Page 1

TI01135T/09/EN/02.14

71262402

Products Solutions Services

Technical Information

Industrial thermowell

TT511

For Oil & Gas applications

Vanstone type, design with collar flange

Application

The thermowell will be used in applications with high process requirements. The

predominant industries are Oil & Gas and Petrochemical. The process connection

flange ist not welded on the thermowell stem but designed as collar flange. This

special Vanstone thermowell design enables a wide variety of applications and is

suitable for resistance and thermocouple thermometers.

Your benefits

• Solid thermowell, made of drilled barstock material.

• Fulfillment of various, industry specific requirements with a standard product.

Flexible selection of immersion length and thermowell geometry according to the

process specifications.

• In accordance with Shell specification: S.38.113 rev.D and S.38.114 rev.D

• Exact thermowell stress calculation ensuring safe plant operation.

• Vanstone design with outstanding cost effectiveness:

– Reuse of the flange if the thermowell has to be replaced.

– Use of a standard lap joint flange according to ANSI/ASME B16.5 and

EN 1092-1.

– Flexible selection of the flange material, independent from process conditions

and thermowell as it is not in contact with the process medium and it is not

welded on.

– Reduced spare parts and storing concept: one flange can be used for a variety of

thermowells.

Page 2

Function and system design

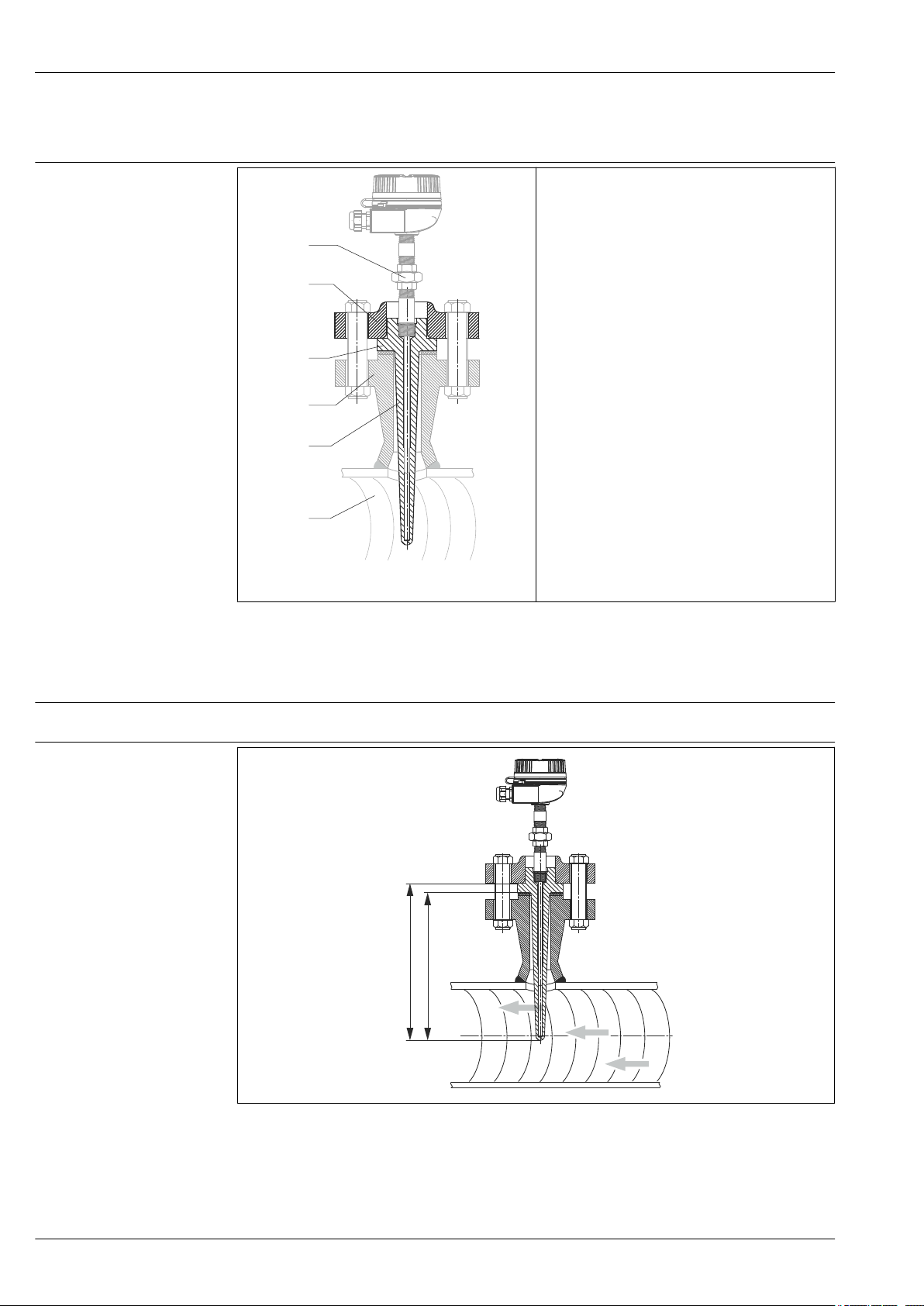

1

2

3

4

5

6

L

U

Industrial thermowell TT511

Device architecture

The TT511 Vanstone thermowell is designed as a

special thermowell for thermometer installation (1).

The thermowell shaft (5) and the flange (2) as the

process connection are not interconnected. For

installation in the process (6), the collar (3) of the

thermowell is fitted between two flanges. The flange

(2) on the thermowell side is a slip-on flange that is

fitted onto the thermowell (2) and is bolted to the

connection nozzle (4) on the process side. Many

different flange versions are available to secure the

unit to the permanently installed nozzle flange (4) on

the process side.

The thermowell is machined from solid bar stock.

A0021985

1 TT511 design

Orientation

Installation instructions

Installation

No restrictions.

A0021995

Mounting the TT511

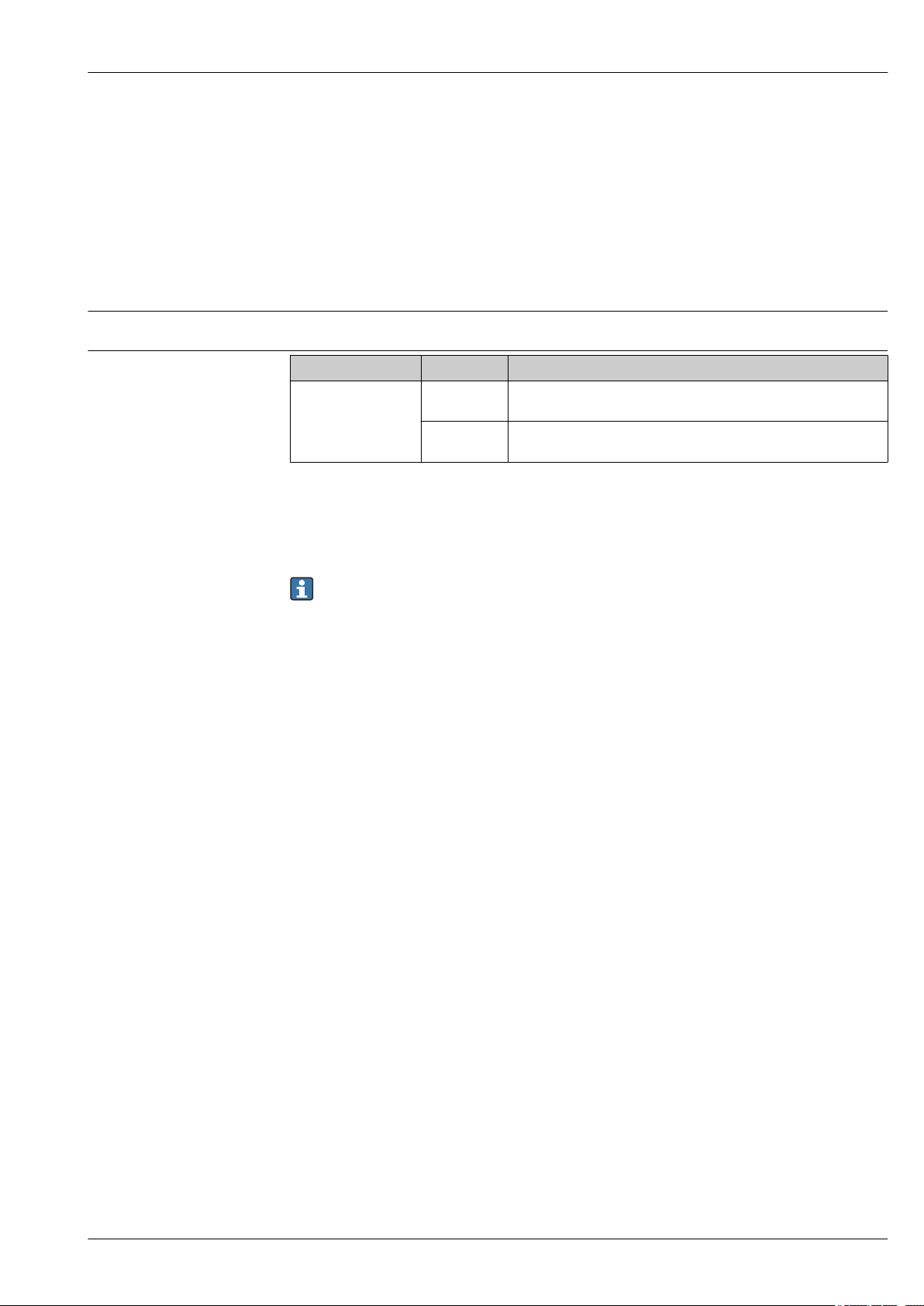

2

The immersion length U of the thermowell can influence the accuracy. If the immersion length is too

small, heat conduction via the process connection and the container wall can cause measurement

errors in the installed thermometer. Therefore, if installing into a pipe the immersion length should

2

Page 3

Industrial thermowell TT511

ideally be half of the pipe diameter. When determining the immersion length or installation depth,

all parameters of the thermowell and the process to be measured must be taken into account (e.g.

flow velocity, process pressure). The counterpieces for the process connections and the seals or

sealing rings are not included in the scope of supply for the thermowell.

Installation possibilities: pipes, tanks or other plant components

Process

Process temperature range

Process pressure (static)

For the maximum operating temperatures, see the 'Material' section. (

Process connection Standard Max. process pressure

Flange EN1092-1 Depending on the flange pressure rating PN:

ASME B16.5 Depending on the flange pressure rating:

Permitted flow velocity depending on the immersion length

The maximum flow velocity tolerated by the thermowell diminishes with increasing thermowell

immersion length exposed to the stream of the fluid. In addition, it depends on the shape and size of

the thermowell, the medium type, process temperature and process pressure.

Thermowell sizing tool

It is possible to check the mechanical loading capacity as a function of the installation and

process conditions online in the TW Sizing Module for thermowells in the Endress+Hauser

Applicator software. See https://wapps.endress.com/applicator

, 63 bar, 100 bar or 160 bar.

40 bar

150 psi, 300 psi, 400 psi, 600 psi, 900 psi, 1500 psi, 2500 psi

→ 7)

3

Page 4

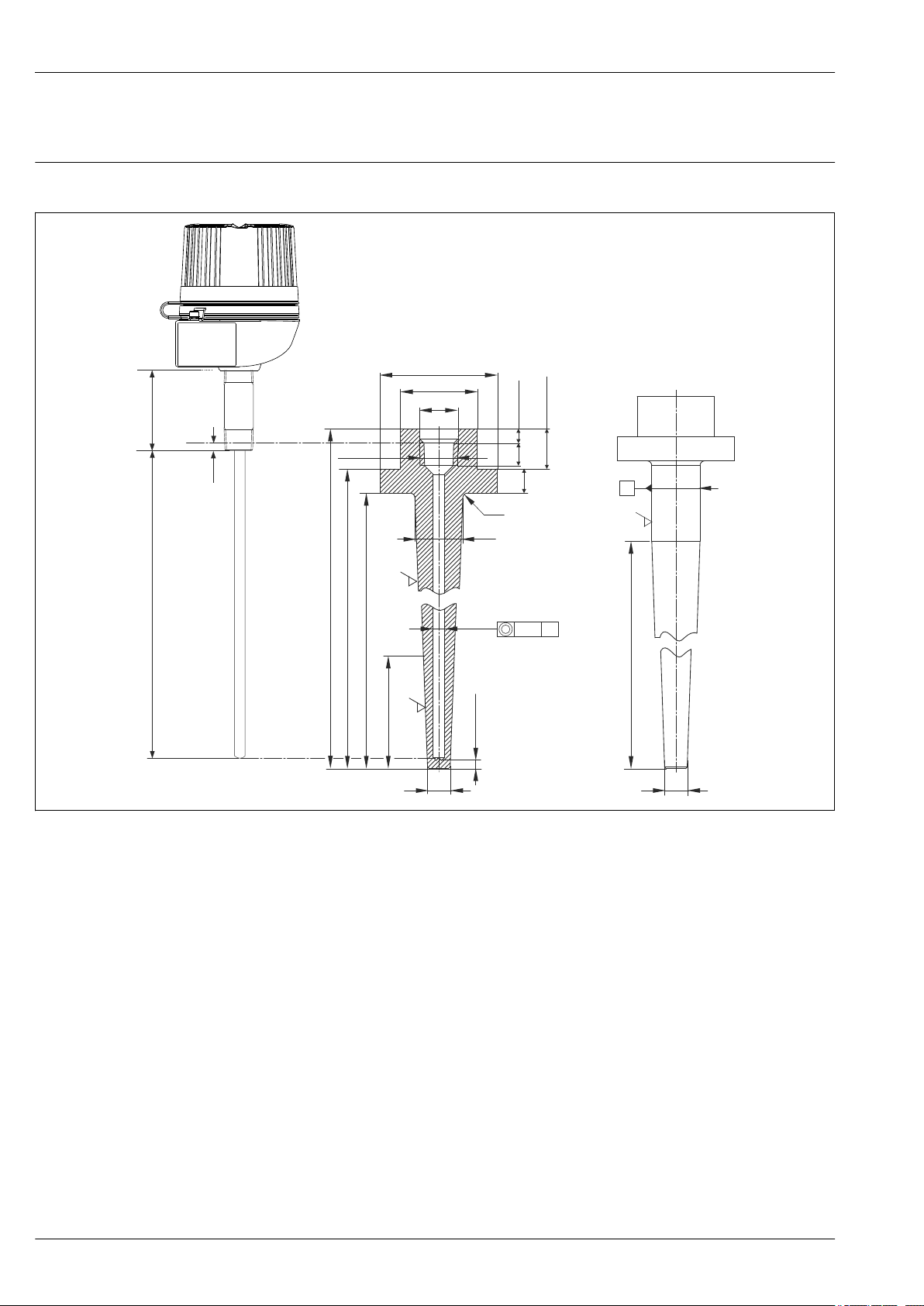

Mechanical construction

5 (0.2)

Q2

!7

(0.28)

1 2

U

L

120 (4.72)

Q1

R3

X

9 (0.35)

14

(0.55)

25 (0.98)

½“ NPT

!24

(0.95)

!B

!A

L

T

Q2

R

Q1

Ra

Ra

Ra

!0.2

A

A

N

TL

ML

Design, dimensions Vanstone thermowell, type 1

Industrial thermowell TT511

A0022004

All dimensions in mm (in)

3

1 Version DN40 (NPS 1-½") or DN50 (NPS 2"), tapered

2 Version DN40 (NPS 1-½") for L > 300 mm (11.81 in): straight with tapered tip

U Immersion length

R Length of tapered tip

L Standard length

LT Complete thermowell length

ML Insertion length

TL Thread length

N Extension neck length

4

Page 5

Industrial thermowell TT511

The insertion length ML is calculated as follows:

ML = LT - 9 mm

(0.35 in) - 8 mm (0.31 in)

1)

- 5 mm (0.197 in)

Short form: ML = LT - 19 mm (0.75 in)

2)

+ 3 mm (0.12 in)

3)

Version L L

DN40 (NPS 1½") 230 mm

DN50 (NPS 2") 230 mm

in)

(9.1

255 mm

(10.04 in)

305 mm

(12 in)

355 mm

(13.98 in)

405 mm

(15.95 in)

455 mm

(17.91 in)

(9.1 in)

255 mm

(10.04 in)

T

255 mm

(10.04 in)

280 mm

(11.02 in)

330 mm

(13 in)

380 mm

(15 in)

430 mm

(16.93 in)

480 mm

(19 in)

255 mm

(10.04 in)

280 mm

(11.02 in)

U R ExtensionX⌀A ⌀B ⌀Q1 ⌀Q2

215 mm

(8.46 in)

240 mm

(9.45 in)

290 mm

(11.42 in)

340 mm

(13.39 in)

390 mm

(15.35 in)

440 mm

(17.32 in)

210 mm

(8.27 in)

235 mm

(9.25 in)

R = U

240 mm

(9.45 in)

R = U

15 mm

(0.6 in)

20 mm

(0.79 in)

73 mm

(2.87 in)

92 mm

(3.62 in)

48 mm

(1.89 in)

60 mm

(2.36 in)

30 mm

(1.18 in)

30 mm

(1.18 in)

Laser treated specification marking on the lateral surface, e. g. DN50 (nominal diameter),

PN160 (pressure rating), L300 (standard length)-7 (bore diameter), 1.4571 (material), S/N

(serial number), Heat (heat number), TAG

Examples of product configuration

19 mm (³⁄₄ in)

19 mm (³⁄₄ in)

Type 1: DN40 (NPS 1-½")

TT511- A 11 B 12 A 13 B 14

A Nominal diameter, material: DN40 (NPS 1-½"); 316

11 Extension: 15 mm (⁵⁄₈ in) + 25 mm (1 in) DN40 (NPS 1-½")

B Thermometer connection: thread NPT ½"

12 Thermowell geometry: Q1 = 30 mm (¹⁹⁄₁₆ in), Q2 = 19 mm (³⁄₄ in), R = 240 mm (9.45 in)

A Bore diameter: 7 mm (¹⁄₄ in)

13 Bottom thickness; bore shape; tip: D = 5 mm (¹⁄₅ in); standard; flat chamfered

B Surface: Ra ≤ 0.8

14 Standard length: 355 mm (14 in) → selectable according to requirements

Type 1: DN50 (NPS 2")

TT511- B 12 B 11 A 13 A 11

B Nominal diameter, material: DN50 (NPS 2"); 316

12 Extension: 20 mm (³⁄₄ in) + 25 mm (1 in) DN50 (NPS 2")

B Thermometer connection: thread NPT ½"

11 Thermowell geometry: Q1 = 30 mm (¹⁹⁄₁₆ in), Q2 = 19 mm (³⁄₄ in), tapered

1) TL = Thread length

2) Bottom thickness

Distance spring load

3)

5

Page 6

TT511- B 12 B 11 A 13 A 11

R

8 (0.31)

Q2 = !13

(0.51)

!7

(0.28)

R15

(0.6)

L

!50 (1.97)

10 (0.4)

Q1 =

!20 (0.79)

U

5 (0.2)

R1.5

(0.06)

3 (0.12)

30°

!92 (3.62)

1 2

!0.5

A

A

ML

10

(0.4)

A Bore diameter: 7 mm (¹⁄₄ in)

13 Bottom thickness; bore shape; tip: D = 5 mm (¹⁄₅ in); standard; flat chamfered

A Surface: roughened Ra = 6

11 Standard length: 230 mm (9.055 in) → selectable according to requirements

Vanstone thermowell, type 2

Industrial thermowell TT511

4) Bottom thickness

5) Distance spring load

6

All dimensions in mm (in)

4

1 Version DN25, round tip, surface roughness Ra ≤ 1.6

2 Version DN50, round tip, surface roughness Ra ≤ 1.6, full penetration welded collar

U Immersion length

L Standard length in a range from 150 mm (5.9 in) to 500 mm (19.7 in) in 50 mm (1.97 in) increments

R Tapered length 150 mm (5.9 in) or 175 mm (6.9 in), dependent on standard length L

ML Insertion length

The insertion length ML is calculated as follows:

ML = L - 8 mm

(0.31 in)

Short form: ML = L + 5 mm (0.197 in)

4)

+ 10 mm (0.4 in) + 3 mm (0.12 in)

5)

A0021954

Page 7

Industrial thermowell TT511

Examples of product configuration

Type 2: DN25

TT511- C 31 A 31 A 31 C 22

C Nominal diameter, material: DN25; 1.4571

31 Extension: 10 mm (0.4 in)

A Thermometer connection: without

31 Thermowell geometry: Q1 = 20 mm (³⁄₄ in), Q2 = 13 mm (0.51 in), R = 100 mm (3.94 in)

A Bore diameter: 7 mm (¹⁄₄ in)

31 Bottom thickness; bore shape; tip: D = 8 mm (0.32 in); flat; round R15

C Surface: Ra ≤ 1.6

22 Standard length: 200 mm (7.87 in) → selectable according to requirements

Type 2: DN50

TT511- D 32 A 32 A 31 C 26

D Nominal diameter, material: DN50; 1.4571

32 Extension: 10 mm (0.4 in), welded version

A Thermometer connection: without

32 Thermowell geometry: Q1 = 20 mm (³⁄₄ in), Q2 = 13 mm (0.51 in), R = 175 mm (6.9 in)

A Bore diameter: 7 mm (¹⁄₄ in)

31 Bottom thickness; bore shape; tip: D = 8 mm (0.32 in); flat; round R15

C Surface: Ra ≤ 1.6

26 Standard length: 400 mm (15.75 in) → selectable according to requirements

Weight

Material

Laser treated specification marking on the lateral surface, e. g. DN50 (nominal diameter),

PN160 (pressure rating), B300 (standard length)-7 (bore diameter), 1.4571 (material), S/N

(serial number), Heat (heat number), TAG

Variable, according to version and standard length. Some examples:

Version DN40 (NPS 1½") 1.9 kg (4.2 lb) with L = 305 mm (12 in)

Version DN40 (NPS 2") 2.3 kg (5 lb) with L = 230 mm (9.05 in)

Version DN25, round tip 0.6 kg (1.32 lb) with L = 300 mm (11.81 in)

Version DN50, round tip,

full penetration welded

collar

1.1 kg (2.43 lb) with L = 300 mm (11.81 in)

Thermowell and process connections

The temperatures for continuous operation specified in the following table are only intended as

reference values for use of the various materials in air and without any significant compressive load.

7

Page 8

Industrial thermowell TT511

!l

!D

!k

b

h

!J

!m

The maximum operation temperatures are reduced considerably in some cases where abnormal

conditions such as high mechanical load occur or in aggressive media.

Material name Short form Recommended

max. temperature

for continuous use

in air

AISI

316/1.4401

AISI

A105/1.0460

AISI 316Ti/

1.4571

X5CrNiMo 17-12-2 650 °C (1 202 °F) •

C22.8 450 °C (842 °F) • Heat-resistant steel

X6CrNiMoTi17-12-2 700 °C (1 292 °F) • Addition of titanium means increased

Properties

Austenitic, stainless steel

• High corrosion resistance in general

• Particularly high corrosion resistance in

chlorine-based and acidic, non-oxidizing

atmospheres through the addition of

molybdenum (e.g. phosphoric and sulfuric

acids, acetic and tartaric acids with a low

concentration)

• Resistant to atmospheres which contain

nitrogen and are low in oxygen; not suitable

for acids or other aggressive media

• Often used for boilers, water and steam pipes,

pressure vessels

resistance to intergranular corrosion even

after welding

• Broad range of uses in the chemical,

petrochemical and oil industries as well as in

coal chemistry

• Can only be polished to a limited extent,

titanium streaks can form

Process connection

The process connection is provided via the following specified flange connections. The figures shown

below feature the relevant dimensions.

• Standard lap joint flange according to ASME B16.5 for thermowell types DN40 (NPS 1-½") and

DN50 (NPS 2").

• Special design flange (lap joint flange) similar

to DIN EN 1092-1, including safety plug with

chain, length = 150 mm (5.9 in).

5 Dimensions of process connection flange DN40 (NPS 1-½") and DN50 (NPS 2") according to ASME B16.5

Dimensions of process connection flange according to ASME B16.5 in mm (in)

Version Nominal pressure

steps in lb/in²

DN40 (1½") 150 127 (5) 17.5 (0.69) 22.4 (0.88) 98.6 (3.88) 15,7 (0,62) x4

300

900/1500 177.8 (7) 31.8 (1.25) 44.5 (1.75) 124 (4.88) 28.4 (1.12) x4

⌀D b h ⌀k ⌀l ⌀J ⌀m

155.4 (6.12)

20.6 (0.81) 30.2 (1.19)

114.3 (4.5) 22.4 (0.88) x4

A0022167

65 (2,56)

50 (1,97)

69.9 (2.75)400/600 22.4 (0.88) 31.8 (1.25)

8

Page 9

Industrial thermowell TT511

G½“

3.5

(0.14)

2 (0.08)

18

(0.71)

10

(0.4)

!N

!14 (0.55)

C

!w

!x

!L

!K

!D

H

G½“

3.5

(0.14)

18

(0.71)

10

(0.4)

"14

(0.55)

2 (0.08)

"N

C

"L

"K

"D

H

"94 (3.7)

Version Nominal pressure

steps in lb/in²

DN50 (2") 150 152.4 (6) 19.1 (0.75) 25.4 (1) 120.7 (4.75) 19.1 (0.75) x4

300

400/600 25.4 (1) 36.6 (1.44)

900/1500 215.9 (8.5) 38.1 (1.5) 57.2 (2.25) 165.1 (6.5) 25.4 (1) x8 104.6 (4.12)

2500 235 (9.25) 50.8 (2) 69.9 (2.75) 171.5 (6.75) 28.4 (1.12) x8 95.3 (3.75)

⌀D b h ⌀k ⌀l ⌀J ⌀m

165.1 (6.5)

22.4 (0.88) 33.3 (1.31)

127 (5) 19.1 (0.75) x8 84.1 (3.31)

77.7 (3.06)

62.5 (2.46)

6 Dimensions of process connection flange

similar to DIN EN 1092-1, version DN25, PN40 - PN160

Dimensions of process connection flange according to DIN EN 1092-1 in mm (in)

Version ⌀D C H ⌀K ⌀L ⌀N ⌀w ⌀x

DN25/PN40 115 (4.53) 18 (0.71)

DN25/PN100,

PN160

140 (5.51) 24 (0.95) 100 (3.94) 18 (0.71), x4 52 (2.05) 65 (2.56)

30 (1.18)

85 (3.35) 14 (0.55), x4 46 (1.81)

51 (2)

A0022168

68 (2.7)

7 Dimensions of process connection flange

PN100 - PN160 and DN80, PN40

A0022224

similar to DIN EN 1092-1, version DN50, PN40, PN63,

9

Page 10

Industrial thermowell TT511

25 (0.98)

10

(0.4)

G½“

"26

(1.02)

2.5

(0.1)

12 (0.47)

Dimensions of process connection flange according to DIN EN 1092-1 in mm (in)

Version ⌀D C H ⌀K ⌀L ⌀N

DN50/PN40 165 (6.5) 20 (0.79)

DN50, PN63 235 (9.25) 25 (0.98) 180 (7.1) 23 (0.91), x4 90 (3.54)

DN50/PN100,

PN160

DN80, PN40 200 (7.9) 24 (0.94) 160 (6.3) 18 (0.71), x4 105 (4.13)

195 (7.7) - 145 (5.71) 27 (1.06), x4 -

8 Safety plug with chain

30 (1.18)

125 (4.9) 18 (0.71), x4 75 (2.95)

A0022217

PED approval

Material certification

Canadian Registration Number (CRN)

Test on thermowell

Certificates and approvals

The thermowell complies with Art. 3.3 of Pressure Equipment Directive 97/23/EC and is not labeled

separately.

The material certificate 3.1 (according to standard EN 10204) can be selected directly in the order

code. Other material-specific certificates can be requested separately. The "short form" certificate

includes a simplified declaration and has no enclosures of documents related to the materials used,

but guarantees the traceability of the materials through the identification number of the thermowell.

The data related to the origin of the materials can subsequently be requested by the client if

necessary.

CRN-No: OF16064.5

The CRN approval applies for the following thermowell options:

• Nominal diameter DN40 (NPS 1½") for a standard length L up to 455

mm (18 in)

• Nominal diameter DN50 (NPS 2") for a standard length L up to 255 mm (10 in)

More detailed information is available:

• In the download section of the Endress+Hauser website: www.endress.com → Select country →

Download → Enter product root/device → Search area: approvals & certificates → Select certificate

type → Start search

• From your Endress+Hauser Sales Center: www.endress.com/worldwide

Helium leak test as per EN 1779 Leak test for thermowells, welding seams and threaded joints. Depending

on the design and size of the thermowell, it can be subjected to helium gas

internally or externally.

With inspection certificate

Hydrostatic pressure test External and internal pressure test with maximum 400 bar (5 801 psi) to

check the pressure resistance and leak-tightness of thermowells, without

flanges. Internal pressure test only possible for thermowells with an

internal thread (type 1).

With inspection certificate

6)

7)

6) Product configuration, item 10, option A

7) Product configuration, item 10, option B

10

Page 11

Industrial thermowell TT511

Positive material identification

(PMI) test

Load capacity calculation for the

thermowell

Dye penetration test as per ASME

V and EN571-1

Bore concentricity test for

thermowells

Radiographic test as per ASME V,

VIII, TW welding

Nondestructive material identification and testing of welded joints.

Material identification check, X-ray fluorescence analysis

With inspection certificate

In accordance with DIN 43772 or ASME PTC19.3 with calculation

certificate

Suitable for checking welding seam surfaces, e.g. detection of small cracks,

etc.

With inspection certificate

With inspection certificate

With inspection certificate

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser web site: www.endress.com

country → Products → Select measuring technology, software or components → Select product

(picklists: measurement method, product family etc.) → Device support (right-hand column):

Configure the selected product → The Product Configurator for the selected product is opened.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

Depending on the device: Direct input of measuring point-specific information such as

•

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

→ Choose your

Service-specific accessories

Accessories

Accessories Description

Applicator Software for selecting and sizing Endress+Hauser measuring devices:

• Calculation of all the necessary data for identifying the optimum measuring

device: e.g. pressure loss, accuracy or process connections.

Graphic illustration of the calculation results

•

Administration, documentation and access to all project-related data and

parameters over the entire life cycle of a project.

Applicator is available:

• Via the Internet: https://wapps.endress.com/applicator

• On CD-ROM for local PC installation.

Konfigurator

+temperature

Software for selecting and configuring the product depending on the measuring

task, supported by graphics. Includes a comprehensive knowledge database and

calculation tools:

• For temperature competence

Quick and easy design and sizing of temperature measuring points

•

• Ideal measuring point design and sizing to suit the processes and needs of a wide

range of industries

The Konfigurator is available:

On request from your Endress+Hauser sales office on a CD-ROM for local PC

installation.

11

Page 12

Industrial thermowell TT511

W@M Life cycle management for your plant

W@M supports you with a wide range of software applications over the entire

process: from planning and procurement, to the installation, commissioning and

operation of the measuring devices. All the relevant device information, such as

the device status, spare parts and device-specific documentation, is available for

every device over the entire life cycle.

The application already contains the data of your Endress+Hauser device. Endress

+Hauser also takes care of maintaining and updating the data records.

W@M is available:

• Via the Internet: www.endress.com/lifecyclemanagement

On CD-ROM for local PC installation.

•

FieldCare FDT-based plant asset management tool from Endress+Hauser.

It can configure all smart field units in your system and helps you manage them. By

using the status information, it is also a simple but effective way of checking their

status and condition.

For details, see Operating Instructions BA00027S and BA00059S

www.addresses.endress.com

Loading...

Loading...