Page 1

BA00380P/00/EN/15.15

71293257

Valid as of version

01.00.zz

Products Solutions Services

Operating Instructions

Waterpilot FMX21

Hydrostatic level measurement

HART

Page 2

Waterpilot FMX21

TAG No.: XXX000

Ser. No.: X000X000000

Order code 00X00-XXXX0XX0XXX

www.endress.com/deviceviewer Endress+Hauser Operations App

Serial number

• Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

• To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to

these Instructions.

A0023555

2 Endress+Hauser

Page 3

Waterpilot FMX21 Table of contents

Table of contents

1 Document information .............. 5

1.1 Document function ..................... 5

1.2 Symbols used .......................... 5

1.3 Documentation ........................ 6

1.4 Terms and abbreviations ................. 7

2 Basic safety instructions ............ 8

2.1 Requirements concerning the staff .......... 8

2.2 Designated use ........................ 8

2.3 Workplace safety ....................... 8

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 9

3 Product description ................ 10

3.1 Function ............................ 10

4 Incoming acceptance and product

identification ..................... 11

4.1 Incoming acceptance ................... 11

4.2 Product identification ................... 12

4.3 Nameplates .......................... 13

4.4 Identification of sensor type .............. 14

4.5 Storage and transport .................. 14

4.6 Scope of delivery ...................... 14

5 Installation ....................... 16

5.1 Installation conditions .................. 16

5.2 Additional mounting instructions .......... 17

5.3 Dimensions .......................... 17

5.4 Mounting the Waterpilot with a mounting

clamp .............................. 18

5.5 Mounting the Waterpilot with a cable

mounting screw ....................... 19

5.6 Mounting the terminal box .............. 20

5.7 Mounting the TMT182 temperature head

transmitter with terminal box ............ 20

5.8 Mounting the terminal strip for the Pt100

passive (without TMT182) ............... 21

5.9 Post-installation check .................. 21

7 Operation options ................. 32

7.1 Overview of operating options ............ 32

7.2 Operating concept ..................... 33

7.3 Structure of the operating menu ........... 33

7.4 Locking/unlocking operation ............. 34

7.5 Resetting to factory settings (reset) ........ 35

8

Integrating device via HART

®

protocol .......................... 36

8.1 HART process variables and measured

values .............................. 36

8.2 Device variables and measured values ....... 37

9 Commissioning .................... 38

9.1 Post-installation check and function check ... 38

9.2 Unlocking/locking configuration .......... 38

9.3 Commissioning ....................... 38

9.4 Selecting the language .................. 39

9.5 Measuring mode selection ............... 39

9.6 For selecting the pressure engineering unit ... 40

9.7 Position adjustment .................... 40

9.8 Configuring the damping ................ 41

9.9 Configuring pressure measurement ........ 41

9.10 Configuring level measurement ........... 43

9.11 Automatic density compensation .......... 56

9.12 Linearization ......................... 59

9.13 Manual entry of a linearization table via

operating tool ........................ 62

9.14 Backing up or duplicating the device data .... 63

10 Diagnostics and troubleshooting ... 64

10.1 Troubleshooting ...................... 64

10.2 Diagnostic events ...................... 64

10.3 Troubleshooting specific to Waterpilot

FMX21 with optional Pt100 .............. 67

10.4 Troubleshooting specific to TMT182

temperature head transmitter ............ 68

10.5 Response of output to errors .............. 68

10.6 Firmware history ...................... 69

6 Electrical connection .............. 23

6.1 Connecting the device .................. 23

6.2 Supply voltage ........................ 25

6.3 Cable specifications .................... 25

6.4 Power consumption .................... 25

6.5 Current consumption ................... 26

6.6 Maximum load ....................... 26

6.7 Connecting the measuring unit ........... 27

6.8 Post-connection check .................. 31

Endress+Hauser 3

11 Maintenance ...................... 70

11.1 Exterior cleaning ...................... 70

12 Repairs ........................... 71

12.1 General notes ........................ 71

12.2 Spare parts .......................... 71

12.3 Return .............................. 71

12.4 Disposal ............................ 71

Page 4

Table of contents Waterpilot FMX21

13 Overview of the operating menu .... 72

13.1 Overview of parameters in the "Expert"

menu .............................. 75

14 Description of device parameters ... 80

14.1 Expert → System ...................... 80

14.2 Expert → System → Instrument info ........ 81

14.3 Expert → System → Management .......... 83

14.4 Expert → Measurement → Measuring mode .. 83

14.5 Expert → Measurement → Basic setup ....... 84

14.6 Expert → Measurement → Pressure ........ 86

14.7 Expert → Measurement → Level ........... 88

14.8 Expert → Measurement → Linearization ..... 93

14.9 Expert → Measurement → Sensor limits ..... 96

14.10 Expert → Measurement → Sensor trim ...... 97

14.11 Expert → Output → Current output ......... 98

14.12 Expert→ Communication → HART config. ... 102

14.13 Expert→ Communication → HART info ..... 104

14.14 Expert→ Communication → HART output ... 106

14.15 Expert→ Communication → HART input .... 109

14.16 Expert → Application .................. 111

14.17 Expert → Diagnosis ................... 112

14.18 Expert → Diagnosis → Diagnostic list ....... 114

14.19 Expert → Diagnosis→ Event logbook ....... 115

14.20 Expert → Diagnosis → Simulation ......... 116

15 Accessories ...................... 118

15.1 Suspension clamp .................... 118

15.2 Terminal box ........................ 118

15.3 Additional weight .................... 118

15.4 Temperature head transmitter TMT182 (4 to

20 mA HART) ....................... 119

15.5 Pt-100 resistance thermometer .......... 119

15.6 Cable mounting screws ................ 119

15.7 Terminals .......................... 119

15.8 Cable shortening kit ................... 119

15.9 Cable marking ....................... 119

15.10 Testing adapter ...................... 120

16 Technical data ................... 122

16.1 Input .............................. 122

16.2 Output ............................ 124

16.3 Performance characteristics ............. 127

16.4 Environment ........................ 129

16.5 Process ............................ 131

16.6 Additional technical data ............... 131

Index ................................. 132

4 Endress+Hauser

Page 5

Waterpilot FMX21 Document information

DANGER

WARNING

CAUTION

NOTICE

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

1.2.3 Tool symbols

Symbol Meaning

Flat blade screwdriver

A0011220

Philips screwdriver

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line

or a star grounding system depending

on national or company codes of

practice.

A0011219

Endress+Hauser 5

Page 6

Document information Waterpilot FMX21

,…,

,…,

Symbol Meaning

Allen key

A0011221

Open-ended wrench

A0011222

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

1.3 Documentation

The document types listed are available:

In the Downloads area of the Endress+Hauser website: www.endress.com →

Downloads

1.3.1 Technical Information (TI): planning aid for your device

TI00431P:

The document contains all the technical data on the device and provides an overview of

the accessories and other products that can be ordered for the device.

6 Endress+Hauser

Page 7

Waterpilot FMX21 Document information

1.3.2 Brief Operating Instructions (KA): getting the 1st measured value quickly

KA01189P:

The Brief Operating Instructions contain all the essential information from incoming

acceptance to initial commissioning.

1.3.3 Safety Instructions (XA)

Depending on the approval, the following Safety Instructions (XA) are supplied with the

device. They are an integral part of the Operating Instructions.

Directive Type of protection Category Documentation Option

ATEX Ex ia IIC II 2 G XA00454P BD

ATEX Ex nA IIC II 3 G XA00485P BE

IECEx Ex ia IIC n/a XA00455P IC

CSA C/US Ex ia IIC n/a ZD00232P

(960008976)

FM AEx ia IIC n/a ZD00231P

(960008975)

NEPSI Ex ia IIC n/a XA00456P NA

INMETRO Ex ia IIC n/a XA01066P MA

1) Product Configurator order code for "Approval"

CE

FE

The nameplate indicates the Safety Instructions (XA) that are relevant to the device.

1.4 Terms and abbreviations

Term/abbreviation Explanation

XA Document type "Safety Instructions"

KA Document type "Brief Operating Instructions"

BA Document type "Operating Instructions"

SD Document type "Special Documentation"

1)

TD Turn down

Set span and zero-based span.

Endress+Hauser 7

Page 8

Basic safety instructions Waterpilot FMX21

2 Basic safety instructions

2.1 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists: must have a relevant qualification for this specific

‣

function and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

‣

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

‣

facility's owner-operator

Following the instructions in these Operating Instructions

‣

2.2 Designated use

2.2.1 Application and media

The Waterpilot FMX21 is a hydrostatic pressure sensor for measuring the level of fresh

water, wastewater and salt water. The temperature is measured simultaneously in the case

of sensor versions with a Pt100 resistance thermometer. An optional temperature head

transmitter converts the Pt100 signal to a 4 to 20 mA signal with superimposed digital

communication protocol HART 6.0.

2.2.2 Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance

‣

in verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability.

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

Switch off the supply voltage before connecting the device.

‣

2.4 Operational safety

Risk of injury!

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

8 Endress+Hauser

Page 9

Waterpilot FMX21 Basic safety instructions

Modifications to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

Repairs

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from Endress+Hauser only.

‣

Hazardous area

To eliminate danger to persons or the facility when the device is used in the approvalrelated area (e.g. explosion protection, pressure vessel safety):

Check the nameplate to verify if the device ordered can be put to its intended use in the

‣

approval-related area.

Observe the specifications in the separate supplementary documentation that is an

‣

integral part of these Instructions.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

Endress+Hauser 9

Page 10

Product description Waterpilot FMX21

h

2

1

p

atm

p

hydr.

p = p + p

atm hydr.

p

atm

p

atm

h ~ p

r • g

h =

p

Rel.: p =

sens

(p + p ) - p

atm hydr. atm

p = p + p

atm hydr.

Abs.: p =

sens

(p + p )

atm hydr.

3 Product description

3.1 Function

The ceramic measuring cell is a dry measuring cell i.e. the pressure acts directly on the

robust, ceramic process isolating diaphragm of the Waterpilot FMX21. Potential changes

in air pressure are guided via a pressure compensation tube through the extension cable to

the rear of the ceramic process isolating diaphragm and are compensated for. A pressuredependent change in capacitance, caused by the movement of the process isolating

diaphragm, is measured at the electrodes of the ceramic carrier. The electronics unit then

converts this to a signal that is proportional to the pressure and linear to the level.

1 Ceramic measuring cell

2 Pressure compensation tube

h Height level

p Total pressure = atmospheric pressure + hydrostatic pressure

ρ Density of the medium

g Acceleration due to gravity

P

Hydrostatic pressure

hydr.

P

Atmospheric pressure

atm

P

Pressure displayed on the sensor

sens

A0019140

10 Endress+Hauser

Page 11

Waterpilot FMX21 Incoming acceptance and product identification

DELIVERY NOTE

1 = 2

Dat./Insp.:

FW.Ver.:

Dev.Rev.:

Cal./Adj.

Mat:

L=

Ser. no.:

Order code:

Ext.order code:

TAG:

Waterpilot FMX21

Made in Germany,D-79689 Maulburg

p

DELIVERYNOTE

Dat./Insp.:

FW.Ver.:

Dev.Rev.:

Cal./Adj.

Mat:

L=

Ser. no.:

Order code:

Ext. order code:

TAG:

Waterpilot FMX21

Made in Germany,D-79689 Maulburg

p

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

A0015502

A0016870

Is the order code on the delivery note (1) identical to the order code on

the product sticker (2)?

A0015502

A0015502

A0026535

A0026536

Are the goods undamaged?

A0026537

Do the data on the nameplate correspond to the order specifications and

the delivery note?

Endress+Hauser 11

Page 12

Incoming acceptance and product identification Waterpilot FMX21

A0015502

A0022106

Is the documentation available?

If required (see nameplate): Are the safety instructions (XA) present?

If one of these conditions does not apply, please contact your

Endress+Hauser sales office.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is

displayed.

For an overview of the technical documentation provided, enter the serial number from

the nameplates in the W@M Device Viewer (www.endress.com/deviceviewer)

12 Endress+Hauser

Page 13

Waterpilot FMX21 Incoming acceptance and product identification

Dat./Insp.:

FW.Ver.:

Dev.Rev.:

Cal./Adj.

Mat:

L=

Ser. no.:

Order code:

Ext. order code:

TAG:

Waterpilot FMX21

Made in Germany, D-79689 Maulburg

p

1

2

17

16

15

14

3 4

5

6/7

89

101112

13

Mat.: 316L/1.4435/1.4404, Al O , PE, EPDM, PPO

2 3

For use in drinking water according to:

Made in Germany, D-79689 Maulburg

Waterpilot FMX21

250002737-B

1

23

4.3 Nameplates

4.3.1 Nameplates on extension cable

A0018802

1 Order code (shortened for reordering); The meaning of the individual letters and digits is explained in the

order confirmation details.

2 Extended order number (complete)

3 Serial number (for clear identification)

4 TAG (device tag)

5 FMX21 connection diagram

6 Pt100 connection diagram (optional)

7 Warning (hazardous area), (optional)

8 Length of extension cable

9 Approval symbol, e.g. CSA, FM, ATEX (optional)

10 Text for approval (optional)

11 Materials in contact with process

12 Test date (optional)

13 Software version/device version

14 Supply voltage

15 Output signal

16 Set measuring range

17 Nominal measuring range

Additional nameplate for devices with approvals

1 Approval symbol (drinking water approval)

2 Reference to associated documentation

3 Approval number (marine approval)

Endress+Hauser 13

A0018805

Page 14

Incoming acceptance and product identification Waterpilot FMX21

x

Install per dwg. 96000xxxx-

Ser.-No.:

p

Waterpilot FMX21

Cal./Adj.

1 2 3 4 5 6 7

4.3.2 Additional nameplate for devices with external diameter 22 mm (0.87 in) and 42 mm (1.65 in)

A0018804

1 Serial number

2 Nominal measuring range

3 Set measuring range

4 CE mark or approval symbol

5 Certificate number (optional)

6 Text for approval (optional)

7 Reference to documentation

4.4 Identification of sensor type

With relative pressure or absolute pressure sensors, the "Pos.zero adjust" parameter is

displayed in the operating menu. With absolute pressure sensors, the "Calib. offset"

parameter is displayed in the operating menu.

4.5 Storage and transport

4.5.1 Storage conditions

Use original packaging.

Store the measuring device in clean and dry conditions and protect from damage caused by

shocks (EN 837-2).

Storage temperature range

• FMX21: –40 to +80 °C (–40 to +176 °F)

• TMT182: –40 to +100 °C (–40 to +212 °F)

• Terminal box: –40 to +80 °C (–40 to +176 °F)

4.5.2 Transporting the product to the measuring point

WARNING

L

Incorrect transport!

Device or cable may become damaged, and there is a risk of injury!

Transport measuring device in the original packaging.

‣

Follow the safety instructions and transport conditions for devices weighing more than

‣

18 kg (39.6 lbs).

4.6 Scope of delivery

The scope of delivery comprises:

• Waterpilot FMX21, optionally with integrated Pt100 resistance thermometer

• Optional accessories

14 Endress+Hauser

Page 15

Waterpilot FMX21 Incoming acceptance and product identification

Documentation supplied:

• The Operating Instructions BA00380P are available on the internet. → see:

www.de.endress.com → Downloads.

• Brief Operating Instructions KA01189P

• Final inspection report

• Drinking water approvals (optional): SD00289P, SD00319P, SD00320P

• Devices that are suitable for use in hazardous areas: Additional documentation e.g.

Safety Instructions (XA, ZD)

Endress+Hauser 15

Page 16

Installation Waterpilot FMX21

1

2

3

4

5

6

7

8

9

Dat./Insp.:

FW.Ver.: xxxx

Dev.Rev.: xxxx

Cal./Adj.

Mat:

L=

Ser. no.:xxxxxxxxxxxxx

Order code: xxxxxxxxxxxxxxxxxxxxxx

Ext. order code:xxxxxxxxxxxxxxxxxxxxxx

TAG:xxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxx

Waterpilot FMX21

Made in Germany,D-79689 Maulburg

p

Ex ia IICT6-T4

£

-10°C Ta 70°C

£

Ta 40°C forT6

£

Ta 70°C forT4

£

Ui 30VDC ; Ii 133mA; Pi 1W

£

£

£

II 2G

Ci= 5nF + 180pF/m ; Li= 1 µH/m

Warning!

Avoid electrostatic

charge

0...400mbar

4... 20 mA

0...600mbar

red

+

black

-

yellow-green

4…20 mA

Sensor

250002736--

10,5... 35VDC

XAxxxxxP-

XX/XXXX

TÜV 01ATEX 1685

PPS/Polyolefin

AL2O3

FEPEPDM

OPEN

CLOSE

90°

90°

Warning:

Avoid electrostatic charge in explosive atmosphere.

See instructions

Terminal Box for FMX21

5 Installation

5.1 Installation conditions

A0018770

1 Cable mounting screw (can be ordered as an accessory)

2 Terminal box (can be ordered as an accessory)

3 Bending radius of extension cable > 120 mm (4.72 in)

4 Mounting clamp (can be ordered as an accessory)

5 Extension cable

6 Guide tube

7 Waterpilot FMX21

8 Additional weight can be ordered as an accessory for the FMX21 with external diameter of 22 mm (0.87 in)

and 29 mm (1.14 in)

9 Protection cap

16 Endress+Hauser

Page 17

Waterpilot FMX21 Installation

5.2 Additional mounting instructions

• Cable length

– Customer-specific in meters or feet.

– Limited cable length when performing installation with freely suspended device with

cable mounting screw or mounting clamp, as well as for FM/CSA approval: max. m/ft.

300 m (984 ft).

• Sideways movement of the level probe can result in measuring errors. For this reason,

install the probe at a point free from flow and turbulence, or use a guide tube. The

internal diameter of the guide tube should be at least 1 mm (0.04 in) greater than the

external diameter of the selected FMX21.

• To avoid mechanical damage to the measuring cell, the device is equipped with a

protection cap.

• The cable must end in a dry room or a suitable terminal box. The terminal box from

Endress+Hauser provides optimum protection from the effects of humidity and weather

conditions and is suitable for outdoor installation→ 118.

• Cable length tolerance: < 5 m (16 ft): ±17.5 mm (0.69 in); > 5 m (16 ft): ±0.2 %

• If the cable is shortened, the filter at the pressure compensation tube must be

reattached. Endress+Hauser offers a cable shortening kit for this purpose

(documentation SD00552P/00/A6).

• Endress+Hauser recommends using twisted, shielded cable.

• In shipbuilding applications, measures are required to restrict the spread of fire along

cable looms.

• The length of the extension cable depends on the intended level zero point. The height

of the protection cap must be taken into consideration when designing the layout of the

measuring point. The level zero point (E) corresponds to the position of the process

isolating diaphragm. Level zero point = E; tip of probe = L (see the following diagram).

5.3 Dimensions

For dimensions, please refer to the Technical Information TI00431P/00/EN, "Mechanical

construction" section (see also: www.de.endress.com → Downloads → Media Type:

Documentation).

Endress+Hauser 17

Page 18

Installation Waterpilot FMX21

1

2

3

5.4 Mounting the Waterpilot with a mounting clamp

1 Extension cable

2 Suspension clamp

3 Clamping jaws

5.4.1 Mounting the suspension clamp:

1. Installing the mounting clamp (item 2) . When selecting the place to attach the unit,

note the weight of the extension cable (item 1) and of the device.

2. Raise the clamping jaws (item 3). Hold the extension cable in position (item 1)

between the clamping jaws as illustrated in the diagram.

3. Hold the extension cable in position (item 1) and push the clamping jaws (item 3)

back down. Tap the clamping jaws gently from above to fix them in place.

A0018793

18 Endress+Hauser

Page 19

Waterpilot FMX21 Installation

+40

( +1.57)

1

6

8

7

2

3

4

5

36

41

5.5 Mounting the Waterpilot with a cable mounting screw

A0018794

1 Extension cable

2 Cover for cable mounting screw

3 Sealing ring

4 Clamping sleeves

5 Adapter for cable mounting screw

6 Top edge of clamping sleeve

7 Desired length of extension cable and Waterpilot probe prior to assembly

8 After assembly, item 7 is located next to the mounting screw with G 1½" thread: height of sealing surface of

the adapter or NPT 1½" thread height of thread run-out of adapter

Engineering unit mm (in). Illustrated with G 1½" thread

If you want to lower the level probe to a certain depth, position the top edge of the

clamping sleeve 40 mm (4.57 in) higher than the required depth. Then push the

extension cable and the clamping sleeve into the adapter as described in Step 6 in the

following section.

5.5.1 Mount cable mounting screw with G 1½" or NPT 1½" thread:

1. Mark the desired length of extension cable on the extension cable

2. Insert the probe through the measuring aperture and carefully lower on the

extension cable. Fix the extension cable to prevent it from slipping.

3. Push the adapter (item 5) over the extension cable and screw it tightly into the

measuring aperture.

4. Push the sealing ring (item 3) and cover (item 2) onto the cable from above. Press

the sealing ring into the cover.

5. Place clamping sleeves (item 4) around the extension cable (item 1) at the marked

position as illustrated in the diagram.

6. Push the extension cable with the clamping sleeves (item 4) into the adapter (item 5)

7. Slide the cover (item 2) with sealing ring (item 3) onto the adapter (item 5) and

screw tightly to the adapter.

To remove the cable mounting screw, perform this sequence of steps in reverse.

CAUTION

L

Risk of injury!

Use only in unpressurized vessels.

‣

Endress+Hauser 19

Page 20

Installation Waterpilot FMX21

1

3

2

6

5

4

3

CLOSE

90°

OPEN

90°

Warning:

Avoid electrostatic charge in explosive atmosphere.

See instructions

Terminal Box for FMX21

1

2

3

4

5

5.6 Mounting the terminal box

The optional terminal box is mounted using four screws (M4). For the dimensions of the

terminal box, please see the Technical Information TI00431P/00/ EN, "Mechanical

construction" section (see also: www.de.endress.com → Downloads → Media Type:

Documentation).

5.7 Mounting the TMT182 temperature head transmitter with terminal box

1 Mounting screws

2 Mounting springs

3 TMT182 temperature head transmitter

4 Circlips

5 Terminal box

Only open the terminal box with a screwdriver.

WARNING

L

Risk of explosion!

The TMT182 is not designed for use in hazardous areas.

‣

5.7.1 Mounting the temperature head transmitter:

1. Guide the mounting screws (item 1) with the mounting springs (item 2) through the

hole in the temperature head transmitter (item 3)

2. Secure the mounting screws with the circlips (item 4). Circlips, mounting screws and

springs are included in the scope of delivery for the temperature head transmitter.

3. Screw the temperature head transmitter into the field housing tightly. (width of

screwdriver blade max. 6 mm (0.24 in))

NOTICE

Avoid damage to the temperature head transmitter.

Do not overtighten the mounting screw too.

‣

A0018813

20 Endress+Hauser

Page 21

Waterpilot FMX21 Installation

>7 (0.28)

A0018696

Engineering unit mm (in)

NOTICE

Incorrect connection!

A distance of >7 mm (> 0.28) must be maintained between the terminal strip and the

‣

TMT182 temperature head transmitter.

5.8 Mounting the terminal strip for the Pt100 passive (without TMT182)

If the FMX21 with optional Pt100 is supplied without the optional TMT182 temperature

head transmitter, a terminal strip is provided with the terminal box for the purpose of

wiring the Pt100.

WARNING

L

Risk of explosion!

The Pt100, as well as the terminal strip, are not designed for use in hazardous areas.

‣

A0018815

5.9 Post-installation check

Endress+Hauser 21

Is the device undamaged (visual inspection)?

Does the device conform to the measuring point specifications?

For example:

• Process temperature

• Process pressure

• Ambient temperature

• Measuring range

Are the measuring point identification and labeling correct (visual inspection)?

Page 22

Installation Waterpilot FMX21

Is the device adequately protected from precipitation and direct sunlight?

Check that all screws are firmly seated.

22 Endress+Hauser

Page 23

Waterpilot FMX21 Electrical connection

RD

BK

RD

BK

WH

YE BU

BR

a

A B

e

)

)

)

)

c

c

d

d

b

b

a

FMX21

FMX21

6 Electrical connection

WARNING

L

Electrical safety is compromised by an incorrect connection!

When using the measuring device in a hazardous area, the relevant national standards

‣

and guidelines as well as the Safety Instructions (XAs) or installation or control

drawings (ZDs) must be adhered to. All data relating to explosion protection can be

found in separate documentation which is available on request. This documentation is

supplied with the devices as standard → 7

6.1 Connecting the device

WARNING

L

Electrical safety is compromised by an incorrect connection!

The supply voltage must match the supply voltage specified on the nameplate → 13

‣

Switch off the supply voltage before connecting the device.

‣

The cable must end in a dry room or a suitable terminal box. The IP66/IP67 terminal

‣

box with GORE-TEX® filter from Endress+Hauser → 20 is suitable for outdoor

installation.

Connect the device in accordance with the following diagrams. Reverse polarity

‣

protection is integrated into the Waterpilot FMX21 and the TMT182 temperature head

transmitter. Changing the polarities will not result in the destruction of the devices.

A suitable circuit breaker should be provided for the device in accordance with IEC/EN

‣

61010.

6.1.1 Waterpilot with Pt100

A0019441

A Waterpilot FMX21

B Waterpilot FMX21 with Pt100 (not for use in hazardous areas); option "NB", Product Configurator order code

for "Accessories"

a Not for the FMX21 with external diameter of 29 mm (1.14 in)

b 10.5 to 30 V DC (hazardous area), 10.5 to 35 V DC

c 4...20 mA

d Resistance (RL)

e Pt100

Endress+Hauser 23

Page 24

Electrical connection Waterpilot FMX21

)

)

a

b

c

e

f

d

cd

g

RD BKWHYE

BU

BR

6

5

4

3

2

1

FMX21

6.1.2 Waterpilot with Pt100 and TMT182 temperature head transmitter (4 to 20 mA)

a Not for the FMX21 with external diameter of 29 mm (1.14 in)

b 10.5 to 35 V DC

c 4...20 mA

d Resistance (RL)

e Temperature head transmitter TMT182 (4 to 20 mA) (not for use in hazardous areas)

f 11.5 to 35 V DC

g Pt100

Ordering information: options "NB" and "PT", Product Configurator order code for

"Accessories mounted" and "Accessories enclosed"

6.1.3 Wire colors

RD = red, BK = black, WH = white, YE = yellow, BU = blue, BR = brown

Connection classification as per IEC 61010-1:

• Overvoltage category 1

• Pollution level 1

6.1.4 Connection data

Connection classification as per IEC 61010-1:

• Overvoltage category 1

• Pollution level 1

A0018780

Connection data in the hazardous area

See relevant XA.

24 Endress+Hauser

Page 25

Waterpilot FMX21 Electrical connection

6.2 Supply voltage

WARNING

L

Supply voltage might be connected!

Risk of electric shock and/or explosion!

When using the measuring device in hazardous areas, installation must comply with

‣

the corresponding national standards and regulations as well as the Safety Instructions.

All explosion protection data are given in separate documentation which is available

‣

upon request. The Ex documentation is supplied as standard with all devices approved

for use in explosion hazardous areas.

6.2.1 FMX21 + Pt100 (optional)

• 10.5 to 35 V (not hazardous areas)

• 10.5 to 30 V (hazardous areas)

6.2.2 TMT182 temperature head transmitter (optional)

11.5 to 35 V DC

6.3 Cable specifications

In the following cases, Endress+Hauser recommends the use of a shielded cable as the

cable extension:

• For large distances between the end of the extension cable and the display and/or

evaluation unit

• For large distances between the end of the extension cable and the temperature head

transmitter

• When directly connecting the Pt100 signal to a display and/or evaluation unit

The extension cables are shielded for device versions with external diameters of 22

mm (0.87 in) and 42 mm (1.65 in).

6.3.1 FMX21 + Pt100 (optional)

• Commercially available instrument cable

• Terminals, terminal box: 0.08 to 2.5 mm2 (28 to 14 AWG)

6.3.2 TMT182 temperature head transmitter (optional)

• Commercially available instrument cable

• Terminals, terminal box: 0.08 to 2.5 mm2 (28 to 14 AWG)

• Transmitter connection: max. 1.75 mm2 (15 AWG)

6.4 Power consumption

6.4.1 FMX21 + Pt100 (optional)

• ≤ 0.805 W at 35 V DC (non-hazardous area)

• ≤ 0.690 W at 30 V DC (hazardous area)

6.4.2 TMT182 temperature head transmitter (optional)

≤ 0.805 W at 35 V DC

Endress+Hauser 25

Page 26

Electrical connection Waterpilot FMX21

R

Lmax

– 2 0.09•

• L – R

U – 10.5 V

23 mA

W

m

£

413

630

195

1065

35

20

25

10.5

15

847

30

R

[ ]W

U

[ ]

V

– R

U – 11.5 V

0.023 A

£

R

Lmax

370

587

152

1022

35

20

25

11.5

15

804

30

R

[ ]W

U

[ ]

V

A B

add add

6.5 Current consumption

6.5.1 FMX21 + Pt100 (optional)

• Max. current consumption: ≤ 23 mA

Min. current consumption: ≥ 3.6 mA

• Pt100: ≤ 0.6 mA

6.5.2 TMT182 temperature head transmitter (optional)

• Max. current consumption: ≤ 23 mA

• Min. current consumption: ≥ 3.5 mA

• Pt100 via temperature head transmitter: ≤ 0.6 mA

6.6 Maximum load

The maximum load resistance depends on the supply voltage (U) and must be determined

individually for each current loop, see formula and diagrams for FMX21 and temperature

head transmitter.

The total resistance resulting from the resistances of the connected devices, the

connecting cable and, where applicable, the resistance of the extension cable may not

exceed the load resistance value.

A FMX21 load chart for estimating the load resistance. Additional resistances, such as the resistance of the

extension cable, have to be subtracted from the value calculated as shown in the equation.

B Load diagram for TMT182 temperature head transmitter for estimating the load resistance. Additional

resistances must be subtracted from the value calculated as shown in the equation

R

Max. load resistance [Ω]

Lmax

R

Additional resistances, such as resistance of the evaluation unit and/or display unit, cable resistance [Ω]

add

U Supply voltage [V]

L Basic length of extension cable [m] (cable resistance per wire 0.09 Ω/m)

26 Endress+Hauser

• When using the measuring device in a hazardous area, the relevant national

standards and regulations as well as the Safety Instructions or installation or control

drawings (XA) must be adhered to.

• When operating via a handheld terminal or via a PC with an operating program, a

minimum communication resistance of 250 Ω must be taken into account.

A0026500-EN

Page 27

Waterpilot FMX21 Electrical connection

1

3

4

3

4

5

5

5

5

5

5

5

6

6

6

2

A

B

B

C

2

6.7 Connecting the measuring unit

6.7.1 Overvoltage protection

To protect the Waterpilot and the TMT182 temperature head transmitter from large

interference voltage peaks, Endress+Hauser recommends installing overvoltage protection

upstream and downstream of the display and/or evaluation unit as shown in the graphic.

A Power supply, display and evaluation unit with one input for Pt100

B Power supply, display and evaluation unit with one input for 4 to 20 mA

C Power supply, display and evaluation unit with two inputs for 4 to 20 mA

1 Waterpilot FMX21 HART

2 Connection for integrated Pt100 in the FMX21

3 4 to 20 mA HART (temperature)

4 4 to 20 mA HART (level)

5 Overvoltage protection, e.g. HAW from Endress+Hauser (not for use in hazardous areas).

6 Power supply

A0018941

Further information on the TMT182 temperature head transmitter for HART

applications from Endress+Hauser can be found in the Technical Information

TI00078R/09/EN.

6.7.2 Connecting the Commubox FXA195

Endress+Hauser 27

The Commubox FXA195 connects intrinsically safe transmitters with HART protocol to the

USB interface of a computer. This enables remote operation of the transmitter using the

Endress+Hauser operating program FieldCare. The power is supplied to the Commubox via

Page 28

Electrical connection Waterpilot FMX21

3

7 6

4

1

5

2

the USB interface. The Commubox is also suitable for connecting to intrinsically safe

circuits. For further information, see the Technical Information TI00404F/00/EN.

6.7.3 Connecting the Field Xpert SFX

Compact, flexible and robust industrial handheld terminal for remote configuration and for

obtaining measured values via the HART current output (4 to 20 mA). For details, see

Operating Instructions BA00060S/04/EN.

A0018811

1 Waterpilot FMX21

2 Required communication resistor ≥ 250 Ω

3 Computer with operating tool (e.g. FieldCare)

4 Commubox FXA195 (USB)

5 Transmitter power supply unit, e.g. RN221N (with communication resistor)

6 Field Xpert SFX

7 VIATOR Bluetooth modem with connecting cable

Only use certified operating devices in hazardous area!

WARNING

L

Risk of explosion!

Do not change the battery of the handheld terminal in the hazardous area.

‣

When using the measuring device in a hazardous area, the relevant national standards

‣

and regulations as well as the Safety Instructions (XAs) or installation or control

drawings (ZDs) must be adhered to.

28 Endress+Hauser

Page 29

Waterpilot FMX21 Electrical connection

FXN520

1 2 3 4

6.7.4 Connecting for air pressure compensation with external measured value

A0018757

1 Fieldgate FXA520

2 Multidrop connector FXN520

3 Cerabar

4 Waterpilot FMX21

For applications in which condensation may occur, the use of an absolute pressure probe is

recommended. For level measurement using an absolute pressure probe, the measured

value is affected by fluctuations in the ambient air pressure. To correct the resulting

measured error, you can connect an external absolute pressure sensor (e.g. Cerabar) to the

HART signal cable, switch the Waterpilot to burst mode and operate the Cerabar in "Electr.

Delta P" mode.

By switching on the "Electr. Delta P" application, the external absolute pressure sensor

calculates the difference between the two pressure signals and can thus determine the

level precisely. Only one level measured value can be corrected in this way.

If using intrinsically safe devices, the regulations which apply to interconnecting

intrinsically safe circuits as outlined in IEC 60079-14 (proof of intrinsic safety) must

be observed.

6.7.5 Connecting an external temperature sensor/temperature head transmitter for density compensation

The Waterpilot FMX21 can correct measured errors that result from fluctuations in the

density of the water caused by temperature. Users can choose from the following options:

Use the internally measured sensor temperature of the FMX21

The internally measured sensor temperature is calculated in the Waterpilot FMX21 for

density compensation. The level signal is thus corrected according to the density

characteristic line of the water.

Use the optional internal Pt100 temperature sensor for density compensation in a

suitable HART master (e.g. PLC)

The Waterpilot FMX21 is available with an optional Pt100 temperature sensor. Endress

+Hauser additionally offers the TMT182 temperature head transmitter to convert the

Pt100 signal to a 4 to 20 mA HART signal. The temperature and pressure signal is

requested by a HART master (e.g. PLC), where a corrected level value can be generated

using a stored linearization table or density function (of a chosen medium).

Endress+Hauser 29

Page 30

Electrical connection Waterpilot FMX21

1 2 3 4

FXN520

FXN520

1 2 3 4

A0018763

1 HART master, e.g. PLC (programmable logic controller)

2 Multidrop connector FXN520

3 Temperature head transmitter TMT182

4 Waterpilot FMX21

Use an external temperature signal which is transmitted to the FMX21 via HART

burst mode

The Waterpilot FMX21 is available with an optional Pt100 temperature sensor. In this

case, the signal of the Pt100 is analyzed using a HART-compliant (min. HART 5.0)

temperature head transmitter that supports burst mode. The temperature signal can thus

be transmitted to the FMX21. The FMX21 uses this signal for density correction of the

level signal.

The TMT182 temperature head transmitter is not suitable for this configuration.

1 Fieldgate FXA520

2 Multidrop connector FXN520

3 Temperature head transmitter TMT182 (burst mode)

4 Waterpilot FMX21

Without additional compensation due to the anomaly of water, errors of up to 4% may

occur at a temperature of +70 °C (+158 °F), for example. With density compensation, this

error can be decreased to 0.5 % in the entire temperature range from

0 to +70 °C (+32 to +158 °F).

For further information on the devices, please refer to the relevant Technical

Information:

• TI00078R: Temperature head transmitter TMT182 (4 to 20 mA HART)

• TI00369F: Fieldgate FXA520

• TI00400F: Multidrop connector FXN520

30 Endress+Hauser

A0018764

Page 31

Waterpilot FMX21 Electrical connection

6.8 Post-connection check

Is the device or cable undamaged (visual check)?

Do the cables comply with the requirements ?

Do the cables have adequate strain relief?

Are all cable glands installed, securely tightened and leak-tight?

Does the supply voltage match the specifications on the nameplate?

Is the terminal assignment correct ?

Endress+Hauser 31

Page 32

Operation options Waterpilot FMX21

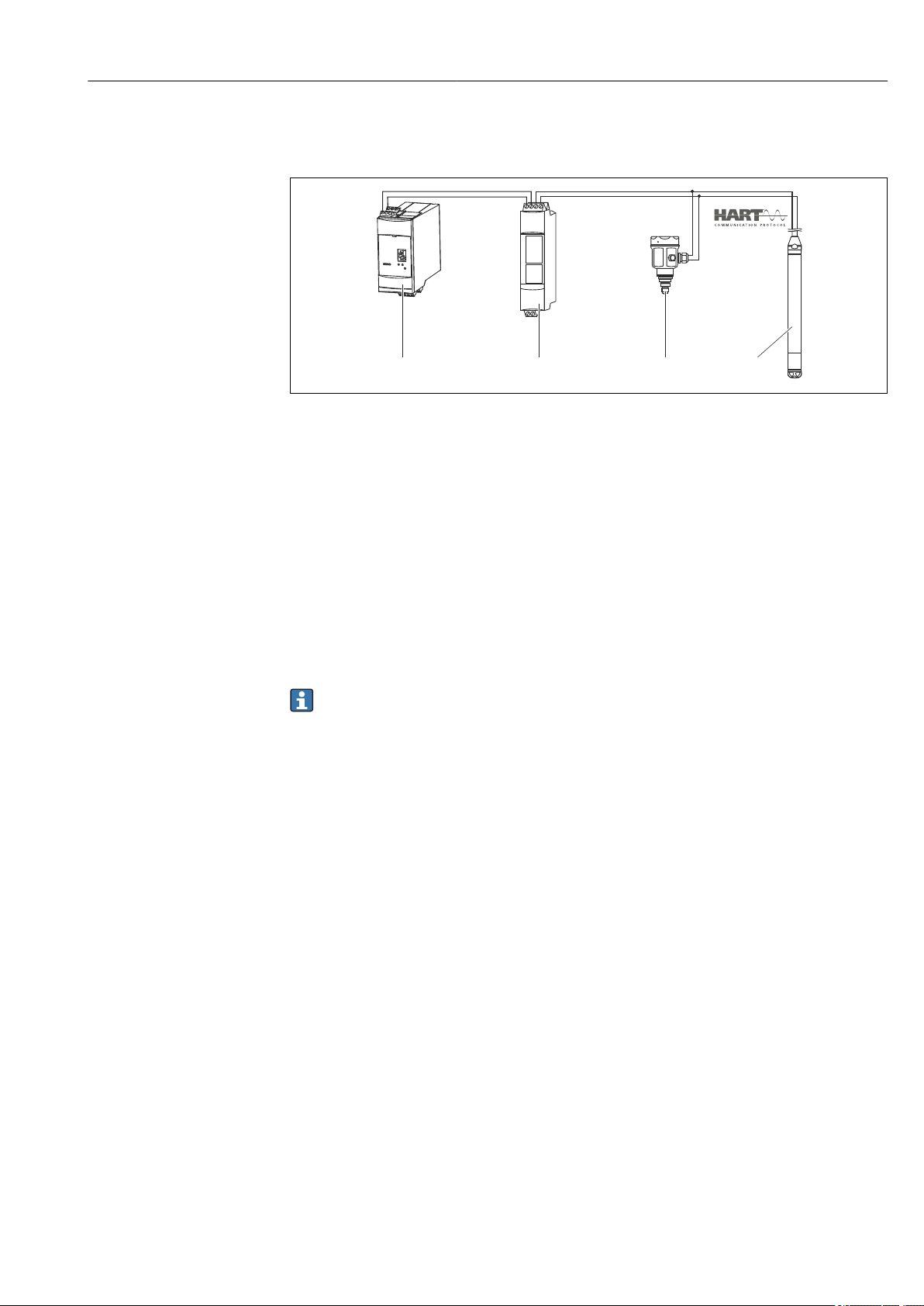

7 Operation options

Endress+Hauser offers comprehensive measuring point solutions with display and/or

evaluation units for the Waterpilot FMX21 and TMT182 temperature head transmitter.

Your Endress+Hauser service organization would be glad to be of service if you have

any other questions. Contact addresses can be found on the website at

www.endress.com/worldwide

7.1 Overview of operating options

7.1.1 Operation using Endress+Hauser operating program

The FieldCare operating program is an Endress+Hauser plant asset management tool

based on FDT technology. With FieldCare, you can configure all Endress+Hauser devices as

well as devices from other manufacturers that support the FDT standard.

Hardware and software requirements can be found on the Internet:

www.de.endress.com → Search: FieldCare → FieldCare → Technical Data.

FieldCare supports the following functions:

• Configuration of transmitters in online/offline mode

• Loading and saving device data (upload/download)

• Documentation of the measuring point

Connection options:

• HART via Commubox FXA195 and the USB port of a computer

• HART via FXA520 Fieldgate

• Further information on FieldCare and software download can be found on the

internet (www.de.endress.com ® Downloads ® Text Search: FieldCare).

• Connecting the Commubox FXA195

• As not all internal device dependencies can be mapped in offline operation, the

consistency of the parameters must be checked once again before they are

transmitted to the device.

7.1.2 Operation using Field Xpert SFX

Compact, flexible and robust industrial handheld terminal for remote configuration and for

obtaining measured values via the HART current output or FOUNDATION Fieldbus. For

details, see the Operating Instructions BA00060S/04.

32 Endress+Hauser

Page 33

Waterpilot FMX21 Operation options

7.2 Operating concept

Operation with an operating menu is based on an operation concept with "user roles" .

User role Meaning

Operator Operators are responsible for the devices during normal "operation". This is usually limited to

reading process values either directly at the device or in a control room. If the work with the

devices goes beyond reading, it concerns simple, application-specific functions that are used in

operation. Should an error occur, these users simple forward the information on the errors but

do not intervene themselves.

Maintenance Service engineers usually work with the devices in the phases following device commissioning.

They are primarily involved in maintenance and troubleshooting activities for which simple

settings have to be made at the device. Technicians work with the devices over the entire life

cycle of the product. Thus, commissioning and advanced settings and configurations are some of

the tasks they have to carry out.

Expert Experts work with the devices over the entire life cycle of the device, but, in part, have high

requirements on the devices. Individual parameters/functions from the overall functionality of

the devices are required for this purpose time and again. In addition to technical, processoriented tasks, experts can also perform administrative tasks (e.g. user administration). "Experts"

can avail of the entire parameter set.

7.3 Structure of the operating menu

User role Submenu Meaning/use

Operator Display/

operat.

Maintenance setup Contains all the parameters that are needed to commission measuring operations.

Contains parameters that are needed to configure the measured value display

(selecting the values displayed, display format, etc.). With this submenu, users can

change the measured value display without affecting the actual measurement.

This submenu has the following structure:

• Standard setup parameters

A wide range of parameters, which can be used to configure a typical application,

is available at the start. The measuring mode selected determines which

parameters are available. After making settings for all these parameters, the

measuring operation should be completely configured in the majority of cases.

• "Extended setup" submenu

The "Extended setup" submenu contains additional parameters for more in-depth

configuration of the measurement operation, for conversion of the measured

value and for scaling the output signal. This menu is split into additional

submenus depending on the measuring mode selected.

Endress+Hauser 33

Page 34

Operation options Waterpilot FMX21

User role Submenu Meaning/use

Maintenance Diagnosis Contains all the parameters that are needed to detect and analyze operating errors.

This submenu has the following structure:

• Diagnostic list

contains up to 10 currently pending error messages.

• Event logbook

contains the last 10 error messages (no longer pending).

• Instrument info

contains information for identifying the device.

• Measured values

contains all current measured values.

• Simulation

Is used to simulate pressure, level, current and alarm/warning.

• Enter reset code

Expert Expert Contains all the parameters of the device (including those already in one of the

submenus). The "Expert" submenu is structured by the function blocks of the device.

It thus contains the following submenus:

• System

contains all device parameters that do not affect either measurement or

integration into a distributed control system.

• Measurement

contains all parameters for configuring the measurement.

• Output

contains all parameters for configuring the current output.

• Communication

contains all parameters for configuring the HART interface.

• Diagnosis

contains all parameters required to detect and analyze operating errors.

7.4 Locking/unlocking operation

Once you have entered all the parameters, you can lock your entries against unauthorized

and undesired access.

The "Operator code" parameter is used to lock/unlock the device.

Operator code

Navigation Setup → Extended setup → Operator code

Read permission Operators/Service engineers/Expert

Write permission Operators/Service engineers/Expert

Description Use this function to enter a code to lock or unlock operation.

User entry •

Factory setting 0

Note The release code is "0" in the order configuration. Another release code can be defined in

To lock: Enter a number ¹ the release code (value range: 1 to 65535).

• To unlock: Enter the release code.

the "Code definition" parameter. If the user has forgotten the release code, the release code

can be visible by entering the number "5864".

The release code is defined in the "Code definition" parameter.

Code definition

34 Endress+Hauser

Page 35

Waterpilot FMX21 Operation options

Navigation Setup → Extended setup → Code definition

Read permission Operators/Service engineers/Expert

Write permission Operators/Service engineers/Expert

Description Use this function to enter a release code with which the device can be unlocked.

User entry A number from 0 to 9999

Factory setting 0

7.5 Resetting to factory settings (reset)

By entering a certain code, you can completely or partially reset the entries for the

parameters to the factory settings

1)

. Enter the code via the "Enter reset code"

parameter (menu path: "Diagnosis" → "Enter reset code").

There are various reset codes for the device. The following table illustrates which

parameters are reset by the particular reset codes. To perform a reset, operation must

be unlocked (see "Locking/unlocking operation" section → 34).

Any customer-specific configuration carried out at the factory is not affected by a

reset (customer-specific configuration remains). If you want to change the customerspecific configuration carried out at the factory, please contact Endress+Hauser

Service. As there is no separate service level, the order code and serial number can be

changed without a specific release code.

Reset code

62 PowerUp reset (warm start)

333 User reset

7864 Total reset

1)

Description and effect

• The device is restarted.

• Data is read back anew from the EEPROM (process is reinitialized).

• Any simulation which may be running is ended.

• This code resets all the parameters apart from:

- Device tag

- Linearization table

- Operating hours

- Event logbook

- Curr. trim 4 mA

- Curr. trim 20 mA

• Any simulation which may be running is ended.

• The device is restarted.

• This code resets all the parameters apart from:

- Operating hours

- Event logbook

• Any simulation which may be running is ended.

• The device is restarted.

1) To be entered in "System" → "Management" → "Enter reset code"

After a "Total reset" in FieldCare you have to press the "refresh" button in order to

ensure that the measuring units are also reset.

1) . The factory setting for the individual parameters is specified in the parameter description

Endress+Hauser 35

Page 36

Integrating device via HART® protocol

Waterpilot FMX21

8

Integrating device via HART® protocol

Version data for the device

Firmware version 01.00.zz • On the title page of the Operating instructions

• On nameplate

• Firmware Version parameter

Diagnosis→ Instrument info → Firmware version

Manufacturer ID 17 (0x11) Manufacturer ID. parameter

Diagnosis → Instrument info→ Manufacturer ID

Device type code 36 (0x24) Device type parameter

Diagnosis → Instrument info → Device type

HART protocol revision 6.0 ---

Device revision 1 • On transmitter nameplate

• Device revision parameter

Diagnosis→ Instrument info → Device revision

The suitable device description file (DD) for the individual operating tools is listed in the

table below, along with information on where the file can be acquired.

Operating tools

Operating tool Reference sources for device descriptions (DD and DTM)

FieldCare • www.endress.com → Downloads area

• CD–ROM (contact Endress+Hauser)

• DVD (contact Endress+Hauser)

AMS Device Manager

(Emerson Process Management)

SIMATIC PDM

(Siemens)

Field Communicator 375, 475

(Emerson Process Management)

www.endress.com → Downloads area

www.endress.com → Downloads area

Use update function of handheld terminal

8.1 HART process variables and measured values

The following numbers are assigned to the process variables in the factory:

Process variable Meas. Level

Linear Table active

First process variable

(Primary variable)

Second process variable

(Secondary variable)

(Pressure measured)

0

2

(Corrected press.)

8

(Level before

linearization)

0

(Pressure measured)

(Tank content)

(Level before

linearization)

9

8

36 Endress+Hauser

Page 37

Waterpilot FMX21

Process variable Meas. Level

Third process variable

(Tertiary variable)

Fourth process variable

(Quaternary variable)

3

(Sensor pressure)

The assignment of the device variables to the process variable is displayed in the

Expert → Communication → HART output menu.

The assignment of the device variables to the process variable can be changed using

HART command 51.

An overview of the possible device variables can be found in the following section.

8.2 Device variables and measured values

The following measured values are assigned to the individual device variables:

Device variable code Device variable Measured value

0 PRESSURE_1_FINAL_VALUE Pressure measured All

1 PRESSURE_1_AFTER_DAMPING Press after damping All

2 PRESSURE_1_AFTER_CALIBRATION Corrected press. All

3 PRESSURE_1_AFTER_SENSOR Corrected press. All

4 MEASURED_TEMPERATURE_1 Sensor temp. All

8 MEASURED_LEVEL_AFTER_ SIMULATION Level before lin. Only level

9 MEASURED_TANK_CONTENT_AFTER_ SIMULATION Tank content Only level

10 CORRECTED_MEASUREMENT_ DENSITY Process density Only level

12 HART_INPUT_VALUE HART input val. Cannot be selected as output

251 None (no device variable is mapped) - All (but only for quaternary variable)

Integrating device via HART® protocol

Linear Table active

2

(Corrected press.)

4

(Sensor temp.)

(Pressure measured)

0

The device variables can be queried from a HART® master using HART® command 9 or

33.

Endress+Hauser 37

Page 38

Commissioning Waterpilot FMX21

9 Commissioning

NOTICE

If a pressure smaller than the minimum permitted pressure or greater than the

maximum permitted pressure is present at the device, the following messages are

output in succession:

"S140 Working range P" or "F140 Working range P" (depending on the setting in the

‣

"Alarm behav. P" parameter)

"S841 Sensor range" or "F841 Sensor range" (depending on the setting in the "Alarm

‣

behav. P" parameter)

"S971 Adjustment" (depending on setting in "Alarm behav. P" parameter

‣

9.1 Post-installation check and function check

Before commissioning your measuring point, ensure that the post-installation and postconnection check have been performed.

• "Post-installation check" checklist → 21

• "Post-connection check" checklist → 31

9.2 Unlocking/locking configuration

If the device is locked to prevent configuration, it must first be unlocked.

9.2.1 Locking/unlocking software

If the device is locked via the software (device access code), the key symbol appears in the

measured value display. If an attempt is made to write to a parameter, a prompt for the

device access code appears. To unlock, enter the user-defined device access code.

9.3 Commissioning

Commissioning comprises the following steps:

• Function check → 38

• Selecting the language, measuring mode and pressure unit → 39

• Position adjustment → 40

• Configuring measurement:

– Pressure measurement → 41

– Level measurement → 43

38 Endress+Hauser

Page 39

Waterpilot FMX21 Commissioning

9.4 Selecting the language

9.4.1 Configure language

9.5 Measuring mode selection

The device is configured for the "Pressure" measuring mode as standard. The

measuring range and the unit in which the measured value is transmitted correspond

to the data on the nameplate.

WARNING

L

Changing the measuring mode affects the span (URV)

This situation can result in product overflow.

If the measuring mode is changed, the setting for the span (URV) must be checked in

‣

the "Setup" operating menu and readjusted if necessary.

Measuring mode

Navigation Setup → Measuring mode

Write permission Operators/Service engineers/Expert

Description Select the measuring mode.

The operating menu is structured differently depending on the measuring mode selected.

A0017654-EN

Options • Meas.

• Level

Factory setting Level

Endress+Hauser 39

Page 40

Commissioning Waterpilot FMX21

9.6 For selecting the pressure engineering unit

Press. eng. unit

Navigation Setup → Press. eng. unit

Write permission Operators/Service engineers/Expert

Description Select the pressure engineering unit. If a new pressure engineering unit is selected, all

pressure-specific parameters are converted and displayed with the new unit.

Options • mbar, bar

• mmH2O, mH2O, inH2O

• ftH2O

• Pa, kPa, MPa

• psi

• mmHg, inHg

• kgf/cm

2

Factory setting mbar or bar depending on the nominal measuring range of the sensor module, or as per

order specifications

9.7 Position adjustment

The pressure resulting from the orientation of the device can be corrected here.

Pos. zero adjust (relative pressure sensor)

Navigation Setup → Pos. zero adjust

Write permission Operators/Service engineers/Expert

Description Position adjustment – the pressure difference between zero (set point) and the measured

pressure need not be known.

Options • Confirm

• Cancel

Example • Measured value = 2.2 mbar (0.033 psi)

• You correct the measured value via the "Pos. zero adjust" parameter with the "Confirm"

option. i.e. This means that you are assigning the value 0.0 to the pressure present.

• Measured value (after pos. zero adjust) = 0.0 mbar

• The current value is also corrected.

Factory setting Cancel

Calib. offset (absolute pressure sensor)

40 Endress+Hauser

Page 41

Waterpilot FMX21 Commissioning

Navigation Setup → Calib. offset

Write permission Operators/Service engineers/Expert

Description Position adjustment – the pressure difference between zero (set point) and the measured

pressure must be known.

Options • Confirm

• Cancel

Example • Measured value = 982.2 mbar (15 psi)

• You correct the measured value via the "Calib. offset" parameter with the "Confirm"

option. i.e. This means that you are assigning the value 980.0 to the pressure present.

• Measured value (after position adjustment) = 980 mbar (15 psi)

• The current value is also corrected.

Factory setting Cancel

9.8 Configuring the damping

The pressure resulting from the orientation of the device can be corrected here.

Damping

Navigation Setup → Damping

Write permission Operators/Service engineers/Expert

(if the "Damping" DIP switch is set to "on")

Description

Input range 0.0 to 999.0 s

Factory setting 2.0 sec. or according to order specifications

Enter damping time (time constant t) ("Damping" DIP switch set to "on")

Display damping time (time constant t) ("Damping" DIP switch set to "off").

The damping affects the speed at which the measured value reacts to changes in pressure.

9.9 Configuring pressure measurement

9.9.1 Calibration with reference pressure (wet calibration)

Example:

In this example, a device with a 400 mbar (6 psi) sensor module is configured for the

0 to +300 mbar (0 to 4.5 psi) measuring range i.e. 0 mbar is assigned to the 4 mA value

and 300 mbar (4.5 psi) is assigned to the 20 mA value.

Endress+Hauser 41

Page 42

Commissioning Waterpilot FMX21

i

p

A

B

Prerequisite:

The pressure values 0 mbar and 300 mbar (4.5 psi) can be specified. For example, the

device is already installed.

Due to the orientation of the device, there may be pressure shifts in the measured

value, i.e. the measured value is not zero in a pressureless condition. For information

on how to perform a position adjustment, see → 40.

Description

1 Select the "Pressure" measuring mode via the

"Measuring Mode" parameter.

Menu path: Setup → Measuring mode

WARNING

L

Changing the measuring mode affects the

span (URV)

This situation can result in product overflow.

If the measuring mode is changed, the

‣

setting for the span (URV) must be

checked in the "Setup" operating menu and

readjusted if necessary.

2 Select a pressure unit via the "Press. eng. unit"

parameter, here "mbar" for example.

Menu path: Setup → Press. eng. unit

3 The pressure for the LRV (4 mA value) is

present at the device, 0 mbar for example.

Select the "Get LRV" parameter.

Menu path: Setup → Extended setup → Current

output → Get LRV

Confirm the present value by selecting "Apply".

The present pressure value is assigned to the

lower current value (4 mA).

4 The pressure for the URV (20 mA value) is

present at the device, 300 mbar (4.5 psi).

Select the "Get URV" parameter.

Menu path: Setup → Extended setup → Current

output → Get URV

Confirm the present value by selecting "Apply".

The present pressure value is assigned to the

upper current value (20 mA).

5 Result:

The measuring range is configured for

0 to +300 mbar (0 to 4.5 psi).

A See table, step 3.

B See table, step 4.

i Current value

p Meas.

A0017671

9.9.2 Calibration without reference pressure (dry calibration)

Example:

In this example, a device with a 400 mbar (6 psi) sensor module is configured for the

0 to +300 mbar (0 to 4.5 psi) measuring range, i.e. 0 mbar is assigned to the 4 mA value

and 300 mbar (4.5 psi) is assigned to the 20 mA value.

Prerequisite:

42 Endress+Hauser

This is a theoretical calibration, i.e. the pressure values for the lower and upper range are

known.

Due to the orientation of the device, there may be pressure shifts in the measured

value, i.e. the measured value is not zero in a pressureless condition. For information

on how to perform a position adjustment, see → 40.

Page 43

Waterpilot FMX21 Commissioning

i

p

A

B

Description

1 Select the "Pressure" measuring mode via the

"Measuring Mode" parameter.

Menu path: Setup → Measuring mode

WARNING

L

Changing the measuring mode affects the

span (URV)

This situation can result in product overflow.

If the measuring mode is changed, the

‣

setting for the span (URV) must be

checked in the "Setup" operating menu and

readjusted if necessary.

2 Select a pressure unit via the "Press. eng. unit"

parameter, here "mbar" for example.

Menu path: Setup → Press. eng. unit

3 Select the "Set LRV" parameter.

Menu path: Setup → Extended setup → Current

output → Set LRV

Enter the value for the "Set LRV" parameter

(here 0 mbar) and confirm. This pressure value

is assigned to the lower current value (4 mA).

4 Select the "Set URV" parameter.

Menu path: Setup → Extended setup → Current

output → Set URV

Enter the value for the "Set URV" parameter,

here 300 mbar (4.5 psi), and confirm. This

pressure value is assigned to the upper current

value (20 mA).

5 Result:

The measuring range is configured for

0 to +300 mbar (0 to 4.5 psi).

A See table, step 3.

B See table, step 4.

i Current value

p Meas.

A0017671

9.10 Configuring level measurement

9.10.1 Information on level measurement

You have a choice of two methods for calculating the level: "In pressure" and "In

height". The table in the "Overview of level measurement" section that follows

provides you with an overview of these two measuring tasks.

• The limit values are not checked, i.e. the values entered must be appropriate for the

sensor module and the measuring task for the device to be able to measure

correctly.

• Customer-specific units are not possible.

• The values entered for "Empty calib./Full calib.", "Empty pressure/Full pressure",

"Empty height/Full height" and "Set LRV/Set URV" must be at least 1% apart. The

value will be rejected, and a warning message displayed, if the values are too close

together.

Endress+Hauser 43

Page 44

Commissioning Waterpilot FMX21

1000 l

0 l

400 mbar

r = 1

g

cm

3

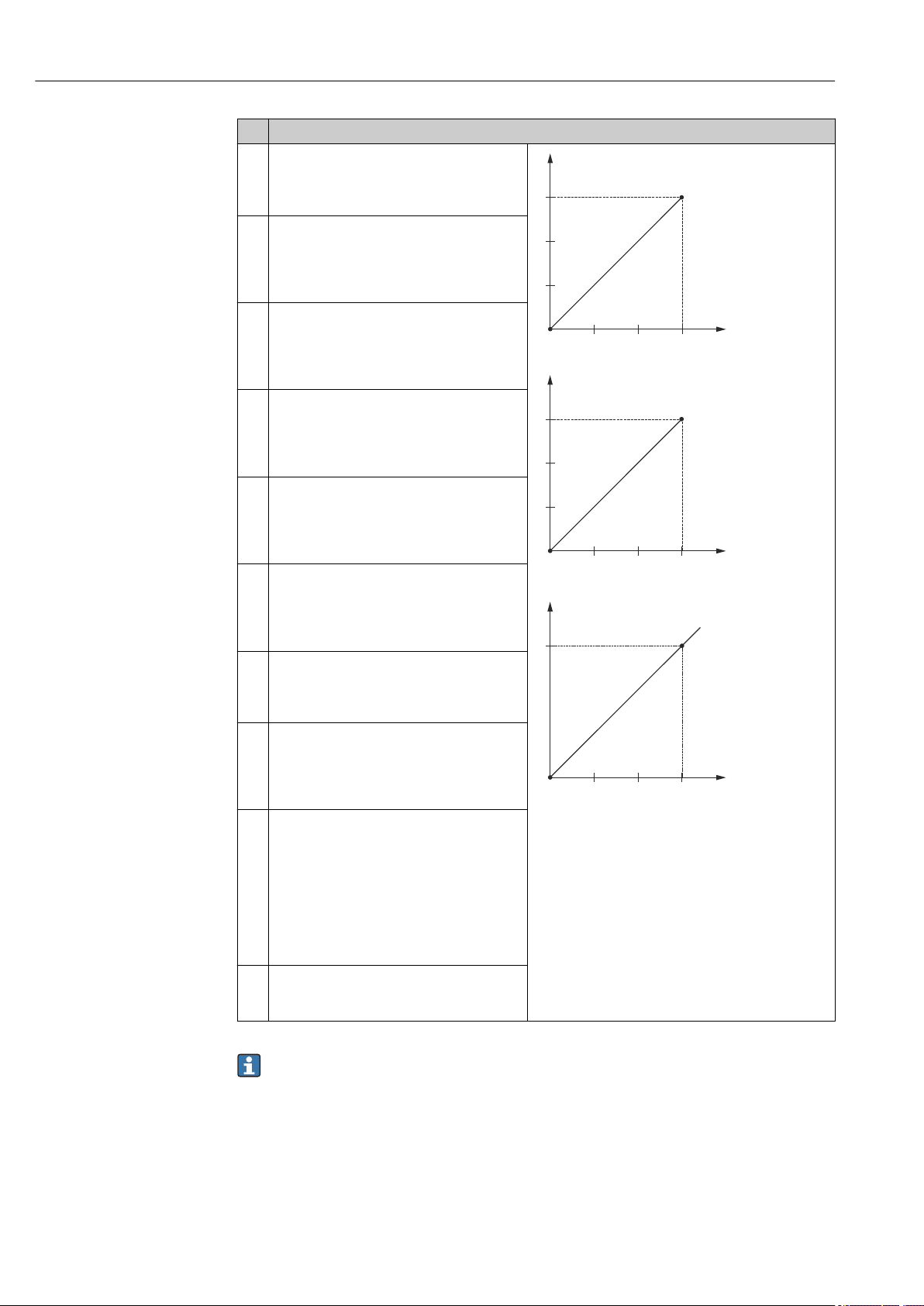

9.10.2 Overview of level measurement

Measuring task Level

selection

Calibration is

performed by

entering two

pressure-level value

pairs.

Calibration is

performed by

entering the density

and two height-level

value pairs.

"In

pressure"

"In height" • Calibration with

Measured variable

options

Via the "Output unit"

parameter :

%, level, volume or

mass units

Description Measured value

display

• Calibration with

reference pressure

(wet calibration)

→ 46

• Calibration without

reference pressure (dry

calibration) → 44

reference pressure

(wet calibration)

→ 51

• Calibration without

reference pressure (dry

calibration) → 48

The measured value

display and the "Level

before lin" parameter

display the measured

value.

9.10.3 "In pressure" level selection Calibration without reference pressure (dry calibration)

Example:

In this example, the volume in a tank should be measured in liters. The maximum volume

of 1 000 l (264 gal) corresponds to a pressure of 400 mbar (6 psi).

The minimum volume of 0 liters corresponds to a pressure of 0 mbar since the process

isolating diaphragm of the probe is at the start of the level measuring range.

Prerequisite:

• The measured variable is in direct proportion to the pressure.

• This is a theoretical calibration i.e. the pressure and volume values for the lower and

upper calibration point must be known.

• The values entered for "Empty calib./Full calib.", "Empty pressure/Full pressure" and

"Set LRV/Set URV" must be at least 1% apart. The value will be rejected, and a

warning message displayed, if the values are too close together. Further limit values

are not checked, i.e. the values entered must be appropriate for the sensor module

and the measuring task for the device to be able to measure correctly.

• Due to the orientation of the device, there may be pressure shifts in the measured

value, i.e. when the vessel is empty or partly filled, the measured value is not zero.

For information on how to perform a position adjustment, see → 40.

Description

1 Select the "Level" measuring mode via the

"Measuring mode" parameter.

Menu path: Setup → Measuring mode

WARNING

L

Changing the measuring mode affects the

span (URV)

This situation can result in product overflow.

If the measuring mode is changed, the

‣

setting for the span (URV) must be

checked in the "Setup" operating menu and

2 Select a pressure unit via the "Press. eng. unit"

readjusted if necessary.

parameter, here "mbar" for example.

Menu path: Setup → Press. eng. unit

44 Endress+Hauser

A0018818

Page 45

Waterpilot FMX21 Commissioning

C

D

E

F

G

H

v

p

i

v

Description

3

Select the "In pressure" level mode via the "Level

selection" parameter.

Menu path: Setup → Extended setup → Level →

Level selection.

4 Select a volume unit via the "Unit before lin."

parameter, here "l" (liter) for example.

Menu path: Setup → Extended setup → Level→

Unit before lin.

5 Select the "Dry" option via the "Calibration

mode" parameter.

Menu path: Setup → Extended setup → Level →

Calibration mode

6 Enter the volume value for the lower

calibration point via the "Empty calib."

parameter, here 0 liters for example.

Menu path: Setup → Extended setup → Level →

Empty calib.

7 Enter the pressure value for the lower

calibration point via the "Empty pressure"

parameter, here "0 mbar" for example.

Menu path: Setup → Extended setup → Level →

Empty pressure

8 Enter the volume value for the upper

calibration point via the "Full calib." parameter,

here 1 000 l (264 gal).

Menu path: Setup → Extended setup → Level →

Full calib.

9 Enter the pressure value for the upper

calibration point via the "Full pressure"

parameter, here 400 mbar (6 psi).

Menu path: Setup → Extended setup → Level →

Full pressure

10 "Adjust density" contains the factory setting 1.0

but can be changed if required. The value pairs

subsequently entered must correspond to this

density.

Menu path: Setup → Extended setup → Level →

Adjust density

11 Set the volume value for the lower current

value (4 mA) via the "Set LRV" parameter (0 l).

Menu path: Setup → Extended setup → Current

output → Set LRV

12 Set the volume value for the upper current

value (20 mA) via the "Set URV" parameter

(1 000 l (264 gal)).

Menu path: Setup → Extended setup → Current

output → Set URV

13 If the process uses a medium other than that

on which the calibration was based, the new