Page 1

Technical Information

TWF11, TWF16

Metal or ceramic thermowells

For high temperature assemblies TAF11 and TAF16

Adjustable process connection

Application

TWF11

• Applicable for steel treatment (annealing), concrete

furnaces and primaries. Accessory for high

temperature assembly TAF11.

TWF16

• Applicable for cement production, steel treatment,

incinerators and fluidized bed furnaces. Accessory for

high temperature assembly TAF16.

Process temperatures:

• TWF11 up to +1600 °C (+2912 °F)

• TWF16 up to +1700 °C (+3092 °F)

Your benefits

• Long lifetime by usage of innovative thermowell

materials with increased wear and chemical resistance

• Long term stable measurement due to sensor

protection with non-porous materials

• Replaceable parts

TI01015T/09/en

71131970

Page 2

TWF11, TWF16

Performance characteristics

Operating conditions Process temperature

Depends on material, details see section ’Material’.

Process pressure

Depends on material.

Thermowells in high temperature applications are generally designed for use in pressureless processes.

Available process connections can be gastight up to 1 bar, details ä 5.

Permitted flow rate as a function of immersion length

Depends on material and application. For process pressures 1 bar and a flow rate 1 m/s it is recommended

to order a thermowell stress calculation, please contact your nearest Endress+Hauser sales organisation.

Material The temperatures for continuous operation specified in the following table are only intended as reference values

for use of the various materials in air and without any significant compressive load. The maximum operation

temperatures are reduced considerably in some cases where abnormal conditions such as high mechanical load

occur or in aggressive media.

Endress+Hauser supplies DIN/EN threaded process connections and flanges made of stainless steel according

to AISI 316L (DIN/EN material number 1.4404 or 1.4435). With regard to their temperature stability

properties, the materials 1.4404 and 1.4435 are grouped under 13E0 in EN 1092-1 Tab. 18. The chemical

composition of the two materials can be identical.

Material name Short form Recommended

max. temperature

for continuous use

in air

AISI 316L/

1.4404

1.4435

AISI 310/

1.4841

AISI 304/

1.4301

AISI 446/

~1.4762/

~1.4749

INCONEL

/ 2.4816

INCONEL

/ 2.4851

X2CrNiMo17-12-2

X2CrNiMo18-14-3

X15CrNiSi25-20 1100 °C (2012 °F) • Austenitic, stainless steel

X5CrNi18-10 850 °C (1562 °F) • Austenitic, stainless steel

X10CrAl24 /

X18CrNi24

®

600

NiCr15Fe 1100 °C (2012 °F) • A nickel/chromium alloy with very good resistance to aggressive, oxidizing and reducing

®

601

NiCr23Fe 1200 °C (2192 °F) • High temperature corrosion resistance enhanced by aluminum content

650 °C (1200 °F)

1100 °C (2012 °F) • A ferritic, heat resistant, high-chromium stainless steel

Properties

1)

• Austenitic, stainless steel

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorine-based and acidic, non-oxidizing atmospheres

through the addition of molybdenum (e.g. phosphoric and sulfuric acids, acetic and tartaric acids

with a low concentration)

• Increased resistance to intergranular corrosion and pitting

• Compared to 1.4404, 1.4435 has even higher corrosion resistance and a lower delta ferrite

content

• Good resistance to oxidizing and reducing atmospheres

• Due to the higher chromium content well resistant to oxidizing aqueous solution and neutral

salts melting at higher temperatures

• Only weakly resistant to sulphurous gases

• Well usable in water and lowly pollute waste water

• Only at relatively low temperatures resistant to organic acids, saline solutions, sulphates, alcaline

solutions, etc.

• Very high resistance to reducing sulphurous gases and salts with low content of oxygen

• Very good resistance to constant as well as cyclical thermal stress, to incineration ash-corrosion

and to melts of copper, lead and tin

• Poorly resistant to gases containing nitrogen

atmospheres, even at high temperatures

• Resistant to corrosion caused by chlorine gas and chlorinated media as well as many oxidizing

mineral and organic acids, sea water etc.

• Corrodible by ultrapure water

• Not to be used in a sulfur-containing atmosphere

• Resistance to oxide spalling and carburization under thermal cycling

• Good resistance against molten salt corrosion

• Particularly susceptible to sulfidation

2 Endress+Hauser

Page 3

TWF11, TWF16

Material name Short form Recommended

Properties

max. temperature

for continuous use

in air

INCOLOY®800

HT / 1.4959

X8NiCrAlTi32-21 1100 °C (2012 °F) • A nickel/chromium/iron alloy based on the same composition as INCOLOY®800, but has

significantly higher creep rupture strength, resultant from the close control of the carbon,

aluminum and titatinium contents.

• Good strength and excellent resistance to oxidation and carburization at high temperature

environments.

• Good resistance to stress corrosion cracking, attack by sulfur, internal oxidation, scaling and

corrosion in a multitude of industrial environments. Suitable for sulfurous environments.

HASTELLOY

/ 2.4665

®

X

NiCr22Fe18Mo 1150 °C (2102 °F) • A nickel/chromium/iron/molybdenum alloy

• Very resistant to oxidizing and reducing atmospheres

• Good strength and ductility at high temperatures

Kanthal AF FeCrAl 1400 °C (2552 °F) • A high-temperature ferritic iron/chrominum/aluminum alloy

• High resistance to sulfurous, carburizing and oxidising environments

• Good hardness and weldability

• Good form stability at high temperature

• Not to be used in a chloride-containing atmosphere and nitrogenous gases (cracked ammonia)

Special nickel/

cobalt alloy

NiCo 1200 °C (2192 °F) • A nickel/cobalt alloy

• Very good resistance to sulfidation and chloride environment

• Exceptionally good resistance to oxidation, hot corrosion, carburization, metal dusting, and

nitridation

• Good creep resistance

• Average surface hardness

• High wear resistance

Recommended applications

• Cement industry

– gas standpipe: successfully tested with up to 20 times longer lifespan compared to AISI310

– clincker cooler: successfully tested with up to 5 times longer lifespan compared to AISI310

• Waste incinerators: successfully tested with up to 12 times longer lifespan than INCONEL

and C276)

• Fluidized bed furnace (biogas reactor): successfully tested with up to 5 times longer lifespan than

e.g. INCOLOY

®

800HT or INCONEL® 600.

Ceramic material types according to DIN VDE0335

C610 1500 °C (2732 °F) • Al

-content approx. 60 %, alkali-content 3 %

2O3

• The most economic non porous ceramic material

• Highly resistant to hydrogen fluoride, temperature shocks and mechanical influences, normally

used for internal and external thermowells as well as insulators

Sinterized silicon

carbide

SiC 1650 °C (3000 °F) • High thermal shock resistance due to its porosity

• Good thermal conductivity

• Very hard and stable at high temperature

Recommended applications

• Glass industry: glass feeders, float glass production

• Ceramic industry

• Furnaces

Kanthal Super MoSi

with a glass

2

phase component

1700 °C (3092 °F) • It is not affected by thermal shock

• Very low porosity (< 1%) and very high hardness

• Not to be used in environments with chlorine and fluorine compounds

• Not suitable for mechanical shock affected applications

• Not to be used in applications with powder

Special silicon

nitride ceramic

SiN 1400 °C (2552 °F) • Excellent wear and thermal shock resistance

• No porosity

• Good heat response

• Not resistant to impacts (brittleness)

Recommended applications

• Cement industry

– Cyclone preheater: successfully tested with up to 5 times longer lifespan compared to AISI310

– Secondary airpipe

• Generally all applications with extreme abrasive conditions; mechanical shocks/impacts have to

be avoided because of brittleness

®

600

1) Can be used to a limited extent up to 800 °C (1472 °F) for low compressive loads and in non-corrosive media. Please contact your Endress+Hauser sales team

for further information.

Endress+Hauser 3

Page 4

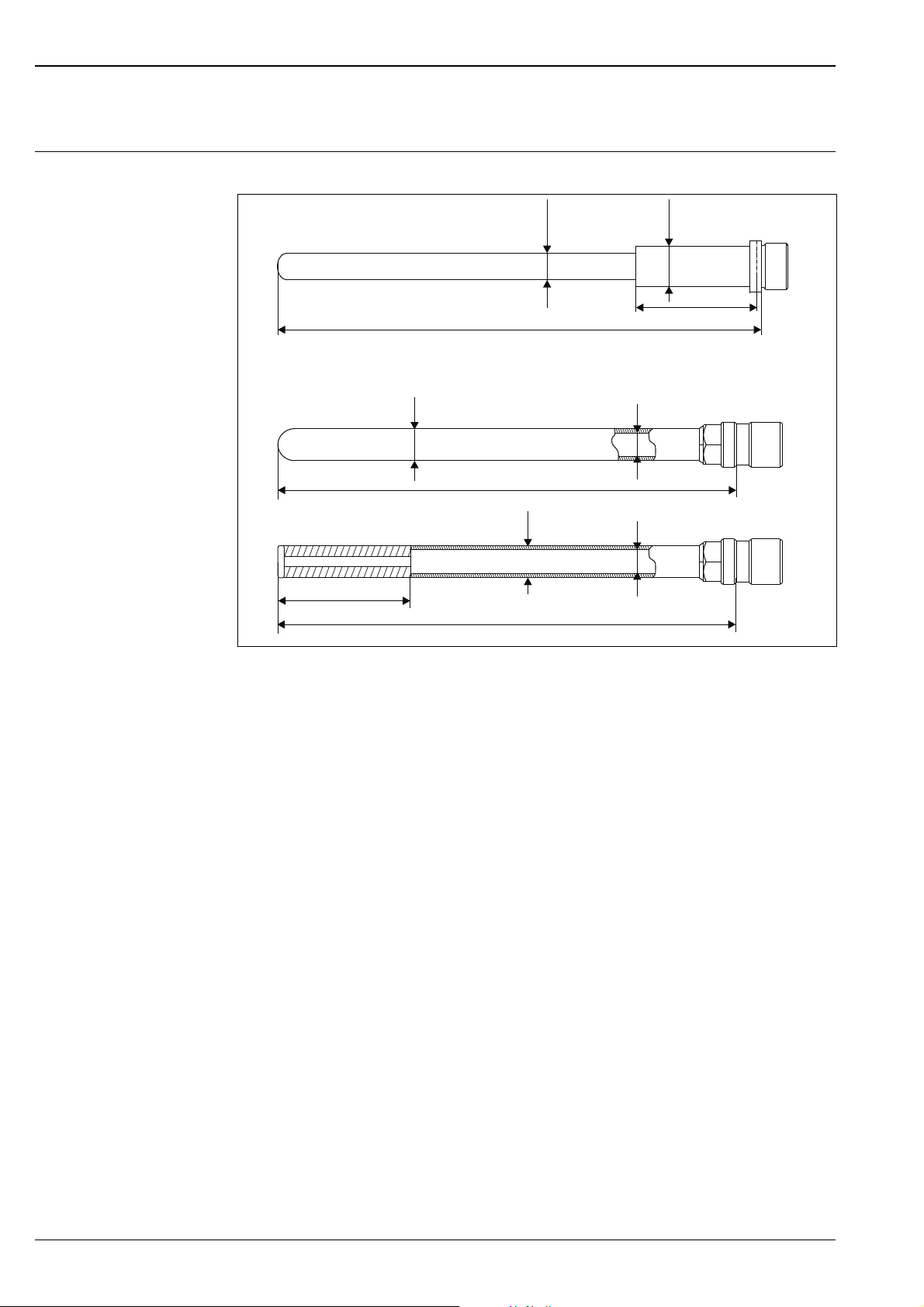

Mechanical construction

Lg

Lm

Ø Lm

Ø Lg

Lg

ØT

Ø

i

TWF11

TWF16

L2

Lg

ØT

Ø

i

C

C

C

A

B

Design, dimensions All dimensions in mm (in).

TWF11, TWF16

TWF11

Sheath diameter

Sleeve length

Sleeve diameter

Length bar stock tip

Immersion length

Thermowell outer diameter

Thermowell inner diameter

CLgTerminal head connection:

M24x1.5 or groove for DIN A head

Immersion length

TWF16

A

Version thermowell made from tube

B

Version thermowell made from tube

and bar stock tip

Terminal head connection:

C

M24x1.5 or groove for DIN A head

Thermowell

• Metallic thermowell, usually machined from tubes or bars.

Ø Lg

Lm

Ø Lm

L2

Lg

ØT

Øi

• Ceramic thermowell.

The selection of the thermowell materials majorly depends on the following material properties, which will

directly influence the lifetime of the sensor:

• Hardness

• Chemical resistance

• Maximum operating temperature

• Wear/abrasion resistance

• Brittleness

• Porosity for process gases

• Creep resistance

Ceramic materials are commonly used for highest temperatures and, due to their hardness, for applications

with high abrasion rates. Attention has to be paid regarding the brittleness of these materials when exposed to

high mechanical loads inside the process. When using porous ceramics as external protection sheath, an

additional, non-porous inner protection sheath has to be used in order to protect the noble sensor elements

from contamination leading to temperature drifts.

4 Endress+Hauser

a0015111

Page 5

TWF11, TWF16

Metal alloys generally show higher mechanical resistance but lower maximum temperature limits and less

abrasion resistance. All metal alloys are non-porous and usually there is no need for an additional inner

protection sheath.

Metal sleeve and process connection

The TWF11 ceramic thermowells are mounted into a metal sleeve which connects them towards the terminal

head. Also the process connection is fitted on the metal sleeve due to its higher mechanical strength. The

dimensions and material type for the sleeve are related to the process temperatures and immersion lengths of

the ceramic thermowells.

All high temperature thermowells are available with an adjustable flange, stop flanges or gas tight compression

fittings.

Weight Depending on length and diameter. Some examples:

• TWF11:

Material SiC or SiN, Ø Lg = 17 mm (0.7 in), Lg = 800 mm (31.5 in), Lm = 300 mm (11.8 in), material

sleeve: AISI 310): 0.8 kg (1.8 lbs)

• TWF16:

Material SiN, Ø A = 26 mm (1.02 in), Lg = 800 mm (31.5 in): 1.4 kg (3.1 lbs)

Material Kanthal AF, Lg = 1000 mm (39.4 in): 0.6 kg (1.3 lbs)

Material NiCo, ¾" schedule 40s, Lg = 1000 mm (39.4 in): 1.9 kg (4.2 lbs)

Process connection

Type

Adjustable flange

Stop flange according to DIN EN 50446

• Max. temperature: +350 °C (+662 °F)

• Material: Aluminum

• Ø depends on sleeve (TWF11) or thermowell pipe (TWF16) diameter

• No gas tight connection

a0015177

• Max. temperature: +400 °C (+752 °F)

• Material: Cast iron

• No gas tight connection

• Counter flange and gasket is not provided

d2 in mm (in) a in mm (in) c in mm (in) clampable sleeve

diameter in mm (in):

23 (0.91) 90 (3.54) 70 (2.76) 21...22 (0.83...0.87) 60000516

33 (1.3) 90 (3.54) 70 (2.76) 31...33 (1.22...1.3) 60000517

Order numbers for reorder as

spare part:

16 (0.63) 75 (2.95) 55 (2.16) 14...15 (0.55...0.59) 60008385

29 (1.14) 90 (3.54) 70 (2.76) 27...28 (1.06...1.1) 71039792

a0015178

Endress+Hauser 5

Page 6

Type

Gas tight GCP assembly

• Max. temperature: +350 °C (+662 °F)

• Material: AISI 316Ti

• Maximum process pressure 1 bar (14.5 psi)

D C in mm (in) Clampable sleeve diameter

in mm (in)

G½" 15.5 (0.61)

17.5 (0.69)

G¾" 15.5 (0.61)

G1" 15.5 (0.61)

a0015179

G1¼" 29 (1.14) 27.5...28 (1.1) 55 71125353

G1½" 22.5 (0.89)

18 (0.71)

19 (0.75)

22.5 (0.89)

18 (0.71)

19 (0.75)

22.5 (0.89)

28 (1.1)

29 (1.14)

35 (1.38)

13.7...14 (0.54...0.55)

17...17.2 (0.67)

13.7...14 (0.54...0.55)

17...17.2 (0.67)

17.5...18 (0.69...0.71)

21.3...22 (0.84...0.86)

13.7...14 (0.54...0.55)

17...17.2 (0.67)

17.5...18 (0.69...0.71)

21.3...22 (0.84...0.86)

26.7...27 (1.05...1.06)

21.3...22 (0.84...0.86)

27.5...28 (1.1)

33.4...34 (1.32...1.34)

SW/Wr. Order numbers for reorder as

36

36

36

36

36

41

41

41

41

41

46

55

55

55

TWF11, TWF16

spare part

60019126

60019129

71031438

60019130

71125362

60020836

60022699

60021758

71125364

60021757

71001827

60021425

71125354

60022497

Installation conditions

Orientation Vertical and horizontal installation. A vertical installation should be preferred due to possible irreversible

bending of metal tubes and the brittleness of the ceramic materials, which could be hit by falling parts.

Installation instructions Recommended maximum immersion length Lg for horizontal mounting:

• 1500 mm (59 in) for diameter > 20 mm (0.8 in)

• 1200 mm (47.3 in) for diameter < 20 mm (0.8 in)

!

Note!

When installing longer lengths than the recommended maximum in horizontal position, the thermowell might

be bend irreversibly under its own weight in the hot environment.

Installation of ceramic sheaths

Thermowells made of ceramic (especially gas tight) are sensitive to fast temperature changes: in order to reduce

the risk of thermal shock and prevent the sheaths from failure, gas tight ceramic sheaths must be heated before

installation. Two possibilities are applicable:

• Installation with pre-heating

When the process is already operating at its running conditions at about 1000 °C (1832 °F) or more, the

ceramic part of the thermowell must be pre-heated from room temperature to 400 °C (752 °F). It is

suggested to use a horizontal, cylindrical cross-section oven or cover the ceramic part with electric heating

elements. Do not use direct flames.

It is suggested to pre-heat the ceramic sheath in situ and then proceed immediately with the insertion. The

measuring system shall be installed carefully with an insertion rate of 100 mm/min, avoiding any mechanical

shock. If it is not possible to run the pre-heating phase near the plant, the insertion rate must be lowered to

30 mm/min because of the cooling of the system during the transportation.

• Installation without pre-heating

If the process is running at its working temperature, the thermowell shall be installed inserting the ceramic

sheath in the plant for a length equal to the wall thickness (including the insulation material) and left in that

position for 2 hours.

After this time, the device shall be installed at a rate of 30 mm/min avoiding any mechanical shock. At

process temperature < 80 °C (176 °F) it is not necessary to consider any insertion rate. It is recommended

to avoid any impact or collision among the ceramic sheath and the components of the plant.

6 Endress+Hauser

Page 7

TWF11, TWF16

Certificates and approvals

CE Mark The device meets the legal requirements of the EC directives if applicable. Endress+Hauser confirms that the

device has been successfully tested by applying the CE mark.

Other standards and

guidelines

DIN EN 50446: Straight thermocouple assembly with metal or ceramic protection tube and accessories,

including terminal heads

PED approval The thermowells comply with paragraph 3.3 of the Pressure Equipment Directive (97/23/CE) and are not

marked separately.

Ordering information

This information provides an overview of the order options available. The information is not exhaustive,

however, and may not be fully up to date. More detailed information is available from your local

Endress+Hauser representative.

Product structure TWF11

Thermowell TWF11 - High temperature, max. 1600 °C (2912 °F)

010 Sheath material; Diameter Lg; max. length Lg, max. temperature:

AA C610; 14 mm; 600 mm; max. Temp. 1500 °C (2732 °F)

AB C610; 14 mm; 1000 mm; max. Temp. 1500 °C (2732 °F)

AC C610; 14 mm; 1500 mm; max. Temp. 1500 °C (2732 °F)

AD C610, 17 mm; 600 mm; max. Temp. 1500 °C (2732 °F)

AE C610; 17 mm; 1000 mm; max. Temp. 1500 °C (2732 °F)

AF C610; 17 mm; 1500 mm; max. Temp. 1500 °C (2732 °F)

AG C610; 24 mm; 600 mm; max. Temp. 1500 °C (2732 °F), internal sheath C610 diameter 17 mm

AH C610; 24 mm; 1000 mm; max. Temp. 1500 °C (2732 °F), internal sheath C610 diameter 17 mm

AJ C610; 24 mm; 1500 mm; max. Temp. 1500 °C (2732 °F), internal sheath C610 diameter 17 mm

BA SiC; 17 mm; 550 mm; max. Temp. 1600 °C (2912 °F)

BB SiC; 17 mm; 850 mm; max. Temp. 1600 °C (2912 °F)

BC SiC; 17 mm; 1150 mm; max. Temp. 1600 °C (2912 °F)

BD SiC; 26.6 mm; 600 mm; max. Temp. 1600 °C (2912 °F)

BE SiC; 26.6 mm; 800 mm; max. Temp. 1600 °C (2912 °F)

BF SiC; 26.6 mm; 1000 mm; max. Temp. 1600 °C (2912 °F)

BG SiC; 26.6 mm; 1200 mm; max. Temp. 1600 °C (2912 °F)

BH SiC; 26.6 mm; 1400 mm; max. Temp. 1600 °C (2912 °F)

BI SiC; 26.6 mm; 1700 mm; max. Temp. 1600 °C (2912 °F)

CA SiN; 16 mm; 600 mm; max. Temp. 1400 °C (2552 °F)

CB SiN; 16 mm; 900 mm; max. Temp. 1400 °C (2552 °F)

CC SiN; 16 mm; 1200 mm; max. Temp. 1400 °C (2552 °F)

CD SiN; 22 mm; 900 mm; max. Temp. 1400 °C (2552 °F)

CE SiN; 22 mm; 1100 mm; max. Temp. 1400 °C (2552 °F)

CF SiN; 22 mm; 1300 mm; max. Temp. 1400 °C (2552 °F)

CG SiN; 22 mm; 1500 mm; max. Temp. 1400 °C (2552 °F)

020 Immersion length Lg:

AA 250 mm

AB 300 mm

AC 400 mm

AD 450 mm

AE 500 mm

AF 550 mm

AG 600 mm

AH 700 mm

AI 750 mm

BA 800 mm

BB 850 mm

BC 900 mm

BD 1000 mm

BE 1050 mm

BF 1100 mm

BG 1150 mm

BH 1200 mm

BI 1300 mm

Endress+Hauser 7

Page 8

020 Immersion length Lg:

CA 1400 mm

CB 1500 mm

CD 1600 mm

CE 1700 mm

X1 ..... mm, as specified (300...600 mm)

X2 ..... mm, as specified (601...1000 mm)

X3 ..... mm, as specified (1001...1500 mm)

030 Sleeve length Lm; Diameter Lm; Material:

B 65 mm; 21.34 mm; AISI 304

F 100 mm; 21.34 mm; AISI 304

G 150 mm; 21.34 mm; AISI 304

H 200 mm; 21.34 mm; AISI 304

J 185 mm; 33.4 mm, AISI 304

K 300 mm; 33.7 mm; AISI 446

L 300 mm; 22 mm; AISI 446

M 400 mm; 33.4 mm; AISI 310

N 400 mm; 22 mm; AISI 310

040 Connection terminal head:

B Thread M24x1.5

F Groove for DIN A head

520 Process connection:

CA Adjustable flange, D=70 mm

CC Stop flange DIN EN 50446, 21...22 mm, clampable, d2=23 mm, a=90 mm, c=70 mm

CE Stop flange DIN EN 50446, 31...33 mm, clampable, d2=33 mm, a=90 mm, c=70 mm

CM GCP assembly, D=G ¾", C=22.5 mm, gas tight, clampable 21.3...22 mm, Wr.=41

CR GCP assembly, D=G 1", C=22.5 mm, gas tight, clampable 21.3...22 mm, Wr.=41

CU GCP assembly, D=G 1½", C=22.5 mm, gas tight, clampable 21.3...22 mm, Wr.=55

CW GCP assembly, D=G 1½", C=35 mm, gas tight, clampable 33.4...34 mm, Wr.=55

895 Marking:

Z1 Tagging (TAG), metal

Z3 Commissioning label, paper

Z6 Tagging (TAG), by customer

TWF11- Order code (complete)

TWF11, TWF16

8 Endress+Hauser

Page 9

TWF11, TWF16

Product structure TWF16

Thermowell TWF16 - High temperature, max. 1700 °C (3092 °F)

010 Material thermowell; maximum temperature:

A AISI 310; 1100 °C (2012 °F)

B AISI 316; 800 °C (1472 °F)

C AISI 446; 1100 °C (2012 °F)

D INCONEL 600; 1100 °C (2012 °F)

E INCONEL 601; 1200 °C (2192 °F)

F INCOLOY 800HT; 1100 °C (2012 °F) (with bar stock tip)

G Kanthal Super; 1700 °C (3092 °F)

H Kanthal AF; 1300 °C (2372 °F)

I Hastelloy X; 1200 °C (2192 °F)

J NiCo; 1200 °C (2192 °F)

K SiN; 1400 °C (2552 °F)

020 Thermowell diameter T:

A1 14 x 11 mm (AISI 310)

A2 17.2 x 14.2 mm (AISI 310)

A3 21.3 x 16.3 mm (AISI 310)

A4 22 x 18 mm (AISI 310)

A5 26.7 x 23.7 mm (AISI 310)

B1 21.3 x 15.76 mm (½" schedule 40, AISI 316)

B2 26.7 x 20.96 mm (¾" schedule 40, AISI316)

C1 21.3 x 15.76 mm (½" schedule 40, AISI 446)

C2 26.7 x 20.96 mm (¾" schedule 40, AISI 446)

D1 15 x 12 mm (INCONEL 600)

D2 17.2 x 13.2 mm (INCONEL 600)

D3 21.3 x 15.76 mm (½" schedule 40, INCONEL 600)

D4 22 x 18 mm (INCONEL 600)

D5 26.7 x 20.96 mm (¾" schedule 40, INCONEL 600)

E1 21.3 x 15.76 mm (½" schedule 40s, INCONEL 601

E2 22 x 18 mm (INCONEL 601)

F1 26.7 x 18.85 mm (¾", schedule 80, INCOLOY 800HT)

G1 18 x 10 mm (Kanthal Super), Lmax = 2000 mm

G2 22 x 13 mm (Kanthal Super) Lmax = 2000 mm

H1 21.3 x 15.76 mm (½" schedule 40, Hastelloy X)

H2 26.7 x 20.96 mm (¾" schedule 40, Hastelloy X)

J1 21.3 x 15.76 mm (½" schedule 40s, NiCo) Lmax = 2000mm

J2 26.7 x 20.96 mm (¾" schedule 40s, NiCo) Lmax = 2000mm

K1 22 x 19.4 mm (Kanthal AF), Lmax = 1000 mm

L1 22 x 12 mm (SiN), Lmax = 1550 mm

L2 28 x 16 mm (SiN), Lmax = 1550 mm

030 Thermowell length (immersion length Lg):

A1 660 mm (SiN)

A2 810 mm (SiN)

A3 960 mm (SiN)

A4 1060 mm (SiN)

A5 1160 mm (SiN)

A6 1260 mm (SiN)

A7 1560 mm (SiN)

X1 ..... mm (200...2000) only for Kanthal Super / NiCo

X2 ..... mm (200...1000) only for Kanthal AF

X3 ..... mm (200...2200)

040 Bar stock tip; Diameter:

0 Not needed

1 INCOLOY 800HT; 26.7 mm

2 NiCo; 21.3 mm

3 NiCo; 26.7 mm

050 Length bar stock tip (L2):

A0 Not needed

A1 300 mm

A2 400 mm

X1 ... mm (200...400)

060 Connection terminal head:

1 Thread M24x1.5

2 Groove for DIN A head

Endress+Hauser 9

Page 10

520 Process connection:

Instruments International

Endress+Hauser

Instruments International AG

Kaegenstrasse 2

4153 Reinach

Switzerland

Tel.+41 61 715 81 00

Fax+41 61 715 25 00

www.endress.com

info@ii.endress.com

CA Adjustable flange diameter 70 mm

CB Stop flange DIN EN 50446, 14...15 mm, clampable, d2=16 mm, a=75 mm,

c=55 mm

CC Stop flange DIN EN 50446, 21...22 mm, clampable, d2=23 mm, a=90 mm,

c=70 mm

CD Stop flange DIN EN 50446, 27...28 mm, clampable, d2=29 mm, a=90 mm,

c=70 mm

CH GCP assembly, D=G ½", C=15.5 mm, gas tight, clampable 13.7...15 mm, Wr.=36

CI GCP assembly, D=G ½", C=17.5 mm, gas tight, clampable 17...17.2 mm, Wr.=36

CJ GCP assembly, D=G ¾", C=15.5 mm, gas tight, clampable 13.7...15 mm, Wr.=36

CK GCP assembly, D=G ¾", C=18 mm, gas tight, clampable 17...17.2 mm, Wr.=36

CL GCP assembly, D=G ¾", C=19 mm, gas tight, clampable 17.5...18 mm, Wr.=36

CM GCP assembly, D=G ¾", C=22.5 mm, gas tight, clampable 21.3...22 mm, Wr.=41

CN GCP assembly, D=G 1", C=15.5 mm, gas tight, clampable 13.7...15 mm, Wr.=41

CP GCP assembly, D=G 1", C=18 mm, gas tight, clampable 17...17.2 mm, Wr.=41

CQ GCP assembly, D=G 1", C=19 mm, gas tight, clampable 17.5...18 mm, Wr.=41

CR GCP assembly, D=G 1", C=22.5 mm, gas tight, clampable 21.3...22 mm, Wr.=41

CS GCP assembly, D=G 1", C=28 mm, gas tight, clampable 26.7...27 mm, Wr.=46

CT GCP assembly, D=G 1 ¼", C=29 mm, gas tight, clampable 27.5...28 mm, Wr.=55

CU GCP assembly, D=G 1½", C=22.5 mm, gas tight, clampable 21.3...22 mm, Wr.=55

CV GCP assembly, D=G 1 ½", C=29 mm, gas tight, clampable 27.5...28 mm, Wr.=55

895 Marking:

Z1 Tagging (TAG), metal

Z3 Commissioning label, paper

Z6 Tagging (TAG), by customer

TWF16- Order code (complete)

TWF11, TWF16

Documentation

High temperature assemblies Omnigrad S TAF11, TAF12x, TAF16 (TI251t/02/en)

TI01015T/09/en/01.11

71131970

FM+SGML 6.0

Loading...

Loading...