Page 1

Products Solutions Services

РЭ 000002R/01/05.16

BA01649T/09/EN/01.16

71369699

Operating instructions

Thermowells for thermometers

Page 2

__________________________________________________________________________________

2

Page 3

Thermowells for thermometers

__________________________________________________________________________________

Table of contents:

1 Scope and benefits .......................................................................................................................................................... 4

1.1 Scope ....................................................................................................................................................................... 4

1.2 Benefits ................................................................................................................................................................... 4

2 Construction ................................................................................................................................................................... 5

2.1 Genereal information ............................................................................................................................................. 5

2.2 Process temperature range .................................................................................................................................... 7

2.3 Mechanical construction of TA541 ...................................................................................................................... 8

2.4 Mechanical construction of TA414 ...................................................................................................................... 9

2.5 Mechanical construction of TA540 .................................................................................................................... 10

2.6 Mechanical construction of ТА556 .................................................................................................................... 11

2.7 Mechanical construction of ТА560 .................................................................................................................... 12

2.8 Mechanical construction of ТА565 .................................................................................................................... 13

2.9 Mechanical construction of ТА566..................................................................................................................... 14

2.10 Mechanical construction of ТА570, ТА571, ТА572 ....................................................................................... 15

2.11 Mechanical construction of ТА575, ТА576 .................................................................................................... 16

2.12 Mechanical construction of ТА535 .................................................................................................................. 17

2.13 Mechanical construction of ТА550 .................................................................................................................. 18

2.14 Mechanical construction of ТА555 .................................................................................................................. 19

2.15 Mechanical construction of ТА557 .................................................................................................................. 20

2.16 Mechanical construction of ТА562 .................................................................................................................. 21

2.17 Mechanical construction of ТW10 ................................................................................................................... 22

2.18 Mechanical construction of ТW11 ................................................................................................................... 23

2.19 Mechanical construction of ТW12 ................................................................................................................... 24

2.20 Mechanical construction of ТW13 ................................................................................................................... 25

2.21 Mechanical construction of ТW15 ................................................................................................................... 26

2.22 Mechanical construction of ТW45 ................................................................................................................... 27

2.23 Mechanical construction of ТW47 ................................................................................................................... 28

2.24 Mechanical construction of MLTWS01 ............................................................................................................ 29

2.25 Mechanical construction of TW251 ................................................................................................................. 30

2.26 Mechanical construction of TWF11 и TWF16 ................................................................................................ 31

2.27 Mechanical construction of TT411 ................................................................................................................... 32

2.28 Mechanical construction of TT511 ................................................................................................................... 33

2.29 Mechanical construction of TTSP ...................................................................................................................... 34

3 Installation .................................................................................................................................................................... 35

4 Comissioning ................................................................................................................................................................ 36

5 Maintenance and repair .............................................................................................................................................. 36

6 Storage and transport .................................................................................................................................................. 36

7 Conservation ................................................................................................................................................................. 36

8 Assigned indicators ...................................................................................................................................................... 36

9 Limit state criteria ....................................................................................................................................................... 36

10 Occurrence of critical failures ................................................................................................................................... 36

11 Dismantling ................................................................................................................................................................. 36

12 Disposal ....................................................................................................................................................................... 37

13 Marking ...................................................................................................................................................................... 37

14 Manufacturer ............................................................................................................................................................. 37

3

Page 4

Thermowells for thermometers

__________________________________________________________________________________

1 Scope and benefits

1.1 Scope

Thermowells are used for the following purposes:

• To protect thermometers from mechanical and chemical influences of the processes.

• To protect thermometers from unfluences of pressure in pipelines, reactors and tanks.

1.2 Benefits

Thermowells are made from bar stock and from pipe.

Process connection can be threaded, flanged, welded and clamp.

Thermowells are made of different materials that provide corrosion resistance in any of the process.

Possibility of calibration, repair and maintenance of thermometer without stopping of the process.

4

Page 5

Thermowells for thermometers

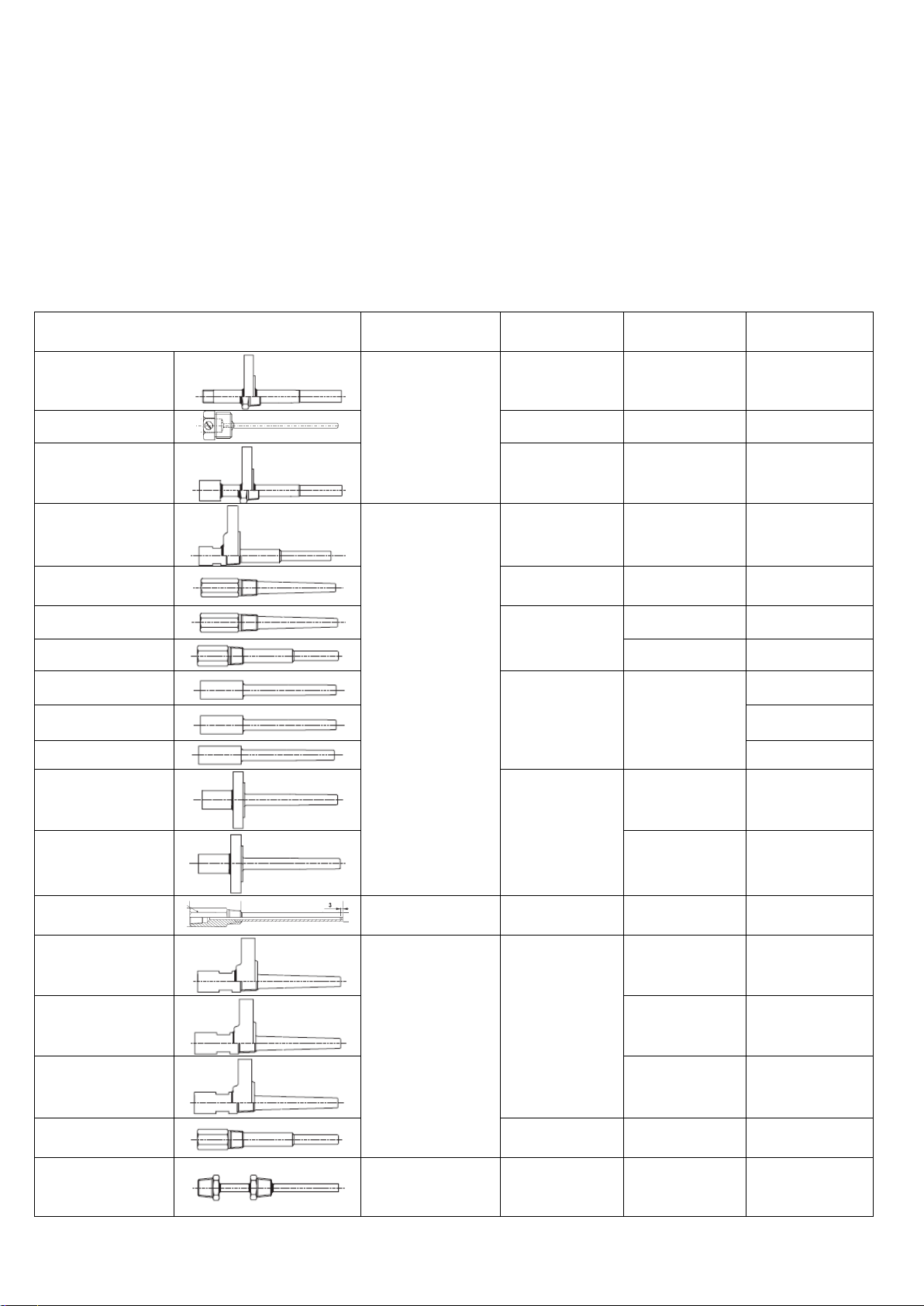

Thermowell model

Type

Material

1

Process

connection

max. process

pressure, MPa2

TA541

Welded extension

pipe

AISI 316, 316L,

A105, 446

Flange DN 25;

50

10

TA414

AISI 316Ti

Thread G1/2”

1

TA540

AISI 316, 316L,

A105, 446

Flange DN 25;

50

10

TA556

Bar stock

AISI 316, 316L

Flange DN 25;

50

30

TA560

AISI 304, 316,

316L, 316Ti

Thread

3/4”NPT

30

TA565

AISI 316, 316L,

316Ti

Thread 1”NPT

30

TA566

Thread 1”NPT

30

TA570

AISI 316, 316L,

316Ti, 321

Socket weld-in

30

TA571

30

TA572

30

TA575

AISI 316, 316L,

316Ti, A105

Flange DN 25;

50

10

TA576

Flange DN 25;

50

30

TA535

Welded extension

pipe

AISI 316L

Threads ½”, ¾”

7,5

TA550

Bar stock

AISI 316, 316L

Flange DN 25;

50

30

TA555

Flange DN 25;

50

30

TA557

Flange DN 25;

50

30

TA562

AISI 316, 316L,

316Ti

Threads ½”, ¾”

30

TW10

Welded extension

pipe

AISI 316L,

316Ti,

Hastelloy C

Threads ½”, ¾”

7,5

__________________________________________________________________________________

2 Construction

2.1 Genereal information

Endress+Hauser offers a complete range of standardized thermowells. Its construction covers a very large

amount of industrial standards as DIN, Dow Chemical, Du Pont, ENI, etc.

Two different types of thermowell construction are available: from drilled bar stock and from pipe.

Herein you can find general information about thermowells.

5

Page 6

Thermowells for thermometers

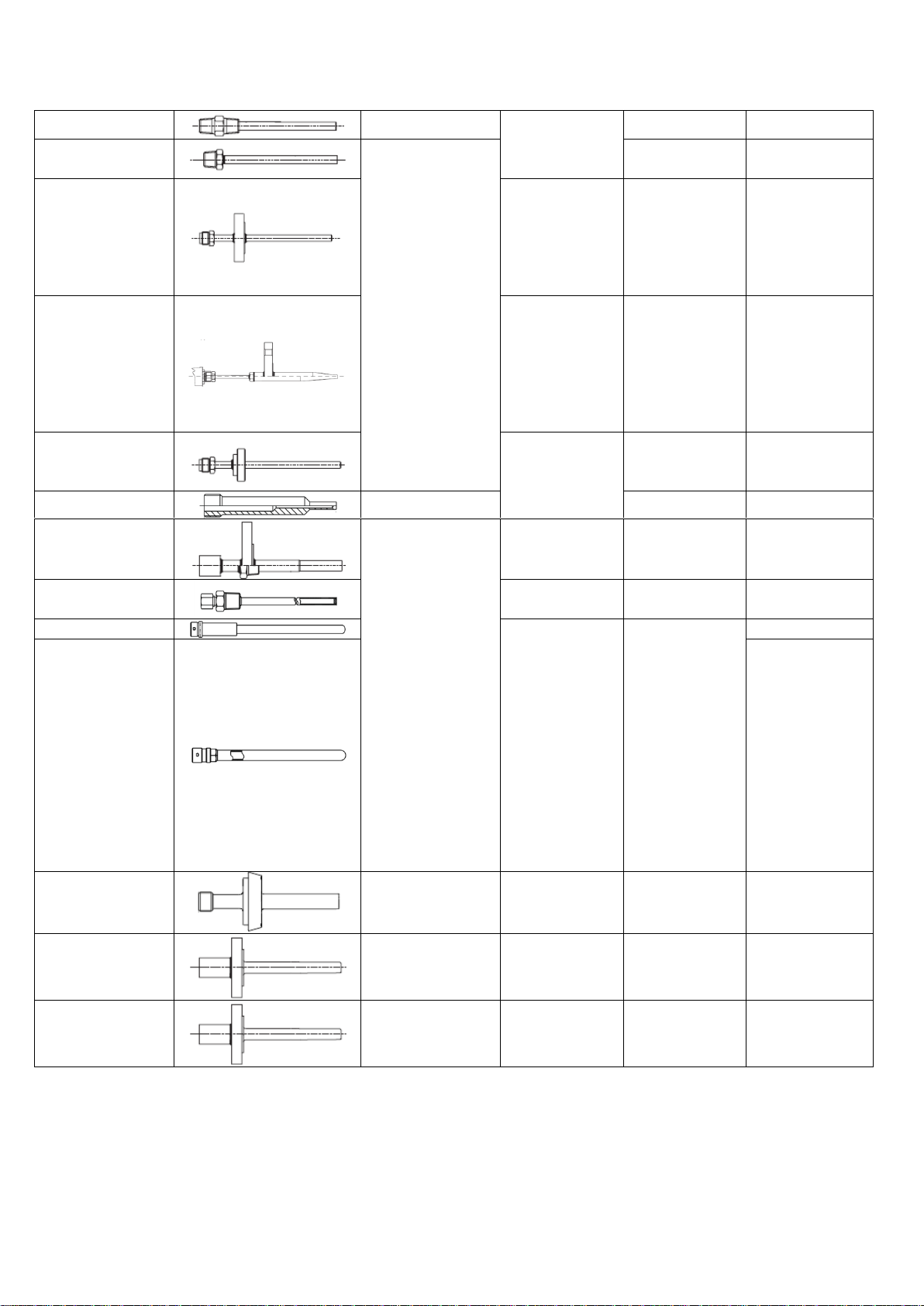

TW11

AISI 316L,

316Ti

Threads ½”, ¾”

7,5

TW12

Welded extension

pipe

Compression

fitting

4

TW13

AISI 316L,

316Ti,

Hastelloy C276,

Inconel 600,

PTFE, PVDF,

Tantalum

Flange DN 25;

50

7,5

TW15

AISI 316Ti,

A182, A105,

Hastelloy C276,

Titanium,

Duplex

SAF2205,

1.5415, 1.7380

Flange DN 25;

50

30

TW45

AISI 316L

Hygienic

adapters up to

2”

4

TW47

Bar stock

Socket weld-in

4

MLTWS01

Welded extension

pipe

AISI 316Ti

Flange DN 25

6,3

TW251

AISI 316L

Socket weld-in,

Threads ¼”, ½”

5

TWF11

AISI 316L, 310,

304, 446,

Inconel 600,

601, Incoloy

800, Hastelloy

X, Kanthal AF,

сплав NiCО,

керамические

материалы:

C610, SiC

сплав, Kanthal

Super, SiN

сплав

Compression

fitting

0,5

TWF16

0,5

TT411

Welded extension

pipe / Bar stock

AISI 316L,

1.4435+316L

Hygienic

adapters up to

2”

0,1

TT511

Bar stock

AISI 316,

A105, 316Ti

Flange DN 25;

50

0,1

TTSP-WT****

Special version,

any construction

Any of

materials

Any of

connections

Any of pressure

__________________________________________________________________________________

1

– depends of ordercode, for special version can be different

2

– depends of ordercode

6

Page 7

Thermowells for thermometers

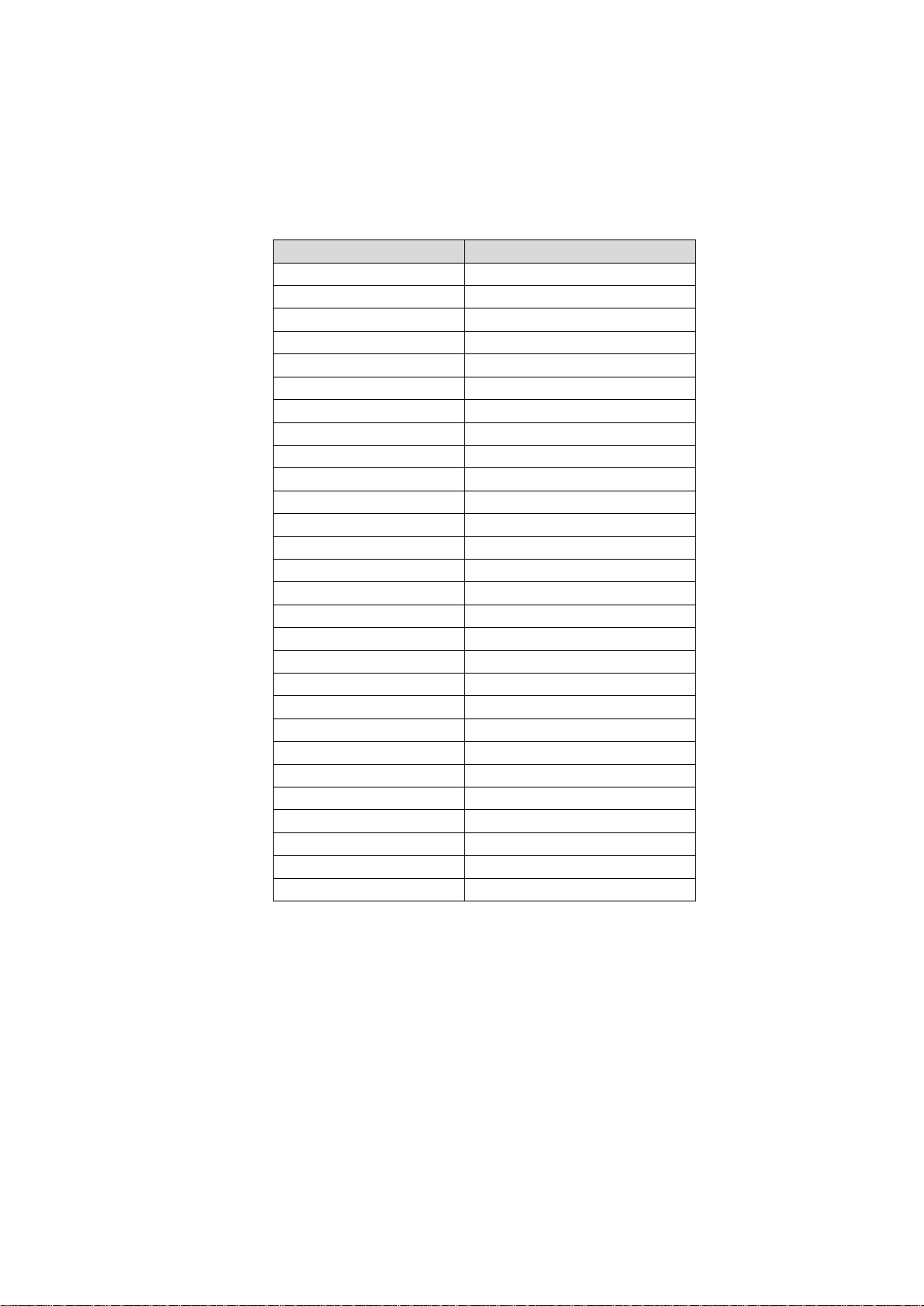

Thermowell material

Max. process temperature, С

AISI 316

650

AISI 316Ti

700

AISI 316L

650

AISI 321

650

AISI 446

1100

A105 (C22.8)

450

Hastelloy C276

1100

Inconel 600

1100

Tantalum

250

PTFE

200

PVDF

280

Titanium

600

Duplex SAF2205

300

1.5415

530

1.7380

550

AISI 304

850

AISI 310

1100

Inconel 601

1200

Incoloy 800

1100

Hastelloy X

1100

Kanthal AF

1300

NiCo

1200

SiC

1650

Kanthal Super

1700

SiN

1400

C530

1400

C610

1500

C799

1800

__________________________________________________________________________________

2.2 Process temperature range

Process temperature range depends of thermowell material, herein you can find maximum process temperature

ranges:

7

Page 8

Thermowells for thermometers

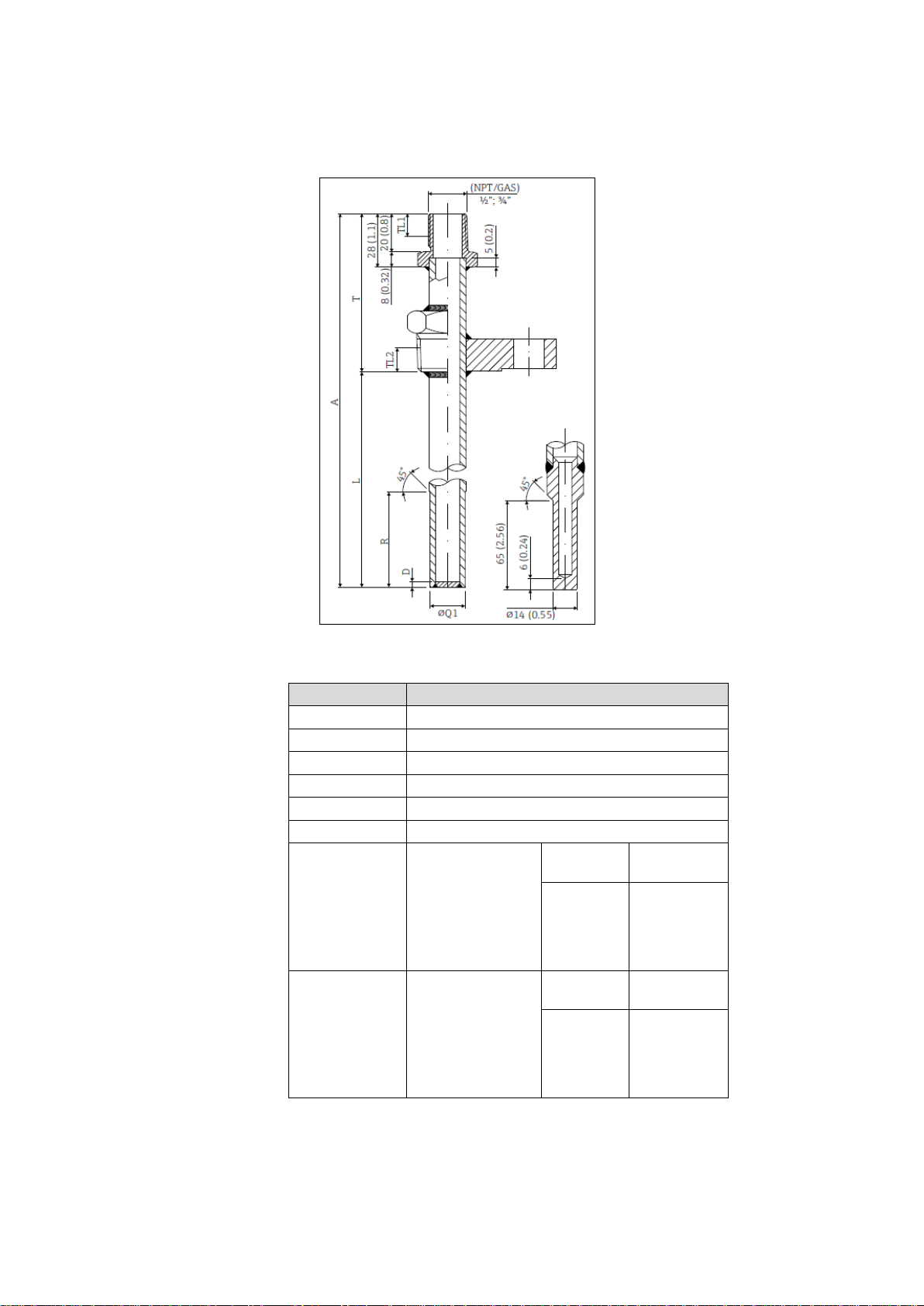

Position

Description

A

Total length (A=T+L)

L

Immersion length

øQ1

Diameter protection tube tip

R

Length of protection tube tip

T

Extension

D

Bottom thickness

TL1

Thread length for

thread connection

on thermometer

Length in

mm

Thread

20

8

8,5

G½", G¾"

½" NPT

¾" NPT

TL2

Thread length for

thread connection

on process

Length in

mm

Thread

8,5

10

10,5

¾" NPT

1" NPT

1½"NPT

__________________________________________________________________________________

2.3 Mechanical construction of TA541

Pic. 1 – thermowell ТА541 – dimensions in mm (in)

Thermowell ТА541 is made from pipe with bottom thickness 5 mm, outer diameter 13,7mm, 21,34mm or

26,67mm (depends of ordercode), threaded or flanged process connections.

8

Page 9

Thermowells for thermometers

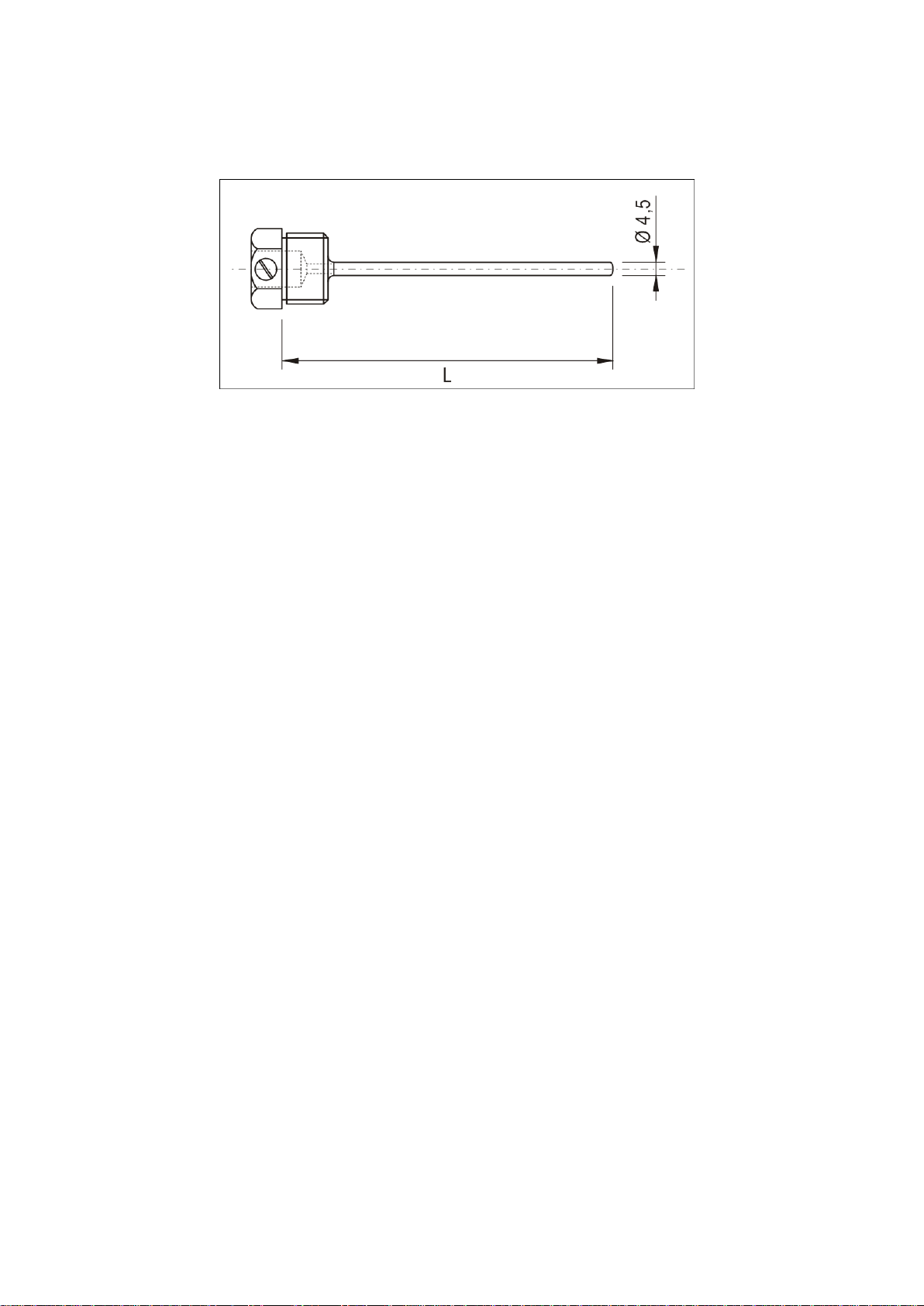

__________________________________________________________________________________

2.4 Mechanical construction of TA414

Pic.2 – thermowell TA414 – dimensions in mm

L – immersion length

Thermowell ТА414 is made from pipe with bottom thickness 3 mm, outer diameter 4,5mm, threaded process

connections, thermowell is used for thermometers with diameter of measuring insert 3 mm.

9

Page 10

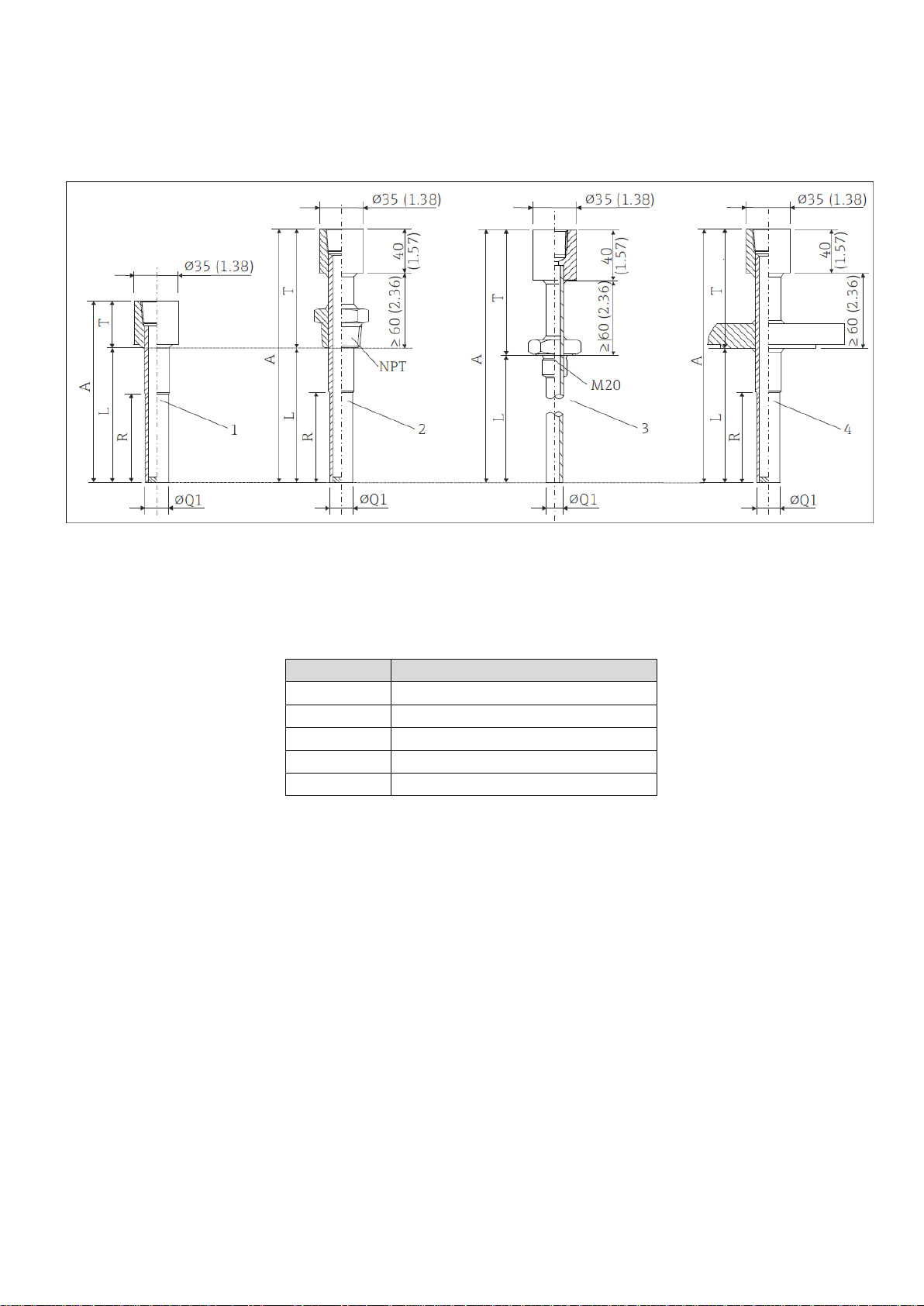

Thermowells for thermometers

Position

Description

A

Total length (A=T+L)

L

Immersion length

øQ1

Diameter protection tube tip

R

Length of protection tube tip

T

Extension

__________________________________________________________________________________

2.5 Mechanical construction of TA540

Pic. 3 – thermowell ТА540 – dimensions in mm (in)

1 without process connection

2 thread NPT

3 thread М20

4 flanged process connection

Thermowell ТА540 is made from pipe with bottom thickness 5 mm, outer diameter 13,7mm, 21,34mm or

26,67mm (depends of ordercode), threaded or flanged process connections.

10

Page 11

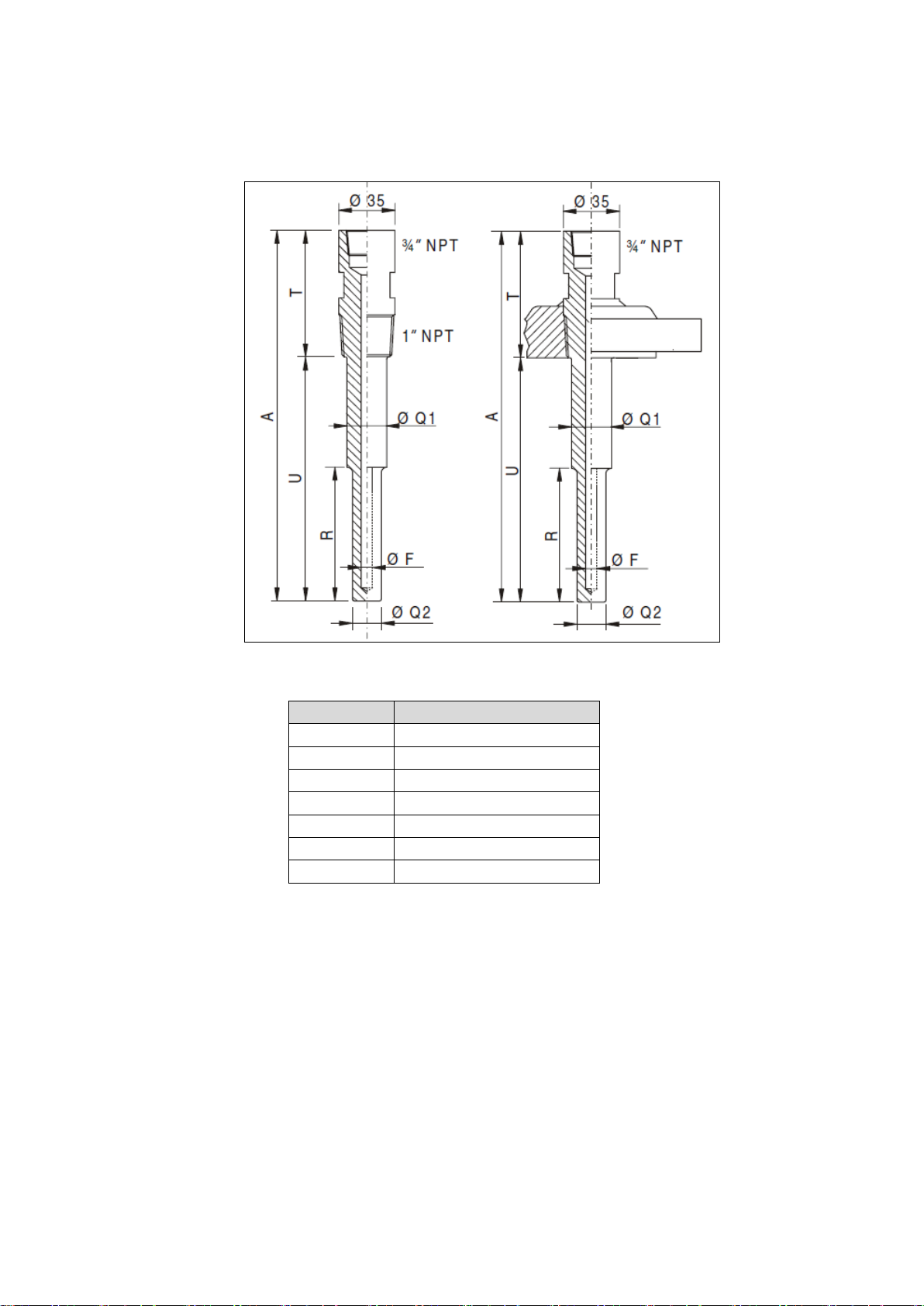

Thermowells for thermometers

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

R

Length of protection tube tip

T

Extension

øF

Bore diameter

__________________________________________________________________________________

2.6 Mechanical construction of ТА556

Pic. 4 – thermowell ТА556 - dimensions in mm (in)

Thermowell ТА556 is made from round bar stock (drilled) with bore diameter 10 mm or 14mm (special version

for other diameters), cylindrical form with straight or tapered bottom shape, threaded or flanged process

connections.

11

Page 12

Thermowells for thermometers

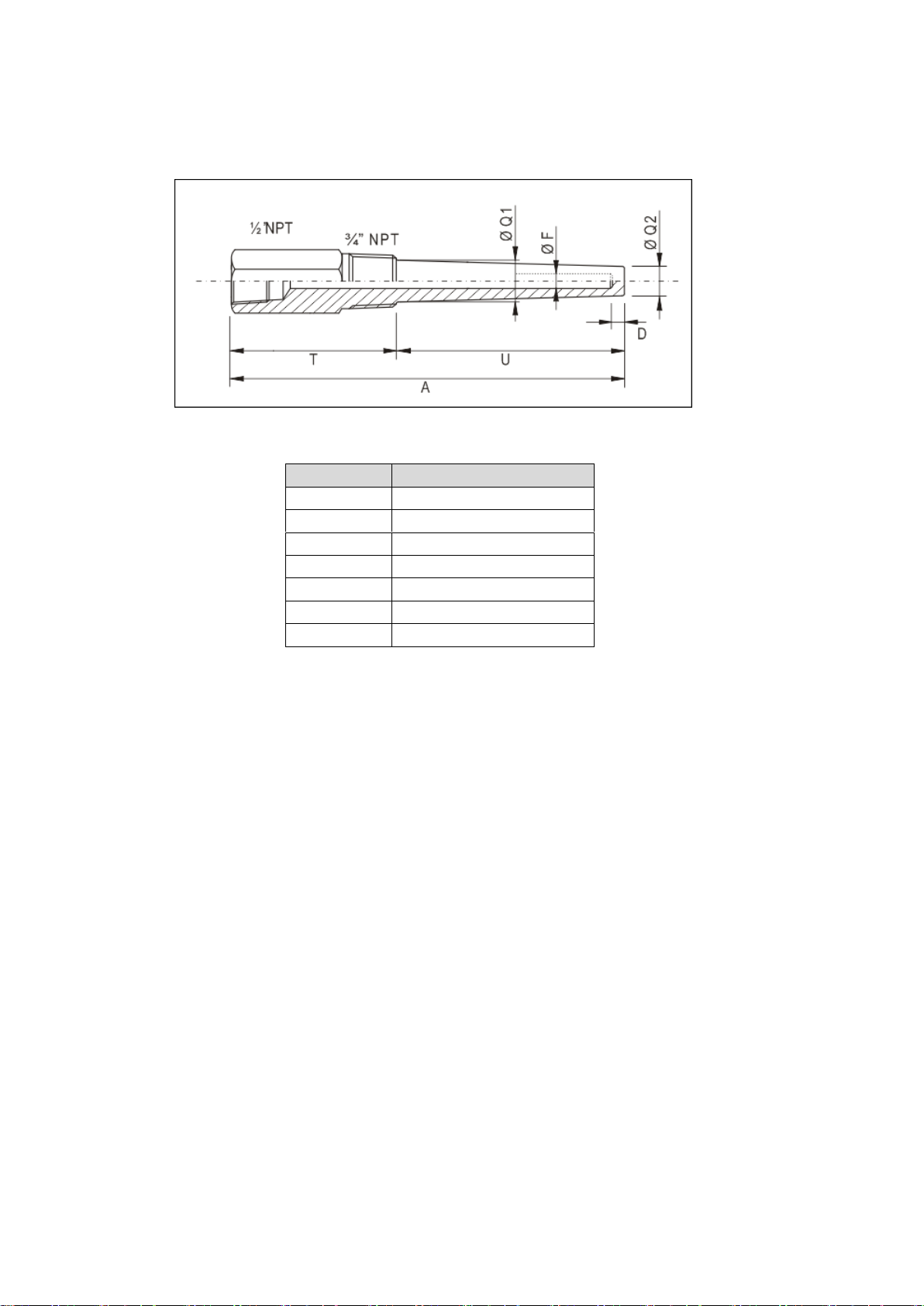

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øF

Bore diameter

D

Bottom thickness

__________________________________________________________________________________

2.7 Mechanical construction of ТА560

Pic. 5 – thermowell ТА560

Thermowell ТА560 is made from round bar stock (drilled) with bore diameter 6.5 mm or 10 mm (special version

for other diameters), cylindrical form with straight or tapered bottom shape, threaded process and thermometer

connections.

12

Page 13

Thermowells for thermometers

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øF

Bore diameter

D

Bottom thickness

__________________________________________________________________________________

2.8 Mechanical construction of ТА565

Pic. 6 – thermowell ТА565

Thermowell ТА565 is made from round bar stock (drilled) with bore diameter 6.5 mm or 10 mm (special version

for other diameters), cylindrical form with straight or tapered bottom shape, threaded process and thermometer

connections.

13

Page 14

Thermowells for thermometers

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øF

Bore diameter

D

Bottom thickness

R

Length of protection tube tip

__________________________________________________________________________________

2.9 Mechanical construction of ТА566

Pic. 7– thermowell ТА566

Thermowell ТА566 is made from round bar stock (drilled) with bore diameter 6.5 mm or 13 mm (special version

for other diameters), cylindrical form with straight or tapered bottom shape, threaded process and thermometer

connections.

14

Page 15

Thermowells for thermometers

Position

Description

ТА570

ТА571

ТА572

U

Immersion length

øQ1

øQ2

Diameter thermowell tip, specification see ordering information

Min. wall thickness 3 mm (0.12 in), (Q2-F1)/2≥3 mm

T

Extension

øF1

Bore diameter

D

Bottom thickness

R

Tapered tip length

S

Thermometer connection thread

øD1

Diameter(extension)

35…49

mm

30…35

mm

25…29 mm

__________________________________________________________________________________

2.10 Mechanical construction of ТА570, ТА571, ТА572

Pic. 8 – thermowells ТА570, ТА571, ТА572

1 Continuous straight shape, flat bottom shape

2 Conical tip shape, flat bottom shape

3 Conical tapered tip shape, flat bottom shape

4 Round bottom shape

Thermowells ТА570, TA571 and TA572 are made from round bar stock (drilled) with bore diameter from 7 mm

and outer diameter up to 27 mm, cylindrical or conical form (depends of ordercode) with welded process

connection.

15

Page 16

Thermowells for thermometers

Position

Description

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

R

Tapering length, if R = 0 tip shape is straight or

completely conical

T

Extension

øF1

Bore diameter

D

Bottom thickness

S

Connection for thermometer

__________________________________________________________________________________

2.11 Mechanical construction of ТА575, ТА576

Pic. 9 – thermowells ТА575, ТА576

1. Continuous straight shape, flat bottom shape

2. Full penetration welding

3. Standard welding

4. Conical tip shape, flat bottom shape

5. Conical tapered tip shape, flat bottom shape

Thermowells ТА575 and TA576 are made from round bar stock (drilled) with bore diameter from 6,5 mm and

outer diameter up to 27 mm (TA575) and to 28 mm (TA576), cylindrical or conical form (depends of ordercode)

with flanged process connection.

16

Page 17

Thermowells for thermometers

Position

Description

A

Thread

ø

Outer diameter

T

Extension

L

Immersion length

__________________________________________________________________________________

2.12 Mechanical construction of ТА535

Pic. 10 – thermowell ТА535

Pic. 11 – extension – dimensions in mm (in)

1 Process connections: 1/2" NPT or 3/4" NPT

2 Process connections: G½", G3/4" or M20×1,5

Т Extension

Thermowell ТА535 is made from pipe with bottom thickness 3 mm, inner/outer diameter 9/6,5, 10/6,4 or 12/8

mm (depends of ordercode), threaded process and thermometer connections.

17

Page 18

Thermowells for thermometers

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øF

Bore diameter

__________________________________________________________________________________

2.13 Mechanical construction of ТА550

Pic. 12 – thermowell ТА550 – dimensions in mm

Thermowell ТА550 is made from round bar stock (drilled) with bore diameter 7 mm or 8 mm, outer diameter 20

mm and 16 mm (special version for other diameters), threaded or flanged process connections.

18

Page 19

Thermowells for thermometers

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øА1

Bore diameter of protection tube tip

R

Length of protection tube tip

øА2

Bore diameter

__________________________________________________________________________________

2.14 Mechanical construction of ТА555

Pic. 13 – thermowell ТА555 - dimensions in mm

Thermowell ТА555 is made from round bar stock (drilled) with bore diameter 6,5 mm, 7 mm or 8 mm, outer

diameter 24 mm and 14 mm (special version for other diameters), threaded or flanged process connections.

19

Page 20

Thermowells for thermometers

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øF

Bore diameter

__________________________________________________________________________________

2.15 Mechanical construction of ТА557

Pic. 14 – thermowell ТА557 - dimensions in mm

Thermowell ТА557 is made from round bar stock (drilled) with bore diameter 8 mm, outer diameter 25 mm and

14 mm (special version for other diameters), threaded or flanged process connections.

20

Page 21

Thermowells for thermometers

Position

Description

A

Total length (A=T+U)

U

Immersion length

øQ1

Outer diameter

øQ2

Diameter protection tube tip

T

Extension

øF

Bore diameter

D

Bottom thickness

R

Length of protection tube tip

__________________________________________________________________________________

2.16 Mechanical construction of ТА562

Pic. 15– thermowell ТА562 – dimensions in mm

Thermowell ТА562 is made from round bar stock (drilled) with bore diameter 6.5 mm or 10 mm (special version

for other diameters), cylindrical form with straight or tapered bottom shape, threaded process and thermometer

connections.

21

Page 22

Thermowells for thermometers

__________________________________________________________________________________

2.17 Mechanical construction of ТW10

Pic. 16– thermowell ТW10 – dimensions in mm

L – immersion length

E – extension

Thermowell ТW10 is made from pipe with outer diameter 9, 11, 12, 14 or 15 mm, threaded process connections.

22

Page 23

Thermowells for thermometers

__________________________________________________________________________________

2.18 Mechanical construction of ТW11

Pic. 17– thermowell ТW11 – dimensions in mm

L – immersion length

L1 – thread length

Thermowell ТW11 is made from pipe with outer diameter 8, 9, 11, 12, 14 or 15 mm, threaded process

connections.

23

Page 24

Thermowells for thermometers

__________________________________________________________________________________

2.19 Mechanical construction of ТW12

Pic. 18– thermowell ТW12 – dimensions in mm, L – immersion length

Thermowell ТW12 is made from pipe with outer diameter 9, 11, 12, 14 or 15 mm, as process connection is used

compression fitting.

24

Page 25

Thermowells for thermometers

__________________________________________________________________________________

2.20 Mechanical construction of ТW13

Pic. 19– thermowell ТW13 – dimensions in mm

1 M24×1,5 connection; sliding on the neck

2 ½"NPT connection; welded, not sliding on the neck

Е Neck tube length

L Immersion length

øD Diameter

Thermowell ТW13 is made from pipe with outer diameter 9, 11, 12, 14 or 15 mm, flanged process connections.

25

Page 26

Thermowells for thermometers

Position

Description

T

Thread neck tube connection to thermowell

L

Immersion length

U

Length of conical tip

U1

Immersion length; length of the part of the

thermowell in contact with the process from the

tip to the sealing surface of the flange

E

Neck tube length

__________________________________________________________________________________

2.21 Mechanical construction of ТW15

Pic. 20 – thermowell ТW15 – dimensions in mm (in)

Thermowell ТW15 is made from round bar stock (drilled) with outer diameter 24 mm or 18 mm, inner diameter

6,5 mm flanged or welded process connections.

26

Page 27

Thermowells for thermometers

__________________________________________________________________________________

2.22 Mechanical construction of ТW45

Pic. 21 – thermowell ТW45

Е Neck tube length

L Immersion length

øD Pipe diameter

ød Neck tube diameter

Thermowell ТW45 is made from pipe with bottom thickness 3 mm with outer diameter 9 mm: threaded, clamp,

flanged and other hygienic process connections.

27

Page 28

Thermowells for thermometers

__________________________________________________________________________________

2.23 Mechanical construction of ТW47

Pic. 22 – thermowell ТW47– dimensions in mm

TL – total length

L – immersion length

Thermowell ТW47 is made from round bar stock (drilled) with outer diameter 13 mm and 5,3 mm (special

version for other diameters), welded process connections.

28

Page 29

Thermowells for thermometers

__________________________________________________________________________________

2.24 Mechanical construction of MLTWS01

Pic. 23 – thermowell MLTWS01 – dimensions in mm (in)

E– neck length

L – immersion length

Thermowell MLTWS01 is made from pipe with outer diameter 16 mm with flanged process connections.

29

Page 30

Thermowells for thermometers

__________________________________________________________________________________

2.25 Mechanical construction of TW251

Pic. 24 – thermowell TW251 – dimensions in mm

ID – inner diameter

IL – immersion length

Thermowell ТW251 is made from round bar stock (drilled) with diameter 6 mm and 9 mm with threaded or

welded process connections.

30

Page 31

Thermowells for thermometers

Position

Description

Lg

Immersion length

øLg

Sheath diameter

Lm

Sleeve length

øLm

Sleeve diameter

øT

Thermowell outer diameter

øi

Thermowell inner diameter

C

Terminal head connection

A

Version thermowell made from tube

B

Version thermowell made from tube and bar stock tip

L2

Length bar stock tip

__________________________________________________________________________________

2.26 Mechanical construction of TWF11 и TWF16

Pic. 25 – thermowells TWF11 and TWF16

Thermowells ТWF11 and TWF16 are made from metallic or ceramic round bar stock (drilled) with outer

diameter from 14 mm and 26,7 mm (special version for other diameters) for installation in adjustable or stop

flange, or in threaded assembly.

31

Page 32

Thermowells for thermometers

Position

Description

L

Total length (U+T)

U

Immersion length

Т

Length of protection tube shaft

__________________________________________________________________________________

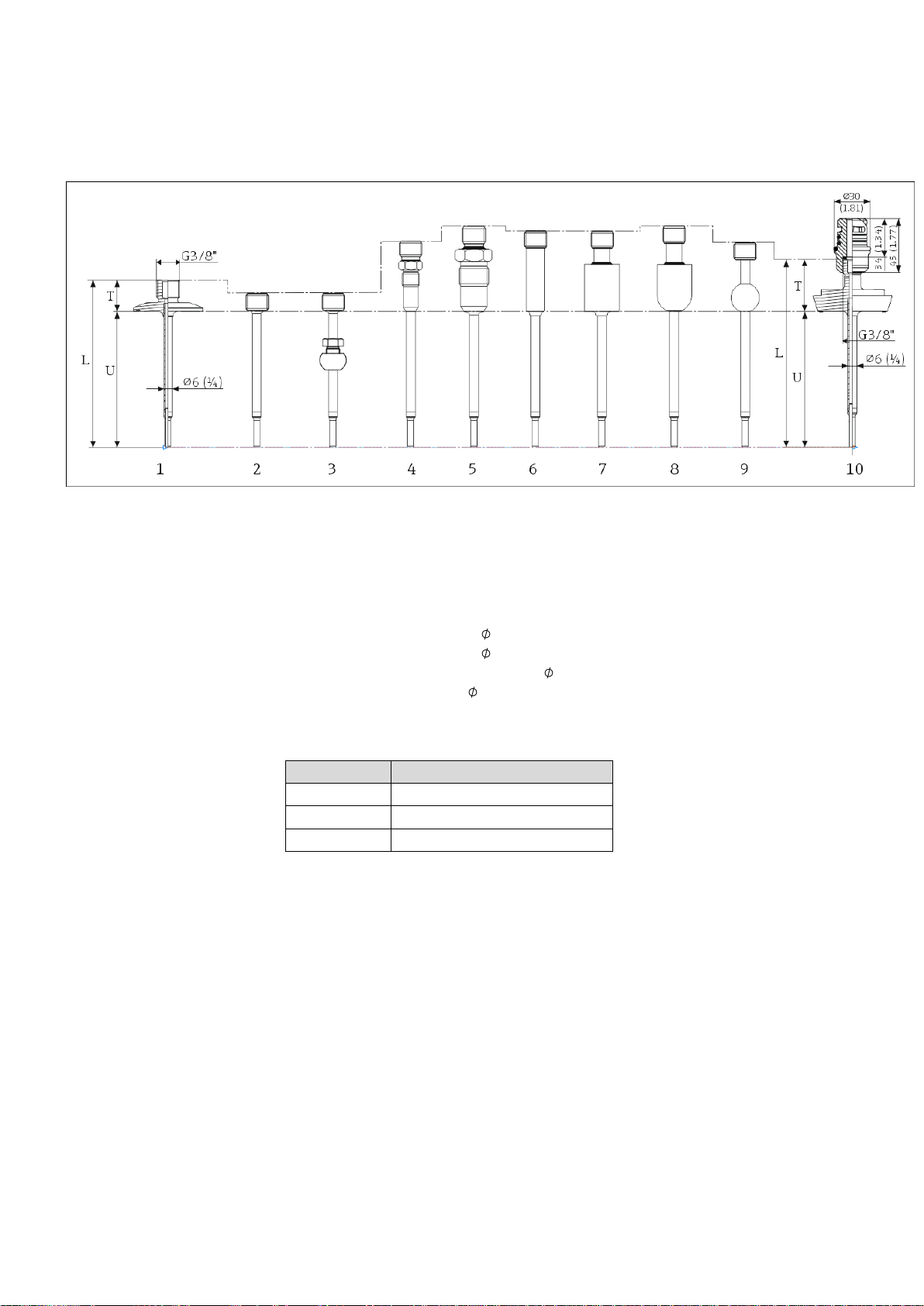

2.27 Mechanical construction of TT411

Pic. 26 – thermowell TТ411 – dimensions in mm (in)

1 Clamp version

2 Without process connection

3 Spherical compression fitting TK40

4 Metal sealing system M12x1

5 Metal sealing system G½"

6 Cylindrical weld-in adapter 12 x 40 mm

7 Cylindrical weld-in adapter 30 x 40 mm

8 Spherical-cylindrical weld-in adapter 30 x 40 mm

9 Spherical weld-in adapter 25 mm

10 Sanitary connection according to DIN 11851 with threaded base part

iTHERM QuickNeck

Thermowell TT411 is made from pipe and round bar stock (drilled) with outer diameter from 6 mm to 12,7 mm

(special version for other diameters), hygienic and welded process connections.

32

Page 33

Thermowells for thermometers

Position

Description

L

Standard length

U

Immersion length

LТ

Complete thermowell length (L+U)

TL

Thread length

ML

Insertion length

N

Extension neck length

R

Length of tapered tip

øQ1

Outer diameter

øQ2

Diameter protection tube tip

__________________________________________________________________________________

2.28 Mechanical construction of TT511

Pic. 27 – thermowell TТ511 – dimensions in mm (in)

1 Version DN40 (NPS 1-½") or DN50 (NPS 2"), tapered

2 Version DN40 (NPS 1-½") for L > 300 mm (11.81 in): straight with tapered tip

Thermowell TT511 is made from round bar stock (drilled) with bore diameter 7 mm and outer diameter 19 mm b

30 mm(special version for other diameters), lap joint flange process connections.

33

Page 34

Thermowells for thermometers

__________________________________________________________________________________

2.29 Mechanical construction of TTSP

Pic. 27 – examples of construction of thermowell TTSP – dimensions in mm

TTSP is a special version thermowell made according to customer specification, can be constructed by any

method, with any dimensions and process connections.

34

Page 35

Thermowells for thermometers

__________________________________________________________________________________

3 Installation

Installation of thermowells should be carried out only by qualified and authorized specialists in the

complete absence of pressure at the installation point. Thermowells can be installed on pipes, tanks and

any other parts of the equipment where it is necessary. Seals and gaskets for process connection are

usually not included in the delievery set and customer should provide it separately.

Pic. 28 – thermometer TR62 in connection with thermowell ТА576

35

Pic. 29 – istallation examples in pipes

Page 36

Thermowells for thermometers

Description and cause of accident

Personnel action

Leakage of the working medium (violation

of integrity of the welds between the

submerged part of thermowell and process

connection)

Re-weld the leakage point or replace with a

new thermowell

Leakage of the working medium through

seals (wear of seals the weakening of the

threaded connections)

Tighten threaded connections or replace

gasket

Corrosive or abrasive wear of thermowell

(damage, abrasion, occurrence of holes on

the submersible part due to incorrect choice

of material)

It is necessary to replace it with thermowell

produced of another material, which will

ensure its resistance to mechanical or

corrosive exposure of the working medium.

Assigned storage time

2 years

Assigned lifetime

20 years

__________________________________________________________________________________

4 Comissioning

After mounting of thermowells it is necessary to check tightness of connection on the installation point.

5 Maintenance and repair

Thermowells doesn’t require any special actions for maintenance and repair.

6 Storage and transport

• Transport thermowells to the installation point in original packaging

• Store in a dry and dust-free place

• Storage temperatures: -60…+85°С

7 Conservation

Conservation of thermowells is carried out upon removal from the facility for long term storage. For conservation

it is necessary to eliminate traces of the measured liquid from the surface of the thermowell and remaining oil

from the inside, and then install plugs on it. Conservation of thermowells should be performed according to GOST

9.014-78.

8 Assigned indicators

9 Limit state criteria

The following limit states for operating conditions for thermowells are unacceptable:

• Loss of thermowell tightness

• Occurrence of cracks on the surface of thermowell

10 Occurrence of critical failures

11 Dismantling

In the case if a thermowell reached its limit state, it is necessary to dismantle it, making sure that the system

pressure is shut down.

36

Page 37

Thermowells for thermometers

__________________________________________________________________________________

12 Disposal

The disposal process of thermowells and recycling of materials should be organized so as to prevent pollution of

air, soil and water bodies with harmful substances. Dispose of materials and waste according to the local

regulations.

In general, the safety process for recycling and/or disposal should be provided by:

• Automation and mechanization of technological processes.

• Conduct technological processes in strict compliance with the technical and standard.

• The use of local and general ventilation.

Disposed thermowells do not pose any danger to life, health and the environment. Flowmeters do not contain

any chemical, biological or radioactive elements that could be harmful to human health or the environment.

13 Marking

On thermowell is mentioned its order code, thread type (flange), hole diameter, material of thermowell, lengths

(immersion length, length of conical or truncated tip), the trademark of the manufacturer.

Construction of thermowells doesn't allow to apply on its surface a uniform mark of production circulation at the

market of member States of the Eurasian economic Union, therefore, this sign is applied to technical

documentation package (technical passport, operating instructions).

14 Manufacturer

Endress+Hauser Sicestherm S.r.L., Italy

Address: Via M.Luther King 7, 20060 Pessano con Bornago, Italy

Tel.: +39 02 95 96 41, факс: +39 02 95 96 44 05

e-mail: info@sicestherm.endress.com

37

Page 38

Thermowells for thermometers

__________________________________________________________________________________

38

Page 39

Thermowells for thermometers

__________________________________________________________________________________

39

Page 40

40

Loading...

Loading...