Endress+Hauser Turbimax CUS51D Operating Instructions Manual

Products Solutions Services

BA00461C/07/EN/15.13

71219749

Operating Instructions

Turbimax CUS51D

Sensor for turbidity and solids content

Endress+Hauser

About this document

Notes on safety icons

The structure, signal words and safety colors of the signs comply with the specifications of

ANSI Z535.6 ("Product safety information in product manuals, instructions and other

collateral materials").

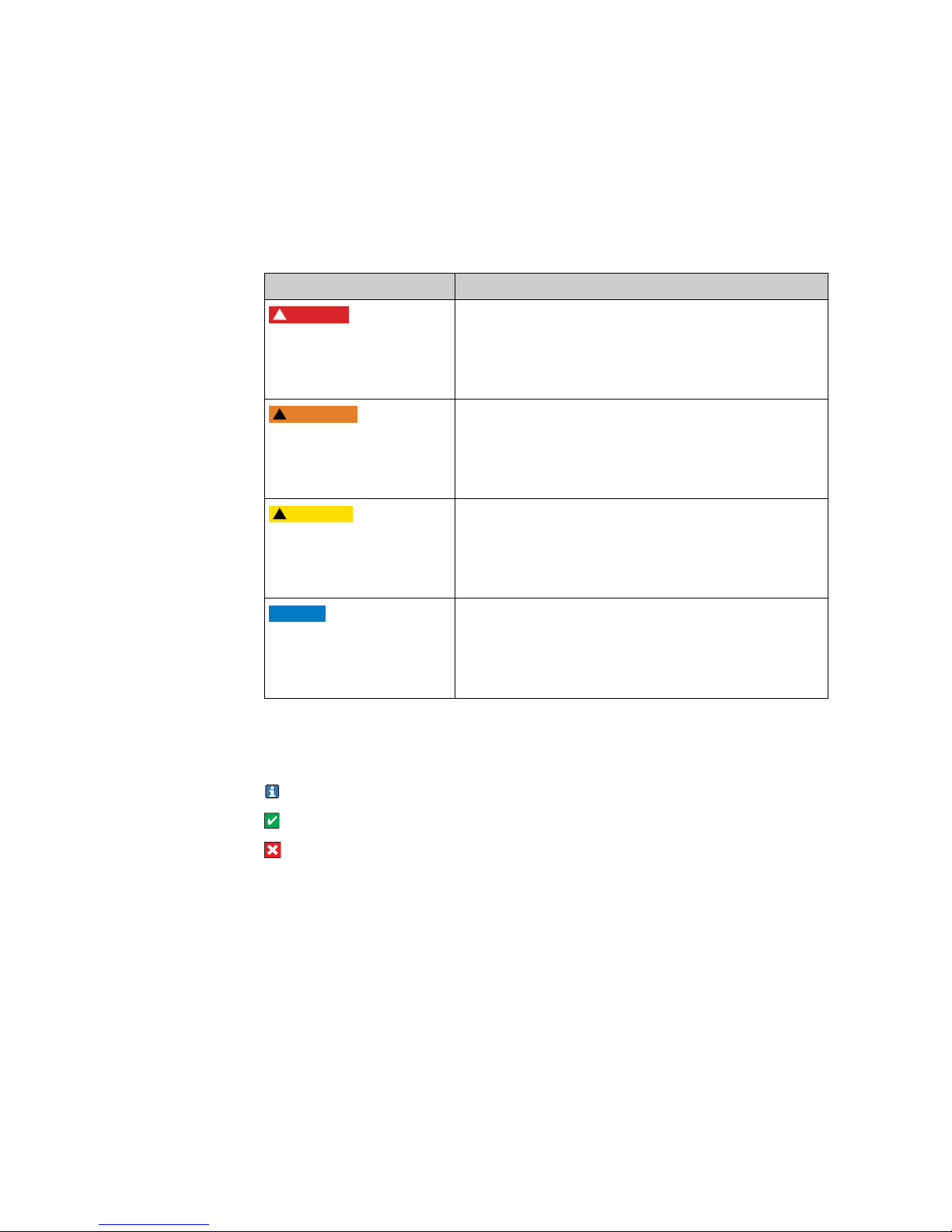

Symbols

Safety message structure Meaning

DANGER

!

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the situation will result in a fatal or serious

injury.

WARNING

!

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the situation can result in a fatal or serious

injury.

CAUTION

!

Cause (/consequences)

Consequences if safety

message is not heeded

‣ Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or

medium injury.

NOTICE

Cause/situation

Consequences if safety

message is not heeded

‣ Action/note

This symbol alerts you to situations that can result in

damage to property and equipment.

Additional information, tips

Permitted or recommended

Forbidden or not recommended

Turbimax CUS51D

Endress+Hauser 3

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . 4

1.1 Requirements for the personnel . . . . . . . . . . . . . . . 4

1.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 6

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installation examples . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . 14

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1 Connecting to the transmitter . . . . . . . . . . . . . . . 15

4.2 Post-connection check . . . . . . . . . . . . . . . . . . . . . 15

5 Device description . . . . . . . . . . . . . . . . .16

5.1 Sensor design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Measuring principle . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Measuring methods . . . . . . . . . . . . . . . . . . . . . . . 19

5.4 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.5 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6 Stability criterion . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.7 Cyclic cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Diagnostics and troubleshooting . . . . .30

7 Maintenance . . . . . . . . . . . . . . . . . . . . . .31

7.1 Cleaning the sensor . . . . . . . . . . . . . . . . . . . . . . . 31

8 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.1 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9 Accessories . . . . . . . . . . . . . . . . . . . . . . .33

9.1 Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.2 Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.3 Compressed air cleaning . . . . . . . . . . . . . . . . . . . 34

9.4 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10 Technical Data. . . . . . . . . . . . . . . . . . . . 35

10.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.2 Performance characteristics . . . . . . . . . . . . . . . . . 36

10.3 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.4 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.5 Mechanical construction . . . . . . . . . . . . . . . . . . . . 38

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Safety instructions Turbimax CUS51D

4 Endress+Hauser

1 Safety instructions

1.1 Requirements for the personnel

‣

Installation, commissioning, operation and maintenance of the measuring system must

only be carried out by trained technical personnel.

‣ The technical personnel must be authorized by the plant operator to carry out the

specified activities.

‣ The electrical connection may only be performed by an electrical technician.

‣ The technical personnel must have read and understood these Operating Instructions

and must follow the instructions they contain.

‣ Measuring point faults may only be rectified by authorized and specially trained

personnel.

Repairs not described in the enclosed Operating Instructions may only be carried out

directly at the manufacturer's or by the service organization.

1.2 Designated use

CUS51D is a sensor designed to measure the turbidity and solids content of water and

wastewater.

The sensor is particularly suited for use in the following applications:

• Turbidity measurement in the outlet

• Suspended solids in the activated sludge basin and in the recirculation

• Suspended solids in the sludge treatment

• Filterable solids in the outlet

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Regulations for explosion protection

• Installation instructions

• Local standards and regulations

Electromagnetic compatibility

With regard to electromagnetic compatibility, this device has been tested in accordance with

the applicable European standards for industrial applications.

The electromagnetic compatibility indicated only applies to a device that has been connected

in accordance with the instructions in these Operating Instructions.

1.4 Operational safety

‣

Before commissioning the entire measuring point, make sure all the connections are

correct. Ensure that electrical cables and hose connections are not damaged.

‣ Do not operate damaged products, and safeguard them to ensure that they are not

operated inadvertently. Mark the damaged product as defective.

‣ If faults cannot be rectified, the products must be taken out of service and secured against

unintentional commissioning.

Turbimax CUS51D Safety instructions

Endress+Hauser 5

1.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested and

left the factory in a condition in which it is safe to operate. Relevant regulations and

European standards have been observed.

Incoming acceptance and product identification Turbimax CUS51D

6 Endress+Hauser

2 Incoming acceptance and product

identification

2.1 Incoming acceptance

‣

Make sure the packaging is undamaged!

‣ Inform the supplier about any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

‣ Make sure the contents are undamaged!

‣ Inform the supplier about damage to the contents. Keep the damaged products until the

matter has been settled.

‣ Check that the order is complete and agrees with your shipping documents.

‣ The packaging material used to store or to transport the product must provide shock

protection and humidity protection. The original packaging offers the best protection.

Also, keep to the approved ambient conditions (see "Technical data").

‣ If you have any questions, please contact your supplier or your local sales center.

2.2 Product identification

2.2.1 Nameplate

The nameplate contains the following information:

• Manufacturer data

•Order code

• Extended order code

• Serial number

• Operating conditions

•Safety icons

Compare the order code on the nameplate with your order.

2.2.2 Identifying the product

The order code and serial number of your device can be found in the following locations:

• On the nameplate

• On the front page of these Operating Instructions

• In the delivery papers

To find out the version of your device, enter the order code indicated on the nameplate

in the search screen at the following address:

www.products.endress.com/order-ident

2.3 Scope of delivery

The scope of delivery comprises:

• 1 sensor Turbimax CUS51D in the ordered version

• 1 Operating Instructions BA00461C/07/EN

If you have any questions, please contact your supplier or your local sales center.

2.4 Certificates and approvals

Declaration of conformity

The product meets the requirements of the harmonized European standards. It thus

complies with the legal requirements of the EC directives.

The manufacturer confirms successful testing of the product by affixing the 4 symbol.

Turbimax CUS51D Installation

Endress+Hauser 7

3Installation

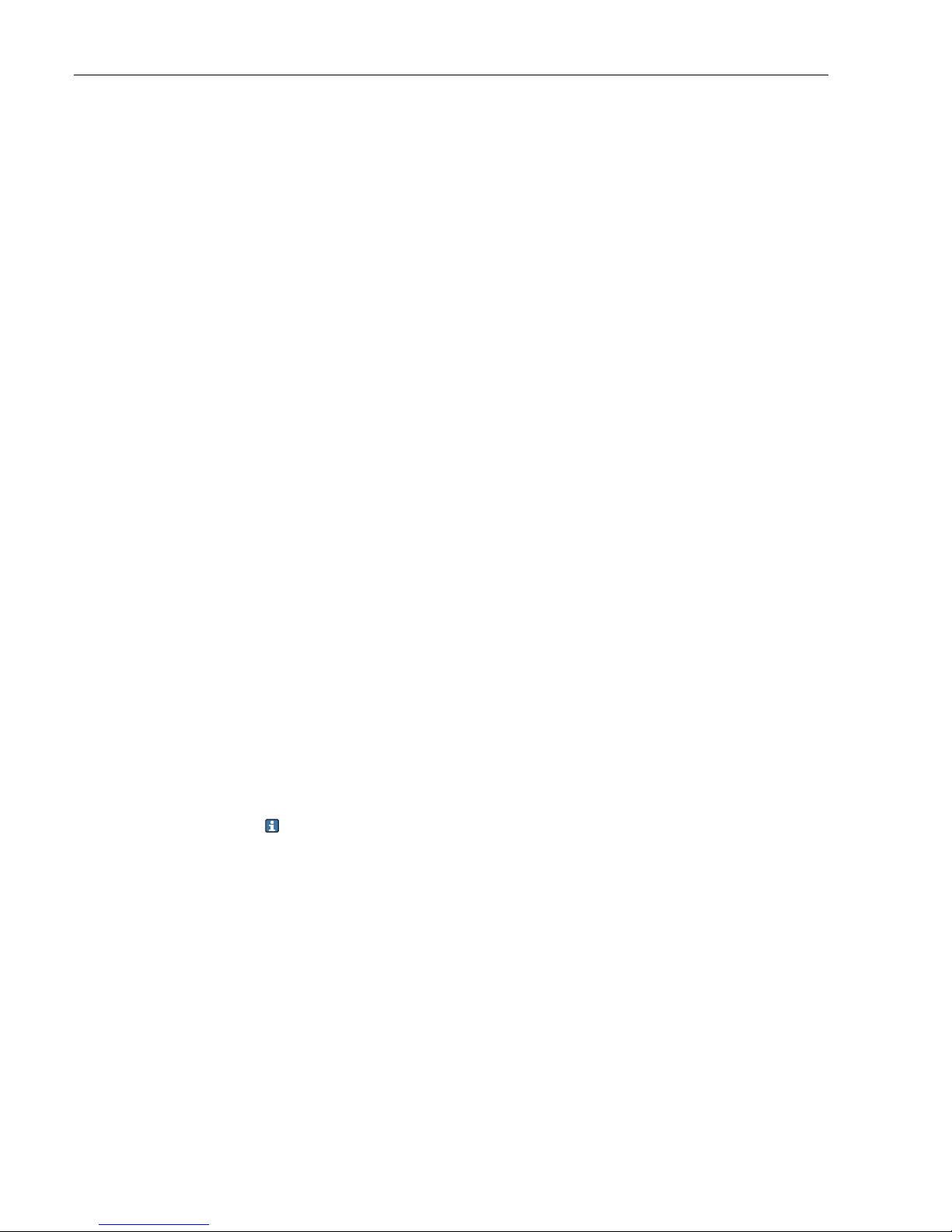

3.1 Dimensions

a0013179

Fig. 1: Dimensions

See the "Accessories" section for the dimensions of the cleaning unit

Installation Turbimax CUS51D

8 Endress+Hauser

3.2 Installation instructions

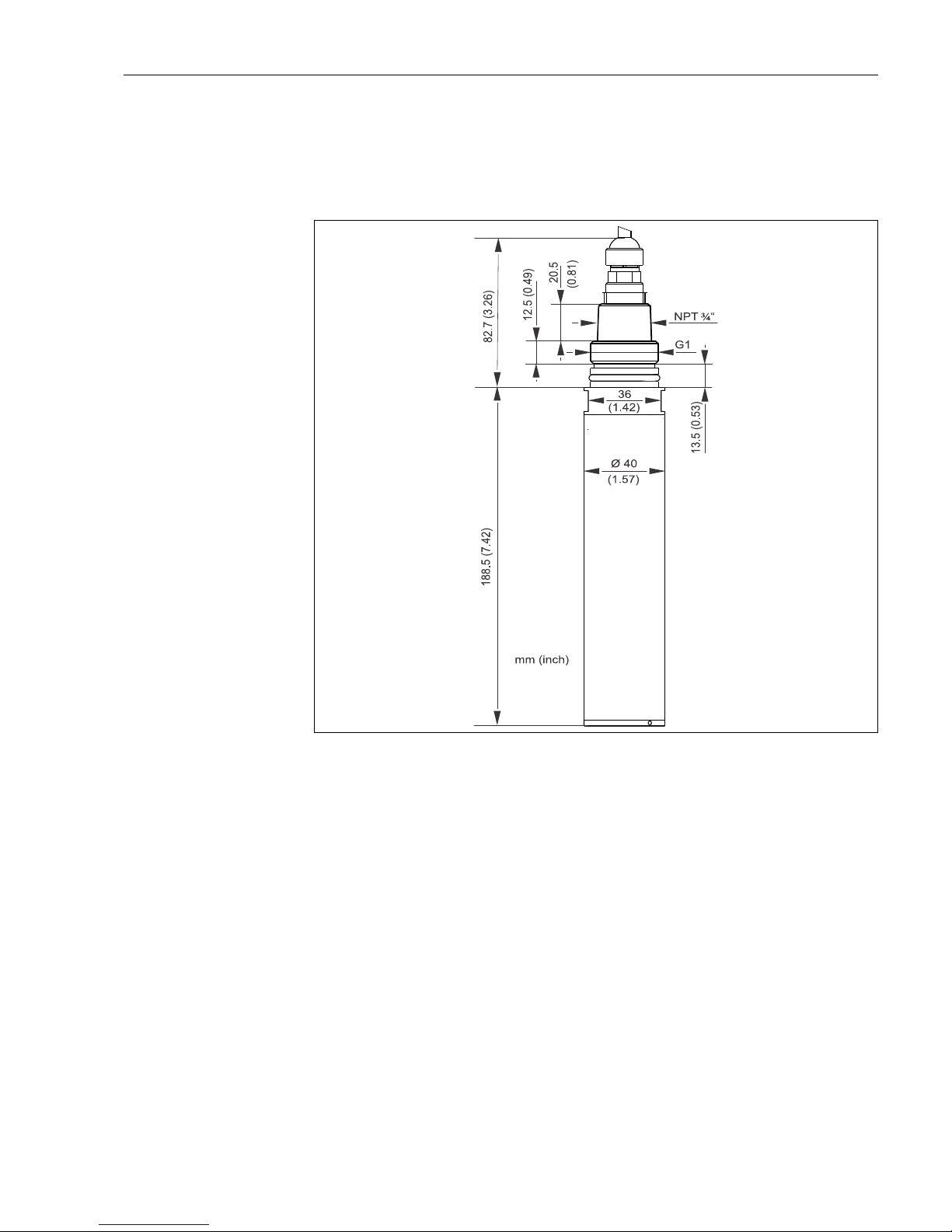

3.2.1 Measuring system

A complete measuring system comprises:

• Turbidity sensor Turbimax CUS51D

• Transmitter Liquiline

• Assembly:

– Assembly Flexdip CYA112 and holder system Flexdip CYH112 or

– Retractable assembly , e.g. Cleanfit CUA451

a0012965

Fig. 2: Measuring system with immersion assembly (example)

1

2

3

1

4

5

1 Holder system Flexdip CYH112 4 Assembly Flexdip CYA112

2 Transmitter Liquiline 5 Turbidity sensor Turbimax CUS51D

3 Weather protection roof

Turbimax CUS51D Installation

Endress+Hauser 9

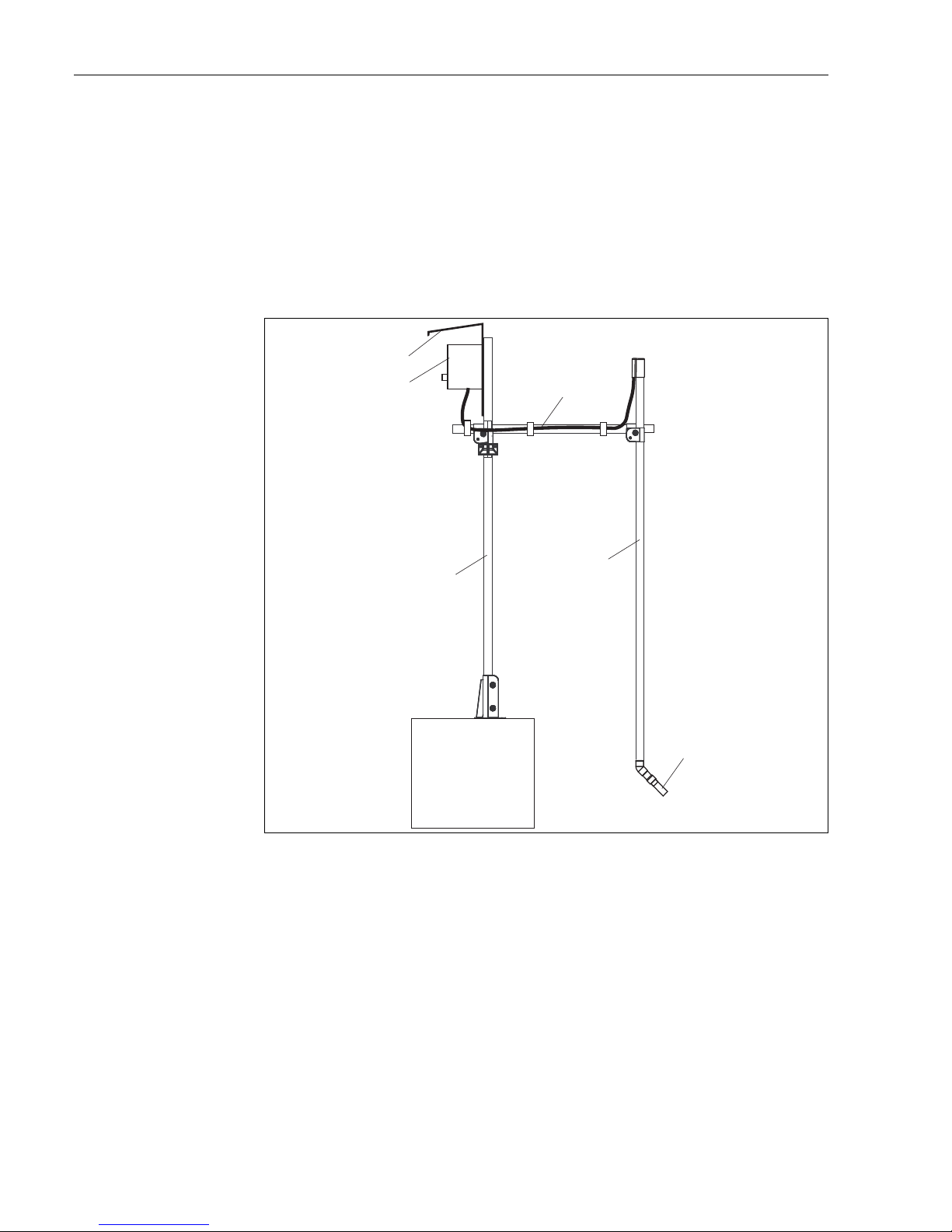

a0013334

Fig. 3: Measuring system with immersion assembly (example)

2

3

5

4

1

1 Transmitter Liquiline 4 Assembly Flexdip CYA112

2 Weather protection roof 5 Turbidity sensor Turbimax CUS51D

3 Holder system Flexdip CYH112

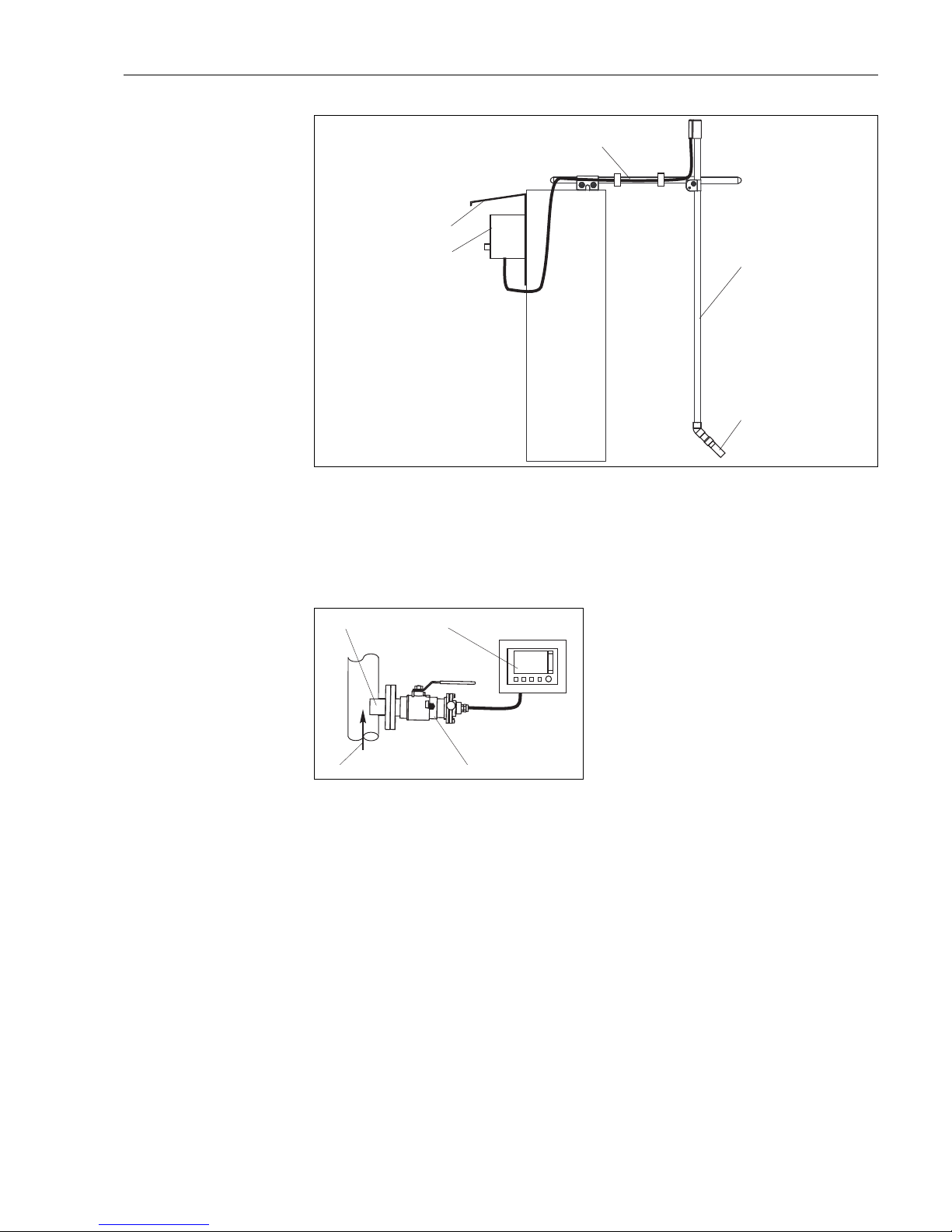

a0012964

Fig. 4: Measuring system with retractable assembly

(example)

1 Turbidity sensor Turbimax CUS51D

2 Transmitter Liquiline

3 Retractable assembly Cleanfit CUA451

4 Flow direction

1

3

4

2

Installation Turbimax CUS51D

10 Endress+Hauser

3.3 Installation examples

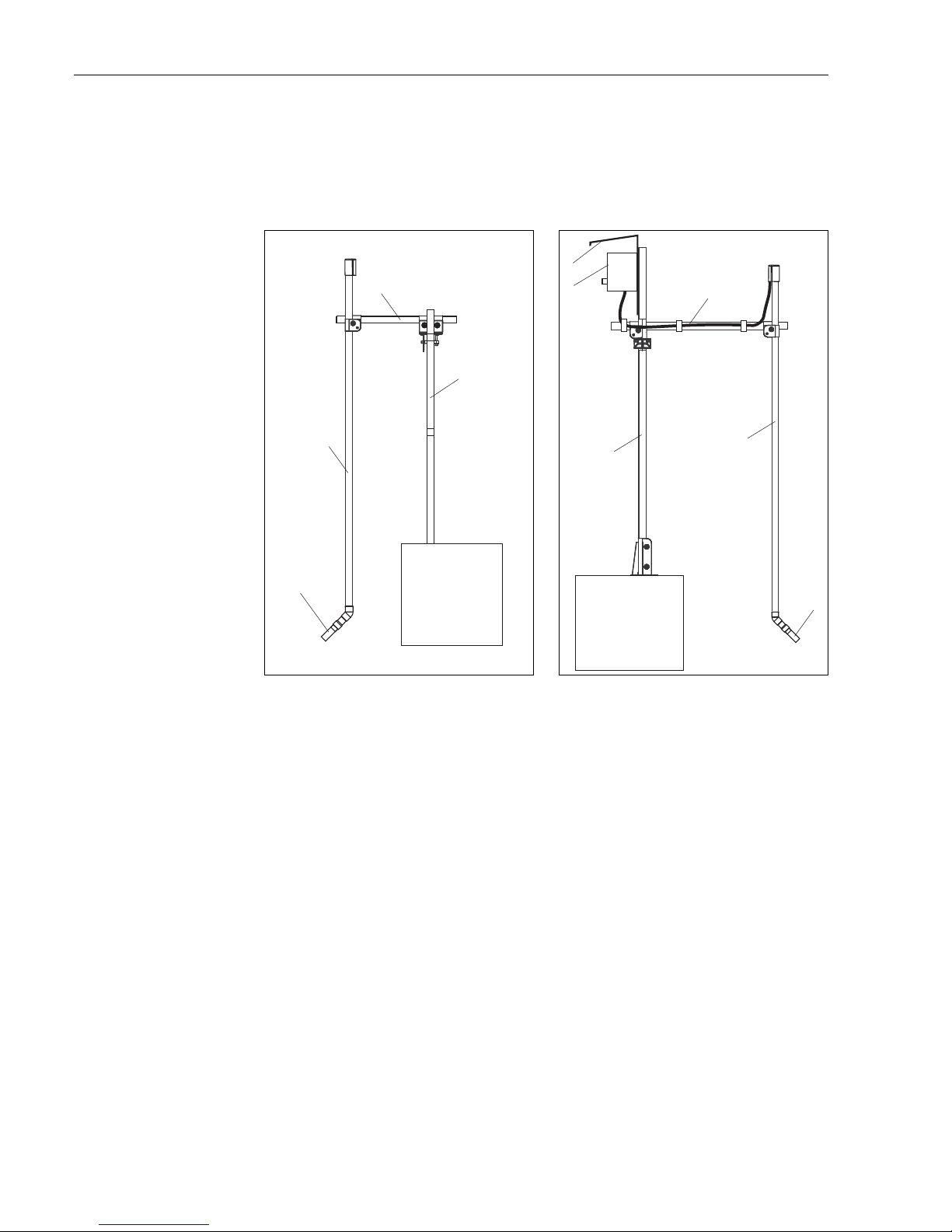

3.3.1 Immersion operation

Fixed installation with wastewater assembly

This type of installation is particularly suitable for strong or turbulent flow

(>0.5 m/s (1.6 ft/ s)) in the basin or channels.

a0013383

Fig. 5: Installation secured on railing

1 Turbidity sensor Turbimax CUS51D

2 Flexdip CYA112 wastewater assembly

3 Flexdip CYH112 holder

4 Railing

a0012965

Fig. 6: Installation with upright post

1 Flexdip CYH112 holder

2 Multichannel transmitter Liquiline CM44x

3 Weather protection cover

4 Flexdip CYA112 wastewater assembly

5 Turbidity sensor Turbimax CUS51D

1

2

3

4

1

2

3

1

4

5

Turbimax CUS51D Installation

Endress+Hauser 11

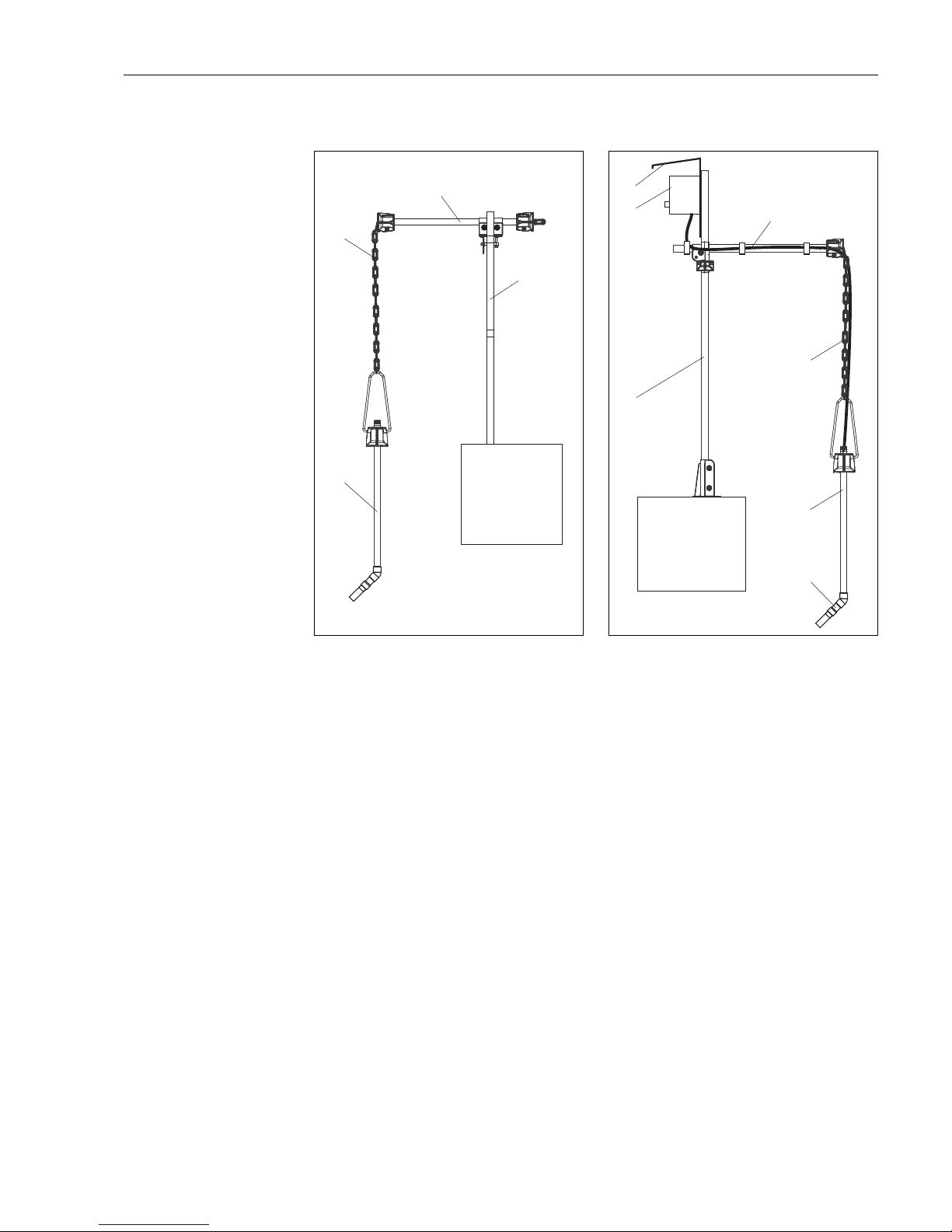

Installation with chain retainer

The chain retainer is particularly suitable for applications that require a sufficient distance

between the mounting location and the edge of the aeration basin. As the assembly is freely

suspended, any vibration of the upright post is practically ruled out.

The swinging movement of the chain retainer enhances the self-cleaning effect of the

optical window.

a0013384

Fig. 7: Chain retainer on railing

1 Flexdip CYA112 wastewater assembly with Turbimax

CUS51D turbidity sensor

2 Chain

3 Flexdip CYH112 holder

4 Railing

a0013386

Fig. 8: Chain retainer on upright post

1 Flexdip CYH112 holder

2 Multichannel transmitter Liquiline CM44x

3 Weather protection cover

4 Flexdip CYA112 wastewater assembly

5 Turbidity sensor Turbimax CUS51D

1

2

3

4

1

2

3

1

4

5

4

Installation Turbimax CUS51D

12 Endress+Hauser

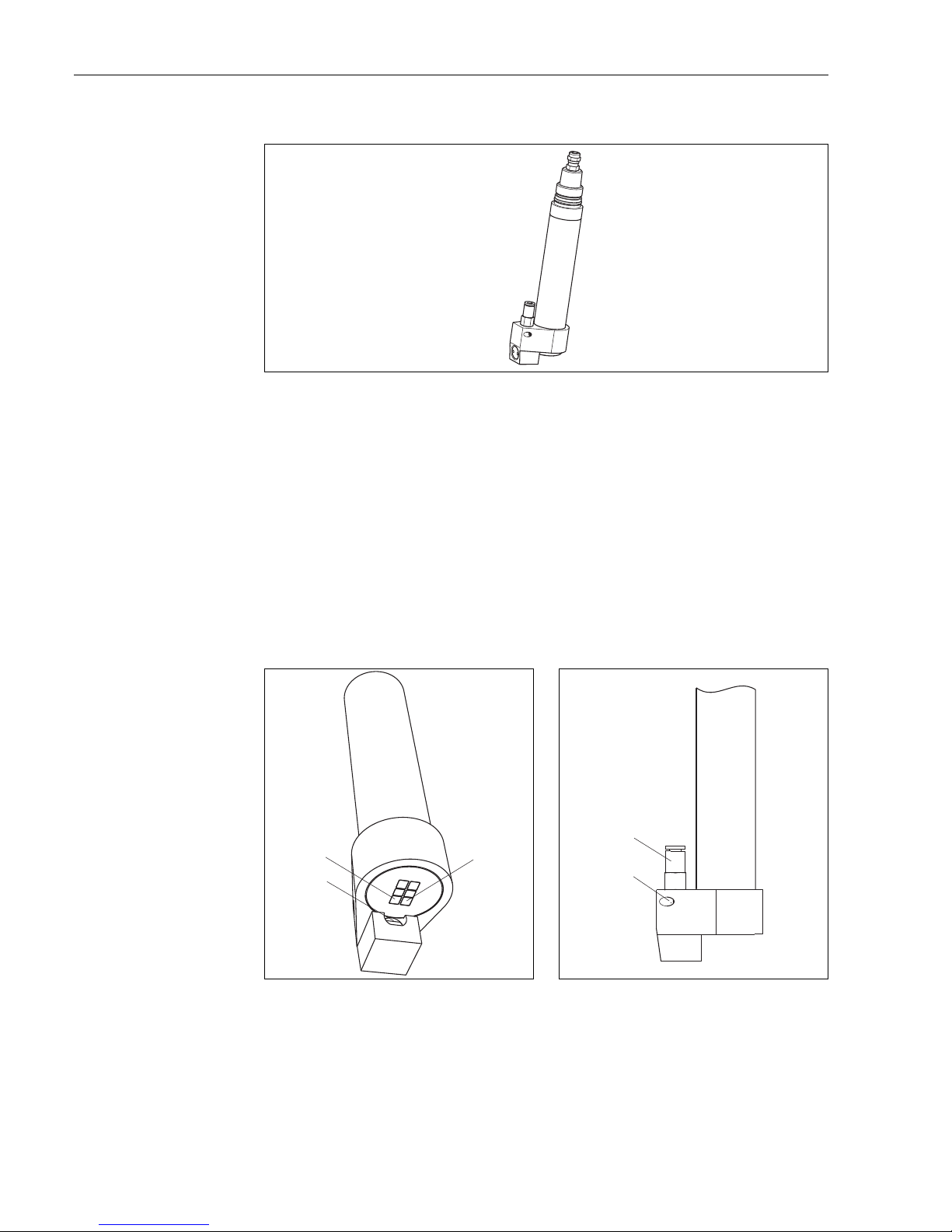

Cleaning unit

a0013259

Fig. 9: Turbimax CUS51D sensor with cleaning unit

The cleaning unit is particularly suitable for clear water and media containing fats/oils that

tend to cause heavy buildup.

Mount the cleaning unit as follows:

1. Fit the cleaning unit onto the sensor as far as it will go.

2. Locate the two LEDs (they are installed at an angle and have a bright enclosure).

3. Position the cleaning unit in such a way that the nozzle is located at the side of the two

LEDs (see å 10).

4. Fix the cleaning unit in place with the securing screw (max. torque: 0.5 Nm

(0.37 lbf ft)).

5. Insert the compressed air hose of the compressor into the hose connection.

a0013410

Fig. 10: Aligning the cleaning unit

1LEDs

2Nozzle

a0013411

Fig. 11: Fixing the cleaning unit

1 Hose connection

2Securing screw

1

2

1

1

2

Turbimax CUS51D Installation

Endress+Hauser 13

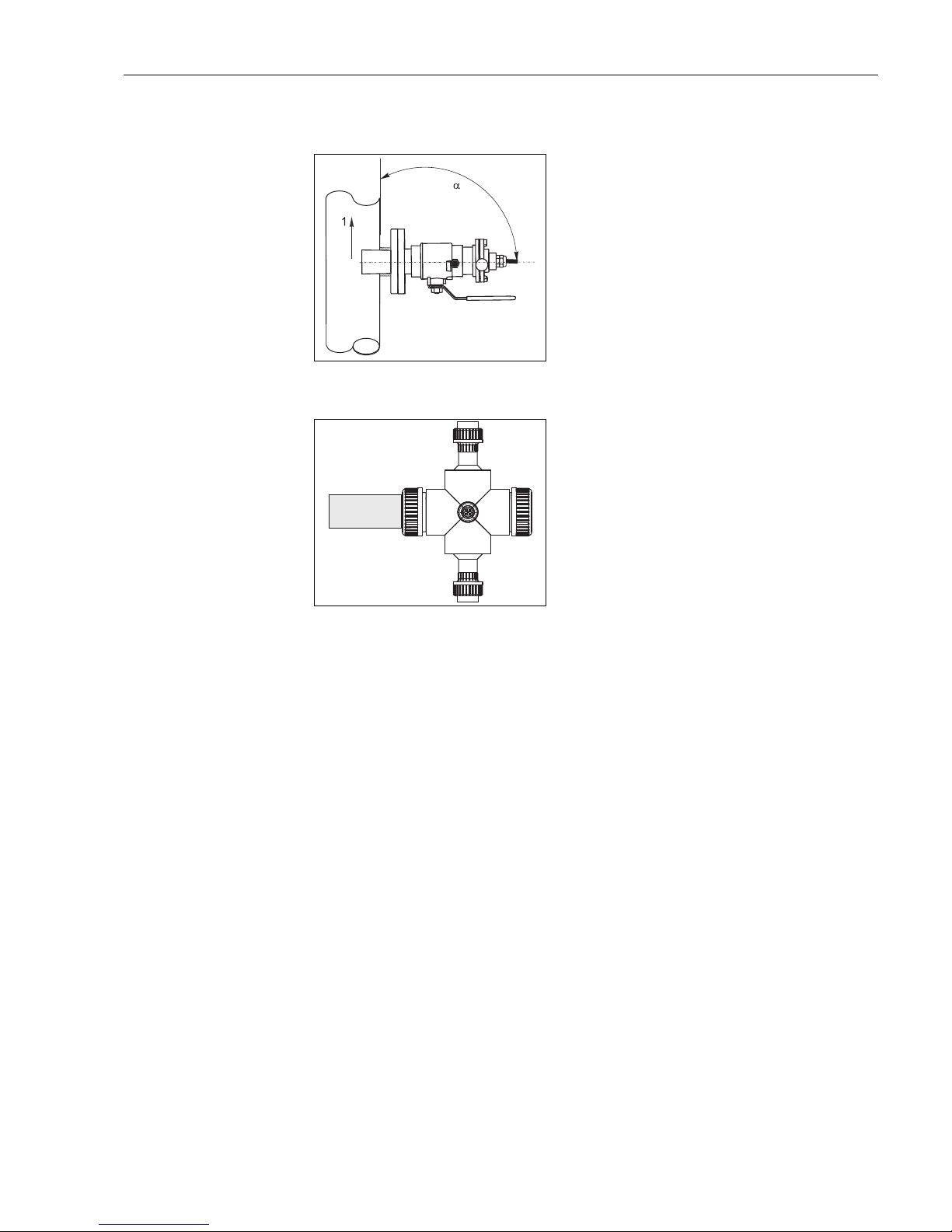

3.3.2 Pipe installation

a0013009

Fig. 12: Installation with retractable assembly

Arrow 1 shows the flow direction.

The installation angle must not exceed 90°.

The recommended installation angle is 75°.

The optical windows of the sensor have to be aligned

parallel to the flow direction ( = 90°) or face the

flow direction ( < 90°).

For manual insertion/retraction of the assembly the

medium pressure may not exceed 2 bar (29 psi).

a0015169

Fig. 13: Installation with flow assembly CYA251

The installation angle is 90°.

Turbidity measurement < 200 FNU will result in

erroneous measuring results due to backscattering of

pipe wall.

Loading...

Loading...