Products Solutions Services

РЭ 000002R/01/05.16

BA01649T/09/EN/01.16

71369699

Operating instructions

Thermowells for thermometers

__________________________________________________________________________________

2

Thermowells for thermometers

__________________________________________________________________________________

Table of contents:

1 Scope and benefits .......................................................................................................................................................... 4

1.1 Scope ....................................................................................................................................................................... 4

1.2 Benefits ................................................................................................................................................................... 4

2 Construction ................................................................................................................................................................... 5

2.1 Genereal information ............................................................................................................................................. 5

2.2 Process temperature range .................................................................................................................................... 7

2.3 Mechanical construction of TA541 ...................................................................................................................... 8

2.4 Mechanical construction of TA414 ...................................................................................................................... 9

2.5 Mechanical construction of TA540 .................................................................................................................... 10

2.6 Mechanical construction of ТА556 .................................................................................................................... 11

2.7 Mechanical construction of ТА560 .................................................................................................................... 12

2.8 Mechanical construction of ТА565 .................................................................................................................... 13

2.9 Mechanical construction of ТА566..................................................................................................................... 14

2.10 Mechanical construction of ТА570, ТА571, ТА572 ....................................................................................... 15

2.11 Mechanical construction of ТА575, ТА576 .................................................................................................... 16

2.12 Mechanical construction of ТА535 .................................................................................................................. 17

2.13 Mechanical construction of ТА550 .................................................................................................................. 18

2.14 Mechanical construction of ТА555 .................................................................................................................. 19

2.15 Mechanical construction of ТА557 .................................................................................................................. 20

2.16 Mechanical construction of ТА562 .................................................................................................................. 21

2.17 Mechanical construction of ТW10 ................................................................................................................... 22

2.18 Mechanical construction of ТW11 ................................................................................................................... 23

2.19 Mechanical construction of ТW12 ................................................................................................................... 24

2.20 Mechanical construction of ТW13 ................................................................................................................... 25

2.21 Mechanical construction of ТW15 ................................................................................................................... 26

2.22 Mechanical construction of ТW45 ................................................................................................................... 27

2.23 Mechanical construction of ТW47 ................................................................................................................... 28

2.24 Mechanical construction of MLTWS01 ............................................................................................................ 29

2.25 Mechanical construction of TW251 ................................................................................................................. 30

2.26 Mechanical construction of TWF11 и TWF16 ................................................................................................ 31

2.27 Mechanical construction of TT411 ................................................................................................................... 32

2.28 Mechanical construction of TT511 ................................................................................................................... 33

2.29 Mechanical construction of TTSP ...................................................................................................................... 34

3 Installation .................................................................................................................................................................... 35

4 Comissioning ................................................................................................................................................................ 36

5 Maintenance and repair .............................................................................................................................................. 36

6 Storage and transport .................................................................................................................................................. 36

7 Conservation ................................................................................................................................................................. 36

8 Assigned indicators ...................................................................................................................................................... 36

9 Limit state criteria ....................................................................................................................................................... 36

10 Occurrence of critical failures ................................................................................................................................... 36

11 Dismantling ................................................................................................................................................................. 36

12 Disposal ....................................................................................................................................................................... 37

13 Marking ...................................................................................................................................................................... 37

14 Manufacturer ............................................................................................................................................................. 37

3

Thermowells for thermometers

__________________________________________________________________________________

1 Scope and benefits

1.1 Scope

Thermowells are used for the following purposes:

• To protect thermometers from mechanical and chemical influences of the processes.

• To protect thermometers from unfluences of pressure in pipelines, reactors and tanks.

1.2 Benefits

Thermowells are made from bar stock and from pipe.

Process connection can be threaded, flanged, welded and clamp.

Thermowells are made of different materials that provide corrosion resistance in any of the process.

Possibility of calibration, repair and maintenance of thermometer without stopping of the process.

4

Thermowells for thermometers

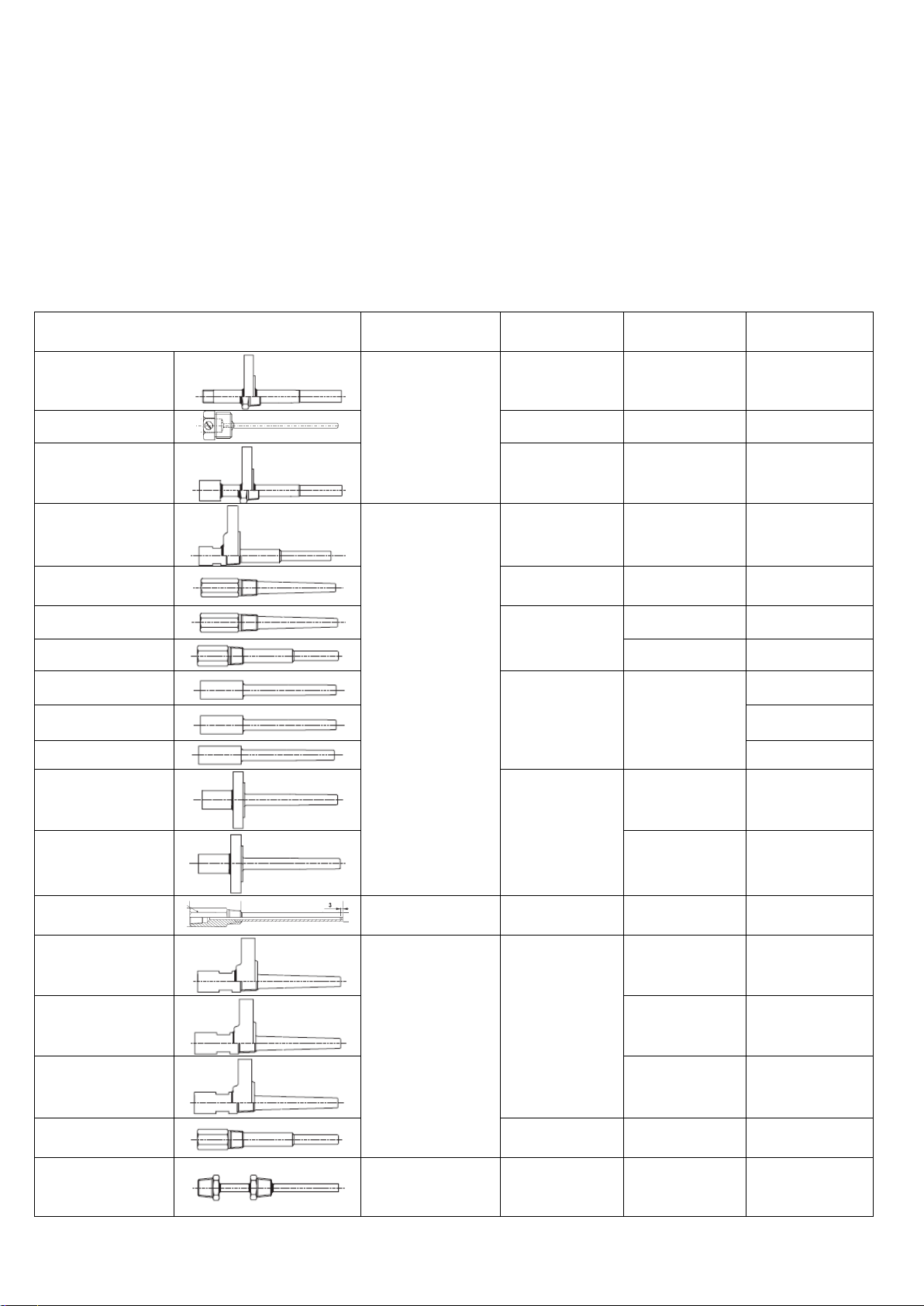

Thermowell model

Type

Material

1

Process

connection

max. process

pressure, MPa2

TA541

Welded extension

pipe

AISI 316, 316L,

A105, 446

Flange DN 25;

50

10

TA414

AISI 316Ti

Thread G1/2”

1

TA540

AISI 316, 316L,

A105, 446

Flange DN 25;

50

10

TA556

Bar stock

AISI 316, 316L

Flange DN 25;

50

30

TA560

AISI 304, 316,

316L, 316Ti

Thread

3/4”NPT

30

TA565

AISI 316, 316L,

316Ti

Thread 1”NPT

30

TA566

Thread 1”NPT

30

TA570

AISI 316, 316L,

316Ti, 321

Socket weld-in

30

TA571

30

TA572

30

TA575

AISI 316, 316L,

316Ti, A105

Flange DN 25;

50

10

TA576

Flange DN 25;

50

30

TA535

Welded extension

pipe

AISI 316L

Threads ½”, ¾”

7,5

TA550

Bar stock

AISI 316, 316L

Flange DN 25;

50

30

TA555

Flange DN 25;

50

30

TA557

Flange DN 25;

50

30

TA562

AISI 316, 316L,

316Ti

Threads ½”, ¾”

30

TW10

Welded extension

pipe

AISI 316L,

316Ti,

Hastelloy C

Threads ½”, ¾”

7,5

__________________________________________________________________________________

2 Construction

2.1 Genereal information

Endress+Hauser offers a complete range of standardized thermowells. Its construction covers a very large

amount of industrial standards as DIN, Dow Chemical, Du Pont, ENI, etc.

Two different types of thermowell construction are available: from drilled bar stock and from pipe.

Herein you can find general information about thermowells.

5

Thermowells for thermometers

TW11

AISI 316L,

316Ti

Threads ½”, ¾”

7,5

TW12

Welded extension

pipe

Compression

fitting

4

TW13

AISI 316L,

316Ti,

Hastelloy C276,

Inconel 600,

PTFE, PVDF,

Tantalum

Flange DN 25;

50

7,5

TW15

AISI 316Ti,

A182, A105,

Hastelloy C276,

Titanium,

Duplex

SAF2205,

1.5415, 1.7380

Flange DN 25;

50

30

TW45

AISI 316L

Hygienic

adapters up to

2”

4

TW47

Bar stock

Socket weld-in

4

MLTWS01

Welded extension

pipe

AISI 316Ti

Flange DN 25

6,3

TW251

AISI 316L

Socket weld-in,

Threads ¼”, ½”

5

TWF11

AISI 316L, 310,

304, 446,

Inconel 600,

601, Incoloy

800, Hastelloy

X, Kanthal AF,

сплав NiCО,

керамические

материалы:

C610, SiC

сплав, Kanthal

Super, SiN

сплав

Compression

fitting

0,5

TWF16

0,5

TT411

Welded extension

pipe / Bar stock

AISI 316L,

1.4435+316L

Hygienic

adapters up to

2”

0,1

TT511

Bar stock

AISI 316,

A105, 316Ti

Flange DN 25;

50

0,1

TTSP-WT****

Special version,

any construction

Any of

materials

Any of

connections

Any of pressure

__________________________________________________________________________________

1

– depends of ordercode, for special version can be different

2

– depends of ordercode

6

Thermowells for thermometers

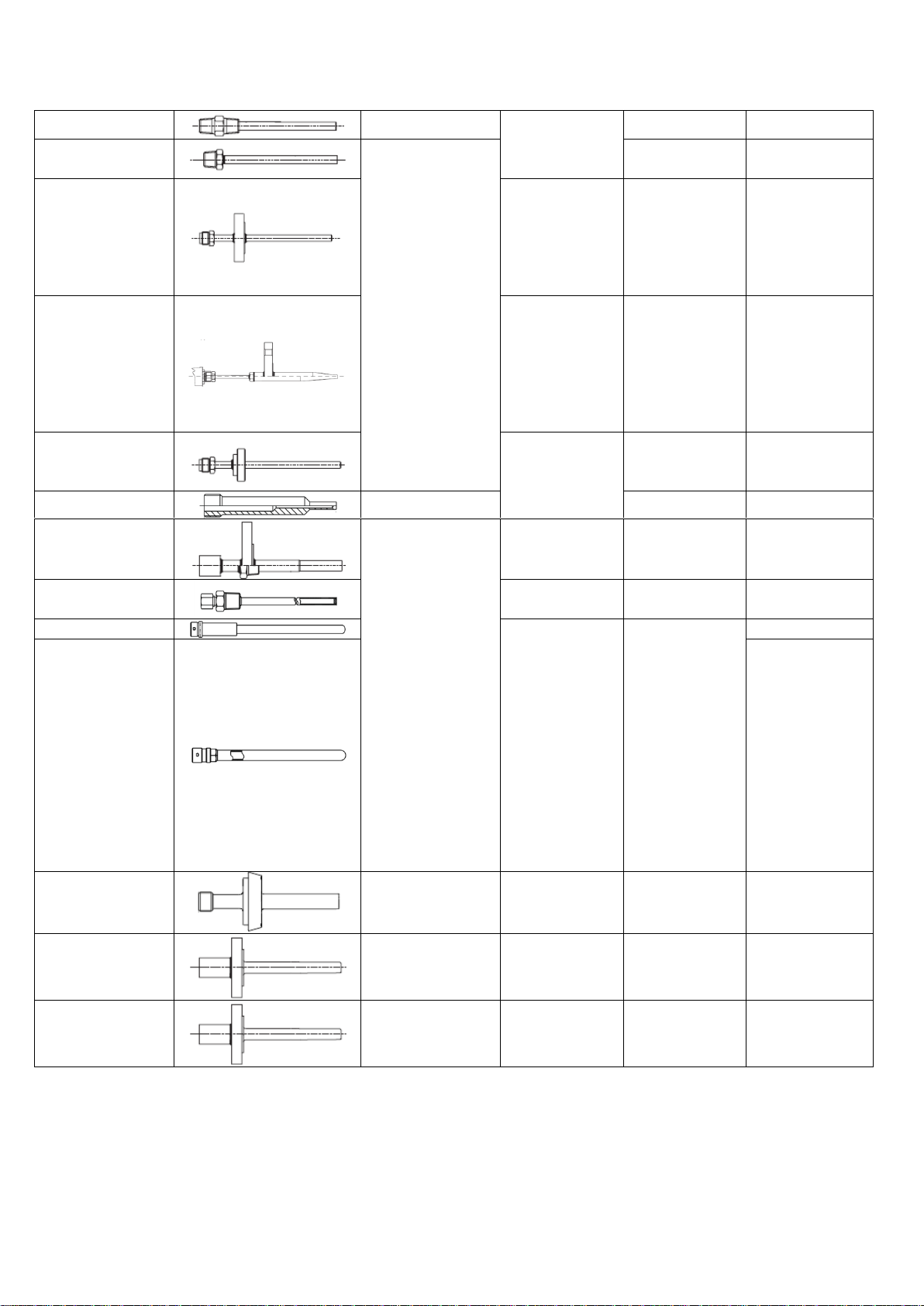

Thermowell material

Max. process temperature, С

AISI 316

650

AISI 316Ti

700

AISI 316L

650

AISI 321

650

AISI 446

1100

A105 (C22.8)

450

Hastelloy C276

1100

Inconel 600

1100

Tantalum

250

PTFE

200

PVDF

280

Titanium

600

Duplex SAF2205

300

1.5415

530

1.7380

550

AISI 304

850

AISI 310

1100

Inconel 601

1200

Incoloy 800

1100

Hastelloy X

1100

Kanthal AF

1300

NiCo

1200

SiC

1650

Kanthal Super

1700

SiN

1400

C530

1400

C610

1500

C799

1800

__________________________________________________________________________________

2.2 Process temperature range

Process temperature range depends of thermowell material, herein you can find maximum process temperature

ranges:

7

Thermowells for thermometers

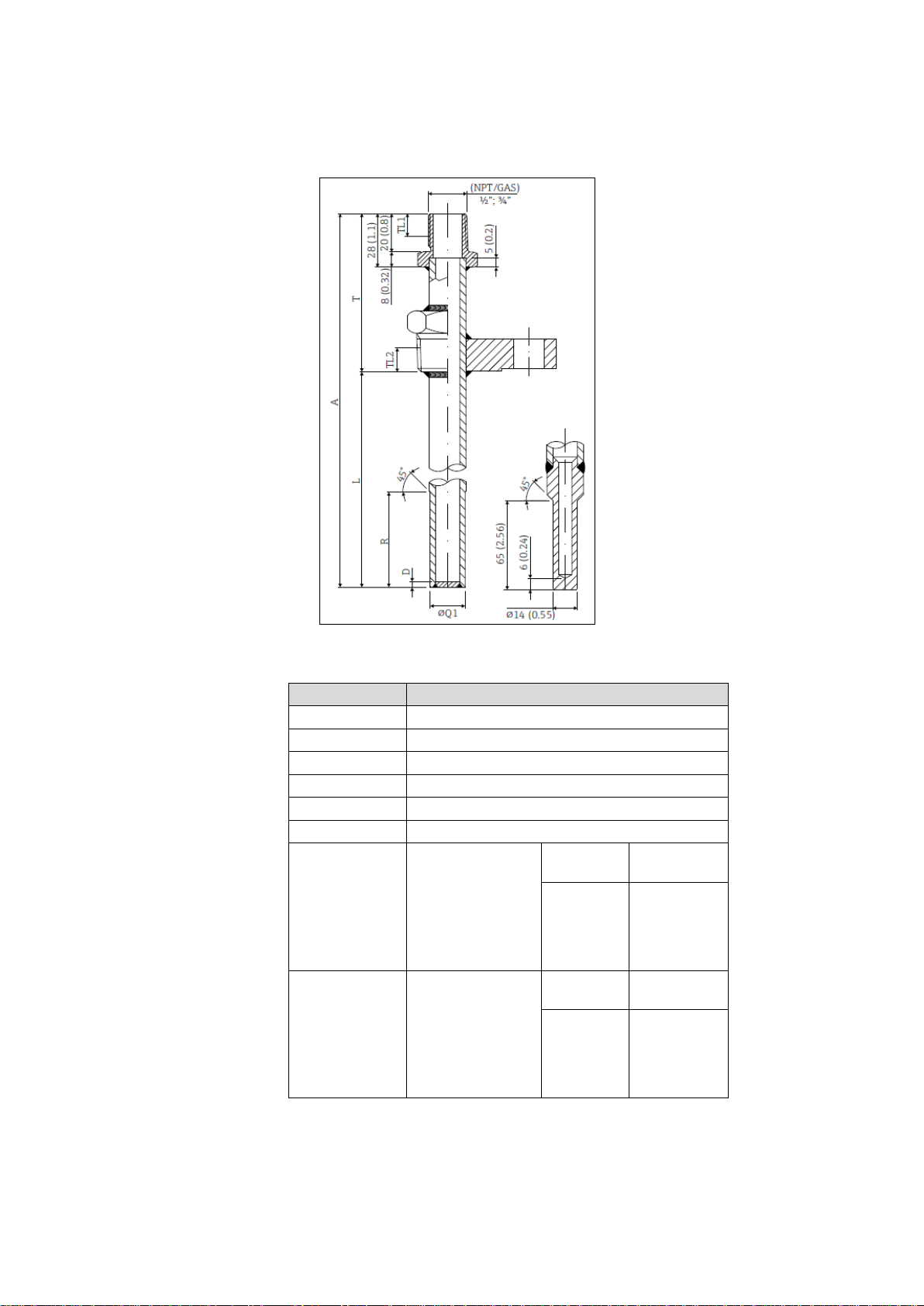

Position

Description

A

Total length (A=T+L)

L

Immersion length

øQ1

Diameter protection tube tip

R

Length of protection tube tip

T

Extension

D

Bottom thickness

TL1

Thread length for

thread connection

on thermometer

Length in

mm

Thread

20

8

8,5

G½", G¾"

½" NPT

¾" NPT

TL2

Thread length for

thread connection

on process

Length in

mm

Thread

8,5

10

10,5

¾" NPT

1" NPT

1½"NPT

__________________________________________________________________________________

2.3 Mechanical construction of TA541

Pic. 1 – thermowell ТА541 – dimensions in mm (in)

Thermowell ТА541 is made from pipe with bottom thickness 5 mm, outer diameter 13,7mm, 21,34mm or

26,67mm (depends of ordercode), threaded or flanged process connections.

8

Thermowells for thermometers

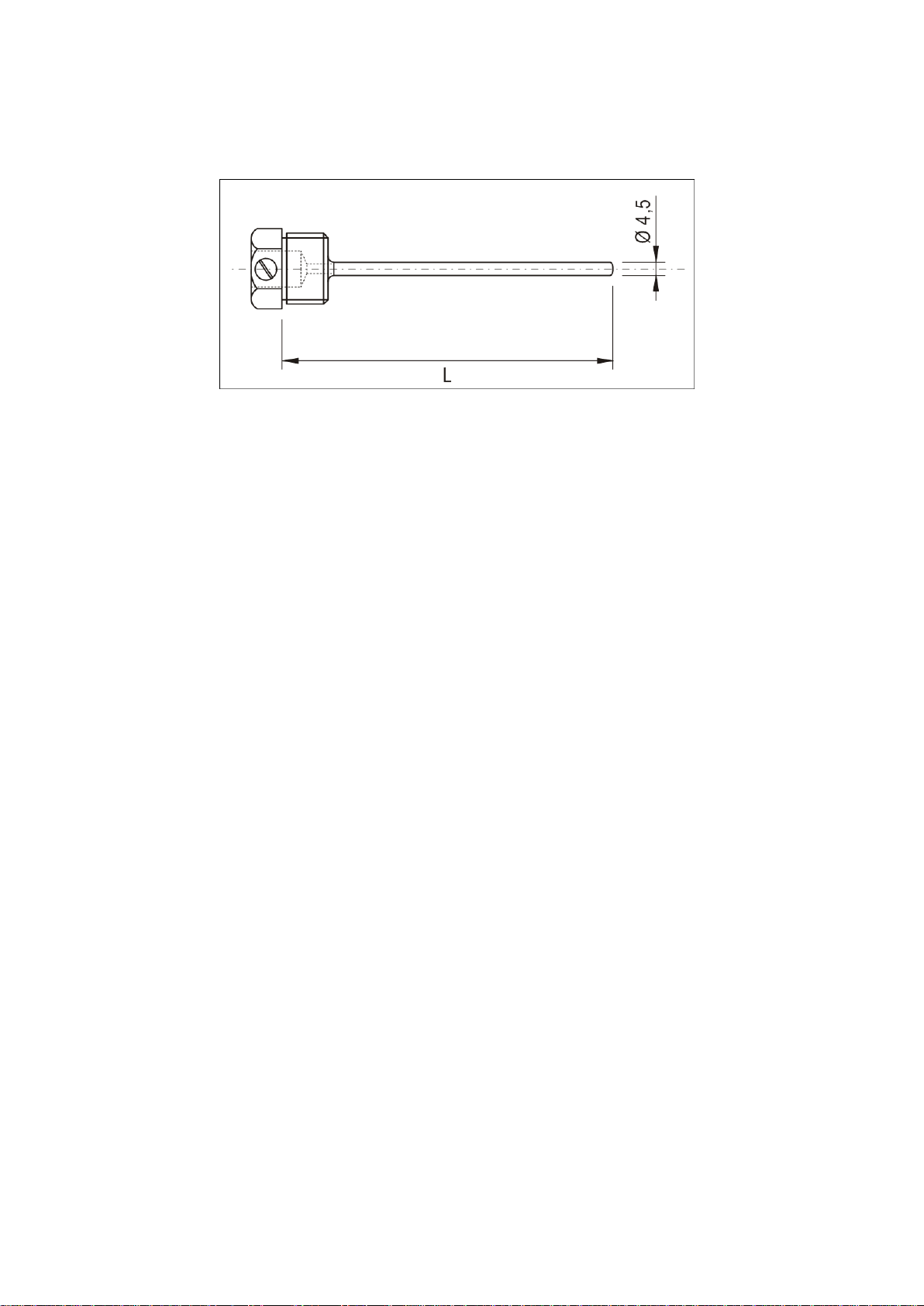

__________________________________________________________________________________

2.4 Mechanical construction of TA414

Pic.2 – thermowell TA414 – dimensions in mm

L – immersion length

Thermowell ТА414 is made from pipe with bottom thickness 3 mm, outer diameter 4,5mm, threaded process

connections, thermowell is used for thermometers with diameter of measuring insert 3 mm.

9

Thermowells for thermometers

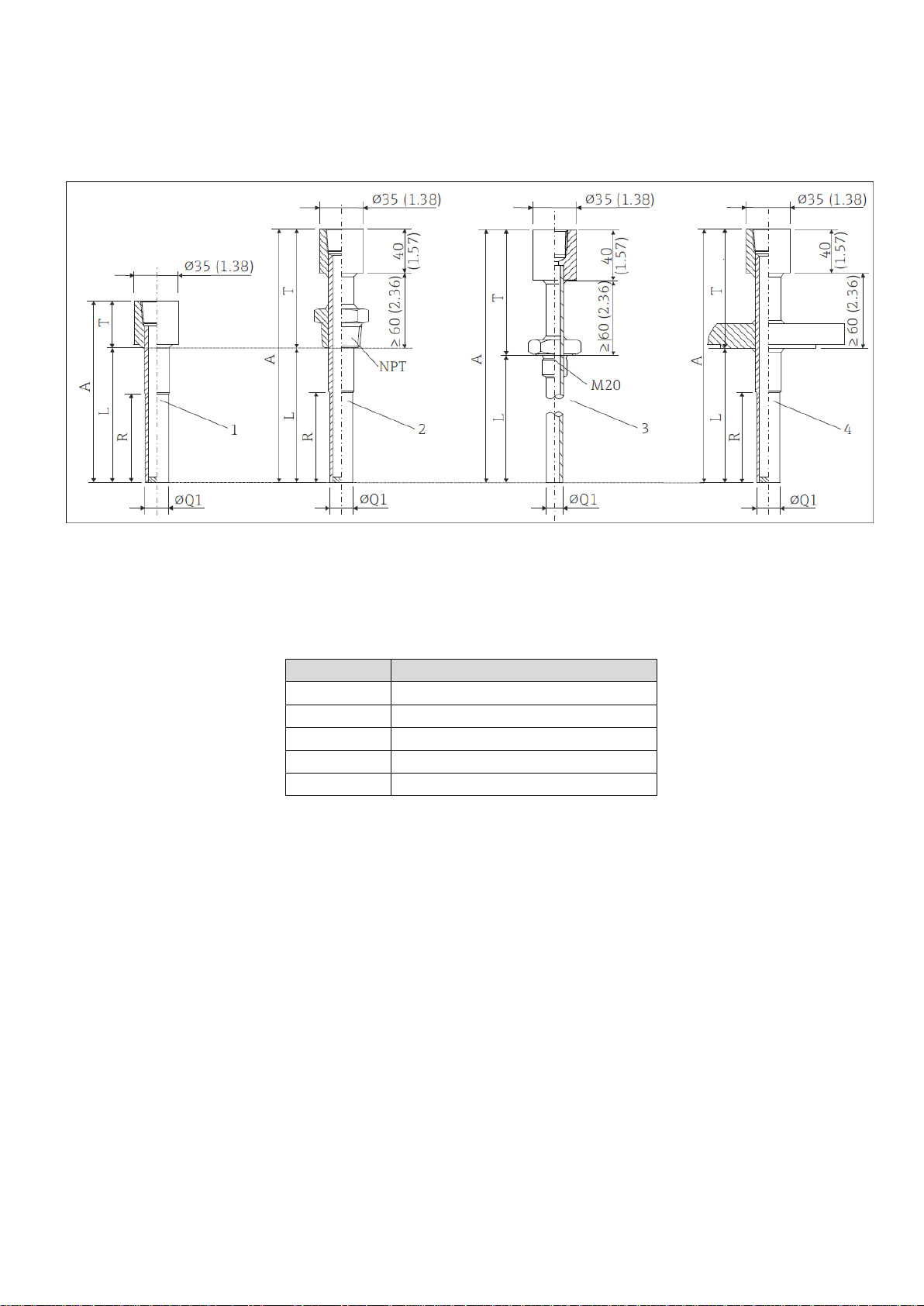

Position

Description

A

Total length (A=T+L)

L

Immersion length

øQ1

Diameter protection tube tip

R

Length of protection tube tip

T

Extension

__________________________________________________________________________________

2.5 Mechanical construction of TA540

Pic. 3 – thermowell ТА540 – dimensions in mm (in)

1 without process connection

2 thread NPT

3 thread М20

4 flanged process connection

Thermowell ТА540 is made from pipe with bottom thickness 5 mm, outer diameter 13,7mm, 21,34mm or

26,67mm (depends of ordercode), threaded or flanged process connections.

10

Thermowells for thermometers

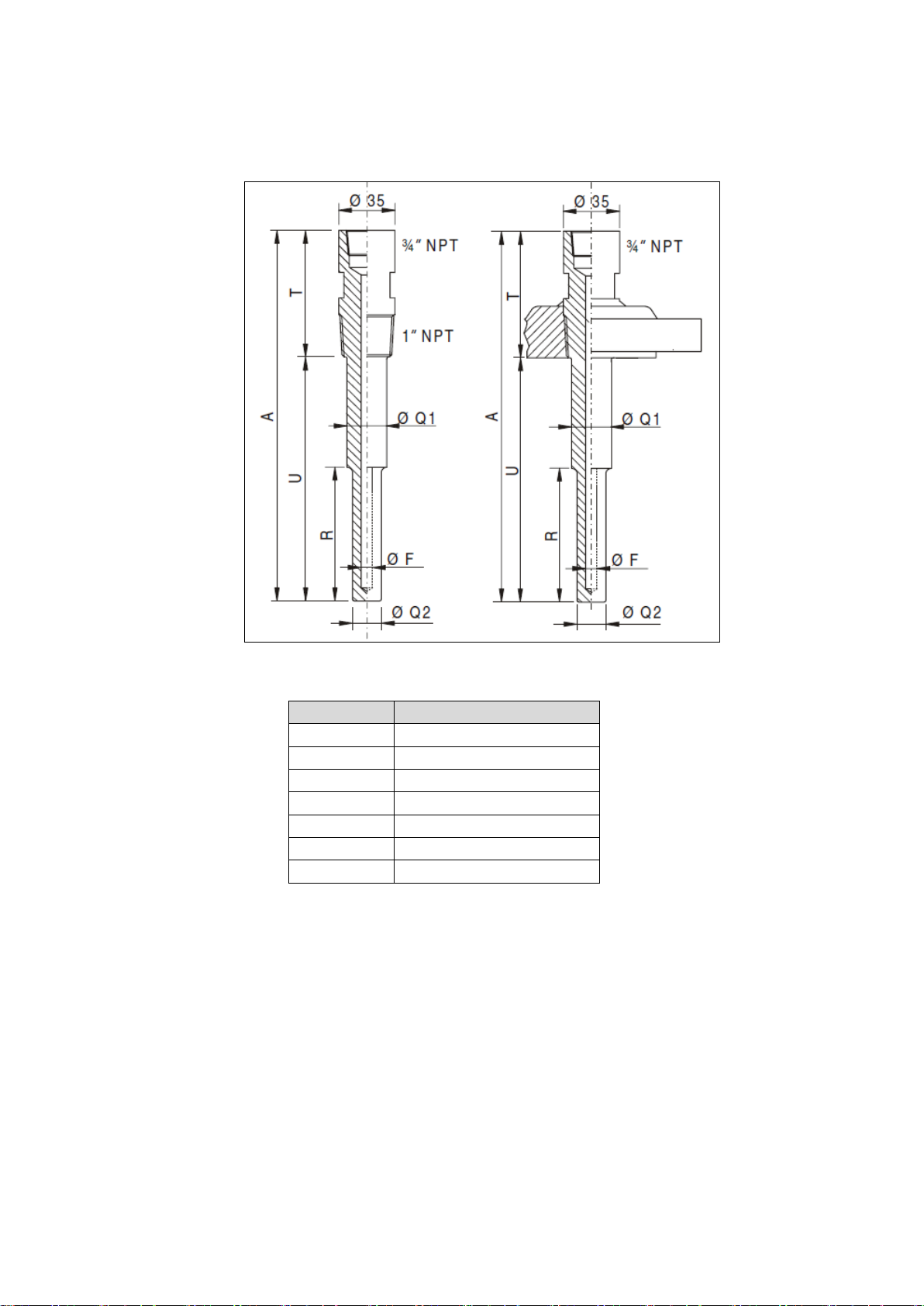

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

R

Length of protection tube tip

T

Extension

øF

Bore diameter

__________________________________________________________________________________

2.6 Mechanical construction of ТА556

Pic. 4 – thermowell ТА556 - dimensions in mm (in)

Thermowell ТА556 is made from round bar stock (drilled) with bore diameter 10 mm or 14mm (special version

for other diameters), cylindrical form with straight or tapered bottom shape, threaded or flanged process

connections.

11

Thermowells for thermometers

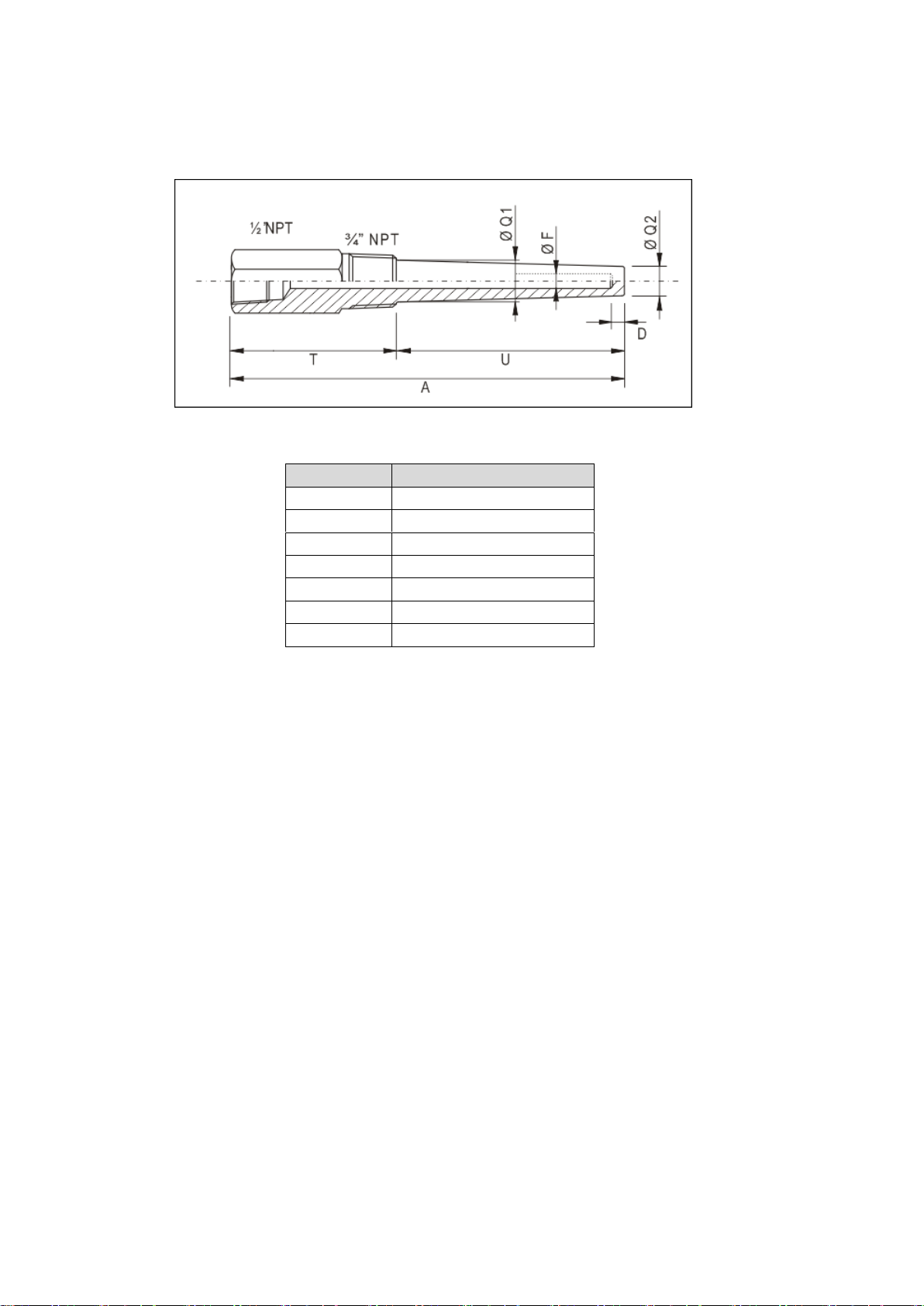

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øF

Bore diameter

D

Bottom thickness

__________________________________________________________________________________

2.7 Mechanical construction of ТА560

Pic. 5 – thermowell ТА560

Thermowell ТА560 is made from round bar stock (drilled) with bore diameter 6.5 mm or 10 mm (special version

for other diameters), cylindrical form with straight or tapered bottom shape, threaded process and thermometer

connections.

12

Loading...

Loading...