Page 1

BA00148D/06/EN/03.14

71245150

Valid as of version

V 5.05.zz (device software)

Products Solutions Services

Operating Instructions

Proline Promag W 800

Electromagnetic flowmeter

Page 2

Proline Promag W 800

• Make sure the document is stored in a safe place such that it is always available when

working

on or with the device.

• To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to

these Instructions.

2 Endress+Hauser

Page 3

Proline Promag W 800

Table of contents

1 Document information . . . . . . . . . . . . . . 5

1.1 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Basic safety instructions . . . . . . . . . . . . . 8

2.1 Personnel requirements . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Occupational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Product description . . . . . . . . . . . . . . . . 11

3.1 Product structure . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . 12

4.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Product identification . . . . . . . . . . . . . . . . . . . . . . 13

5 Storage, transport and disposal of

packaging . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Transporting the product . . . . . . . . . . . . . . . . . . . 16

5.3 Disposing of the packaging . . . . . . . . . . . . . . . . . 17

9.2 Commissioning without the GSM/GPRS modem 67

9.3 Inserting the SIM card . . . . . . . . . . . . . . . . . . . . . . 68

9.4 Switching on the measuring device . . . . . . . . . . . 69

9.5 Establishing wireless communication . . . . . . . . . 70

9.6 Data logger file with process data . . . . . . . . . . . . 85

9.7 Setting the operating language . . . . . . . . . . . . . . 87

9.8 Managing the configuration . . . . . . . . . . . . . . . . . 87

9.9 Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.10 Protecting settings from unauthorized access . . 89

10 Operation . . . . . . . . . . . . . . . . . . . . . . . . 90

10.1 Changing the operating language . . . . . . . . . . . . 90

10.2 Switching the display . . . . . . . . . . . . . . . . . . . . . . . 90

10.3 Reading measured values . . . . . . . . . . . . . . . . . . . 90

10.4 Performing a totalizer reset . . . . . . . . . . . . . . . . . 90

10.5 Battery power consumption . . . . . . . . . . . . . . . . . 91

11 Custody transfer (optional). . . . . . . . . 93

11.1 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.2 Permanent flowrate characteristics . . . . . . . . . . . 94

11.3 Device as-delivered state . . . . . . . . . . . . . . . . . . . . 94

11.4 Custody transfer measurement (European

Measuring Instruments Directive 2004/22/EC,

Annex MI-001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11.5 Custody transfer measurement

(national approval, OIML R49) . . . . . . . . . . . . . . . 95

11.6 Reapproval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6 Installation . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . 18

6.2 Installing the measuring device . . . . . . . . . . . . . 25

6.3 Post-installation check . . . . . . . . . . . . . . . . . . . . . 30

7 Electrical connection . . . . . . . . . . . . . . . 31

7.1 Preparing the measuring device . . . . . . . . . . . . . 31

7.2 Connecting the measuring device . . . . . . . . . . . . 34

7.3 Inserting and connecting the batteries . . . . . . . . 40

7.4 Potential equalization . . . . . . . . . . . . . . . . . . . . . . 43

7.5 Guaranteeing the degree of protection of the

measuring device . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.6 Post-connection check . . . . . . . . . . . . . . . . . . . . . 46

8 Operating options . . . . . . . . . . . . . . . . .47

8.1 Overview of operating options . . . . . . . . . . . . . . 47

8.2 Structure and function of the operating menu . 47

8.3 Access to the operating menu via

the onsite display . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.4 Access to the operating menu via

the operating tool . . . . . . . . . . . . . . . . . . . . . . . . . 51

12 Diagnostics and troubleshooting . . . . 97

12.1 Diagnostic event on the onsite display . . . . . . . . . 97

12.2 Diagnostic event in the operating tool . . . . . . . 100

12.3 Communication diagnostic event . . . . . . . . . . . 101

12.4 Overview of diagnostic events . . . . . . . . . . . . . . 101

13 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.3 Endress+Hauser services . . . . . . . . . . . . . . . . . . 104

14 Maintenance . . . . . . . . . . . . . . . . . . . . 105

14.1 Maintenance work . . . . . . . . . . . . . . . . . . . . . . . 105

14.2 Measuring and testing equipment . . . . . . . . . . 105

14.3 Endress+Hauser services . . . . . . . . . . . . . . . . . . 105

15 Accessories. . . . . . . . . . . . . . . . . . . . . . 106

16 Return . . . . . . . . . . . . . . . . . . . . . . . . . . 107

17 Disposal . . . . . . . . . . . . . . . . . . . . . . . . 108

9 Commissioning. . . . . . . . . . . . . . . . . . . . 67

9.1 Commissioning with the GSM/GPRS modem . . 67

Endress+Hauser 3

17.1 Disassembling the measuring device . . . . . . . . 108

17.2 Disposing of the measuring device . . . . . . . . . . 108

Page 4

Proline Promag W 800

17.3 Disposing of the batteries . . . . . . . . . . . . . . . . . . 108

18 Technical data. . . . . . . . . . . . . . . . . . . .109

18.1 Technical data at a glance . . . . . . . . . . . . . . . . . . 109

19 Appendix . . . . . . . . . . . . . . . . . . . . . . . .124

19.1 Description of device parameters . . . . . . . . . . . . 124

19.2 Access to parameters . . . . . . . . . . . . . . . . . . . . . . 128

19.3 Quick Start menu . . . . . . . . . . . . . . . . . . . . . . . . . 129

19.4 Parameter descriptions . . . . . . . . . . . . . . . . . . . . 130

19.5 Information on configuring the

measuring device . . . . . . . . . . . . . . . . . . . . . . . . . 165

19.6 Operating commands of the Config5800

operating tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

19.7 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

19.8 Factory setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . .181

4 Endress+Hauser

Page 5

Proline Promag W 800 Document information

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in the various

phases of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to troubleshooting,

maintenance and disposal.

The document also provides a detailed explanation of each individual parameter.

It contains all the parameters required for operation and commissioning. The parameter

descriptions are aimed at individuals who bear responsibility for the device during normal

measuring operation or who must make settings at the device for maintenance and

troubleshooting purposes.

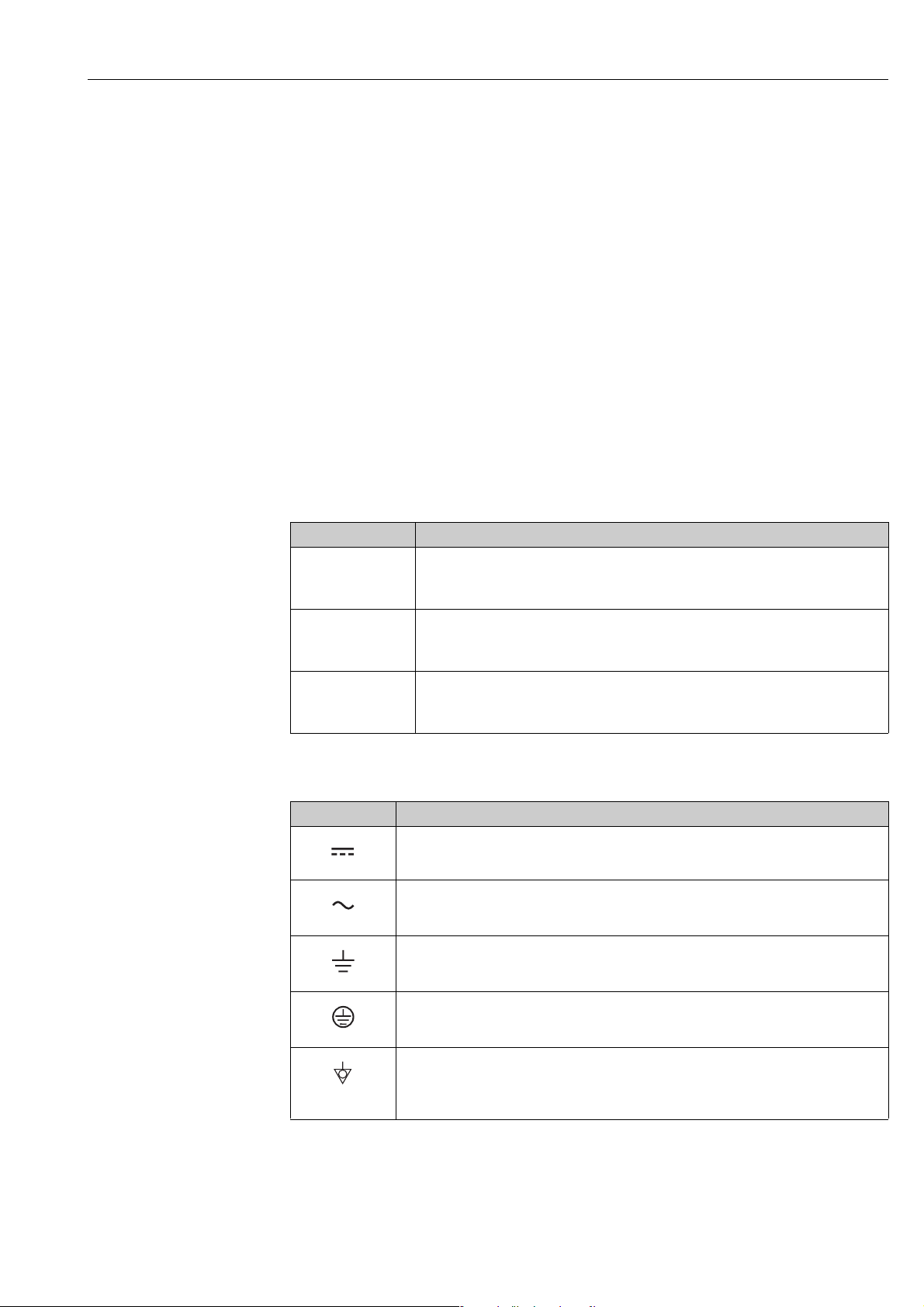

1.2 Symbols used

1.2.1 Safety symbols

Symbol Device particularities and document content

“Caution” indicates an action or procedure which, if not performed correctly, can result

"

#

!

Caution!

Warning!

Note!

in incorrect operation or destruction of the device.

Comply strictly with the instructions.

"Warning" indicates an action or procedure which, if not performed correctly, can result

in injury or a safety hazard. Comply strictly with the instructions and proceed with

care.

"Note" indicates an action or procedure which, if not performed correctly, can have an

indirect effect on operation or trigger an unexpected response on the part of the

device.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

A terminal at which DC voltage is present or through which direct current flows.

A0011197

Alternating current

A terminal at which alternating voltage (sinusoidal) is present or through which

A0011198

A0011200

A0011199

A0011201

alternating current flows.

Ground connection

A grounded terminal which, from the viewpoint of the user, is grounded via a grounding

system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that must be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or company

codes of practice.

Endress+Hauser 5

Page 6

Document information Proline Promag W 800

1.2.3 Tool symbols

Symbol Meaning

Torx screwdriver

A0013442

Slotted screwdriver

A0011220

Phillips head screwdriver

A0011219

Allen screw

A0011221

Open-ended wrench

A0011222

1.2.4 Symbols for types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Preferred

Indicates procedures, processes or actions that are preferred.

A0011183

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011200

Tip

Indicates additional information.

A0011193

Reference to documentation

Refers to the corresponding device documentation.

A0011194

Reference to page

Refers to the corresponding page number.

A0011195

1., 2., 3. … Series of steps

Ã

Result of a sequence of actions

Help in the event of a problem

A0013562

6 Endress+Hauser

Page 7

Proline Promag W 800 Document information

-

.

1.2.5 Symbols for graphics

Symbol Meaning

1, 2, 3 … Item numbers

A, B, C etc. Views

A-A, B-B, C-C etc. Item numbers

Flow direction

A0013441

Hazardous area

Indicates the hazardous area.

A0011187

Safe area (non-hazardous area)

Indicates the non-hazardous area.

A0011187

1.3 Documentation

1.3.1 Standard documentation

Document type Purpose and content of the document

Technical Information Planning aid for your device

The document contains all the technical data on the device and provides an

overview of the accessories and other products that can be ordered for the

device.

Brief Operating Instructions Guides you quickly to the 1st measured value

The document types listed are available:

• On the CD supplied with the device

• In the Download Area of the Endress+Hauser Internet site:

www.endress.com Download

1.3.2 Supplementary device-dependent documentation

Always comply strictly with the instructions in the supplementary documentation.

The supplementary documentation is an integral part of the device documentation.

Document type Device particularities and document content

Installation Instructions Ordered accessory

The Brief Operating Instructions contain all the essential information from

incoming acceptance to initial commissioning.

The Installation Instructions contain all the information needed to install the

ordered accessory or spare part.

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com

Download

Endress+Hauser 7

Page 8

Basic safety instructions Proline Promag W 800

2 Basic safety instructions

2.1 Personnel requirements

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists must have a relevant qualification for this specific function

and task.

• Are authorized by the plant owner/operator.

• Are familiar with federal/national regulations.

• Before beginning work, the specialist staff must have read and understood the instructions

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application).

• Follow instructions and comply with conditions.

The operating personnel must fulfill the following requirements:

• Be instructed and authorized according to the requirements of the task by the facility's

owner-operator.

• Follow the instructions in these Operating Instructions.

!

2.2 Designated use

Application and fluids

The measuring device desc ribed in this manual is to b e used only for measu ring the flow rate

of conductive liquids in closed pipes.

A minimum conductivity of 50 S/cm is required for measuring purposes.

The measuring device is designed to measure the following fluids:

• Drinking water

•Rain water

• Spring water

In compliance with the limit values specified in the "Technical data" section and the general

conditions indicated in the manual and supplementary documentation, the measuring

device may only be used for the following measurements:

• Measured measured variables: volume flow

• Calculated measured variables: mass flow

To ensure that the measuring device remains in proper operating condition for its service

life:

• Only use the measuring device for fluids to which the process-wetted materials are

adequately resistant.

• Comply with the limit values in the "Technical data" section.

Note!

As an option, Promag W 800 is tested in accordance with OIML R49 and has an EC typeexamination certificate as per Measuring Instruments Directive 2004/22/EC (MID) for

service subject to legal metrological control ("custody transfer") for cold water (Annex MI-

001).

The permitted fluid temperature in these applications is 0 to +50 °C (+32 to +122 °F).

It is used with a legally controlled totalizer on the local display.

8 Endress+Hauser

Page 9

Proline Promag W 800 Basic safety instructions

Incorrect use

The manufacturer is not liable for damage resulting from improper or non-designated use.

An improper or non-designated use can affect the safety.

Clarification of borderline cases:

• With regard to special fluids and media used for cleaning, Endress+Hauser will be happy

to assist in clarifying the corrosion-resistant properties of wetted materials but gives no

guarantee or warranty as to the suitability of the materials.

Residual risks

#

Warning!

Due to the power throughput in the electronic components, the outer housing surfaces can

heat up by a maximum of 20 K. When hot fluid passes through the measuring tube, the

surface temperature of the housing increases. In the case of the sensor, in particular, users

should expect temperatures that can be close to the fluid temperature.

Hot fluids can present a burn hazard!

• For elevated fluid temperatures, ensure adequate protection against contact to prevent

burns.

2.3 Occupational safety

When working on or with the device:

• Always wear the necessary personal protective equipment as defined in national

regulations.

When performing welding work on the pipe:

• Do not ground the welding equipment via the measuring device.

When working with batteries:

• The device is powered by lithium-thionyl chloride high-power batteries. This has

implications for occupational safety and device storage.

Warning!

#

Lithium-thionyl chloride high-power batteries are categorized as Class 9:

"Miscellaneous Hazardous Materials". Comply strictly with the hazardous material

regulations described in the safety data sheet.

You can request the safety data sheet from your Endress+Hauser Sales Center.

2.4 Operational safety

Risk of injury.

• Only operate the device if it is in a perfect technical condition free from errors and faults.

• The operator is responsible for the trouble-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers:

• If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure operational safety:

• Only perform repair work on the device if this is expressly permitted.

• Comply strictly with national regulations concerning the repair of electrical equipment.

• Only use genuine Endress+Hauser spare parts and accessories.

Endress+Hauser 9

Page 10

Basic safety instructions Proline Promag W 800

Hazardous area

To exclude any risks to individuals or the facility when operating the device in the hazardous

areas:

• Based on the nameplate, check whether the ordered device is permitted for the intended

use in the hazardous area.

2.5 Product safety

This measuring device is designed to meet state-of-the-art safety requirements in

accordance with sound engineering practice, has been tested and left the factory in a

condition in which it is safe to operate.

It meets the general safety requirements and legal requirements. Furthermore, it complies

with the EC directives which are listed in the device-specific EC Declaration of Conformity.

Endress+Hauser confirms this by affixing the CE mark to the device.

10 Endress+Hauser

Page 11

Proline Promag W 800 Product description

1

2

3

4

5

6

7

8

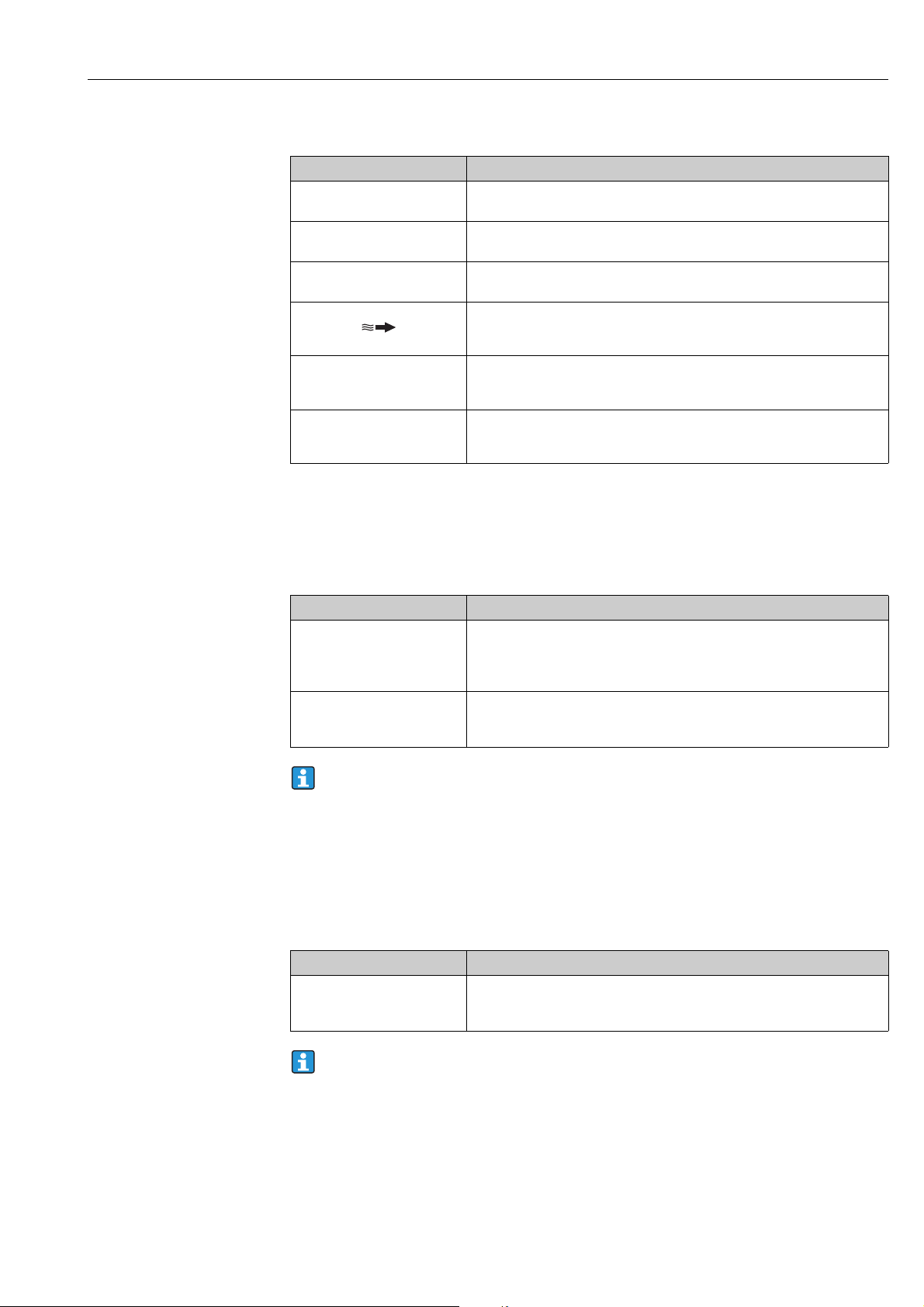

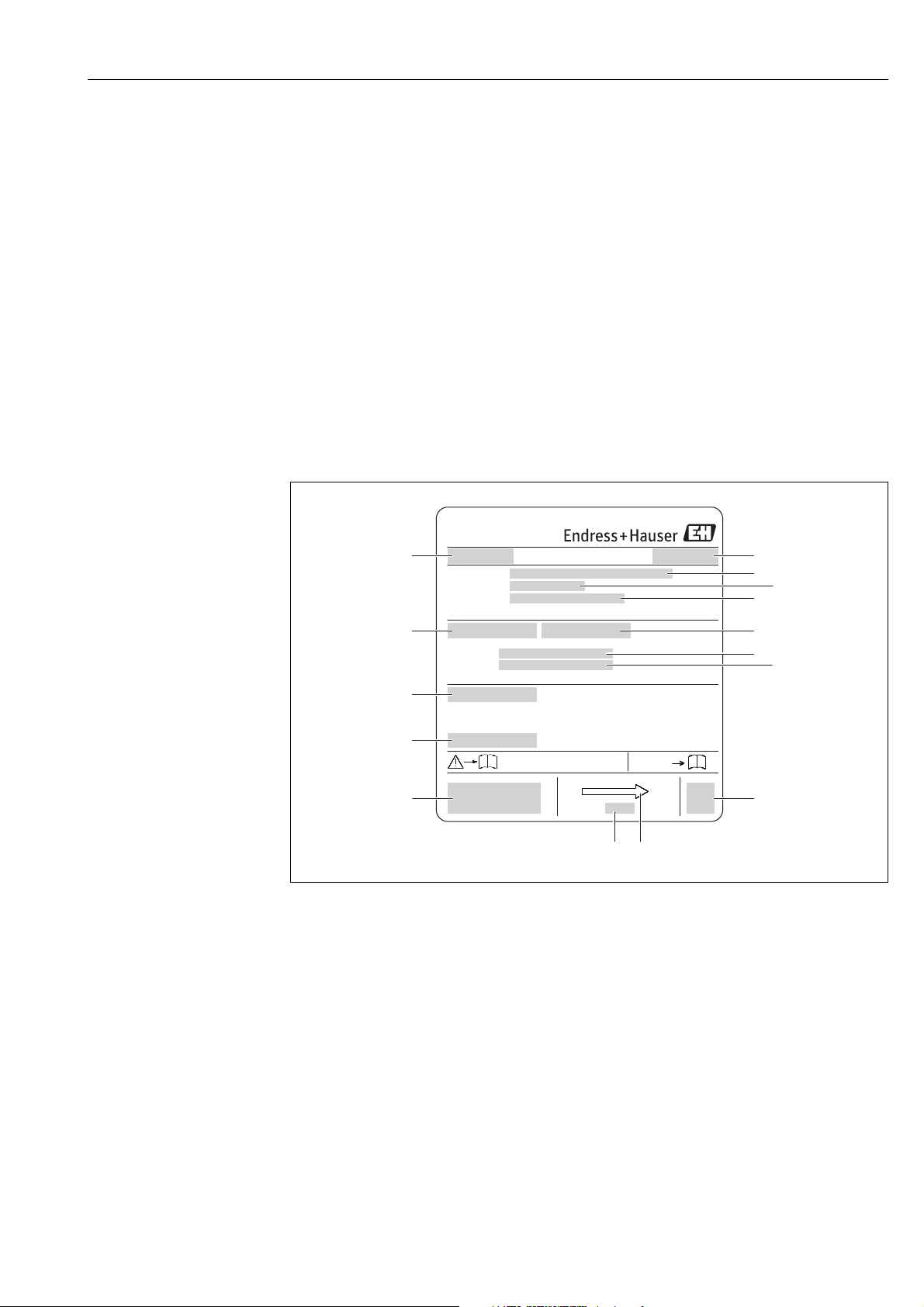

3 Product description

3.1 Product structure

A0016254

Fig. 1: Primary components of the measuring device

1Transmitter housing cover

2 Display and operating module

3 Battery cover

4 GSM antenna

5Batteries

6 Electronics board carrier incl. battery compartment

7Transmitter housing

8Sensor

Endress+Hauser 11

Page 12

Incoming acceptance and product identification Proline Promag W 800

1

+

2

1

+

2

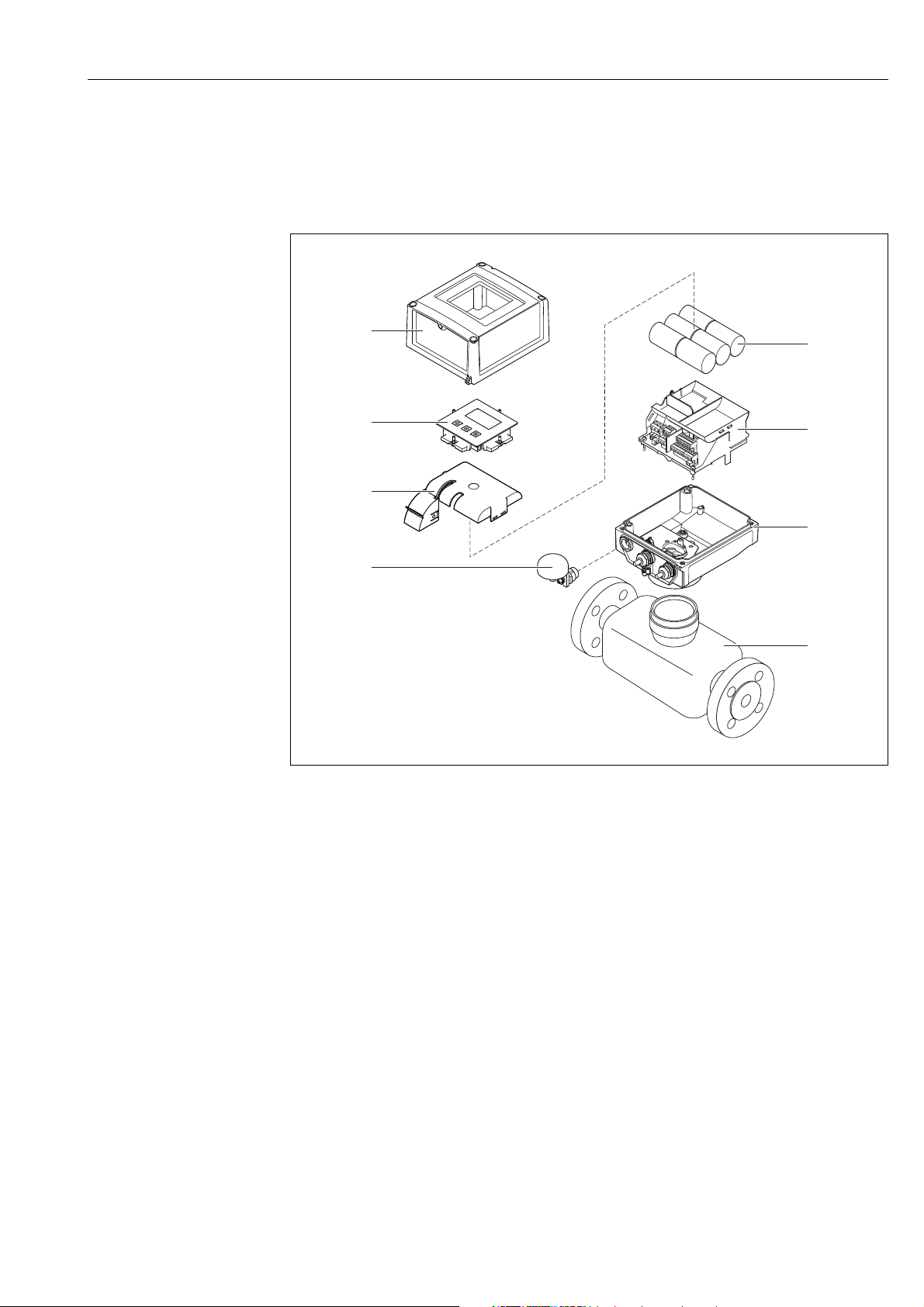

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

!

"

A0013696 A0013843

Is the order code in the delivery note (1) identical to the order code on the product

sticker (2)?

A0013695

Note!

The lithium-thionyl chloride high-power batteries are provided in a separate package.

Pay attention to the occupational safety instructions when handling batteries → 9.

A0013696 A0013698

Goods undamaged?

Caution!

If batteries are damaged, comply strictly with the hazardous material regulations described

in the safety data sheet. You can request the safety data sheet from your Endress+Hauser

Sales Center.

A0013696 A0013699

A0013696 A0013697

Do the data on the nameplate correspond to the order data on the delivery note?

CD-ROM available with technical documentation and documents?

If you have answered "no" to one of the questions above:

Contact your Endress+Hauser Sales Center.

12 Endress+Hauser

Page 13

Proline Promag W 800 Incoming acceptance and product identification

i

Patents

i

Material:

Tm:

Ext. ord. cd.:

Order Code:

Ser.No.:

Date:

21

3

4

5

6 7

8

9

10

11

13

12

14

15

4.2 Product identification

It is possible to identify the measuring device in the following ways:

• Using the nameplate specifications

• Using the order code with a breakdown of the device features on the delivery note

• By entering the serial number on the nameplates into the W@M Device Viewer

(www.endress.com/deviceviewer): All the information pertaining to the measuring device

is displayed.

For an overview of the scope of the Technical Documentation provided, please see:

• The "Additional standard documentation on the device" (→ 7) and

"Supplementary device-dependent documentation" (→ 7) sections.

•The W@M Device Viewer: Enter the serial number on the nameplate

(www.endress.com/deviceviewer)

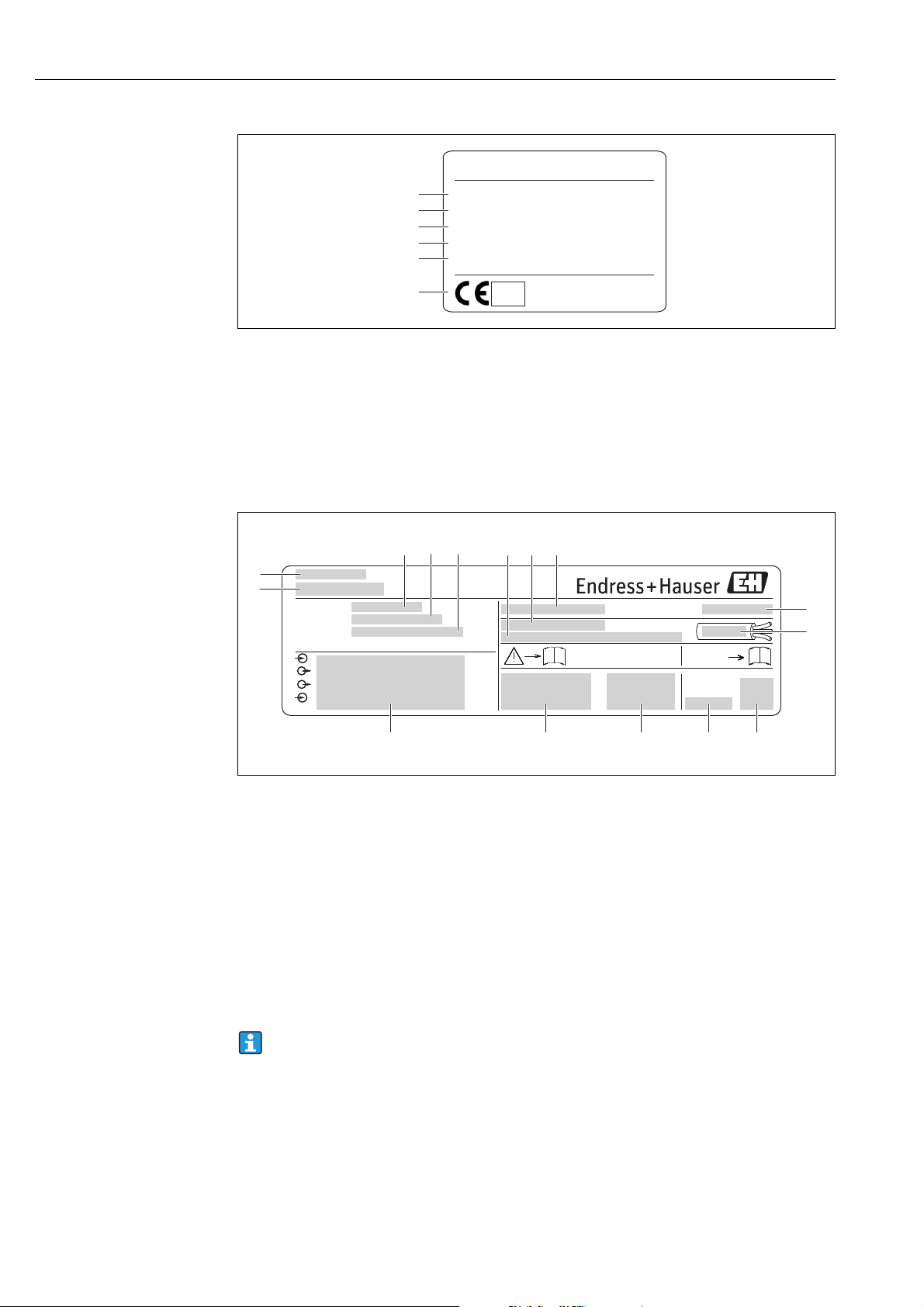

4.2.1 Nameplates

Sensor

Fig. 2: Example of sensor nameplate

1 Name of sensor

2 Place of manufacture

3Order code

4 Serial number (Ser.No.)

5 Extended order code (Ext. ord. co.)

6 Nominal diameter of the sensor

7 Test pressure of the sensor

8 Fluid temperature range

9 Measuring tube lining and electrodes material

10 Degree of protection: e.g. IP, NEMA

11 Permitted ambient temperature (T

12 2-D matrix code

13 CE mark, C-tick

14 Flow direction

15 Date of manufacture: year-month

Endress+Hauser 13

A0017186

)

Page 14

Incoming acceptance and product identification Proline Promag W 800

1

Promag W 800 DN100

Environmental Class: E1/M2

2

Q3: 250 m3/h

3

Q3 / Q1: 160

4

Medium Temp.: 0…+50 °C

5

Tamb: –25…+40 °C

1259 ATLab–I13–001

M13

6

Order code:

i

Ext. ord. cd.:

Ser. no.:

Patents

i

Date:

2

1

345

9

86 7

10

14 13 12 1115

A0020811

Fig. 3: Additional nameplate for measuring devices subject to legal metrological control (optional) (example)

1 Electromagnetic/mechanical environment class

2 Permanent flowrate Q3

3 Permanent flow ratio Q3/Q1

4 Permitted fluid temperature range

5 Permitted ambient temperature range

6 Conformity marking with CEM mark, year, notified body and number of the EC type-examination certificate

Transmitter

Fig. 4: Example of transmitter nameplate

1 Name of transmitter

2 Place of manufacture

3Order code

4 Serial number (Ser.No.)

5 Extended order code (Ext. ord. co.)

6 Firmware version (FW) and device revision (Dev.Rev.) from factory

7 Permitted ambient temperature range (T

8 FCC-ID (Federal Communications Commission)

9 Degree of protection: e.g. IP, NEMA

10 Permitted temperature range for cables

11 2-D matrix code

12 Date of manufacture: year-month

13 FCC symbol

14 CE mark, C-tick

15 Electrical connection data: e.g. inputs and outputs available, supply voltage

)

Order code

The measuring device is reordered using the order code.

Extended order code

14 Endress+Hauser

• The device type (product root) and basic specifications (mandatory features) are always

listed.

• Of the optional specifications (optional features), only the specifications relating to safety

and hazardous areas are listed (e.g. LA). If other optional specifications are also ordered,

these are indicated collectively using the placeholder symbol "#" (e.g. #LA#).

A0017187

Page 15

Proline Promag W 800 Incoming acceptance and product identification

• If the ordered optional specifications do not include any safety and approval-related

specifications, they are indicated by the placeholder symbol "+" (e.g. 5W8B50–

AACCCAAD2S1+).

4.2.2 Symbols on the device

Symbol Meaning

"Warning" indicates an action or procedure which, if not performed correctly,

#

Warning!

A0011199

A0011194

can result in injury or a safety hazard. Comply strictly with the instructions and

proceed with care.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Reference to documentation

Refers to the corresponding device documentation.

Endress+Hauser 15

Page 16

Storage, transport and disposal of packaging Proline Promag W 800

5 Storage, transport and disposal of packaging

5.1 Storage conditions

Note the following when storing the device:

• Store in the original packaging to protect against impact.

• Do not remove protective covers or protection caps mounted on process connections.

They prevent mechanical damage to the sealing surfaces and fouling in the measuring

pipe.

• Protect from sunlight to avoid impermissibly high surface temperatures.

• Choose a storage location where moisture does not collect in the measuring device. This

will help prevent fungus and bacteria infestation which can damage the liner.

• Store in a dry, dust-free atmosphere.

• Do not store outdoors.

• Storage temperature → 114.

• Also be mindful of the following when storing the batteries:

– Avoid any short-circuiting of the battery poles.

– The storage temperature should preferably be 21 °C (70 °F).

– Store in a dry, dust-free atmosphere that is not subject to large fluctuations in

temperature.

– Protect from sunlight.

– Do not store near heaters.

#

"

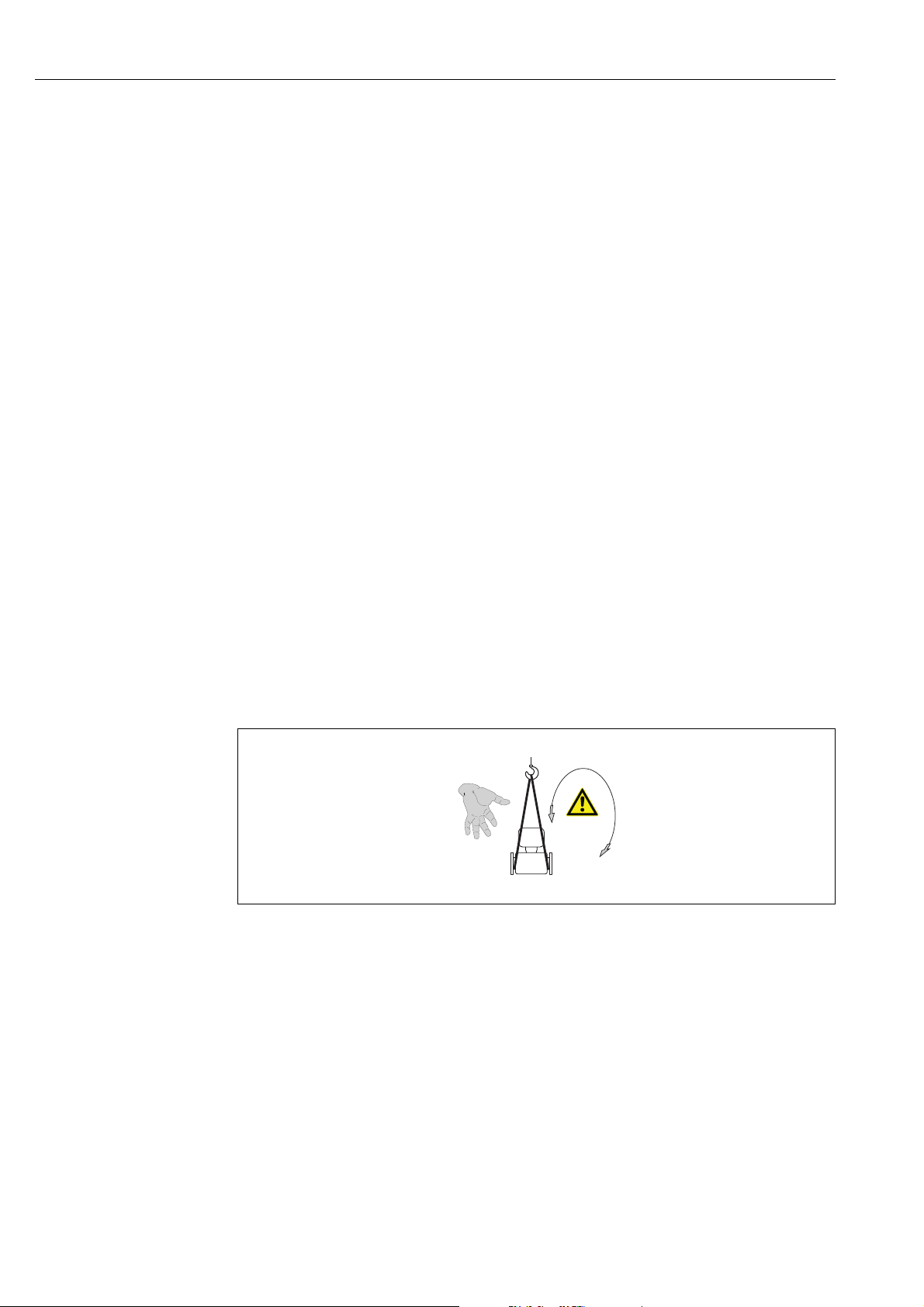

5.2 Transporting the product

Warning!

Risk of injury if the measuring device slips.

The center of gravity of the measuring device is higher than the points around which the

webbing slings are slung.

• Secure the measuring device so that it does not turn around its axis or slip.

A0015606

Fig. 5: Risk of injury if the measuring device slips when transporting sensors

Caution!

Note the following when transporting the device:

• Transport the measuring device to the measuring point in its original packaging.

• Do not remove protective covers or protection caps mounted on process connections.

They prevent mechanical damage to the sealing surfaces and fouling in the measuring

pipe.

• Pay attention to the weight information on the packaging (adhesive label).

• Observe the transportation instructions on the adhesive label on the electronics

compartment cover.

• Do not lift the measuring device by the transmitter housing or the connection housing of

the remote version.

• Lifting tool

– Use webbing slings (avoid chains as these could damage the housing).

16 Endress+Hauser

Page 17

Proline Promag W 800 Storage, transport and disposal of packaging

– For wood crates, the floor structure enables these to be loaded lengthwise or broadside

using a

forklift.

• Using the webbing slings, lift the measuring device by the process connections, not by the

transmitter housing.

5.3 Disposing of the packaging

All the packaging material is environmentally friendly and 100 % recyclable:

• Measuring device secondary packaging:

Polymer stretch wrap that meets the requirements of EU Directive 2002/95/EC (RoHS).

•Packaging

– Wooden crate: treated in accordance with standard ISPM 15,

which is confirmed by the IPPC logo affixed to the crate.

or

– Cardboard: in accordance with European Directive 94/62/EC on packaging and

packaging waste;

recyclability is confirmed by the Resy symbol affixed to the packaging.

• Seaworthy packaging (optional):

Wooden crate, treated in accordance with standard ISPM 15, which is confirmed by the

IPPC logo affixed to the crate.

• Carrier and fastening material:

– Plastic disposable pallet

– Plastic straps

– Plastic adhesive strips

• Filler material: paper pads

Endress+Hauser 17

Page 18

Installation Proline Promag W 800

h

h

2

1

6Installation

6.1 Installation conditions

No special measures such as supports are necessary. External forces are absorbed by the

construction of the device.

6.1.1 Mounting position

Mounting location

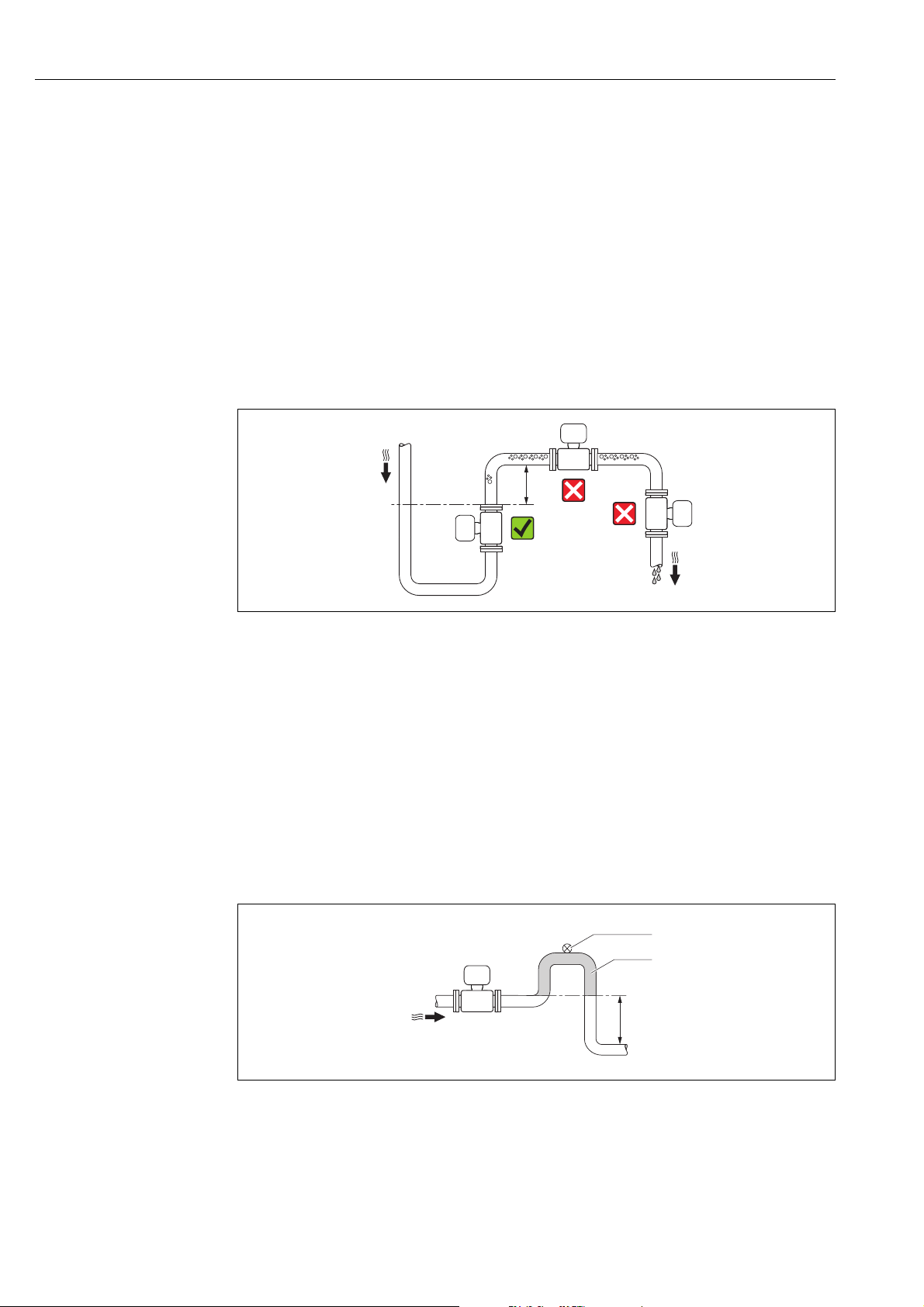

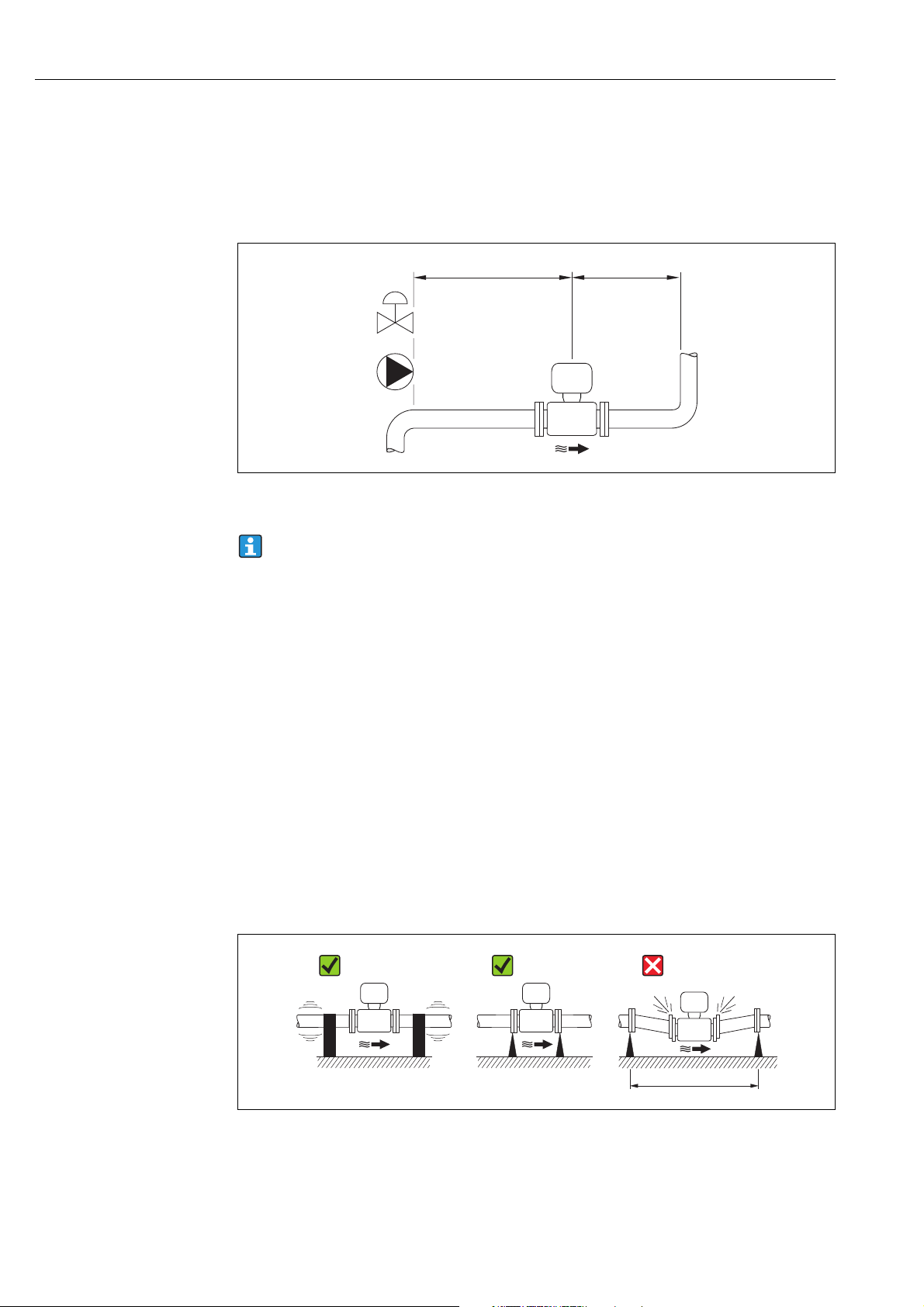

Preferably install the sensor in an ascending pipe, and ensure a sufficient distance (

2 × DN) to the next pipe elbow.

A0017061

Fig. 6: Selecting the mounting location

To prevent measuring errors from gas bubbles accumulating in the measuring tube, avoid

the following mounting locations in the pipe:

• Highest point of a pipeline

• Directly upstream of a free pipe outlet in a down pipe

Installation in down pipes

Install a siphon or a vent valve downstream of the sensor in down pipes whose length

h 5 m (16.4 ft), (→ 7). This precaution is to avoid low pressure and the consequent risk

of damage to the lining of the measuring tube. This measure also prevents the system losing

prime, which could cause air pockets.

Information on the lining's resistance to partial vacuum can be found on → 116.

A0017064

Fig. 7: Measures for installation in a down pipe

1Vent valve

2Pipe siphon

hLength of down pipe, h

18 Endress+Hauser

5 m (16.4 ft)

Page 19

Proline Promag W 800 Installation

³ 5 x DN

³ 2 x DN

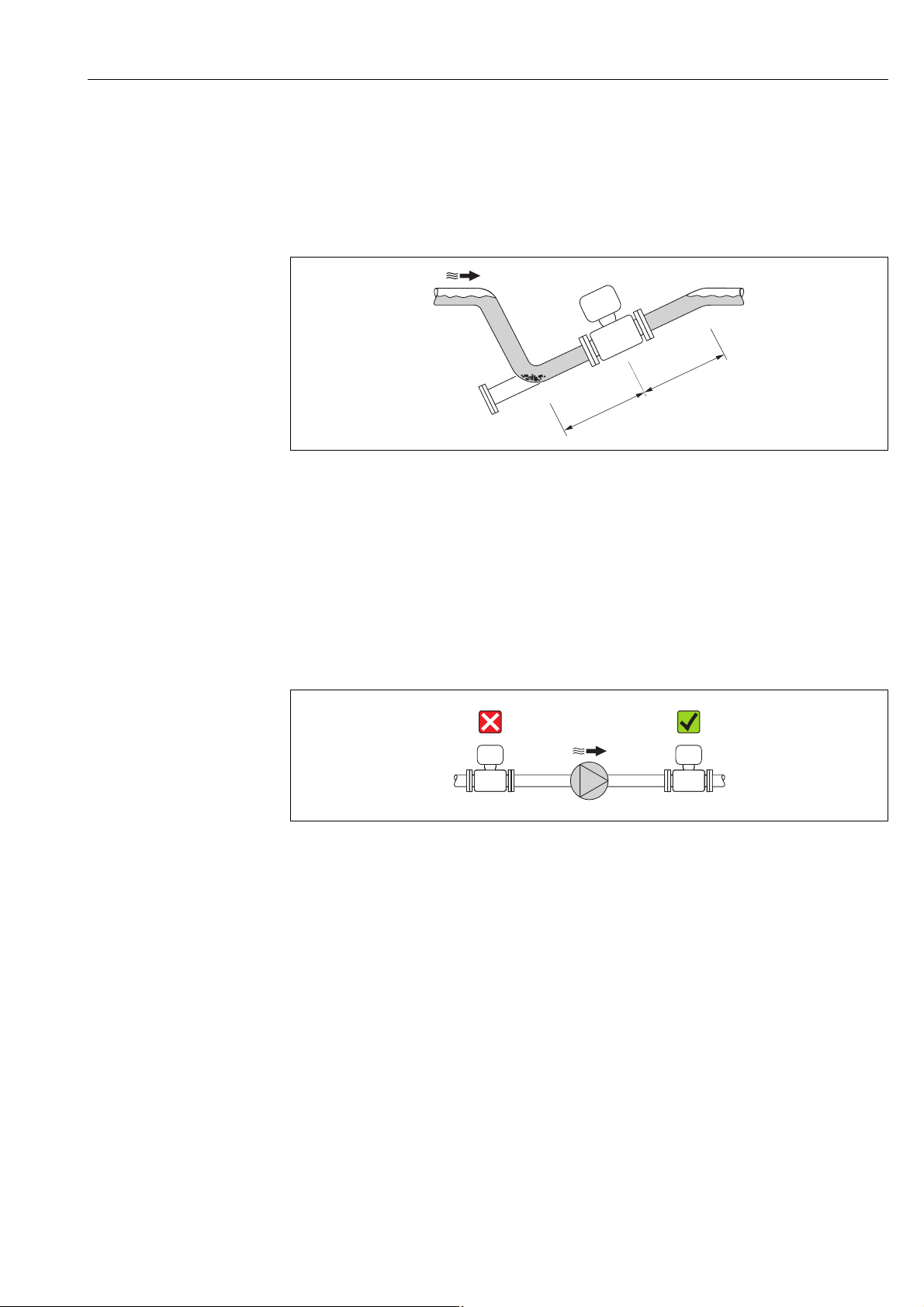

Installation in partially filled pipes with a gradient

Partially filled pipes with gradients necessitate a drain-type configuration.

Caution!

"

Risk of solids accumulating.

• Do not install the sensor at the lowest point in the drain.

• It is advisable to install a cleaning valve.

A0017063

Fig. 8: Installation in a partially filled pipe

If using pumps

• If pumps are used, do not install the sensor on the intake side of a pump.

This precaution is to avoid low pressure and the consequent risk of damage to the lining

of the measuring tube. Information on the lining's resistance to partial vacuum can be

found on → 116.

• If reciprocating, diaphragm or peristaltic pumps are used,

it might be necessary to install pulse dampers. For information on the measuring system's

resistance to vibration and shock → 115.

Fig. 9: Installation if using pumps

A0015594

Endress+Hauser 19

Page 20

Installation Proline Promag W 800

££3 ( 10)

m (ft)

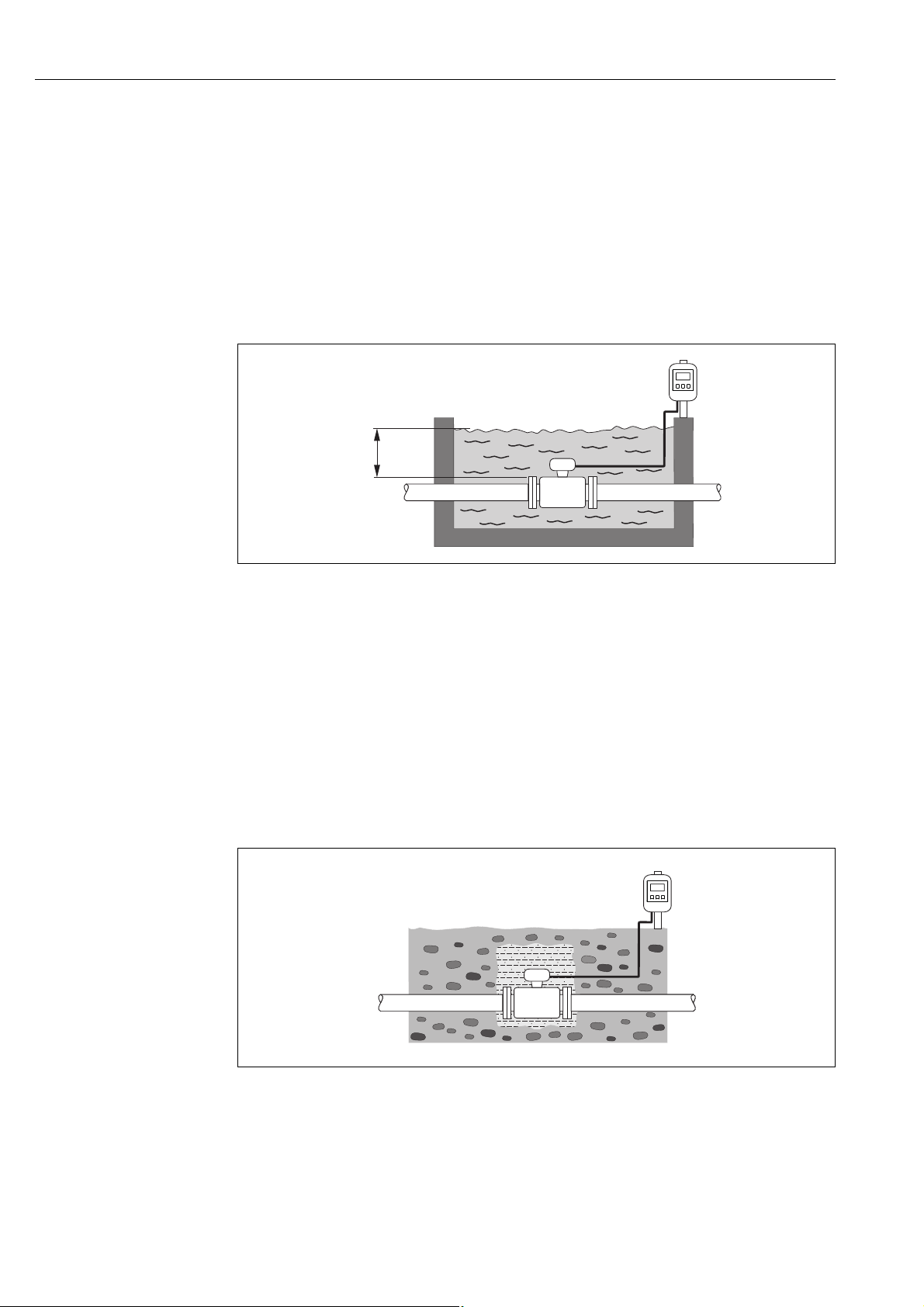

For permanent immersion in water

The fully welded remote version of the measuring device can be immersed permanently in water to a

depth of 3 m (10 ft) or 48 h at 10 m (30 ft).

The measuring device satisfies diverse corrosion

protection categories in accordance with EN ISO 12944. The fully welded design along with

the connection compartment sealing system ensure that moisture cannot enter the

measuring device.

The connecting cables of the remote version can be ordered:

• With pre-terminated cables that are already connected to the sensor.

• Optionally: With pre-terminated cables, where the cables are connected by the customer

onsite (incl. tools for sealing the connection compartment).

A0017296

Fig. 10: Installation for permanent immersion in water

For buried applications

The fully welded remote version of the measuring device can be used for buried applications.

The measuring device satisfies the certified corrosion protection Im3 in accordance with

EN ISO 12944. It can be used directly underground without the need for additional

protective measures. The device is installed in accordance with the usual regional

installation regulations (e.g. EN DIN 1610).

The connecting cables of the remote version can be ordered:

• With pre-terminated cables that are already connected to the sensor.

• Optionally: With pre-terminated cables, where the cables are connected by the customer

onsite (incl. tools for sealing the connection compartment).

Fig. 11: Installation for buried applications

20 Endress+Hauser

A0017298

Page 21

Proline Promag W 800 Installation

A

A

1

2

3

2

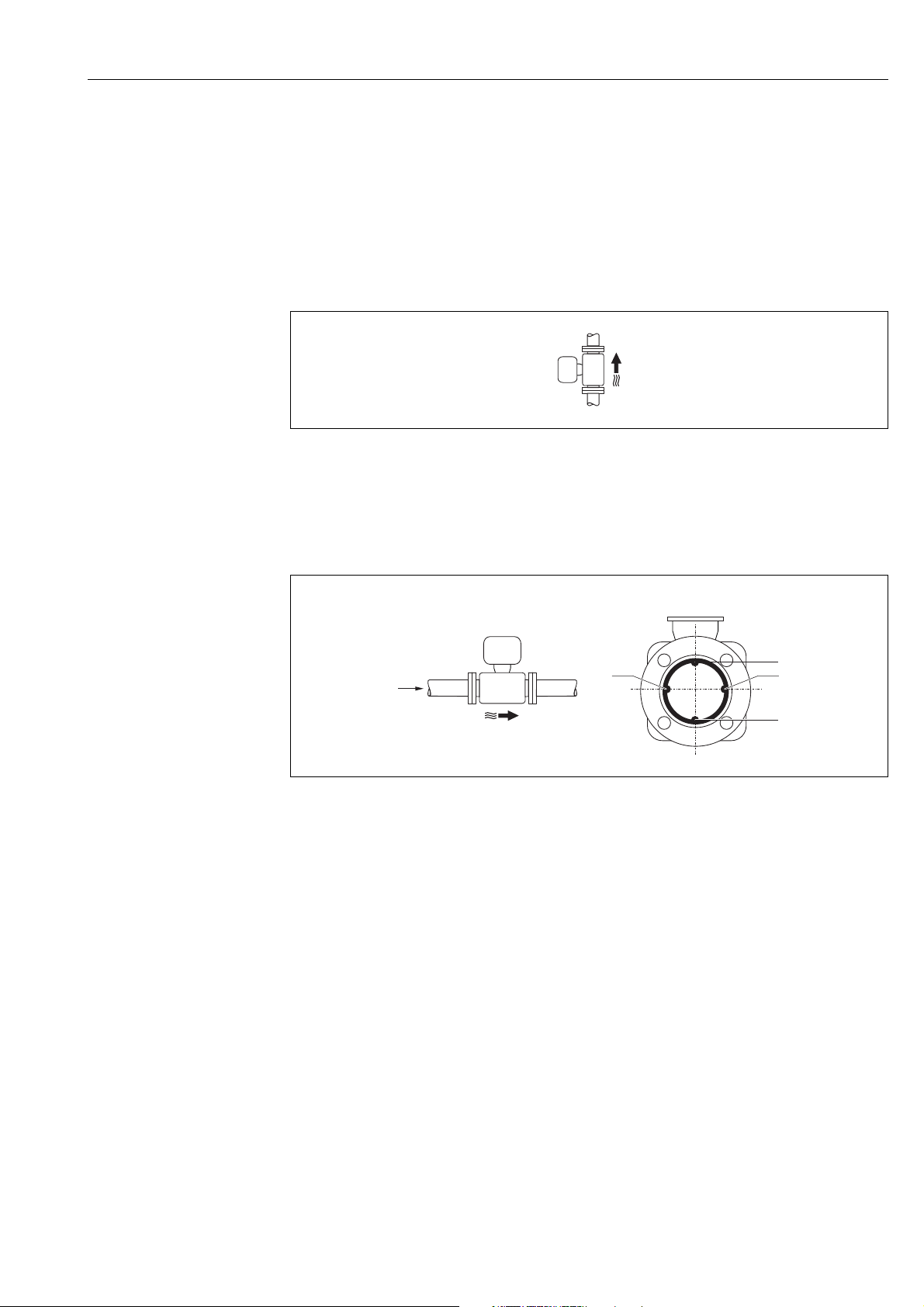

Orientation

An optimum orientation position helps avoid gas and air accumulations and deposits in the

measuring tube.

Vertical orientation

Vertical orientation is optimal in the following scenarios:

• For self-emptying piping systems.

• For sludge containing sand or stones where the solids tend to settle at the bottom.

A0015591

Fig. 12: Vertical orientation

Horizontal orientation

The measuring electrode plane should be horizontal in the case of horizontal orientation.

This prevents brief insulation of the two measuring electrodes by entrained air bubbles.

A0016260

Fig. 13: Horizontal orientation

1 EPD electrode for the detection of empty pipes (not supported by the transmitter)

2 Measuring electrodes used for measuring signal pick up and empty pipe detection (EPD). An EPD alarm is triggered if there

is no fluid between electrodes.

3 Reference electrode for potential equalization

Endress+Hauser 21

Page 22

Installation Proline Promag W 800

5 × DN³

³ 2 × DN

L

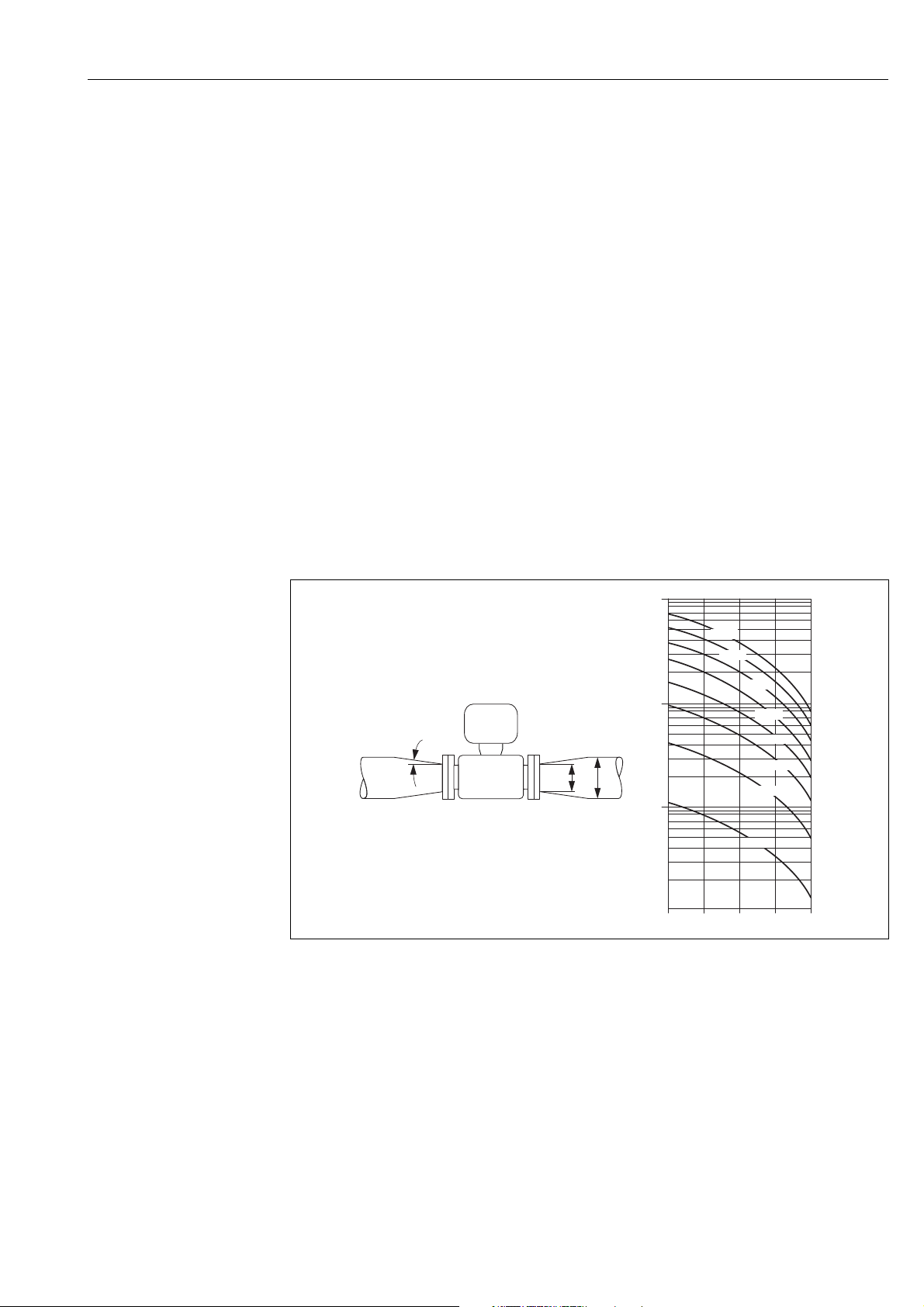

Inlet and outlet runs

If possible, install the sensor upstream from fittings such as valves, T-pieces, elbows, etc.

Observe the following inlet and outlet runs in order to meet accuracy specifications:

•Inlet run 5 × DN

•Outlet run 2 × DN

A0016275

Fig. 14: Inlet and outlet runs

No special requirements must be observed at the inlet and outlet runs to keep within

the in-service maximum permissible errors for custody transfer.

6.1.2 Environmental and process-specific requirements

Ambient temperature range

→ 114

Pressure tightness

→ 116

Vibrations

In the event of strong vibrations: support and fix the pipe and sensor.

Caution!

"

If vibrations are too severe, we recommend the sensor and transmitter be mounted

separately. Information on resistance to vibration and shock can be found on → 115.

Fig. 15: Measures to prevent vibration of the device (L > 10 m (33 ft))

A0016266

22 Endress+Hauser

Page 23

Proline Promag W 800 Installation

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

Corrosive environment

The fully welded remote version of the measuring device can be immersed permanently in corrosive

(saline) environments

. The measuring device satisfies the certified corrosion protection in

accordance with EN ISO 12944 C5M. The fully welded design along with the varnish finish

ensure that the device can be used in saline environments.

6.1.3 Special installation

Adapters

Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor

in larger-diameter pipes.

The resultant increase in the rate of flow improves measuring accuracy with very slowmoving fluids. The nomogram shown here can be used to calculate the pressure loss caused

by reducers and expanders.

!

Note!

The nomogram only applies to liquids of viscosity similar to water.

Determining the pressure loss:

1. Calculate the ratio of the diameters d/D.

2. From the nomogram read off the pressure loss as a function of flow velocity

(downstream from the reduction) and the d/D ratio.

A0016359

Fig. 16: Pressure loss due to adapters

Nominal diameter and flow rate

The diameter of the pipe and the flow rate determine the nominal diameter of the sensor.

Therefore, please note the following:

!

• The optimum velocity of flow is between 2 and 3 m/s (6.5 to 9.8 ft/s).

• Match the velocity of flow (v) to the physical properties of the fluid:

– v < 2 m/s (6.5 ft/s): for abrasive fluids

– v > 2 m/s (6.5 ft/s): for fluids producing buildup

Note!

If it is necessary to increase the flow velocity:

Use adapters to reduce the nominal diameter of the sensor → 23.

Endress+Hauser 23

Page 24

Installation Proline Promag W 800

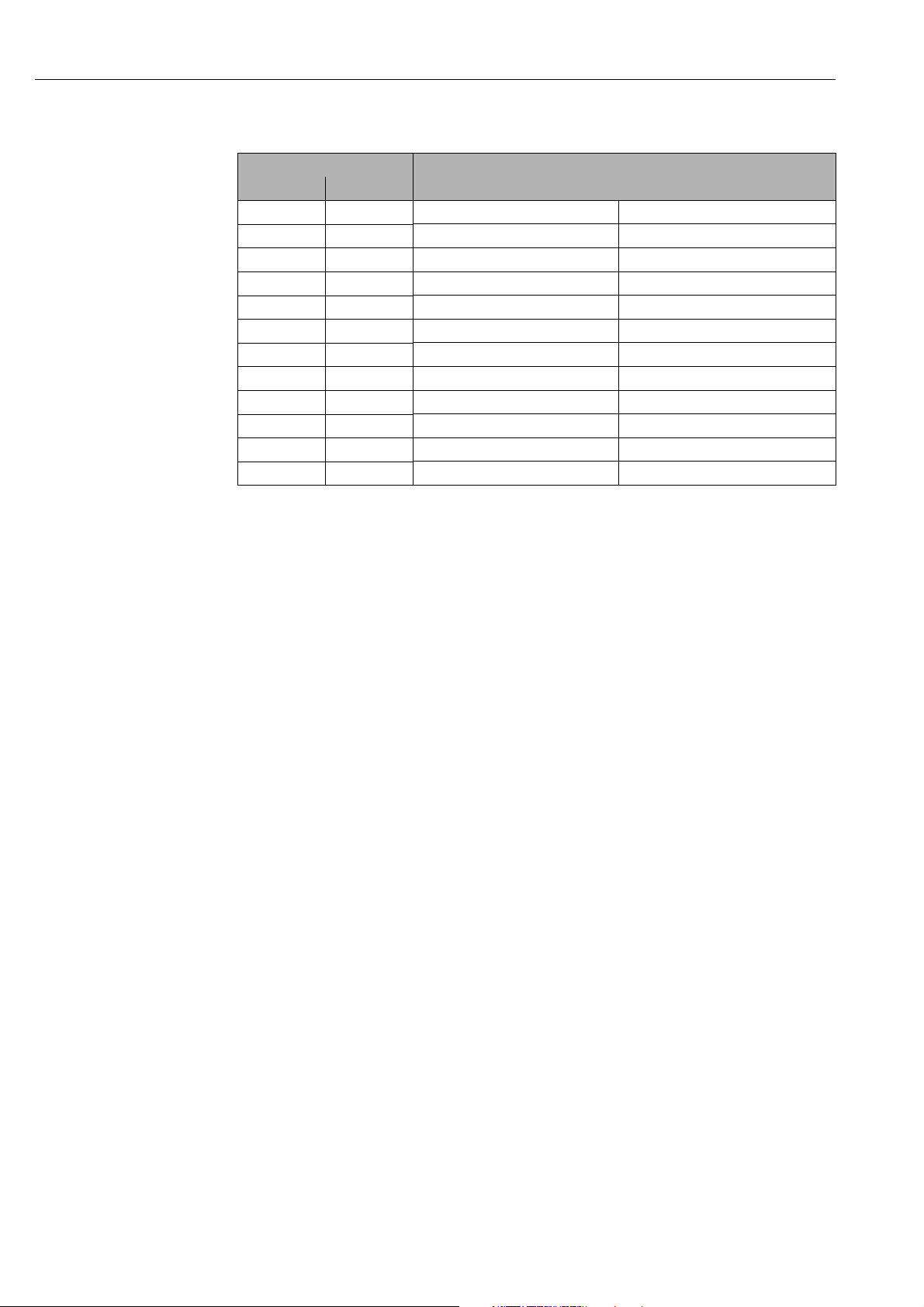

Recommended flow

Nominal diameter Recommended flow

[mm] [in] Min./max. full scale value (v 0.5 or 10 m/s)

25 1" 15 to 295 dm³/min 4 to 80 gal/min

32 – 25 to 485 dm³/min 7 to 130 gal/min

40 – 40 to 755 dm³/min 10 to 200 gal/min

50 2" 60 to 1180 dm³/min 16 to 320 gal/min

65 – 100 to 2000 dm³/min 28 to 530 gal/min

80 3" 150 to 3020 dm³/min 40 to 800 gal/min

100 4" 240 to 4750 dm³/min 65 to 1200 gal/min

125 – 370 to 7400 dm³/min 100 to 1900 gal/min

150 6" 32 to 640 m³/h 142 to 2800 gal/min

200 8" 58 to 1135 m³/h 250 to 4900 gal/min

250 10" 90 to 1800 m³/h 390 to 7700 gal/min

300 12" 130 to 2500 m³/h 570 to 11000 gal/min

!

Note!

For service subject to legal metrological control the approved flow values apply → 94.

Connecting cable

In order to ensure measuring accuracy, comply with the following instructions when

installing a remote version:

• Fix the cable run or route it in an armored conduit. Cable movements can falsify the

measuring signal especially in the case of low fluid conductivities.

• Route the cable well clear of electrical machines and switching elements.

• Ensure potential equalization between sensor and transmitter, if necessary.

• The maximum connecting cable length is 20 m (35.6 ft).

GSM/GPRS antenna

Check the signal strength of the mobile communications network before mounting the

antenna → 37.

Display protection

To ensure that the optional display protection can be easily opened, maintain the following

minimum head clearance: 350 mm (13.8 in)

24 Endress+Hauser

Page 25

Proline Promag W 800 Installation

6.2 Installing the measuring device

6.2.1 Sensor installation

Required mounting tools

For flange and other process connections:

• Bolts, nuts, seals, etc. These items are not included in the scope of supply and must be

supplied by the customer.

• Appropriate mounting tools

Installing the sensor

Mount the sensor between the pipe flanges.

In doing so, please note the following:

• Required screw tightening torques → 25.

• If using ground disks:

Comply with the Installation Instructions provided with the ground disks.

Mounting the seals

Caution!

"

Risk of short circuit!

Do not use electrically conductive sealing compounds such as graphite! An electrically

conductive layer could form on the inside of the measuring tube and short-circuit the

measuring signal.

Comply with the following instructions when installing seals:

• For hard rubber lining: additional seals are always required.

• For polyurethane lining: generally additional seals are not required.

• For DIN flanges: only use seals according to EN 1514-1.

• Make sure that the seals do not protrude into the piping cross-section.

Mounting the ground cable

Comply with the following instructions when installing the ground cable:

• Comply with the information on potential equalization and detailed mounting instructions

for the use of ground cables on → 43

• If necessary, you can order special ground cables for potential equalization as an accessory

(→ 106).

Screw tightening torques for mounting the sensor

Please note the following:

• The tightening torques listed below are for lubricated threads only.

• Tighten the screws uniformly and in diagonally opposite sequence.

• Overtightening the screws will deform the sealing faces or damage the seals.

• The tightening torques listed below apply only to pipes not subjected to tensile stress.

Tightening torques for:

•EN (DIN) → 26

•ASME → 26

•AS → 27

•JIS → 27

Endress+Hauser 25

Page 26

Installation Proline Promag W 800

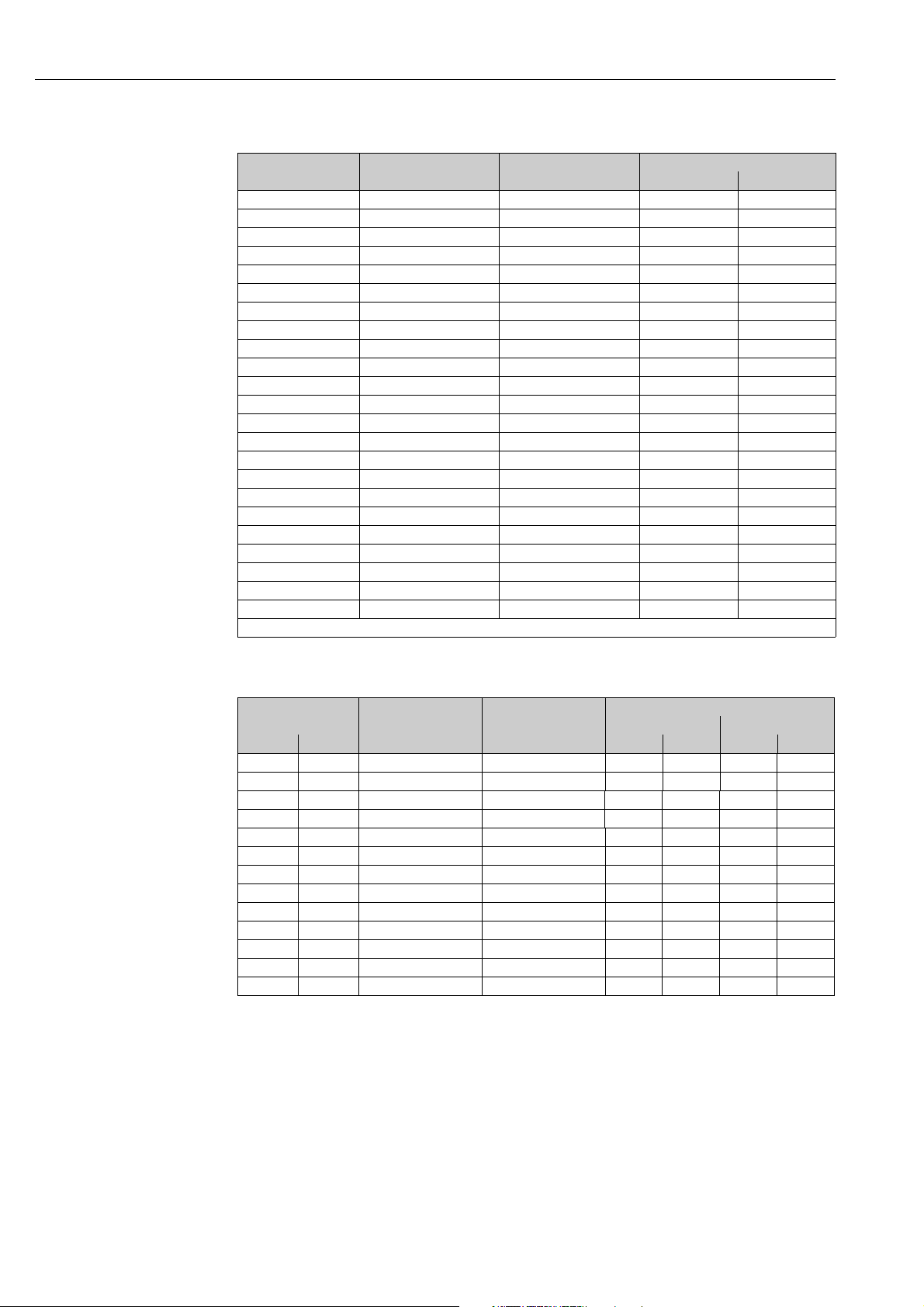

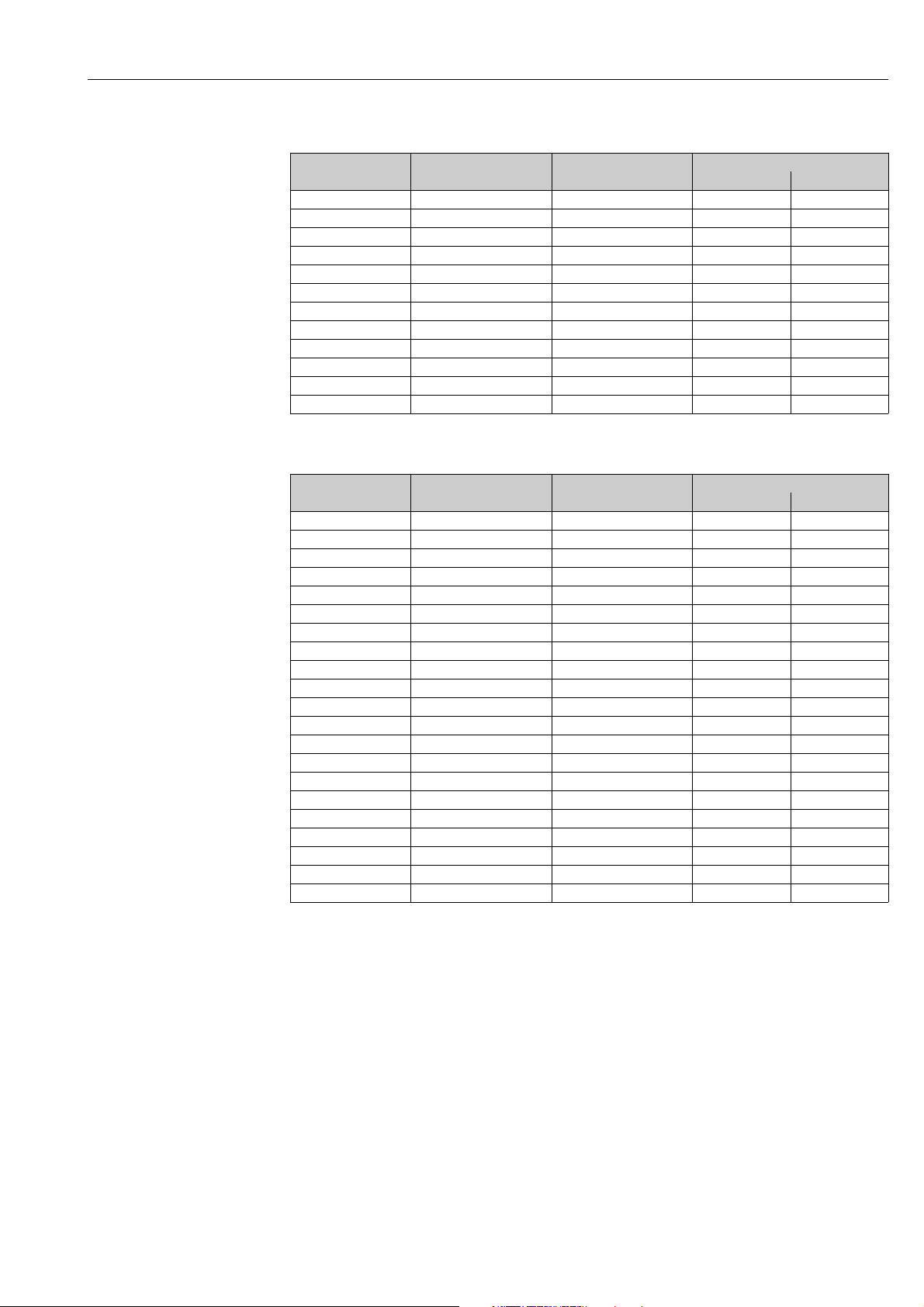

Promag W tightening torques for EN (DIN)

Nominal diameter EN (DIN) Max. tightening torque [Nm]

[mm] Pressure rating [bar] Threaded fasteners Hard rubber Polyurethane

25 PN 40 4 × M 12 – 15

32 PN 40 4 × M 16 – 24

40 PN 40 4 × M 16 – 31

50 PN 40 4 × M 16 48 40

65* PN 16 8 × M 16 32 27

65 PN 40 8 × M 16 32 27

80 PN 16 8 × M 16 40 34

80 PN 40 8 × M 16 40 34

100 PN 16 8 × M 16 43 36

100 PN 40 8 × M 20 59 50

125 PN 16 8 × M 16 56 48

125 PN 40 8 × M 24 83 71

150 PN 16 8 × M 20 74 63

150 PN 40 8 × M 24 104 88

200 PN 10 8 × M 20 106 91

200 PN 16 12 × M 20 70 61

200 PN 25 12 × M 24 104 92

250 PN 10 12 × M 20 82 71

250 PN 16 12 × M 24 98 85

250 PN 25 12 × M 27 150 134

300 PN 10 12 × M 20 94 81

300 PN 16 12 × M 24 134 118

300 PN 25 16 × M 27 153 138

* Designed acc. to EN 1092-1 (not to DIN 2501)

Promag W tightening torques for ASME

Nominal diameter ASME Max. tightening torque

Pressure rating [lbs] Threaded fasteners Hard rubber Polyurethane

[mm] [in] [Nm] [lbf · ft] [Nm] [lbf · ft]

25 1" Class 150 4 × ½" – – 7 5

25 1" Class 300 4 × 5/8" – – 8 6

50 2" Class 150 4 × 5/8" 35 26 22 16

50 2" Class 300 8 × 5/8" 18 13 11 8

80 3" Class 150 4 × 5/8" 60 44 43 32

80 3" Class 300 8 × ¾" 38 28 26 19

100 4" Class 150 8 × 5/8" 42 31 31 23

100 4" Class 300 8 × ¾" 58 43 40 30

150 6" Class 150 8 × ¾" 79 58 59 44

150 6" Class 300 12 × ¾" 70 52 51 38

200 8" Class 150 8 × ¾" 107 79 80 59

250 10" Class 150 12 × 7/8" 101 74 75 55

300 12" Class 150 12 × 7/8" 133 98 103 76

26 Endress+Hauser

Page 27

Proline Promag W 800 Installation

Promag W tightening torques for AS

Nominal diameter AS Max. tightening torque [Nm]

[mm] Pressure rating Threaded fasteners Hard rubber Polyurethane

80 Table E 4 × M 16 49 –

80 PN 16 4 × M 16 49 –

100 Table E 8 × M 16 38 –

100 PN 16 4 × M 16 76 –

150 Table E 8 × M 20 64 –

150 PN 16 8 × M 20 52 –

200 Table E 8 × M 20 96 –

200 PN 16 8 × M 20 77 –

250 Table E 12 × M 20 98 –

250 PN 16 8 × M 20 147 –

300 Table E 12 × M 24 123 –

300 PN 16 12 × M 24 103 –

Promag W tightening torques for JIS

Nominal diameter JIS Max. tightening torque [Nm]

[mm] Pressure rating Threaded fasteners Hard rubber Polyurethane

25 20K 4 × M 16 – 19

32 20K 4 × M 16 – 22

40 20K 4 × M 16 – 24

50 10K 4 × M 16 40 33

50 20K 8 × M 16 20 17

65 10K 4 × M 16 55 45

65 20K 8 × M 16 28 23

80 10K 8 × M 16 29 23

80 20K 8 × M 20 42 35

100 10K 8 × M 16 35 29

100 20K 8 × M 20 56 48

125 10K 8 × M 20 60 51

125 20K 8 × M 22 91 79

150 10K 8 × M 20 75 63

150 20K 12 × M 22 81 72

200 10K 12 × M 20 61 52

200 20K 12 × M 22 91 80

250 10K 12 × M 22 100 87

250 20K 12 × M 24 159 144

300 10K 16 × M 22 74 63

300 20K 16 × M 24 138 124

Endress+Hauser 27

Page 28

Installation Proline Promag W 800

PH 2

4 x

TX 20

4 x

3.

4 x

SW 7

2.

4.

5.

6.

1.

1.3 Nm

1.5 Nm

3.0 Nm

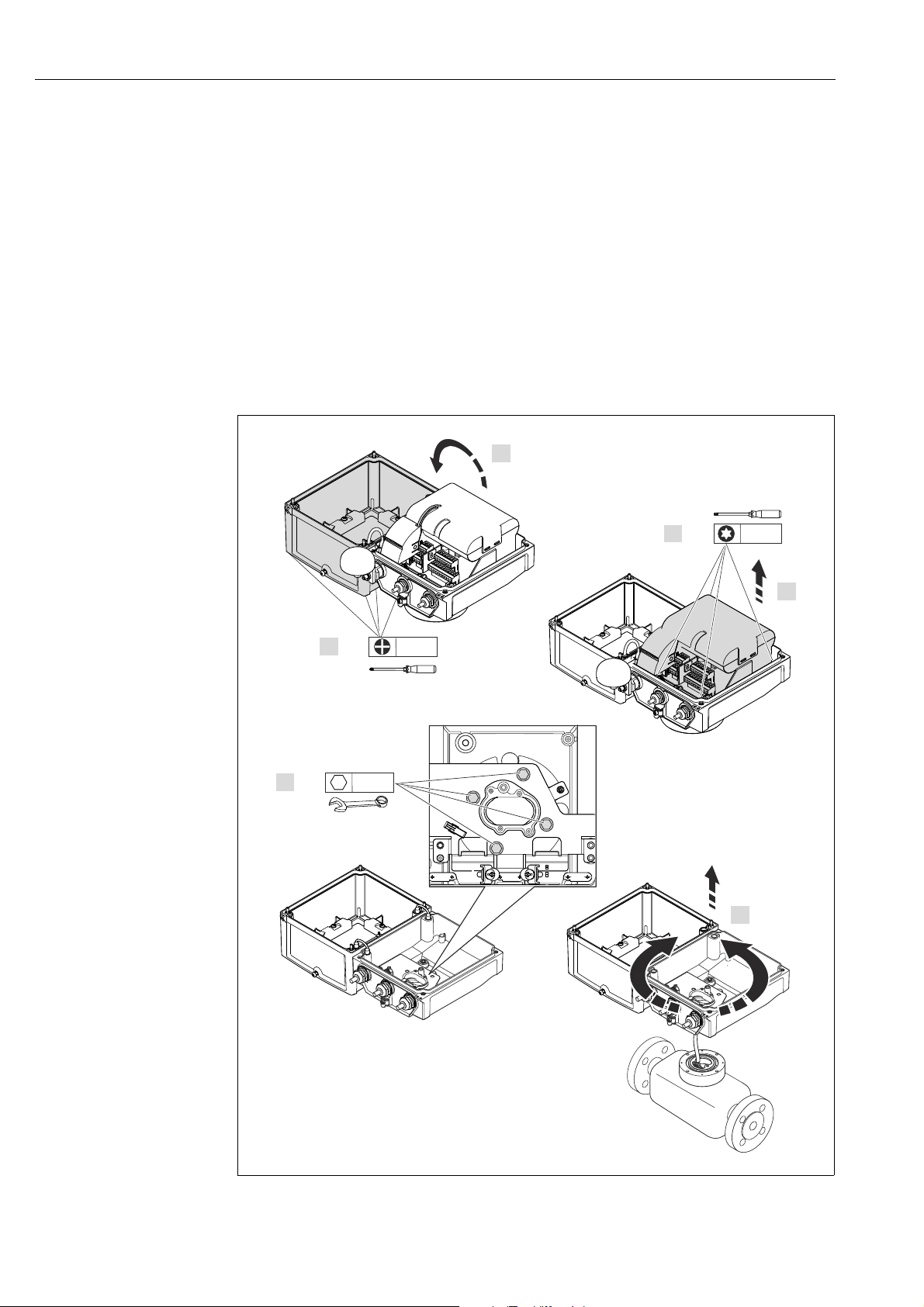

6.2.2 Turning the transmitter housing

1. Release the four screws on the housing cover.

2. Lift the housing cover slightly and tip it to the left.

Two flexible fasteners secure the housing cover to the housing.

3. Release the four screws on the electronics board carrier.

(one screw is located under the folding part of the battery cover).

4. Gently lift up the electronics board carrier until it is possible to access the connection

between the signal cable and the sensor. Disconnect the signal cable from the sensor

and remove the carrier from the transmitter housing.

5. Release the four screws on the transmitter housing.

6. Lift the transmitter housing slightly and turn it to the required position.

Reverse the sequence to install the transmitter housing.

A0017378

Fig. 17: Turning the transmitter housing

28 Endress+Hauser

Page 29

Proline Promag W 800 Installation

149 (5.85)

210.5 (8.29)

=

5.8 (0.23)

mm (in)

18 (0.71) =

14 (0.55)

5.8 (0.23)

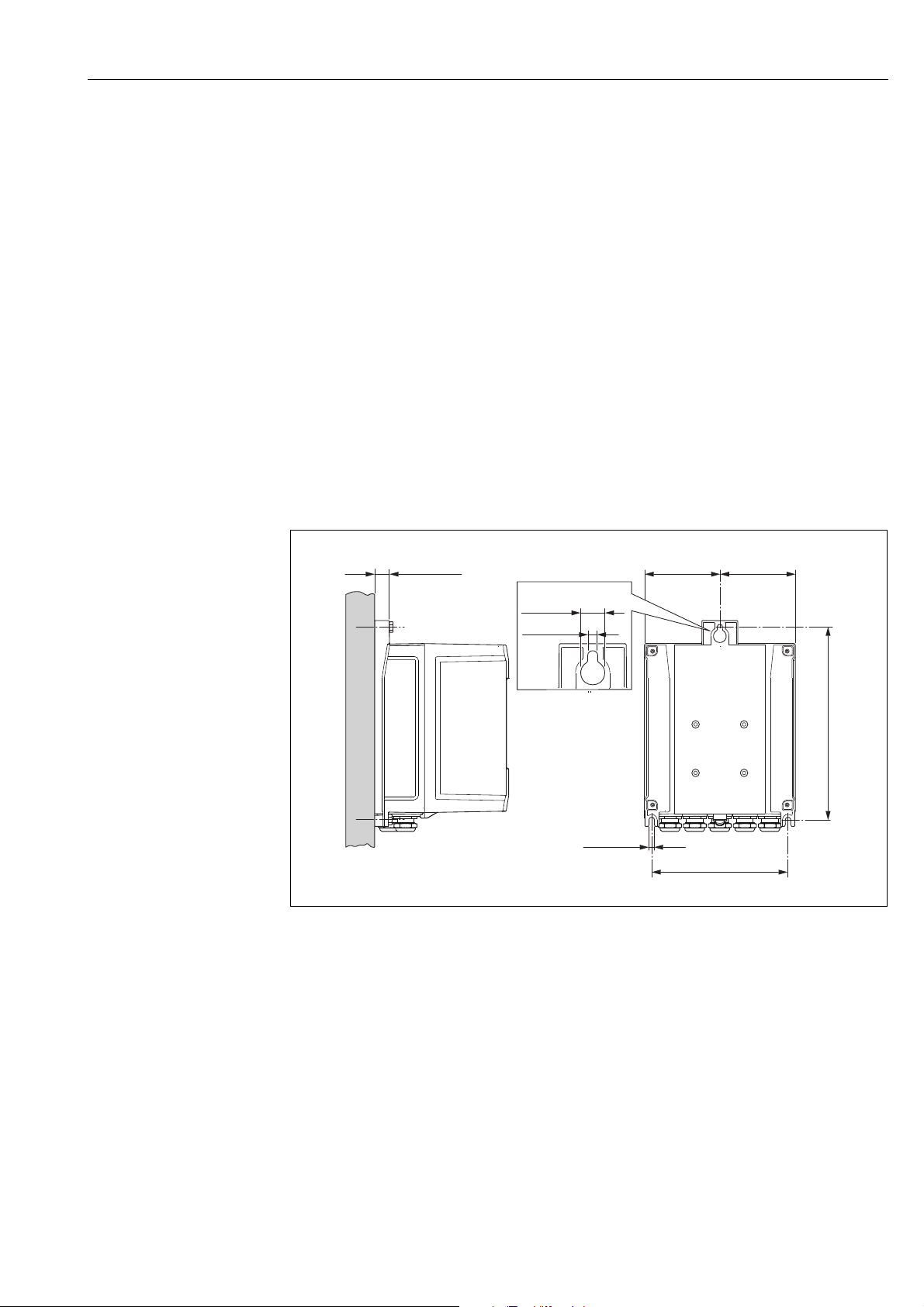

6.2.3 Installing the wall-mount housing

There are various ways of installing the wall-mount transmitter housing:

• Direct wall mounting

• Pipe mounting (with separate mounting kit, accessories)→ 30

Caution!

"

The permitted operating temperature range → 114 may not be exceeded or undershot.

Note the following points:

• Install the measuring device in a shady location. Avoid direct sunlight, particularly in warm

climatic regions.

• The transmitter must be mounted separate from the sensor if both the ambient and fluid

temperatures are high.

Direct wall mounting

1. Drill the holes as illustrated in the graphic.

2. Screw in the securing screws slightly at first.

3. Fit the transmitter housing over the securing screws and mount in place.

4. Tighten the securing screws.

Fig. 18: Direct wall mounting

Endress+Hauser 29

A0016411

Page 30

Installation Proline Promag W 800

ø 20…70

( 0.79…2.75)

ø

mm (in)

PH 2

SW 8

4 x

4 x

~ ~ 6.7)170 (

Pipe mounting

The assembly should be performed by following the instructions in the graphic.

Caution!

"

If using a warm pipe, make sure that temperatures do not exceed the permitted ambient

temperature range → 114.

Fig. 19: Pipe mounting (wall-mount housing)

6.3 Post-installation check

Is the measuring device undamaged (visual inspection)?

Does the measuring device meet the specifications of the measuring point?

For example:

• Process temperature → 115

• Process pressure (see the "Material load diagrams" section in the "Technical Information" document")

• Ambient temperature range → 114

• Measuring range → 110

Has the correct orientation been selected for the sensor → 18?

• According to sensor type

• According to fluid temperature

• According to fluid properties (outgassing, with entrained solids)

Does the arrow on the sensor nameplate match the actual direction of fluid flow through the pipe?

Are the measuring point identification and labeling correct (visual inspection)?

Is the device adequately protected from precipitation and direct sunlight?

Have the fastening elements been tightened with the correct tightening torque?

Has the signal strength for the GSM/GPRS modem been checked at the mounting location?

Is the signal strong enough for operation purposes?

A0016412

30 Endress+Hauser

Page 31

Proline Promag W 800 Electrical connection

7 Electrical connection

7.1 Preparing the measuring device

7.1.1 Required mounting tools

• For cable entries: use an appropriate tool.

• For the housing cover: use a Phillips head screwdriver.

• Cable stripper.

• For stranded cables: use a crimper for wire end ferrules.

• To remove cables from terminals: use a slotted screwdriver 3 mm (0.12 in).

7.1.2 Connecting cable requirements

The connecting cables provided by the customer must meet the following criteria:

Electrical safety

According to national regulations.

Cable specification

• Permitted temperature range: –40 to 80 °C (–40 to 176 °F);

Minimum ambient temperature: + 20 K

• A shielded cable is recommended

• Stripped length: 6 mm

• Strand (flexible): 2.5 mm²

• Cable diameter

– With cable glands supplied:

M20 × 1.5 with cable Ø 6 to 12 mm (0.24 to 0.47 in)

– Plug-in screw terminals: core cross-sections 0.5 to 2.5 mm² (20 to 14 AWG)

7.1.3 Connecting cable requirements for the remote version

The connecting cables for the remote version provided by the customer must meet the

following criteria:

Cable specifications

Electrode cable

• 3 × 0.38 mm² PVC cable with common, braided copper shield ( 7 mm) and individually

shielded cores

• Conductor resistance: 50 km

• Capacitance: core/shield: 420 pF/m

• Operating temperature: –20 to +80 °C (–4 to 176 °F)

• Cable cross-section: max. 2.5 mm

Coil current cable

• 2 × 0.75 mm² PVC cable with common, braided copper shield (Ø 7 mm)

• Conductor resistance: 37 km

• Capacitance: core/core, shield grounded: 120 pF/m

• Operating temperature: –20 to +80 °C (–4 to 176 °F)

• Cable cross-section: max. 2.5 mm²

• Test voltage for cable insulation: 1433 V AC r.m.s 50/60 Hz or 2026 V DC

Endress+Hauser 31

Page 32

Electrical connection Proline Promag W 800

1

2

3

4

5

6

7

ab

A0003194

Fig. 20: Cable cross-section

a Electrode cable

b Coil current cable

1Core

2 Core insulation

3 Core shield

4 Core jacket

5 Core reinforcement

6 Cable shield

7 Outer jacket

Reinforced connecting cables

As an option, Endress+Hauser can also deliver reinforced connecting cables with an

additional, reinforcing metal braid.

Use a reinforced connecting cable in the following situations:

• When laying the cable directly in the ground

• Where there is a risk of damage from rodents

• If using the device below IP68 degree of protection

Operation in zones of severe electrical interference

The measuring device complies with the general safety requirements in accordance with

EN 61010-1 and the EMC requirements of IEC/EN 61326.

Caution!

"

Grounding is by means of the ground terminals provided for the purpose inside the

connection housing. Ensure that the stripped and twisted lengths of cable shield to the

ground terminal are as short as possible.

32 Endress+Hauser

Page 33

Proline Promag W 800 Electrical connection

A

B

GND

80 (3.15)

50 (1.97)

18.5 (0.73)

6 (0.24)

100 (3.94)*

mm (inch)

1

2

1

2

1

2

A

B

115 (4.53)*

70 (2.76)

50 (1.97)

10 (0.39)8 (0.31)

mm (inch)

1

A

B

GND

80 (3.15)

50 (1.97)

6 (0.24)

³1 (0.04)

170 (6.69)*

20 (0.79)*

18.5 (0.73)

1

2

2

2

1

A

B

70 (2.76)

50 (1.97)

10 (0.39)

8 (0.31)

160 (6.30)*20 (0.79)*

1

1

1

7.1.4 Preparing the electrode and coil current cable

Terminate the electrode and coil current cables as shown in the figure below (Detail A).

Fit the fine-wire cores with wire end ferrules (Detail B).

Caution!

"

Please note the following when terminating the cables:

• In the case of electrode cable, make sure that the ferrules do not touch the wire shield on

the sensor side. Minimum distance = 1 mm (exception “GND” = green cable).

• In the case of coil current cables, insulate one core of the three-core wire at the level of the

core reinforcement. You only require two cores for the connection.

TRANSMITTER

Electrode cable Coil current cable

A0016477 A0016479

SENSOR

Electrode cable Coil current cable

1 = Red ferrules, Ø 1.0 mm

2 = White ferrules, Ø 0.5 mm)

* Stripping only for reinforced cables

A0016488 A0016489

Endress+Hauser 33

Page 34

Electrical connection Proline Promag W 800

123

1234

5

7.1.5 Preparing the measuring device

• Remove any dummy plugs.

Caution!

"

Poor sealing in the housing can affect the operational reliability of the measuring device.

Use suitable cable glands that correspond to the degree of protection.

If the measuring device is supplied without cable glands, provide appropriate cable glands

for the connecting cable that comply with IP protection requirements.

• If the measuring device is supplied with cable glands, observe the cable specifications.

Cable entry

Compact version Remote version

#

!

Fig. 21: Cable entries for the compact version

1 Connection terminal for GSM antenna (optional)

2 External power supply (optional)

3 Inputs/outputs

A0016457

Fig. 22: Cable entries for the remote version

1 Connection terminal for GSM antenna (optional)

2 External power supply (optional)

3 Inputs/outputs

4 Coil current cable

5Electrode cable

A0016458

7.2 Connecting the measuring device

Warning!

• Risk of electric shock!

Switch off the power supply before opening the device. Do not install or wire the device

while it is energized. Failure to comply with this precaution can result in irreparable

damage to the electronics.

• Risk of electric shock!

Connect the protective conductor to the ground terminal on the housing before the power

supply is applied (not necessary if the power supply is galvanically isolated).

• Compare the specifications on the nameplate with the local voltage supply and frequency.

Also comply with national regulations governing the installation of electrical equipment.

Note!

Incorrect connection work can reduce electrical safety!

• Connection work must only be performed by properly trained specialists.

• Observe national regulations governing the installation of electrical equipment.

• Comply with local workplace safety regulations.

34 Endress+Hauser

Page 35

Proline Promag W 800 Electrical connection

17

16 15 14

10

98765

13

12 11

4321

–2+– +1–+

3

7.2.1 Connecting the inputs and outputs

Different production steps are required to commission the measuring device and must

be followed in a set order. Before performing a specific production step, check whether

all the previous steps have been completed accordingly → 67.

1. Open the housing cover.

– Release the four screws with a Phillips head screwdriver.

– Lift the housing cover slightly and tip it to the left. Two flexible fasteners secure the

housing cover to the housing.

2. Push the cable through the cable entry → 34.

To ensure tight sealing, do not remove the sealing ring from the cable entry.

3. Strip the cable ends over 6 mm (0.24 in).

In the case of stranded cables, also attach wire end ferrules.

4. Connect the cables in accordance with the terminal assignment.

When connecting the cable shield to the ground terminal, observe the grounding

concept of the facility. Rigid conductors or flexible conductors with wire end ferrules can

be inserted directly into the terminal without pressing on the wire release.

Fig. 23: Connecting the outputs

1 Output 1

2 Output 2

3 Input 1

Terminal assignment

Inputs Outputs

Terminal Connection Terminal Connection

5 Input 1 (+) 14 Shield, output 1 and 2

6 Input 1 (–) 15 Output 1 (+)

16 Output 2 (+)

17 Output 1 and 2 (–)

5. Fit the cable anchorage and firmly tighten the cable glands.

6. Secure the housing cover.

– Fix the housing cover on the housing.

– Tighten the four screws with a Phillips head screwdriver.

A0017026

Endress+Hauser 35

Page 36

Electrical connection Proline Promag W 800

1

2

3

4

17

16 15 14

10

987 65

13

12 11

4 321

5 743742 41

7.2.2 Connecting the connecting cable in the remote version

Different production steps are required to commission the measuring device and must

be followed in a set order. Before performing a specific production step, check whether

all the previous steps have been completed accordingly → 67.

1. Open the housing cover.

– Release the four screws with a Phillips head screwdriver.

– Lift the housing cover slightly and tip it to the left.

Two flexible fasteners secure the housing cover to the housing.

2. Push the cable through the cable entry → 34.

To ensure tight sealing, do not remove the sealing ring from the cable entry.

3. Strip the cable ends and fit wire end ferrules → 33.

4. Connect the cables in accordance with the terminal assignment.

When connecting the cable shield to the ground terminal, observe the grounding

concept of the facility.

Fig. 24: Connecting the remote version

1 Transmitter terminals

2 Sensor terminals

3 Coil current cable

4 Electrode cable

Terminal assignment

Sensor Transmitter

Terminal Connection Terminal Connection

5 Electrode E1 (brown) 1 Electrode E1 (brown)

7Electrode E2 (white) 2Electrode E2 (white)

4

Reference electrode,

Terminals bridged (green)

37 4 Shield, electrode E2 (white)

41 Coil current cable B2 (black) 11 Reference electrode (green)

42 Coil current cable B1 (black) 12 Coil current cable B2 (black)

3 Shield, electrode E1 (brown)

13 Coil current cable B1 (black)

5. Fit the cable anchorage and firmly tighten the cable glands.

6. Secure the housing cover.

– Fix the housing cover on the housing.

– Tighten the four screws with a Phillips head screwdriver.

A0017027

36 Endress+Hauser

Page 37

Proline Promag W 800 Electrical connection

2.5 mm

£ 20°

£ 20°

7.2.3 Connecting and mounting the GSM/GPRS antennae

Different production steps are required to commission the measuring device and must

be followed in a set order. Before performing a specific production step, check whether

all the previous steps have been completed accordingly → 67.

Checking the signal strength to determine the type of mounting

Check whether and where a sufficiently strong signal of the mobile communications

network is present. A cell phone or the measuring device can be used for this purpose:

• Hold a cell phone, containing a SIM card from the same provider, at the desired antenna

mounting point and read how strong the signal is.

• If the measuring device is already operational (batteries inserted and battery power

switched on → 42), the signal strength can be read:

– On the onsite display by calling up the status of the antenna signal → 49.

– In the operating tool by using the ANTSS parameter to read the signal strength →

164.

If the signal strength 30 %, the antenna must be mounted separately from the measuring

device.

Connecting and mounting the antenna

• Mount the antenna:

– Signal strength > 30 %: mount the antenna on the measuring device → 25.

– Signal strength 30 %: mount the antenna separately from the measuring device →

27.

• Connect the antenna to the measuring device → 26.

Mounting the antenna directly on the measuring device

When mounting, make sure the antenna holder is as vertical as possible!

Fig. 25: Mounting the antenna directly on the measuring device

Connecting the antenna to the measuring device

A0017387

A0017388

Fig. 26: Connecting the antenna

Endress+Hauser 37

Page 38

Electrical connection Proline Promag W 800

³ 77 (3)

mm (in)

³ 75 (2.9)

M12

Mounting the antenna separately from the measuring device

• Mount the antenna as high as possible above the ground.

• Do not mount it beneath metal objects, covers, floors and ceilings.

• Make sure you maintain the minimum distance from walls and ceilings specified in

→ 27.

• Do not extend the antenna cable.

A0016487

Fig. 27: Mounting the antenna separately from the measuring device

7.2.4 Connecting the external power supply (optional)

Preparing the connection

It is possible to power the measuring device directly via an external power supply.

In addition, batteries are to be used as a backup if the power supply fails and to operate the

GSM/GPRS module.

Possible combinations:

Ordered feature

"Power supply"

5W8B**-***J*********

5W8B**-***K*********

If the measuring device is powered via an external power supply, energy from the batteries

is not used. In such instances, the measuring device can work with maximum measured

value acquisition cycles (Prof./ MPROF parameter → 135).

To ensure the device continues measuring if the external power supply fails, a battery is used

as the backup power supply at the B1 terminal → 40.

The external power supply only supports measuring operation. Additional batteries must be

inserted at the B3 terminal for communication via the GSM/GPRS modem → 40.

Power

supply

100 to 240 V AC

12 to 60 V DC

100 to 240 V AC

12 to 60 V DC

Number of

batteries

1 back-up battery

1 back-up battery

3 batteries for GSM/GPRS module

The batteries are not charged if an external power supply is used.

The current state of charge of the batteries can be read on the onsite display or in the

BATTS parameter → 164.

38 Endress+Hauser

Page 39

Proline Promag W 800 Electrical connection

17

16 15 14

10

98765

13

12 11

4321

N– L+

)

)

12

3

Measuring device requirements

• Integrate the measuring system into the potential equalization system → 43.

• The power supply line must be equipped with an external protection for overload current

(fuse or automatic circuit breaker).

• The measuring device must have a suitably labeled and easy-to-reach ON/OFF switch.

Power supply and power supply unit requirements

• The power supply must be within the range indicated on the nameplate (Electrical

connection → 112).

• Take the cable specification of the connecting cable into consideration → 112.

• Take the connecting cable requirements into consideration → 112.

Connecting the external power supply

Different production steps are required to commission the measuring device and must

be followed in a set order. Before performing a specific production step, check whether

all the previous steps have been completed accordingly → 67.

1. Open the housing cover.

– Release the four screws with a Phillips head screwdriver.

– Lift the housing cover slightly and tip it to the left. Two flexible fasteners secure the

housing cover to the housing.

2. Fold up the protective cover.

3. Push the cable through the cable entry → 34.

To ensure tight sealing, do not remove the sealing ring from the cable entry.

4. Strip the cable ends over 6 mm (0.24 in).

In the case of stranded cables, also attach wire end ferrules.

5. Connect the cables in accordance with the terminal assignment.

When connecting the cable shield to the ground terminal, observe the grounding

concept of the facility.

Fig. 28: Connecting the external power supply (optional)

Terminal assignment

External power supply

Terminal Connection

1Protective ground

2N –

3L +

A0017028

6. Fold down the protective cover.

7. Fit the cable anchorage and firmly tighten the cable glands.

8. Secure the housing cover.

– Fix the housing cover on the housing.

– Tighten the four screws with a Phillips head screwdriver.

Endress+Hauser 39

Page 40

Electrical connection Proline Promag W 800

B2

B1

B1 B2 B3

B1

B1 B2 B3

B2

B1 B2 B3

B2B1

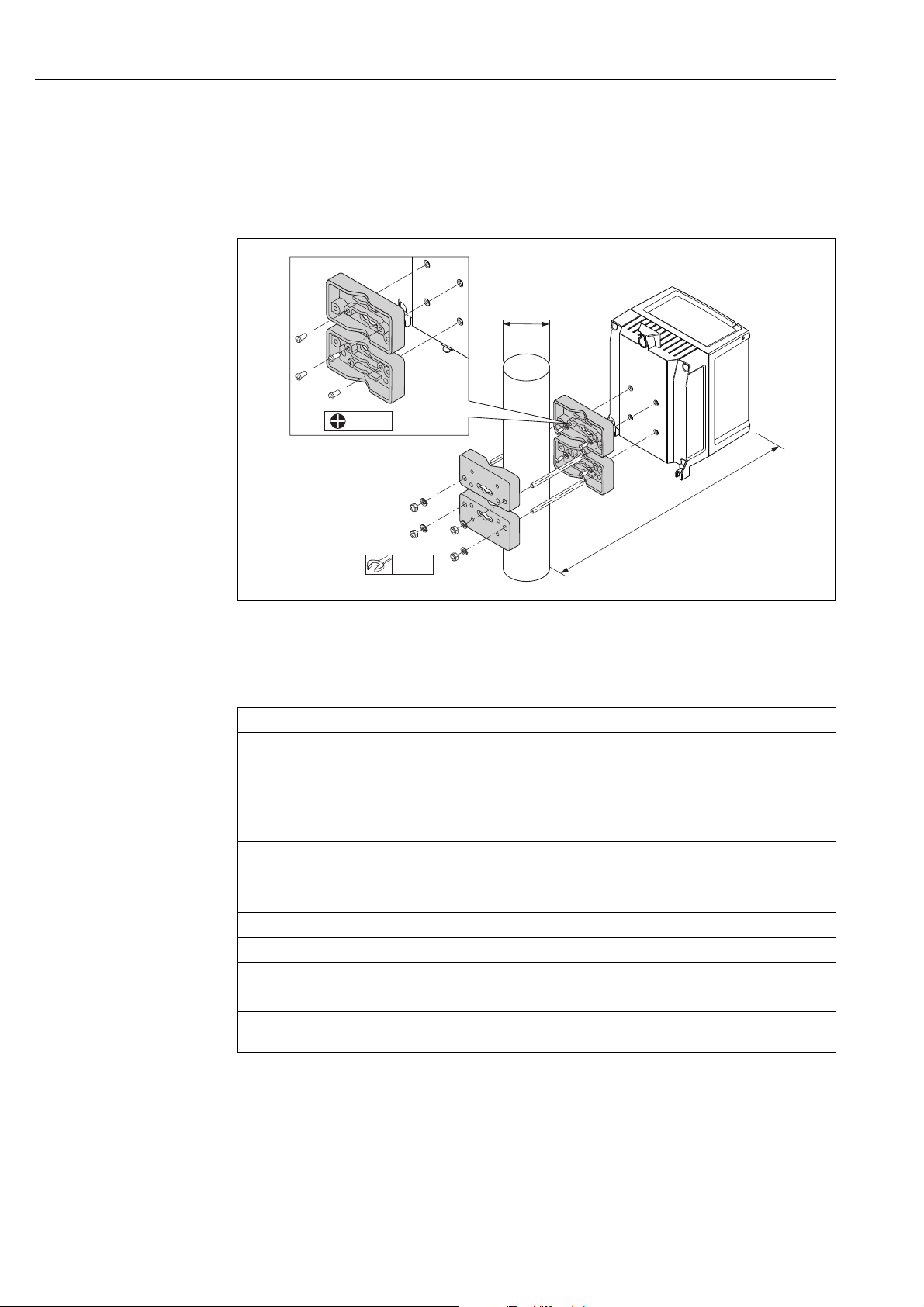

7.3 Inserting and connecting the batteries

7.3.1 Overview of battery arrangement options

Three battery terminals are available in the measuring device. These terminals are assigned

different uses depending on the number and arrangement of the batteries. B1 and B2 are

the terminals for power supply to the measuring device, B3 is the terminal for the GSM/

GPRS modem.

The measuring device is initially powered by the batteries in terminal B2. If the voltage

supplied by these batteries becomes too low, the measuring device issues a message and

switches automatically to the battery in terminal B1.

If power is supplied to the measuring device externally and the power supply fails, the

battery in terminal B1 acts as a backup power supply.

The GSM/GPRS modem is always powered by the battery in terminal B3.

This is also the case if the measuring device uses an external power supply.

The batteries are not charged if an external power supply is used.

The current state of charge of the batteries can be read on the onsite display or in the

BATTS parameter → 164.

Possible configurations

Configuration 1

Configuration of

batteries

A0017127

Configuration 2

Configuration of

batteries

Connectors

"Power supply" order feature for this configuration: 5W8B**–***F0********

!

Not permitted in custody transfer!

Connectors

"Power supply" order feature for this configuration: 5W8B**–***G0********

Number of

batteries

B 1 1 Backup power supply for the measuring device

B 2 1 Power supply for the measuring device

B 3 – Power supply for the GSM/GPRS modem

Note!

Number of

batteries

B 1 1 Backup power supply for the measuring device

B 2 3 Power supply for the measuring device

B 3 – Power supply for the GSM/GPRS modem

Battery usage

Battery usage

A0017128

Configuration 3

Configuration of

batteries

A0017129

40 Endress+Hauser

Connectors

B 1 3 Backup power supply for the measuring device

B 2 3 Power supply for the measuring device

B 3 – Power supply for the GSM/GPRS modem

"Power supply" order feature for this configuration: 5W8B**–***H0********

Number of

batteries

Battery usage

Page 41

Proline Promag W 800 Electrical connection

B1

B1 B2 B3

B1

B1 B2 B3

B3

B2

B1

B1 B2 B3

B3

Configuration 4

Configuration of

batteries

Configuration 5

Configuration of

batteries

Connectors

B 1 1 Backup power supply for the measuring device

B 2 – Power supply for the measuring device

B 3 – Power supply for the GSM/GPRS modem

Powered via external power

A0017130

"Power supply" order feature for this configuration: 5W8B**–***J0********

Connectors

B 1 1 Backup power supply for the measuring device

B 2 2 Power supply for the measuring device

B 3 3 Power supply for the GSM/GPRS modem

"Power supply" order feature for this configuration: 5W8B**–***HP********

supply

Number of

batteries

Number of

batteries

Battery usage

Power supply for the measuring device

Battery usage

Configuration 6

Configuration of

batteries

A0017131

Connectors

Number of

batteries

Battery usage

B 1 1 Backup power supply for the measuring device

B 2 – Power supply for the measuring device

B 3 3 Power supply for the GSM/GPRS modem

Powered via external power

Power supply for the measuring device

supply

A0017132

"Power supply" order feature for this configuration: 5W8B**–***KP********

Endress+Hauser 41

Page 42

Electrical connection Proline Promag W 800

B1 B2 B3

7.3.2 Inserting and connecting the batteries

Different production steps are required to commission the measuring device and must

be followed in a set order. Before performing a specific production step, check whether

all the previous steps have been completed accordingly → 67.

#

"

Warning!

Risk of electric shock!

Switch off the power supply before opening the device.

Caution!

Can damage the electronic of the device!

Only use batteries provided by Endress+Hauser.

1. Open the housing cover.

– Release the four screws with a Phillips head screwdriver.

– Lift the housing cover slightly and tip it to the left. Two flexible fasteners secure the

housing cover to the housing.

2. Remove the battery cover.

– Release the securing screw with a Phillips head screwdriver.

– Turn the battery cover in a slightly clockwise direction to remove it (two guides which

hold the battery cover in position are located on the right-hand side).

3. Insert the batteries.

Place the batteries into the compartment. In doing so, route the battery cables in the

direction of the cable inlet in the battery cover → 30.

If not all the batteries are inserted, the partition plate can be used to prevent any

inserted batteries from becoming dislodged.

Fig. 29: Example of a battery arrangement (configuration 5)

B1 Battery connection to back up the power supply for the measuring device

B2 Battery connection to power the measuring device

B3 Battery connection to power the GSM/GPRS module

4. Connect the batteries.

– Insert the battery cables into the appropriate receptacle → 30.

5. Set the DIP switches → 30.

The following options are available:

– Set the DIP switch to ON to switch on the battery power supply.

If battery power supply is switched on, the red CPU LED flashes → 69 and the

startup sequence appears on the onsite display → 69.

– Set the DIP switch to OFF to switch off the battery power supply.

42 Endress+Hauser

A0016648

Page 43

Proline Promag W 800 Electrical connection

1

B2

B1

B3

B1 B2 B3

ON

12

B1/B2

ON

B3

ON

12

17

16 15 14

10

987 65

13

12 11

4 321

LOCK

CPU

GSM

2

B1 B2 B3

3

ON

12

B1/B2

ON

B3

ON – OFF

B3

B1/B2

4

ON

12

LOCK

ON – OFF

A0017025

Fig. 30: Connecting the batteries, switching on the battery power supply

1 Cable inlet in the battery cover

2 Receptacles for terminals B1 and terminals B2 and B3

3 DIP switch (ON/OFF) for switching the batteries on and off:

- Switch 1: terminals B3

- Switch 2: terminals B1 and B2

4 DIP switch (ON/OFF) to disable the controls of the local display

#

6. Secure the battery cover.

– Route the battery cables in the direction of the cable inlet in the battery cover → 30.

– Fit the battery cover in place. In doing so, position the guides into the slots in the

battery cover.

– Tighten the securing screw with a Phillips head screwdriver.

– Fold down the protective cover for the external power supply.

7. Secure the housing cover.

– Fix the housing cover on the housing.

– Tighten the four screws with a Phillips head screwdriver.

Comply with instructions for battery disposal → 108.

7.4 Potential equalization

Warning!

Integrate the measuring system into the potential equalization system.

7.4.1 Potential equalization requirements

Please consider the following to ensure correct measurement:

• The fluid and sensor have the same electrical potential

• Company-internal grounding concepts

• Material and grounding of the pipes

Endress+Hauser 43

Page 44

Electrical connection Proline Promag W 800

7.4.2 Connection examples for potential equalization

Connection example in standard situations

Metal, grounded pipe

A0016315

Fig. 31: Potential equalization via Measuring tube

Connection example in special situations

Metal, ungrounded pipe without liner

This connection method is also to be used when:

• Potential equalization is not customary

• Equalizing currents are present

A0022704

Fig. 32: Potential equalization via ground terminal and pipe flanges

For mounting consider the following:

• Connect both sensor flanges to the particular pipe flange via a ground cable and ground

them.

Ground cable = copper wire, at least 6 mm² (0.0093 in

²

).

• Connect the transmitter or sensor connection housing, as applicable, to ground potential

by me ans of the ground termin al provided for the purpose. For mounting the ground cable:

– Mount the ground cable directly on the conductive flange coating of the sensor with the

flange screws.

For remote version: The ground terminal in the example refers to the sensor and not

to the transmitter.

The required ground cable can be ordered from Endress+Hauser.

44 Endress+Hauser

Page 45

Proline Promag W 800 Electrical connection

1 /

+

–

2 /

2 /

3 /

Plastic pipe or pipe with insulating lining

This connection method is also to be used when:

• Potential equalization is not customary

• Equalizing currents are present

A0016318

Fig. 33: Potential equalization via ground terminal and ground disk

For mounting consider the following:

The ground disks have to be connected to the ground terminal via a ground cable and to the

ground potential. Ground cable = copper wire, at least 6 mm² (0.0093 in²).

For remote version: The ground terminal in the example refers to the sensor and not

to the transmitter.

The required ground cable can be ordered from Endress+Hauser.

Pipe with cathodic protection

This connection method only take place, if both of the following requirements are fulfilled:

• Metal pipe without liner or pipe with electrically conductive liner

• Cathodic protection is integrated in the operator protection

A0016319

Fig. 34: Potential equalization and cathodic protection

1 Isolating transformer power supply

2 Electrically isolated to pipe

3 Capacitor

1. Connect the measuring device potential-free compared to protective earth to the power

supply.

2. Install the measuring device electrically isolated in the pipe.

3. Connect the two flanges of the pipe with a ground cable.

Ground cable = copper wire, at least 6 mm² (0.0093 in²).

4. By connecting the shielding of the signal cables a capacitor has to be used.

For remote version: The ground terminal in the example refers to the sensor and not

to the transmitter.

The required ground cable can be ordered from Endress+Hauser.

Endress+Hauser 45

Page 46

Electrical connection Proline Promag W 800

7.5 Guaranteeing the degree of protection of the measuring device

Caution!

"

Do not loosen the threaded fasteners of the sensor housing, as otherwise the degree of

protection guaranteed by Endress+Hauser no longer applies.

To guarantee the degree of protection of the measuring device → 115.

Perform the following steps after electrical connection:

• Check that the housing seals of the connection and electronics compartment are clean and

fitted correctly. Dry, clean or replace the seals if necessary.

• Tighten all housing screws and screw covers.

• Firmly tighten the cable glands.

• To ensure that moisture does not enter the cable entry, route the cable so that it loops

down before the cable entry ("water trap").

Fig. 35: Cable looped down before the cable entry

• Insert dummy plugs into unused cable entries.

• Notes on measuring devices with IP68 option → 20.

7.6 Post-connection check

Is the measuring device undamaged (visual inspection)?