHART Fieldgate SWG70 and press OK.

3. The dialog closes and the Fieldgate SWG70 DTM is added below the HART IP node.

4. If the factory IP address (192.168.1.1) or the Ethernet Port (5094) of the Fieldgate

SWG70 has been changed, right-click on the HART IP Communication node and select

Additional Functions => Set DTM Addresses...

– The Set DTM Addresses Dialog opens:

5. Enter the new IP address and/or Ethernet UDP Port number and press Update Changed

Data.

6. Close the dialog – the Fieldgate SWG70 can now be put online.

36 Endress+Hauser

Page 37

WirelessHART Fieldgate SWG70 Commissioning

7.3.3 Parameterizing Fieldgate SWG70

1. Right-click HART IP Communication and select Connect:

– The HART IP CommDTM is put on-line and the two arrows turn green.

2. Right-click on the Fieldgate SWG70 node and select Connect.

– The Fieldgate SWG70 DTM is put on-line and the two arrows turn green.

3. Right-click on the Fieldgate SWG70 node and select Online Parameterize:

– The DTM of Fieldgate SWG70 opens.

4. Expand all the submenus of the directory tree to reveal the parameter blocks. (The

"Identification" page is open in the graphic below):

– You are now ready to configure the device. See Chapter 8 "Fieldgate configuration" on

page 42.

Endress+Hauser 37

Page 38

Commissioning WirelessHART Fieldgate SWG70

7.3.4 Scanning for wireless devices in the network

After Fieldgate SWG70 has been configured, see Chapter 8.2 onwards, you may want to

scan for other devices in the network.

1. Right-click on the Fieldgate SWG70 node and select Create Network..:

– You can also click on the Create Network icon to do this.

– The Fieldgate SWG70 is put on-line and the two arrows turn green.

2. The Fieldgate CommDTM now scans the wireless network and automatically adds all

WirelessHART devices found to the network (in our case the SWA70 adapters):

NOTICE!

• If no device is found although communication has been established, check that the

adapters have been configured with the correct network identification and join key.

• It may take up to ten minutes for a wireless device to join the network after download of

the Network ID and Join Key.

• To increase the performance of a connection to an adapter it is possible to open a fast pipe.

See Chapter 8.2.3 "Operating Modes" on page 47.

38 Endress+Hauser

Page 39

WirelessHART Fieldgate SWG70 Commissioning

7.3.5 Scanning for devices connected to adapters

It is also possible to scan for the devices connected to the adapters. Depending on the size of

the network and the connected field devices, however, it is possible that time out problems

occur. In this case, FieldCare issues a warning and the user can choose to cut the connection,

wait for connection or retry the connection.

1. Open a fast pipe to the corresponding adapter. See Chapter 8.2.3 "Operating Modes" on

page 47.

2. Right-click on the Adapter node and select Create Network...:

– You can also click on the Create Network icon to do this.

3. The adapter DTM now scans the wired interface and automatically adds all the HART

devices found to the network (in this case, the temperature transmitter TMT162):

– Depending upon FieldCare configuration and number of devices, this may occur

automatically or after confirmation with OK in the Scanning Result dialog.

– Depending upon FieldCare configuration, if only one device is found, the

corresponding Device DTM will open, see below.

4. Repeat the process for all adapters in the network.

5. To open the Device DTM of an unconnected transmitter right-click on the Transmitter

node and select Connect, then right-click again and select Online Parameterization.

Endress+Hauser 39

Page 40

Commissioning WirelessHART Fieldgate SWG70

7.4 User interface

The Web Server and DTM of the Fieldgate SWG70 are structured in the same manner, so

that the configuration is identical. Before starting, the Web Server must be open, (see

Chapter 7.1.1) or the Online parameterization dialog of the DTM must be open, see

(Chapter 7.3.3). The user interface is structured as follows:

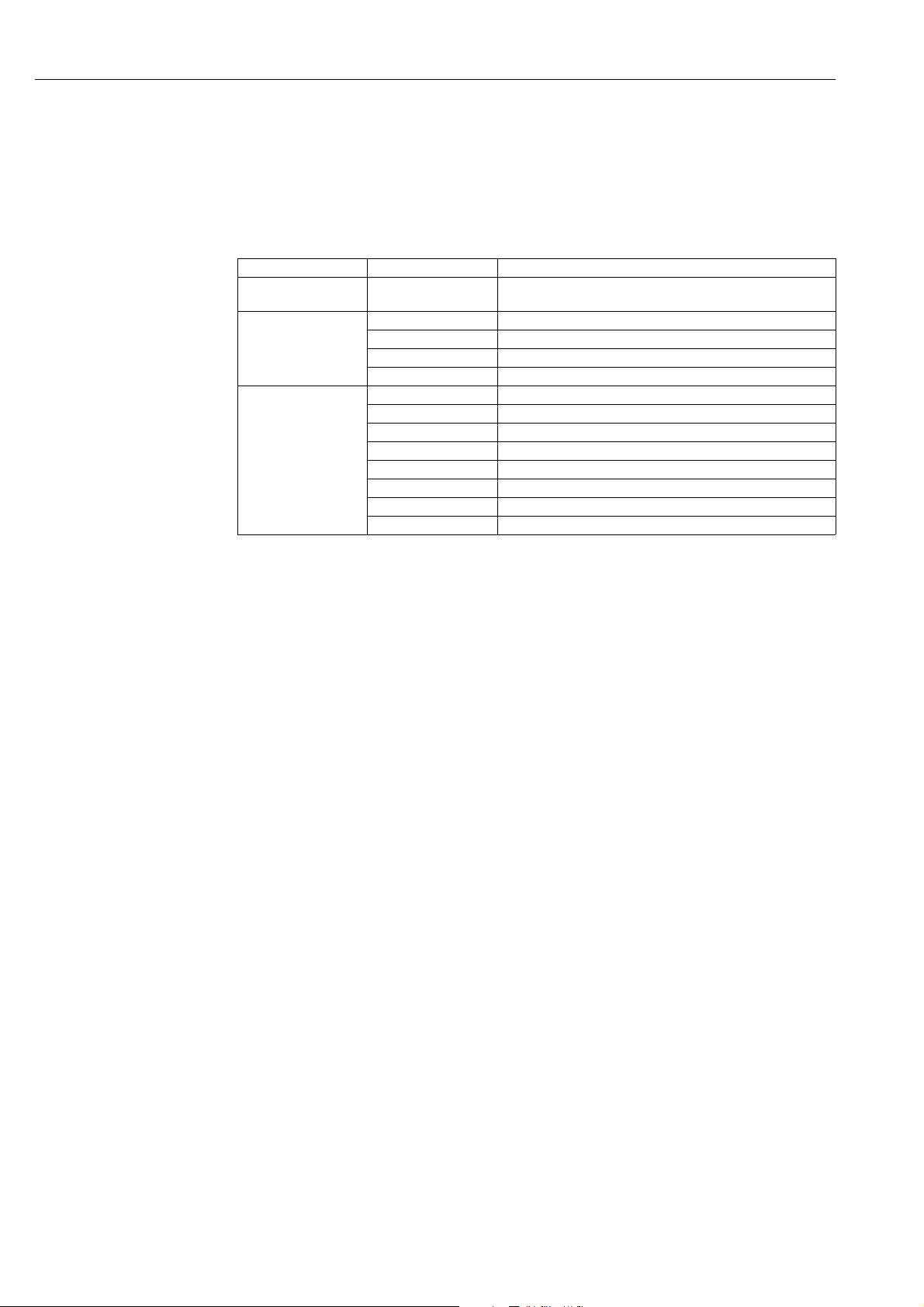

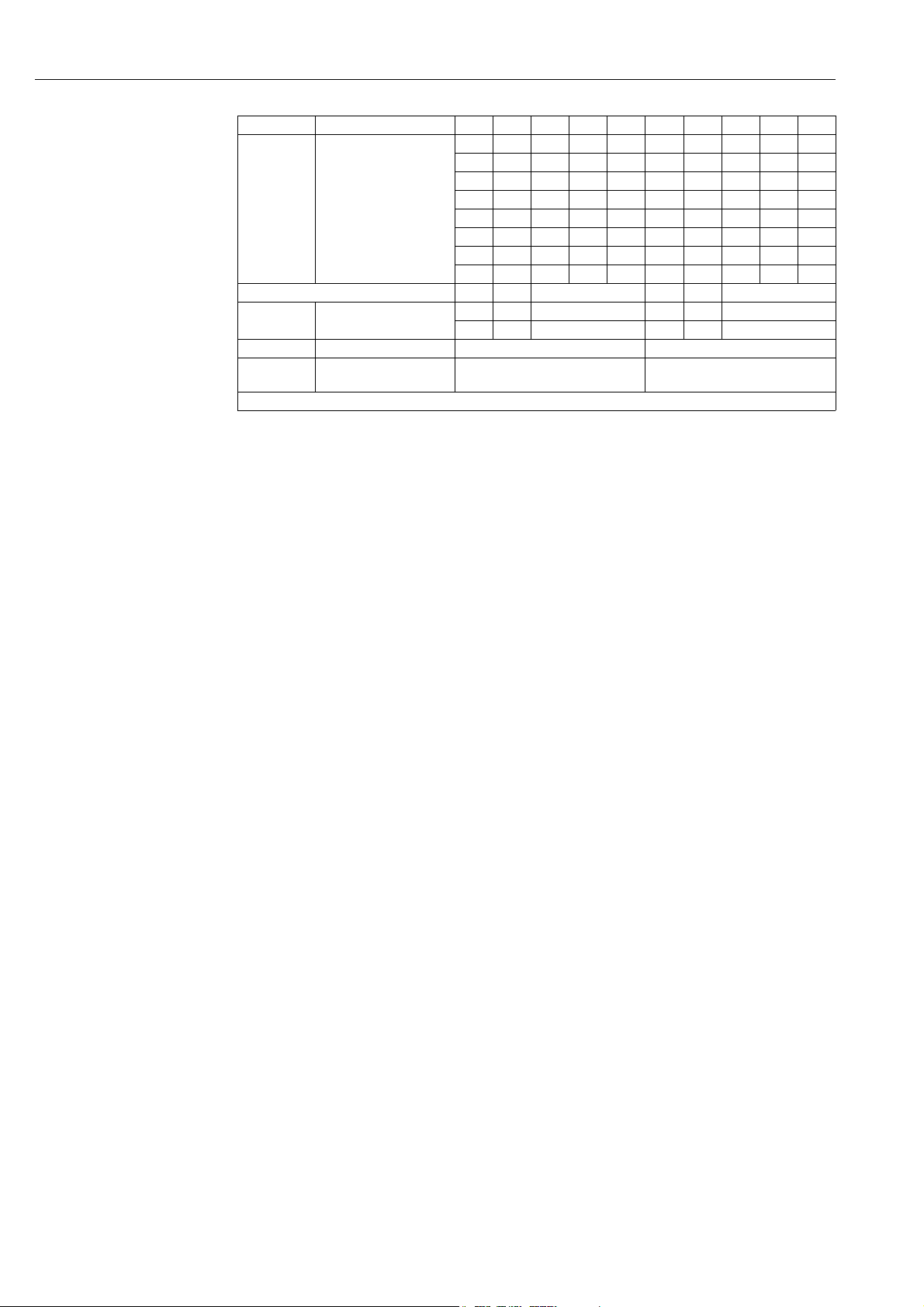

Structure Chapter Modbus OPC EtherNet/IP

Fieldgate configuration Chapter 8

Identification Chapter 8.1 X X X

Wireless Communication Chapter 8.2 X X X

Basic Setup and

Advanced Setup

Operating Modes Chapter 8.2.3 X X X

Interfaces (wired communication) Chapter 8.3 X X X

Ethernet Chapter 8.3.1 X X X

Serial (RS-485) Chapter 8.3.2 X X X

Protocols (wired communication) Chapter 8.4

Modbus via Ethernet or RS-485 Chapter 8.4.1 X

EtherNet/IP via Ethernet Chapter 8.4.2 X

HART via Ethernet or RS-485 Chapter 8.4.3 X X X

AMS via Ethernet Chapter 8.4.4 X X X

Diagnostics Chapter9XXX

Identification Chapter 9.1 X X X

Wireless Communication Chapter 9.2 X X X

Overview Chapter 9.2.1 X X X

Details Chapter 9.2.2 X X X

Burst Lists Chapter 9.2.3 X X X

Topology View (Diagnostics) Chapter 9.2.4 X X X

Wired Communication Chapter9.3XXX

Overview Chapter 9.3.1 X X X

HART Chapter 9.3.2 X X X

Engineering Chapter 10 X X X

Instrument List Chapter 10.1 X X X

General Chapter 10.1.1 X X X

Creating and editing an Instrument List Chapter 10.1.2 X X X

Topology View (Engineering) Chapter 10.2 X X X

Configuring Modbus Chapter 10.3 X X

Modbus Settings Chapter 10.3.1 X

Input Status Chapter 10.3.2 X

Input Register Chapter 10.3.3 X

Configuring a WirelessHART OPC server Chapter 10.4 X

System architecture of an OPC WirelessHART network Chapter 10.4.1 X

Configuring the WirelessHART OPC server with "WirelessHART

Fieldgate OPC Configurator"

Description of the WirelessHART Fieldgate OPC Configurator Chapter 10.4.3 X

Configuring bursts using the WirelessHART OPC server Chapter 10.4.4 X

EtherNet/IP configuration Chapter 10.5 X

Setting up an EtherNet/IP connection Chapter 10.5.1 X

Assigning data exchange connections via HART descriptors Chapter 10.5.2 X

Burst commands for cyclic data exchange Chapter 10.5.3 X

Integrating SWG70 into a PLC via EtherNet/IP Chapter 10.5.4 X

Cyclic data exchange via the ControlLogix® controller system Chapter 10.5.5 X

Connection parameters for cyclic data exchange Chapter 10.5.6 X

Diagnostic bits in cyclic data exchange Chapter 10.5.7 X

Chapter 8.2.1

and

Chapter 8.2.2

Chapter 10.4.2 X

XXX

40 Endress+Hauser

Page 41

WirelessHART Fieldgate SWG70 Commissioning

Structure Chapter Modbus OPC EtherNet/IP

Downstream Communication (for discreet field devices) Chapter 10.6 X X

Substitution value (substitution value to DCS) Chapter 10.7 X X

Burst message monitoring Chapter 10.7.1 X X

Factory Acceptance Test (FAT) Chapter 10.7.2 X X

Security – Whitelist, Temporary Join Key Chapter 10.8 X X

Additional Functions Chapter 11 X X X

Reset Chapter 11.1 X X X

Self Test Chapter 11.2 X X X

Firmware Upgrade (Web Server) Chapter 11.3 X X X

Change Password (Web Server) Chapter 11.4 X X X

Set DTM Addresses (DTM) Chapter 11.5 X X X

Set Device Addresses (DTM) Chapter 11.6 X X X

Upload Certificate (Web server) Chapter 11.7 X X X

Auto Refresh Chapter 11.7 X X

Measurement Chapter 12 X X X

The Web interface differs from the DTM only in the presentation of the parameters. In the

case of the Web interface, the parameters are presented in a single tree. In the case of the

DTM, configuration, diagnostics and other functions are presented in separate DTM dialog

boxes. To open the dialog boxes, you must right-click the Fieldgate SWG70 and select the

desired option from the context menu. The DTM offers addition functions which are FDTframe specific, e.g. Set Device Addresses. In both cases parameters are registered by pressing

Enter. In some cases, in which more than one parameter is registered, an additional button

must be pressed for the changes to take effect.

Endress+Hauser 41

Page 42