Page 1

TI00105R/09/EN/15.18

71415693

Products Solutions Services

Technical Information

Temperature Switch

Thermophant T

TTR31, TTR35

Temperature switch for the safe measurement,

monitoring and control of process temperatures

Application

Temperature switch for the monitoring, display and control of process temperatures in

a range from -50 to 200 °C (-58 to 392 °F):

Thermophant T TTR31 - with thread connections or coupling

Thermophant T TTR35 - for hygienic applications

• Versions for use in hygienic applications

• Electronic versions

– one PNP switch output

– two PNP switch outputs

– 2 x PNP switch outputs or one PNP switch output and 4 to 20 mA output (active)

Benefits at a glance

This compact temperature switch impresses with the latest in technology being used:

• Integrated switching electronics for decentral and economic process monitoring and

control

• High reproducibility and long-term stability

• Function check and information onsite thanks to LEDs and digital display

• Long-term stable temperature sensor made of platinum (Pt100 class A as per

IEC 60751)

• High accuracy across the entire ambient temperature range and short response time

• Operation and visualization also with PC and ReadWin 2000 or FieldCare

configuration software

• Upper part of housing can be rotated by 310°

• DESINA-compliant

• TTR35: 3-A marked

Page 2

TTR31, TTR35

Function and system design

Measuring principle Electronic recording and conversion of input signals in industrial temperature measurement. A

platinum sensor located at the measuring tip changes its resistance value depending on the

temperature. This resistance value is recorded electronically. The relation of the measured resistance

value and temperature is defined by the international standard IEC 60751.

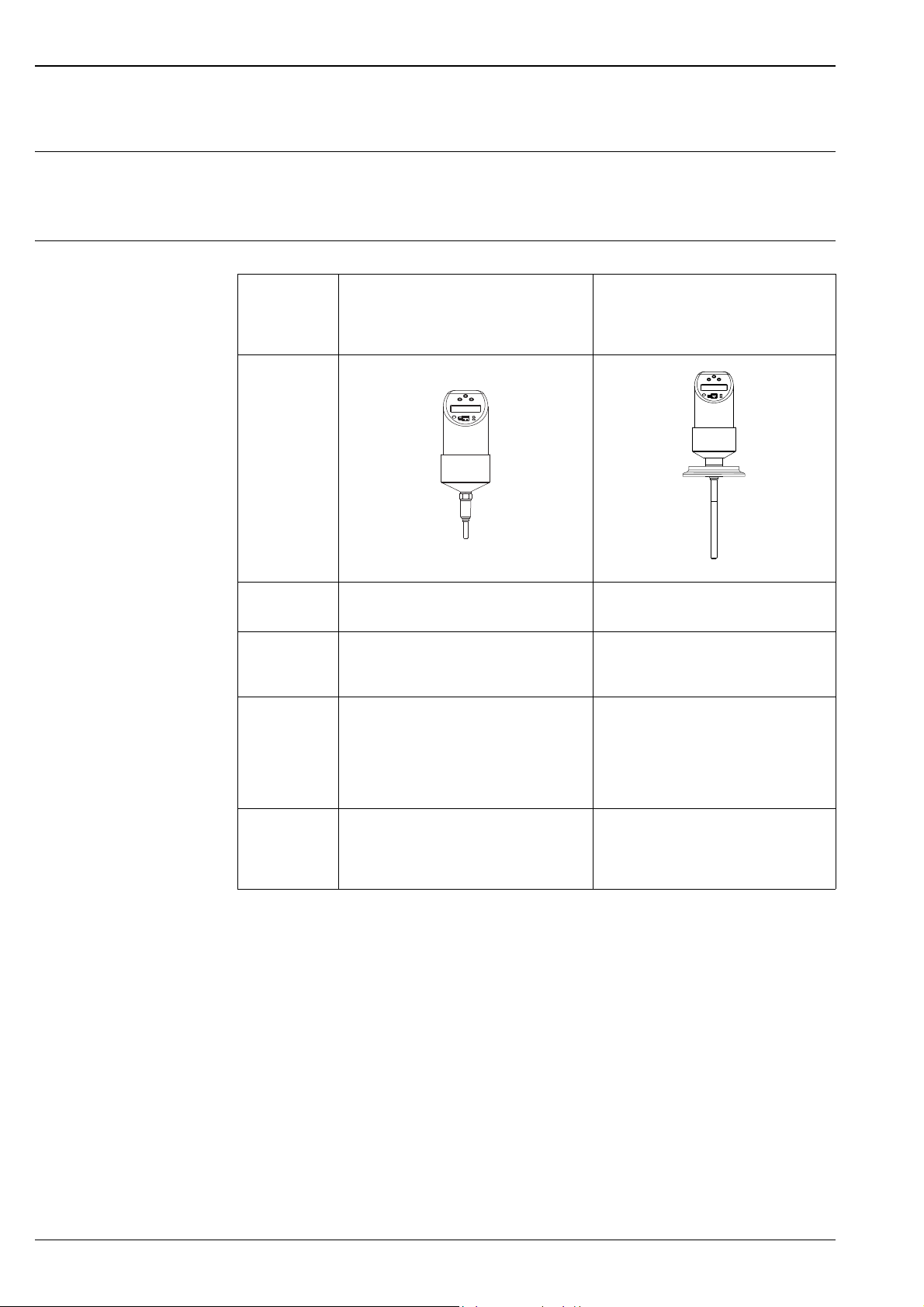

Measuring system Overview

Thermophant

product

family

Sensor

element

Field of

application

Process

connection

TTR31 TTR35

A0005276

Pt100 Pt100

Measurement and monitoring and control of

process temperatures.

• Coupling, sensor length 100 mm

(3.94 in)

•Thread

G½" and G¼"

ANSI NPT ¼" and NPT ½"

Measurement and monitoring and control

of process temperatures in hygienic

processes.

•Hygiene

Conical metal-metal G½"

Clamp 1" - 1½", 2"

Varivent F, N

DIN 11851

APV inline

A0023194

Measuring

range (process

temperature

range)

-50 to +150 °C (-58 to +302 °F)

-50 to +200 °C (-58 to +392 °F) with neck

-50 to +150 °C (-58 to +302 °F)

-50 to +200 °C (-58 to +392 °F) with neck

in hygienic processes

2 Endress+Hauser

Page 3

TTR31, TTR35

é

T

é

T

é

T

2

2

2

A

B

C

1

3

RNB130

24V OVOV24V OV

OV

INAC

24V 13

1

RNB130

24V OVOV24V OV

OV

INAC

24V 13

1

RNB130

24V OVOV24V OV

OV

INAC

24V 13

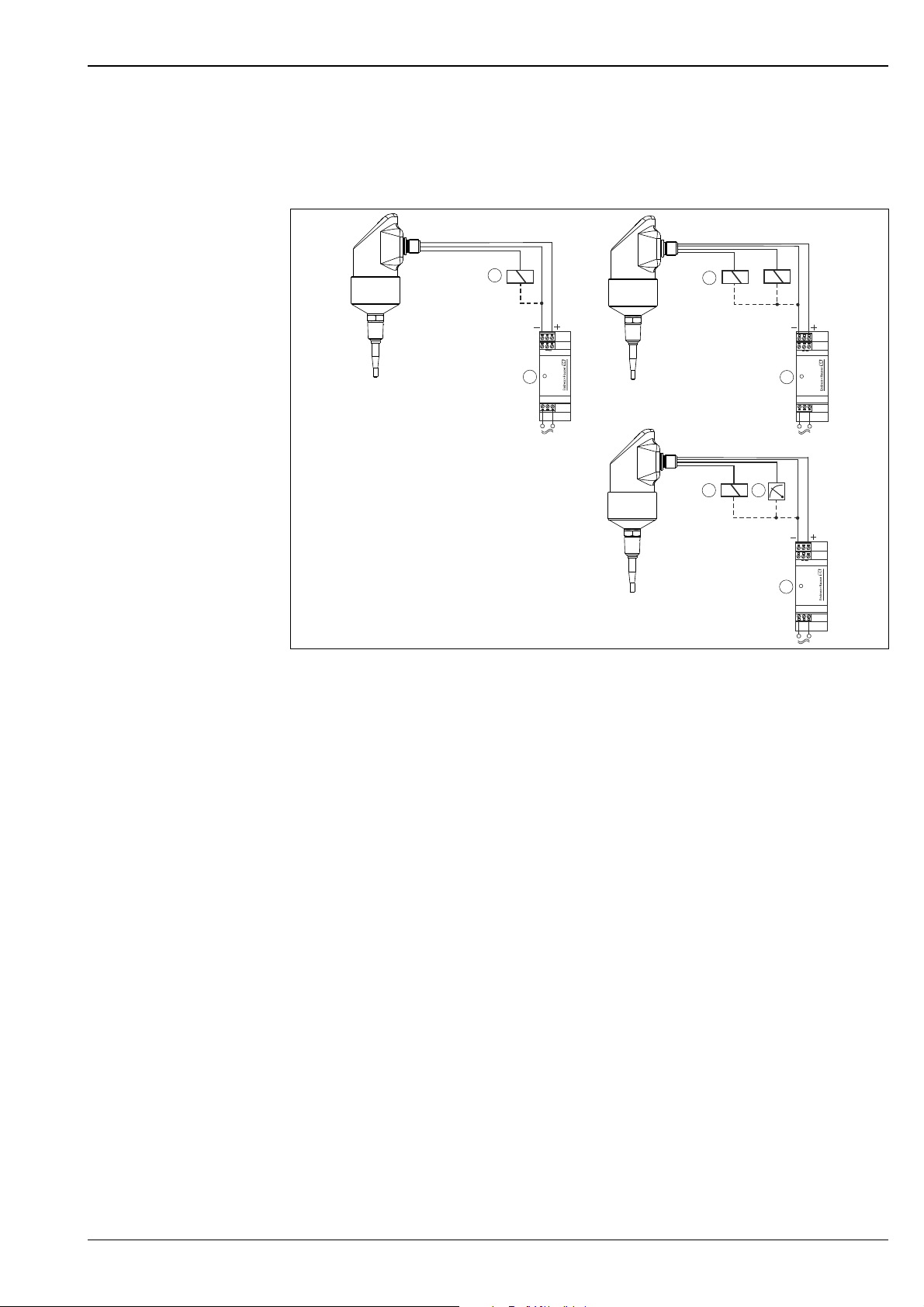

DC voltage version

PNP switch output of electronics.

Power supply e.g. with a power supply unit.

Preferably in conjunction with programmable logic controllers (PLC) or for controlling a relay.

A0023242

A: 1x PNP switch output

B: 2x PNP switch output

C: PNP switch output with additional analog output 4 to 20 mA

Power supply unit e.g. RNB130

Load (e.g. programmable logic controller, process control system, relay)

Display e.g. RIA452 or recorder e.g. Ecograph T or Minilog B (at 4 to 20 mA analog output)

Power supply “Easy Analog RNB130”:

Primary switched-mode power supply for sensors. Space saving DIN rail mounting as per IEC 60715.

Wide-range nominal voltage input: 100 to 240 V AC; Output: 24 V DC, max. 30 V in the event of a

fault; Nominal output current: 1.5 A. Connection to monophased a.c. networks or to two phase

conductors of three-phase supply networks.

Process display RIA452:

If you would like to read off the instantaneous value of the temperature not only locally, but also e.g.

directly from a control room or in the PC network, then one suitable device is the process display

RIA452: Digital process display unit in 96 x 96 mm (3.78 x 3.78 in) panel mounted housing for

monitoring and displaying analog measured values with pump control and batch functions.

Multicoloured 7-digit 14-segment LC display with large bargraph. Configuration and visualisation via

RS232 interface and ReadWin 2000 PC operating software.

Universal Graphic Data Recorder Ecograph T, Data logger Minilog B:

If you would like to read off the instantaneous value of the temperature not only locally, but also record,

analyze and display it e.g. directly from a control room or in the PC network, then the following devices

are suitable:

Endress+Hauser 3

Page 4

• Universal Graphic Data Manager Ecograph T

144 x 144 mm (5.67 x 5.67 in) panel mounted housing for electronic acquisition, display, recording,

analysis, remote transmission and archiving of analog and digital input signals. Multichannel data

recording system with multicoloured TFT display (145 mm (5.7 in) screen size), galvanically isolated

universal inputs (U, I, TC, RTD, pulse, frequency), digital inputs, transmitter power supply, limit relay,

communication interfaces (USB, Ethernet, optional RS232/485), 128 MB internal memory, external

SD card and USB stick. The Field Data Manager Software (FDM) supports data analysis at the PC;

configuration is done via FieldCare or the integrated web server.

• Data logger Minilog B

Battery powered measured value collector with 2 input channels for storing analog and digital

values. Internal memory 128 kB for max. 84000 measured values. Configuration and visualisation

via RS232 interface and ReadWin 2000 PC operating software. Optionally with telealarm function.

Input

Measured variable Temperature (temperature-linear transmission behaviour)

TTR31, TTR35

Measuring range

Designation Measuring range limits Min. span

Pt100 as per IEC 60751 -50 to +150 °C (-58 to +302 °F)

-50 to +200 °C (-58 to +392 °F) with neck

• Sensor current: 0.6 mA

20 K (36 °F)

Output

Output signal DC voltage version: (short-circuit proof version)

• 1x PNP switch output

• 2x PNP switch outputs

• 2x PNP switch outputs or one PNP switch output and 4 to 20 mA output (active)

Signal on alarm •Analog output: 3.6 mA or 21.0 mA adjustable (if setting 21.0 mA the output is 21.5 mA)

• Switch outputs: at safety condition (switch open)

Load Max. (V

Range of adjustment • Switch output:

• Analog output (if available):

• Damping: can be set anywhere between 0...40 s in increments of 0.1 s

•Unit: °C, °F, K

power supply

Switch point (SP) and Switch-back point (RSP) in increments of 0.1 °C (0.18 °F)

Min. distance between SP and RSP: 0.5 °C (0.8 °F)

Lower range value (LRV) and upper range value (URV) can be set anywhere within the sensor range

(min. measuring range 20 K (36 °F))

- 6.5 V) / 0.022 A (current output)

Switching capacity DC voltage version:

• Switch status ON: I

• Switching cycles: > 10,000,000

• Voltage drop PNP: 2 V

• Overload protection: Automatic testing of switching current; output is switched off in case of

overcurrent, the switching current is tested again every 0.5 s; max. capacitance load: 14 F for max.

supply voltage (without resistive load) Periodic disconnection from a protective circuit in event of

overcurrent (f = 2 Hz) and indication of ’Warning’

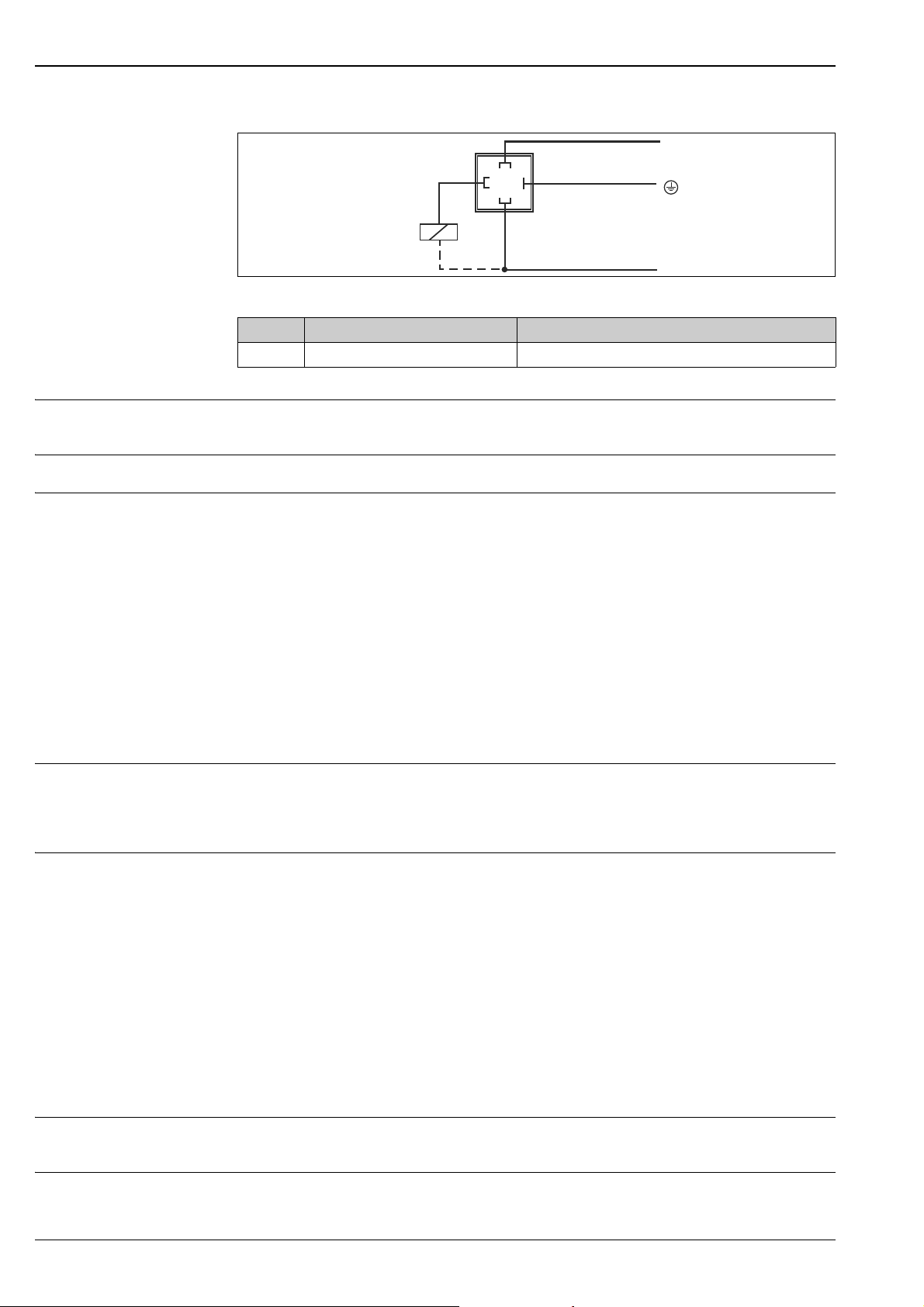

Inductive load To prevent electrical interference, only operate an inductive load (relays, contactors, solenoid valves)

when directly connected to a protective circuit (free-wheeling diode or capacitor).

250 mA, switch status OFF: Ia 1 mA

a

4 Endress+Hauser

Page 5

TTR31, TTR35

AB

M16x1.5 / NPT ½”

M12x1

4...20mA

4...20mA

L–

L–L–

L–

L+

L+L+

L+

2

22

2

1

11

1

3

33

3

4

44

4

R1

m

R1

R1

A1

A2

A2’

A4

A4’

A3

m

Power supply

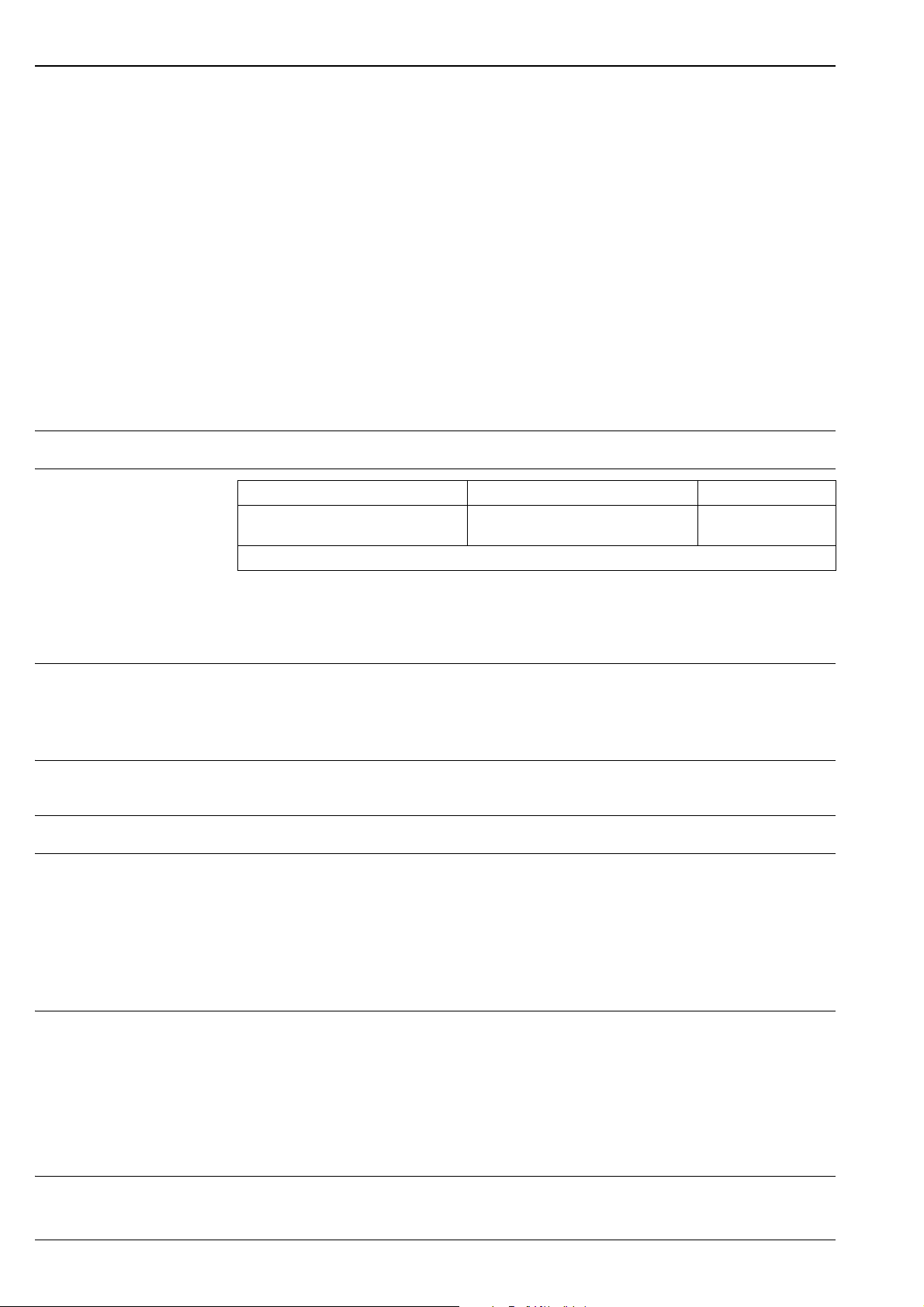

Electrical connection Plug connection

TTR35: Electrical cables must comply with 3-A standard, must be smooth, corrosion resistant

and cleanable.

A: M12x1 connector

B: M16x1.5 or NPT ½" valve plug

A0023196

Device connection

• DC voltage version with M12x1 connector

Pos.-No. Output setting Order code (see chap. ordering information 15)

A1 1x PNP switch output TTR3x-A1A*******

A2 2x PNP switch output R1 and (R2) TTR3x-A1B*******

A2’ 2x PNP switch output R1 and

(diagnosis/break contact with

adjustment "DESINA")

A3 1x PNP switch output and 1x analog

output (4 to 20 mA)

A4 1x analog output (4 to 20 mA) and

A4’ 1x analog output (4 to 20 mA) and

1x PNP switch output (R2)

1x PNP switch output (diagnosis/

break contact with adjustment "DESINA")

A0023243

TTR3x-A1B*******

TTR3x-A1C*******

TTR3x-A1C*******

TTR3x-A1C*******

• DC voltage version with M16x1.5 or NPT ½" valve plug

Endress+Hauser 5

Page 6

Pos.-No. Output setting Order code (see chap. ordering information 15)

1

3

L–

L+

2

R

B

B 1x PNP switch output TTR3x-A2A*******; TTR3x-A3A*******

Supply voltage • DC voltage version

12 to 30 V DC (reverse polarity protection)

Current consumption without load < 60 mA, with reverse polarity protection

TTR31, TTR35

A0023449

Power supply failure • Behaviour in case of overvoltage (> 30 V)

The device works continuously up to 34 V DC without any damage.

No damage is caused to the device in case of a short-term overvoltage up to 1 kV (as per

EN 61000-4-5). The specific properties are no longer guaranteed if the supply voltage is exceeded

• Behaviour in case of undervoltage

If the supply voltage drops below the minimum value, the device switches off (status as if not

supplied with power = switch open).

Performance characteristics

The percentage information in the “Performance characteristics” section refers to the sensor nominal

value.

Reference operating conditions

Maximum measured error switch point and display

As per DIN IEC 60770 or DIN IEC 61003

T = 25 °C (77 °F), relative humidity 45 to 75%, ambient air pressure 860 to 1060 kPa (12.47 to

15.37 PSI)

Supply voltage U = 24 V DC

Electronics

± 0.2 K (0.36 °F)

Sensor

• Tolerance class A as per IEC 60751, -50 to +200 °C (-58 to +392 °F)

• Maximum measured error in °C = ± 0.15 + 0.002 ×

T| = Process temperature in °C without taking sign into account.

|

|T|

Total error

Total error = electronics error + sensor error, e.g. for process temperatures:

• -50 to +75 °C (-58 to +167 °F) 0.5 K (0.9 °F)

• +75 to +200 °C (+167 to +392 °F) 0.75 K (1.35 °F)

Non-repeatability

0.1 K (0.18 °F) as per EN 61298-2 (without ambient temperature influence)

switch point

Long-term drift 0.1 K (0.18 °F) per year under reference operating conditions

6 Endress+Hauser

Page 7

TTR31, TTR35

Sensor response time Measured as per IEC 60751, in water flowing at 0.4 m/s (1.3 ft/s)

t

50

< 1.0 s < 2.0 s

Long-term reliability Mean time between failure (MTBF) > 100 years

(calculated according to "British Telecom Handbook of Reliability Data No. 5")

Influence of ambient temperature

Switch output response time 100 ms

Analog output • Maximum measured error = switch point error and display error + 0.1%

• Switch output and display: 30 ppm/K

•Analog output: 50 ppm/K + influence of switch output and display

•Rise time t

• Settling time t99: 500 ms

: 200 ms

90

t

90

Operating conditions: Installation instructions

Installation instructions • Any orientation

• Housing can be rotated up to 310 °

Orientation

No restrictions. However, self-draining in the process must be guaranteed. If there is an opening to

detect leaks at the process connection, this opening must be at the lowest possible point.

Operating conditions: Environment

Ambient temperature range –40...+85 °C (-40 to +185 °F)

Storage temperature –40...+85 °C (-40 to +185 °F)

Degree of protection IP66: M12 x 1 connector

IP65: M16 x 1,5 or ½ NPT valve plug

Shock resistance 50 g as per DIN IEC 68-2-27 (11 ms)

Vibration resistance • 20 g as per DIN IEC 68-2-6 (10-2000Hz)

• 4 g as per German Lloyd GL Guidelines

Electromagnetic

compatibility (EMC)

CE conformity

EMC to all relevant requirements of the IEC/EN 61326-series and NAMUR Recommendation EMC

(NE21). For details, refer to the Declaration of Conformity.

Maximum fluctuations during EMC-tests: < 1% of measuring span.

Interference immunity to IEC/EN 61326-series, requirements for industrial areas

Interference emission to IEC/EN 61326-series, electrical equipment Class B

Endress+Hauser 7

Page 8

Operating conditions: Process

NOTICE

0

20

40

60

80

100

0 30 60 90 120 150 180 210 240 270 300

L (mm)

P (bar)

0

300

600

900

1200

1500

P (psi)

01234 5 78910

11

L (in)

6

12

Process temperature limits -50 to +150 °C (-58 to +302 °F) or -50 to +200 °C (-58 to +392 °F) with neck

Restrictions depending on process connection and ambient temperature:

• No restriction with coupling (see Accessories, order no. 51004751, 51004753) and neck tube

length min. 20 mm (0.79 in)

• with process connection:

Max. ambient temperature Max. process temperature

up to 25 °C (77 °F) no restriction

up to 40 °C (104 °F) 135 °C (275 °F)

up to 60 °C (140 °F) 120 °C (248 °F)

up to 85 °C (185 °F) 100 °C (212 °F)

Process pressure limits Maximum permitted process pressure depending on the insertion length

TTR31, TTR35

A0008063

Maximum permitted process pressure

L = insertion length

p = process pressure

The diagram takes into consideration not only the overpressure but also the pressure load caused by

the flow, whereby a safety factor of 1.9 has been specified for operation with flow. The maximum

permitted static operating pressure is lower at greater insertion lengths due to the increased bending

load caused by the flow. The calculation assumes the maximum permitted medium velocity for the

respective insertion length (see diagram below).

The maximum process pressure for the conical metal-metal hygienic process connection (Option MB)

is 16 bar (232 PSI)!

8 Endress+Hauser

Page 9

TTR31, TTR35

v (ft/s)

01234 5 78910

11

L (in)

6

12

0

5

10

15

20

25

30

35

40

0 30 60 90 120 150 180 210 240 270 300

L (mm)

v (m/s)

0

15

30

45

60

75

90

105

120

135

Permitted flow velocity depending on the insertion length

Permitted flow velocity

L = Insertion length, during flow

v = Flow velocity

Medium: _____ air; _ _ _ _ water

A0008065

The permitted flow velocity is the minimum from resonance velocity (resonance distance 80%) and

load or buckling caused by flow, which would lead to failure of the thermometer tube or to exceedance

of the safety factor (1.9). Calculation was performed for the specified limit operating conditions of

200 °C (392 °F) and 100 bar (1450 PSI) process pressure.

Endress+Hauser 9

Page 10

Design, dimensions

42.3 (1.66)

97.1 (3.82)

42.1 (1.66)

38.7 (1.52)

36 (1.42)

24 (0.95)

52 (2.05)

38.5 (1.52)

LL

6 (0.24)

L

14 (0.55)

35 (1.38)

L

14 (0.55)

35 (1.38)

38.7 (1.52)

24 (0.95)

38.7 (1.52)

24 (0.95)

6 (0.24)

6 (0.24)

6 (0.24)

1

2

3

m

AB

C

n

L

L1

L2

L1 = L2

TTR31, TTR35

TTR31, TTR35

Mechanical construction

TTR31 design, dimensions for process connections

A0023233

All dimensions in mm (in)

1 TTR31 with neck and M12x1 connector as per IEC 60947-5-2

2 TTR35 with neck and M12x1 connector as per IEC 60947-5-2

3 M16x1.5 or NPT ½" valve plug as per DIN 43650A/ISO 4400

L Insertion length

A0007101

Process connection of the device TTR31

Pos.-No. Version TTR31 Thread length L

A Without process connection. For suitable welding

--

1

Thread length L

2

boss and coupling see ’Accessories’.

B Thread process connection:

• ANSI NPT ¼" ( = AF14)

• ANSI NPT ½" ( = AF27)

C Thread process connection as per ISO 228:

•G¼" ( = AF14)

•G½" ( = AF27)

• 14.3 mm (0.56 in)

• 19 mm (0.75 in)

• 12 mm (0.47 in)

• 14 mm (0.55 in)

• 5.8 mm (0.23 in)

• 8.1 mm (0.32 in)

-

10 Endress+Hauser

Page 11

TTR31, TTR35

DB

43.5 (1.71)

50.5 (1.99)

DL

56.5 (2.22)

64 (2.52)

LL

68 (2.68)

84 (3.31)

18 (0.71)

HL

B

100 (3.94)

82 (3.23)

61.5 (2.42)

19 (0.75)

PL

51 (2.01)

68 (2.68)

13 (0.51)

PH

39 (1.54)

56 (2.21)

13 (0.51)

(APV-Inline)

(CLAMP 1”) (CLAMP 2”)

(Varivent N)

LB

18 (0.71)

66 (2.6)

50 (1.97)

(Varivent F)

(DIN 11851)

(DIN 11851)

L

44 (1.73)

13 (0.51)

PG

(DIN 11851)

70.5 (2.78)

77.5 (3.05)

10 (0.39)

DP

(CLAMP 2.5”)

10 (0.39)

MB

L1

SW/AF 22

37 (1.46)

G½”

27 (1.06)

TTR35 design, dimensions for process connections

All dimensions in mm (in)

L = Insertion length

Item No. Process connection versions TTR35

MB Conical metal-metal for hygienic processes, G½" thread. Suitable welding boss available as

accessory. Thread length L

= 14 mm (0.55 in)

1

-

DB Clamp 1"...1½" (ISO 2852) or DN 25...DN 40 (DIN 32676) 3-A marked and EHEDG certification

DL Clamp 2" (ISO 2852) or DN 50 (DIN 32676)

(Sealing according to EHEDG

positions paper, DN25, DN40).

DP Clamp 2½" (ISO 2852)

LB Varivent

1)

F DN25-32, PN 40

3-A marked and EHEDG certified

LL Varivent1) N DN40-162, PN 40

HL APV inline, DN50, PN40, 316L, (B = 6 x Ø8.6 bores + 2 x M8 thread)

PL DIN 11851, DN50, PN40 (including coupling nut)

PG DIN 11851, DN25, PN40 (including coupling nut)

PH DIN 11851, DN40, PN40 (including coupling nut)

3-A marked and EHEDG certification

(only with EHEDG-certified and selfcentering sealing ring).

1) Varivent® process connections are suitable for installation in VARINLINE® housing connection flanges

Weight approx. 300 g (10.6 oz), depends on sensor length and process connection

A0023235

Material • Process connection: AISI 316L

Surfaces in contact with process in hygienic version with surface quality R

0.8 mm (31.5 in)

a

Coupling nut: AISI 304

• Housing: AISI 316L, with surface quality Ra 0.8 mm (31.5 in)

O ring between housing and sensor modul: EPDM

• Electrical connection:

M12 connector: exterior AISI 316L, interior polyamide (PA)

Valve plug: outer polyamide (PA)

M12 connector: exterior 316L

Cable outer covering: polyurethane (PUR)

O ring between electrical connection and housing: FKM

Endress+Hauser 11

Page 12

•Display:

Operating keys

E

Communication jack

for personal computer

LED for status

Green = ok

Red = error/fault

LED red/green blinking = warning

Digital display

Illumination white (= ok)

Illumination red (= error/fault)

Yellow LEDs for switching states

LED on = switch closed

LED off = switch open

Polycarbonate PC-FR (Lexan®)

Seal between display and housing: SEBS THERMOPLAST K

• Keys: Polycarbonate PC-FR (Lexan®)

Human interface

Operating elements Position of display and operating elements

TTR31, TTR35

®

On-site operation Menu-guided operation using operating keys.

Function group Operating options

BASE

(basic functions)

Unit selection: °C, °F, K

Zero point, offset (automatic and manual)

Damping display value, output signal: anywhere between 0...40 s (in increments of

0.1 s)

Display:

Display of measured value or of configured switch point

Rotation of display by 180°

Switching off of display

Behaviour according to DESINA:

The PIN assignment of the M12 connector is in accordance with the guidelines of

DESINA (DESINA = distributed and standardized installation technology for

machine tools and manufacturing systems)

A0020825-EN

12 Endress+Hauser

Page 13

TTR31, TTR35

Function group Operating options

OUT (configuration of

1st output) and

OUT2

(configuration of 2nd

output, only for

corresponding

electronics version)

4-20 (configuration of

analog output, only for

corresponding

electronic version)

SERV

(service functions)

Output function:

Hysteresis or window function

NC contact or NO contact

(See next diagram)

Analog output 4 to 20 mA

Switch point:

Input value

Acceptance of applied value

Switch point anywhere between 0.5...100 % URL (in increments of 0.1 %)

Switch-back point:

Input value

Acceptance of applied value

Switch-back point anywhere between 0...99.5 % URL (in increments of 0.1 %)

Delay of switch point and switch-back point: can be set anywhere between 0...99 s

(in increments of 0.1 s)

Lower Range Value (LRV) and Upper Range Value (URV) of analog output:

Input value

Acceptance of applied value

Setting of error current: choice of 3.6 mA / 21.0 mA / last current value

Resetting of all settings to factory settings

Setting of locking code

Security locking

Static Revision Counter, incremented each time the configuration is changed

Display of last error to occur

Switch output 1, switch output 2 and analog output simulation

Display of max. measured temperature value

Display of min. measured temperature value

Switch point functions

• Hysteresis function

The hysteresis function enables two-point control via a hysteresis. Depending on the temperature T,

the hysteresis can be set via the switch point SP and the switch-back point RSP.

• Window function

The window function enables the setting of a process window.

• NO contact or NC contact

This switch function is freely selectable.

• Delay times for switch point SP and switch-back point can be set in increments of 1 s. By this means

undesirable temperature peaks of short duration or of high frequency can be filtered out.

Endress+Hauser 13

Page 14

Switch point functions

t

t

1

2

3

4

T

A

B

T

SP

SP

RSP

RSP

0

0

0

0

1

1

1

1

132

A Hysteresis function

B Window function

Window - NC contact

Hysteresis - NC contact

Window - NO contact

Hysteresis - NO contact

SP Switch point

RSP Switch-back point

TTR31, TTR35

A0023240

Remote operation with PC

A0008072

Operation, visualization and maintenance with PC and configuration software.

Item 1: PC with configuration software ReadWin 2000 or FieldCare

Item 2: Configuration kit TXU10-AA or FXA291 (see "Accessories")

Item 3: Temperature switch

In addition to the operating options listed in the previous "Onsite operation" section, the ReadWin 2000

or FieldCare configuration software provides further information on the Thermophant T:

Function group Description

SERVICE Number of switch changes

Device status/error

INFO Tag number

Order code

Limit switch serial number

Electronics serial number

Hardware version

14 Endress+Hauser

Software version

Device version

Page 15

TTR31, TTR35

Certificates and approvals

CE-Mark The device meets the legal requirements of the EC directives. Endress+Hauser confirms that the device

has been successfully tested by applying the CE mark.

Other standards and guidelines

Hygiene standard • EHEDG certification TYPE EL CLASS I. Permitted process connections in accordance with EHEDG,

• IEC 60529:

Degree of protection by housing (IP code)

• IEC 61010-1:

Safety requirements for electrical measurement, control and laboratory instrumentation.

• IEC 61326-series:

Electrical equipment for measurement, control and laboratory use - EMC requirements.

•NAMUR:

User association of automation technology in process industries (www.namur.de)

•NEMA:

Standardization association for the electrical industry in North America.

see "Process connections" section 11

• 3-A authorization no. 1144, 3-A sanitary standard. Permitted process connections in

accordance with 3-A, see also "Process connections" section

• FDA-compliant

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website:

www.endress.com Choose your country Products Select measuring technology, software or

components Select product (picklists: measurement method, product family, etc.) Device

support (right-hand column): Configure your selected product The Product Configurator for the

selected product is opened.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration:

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Endress+Hauser 15

Page 16

TTR31, TTR35

G½”

25 (0.98)

36 (1.42)

30 (1.18)

6 (0.24)

4

3

2

1

AF24

25 (0.98)

30 (1.18)

G½”

6 (0.24)

G½”

45 (1.77 )

15 (0.59)

6 (0.24)

+1

+0.04

AF14

AF27

Accessories

Various accessories, which can be ordered with the device or subsequently from Endress+Hauser, are

available for the device. Detailed information on the order code in question is available from your

local Endress+Hauser sales center or on the product page of the Endress+Hauser website:

www.endress.com.

All dimensions in mm (in).

EN10204-3.1 = Material certificate (melt analysis)

Welding boss with sealing taper for TTR31

Collar welding boss for TTR31

Coupling for TTR31

Collar welding boss moveable with sealing taper,

washer and pressure screw G½",

material of wetted parts: 316L, PEEK

max. process pressure: 10 bar (145 psi)

Order number with pressure screw: 51004751

Order number without pressure screw: 51004752

1) pressure screw, 303/304

2) washer, 303/304

3) sealing taper, PEEK

4) collar welding boss, 316L

Material of parts in contact with process: 316L

Order number: 51004752

Clamping ring, movable, different process

connections, e.g. G½", G¾", G1", NPT½"

coupling and parts in contact with process: 316L

Order number: TA50-HB

A0020709-EN

A0020710

16 Endress+Hauser

A0020174-EN

Page 17

TTR31, TTR35

30 (1.18)

16 (0.63)

34 (1.34)

15 (0.6)

G½”

Model F in mm (in) L ~ in mm (in) C in mm

(in)

TA50 G½" SW/AF 27 47 (1,85) - 15 (0,6) SS316

G¾" SW/AF 32 63 (2,48) - 20 (0,8) SS316

G1" SW/AF 41 65 (2,56) - 25 (0,98) SS316

NPT½" SW/AF 22 50 (1,97) - 20 (0,8) SS316

R½" SW/AF 22 52 (2,05) - 20 (0,8) PTFE

R¾" SW/AF 27 52 (2,05) - 20 (0,8) PTFE

B in mm

(in)

Material

ferrule

1)

2)

PTFE

1)

2)

PTFE

1)

2)

PTFE

1)

2)

2)

TA70 weld-in 30 (1,18) 76 (3) 34 (1,34) - Silopren®

Max. process

temperature

800 °C (1 472 °F) 40 bar at 20 °C

200 °C (392 °F) 5 bar at 20 °C

800 °C (1 472 °F) 40 bar at 20 °C

200 °C (392 °F) 5 bar at 20 °C

800 °C (1 472 °F) 40 bar at 20 °C

200 °C (392 °F) 5 bar at 20 °C

800 °C (1 472 °F) 40 bar at 20 °C

200 °C (392 °F) 5 bar at 20 °C

200 °C (392 °F) 5 bar at 20 °C

2)

180 °C (356 °F)

Max. process

pressure

(580 psi at 68 °F)

(72,5 psi at 68 °F)

(580 psi at 68 °F)

(72,5 psi at 68 °F)

(580 psi at 68 °F)

(72,5 psi at 68 °F)

(580 psi at 68 °F)

(72,5 psi at 68 °F)

(72,5 psi at 68 °F)

20 bar at 20 °C

(290 psi at 68 °F)

1) SS316-compression ferrule: Can only be used once, the compression fitting cannot be repositioned on the thermowell after loosening. Fully adjustable immersion length on initial installation.

2) PTFE/Silopren®-compression ferrule: Can be reused, after loosening the fitting can be moved up and down the thermowell. With fully adjustable

immersion length

Welding boss with sealing taper (metal-metal) for TTR35

Welding boss for G½" thread

Seal, metal-metal,

Material of parts in contact with process:

316L/1.4435

Max. process pressure 16 bar (232 PSI)

Order number: 60021387

A0006621

Coupling

Coupling M12x1 for simple user installable

assembly of the connecting cable; straight

connection to M12x1 housing connector

Order number: 52006263

P01-PMP13xxx-00-xx-00-xx-003

Endress+Hauser 17

Page 18

TTR31, TTR35

20

(0.79)

41

(1.61)

35 (1.38)

14.8

(0.58)

1

2 (WH) nc

2

1 (BN) +

4

3 (BU) -

3

4 (BK) nc

ye 1

ye 2 gn

Coupling

Connecting cable (preassembled)

Connecting cable with LED

Coupling M12x1 for simple user installable

assembly of the connecting cable; elbowed;

connection to M12x1 housing connector

IP67, PG7

Order number: 51006327

PVC cable, 4 x 0.34 mm2 (22 AWG) with M12x1

coupling, elbowed, screw plug, length 5 m (16.4

ft), IP67

Order number: 51005148

Core colours:

- 1 = BN brown

- 2 = WH white

- 3 = BU blue

- 4 = BK black

PVC cable, 4 x 0.34 mm2 (22 AWG) with M12x1

coupling, with LED, elbowed, 316L screw plug,

length 5 m (16.4 ft), specially for hygiene

applications, IP 69K

Order number: 52018763

Display:

gn: device operational

ye1: switch status 1

ye2: switch status 2

Not for use at devices with "4 to 20 mA

analog output" option!

A0020722

A0020723

T09-TTR31xxx-00-00-xx-xx-001

Configuration kit

• Configuration kit for PC-programmable

transmitters - ReadWin 2000 setup program

and interface cable for PCs with USB port.

Adapter for transmitters with 4-pole post

connector.

Order code: TXU10-AA

• Configuration kit "Commubox FXA291" with

interface cable for PCs with USB port.

Intrinsically safe CDI interface

(Endress+Hauser Common Data Interface) for

transmitters with 4-pole post connector.

Suitable device configuration tool is e.g.

FieldCare.

Order code: FXA291

18 Endress+Hauser

A0008067

Page 19

TTR31, TTR35

Configuration software

Power supply • Power supply Easy Analog RNB130 by Endress+Hauser with nominal output current IN = 1.5 A.

• ReadWin 2000 and FieldCare ’Device Setup’ can be downloaded free of charge directly from the

internet at the following addresses:

www.endress.com/readwin

www.products.endress.com/fieldcare

For the order of the FieldCare ’Device Setup’ software please ask your Endress+Hauser sales organisation.

Details see Technical information TI120R/09/en.

• Process display RIA452 by Endress+Hauser with transmitter power supply,

max. output current I = 250 mA.

Details see Technical information TI113R/09/en.

Documentation

Technical information • Easy Analog RNB130: TI120R/09/en

• Process display RIA452: TI113R/09/en

• Universal Data Manager Ecograph T: TI01079R/09/en

• Data logger Minilog B: TI089R/09/en

Operating Instructions • Thermophant T TTR31 / TTR35 temperature switch: BA00229R/09/en

• Configuration software ReadWin 2000: BA137R/09/en

• Configuration software FieldCare: BA027S/04/c4

Endress+Hauser 19

Page 20

www.addresses.endress.com

Loading...

Loading...