Endress+Hauser TT411 Specifications

TI01099T/09/EN/05.18

71419903

2018-12-07

Products

Solutions Services

Technical Information

iTHERM TT411

Welded thermowell

Use in hygienic and aseptic applications in the food

& beverages and pharmaceutical industries

Applications

• Specially designed for use in hygienic and aseptic applications in the

Food & Beverages and Life Sciences industries

• Pressure range up to 40 bar (580 psi)

• For increased protection requirements of the temperature sensor regarding

physical and chemical effects

• For use in pipes and containers or tanks

• Ideally suited to all measuring points that require regular recalibration by simply

replacing the insert in closed processes

Your benefits

• iTHERM QuickNeck – cost and time savings thanks to simple, tool-free

recalibration of the insert used

• Over 50 hygienic process connections

• Global portfolio with metric and imperial versions

• International certification: 3-A Sanitary Standard, EHEDG, ASME BPE, FDA, TSE

Certificate of Suitability

• Optional: 1.4435 material, delta ferrite content < 0.5%

• Fast response time owing to reduced tips with thin walls

• State of the art T-pieces and elbow pieces, no welds and dead legs with best-inclass hygienic design

Installation

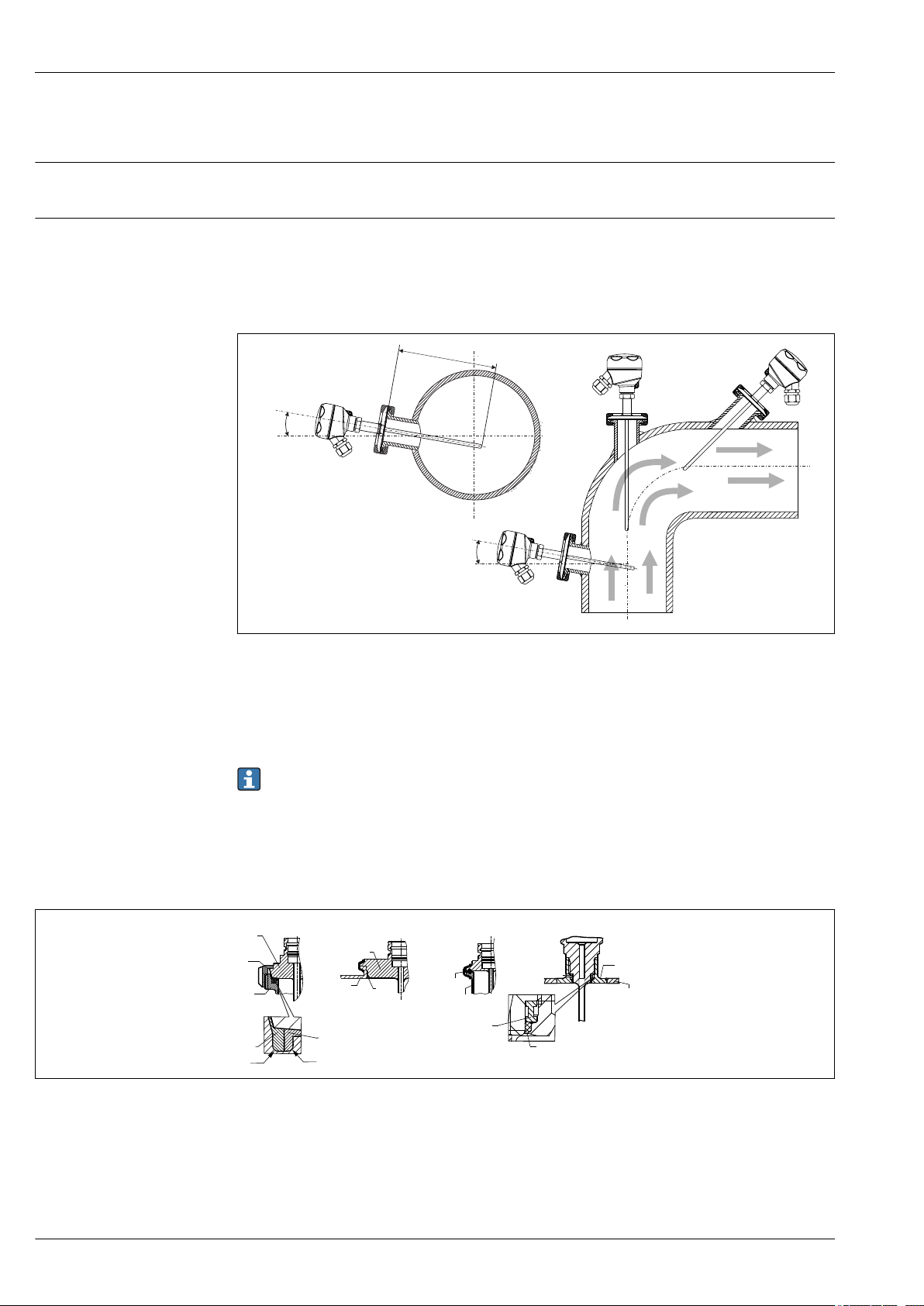

U

≥ 3°

≥ 3°

1

2

3

4

1 2

3

4

R0.4

R0.4

Pressure ring

Sensor with

milk pipe

connection

Sensor with Varivent

connection

Shaped

gasket

Companion

connection

O-ring

Groove

slip-on nut

Centering ring

Sealing

Companion

connection

Companion

connection

O-ring

Welding boss

Vessel wall

iTHERM TT411

Orientation

Installation instructions

No restrictions. However, self-draining in the process must be guaranteed. If there is an opening to

detect leaks at the process connection, this opening must be at the lowest possible point.

The immersion length of the thermometer can influence the accuracy. If the immersion length is too

small then errors in the measurement are caused by heat conduction via the process connection and

the container wall. If installing into a pipe then the immersion length should ideally be half of the

pipe diameter.

Installation possibilities: Pipes, tanks or other plant components

1 Installation examples

1, 2 Perpendicular to flow direction, installed at a min. angle of 3° to ensure self-draining

3 On elbows

4 Inclined installation in pipes with a small nominal diameter

U Immersion length

In the case of pipes with a small nominal diameter, it is advisable for the tip of the thermometer

to project well into the process so that it extends past the pipe axis. Installation at an angle (4)

could be another solution. When determining the immersion length or installation depth all the

parameters of the thermometer and of the medium to be measured must be taken into account

(e.g. flow velocity, process pressure).

For immersion lengths U < 70 mm (27.5 in), the use of iTHERM QuickSens inserts is

recommended..

2 Endress+Hauser

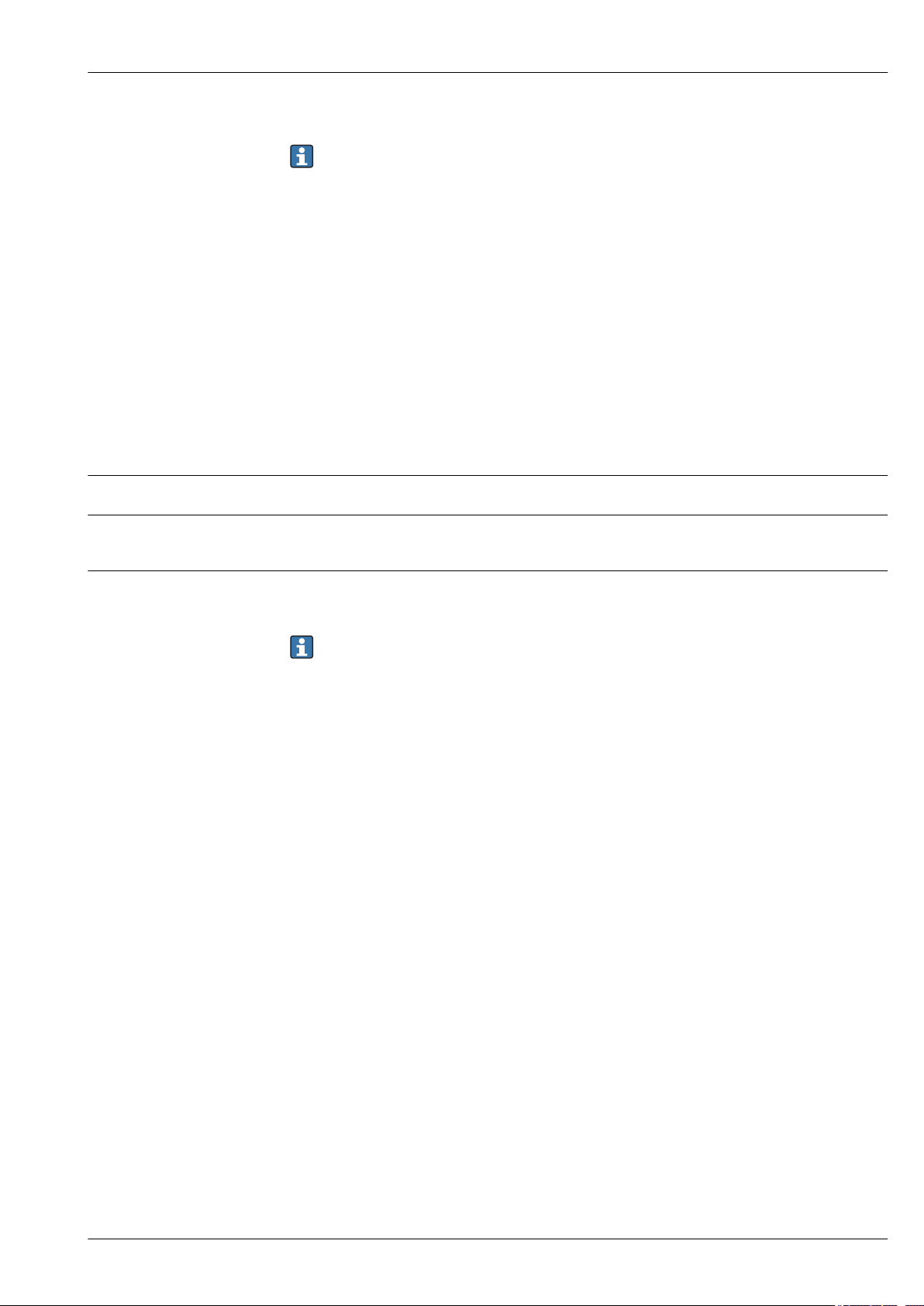

2 Detailed installation instructions for hygiene-compliant installation

1 Sanitary connection according to DIN 11851, only in conjunction with self-centering sealing ring as per

EHEDG position paper

2

Varivent® process connection for VARINLINE® housing

3 Clamp as per ISO 2852, only in conjunction with seal as per EHEDG position paper

4 Process connection Liquiphant-M G1", horizontal installation

A0008946

A0011758-EN

iTHERM TT411

The counterpieces for the process connections and the seals or sealing rings are not included in

the scope of supply for the thermometer. Liquiphant M weld-in adapters with associated seal

kits are available as accessories. .

The following action must be taken if a sealing ring (O-ring) or seal fails:

• Remove the thermometer, clean the thread and the O-ring joint/sealing surface

• Replace the sealing ring or seal

• Perform CIP after installation

In the case of weld-in connections, exercise the necessary degree of care when performing the

welding work on the process side:

• Suitable welding material

• Flush-welded or with welding radius >= 3.2 mm (0.13 in)

• No recesses, folds or gaps

• Honed and polished surface, Ra ≤ 0.76 µm (30 µin)

Process

Process temperature range

Thermal shock

Process pressure range

Maximum –200 to +650 °C (–328 to +1 202 °F)→ 13

Thermal shock resistance in CIP/SIP process with a temperature increase and decrease from

+5 to +130 °C (+41 to +266 °F) within 2 seconds.

The maximum possible process pressure depends on various influencing factors, such as the design,

process connection and process temperature. For information on the maximum possible process

pressures for the individual process connections, see the 'Process connection' section. → 13

It is possible to check the mechanical loading capacity as a function of the installation and

process conditions online in the TW Sizing Module for protection tubes in the Endress+Hauser

Applicator software. This is valid for DIN thermowell calculations. See 'Accessories' section.

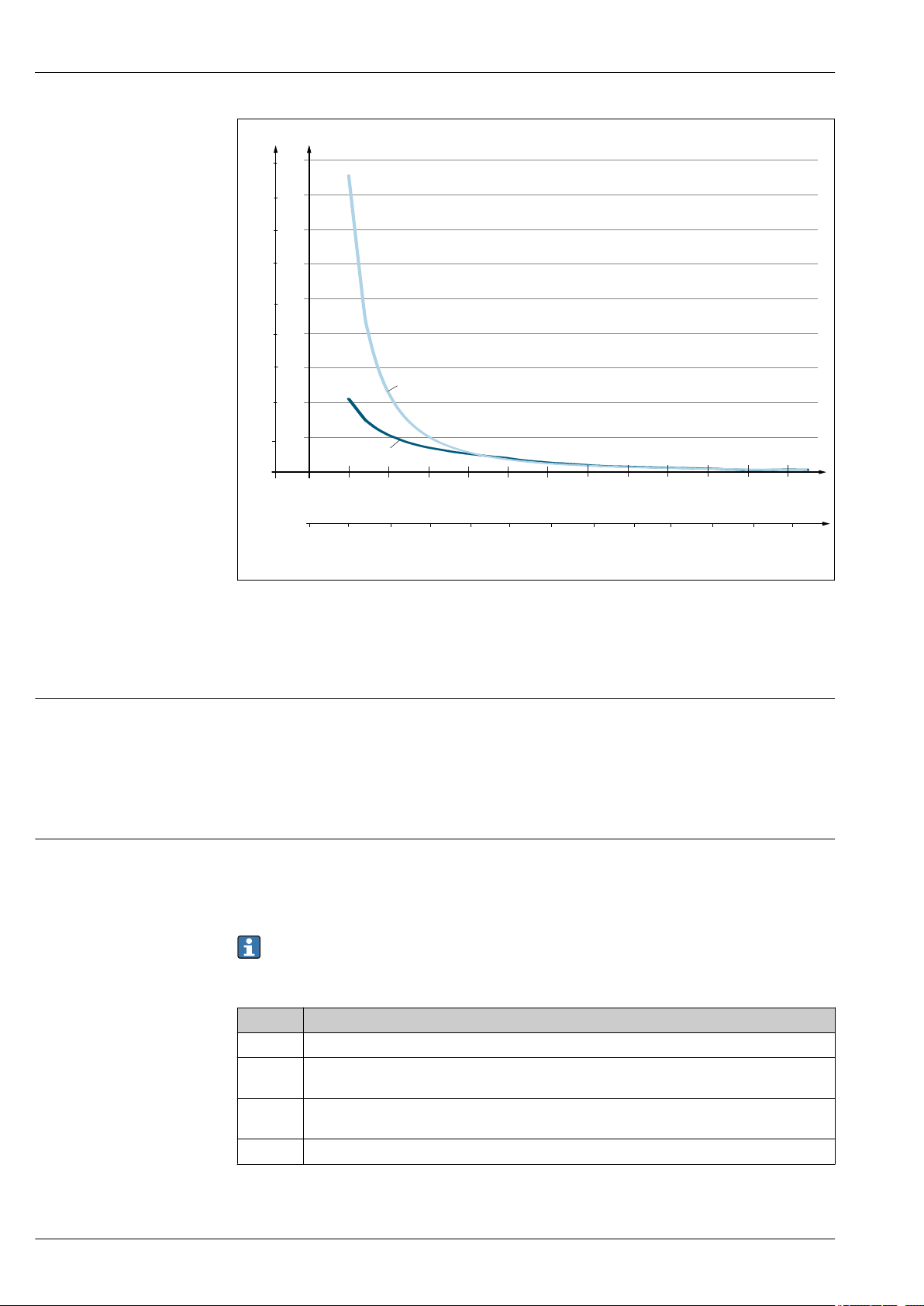

Example of the permitted flow velocity depending on the immersion length and process

medium

The highest flow velocity tolerated by the protection tube diminishes with increasing insert

immersion length exposed to the stream of the fluid. In addition, it is dependent on the diameter of

the tip of the protection tube, the medium type, process temperature and process pressure. The

following figures exemplify the maximum permitted flow velocities in water and superheated steam

at a process pressure of 40 bar (580 PSI).

Endress+Hauser 3

iTHERM TT411

L (mm)

A

10

20

30

40

50

60

70

80

90

100

200

300 400 500

v (m/s)

B

0

4 8 10 16 20

L (in)

0

30

65

100

130

160

200

230

260

290

v (ft/s)

600

0

2 6 12 14 18 22 24

3 Permitted flow velocities, protection tube diameter 9 mm (0.35 in)

A Medium water at T = 50 °C (122 °F)

B Medium superheated steam at T = 160 °C (320 °F)

L Immersion length exposed to flow

v Flow velocity

Medium - state of

Gaseous or liquid (also with high viscosity, e.g. yogurt).

aggregation

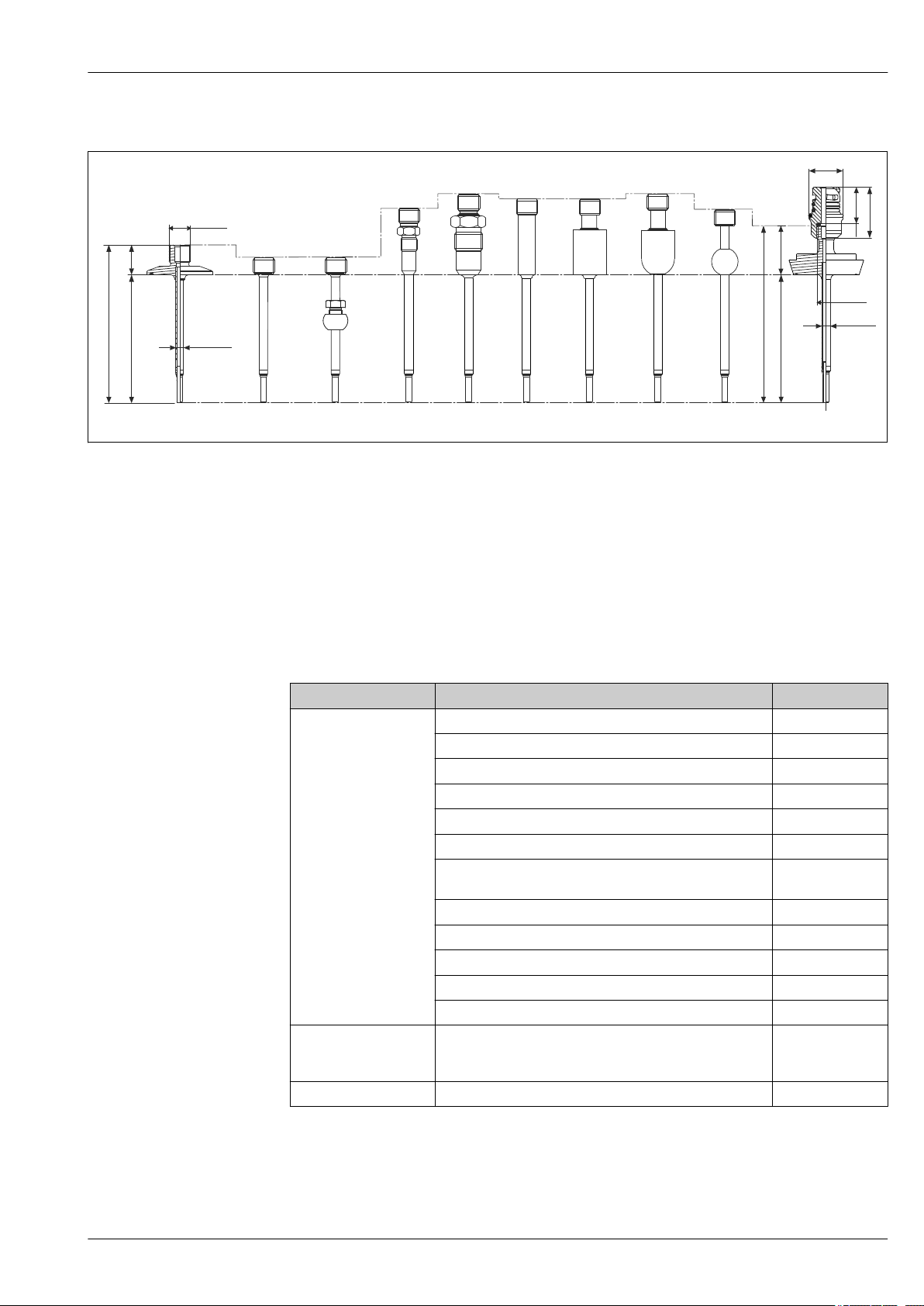

Mechanical construction

Design, dimensions

4 Endress+Hauser

All dimensions in mm (in). The design depends on the thermowell version:

• Diameter 6 mm (¹⁄₄ in)

• Diameter 9 mm (0.35 in)

• Diameter 12.7 mm (¹⁄₂ in)

• T-piece and elbow piece thermowell version as per DIN 11865 / ASME BPE for weld-in

Various dimensions, such as the immersion length U for example, are variable values and are

therefore indicated as items in the following dimensional drawings.

Variable dimensions:

Position Description

L Thermowell length (U+T)

B Thermowell base thickness: predefined, depends on thermowell version (see also the individual

table data)

T Length of thermowell lagging: variable or predefined, depends on thermowell version (see also the

individual table data)

U Immersion length: variable, depending on the configuration

A0032462

iTHERM TT411

T

U

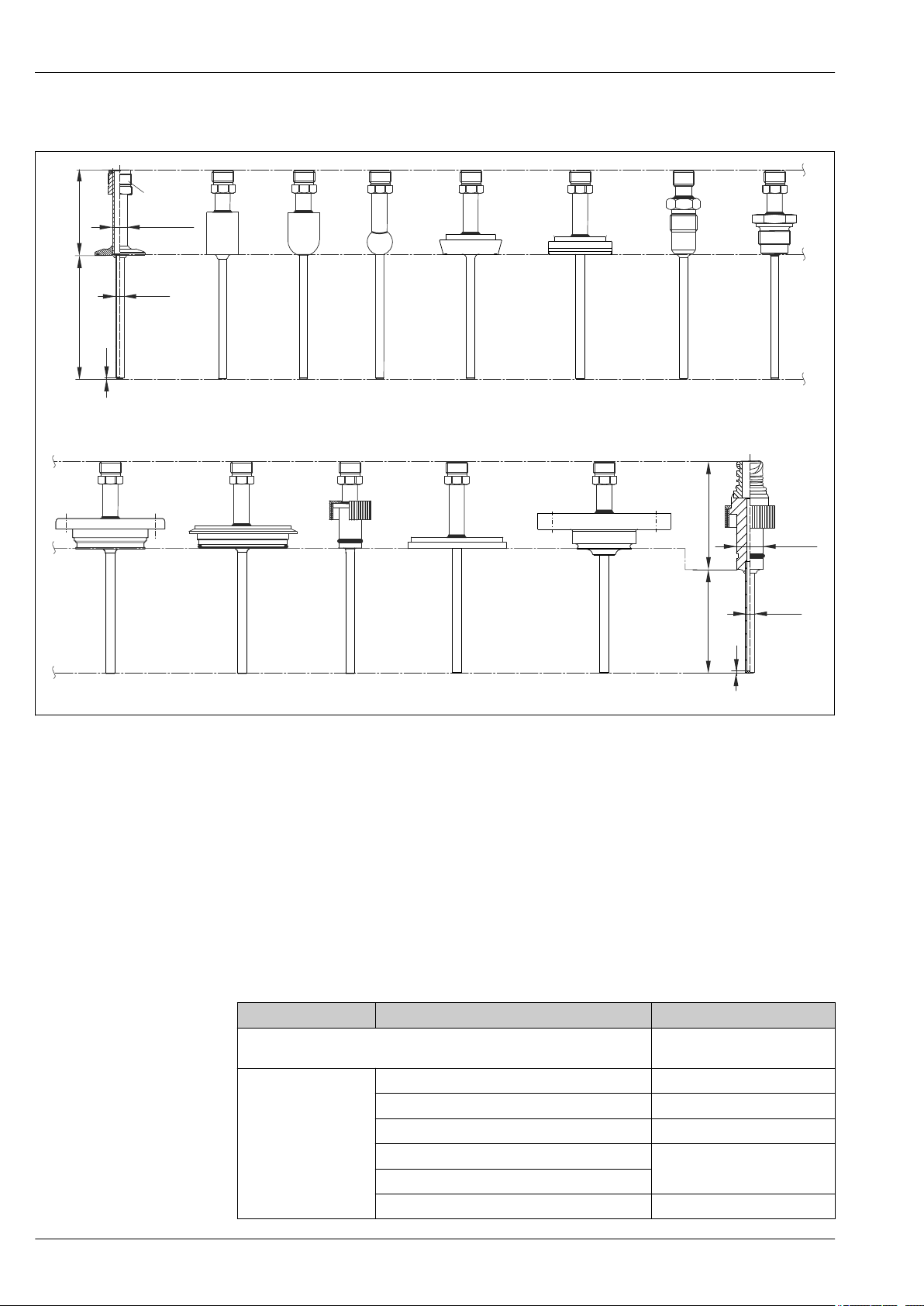

1 2 3 4 5 6 7 8 9 10

U

T

L

!6 (¼)

G3/8"

L

!6 (¼)

G3/8"

!30

(1.81)

34 (1.34)

45 (1.77)

Thermowell diameter 6 mm (¹⁄₄ in)

A0019699

4 Thermowell with extension neck connection G3/8" and various process connection versions:

1 Clamp version

2 Without process connection

3 Spherical compression fitting TK40

4 Metal sealing system M12x1

5 Metal sealing system G½"

6 Cylindrical weld-in adapter 12 x 40 mm

7 Cylindrical weld-in adapter 30 x 40 mm

8 Spherical-cylindrical weld-in adapter 30 x 40 mm

9 Spherical weld-in adapter 25 mm

10 Sanitary connection according to DIN 11851 with threaded bottom part iTHERM QuickNeck, torque

5 Nm (3.69 lbf ft), glued with loctite® 270.

Position Version Length

Metal sealing system M12x1 46 mm (1.81 in)

Metal sealing system G½" 60 mm (2.36 in)

Tri-clamp (0.5"-0.75") 24 mm (0.94 in)

Microclamp (DN8-18) 23 mm (0.91 in)

Clamp DN12 according to ISO 2852 24 mm (0.94 in)

Clamp DN25/DN40 according to ISO 2852 21 mm (0.83 in)

Length of thermowell

lagging T

1)

Sanitary connection DN25/DN32/DN40 according to DIN

29 mm (1.14 in)

11851

Spherical-cylindrical weld-in adapter 58 mm (2.28 in)

Cylindrical weld-in adapter 12 mm (0.47 in) 55 mm (2.17 in)

Without process connection (only G3/8" thread) 11 mm (0.43 in)

Cylindrical weld-in adapter 55 mm (2.17 in)

Spherical weld-in adapter 47 mm (1.85 in)

Variable, depending

on the

Immersion length U Independent of the version

configuration

Base thickness B Reduced tip 4.3 mm (0.17 in) 2 mm (0.08 in)

1) Depends on the process connection

Endress+Hauser 5

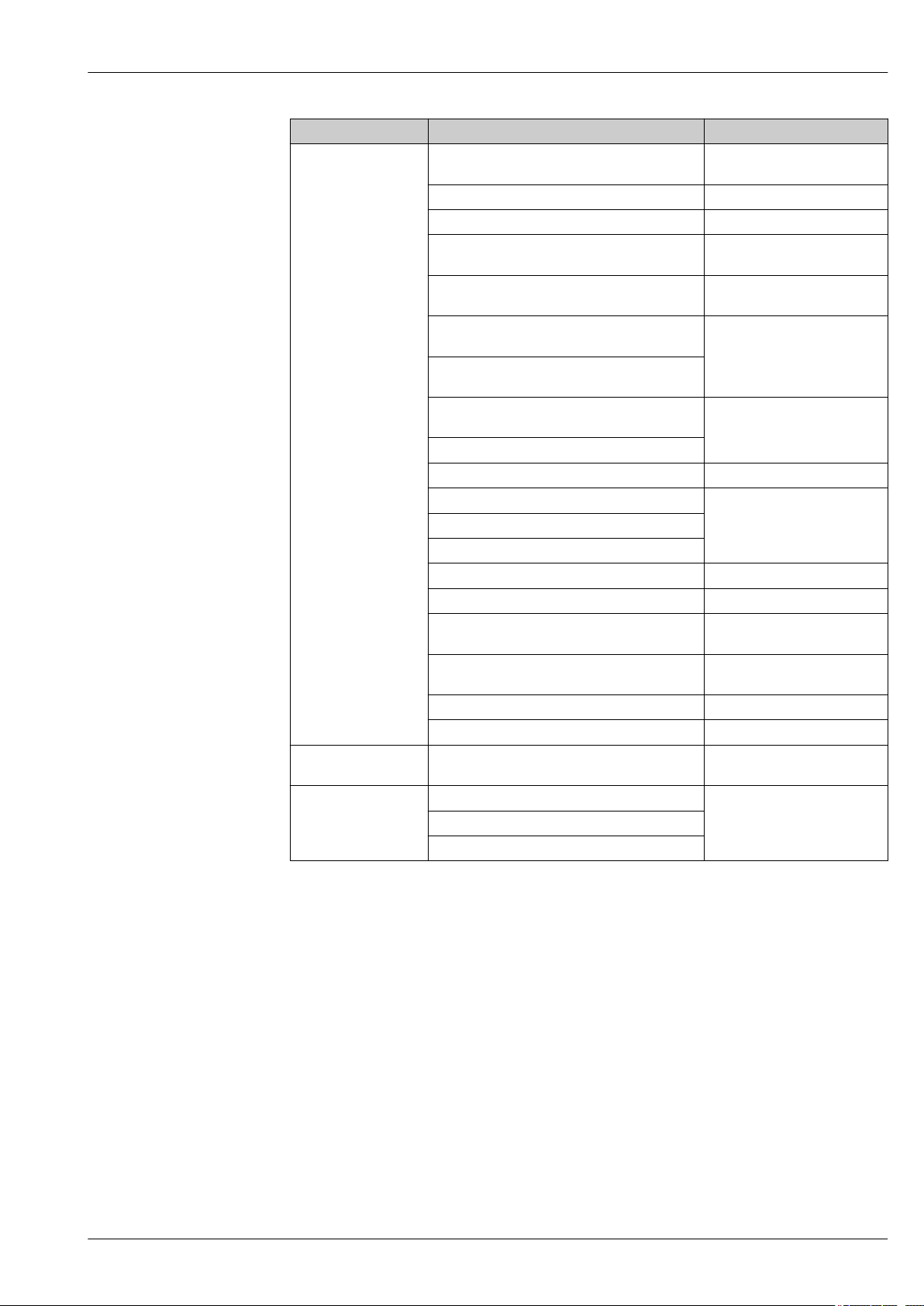

Thermowell diameter 9 mm (0.35 in)

1

2

3 4 5 6 7 8

14

9 10 11 12 13

U

!9

(0.35)

!25

(0.98)

T

U

T

M24x1.5

!9

(0.35)

B

B

!15 (0.6)

iTHERM TT411

A0019729

5 Thermowell with M24x1.5 connection thread and the following process connection versions:

1 Clamp as per ISO2852

2 Cylindrical weld-in adapter 30 x 40 mm

3 Spherical-cylindrical weld-in adapter 30 x 40 mm

4 Spherical weld-in adapter 25 mm

5 Sanitary connection according to DIN 11851

6 Aseptic pipe union according to DIN 11864-1 Form A

7 Metal sealing system G½"

8 Thread according to ISO 228 for Liquiphant weld-in adapter

9 APV Inline

10 Varivent®

11 Ingold connection

12 SMS 1147

13 Neumo Biocontrol

14 Ingold connection, for example with bottom part iTHERM QuickNeck

Position Version Length

Length of thermowell lagging T, without quick-fastening iTHERM

QuickNeck

SMS 1147, DN25 40 mm (1.57 in)

SMS 1147, DN38 41 mm (1.61 in)

With quick-fastening

iTHERM QuickNeck,

depending on the

process connection

SMS 1147, DN51 42 mm (1.65 in)

Varivent®, type F, D = 50 mm (1.97 in)

Varivent®, type N, D = 68 mm (2.67 in)

Varivent®, type B, D = 31 mm (1.22 in) 56 mm (2.2 in)

Variable, depending on the

configuration

52 mm (2.05 in)

6 Endress+Hauser

iTHERM TT411

Position Version Length

G1" thread according to ISO 228 for Liquiphant

weld-in adapter

Spherical-cylindrical weld-in adapter 70 mm (2.76 in)

Cylindrical weld-in adapter 67 mm (2.64 in)

Aseptic pipe union according to DIN11864-A,

DN25

Aseptic pipe union according to DIN11864-A,

DN40

Sanitary connection according to DIN 11851,

DN32

Sanitary connection according to DIN 11851,

DN40

Sanitary connection according to DIN 11851,

DN50

Clamp according to ISO 2852, DN12

Clamp according to ISO 2852, DN25 37 mm (1.46 in)

Clamp according to ISO 2852, DN40

Clamp according to ISO 2852, DN70

Microclamp (DN8-18) 47 mm (1.85 in)

Tri-clamp (0.5"-0.75") 46 mm (1.81 in)

Ingold connection 25 mm (0.98 in) x

30 mm (1.18 in)

Ingold connection 25 mm (0.98 in) x

46 mm (1.81 in)

Metal sealing system G½" 74 mm (2.91 in)

APV-Inline, DN50 51 mm (2.01 in)

Immersion length U Independent of the version

Reduced tip 5.3 mm (0.21 in)x 20 mm (0.79 in)

Base thickness B

Tapered tip 6.6 mm (0.26 in) x 60 mm (2.36 in)

Straight tip

77 mm (3.03 in)

42 mm (1.65 in)

43 mm (1.7 in)

47 mm (1.85 in)

48 mm (1.89 in)

39 mm (1.54 in)Clamp according to ISO 2852, DN63.5

78 mm (3.07 in)

94 mm (3.7 in)

Variable, depending on the

configuration

2 mm (0.08 in)

Endress+Hauser 7

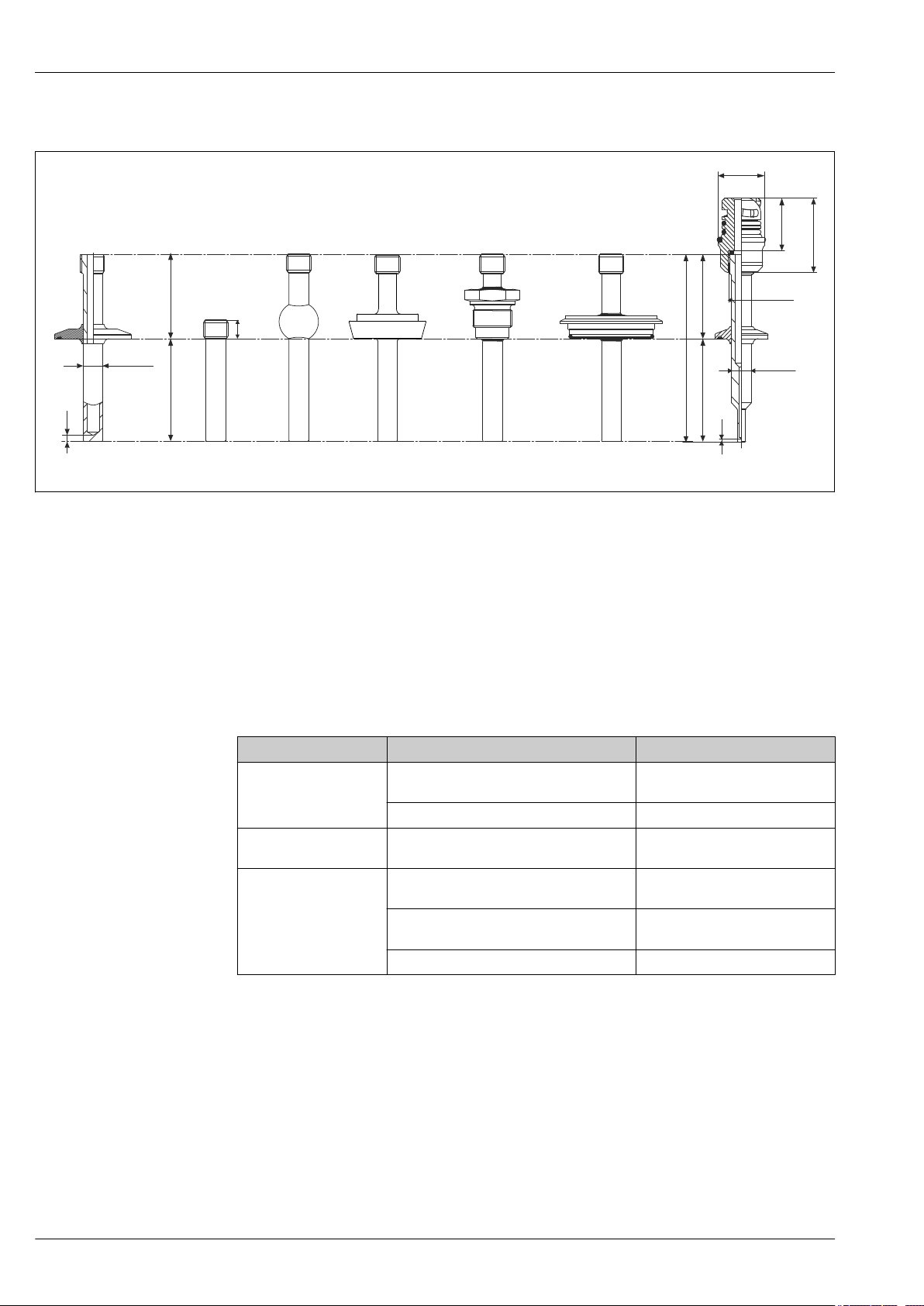

iTHERM TT411

U

T

B

!12.7

(0.5)

T

321 4 5 6 7

!30

(1.81)

34

(1.34)

45 (1.77)

!12.7

(0.5)

U

T

L

G3/8"

B

Thermowell diameter 12.7 mm (¹⁄₂ in)

A0019701

6 Thermowell with extension neck connection G3/8" and various process connection versions:

1 Clamp version

2 Cylindrical weld-in adapter 12.7 mm (0.5 in)

3 Spherical weld-in adapter 25 mm

4 Sanitary connection according to DIN 11851

5 Thread according to ISO 228 for Liquiphant weld-in adapter

6 Varivent®

7 Microclamp, threaded with QuickNeck bottom part, torque 5 Nm (3.69 lbf ft), and glued with loctite® 270,

with reduced tip

• Thermowell made from solid bar stock drilled for L ≤ 200 mm (7.87 in)

• Thermowell welded at the tip for L > 200 mm (7.87 in)

Position Version Length

Length of thermowell

lagging T

Immersion length U Independent of the process connection

Base thickness B

Weld-in adapter, cylindrical,

12.7 mm (¹⁄₂ in)

All other process connections 65 mm (2.56 in)

Reduced tip 5.3 mm (0.21 in)x

20 mm (0.79 in)

Reduced tip 8 mm (0.31 in)x

32 mm (1.26 in)

Straight tip 6 mm (0.24 in)

12 mm (0.47 in)

Variable, depending on the

configuration

2 mm (0.079 in)

4 mm (0.16 in)

8 Endress+Hauser

iTHERM TT411

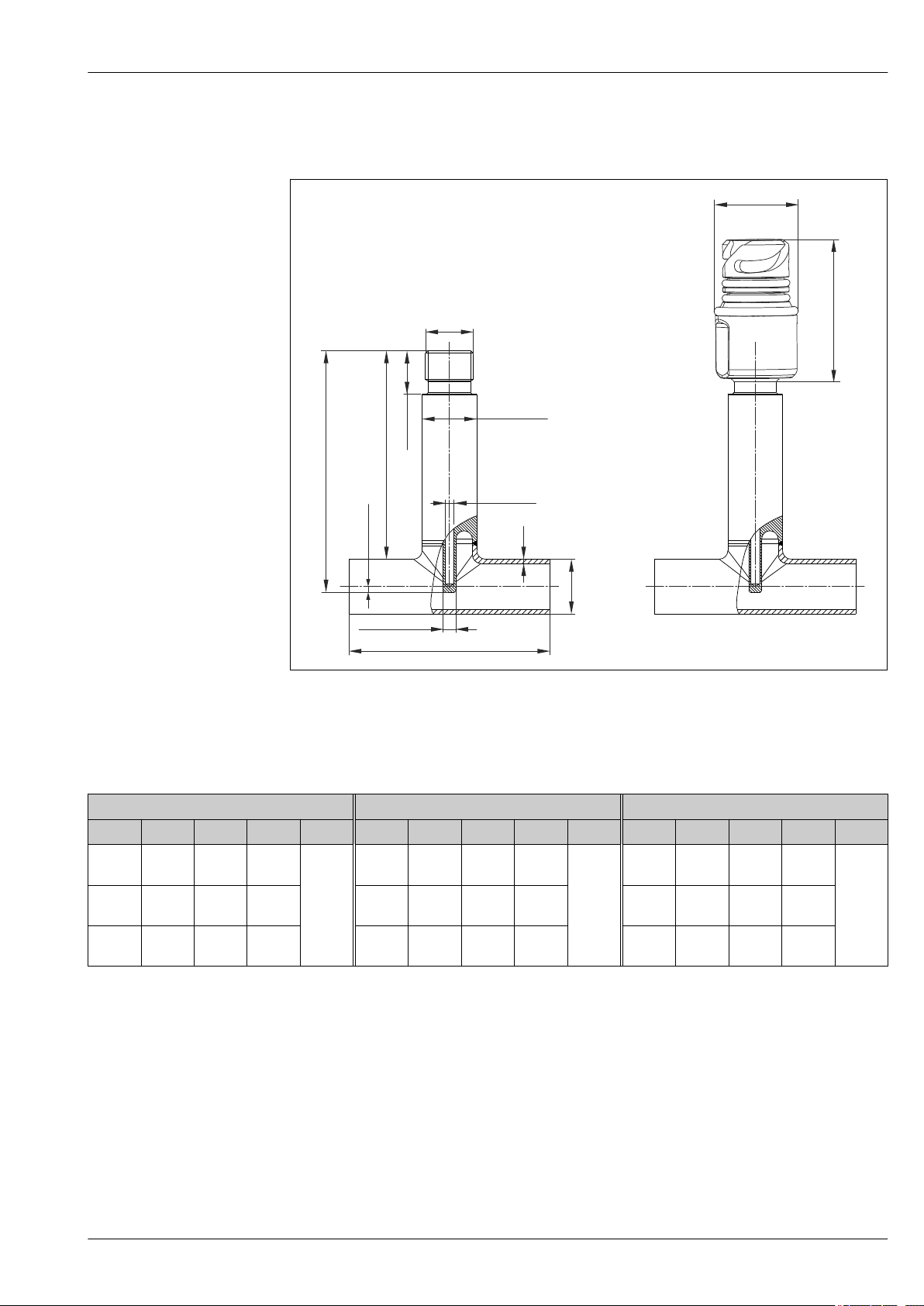

84 (3.31)

X

15 (0.6)

G3/8"

max. !19

(0.75)

!3.1 (0.12)

!D

!4.5 (0.18)

L

s

2 (0.08)

!30

(1.81)

45 (1.77)

1 2

T-piece thermowell version

Welded, with dead legs

7 Thermowell as per DIN11865 or ASME BPE

1 With extension neck connection G3/8"

2 With threaded bottom part QuickNeck, torque 5 Nm (3.69 lbf ft), and glued with loctite® 270.

Dimensions in mm (in):

DIN11865-A DIN11865-B DIN11865-C / ASME BPE

X L ⌀D s X L ⌀D s X L ⌀D s

DN10 76 (3) 70

(2.76)13(0.51)

DN15 73

DN25 68

(2.87)70(2.76)19(0.75)

100

(2.68)

(3.94)29(1.14)

1.5

(0.06)

DN13.5 76 (3) 64

DN17.2 73

DN21.3 71

(2.52)

(2.87)68(2.68)

(2.8)72(2.8)

13.5

(0.53)

17.2

(0.68)

21.3

(0.84)

1.6

(0.063)

DN12.7

(½")

DN19.0

5 (¾")

DN38.1

(1½")63(2.48)

75.6

(2.98)

72.5

(2.85)

95.2

(3.75)

101.6

(4)

120.6

(4.75)

12.7

(0.5)

19.05

(0.75)

38.1

(1.5)

A0019702

1.65

(0.065)

Endress+Hauser 9

Loading...

Loading...